An adjustable chemical plastic production granulator

An adjustable, granulator technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of increasing cutting difficulty, unable to heat plastic melt, unable to realize the efficiency of variable speed work, etc.

Active Publication Date: 2022-05-31

然石功能材料(江苏)有限公司

View PDF4 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0006] In order to overcome the fact that the existing granulator cuts the plastic directly with a cutting knife, the plastic is relatively hard when it is solidified, thus increasing the difficulty of cutting, the time to complete the granulation is fixed, and it is impossible to achieve variable speed To improve the efficiency of work, and it is impossible to maintain continuous heating of the plastic melt, and it is impossible to prevent the plastic melt from adhering to the inside of the device after cooling, which will affect the efficiency of the device for a long time. The technical problem of the present invention is to provide An adjustable chemical plastic production granulator with variable speed and sustainable heating

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

[0040] As shown in FIG. 5, the heating assembly includes a support cone 308, a heating column 3081 and a heating wire 310, and the support cone 308

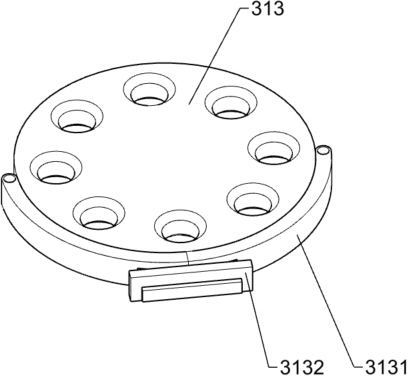

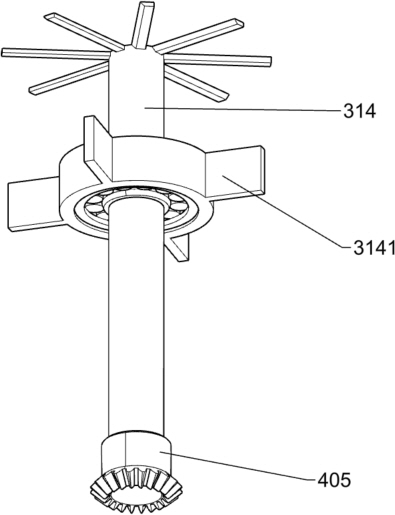

[0042] As shown in Figures 9-10, the cutting mechanism includes a fourth shaft 314, a chuck 3141, a cutting knife 315 and a fan 316.

[0044] As shown in Figure 9 and Figure 11, the adjustment mechanism includes a first conical disc 4, a second conical disc 401, a fifth shaft 402,

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

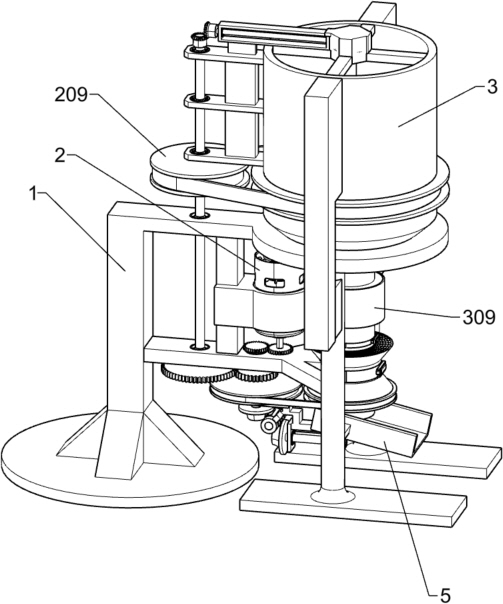

The invention relates to a plastic granulator, in particular to an adjustable chemical plastic production granulator. The technical problem of the present invention is to provide an adjustable chemical plastic production granulator with variable speed and sustainable heating. The technical embodiment of the present invention is an adjustable chemical plastics production granulator, including a first support, a power mechanism, a stirring mechanism, a cutting mechanism, etc.; the power mechanism is fixedly installed on one side of the first support, and the stirring mechanism is fixed Installed on the side of the first bracket close to the power mechanism, the power mechanism is connected to the stirring mechanism, the cutting mechanism is installed on one side of the stirring mechanism, and the cutting mechanism is connected to an adjustment mechanism on a side away from the stirring mechanism. The invention adopts a heating column and an electric heating wire, and the heating column stirs the plastic while the stirring mechanism melts the chemical plastic at high temperature, which can prevent the plastic melt from sticking to the inside of the mixing barrel.

Description

An adjustable chemical plastic production granulator technical field The present invention relates to a kind of plastic granulator, in particular to a kind of adjustable type chemical plastic production granulator. Background technique Plastic granulator is mainly used for processing waste plastic film (industrial packaging film, agricultural mulch film, greenhouse film, beer bag, handbags, etc.), woven bags, agricultural convenience bags, basins, barrels, beverage bottles, furniture, daily necessities, etc., suitable for most common waste Old plastic is the most widely used, most widely used and most popular plastic recycling processing machinery in the waste plastic recycling industry. In industrial production, it is often necessary to process plastics, so that plastics are formed into granules, and then it is necessary to use plastics The appearance of the plastic granulator facilitates industrial production. When the equipment is in use, it is necessary to ensure...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B29B9/10

CPCB29B9/10Y02W30/62

Inventor 师中华

Owner 然石功能材料(江苏)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com