Method for recycling electrolyte of waste lithium ion battery

A lithium-ion battery and electrolyte technology, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of large power battery, waste of raw materials, easy fire and combustion, etc., achieve high recycling efficiency and save resources , The effect of short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

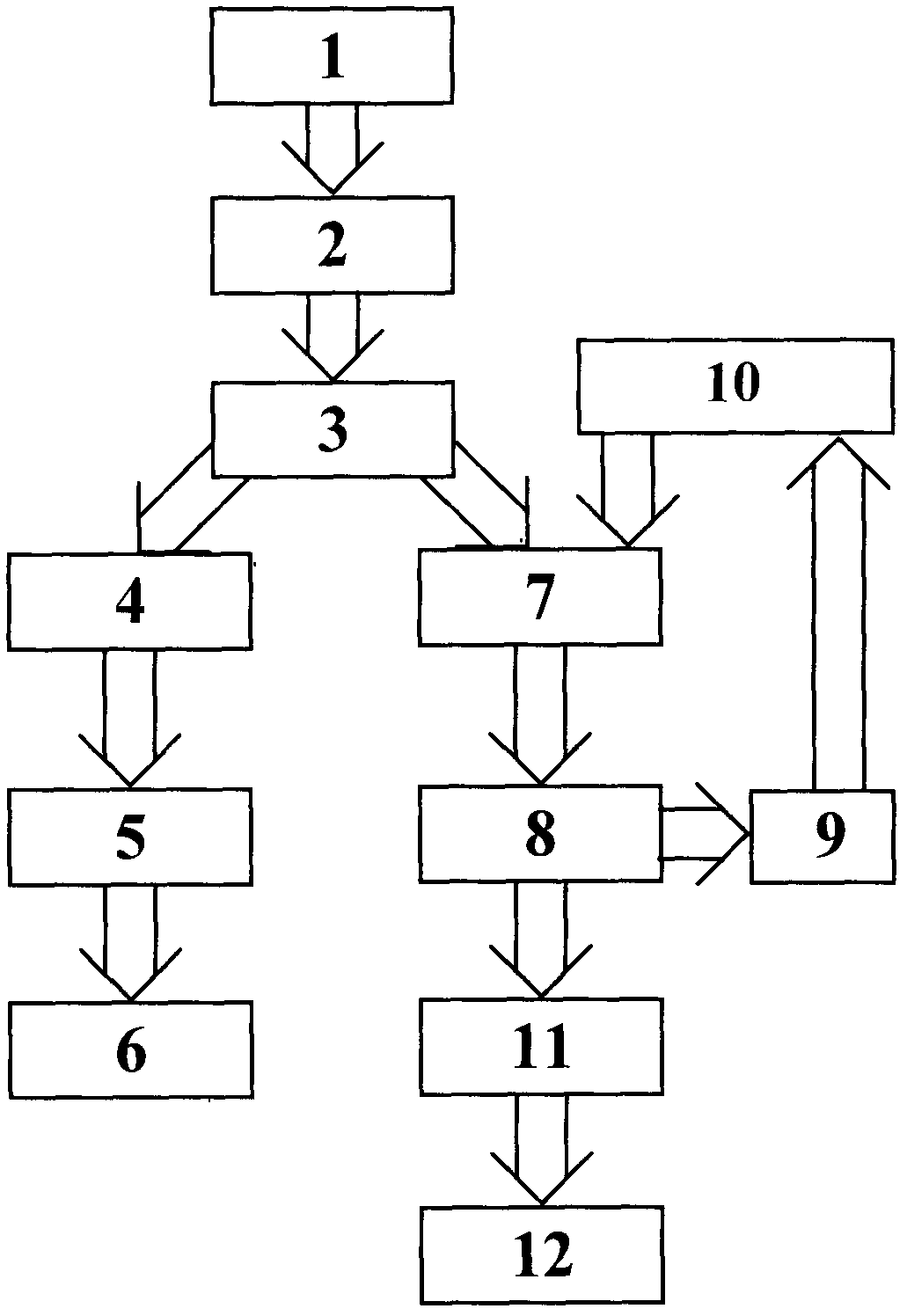

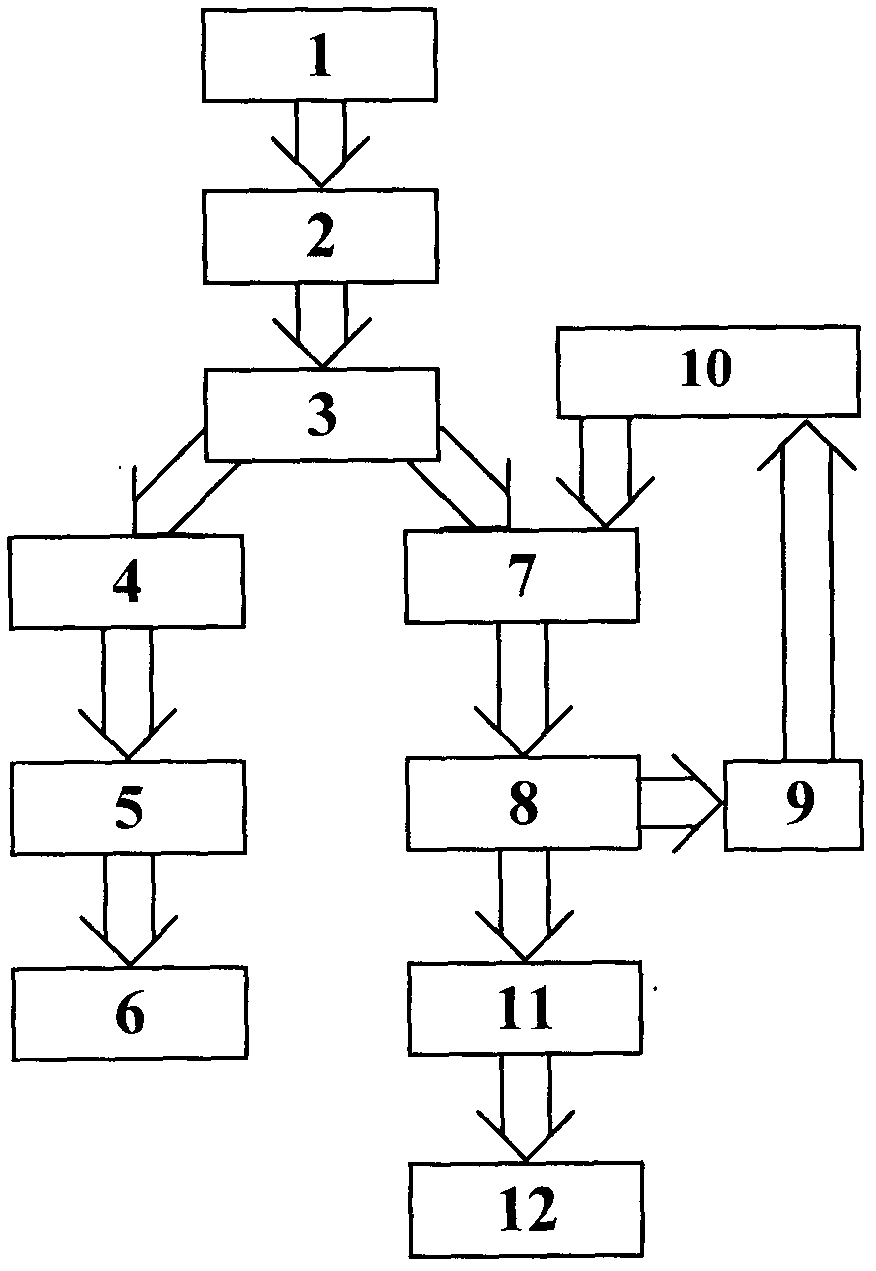

Image

Examples

Embodiment Construction

[0022] The method for recovering the effective components of lithium hexafluorophosphate and solvent in the electrolyte solution of spent lithium-ion batteries according to the present invention will be further described in detail through specific implementation methods.

[0023] The waste lithium ion batteries include lithium cobalt oxide, lithium iron phosphate, lithium manganate, ternary materials and other types of lithium ion batteries.

[0024] The organic solvent recovery process includes intermittent or continuous vacuum rectification, high vacuum rectification and the like.

[0025] The solvent recovered by the method includes, for example, dimethyl carbonate, diethyl carbonate, ethyl methyl carbonate, γ-butyrolactone, tetrahydrofuran, ethylene carbonate and the like.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com