Patents

Literature

668results about How to "Guaranteed capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Transmitting and receiving device and method for continuous outer-loop power control while in DTX mode in a CDMA mobile communication system

InactiveUS6950632B1Shorten the timeMinimize the total transmit powerEnergy efficient ICTPower managementPower controllerSignal-to-noise ratio (imaging)

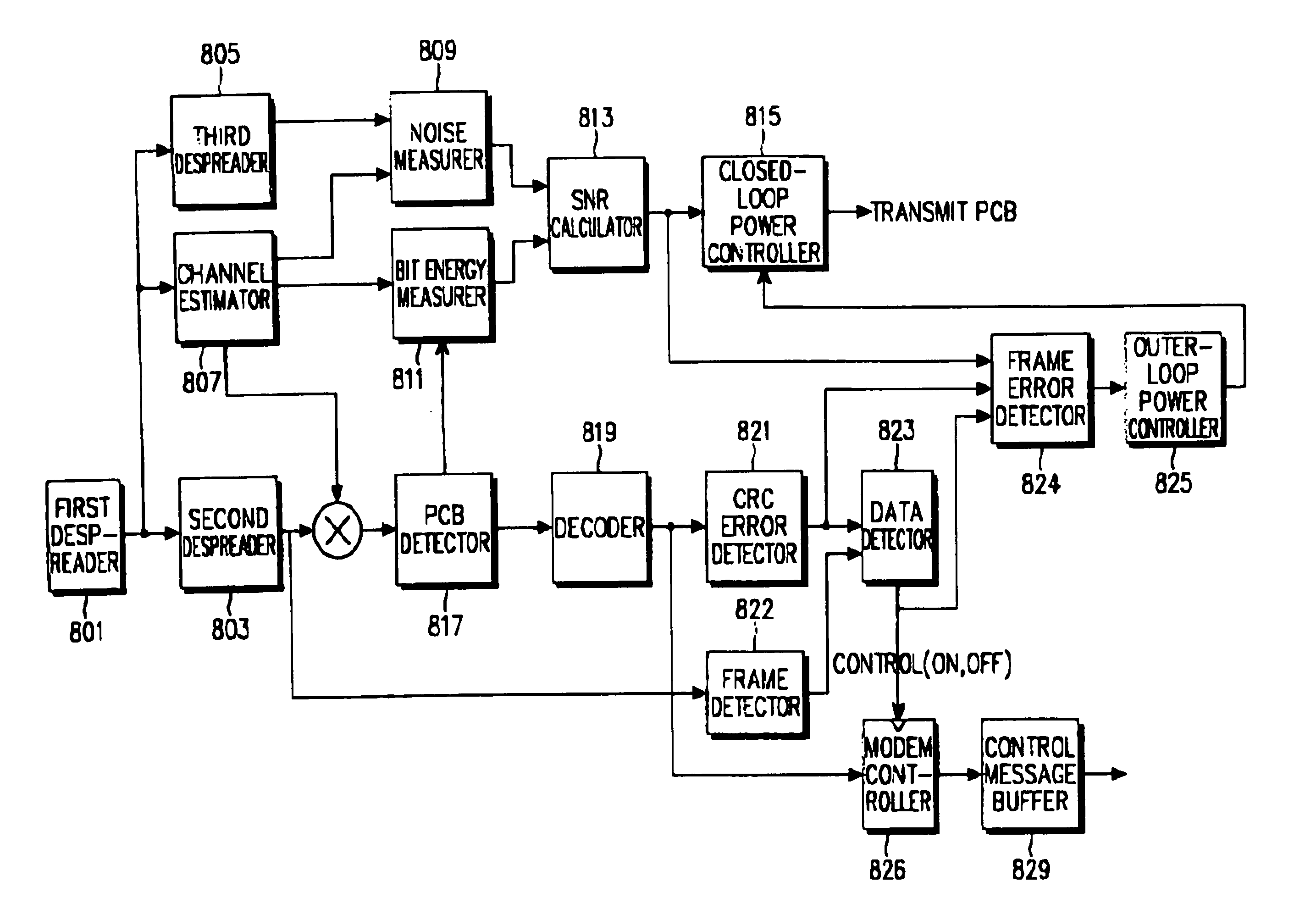

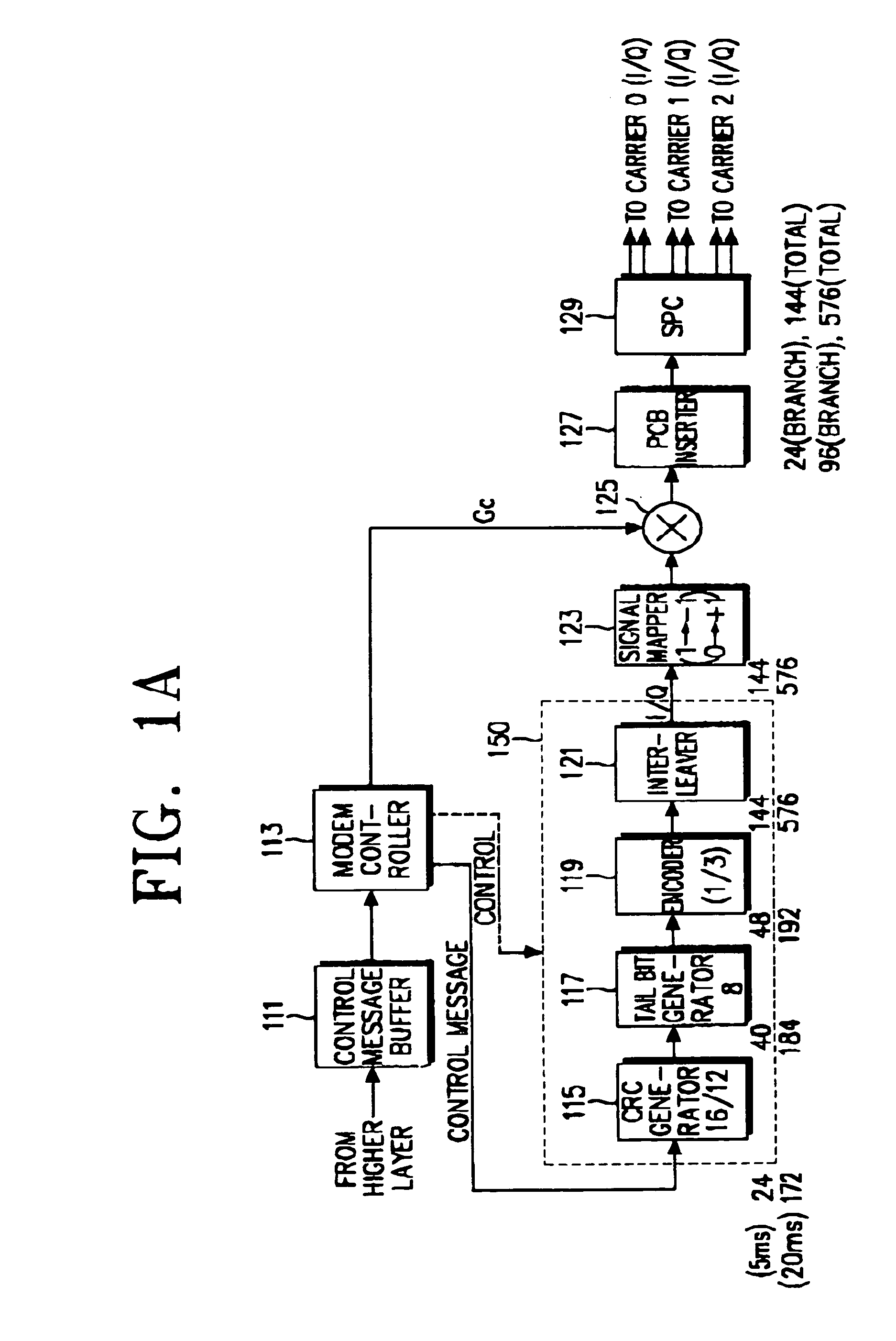

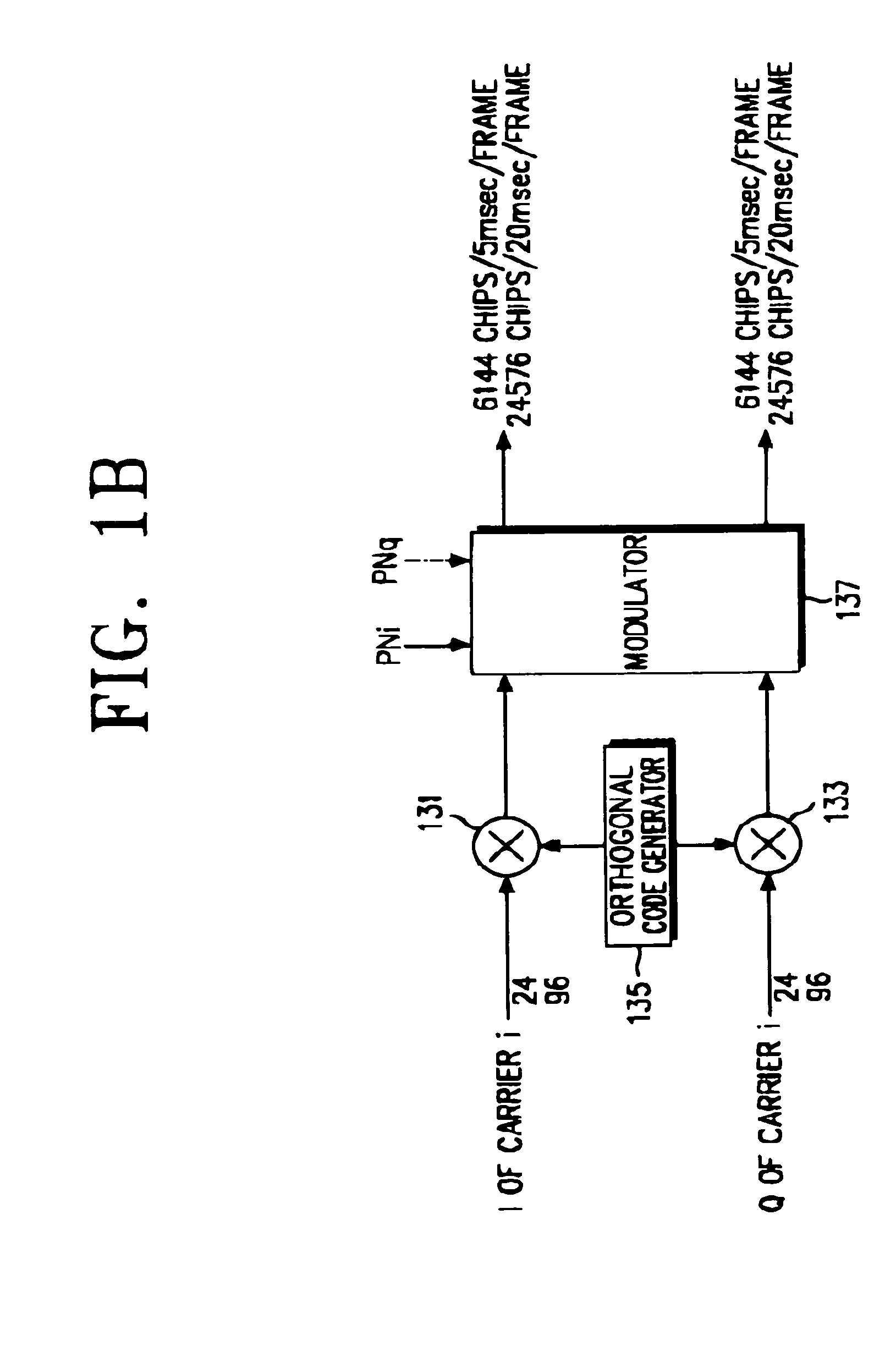

A device and method for continuous outer-loop power control on a physical channel which transmits only power control bits and no data while in discontinuous transmission (DTX) mode in a CDMA mobile communication system is disclosed. In the power controlling device according to one aspect of the present invention, a frame error detector detects an error from a frame of predetermined length and generates an error signal indicating whether an error has been generated. A closed-loop power controller compares a threshold with the signal-to-noise ratio (SNR) in each power control group (PCG) in a plurality of periods of the frame and generates power control information according to the comparison result. An outer-loop power controller increases the threshold in order to generate power control information that commands a power increase in response to an error signal indicating the existence of a frame error, and decreases the threshold in order to generate power control information that commands a power decrease in response to an error signal indicating the absence of a frame error. An offset controlling unit, which is connected to the outer-loop power controller, receives gating information about the gated transmission of data in a frame at a predetermined rate, and generates an offset signal, which indicates an offset corresponding to a changed gating rate if the gating rate is changed.

Owner:SAMSUNG ELECTRONICS CO LTD

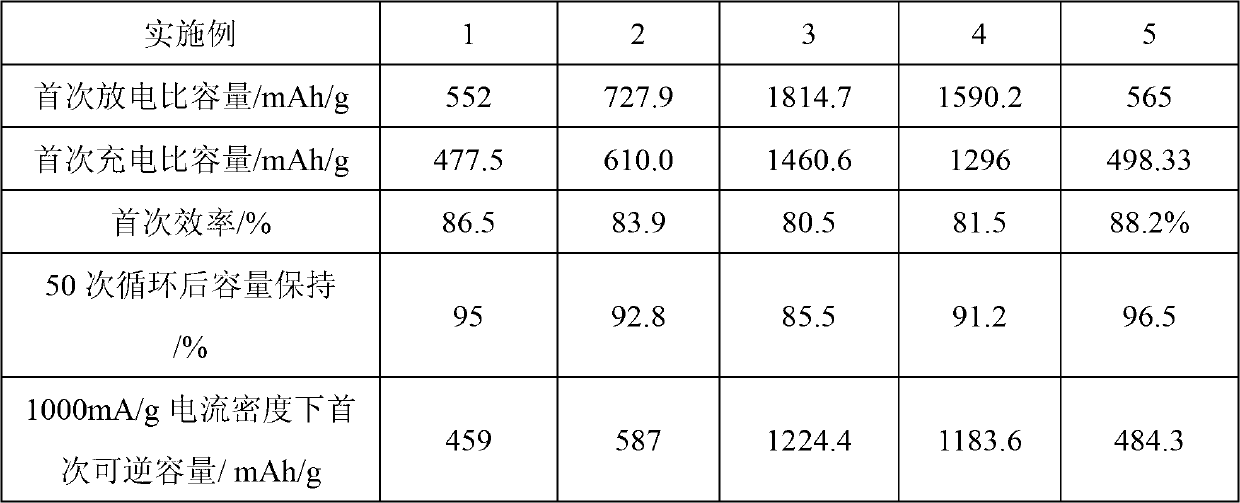

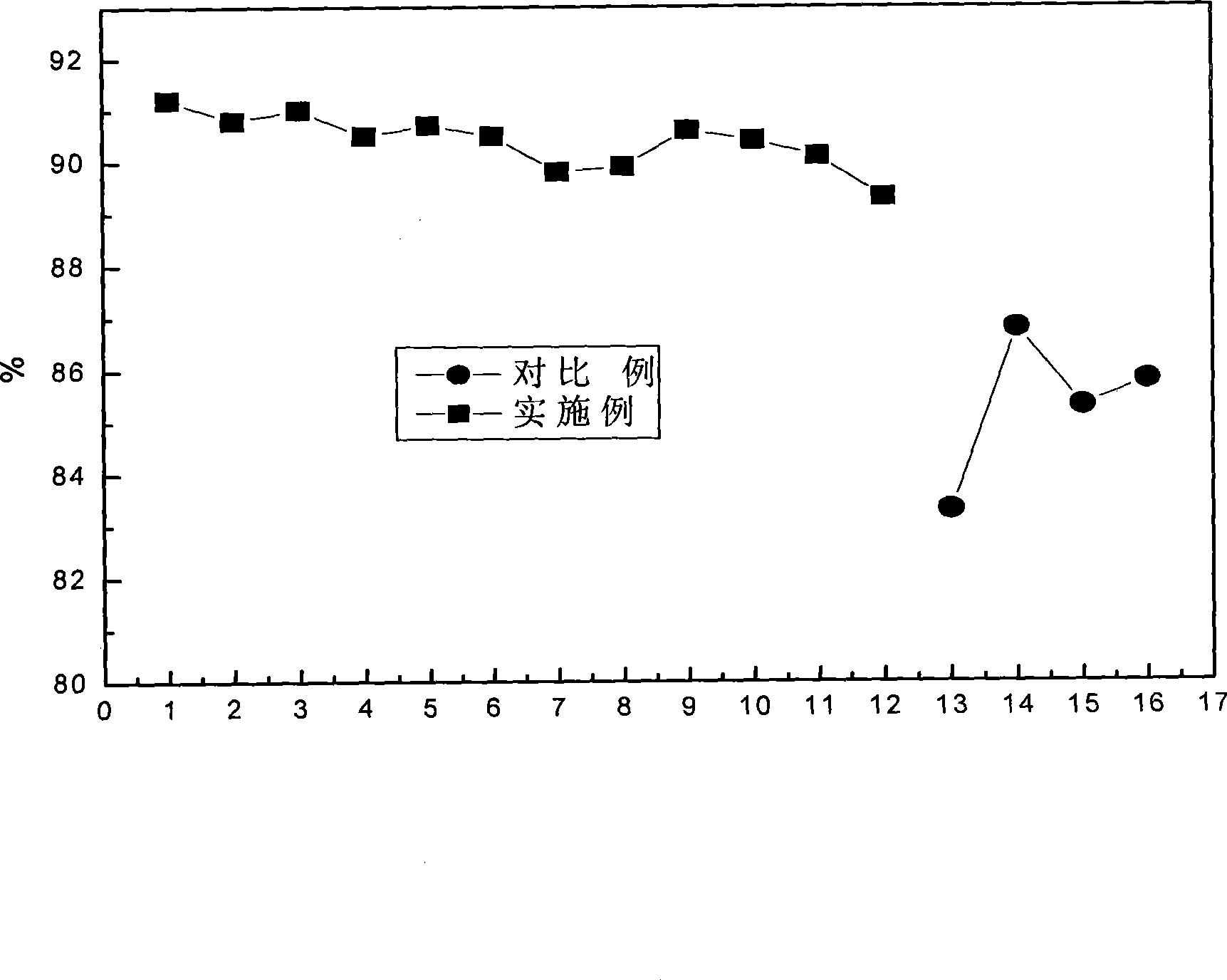

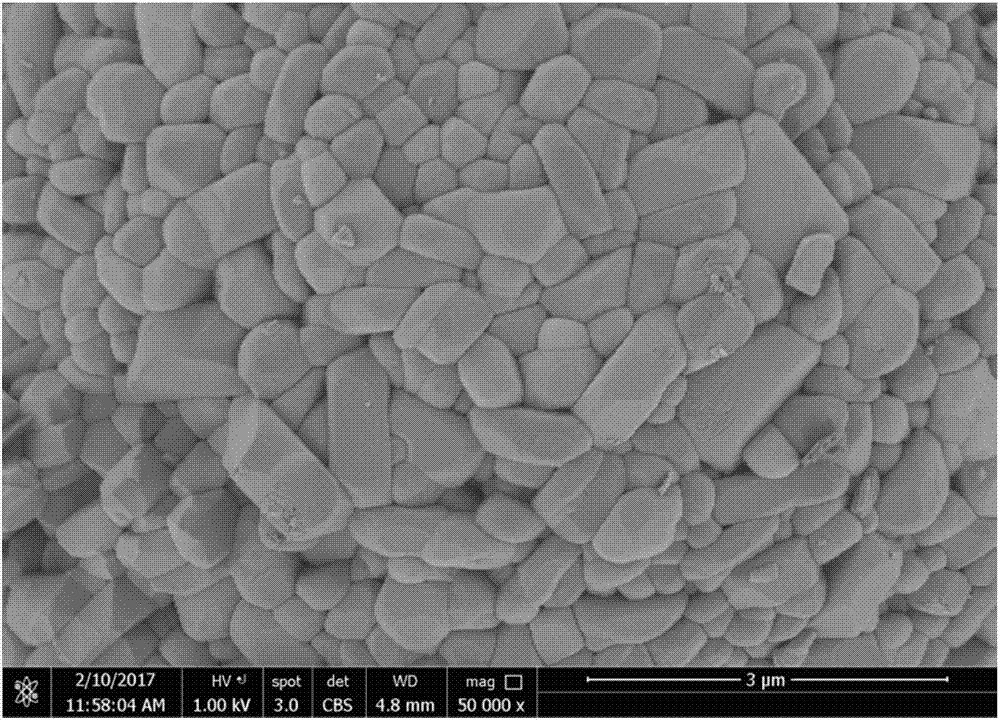

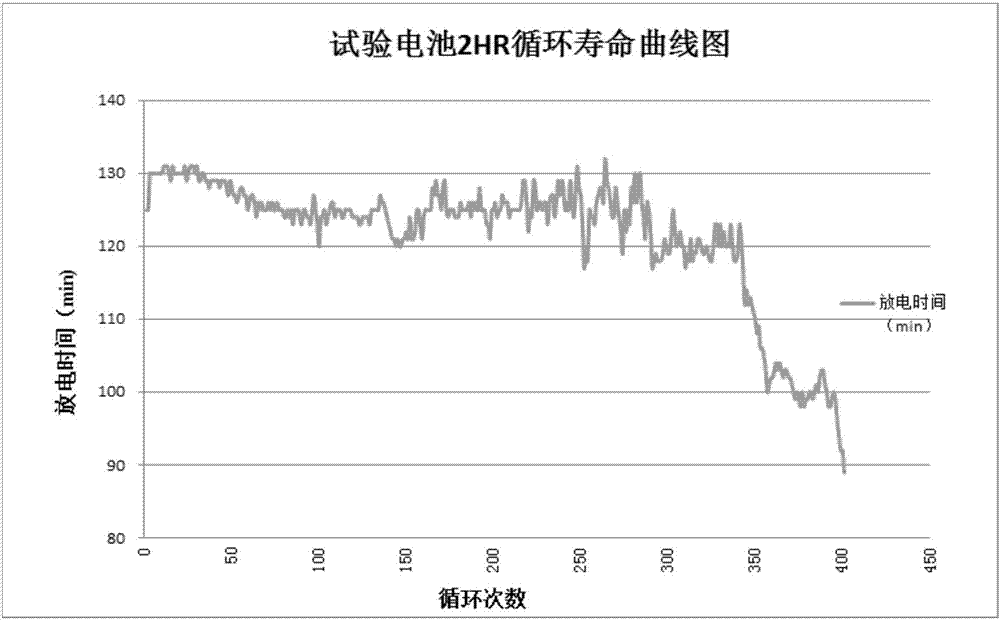

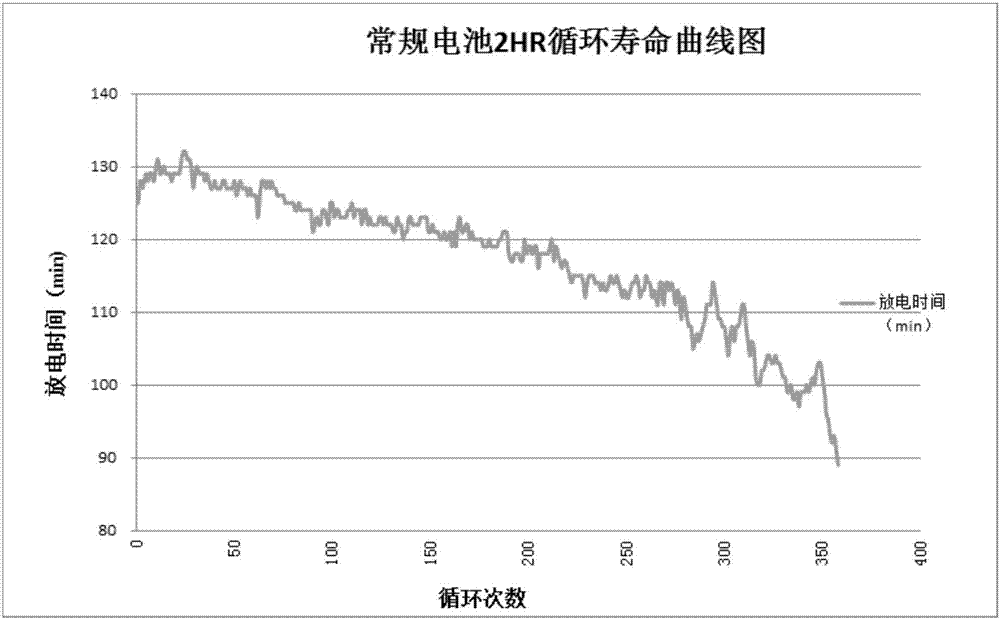

Graded high-nickel ternary anode material, and preparation method and application thereof

InactiveCN109888235AImprove compactionImprove cycle stabilityCell electrodesSecondary cellsSingle crystalMixed materials

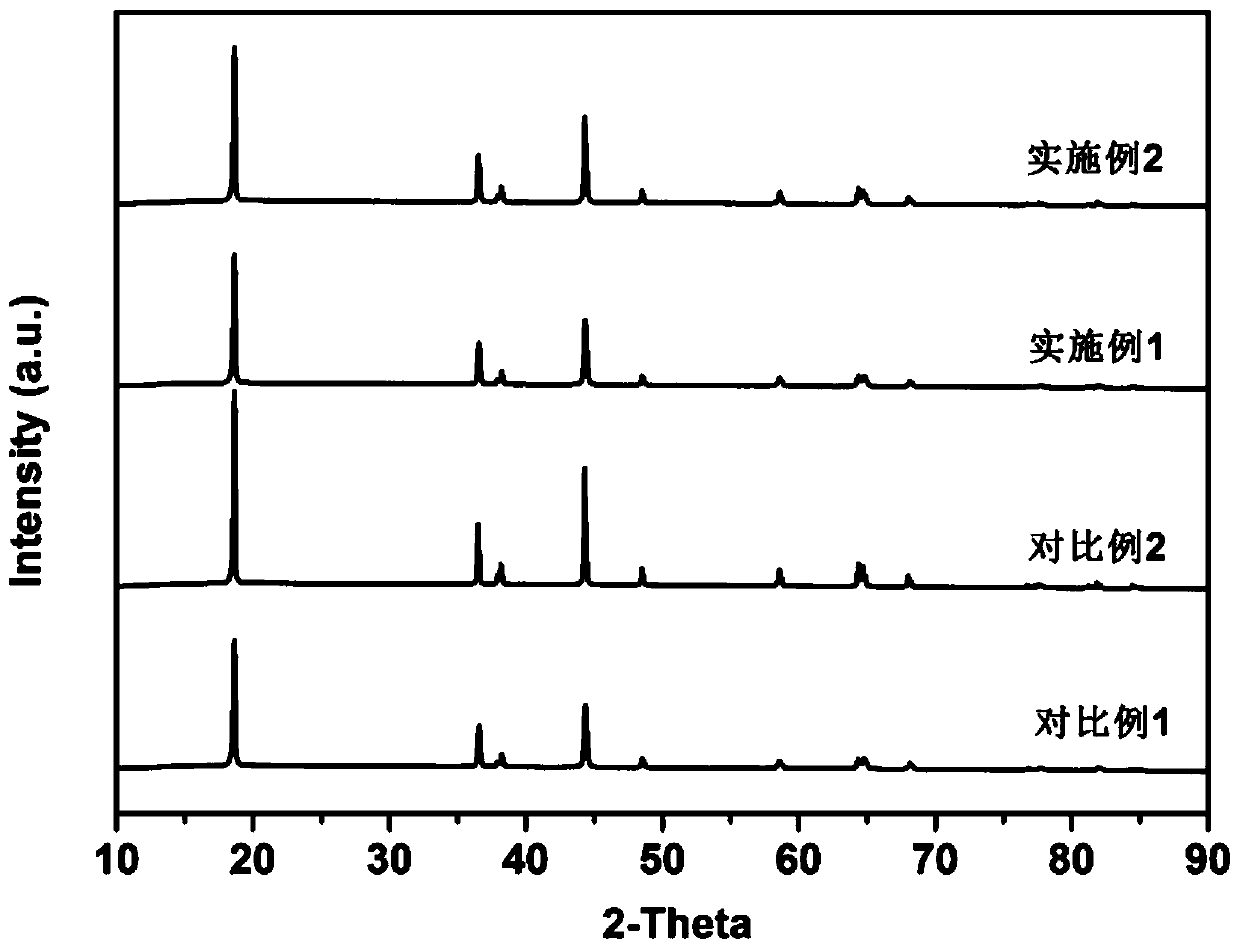

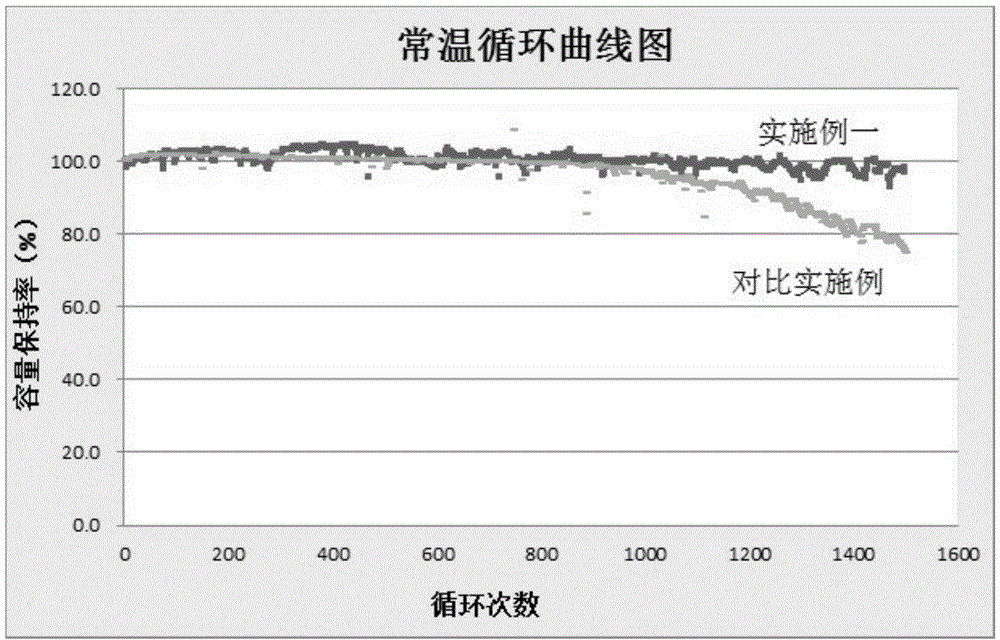

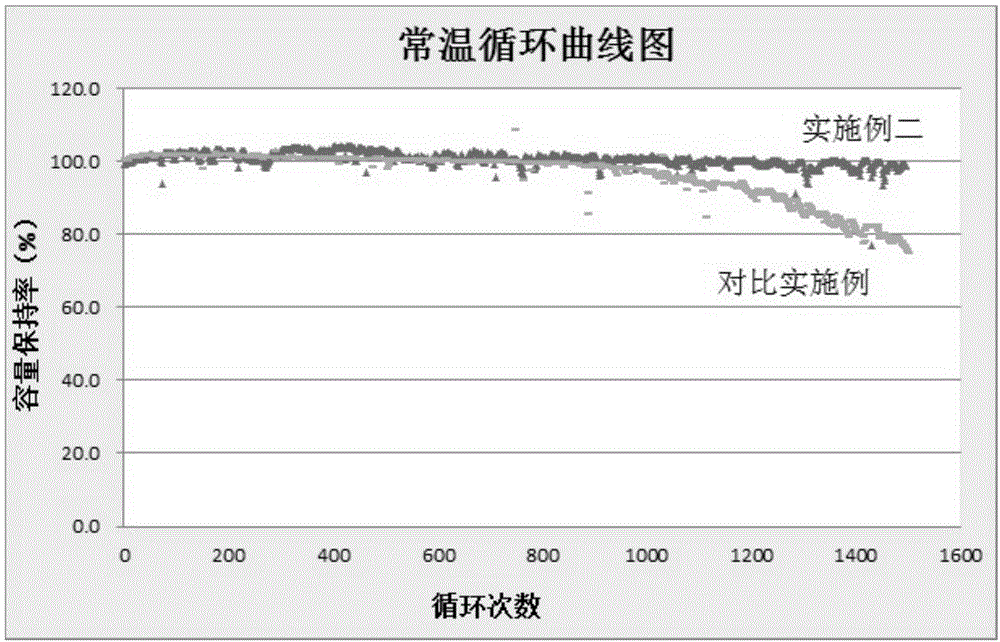

The invention discloses a graded high-nickel ternary anode material, and a preparation method and an application thereof. The graded high-nickel ternary anode material is prepared by the following method: 1) mixing a high-nickel polycrystalline precursor with anhydrous LiOH and a doping additive, performing sintering, mixing the obtained product with a coating additive, and performing sintering toobtain a high-nickel polycrystalline material; 2) mixing a ternary monocrystalline silicon precursor with a lithium source and the doping additive, performing sintering, mixing the obtained product with the coating additive, and performing sintering to obtain a ternary monocrystalline silicon material; and 3) mixing the high-nickel polycrystalline material with the ternary monocrystalline siliconmaterial, or mixing the mixed material with the coating additive, and then performing sintering. The invention further discloses an application of the graded high-nickel ternary anode material in lithium batteries. The graded material prepared by the method provided by the invention has higher compaction and cycle stability than the single polycrystalline material, has higher capacity than the single monocrystalline silicon, and the gas production and service life problems of the battery can be effectively improved after the grading modification.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

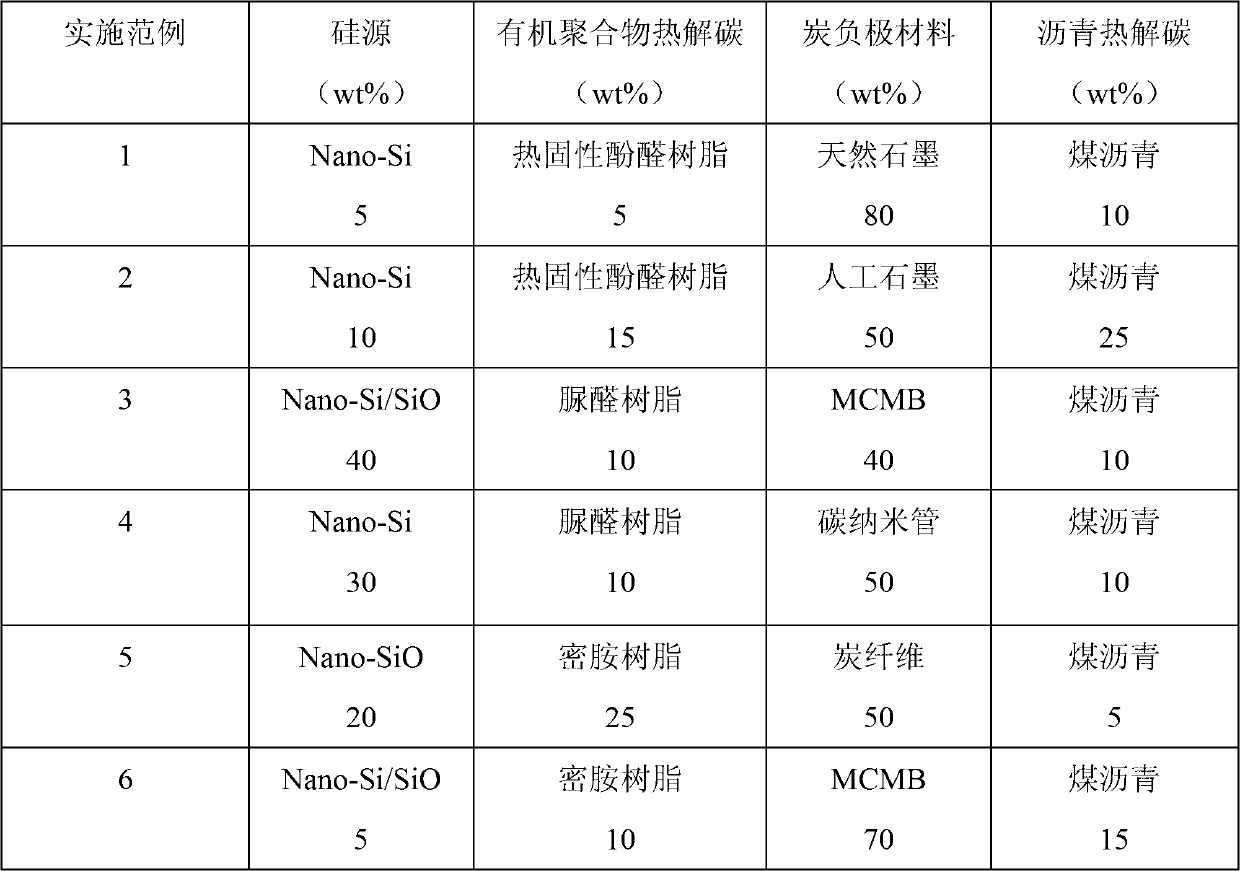

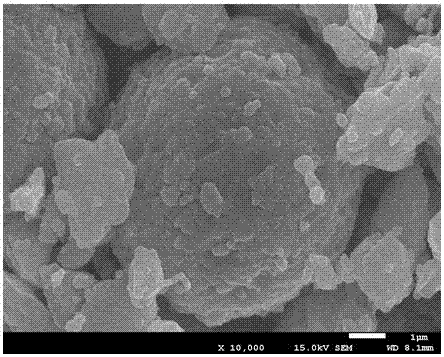

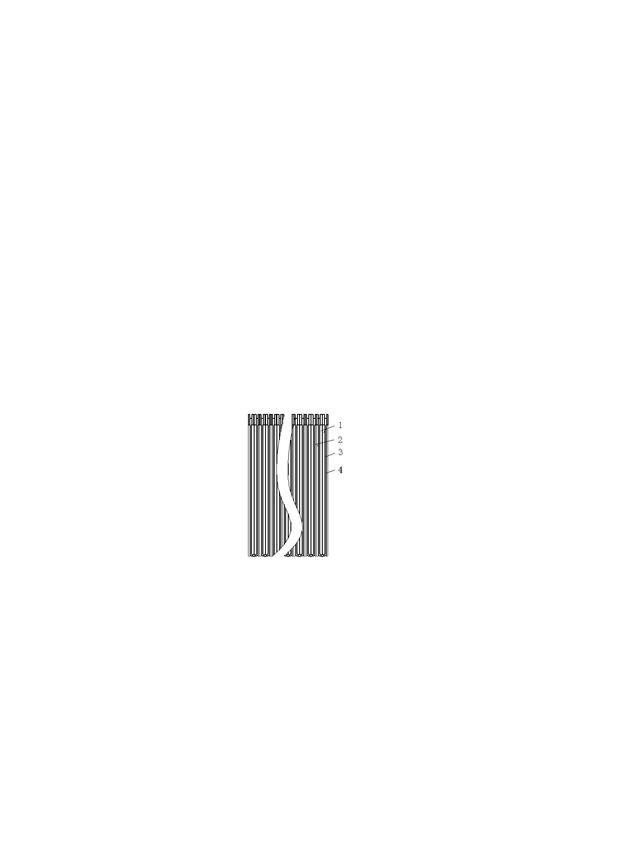

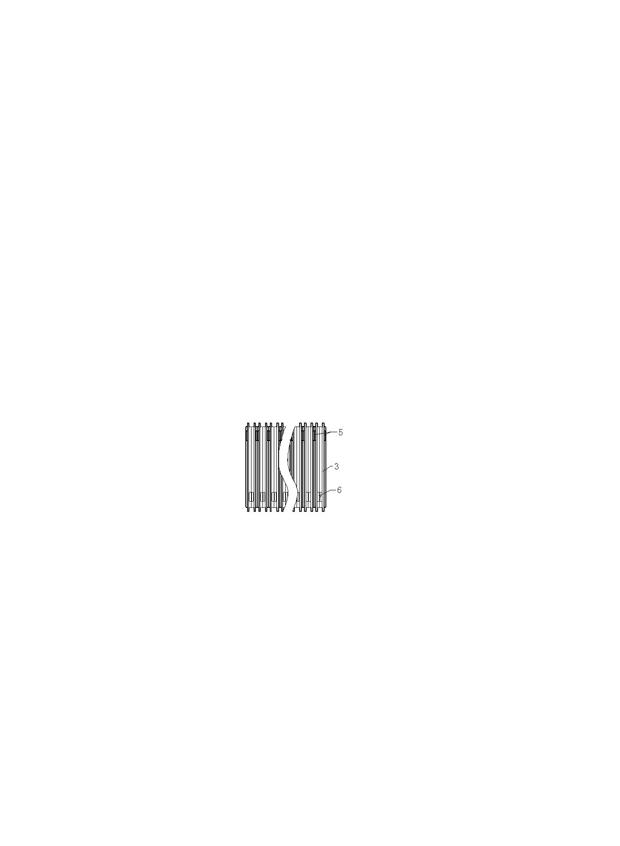

Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

The invention relates to a multi-core core-shell-structure silicon carbon composite negative pole material and a preparation method thereof. The preparation method comprises the following steps: 1. preparation method of high-dispersivity multi-core porous spheres; 2. preparation of high-dispersivity asphalt suspension; and 3. preparation of multi-core core-shell-structure silicon carbon composite negative pole material: adding the porous spheres prepared in the step 1 into the high-dispersivity asphalt suspension prepared in the step 2, carrying out ultrasonic dispersion, heating and drying by distillation while intensely stirring to remove the solvent, transferring the powder particles into a protective atmosphere, and holding at low temperature so that the asphalt liquid enters the inside of the porous spheres to enhance the binding strength between the silicon source and the conducting carbon mesh, carry out secondary coating on the silicon source, overcome the defects in the coating in the step 1 and enhance the capacity performance of the silicon; and carrying out high-heat treatment. The invention is simple and easy to implement, and has the advantage of high practicality. The prepared silicon carbon composite material has the advantages of high reversible capacity, designable capacity, favorable cycle performance, favorable heavy-current discharge capacity, high tap density and the like.

Owner:CENT SOUTH UNIV

Lithium ion secondary battery using lithium iron phosphate as anode material with overall consideration of high and low temperature performance

InactiveCN101394008AExtended operating temperature rangeWide temperature rangeSecondary cellsPhosphateEthyl butyrate

The invention discloses an aqueous electrolyte solution of a secondary lithium ion battery with ferric phosphate considering as the positive material and with both the high temperature performance and the low temperature performance. The aqueous electrolyte solution comprises LiPF6 lithium salt, an organic solvent and a film-forming additive, and is characterized in that the electrolyte solution further comprises high temperature additive; the organic solvent is composed of one or a plurality of carbonic esters and one or more carboxylic esters with low melting point and high boiling point. The carboxylic esters with low melting point and high boiling point are selected from one or a combination of methyl butyrate, ethyl butyrate, propyl butyrate and butyl acetate. The high temperature additive is 1, 3- propane sultone and 1, 4- butane sultone. The electrolyte solution is used for maintaining both the circulation performance in a high temperature state and the low temperature laying performance of the secondary lithium ion battery with the ferric phosphate lithium as the positive material.

Owner:GUANGZHOU TINCI MATERIALS TECH

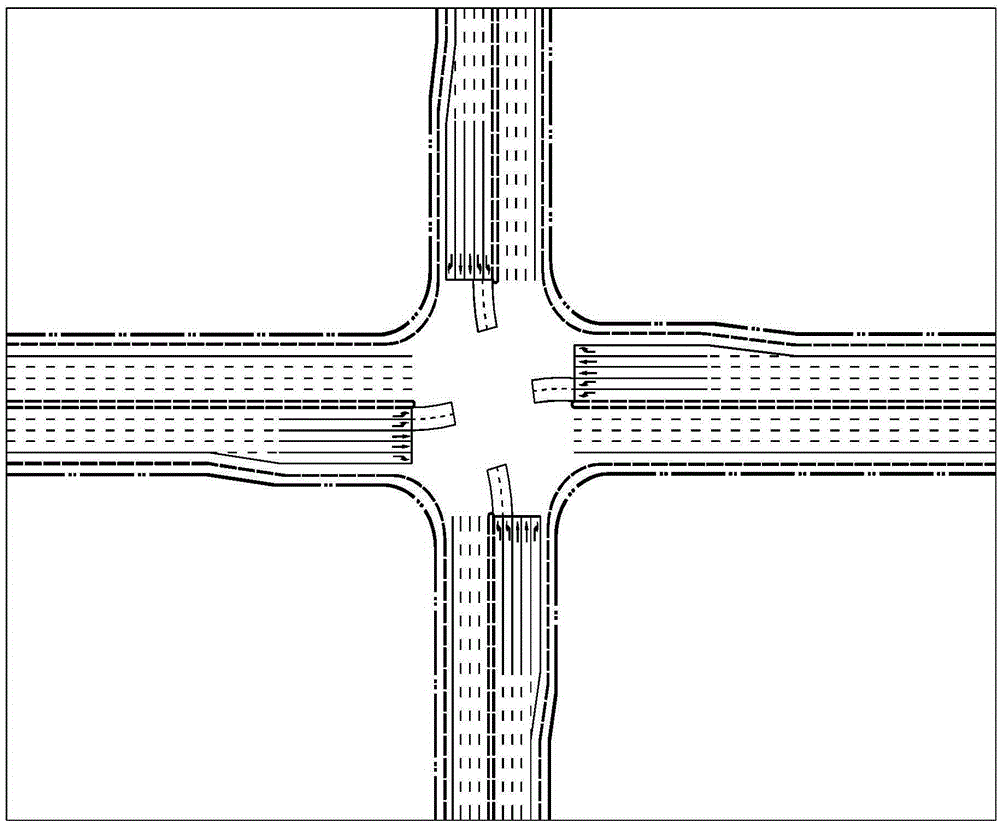

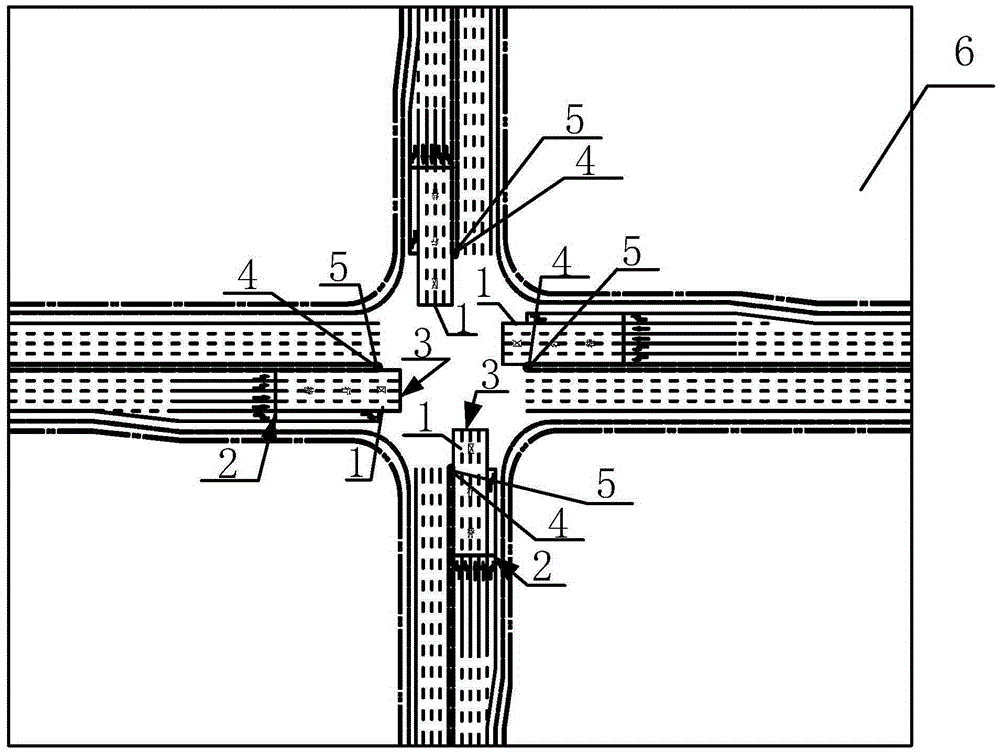

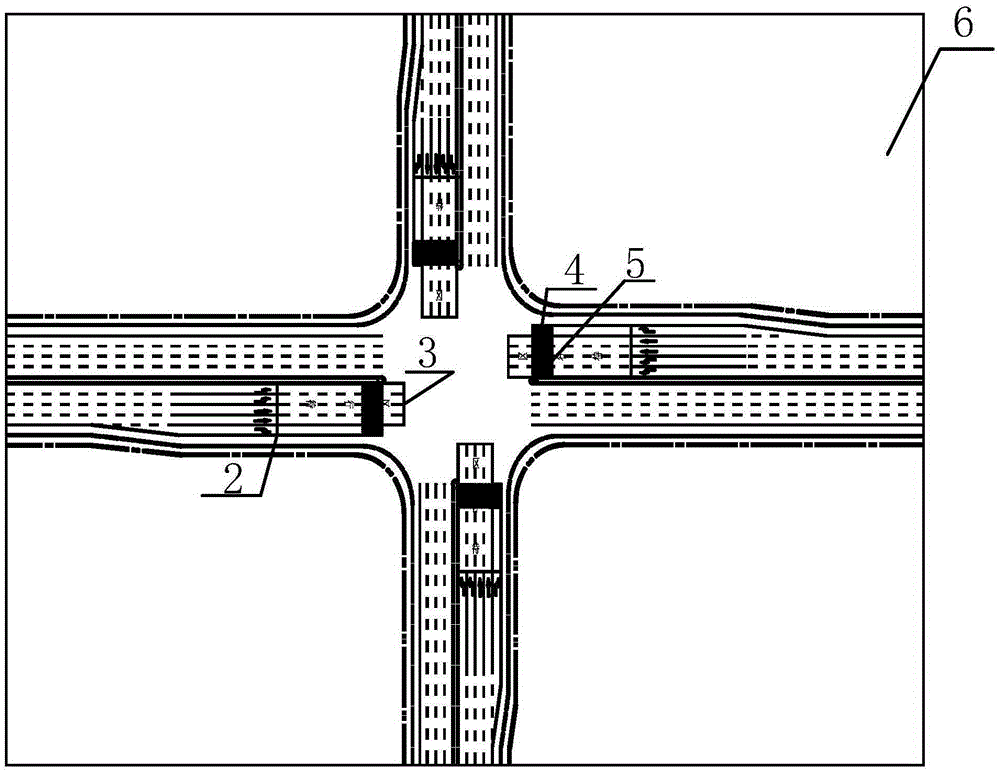

Traffic flow capacity increasing control method for comprehensive waiting area at road intersection

ActiveCN105389973AImprove traffic capacityImprove road storage capacityRoad vehicles traffic controlRoad crossingTraffic capacity

The invention discloses a traffic flow capacity increasing control method for a comprehensive waiting area at a road intersection, comprising the following steps: S1, adding a comprehensive waiting area, setting a primary stopping line and a secondary stopping line at the end of the comprehensive waiting area, and setting the distance between the primary stopping line and the secondary stopping line as the length of the comprehensive waiting area; and S2, adding a variable information board, pre-signal lamps and an induction coil buried under the road surface to the medial strip of the road opposite the comprehensive waiting area, wherein the pre-signal lamps include a pre-signal red lamp and a pre-signal green lamp, and the pre-signal red lamp goes on 10-12 seconds earlier than an original go-straight or turn-left traffic signal green lamp at the intersection. By adopting the method of the invention, the traffic capacity of the intersection is improved greatly, and the space resources of the intersection are prevented from lying idle.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

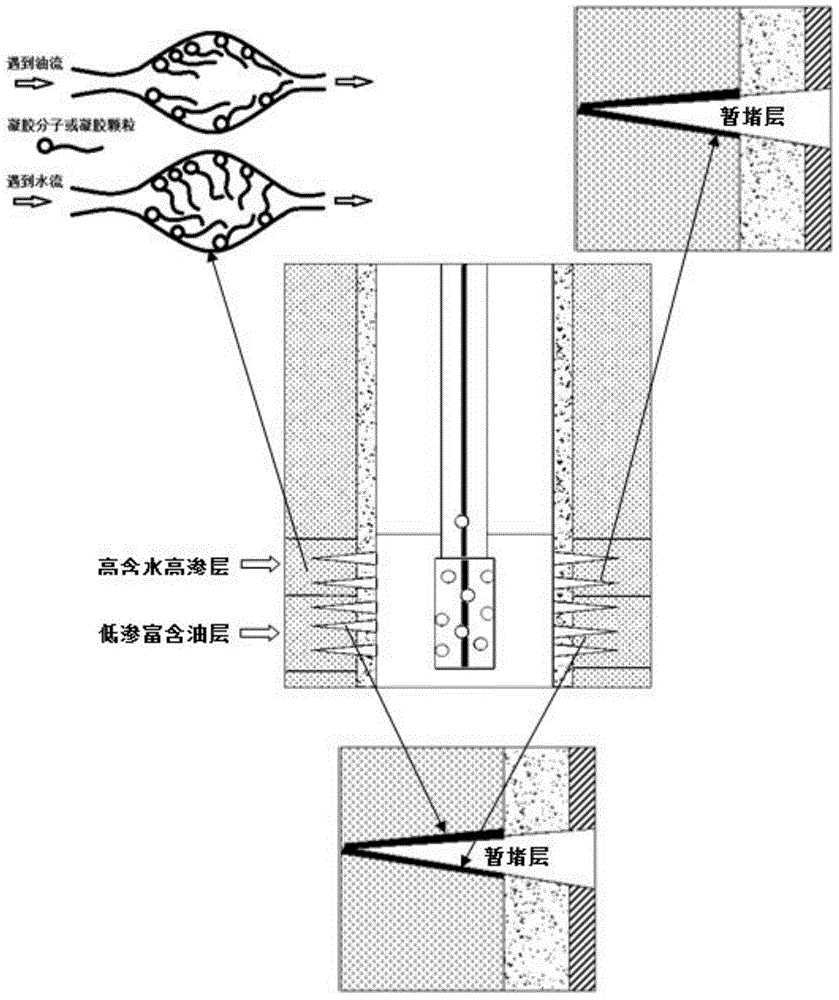

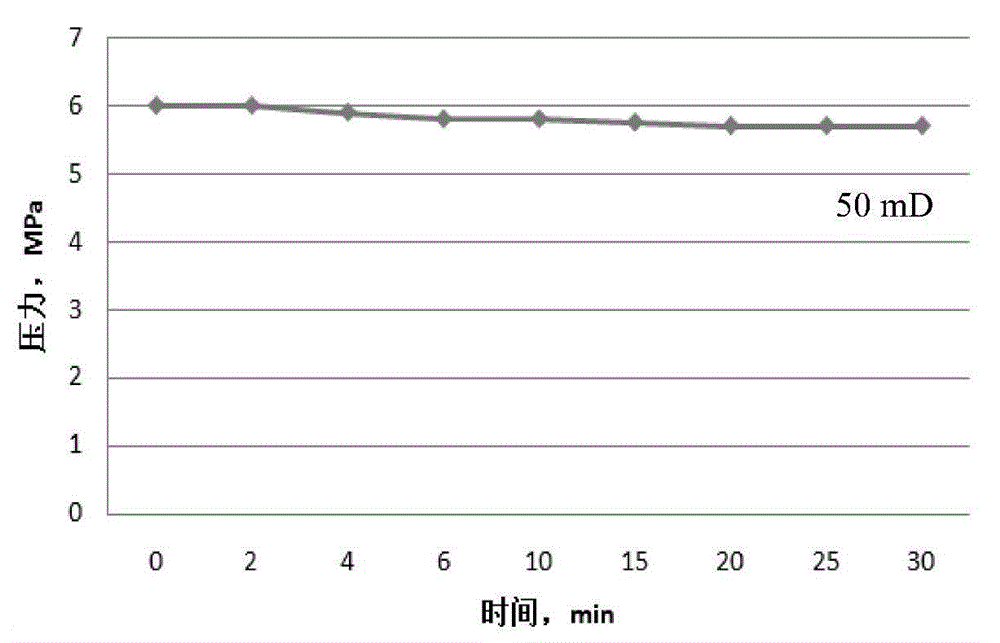

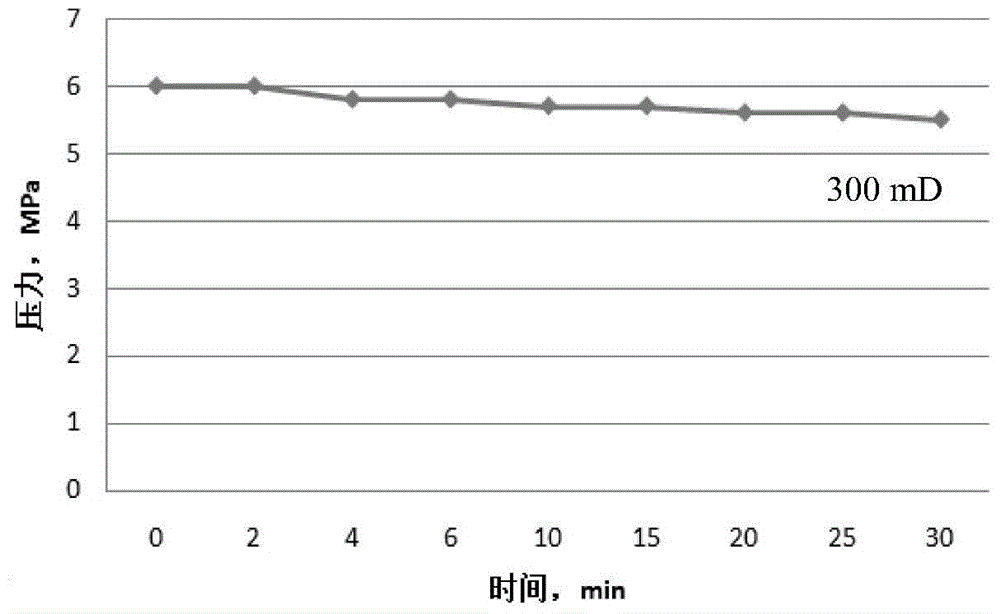

Well-killing workover method used with water plugging

InactiveCN105041261AFew componentsSimple on-site configurationDrilling compositionSealing/packingPolymer gelOil well

The invention discloses a well-killing workover method used with water plugging. The well-killing workover method sequentially comprises the following steps of (1) calculating the use level of required well-killing fluid according to volume of a shaft; (2) determining the density of the well-killing fluid according to formation pressure; (3) determining polymer gel formula which is not easy to degrade in an operation period at formation temperature according to the formation temperature, or determining a gel particle type matched with the size of a pore throat according to characteristics of porosity-permeability of a reservoir; (4) preparing polymer gel or gel particle liquor; and (5) pumping the well-killing fluid into the shaft to perform underground construction operation. By the well-killing workover method, thinking limitation that temporary plugging or lost circulation prevention is often used to recover capacity in existing well-killing workover is overcome, the polymer gel or gel particles with a selective water plugging function serves as the well-killing fluid, two yield increasing technologies comprising oil well water plugging and reservoir temporary plugging protection are combined, a synergistic effect of the two yield increasing technologies is achieved, the capacity after workover of an oil well is improved to a maximum extent, and the well-killing workover method has a wide application prospect in the field of workover of intermediate-high water cut oilfields.

Owner:SOUTHWEST PETROLEUM UNIV

Multi-point radio transmission relay system and wirless device

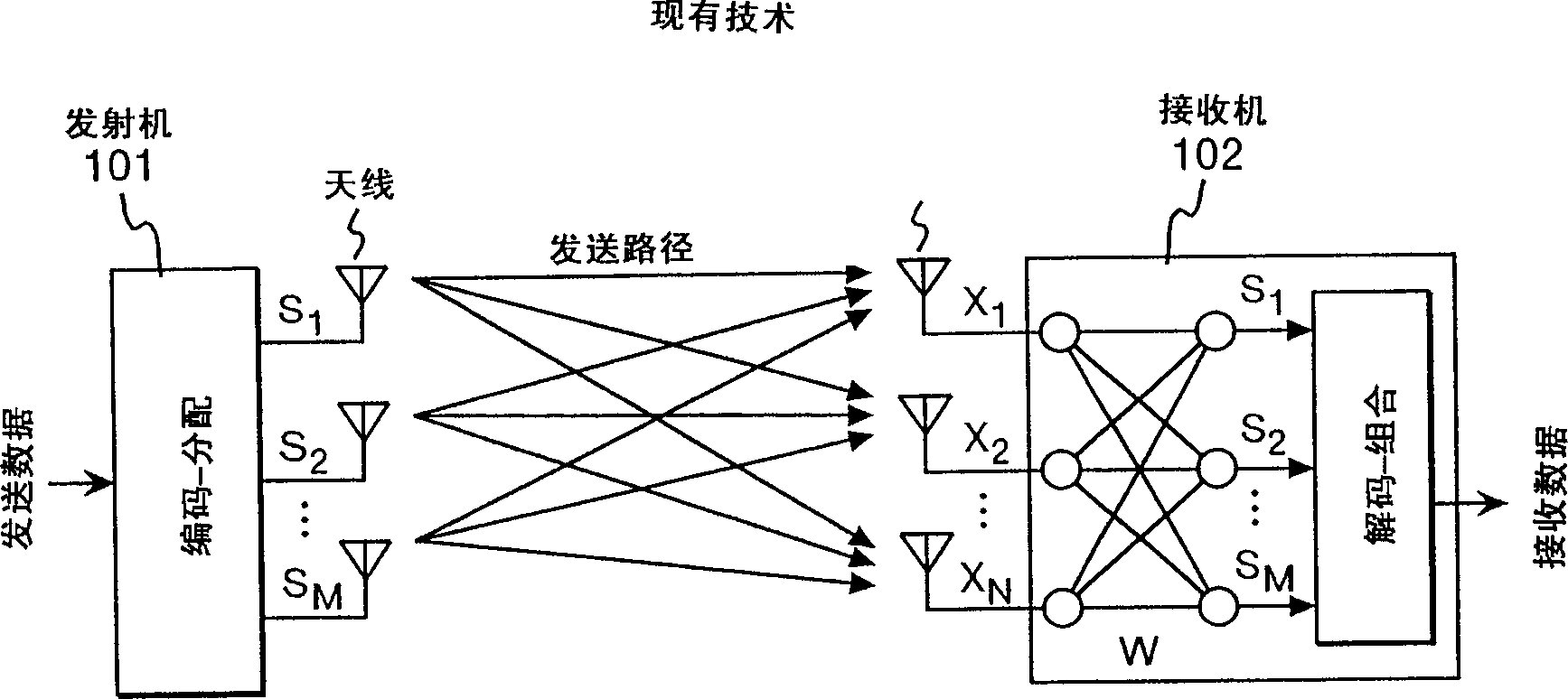

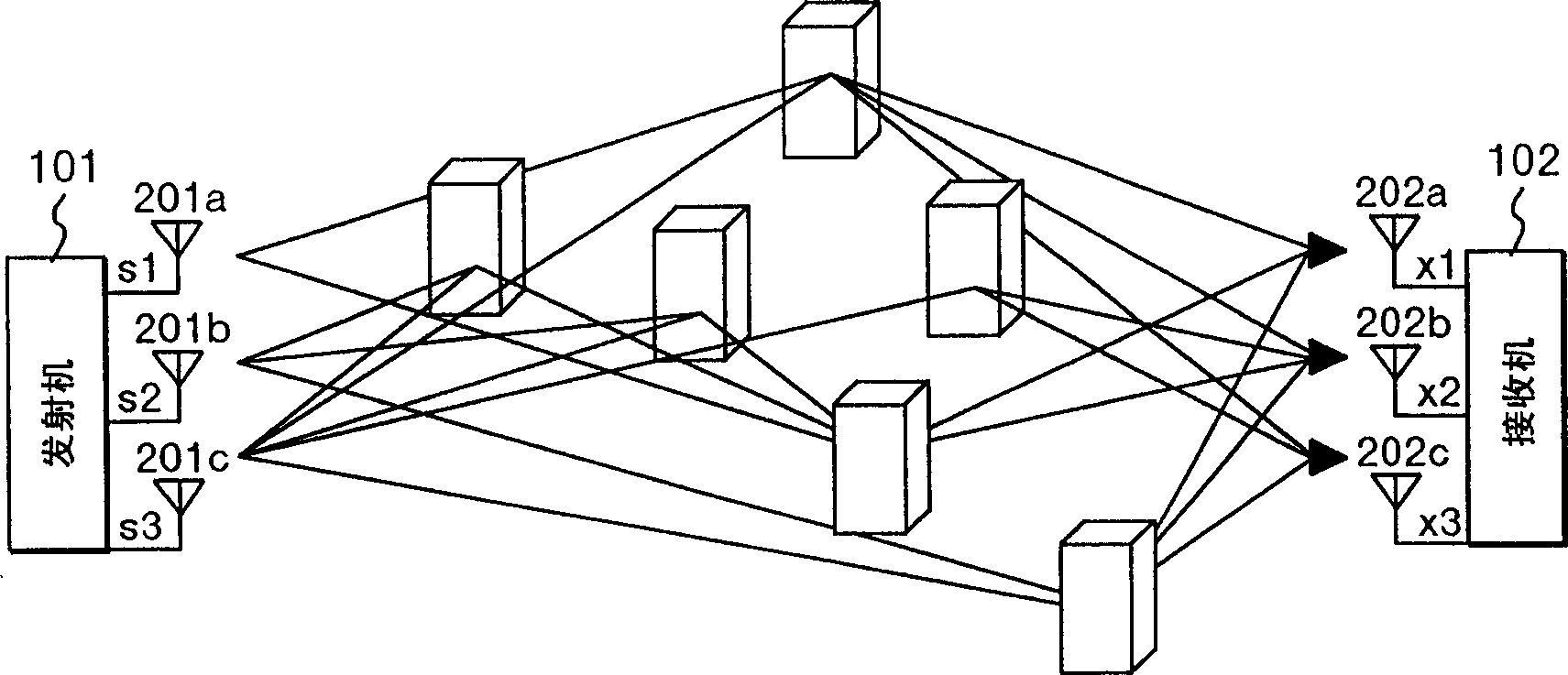

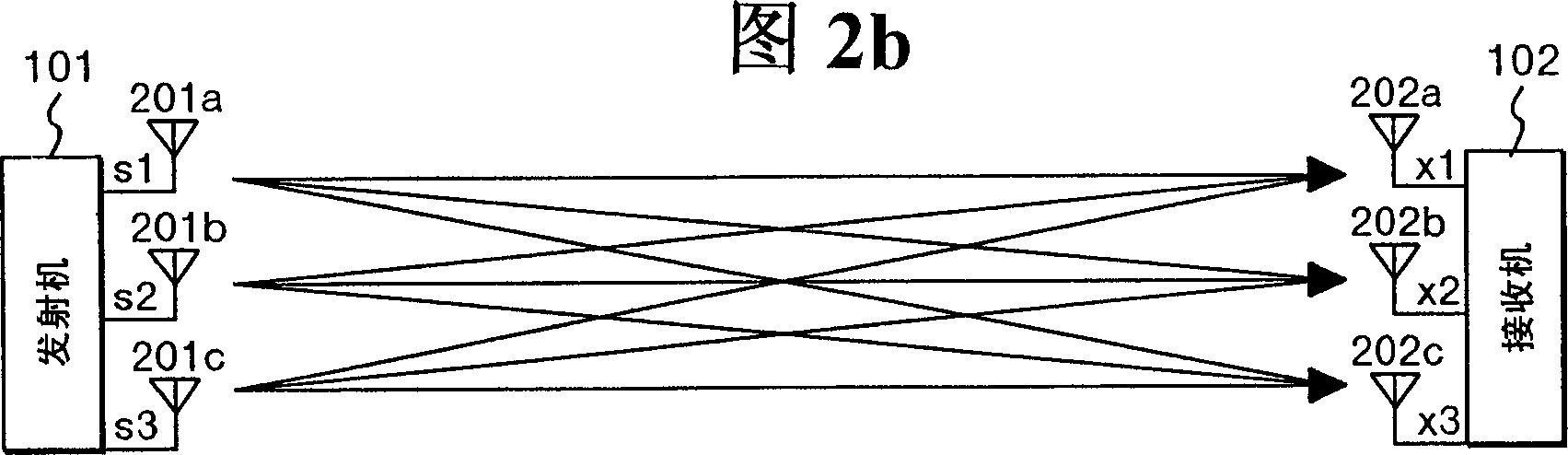

InactiveCN1428943AGuaranteed capacitySpatial transmit diversityActive radio relay systemsControl signalEngineering

A communication system having an excellent communication path capacity characteristic even in an insight transmission environment in which a transmitter and a receiver can see each other directly in an MIMO communication system and a wireless communication device for the communication system, including: a wireless device having a transmitter for distributing transmission data including encoded data and a training signal to a plurality of antennas, and transmitting the data as radio signals from the plurality of antennas at a predetermined timing; a plurality of wireless devices having repeaters each for receiving the radio signal, storing the radio signal into a buffer so that the radio signal is delayed by predetermined time, and transmitting the radio signal delayed; and a wireless device having a receiver for receiving the radio signals from the plurality of second wireless devices by a plurality of antennas and demodulating the encoded data by using the training signal multiplexed on the received radio signal. Each wireless device determines whether relaying operation is necessary or not and transmits a control signal for controlling the relaying operation.

Owner:HITACHI LTD +1

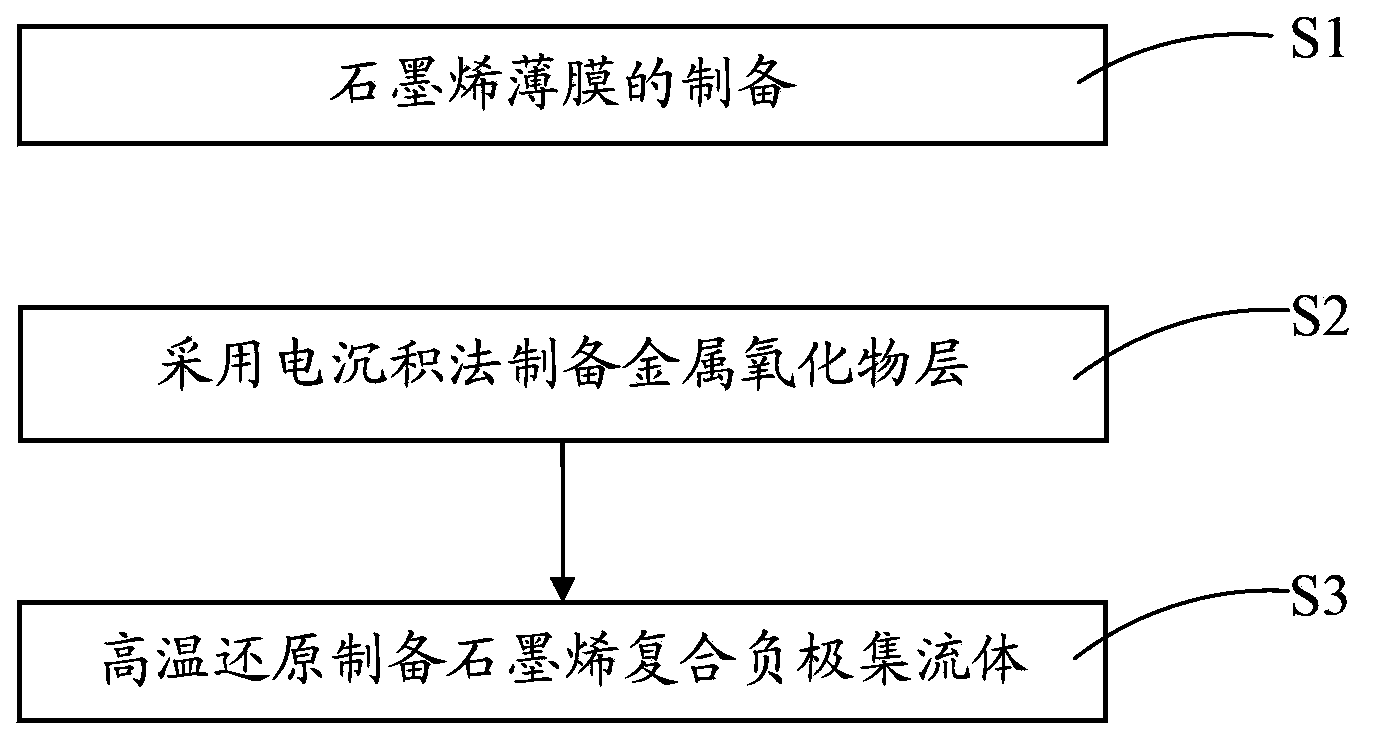

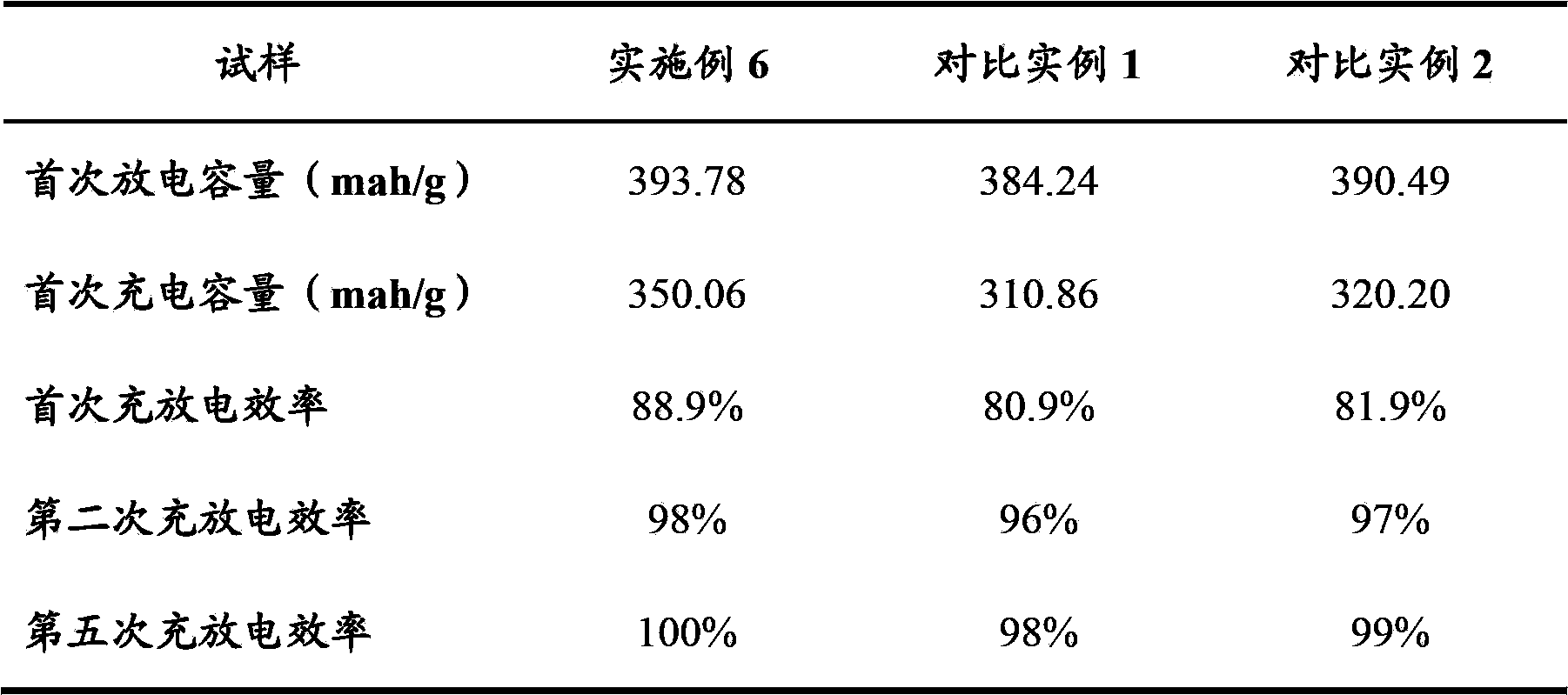

Graphene composite negative current collector, preparation method thereof and lithium ion battery

InactiveCN103579632AHigh mechanical strengthReduce weightElectrode carriers/collectorsSecondary cellsLithium-ion batteryCvd graphene

The invention discloses a graphene composite negative current collector, a preparation method thereof and a lithium ion battery. The graphene composite negative current collector comprises a graphene thin-film layer and a metal oxide layer combining with the surface of the graphene thin-film layer, and the metal oxide in the metal oxide layer is at least one of Cr2O3, MnO2, V2O5 and TiO2. The graphene composite negative current collector is high in mechanical strength and light in weight, and also is capable of effectively preventing lithium ions from being embedded in the graphene thin-film layer, avoiding generation of irreversible capacity and further improving the capacity. The preparation method is simple in technology, easily controllable in conditions and low in equipment requirements.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

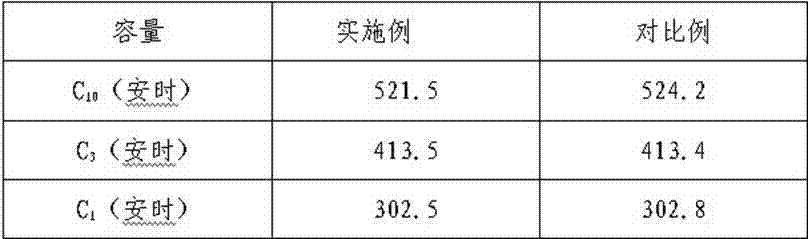

Formation method of lead-acid storage battery

InactiveCN103579686ADepolarizationIncrease profitFinal product manufactureElectrolyte/reactants regenerationPower flowCharge current

The invention provides a formation method of a lead-acid storage battery. The method comprises the steps of firstly, carrying out multi-stage constant-current charge and constant-current discharge, and then carrying out constant-current charge, wherein the total formation time is 45h-70h, and the charge current and the discharge current are 0.05-0.2 C10. The method is used for the formation of the valve-regulated sealed lead-acid storage battery for communication; the polarization phenomenon of the battery in the formation process can be effectively relieved by the multi-stage charge and discharge under the condition that equipment investment is not increased, so that the charging efficiency and the formation efficiency are improved, and the battery capacity is guaranteed.

Owner:HUBEI RUNYANG NEW ENERGY

Lithium ion battery negative electrode active material, preparation method thereof, negative electrode and lithium ion battery comprising negative electrode

InactiveCN107293701AIncrease capacityReduce capacityCell electrodesSecondary cellsCarbon layerSilicon alloy

The invention proposes a lithium ion battery negative electrode active material, a preparation method thereof, a negative electrode and a lithium ion battery comprising the negative electrode. The negative electrode active material is of a core-shell structure, wherein the core comprises lithium silicon alloy particles, and the shell is a carbon layer. In the negative electrode active material employing the core-shell structure of which the core is the lithium silicon alloy particles and the shell is the carbon layer, the volume expansion effect of silicon used as the negative electrode can be effectively reduced; and when the negative electrode is applied to the battery, relatively high capacity of the obtained battery can be maintained, and meanwhile, the battery also has good cycle property.

Owner:BYD CO LTD

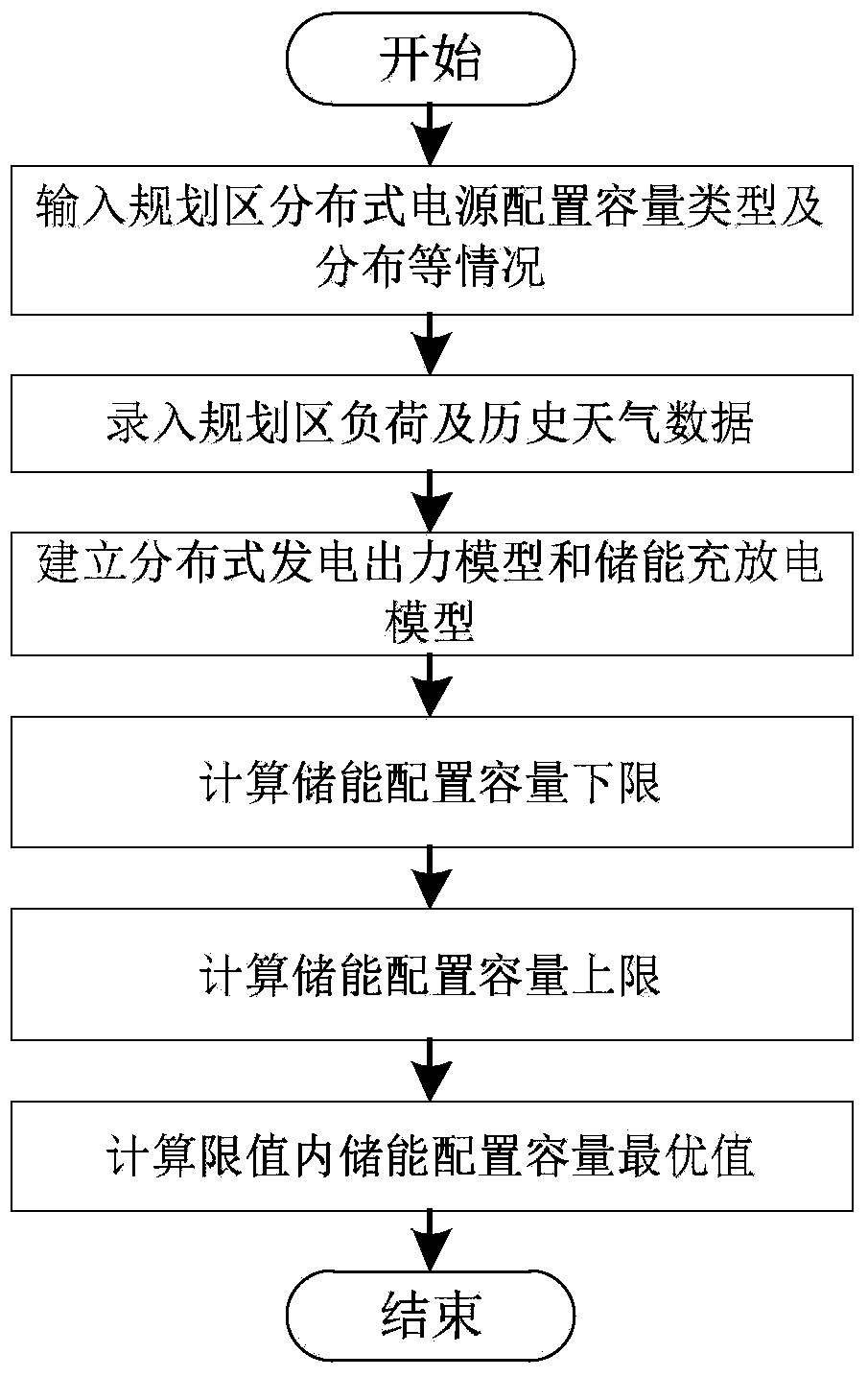

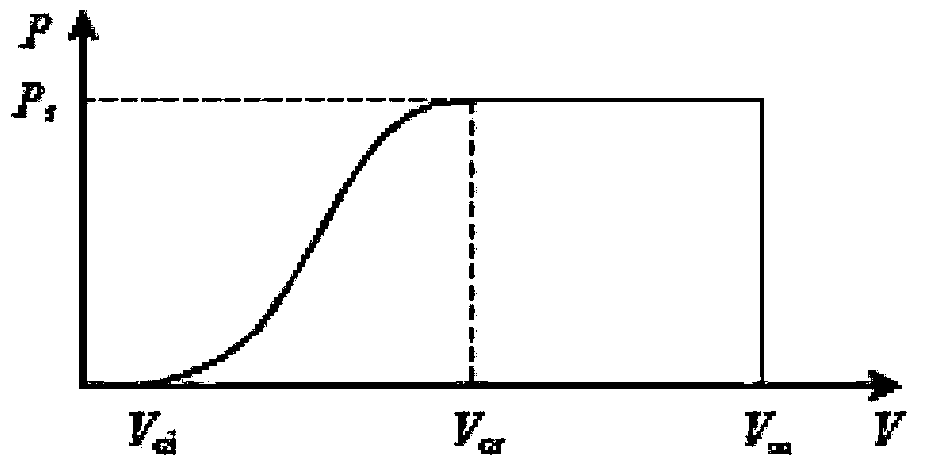

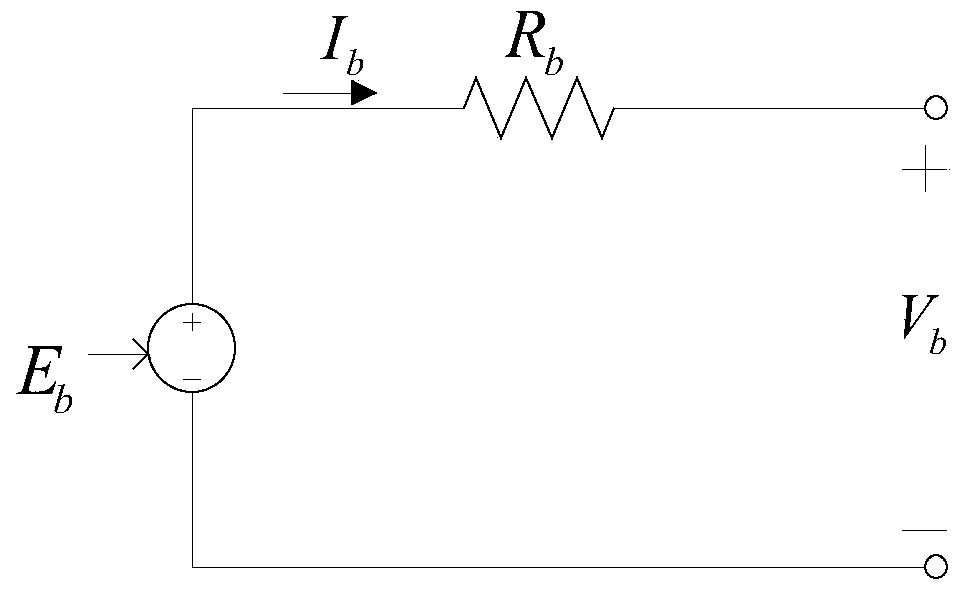

Micro grid energy storage device design method based on capacity limit value constrain

InactiveCN104361405AImprove power supply reliabilityTaking into account the construction economyForecastingSystems intergating technologiesAutomotive engineeringWeather data

A micro grid energy storage device design method based on capacity limit value constrain includes 1, inputting the planning area distribution-type power supply allocation capacity and the type and distribution situation of an energy storage device; 2, inputting the planning area load and historical weather data; 3, establishing a distribution-type power supply force model and an energy storage charging and discharging module; 4, calculating the lower limit of the energy storage device allocation capacity; 5, calculating the upper limit of the energy storage device allocation capacity; 6, calculating the optimal value of the energy storage device allocation capacity in the range of the limit value. By the aid of the method, on the basis that the energy storage device capacity limit value of a connected-type micro grid is met, the optimal energy storage device capacity allocation matching with distribution type power generation is calculated, the requirements on reliability and economy of the micro grid can be met through the energy storage device capacity to the utmost extent, and clean, safe and reliable power is provided for loading.

Owner:ELECTRIC POWER RES INST OF GUANGDONG POWER GRID

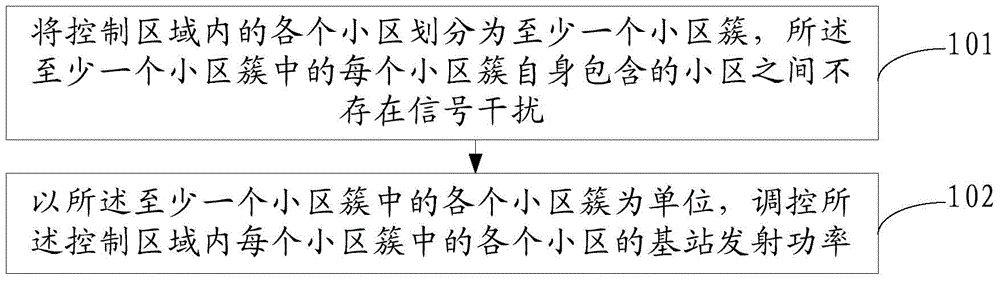

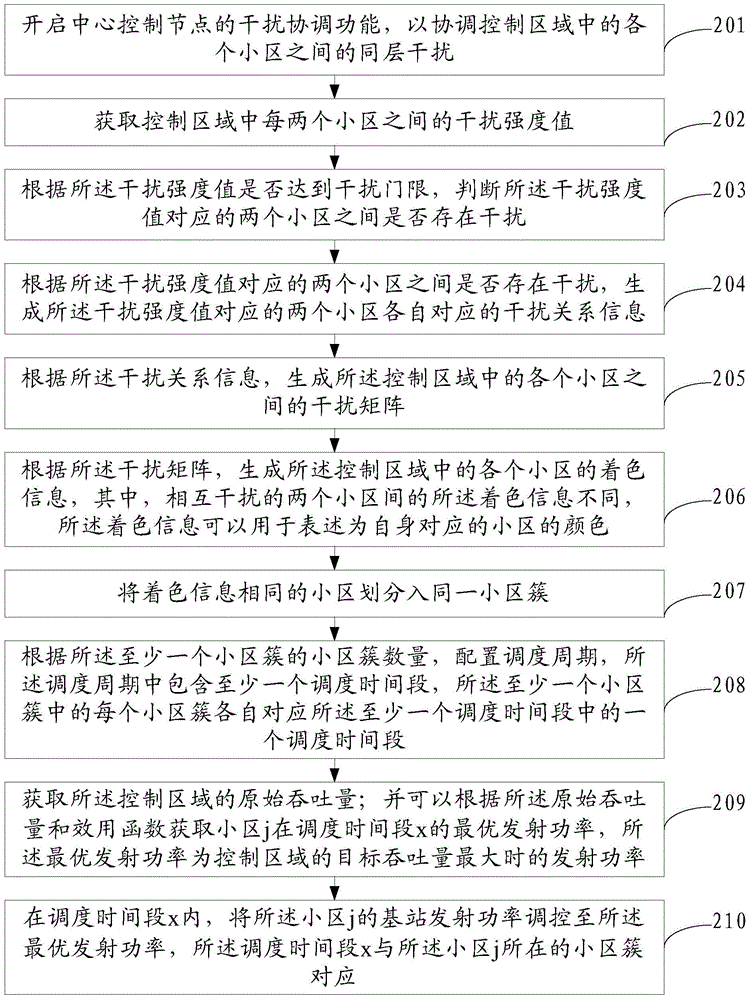

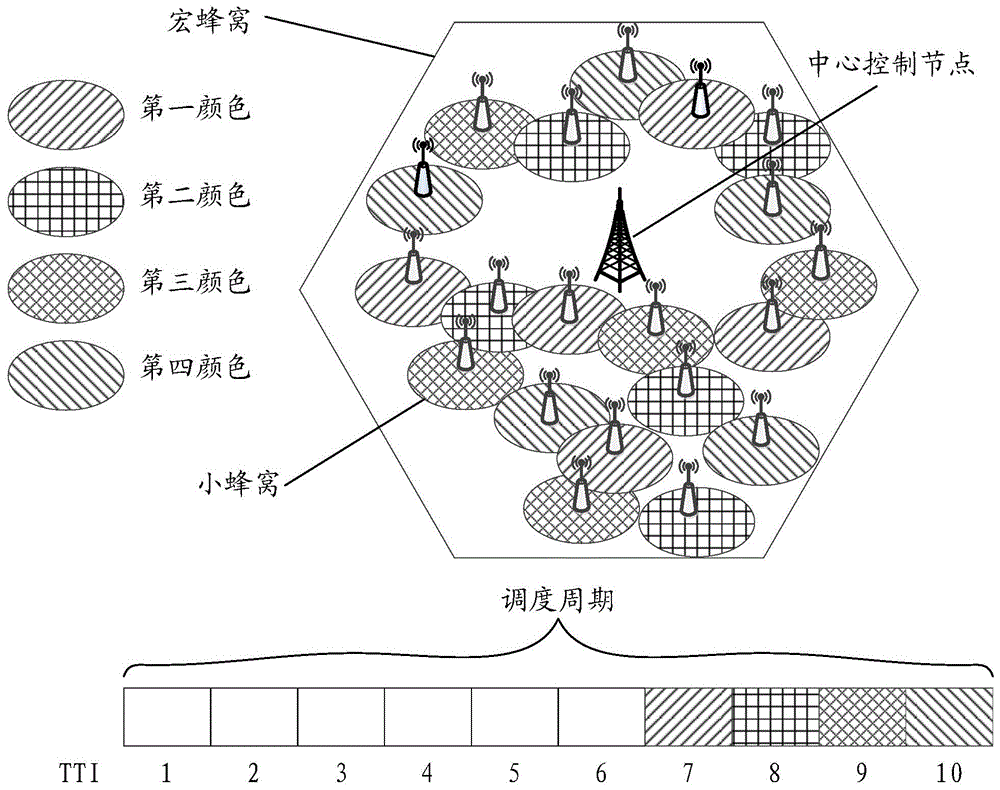

Interference coordination method and device

InactiveCN104640193AAvoid it happening againEnsure normal communicationPower managementSystem capacityTransmitted power

The embodiment of the invention provides an interference coordination method and device, which can reduce interference on a same layer between cells on the premise of guaranteeing the system capacity. The specific scheme comprises the following steps: dividing each cell in a control region into at least one cell cluster, wherein signal interference does not exist between cells included by each cell cluster in the at least one cell cluster; adjusting and controlling base station transmitting power of each cell in each cell cluster in the control region by taking each cell cluster in the at least one cell cluster as a unit. The method and the device are suitable for the field of communication.

Owner:CHINA UNITED NETWORK COMM GRP CO LTD

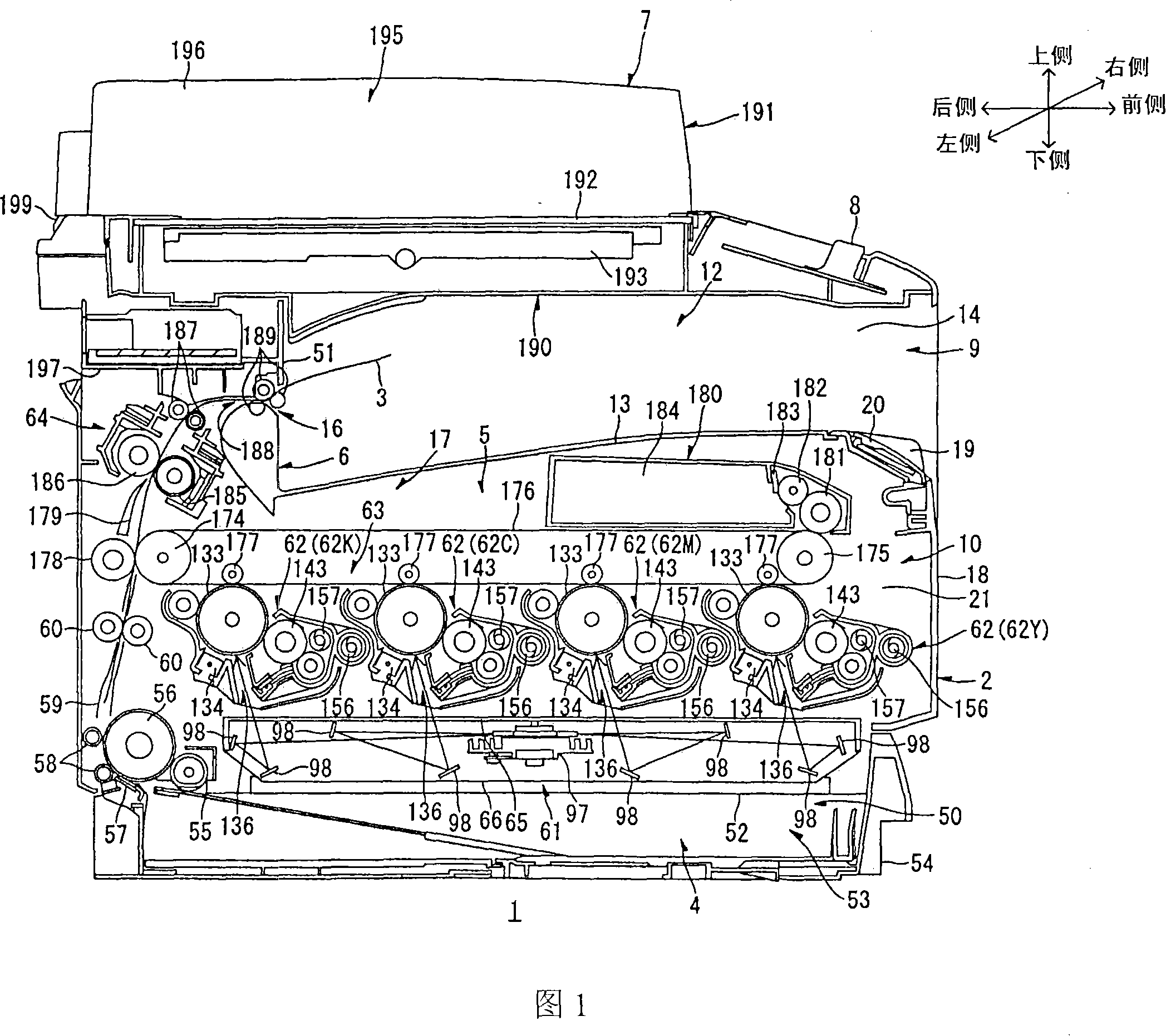

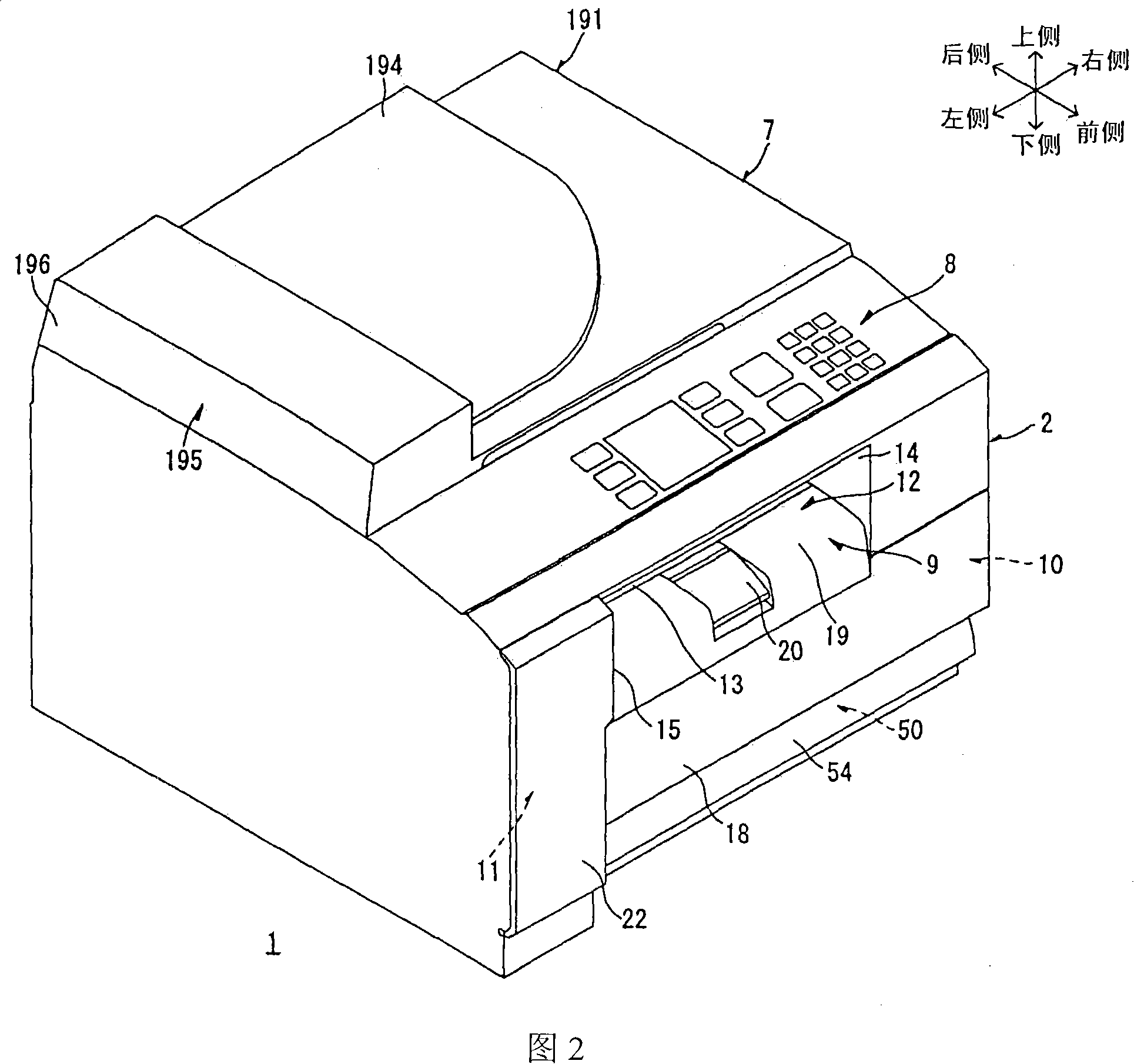

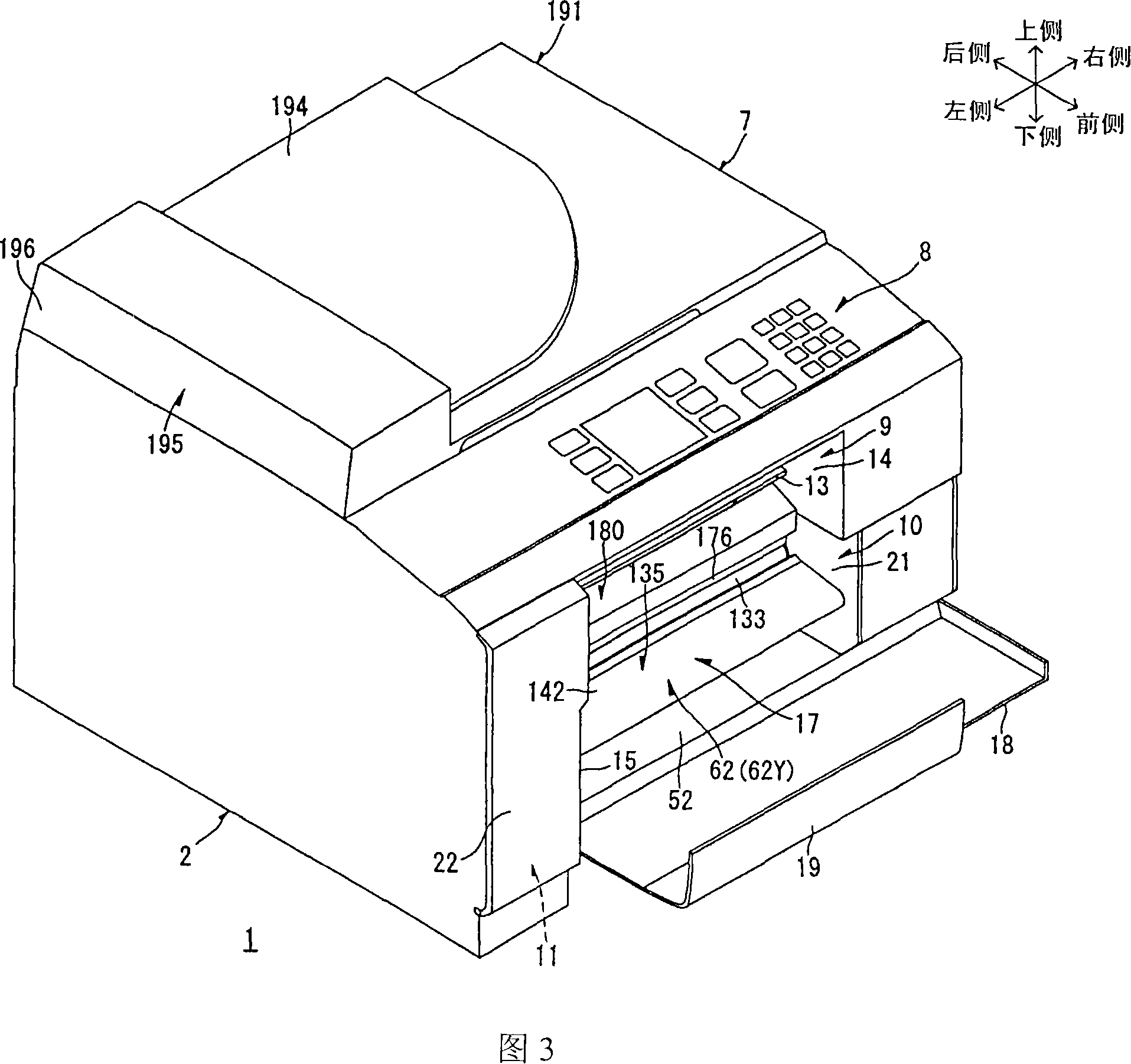

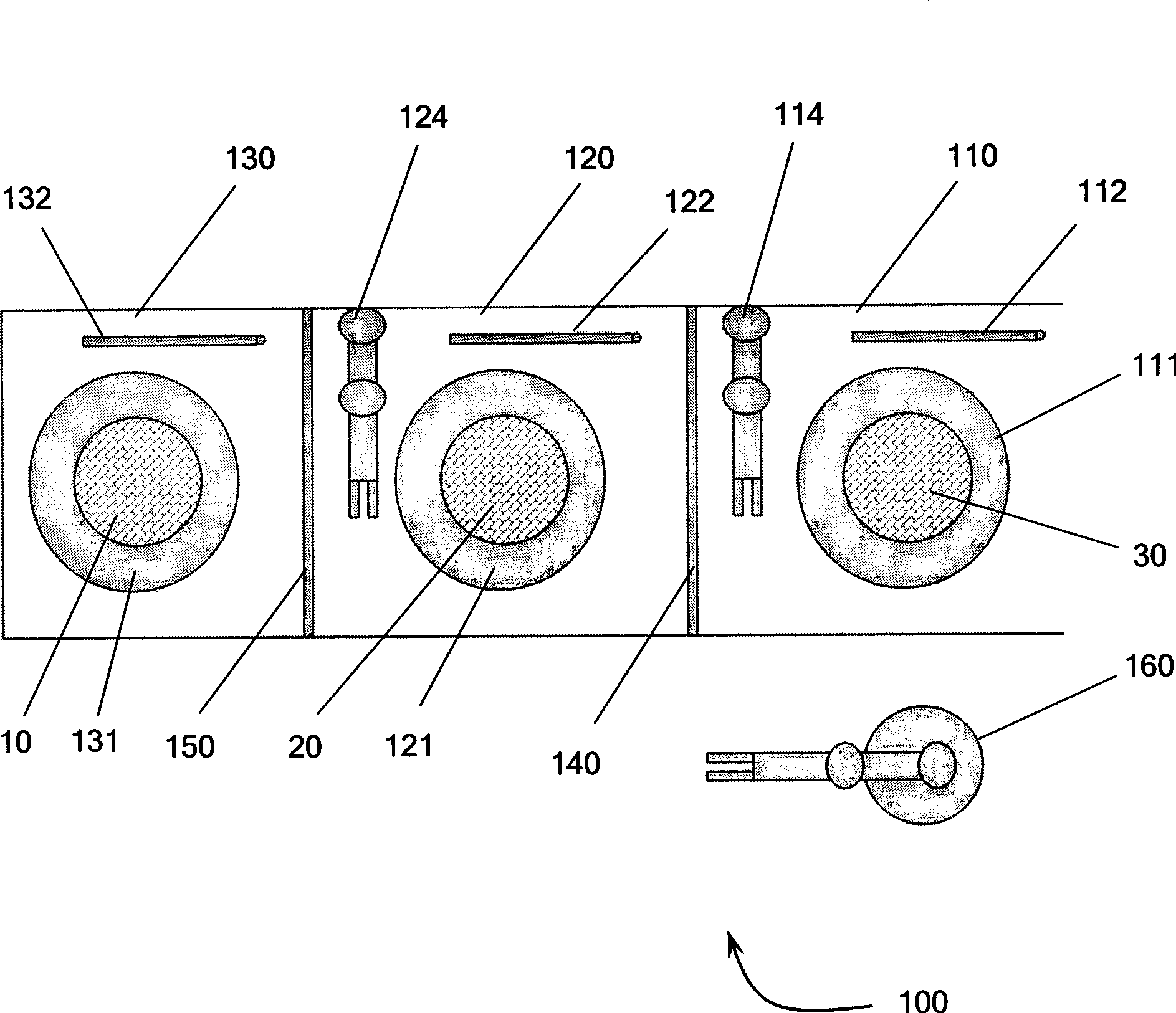

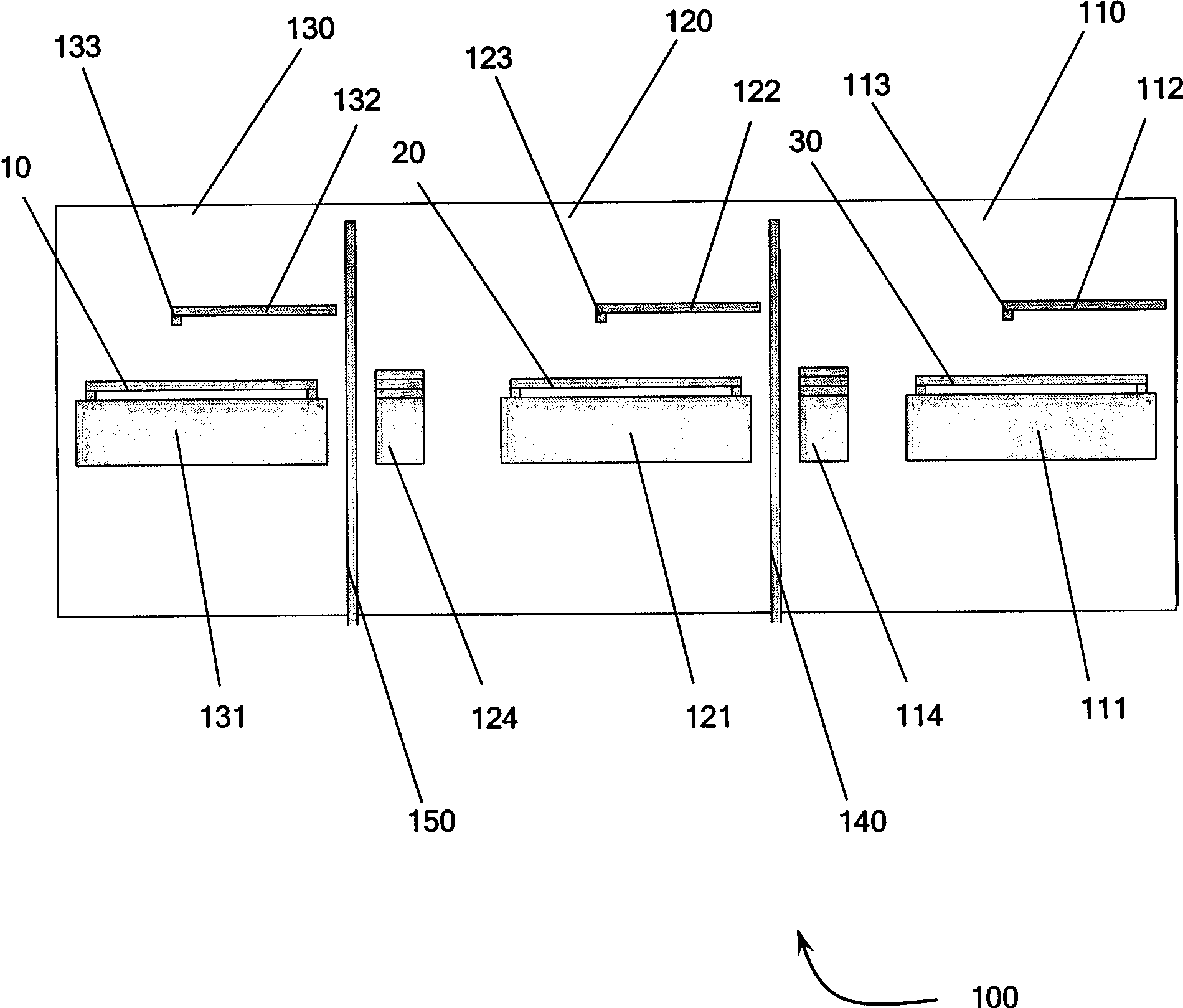

Image forming apparatus and developing agent cartridge

ActiveCN101114145AMiniaturizationEasy to operateElectrographic process apparatusEngineeringElectrical and Electronics engineering

An image forming apparatus is described. The image forming apparatus may include: a casing; a plurality of image carriers parallelly arranged along one direction in the casing, and formed with an electrostatic latent image; a plurality of developing agent carriers opposed to the image carriers, for visualizing the electrostatic latent image by feeding a developing agent to the image carriers; and a plurality of developing agent cartridges, parallelly arranged in the one direction to be opposed to the developing agent carriers in the longitudinal direction of the developing agent carriers, and configured to be together attachable / detachable to / from the casing along the one direction, for accommodating the developing agent fed to the developing agent carriers.

Owner:BROTHER KOGYO KK

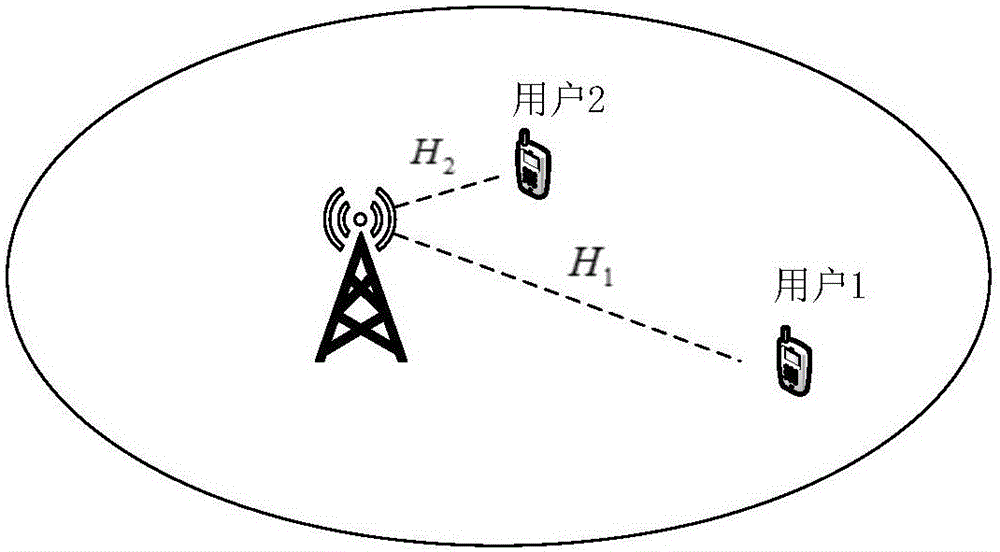

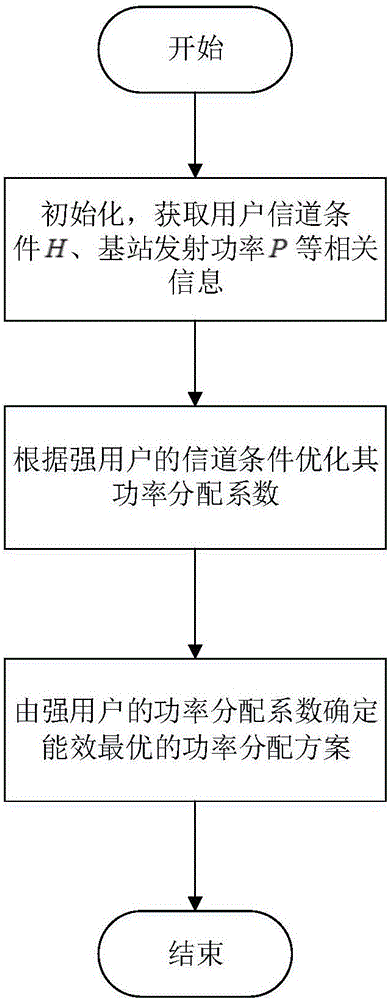

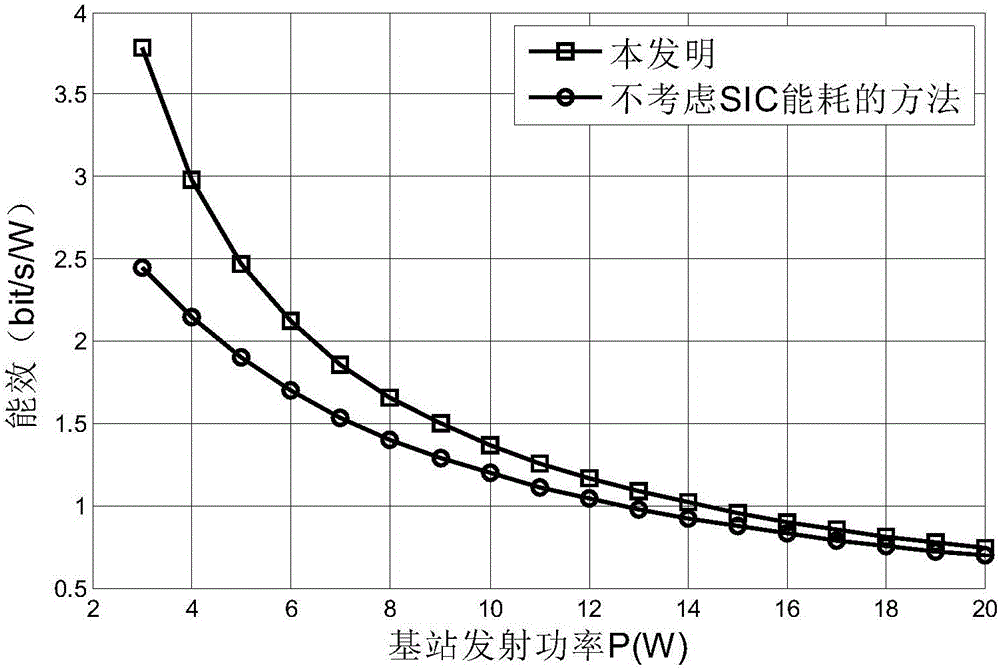

Two-user NOMA (Non-Orthogonal Multiple Access) downlink energy efficiency optimization method in consideration of SIC (Successive Interference Cancellation) energy consumption

InactiveCN106162846AReduce consumptionImprove energy efficiencyPower managementHigh level techniquesSystem capacityVoltage

The invention discloses a two-user NOMA (Non-Orthogonal Multiple Access) downlink energy efficiency optimization method in consideration of SIC (Successive Interference Cancellation) energy consumption. The method comprises steps: firstly, transmitting power P of a base station, a channel condition H1 between a user 1 and the base station, a channel condition H2 between a user 2 and the base station and a signal voltage difference threshold theta for multiplex signal separation needed when a user receiver executes the SIC are acquired; and the user with a good channel condition executes the SIC, a power distribution coefficient is optimized according to the channel condition of the user with the good channel condition, and the optimal power distribution scheme is obtained. The method of the invention is applicable to a two-user NOMA downlink system in consideration of SIC energy consumption, and compared with a two-user NOMA system in no consideration of SIC energy consumption, while the total system capacity is ensured, and the total energy efficiency of the system can be well enhanced.

Owner:HUAZHONG UNIV OF SCI & TECH

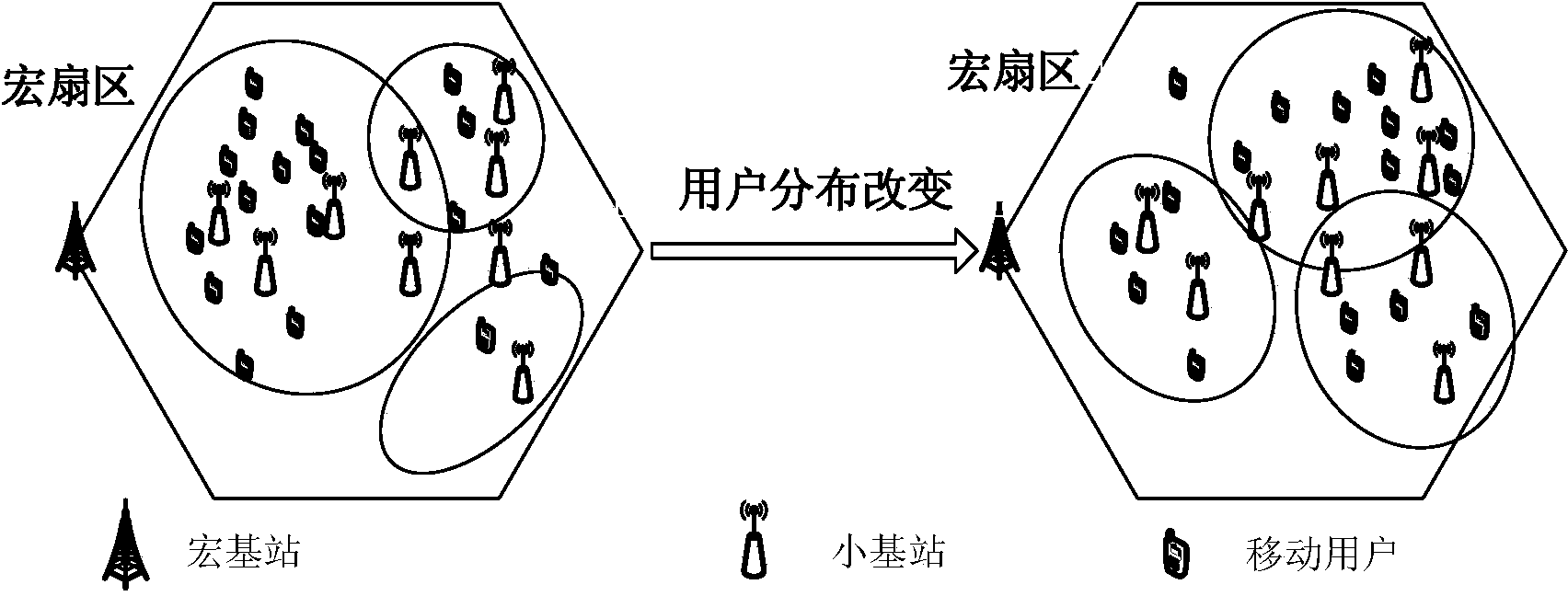

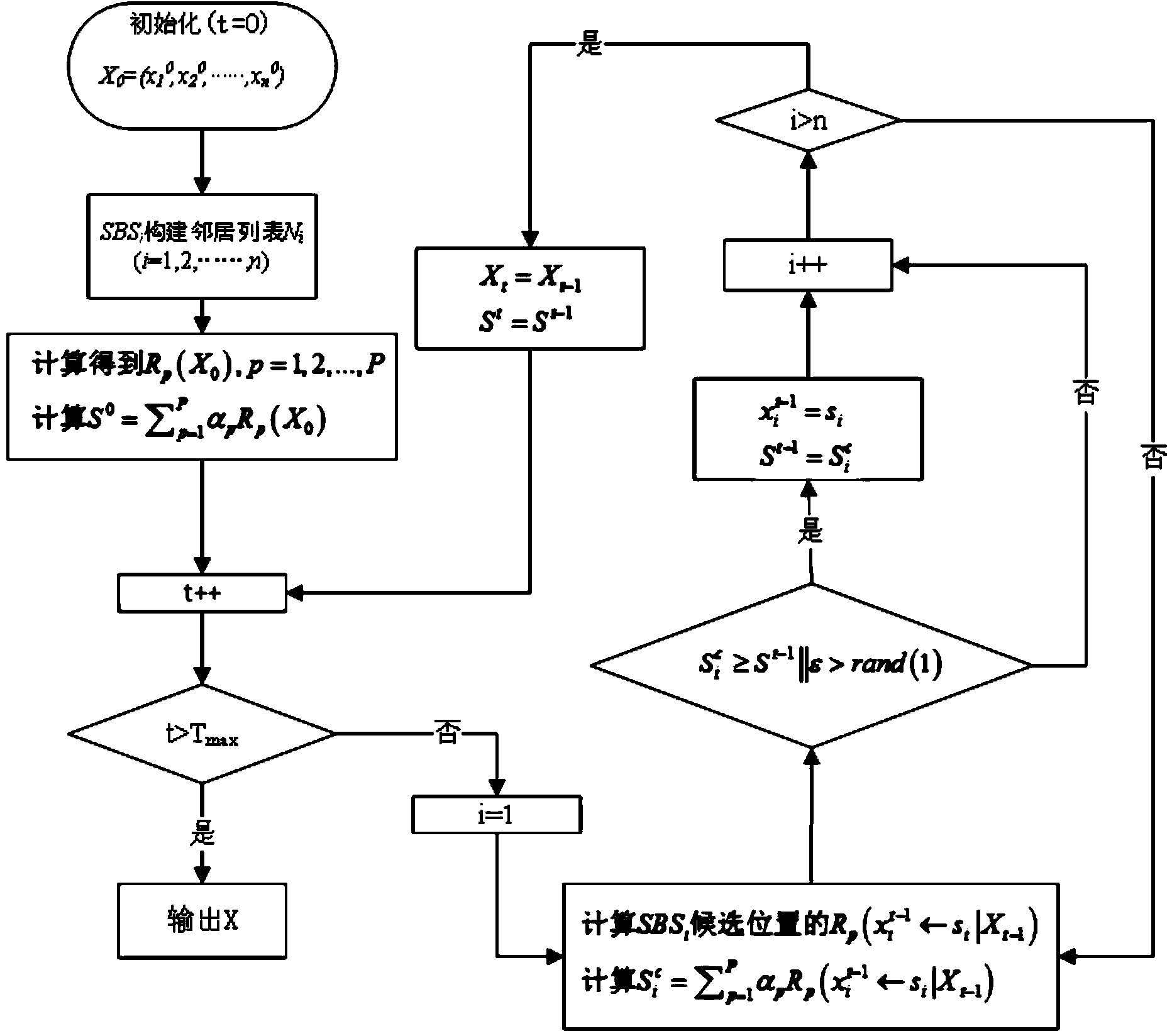

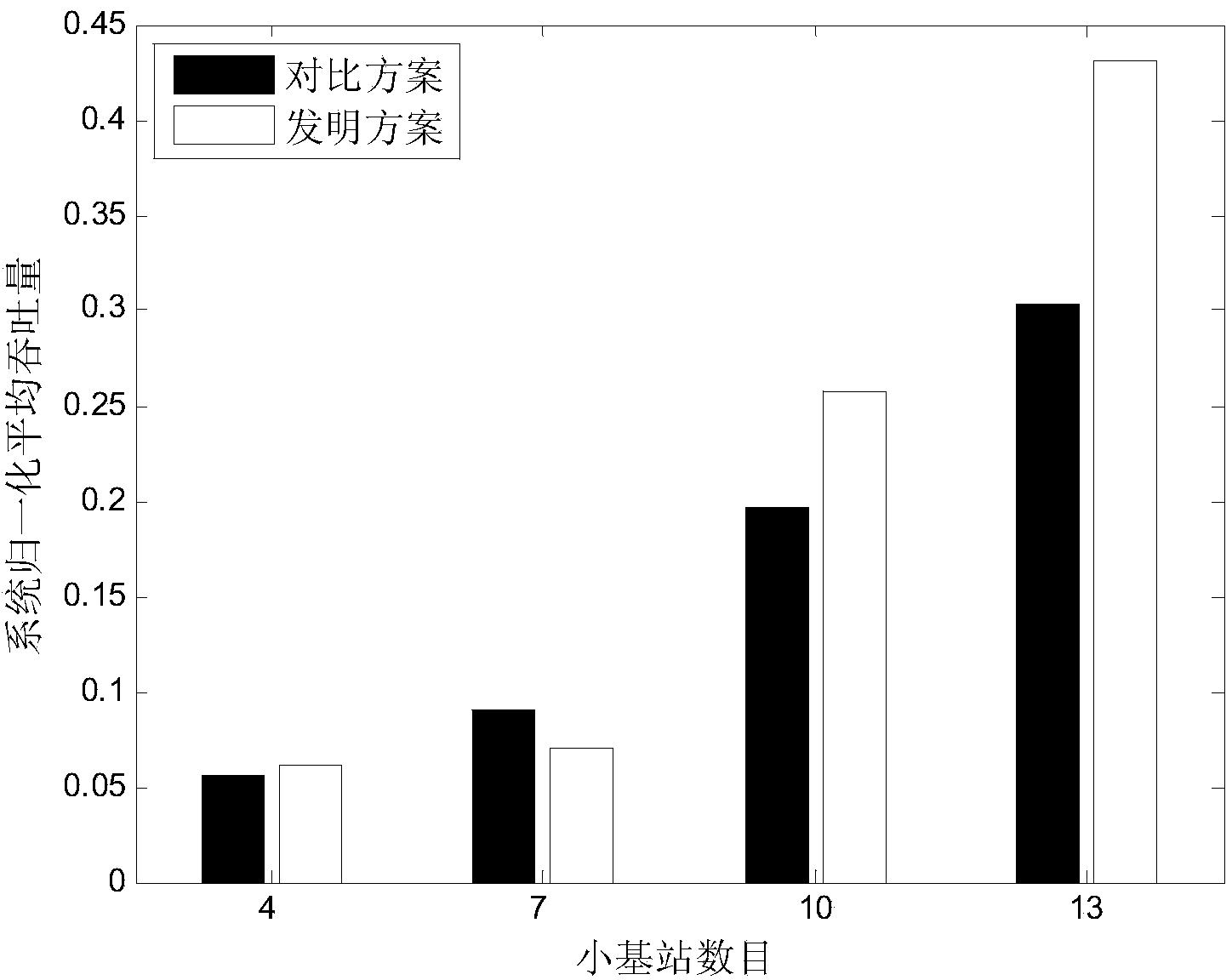

Cell-oriented amorphous coverage small base station deployment method in cellular network

ActiveCN104378772AImprove fairnessGuaranteed performanceNetwork planningDistribution systemCellular network

The invention discloses a cell-oriented amorphous coverage small base station deployment method in a cellular network. The method aims at maximizing multi-user distribution system average throughout capacity. The multi-user distribution system average throughout capacity under different small base station position vectors is calculated by means of a given collaborative cell building and resource scheduling method; a small base station deployment position enabling the throughout capacity to be maximum is found based on a given position updating algorithm, and multi-user distribution is considered to the greatest degree. Compared with a traditional method, the cell-oriented amorphous coverage small base station deployment method is more applicable to an actual site; in consideration of the user distribution tidal phenomenon, when user distribution is changed, the determined small base station position enables adjacent small base stations to change the collaboration way more effectively in real time, so that a traditional fixed cell shape is changed, and the system performance requirement for distribution of different users is met. By the adoption of the cell-oriented amorphous coverage small base station deployment method, the system average throughout capacity, margin user performance and user fairness can be effectively improved.

Owner:CERTUS NETWORK TECHNANJING

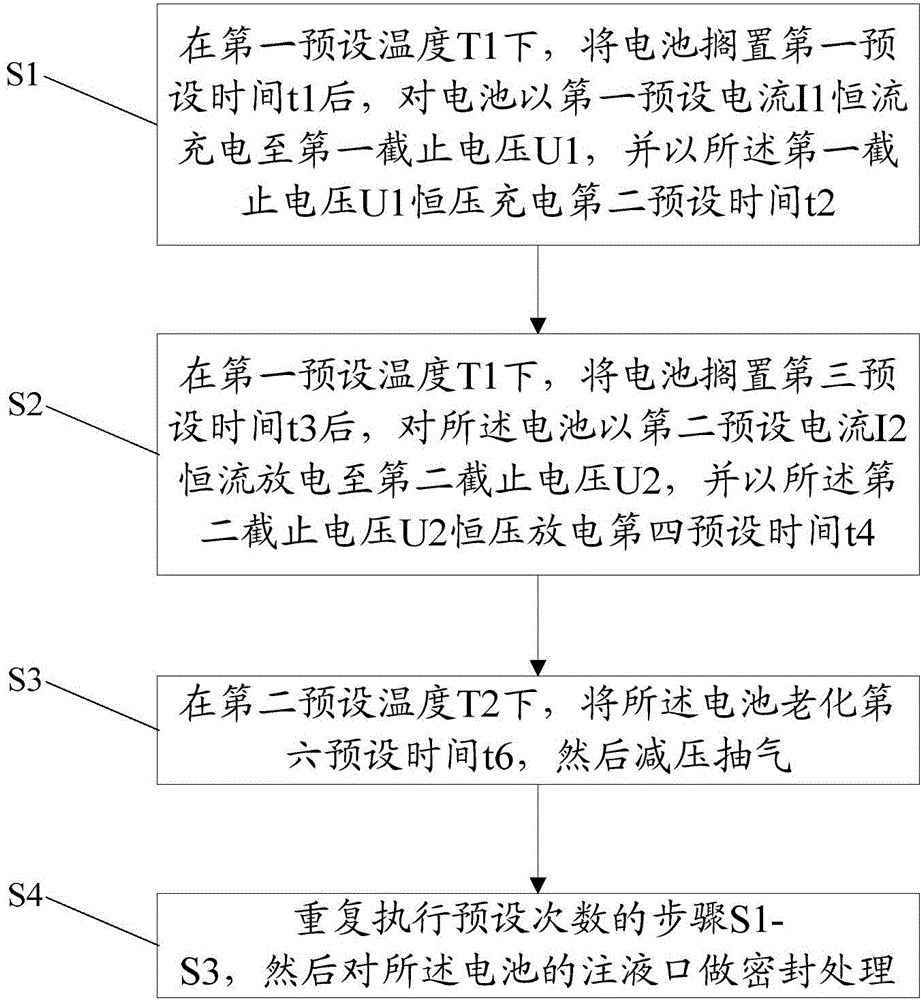

Forming method of lithium titanate battery

ActiveCN104409780AImprove cycle performanceGuaranteed capacityFinal product manufactureElectrolyte accumulators manufactureEngineeringVoltage

The invention discloses a forming method of a lithium titanate battery. The forming method comprises the following steps: S1, lying the battery for first preset time t1 at first preset temperature T1, charging the battery with first preset current I1 constantly until reaching first cut-off voltage, and charging the battery with U1 constantly for second preset time t2; S2, lying the battery for third preset time t3 at the first preset temperature T1, discharging the battery with second preset current I2 constantly until reaching second cut-off voltage, and discharging the battery with U2 for fourth preset time t4; S3, aging the battery for sixth preset time t6 at second preset temperature T2, reducing the pressure and exhausting air; S4, carrying out the step S1 to the step 3 repeatedly for preset frequency, and sealing a liquid filling opening of the battery. According to the forming method of the lithium titanate battery, water in the battery is consumed completely and is generated into gas to be discharged from the battery, so that the capacity of the battery can be ensured, and the cycle performance of the lithium titanate battery can be improved.

Owner:HEBEI YINLONG NEW ENERGY +1

Modified lithium ion battery high-nickel anode material and preparation method thereof

ActiveCN107256955AAvoid capacity loss phenomenonGuaranteed capacityCell electrodesSecondary cellsOxygenLithium-ion battery

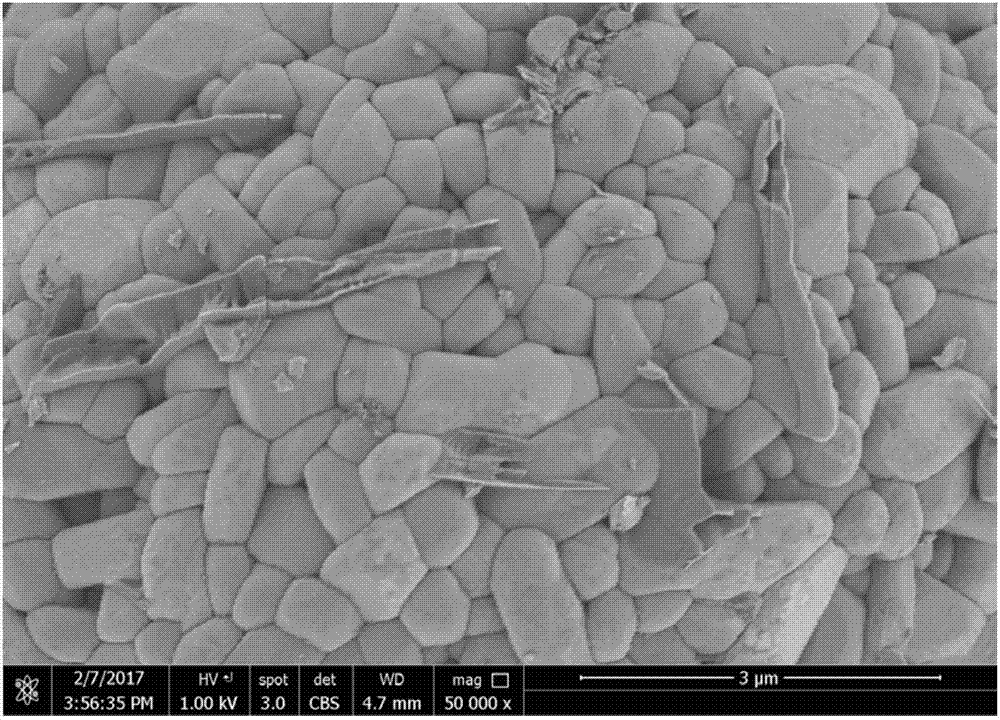

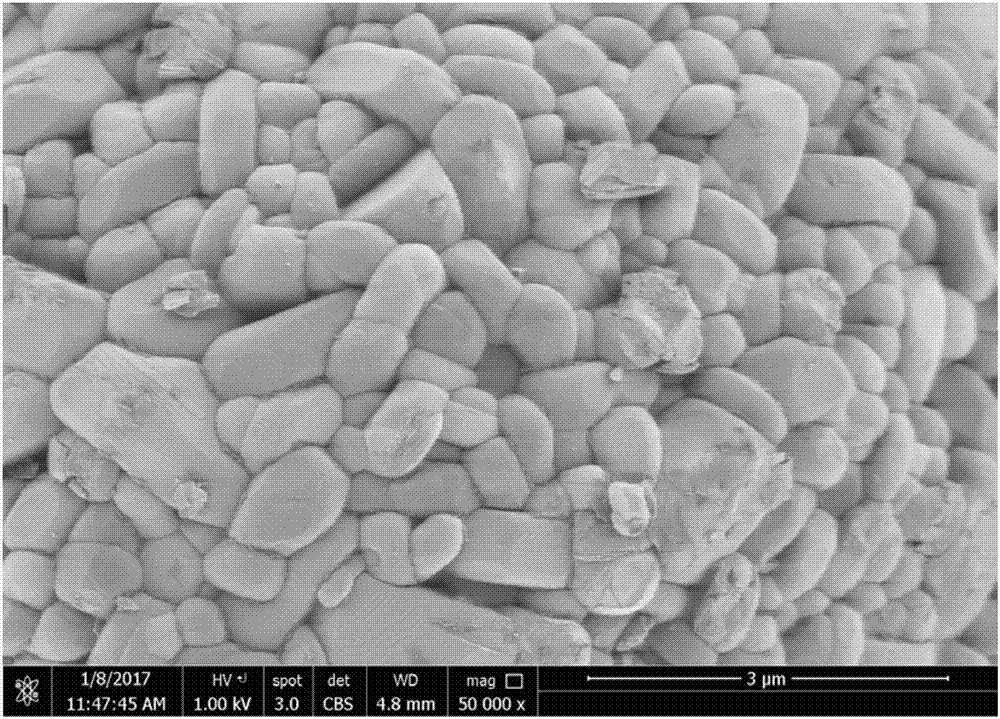

The invention belongs to the technical field of lithium ion battery materials and discloses a water washing and tin coating combined modified lithium ion battery high-nickel anode material and a preparation method thereof. The preparation method includes following steps: (1), adding a high-nickel anode material into water, quickly stirring and washing for 1-20min at a rotating speed of 500-2000r / min, filtering, and drying to obtain a water-washed high-nickel anode material; (2), mixing the water-washed high-nickel anode material with a tin source well, heating to 300-700 DEG C in an oxygen-containing atmosphere at a heating rate of 1-3 DEG C / min, sintering at constant temperature for 3-10h, discharging, and breaking to obtain the modified lithium ion battery high-nickel anode material. According to the method, the high-nickel anode material is quickly washed in the water, the tin source is utilized to absorb residual lithium, and a composite coating layer of lithium stannate and tin oxide is formed on the surface of the material, so that discharging capacity and first effect of a battery are improved, and circulating performance and safety performance are improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +3

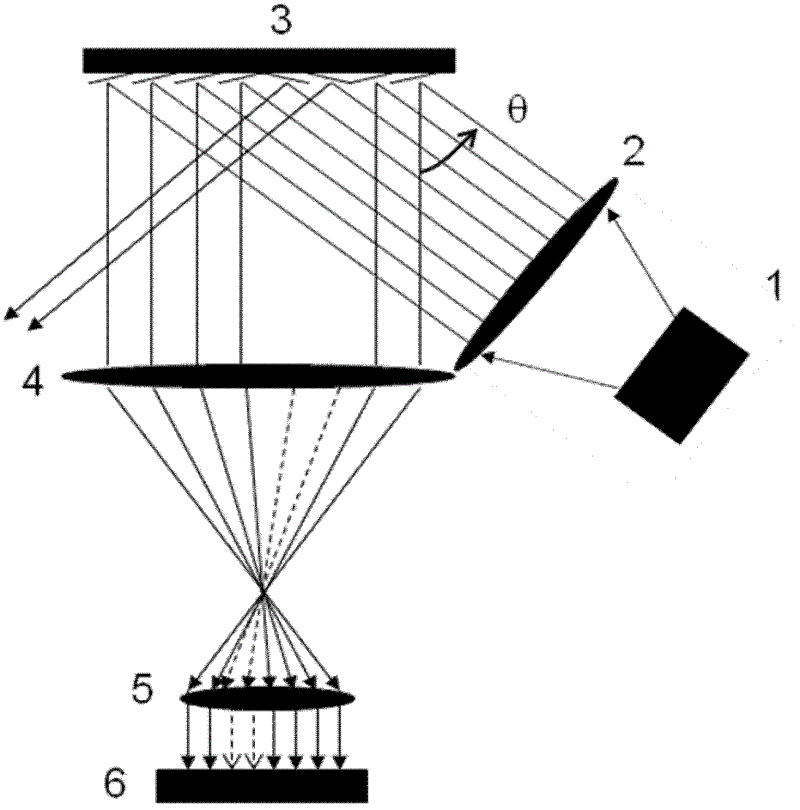

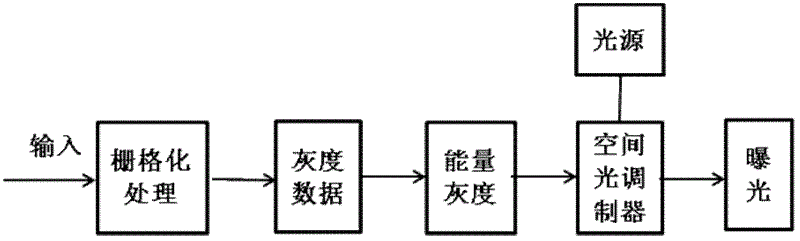

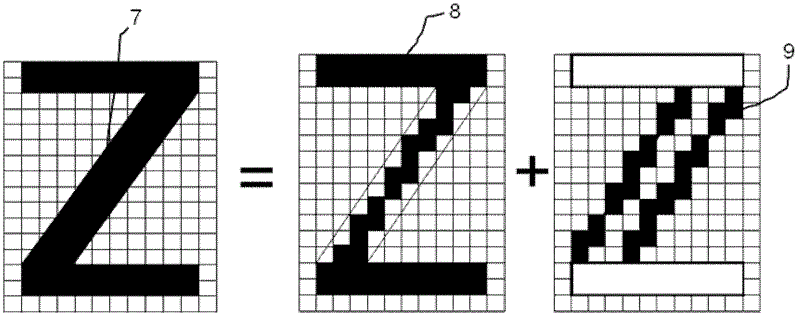

Method of adopting gray scale mode in write-through photoetching system to improve exposure graph quality

ActiveCN102621816AGuaranteed capacityHigh-resolutionPhotomechanical exposure apparatusMicrolithography exposure apparatusGraphicsSpatial light modulator

The invention discloses a method of adopting a gray scale mode in a write-through photoetching system to improve exposure graph quality. Characteristic graphs need to be processed before being sent to a spatial light modulator, and simultaneously an exposure light source is turned on to transfer the characteristic graphs onto a substrate. A process flow includes the following steps that first the characteristic graphs are processed to be bitmap data with graph information through image rasterization; then gray scale data are obtained after edge gray scale processing; and the gray scale data are converted to gray scale energy through a gray scale-energy lookup table and then transmitted to the spatial light modulator. The method does not require additional edge outline smoothing or high-accuracy locating through a workpiece platform. The method is simple to achieve, and achieves improvement of resolution ratio of the write-through photoetching system and exposure graph quality while ensuring capacity of the write-through photoetching system.

Owner:TIANJIN JINXIN MICROELECTRONICS TECH CO LTD

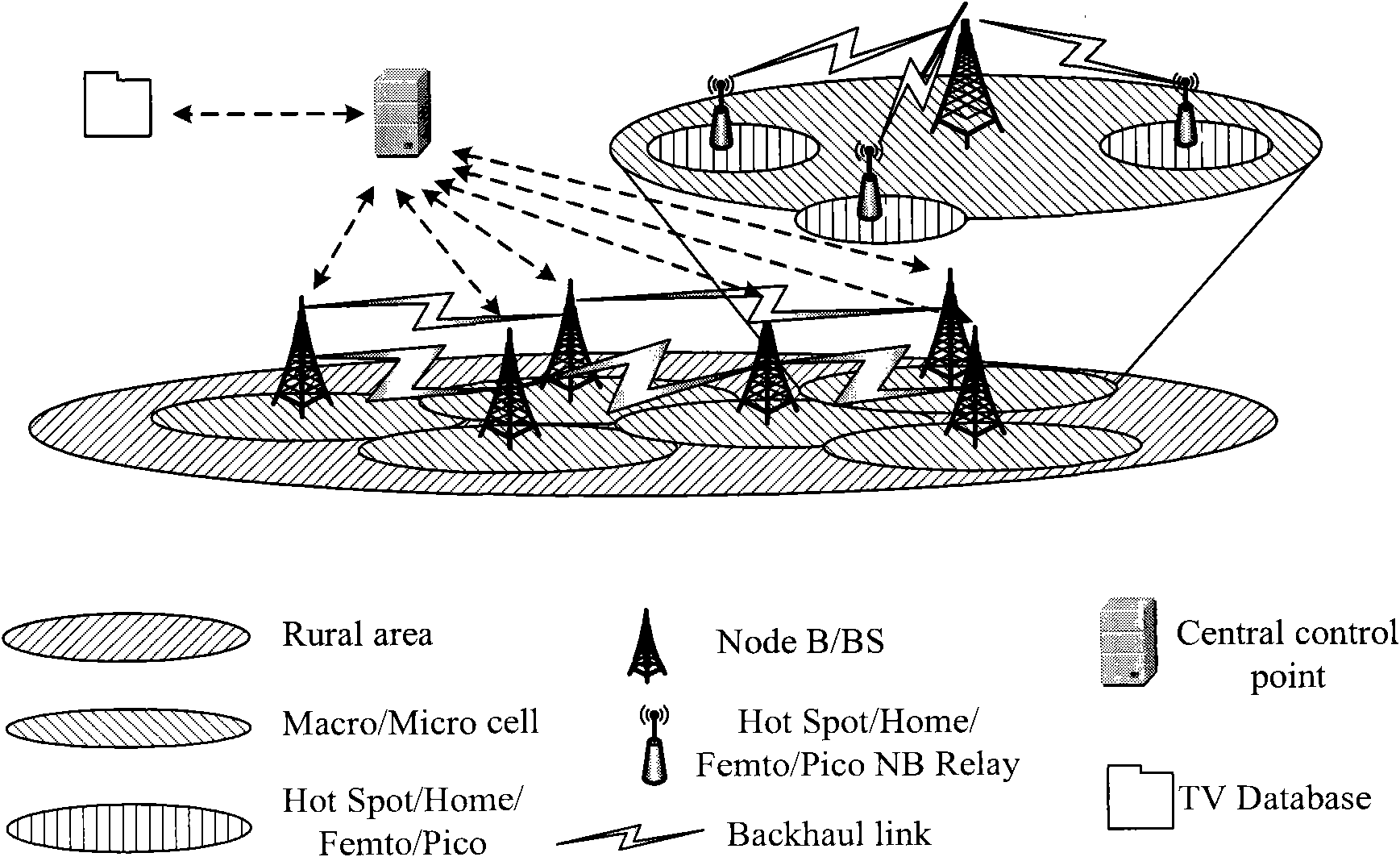

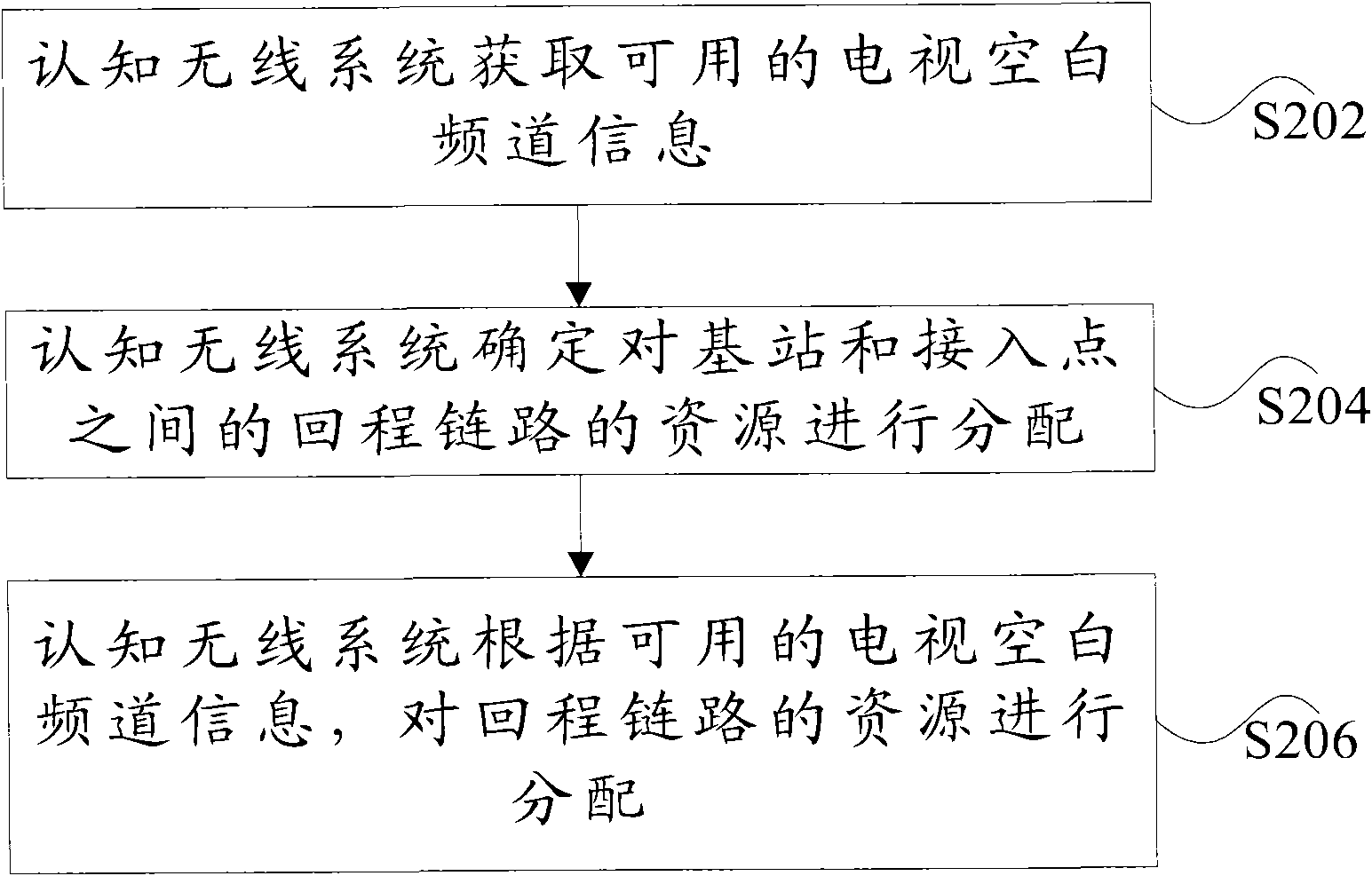

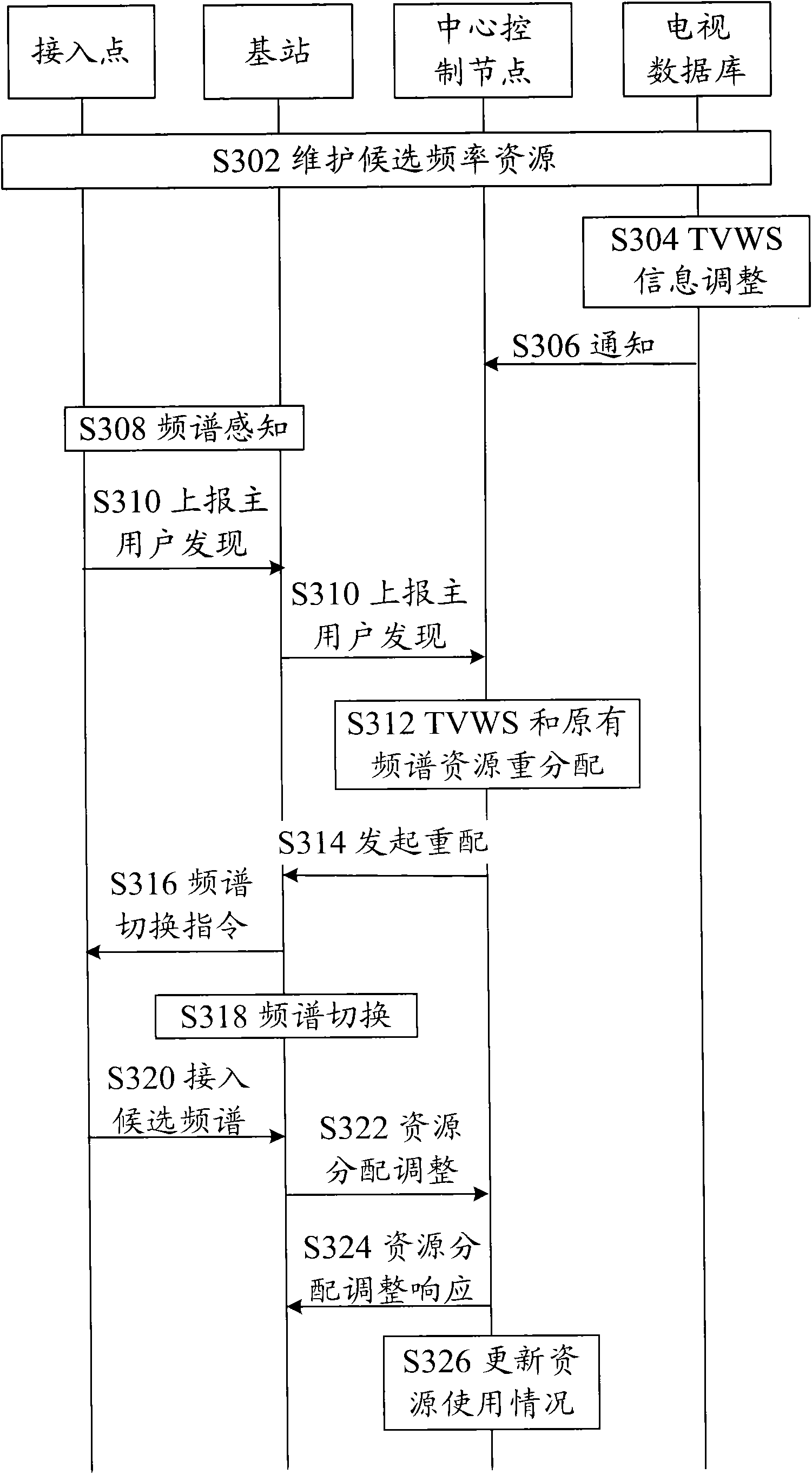

Resource allocation method and cognitive radio system

ActiveCN102387505AIncrease available resourcesSolve capacity problemsNetwork planningQuality of serviceResource allocation

The invention discloses a resource allocation method and system. The method comprises the following steps of: acquiring available television blank channel information by a cognitive radio system; determining the resource allocation of a backhaul link between the base station and an access point by the cognitive radio system; and allocating the resources of the backhaul link by the cognitive radio system according to the available television blank channel information. According to the method and system disclosed by the invention, the capacity and service quality of the backhaul link are guaranteed.

Owner:ZTE CORP

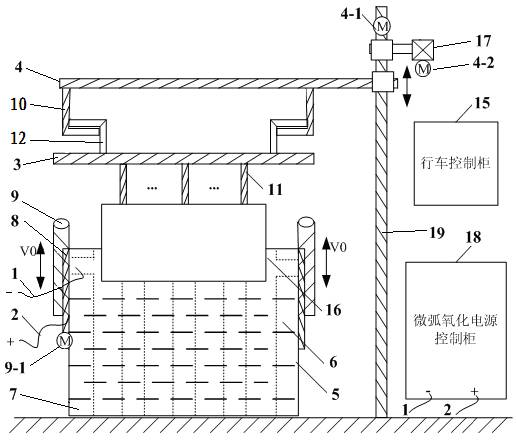

Anode gradual-entering type microarc oxidation treatment method and device with low energy consumption

The invention discloses an anode gradual-entering type microarc oxidation treatment method with low energy consumption. Before a large-area workpiece contacts electrolyte, an electric field with voltage higher than an arcing voltage is applied to the two ends of an electrode, and constant voltage control is adopted for a microarc oxidation power supply. In the process that the workpiece is gradually soaked into the electrolyte, the speed of the workpiece to soak in the electrolyte is correspondingly regulated through detecting the consumed current of the workpiece to realize quick microarc oxidation of the surface of the workpiece. After the workpiece is completely soaked in the electrolyte, the microarc oxidation power supply finishes the microarc oxidation treatment by adopting a constant voltage, constant current or constant power control mode. The invention also discloses a device used by the anode gradual-entering type microarc oxidation treatment method with low energy consumption, and the device comprises a traveling crane, a feiba and an electrobath with an anode capable of ascending and descending. By utilizing the method and the device thereof to carry out the microarc oxidation treatment, quick film forming for large-area workpieces can be easily realized, the resource is saved, the production efficiency and the yield can be improved, and the power supply capacity can be furthest exerted.

Owner:XIAN UNIV OF TECH

Cleaning equipment of semiconductor silicon chip and cleaning method thereof

InactiveCN101533760AGuaranteed capacitySimple equipment structureSemiconductor/solid-state device manufacturingCleaning using gasesSilicon chipProcess engineering

The invention discloses cleaning equipment of a semiconductor silicon chip and a cleaning method thereof. The cleaning equipment comprises a plurality of process cavities which are connected in series, lift separators, rotatable platforms, mechanical arms and cleaning cantilevers, wherein the lift separators are arranged among a plurality of process cavities; the rotatable platforms are arranged in the plurality process cavities for supporting the silicon chip; the mechanical arms are arranged in the plurality of process cavities for conveying the silicon chip among the plurality of process cavities; the cleaning cantilevers are arranged in the plurality of process cavities, and are provided with nozzles which are connected with cleaning agent feed pipelines and inert gas feed pipelines; each process cavity is subjected to different cleaning steps, and is provided with the cleaning agent feed pipeline and the inert gas feed pipeline required by different cleaning steps, thereby greatly simplifying the equipment structure, reducing equipment cost, and improving production efficiency.

Owner:SHANGHAI INTEGRATED CIRCUIT RES & DEV CENT

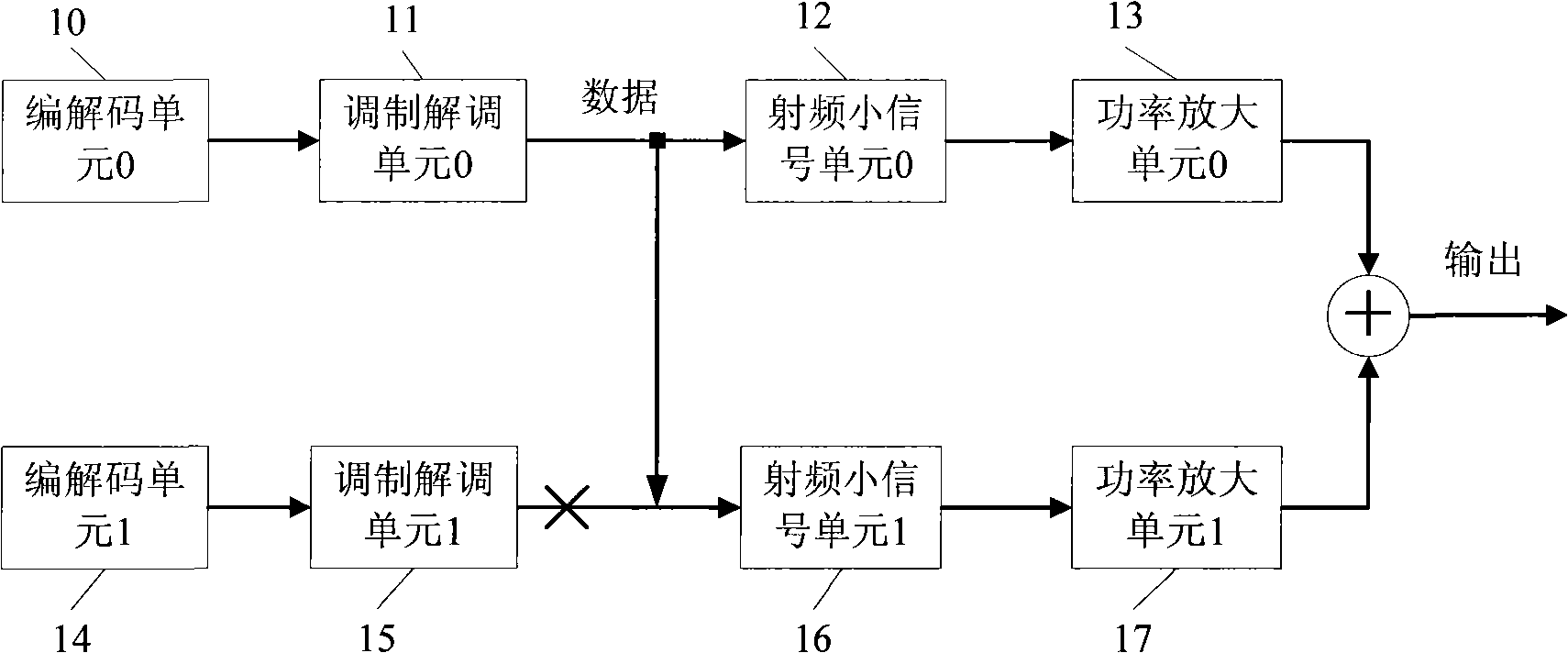

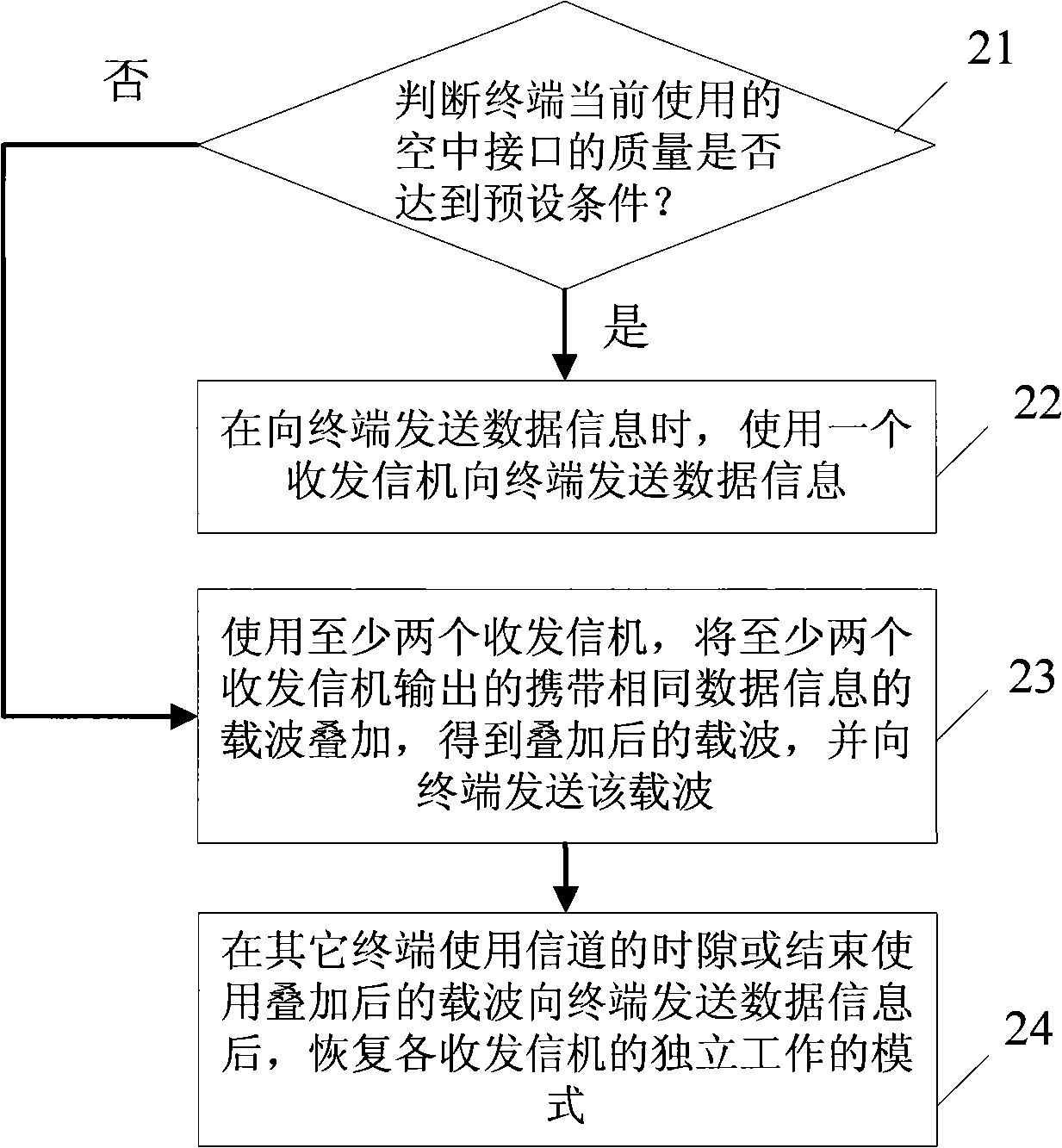

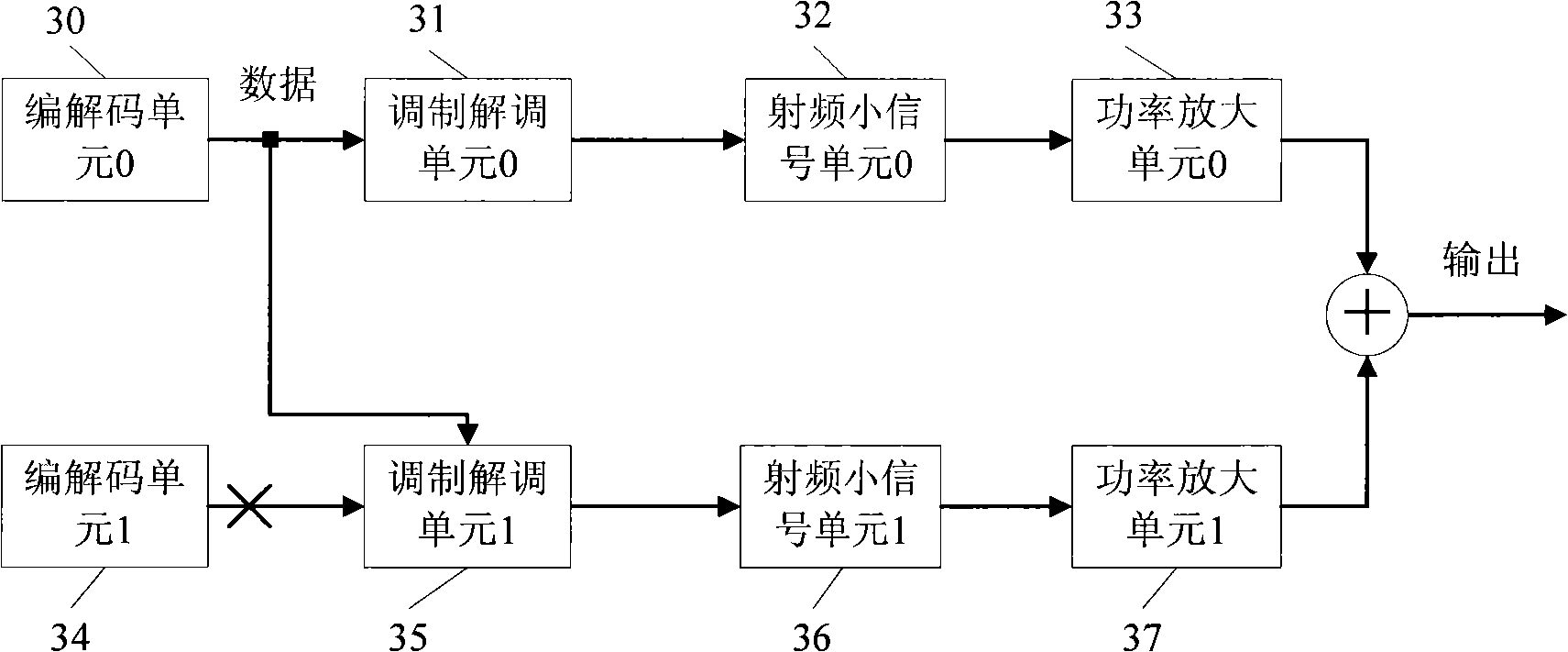

A diversity sending method, device and system

InactiveCN101267233AQuality improvementGuaranteed capacitySpatial transmit diversityTransmission control/equalisingTransceiverAir interface

The present invention provides a diversity transmitting method, a device and a system thereof. The method comprises the following procedures in particular: determining whether the quality of the air interface used by the terminal currently obtains the prearranged condition; if the prearranged condition is obtained, transmitting the data information to the terminal with a transceiver; and if the prearranged condition is not obtained, transmitting the data information to the terminal with at least two transceivers simultaneously. The embodiment of the invention can realize that the number of the used transceivers can be adjusted according to the quality of the air interface used by the terminal currently flexibly, and thereby avoiding that at least two transceivers are taken as one transceiver for transmitting data to the subscriber which can receive wireless signal with better quality when the PBT or diversity technique is not adopted (such as the subscriber nearer to the BTS). The guaranteeing to the network capacity as possible is realized while the quality of the air interface is increased, and the system resource is saved.

Owner:HUAWEI TECH CO LTD

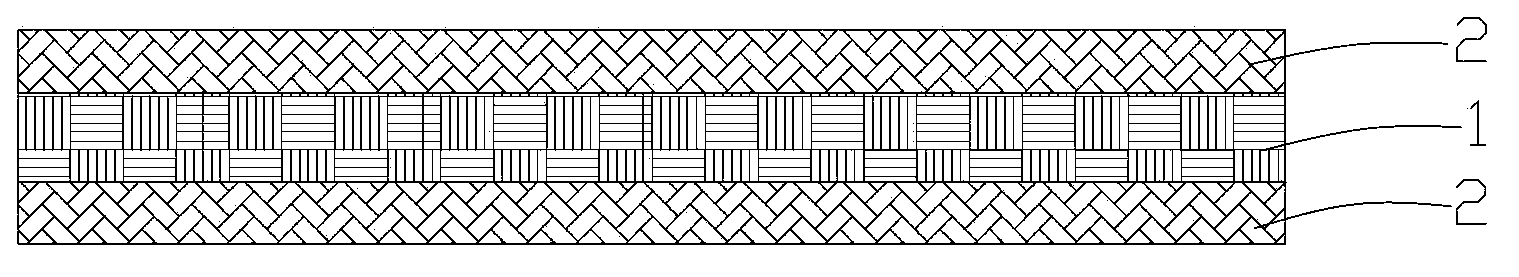

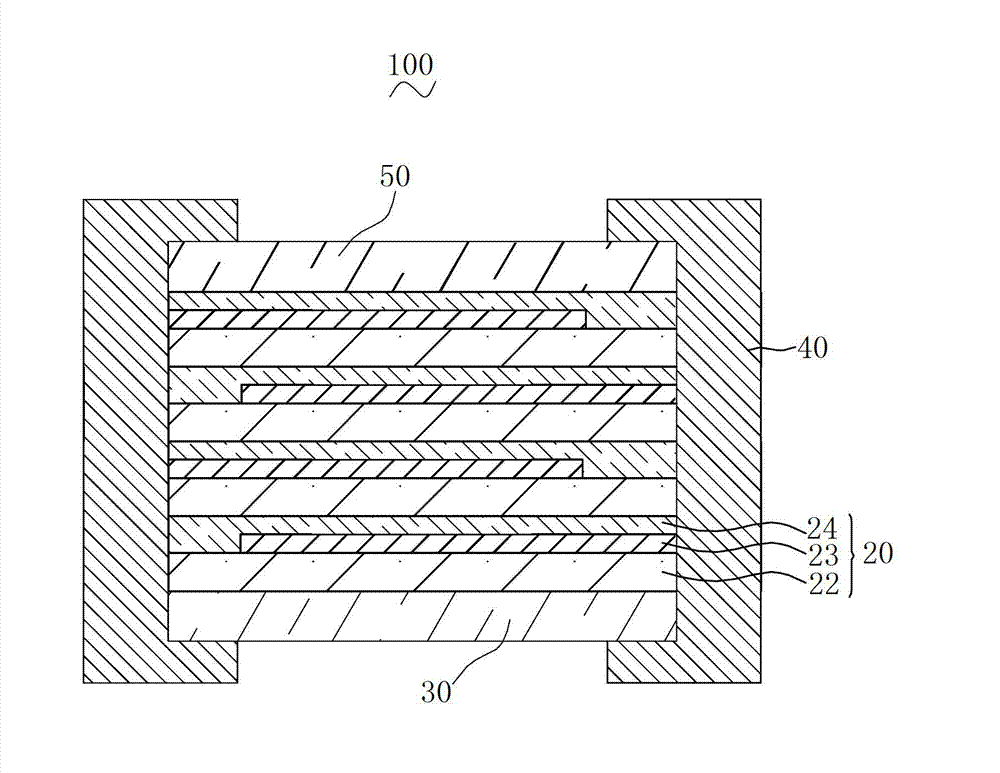

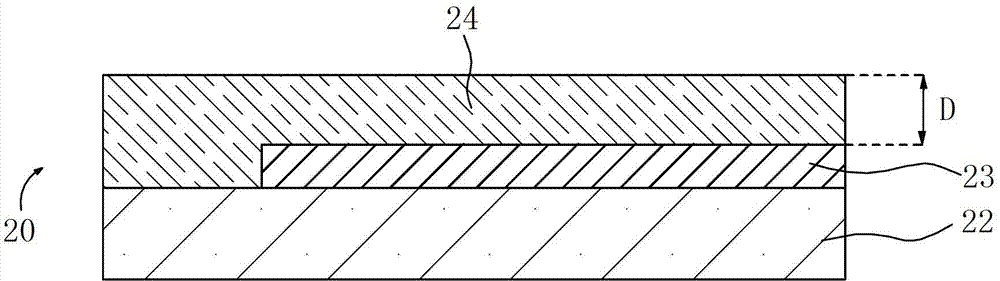

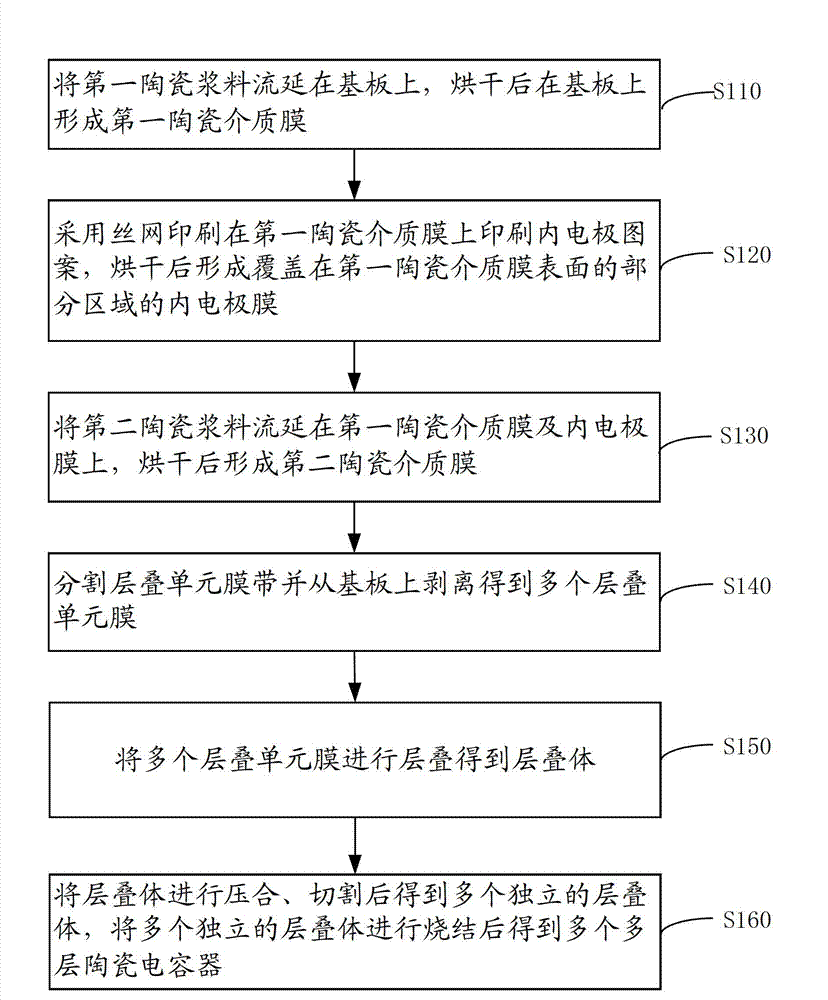

Multilayer ceramic capacitor and preparation method thereof

ActiveCN103050278AGuaranteed capacityIncrease effective capacityFixed capacitor electrodesFixed capacitor dielectricMicrometerMetallurgy

The invention provides a multilayer ceramic capacitor, which comprises a plurality of superposed superposing units, wherein each superposing unit comprises a first ceramic dielectric layer and an inner electrode layer formed in a partial area on the surface of the first ceramic dielectric layer; each superposing unit also comprises a second ceramic dielectric layer which covers the inner electrode layer and an area which is not covered by the inner electrode layer on the surface of the first ceramic dielectric layer; and a distance from the surface of the second ceramic dielectric layer far from the first ceramic dielectric layer to the surface of the inner electrode layer far from the first ceramic dielectric layer is 0.56 to 2.1 micrometers. By the multilayer ceramic capacitor with the structure, height difference and gaps are eliminated, inner electrode layers of two adjacent superposing units can be accurately aligned, and the reliability and effective capacity of the multilayer ceramic capacitor are higher. Furthermore, the invention provides a preparation method for the multilayer ceramic capacitor.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

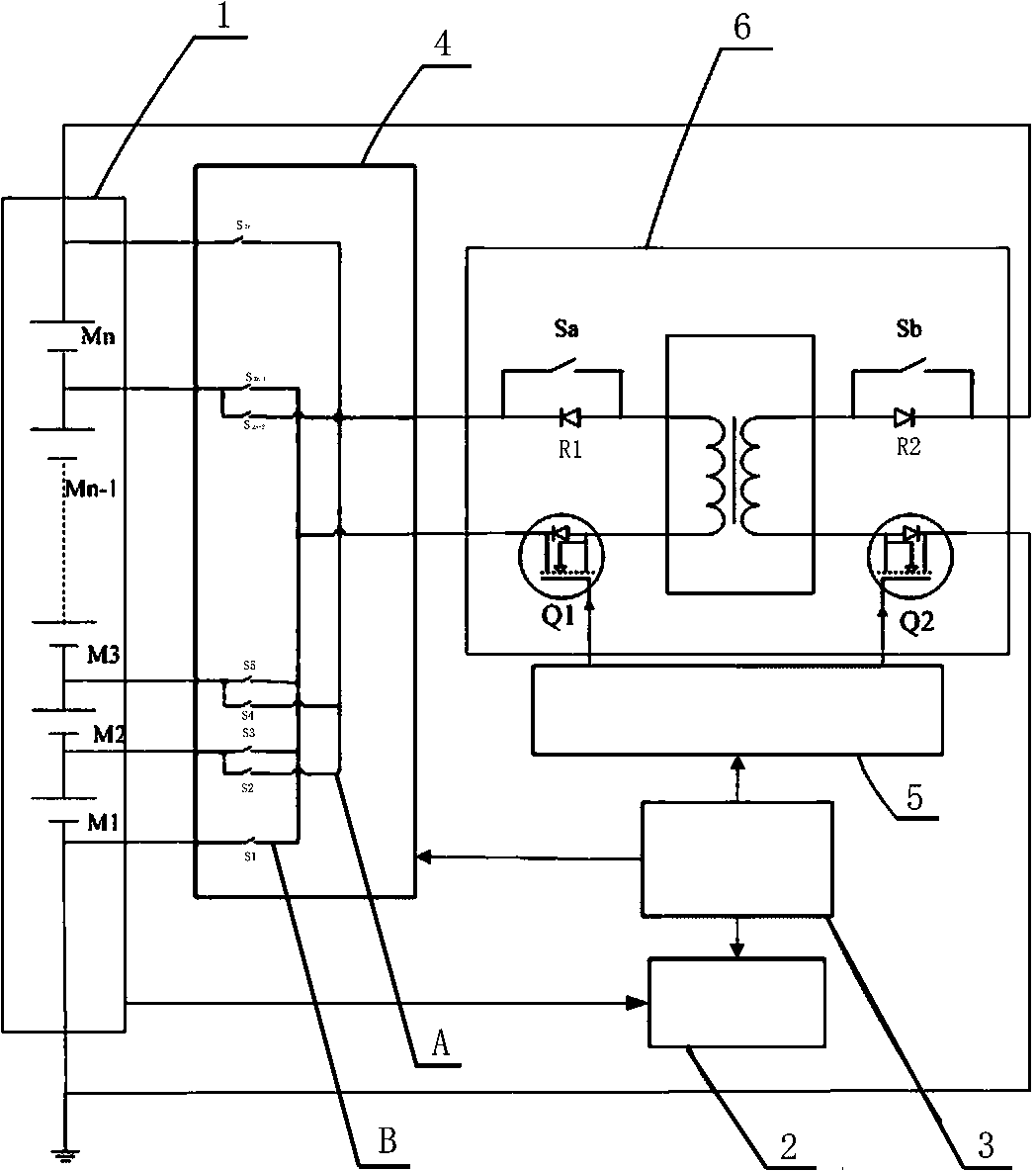

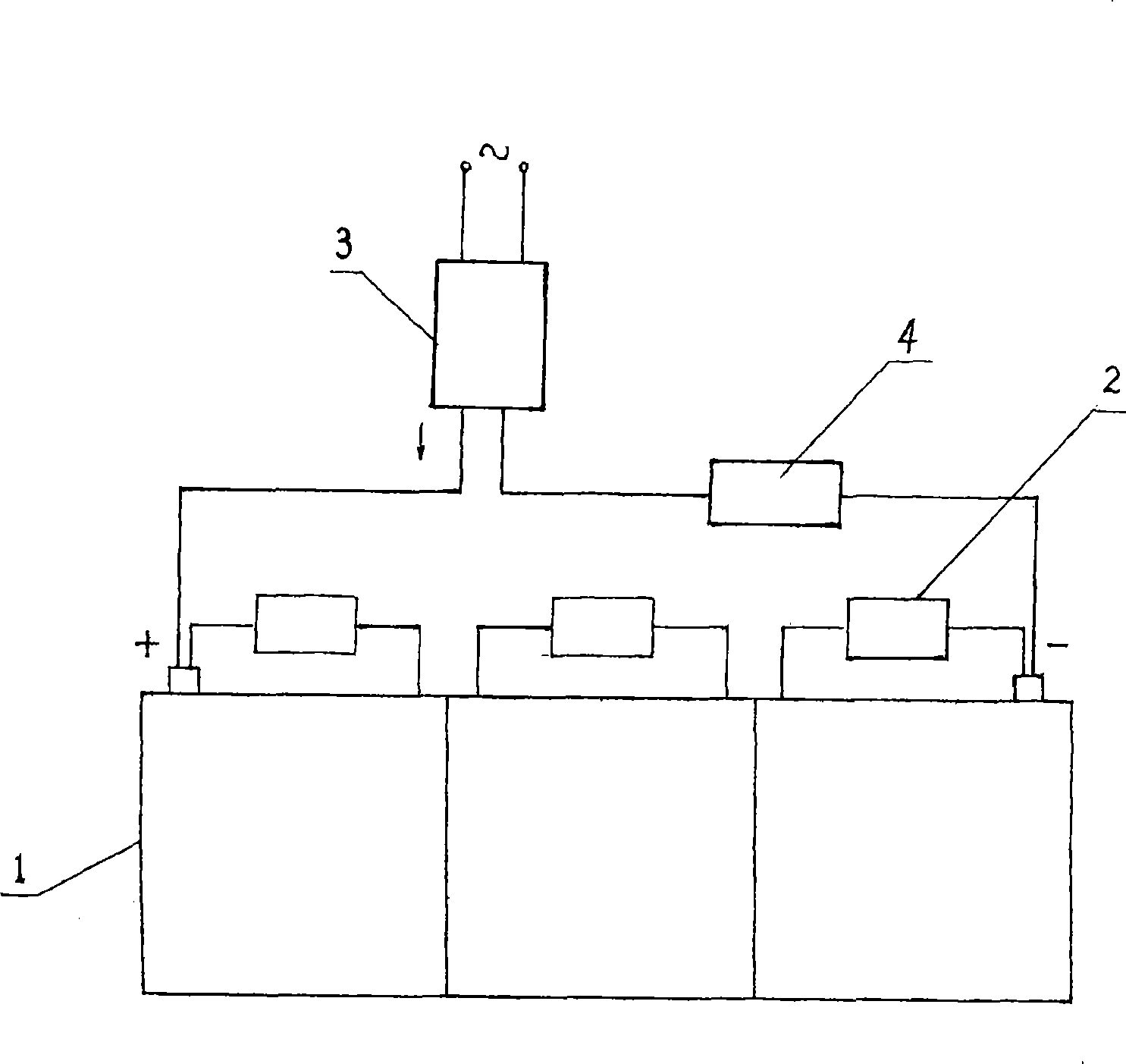

Active equalizing system and equalizing method for power lithium ion battery pack

ActiveCN103236732AWork lessPrevent overchargingBatteries circuit arrangementsElectric powerElectrical batteryTransformer

The invention relates to an active equalizing system and an active equalizing method, in particular to an active equalizing system and an active equalizing method for a power lithium ion battery pack. The active equalizing system comprises a battery module (1), a matrix control circuit (4), a DC / DC (Direct Current to Direct Current) unit (6), a PWM (Pulse Width Modulation) control unit (5), a main control unit (3) and a voltage temperature sampling unit (2); and by control on the DC / DC unit (6) and the matrix control circuit (4), the charging and discharging direction of a transformer T1 is changed and functions of upper limit equalizing, lower limit equalizing and energy compensation on electrical quantities of unit cells in the battery module (1) are implemented. The active equalizing system and the active equalizing method have the following advantages that (1) due to the adoption of a low-loss equalizing technology, service life is prolonged; (2) the current equalizing capacity of a large current equalizing technology reaches over lOA; (3) due to the adoption of a bidirectional equalizing technology, direct bidirectional energy transfer between one random unit cell in the battery pack and the battery module can be implemented; and (4) the active equalizing system adopts a distributed design and has a simple and practical structure and very good expandability.

Owner:CETHIK GRP

Lead acid accumulator renovation system and method thereof

InactiveCN101431170ASmall self-dischargeReduce pollutionCharge equalisation circuitLead-acid accumulatorsSocial benefitsElectrical battery

The invention relates to a lead-acid battery repair system which is designed against the difficult problem of irreversible vulcanization of a lead-acid battery and formed by combining a battery balancer and a devulcanized charger; and a developed repair agent is used for repair. Or a repair instrument is matched with the repair agent for direct repair. The repair technology can repair and use a waste vulcanized battery. The invention realizes the purpose of rapid elimination of the vulcanization by the self-repair and the principle of combing the physics and the chemistry to eliminate the vulcanization. The invention can prolong the service life of various lead-acid batteries to more than two times, lengthen the driving distance of various vehicles and repair various waste lead-acid batteries. The technology has simple operation, low cost, easy promotion, wide range of application and remarkable economic and social benefits.

Owner:邢纪国

Mixed lead paste capable of improving binding force of positive grid of lead-acid storage battery and lead paste and preparation method of mixed lead paste

InactiveCN107887591AEffective solution to bindingSolve the bonding problemLead-acid accumulatorsCell electrodesFiberBinding force

The invention discloses mixed lead paste capable of improving the binding force of a positive grid of a lead-acid storage battery and lead paste and a preparation method of the mixed lead paste. The method comprises the following steps of adding lead powder which is 80-90% of total mass to a paste mixing machine, adding the following raw materials by percentages: 8-10% of sulfuric acid, 0.1-0.3% of stannous sulfate, 0.08-0.10% of conductive fiber, 0.3-0.5% of colloidal graphite, 0.05-0.15% of sodium borate and 1.0-1.2% of antimonic oxide, carrying out dry mixing for 8-10min, adding deionized water, carrying out wet mixing for 2min, adding residual paste and carrying out wet mixing for 8-10min; and dropwise adding the sulfuric acid which is 8-10% of total mass and stirring for 10-12min to obtain the lead paste of which the apparent density is 4.4+ / -0.02g / cm<3>. According to the mixed lead paste, the interface problem between an existing battery grid and an active material of the lead paste can be effectively solved, the bonding force between the positive grid and the lead paste is improved, the strength of a polar plate is improved and the cycle life of the battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

Valve-regulated lead acid storage battery polar group and polar plate packaging method thereof

InactiveCN102082301AGuaranteed capacityIncrease profitFinal product manufactureLead-acid accumulator electrodesElectrical polarityEngineering

The invention discloses a valve-regulated lead acid storage battery polar group and a polar plate packaging method thereof. The valve-regulated lead acid storage battery polar group comprises positive plates, negative plates and partition plates arranged among the positive plates and the negative plates, and is characterized in that: the polar plates positioned on the two sides of the polar group are negative plates; the polar plates, with the same polarity, of the positive plates and the negative plates between the two negative plates serve as a group and are partitioned by the partition plates; positive plate groups and negative plate groups are continuously arranged in turn to a set number and end with a positive plate group; and in each group, the total number of the positive plates is equal to the total number of the negative plates. The valve-regulated lead acid storage battery polar group improves the active material utilization rate of the valve-regulated lead acid storage battery polar group, simultaneously does not influence the service life of the valve-regulated lead acid storage battery polar group, and reduces the overall cost relatively.

Owner:ZHEJIANG TIANNENG BATTERY JIANGSU

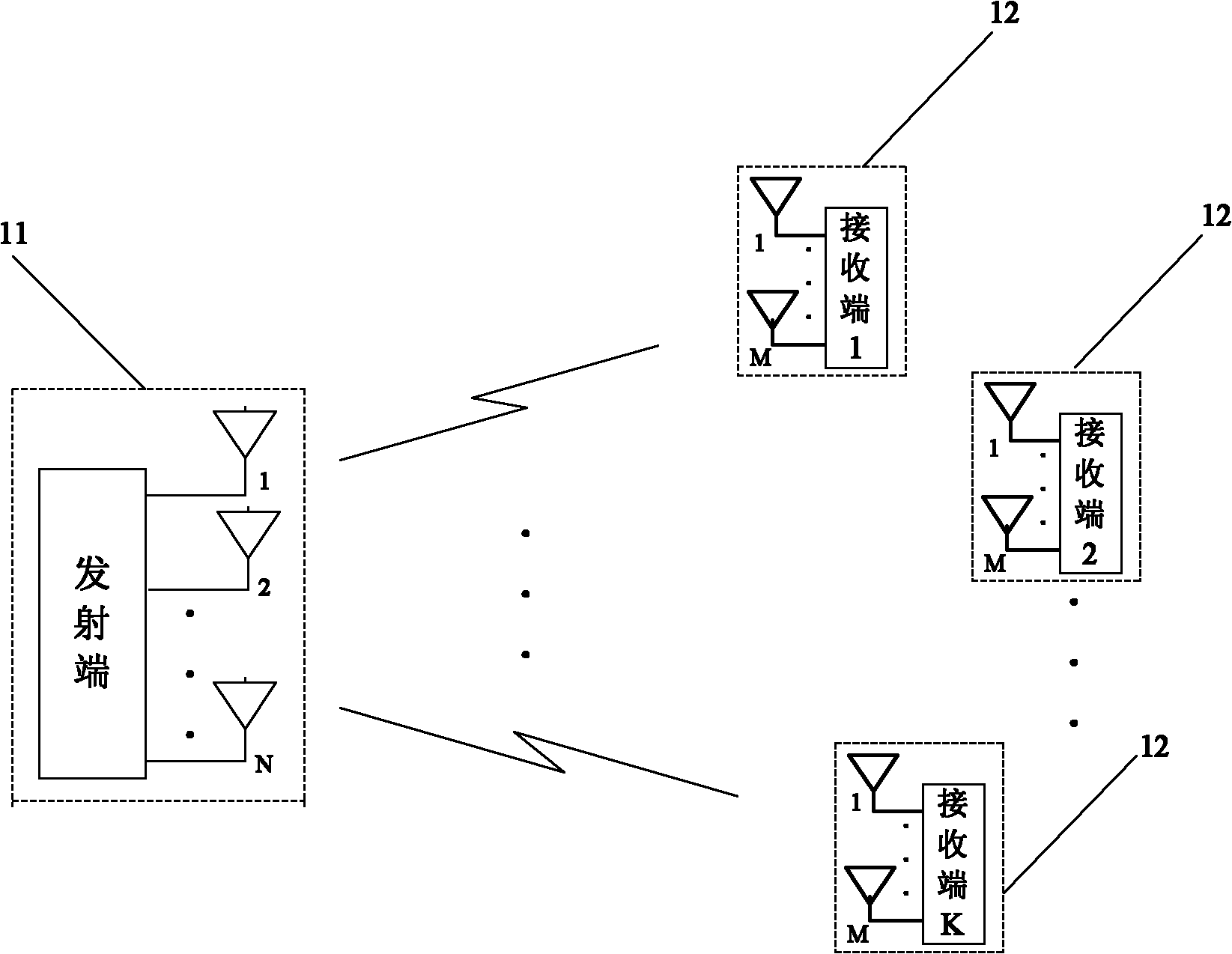

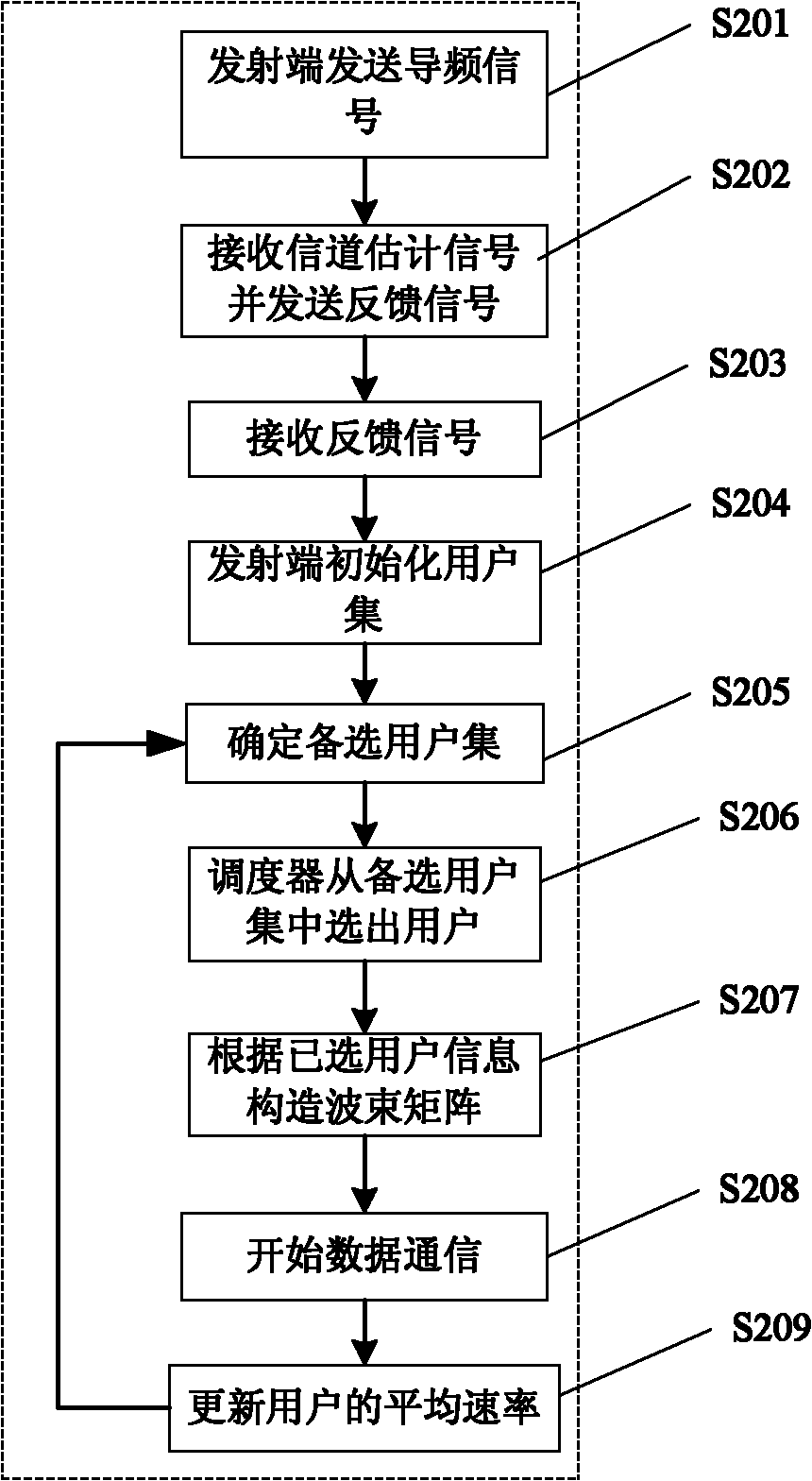

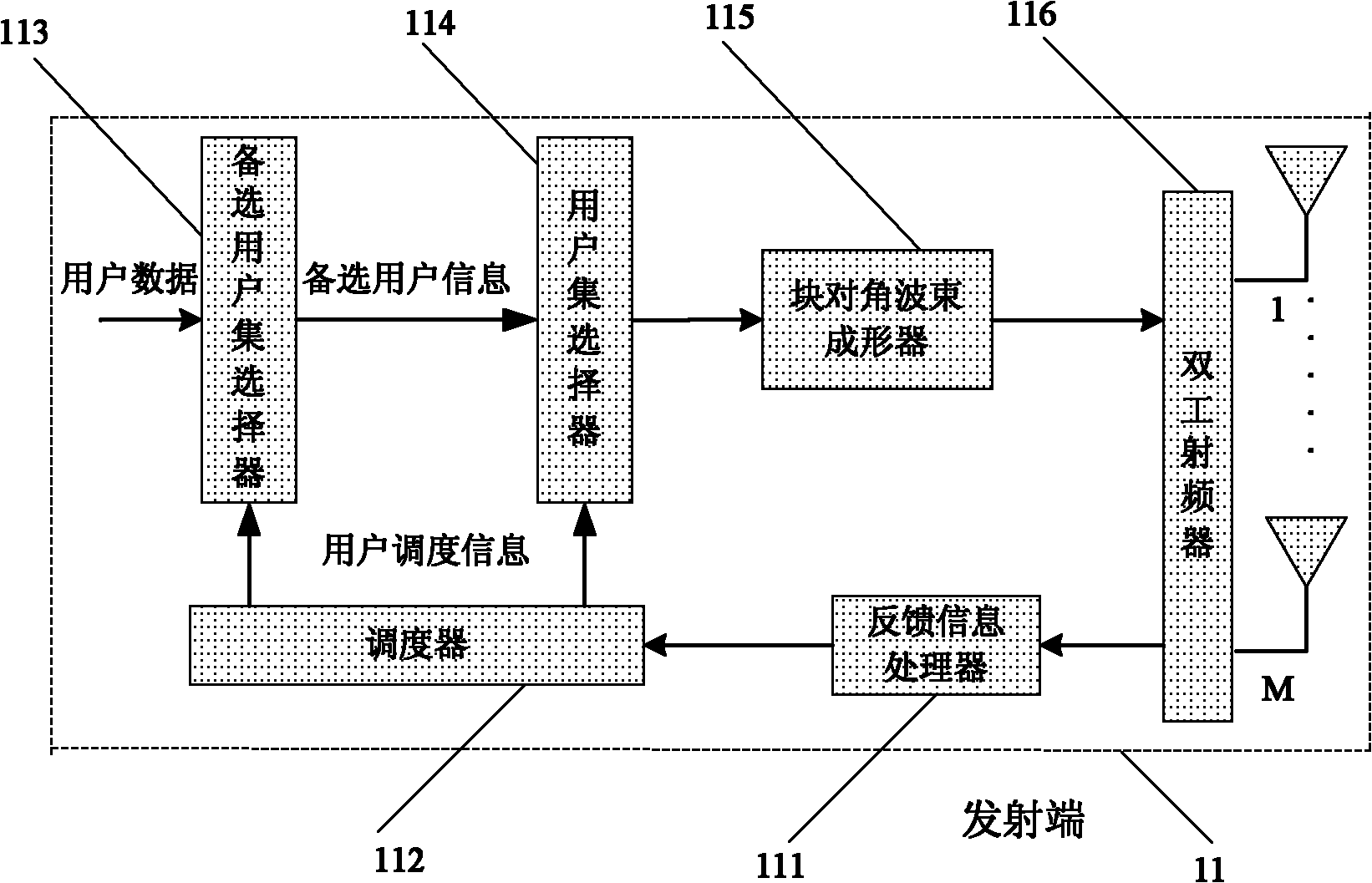

Multiuser MIMO (multiple-input multiple-output) downlink transmitting and dispatching method

InactiveCN101834650AGuaranteed capacitySpatial transmit diversityError prevention/detection by diversity receptionTelecommunicationsMultiple input

The invention discloses a multiuser MIMO (multiple-input multiple-output) downlink transmitting and dispatching method comprising the following steps of: (1) transmitting a pilot signal by a transmitting end; (2) receiving the pilot signal by a receiving end, carrying out channel estimation, and then, transmitting a feedback signal to the transmitting end; (3) receiving the feedback signal by the transmitting end through an uplink channel and obtaining channel matrixes of all users by the transmitting end through the feedback signal; (4) initializing a user set by the transmitting end; (5) determining an optional user set by the transmitting end; (6) selecting users from the optional user set by the transmitting end; (7), constructing a block diagonal beam matrix by the transmitting end; and (8) starting data communication. The multiuser MIMO downlink transmitting and dispatching method combines volume upperbound maximization and proportional fairness algorithm, ensures system justification by adding the optional user set in a user set selecting process, and ensures system volume by selecting a user who can make a system volume upperbound maximum from the optional user set.

Owner:HUAZHONG UNIV OF SCI & TECH

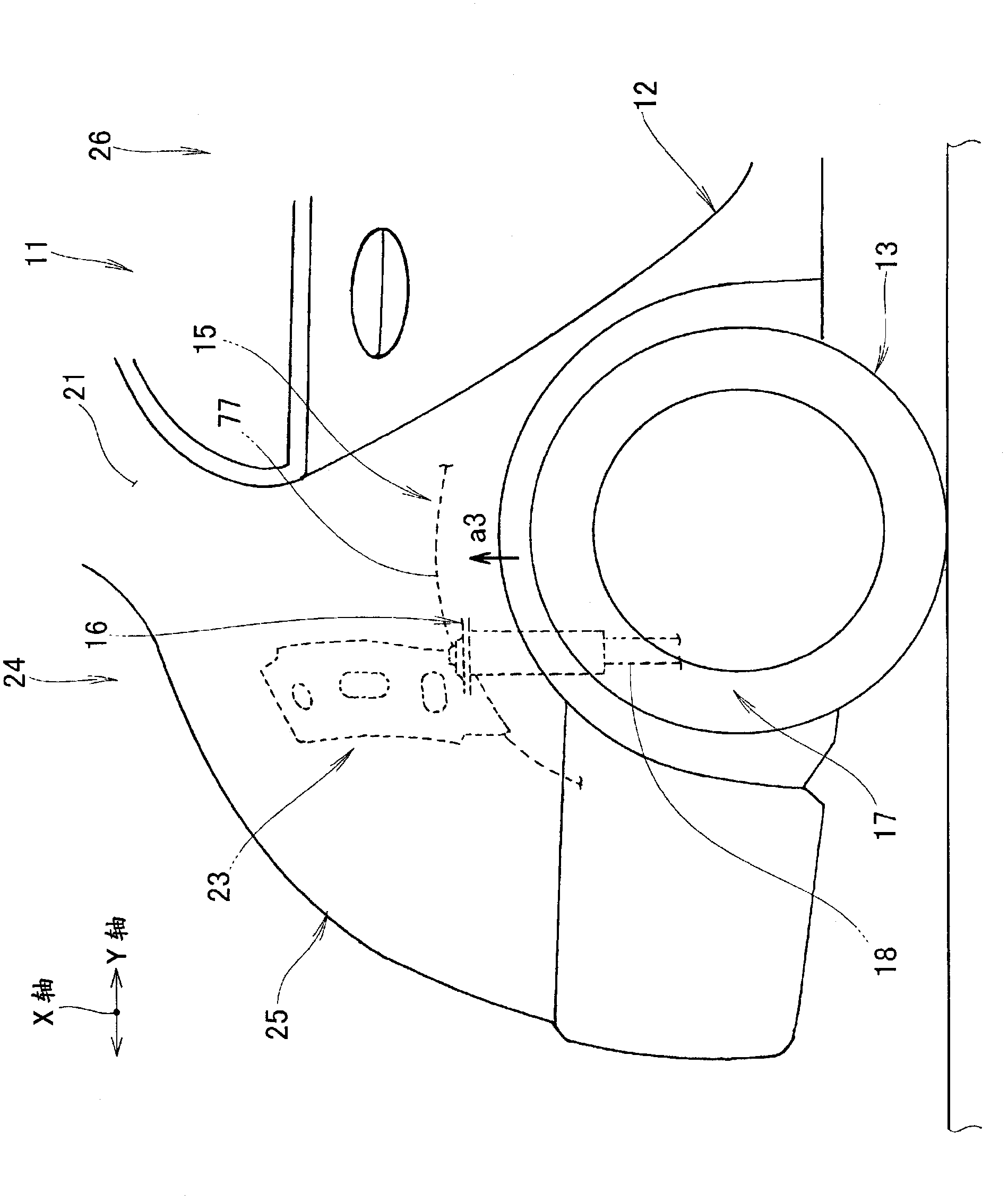

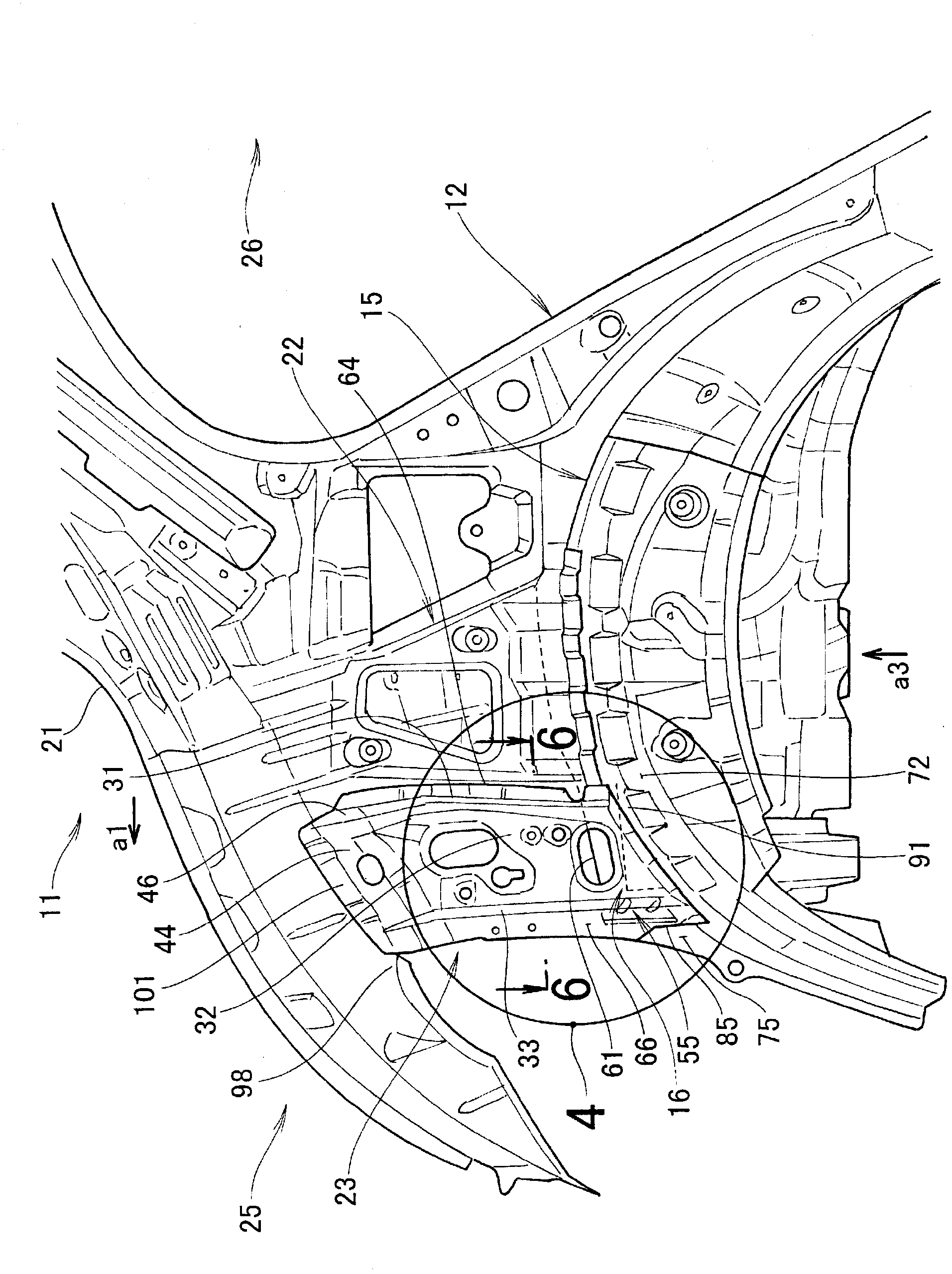

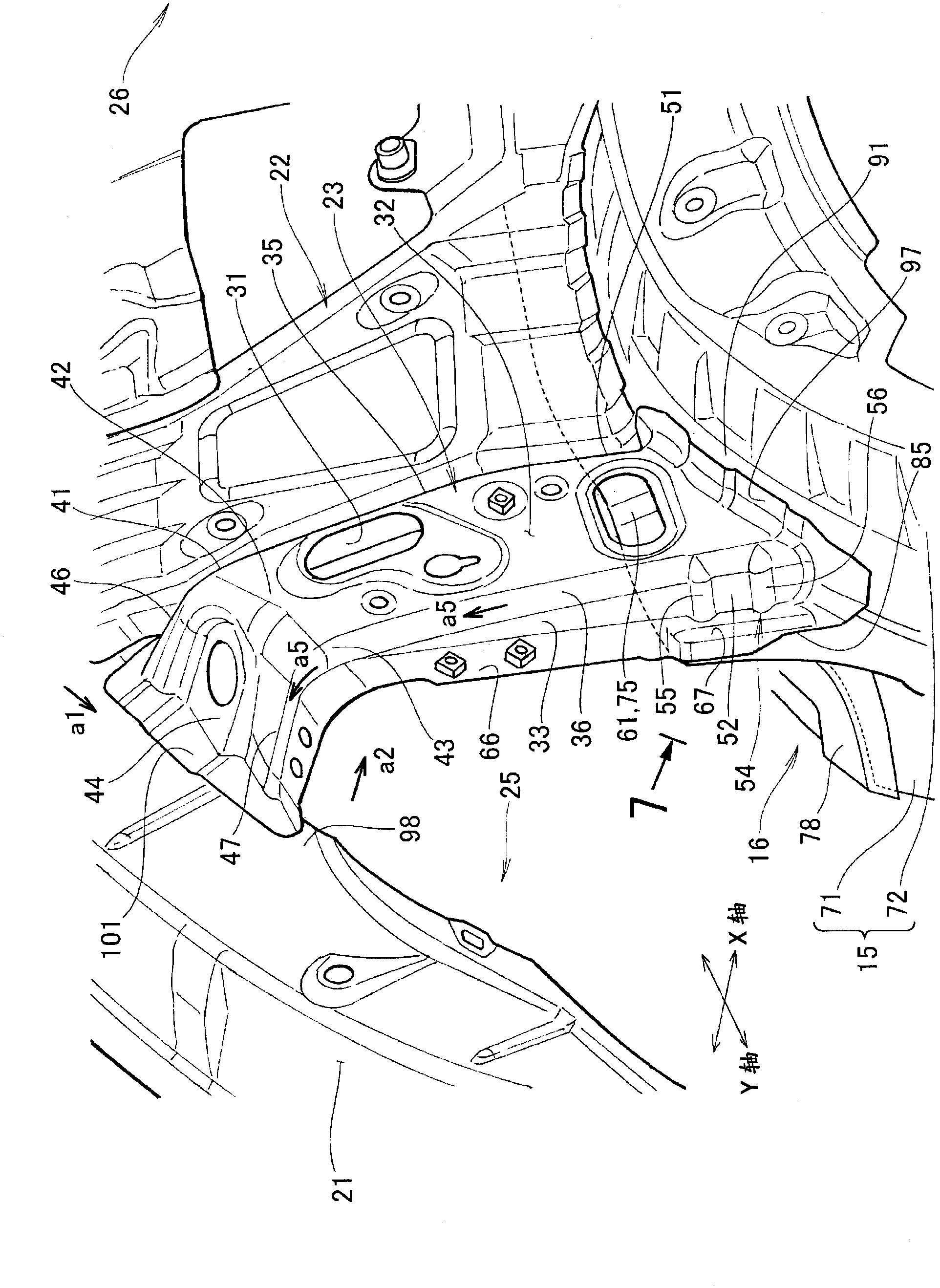

Structure for vehicle body rear portion

ActiveCN103038125AGuaranteed StrengthHigh strengthSuperstructure subunitsEngineeringMechanical engineering

A structure for a vehicle body rear portion has a rear pillar (21), a rear wheel arch (15), a damper stiffener (22) which is connected so that the load of the damper (18) transmitted through the rear wheel arch (15) is dispersed to the rear pillar (21), and a brace (23) which is connected from the rear wheel arch (15) to the rear pillar (21). The brace (23) has a front surface section (31) which faces forward, a side surface section (32), and a rear surface section (33) which faces the front surface section (31). A front ridge line section (35) and / or a rear ridge line section (36) reaches the rear pillar (21) from the rear wheel arch (15).

Owner:HONDA MOTOR CO LTD

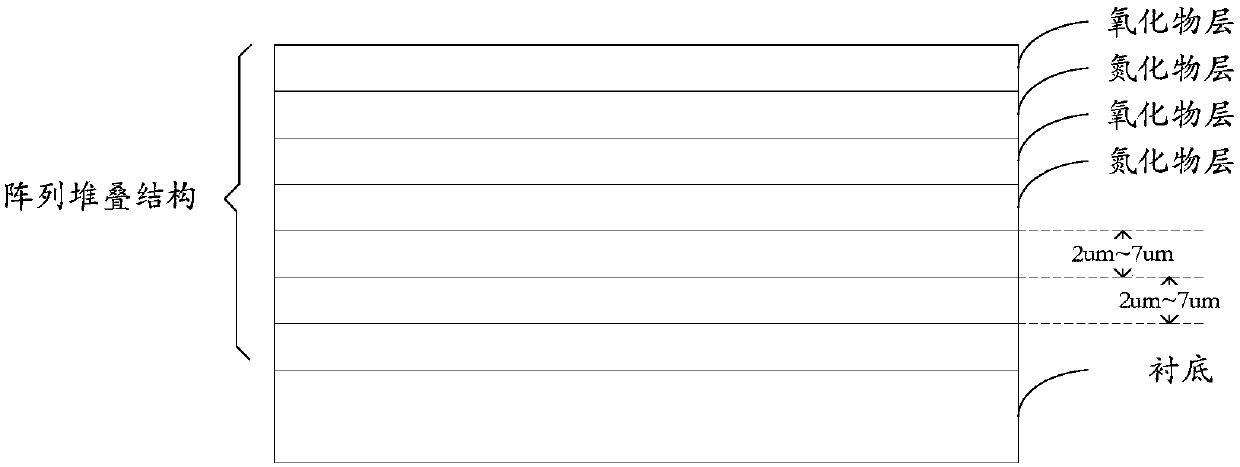

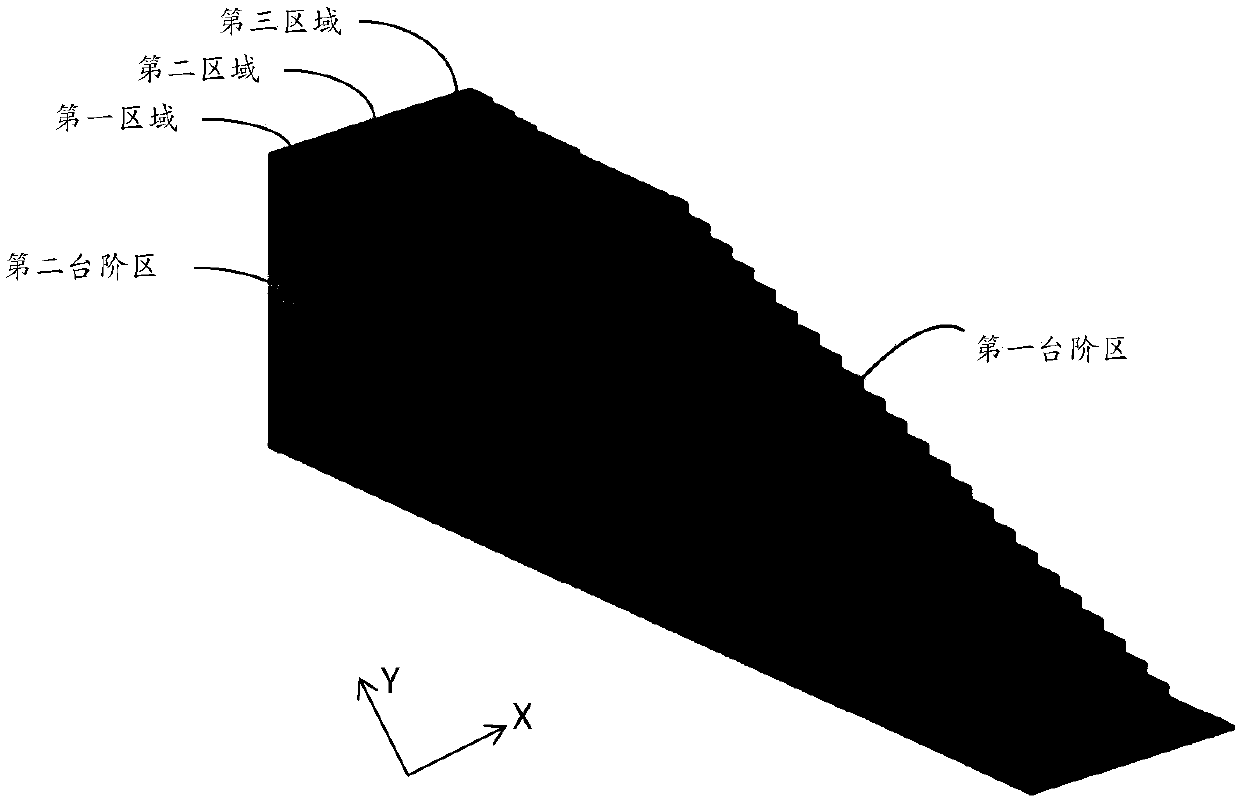

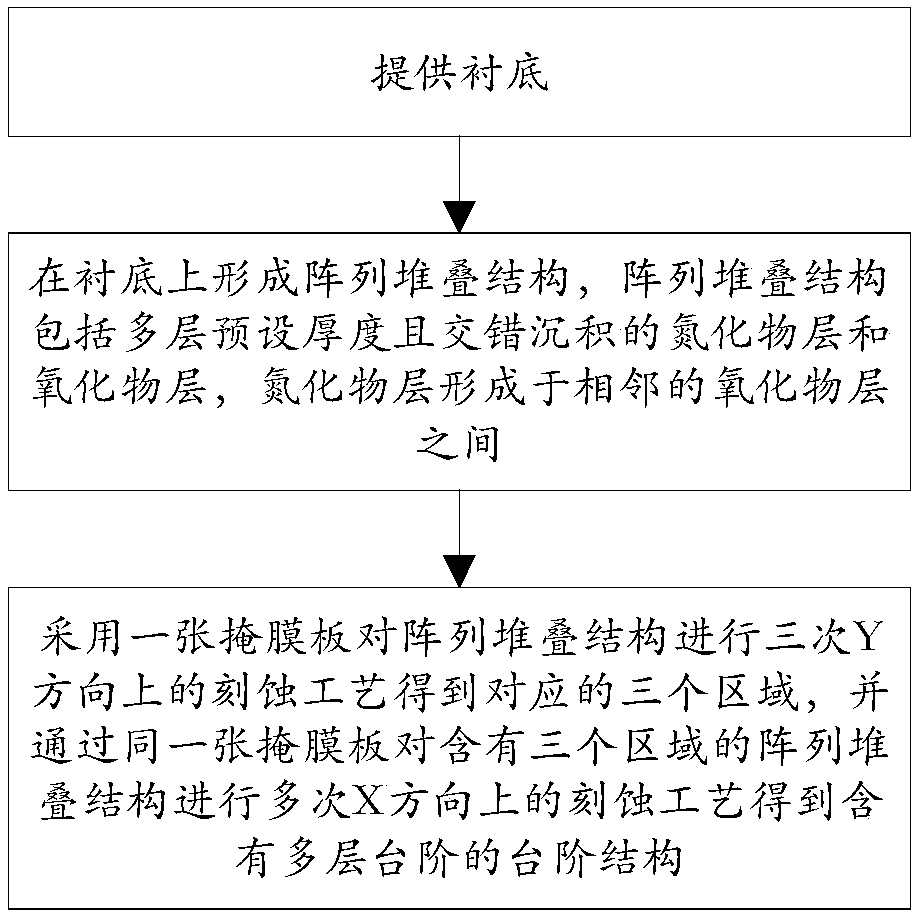

Stage structure of three-dimensional memory and formation method of stage structure

ActiveCN107658224AGuaranteed capacityGuaranteed reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingNitrideSemiconductor

The invention discloses a stage structure of a three-dimensional memory and a formation method of the stage structure, and belongs to the technical field of a semiconductor. The method comprises the steps of providing a substrate; forming an array stacked structure on the substrate, wherein the array stacked structure comprises multiple layers of nitride layers and oxide layers which are depositedin a staggered manner with preset thicknesses, and the nitride layers are formed between adjacent oxide layers; and performing three times of an etching process in a Y direction on the array stackedstructure by adopting a mask plate to obtain three corresponding regions, and performing multiple times of the etching process in an X direction on the array stacked structure comprising the three regions by adopting the same mask plate to obtain the stage structure comprising multiple layers of stages. By virtue of the formation method, on the basis that the capacity and processing reliability ofthe three-dimensional storage are ensured, the volume of the three-dimensional memory is reduced, and the manufacturing cost of the three-dimensional memory is greatly lowered.

Owner:YANGTZE MEMORY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com