Graphene composite negative current collector, preparation method thereof and lithium ion battery

A graphene composite and current collector technology, which is applied in the field of electrochemical power sources, can solve the problems of affecting battery life, metal materials are easily corroded, and battery energy density is low, and achieve chemical stability and corrosion resistance, light weight, and non-embedded The effect of lithium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

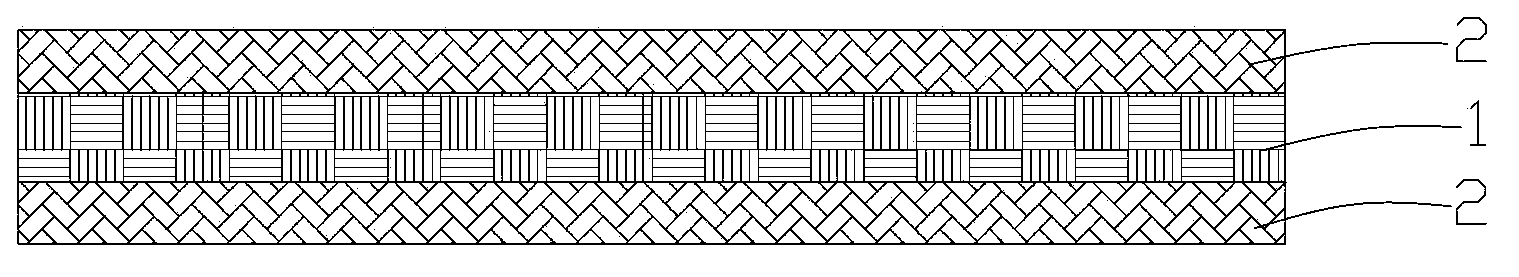

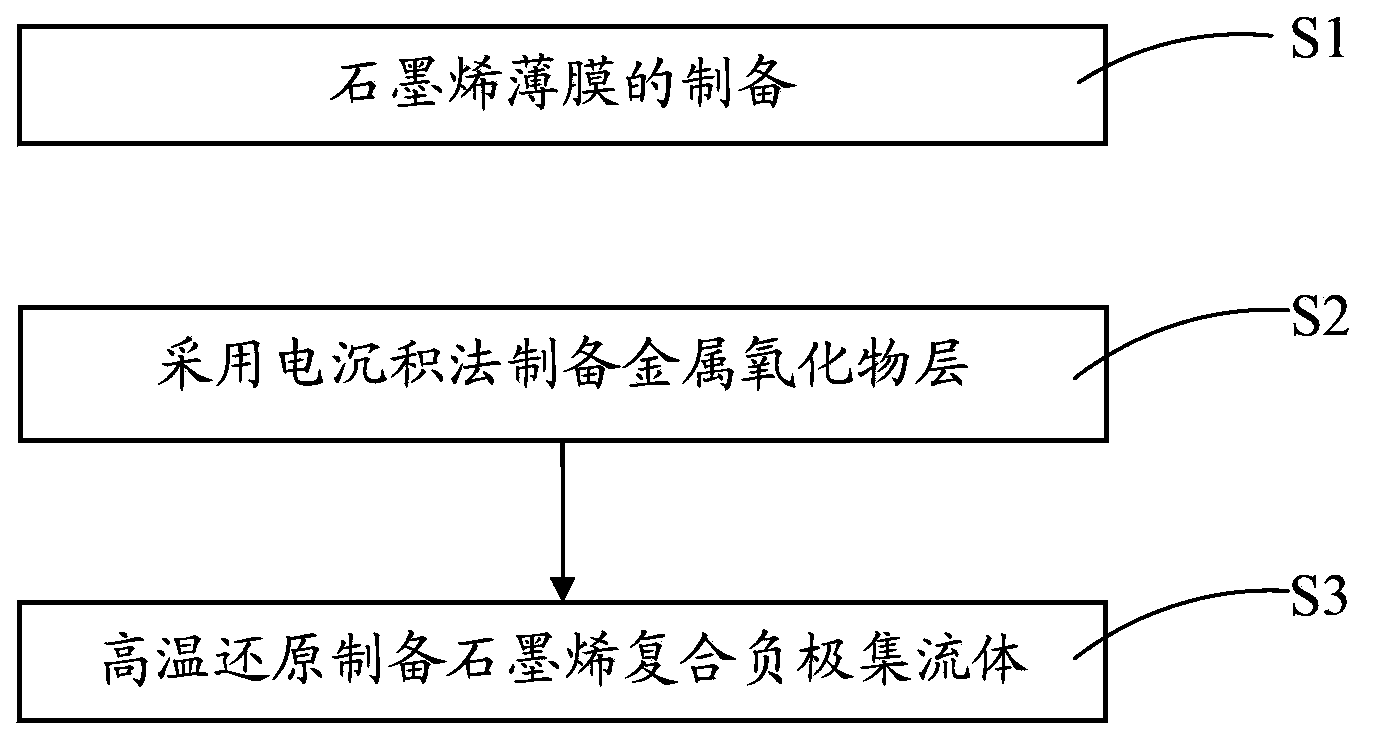

[0025] The example of the present invention also provides a method for preparing a graphene composite negative electrode current collector with simple process, high efficiency, and easy operation and control. For the preparation method process flow of the graphene composite negative electrode current collector, please refer to figure 2 , see also figure 1 , including the following steps:

[0026] Step S01. Preparation of graphene film: vacuum filter the graphene suspension with a microporous membrane, dry the filter cake and separate the microporous membrane to obtain graphene film 1;

[0027] Step S02. Prepare the metal oxide layer 2 by electrodeposition: use the graphene film 1 prepared in step S01 as a working electrode, and place it in an alkaline electrolyte containing a metal salt with a concentration of 0.25-0.5 mol / L. 0.5~3mA / cm 2 Electrodeposition under the action of a constant current for 5 to 10 minutes; wherein, the metal salt in the electrolyte is a metal salt...

Embodiment 1

[0060] A graphene composite negative electrode current collector and preparation method thereof:

[0061] The structure of the graphene composite negative electrode current collector is as follows: figure 1 As shown, it includes a graphene film layer 1 and a metal oxide layer 2 combined on both sides of the graphene film layer 1. Wherein, the thickness of the metal oxide layer 2 is 1 μm, and the oxide is Cr 2 o 3 ; The thickness of the graphene film layer 1 is 3 μm.

[0062] The specific steps of the preparation method of the graphene composite negative electrode current collector are as follows:

[0063] S11. Preparation of graphene oxide suspension: add graphite oxide to deionized water, ultrasonically for 0.5h, configure a uniformly dispersed graphene oxide suspension with a concentration of 0.25mg / ml, then add ammonia water, adjust the pH value, and make it pH value reaches 10;

[0064] S12. Preparation of graphene suspension: add hydrazine hydrate (85%) (wherein mass...

Embodiment 2

[0069] A graphene composite negative electrode current collector and preparation method thereof:

[0070] The graphene composite negative electrode current collector structure in Example 1 of the graphene composite negative electrode current collector structure. Among them, the thickness of the metal oxide layer is 1 μm, and the oxide is MnO 2 ; The thickness of the graphene film layer is 5 μm.

[0071] The specific steps of the preparation method of the graphene composite negative electrode current collector are as follows:

[0072] S21. Preparation of graphene oxide suspension: add graphite oxide to ethanol, ultrasonicate for 1 h, configure a uniformly dispersed graphene oxide suspension with a concentration of 1 mg / ml, then add ammonia water, adjust the pH value, and make the pH value reach 11 ;

[0073] S22. Preparation of graphene suspension: Add hydrazine hydrate (85%) to the graphene oxide suspension (the mass ratio of RN 2 h 4 / GO=7:10) solution, react at a temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com