Patents

Literature

32results about How to "Impact capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

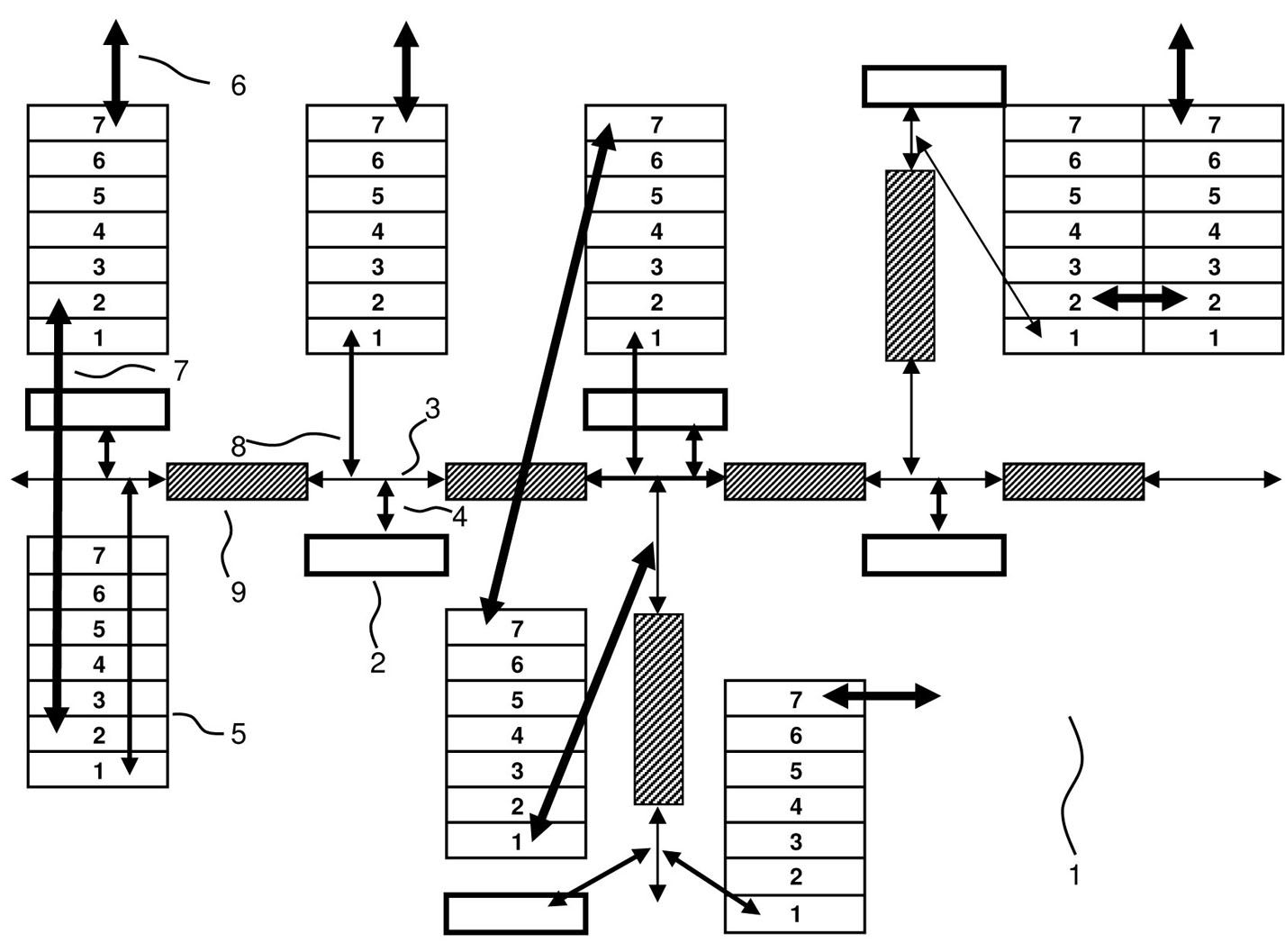

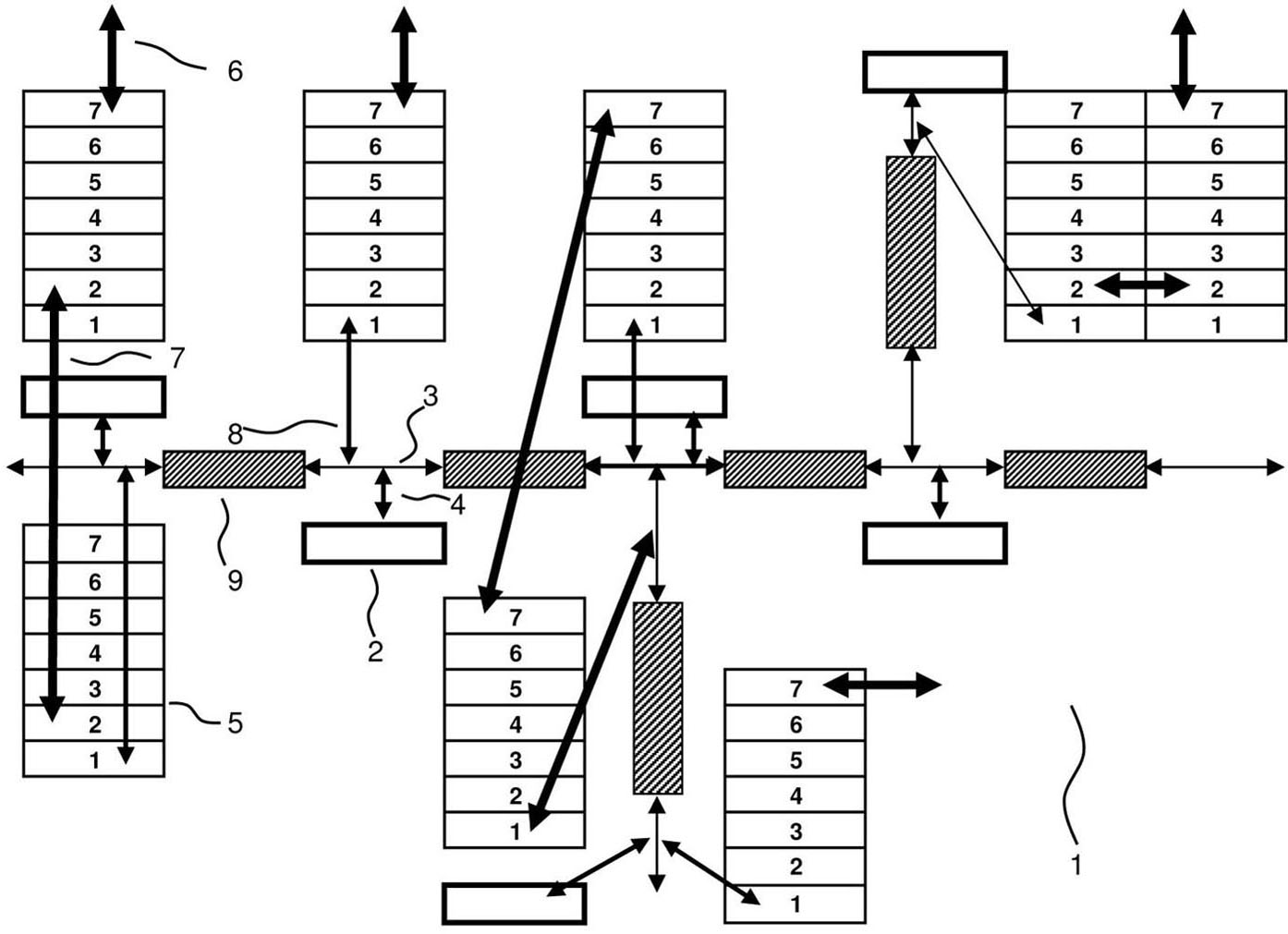

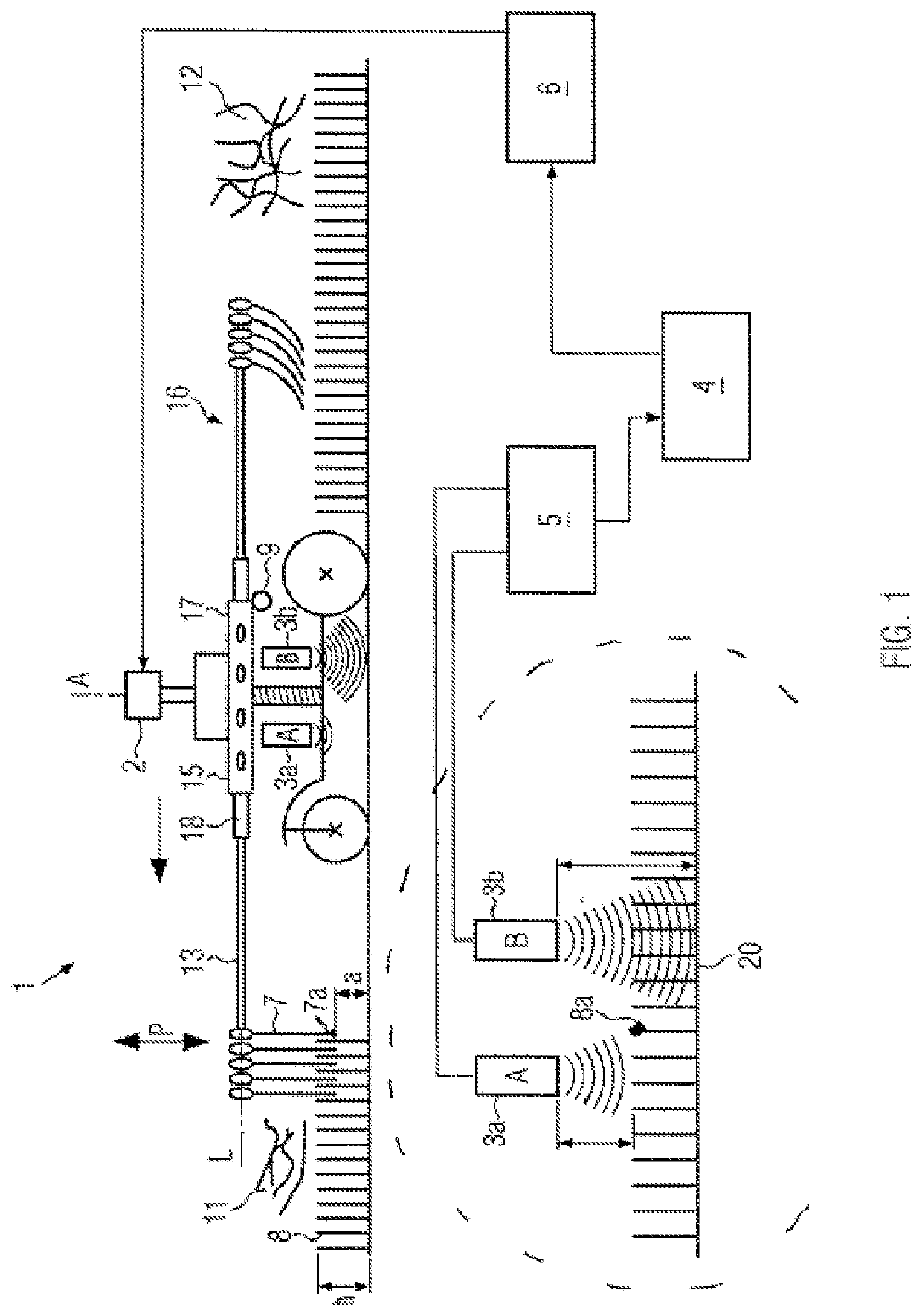

Signal repeater system arrangement for stable data communication

InactiveCN101978613AGuaranteed communication qualityGuaranteed Bit Error RateSystems using filtering and bypassingPower distribution line transmissionPower gridEngineering

Signal repeater system of the general type that facilitates using various standards and various modulation types to improve properties with various infrastructure, in particular power grid systems.

Owner:盖尔.蒙森.瓦维克

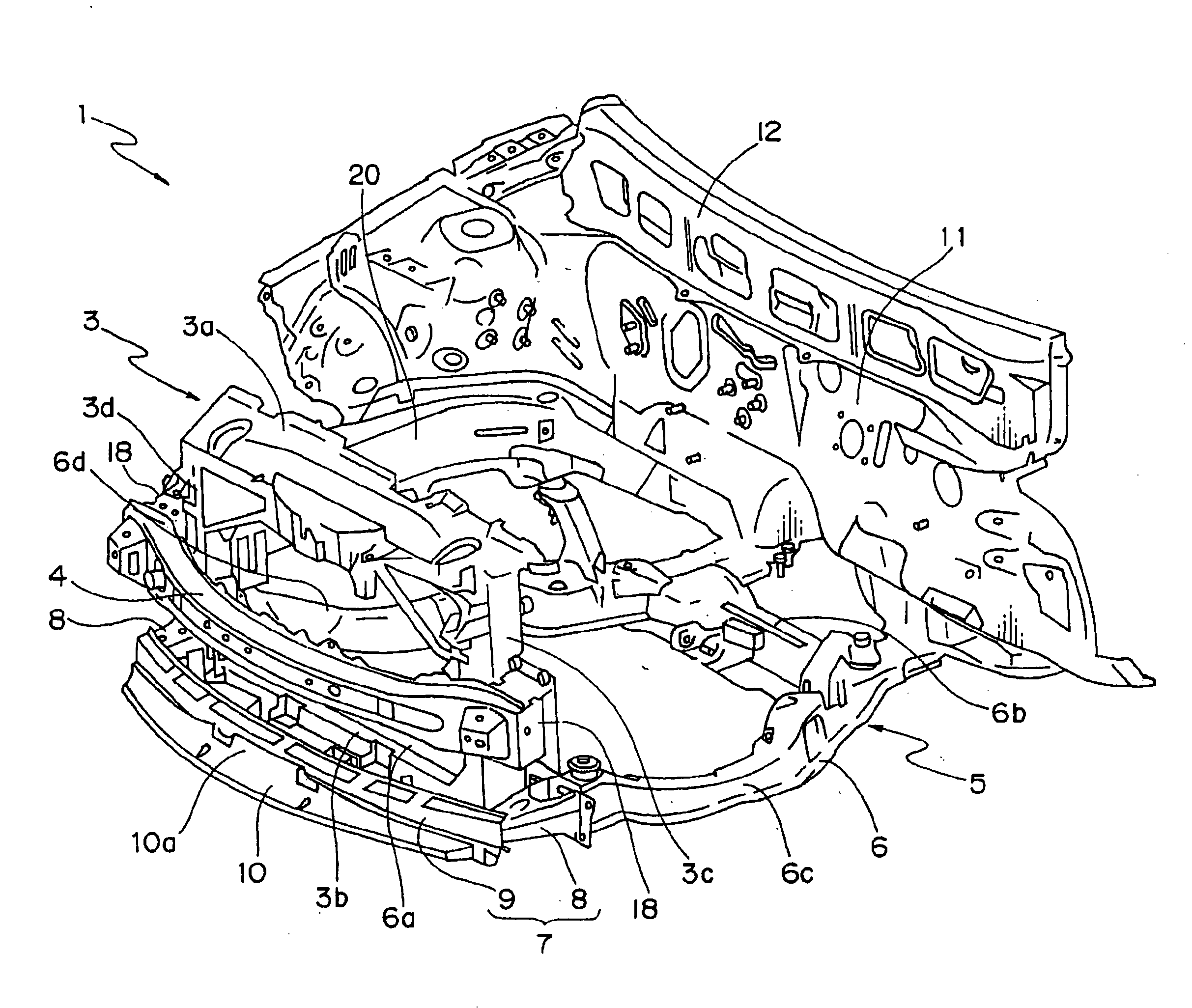

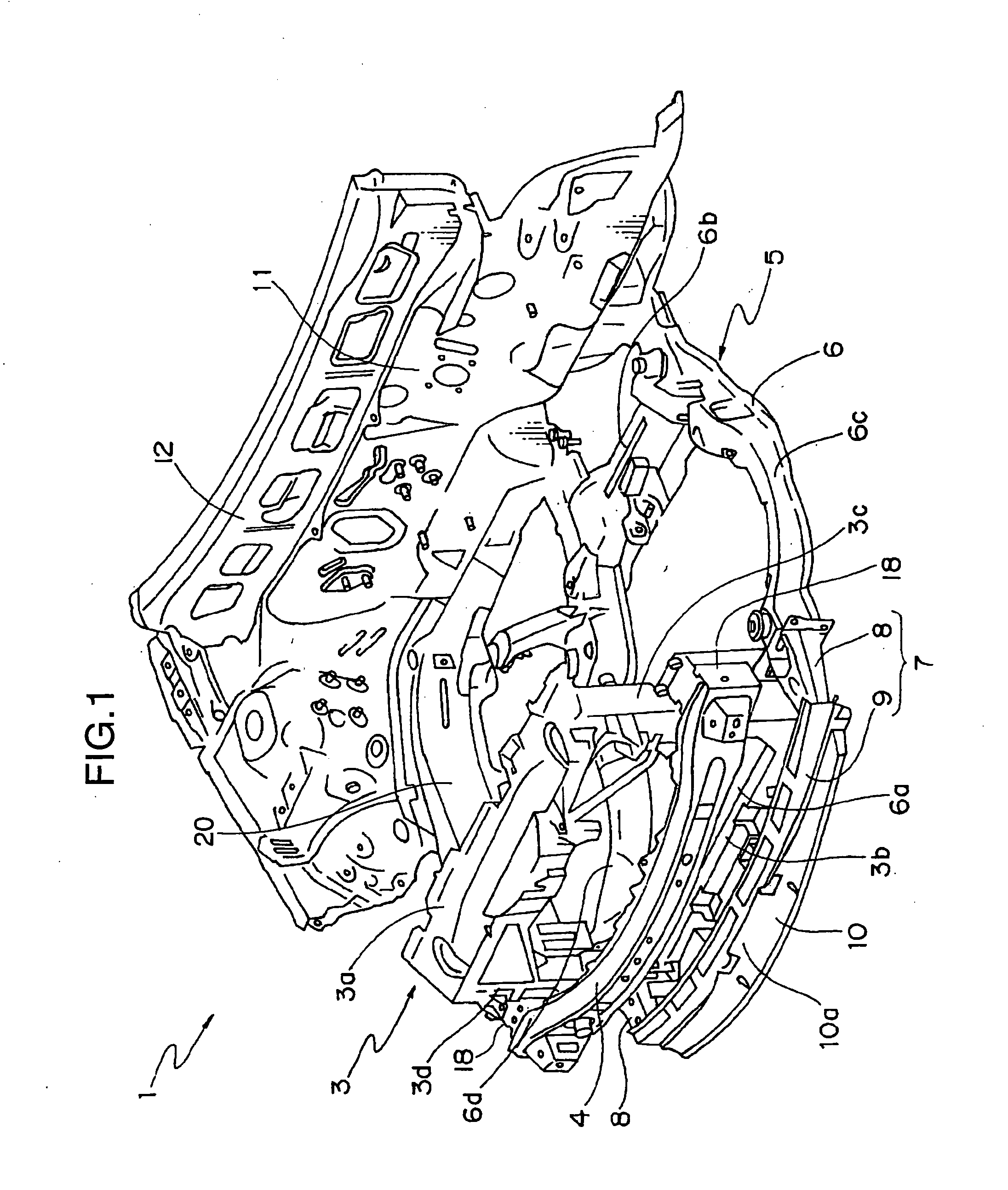

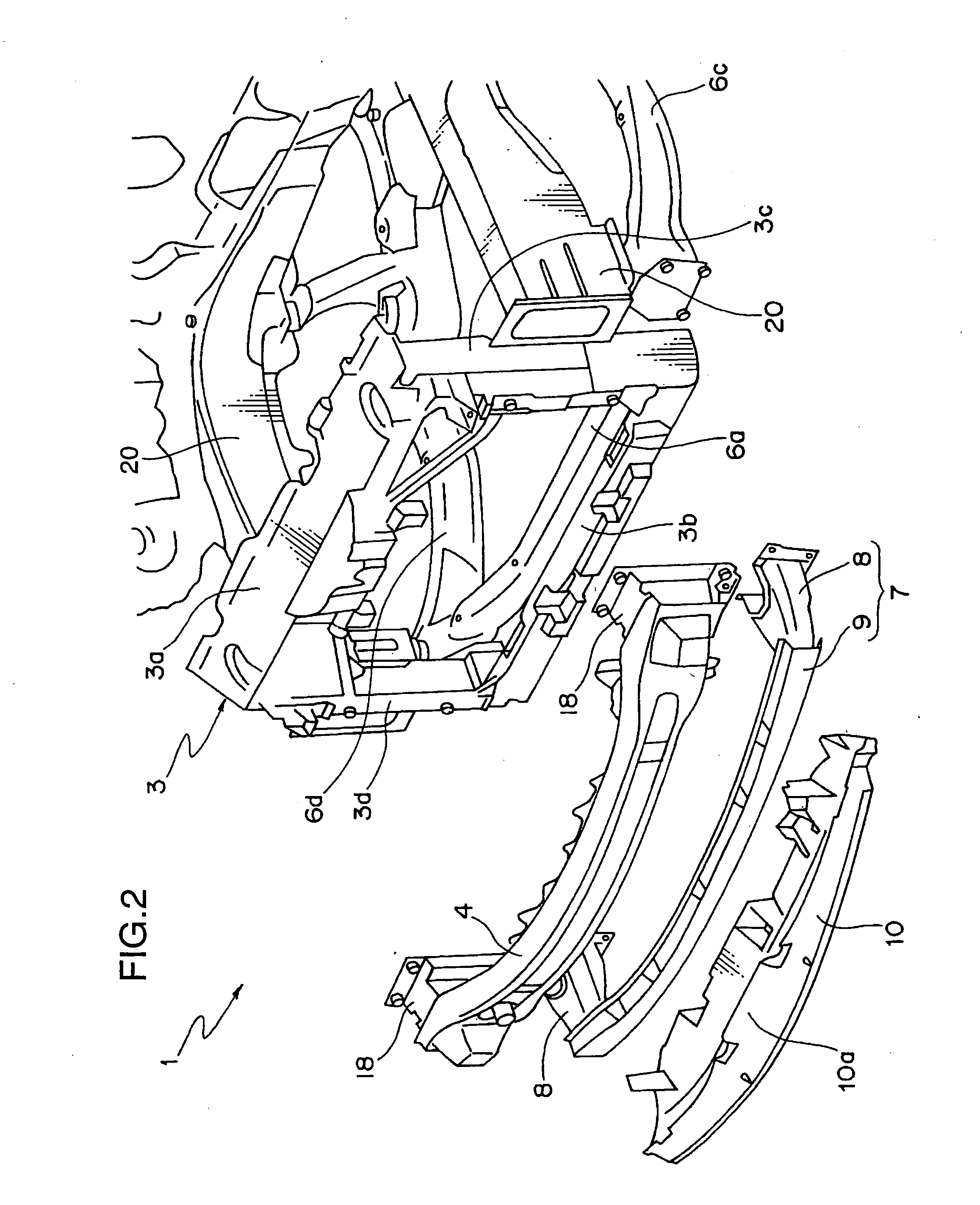

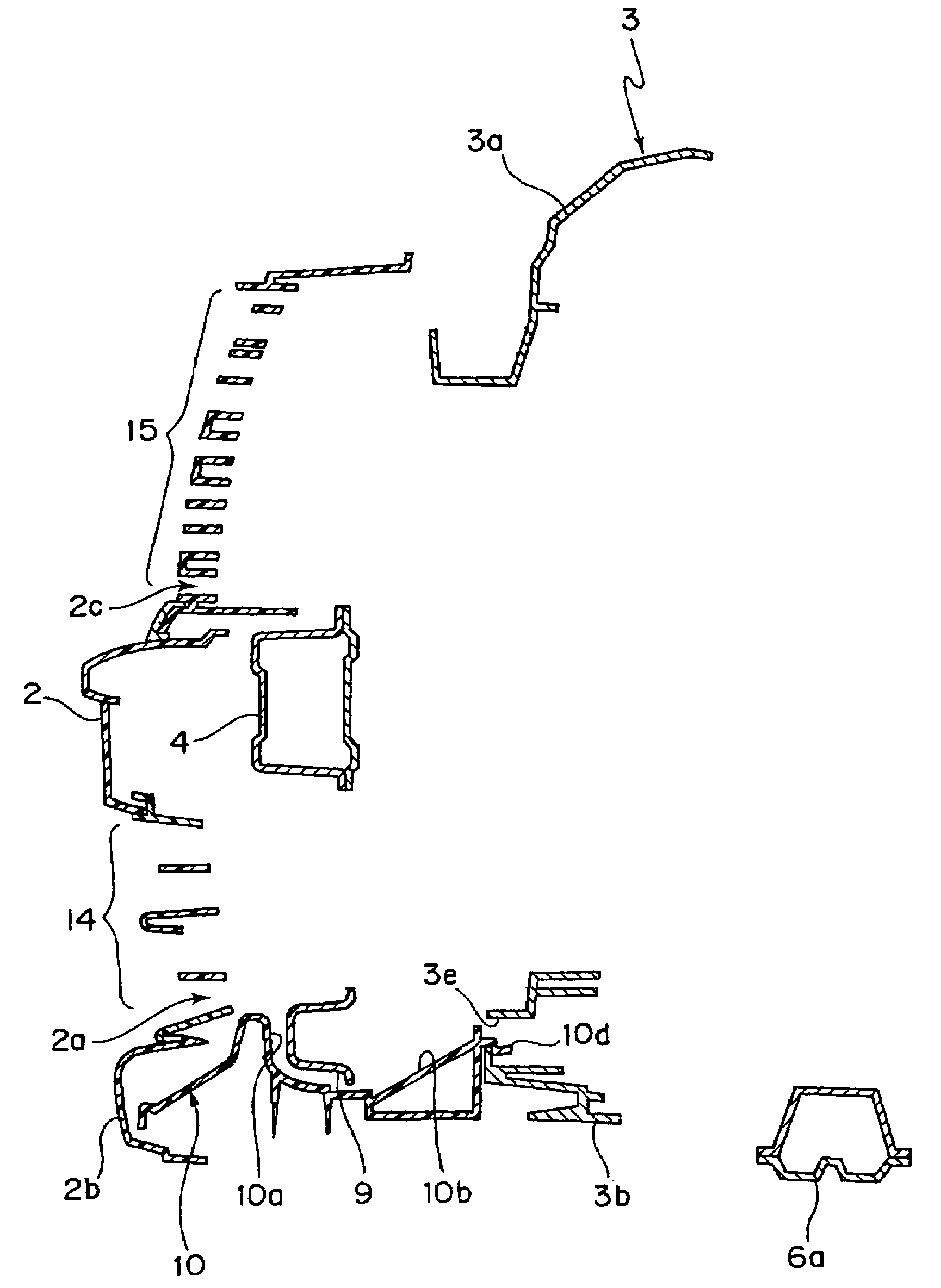

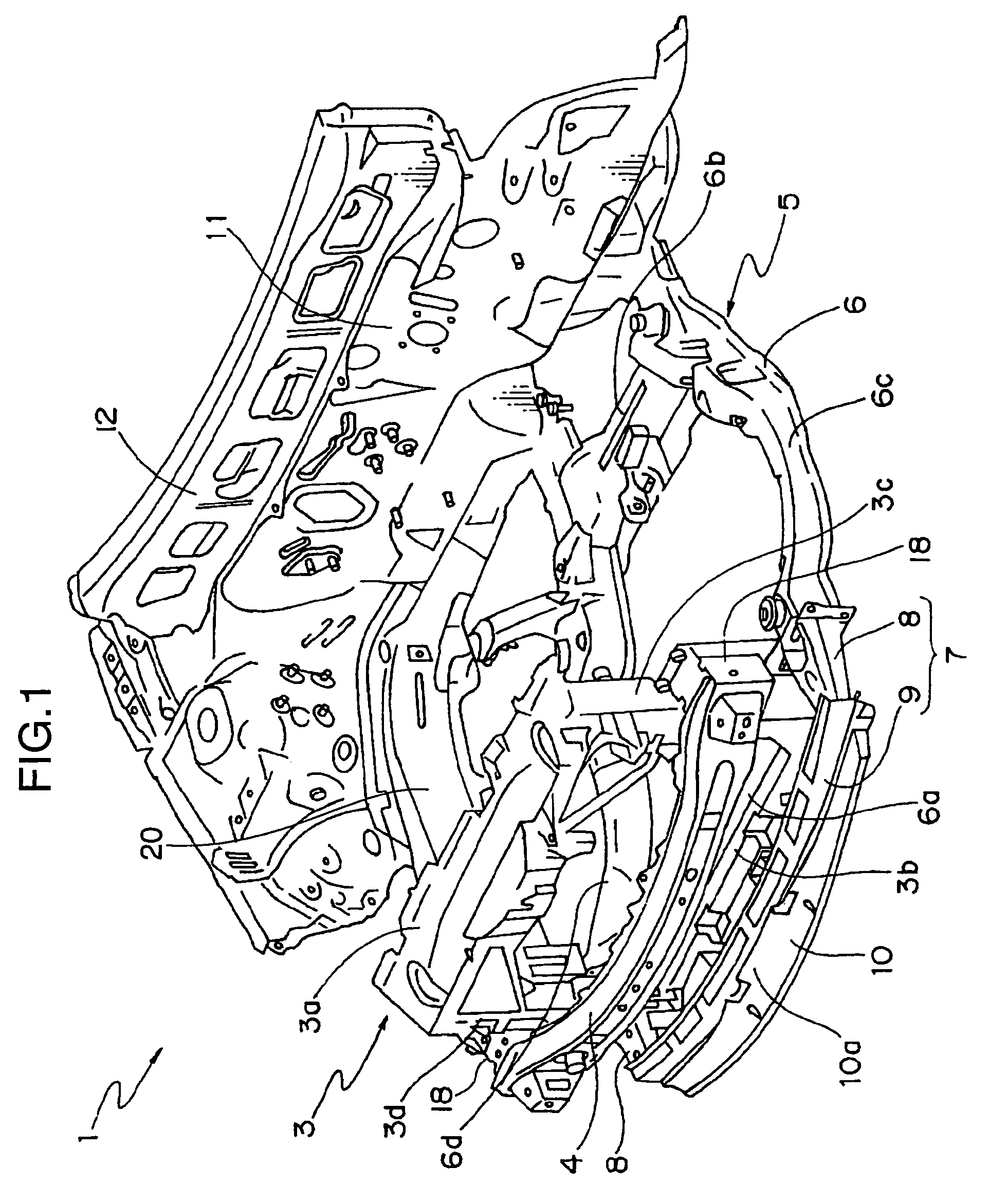

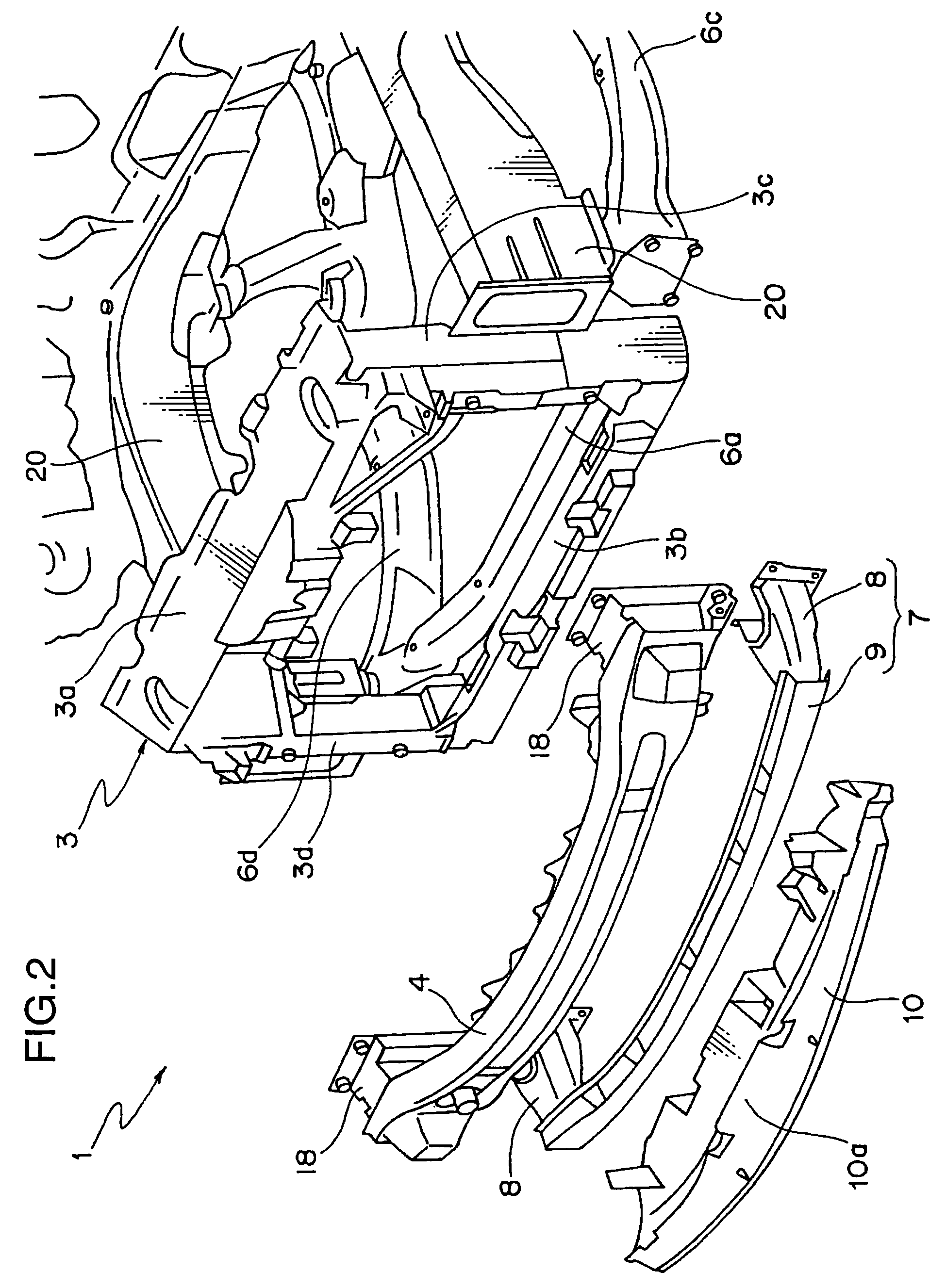

Vehicle front structure

InactiveUS20080067838A1Sufficient pedestrian protection performanceEnhancing impact energy-absorbing capacityVehicle seatsPedestrian/occupant safety arrangementEnergy absorbingVehicle frame

Disclosed is a vehicle front structure, which comprises a bumper fascia 2, a lower shroud member 3b, a subframe 5 including a first shock-absorbing module 7, and a second shock-absorbing module 10 having a stiffness less than that of the first shock-absorbing module 7. A subframe body 6 is formed in an approximately rectangular shape and disposed on a rear side of the lower shroud member 3b. The first shock-absorbing module 7 includes an energy-absorbing section 8, 8 and a beam member 9. The energy-absorbing section 8, 8 has a configuration which extends frontwardly from respective front end regions of the subframe body 6 located on laterally-opposite sides thereof, along respective opposite lateral surfaces of the lower shroud member 3b, and the beam member 9 has a configuration bridging between respective front ends of the energy-absorbing section 8, 8, at a height position approximately equal to or adjacent to that of a lower edge of the lower shroud member 3b. The second shock-absorbing module 10 has a bulging portion 10a which covers at least a part of a front surface of the beam member 9. The vehicle front structure of the present invention can ensure sufficient pedestrian protection performance by means of enhancing impact energy-absorbing capacity, while achieving enhanced repairability in the event of a low-impact collision.

Owner:MAZDA MOTOR CORP

Vehicle front structure

InactiveUS7438348B2Sufficient pedestrian protection performanceImpact capacityVehicle seatsPedestrian/occupant safety arrangementVehicle framePedestrian

Owner:MAZDA MOTOR CORP

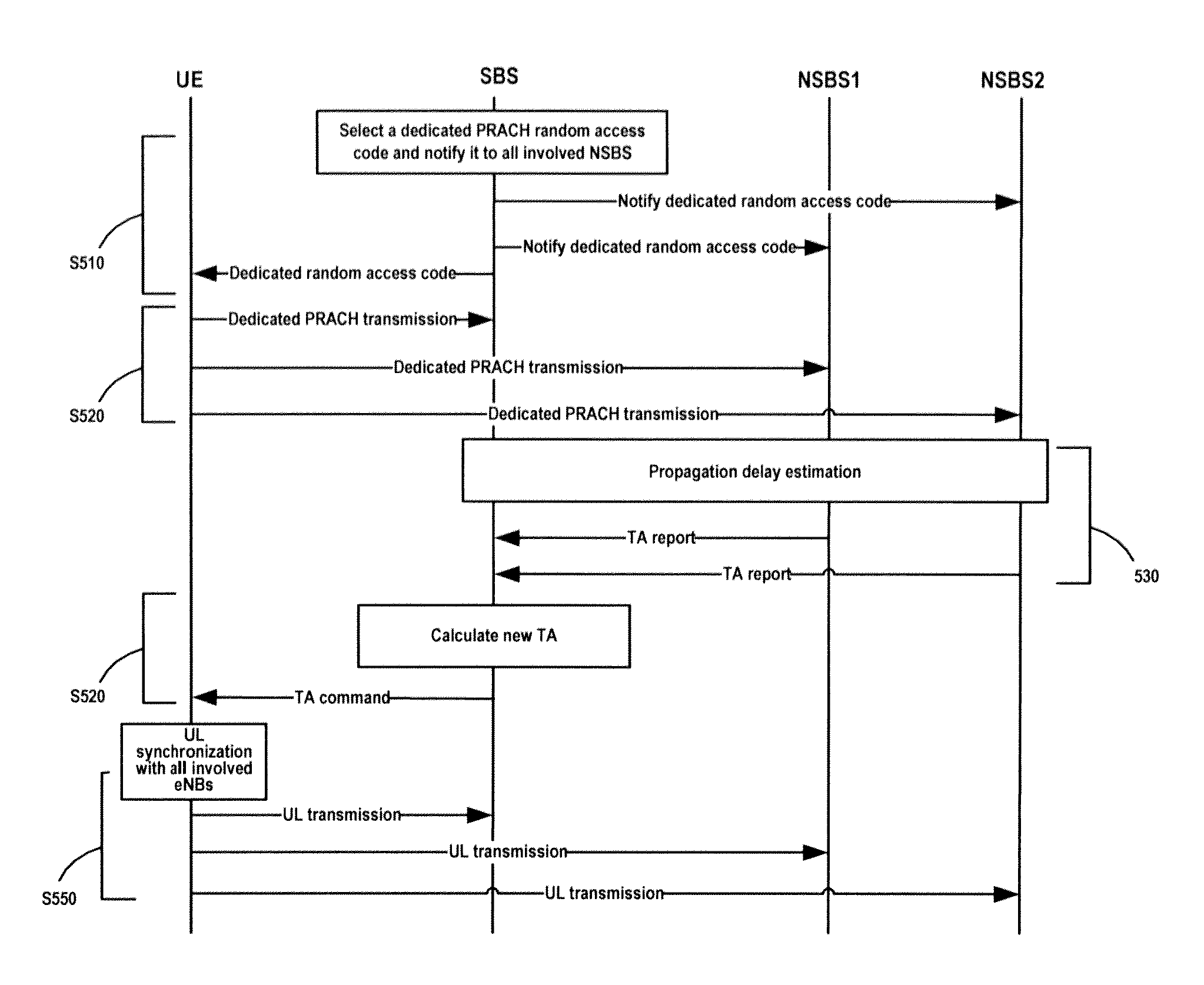

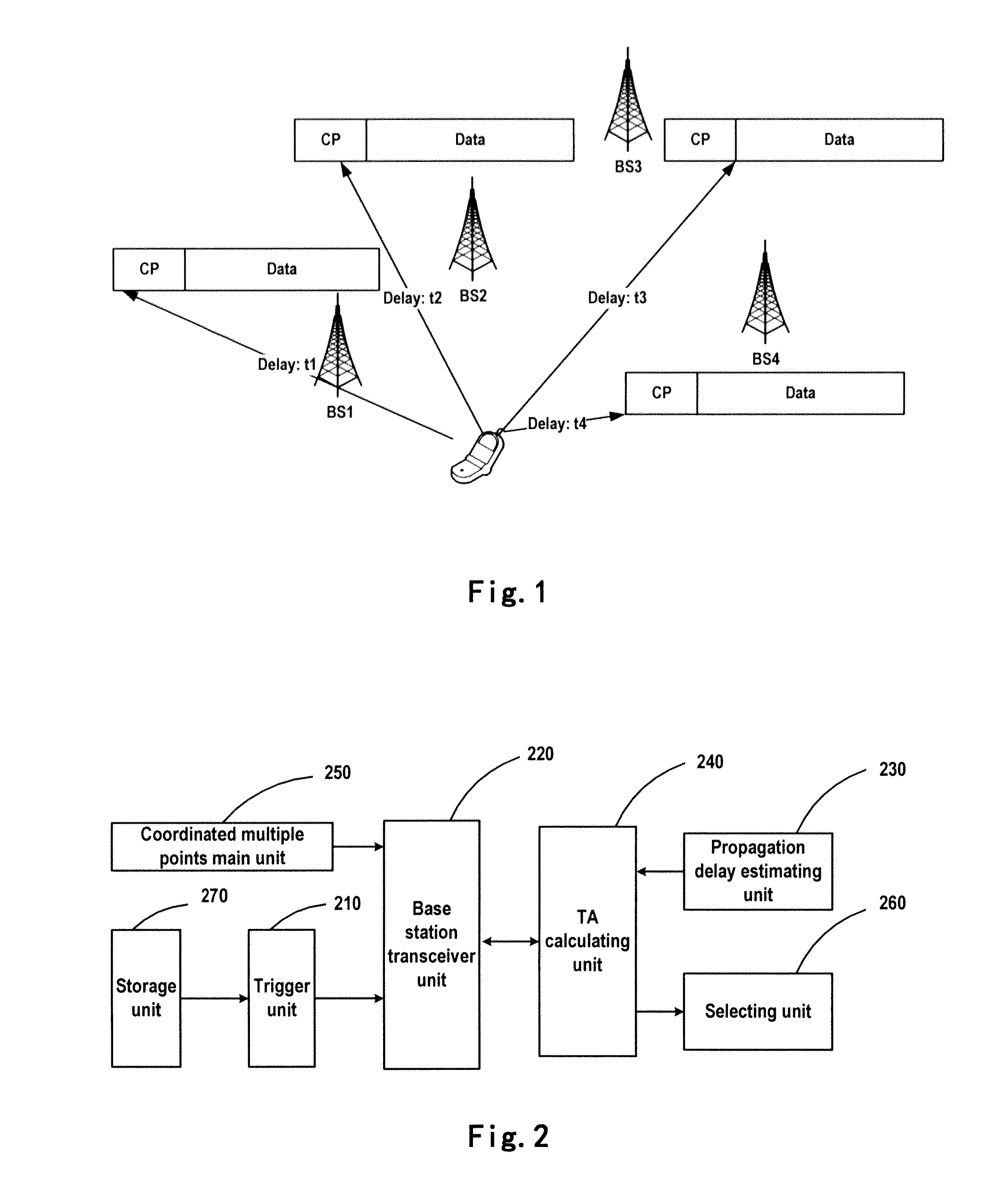

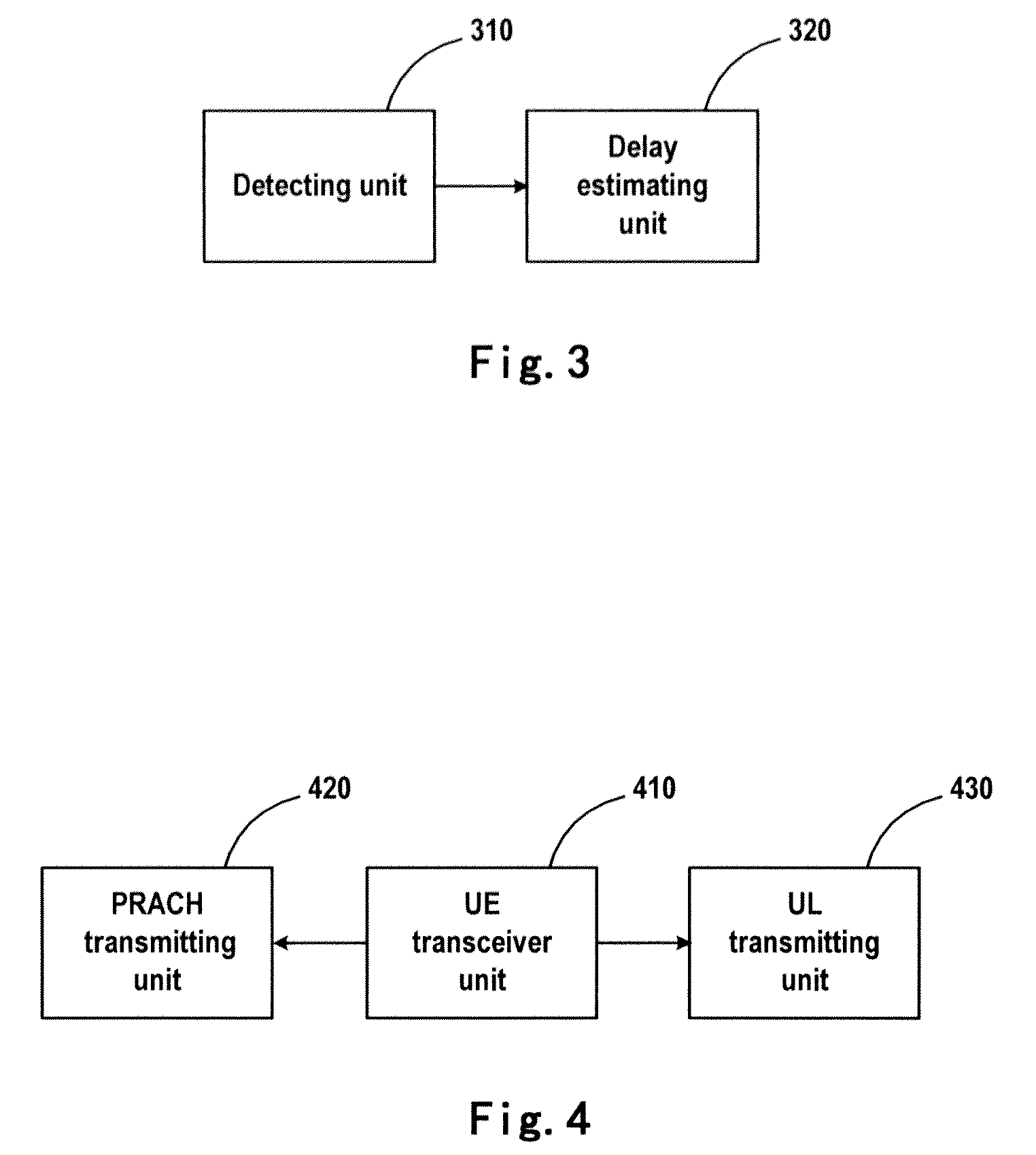

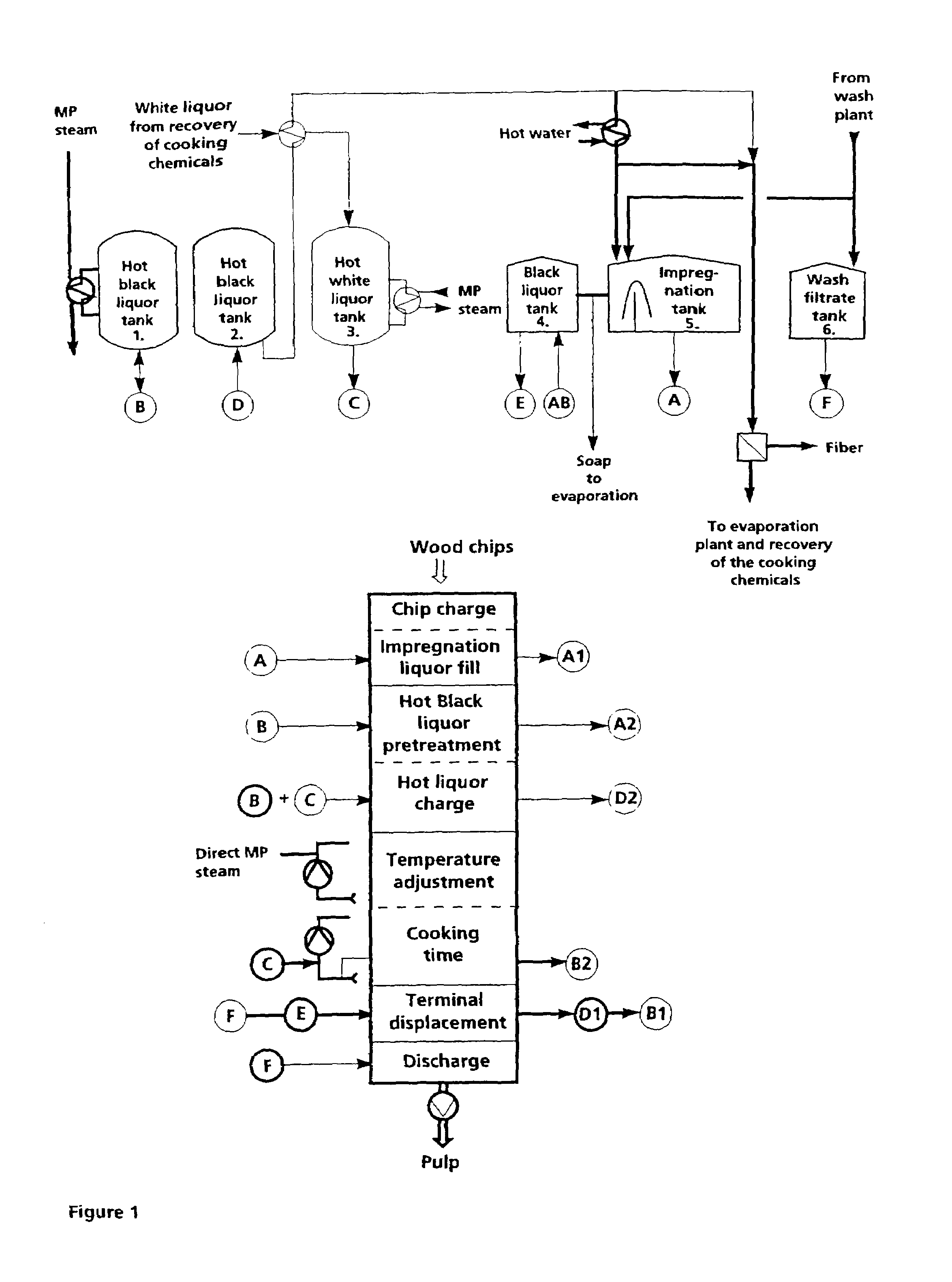

Method and device for implementing uplink synchronization

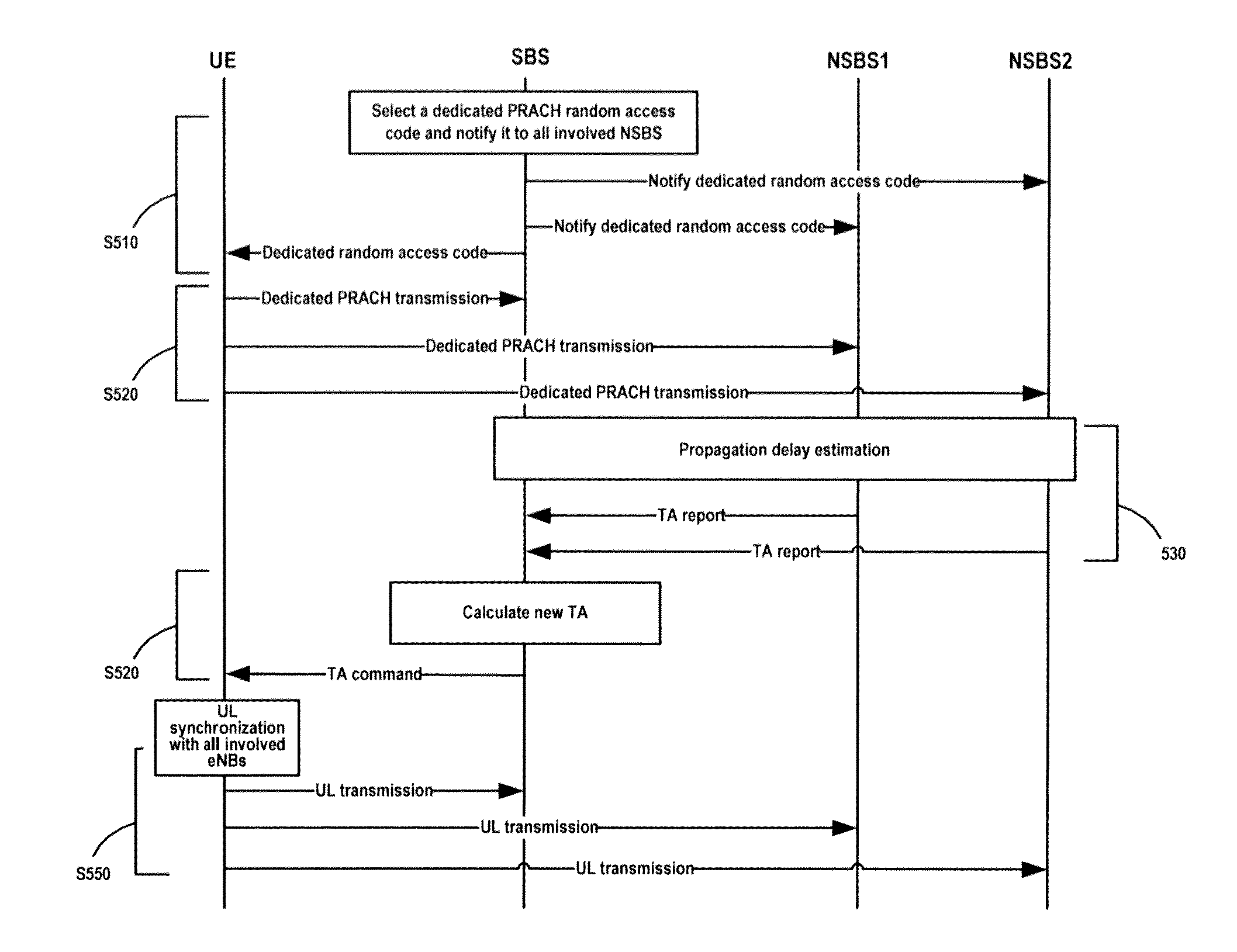

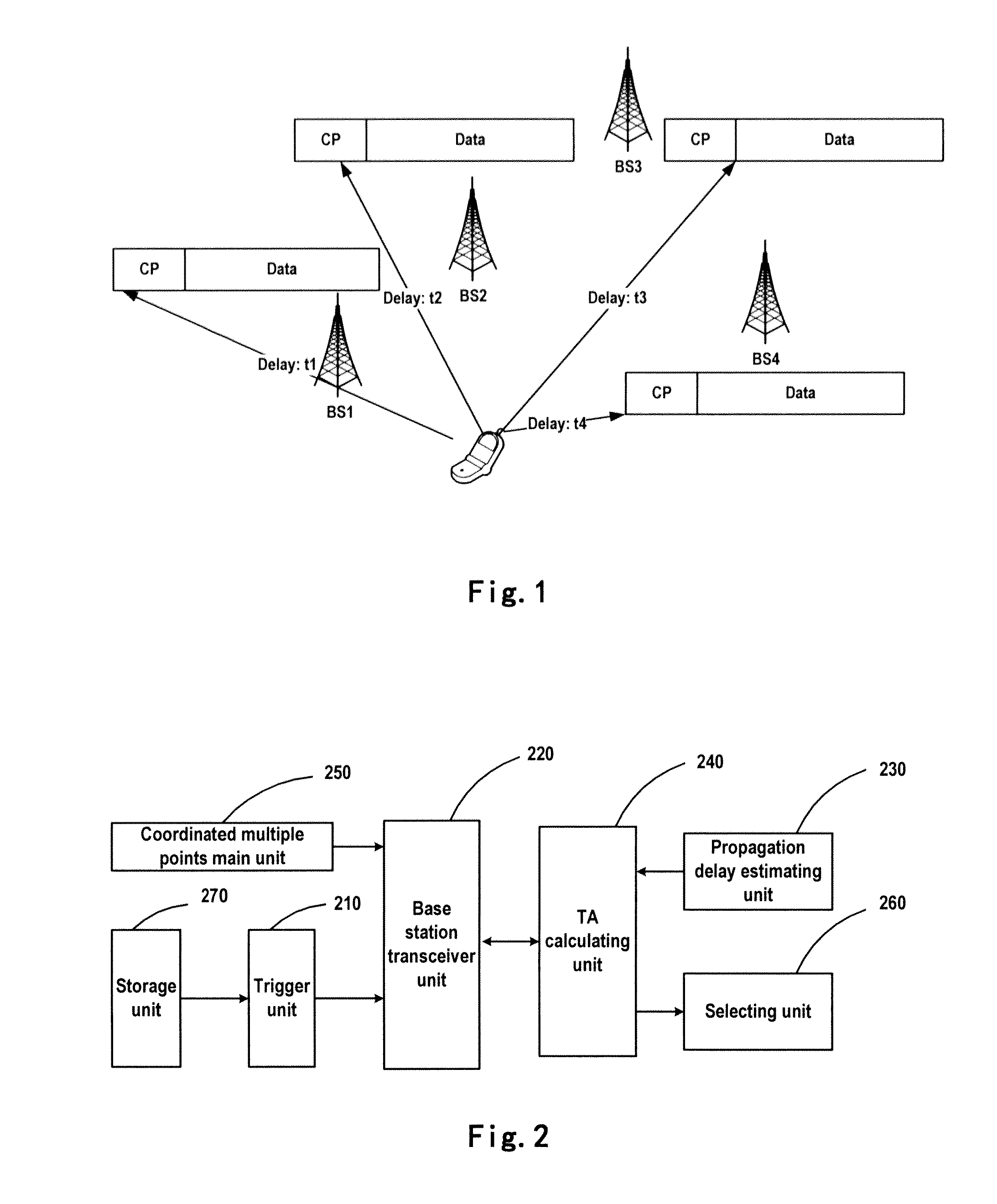

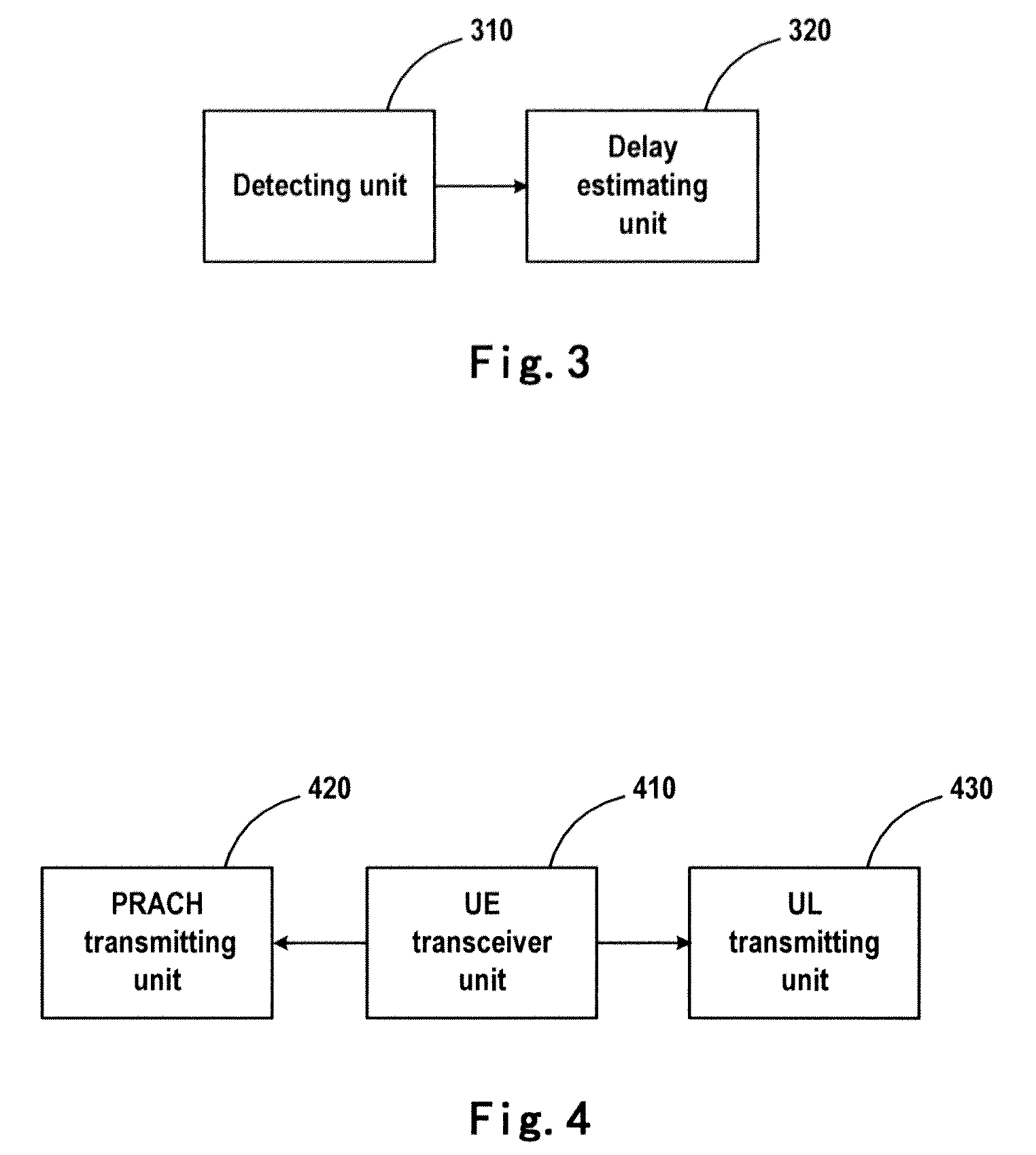

ActiveUS20120149428A1Easy to buildImpact capacitySynchronisation arrangementRadio transmissionPropagation delayTiming advance

Embodiments of the invention provide a method and device for establishing uplink (UL) synchronization. The method includes: instructing a UE to perform a dedicated PRACH transmission; calculating a timing advance (TA) according to first timing information derived by itself and second timing information received from a plurality of non-serving base stations, and sending the timing advance to the UE to enable the UE to establish the uplink synchronization with involved base stations according to the timing advance, wherein the first timing information and the second timing information are associated with propagation delays of the dedicated PRACH transmission performed by the UE. With the above solution, it may be easy to establish UL synchronization between the UE and all involved base stations for UL CoMP.

Owner:ALCATEL LUCENT SAS

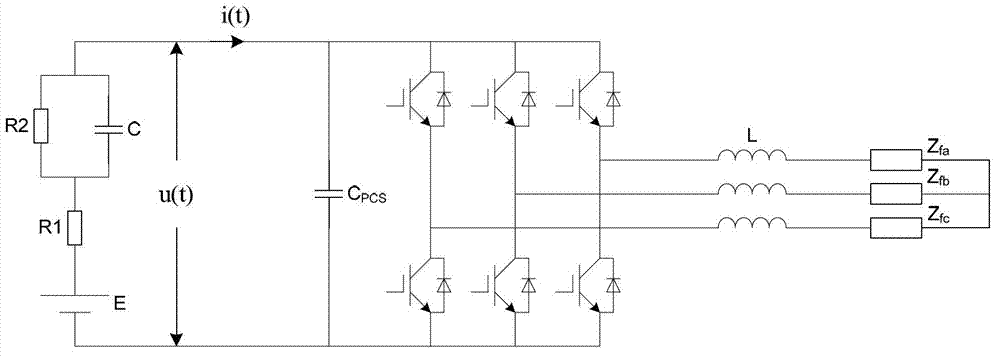

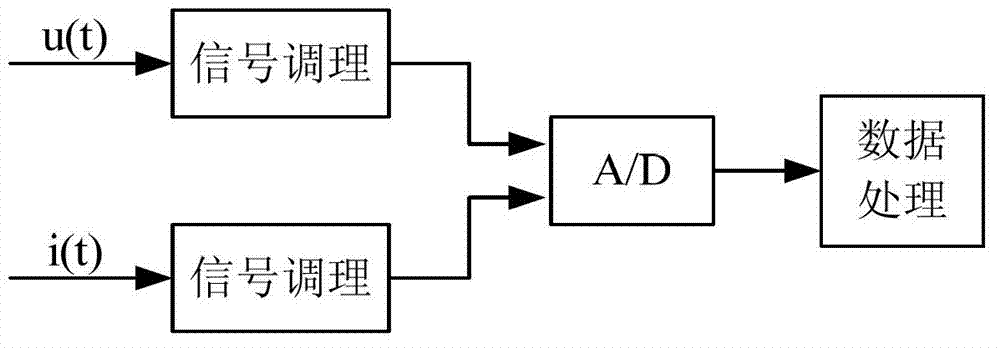

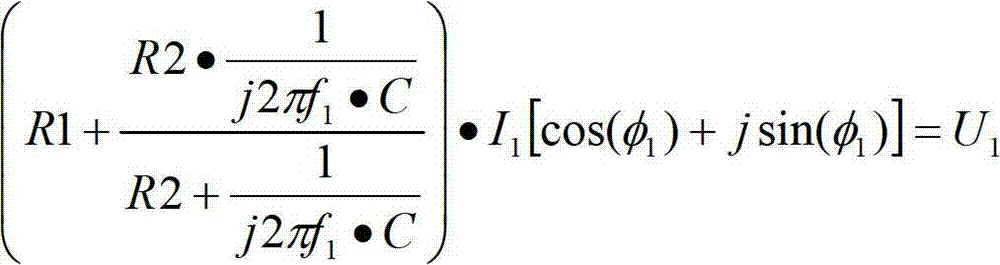

Method for detecting internal resistance of storage battery in energy storage system on line

InactiveCN102768304AImpact capacityAffect performanceResistance/reactance/impedenceHarmonicInternal resistance

The invention discloses a method for detecting internal resistance of a storage battery in an energy storage system on line. The method comprises the following steps of: performing multi-frequency current charging and discharging control; acquiring voltage and current signals; and realizing online detection of the internal resistance of the storage battery through data processing, wherein according to the method, voltage harmonics and current harmonics at different frequencies which are generated by a converter serve as the detection signals in operation. An extra device is not required during charging and discharging control of the storage battery; the capacity and performance of the storage battery are not influenced; the method is different from other measurement methods in which the storage battery is measured only in a static state; the measurement result reflects the comprehensive conditions of the internal resistance of the storage battery in operation; and the result has high credibility.

Owner:SHANGHAI JIAO TONG UNIV

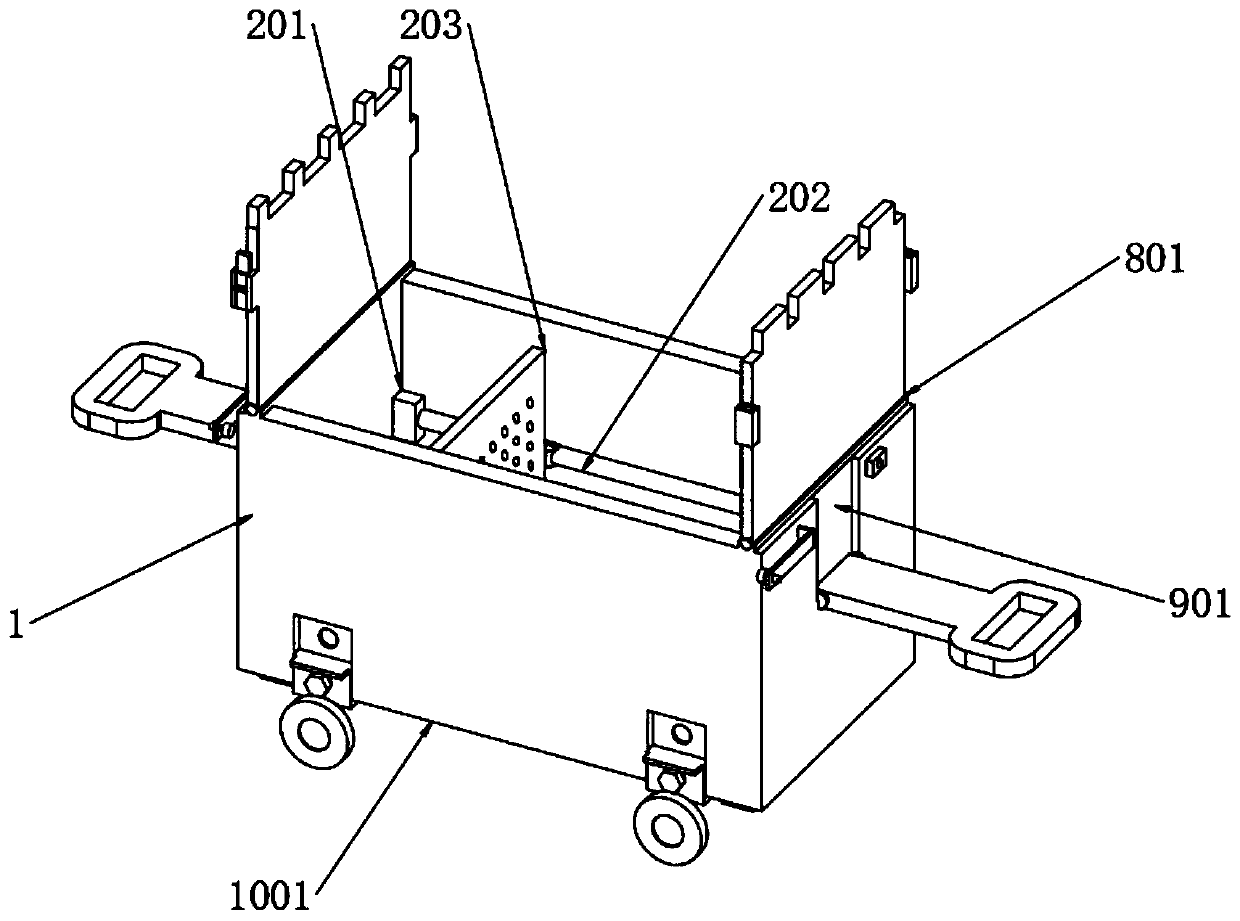

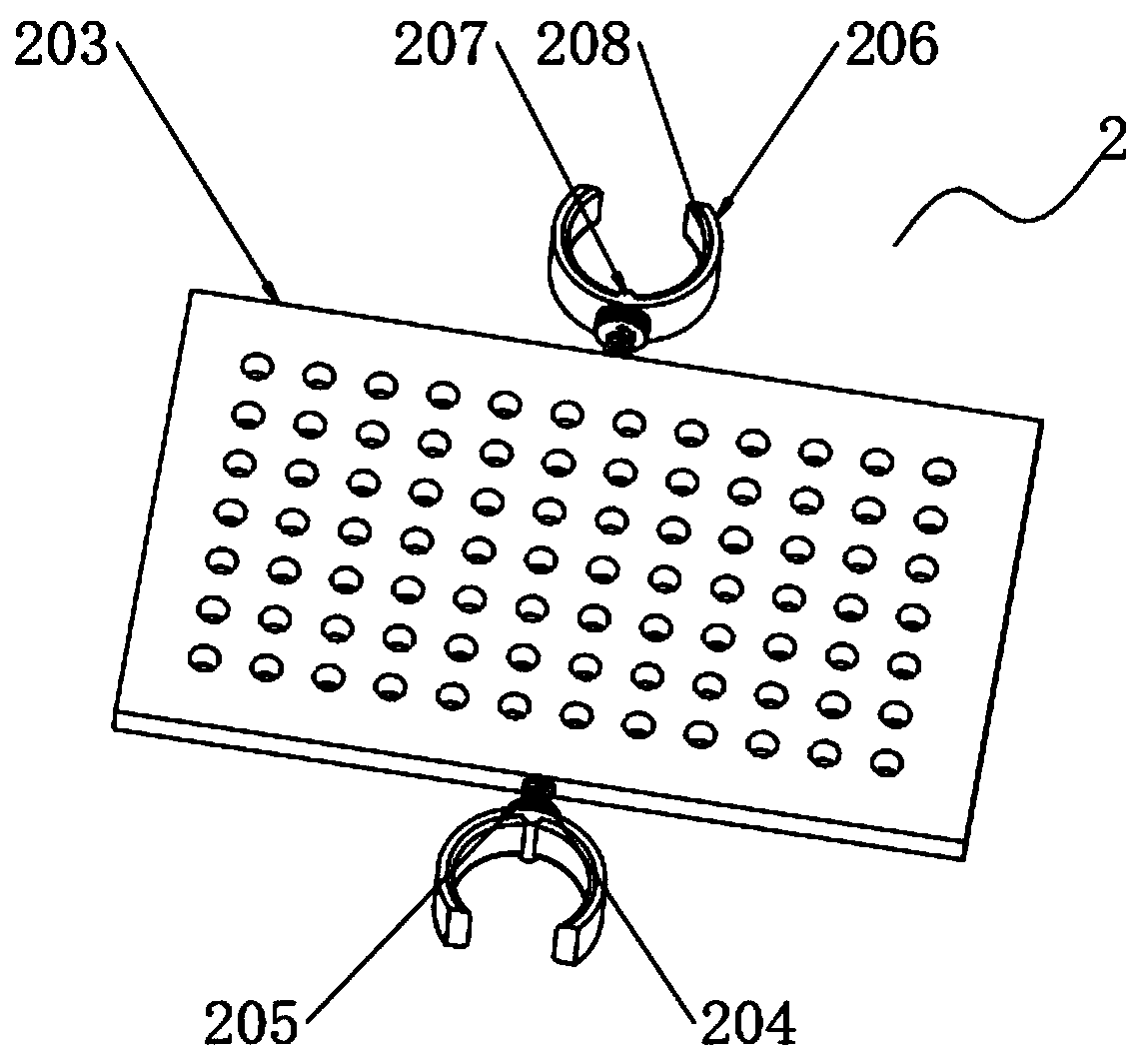

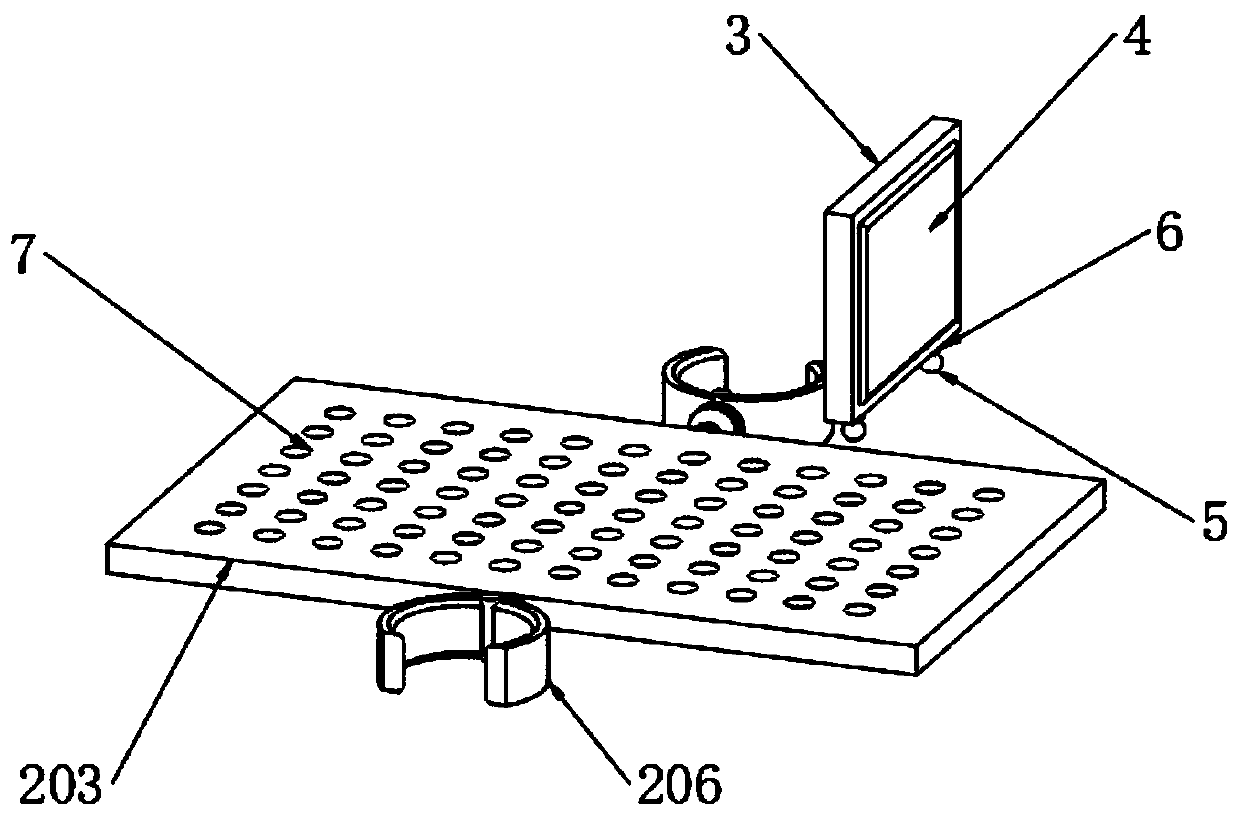

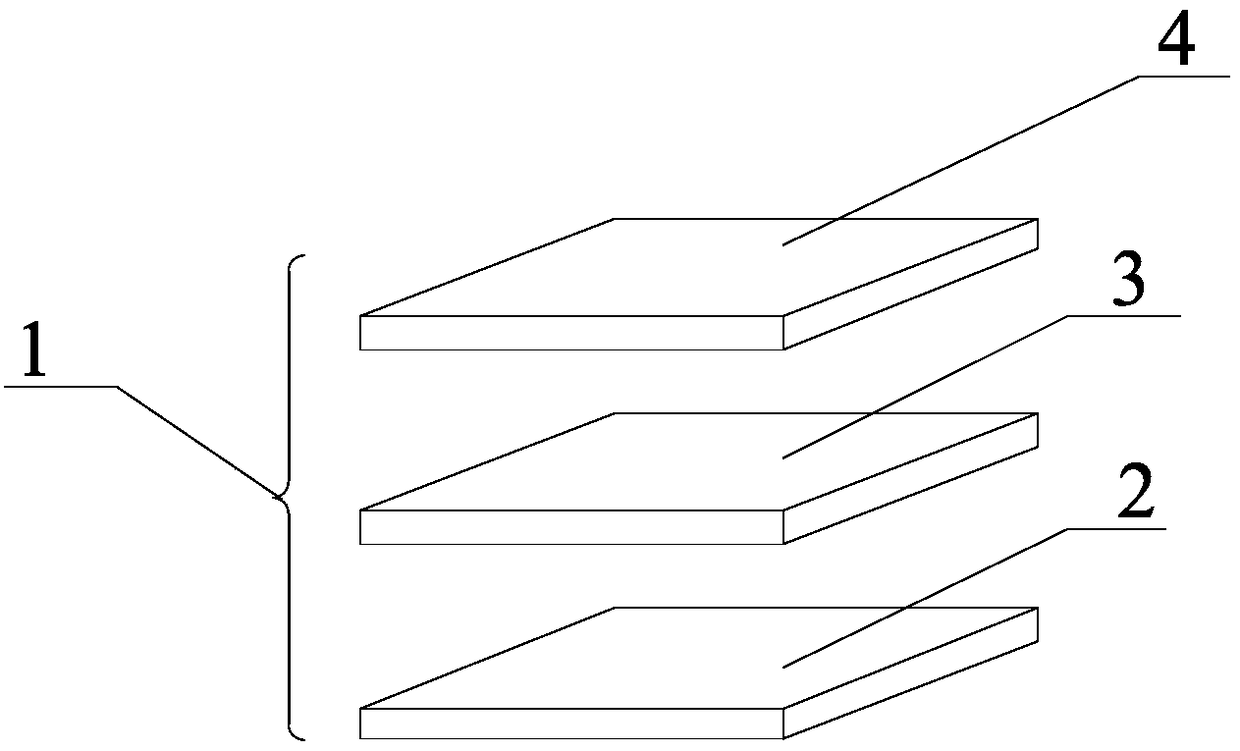

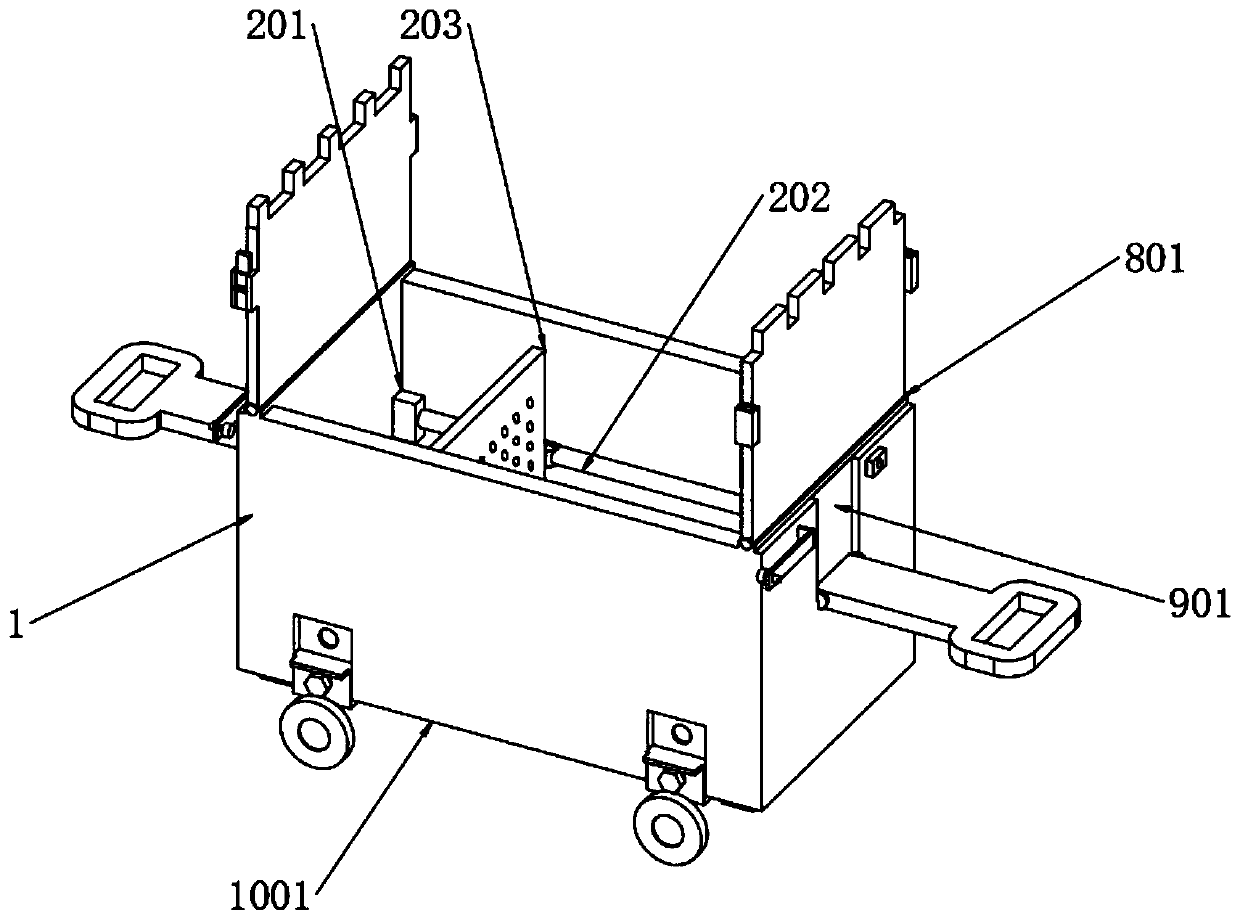

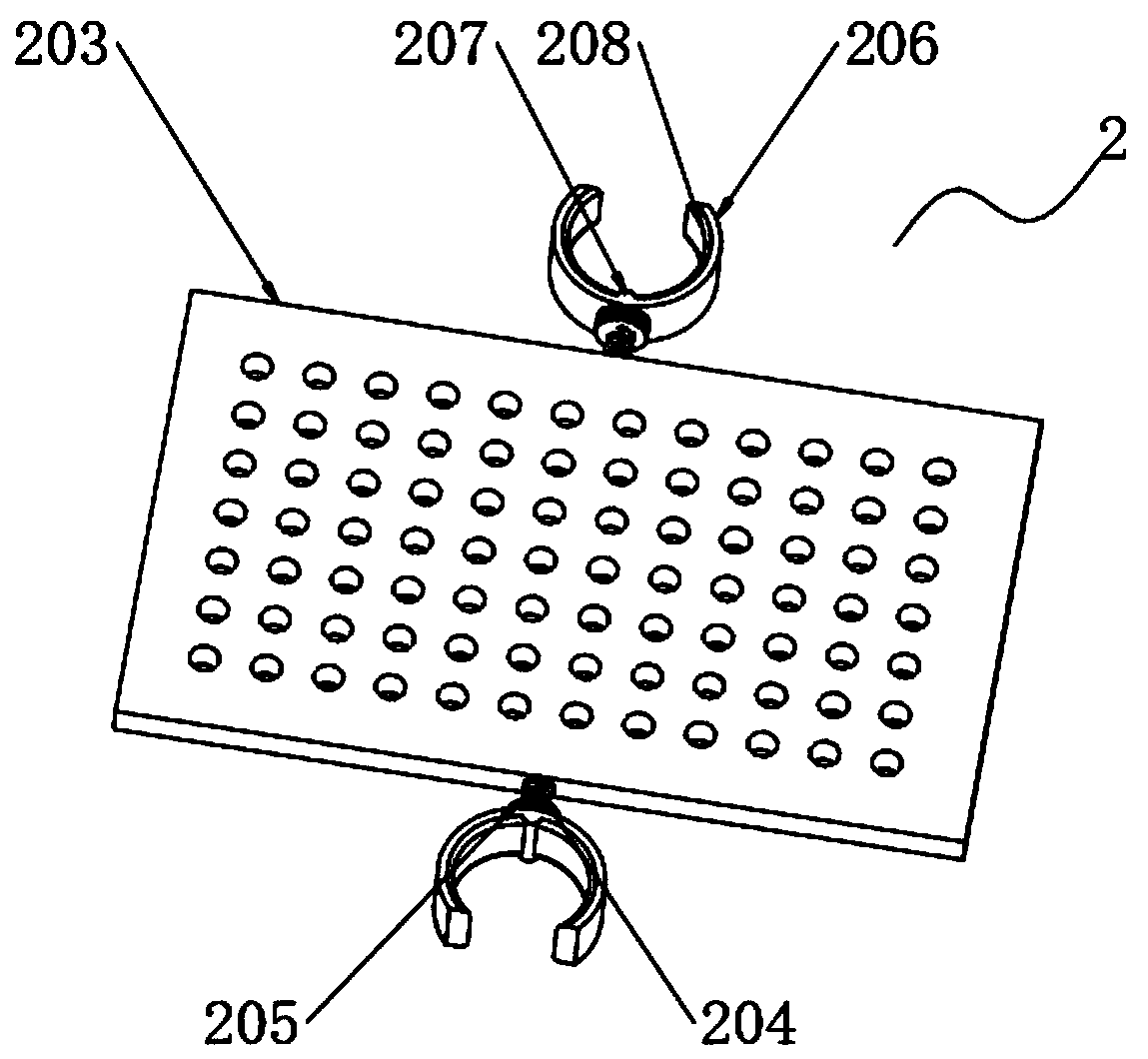

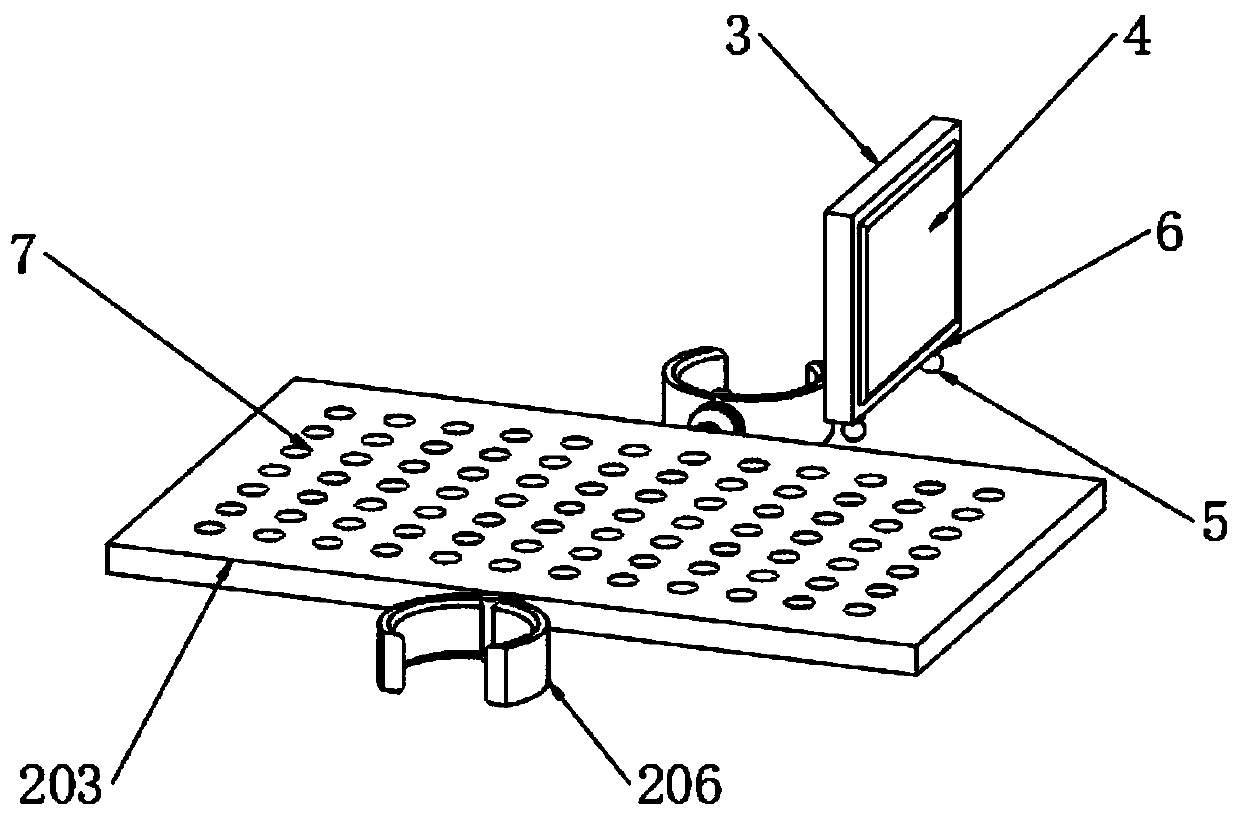

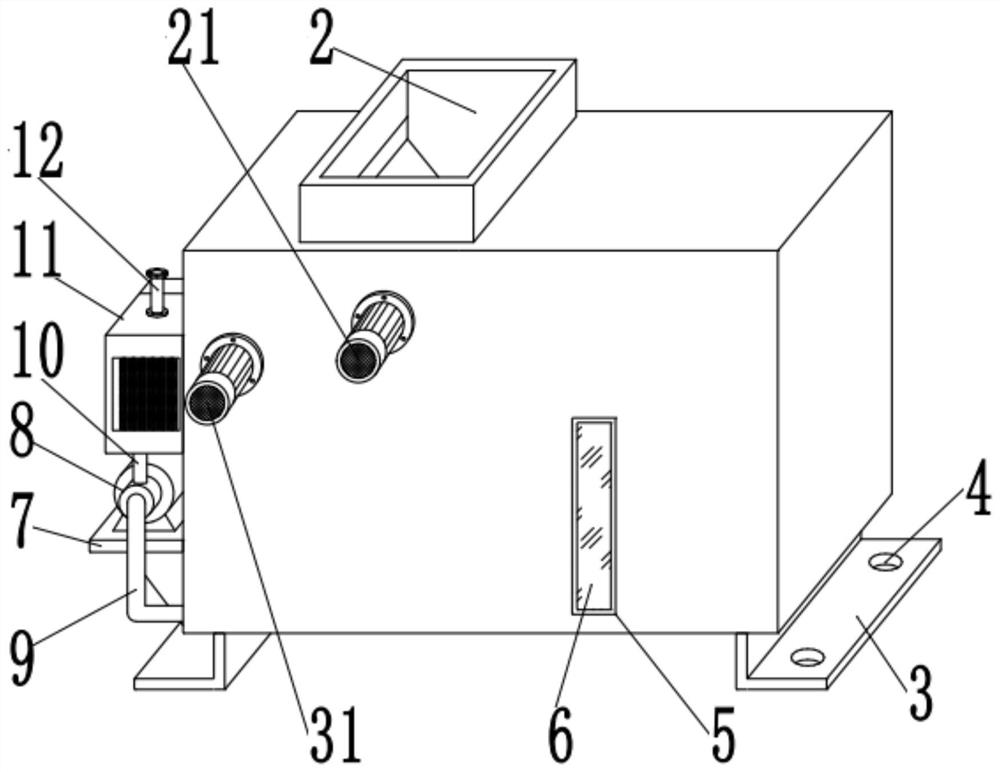

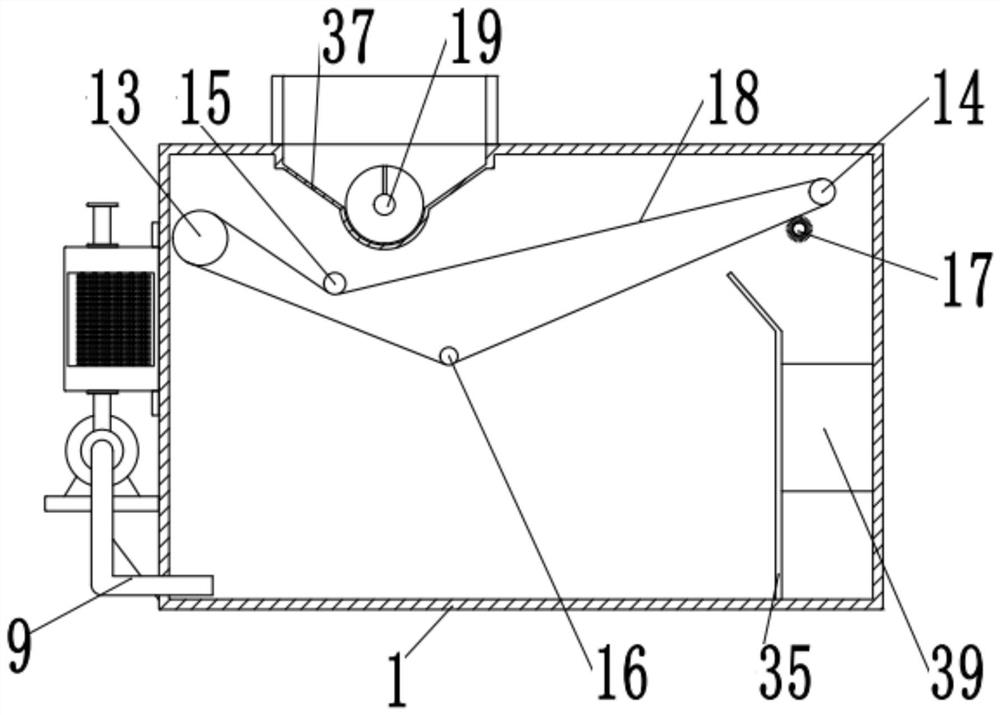

Centralized box for centralized placement of large-size articles and small-size articles for logistics

ActiveCN109733717AScientific and reasonable structureEasy to useContainer handlesExternal fittingsLogistics managementEngineering

The invention discloses a centralized box for centralized placement of large-size articles and small-size articles for logistics. The centralized box comprises a centralized box body, a layered assembly is arranged in the centralized box body, and partition plates are arranged on one side of the layered assembly. The centralized box is scientific and reasonable in structure, and safe and convenient to use; the layered assembly is arranged, through the effects of a sliding rod supporting block, a sliding rod and a layering plate, the interior of the centralized box can be conveniently layered,the space pattern inside the centralized box can be changed according to actual requirements, the articles with different sizes can be placed, so that the orderliness of article placement is improved;through the effects of springs, fixing clamps, movable shafts and the anti-skid inner cushions, the layering plate can be conveniently arranged and disassembled; and the partition plates are arranged, through the effects of elastic clamping ball, connecting rods and connecting through holes, the partition plates with different sizes can be conveniently arranged on one side of the layering plate according to requirements to isolate the articles stored in the centralized box, so that collision between different objects in the moving process is avoided, and the safety of the articles is improved.

Owner:HENGYANG NORMAL UNIV

Method and device for implementing uplink synchronization

ActiveUS8682369B2Easy to buildImpact capacitySynchronisation arrangementRadio transmissionPropagation delayTelecommunications

Embodiments of the invention provide a method and device for establishing uplink (UL) synchronization. The method includes: instructing a UE to perform a dedicated PRACH transmission; calculating a timing advance (TA) according to first timing information derived by itself and second timing information received from a plurality of non-serving base stations, and sending the timing advance to the UE to enable the UE to establish the uplink synchronization with involved base stations according to the timing advance, wherein the first timing information and the second timing information are associated with propagation delays of the dedicated PRACH transmission performed by the UE. With the above solution, it may be easy to establish UL synchronization between the UE and all involved base stations for UL CoMP.

Owner:ALCATEL LUCENT SAS

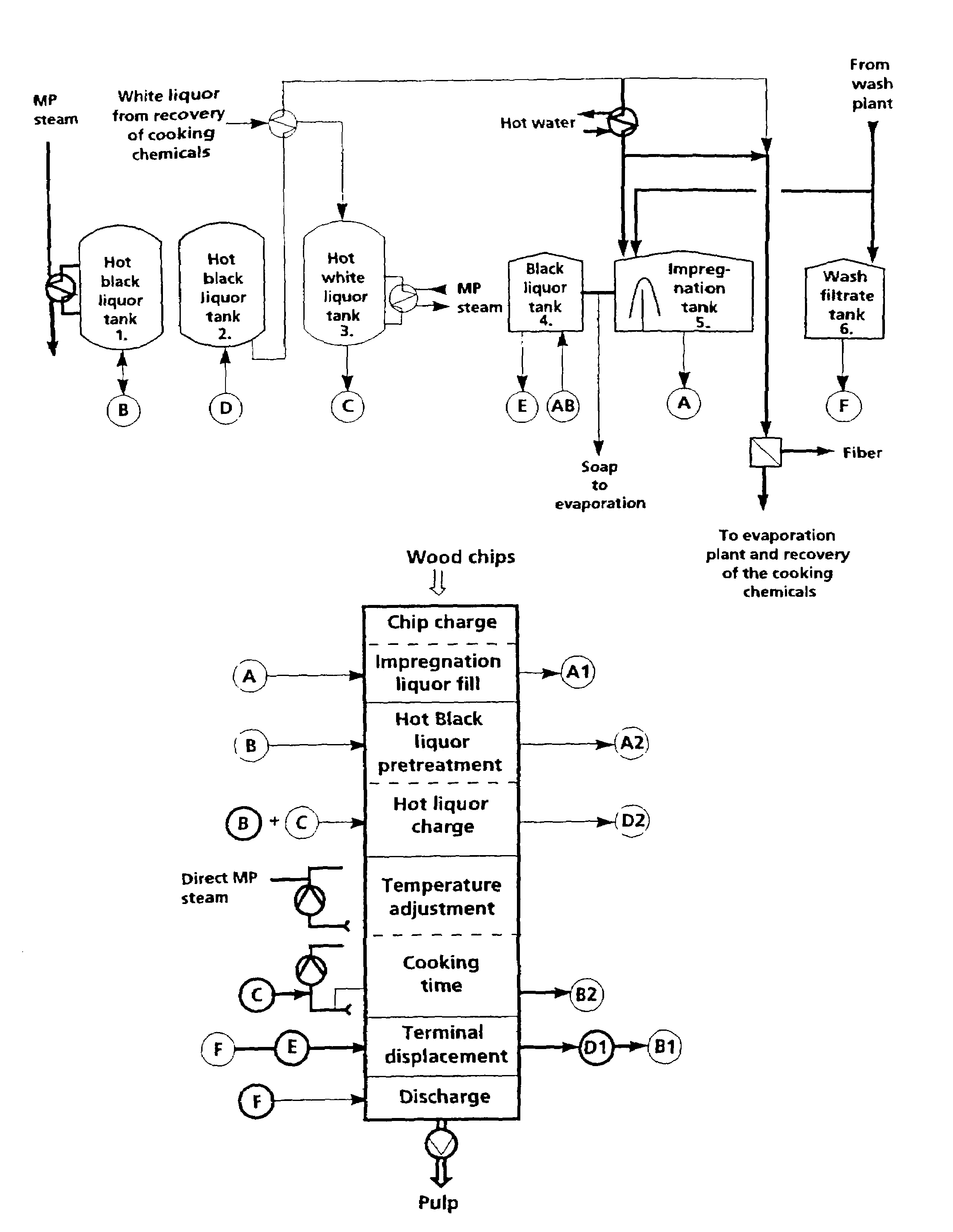

Batch process for producing chemical pulp by removing and reintroducing calcium-containing spent liquor in the digester

InactiveUS6939439B1Increase investment costQuality improvementDigestersPulp bleachingLiquid wastePulp and paper industry

Methods for producing chemical pulp from lignocellulose-containing material in processes for kraft pulp production are disclosed including charging the lignocellulose-containing material to a digester, initially treating the lignocellulose-containing material with an impregnation liquor, and then treating the impregnated lignocellulose-containing material with hot liquor and displacing calcium-containing spent liquor from the digester during that treatment, heating and cooking the heated lignocellulose-containing material to produce cooked lignocellulose-containing material and cooking liquor and displacing the cooking liquor from the digester using at least a portion of the displaced calcium-containing spent liquor.

Owner:METSO PAPER PORI OY

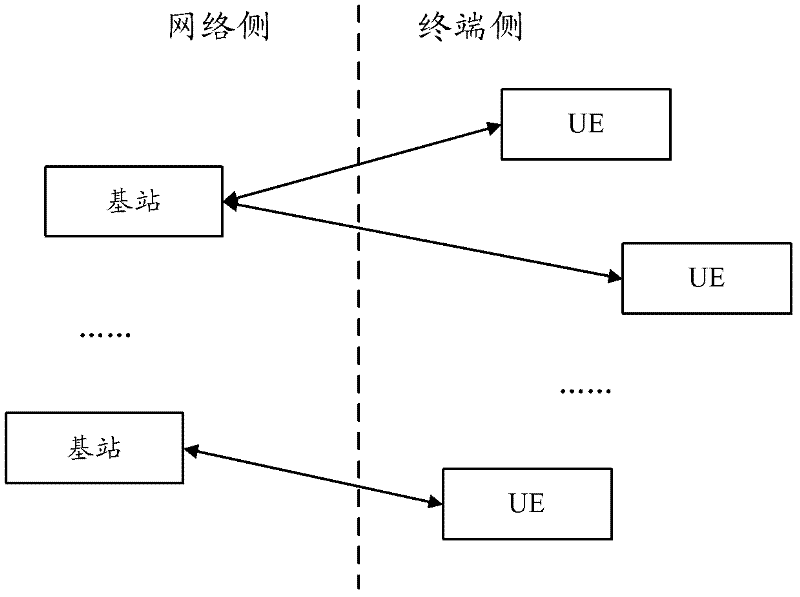

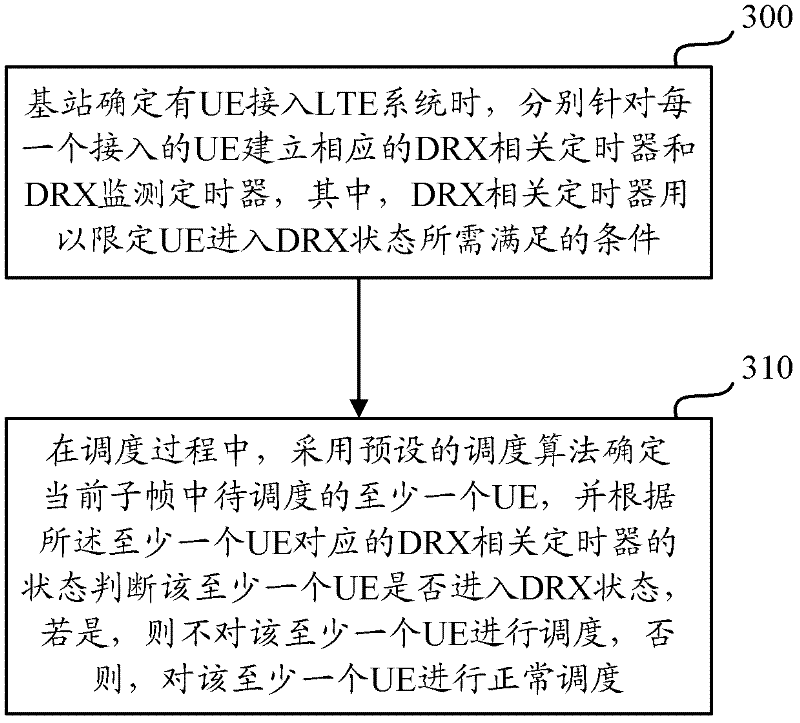

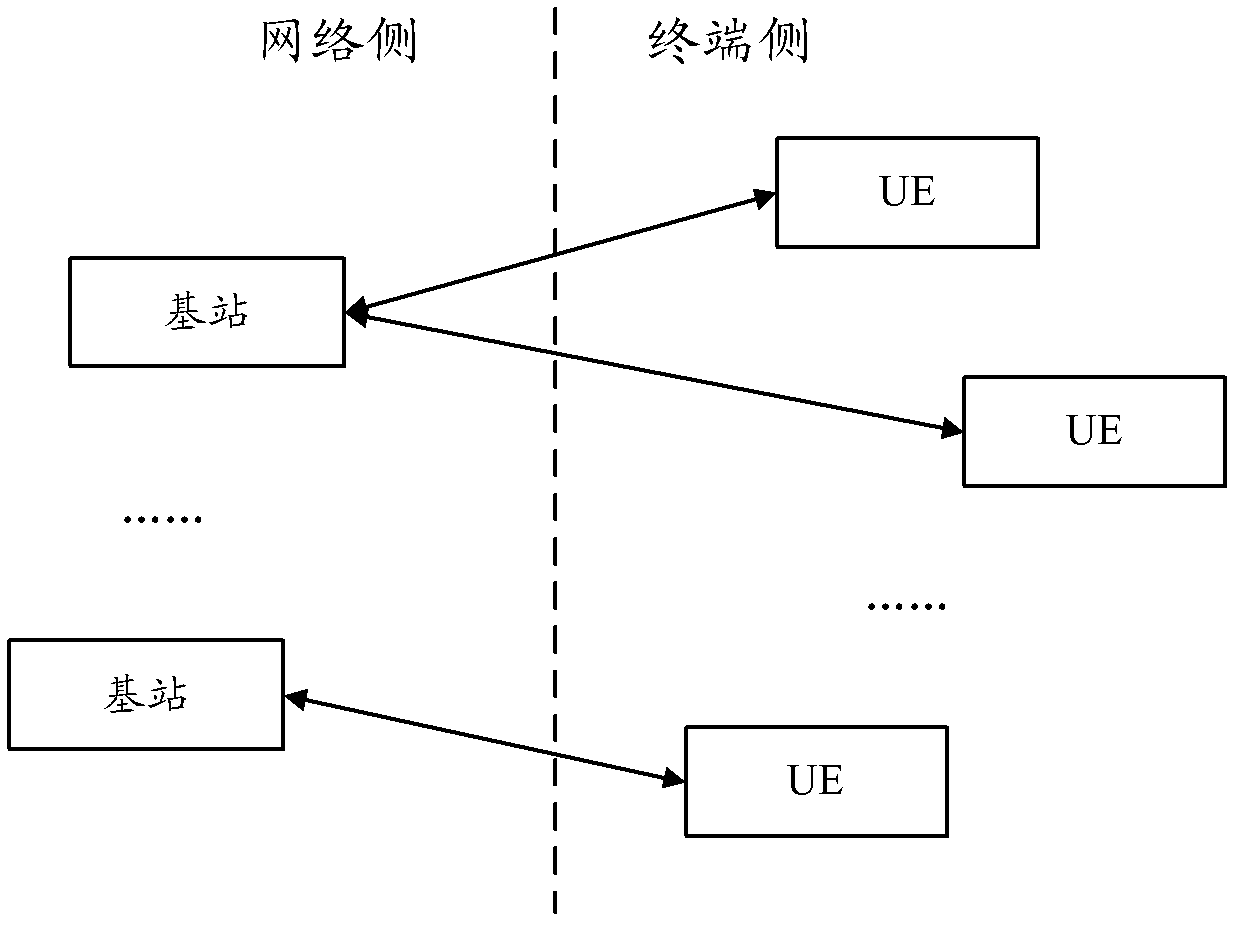

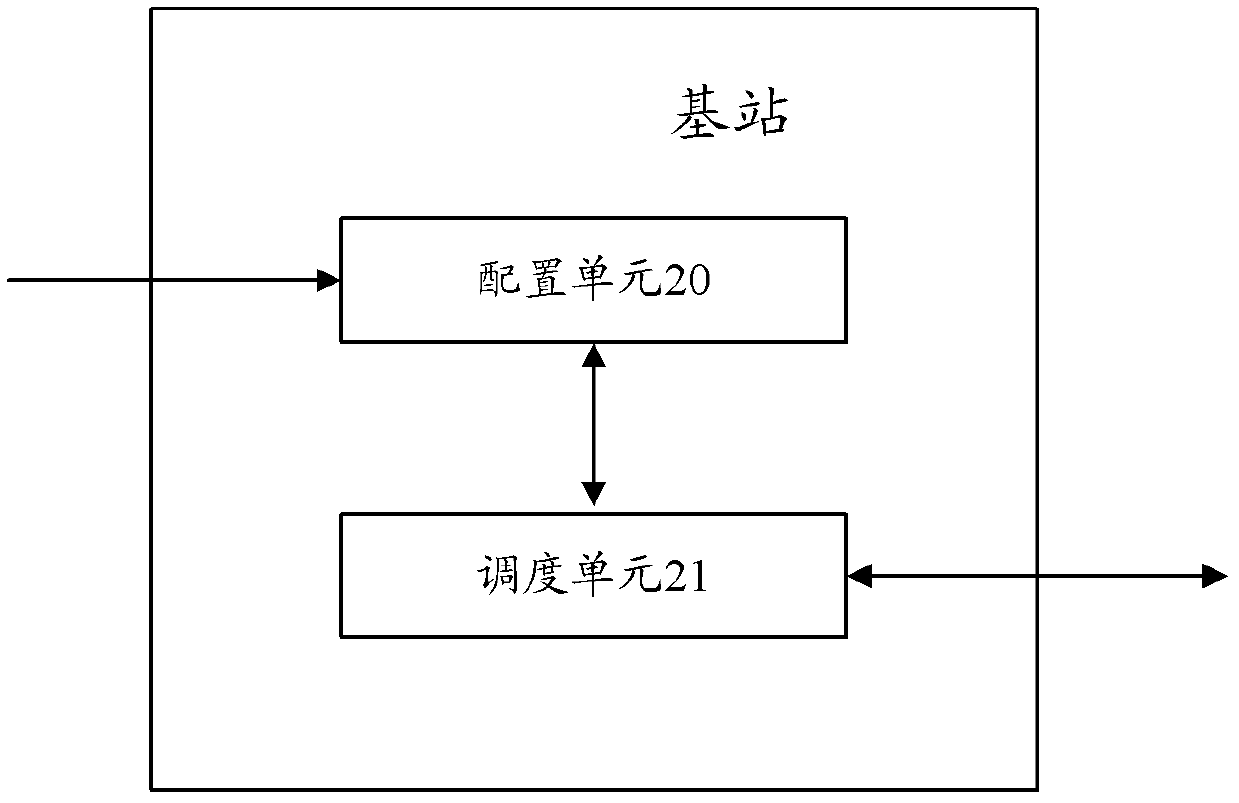

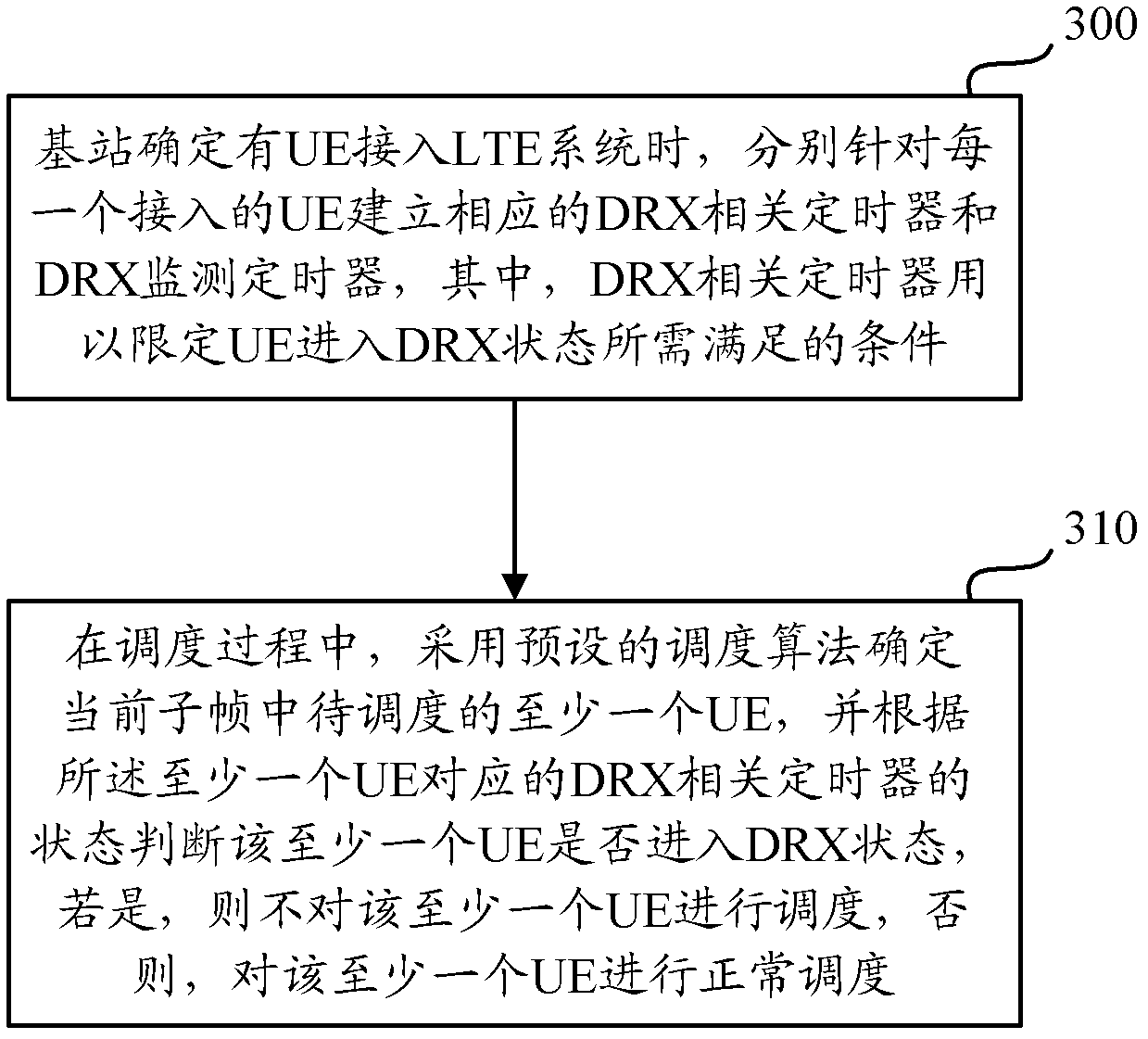

A method and device for realizing drx function

ActiveCN102264148AReduce operating overheadImpact capacityConnection managementTimerDiscontinuous reception

The invention relates to the field of communication and discloses a method and a device for realizing a discontinuous reception (DRX) function, which are used for lowering operation cost of a system on the premise of not increasing equipment cost and not influencing cell capacity. The method comprises the following steps of: establishing DRX related timers for user equipment (UE) by using a base station when the UE accesses the system; and judging whether to schedule the UE or not only according to the states of the DRX related timers of the current UE to be scheduled in the current subframe before scheduling, instead of determining the states of the DRX related timers of all the UE. Therefore, by the method and the device, the operation cost of a network side can be effectively saved, resource waste of the system is avoided, the equipment cost of the network side cannot be increased, and the user capacity of cells cannot be influenced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

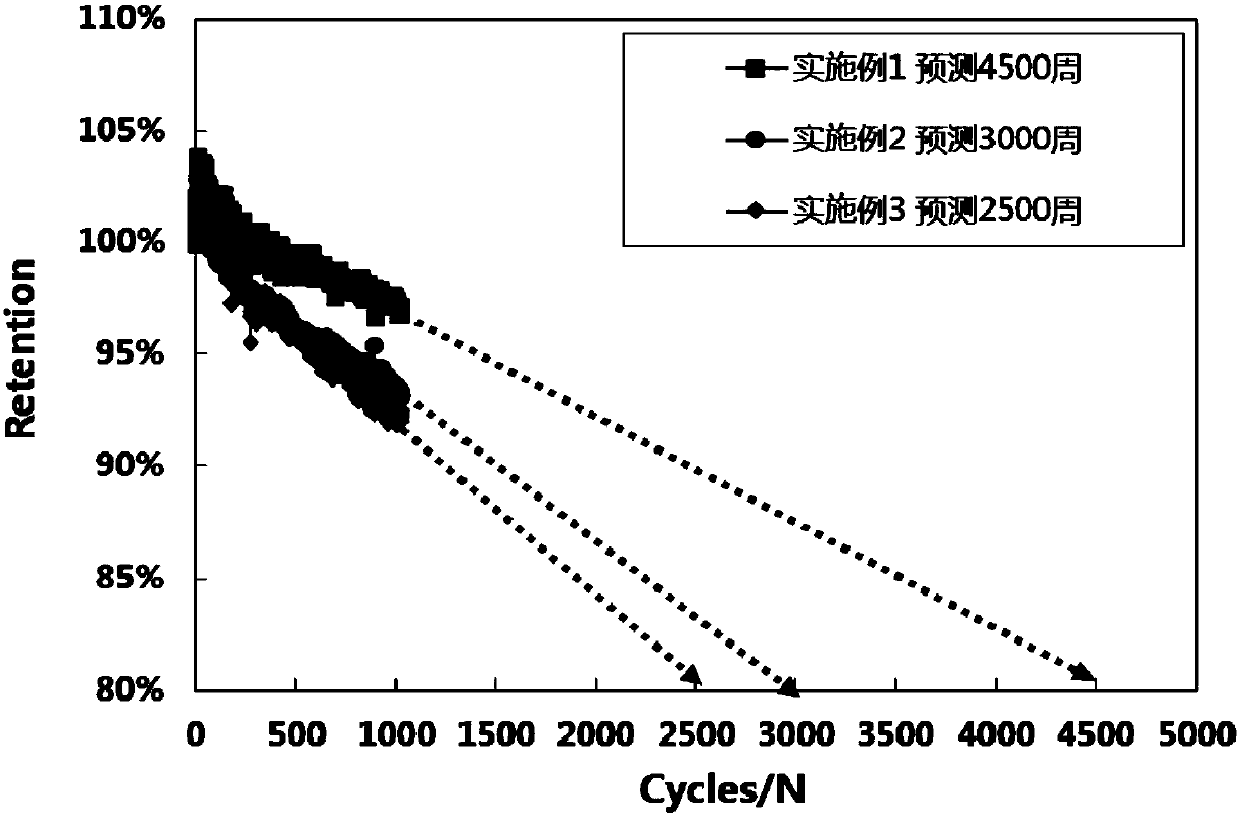

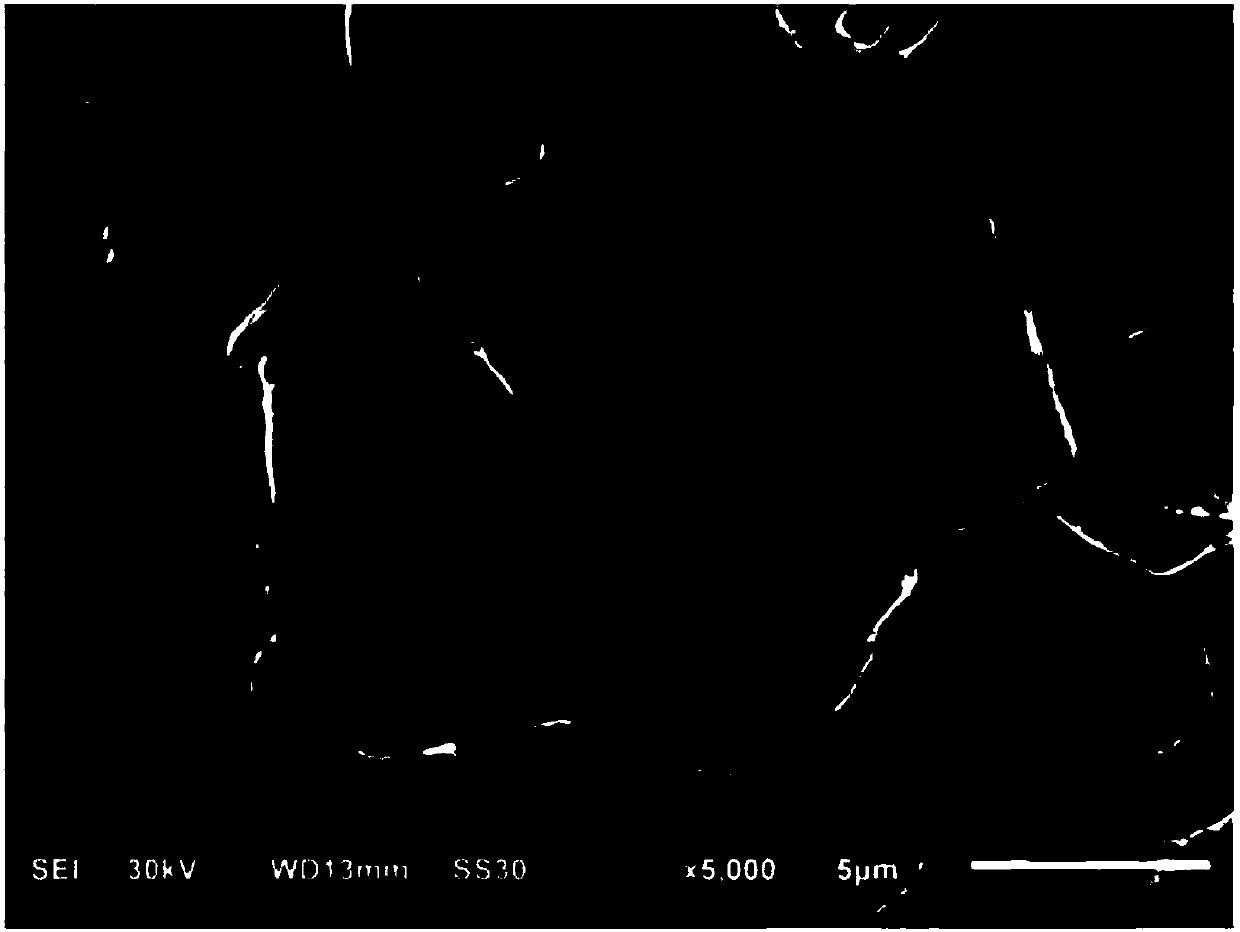

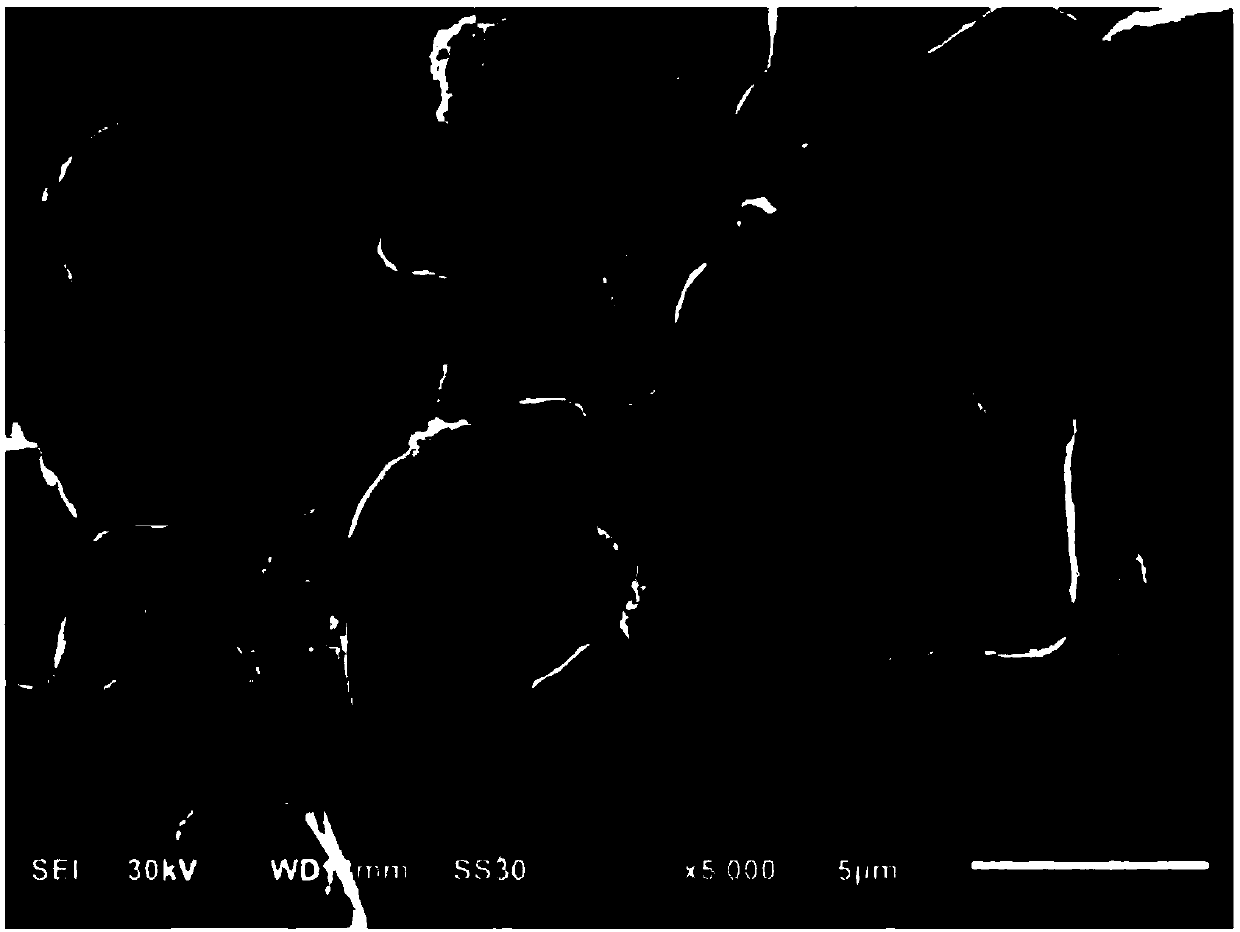

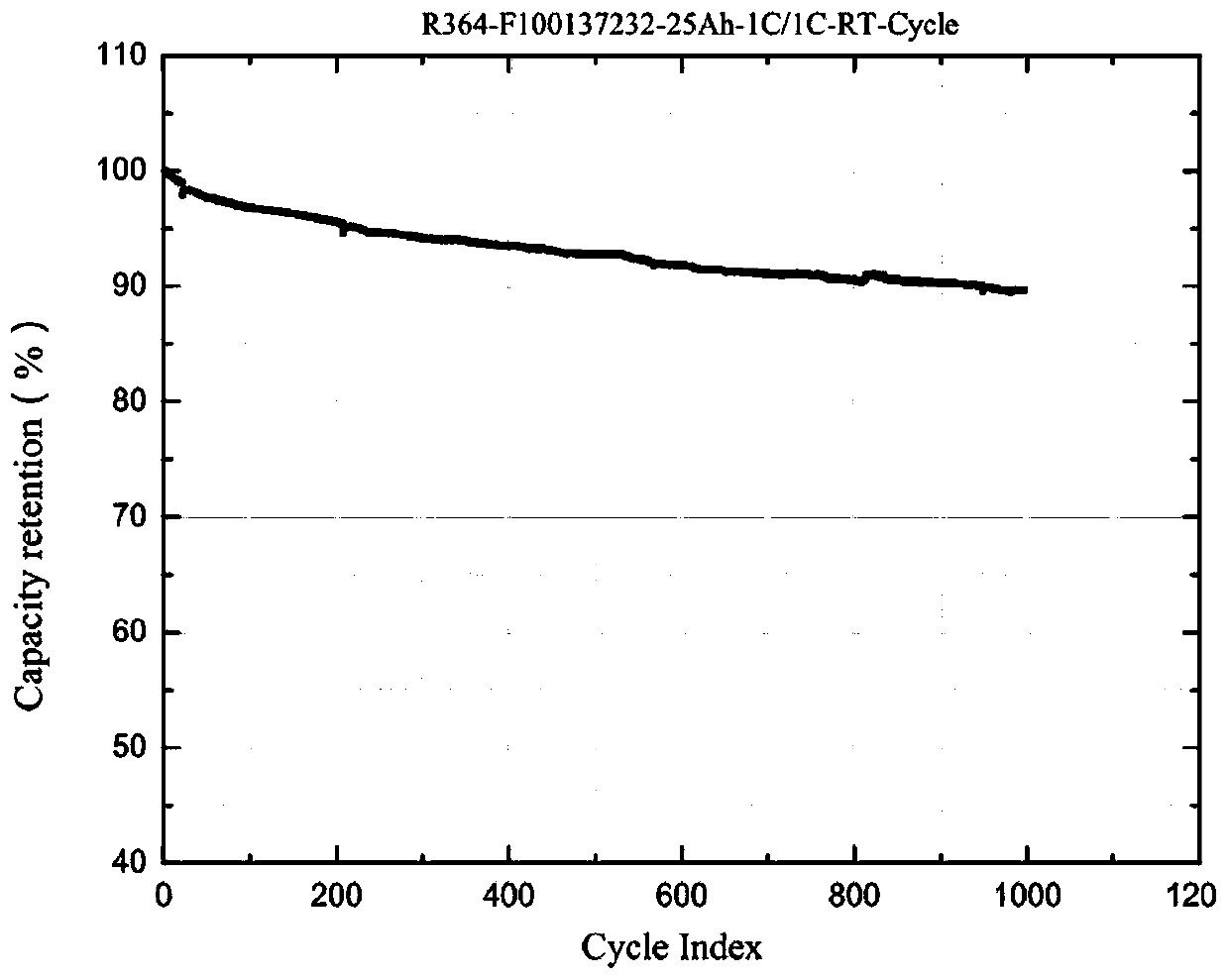

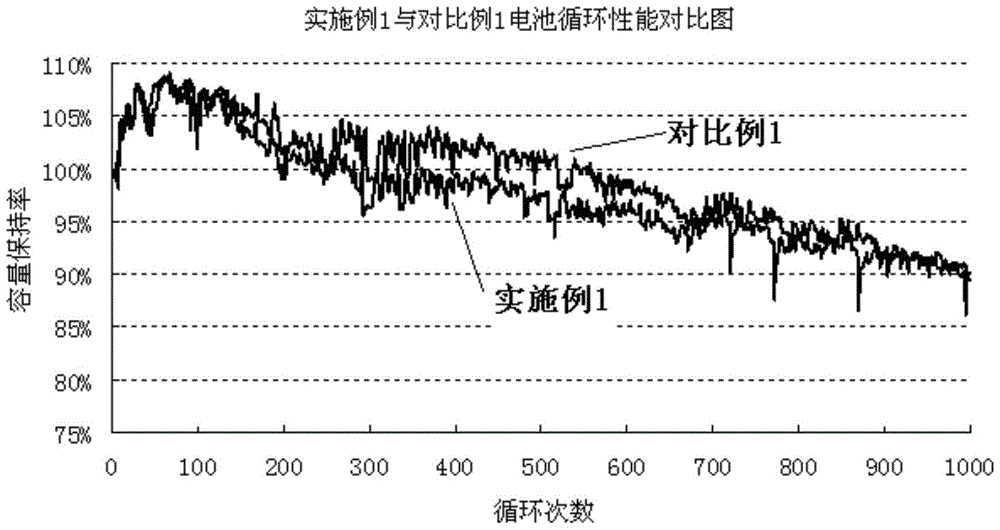

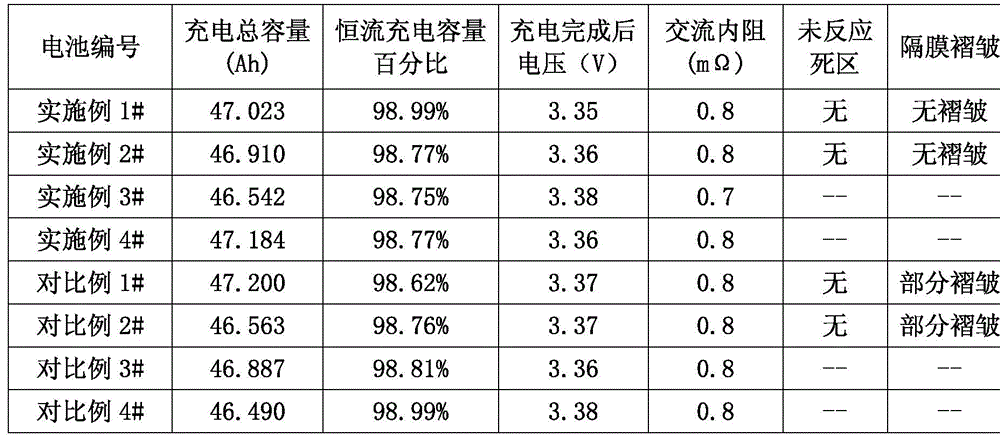

Formation and validation method capable of improving cycle performance of lithium iron phosphate battery

InactiveCN108054436AImprove cycle performanceImpact capacityFinal product manufactureElectrolyte accumulators manufactureLithium iron phosphateInternal resistance

The invention provides a formation and validation method capable of improving the cycle performance of a lithium iron phosphate battery. The method comprises the steps of preparing a square soft package battery; carrying out normal-temperature staged preformation; completing a preformation stage and then carrying out secondary packaging on the battery; and finally carrying out battery capacity grading and validation. A matched formation and validation method capable of improving the cycle performance of the lithium iron phosphate battery is established for a specific square soft package powerbattery system; and in the process of the method, the factors, such as corresponding internal resistance change, fluid loss change, charge-discharge efficiency and scanning interface of the battery are analyzed to form the formation and validation method capable of improving the cycle performance of the lithium iron phosphate battery, which is optimal in SEI film, optimal in battery performance and longest in cycle life.

Owner:桑顿新能源科技(长沙)有限公司

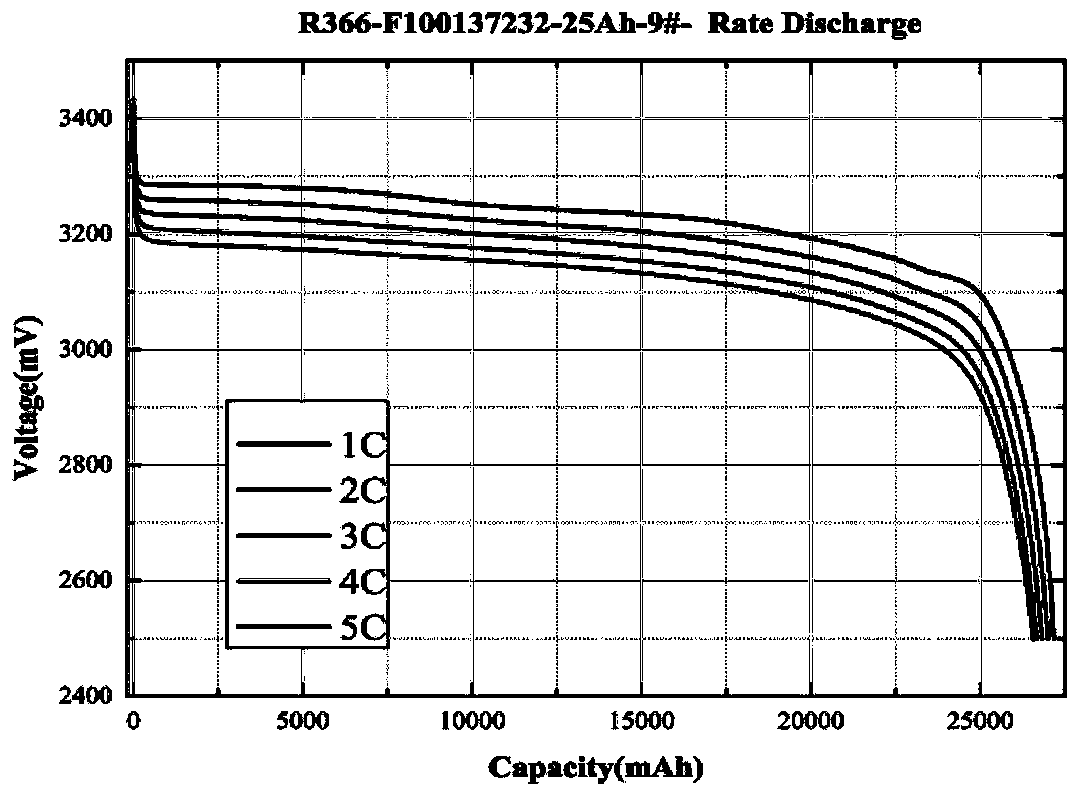

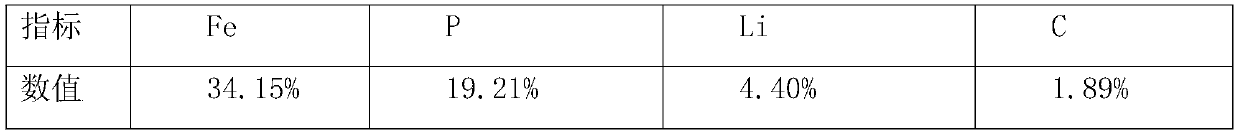

Preparation method of titanium-doped lithium iron phosphate

InactiveCN111498825AIncrease compaction densityImprove electronic conductivityCell electrodesPhosphorus compoundsLithium carbonateTitanium tetrachloride

The invention discloses a preparation method of titanium-doped lithium iron phosphate. The method includes introducing titanium tetrachloride into a phosphoric acid solution, then putting the reactionslurry into a sealed reaction kettle, and carrying out reduced pressure evaporation until water is completely evaporated to dryness; pouring out the evaporated powder, mixing lithium carbonate through jet milling, mixing, slurrying, levigating, spraying and calcining to obtain a primary calcined material; adding the primary calcined material into a polyethylene glycol solution, stirring and slurrying to obtain a slurried material, then adding a ferrous sulfate solution, a phosphoric acid solution and an ammonia water solution into the slurried material together, and filtering, washing and drying the reaction material to obtain an iron-titanium mixture; and mixing the iron-titanium mixture with lithium carbonate and a carbon source, slurrying, grinding, spraying and calcining to obtain a material, carrying out jet milling, screening and iron removal on the material to obtain the titanium-doped lithium iron phosphate. According to the invention, the uniformly titanium-doped lithium ironphosphate can be obtained, the discharge voltage platform is high, the compaction density is high, and the energy density is high.

Owner:蒋央芳

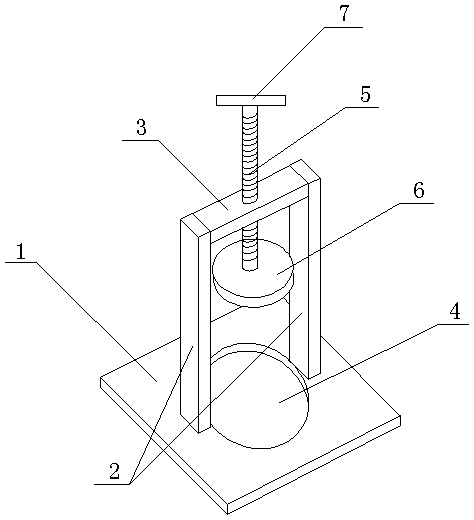

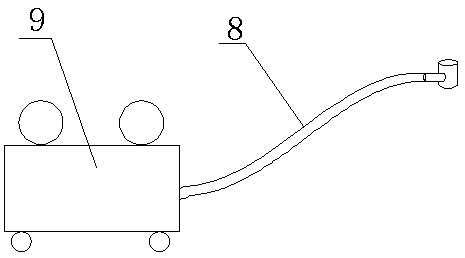

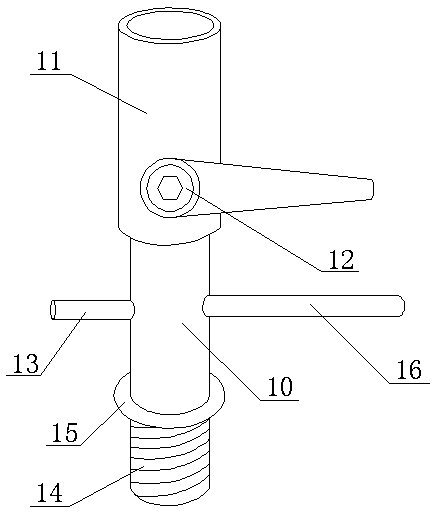

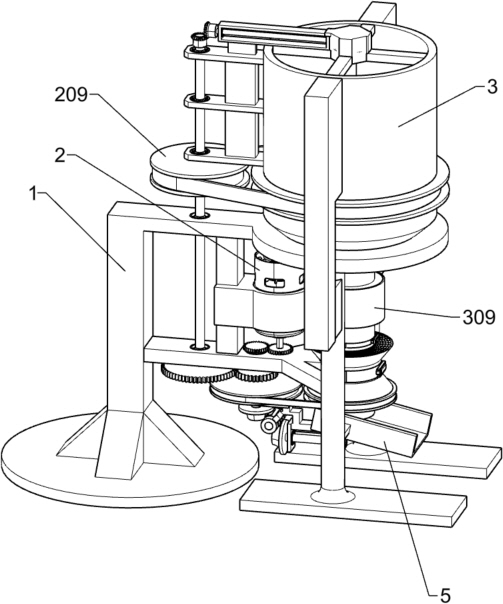

Iron bucket repairing and reshaping device with environmental protection property

The invention discloses an iron bucket repairing and reshaping device with an environmental protection property. The iron bucket repairing and reshaping device comprises a fixing device and an inflating device, wherein the fixing device comprises a base (1) and two stand columns (2) arranged on the base (1), the upper ends of the two stand columns (2) are fixedly connected through a transverse plate (3), a threaded rod (5) is arranged on the transverse plate (3), a cross rod (7) is fixed to the upper end of the threaded rod (5), and a disc (6) is fixed to the lower end of the threaded rod (5); the inflating device comprises an air compressor (9) and an air valve device, and the air compressor (9) and the air valve device are communicated through an air pipe (8). By the adoption of the structure, when reshaped, an iron bucket can be fixed well to ensure reshaping quality, and working efficiency of the reshaping is improved.

Owner:SICHUAN WEST POLY XIN CHEM PACKING

Efficient lithium battery

InactiveCN103840105AEnsure safetyGuaranteed capacityLi-accumulatorsNon-aqueous electrolyte accumulator electrodesInternal pressureElectrical battery

The present invention discloses an efficient lithium battery, which comprises a housing, a positive electrode, a negative electrode and a pressure limitation plate, wherein the pressure limitation plate is arranged on the middle-upper portion inside the housing, the positive electrode and the negative electrode are sequentially arranged below the pressure limitation plate from top to bottom, and are sponge-like porous electrodes, and the housing above the pressure limitation plate is provided with a gas exhaust hole. The technical problem solved by the present invention is to improve the safety of the lithium battery. According to the efficient lithium battery, the pressure limitation plate provided for pressure limitation breaking and arranged inside the housing and the sponge-like porous electrodes are arranged, such that the pressure limitation plate is self-damaged and releases gas when the inner pressure is too high so as to ensure the safety of the lithium battery, effectively avoid breaking of the lithium battery housing, and prevent liquid leakage and generation of corrosion, environmental pollution and other incidents; and the specific surface area of the electrode is improved with the arranged porous electrodes so as to effectively improve the capacity of the battery.

Owner:叶小平

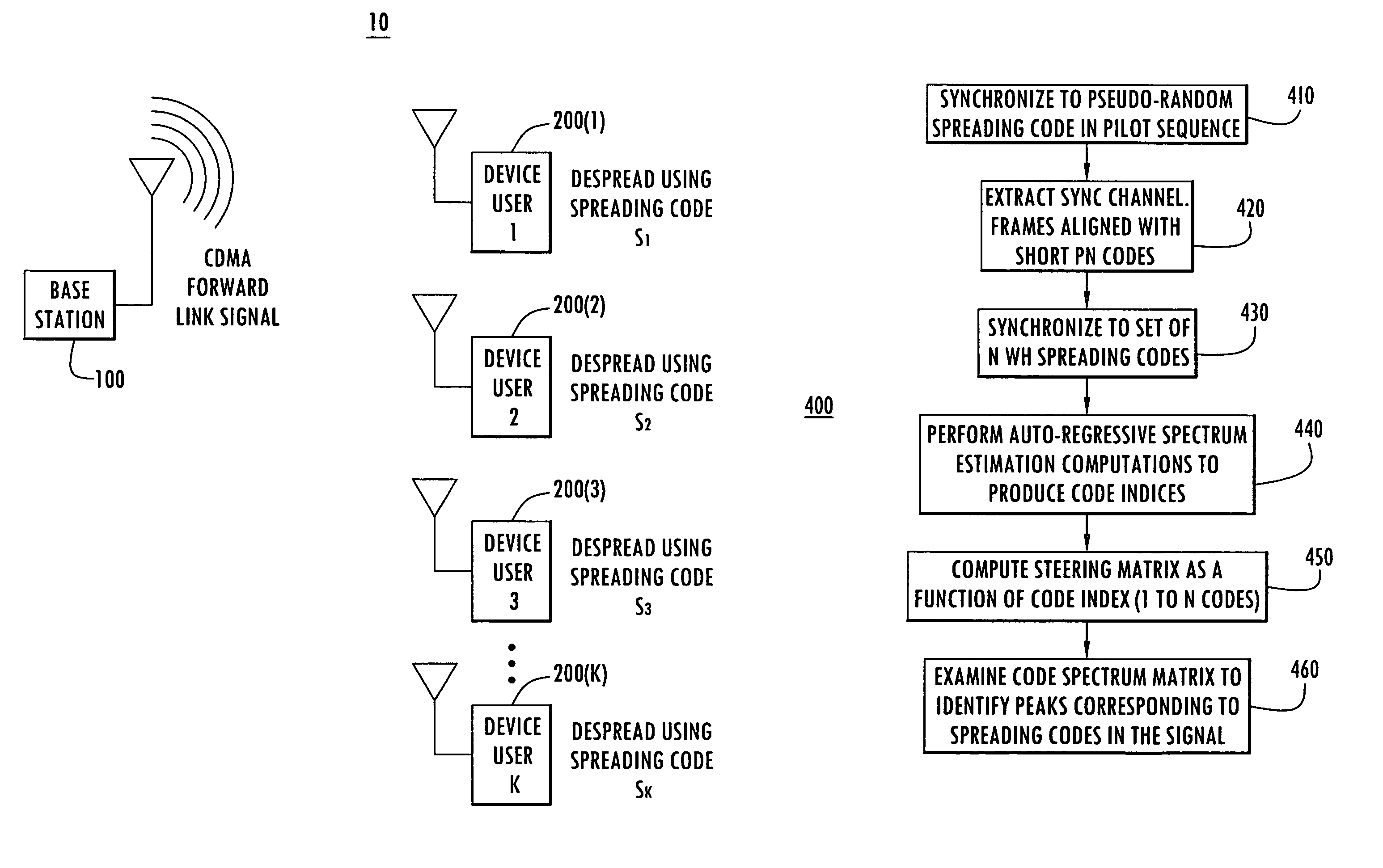

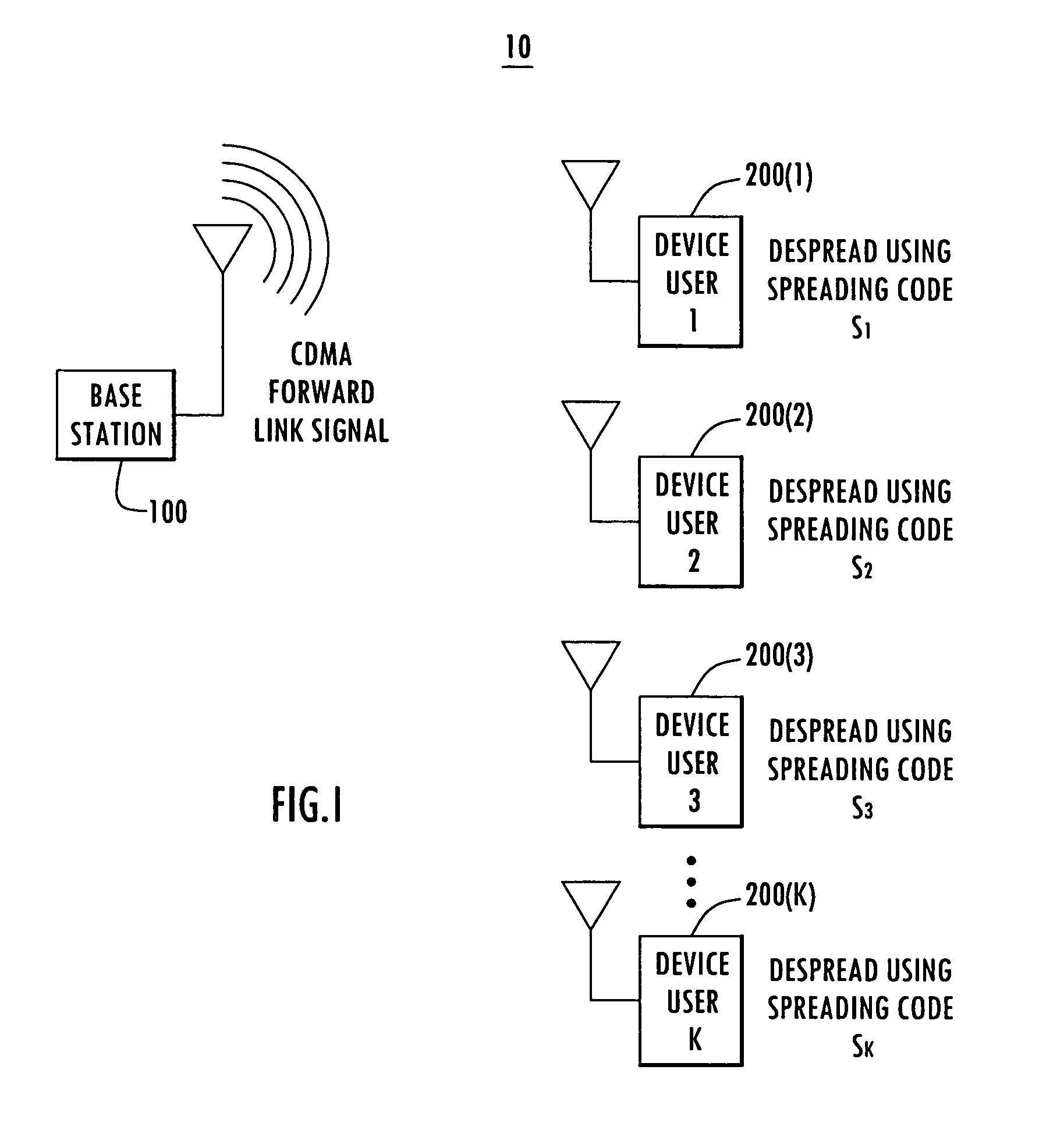

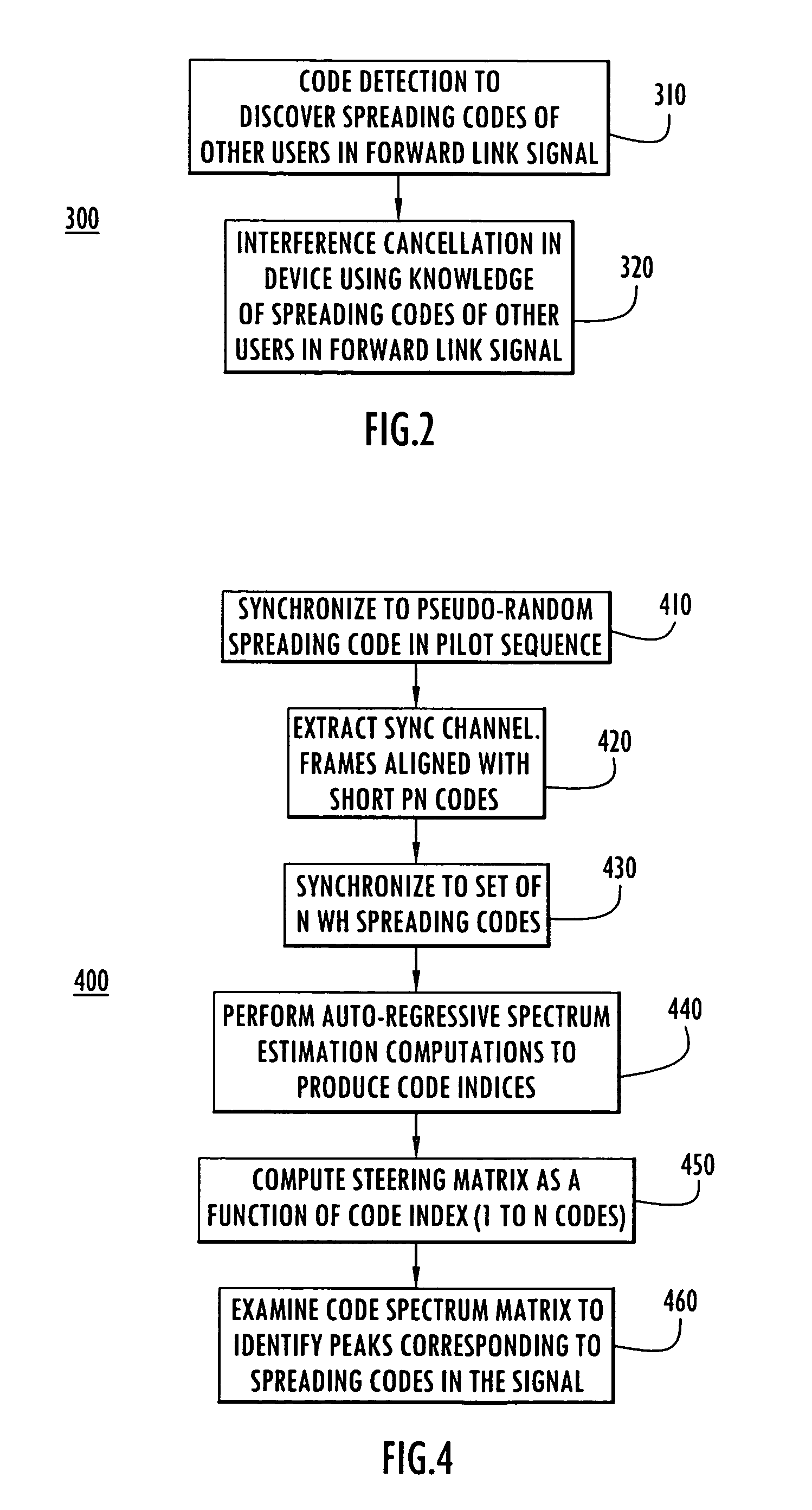

Bit detection using code spectrum transform techniques for interference cancellation

ActiveUS7480493B1Reduces spurious peak in power spectral densityDecrease rankingResonant long antennasRadio transmissionFrequency spectrumInterference cancelation

Spreading code detection methods applying autoregressive spectrum estimation (ARSE) techniques to code division multiple access (CDMA) wireless communication systems allowing the subscriber device to estimate the other users' codes. According to one aspect, ARSE techniques are provided using an augmented Wiener-Hopf solution on a received forward link CDMA signal. The ARSE techniques produce a code spectrum transform yielding a power spectral density versus spreading code index relationship from which the spreading codes in the received forward link signal may be identified. According to another aspect, a reduced rank auto-regression (AR) implementation is provided to produce a code spectrum transform efficiently with improved false code detection rate. With knowledge of other users' spreading codes, interference cancellation can be performed on the forward link of CDMA systems.

Owner:HARRIS CORP

Rapid formation process of lithium iron phosphate battery

InactiveCN104037456BImpact capacityFast and full wettingFinal product manufactureElectrolyte accumulators manufacturePower flowLithium iron phosphate

The invention discloses a rapid formation process of a lithium iron phosphate battery, which comprises the following steps: after the battery is assembled, the battery is vacuumed and injected into the electrolyte in stages, and the seal is sealed; Flip or turn the battery so that each side of the battery faces down and place it for a certain period of time; after the storage is completed, ultrasonically treat the battery for 10-20 minutes; put the battery on the cabinet, charge and activate it in a small current stepwise manner, and add intermittent pulse discharge; After the charging is completed, the battery is deflated and vacuumized once in the glove box, then sealed, aged, and divided. The present invention first allows the electrolyte to fully infiltrate the battery diaphragm and the positive and negative electrodes, and then adopts a stepwise charging with a large current and cooperates with the method of intermittent pulse discharge, which not only greatly shortens the time of the formation process, reduces the energy consumption of the equipment, and completes the formation The performance of the final battery is excellent, no difference from the battery using the traditional formation process.

Owner:LVCHI AUTO TECH SHANGHAI CO LTD

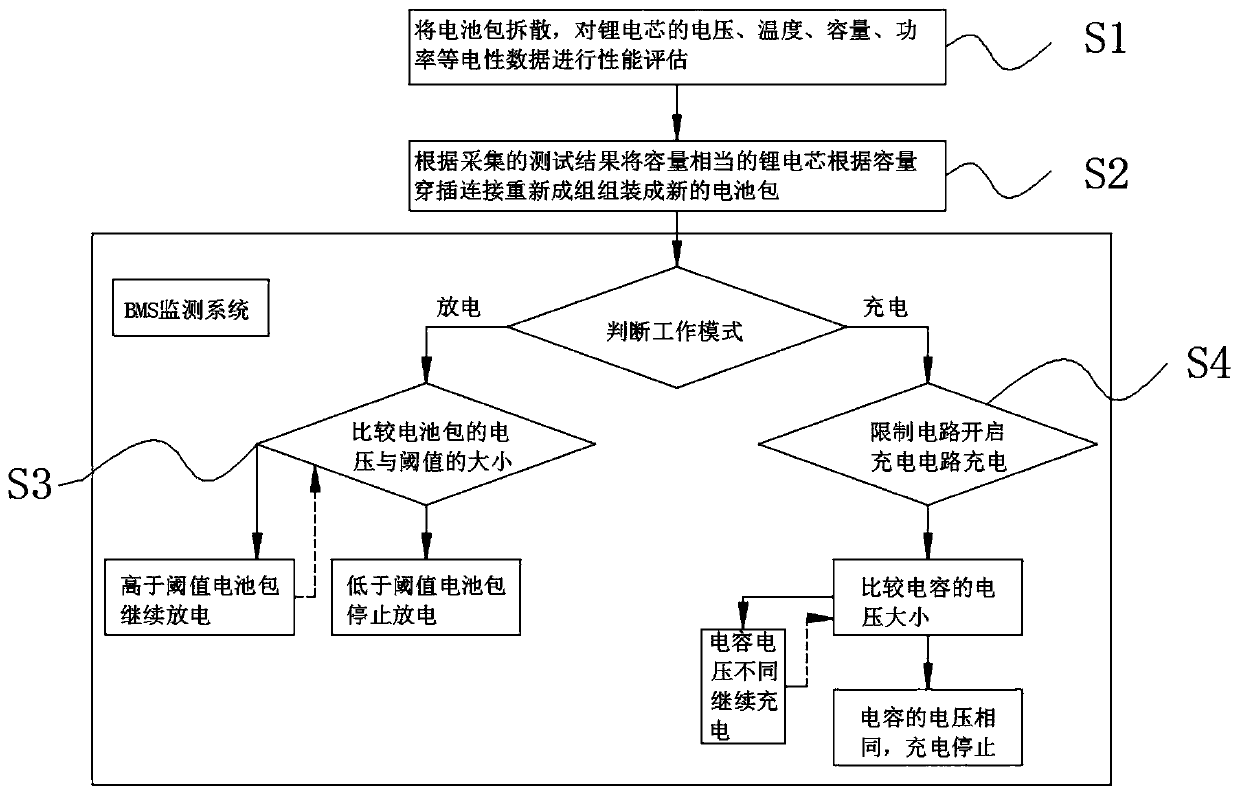

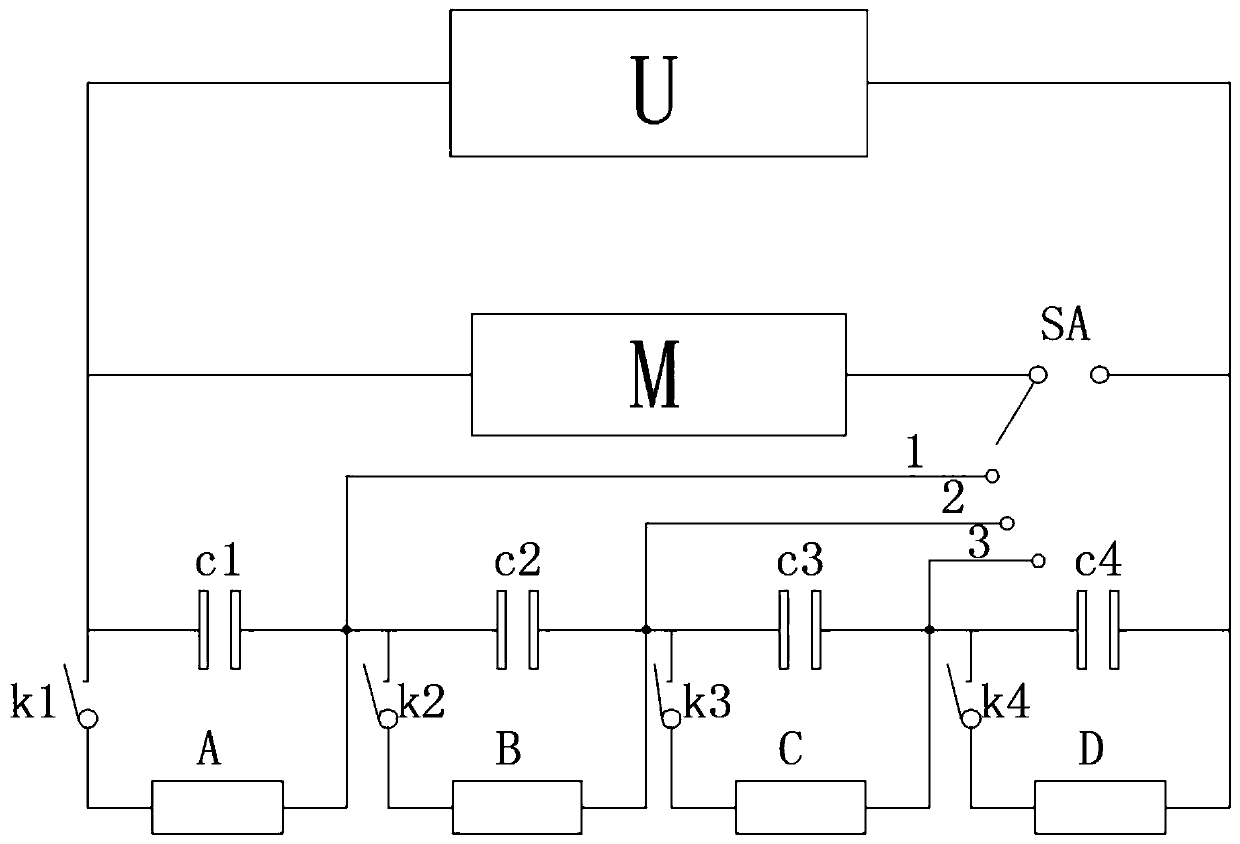

Echelon utilization battery pack control method

InactiveCN111478396AGuaranteed uniform dischargeAvoid excessive dischargeCharge equalisation circuitParallel/serial switchingAutomotive engineeringElectrical battery

The invention discloses an echelon utilization battery pack control method, and particularly relates to the field of power battery reutilization, and the method comprises the steps: S1, disassemblinga battery pack of a retired lithium battery, and carrying out the performance evaluation of the voltage, temperature, capacity, power and other electrical data of a lithium cell in the battery pack; and S2, according to the data acquired by the BMS monitoring system, regrouping and assembling the lithium cells with equivalent capacities into a new battery pack according to the capacities, and judging whether the battery pack enters a discharging or charging mode according to the electrical data. According to the method, the capacitor is arranged, discharge process, the capacitor-dischargeablebattery pack improves electric energy, ensures uniform discharge of the battery pack, avoids over discharge of the battery pack and influences on performance of the battery pack, and during charging,capacitor charging, capacitor voltage being equal to that of the battery pack and changes of capacitor voltage can generate absorption or release of the electric energy, so that capacities of the battery packs tend to be consistent, and consistency of the battery packs is improved.

Owner:深せん市钜力能科技有限公司

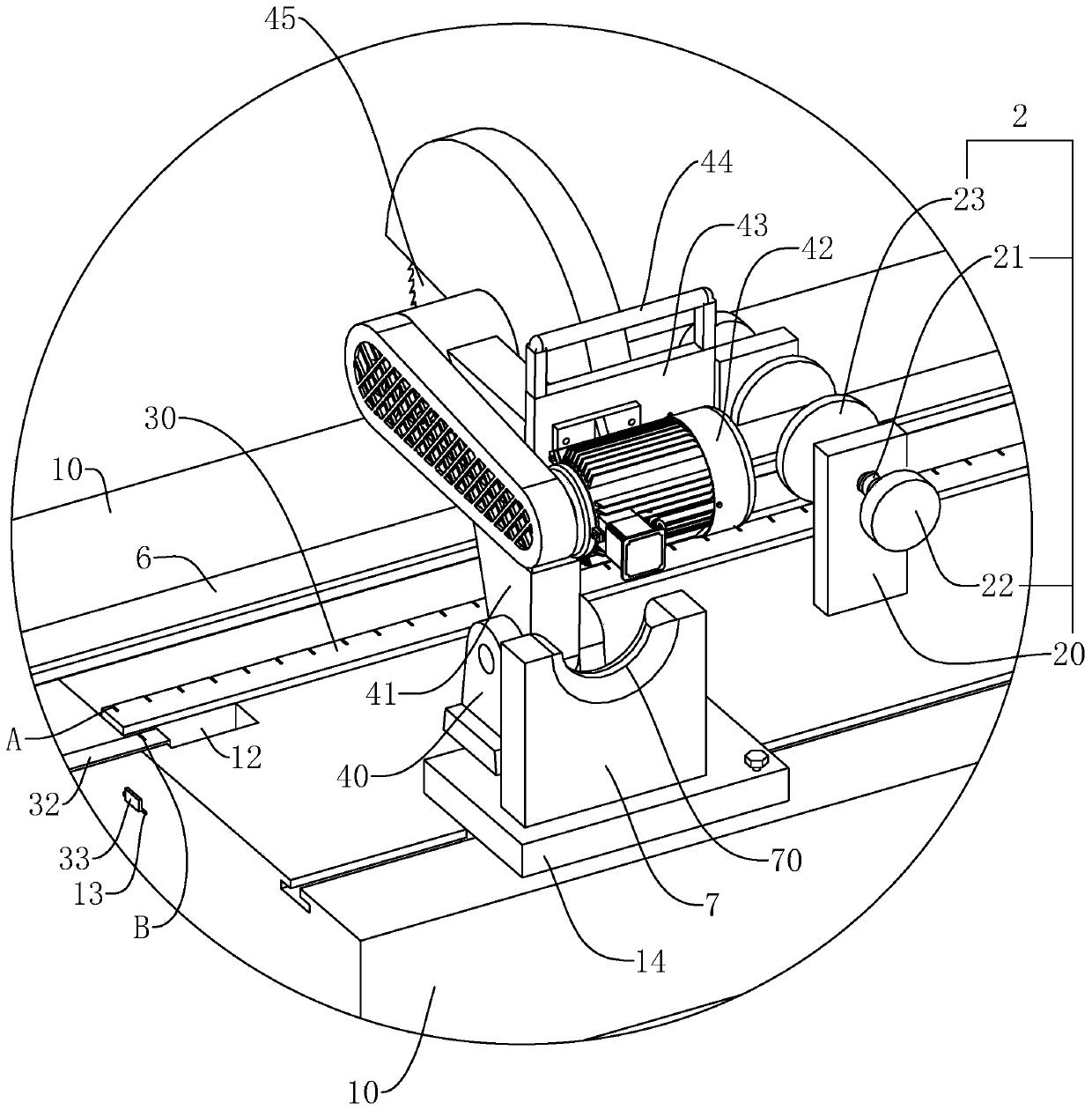

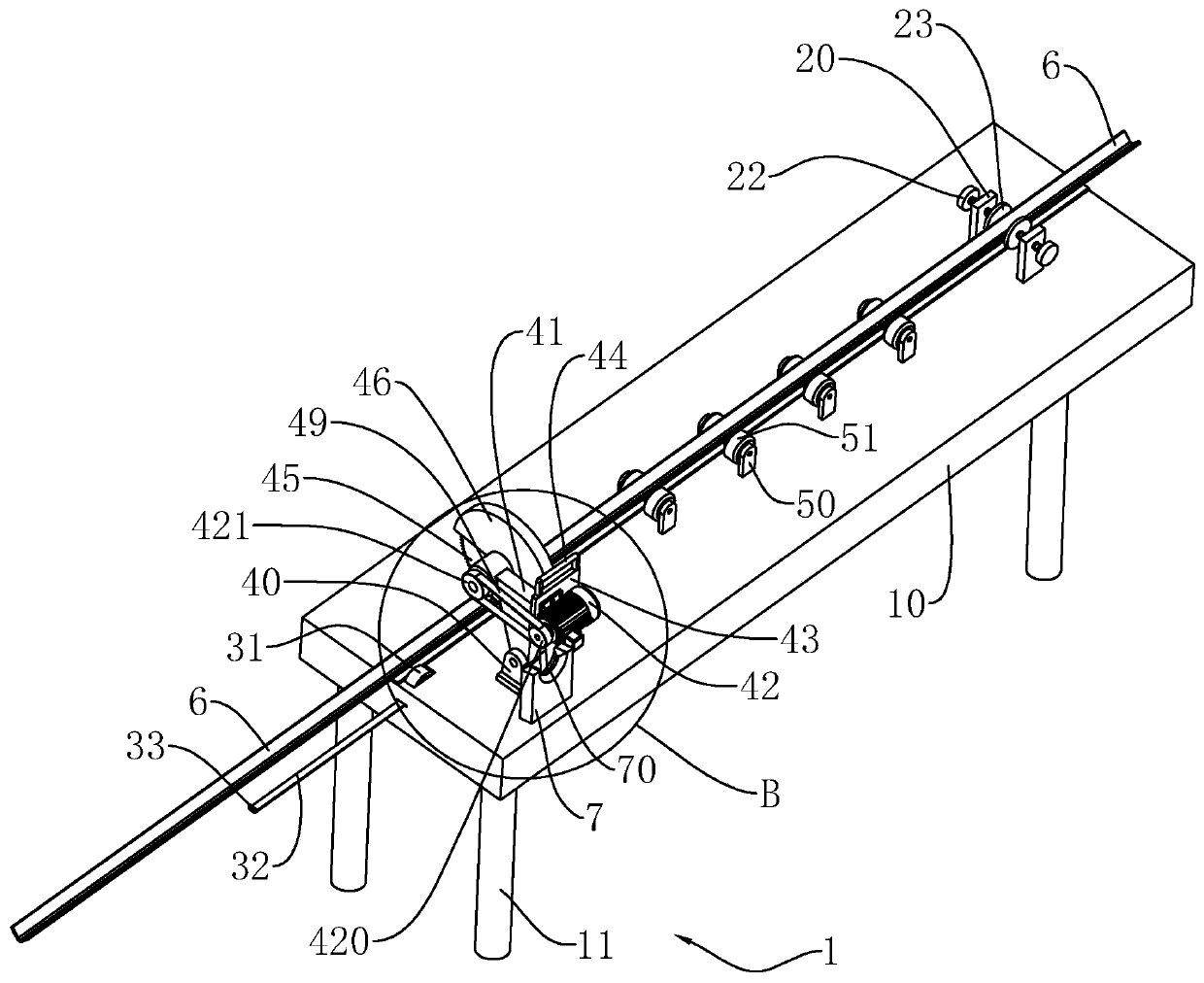

Steel cutting device and ground steel structure construction method

The invention discloses a steel cutting device and a ground steel structure construction method, and relates to the technical field of steel structure construction. According to the technical scheme,the steel cutting device is characterized by comprising a platform plate, a supporting device arranged on the platform plate and used for supporting steel, a measuring device arranged on a supportingplatform and used for measuring the length of the steel as well as a fixing device arranged on the platform plate and used for fixing the steel; a measuring rule located at the bottom of the steel isfixedly connected onto the platform plate; a limiting component for limiting the end of the steel to be aligned to the zero graduation of the measuring rule is arranged at the zero graduation end of the measuring rule; and a cutting device for cutting the steel is arranged on the platform plate. According to the steel cutting device, the technical problem that the steel is cut after manual measurement by the aid of a band tape, the steel is relatively long, measurement errors are caused by the fact that the zero graduation end of the band tape falls easily or displacement of the band tape occurs easily and later mounting is affected is solved, and the device has the advantage of higher measurement precision.

Owner:广东中烨建筑钢构有限公司

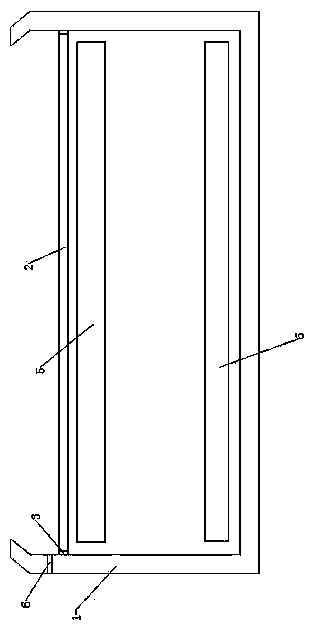

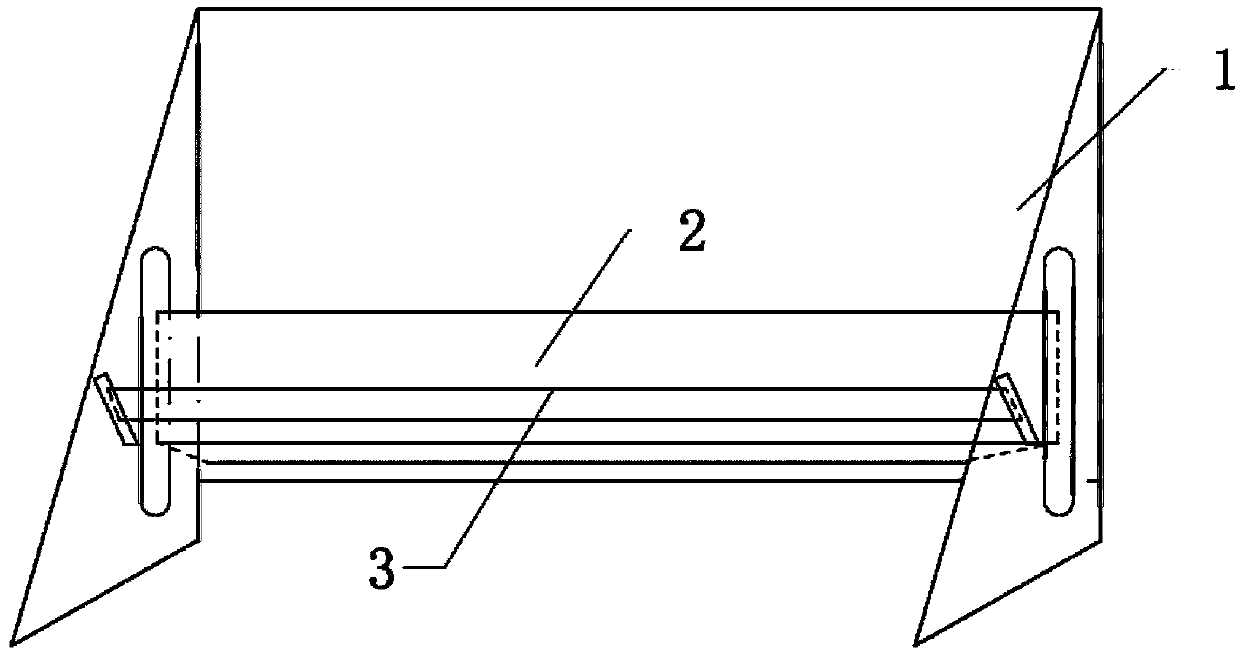

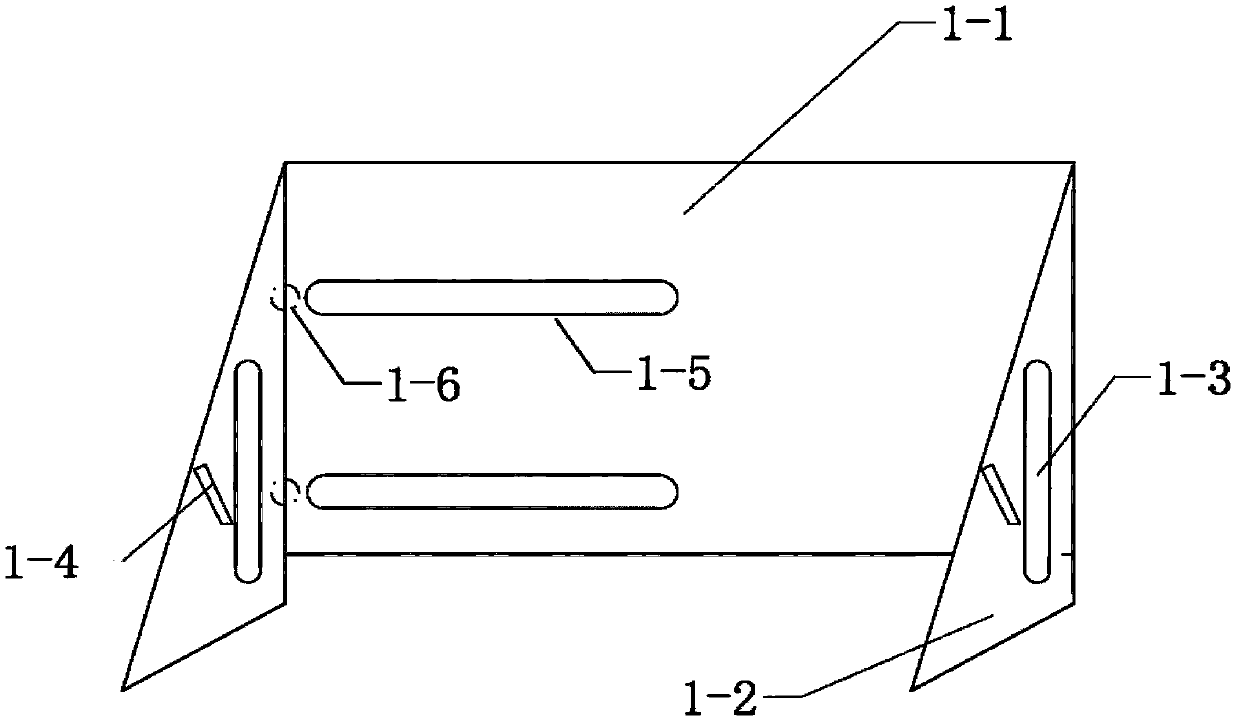

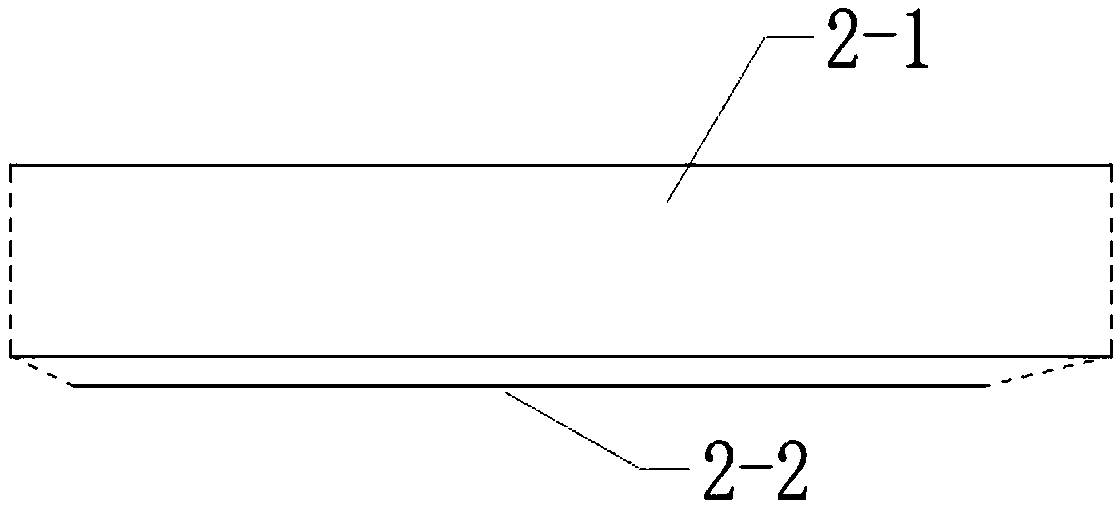

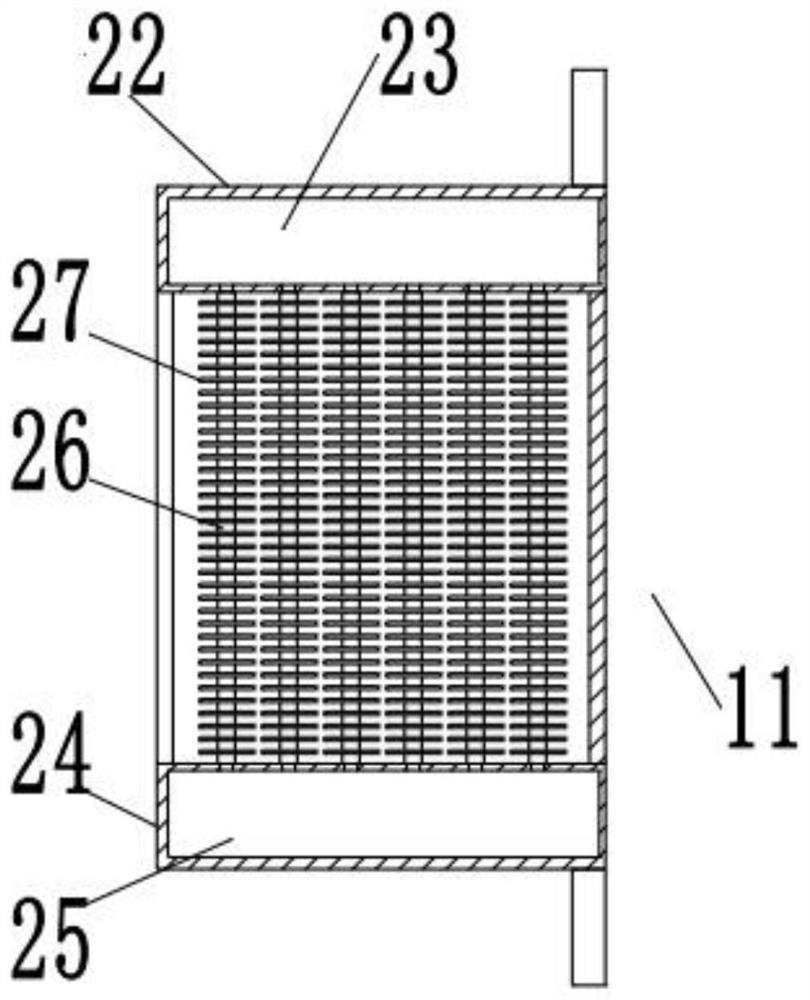

Slurry coating device for lithium ion battery

InactiveCN110355048ARealize semi-automatic feedingGuaranteed smoothLiquid surface applicatorsElectrode collector coatingSlurry coatingSemi automatic

A slurry coating device for a lithium ion battery comprises a fixing frame (1), a scraper (2) and a feeding baffle (3). The fixing frame is composed of a rectangular fixing frame body (1-1) and triangular supporting plates (1-2) on both sides. A scraper height adjusting groove (1-3) and a feeding baffle height adjusting groove (1-4) are specially designed in each triangular supporting plate. The scraper height adjusting grooves (1-3) can realize the coating of slurry of different thicknesses, and the feeding baffle height adjusting grooves can realize semi-automatic feeding. According to the slurry coating device for the lithium ion battery, the conductive slurry coating is performed on current collectors of different specifications without frequent feeding; the method of adjusting the grooves and fixing nuts is adopted to realize the coating of the slurry of different thicknesses, so that the inaccurate coating thickness caused by the aging of an existing scraper spring is avoided; and the triangular support plate arc and graphite coating design minimizes the frictional resistance between the coating device and the current collectors, it is ensured that the scraper can be directlyplaced on the current collectors, and the problem of fluid wrinkles or damage of the current collectors is solved.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

Battery plate for improving active material utilization

InactiveCN108075109AReduce the proportionImprove conductivityElectrode carriers/collectorsLead-acid accumulator electrodesRedoxTitanium

The invention discloses a battery plate for improving the active material utilization. The battery plate comprises a plate grid belt and a lead plaster. The plate grid belt comprises a metal plate belt layer and a lead cladding layer or a lead alloy cladding layer coated on a surface of the metal plate belt layer; the lead plaster is coated on an outer surface of the lead cladding layer or the alloy cladding layer. According to the battery plate for improving the active material utilization provided by the invention, through utilizing the metal plate belt layer containing high-conductivity metal, the proportion of the weight of a plate grid in active materials can be effectively reduced, and the weight of a battery is reduced. Metals such as copper, aluminum and titanium or an alloy material of the metals are adopted as a plate grid matrix, so that the electric conductivity of the plate grid can be effectively improved; the lead layer or the lead alloy layer is cladded onto the metal belt layer, so that firstly, an adhesive force of the lead plaster on the plate grid can be improved, and secondly, other metals can be prevented from contacting acid to produce redox reaction so as toinfluence a battery capacity.

Owner:CHAOWEI POWER CO LTD

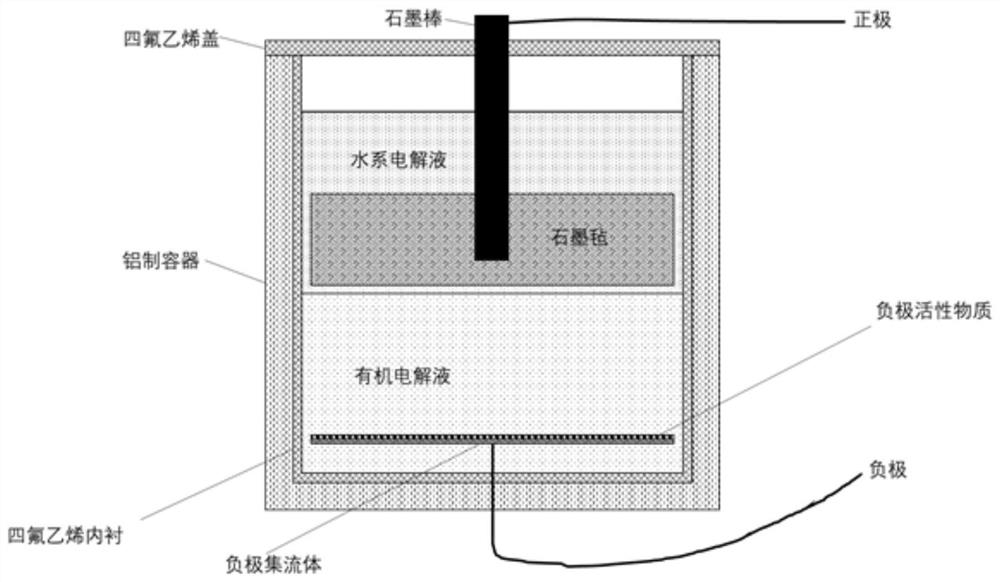

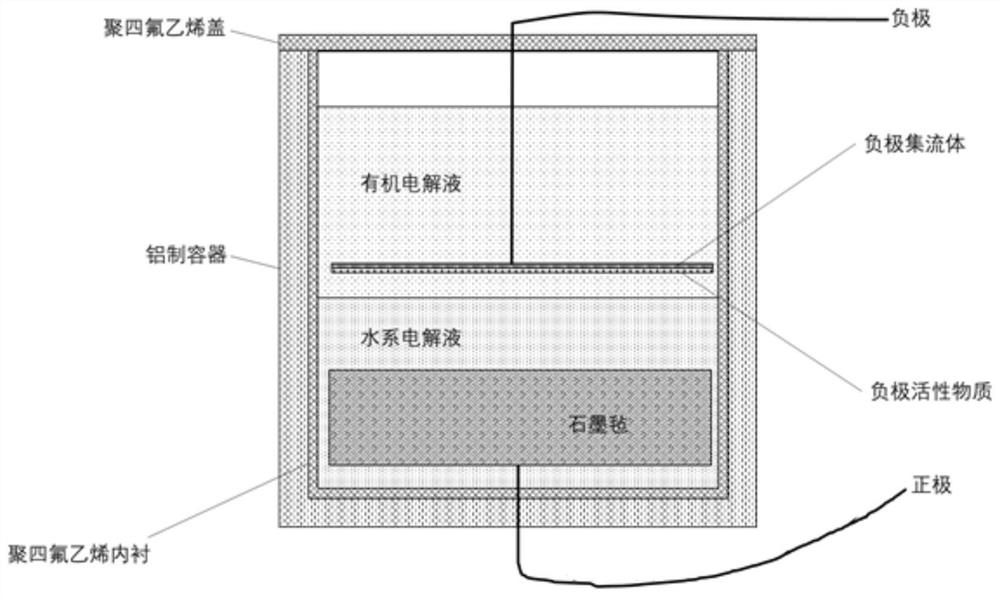

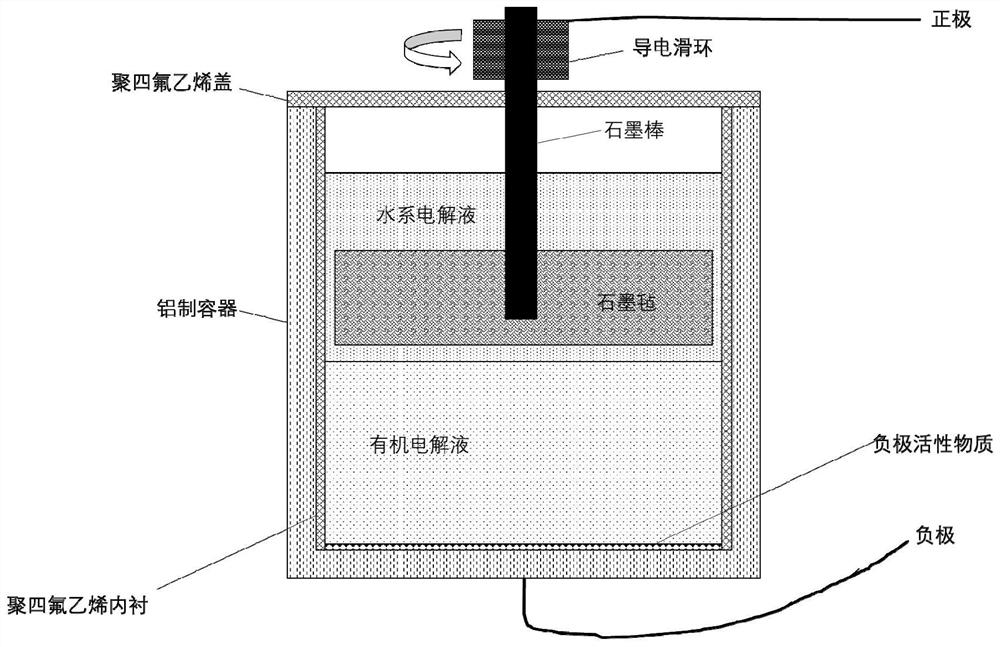

Double-electrolyte secondary battery

PendingCN113346147AIncrease profitIncrease speedCell electrodesFinal product manufactureElectrolytic agentAqueous electrolyte

The invention belongs to the field of secondary batteries, and particularly relates to a double-electrolyte secondary battery. The secondary battery comprises a positive current collector, a positive active material, an aqueous electrolyte, an organic electrolyte, a negative active material and a negative current collector; the positive active material is dissolved in the aqueous electrolyte, and the positive current collector is infiltrated in the aqueous electrolyte in which the positive electrode active material is dissolved; the negative active material is attached to the negative current collector and is soaked in the organic electrolyte; and the aqueous electrolyte and the organic electrolyte are in direct contact and are not dissolved with each other. The positive active material exists in the liquid in the form of solute, adverse effects caused by deterioration of a crystal structure of a solid do not need to be considered in the charging and discharging process, and the ion diffusion rate and the conductivity in the liquid are far higher than those of the solid, so that the utilization rate of the positive active material is greatly improved compared with that of a traditional battery.

Owner:HUAZHONG UNIV OF SCI & TECH

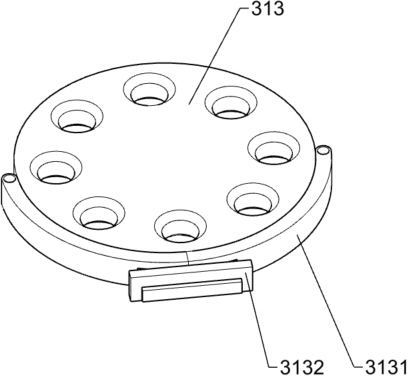

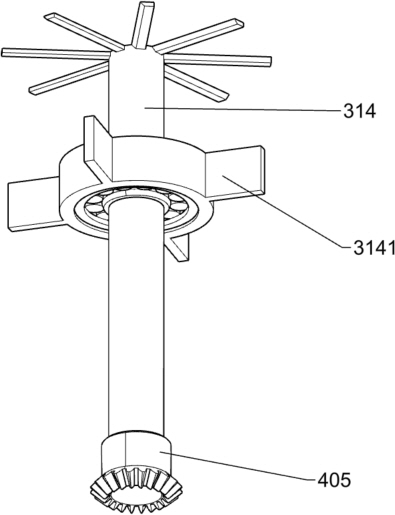

A centralized box for uniformly placing large and small items for logistics

ActiveCN109733717BSmooth rotationPromote stratificationContainer handlesExternal fittingsLogistics managementIndustrial engineering

The invention discloses a centralized box for centralized placement of large-size articles and small-size articles for logistics. The centralized box comprises a centralized box body, a layered assembly is arranged in the centralized box body, and partition plates are arranged on one side of the layered assembly. The centralized box is scientific and reasonable in structure, and safe and convenient to use; the layered assembly is arranged, through the effects of a sliding rod supporting block, a sliding rod and a layering plate, the interior of the centralized box can be conveniently layered,the space pattern inside the centralized box can be changed according to actual requirements, the articles with different sizes can be placed, so that the orderliness of article placement is improved;through the effects of springs, fixing clamps, movable shafts and the anti-skid inner cushions, the layering plate can be conveniently arranged and disassembled; and the partition plates are arranged, through the effects of elastic clamping ball, connecting rods and connecting through holes, the partition plates with different sizes can be conveniently arranged on one side of the layering plate according to requirements to isolate the articles stored in the centralized box, so that collision between different objects in the moving process is avoided, and the safety of the articles is improved.

Owner:HENGYANG NORMAL UNIV

Agricultural working apparatus

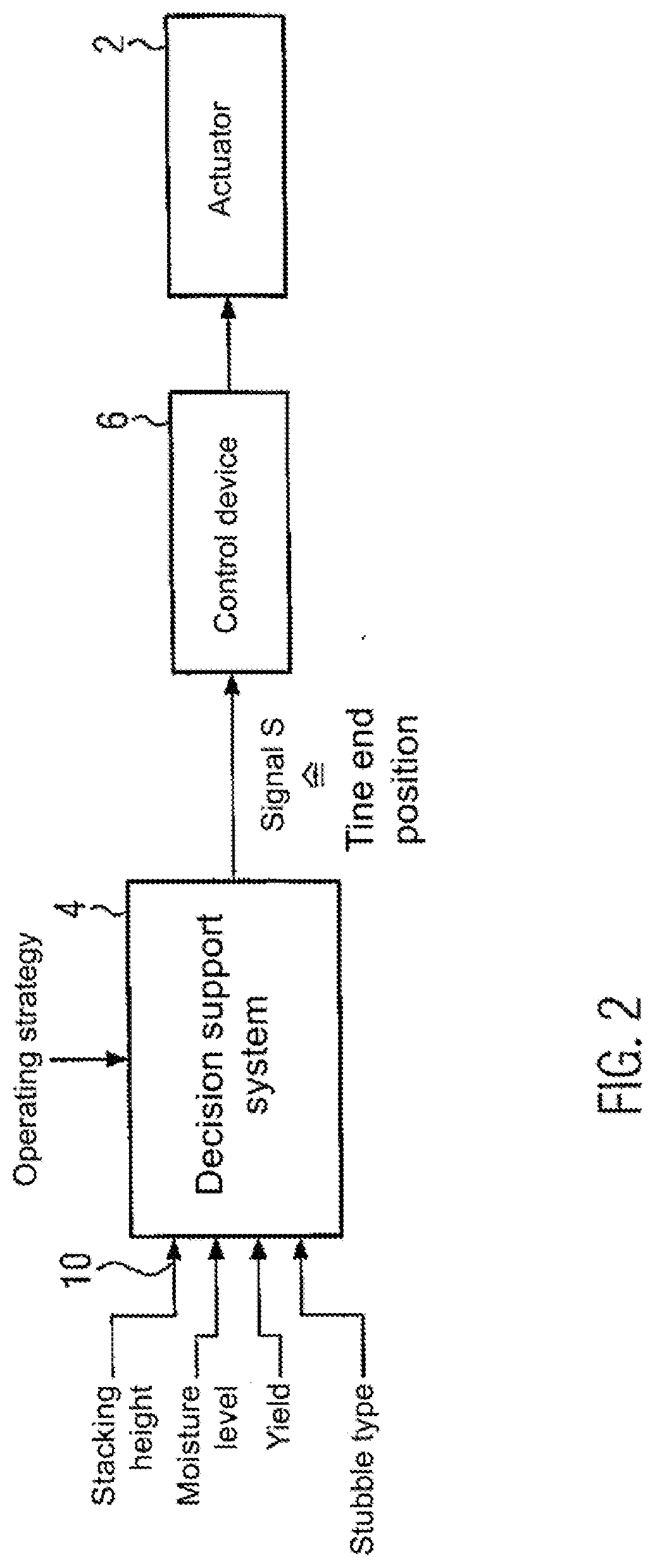

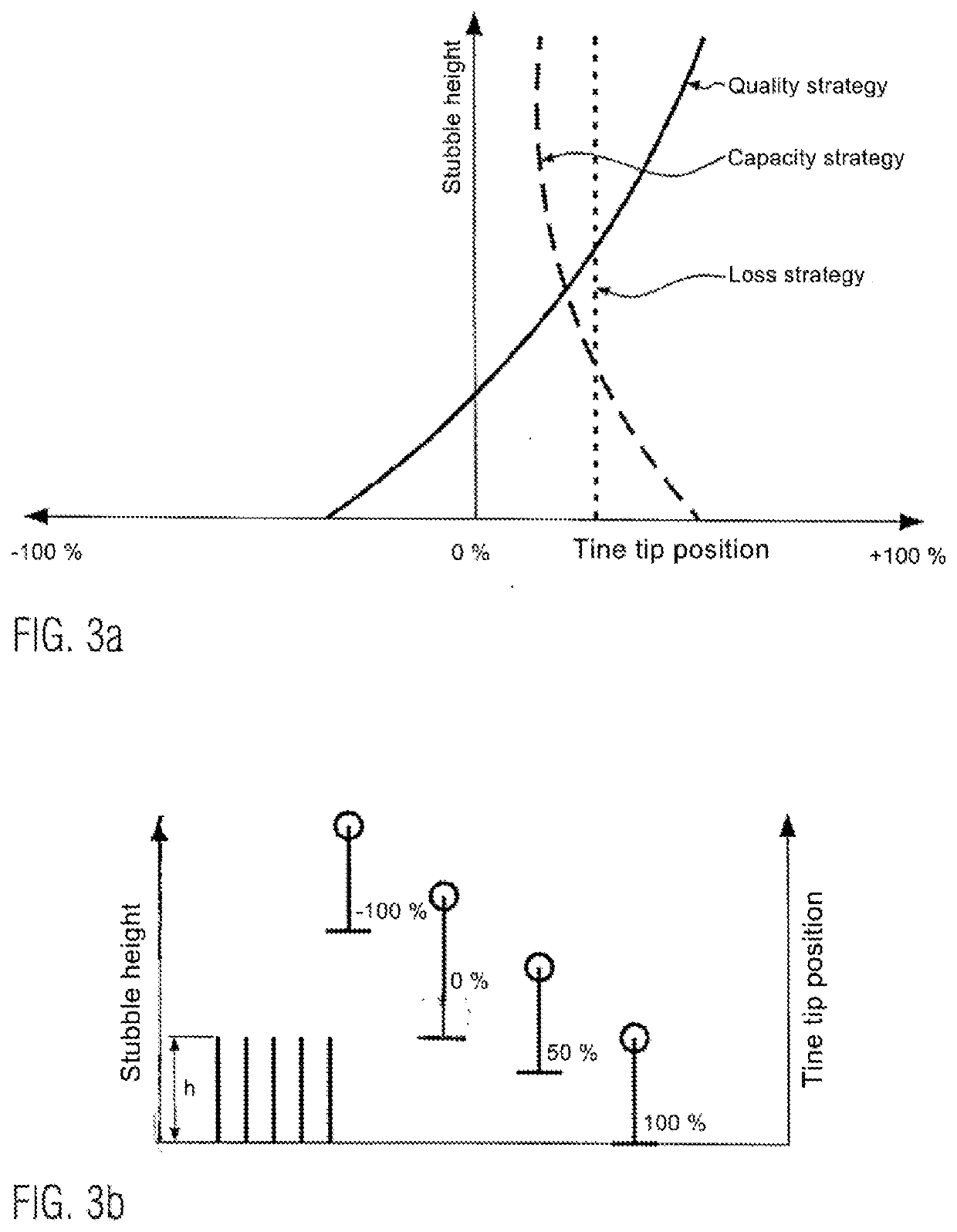

PendingUS20210307228A1Reduce pollutionMinimal lossAgricultural machinesLoadersDecision making support systemsAgricultural science

The invention relates to an agricultural working apparatus for use in forage harvesting and to a corresponding method with tines rotating about an axis A with corresponding tine ends. A device for changing the distance between the tine ends and the ground is also provided, as well as a sensor device for measuring a stubble height. An evaluation unit, in particular a decision support system, is provided to which the sensor device supplies measurement signals for the stubble height and which can determine a position of the tine ends as a function of the measured stubble height. A control device controls the device for changing the distance of the tine ends in order to set the determined position of the tine ends.

Owner:KVERNELAND GROUP KERTEMINDE AS

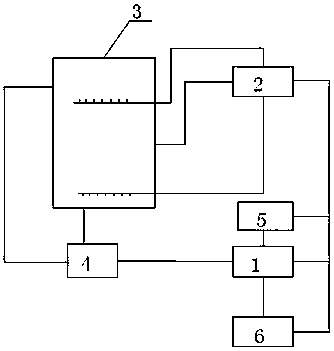

Water cooling system for numerical control machining center

InactiveCN112621366AImprove cooling effectIncrease temperatureMaintainance and safety accessoriesElectric machineryCooling water temperature

The invention relates to the technical field of numerical control machining centers, in particular to a water cooling system for a numerical control machining center. The water cooling system comprises a water tank, wherein a water inlet is formed in the outer wall of the top of the water tank; a rotating shaft is connected between the inner walls of two sides of the water tank through a bearing; an auger plate is welded to the outer wall of the rotating shaft; a gear motor is connected to the outer wall of one side of the water tank through bolts; one end of an output shaft of the gear motor is connected with the rotating shaft through a spline; a filter arc plate is welded between the inner walls of two side of the water tank; and a driving roller column is connected between the inner walls of two sides of the water tank through another bearing. According to the water cooling system, cooling water in the water tank is fed into a cooling device through a water pump body, the cooling water is cooled through heat exchange tubes and cooling fins, air flowing on the surfaces of the heat exchange tubes and the surfaces of the cooling fins is accelerated through a centrifugal fan, and the cooling effects of the heat exchange tubes and the cooling fins on the cooling water are enhanced, therefore, the effect of quickly cooling the cooling water is achieved, and the temperature of the cooling water is prevented from rising.

Owner:意特利(滁州)智能数控科技有限公司

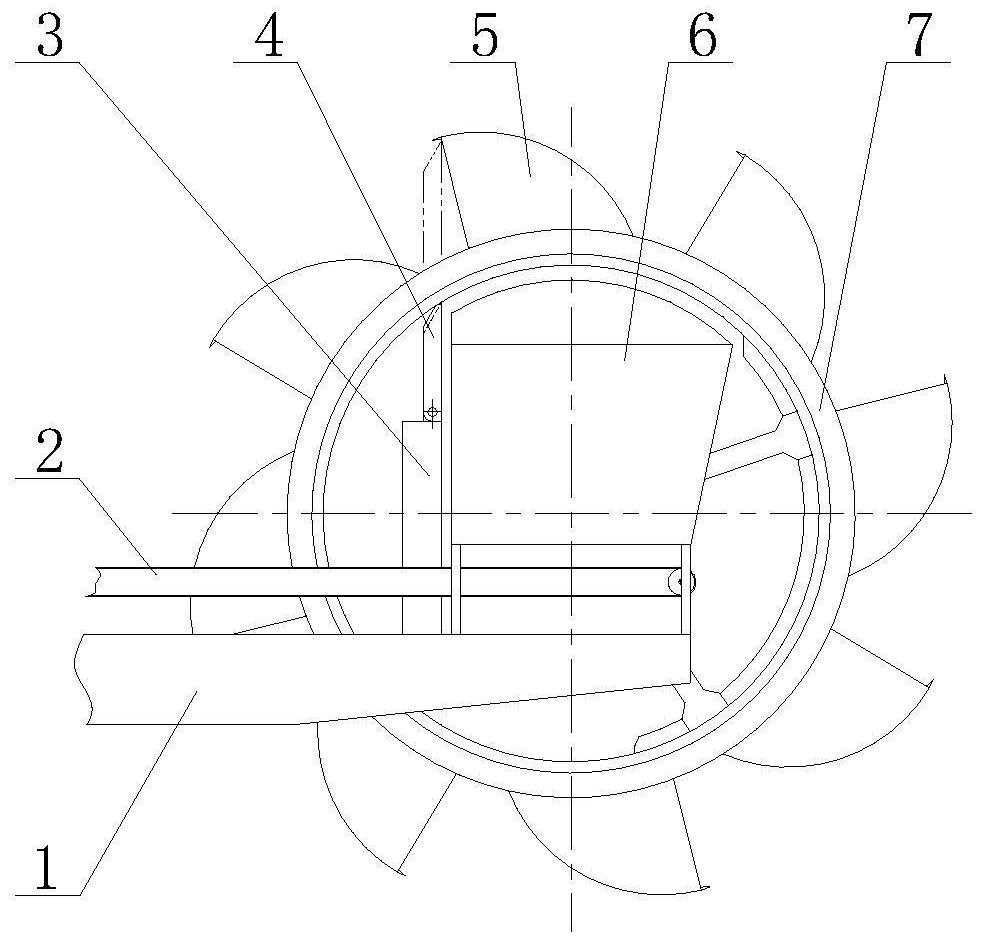

An impurity separation device for petroleum storage tanks

ActiveCN105854409BEasy to separateFast separationMagnetic separationFiltration circuitsBuffer stripEngineering

The invention discloses an impurity separating device used for a petroleum storage tank, and belongs to the field of petroleum storage tanks. The impurity separating device comprises a vertical spindle-shaped separator, wherein the separator is divided into a heavy impurity region, a middle impurity region and a light impurity region from top to bottom; a heavy impurity outlet is formed in the heavy impurity region; the light impurity outlet is formed in the light impurity region; a separating outlet and a separating inlet are separately formed in the opposite two sides of the middle impurity region; a buffer device is arranged in the middle impurity region and comprises a buffer frame and a plurality of flexible buffer strips; the buffer strips are vertically arranged in the separator and are fixed through the buffer frame. In the separator, impurities are quickly decelerated, so that vortexes can be formed in the areas of the buffer strips, the vortexes at different parts easily generate collision, the impurities with different weights are separated in the vortexes under the action of centrifugal force, and the impurity separating speed is increased by 3-5 times in comparison with that under the action of gravity. The spindle type design can reduce floor space of the impurity separating device, and can be beneficial for discharging separated impurities.

Owner:湛江港石化码头有限责任公司

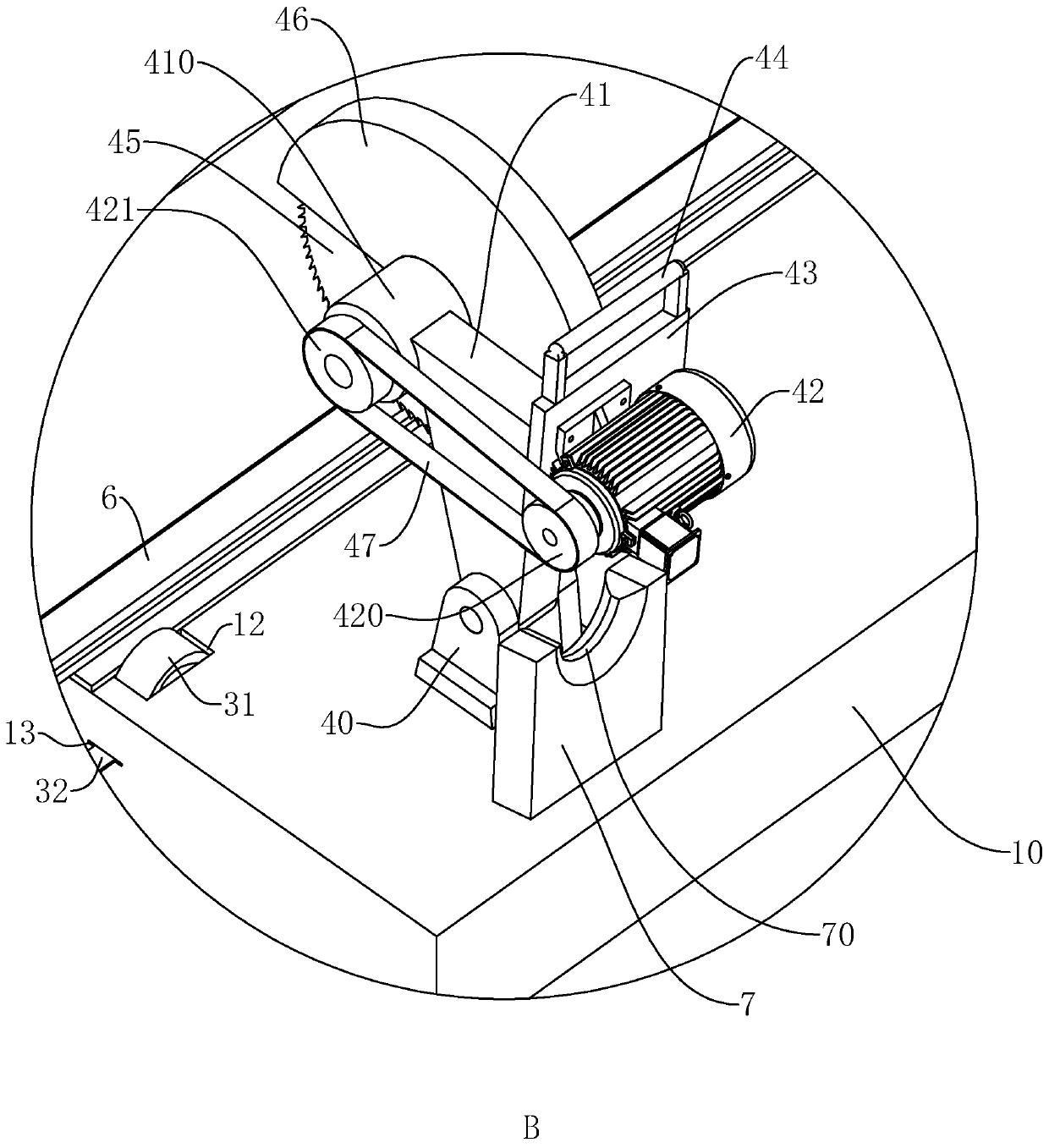

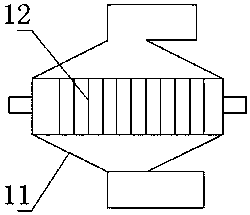

Automatic mud removing device of bucket wheel machine

InactiveCN113275343AImpact capacityResult in lower work efficiencyHollow article cleaningSoil-shifting machines/dredgersStructural engineeringBelt conveyor

The invention belongs to the technical field of bucket wheel machine mud removing, and particularly relates to an automatic mud removing device of a bucket wheel machine. The automatic mud removing device of the bucket wheel machine comprises a bucket wheel disc, evenly-distributed buckets are fixedly arranged on the outer wall of the bucket wheel disc, a bucket wheel supporting truss is fixedly arranged on the front side wall of the bucket wheel disc, a belt conveyor is fixedly arranged on the upper side wall of the bucket wheel supporting truss, and a material receiving hopper is fixedly arranged at the right end of the upper side wall of the belt conveyor and extends towards the position above the rear wall of the belt conveyor to the position below the buckets. A three-face scraper at the upper end is pushed through a scraper mechanism, the three-face scraper makes contact with the inner walls of the buckets, and wall scraping treatment is conducted on mud which is not dumped thoroughly in the buckets; and with rotation of the bucket wheel disc, the bucket wheel disc drives the buckets fixedly connected with the side walls to rotate, so that the three-face scraper treats the mud in the buckets sequentially and circularly, and the situation that after long-time use, a large amount of mud is attached to the inner walls of the buckets, the capacity of the buckets is affected, and the working efficiency is low is avoided.

Owner:张号召

Method and device for realizing discontinuous reception (DRX) function

ActiveCN102264148BReduce operating overheadImpact capacityConnection managementTimerDiscontinuous reception

The invention relates to the field of communication and discloses a method and a device for realizing a discontinuous reception (DRX) function, which are used for lowering operation cost of a system on the premise of not increasing equipment cost and not influencing cell capacity. The method comprises the following steps of: establishing DRX related timers for user equipment (UE) by using a base station when the UE accesses the system; and judging whether to schedule the UE or not only according to the states of the DRX related timers of the current UE to be scheduled in the current subframe before scheduling, instead of determining the states of the DRX related timers of all the UE. Therefore, by the method and the device, the operation cost of a network side can be effectively saved, resource waste of the system is avoided, the equipment cost of the network side cannot be increased, and the user capacity of cells cannot be influenced.

Owner:DATANG MOBILE COMM EQUIP CO LTD

An adjustable chemical plastic production granulator

The invention relates to a plastic granulator, in particular to an adjustable chemical plastic production granulator. The technical problem of the present invention is to provide an adjustable chemical plastic production granulator with variable speed and sustainable heating. The technical embodiment of the present invention is an adjustable chemical plastics production granulator, including a first support, a power mechanism, a stirring mechanism, a cutting mechanism, etc.; the power mechanism is fixedly installed on one side of the first support, and the stirring mechanism is fixed Installed on the side of the first bracket close to the power mechanism, the power mechanism is connected to the stirring mechanism, the cutting mechanism is installed on one side of the stirring mechanism, and the cutting mechanism is connected to an adjustment mechanism on a side away from the stirring mechanism. The invention adopts a heating column and an electric heating wire, and the heating column stirs the plastic while the stirring mechanism melts the chemical plastic at high temperature, which can prevent the plastic melt from sticking to the inside of the mixing barrel.

Owner:然石功能材料(江苏)有限公司

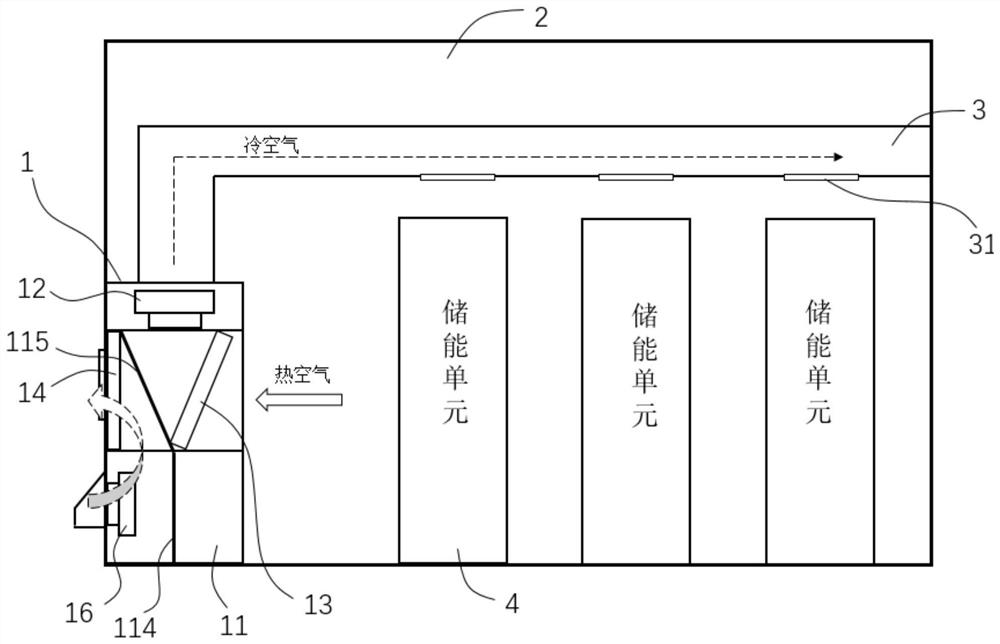

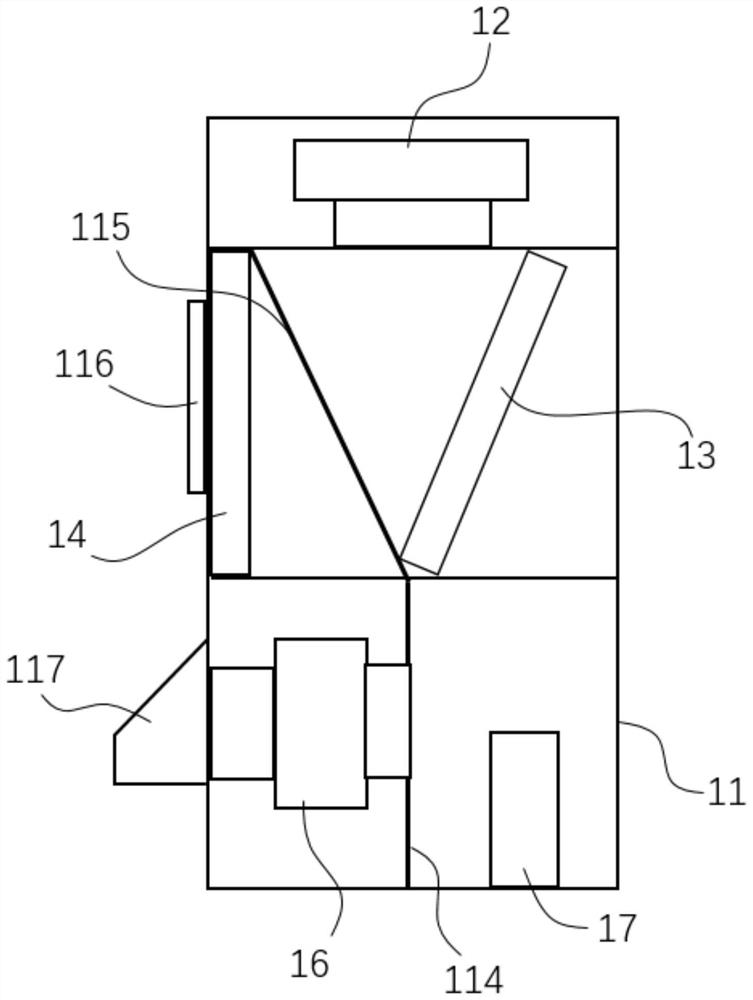

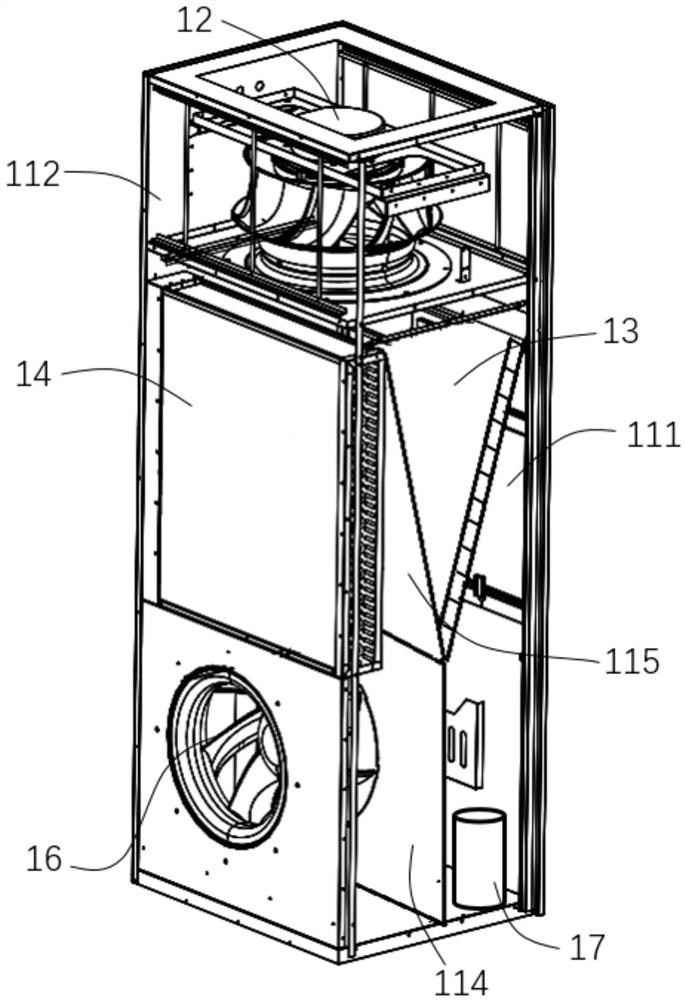

Air conditioner energy storage device

PendingCN113959026AImpact capacityAffect the service lifeFluid heatersMechanical apparatusCold airEngineering

The invention provides an air conditioner energy storage device. The air conditioner energy storage device comprises an air conditioner unit, a box body, an air duct and a plurality of energy storage units, the energy storage units and the air duct are located in the box body, the energy storage units are located below an air outlet of the air duct, and the air conditioner unit comprises a shell, an air feeder, an evaporator, a condenser, an expansion valve, an exhaust fan and a compressor, wherein, the air feeder is located at the top of the shell, and the air supply end of the air feeder is connected with the air duct; the evaporator is located in the middle of the shell; the condenser is located in the middle of the shell; one end of the expansion valve is connected with the condenser, and other end of the expansion valve is connected with the evaporator; the exhaust fan is located on the lower portion of the shell, and the exhaust end of the exhaust fan communicates with a first ventilation opening of the box body; and the compressor is located on the lower portion of the shell, one end of the compressor is connected with the condenser, and the other end of the condenser is connected with the evaporator. In the air conditioner energy storage device, the air conditioner unit converts hot air generated by the energy storage units into cold air, then the cold air is transmitted to the energy storage units through the air duct, the energy storage units are cooled, and the situation that the capacity and the service life are affected due to the fact that the temperature of the energy storage units is too high is prevented.

Owner:NANTONG HUAXIN CENT AIR CONDITIONER

A method for online full inspection of battery positive plate weight

ActiveCN107560697BSimple methodAccurate dataSpecial purpose weighing apparatusElectrical batteryEngineering

The invention provides an on-line and full-inspection method for the weight of a battery positive plate. According to the method, the average value M01 of the actual basis weight of a positive plate corresponding to each volume of the foam nickel is measured and calculated according to the size of the positive plate and the rolling elongation percentage of the foam nickel. The average value M01 ofthe actual basis weight of the positive plate and the weight grading standard of active materials filled in the positive plate are input into a management system. After that, an ID number is marked on each positive plate, and the weight M1 of the single positive plate is weighed. The ID number on the positive plate is read by an instrument. The management system calculates to obtain the weight Mof active materials filled in the positive plate according to a preset formula M=M1-M01. The weight M1 of the positive plate, the weight M of active materials filled in the positive plate, and the IDnumber on the positive plate are stored in the one-to-one correspondence manner. Finally, the management system grades the positive plate according to the input weight grading standard of active materials filled in the positive plate. The method is simple, and positive plates can be graded more accurately. By adopting the method, the capacity consistency of batteries prepared by adopting electrodeplates graded by the present invention is better.

Owner:先进储能材料国家工程研究中心有限责任公司

A handover method in CDMA system

InactiveCN100387094CReduce distractionsImpact capacityCode division multiplexRadio/inductive link selection arrangementsCode division multiple accessHandover

A handover method in CDMA system, which contains 1, RNC receiving the cache shared UE upload measurement report of cofrequency cell, 2, judging whether activation non cofrequency is needed, if it is then followed by step 3, otherwise ending said process, 3, RNC constructing non cofrequency switching reference group according to UE state and cache cofrequency measurement report, 4, RNC generating non cofrequency candidate cell group according to the intersection of near cell in centralized cell, 5, selecting high priority non cofrequency candidate cell as destination cell to activate non cofrequency switching.

Owner:HUAWEI TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com