Rapid forming process of iron phosphate lithium battery

A lithium iron phosphate battery, fast technology, applied in the field of lithium-ion batteries, can solve the problems of long time consumption and low efficiency, and achieve the effect of less energy consumption, high efficiency and time saving

Inactive Publication Date: 2014-09-10

LVCHI AUTO TECH SHANGHAI CO LTD

View PDF10 Cites 48 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Aiming at the problems of long time-consuming and low efficiency of traditional formation process, the present invention discloses a rapid formation process of lithium iron phosphate battery, which includes the following steps:

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

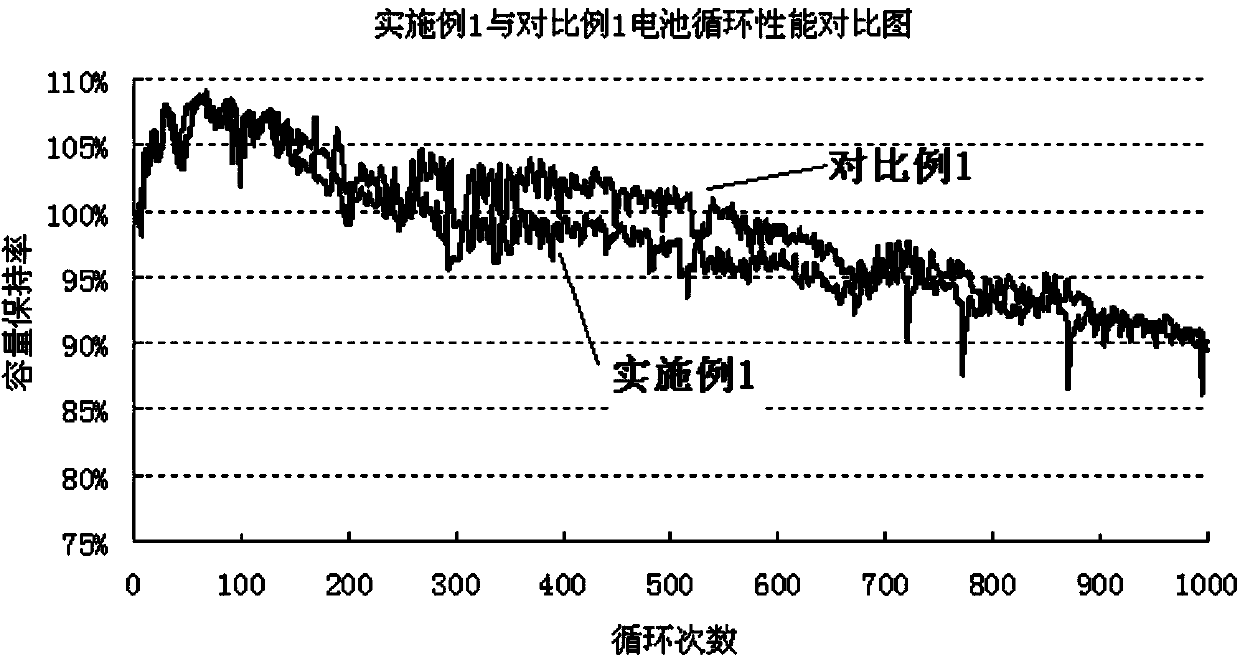

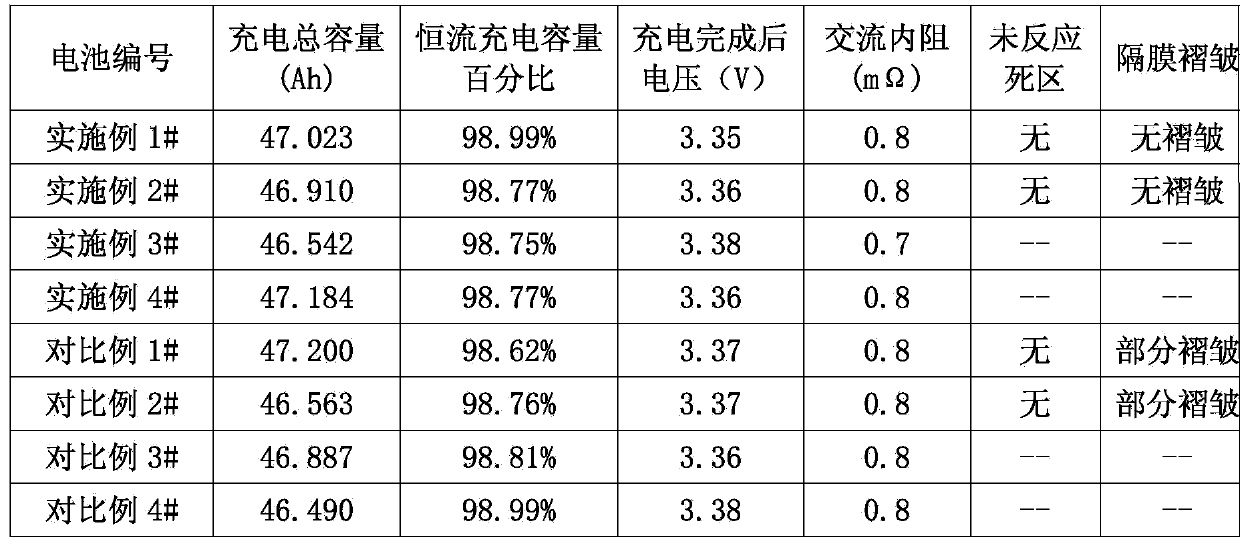

The invention discloses a rapid forming process of an iron phosphate lithium battery. The rapid forming process comprises the following steps: vacuumizing after the battery is assembled, and injecting electrolyte by several times, and sealing the battery; putting the battery into a thermostat, standing for 8-12 hours at 45-50 DEGC, turning or rotating the battery in a standing process so as to putting each face of the battery downwards for a certain time; after the standing, carrying out ultrasonic treatment on the battery for 10-20 minutes; putting the battery on a cabinet, and carrying out low-current step type charging excitation and intermittent pulse discharge on the battery; after the charging is finished, carrying out deflation and one time of vacuumizing on the battery in a glove box, and carrying out sealing, ageing and capacity grading. According to the rapid forming process, firstly a diaphragm, an anode piece and a cathode piece of the battery are adequately infiltrated by virtue of the electrolyte, and then the battery is simultaneously subjected to high-current step type charging and intermittent pulse discharge, so that the time of the forming procedure is substantially shortened, the equipment loss is reduced, the performance of the formed battery is excellent, and the formed battery has no difference from a battery formed by virtue of a traditional forming process.

Description

technical field The invention belongs to the technical field of lithium ion batteries, and in particular relates to a rapid formation process of lithium iron phosphate batteries. Background technique The production process of lithium-ion batteries includes processes such as slurry mixing, coating, rolling, slicing, lamination (winding), assembly, liquid injection, and formation, among which formation is a very important link that determines the performance of lithium batteries. The impact of the formation process on the lithium battery mainly includes: 1. It affects the formation of the SEI film of the negative electrode sheet, its stability and compactness, and then affects the cycle performance of the lithium battery; 2. It affects the capacity of the lithium battery; 3. Incorrect formation The process will directly lead to lithium precipitation at the negative electrode of the lithium battery, forming "lithium dendrites", which will seriously threaten the safety performa...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M10/058

CPCH01M10/058Y02E60/10Y02P70/50

Inventor 张晶晶

Owner LVCHI AUTO TECH SHANGHAI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com