Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

A technology of negative electrode material and core-shell structure, which is applied in the field of lithium-ion battery composite negative electrode materials and its preparation, can solve the problems of electrode cycle performance degradation, limited commercial application, and material structure damage, and solve the problem of poor silicon conductivity and improve Capacity utilization rate and effect of improving tap density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

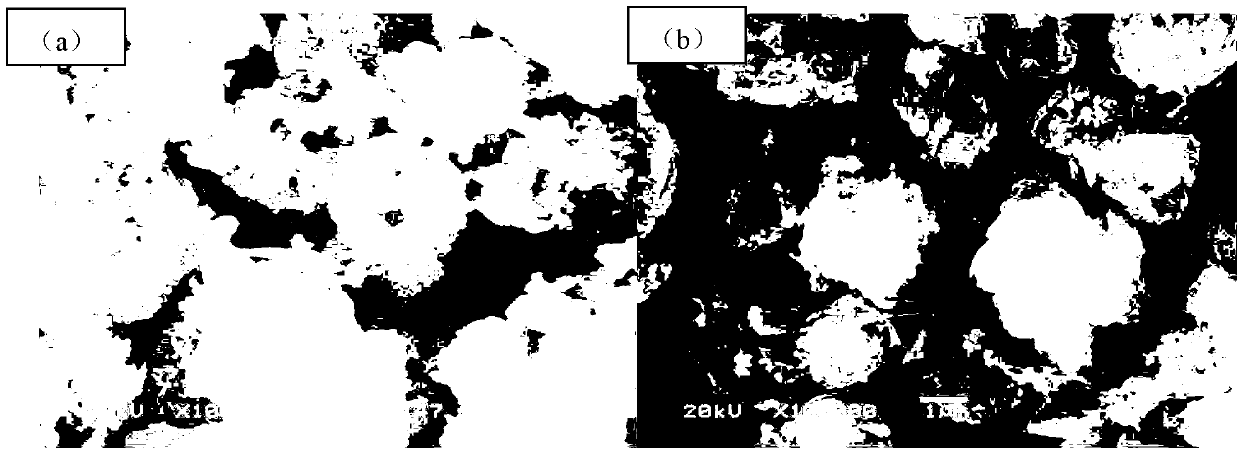

Image

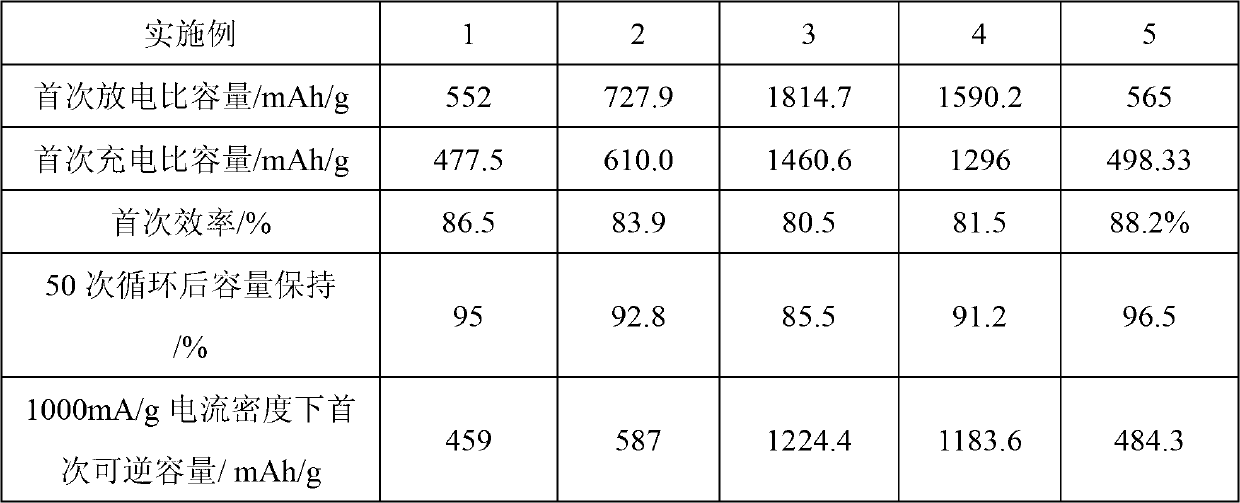

Examples

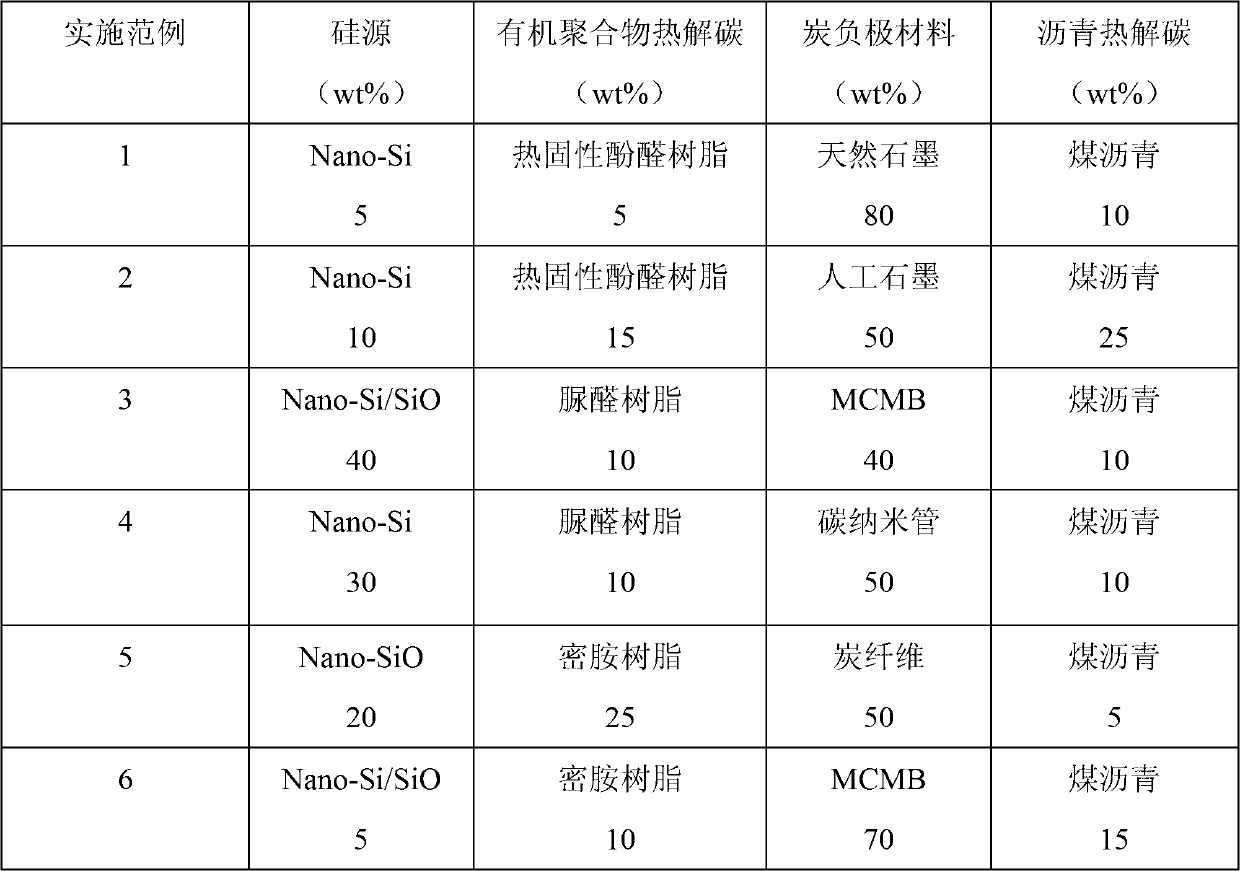

Embodiment 1

[0033](1) High-dispersion multi-nuclear porous balls: add thermosetting phenolic resin (according to the content of pyrolytic carbon in the spherical core material after sintering is 5wt%) into an appropriate amount of de-tetrahydrofuran, stir magnetically to form a solution with a certain viscosity, and then Add silicon powder (according to the mass ratio of silicon / carbon in the spherical core material after sintering: 1:19) and natural graphite (according to 80% of the total mass of the spherical composite material after sintering), then add 10wt% polyethylene glycol dispersant, and ball mill 5h, ultrasonic plus mechanical stirring for 1h, after the uniformly dispersed suspension was spray-dried at 120~200℃, the precursor of multi-nuclear porous spheres was obtained. The obtained powder was transferred into a protective atmosphere at a constant temperature of 500°C for 2 hours, and cooled with the furnace to obtain multi-nuclear porous balls.

[0034] (2) Preparation of hig...

Embodiment 2

[0038] (1) High-dispersion multi-nuclear porous balls: Add polyvinyl alcohol-124 (according to the content of pyrolytic carbon in the composite material after sintering is 15wt.%) into an appropriate amount of deionized water, and magnetically stir to form a solution with a certain viscosity , and then add nano silicon powder (Nano-Si, according to the mass ratio of silicon / carbon in the spherical core material after sintering: 1:10) and natural graphite (50wt.% according to the total mass of the spherical composite material after sintering, and then add 10wt.% Propylene glycol dispersant, ultrasonic plus mechanical stirring to disperse for 1 hour, after spraying and drying the uniformly dispersed suspension at 170~200°C, the precursor of multi-nuclear porous balls is obtained. The obtained powder is transferred to a protective atmosphere at 1000°C for 2 hours, Cooling, that is, polynuclear porous balls.

[0039] (2) Preparation of highly dispersed asphalt suspension: pre-crus...

Embodiment 3

[0043] (1) High-dispersion multi-nuclear porous ball: add urea-formaldehyde resin (according to the content of pyrolytic carbon in the spherical core material after sintering is 10wt.%) into an appropriate amount of deionized water, stir magnetically to form a solution with a certain viscosity, and then Add nano-silica powder and silicon oxide (Si:SiO=1:1, according to the mass ratio of silicon / carbon in the spherical core material after sintering: 2:5) and natural graphite (40wt.% according to the total mass of the spherical composite material after sintering), Then add 1wt.% polyvinyl acetate dispersant, ball mill for 1 hour, ultrasonically add mechanical stirring to disperse for 1 hour, and spray-dry the uniformly dispersed suspension at 170-200°C to obtain the precursor of polynuclear porous balls. The obtained powder was transferred to a protective atmosphere at a constant temperature of 500°C for 5 hours, and cooled with the furnace to obtain multi-nuclear porous balls. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com