Patents

Literature

1166 results about "Glovebox" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A glovebox (or glove box) is a sealed container that is designed to allow one to manipulate objects where a separate atmosphere is desired. Built into the sides of the glovebox are gloves arranged in such a way that the user can place their hands into the gloves and perform tasks inside the box without breaking containment. Part or all of the box is usually transparent to allow the user to see what is being manipulated. Two types of gloveboxes exist. The first allows a person to work with hazardous substances, such as radioactive materials or infectious disease agents, and the second allows manipulation of substances that must be contained within a very high purity inert atmosphere, such as argon or nitrogen. It is also possible to use a glovebox for manipulation of items in a vacuum chamber.

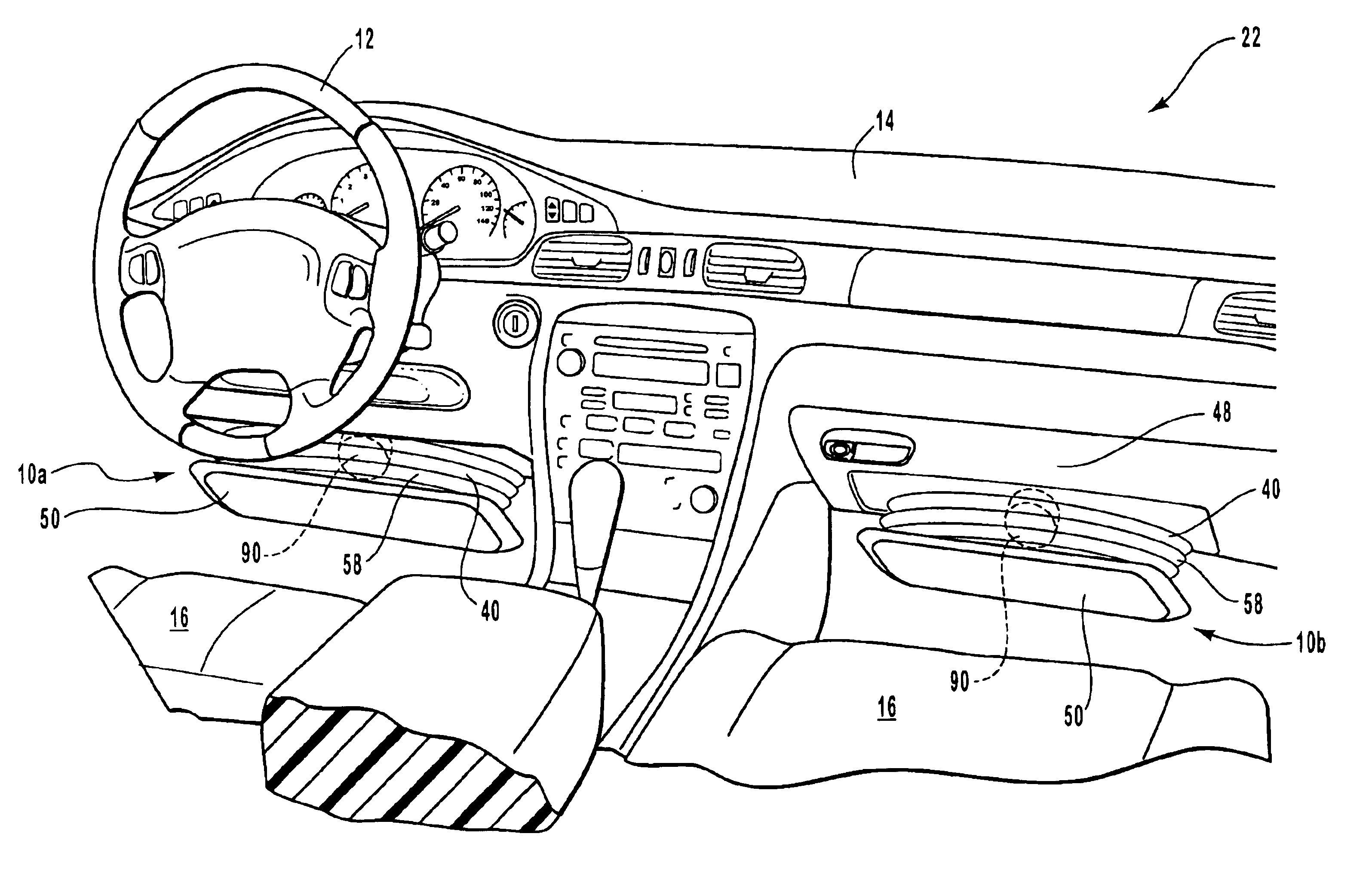

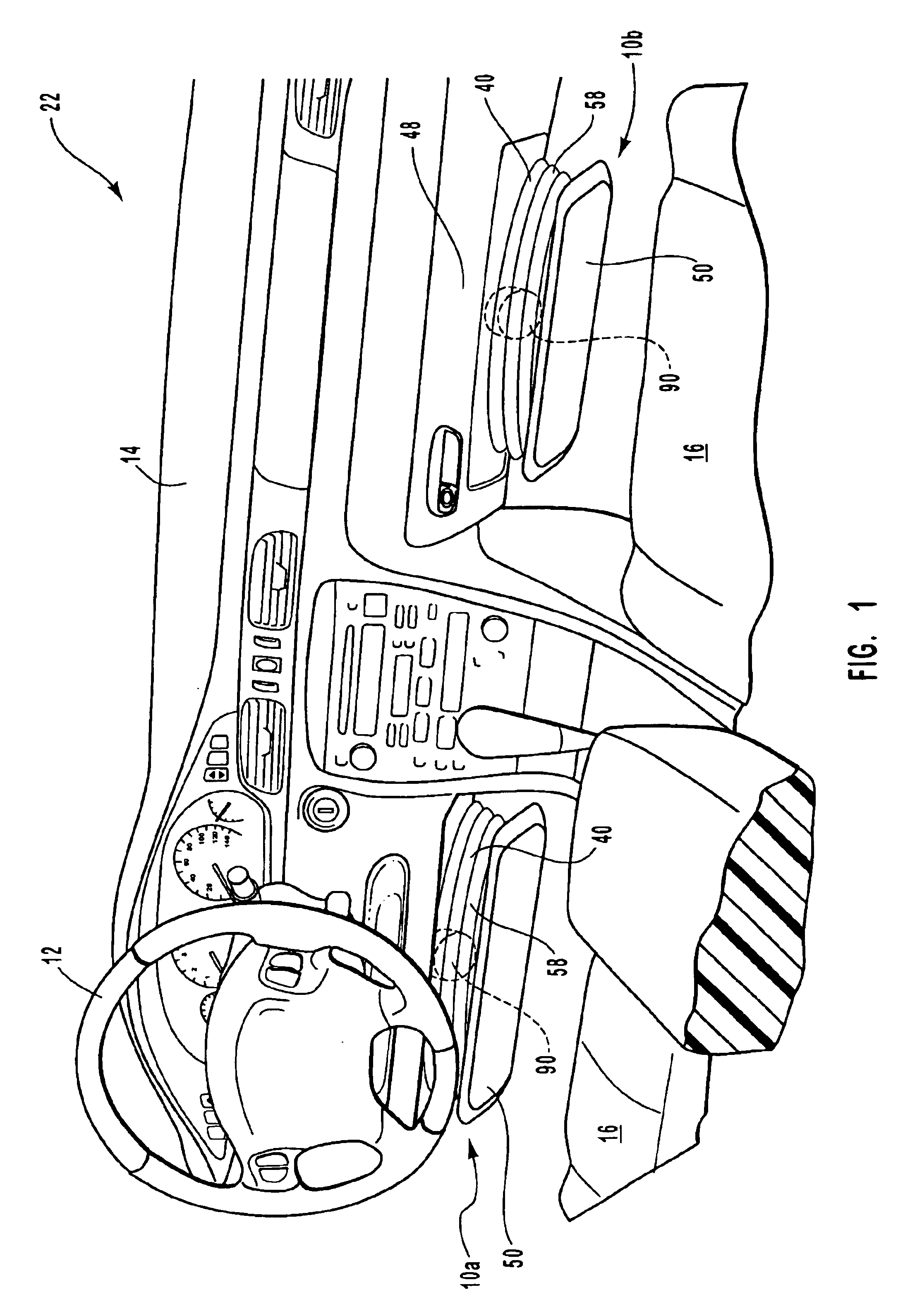

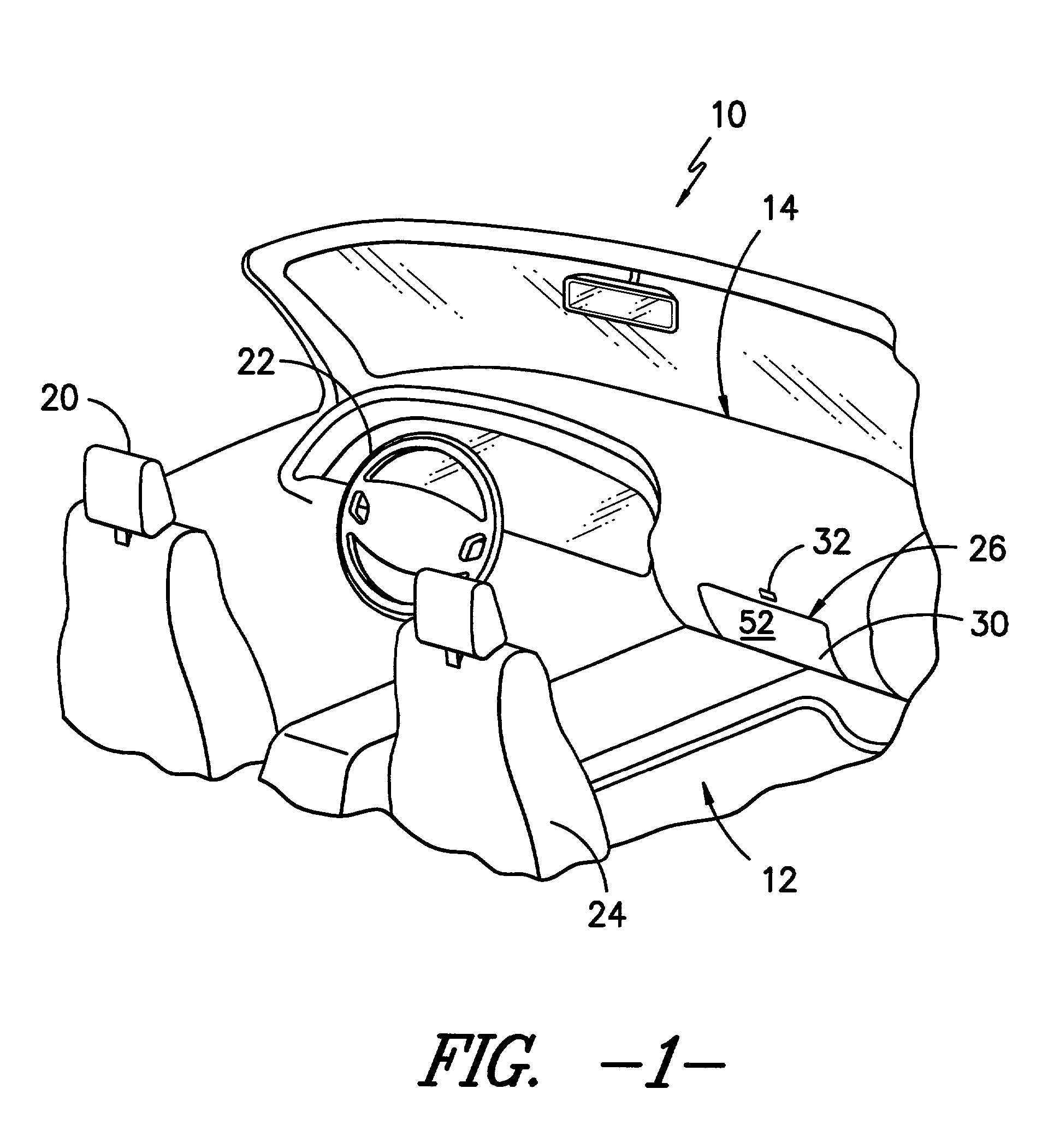

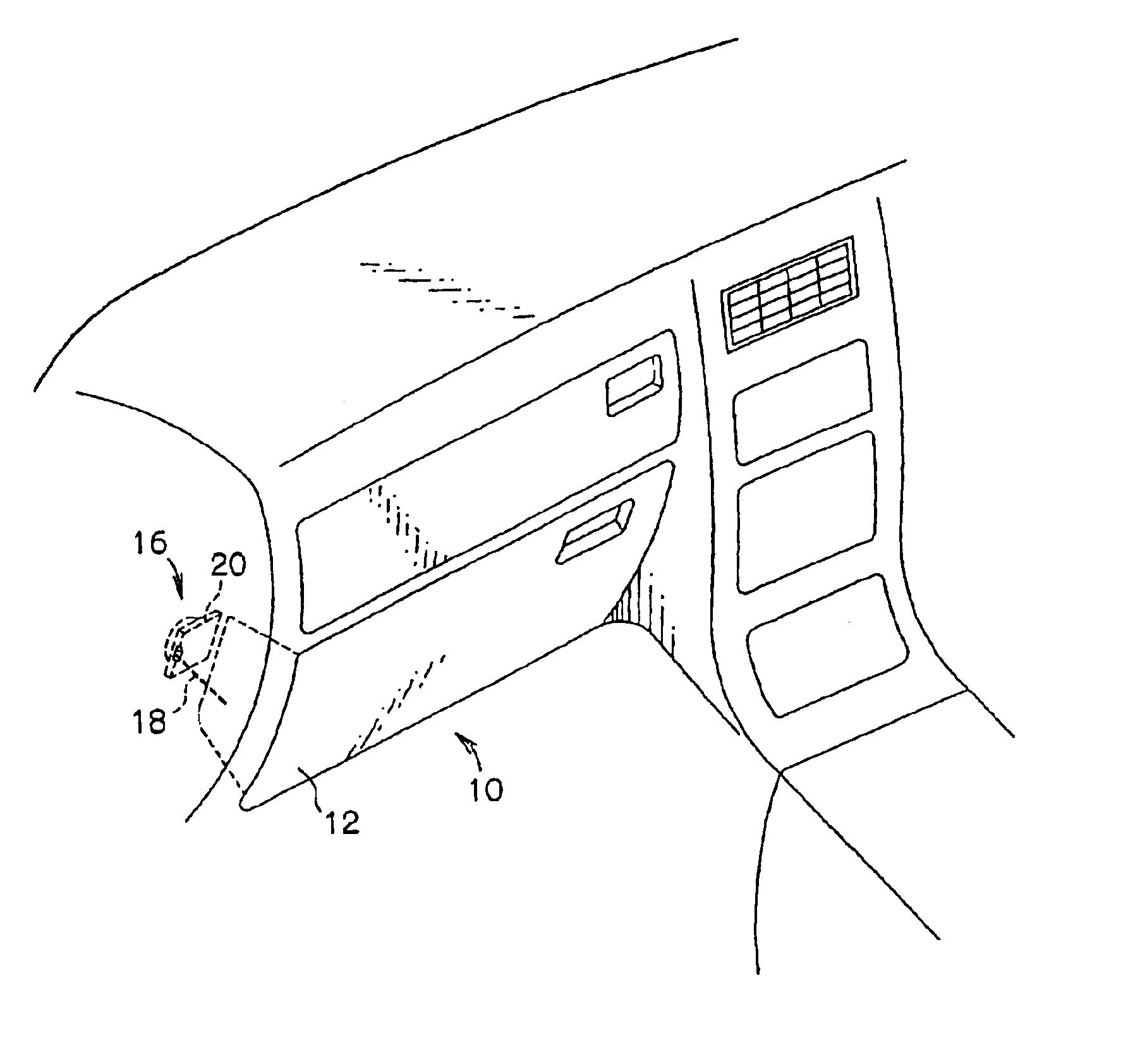

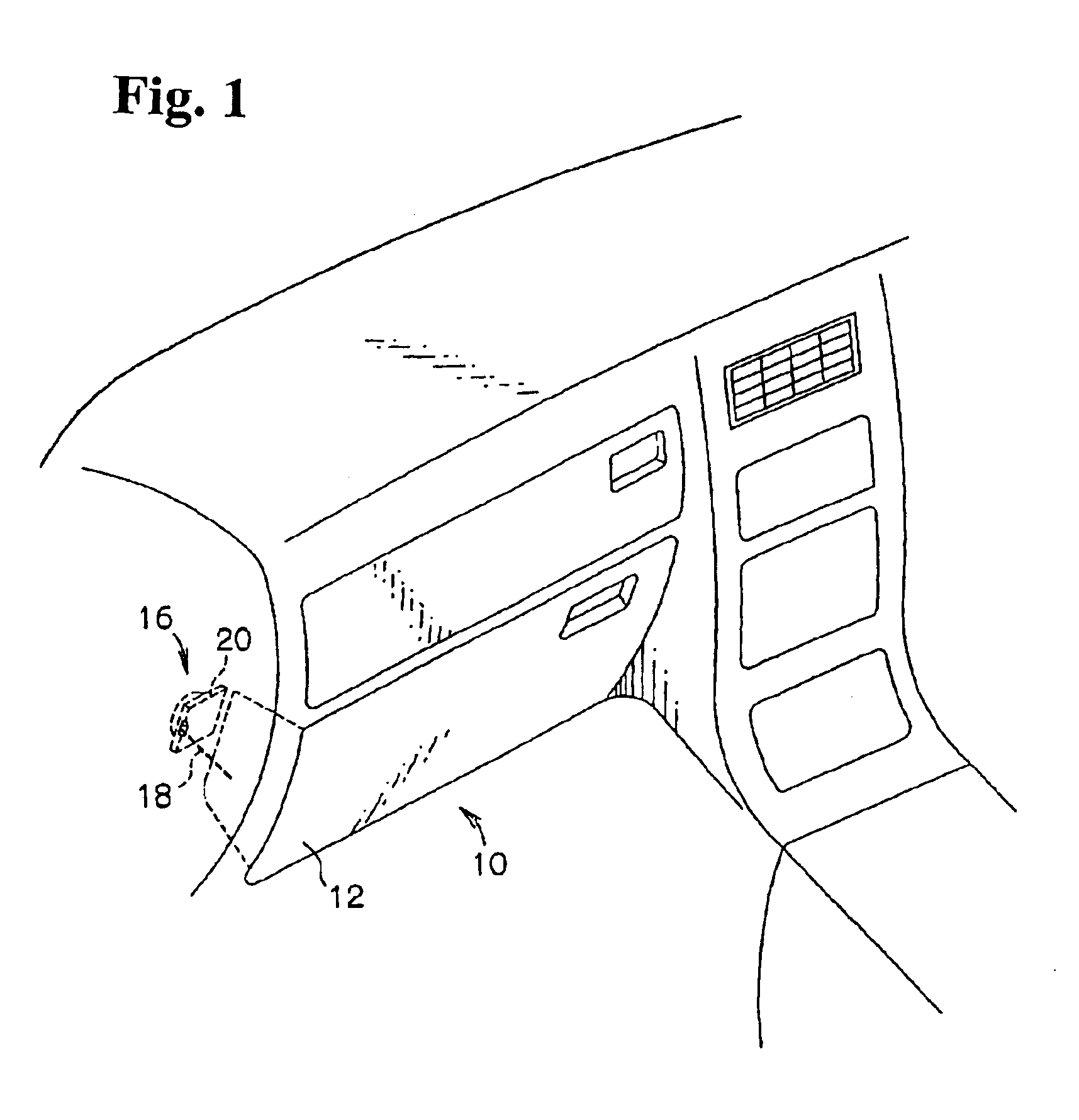

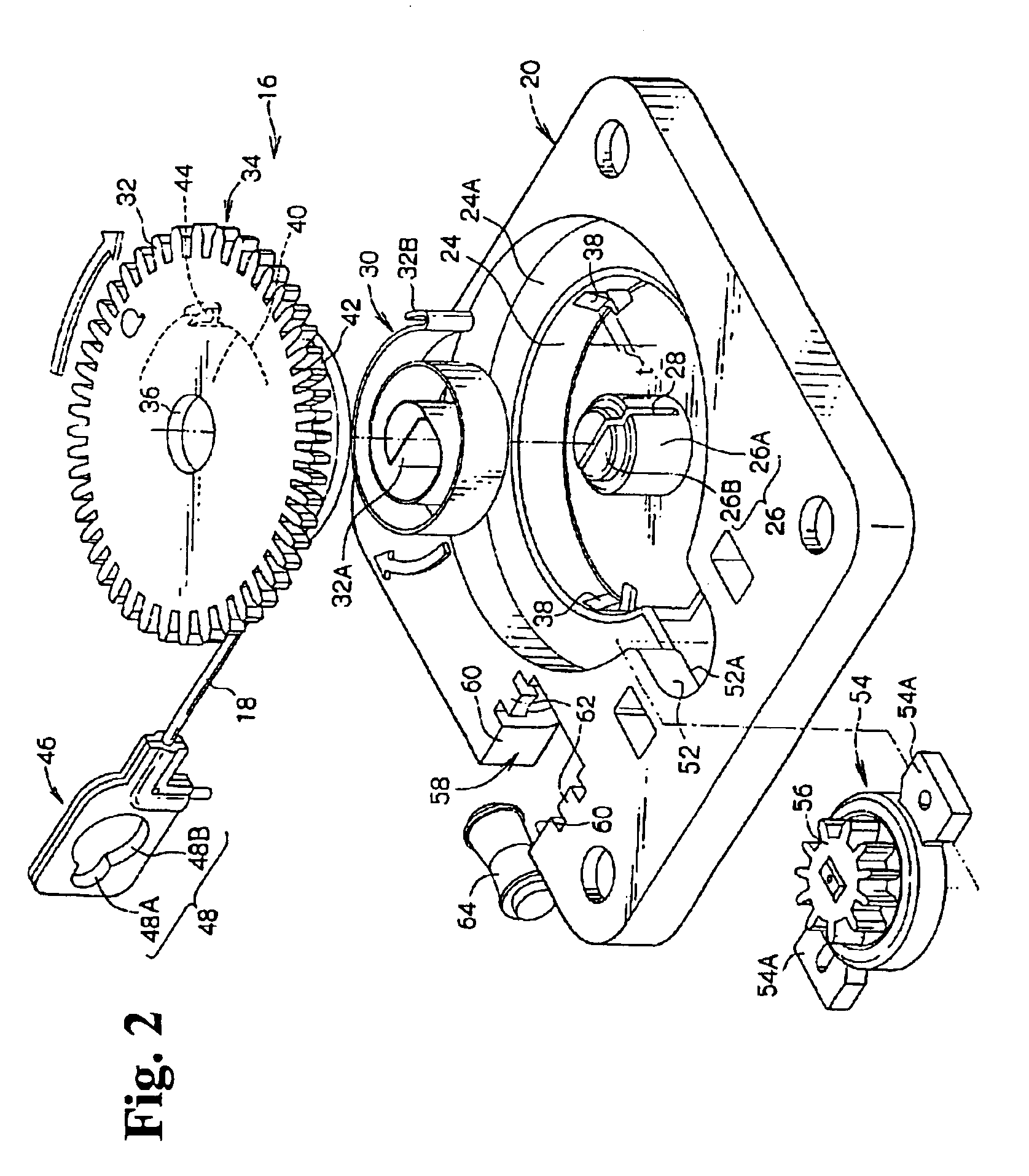

Knee airbag and glove box assembly

Owner:AUTOLIV ASP INC

Expandable rigid knee airbag system

InactiveUS6874811B2Precise positioningEasy to integratePedestrian/occupant safety arrangementSteering columnKinematics

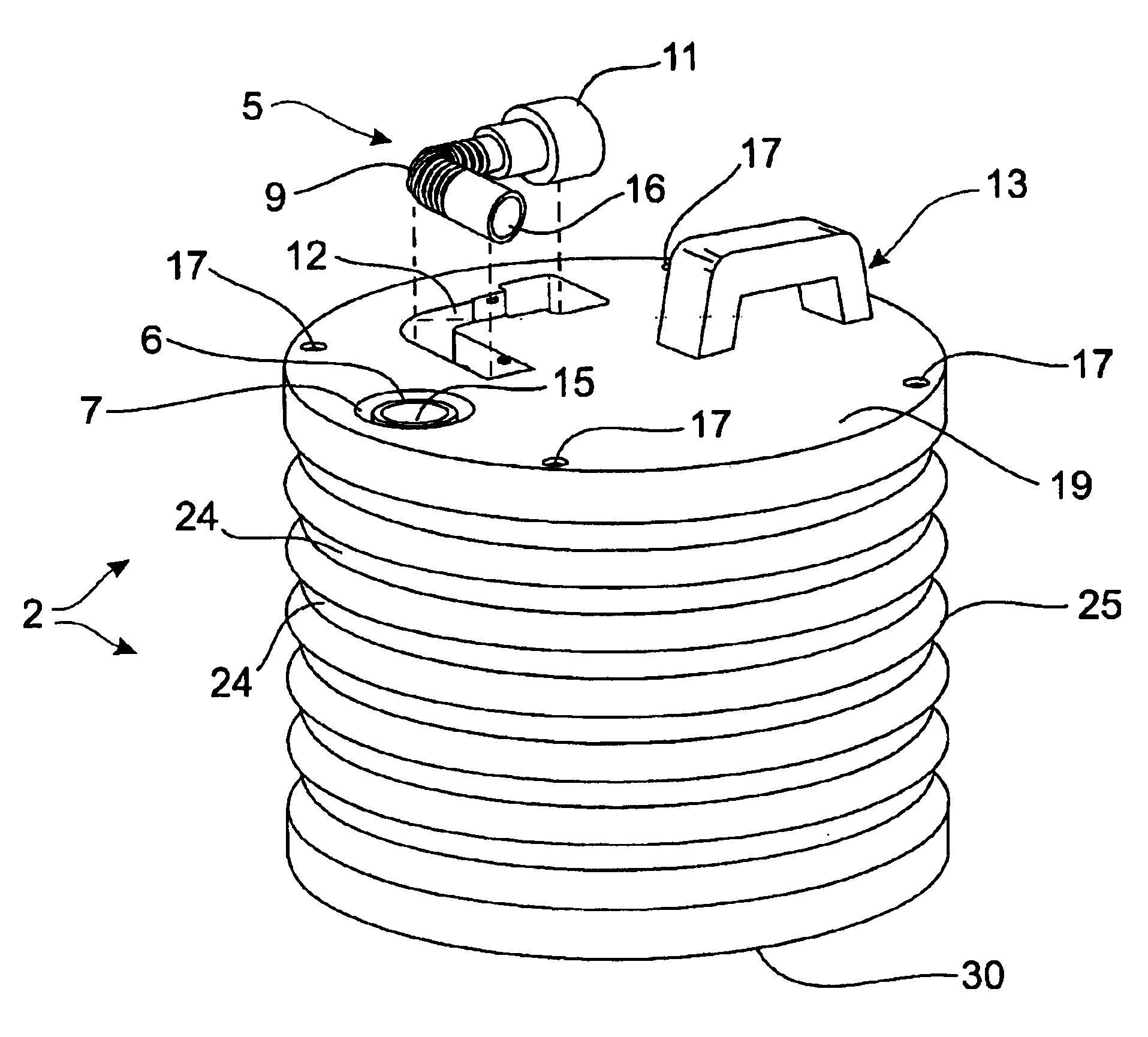

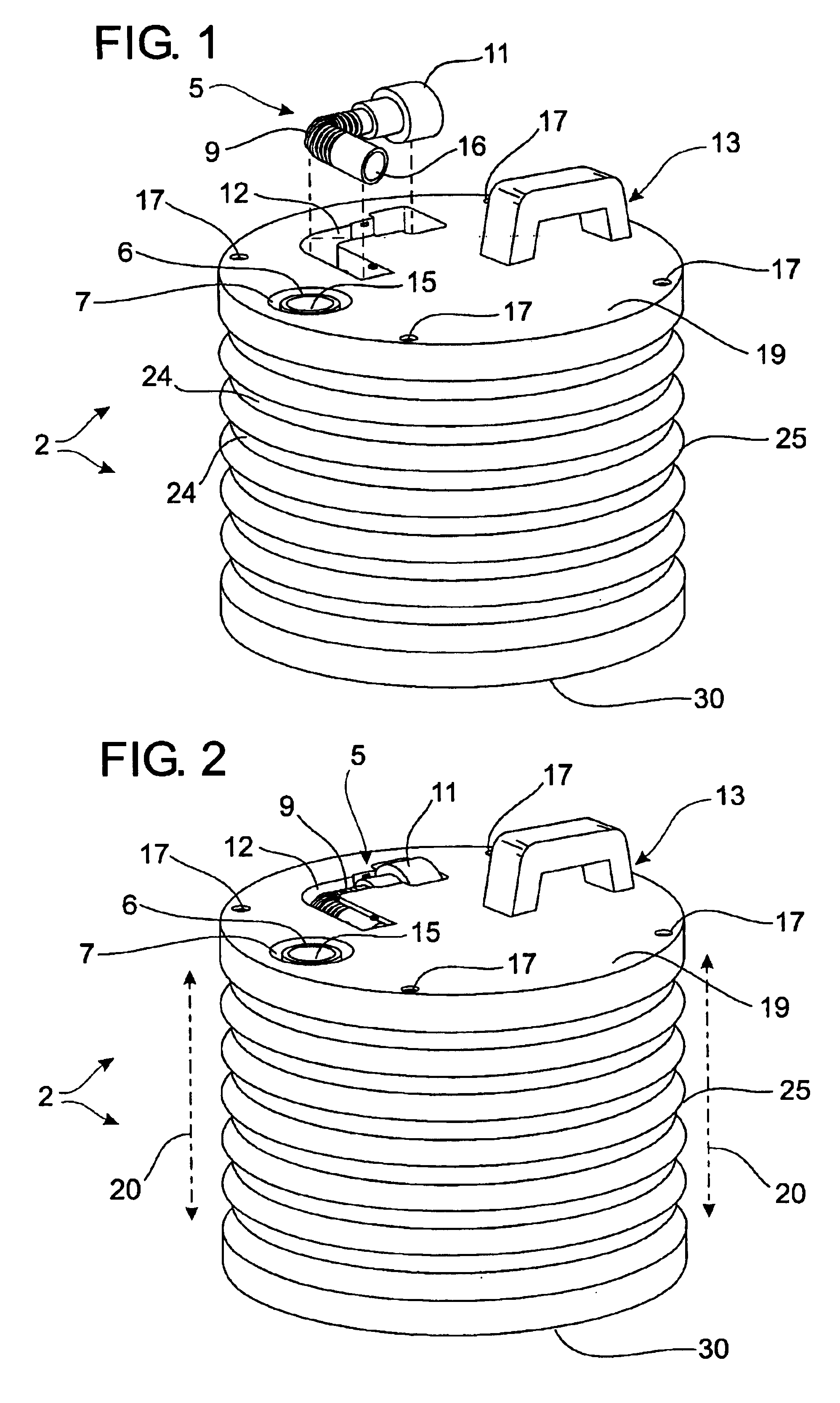

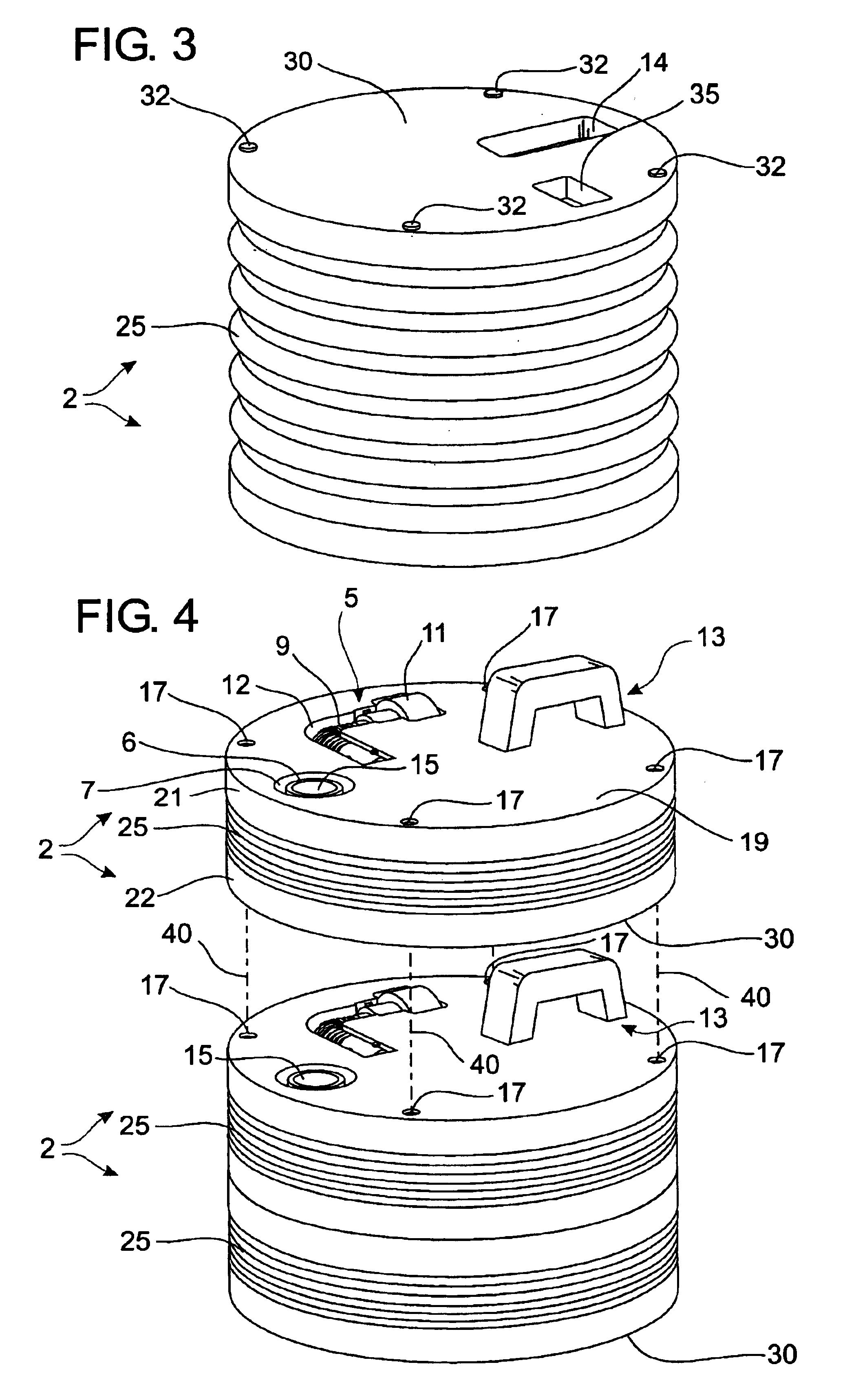

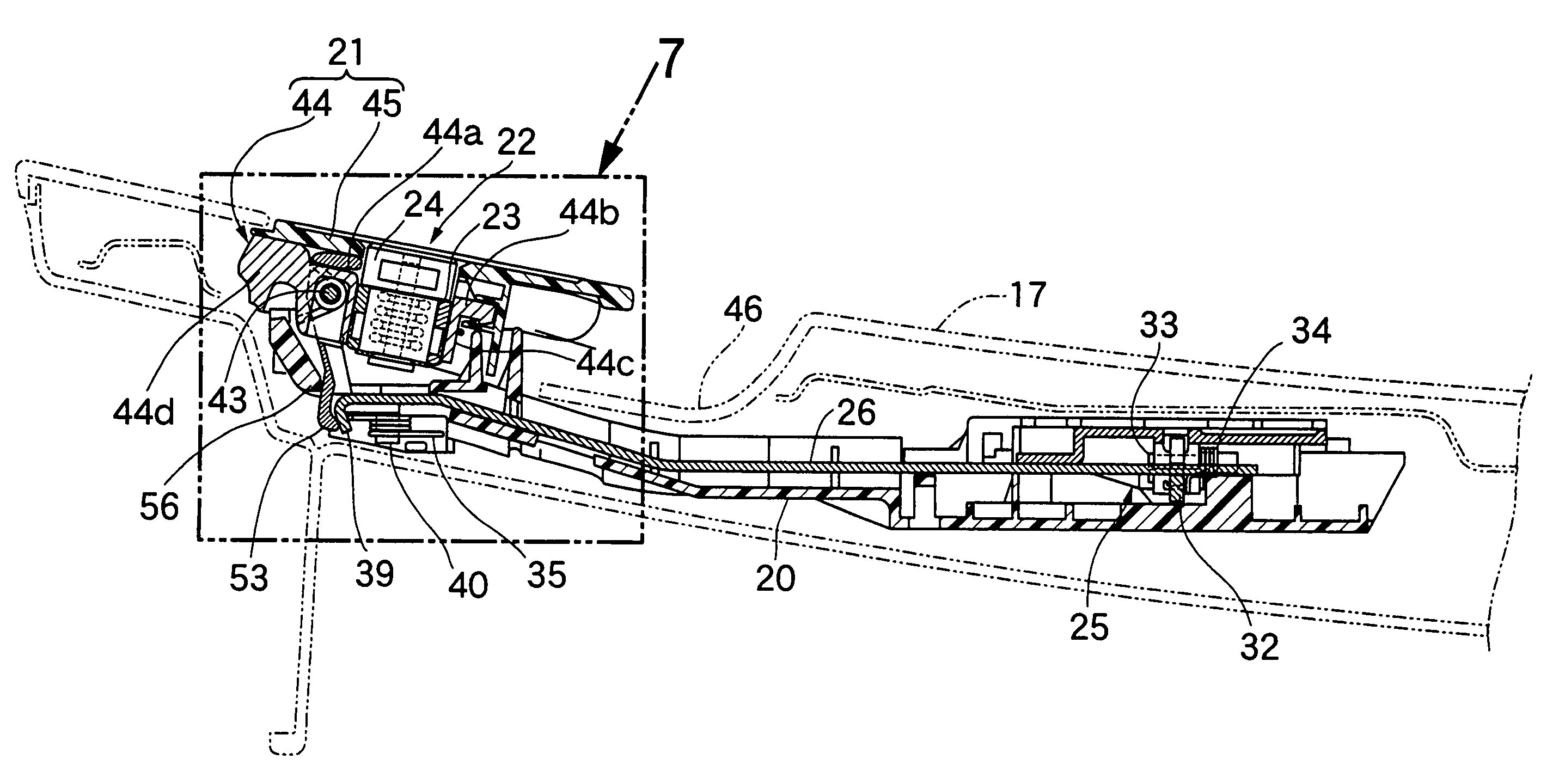

An inflatable rigid knee airbag system for assisting in positioning and decelerating a vehicle occupant is disclosed. The system includes an inflatable knee airbag having a front panel, an annular, accordion-folded bellows panel, and a rear panel having an inflation orifice and mounting brackets; and a pyrotechnic inflator. The system helps to improve the kinematics of a vehicle occupant in relation to a primary airbag cushion by bolstering the knees of the occupant. The system of the invention may be mounted in a vehicle in a panel under the steering column, in the door of a glove box, or in the lower section of the instrument panel of the vehicle directly in front of the occupant's lower legs.

Owner:AUTOLIV ASP INC

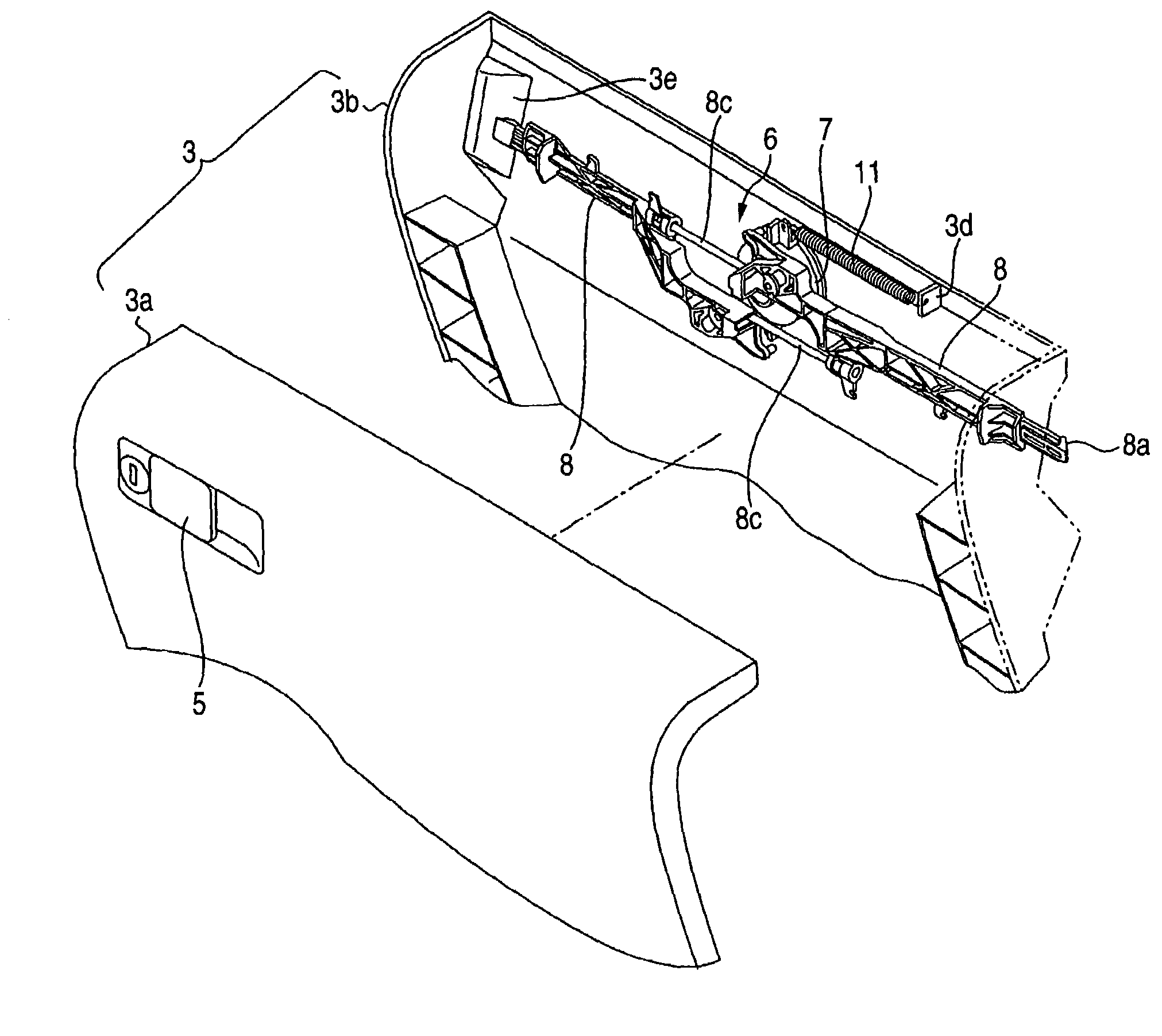

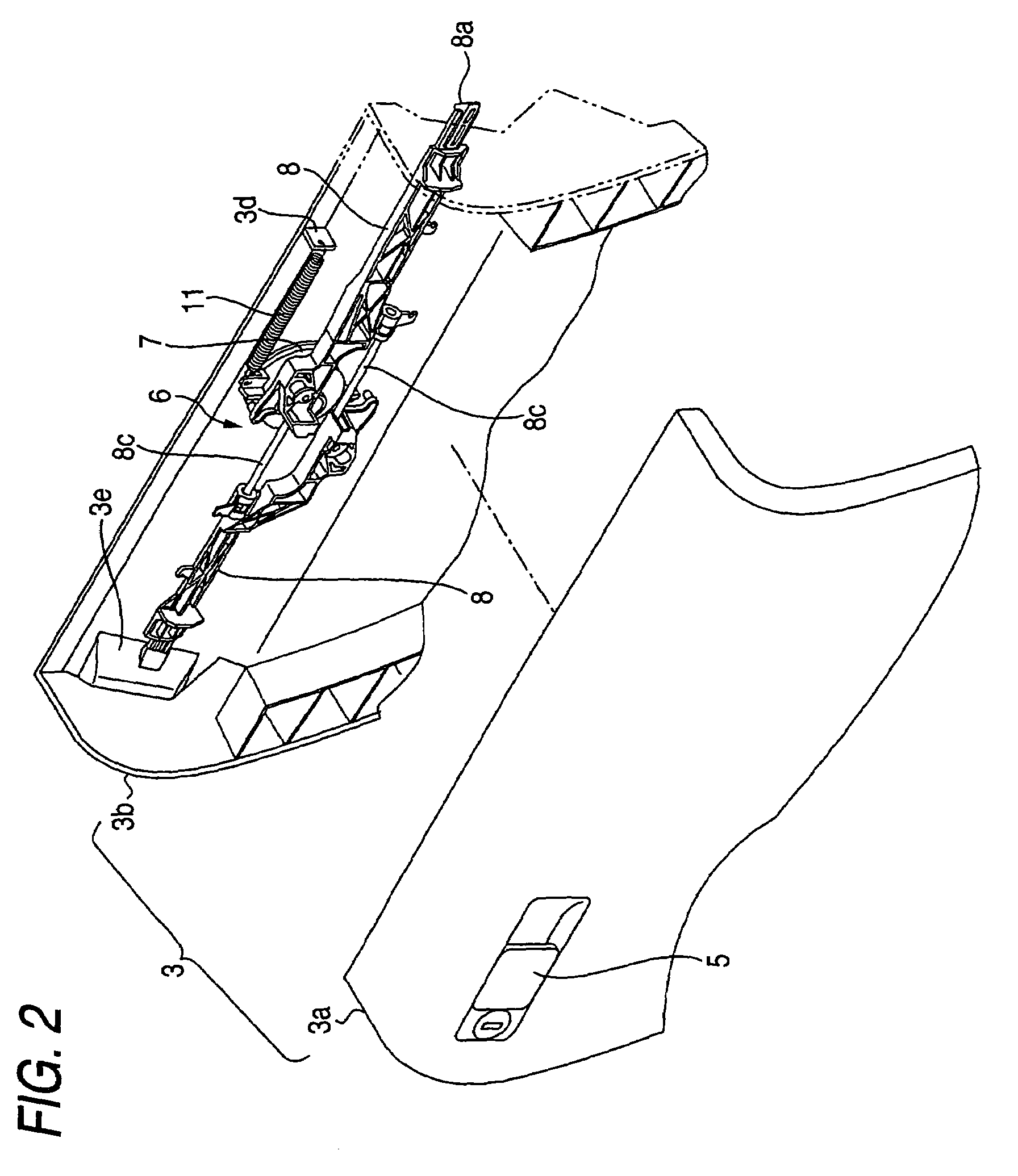

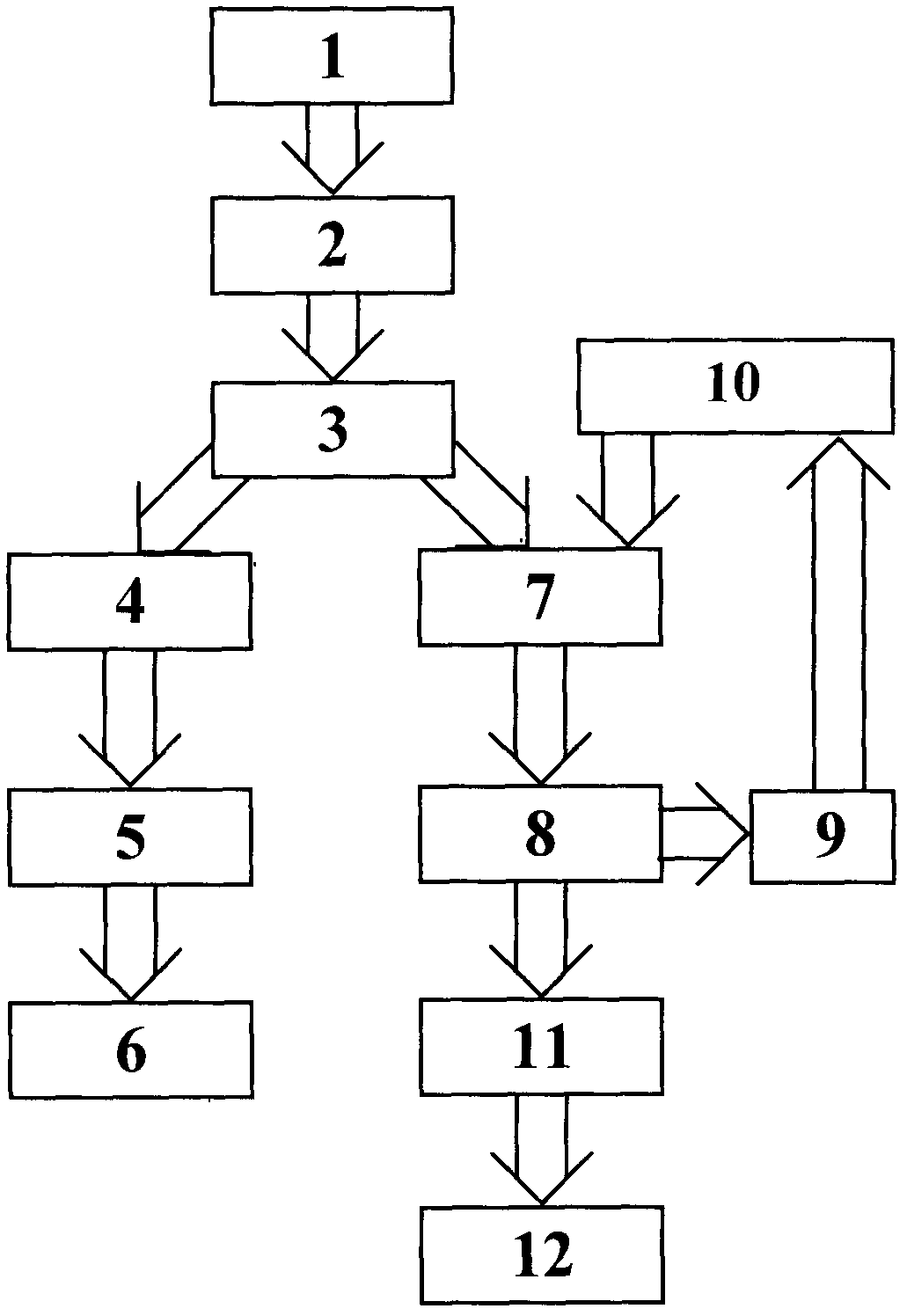

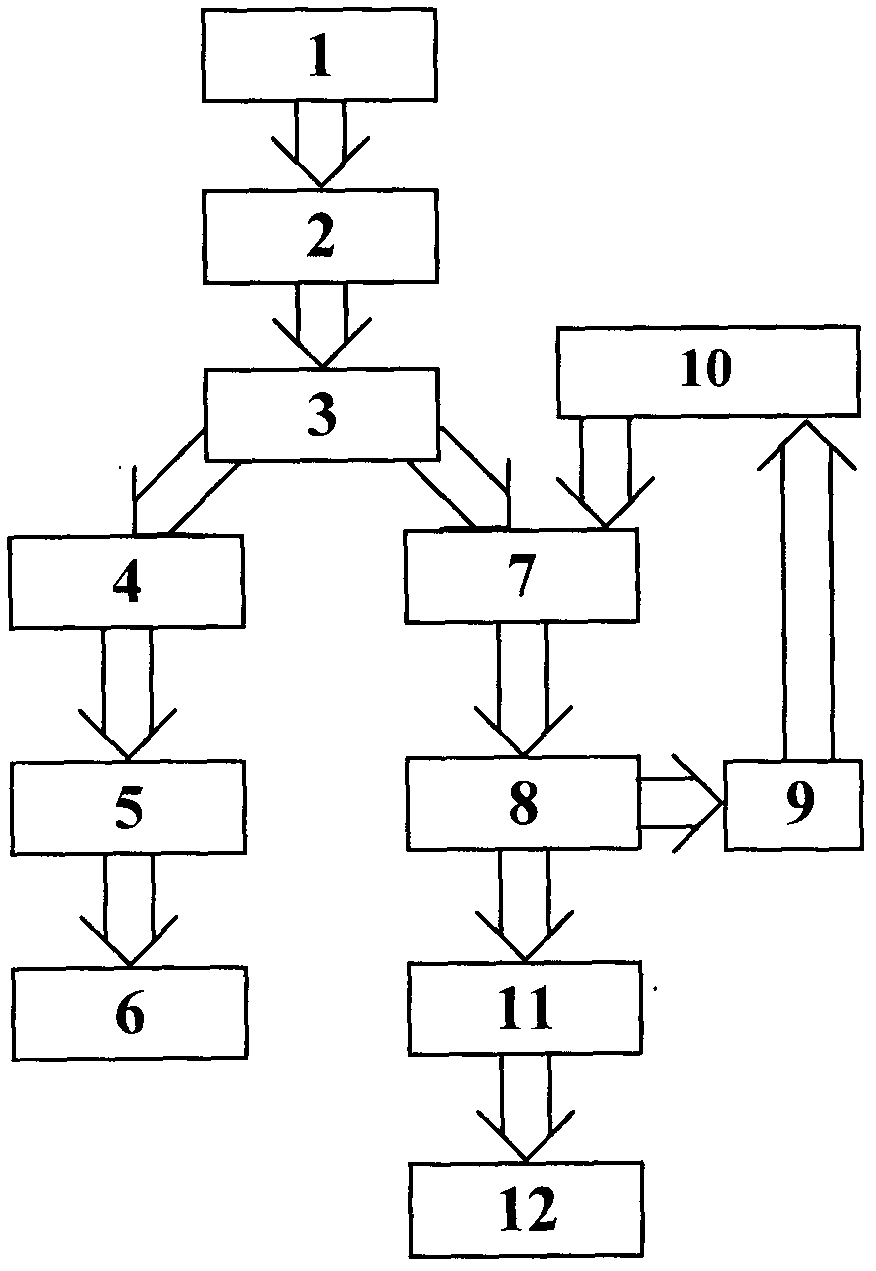

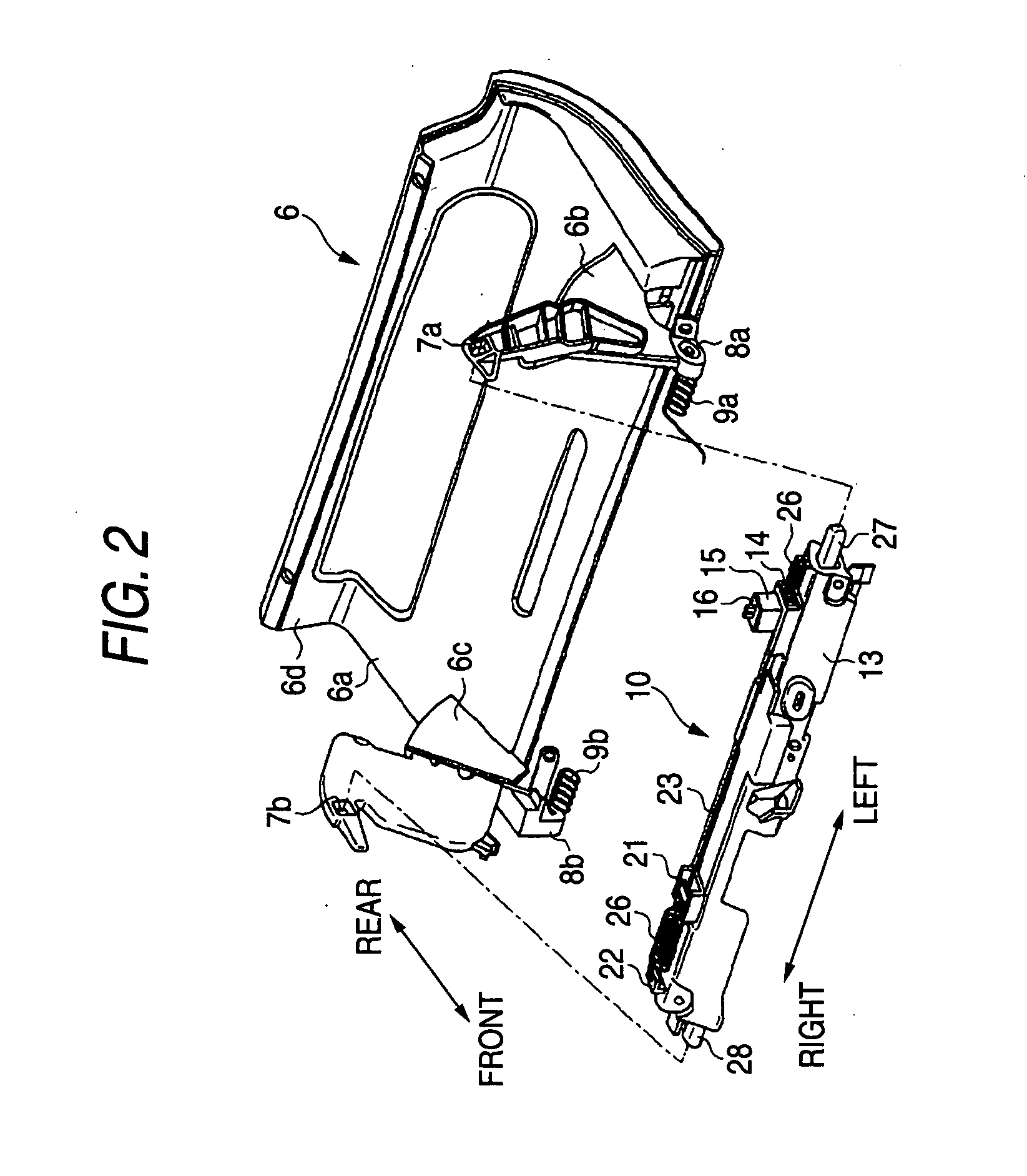

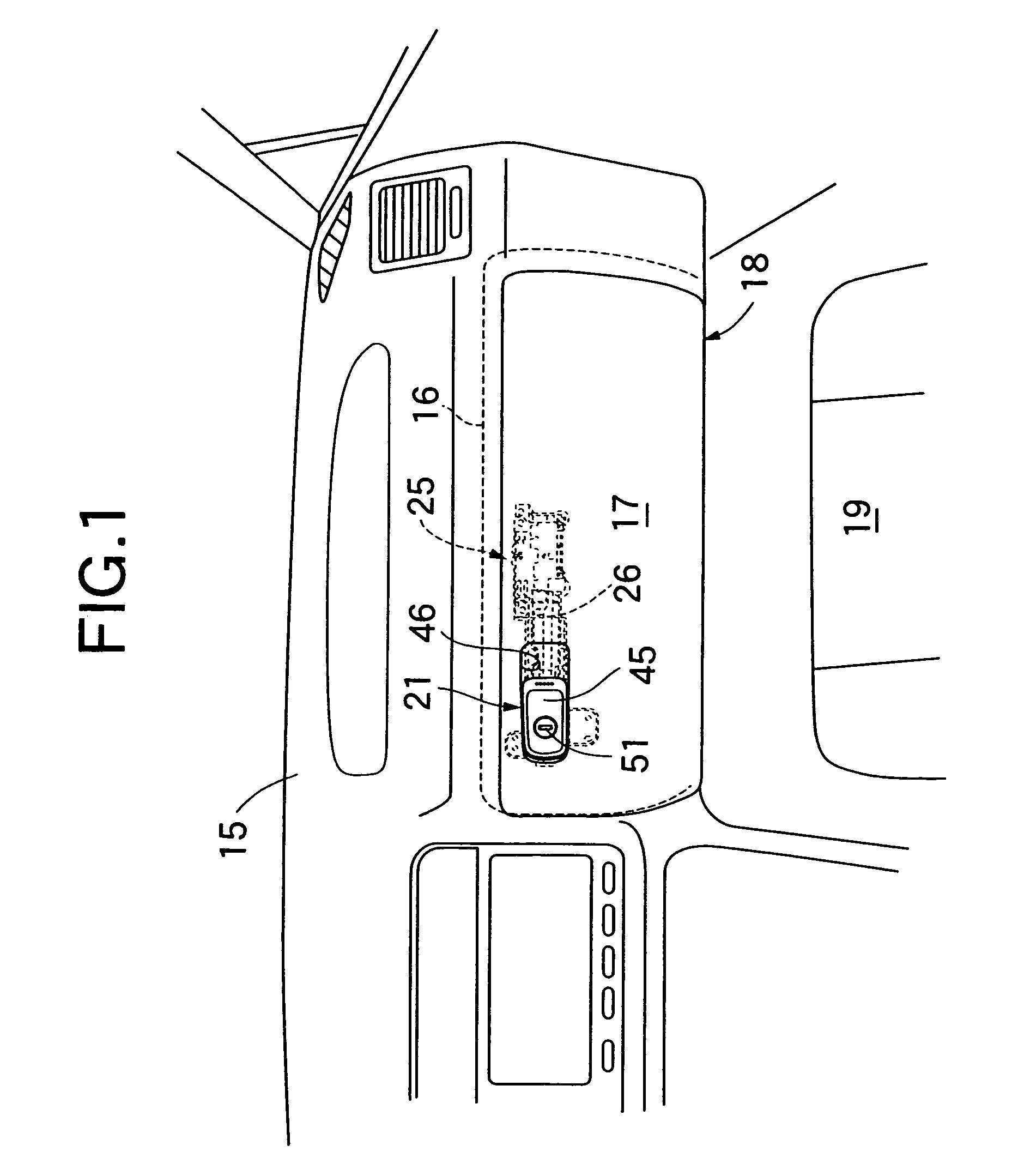

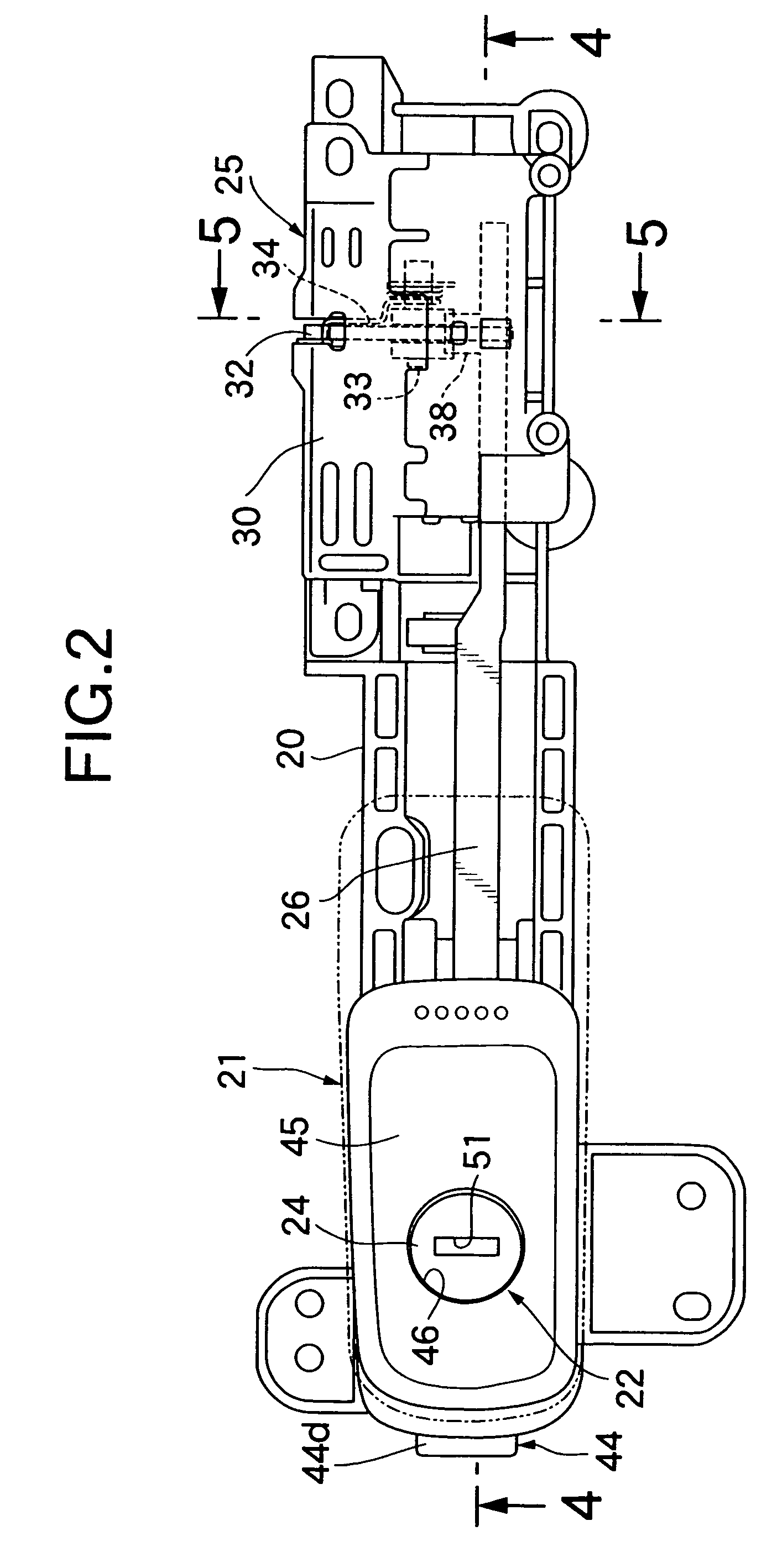

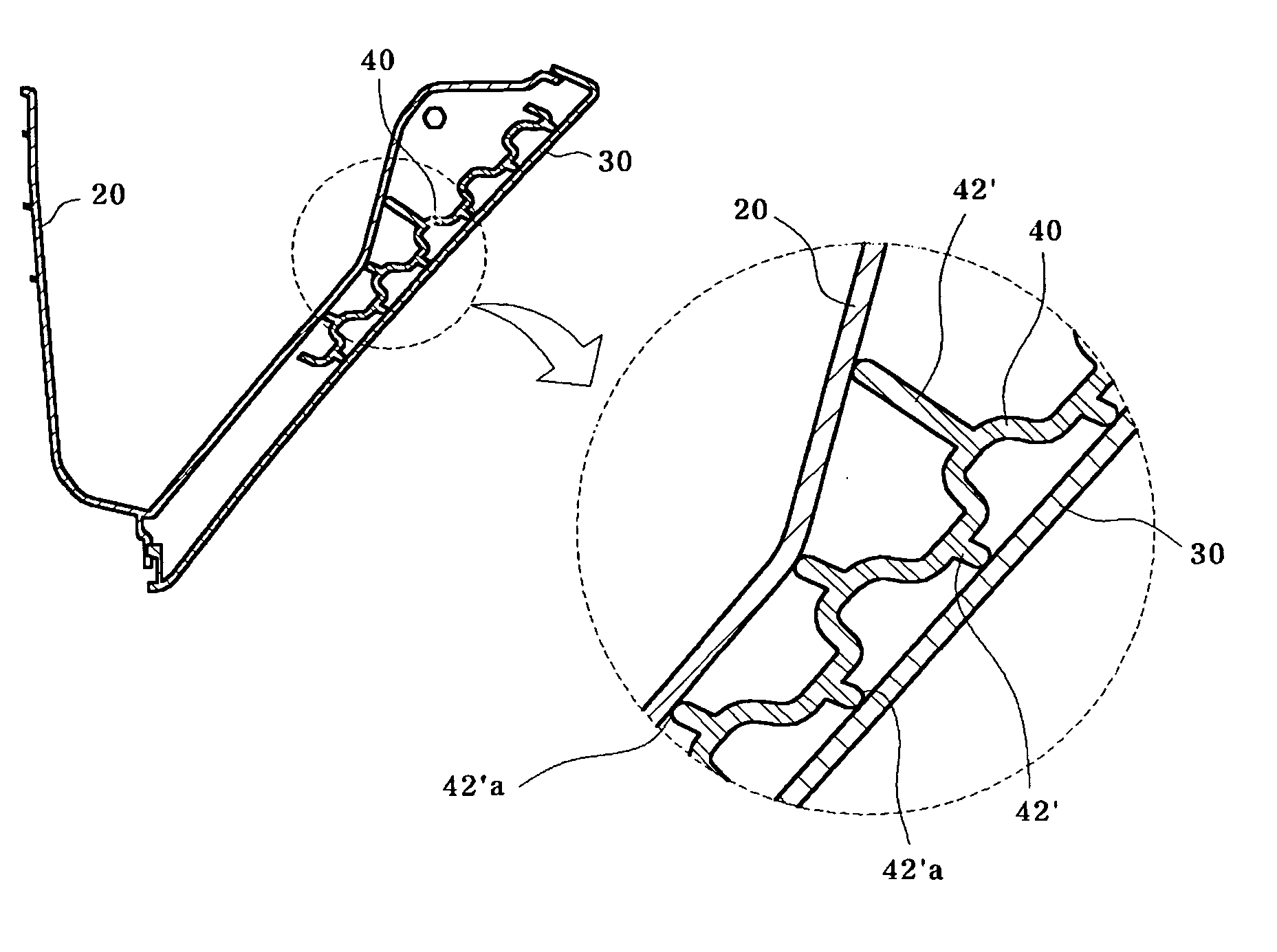

Lid lock apparatus for glove box

InactiveUS7048311B2Smooth movementEasy partition managementPassenger spaceVehicle locksEngineeringCam

A lid lock apparatus for a glove box is attached to inside of a lid to engage hook portions with the glove box. The lid lock apparatus includes a swing member a swing axis of which is rotatably supported by a lid of the glove box; a pair of lock arms, which are disposed in a symmetrical manner with respect to the swing axis, extend in a horizontal direction, and each includes the hook portion at a tip end thereof; and a subassembly member for bringing the lock arms close to each other and forming the lock arms and the swing member in a subassembly. The swing member is disposed in a symmetrical manner with respect to the swing axis and includes a pair of cam grooves extending with slanting. The lock arms include cam pins for engaging with the cam grooves to move the lock arms in opposite directions.

Owner:PIOLAX CO LTD

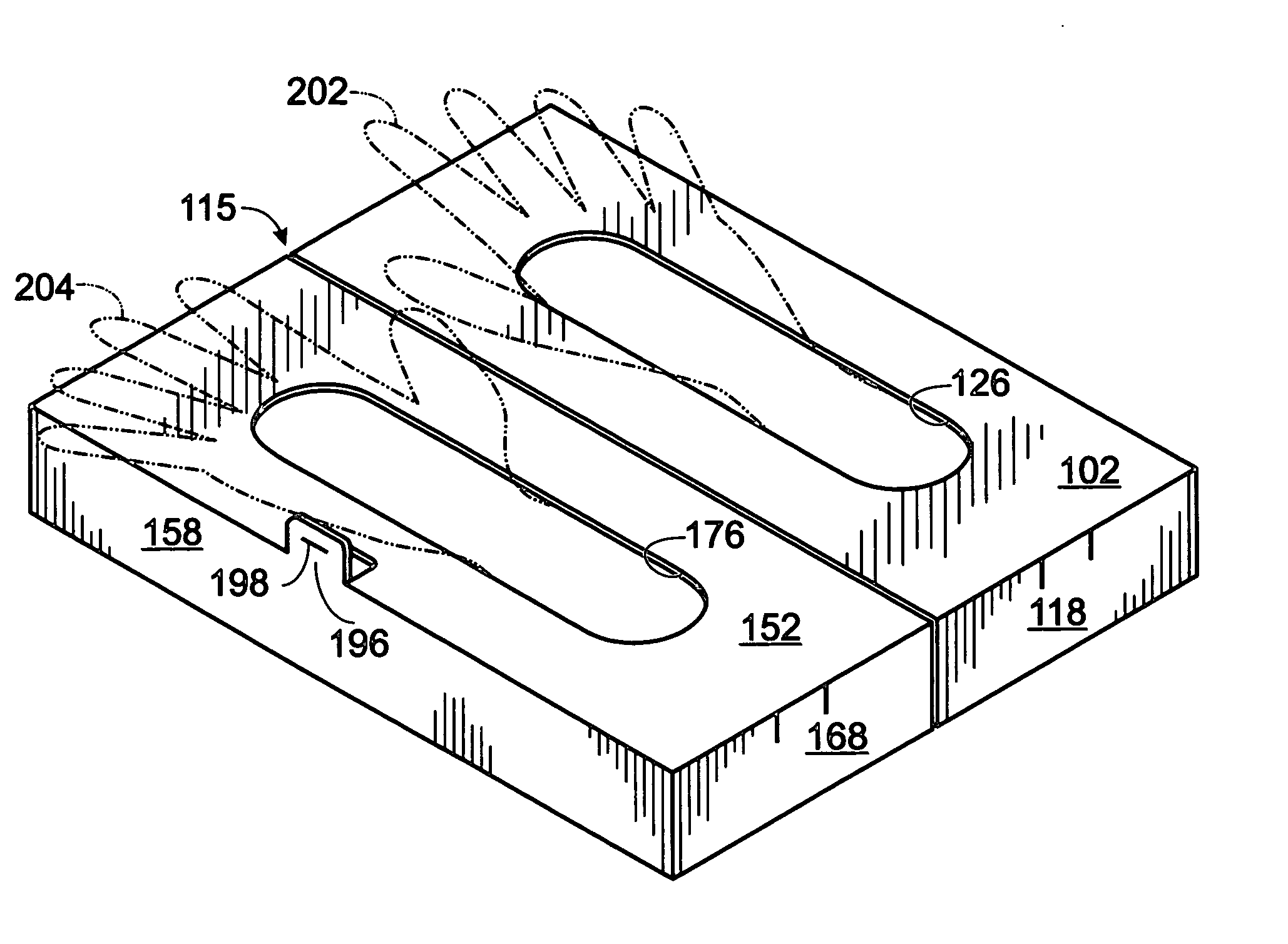

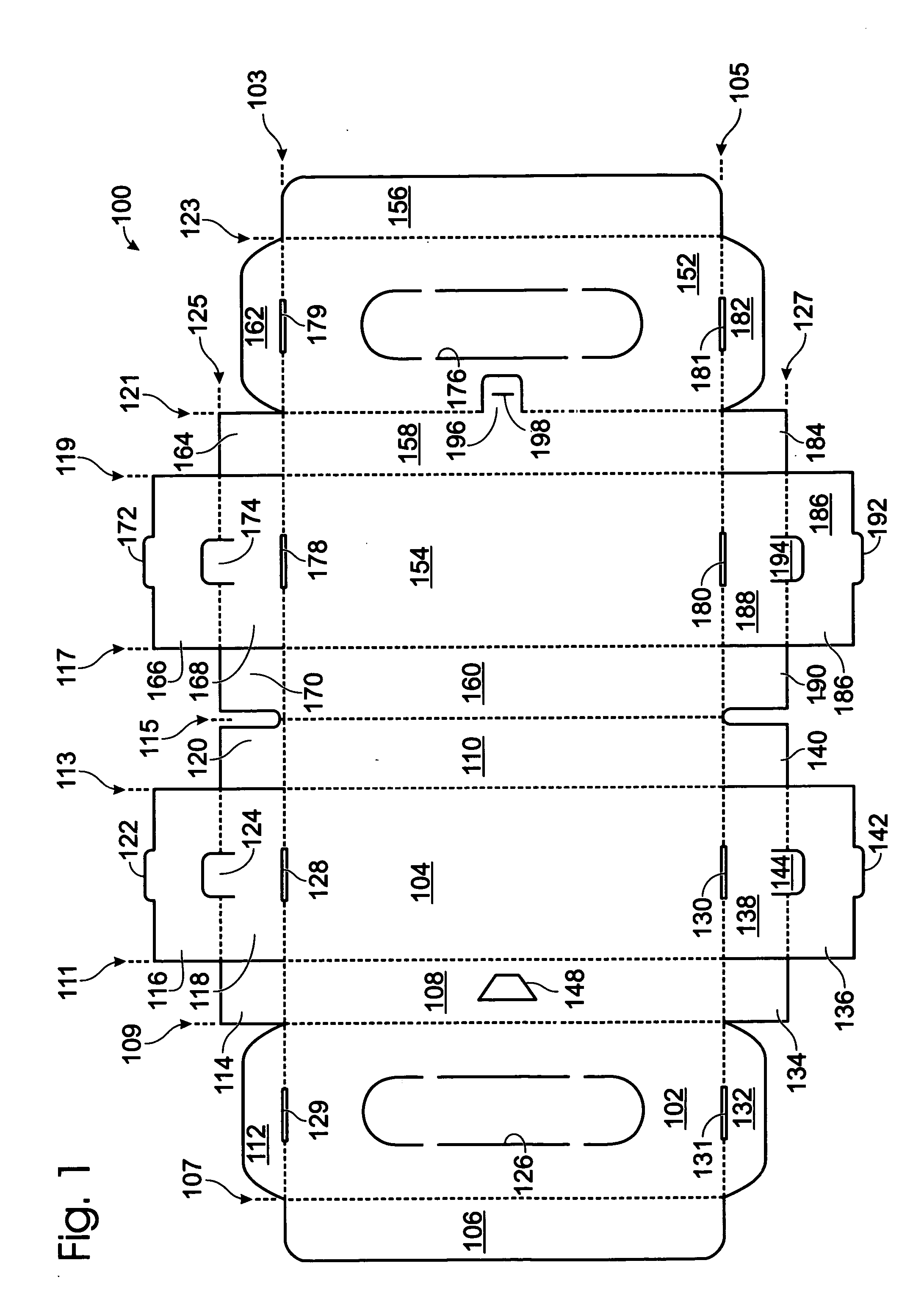

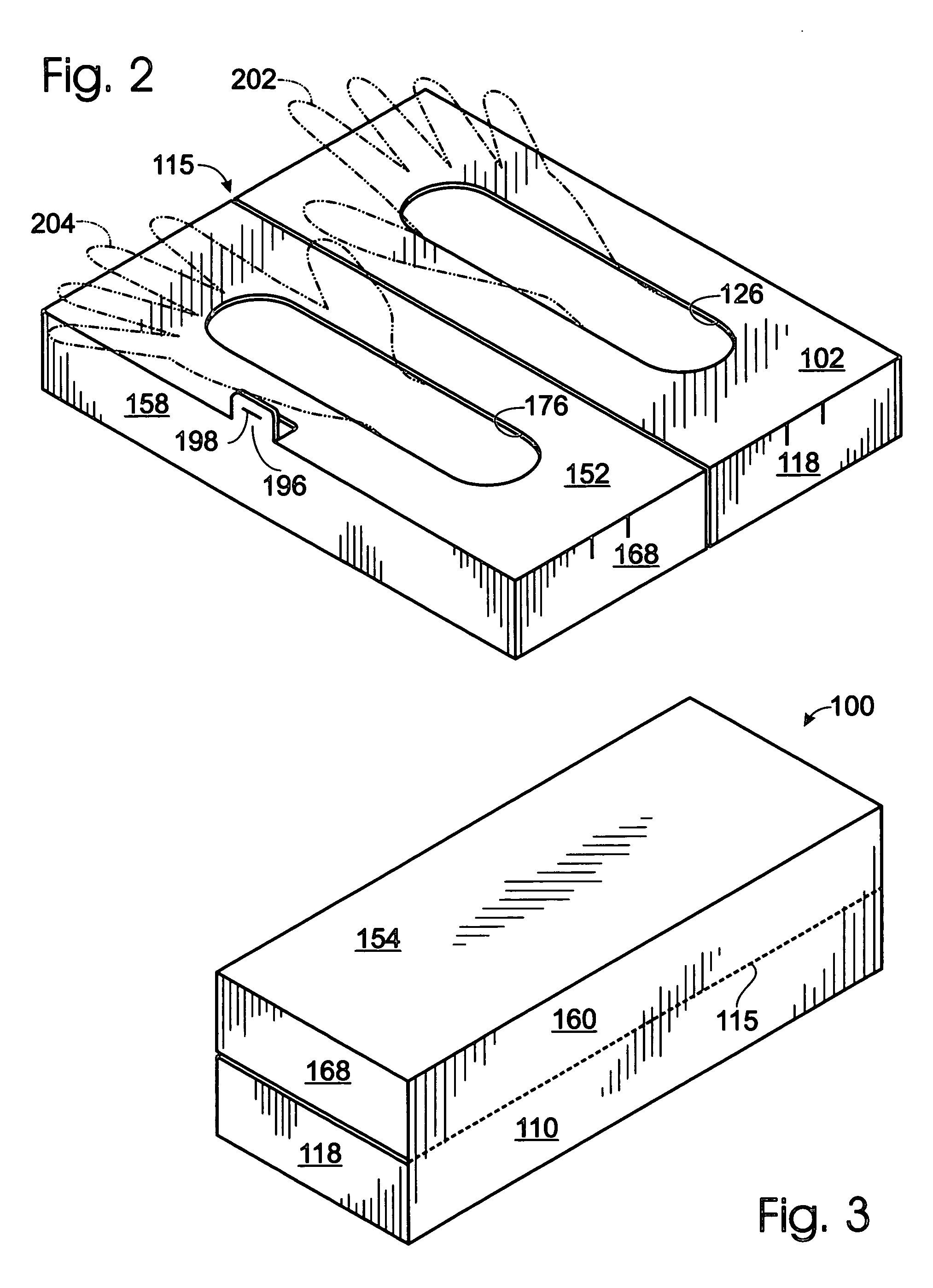

Glove box

A disposable glove dispense and shipping container has a first box and a second box both having dispense apertures disposed therein for dispensing a right hand disposable glove and a left hand disposable glove respectively. The first and second boxes are hingably attached along the first box top and inner surface junction and the second box top and inner surface junction. In the open or dispense position the inner sides of the first box and the second box are both parallel and touching with the top surfaces having the dispense apertures lying flat and side by side for dispensing purposes. In the closed or ship position, the top surface of the first box and the top surface of the second box fold onto one another creating a third box suitable for distribution and shipping.

Owner:FEUSNER JOHN

Method for recycling electrolyte of waste lithium ion battery

ActiveCN102496752AEasy to handleSimple processWaste accumulators reclaimingBattery recyclingSocial benefitsHydrogen fluoride

The invention discloses a method for recycling the electrolyte of a waste lithium ion battery. The method mainly comprises the following steps of: collecting and cleaning the lithium ion battery; after discharge, putting the lithium ion battery in a drying room or a glove box under protection of inert gas; opening the battery, carefully taking out the electrolyte and placing in a material tank; performing high-vacuum decompressed rectification and separation to obtain the organic solvent contained in the electrolyte; performing rectification and purification for recycling; putting a rough product of lithium hexafluorophate into a dissolution kettle, and adding a hydrogen fluoride solution for dissolving the recycled lithium hexafluorophate; filtering the solution and then putting into a crystallization kettle for crystallization and purification; and screening, drying, packaging and recycling to obtain the product lithium hexafluorophate. The method has simple technology, is practical, efficient, clean and environment-friendly and easy to control, and realizes close integration of economic benefits and environmental social benefits.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Locking apparatus and glove box

A locking canceling operation is made to be performed using as a driving force a restoring force produced when a deformable canceling member made of a shape memory alloy is heated to restore its memorized shape.

Owner:TOYODA GOSEI CO LTD

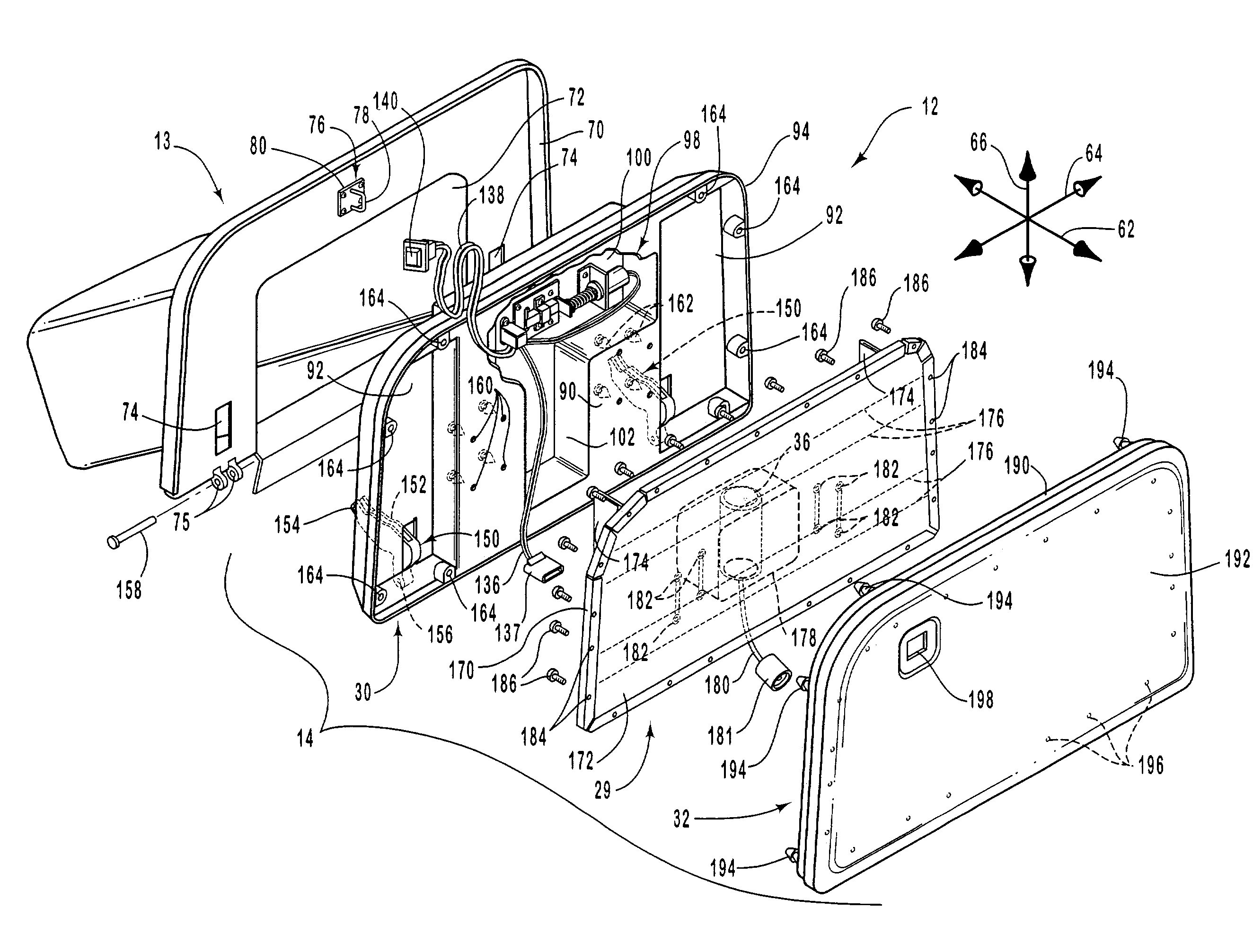

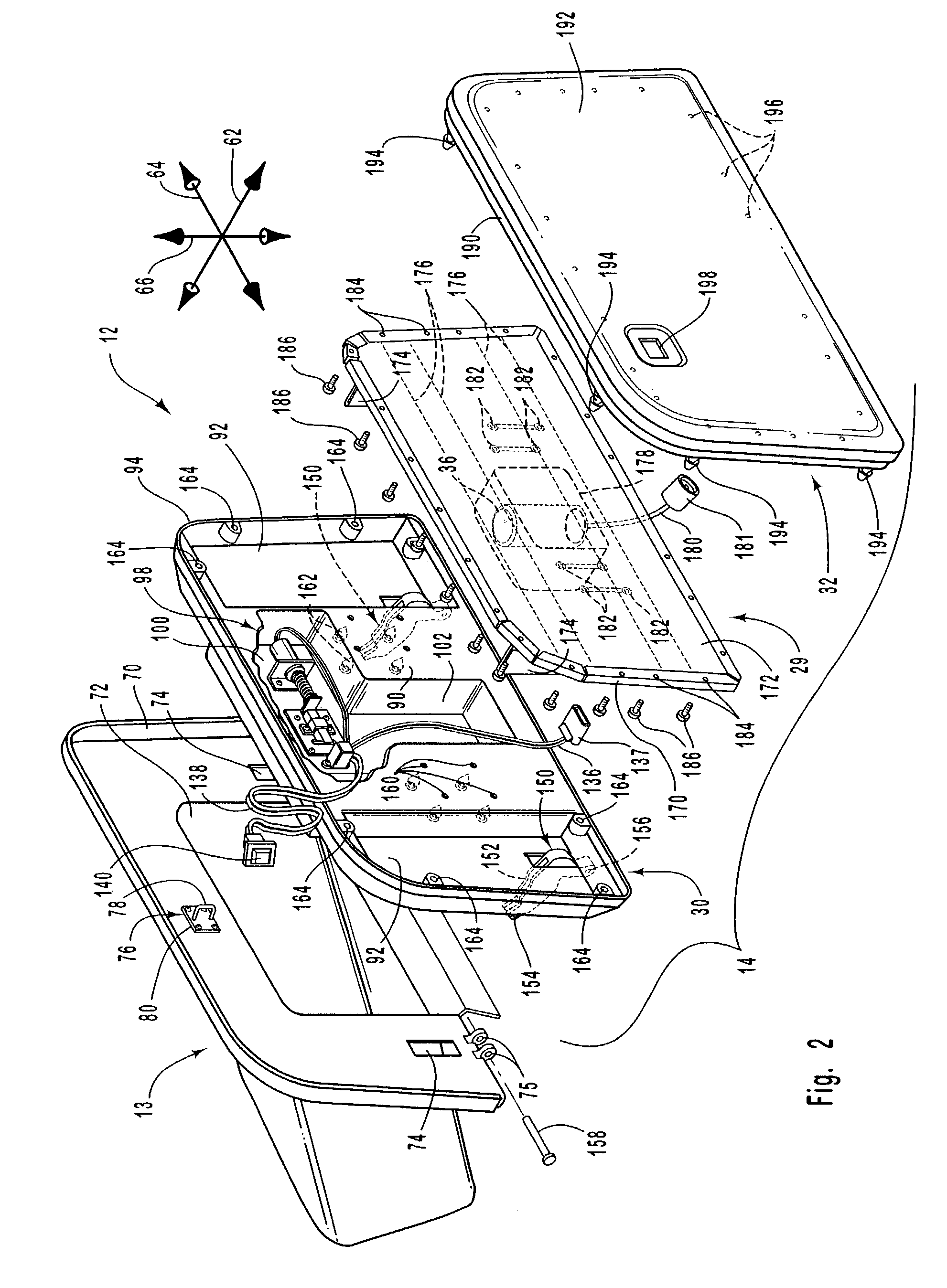

Glove compartment airbag system

InactiveUS6971667B2Improve artSimple designPassenger spacePedestrian/occupant safety arrangementAirbagBack door

A glove compartment assembly incorporates a compact airbag module with a cushion constructed at least partially of a rigid material. The cushion may be sandwiched between front and rear door covers so that inflation of the cushion moves the front door cover toward the knees of a vehicle user to provide antisubmarining protection. The cushion may incorporate the front door cover as a portion of its inflation gas-containing membrane. The glove compartment assembly may utilize a uniquely designed latching system, such as an electric latching assembly, a latching assembly disposed generally off the door, or a break-away latching assembly disposed generally on the front door cover, to permit motion of the front door cover away from the instrument panel without interfering with the airbag module.

Owner:AUTOLIV ASP INC

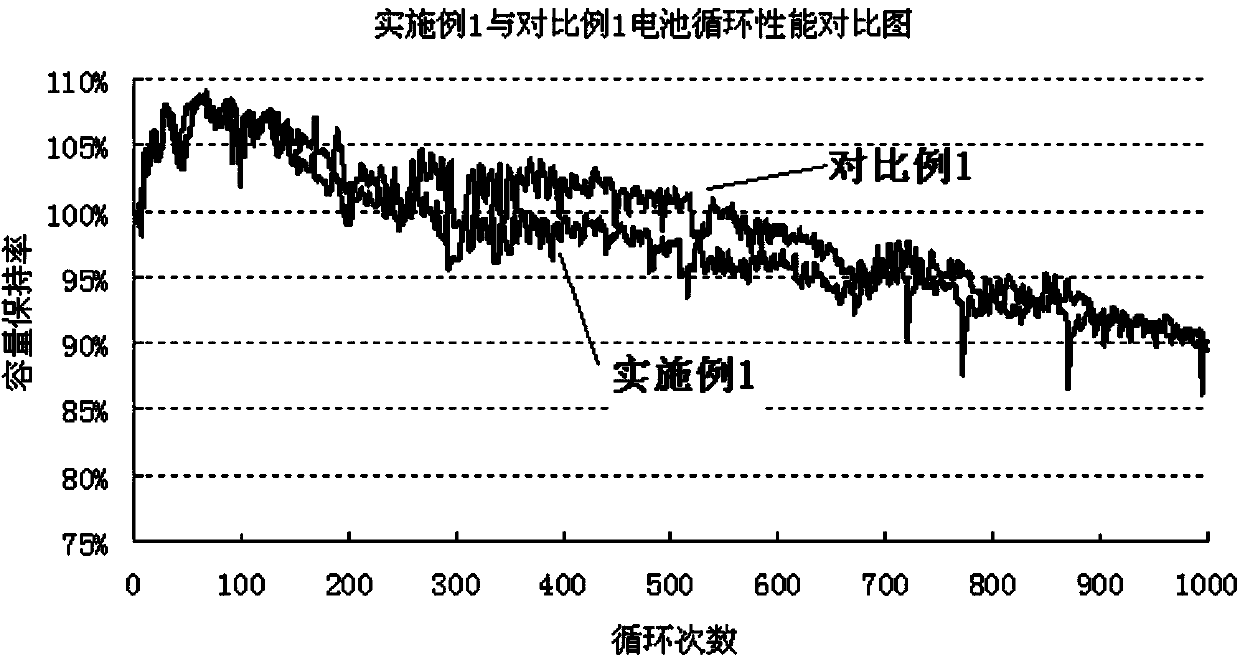

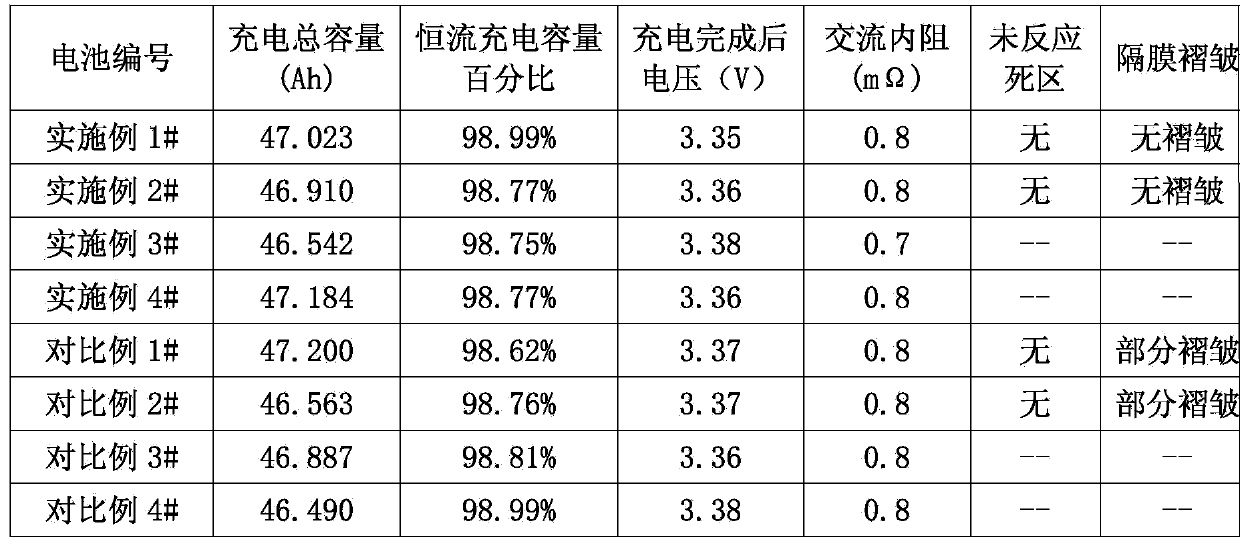

Rapid forming process of iron phosphate lithium battery

InactiveCN104037456AImpact capacityFast and full wettingFinal product manufactureElectrolyte accumulators manufactureLithium iron phosphateThermostat

The invention discloses a rapid forming process of an iron phosphate lithium battery. The rapid forming process comprises the following steps: vacuumizing after the battery is assembled, and injecting electrolyte by several times, and sealing the battery; putting the battery into a thermostat, standing for 8-12 hours at 45-50 DEGC, turning or rotating the battery in a standing process so as to putting each face of the battery downwards for a certain time; after the standing, carrying out ultrasonic treatment on the battery for 10-20 minutes; putting the battery on a cabinet, and carrying out low-current step type charging excitation and intermittent pulse discharge on the battery; after the charging is finished, carrying out deflation and one time of vacuumizing on the battery in a glove box, and carrying out sealing, ageing and capacity grading. According to the rapid forming process, firstly a diaphragm, an anode piece and a cathode piece of the battery are adequately infiltrated by virtue of the electrolyte, and then the battery is simultaneously subjected to high-current step type charging and intermittent pulse discharge, so that the time of the forming procedure is substantially shortened, the equipment loss is reduced, the performance of the formed battery is excellent, and the formed battery has no difference from a battery formed by virtue of a traditional forming process.

Owner:LVCHI AUTO TECH SHANGHAI CO LTD

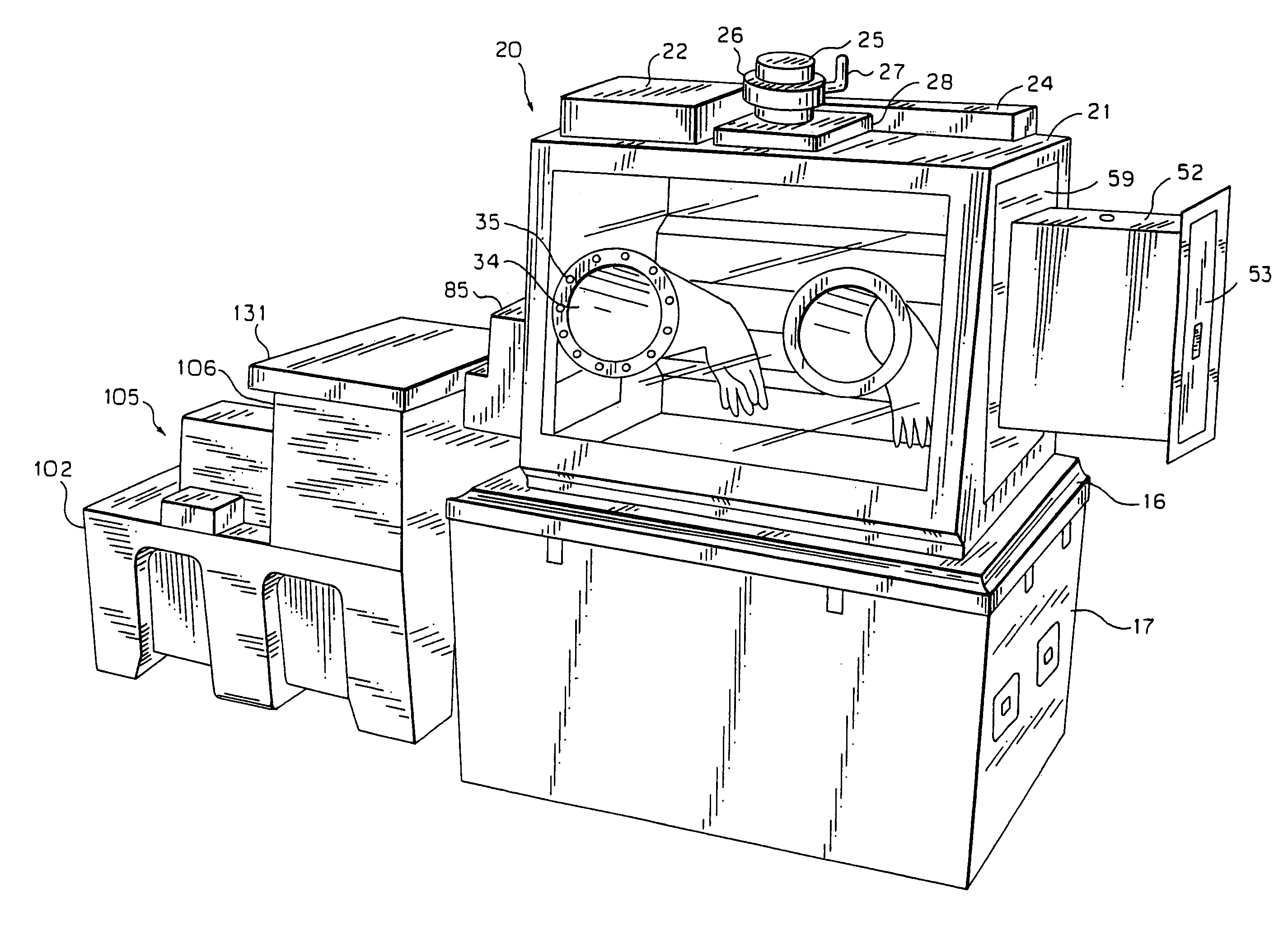

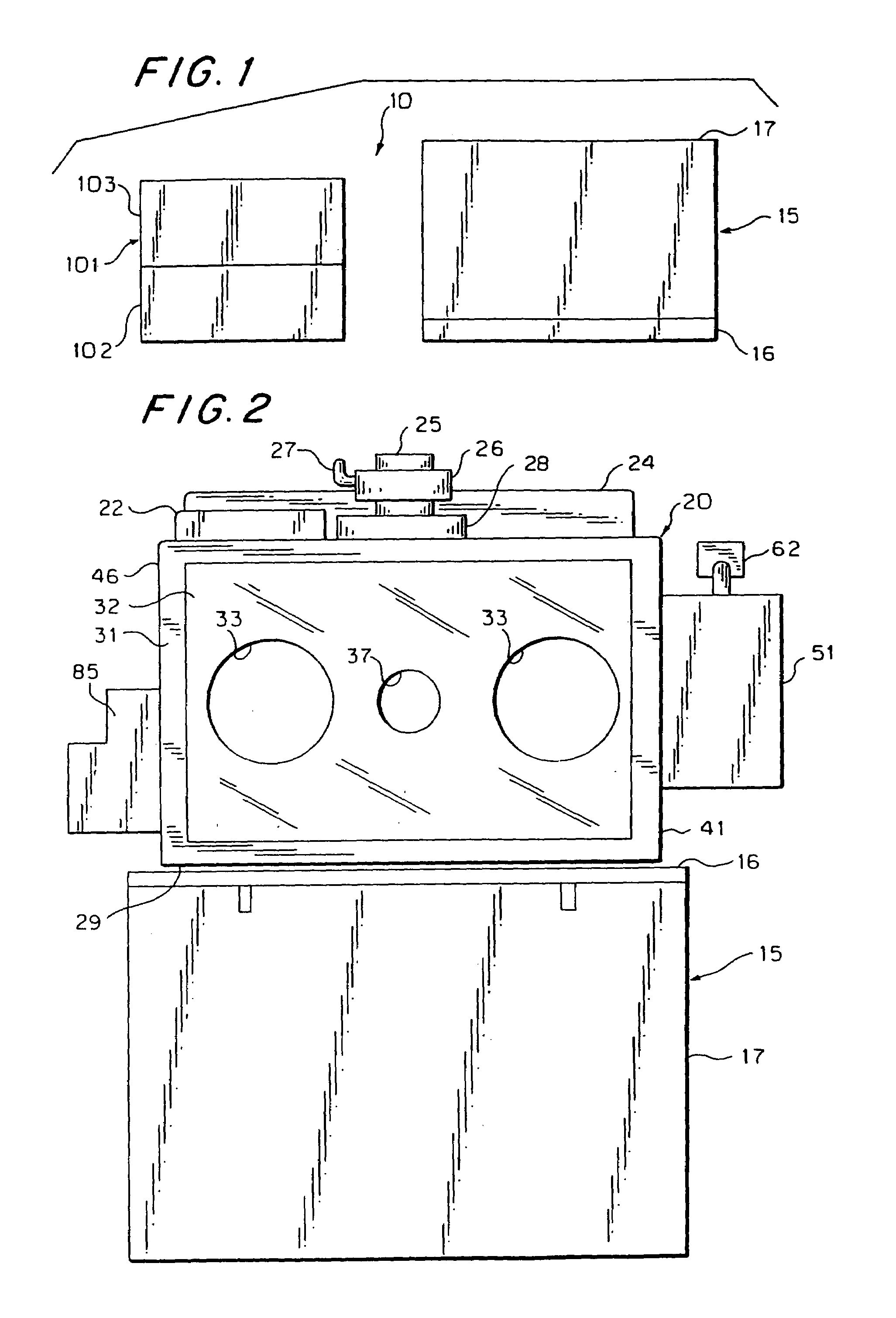

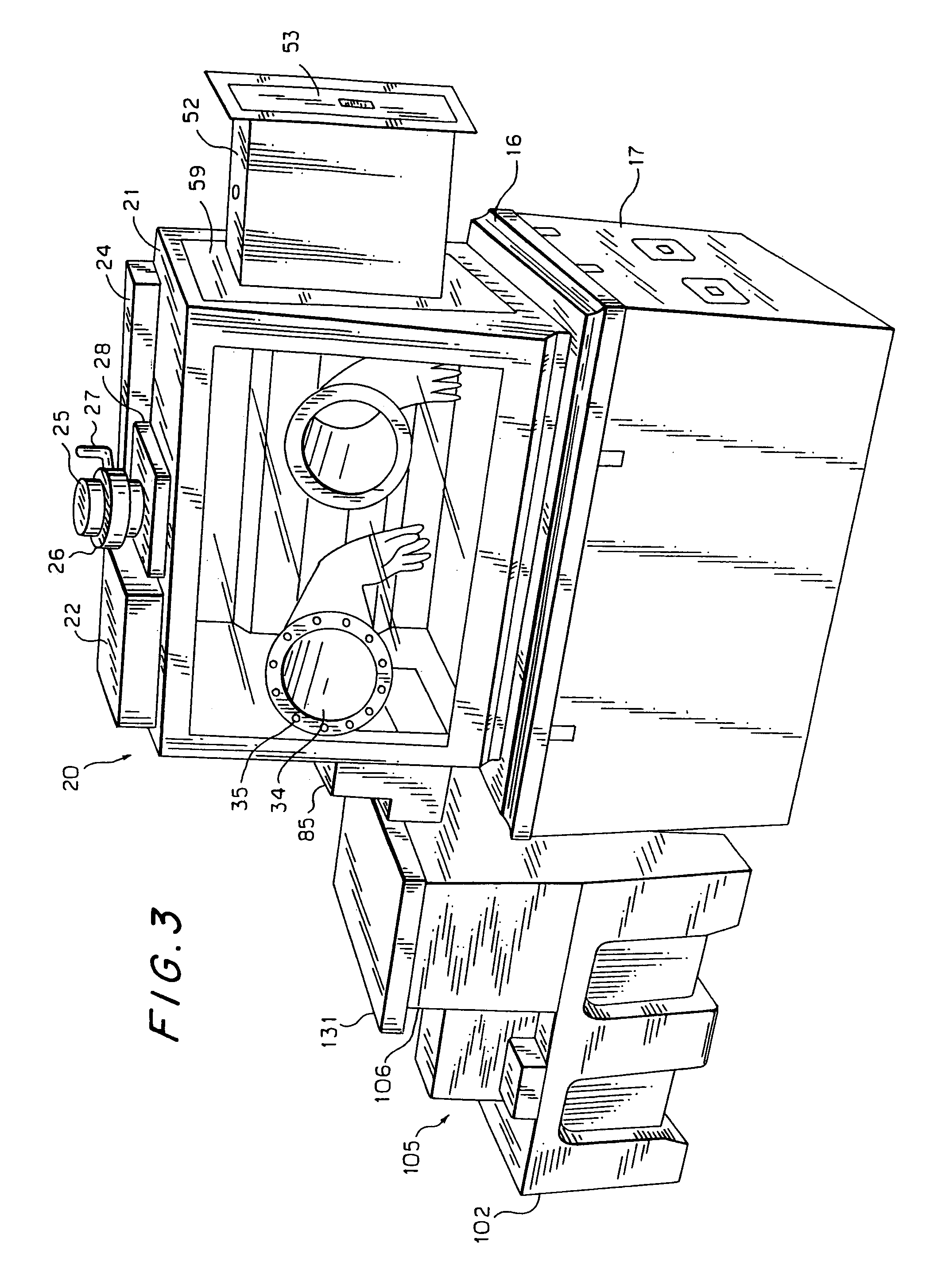

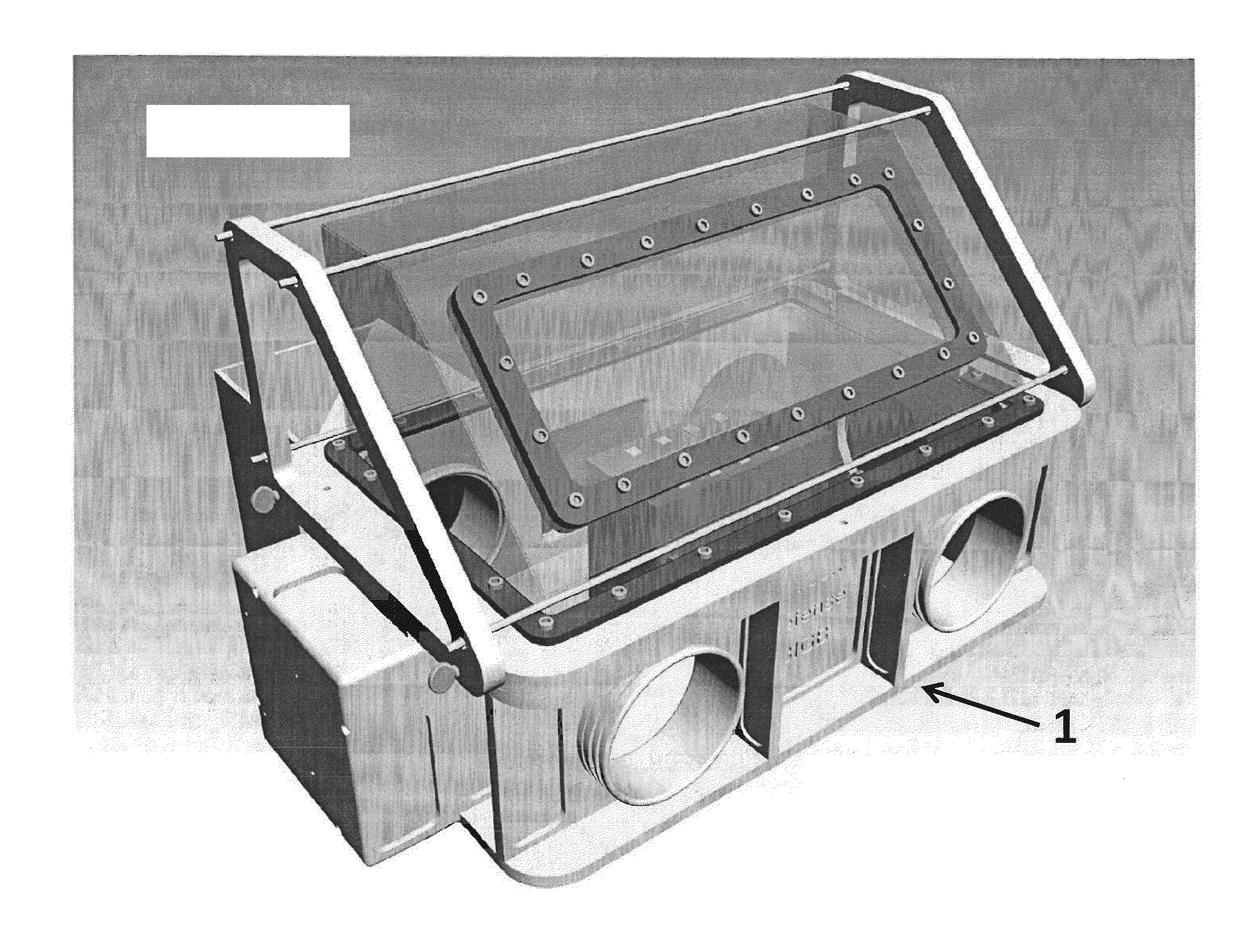

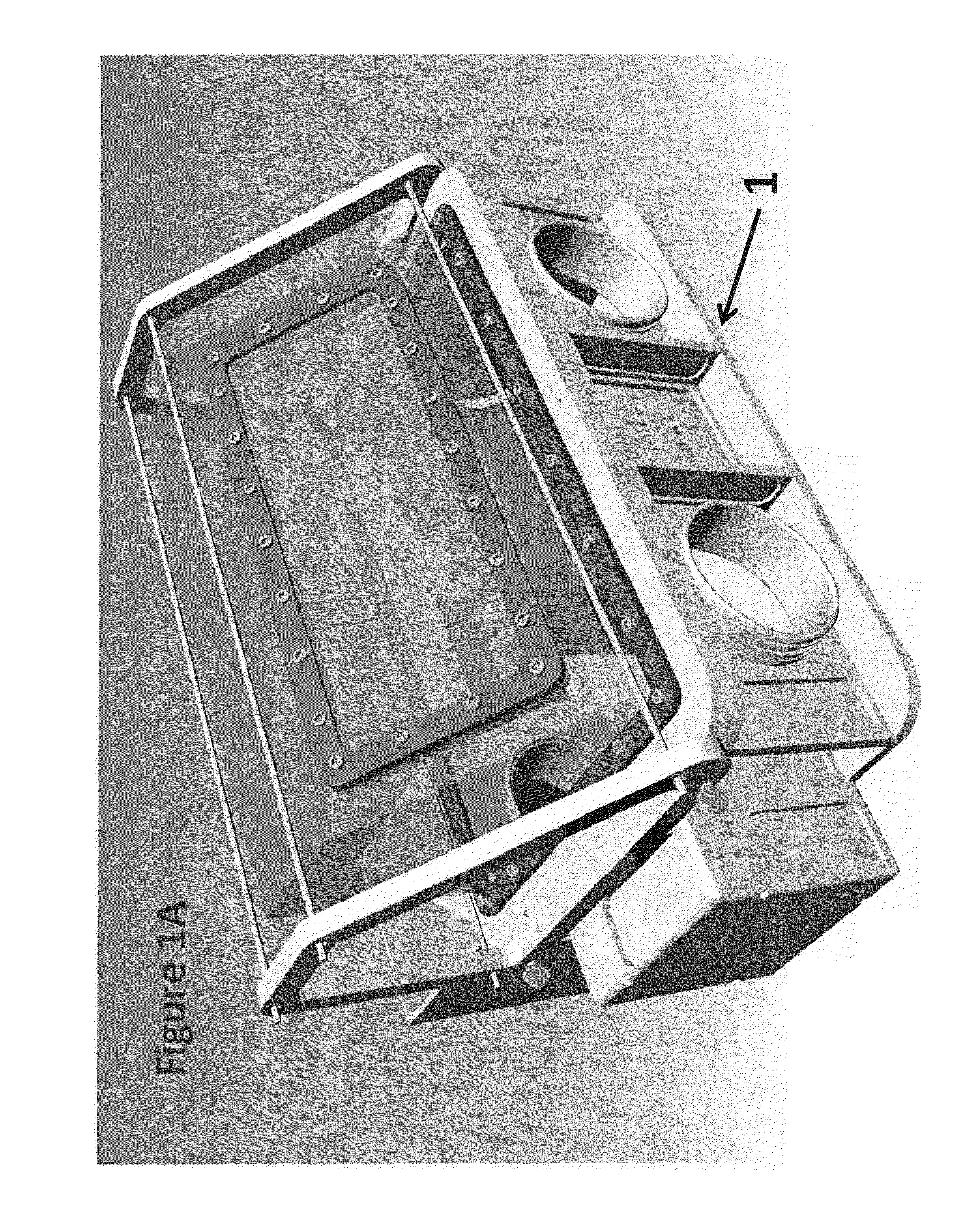

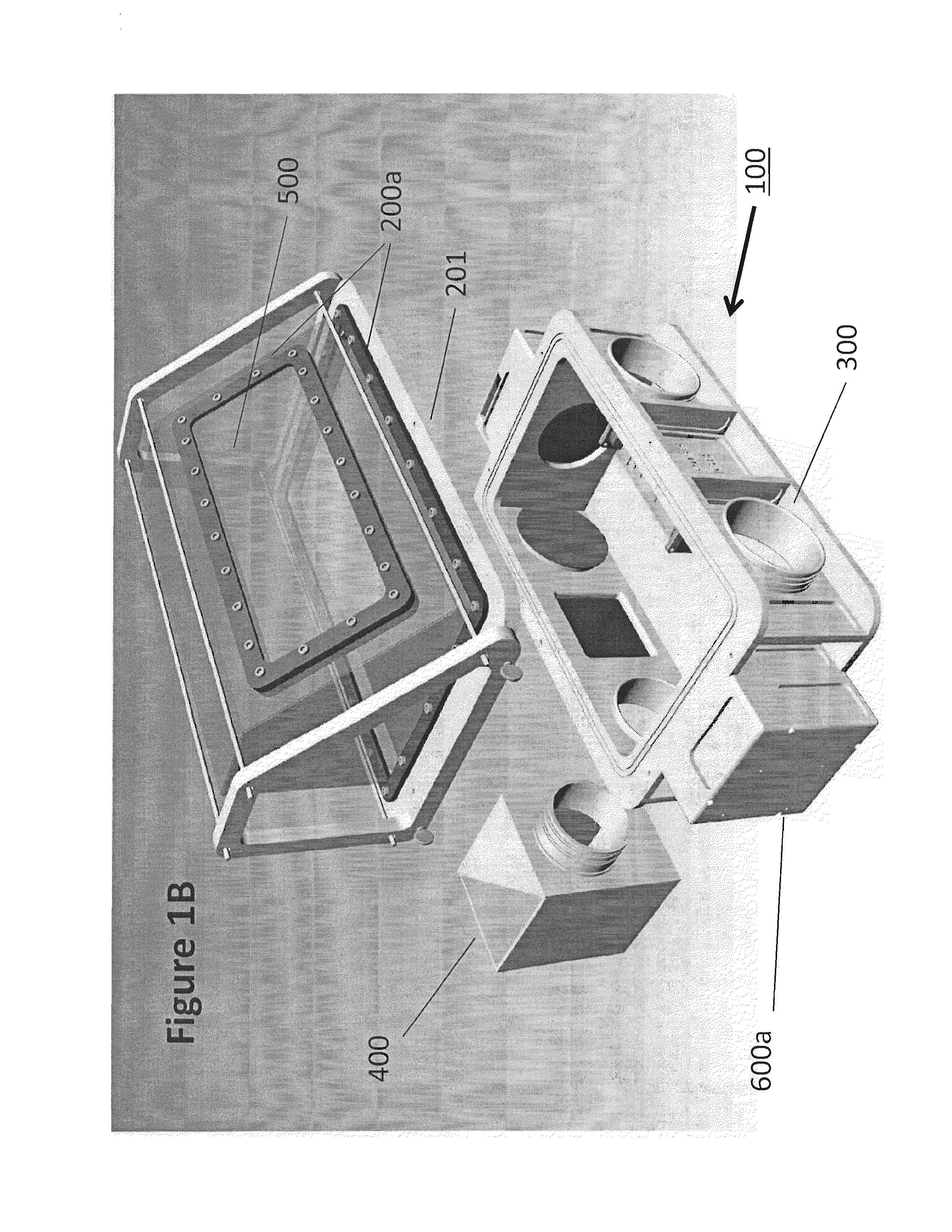

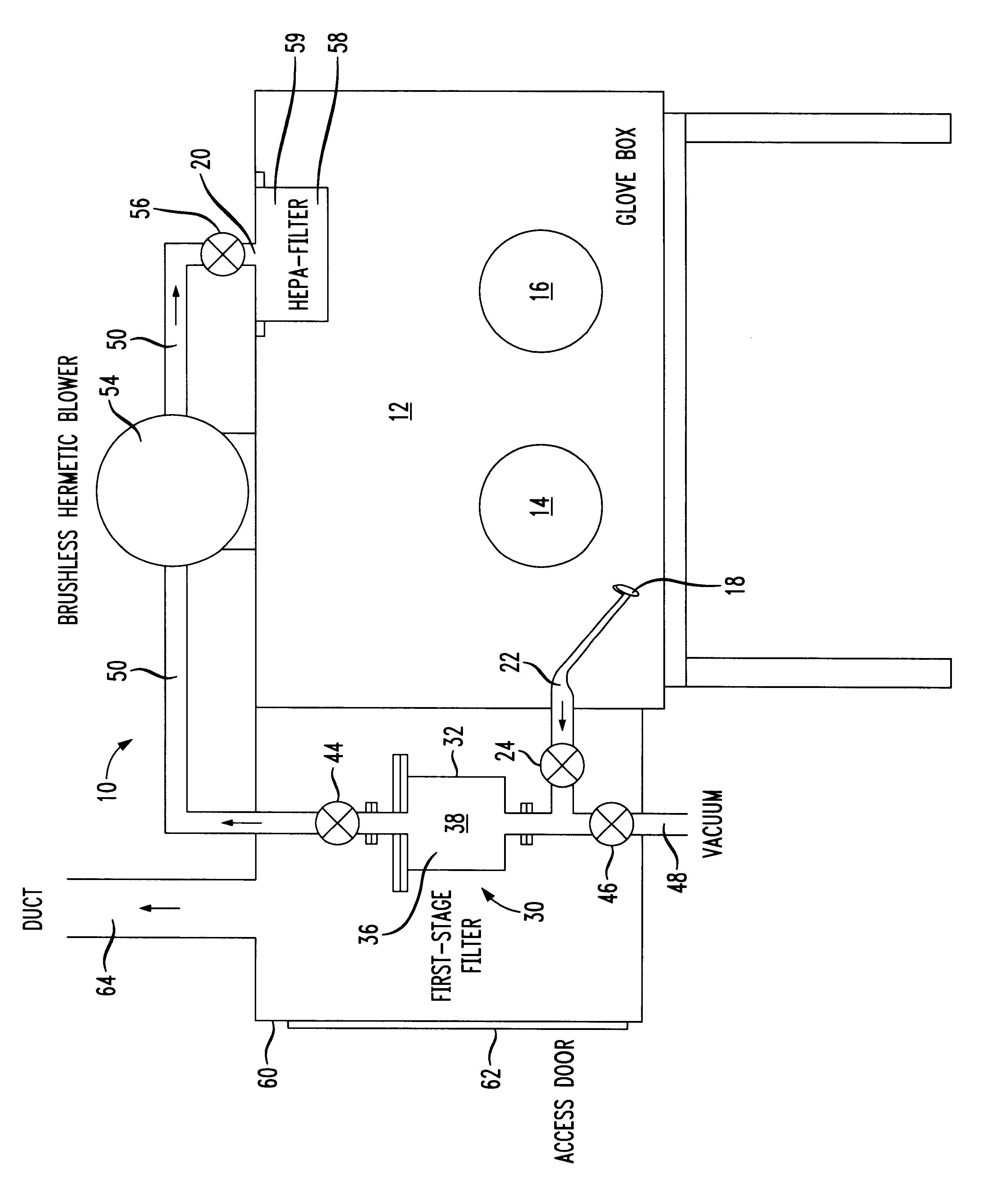

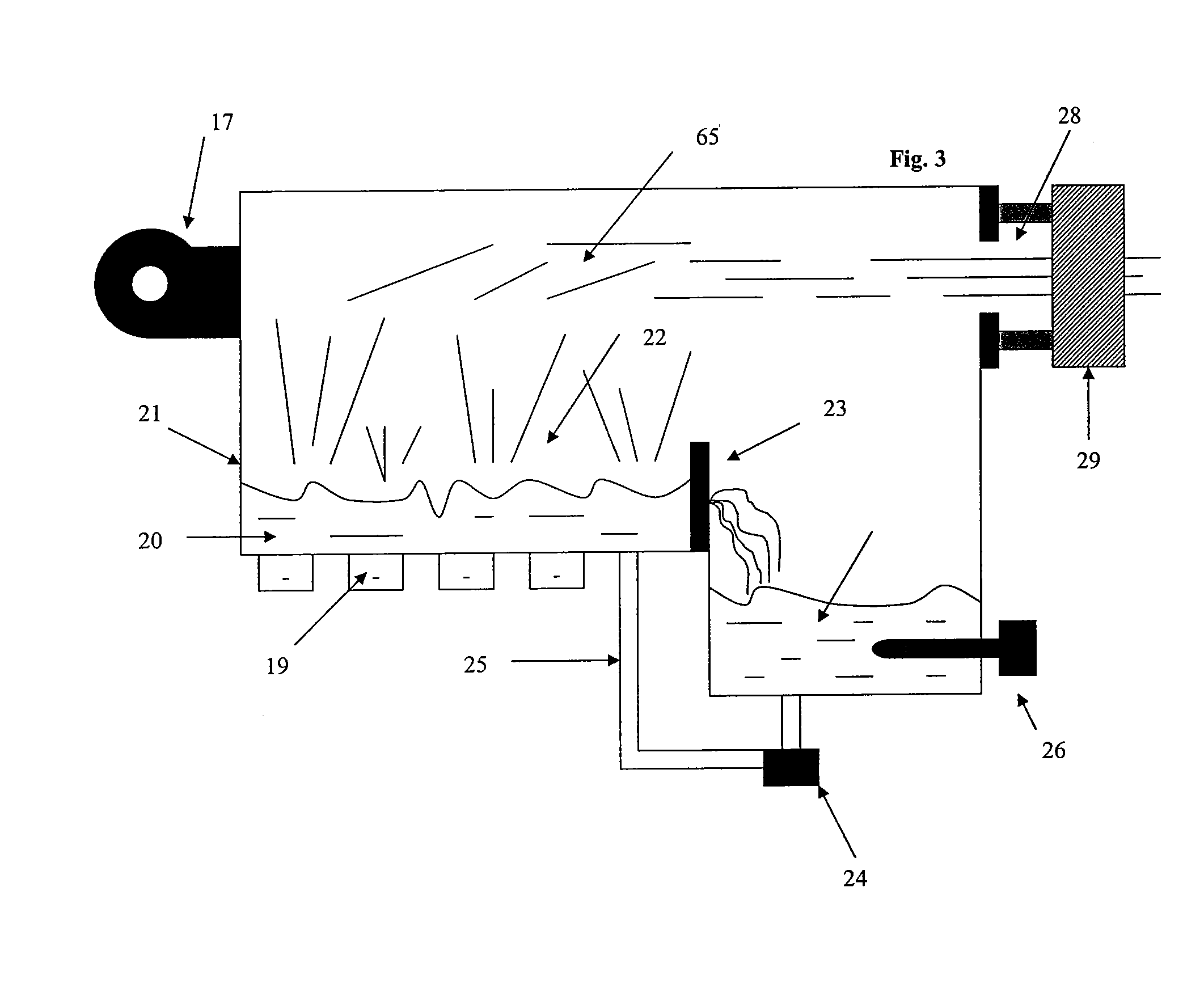

Portable glovebox and filtration system

InactiveUS6974197B1Readily transported and deployedEfficient designDetection of fluid at leakage pointBaby-incubatorsFiltrationFilter system

A portable containment system includes a glovebox apparatus, a self-contained filter unit, and removable conduits extending therebetween. The glovebox apparatus includes a first module for releasably covering a first sidewall opening. The first module, which has body and flange portions, has a storage position where the body portion is positioned through the first sidewall opening into the glovebox interior and an operative position where the body portion is positioned exterior of the glovebox. The glovebox apparatus includes second modules for releasably covering a second sidewall opening where the second modules are smaller than the first sidewall opening for inserting the second modules into the interior of the glovebox for storage. The filter unit includes a plurality of gas filters, an air pump, and detectors for monitoring the air flow through the system.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

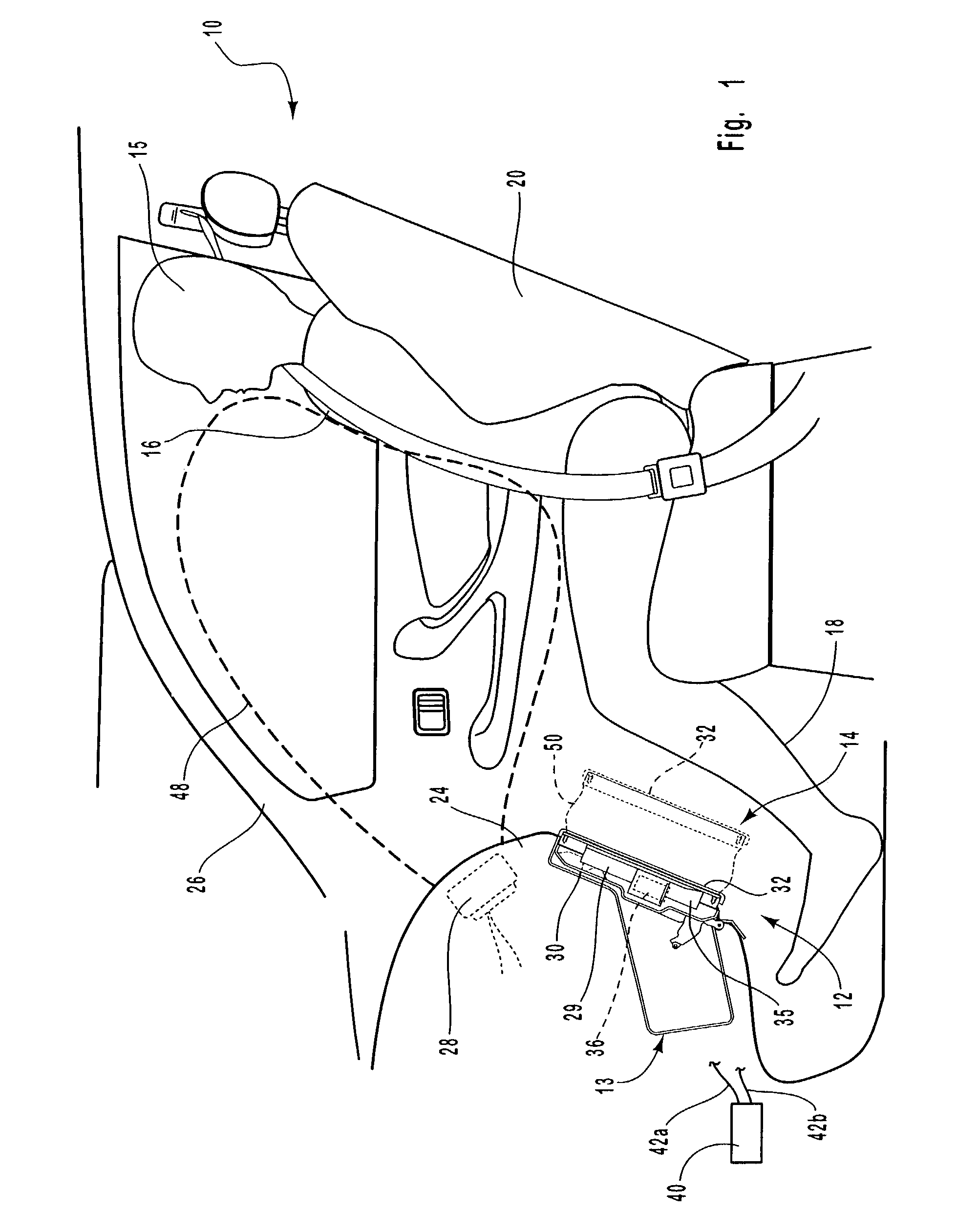

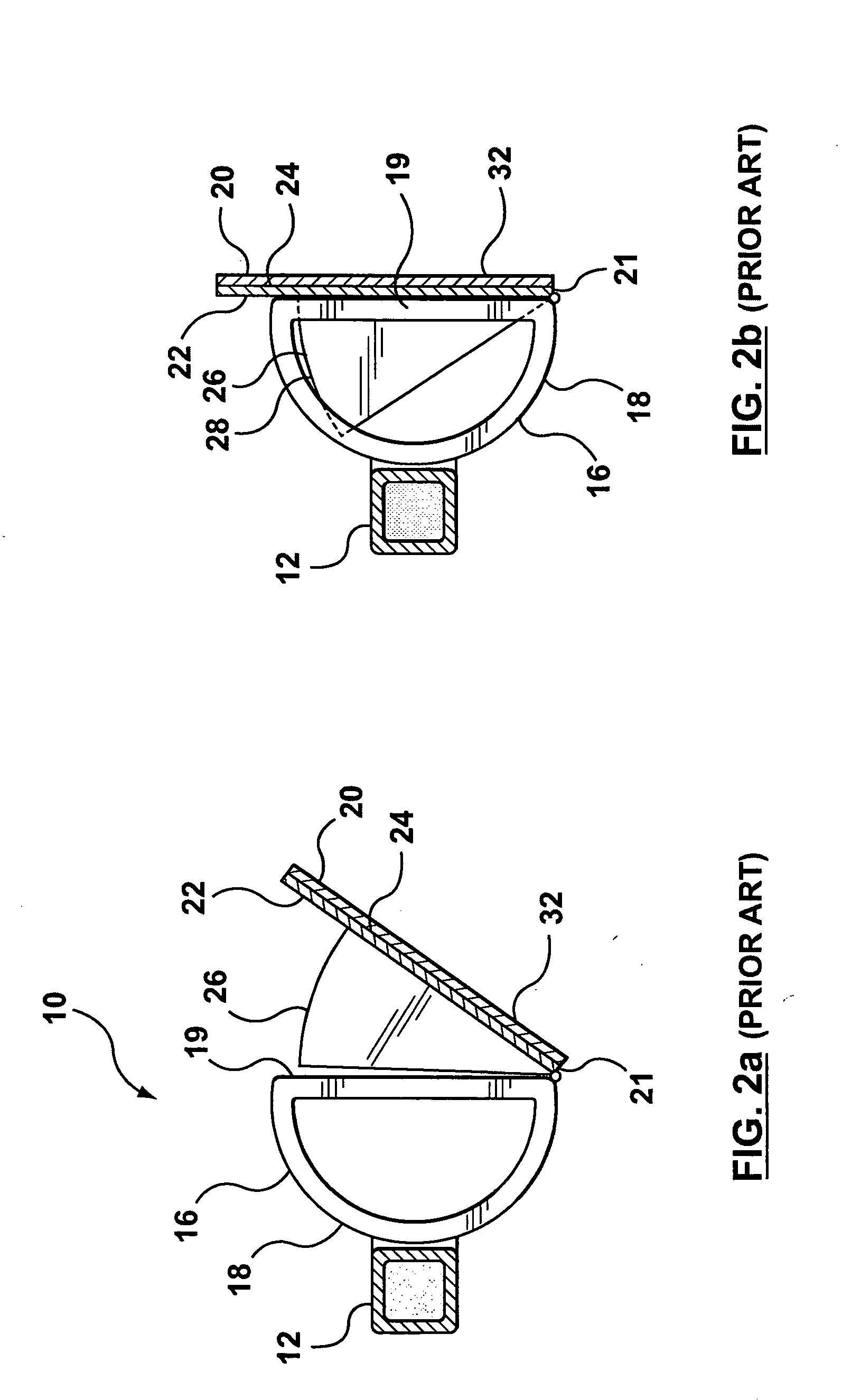

Knee airbag and glove box assembly

A glove box airbag system is disclosed that may be used to protect the knees and / or legs of a vehicle occupant during a crash. The airbag assembly includes a glove box and a housing that encases a knee airbag. The housing is positioned below the glove box. The entirety of the housing may be positioned below the entirety of the glove box. The airbag assembly also has a front member that covers the glove box and the housing. The front member may include a glove box door that covers the glove box and an airbag door that covers the housing. Alternatively, the front member may be a glove box door that covers both the housing and the glove box. Further, the front member may include a glove box door that covers the glove box and an aperture that is positioned in front of the housing. A hinge and / or a latch mechanism that allow the glove box door to move between a closed position and an open position may also be added.

Owner:AUTOLIV ASP INC

Methods and Systems For Providing Protection Against Harmful Materials

A glove box for handling harmful material is formed to be lightweight and modular in design, allowing for use in the field and various remote locations where a full laboratory is not available. The tank portion of the glove box is formed of a rigid, lightweight plastic and includes a number of standard-sized passageways for connecting other components (intake filter, exhaust filter, input / output containers, gasketed gloves, etc), allowing for modularity in its configuration. The top portion of the glove box may include a transparent window for viewing the material within the glove box. Filter components utilize HEPA filter elements and a separate, portable power supply is used to control a vacuum fan included in an exhaust filter. The power supply can also be used to perform diagnostic tests on the glove and may include a battery back-up.

Owner:INTECH DEFENSE

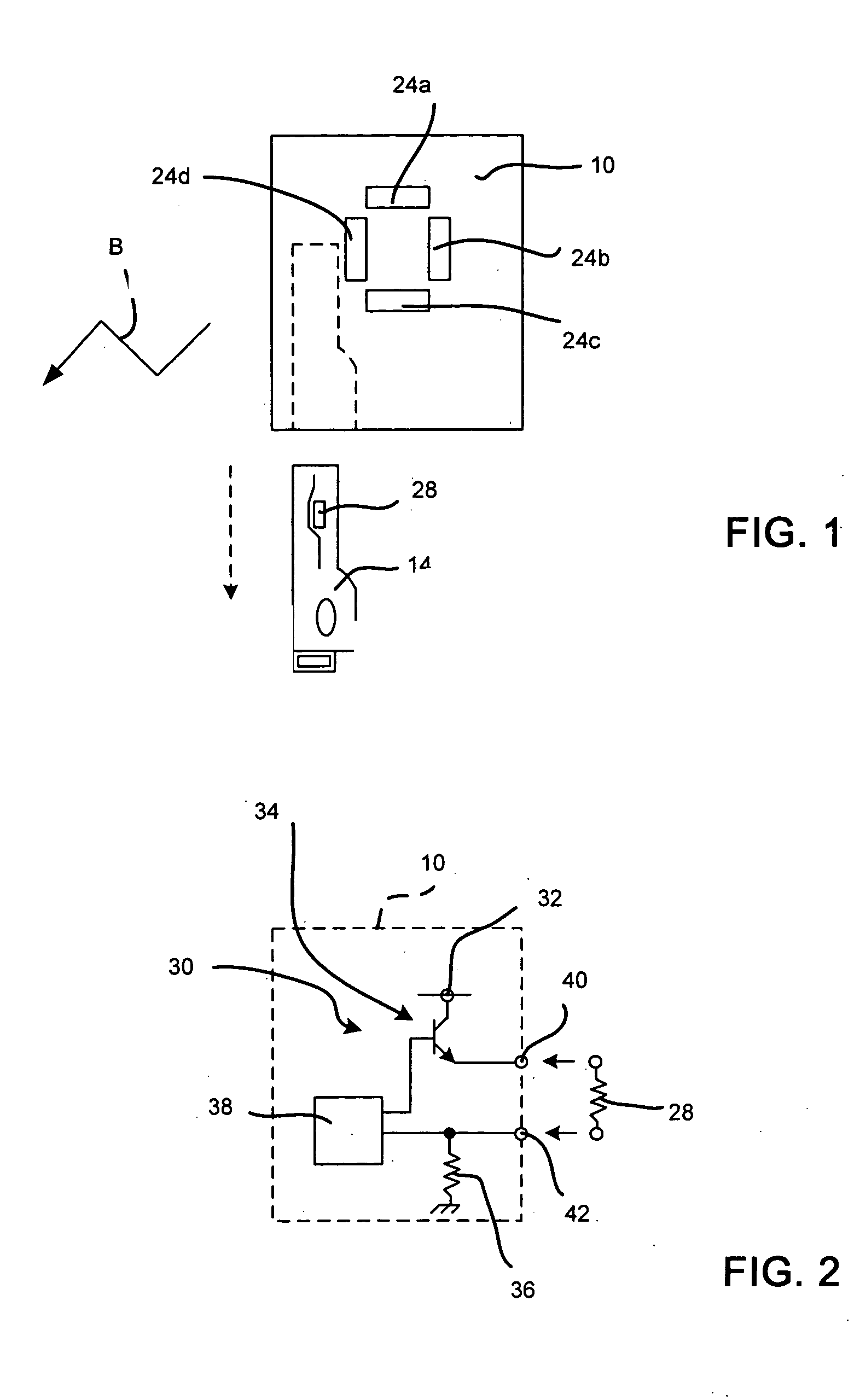

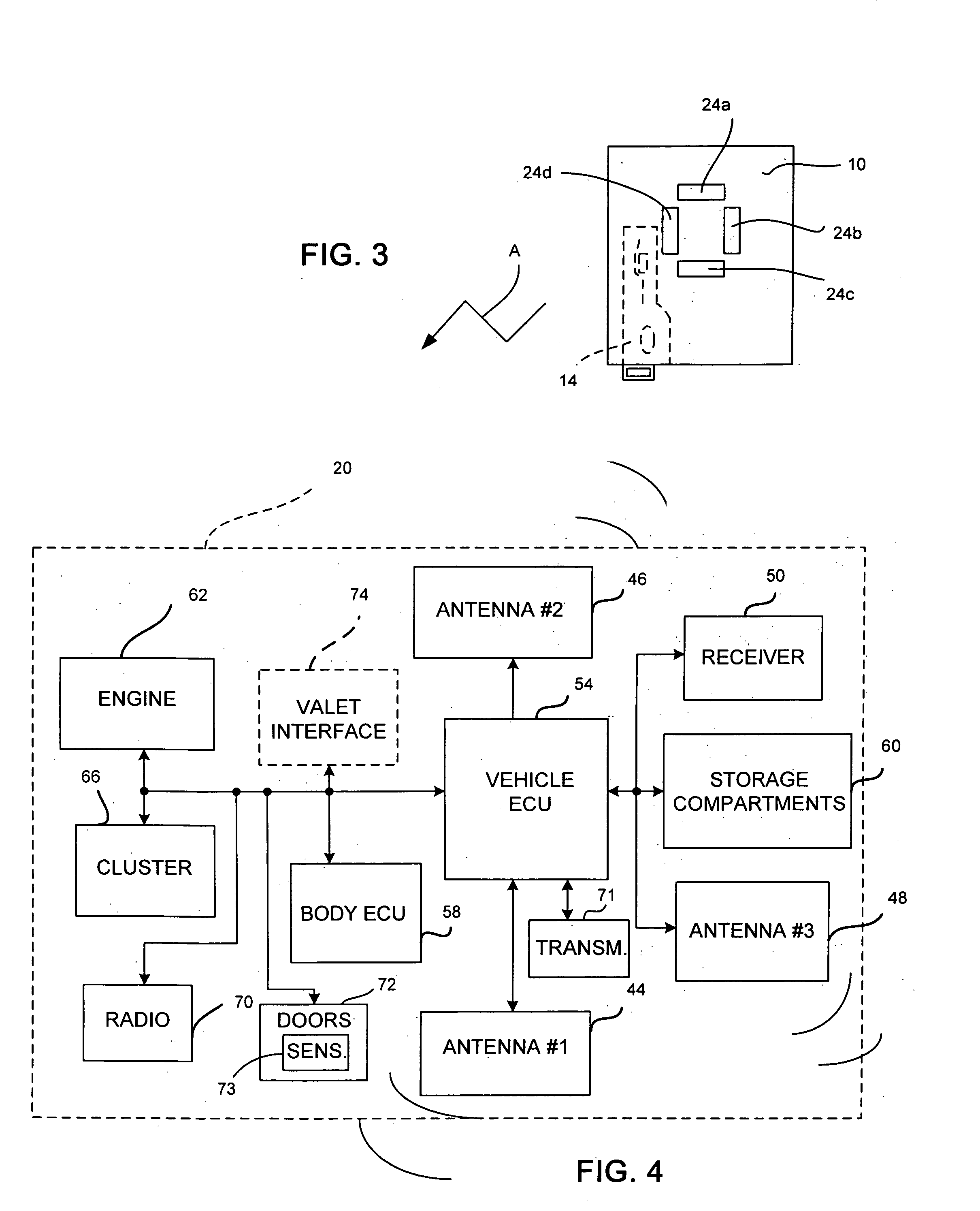

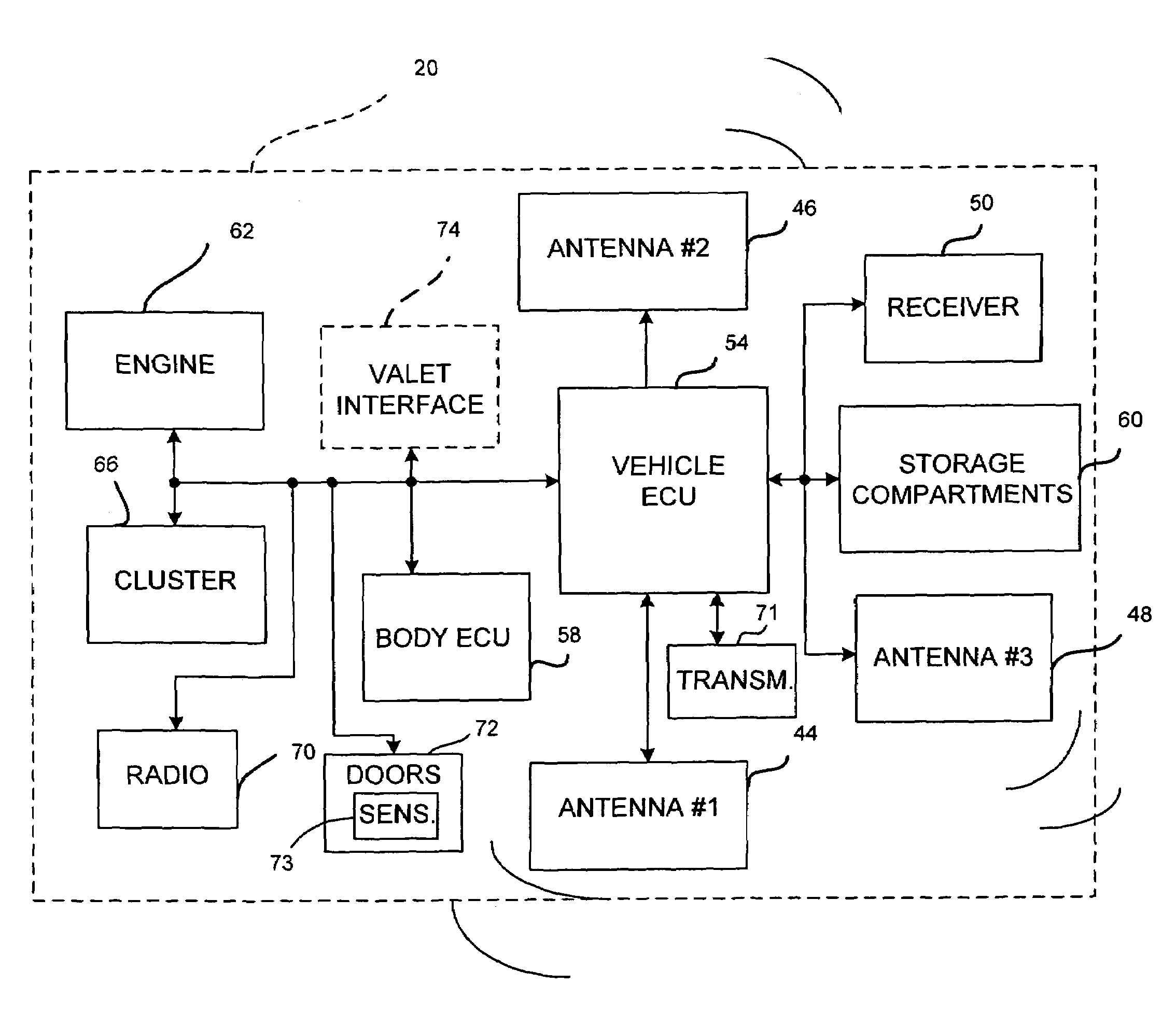

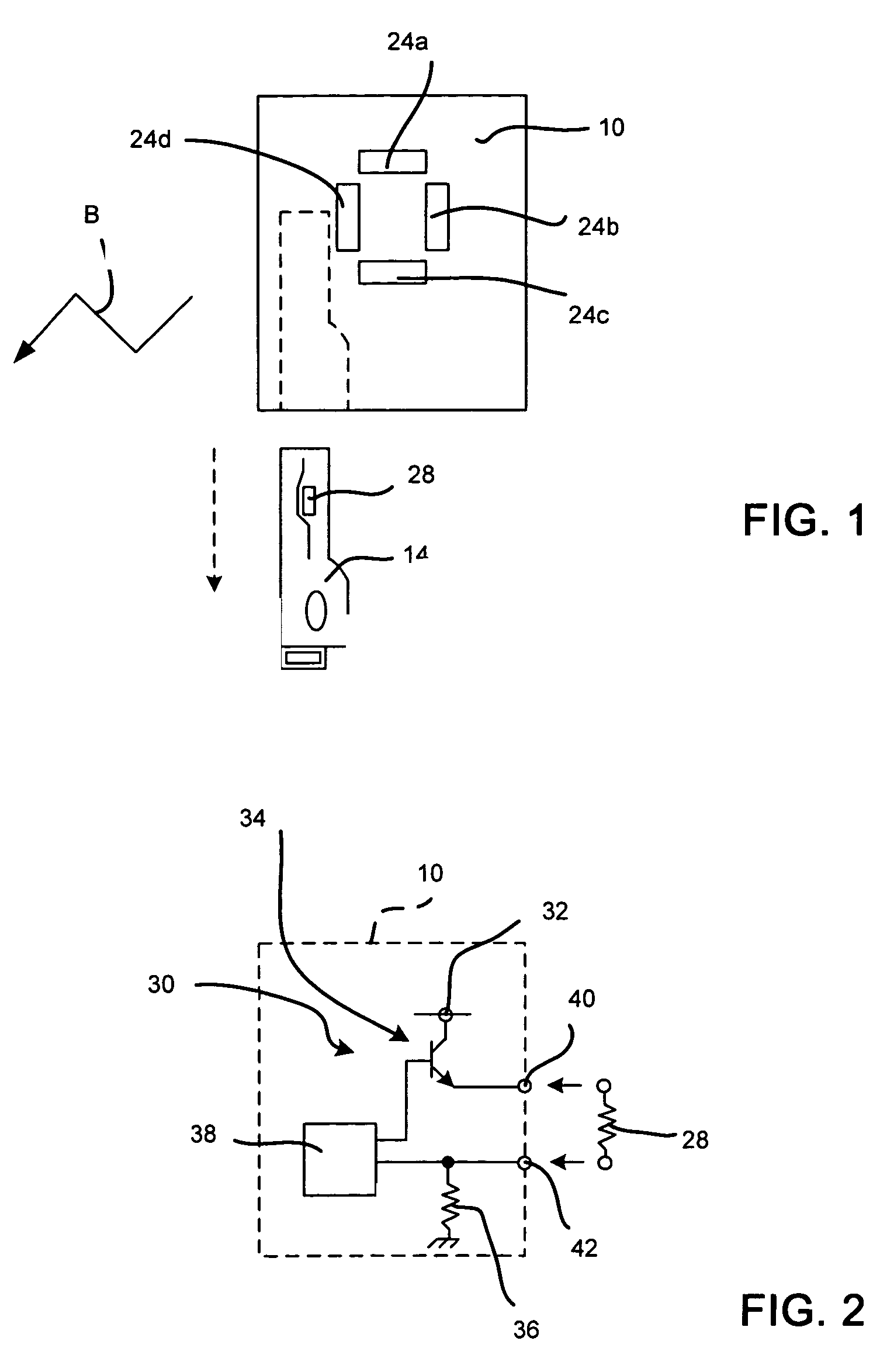

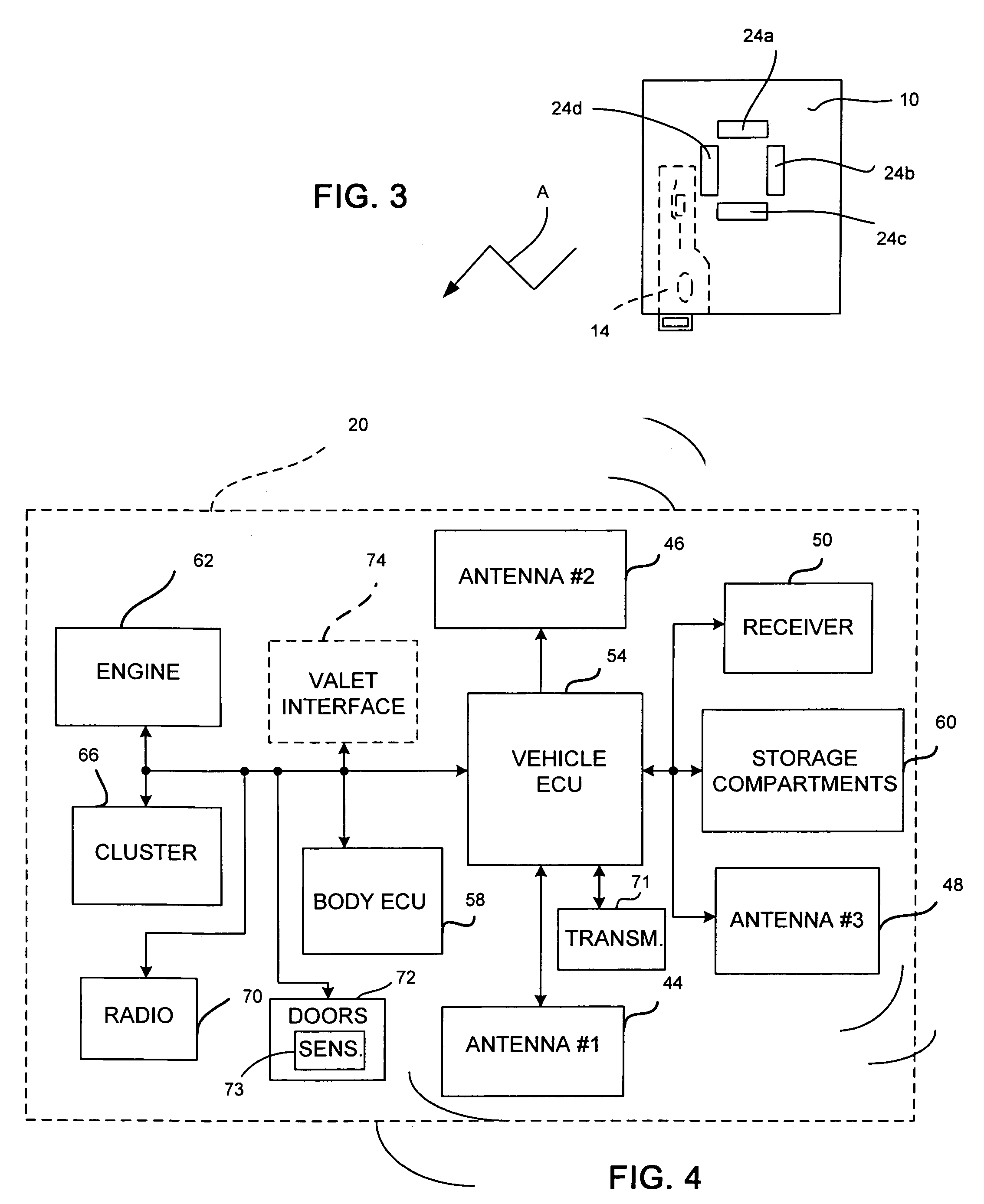

System for controlling a valet mode of a vehicle

ActiveUS20050190039A1Reduce stepsDigital data processing detailsAnti-theft devicesRemote controlOperation mode

A remote control device for controlling a reduced operational mode of a vehicle includes a portable communication device operable to communicate with the vehicle. A detachable component is selectively coupled to the communication device. The communication device is operable to initiate a reduced operational mode for the vehicle upon detachment of the detachable component from the communication device. The portable communication device detects the input in the attached position and initiates a normal operational mode upon the detection. Detachment of the detachable component cause an input voltage to change on the portable device. The reduced operational mode includes inhibiting access to predetermined storage compartments in the vehicle such as a vehicle trunk or glove box. Vehicle speed and RPM are limited in the reduced operational mode.

Owner:DENSO INTERNATIONAL AMERICA

System for controlling a valet mode of a vehicle

A remote control device for controlling a reduced operational mode of a vehicle includes a portable communication device operable to communicate with the vehicle. A detachable component is selectively coupled to the communication device. The communication device is operable to initiate a reduced operational mode for the vehicle upon detachment of the detachable component from the communication device. The portable communication device detects the input in the attached position and initiates a normal operational mode upon the detection. Detachment of the detachable component cause an input voltage to change on the portable device. The reduced operational mode includes inhibiting access to predetermined storage compartments in the vehicle such as a vehicle trunk or glove box. Vehicle speed and RPM are limited in the reduced operational mode.

Owner:DENSO INTERNATIONAL AMERICA

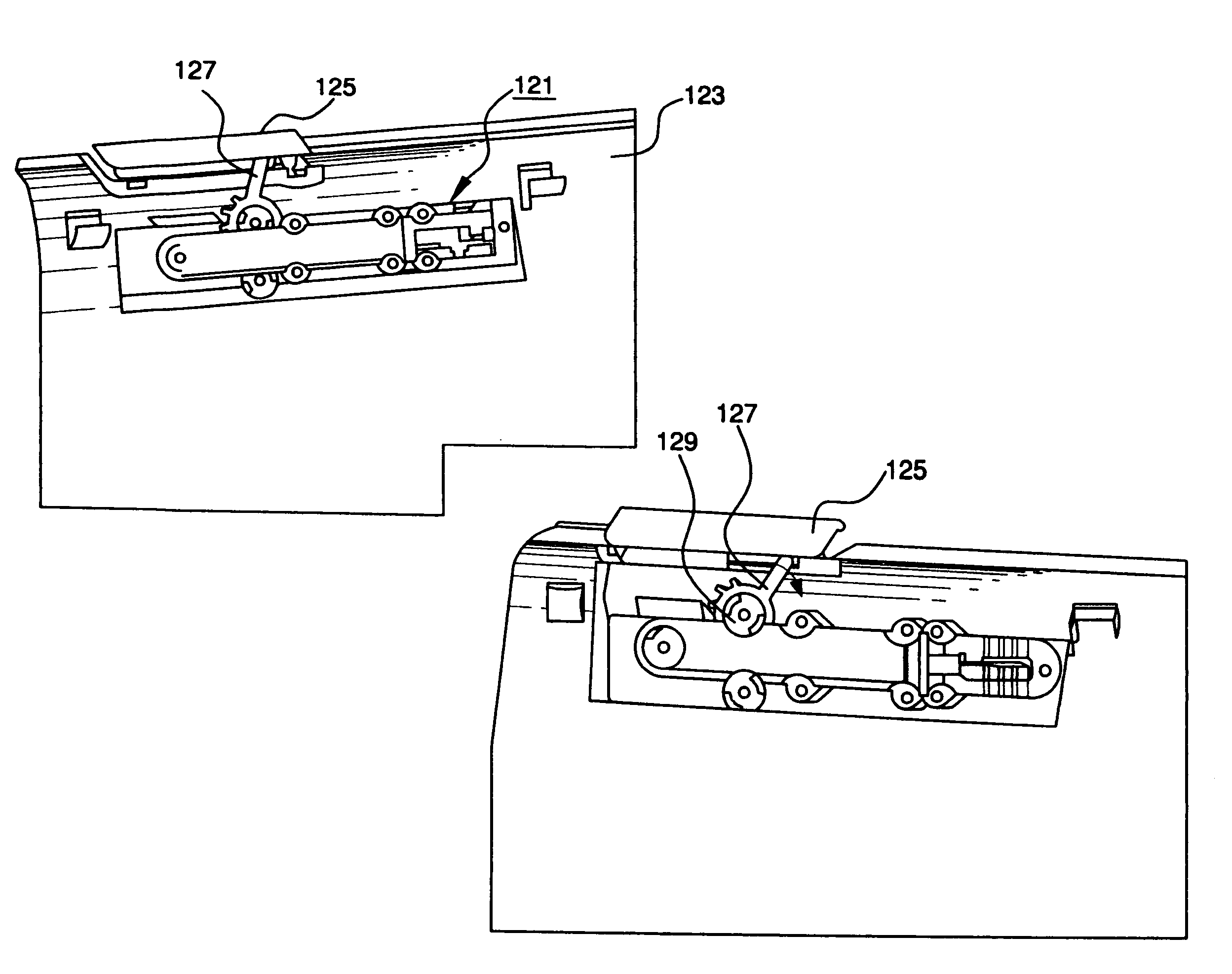

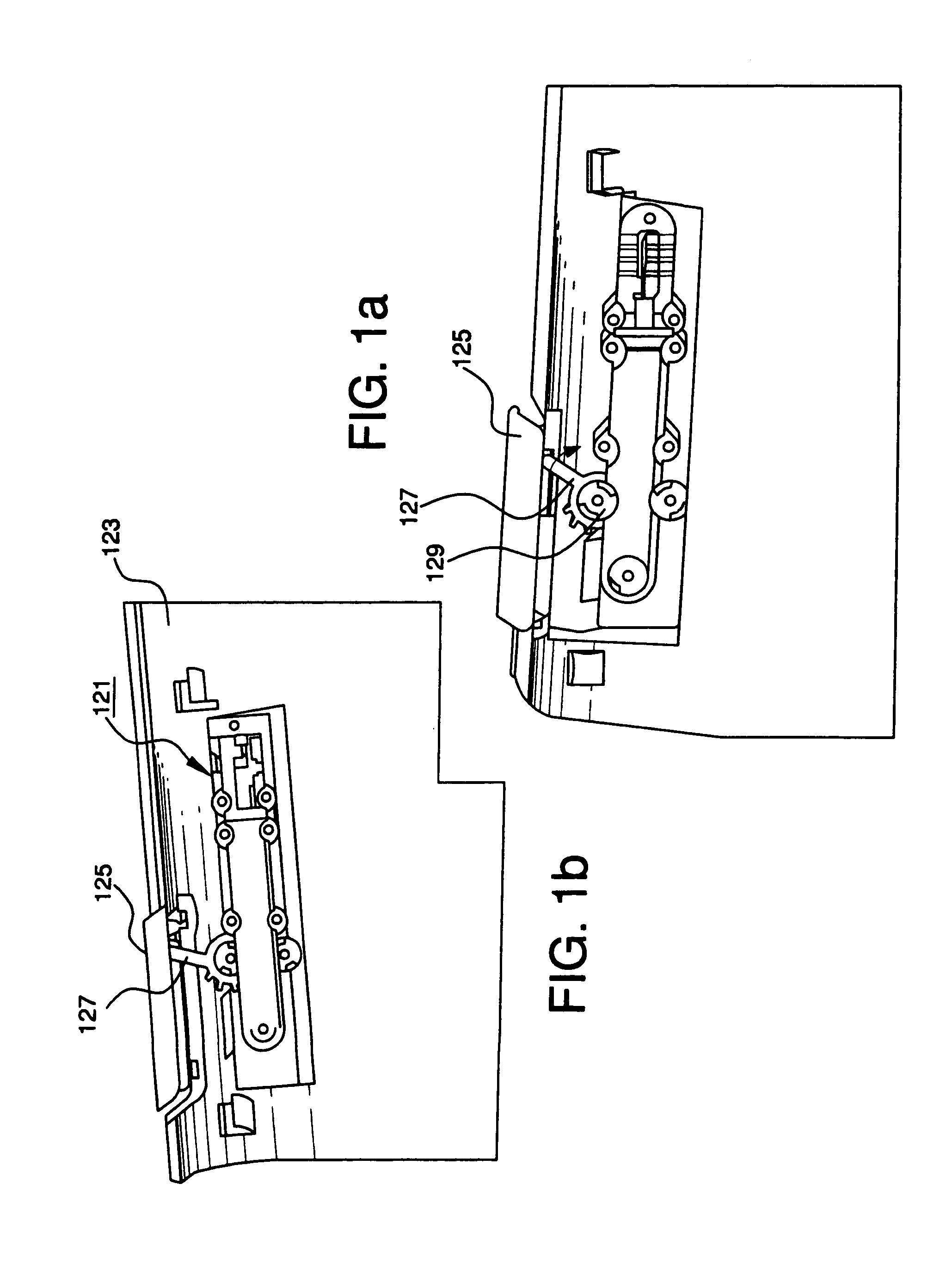

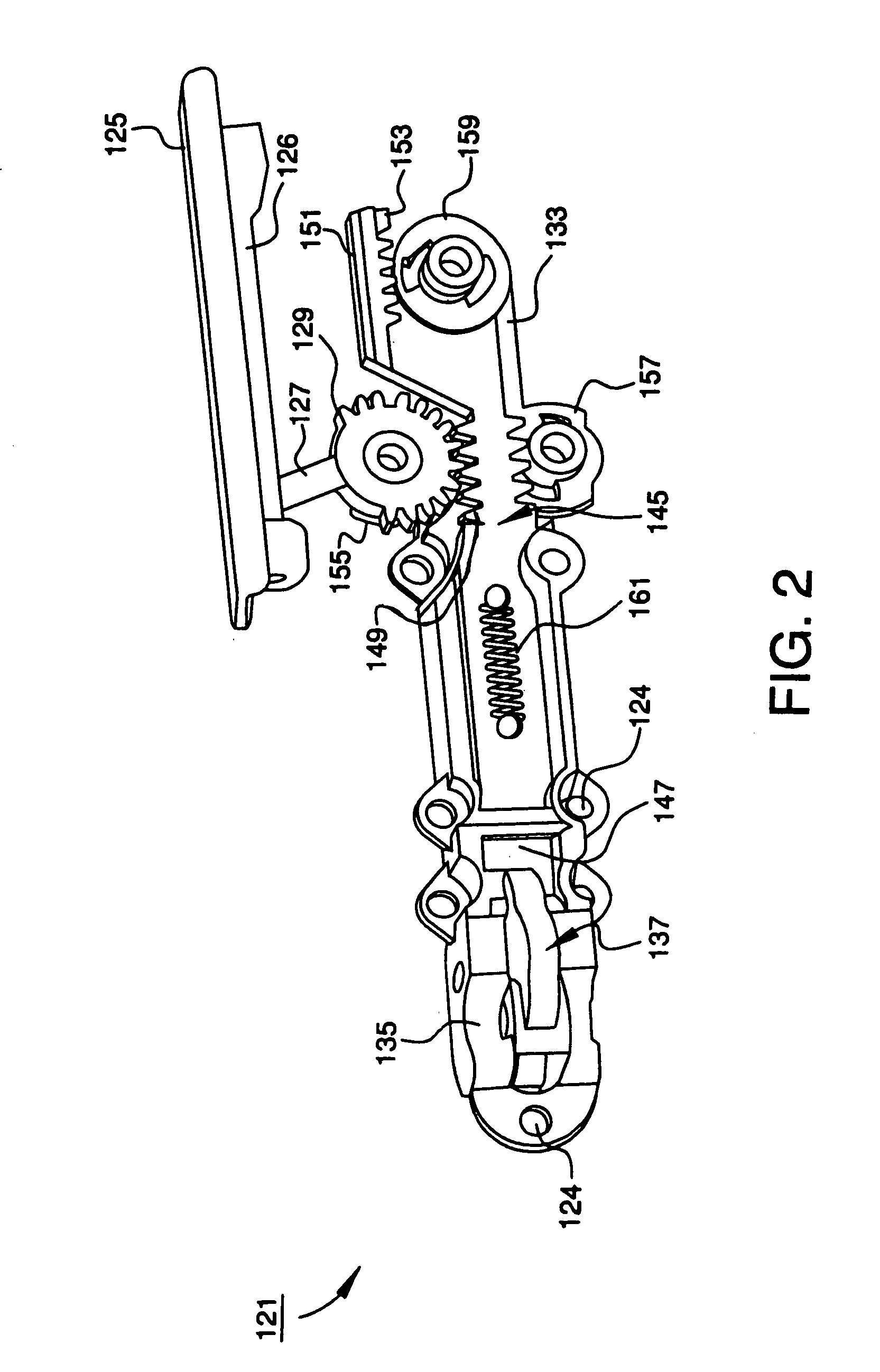

Glovebox latch

ActiveUS7185927B2Easy to reconfigureMeet the requirementsLock parts movement dampingWing fastenersEngineeringSlide plate

A latch assembly is re-configurable for plural orientations. A slide lock plate engages a claw-typed pawl. A rotating activation mechanism links an operator handle to the slide plate. The handle causes the activation mechanism to rotate, thereby retracting the sliding lock plate form the pawl. A cam follower, activated by a pocket cam, is rotated with handle operation. A first pinion gear on the sliding lock plate and a friction clutch dampen movement. A rotating paddle / blade cam, substituted for the paddle / blade, has a projecting arm. The second pinion gear engages teeth on the edge of the slide lock plate. A dog leg-shaped projection, added to the handle end of the slide plate, accommodates second teeth facing opposite the first teeth.

Owner:SOUTHCO

Single use collapsible liquid containment vessel

An expandable single use liquid containment vessel that can fit into restricted spaces such as the trunk or glove compartment of a passenger transport vehicle. The vessel contains a top and bottom wall integrally connected via an outer wall embodying accordion type pleats to allow for vessel compression and expansion. A single piece pouring nozzle is permanently attached to the containment vessel subsequent to introduction of a fluid the containment vessel's interior portion. One end of the filling nozzle secures the nozzle to the containment vessel. At the second end of the nozzle is an exiting orifice which has been dimensioned to preclude insertion therein of publicly accessible fueling nozzles commonly associated with motor vehicle refueling stations.

Owner:HUDKINS BRUCE ERIC

Glove box device

In a glove box device, a cylinder is fixed to an operating handle, a slide member switches between a locking state and an unlocking state in correspondence to sliding motion, and a connecting member is interposed between one end of the slide member and a rotor. The connecting member transmits a turning force of the rotor turning along with the operating handle to the slide member, to move the slide member from a locking position to an unlocking position when the rotor is in the unlocking position. The connecting member cuts off the transmission of turning force between the slide member in the locking position and the rotor, when the rotor is in the locking position. Thus, it is possible to reduce the number of components needed, and also to reduce a gap between a design face of the operating handle and the cylinder lock, thereby improving the appearance.

Owner:HONDA LOCK MFG CO LTD

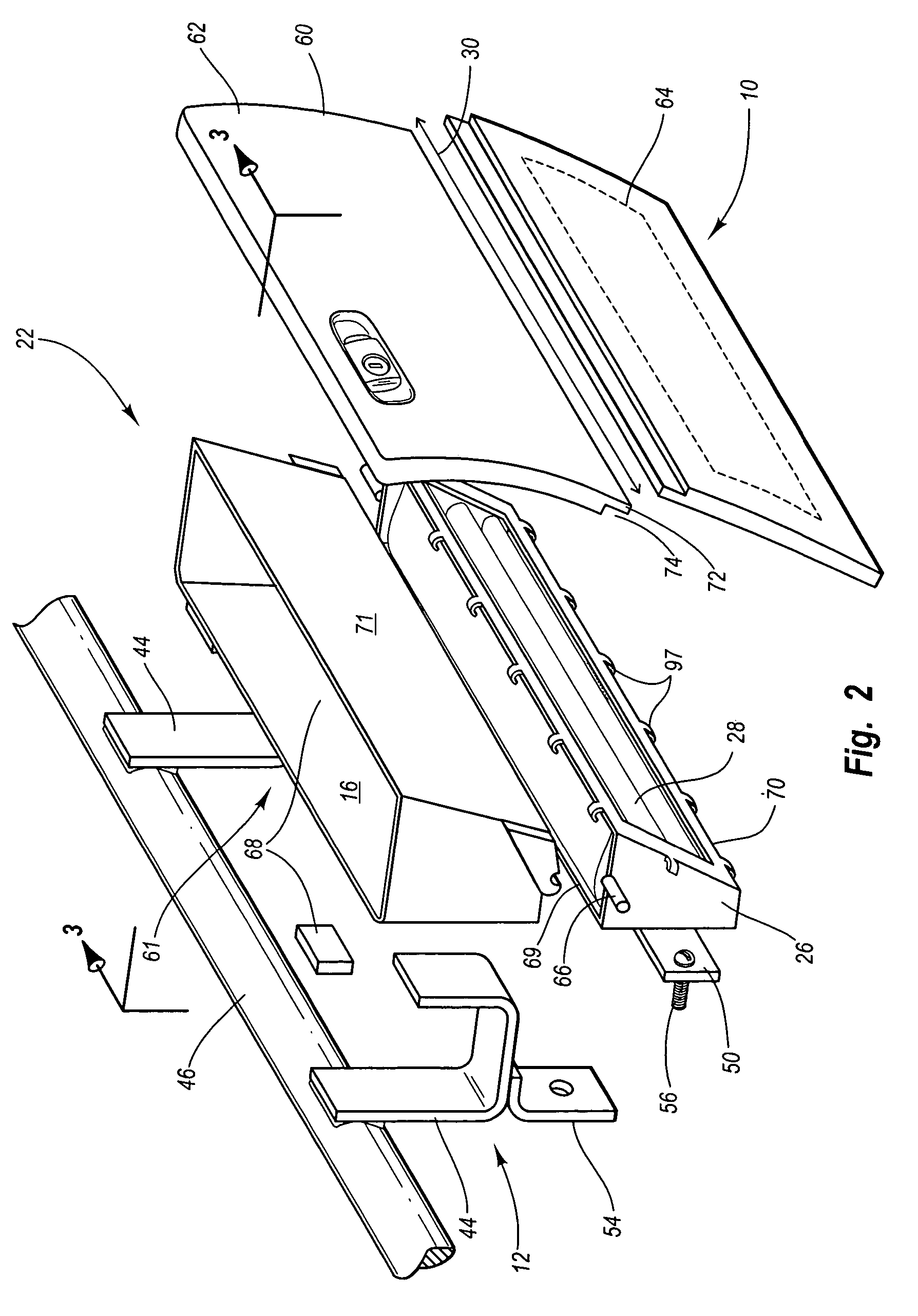

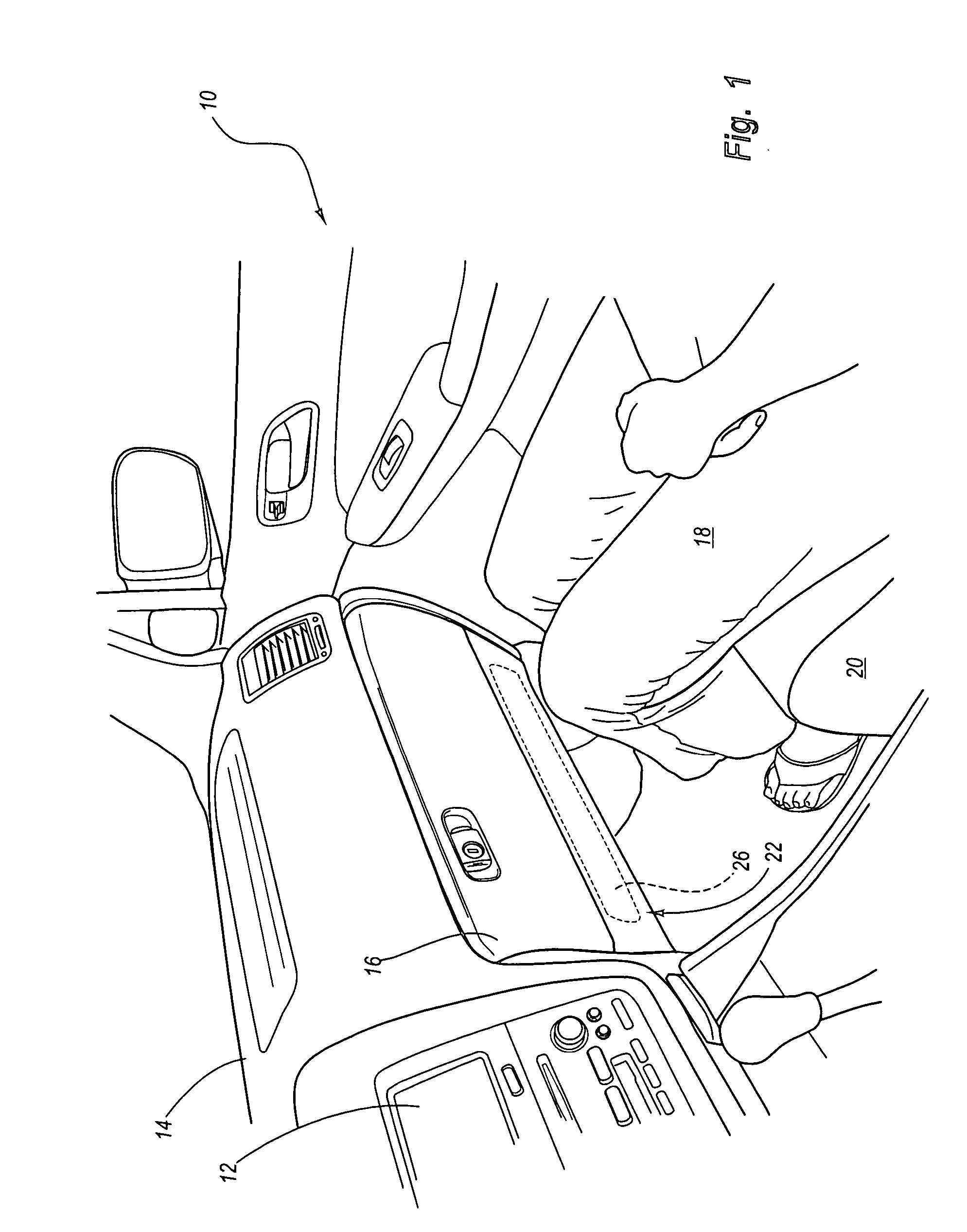

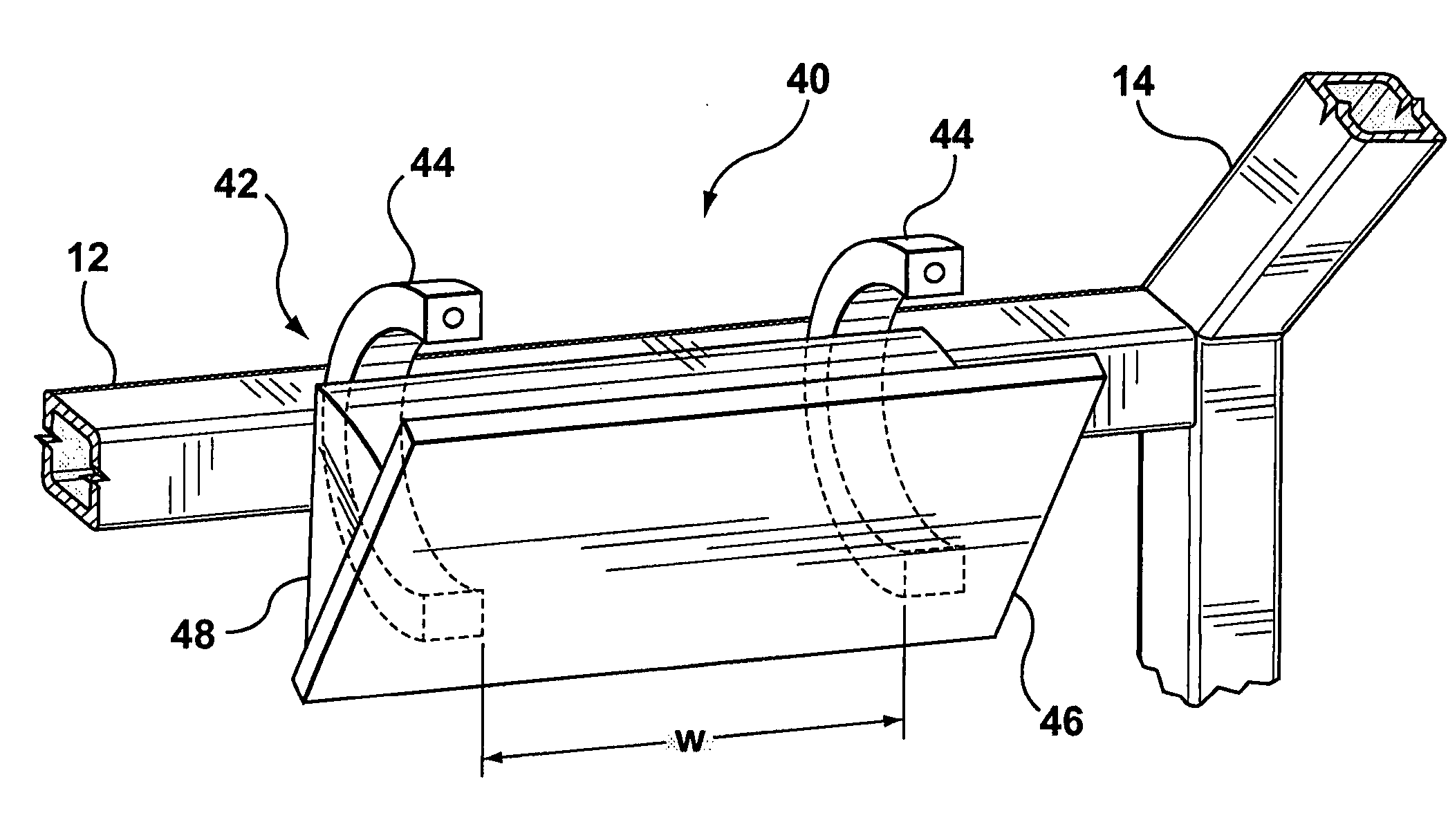

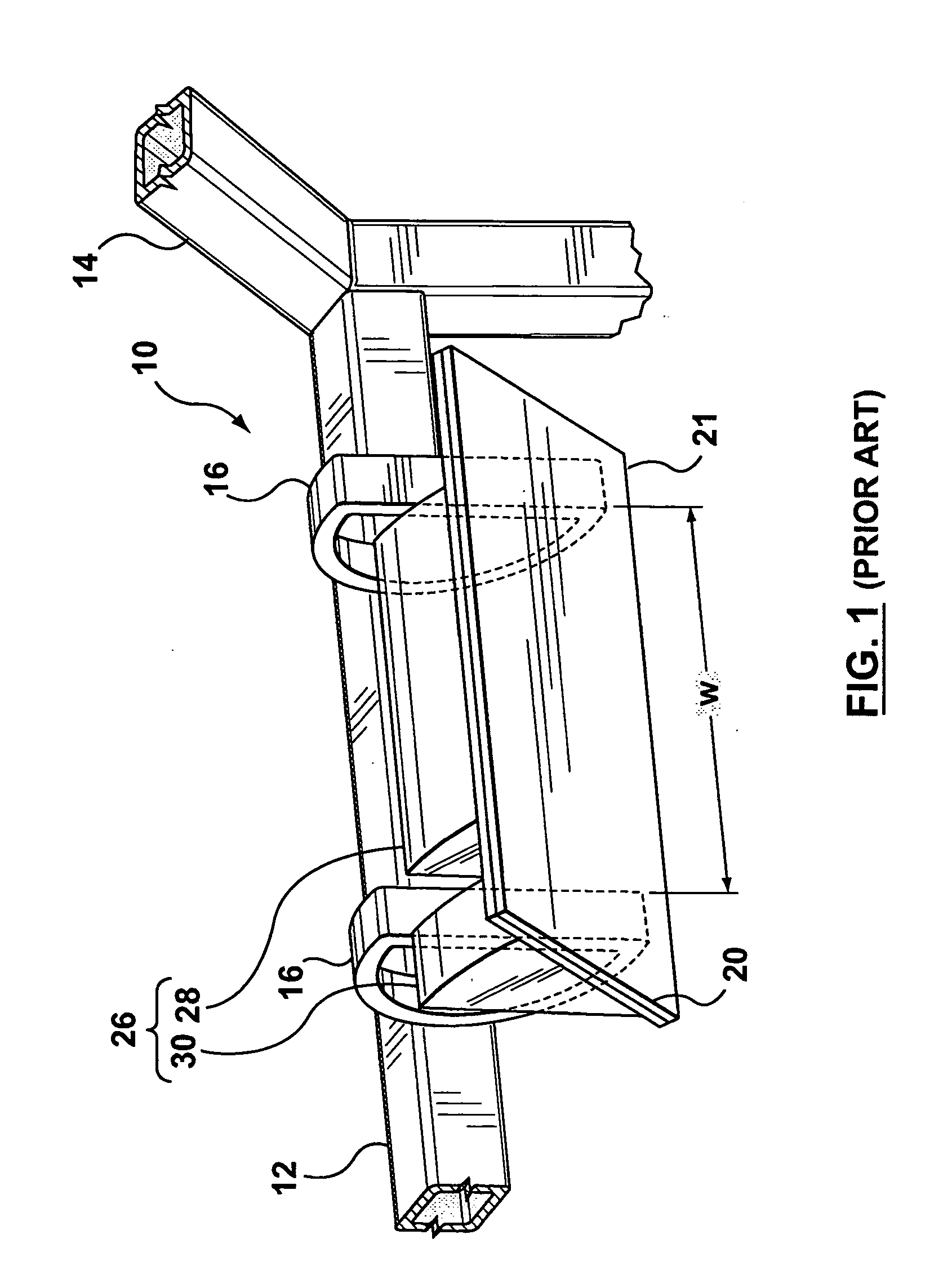

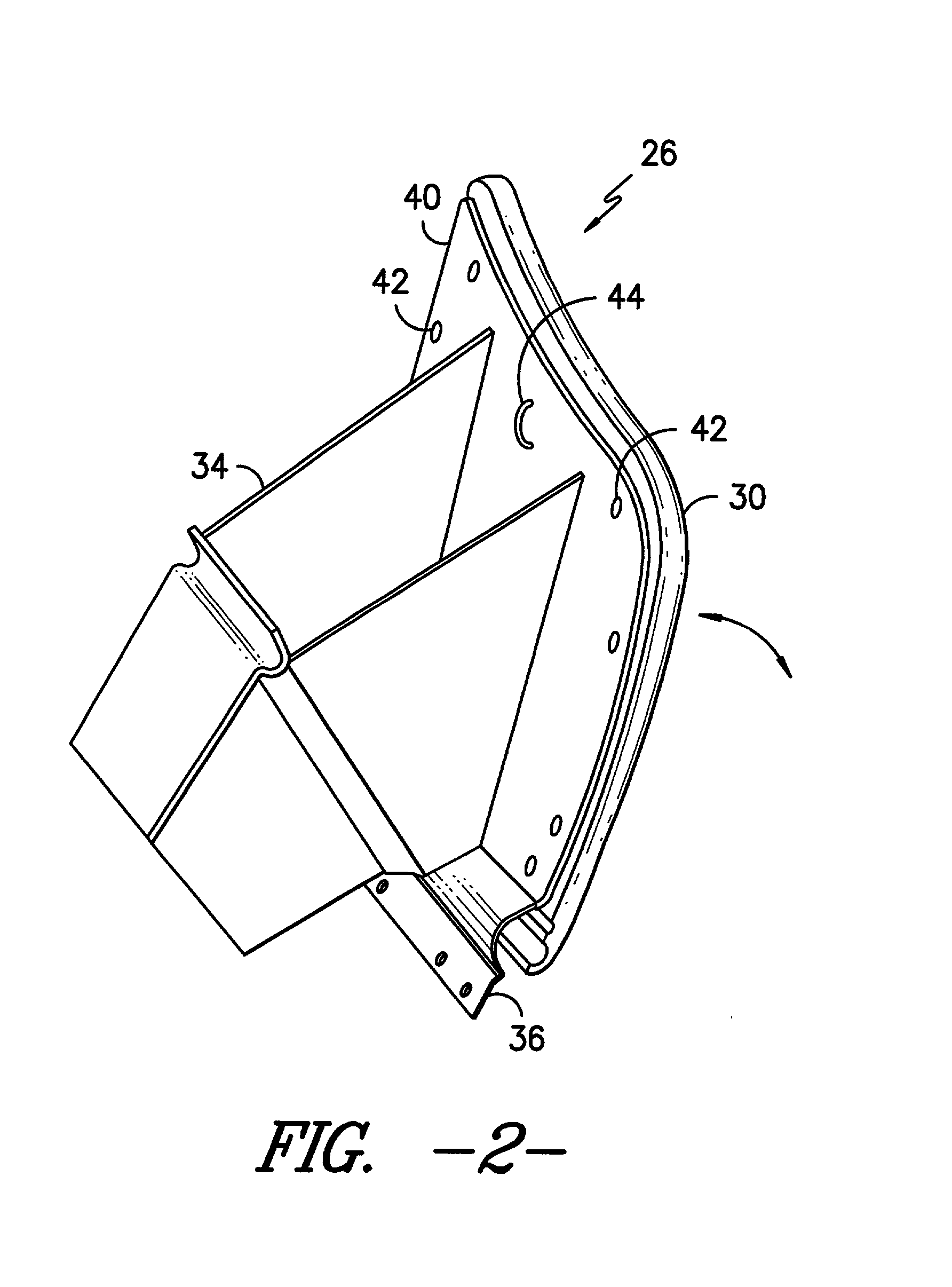

Instrument panel subassembly including a glove box door

An instrument panel subassembly for use in an instrument panel assembly in a motor vehicle is provided. The subassembly includes first and second generally C-shaped energy absorption brackets. The brackets have an aft facing C-section and upper and lower mounting ends. The brackets include attachment means for attaching the brackets to a vehicle structural member. The subassembly further includes a glove box door having an aft surface and a forward surface, and a bin. The glove box door includes hinge means for providing hinged movement of the glove box door relative to the first and second brackets between open and closed positions. The bin is within the C-section of the brackets when the glove box door is in a hingedly closed position.

Owner:ABC GROUP

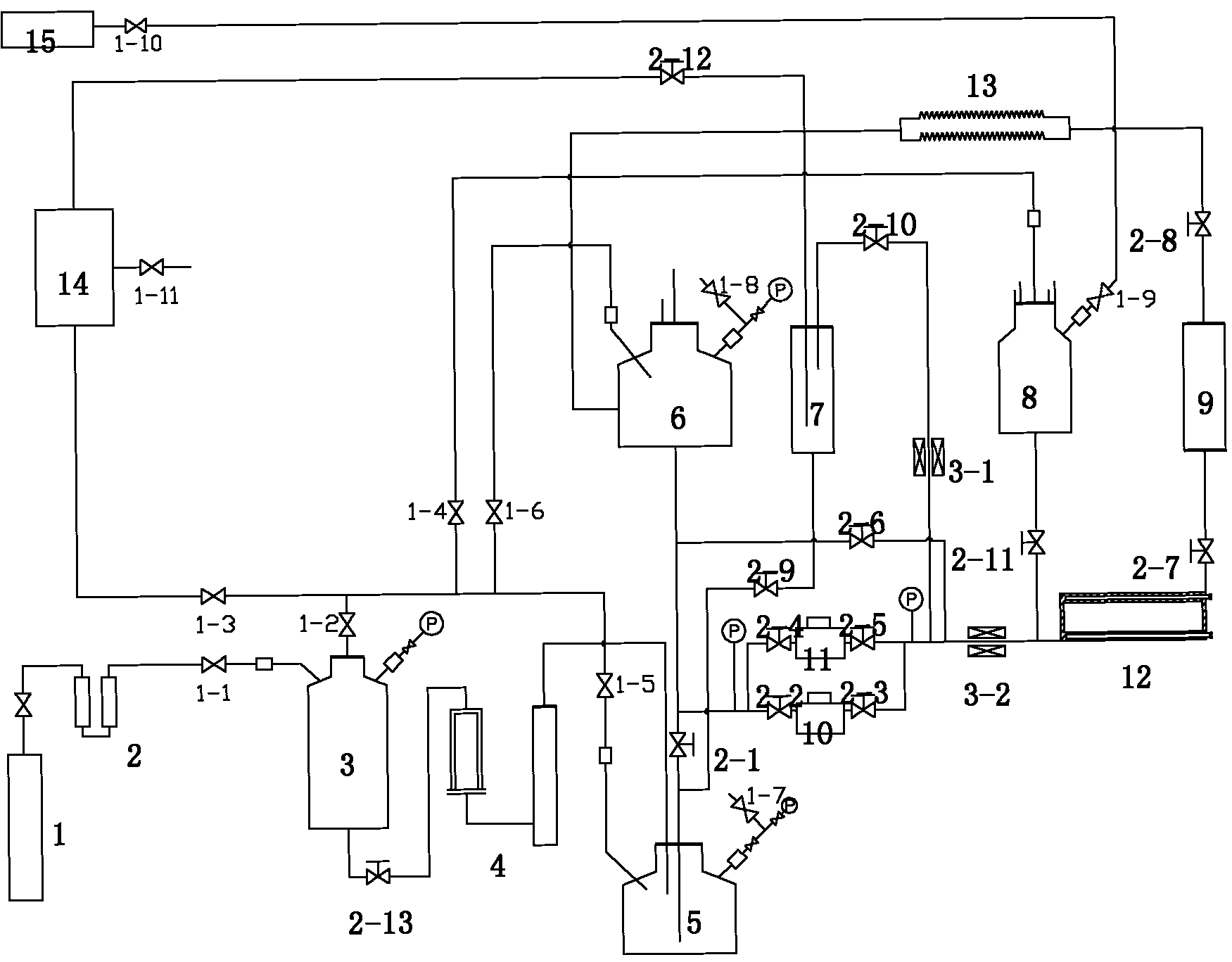

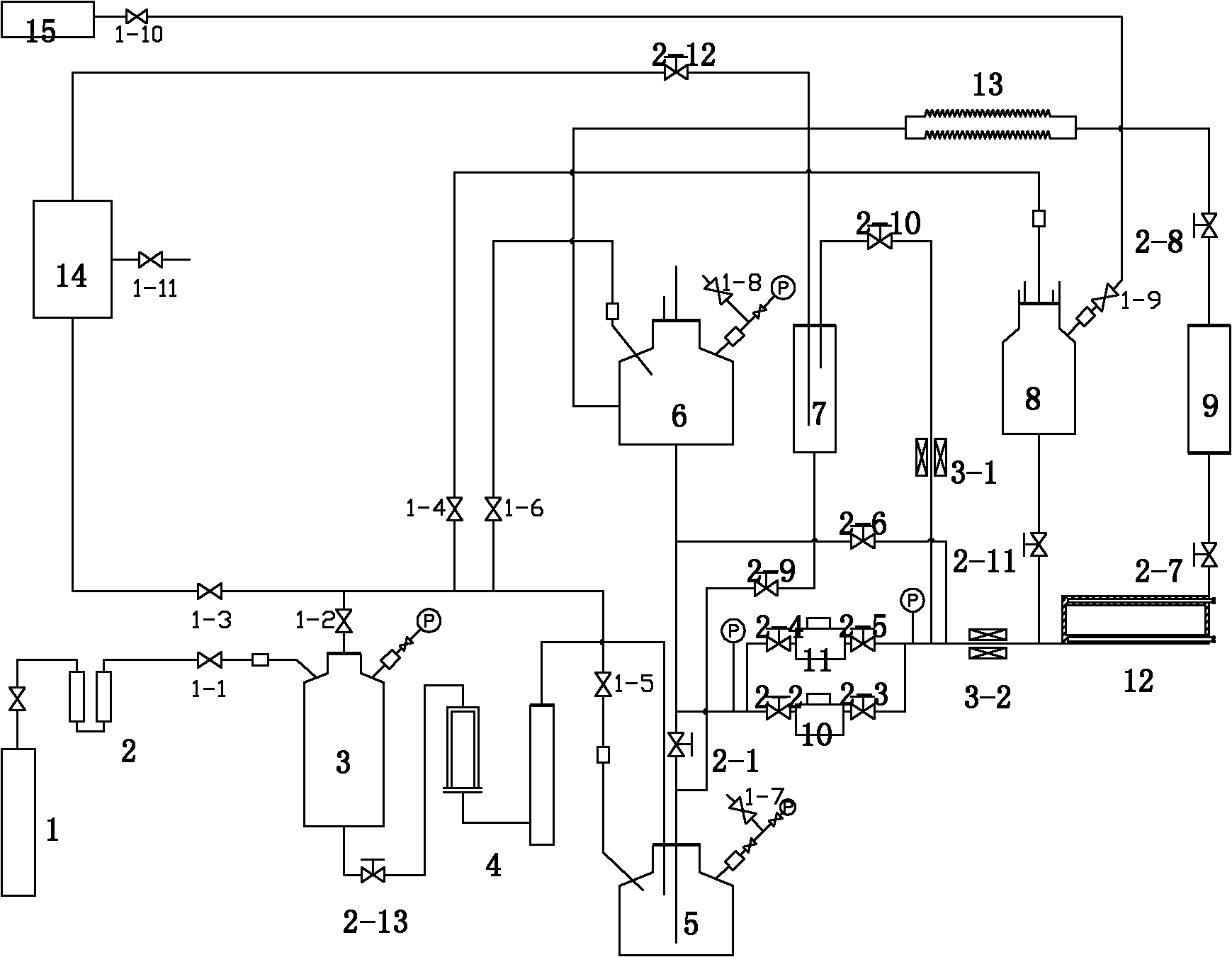

Liquid sodium metal thermohydraulic experimental loop system and using method thereof

InactiveCN102254577ARealize the experimental study of hydraulic characteristics analysisNuclear energy generationNuclear monitoringLiquid stateLiquid metal

The invention discloses a liquid sodium metal thermohydraulic experimental loop system. The loop system comprises a sodium filling system, a loop body, a vacuum system, an argon system and a glove box, wherein the sodium filling system comprises a sodium fusion tank and a sodium filter; the loop body mainly comprises a sodium storage tank, a pump box, a main electromagnetic pump, an auxiliary electromagnetic pump, a preheater, a test section, a radiator, a calibration barrel and a cold trap; and the glove box mainly comprises a sodium sampling analysis device. By the system, sodium filling operation can be realized, liquid sodium metal heat transfer flow characteristics are analyzed, liquid sodium metal is purified on line, an electromagnetic flowmeter is calibrated, and multiple functions of sampling analysis, detection and the like of the liquid sodium metal are realized.

Owner:XI AN JIAOTONG UNIV

Preparation method of high-purity micro-fine low-oxygen titanium powder

The invention provides a preparation method of high-purity micro-fine low-oxygen titanium powder, which belongs to the technical field of powder preparation in the powder metallurgy process. The preparation method is characterized by combining hydrogenation and dehydrogenation with a jet milling process, firstly carrying out hydrogenation treatment on a titanium sponge to prepare titanium hydride powder, then utilizing a jet mill to break the titanium hydride, then carrying out vacuum dehydrogenation, and finally utilizing the jet mill to carry out breaking gradation and vacuum package and obtaining a titanium powder product. Compared with the traditional ball milling process, the jet milling process causes no pollution, and iron impurities caused by collision of steel balls in the ball milling process can be avoided; due to jet milling and high-vacuum dehydrogenation treatment, the content of oxygen can be controlled to be lowest, and the powder taking and packaging operations are respectively carried out in a glove box, so that the powder and the air are isolated in the whole process, and further, the prepared high-purity micro-fine low-oxygen titanium powder is prepared.

Owner:UNIV OF SCI & TECH BEIJING

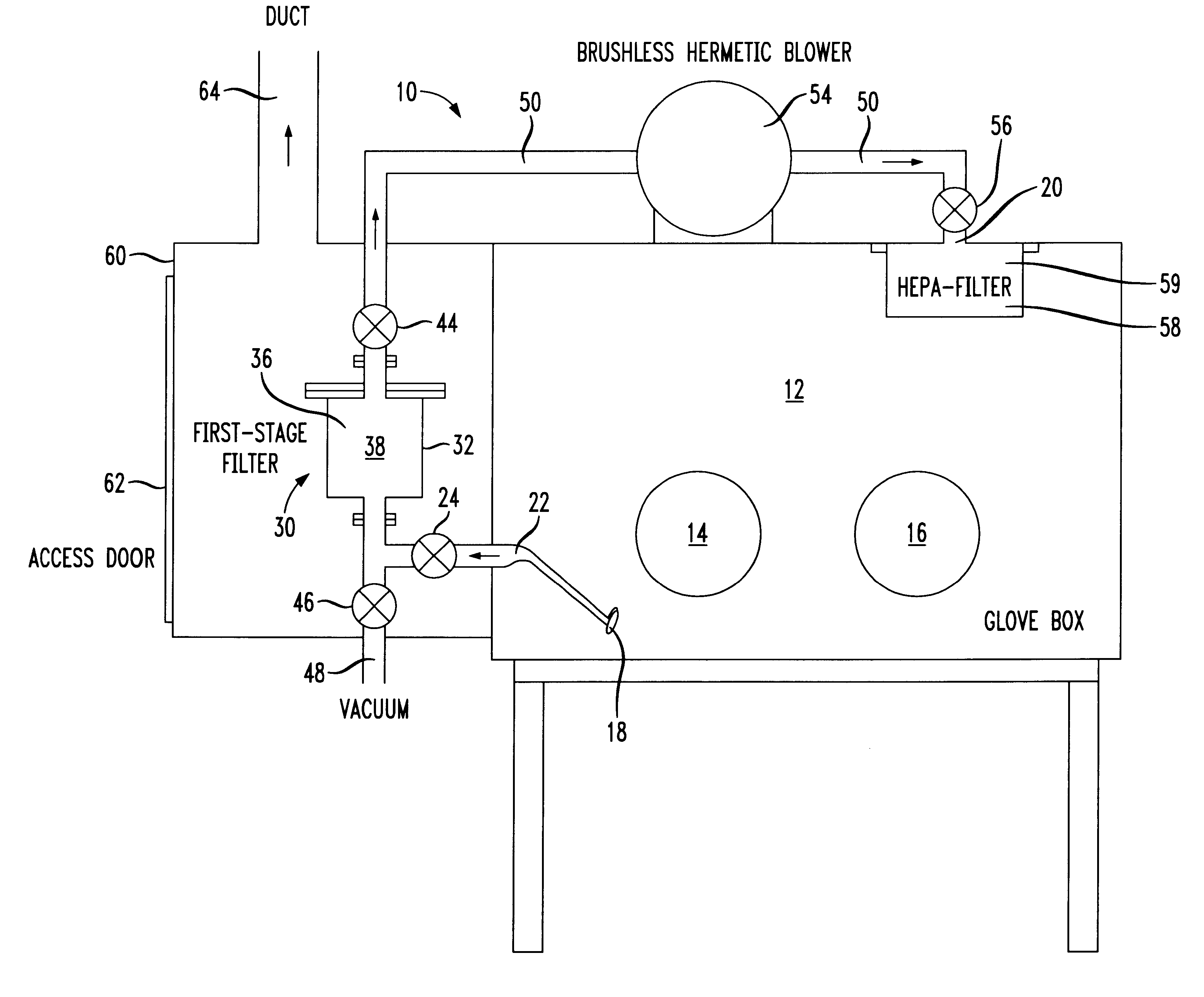

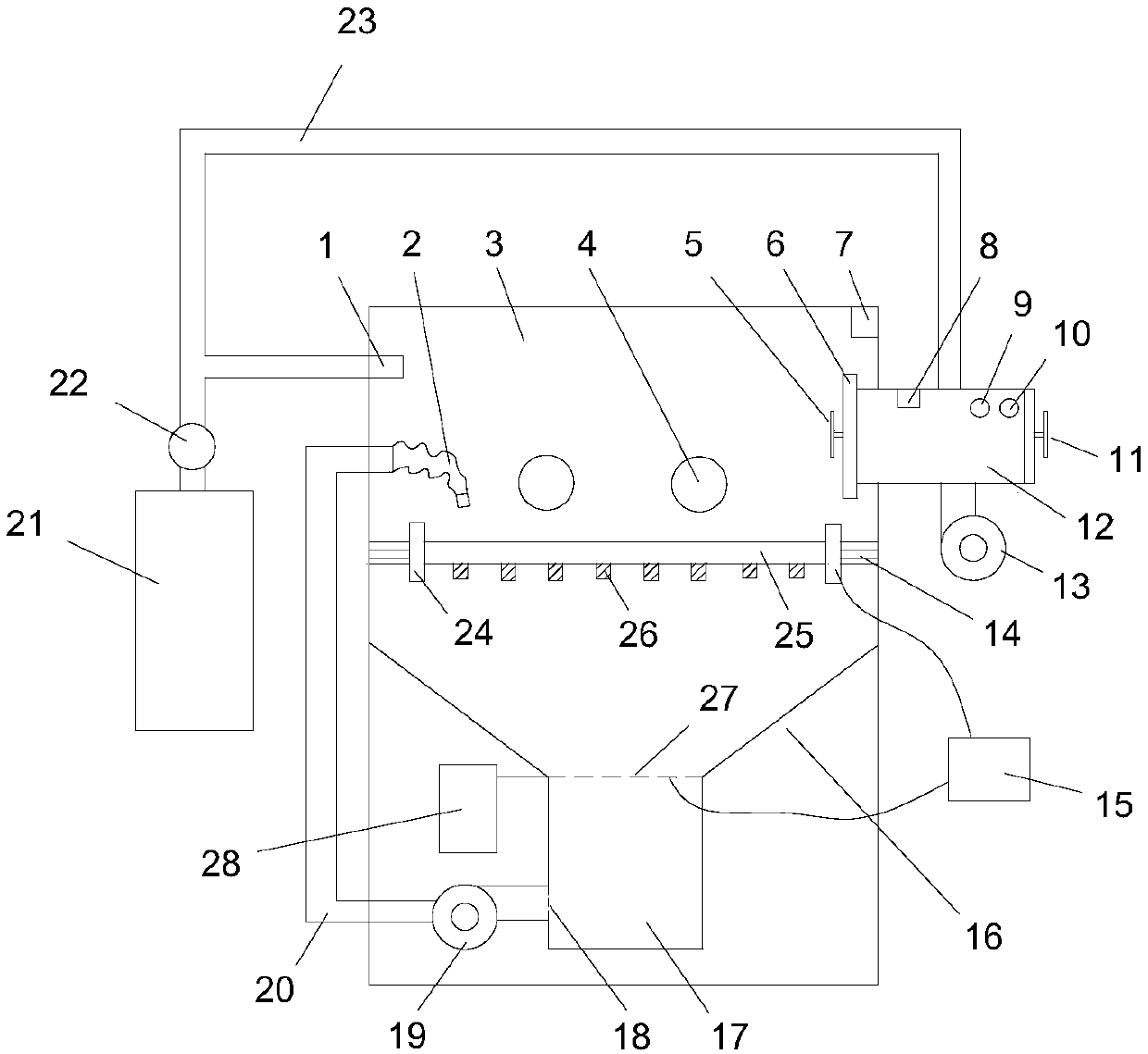

Glove box filter system

A glove box filter system for filtering out particles from a glove box environment defined in a glove box having an outlet and an inlet. The filter system includes a first filter stage for receiving removed gas from the glove box environment. The first filter stage contains a chamber having a first filter through which the removed gas passes for filtering out particles contained in the removed gas. The filtered gas is provided to a circulation conduit connected to a blower for providing movement of the gas through the glove box environment. A second filter stage connected to the glove box inlet is provided for fine-filtering the gas passed by the first filter stage prior to the return of the gas to the glove box environment. The first filter stage is connected to the glove box environment through one or more valves which isolate the first filter stage from the glove box environment when replacement of a first filter contained in the first filter stage occurs. A purging conduit is also provided for purging the first filter stage chamber of particles during replacement of the first filter.

Owner:BELL SEMICON LLC +1

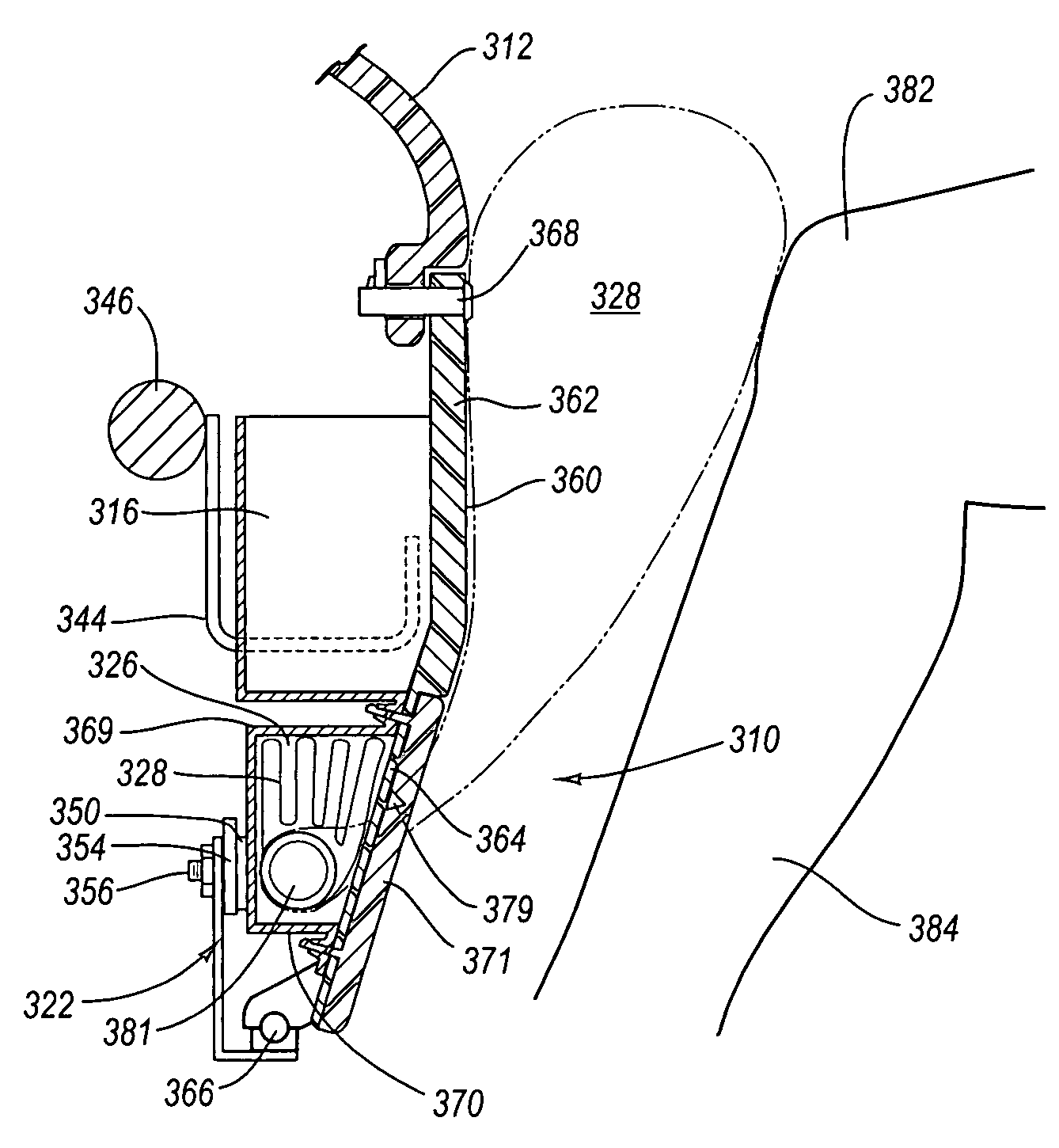

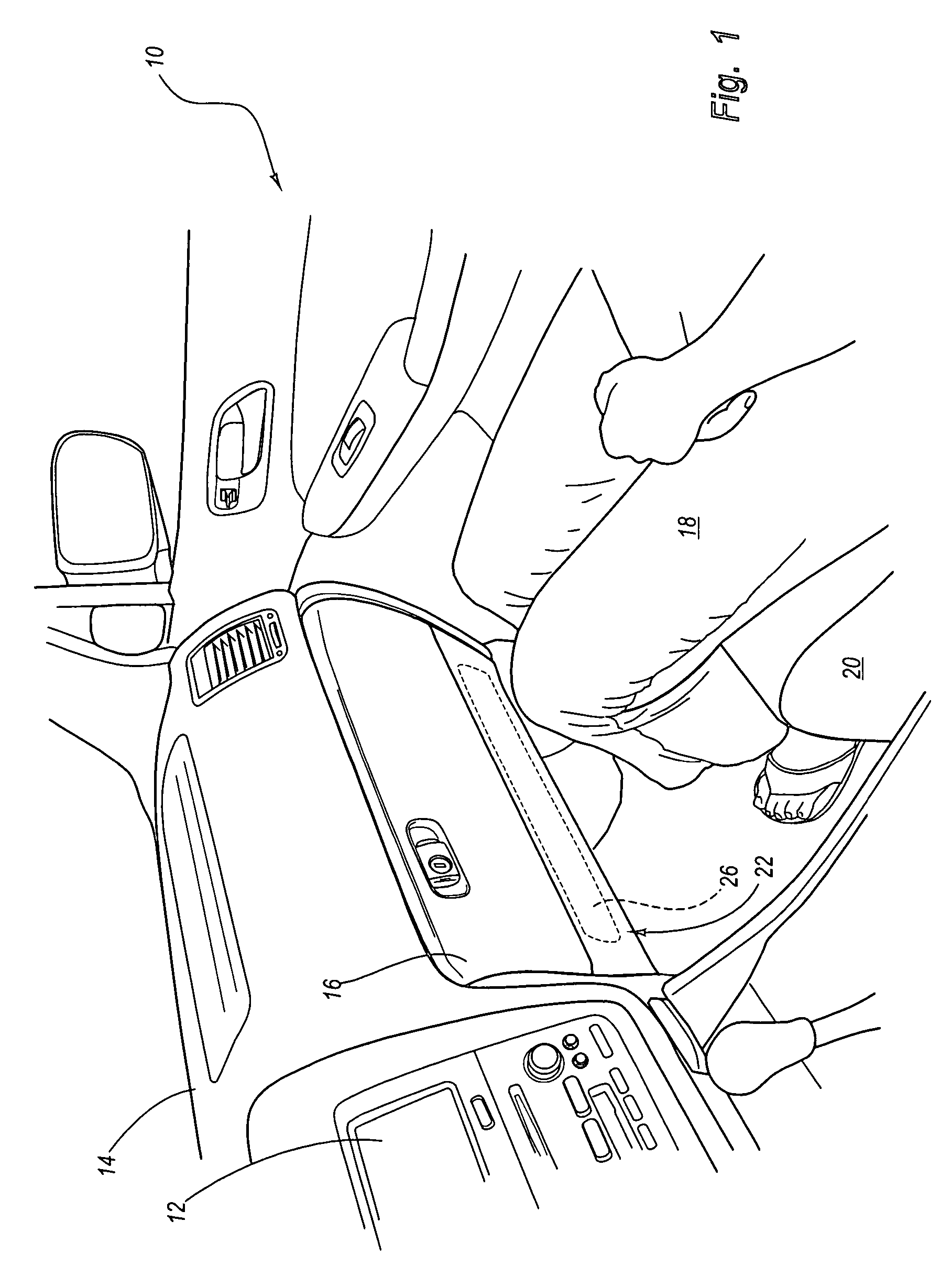

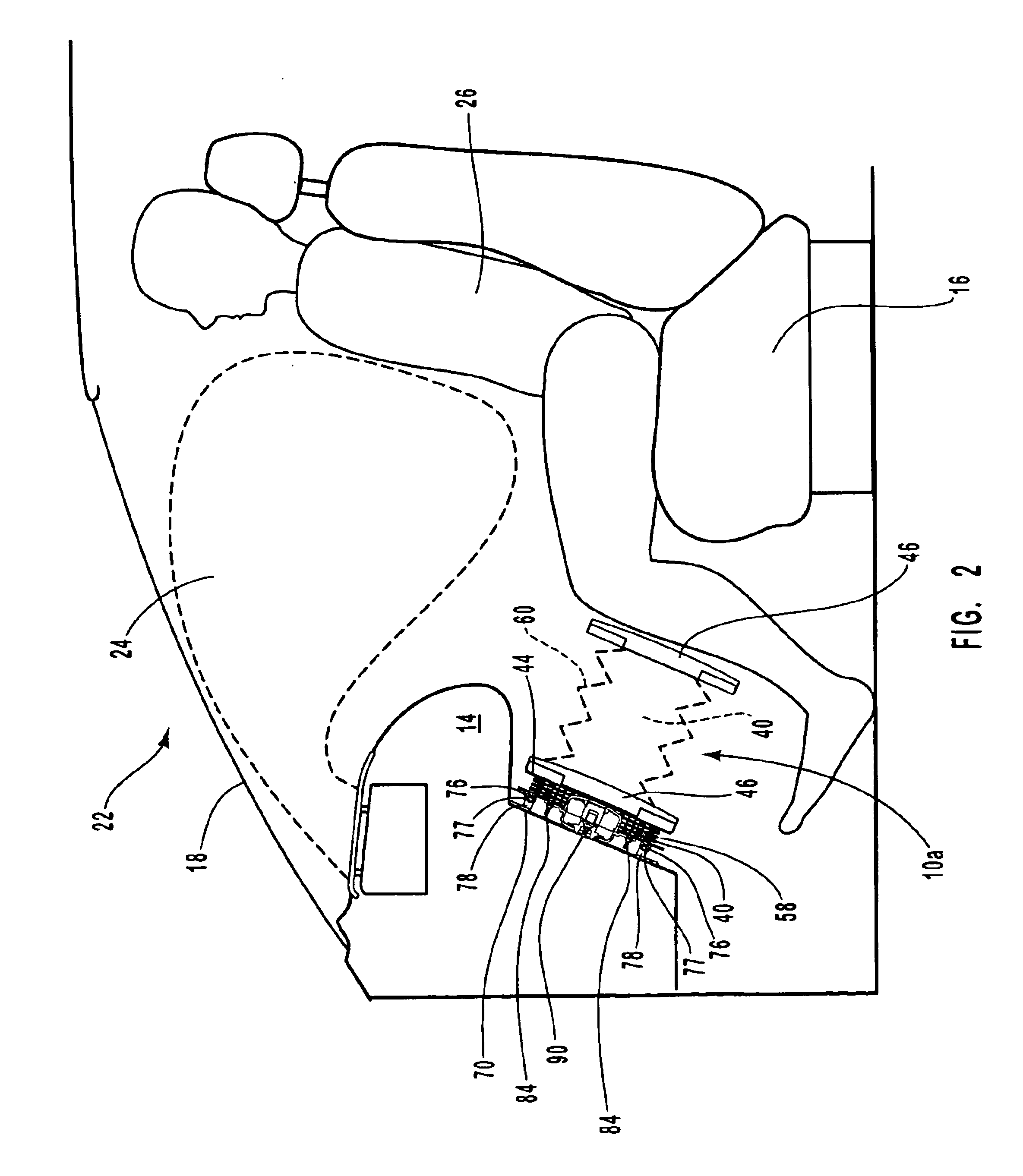

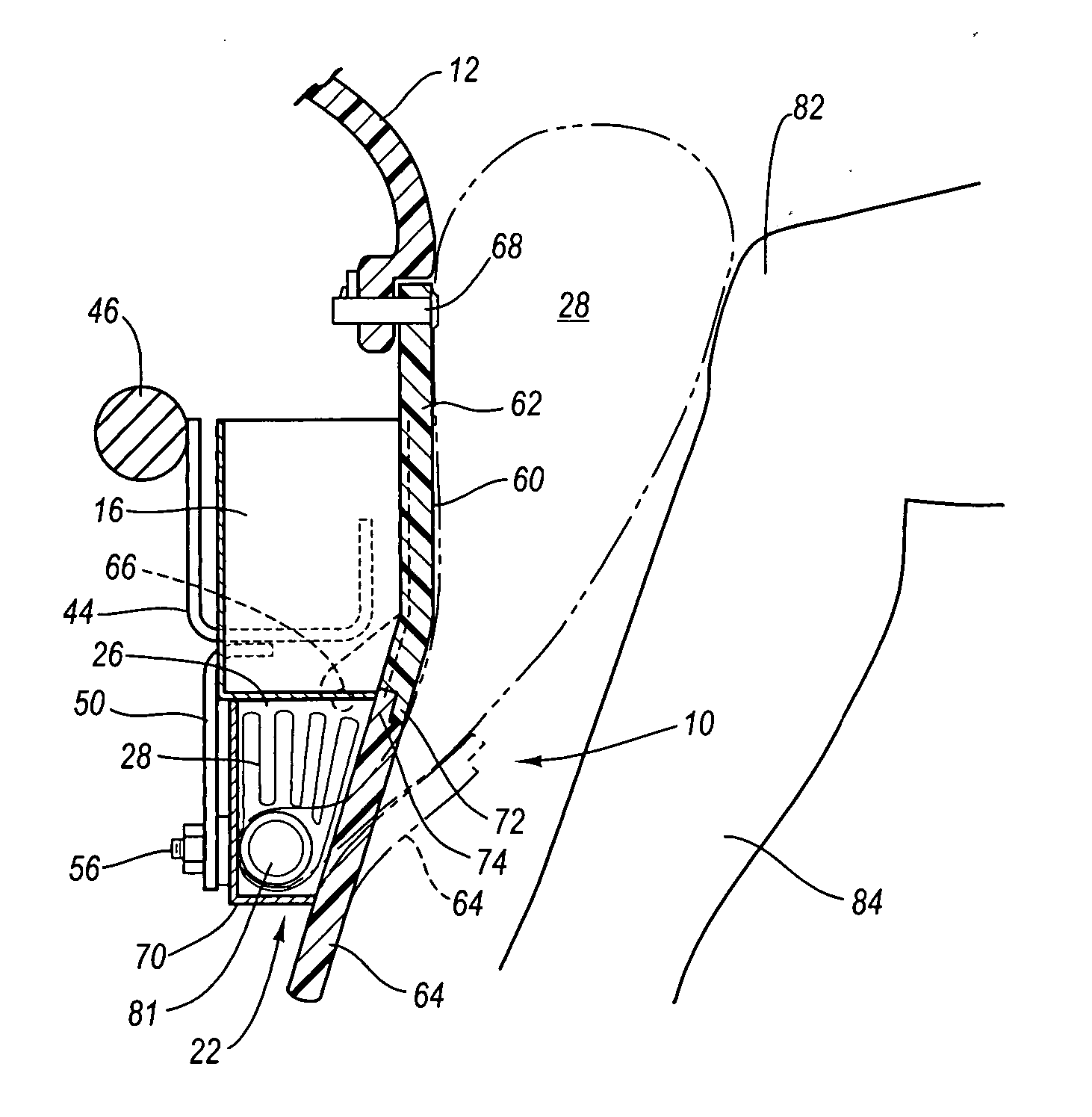

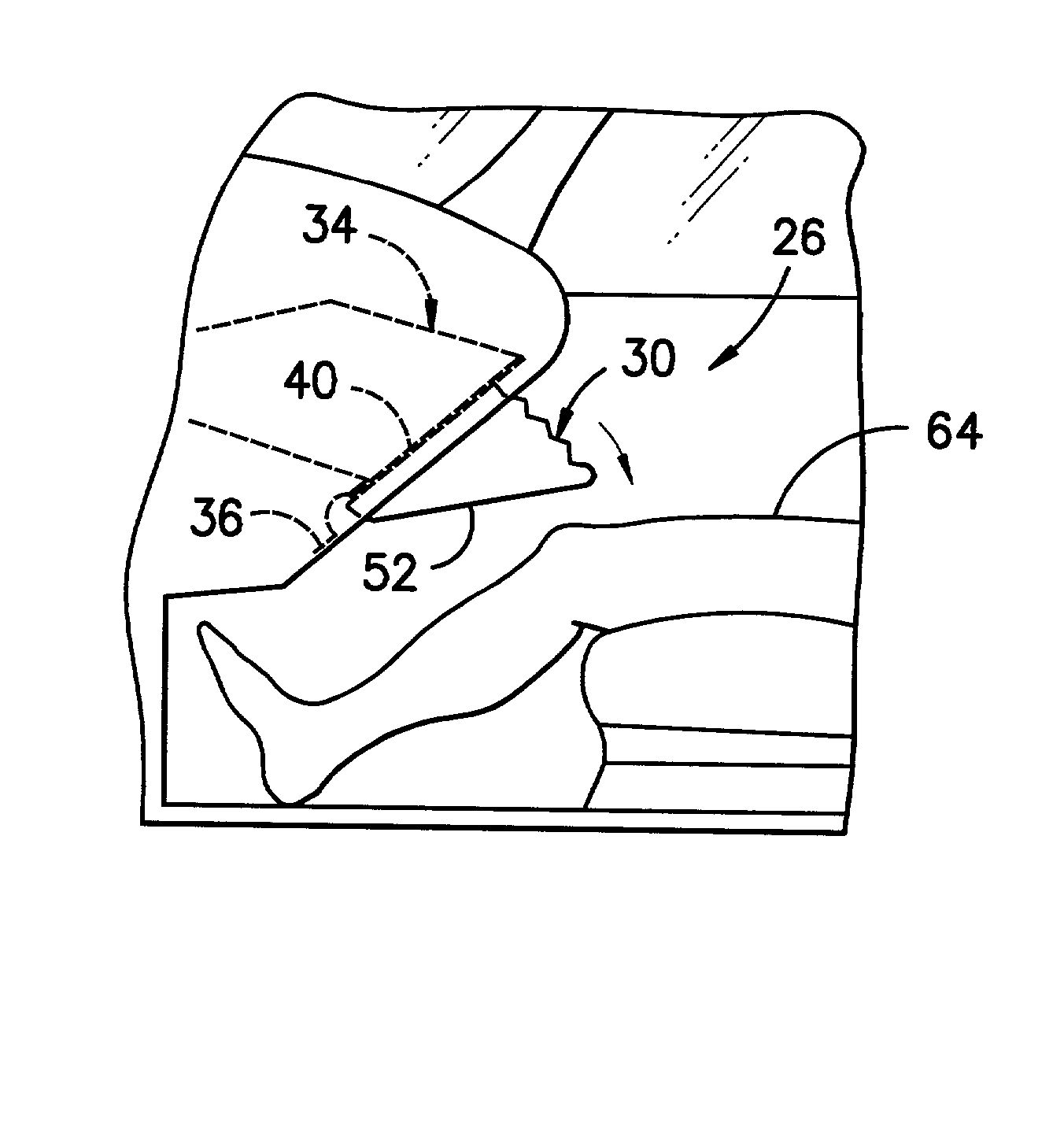

Passenger side active knee bolster

InactiveUS20020125691A1Increase flexibilityWithout occupant protectionPedestrian/occupant safety arrangementStowing appliancesBolsterGlovebox

An automotive glove box assembly. The glove box assembly includes a storage bin and a door disposed in hinging relation to the storage bin. The door includes an expansible body having a face portion facing towards a vehicle occupant and a back portion in opposing relation to the face portion. The expansible body is operatively connected to at least one gas emitting unit such that upon discharge of gas from the gas emitting unit, the expansible body is pressurized and the face portion is projected outwardly to an extended position so as to intercept lower extremities of the occupant.

Owner:AUTOLIV DEV AB

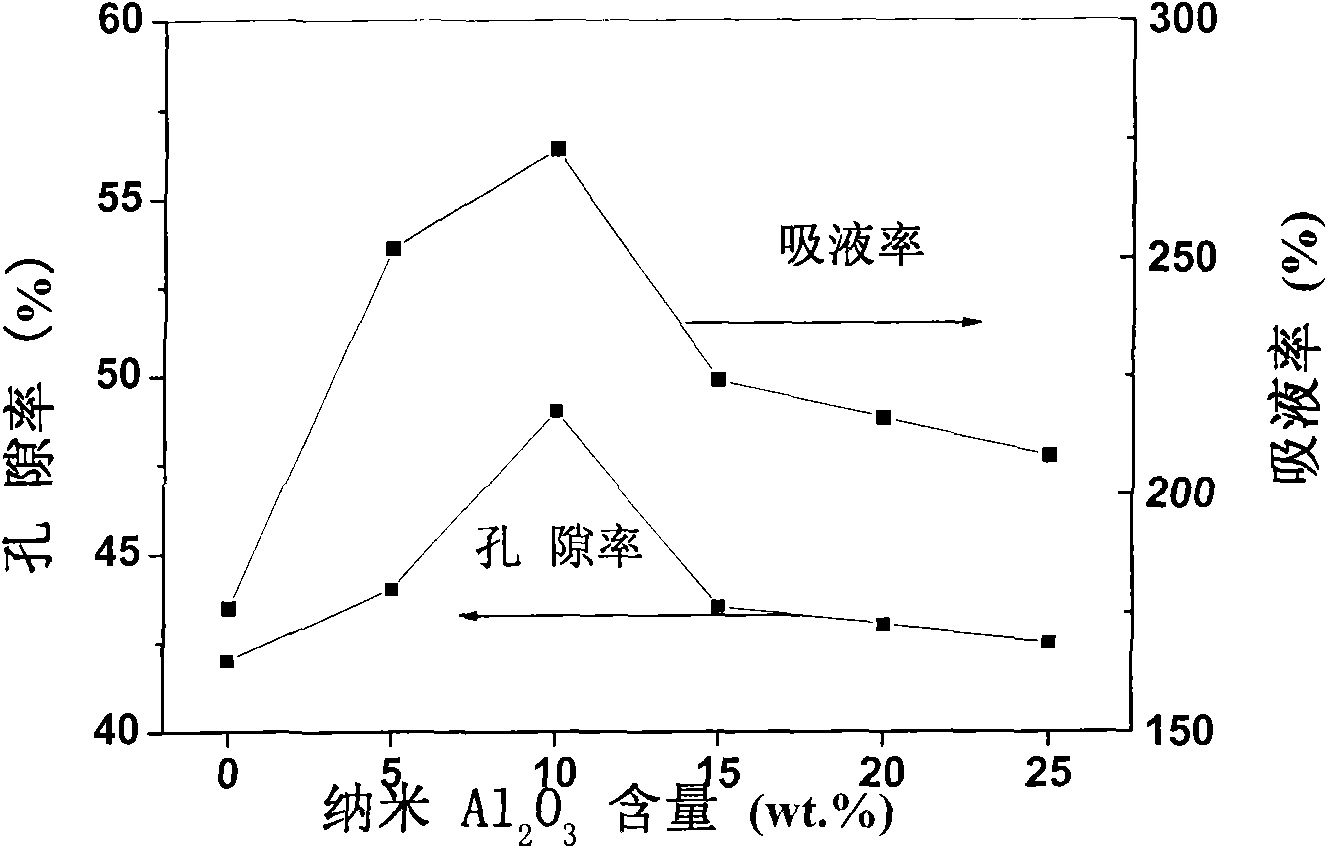

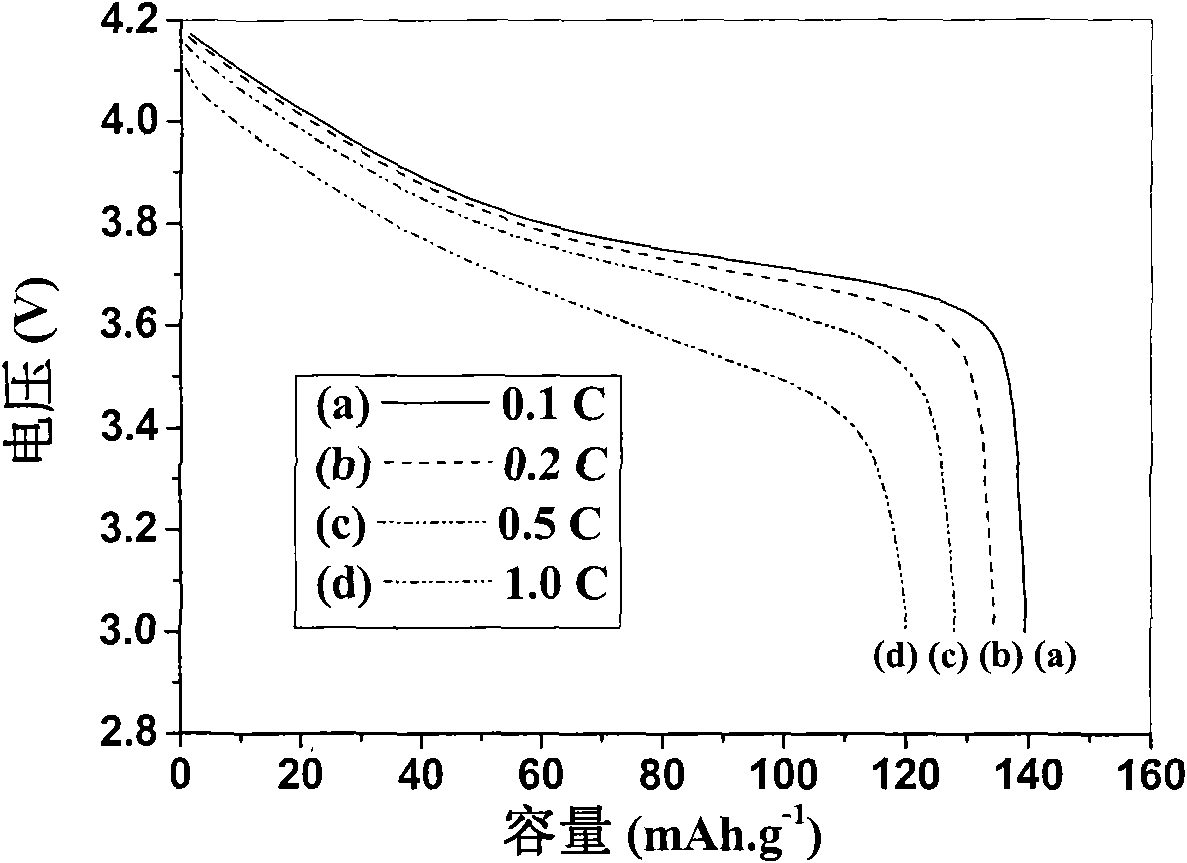

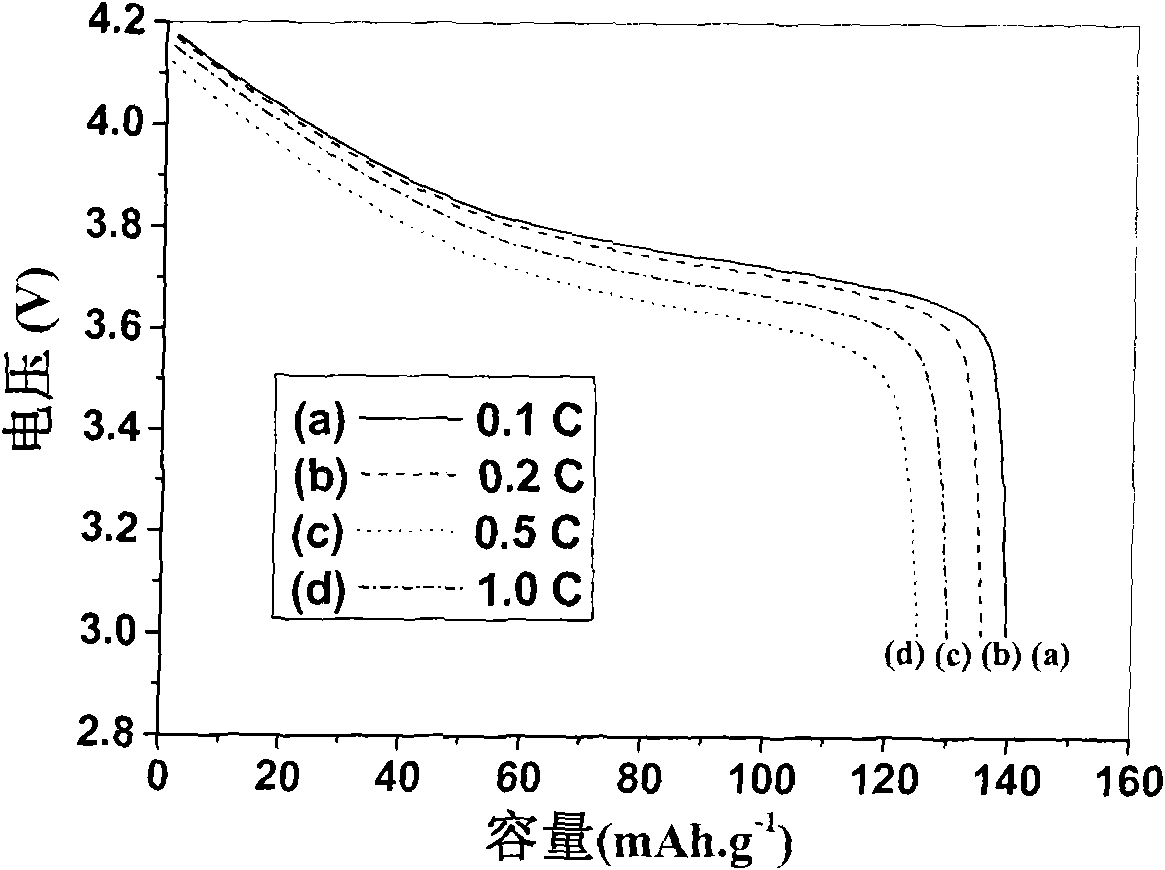

Gel polymer lithium ion battery electrolyte, preparation method and application thereof

ActiveCN101621134AHigh mechanical strengthGood liquid absorptionFinal product manufactureSecondary cellsPolymer electrolytesNanoparticle

The invention discloses lithium ion battery gel polymer electrolyte of supported doped nano particles, a preparation method and an application thereof. The preparation method of the electrolyte comprises the following steps: firstly, nano particles are doped in a mixture PEO and P (VDF-HPF) and are dissolved by using a solvent to obtain gel; then, a supporter membrane which is not activated and has good mechanical strength is soaked in the gel, taken out and aired to obtain a polymer membrane; and finally, after being dried, the membrane is soaked in electrolyte in a glove box so as to obtain the electrolyte. The polymer electrolyte has higher ionic conductivity and mechanical strength; simultaneously, the preparation time is short, the production efficiency is high, the invention is compatible to the existing equipment for preparing liquid state lithium ion batteries, and the production cost required by industrialization is greatly reduced.

Owner:SOUTH CHINA NORMAL UNIVERSITY

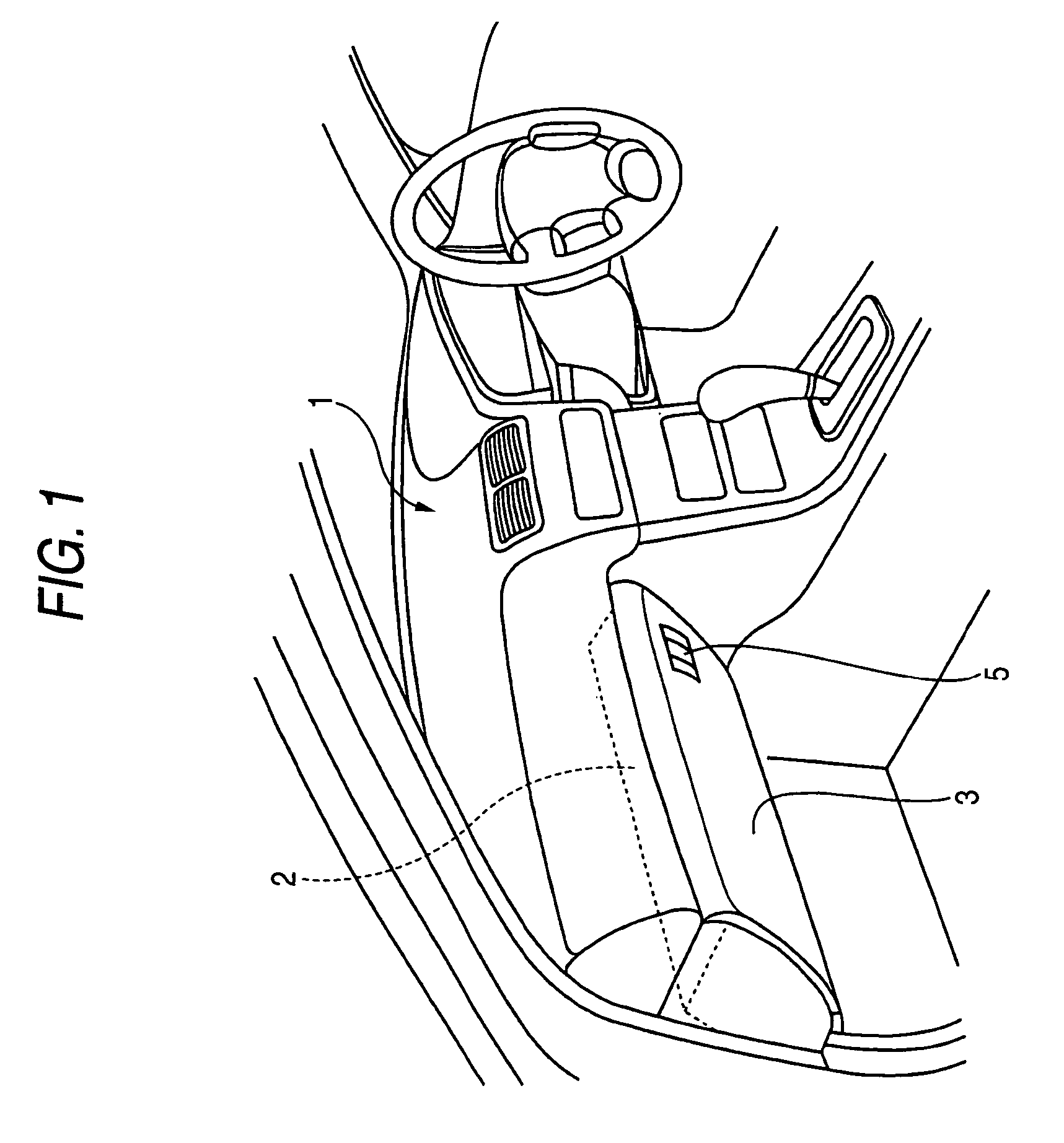

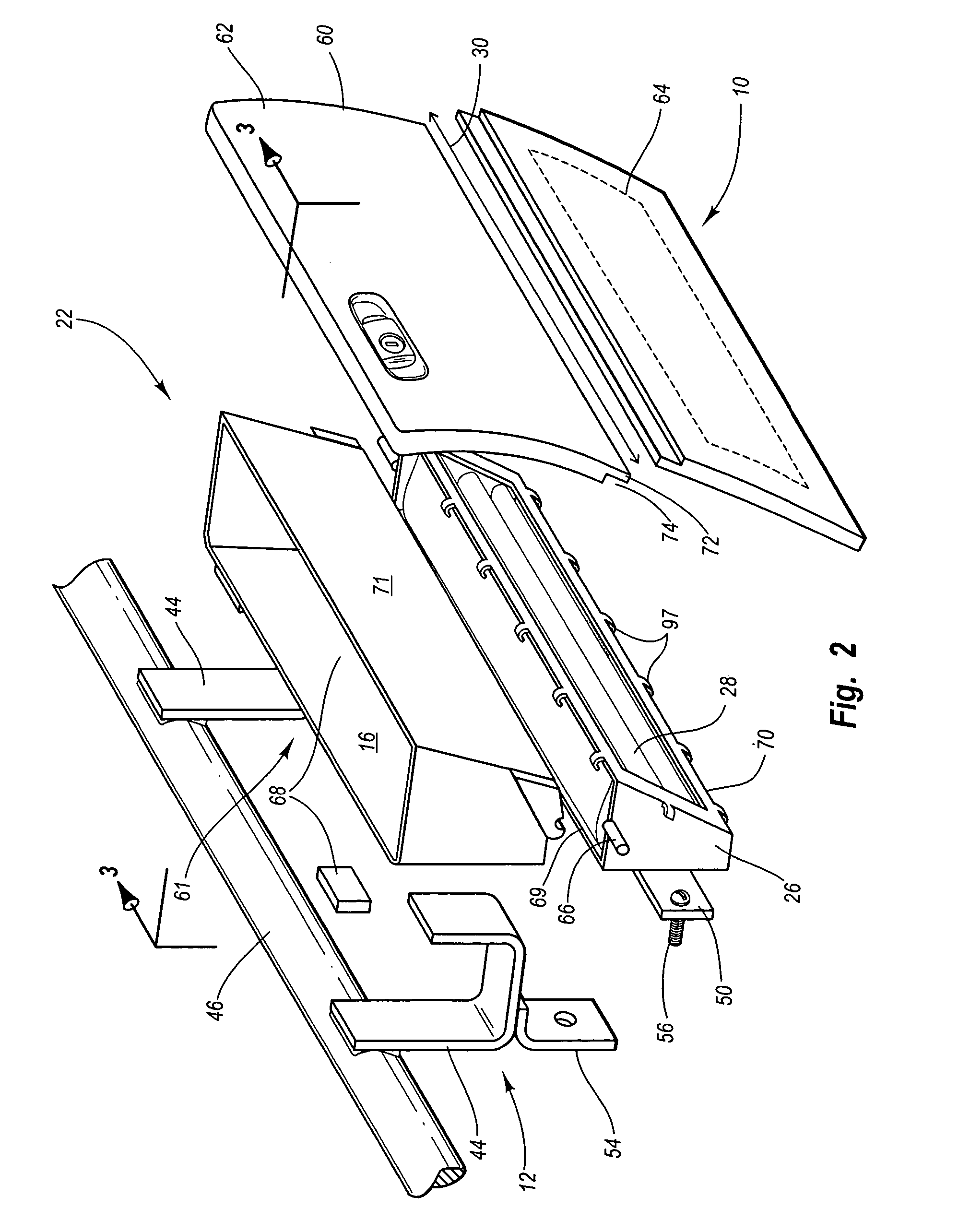

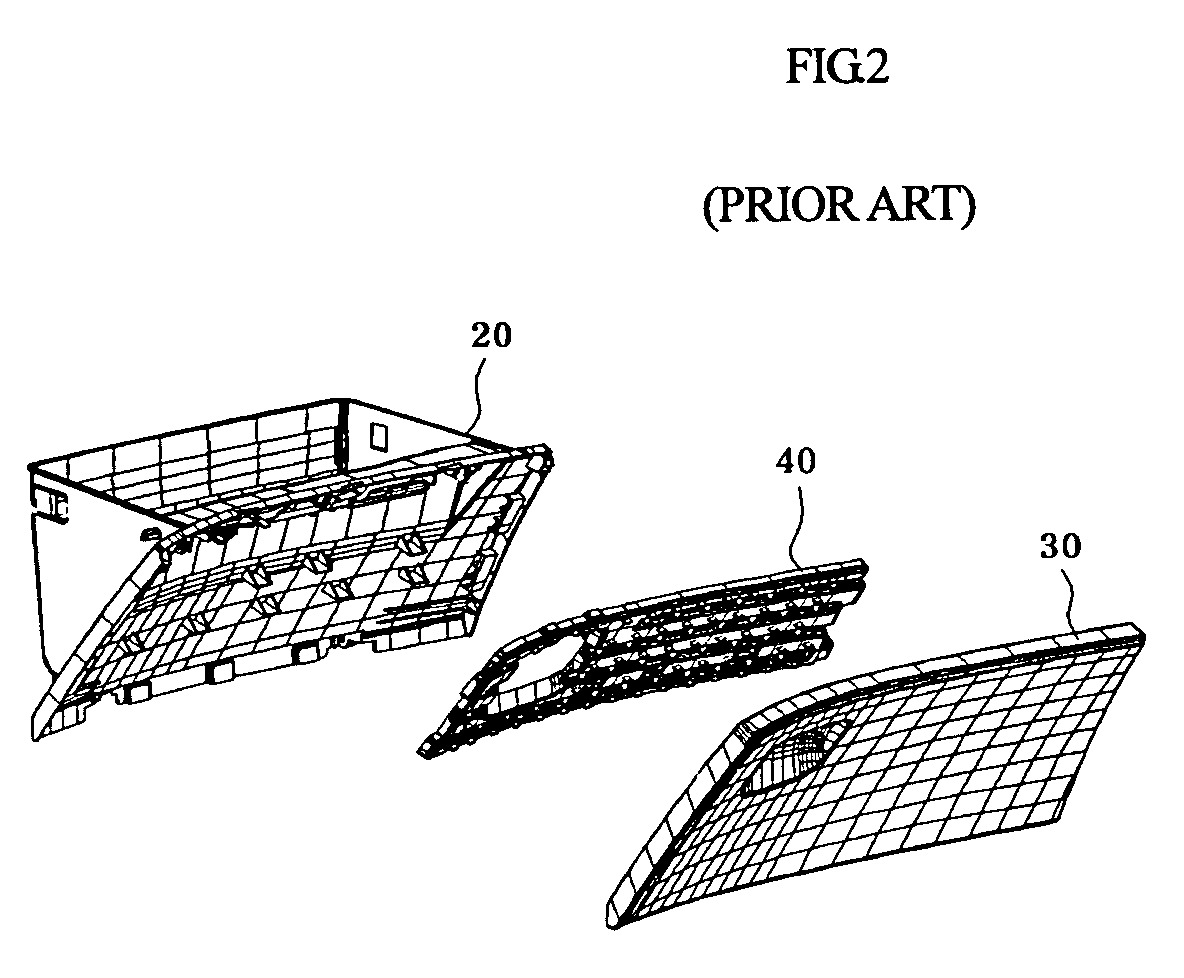

Knee bolster mounting structure for a glove box

InactiveUS20060038390A1Smooth connectionPassenger spacePedestrian/occupant safety arrangementKnee supportEngineering

A knee bolster mounting structure for a glove box having a housing having a predetermined space defined therein, a cover coupled to a front side of the housing to form an outer appearance of the glove box, and a knee bolster interposed between the housing and the cover to absorb impact in case of collision includes a plurality of fuse ribs protruded from front and rear surfaces of the knee bolster and fused thereto by vibration fusion, respectively, and round portions formed on each end of the fuse ribs.

Owner:HYUNDAI MOBIS CO LTD

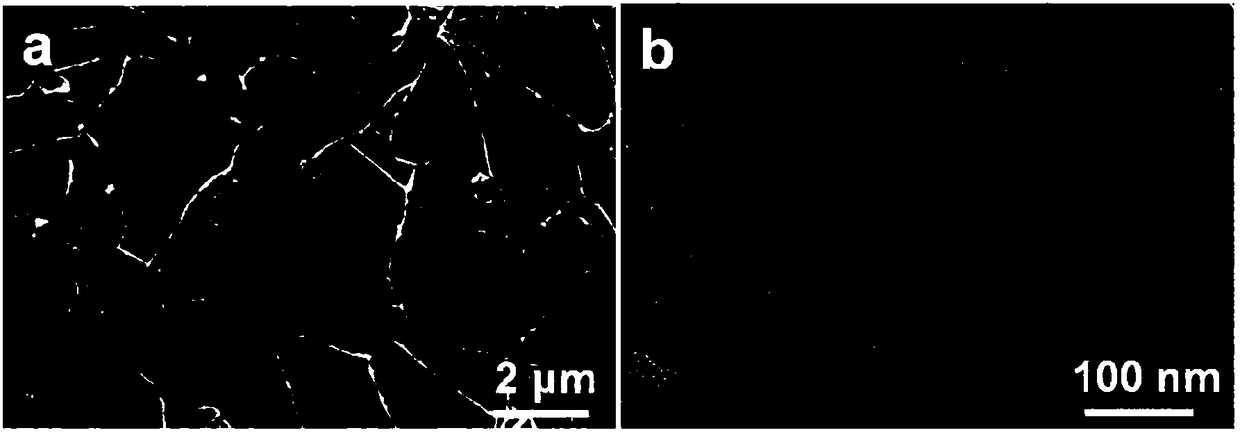

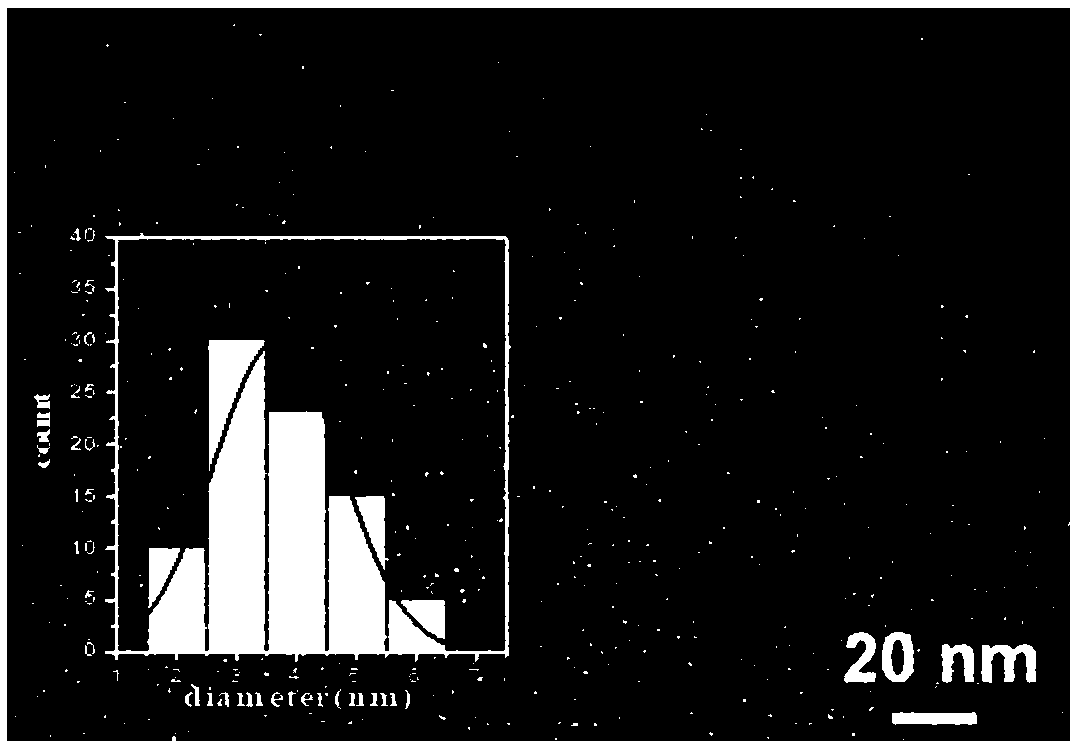

Preparation method and application of black phosphorus quantum dot and titanium carbide nanosheet composite material

ActiveCN108199015AImprove charge/discharge performanceImprove cycle stabilityCell electrodesMetal foilTitanium carbide

The invention relates to a preparation method and application of a black phosphorus quantum dot and titanium carbide nanosheet composite material. The preparation method comprises the following steps:mixing a single layer or a few layers of Ti3C2 nanosheets with black phosphorus quantum dots dispersed uniformly inside an organic solution, and carrying out simple technologies such as ultrasonic treatment, stirring and drying to obtain the black phosphorus quantum dot and titanium carbide (BPQDs / Ti3C2) nanosheet composite material. The BPQDs / Ti3C2 nanosheet composite material coated on a coppersheet is taken as a working electrode of an energy battery, metal foils are taken as a counter electrode and a reference electrode, a glass microfiber filter membrane is taken as a diaphragm, an organic solution is taken as an electrolyte, and a button battery is assembled inside a glove box filled with high-purity argon. The product can serve as a two-dimensional electrode material, is widely applied to the energy field such as lithium ion batteries, and has excellent charge / discharge performance and cycling stability.

Owner:TONGJI UNIV

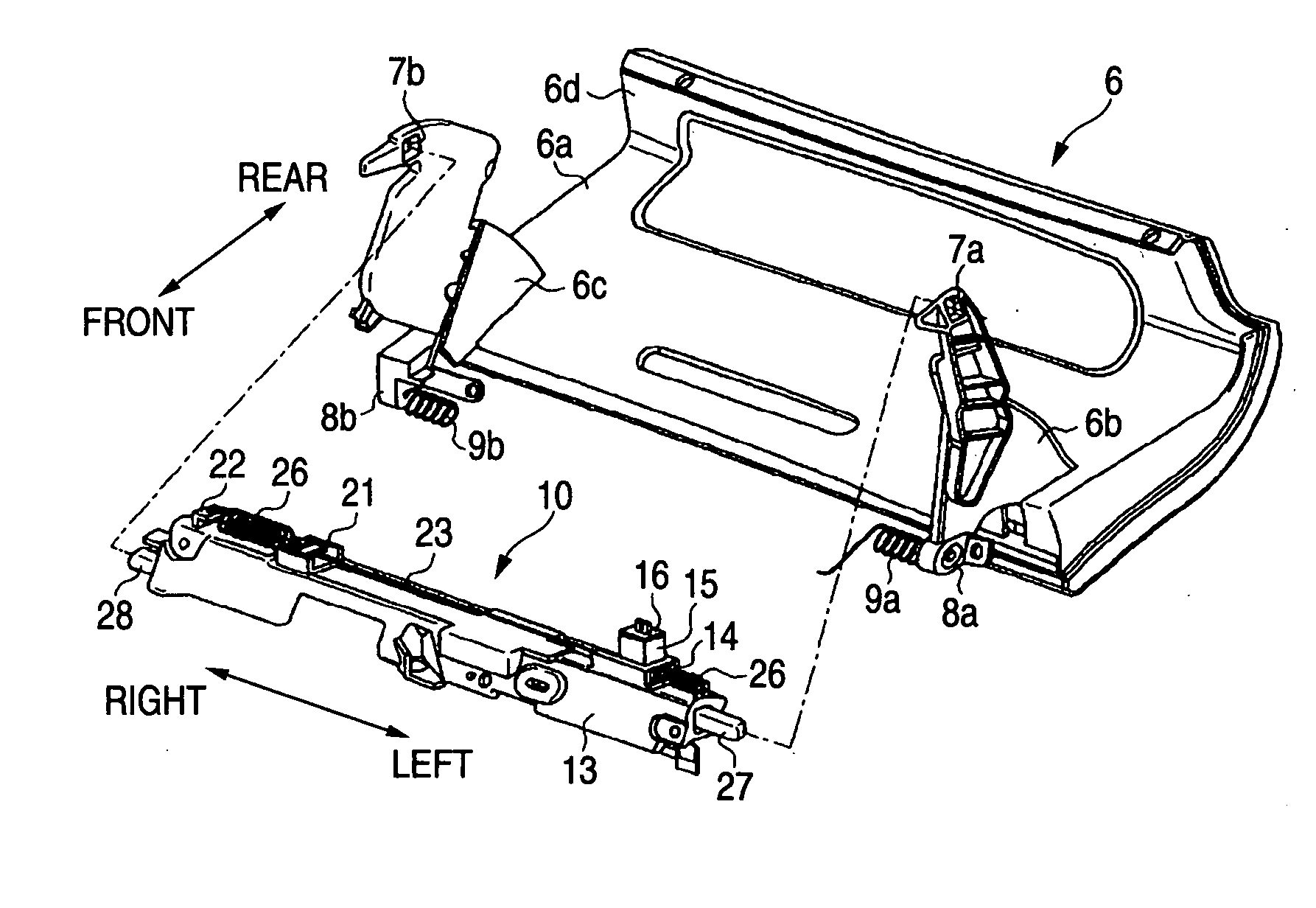

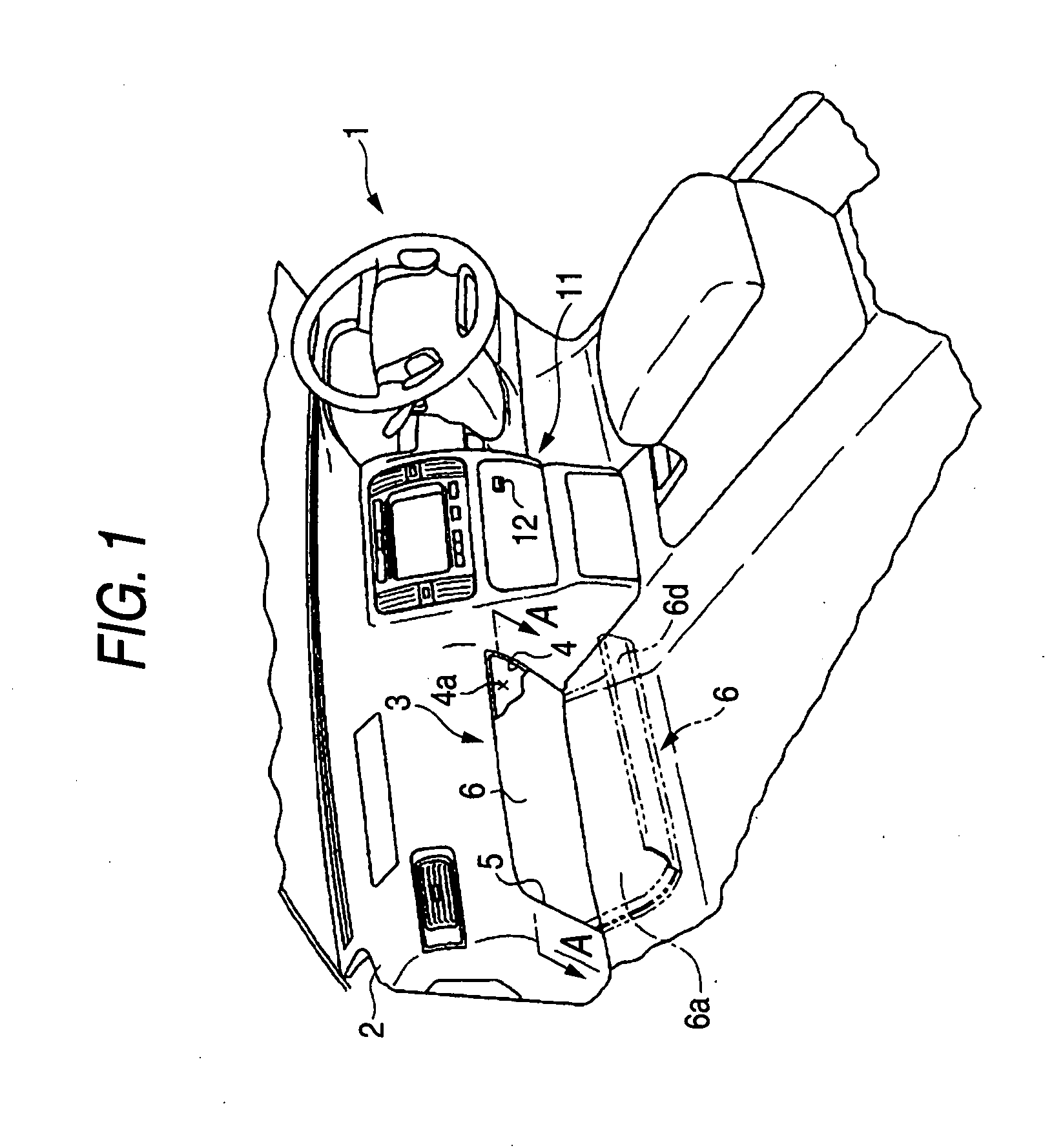

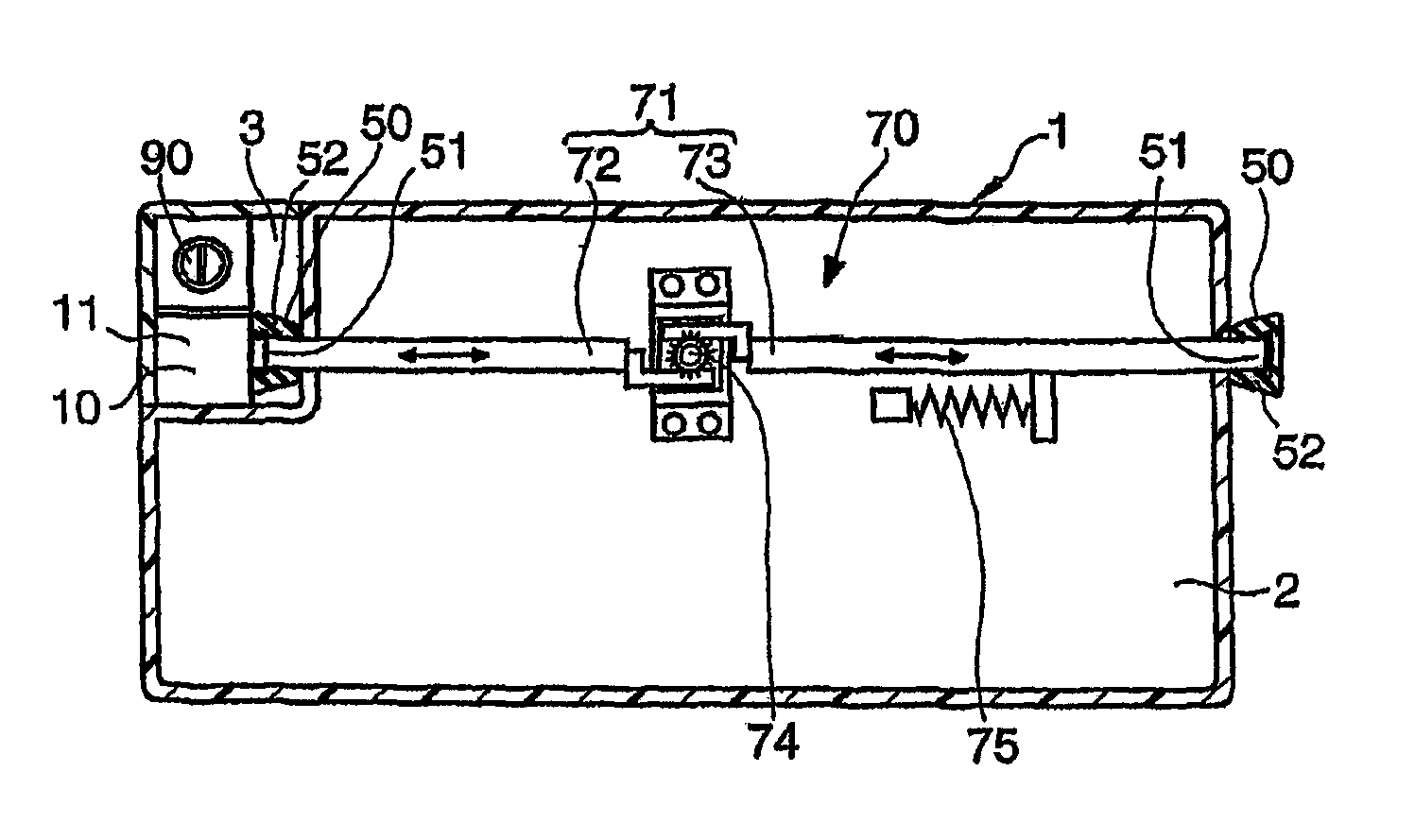

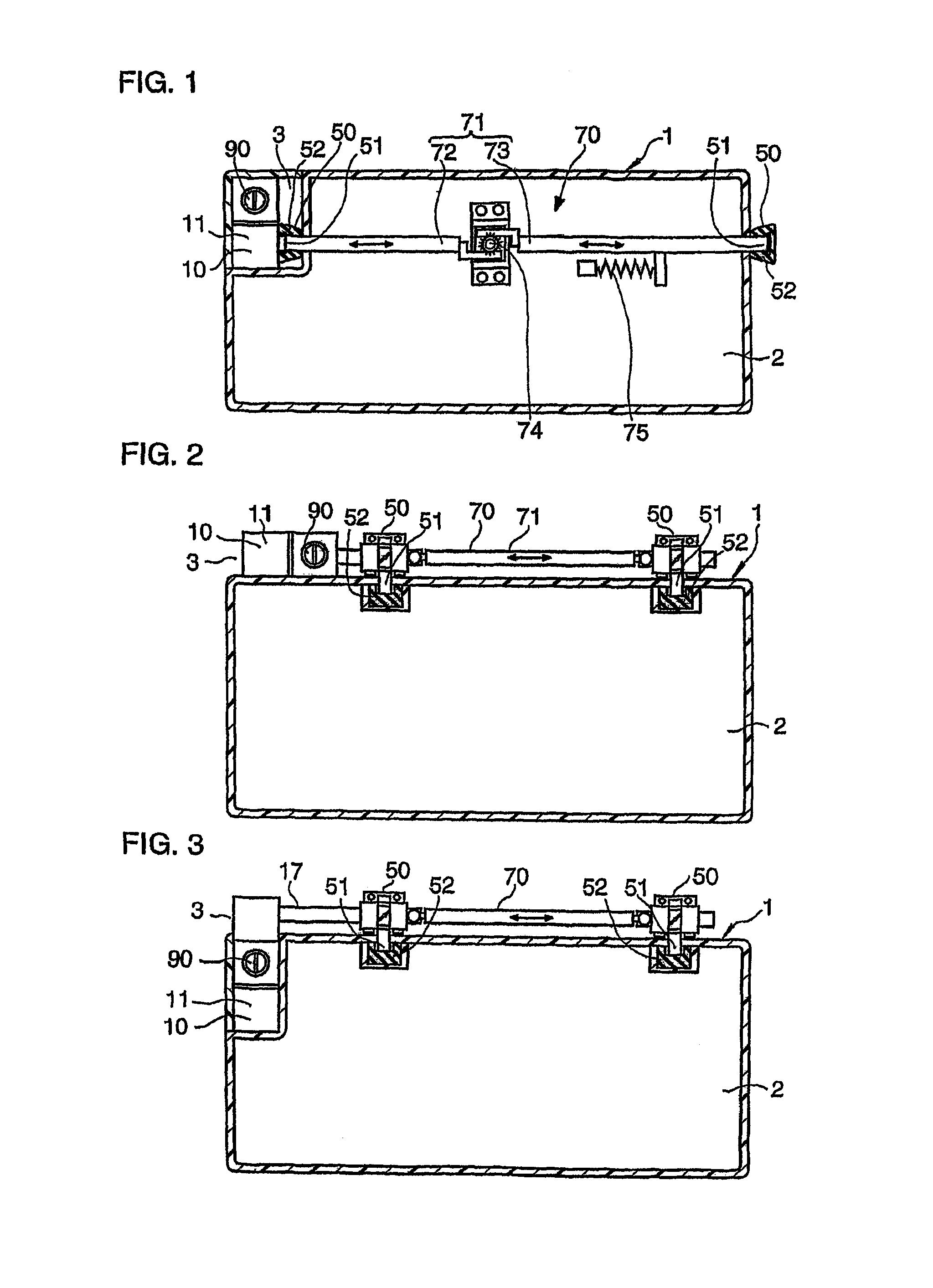

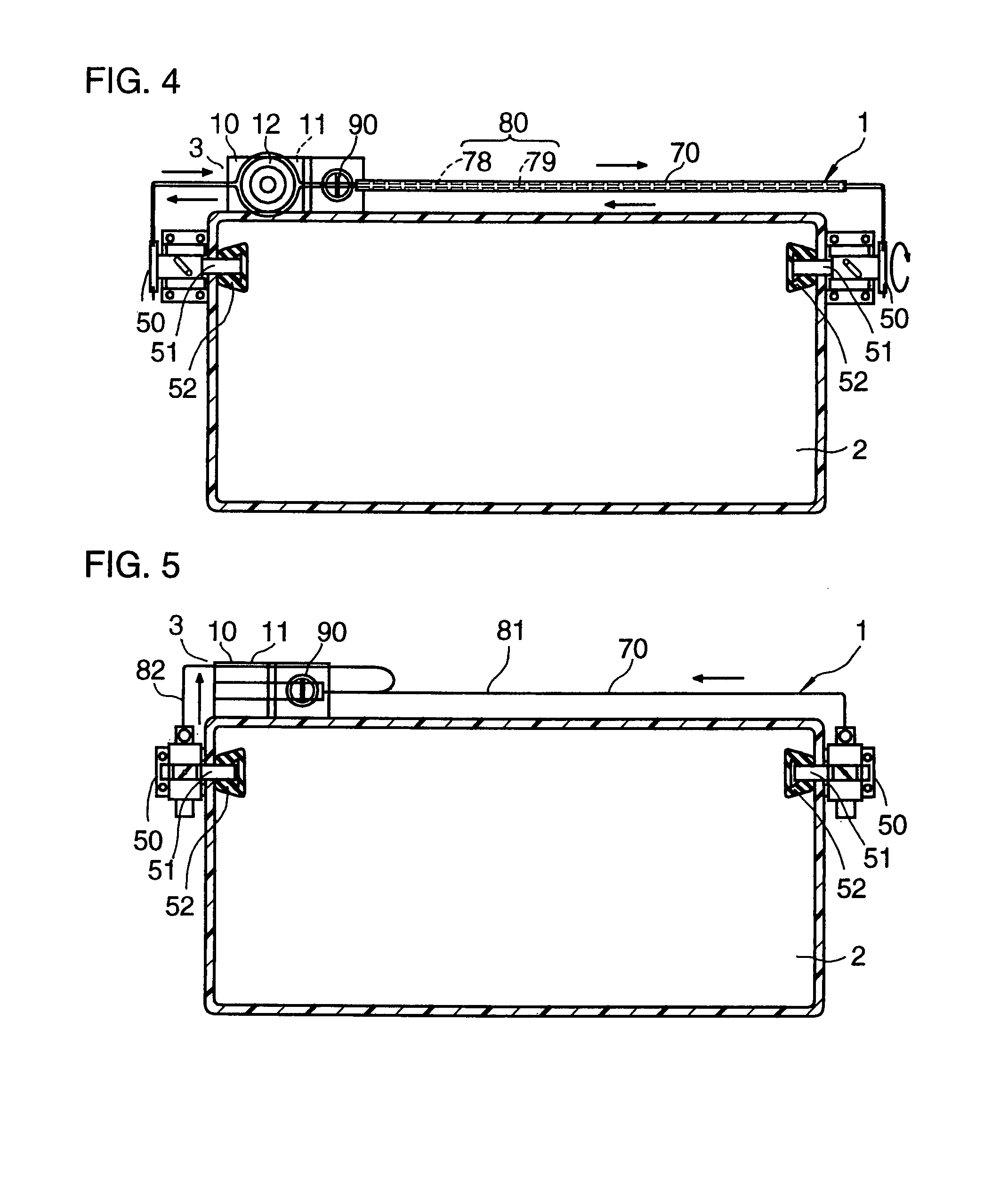

Damper unit and glove box device using the same

InactiveUS6857675B2Improve the sense of qualityForce is smallPassenger spaceBuilding braking devicesGear wheelClassical mechanics

A damper unit includes a gear having a core member projecting at a shaft core portion thereof and rotatably housed in a case, a string wound around the core member, a rotary damper engaging the gear for damping a rotational force of the gear, and a spring. One end of the spring is fixed to the case and the other end thereof is fixed to the core member so that an elastic force is accumulated when the string is pulled out.

Owner:NIFCO INC

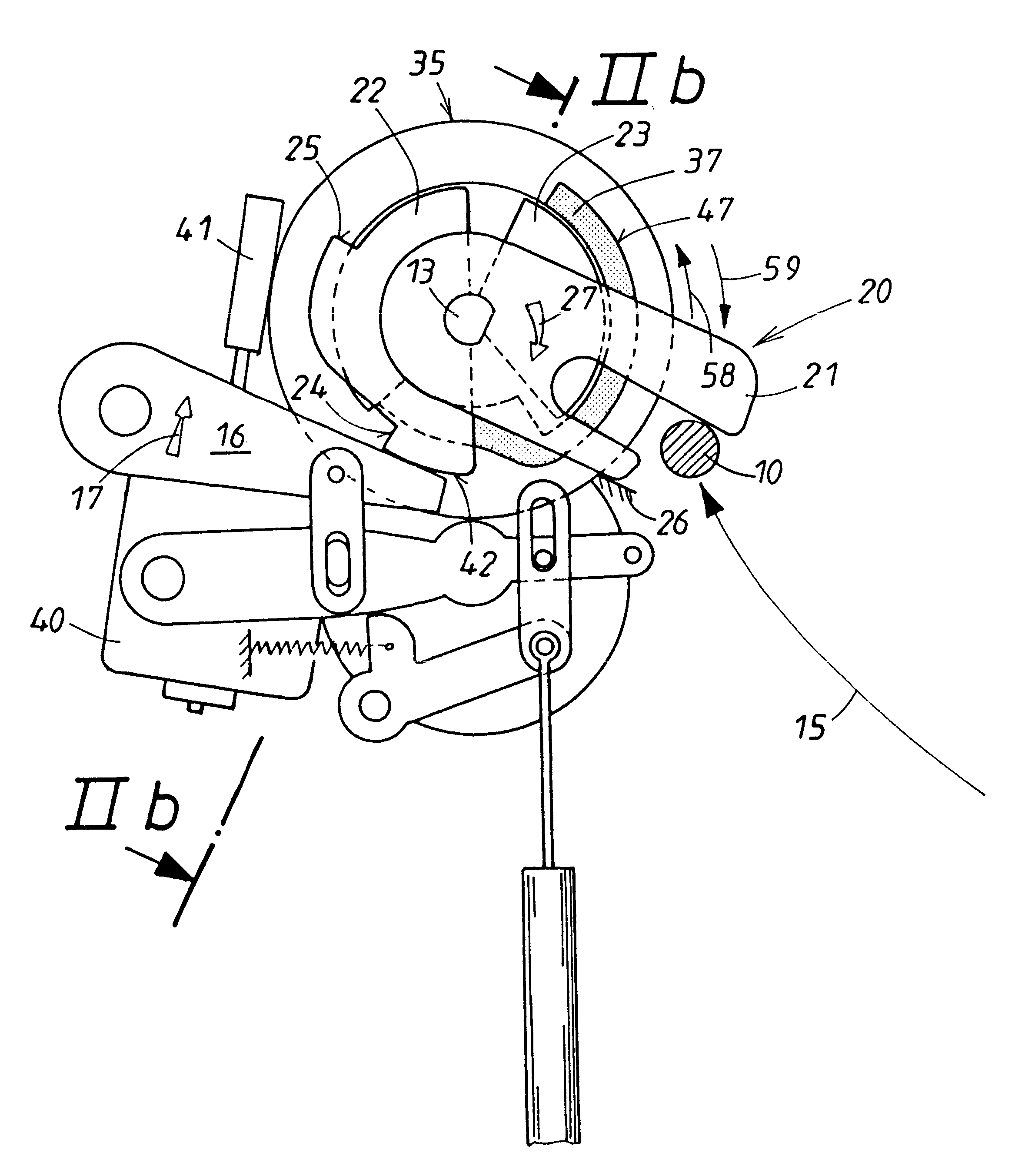

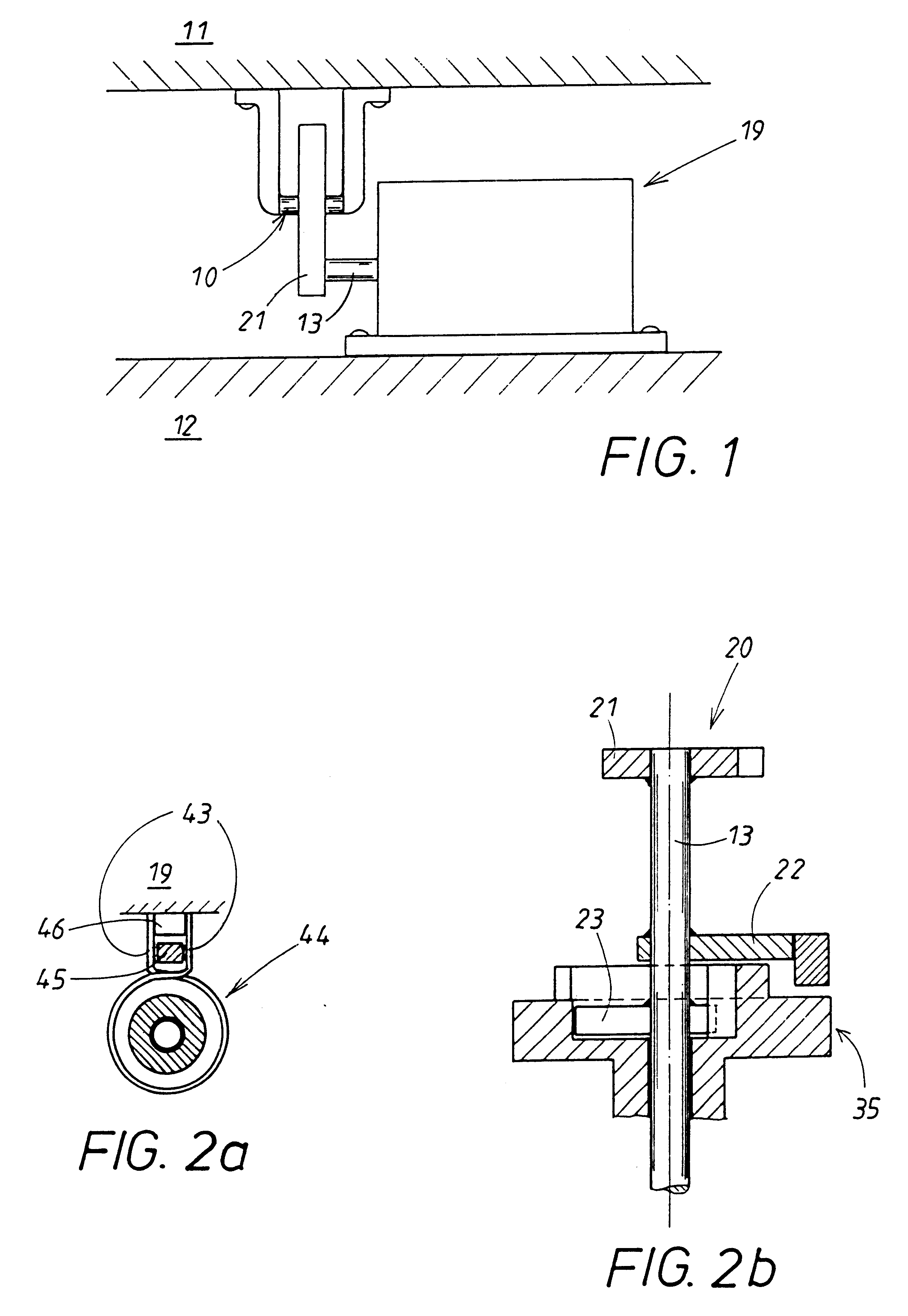

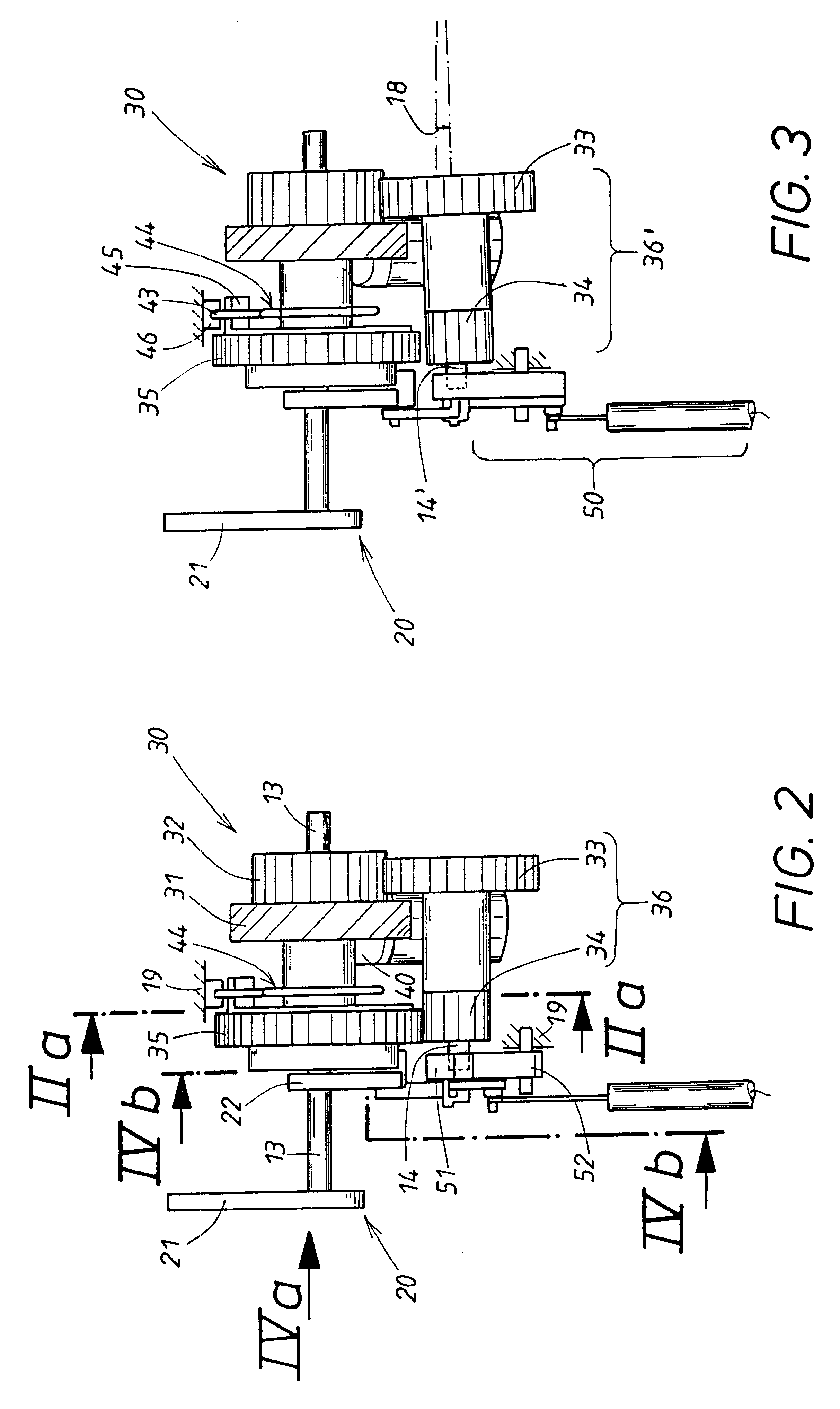

Motorized lock for flaps or doors in motor vehicles, especially a lock for glove compartments

The invention relates to a lock that can be used with a flap, comprising a rotary unit that is made up of a rotary spagnolet that interacts with a closing element (10) and a rotating latch (22). In order to improve operational performance, the rotary unit is provided with a rigid catch (23) that preferably has two counter shoulders running in opposite directions. The output member (35) of a motor (40)-driven gear mechanism is also provided with two corresponding counter shoulders. This enables the motor to provide assistance with closing and, optionally, opening, whereby the rotary unit can be guided in a closing, tilting direction or an opening, tilting direction until the flap is fully closed or opened. The motor (40) comprises a gear mechanism with a group of gears that can be displaced between an engaged position and a separated position. The detent pawl (16) which interacts with the rotating latch (22) is disabled in the separated position, should an emergency arise. When the flap is in a closed or open position, a free area exists between the shoulders and counter shoulders, enabling the flap to be moved manually.

Owner:HUF HULSBECK & FURST GMBH & CO KG

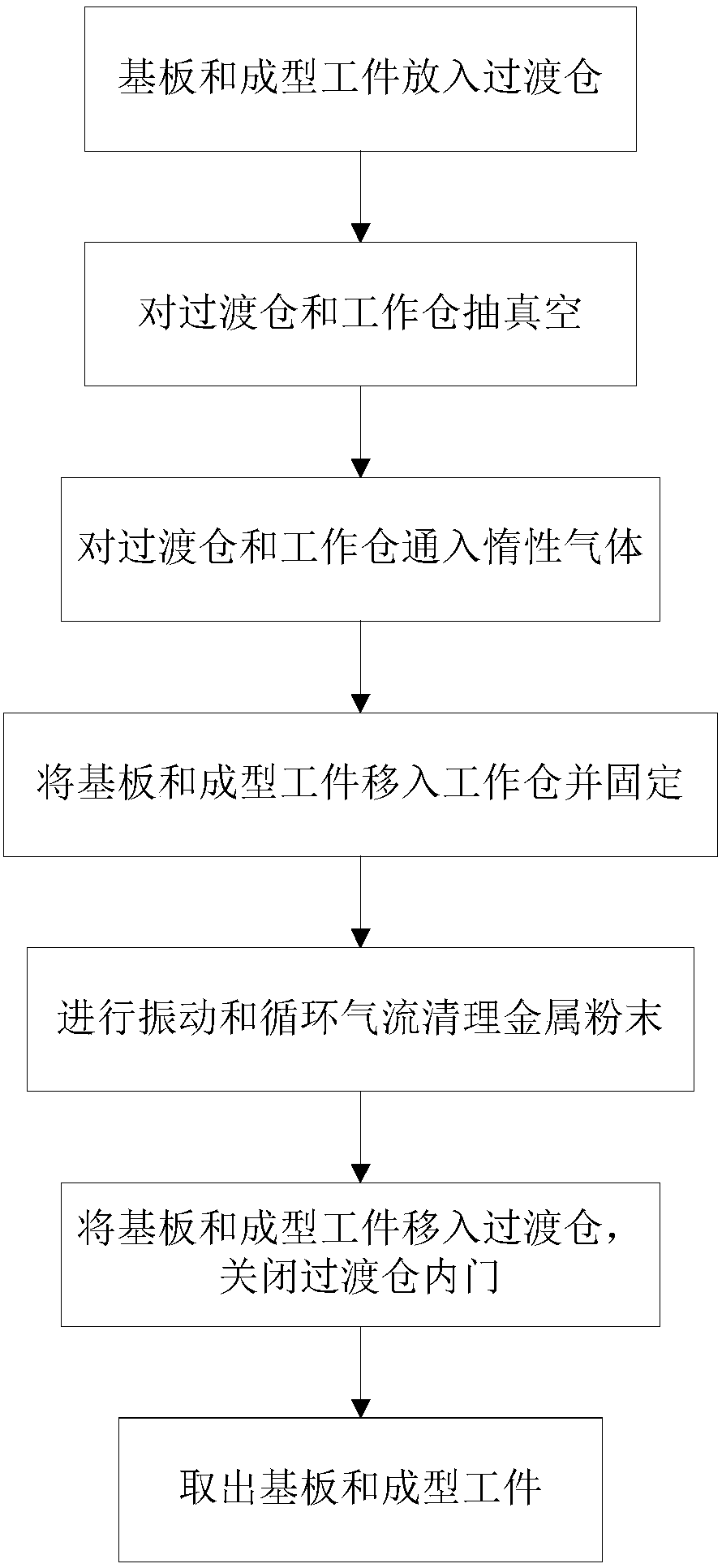

Device and method for recovering residual powder on SLM molding substrates

ActiveCN107671292AAvoid flyingGuaranteed cleanlinessAdditive manufacturing apparatusIncreasing energy efficiencyEngineeringAir blower

The invention relates to a device and a method for recovering residual powder on SLM molding substrates. The device comprises a working bin provided with a glove box inlet; the working bin communicates with a gas storage tank through an inert gas pipe; a rotating shaft with a fixture is arranged in the working bin; a powder guide surface inwards, downwards and aslant extending from the inner sidesurface of the working bin is arranged below the rotating shaft; a filter screen connected with an impurity collecting barrel is arranged in the lowest place of the powder guide surface; a powder collecting barrel is connected below the filter screen; the filter screen and the fixture are connected with a vibrator arranged outside the working bin; the side wall or the bottom surface of the powdercollecting barrel is connected with an intake port of an air blower through a gas circulating screen; and an exhaust port of the air blower communicates with the internal of the working bin above therotating shaft through a gas circulating pipe. The device can effectively recover the residual powder on substrates and parts, effectively maintains cleanness in the working bin, can prevent more lossof inert gas when the substrates and the parts are put in or taken out by multiple times, and effectively saves the production cost.

Owner:OPTIMAL MATERIAL TECH CO LTD

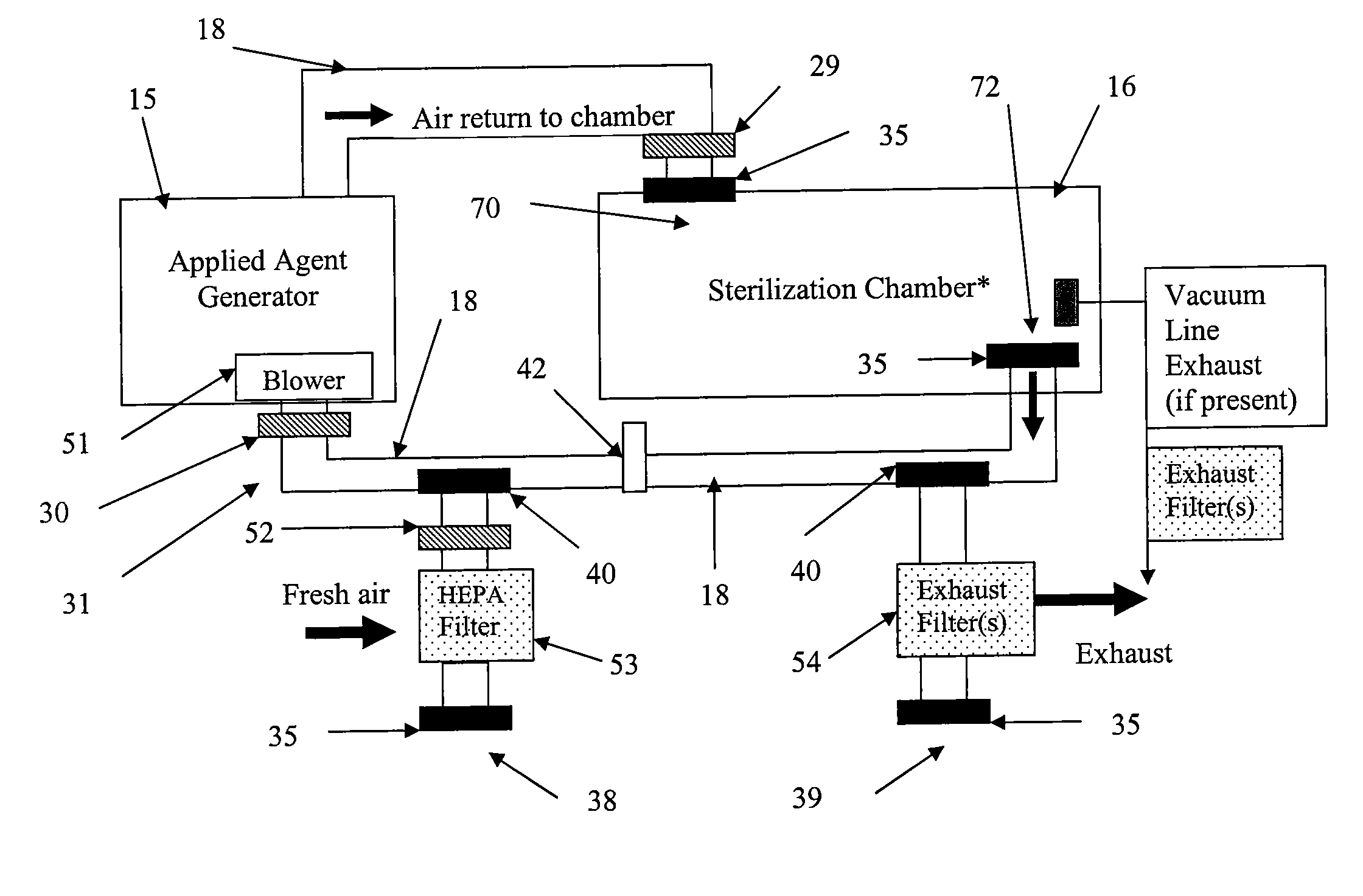

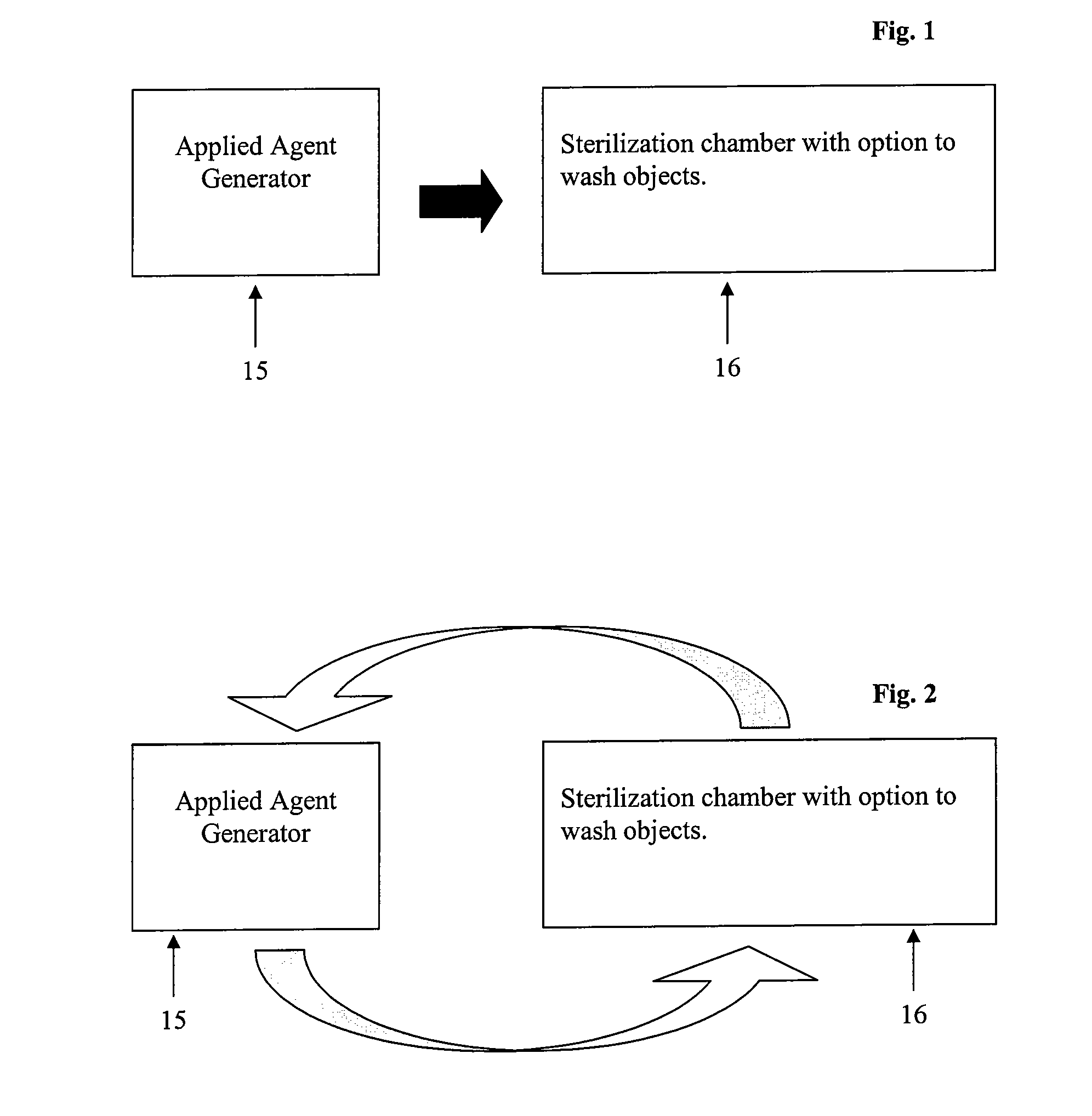

Methods and Apparatuses for the Disinfection of Objects, Devices and Areas

ActiveUS20100226821A1Reduce exposureShorten the timeLavatory sanitoryDeodrantsUltrasonic nebulizersEngineering

A method and apparatus for the sanitization, detoxification, disinfection, high level disinfection, or sterilization of both the interior and exterior surfaces of an object or plurality of objects, including those with lumens and / or channels of various sizes, within a closed space, or closed system of space, in addition to their surrounding atmosphere, and relates particularly, though not exclusively, to the generation of an aerosol including an anti-pathogen / toxin / fungal / sporicidal agent(s) or substance(s)(applied agent), or chemical neutralizing agent(s) or substance(s), by way of one or more ultrasonic nebulizer(s). However the applied agent used in the present invention may also be in the form of any gas, vapor, plasma, aerosol, or other form. The said apparatus and method also includes an option to incorporate and utilize a means to wash the object(s) or endoscope(s). More importantly, the present invention addresses an improvement to the current art, by a new method and apparatus for the application of a positive or negative air / gas pressure to the internal space, lumens, ducts, or channels, of an object or endoscope, in order to apply or administer applied agent, in the form of a gas, plasma, vapor, or aerosol to the surfaces within these locations as well as to the surfaces and areas that interface with the means to apply the positive or negative air / gas pressure to the object or endoscope. The present invention addresses the current problem of obtaining full sanitization, disinfection, high level disinfection, or sterilization, of both the interior and exterior surfaces and areas of an object or endoscope as well as the interfacing surfaces and areas between the applicator for the applied agent and the object or endoscope. The present invention will allow for the complete sanitization, disinfection, high level disinfection, or sterilization of objects in a simple chamber, or in more complex configurations that include, but are not limited to, glove box units, processors with built in interfaces for specialty applications such as endoscope reprocessing, and other application specific designs.

Owner:ALTAPURE

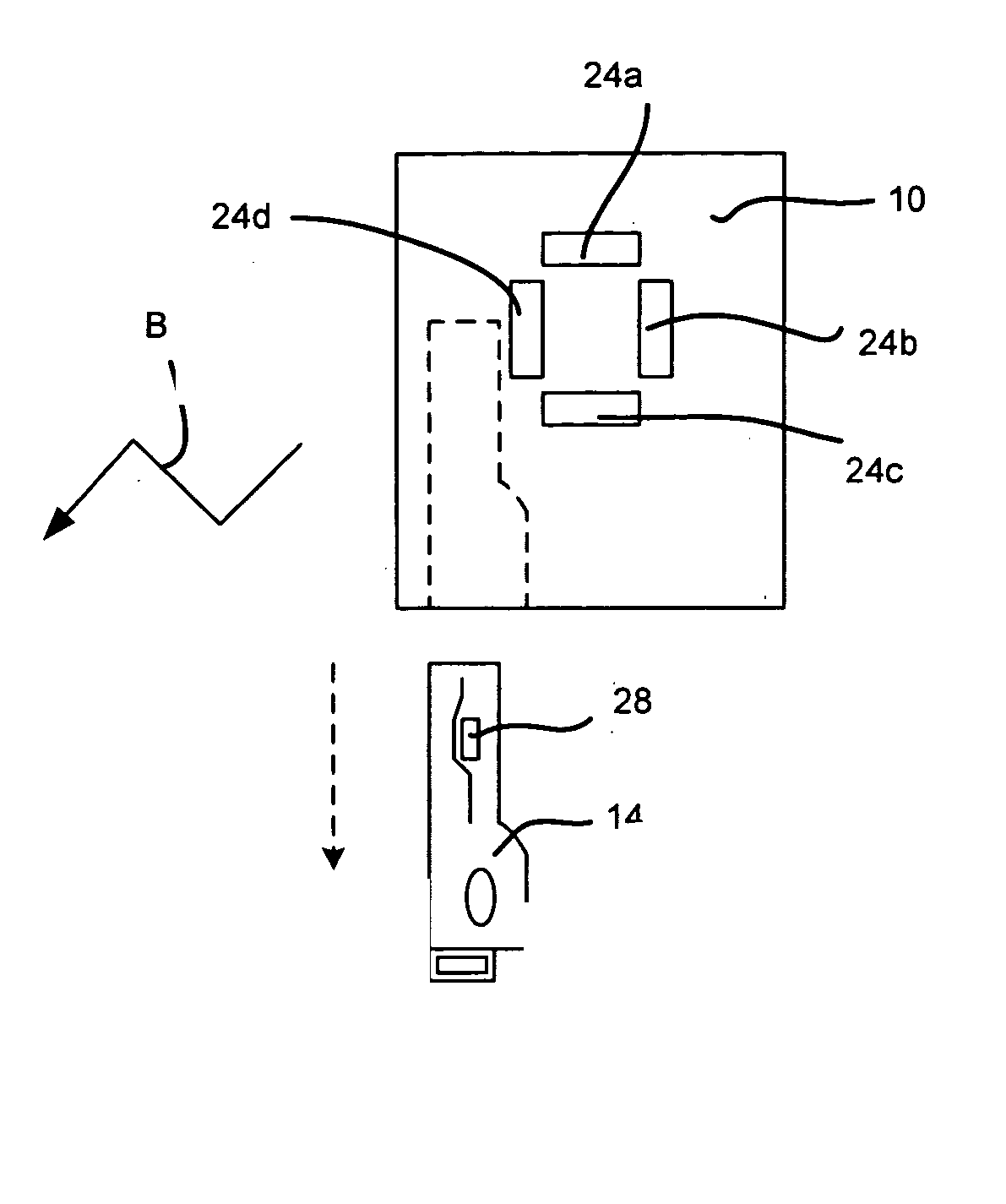

Lock apparatus for a glove box of a vehicle

InactiveUS7832239B2Easy to operatePromote exchangeAnti-theft cycle devicesVehicle locksDriver/operatorLeft direction

A lock apparatus for locking a glove box that is rotatably coupled to an instrument panel of a vehicle. The lock apparatus includes an operating portion with a push-type knob, a pair of lock portions, and a transmitting portion with a transmitting member. The operating portion is located closer to a driver seat than a right and left center of the glove box in a right and left direction of a vehicle. The operating portion is coupled to the instrument panel between the instrument panel and the glove box. Each of the lock portions is located at each of right and left end portions of the glove box. The transmitting portion transmits a motion of the operating portion to each of the pair of lock portions using tension and / or compression of the transmitting member.

Owner:KOJIMA PRESS IND CO LTD

A kind of flexible current collector and lithium battery made of this current collector

ActiveCN102290578AImprove mass energy densityLow costElectrode carriers/collectorsSecondary cellsElectrolytic agentPole piece

The invention relates to a soft current collector and a lithium-ion battery made of a soft current collector, which is characterized in that the manufacturing method is as follows: first, the positive electrode is prepared: the positive electrode slurry is coated on the aluminum layer with a thickness of 0.1-10.0 μm, and the thickness of the plastic is 5.0~30.0μm aluminized plastic, the coating thickness is 0.08~0.20mm, after drying in a vacuum oven at 80~120oC, the positive electrode sheet is obtained; the negative electrode is prepared and the negative electrode slurry is coated on the copper layer with a thickness of 0.2~8.0μm , On the copper-plated plastic with a plastic thickness of 5.0~30.0μm, the coating thickness is 0.06~0.15mm, and the negative electrode sheet is obtained after drying in a vacuum oven at 80~120oC; the positive electrode sheet, PP or PE separator, and the negative electrode are sequentially The pole pieces are stacked and packed with aluminum-plastic film, and an appropriate amount of electrolyte solution 1MLiPF6+EC:DMC (1:1) is injected into the glove box; the aluminum-plastic film is hot-pressed and packaged to obtain a flexible lithium-ion battery. It effectively improves the mass energy density of the battery cell. The cost of the battery monomer is reduced; it has the advantages of low price, because the shape of the lithium-ion battery prepared by it can be arbitrary, ultra-thin, and the mass energy density is high.

Owner:CHINA FIRST AUTOMOBILE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com