Patents

Literature

166results about How to "Improve high-current discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

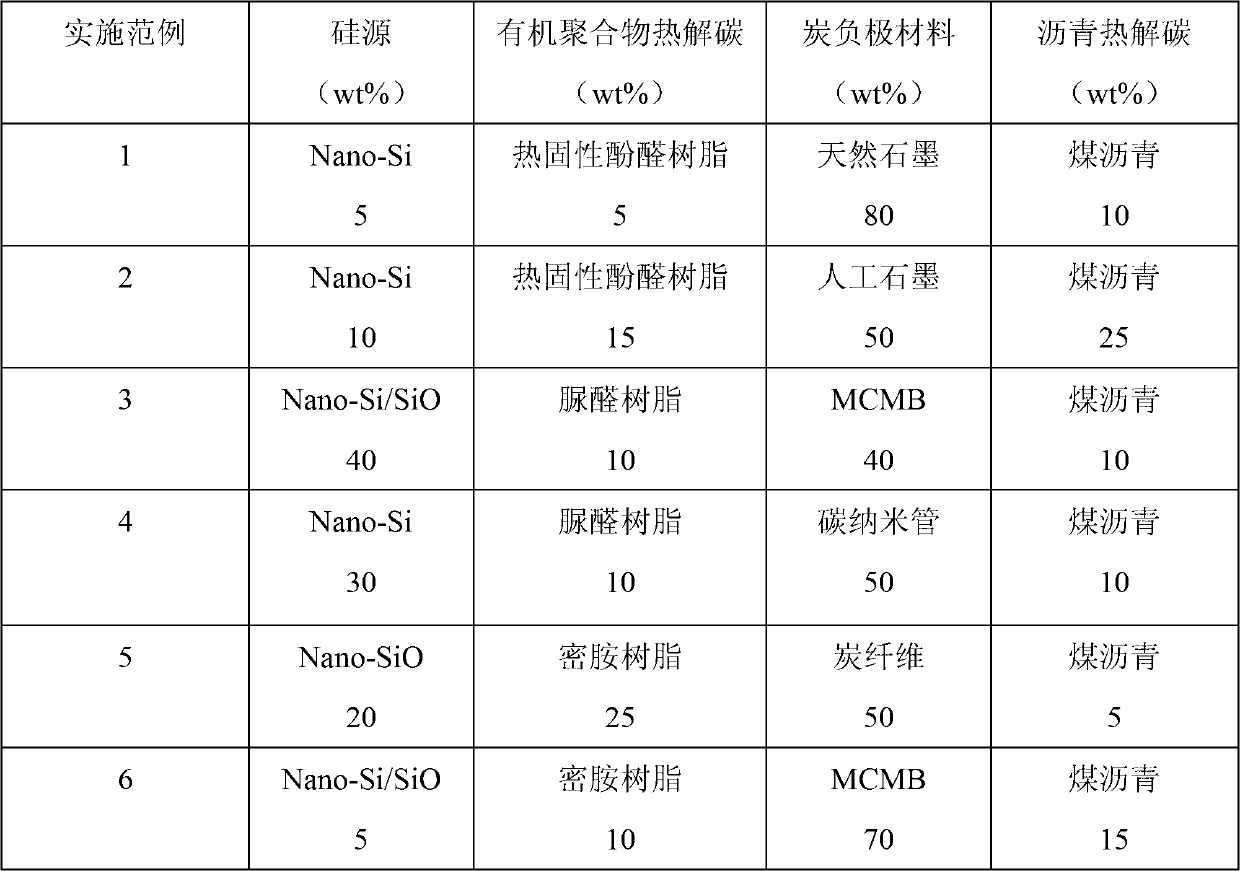

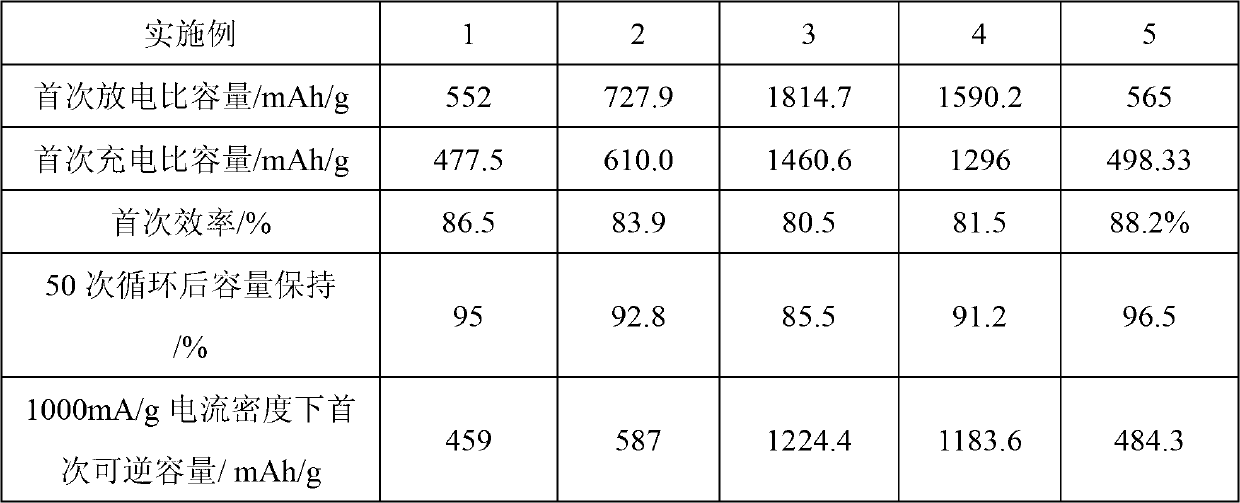

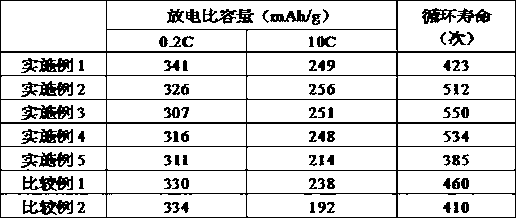

Lithium ion battery composite anode material and preparation method thereof

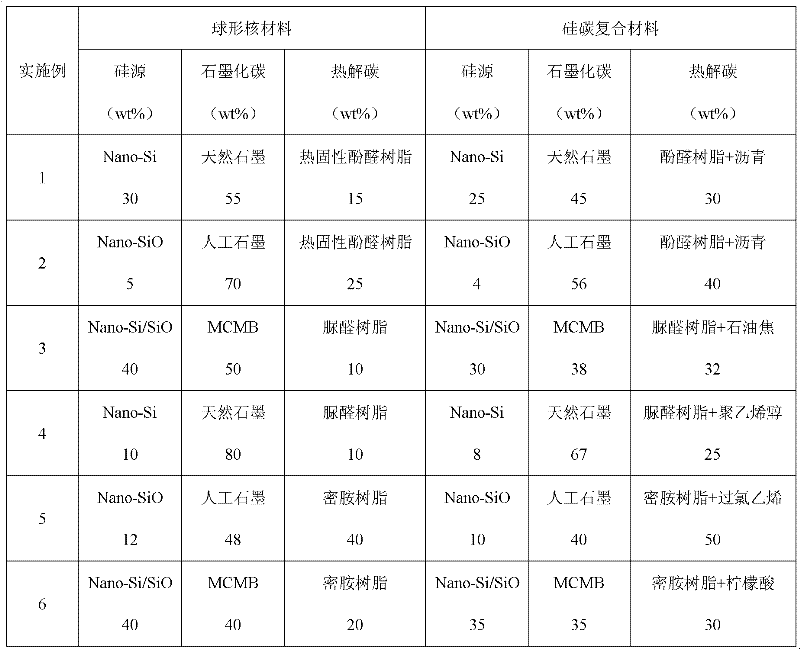

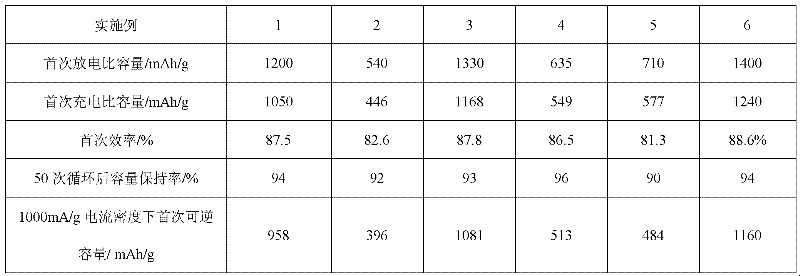

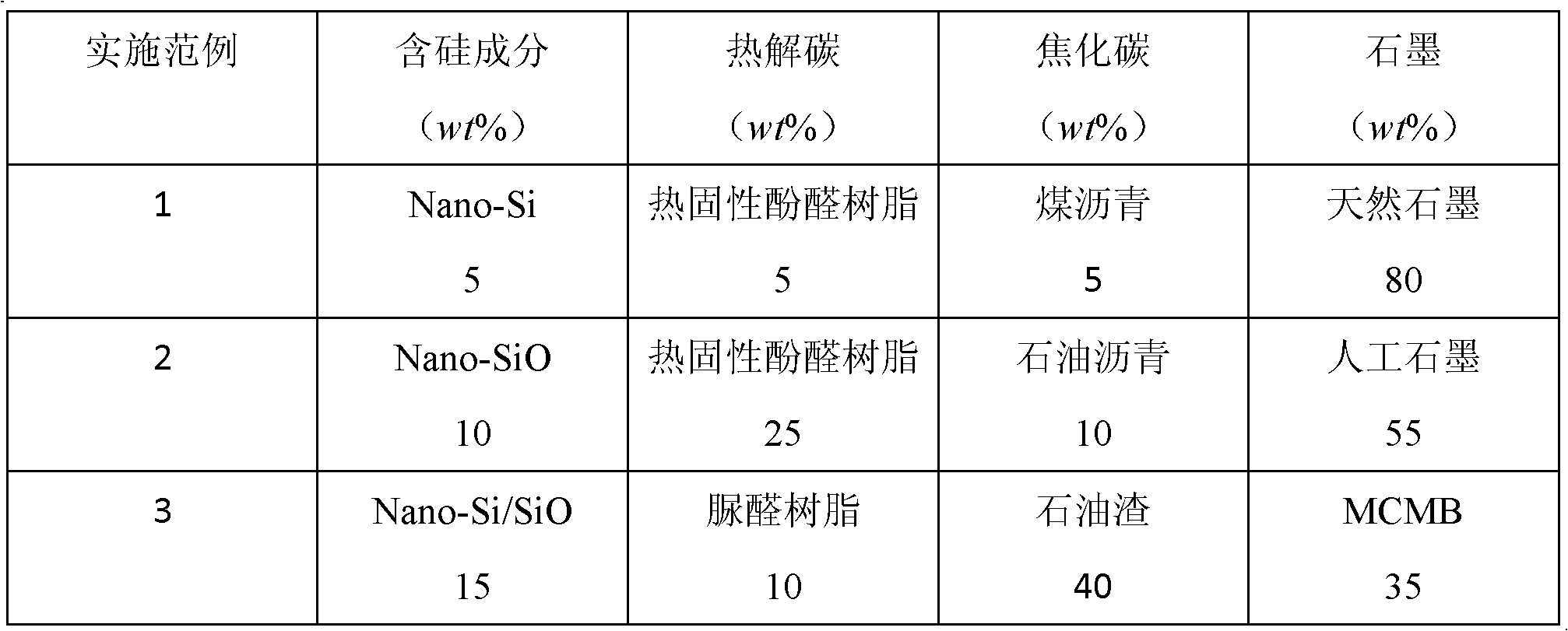

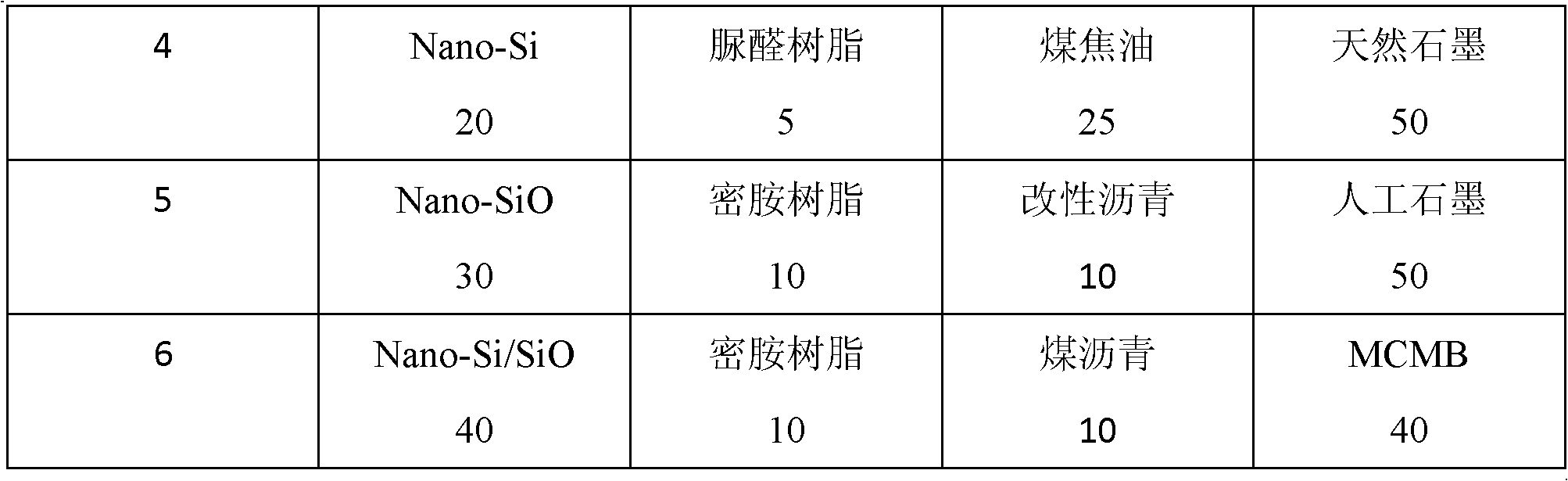

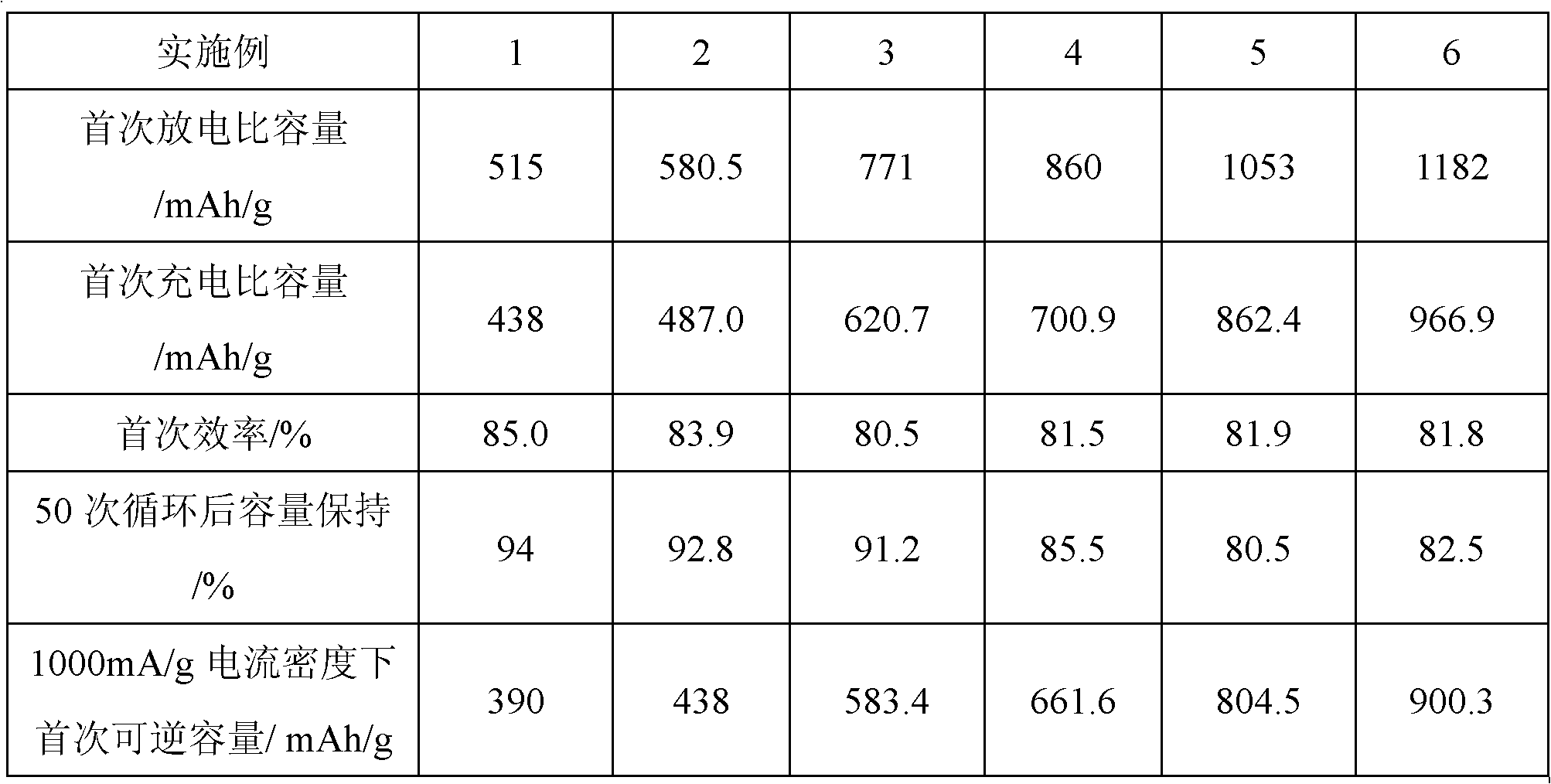

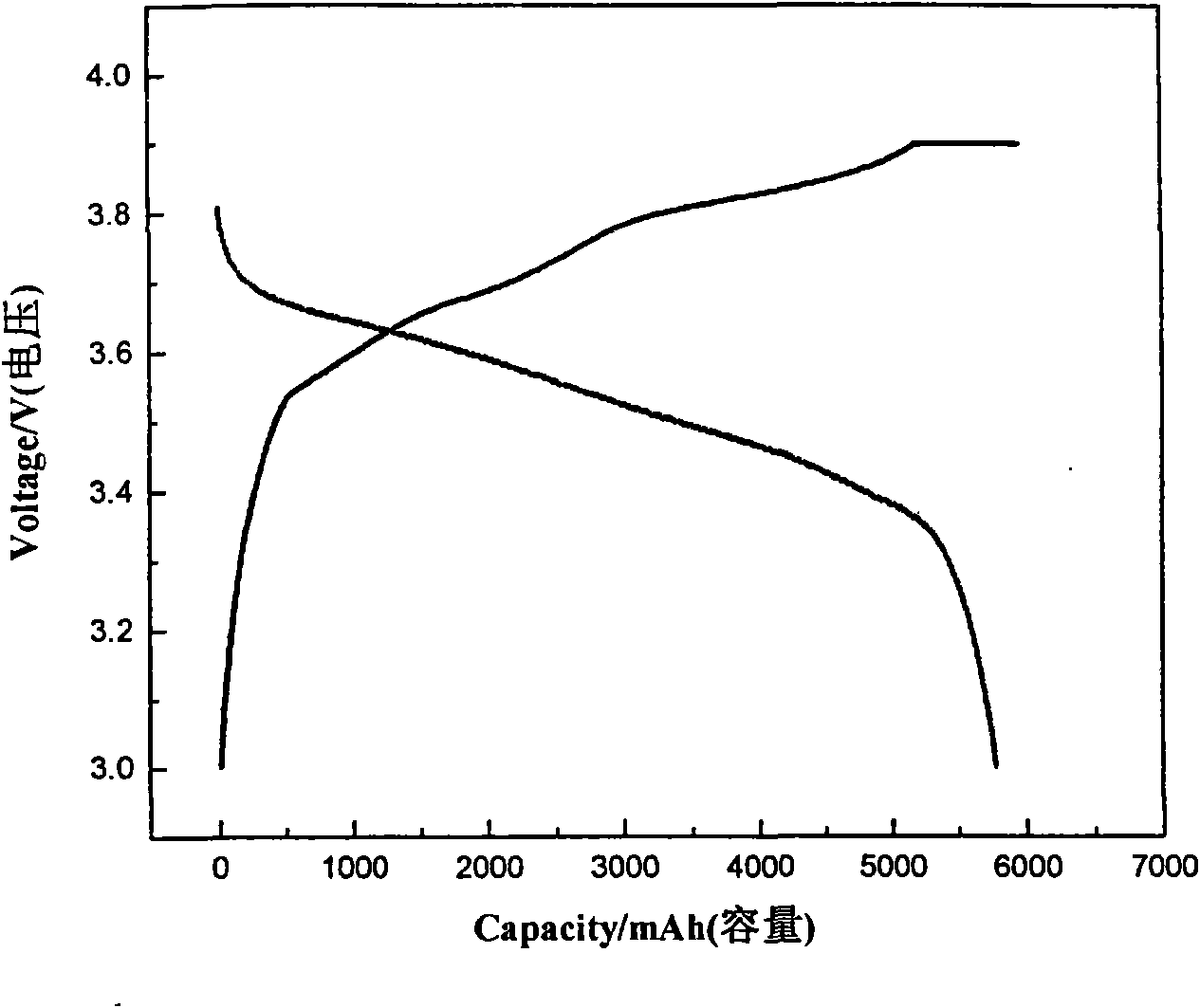

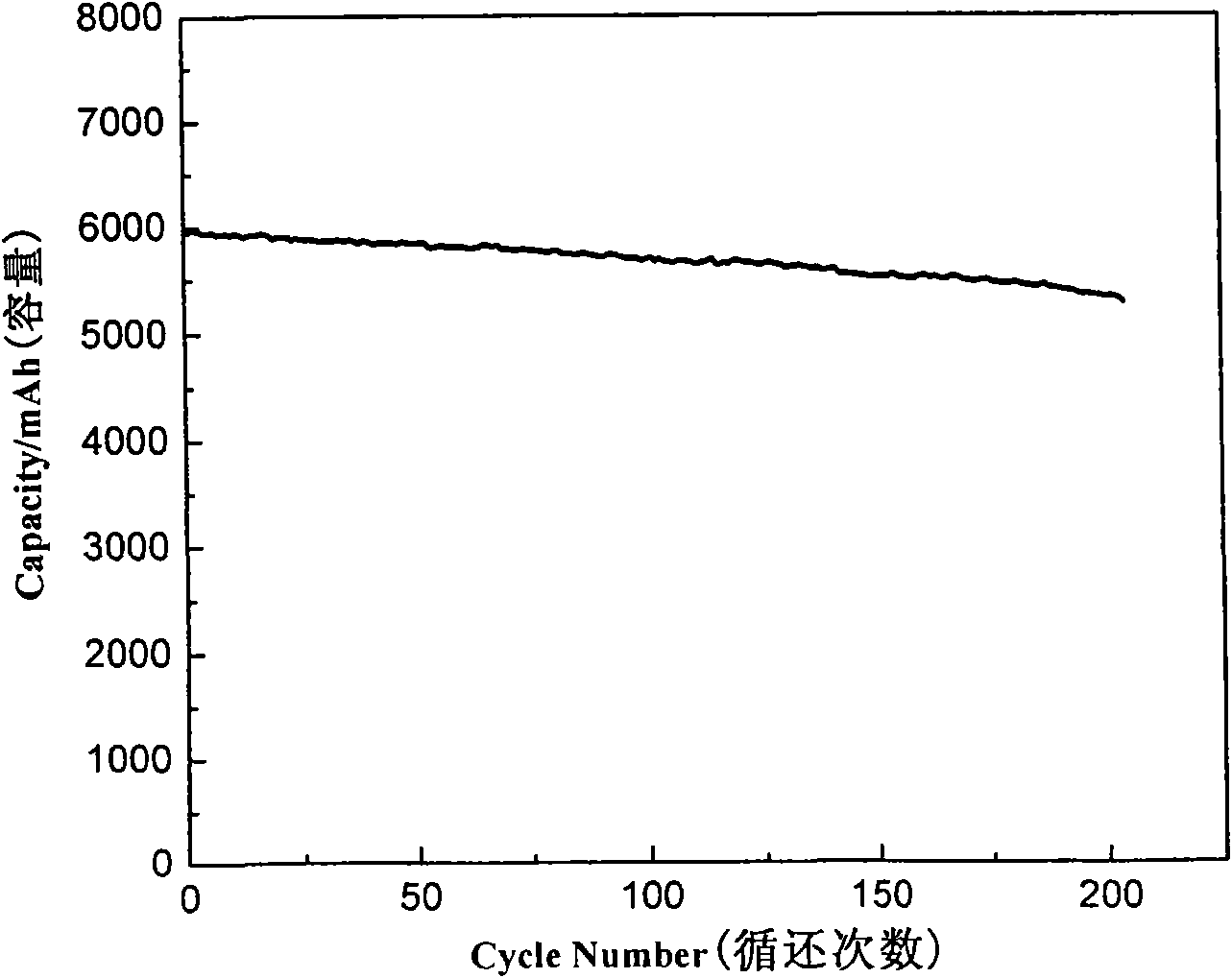

The invention discloses a lithium ion battery silicon carbon composite anode material and a preparation method thereof. The material is prepared by twice spray drying and once sintering. The preparation method comprises the following steps of: 1) dissolving an organic carbon source in an appropriate amount of solvent, adding a silicon source and a dispersing agent for dispersing suspension uniformly, adding graphitized carbon for dispersing the suspension for a certain period of time, and performing primary spray drying on the uniformly dispersed suspension to obtain a spherical nucleus material; and 2) dissolving the organic carbon source in the appropriate amount of the solvent, adding the prepared spherical nucleus material, dispersing the suspension uniformly, performing secondary spray drying on the uniformly dispersed suspension to obtain powder, transferring the powder into a protective atmosphere for sintering, and performing furnace cooling on the powder to obtain the lithium ion battery composite anode material. The preparation method is simple and practicable and has high practicality; and the prepared silicon carbon composite material has the advantages of large reversible capacity, designable capacity, high cycle performance, high rate capability, high tap density and the like.

Owner:CENT SOUTH UNIV

Preparation method for composite cathode material of lithium ion battery

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

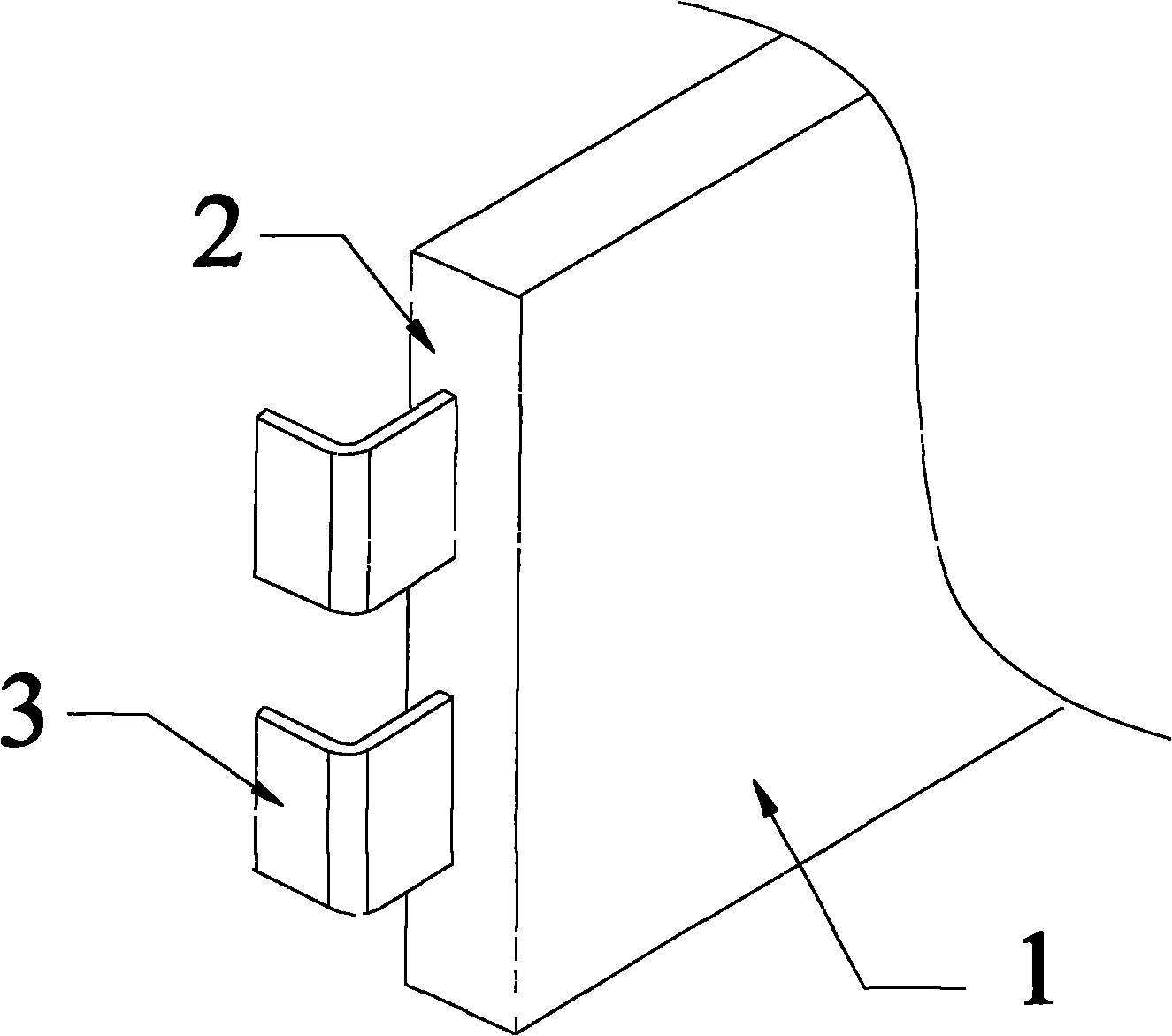

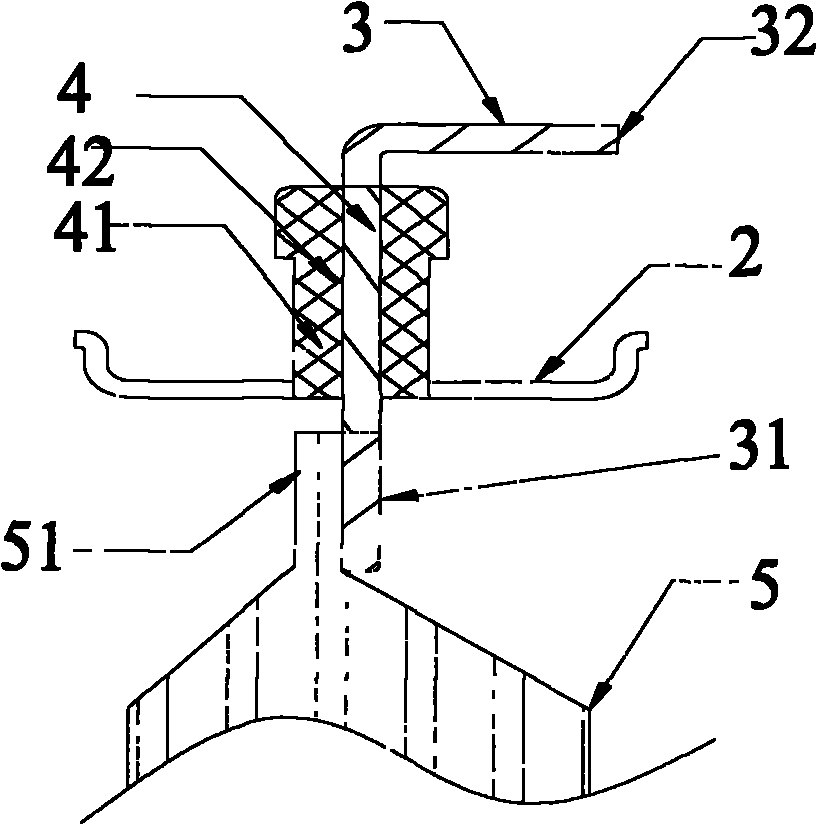

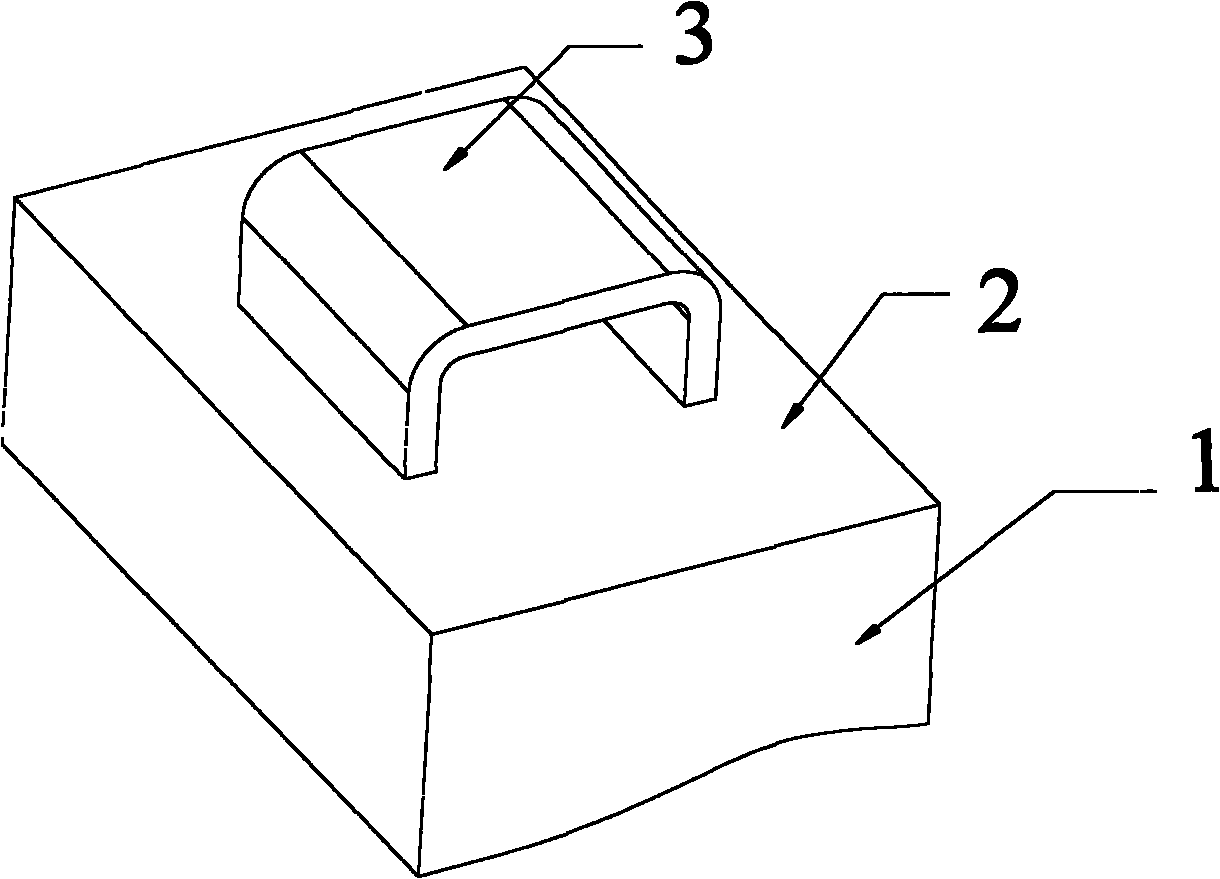

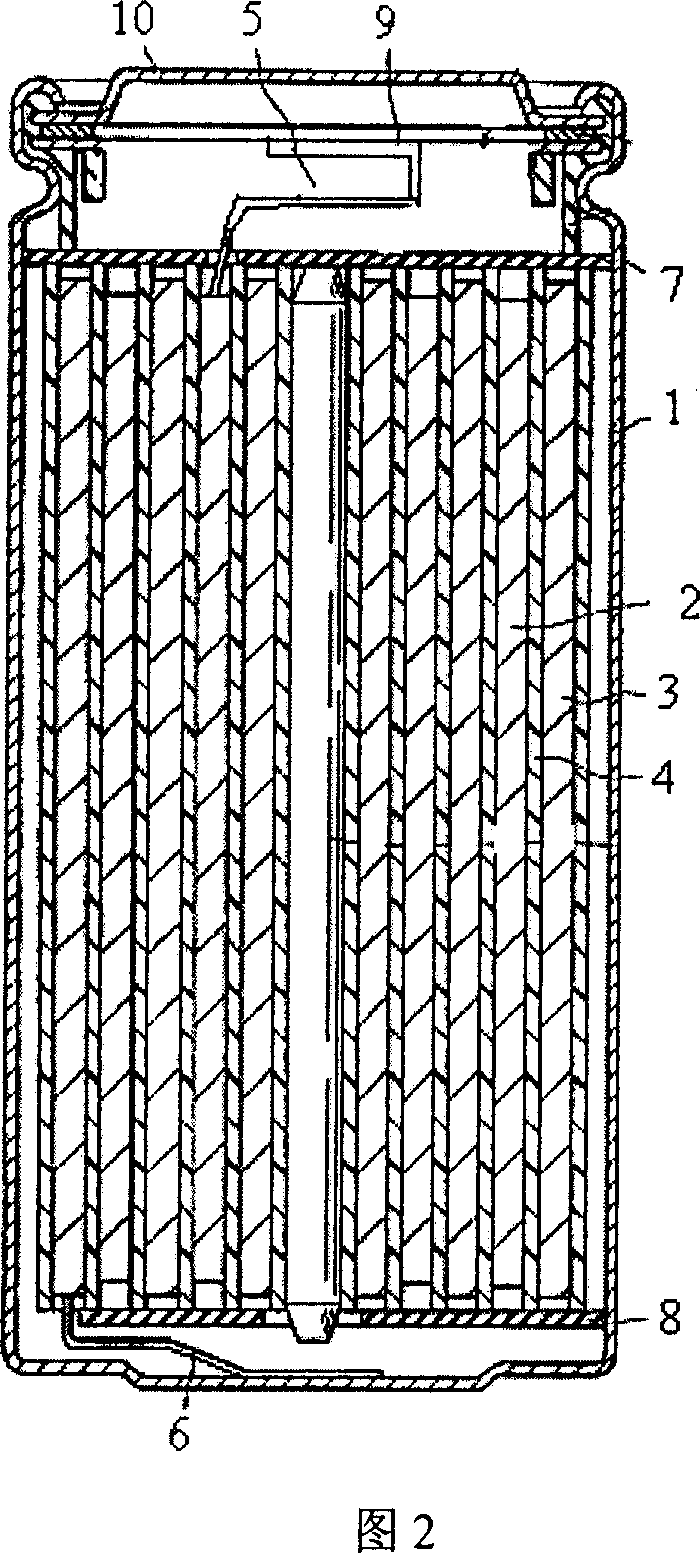

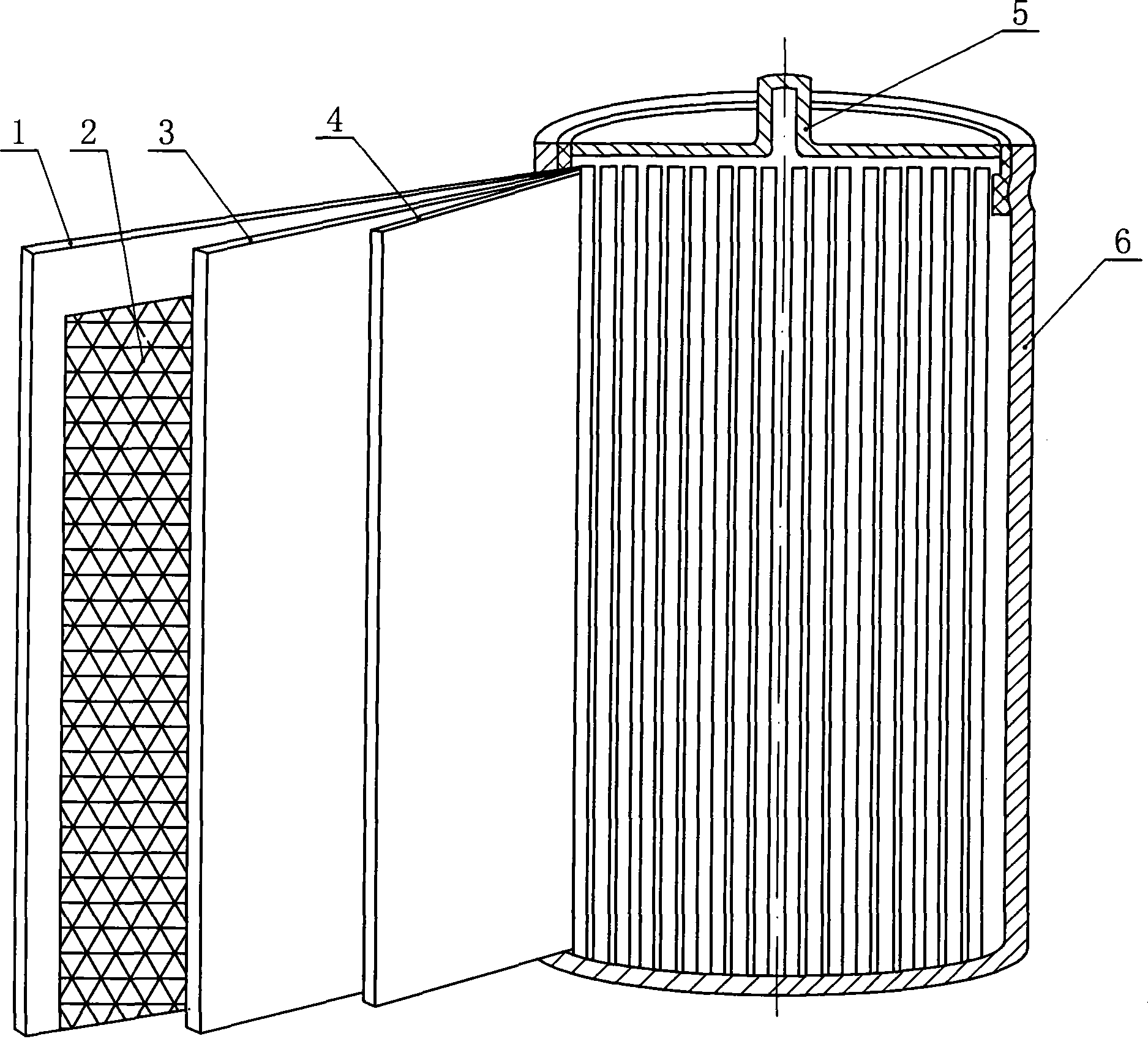

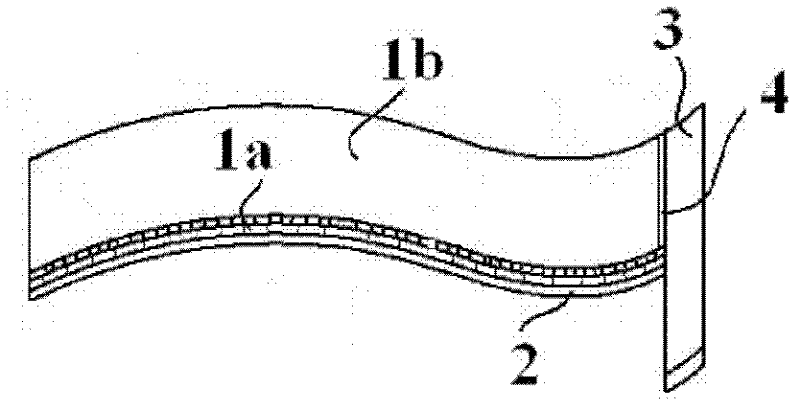

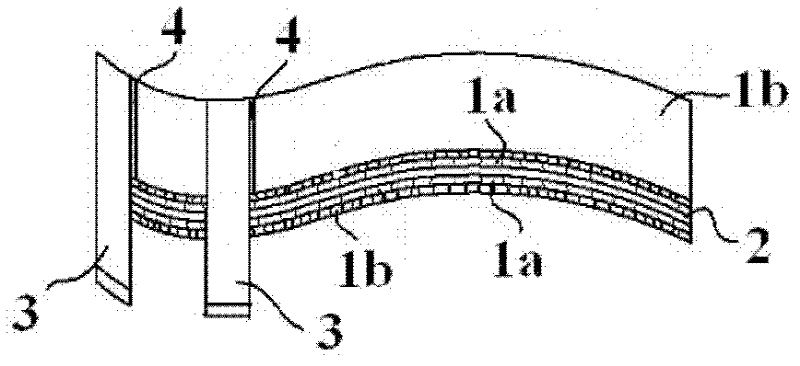

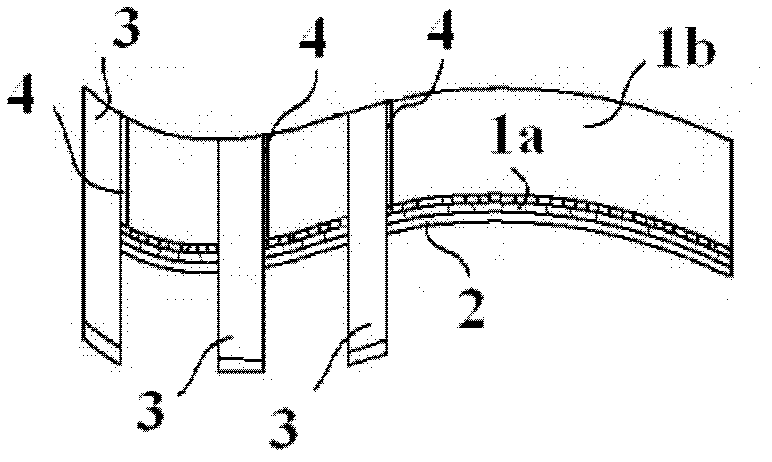

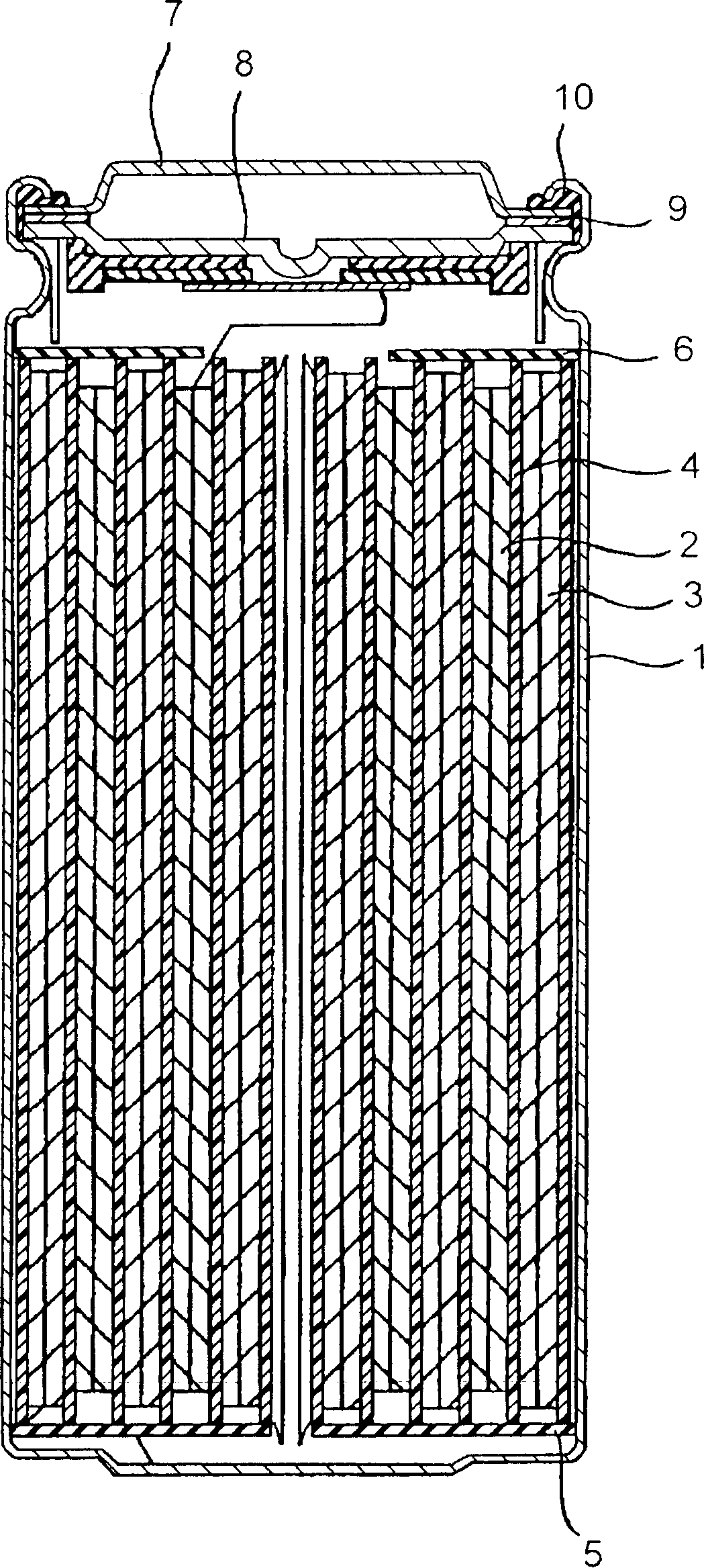

Monomer battery and power battery pack containing same

ActiveCN101877413AImproved high-rate discharge characteristicsIncrease capacityLarge-sized flat cells/batteriesFinal product manufacturePower batteryBattery pack

The invention provides a monomer battery which comprises a battery shell, a cover plate and a polepiece, wherein the cover plate is in a seal connection with the battery shell; the polepiece is positioned in a space formed by the battery shell and the cover plate; pole terminals, which penetrate through the cover plate and are used for leading the current out, are arranged in the cover plate; and each polarity at least has two pole terminals; the invention also provides a power battery pack containing the monomer battery. The battery and the battery pack enhance the high-power discharge characteristic, and especially can further solve the problems in welding, so that the technique is simpler and can further solve the problems in heat emission, weight and the like in the battery. The battery with the structure and the battery pack have the advantages of firmer connection, and higher safety and reliability; and the battery pack has a longer service life.

Owner:BYD CO LTD

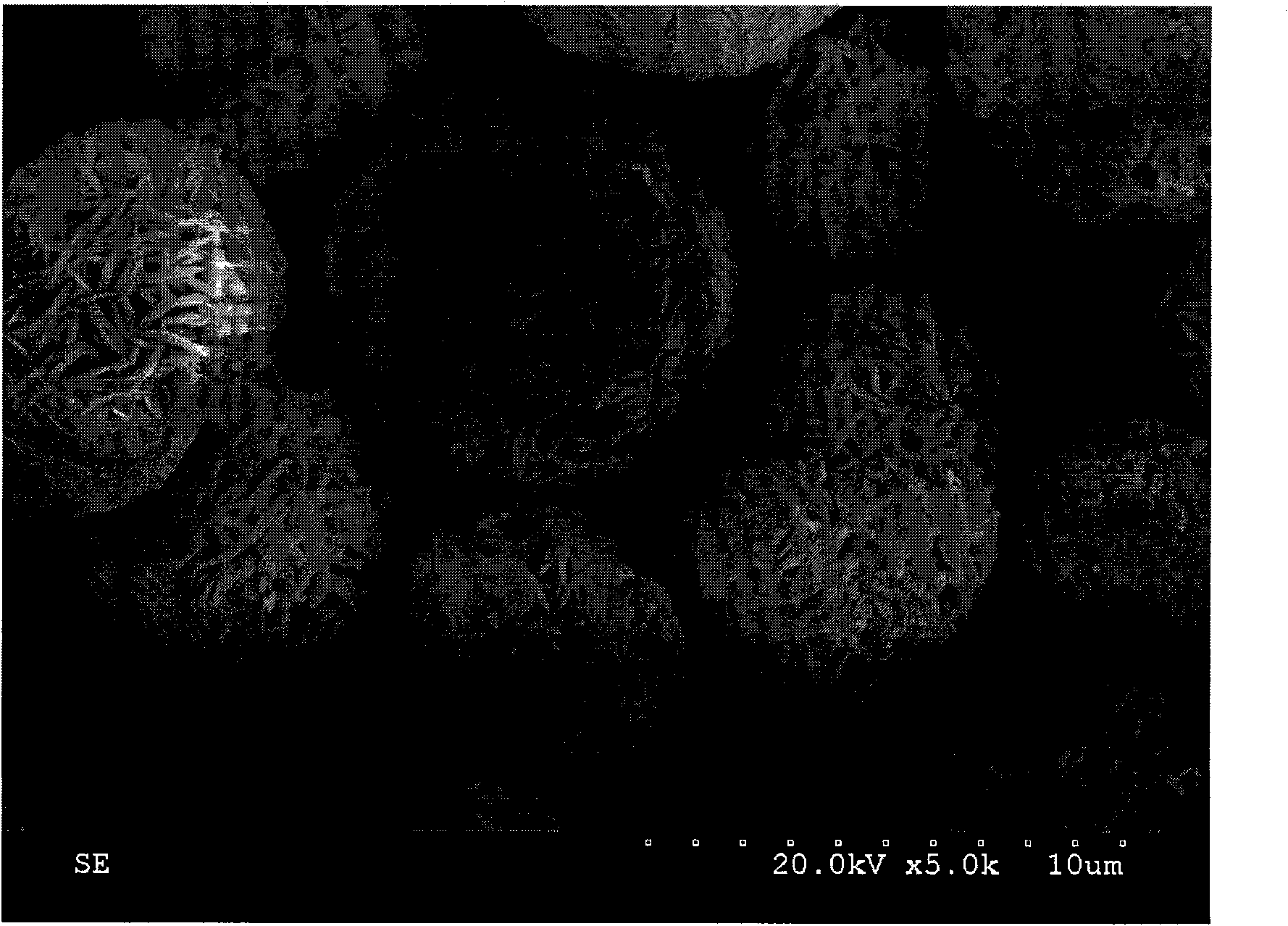

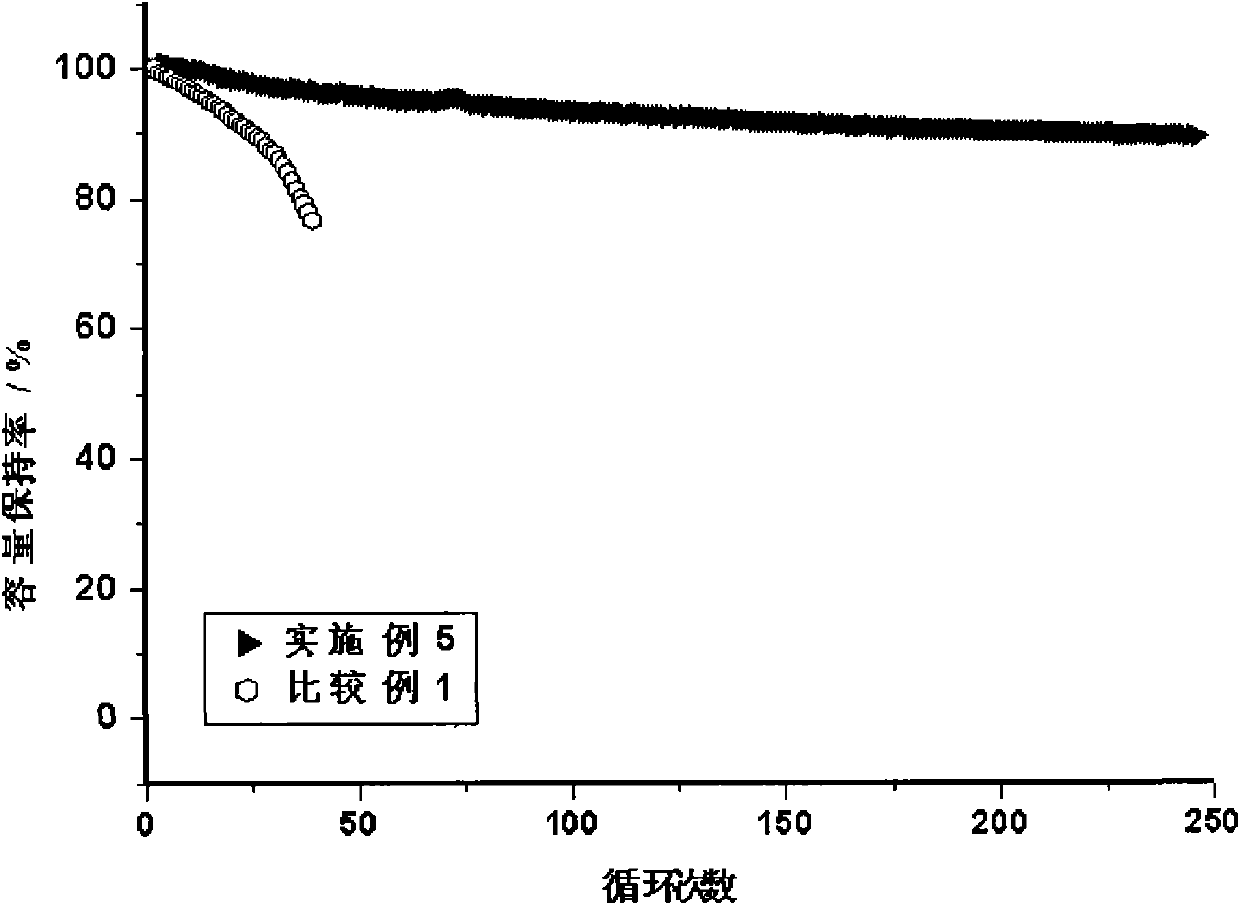

Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

The invention relates to a multi-core core-shell-structure silicon carbon composite negative pole material and a preparation method thereof. The preparation method comprises the following steps: 1. preparation method of high-dispersivity multi-core porous spheres; 2. preparation of high-dispersivity asphalt suspension; and 3. preparation of multi-core core-shell-structure silicon carbon composite negative pole material: adding the porous spheres prepared in the step 1 into the high-dispersivity asphalt suspension prepared in the step 2, carrying out ultrasonic dispersion, heating and drying by distillation while intensely stirring to remove the solvent, transferring the powder particles into a protective atmosphere, and holding at low temperature so that the asphalt liquid enters the inside of the porous spheres to enhance the binding strength between the silicon source and the conducting carbon mesh, carry out secondary coating on the silicon source, overcome the defects in the coating in the step 1 and enhance the capacity performance of the silicon; and carrying out high-heat treatment. The invention is simple and easy to implement, and has the advantage of high practicality. The prepared silicon carbon composite material has the advantages of high reversible capacity, designable capacity, favorable cycle performance, favorable heavy-current discharge capacity, high tap density and the like.

Owner:CENT SOUTH UNIV

High-powered lithium ferric phosphate dynamic battery, and preparation technique

InactiveCN1960040AGuaranteed high current dischargeImprove high-current discharge performanceElectrode manufacturing processesFinal product manufactureCarbon blackEngineering

The dynamic battery includes shell, positive pole piece, negative pole piece, diaphragm, and electrolyte. Positive pole piece / negative pole piece are composed of afflux bodies of positive / negative poles in same size, and active materials painted on the afflux bodies respectively. Ion doped lithium iron phosphate is adopted as positive pole material, and canting pulled aluminum mesh is as afflux body of positive pole. Carbon black, graphite, and Nano Al2O3 are selected for conduction agent. Crylic acid - styrene polymer, and crylic acid - silica polymer are chosen for bonding agent of positive pole material. The invention simplifies technical procedure, paints pole pieces easily, and increases following performances greatly: conductivity, ionic diffusion capability, discharging large current, as well as apparent density and packed density.

Owner:GUANGZHOU GREAT POWER ENERGY & TECH CO LTD

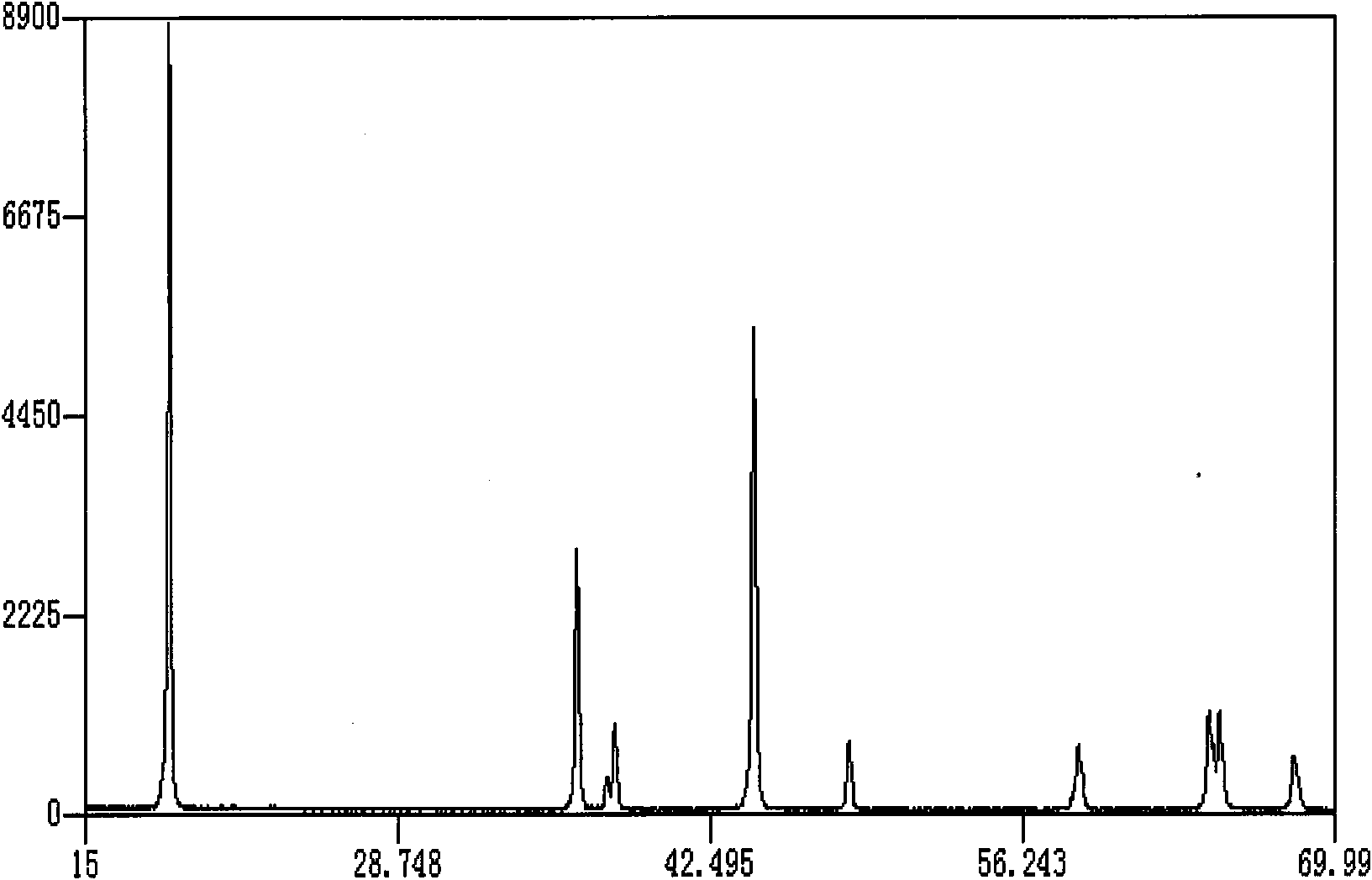

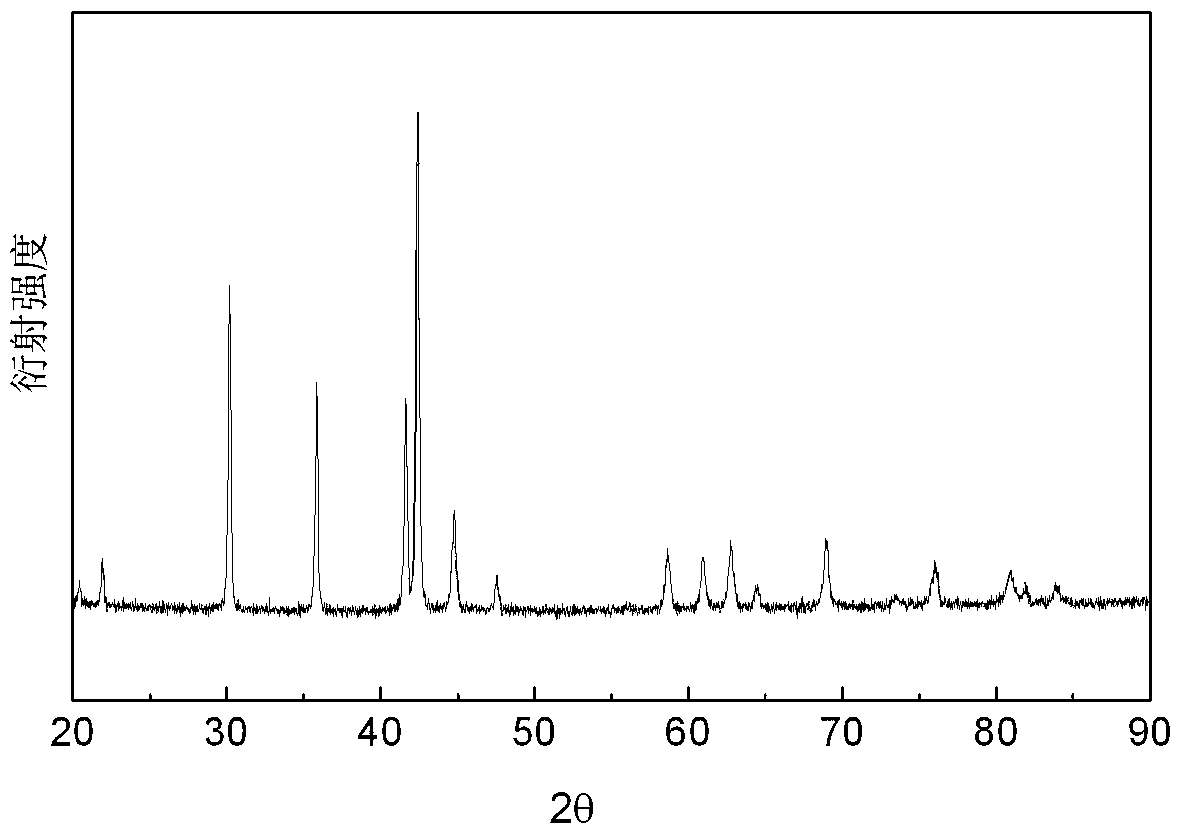

Preparation of stratified lithium ion anode material

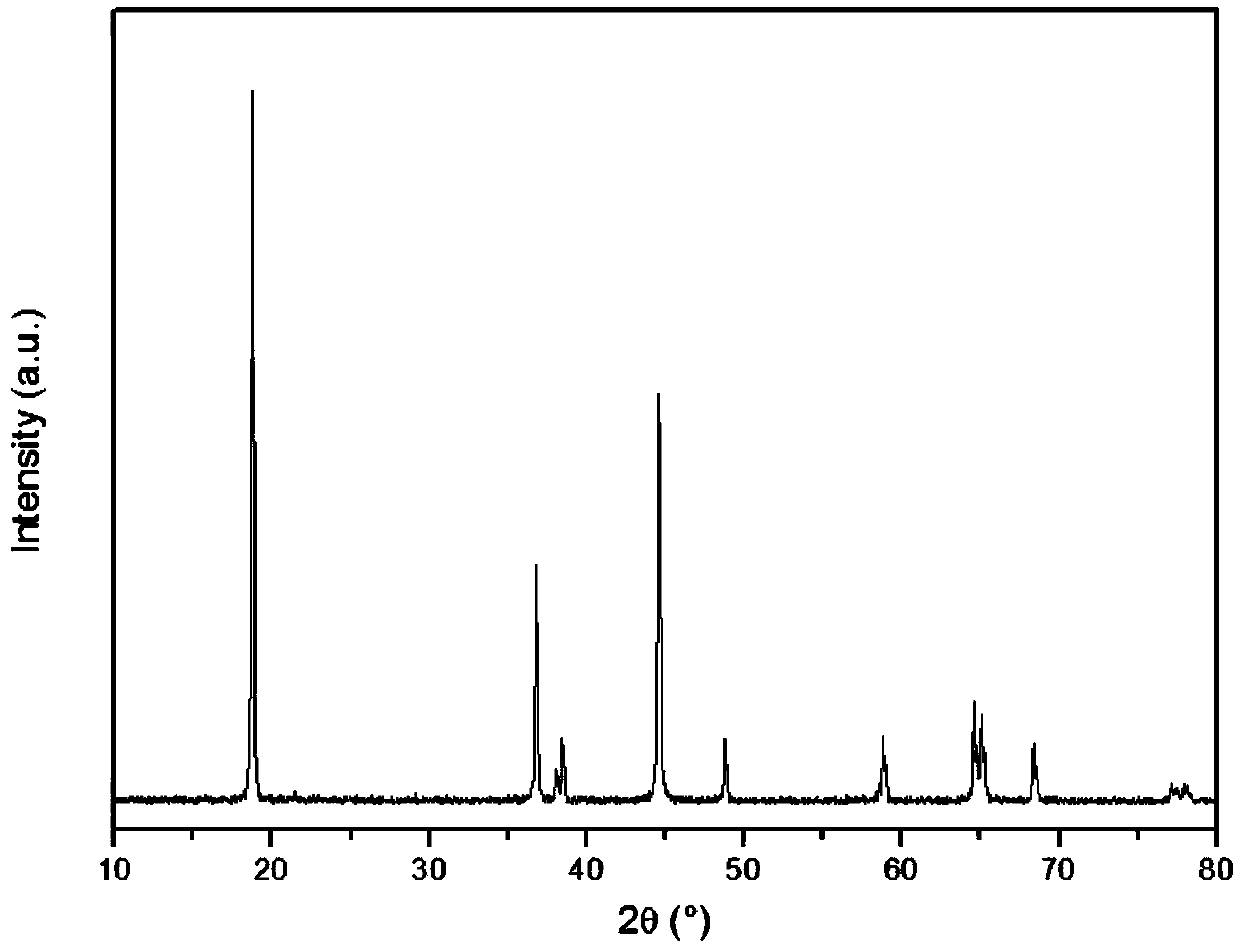

ActiveCN101944610AHigh densityHigh activityElectrode manufacturing processesNickel compoundsManganeseSolid state reaction method

The invention relates to a preparation method of a stratified lithium ion anode material, which comprises the following steps: coating cobalt on the surface of a precursor containing nickel, manganese and a small amount of other metals by a chemical precipitation method; fully mixing with a lithium source; and then, adopting a solid reaction method to prepare the high nickel type lithium ion anode material. The chemical formula of the lithium ion anode material is as follows: LidNiaMnbMcCo1-a-b-c02, wherein 0.9<=d<=1.25, 0.5<=a<=1, 0<b<0.5, 0.9<=a+b+c<1, and M is one or a mixture of more than one of Al, Ti, Mg and Zn. The material has uniform chemical composition and high capacity. Besides, the cycle performance of the material is improved, and the operating voltage platform and the safety of a battery are enhanced, especially after the material is subject to doping and coating modification.

Owner:HENAN KELONG NEW ENERGY CO LTD

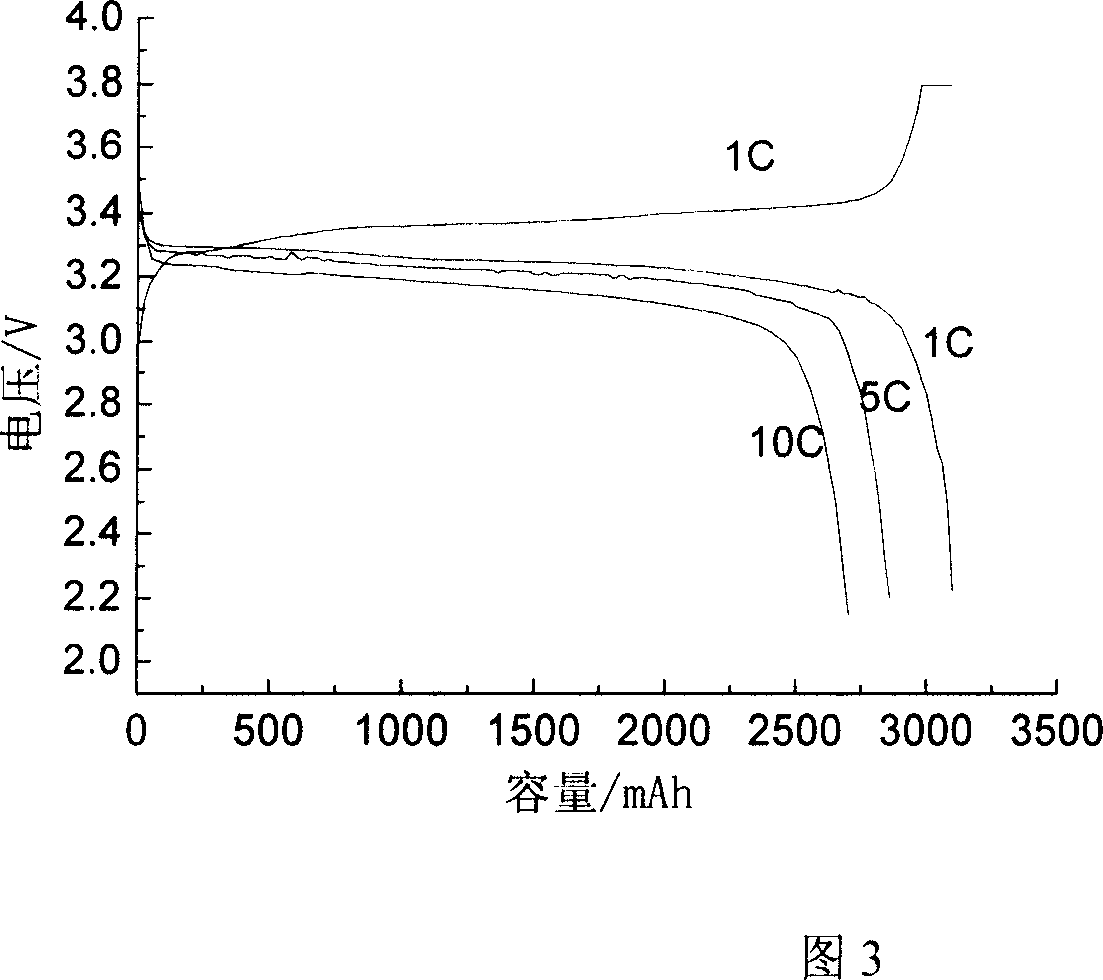

Lithium iron phosphate aluminum shell 8 ampere-hour column battery and producing technique thereof

InactiveCN101183730ALarge capacityIncrease capacityFinal product manufactureSmall-sized cells cases/jacketsDischarge rateCopper foil

The invention relates to an eight ampere-hour column battery with an iron phosphate lithium aluminum shell and the processing technology, belonging to lithium iron power battery field. The invention has an external diameter of 35.0mm plus or minus 0.1mm and a height of 110.0mm plus or minus 0.5mm, omprising a casing, an anode flake, a cathode flake, an electrolyte and a diaphragm; wherein, the anode flake and the cathode flake respectively comprise an anode current collector and a cathode current collector, as well as an anode sizing agent and a cathode sizing agent coated on the anode current collector and the cathode current collector. The casing is an aluminum shell; the anode material uses the iron phosphate lithium; the anode current collector uses aluminum foil; the conductive agent uses one of or the mixture of the superconducting carbon black and the conductive graphite; and the anode material binder uses the polyvinylidene fluorine; the cathode material uses the natural graphite or the artificial graphite; the cathode current collector uses copper foil; the conductive agent uses one of or the mixture of the superconducting carbon black and the conductive graphite; and the cathode material binder uses the polyvinylidene fluorine or the sodium carboxymethylcellulose and the styrene butadiene rubber; the anode flake, the cathode flake and the diaphragm are winded into a cylindrical volume core through the multilayer stack-up. The invention has the advantages of large capacity and high discharge rate.

Owner:山东海霸电池有限公司

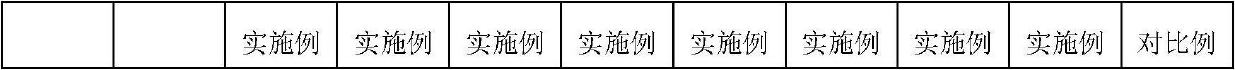

Negative plate of battery, preparation method thereof and battery comprising negative plate

InactiveCN102683708AHold off high current performanceImprove high current performanceFinal product manufactureLead-acid accumulator electrodesFiberCapacitance

The invention discloses a negative plate of a battery, a preparation method thereof and the battery comprising the negative plate. The negative plate is composed of a plate grid and a negative pole material coated on the plate grid, and the negative pole material comprises a battery active material, a capacitor material as well as a conductive steric hindrance agent; the battery active material comprises 100 parts by weight of lead powder, 0.6-2.0 parts by weight of barium sulfate and 0.1-0.5 part by weight of short fiber, and the capacitor material comprises 0.1-10 parts by weight of active carbon; and the additive amount of the electric conduction steric hindrance agent is 0.1-5.0 in parts by weight, and the conductive steric hindrance agent comprises Magneli mutual sulfoxide titanium oxide and / or plumbous acid barium. The raw material of the negative plate of the battery provided by the invention can be used for postponing a negative board sulphate phenomenon through combining the three parts, the cold-starting property is markedly improved, and the heavy-current charge-discharge property is optimized.

Owner:湖南维邦新能源有限公司

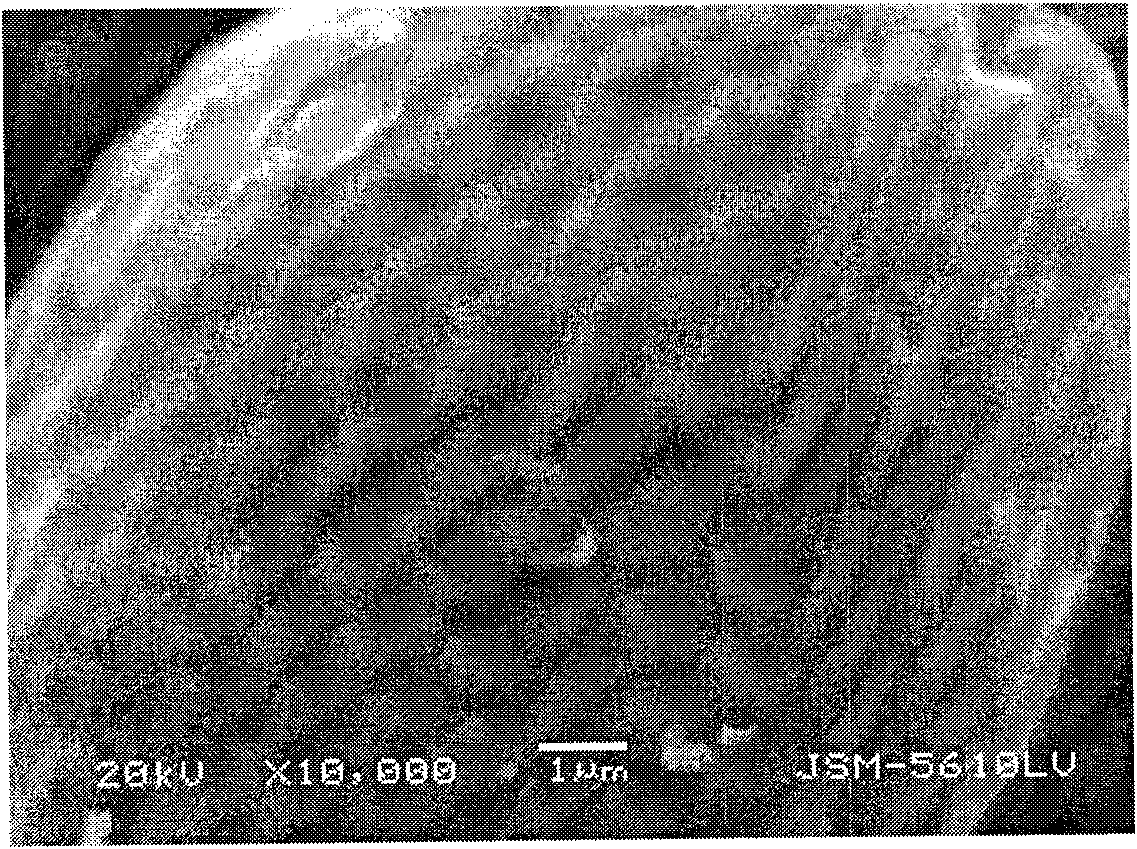

Carbon composite material, and preparation method and application thereof

InactiveCN102050437AImprove high-current discharge performanceImprove low temperature performanceCell electrodesCarbon compositesGraphite

The invention provides a carbon composite material. The carbon composite material comprises a core part and a shell part, wherein the core part comprises graphite; the shell part comprises amorphous carbon; the average grain diameter is 8 to 20 mu m; and the interlamellar spacing specific surface area is 0.3 to 2.5 m<2> / g. The invention also provides a preparation method of the carbon composite material. The preparation method comprises the following steps of: a, adding the graphite into aqueous solution of a carbon-coated precursor and mixing pulp uniformly; b, performing hydro-thermal treatment on the pulp obtained in the step a and the drying; and c, performing heat treatment on a product obtained in the step b under an inert atmosphere or a vacuum condition, wherein the heat treatmentcomprises carbonizing treatment and graphitizing treatment. In the carbon composite material prepared by the method, the appearance is more perfect; a coating layer is coated more uniformly; the grain diameter is controlled more easily; and the big current property is higher. The invention further provides application of the carbon composite material to a lithium battery as a cathode.

Owner:SHANGHAI BYD

Zinc-nickel secondary cell and preparation method thereof

InactiveCN1434534ASimple processQuality controllableFinal product manufactureAlkaline accumulators manufactureCapacitanceElectrolytic agent

This invention relates to a preparation method for ZnNi secondary cell and the cell prepared by the said method which is to isolate the positive and negative plates by diaphragm paper to be put into cell shell after being laminated and winded and fill in electrolyte, the positive plate contacts with the shell of positive collector, the negative is connected with the negative cap in weld via conductive terminal, finally go on with sealing, packing and storage, with the advantags of high voltage, large discharge capacitance, long circulation life, small internal resistance, excellent large current discharging performance.

Owner:SOUTH CHINA UNIV OF TECH

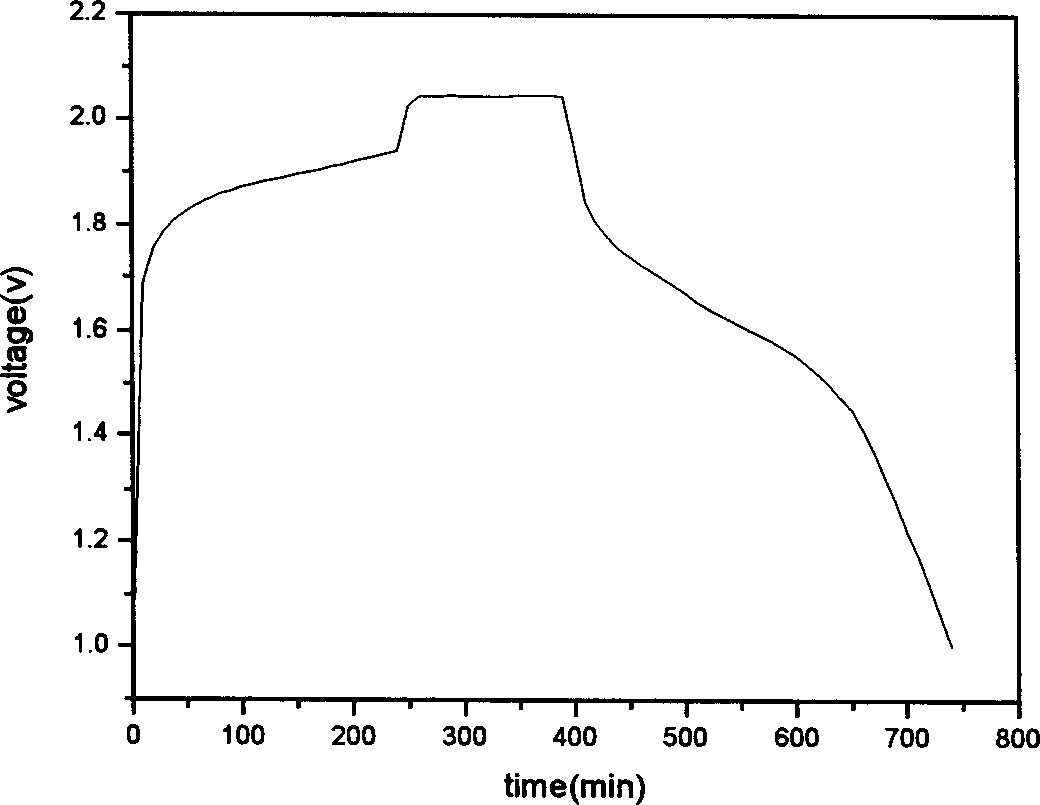

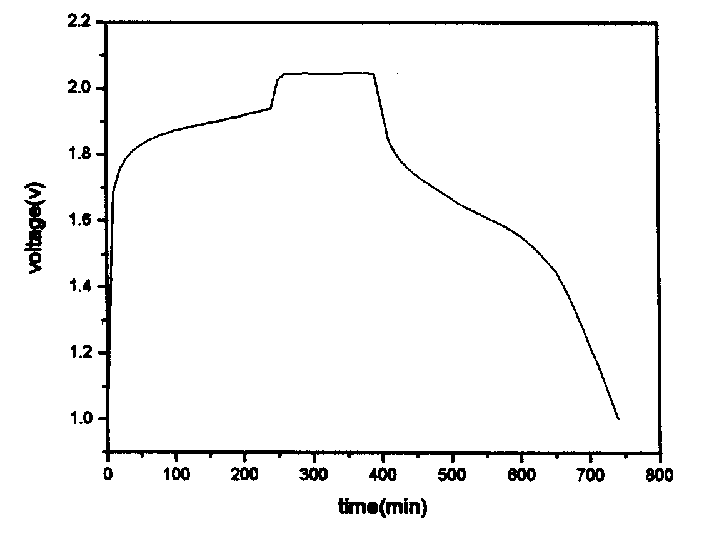

Improved type lithium-ferrous disulfide battery and manufacturing method of the same

InactiveCN101383419AImprove high current discharge capabilityExtended use timePrimary cellsElectrode carriers/collectorsCopper foilPositive current

The invention relates to an improved lithium- ferrous disulfide battery which comprises a shell; a positive pole piece and a negative pole piece in the shell are wound together through a porous isolating film, and organic electrolyte is filled in the shell. The positive pole piece comprises a positive active material and a positive current collector, and the positive active material is ferrous disulfide. The negative pole piece comprises a negative active material and a negative current collector, wherein the negative active material is metal lithium foil, and the negative current collector is selected form a copper net, a hole-shaped aluminum foil, an aluminum net, a hole-shaped copper foil, foamed nickel, a hole-shaped nickel foil or nickel net. The positive pole piece is manufactured by the positive active material, conductive agent and binding agent which are evenly mixed and applied to a metallic matrix; and the negative pole piece is manufactured by pressing the metal lithium foil and the metal net or the hole-shaped foil. Then the organic electrolyte is infused, and the battery is obtained after the packaging. The invention has the advantages of small internal resistance, good large current discharge performance, good pulse discharge performance, high discharge platform, no voltage sag and good consistence of performance.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

Iron-nickel storage battery adopting steel-strip iron electrode as cathode and preparation method of iron-nickel storage battery

ActiveCN102623757AIncrease profitReduce distanceFinal product manufactureElectrode carriers/collectorsPolyolefinSlurry

The invention relates to an iron-nickel storage battery adopting a steel-strip iron electrode as a cathode and a preparation method of the iron-nickel storage battery. The iron-nickel storage battery comprises a vessel with electrolyte, a cathode and an anode, wherein the cathode and the anode are arranged inside the vessel, the anode is a sintered nickel electrode, the cathode is a steel-strip iron electrode, the steel-strip iron electrode comprises a burr steel-strip base body and active substance slurry which is arranged on the surface of the burr steel-strip base body, the active substance slurry is prepared from the following ingredients by weight percent: 85 to 95 percent of ferroferric oxide, 1 to 5 percent of additive, 3 to 7 percent of conductive agent and 1 to 3 percent of binder, the anode and the cathode are assembled in a lamination-type structure, and a polyolefin diaphragm is arranged between the anode and the cathode; and since the sintered nickel electrode is adopted as the anode, the steel-strip iron electrode is adopted as the cathode, and a positive plate and a negative plate are isolated by the thin polyolefin diaphragm in a lamination-type structure when in assembling, the iron-nickel storage battery has the advantages of large capacity, strong large-current discharging capacity and long service life.

Owner:河南创力新能源科技股份有限公司

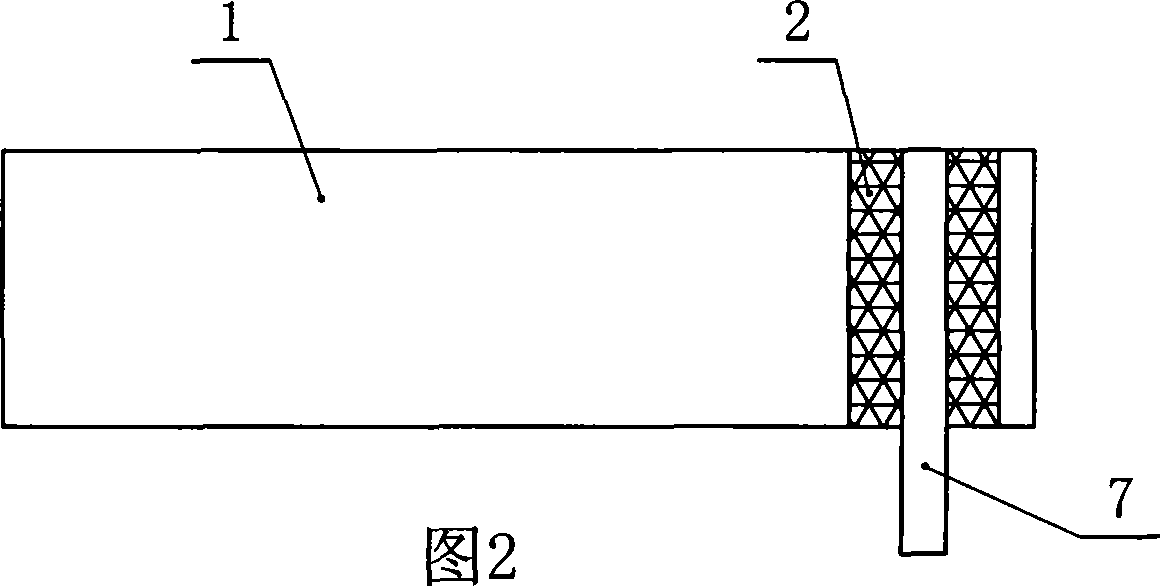

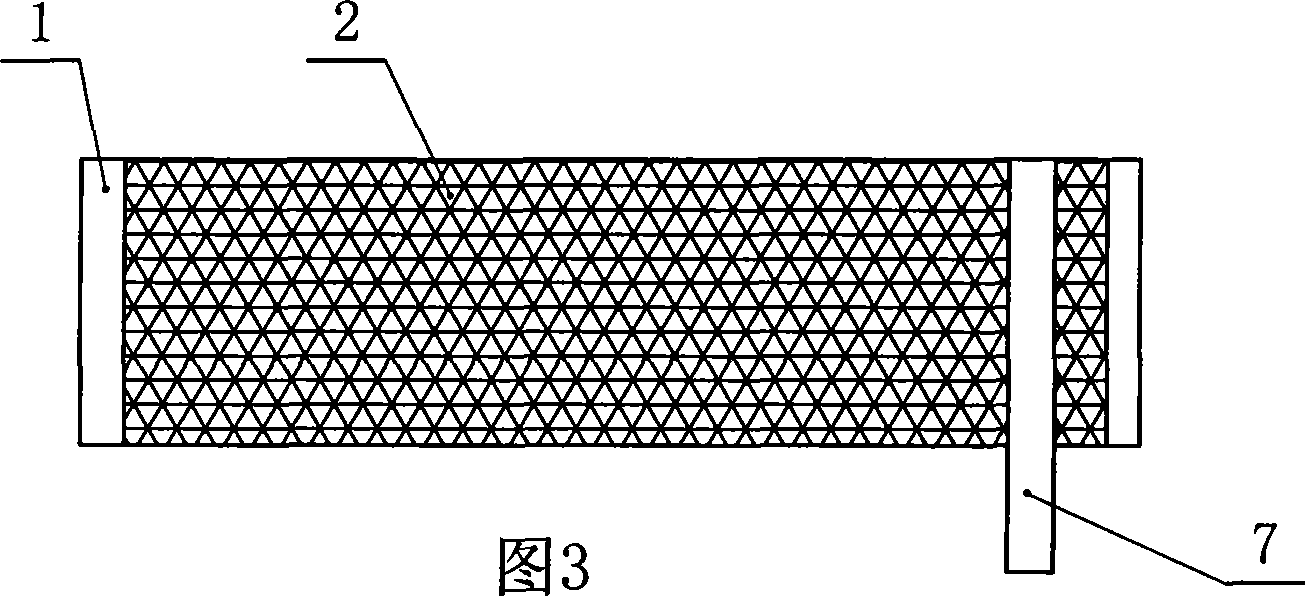

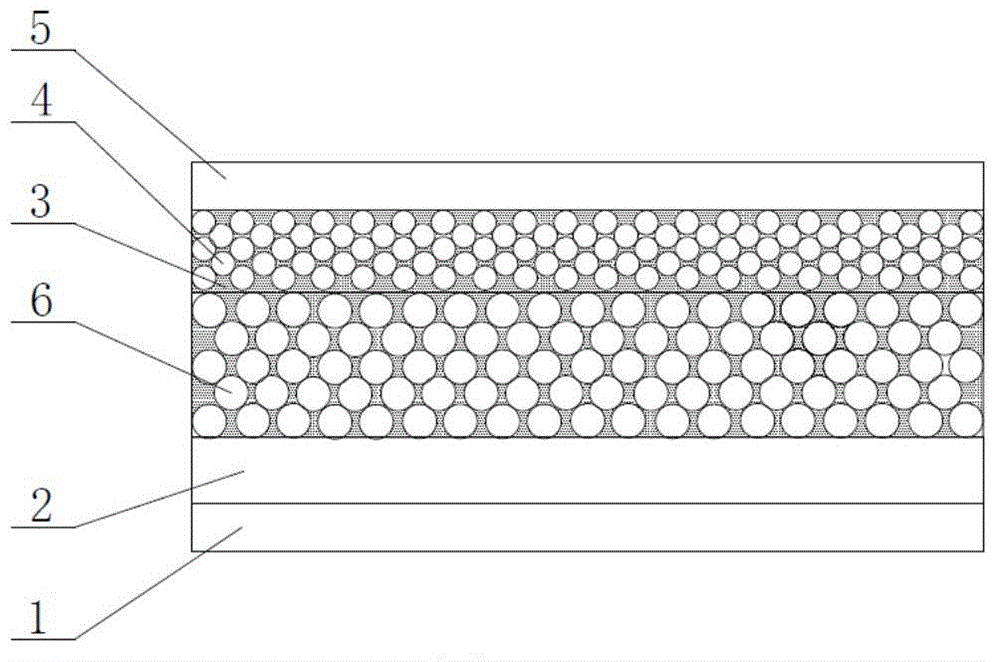

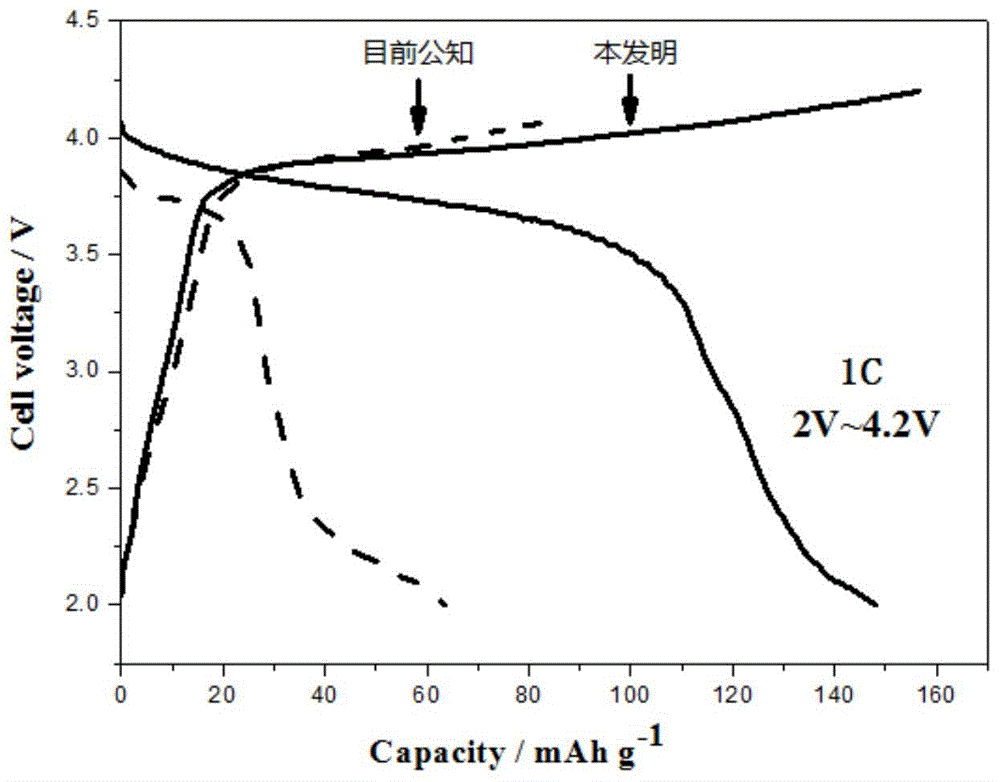

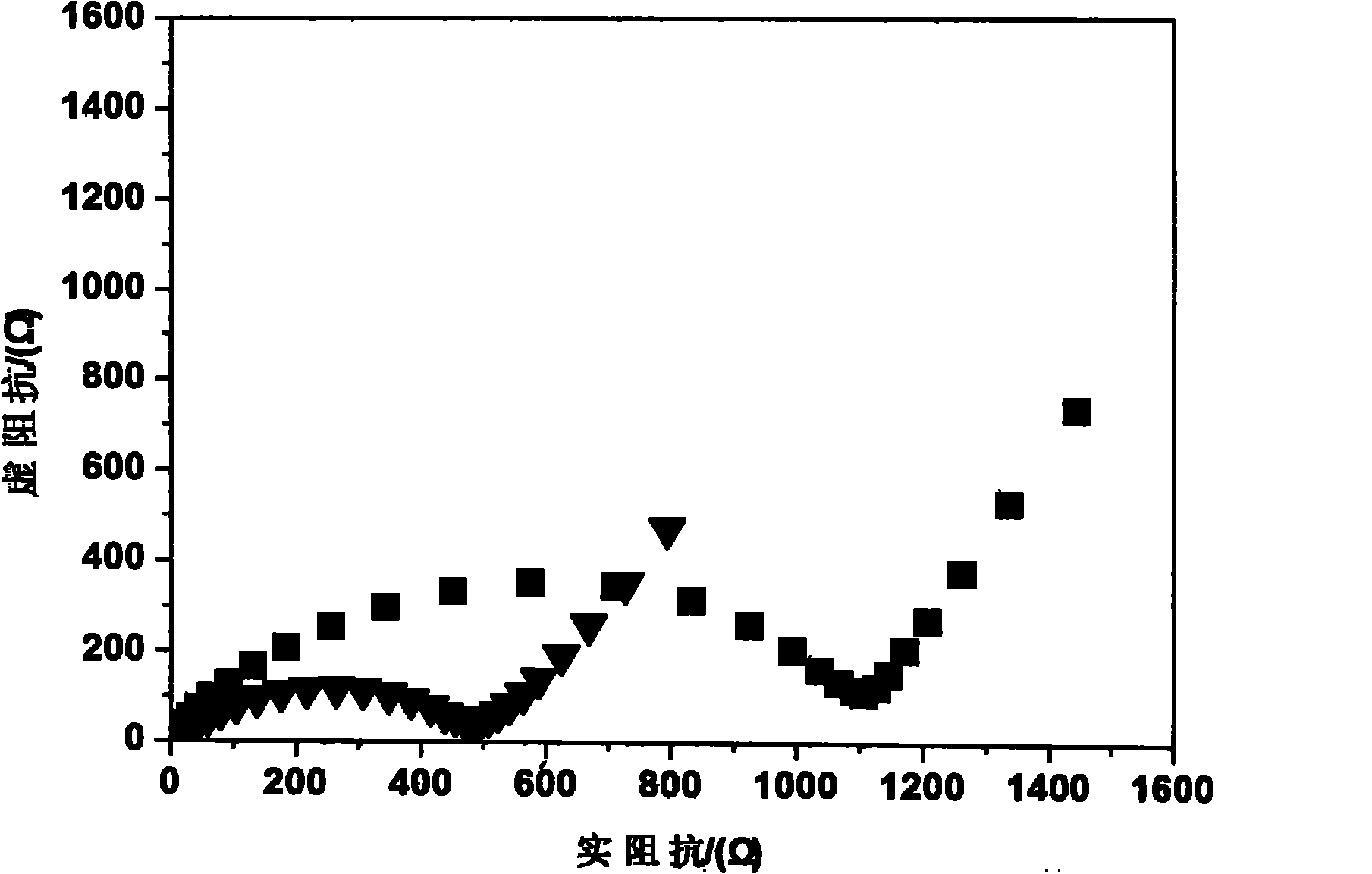

Preparation method of safe high-rate and all-solid-state battery

InactiveCN105789682AEnsure safetyImprove high-current discharge performanceFinal product manufactureLi-accumulatorsHigh rateEngineering

The invention relates to a preparation method of a safe high-rate and all-solid-state battery. The method comprises the following steps: (1) pressing a negative current collector, a negative material, a solid electrolyte, a composite positive electrode and a positive current collector into a whole in a battery pressing mold from bottom to top in a dry environment to form the all-solid-state battery before liquid injection; (2) injecting a liquid electrolyte solution into the all-solid-state battery before liquid injection prepared in the step (1) in a vacuum environment; and (3) carrying out aerating treatment on the vacuum environment into which an ionic liquid is injected in the step (2) to prepare the safe high-rate and all-solid-state battery. The trace electrolyte is injected into the all-solid-state battery molded in a cold-press manner in the dry environment and is subjected to aerating treatment, so that the electrolyte is evenly dispersed into the all-solid-state battery. The trace electrolyte does not react with a solid electrolyte material and has good lithium-ion conduction ability, so that the contact resistance between the internal materials of the all-solid-state battery is reduced by the electrolyte as a transition electrolyte layer; and the high-current discharge capacity of the battery is greatly improved under the premise of ensuring the safety of the battery.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

Rare-earth lead alloy for lead-acid storage battery positive grid

ActiveCN103762369AImprove corrosion resistanceReduce grain gapElectrode carriers/collectorsCeriumLanthanum

The invention discloses rare-earth lead alloy for a lead-acid storage battery positive grid. The rare-earth lead alloy is characterized by being prepared by smelting the following component materials by weight percent: 0.01 to 0.12 percent of calcium, 1.2 to 2.0 percent of tin, 0.02 to 0.05 percent of aluminum, 0.01 to 0.12 percent of lanthanum, 0.01 to 0.12 percent of yttrium, 0.02 to 0.15 percent of cerium and the balance being lead. The rare-earth lead alloy is stable in chemical property, good in mobility, excellent in conductivity and strong in corrosion resistance; a lead-acid storage battery which is assembled by the grid is long in cycling life, strong in current discharging capacity and strong in charging acceptance capacity.

Owner:江苏海宝电池科技有限公司

Manufacturing method of lithium iron phosphate-cobalt acid lithium composite anode plate of lithium ion battery

InactiveCN102386379AImprove high-current discharge performanceShort cycle lifeCell electrodesPole pieceSlurry

The invention discloses a manufacturing method of a lithium iron phosphate-cobalt acid lithium composite anode plate of a lithium ion battery, which comprises the following steps: A, ball-milling and uniformly mixing a nanometer cobalt acid lithium anode active material with a nanometer Super-C conductive agent in proportion to obtain a cobalt acid lithium active material mixture; uniformly mixing the mixture with polyvinylidene fluoride; mixing the mixture with sodium carboxymethylcellulose to obtain anode active material slurry; B, preparing the anode active material slurry: ball-milling and uniformly mixing nanometer lithium iron phosphate with the nanometer Super-C conductive agent in proportion to obtain a lithium iron phosphate active material mixture; mixing the mixture with the sodium carboxymethylcellulose in proportion; adding distilled water into the mixture, ball-milling and mixing uniformly to obtain anode active material slurry B; and C, coating the slurry A on a single surface of an anode current collector, and coating the slurry B on double surfaces of an initial pole piece according to coating process, thus obtaining an anode pole piece. A nickel-metal hydride battery prepared by the invention has high volume, high multiplying power, a good discharging effect, and long circulating service life.

Owner:广州云通锂电池股份有限公司 +1

Method for manufacturing novel lithium iron battery

InactiveCN101901936ALarge design spaceImprove high-current discharge performanceElectrode manufacturing processesFinal product manufactureHigh energyLithium-ion battery

The invention relates to a method for manufacturing a novel lithium iron battery. The novel lithium iron lithium ion battery is manufactured by combining an anode active substance made of a FeF3 / V2O5 composite material and LiMn2O4 with a carbon cathode, wherein the anode active substance is prepared by ballmilling 5 to 85 mass percent of LiMn2O4 and 95 to 15 mass percent of FeF3 / V2O5 composite material for 1 and 8 hours; before the anode active substance is prepared, the FeF3 / V2O5 composite material is prepared first, namely V2O5 accounting for 1 to 50 percent of the total mass of the composite material and FeF3 accounting for 99 to 50 percent of the total mass of the composite material are subjected to high-energy ball mill for 1 to 8 hours and the ground V2O5 and FeF3 are annealed at the temperature of between 100 and 600 DEG C for 1 to 12 hours to form the FeF3 / V2O5 composite material. The method has the advantages of improving the conductivity of the material, prolonging the service life of the battery, improving a discharging platform substantially and enhancing the large-current discharging capacity of the battery, along with high safety performance of the battery.

Owner:HUNAN HAIXING HIGH TECH POWER BATTERY

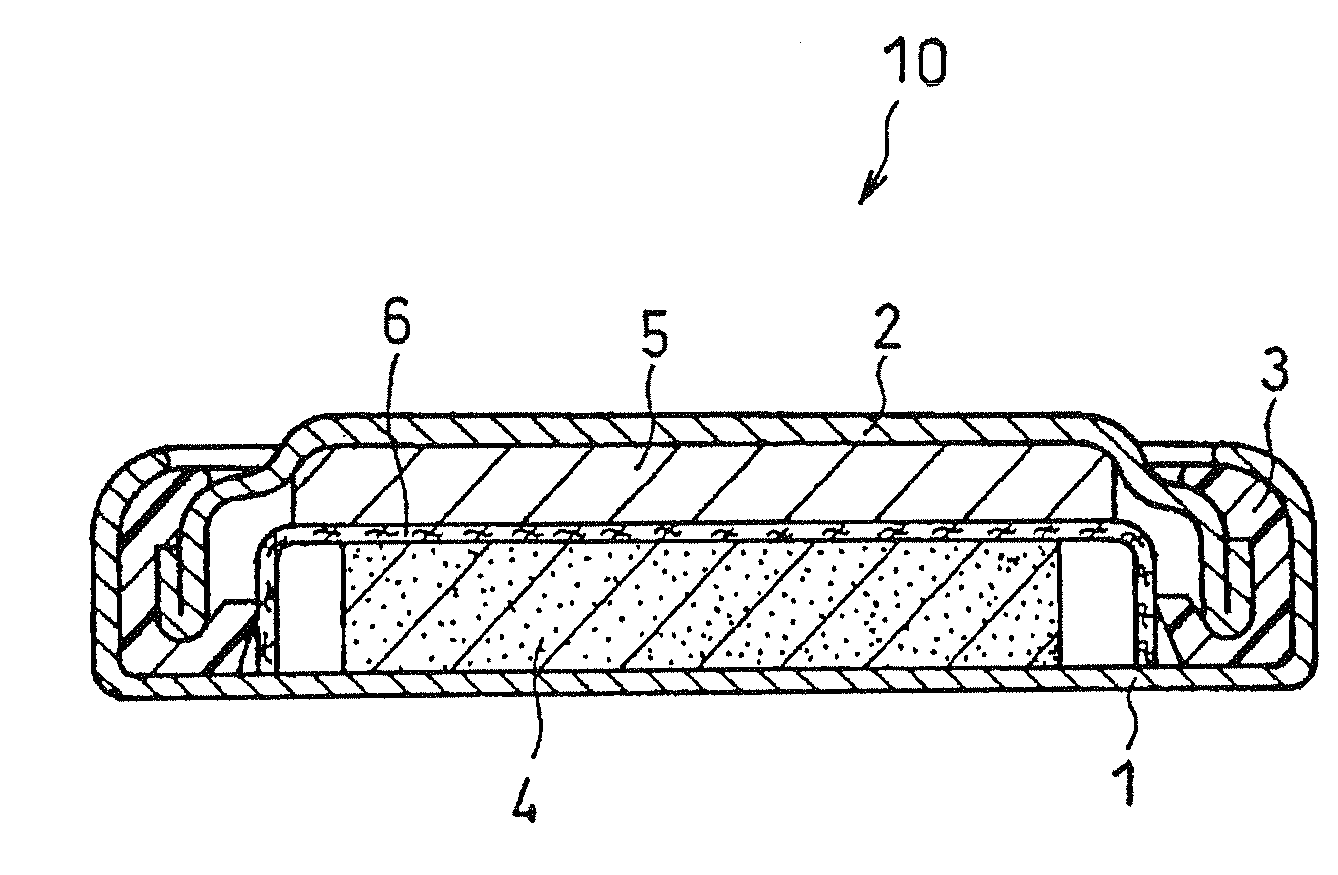

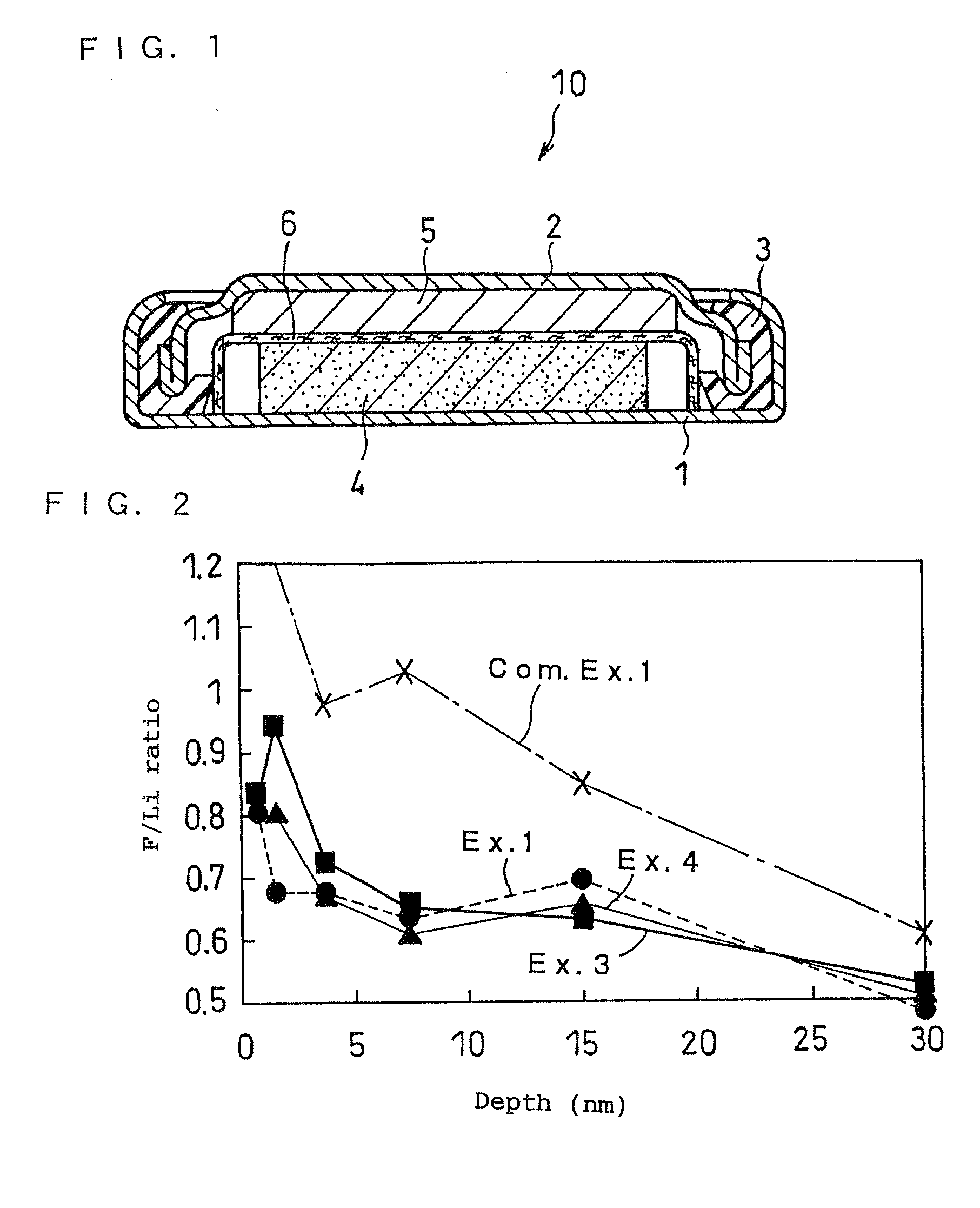

Lithium Primary Battery and Manufacturing Method Therefor

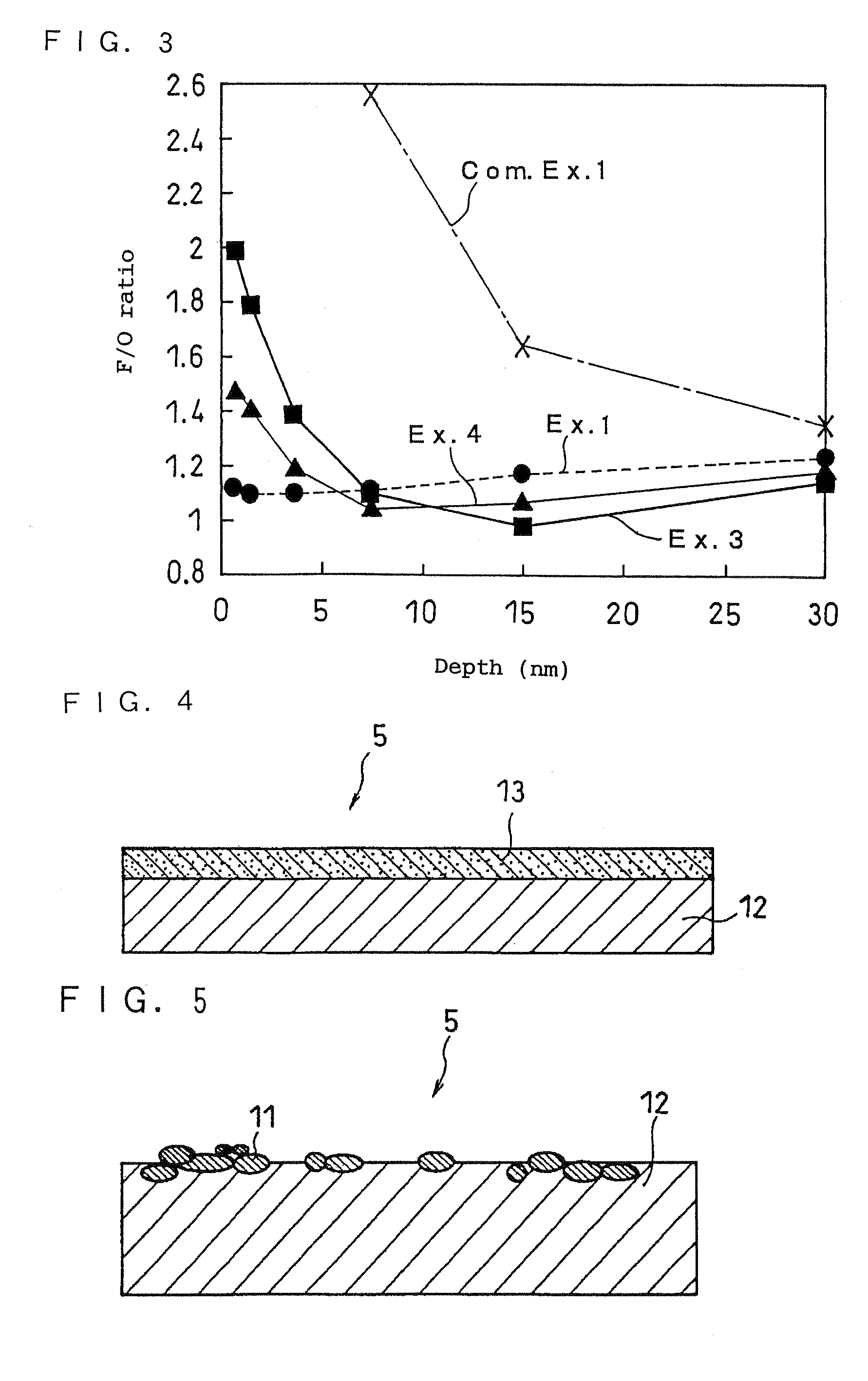

ActiveUS20090123844A1Increase internal resistanceImprove high-current discharge performanceElectrode manufacturing processesElectrode carriers/collectorsSurface layerLithium metal

A lithium primary battery including a positive electrode, a negative electrode, an organic electrolyte, and a separator interposed between the positive electrode and the negative electrode: the negative electrode including a negative electrode active material; the negative electrode active material being at least one selected from the group consisting of lithium metal and a lithium alloy; at least a surface layer portion of the negative electrode including a composite of amorphous carbon material and the negative electrode active material; and the surface layer portion facing the positive electrode with the separator interposed therebetween.

Owner:PANASONIC CORP

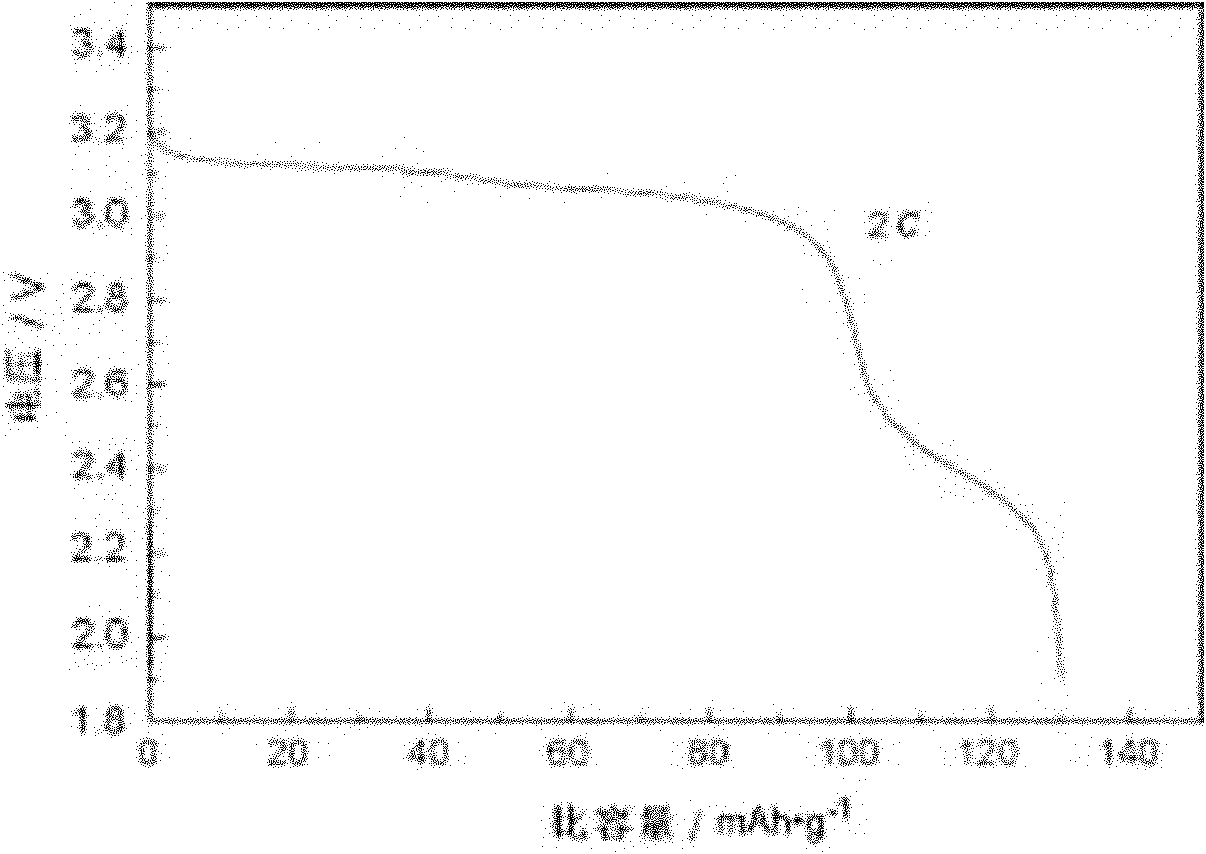

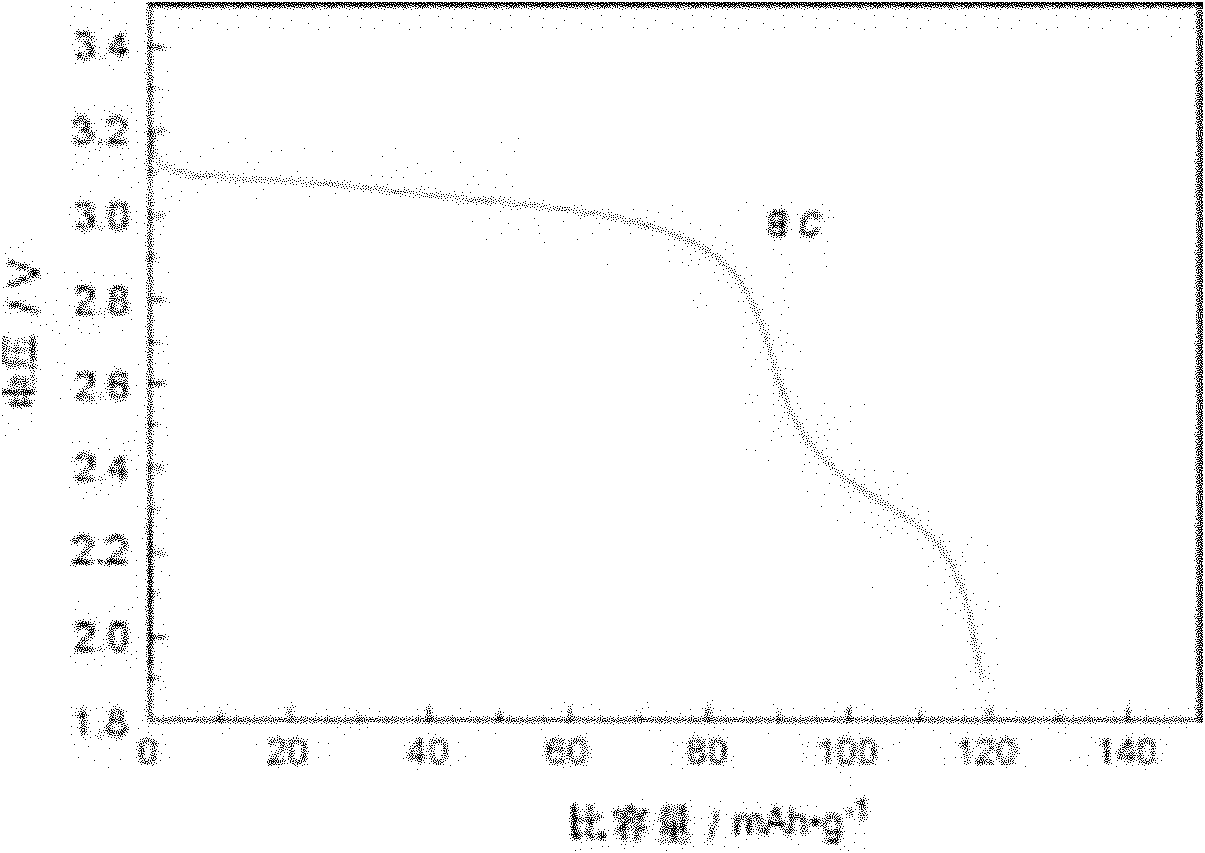

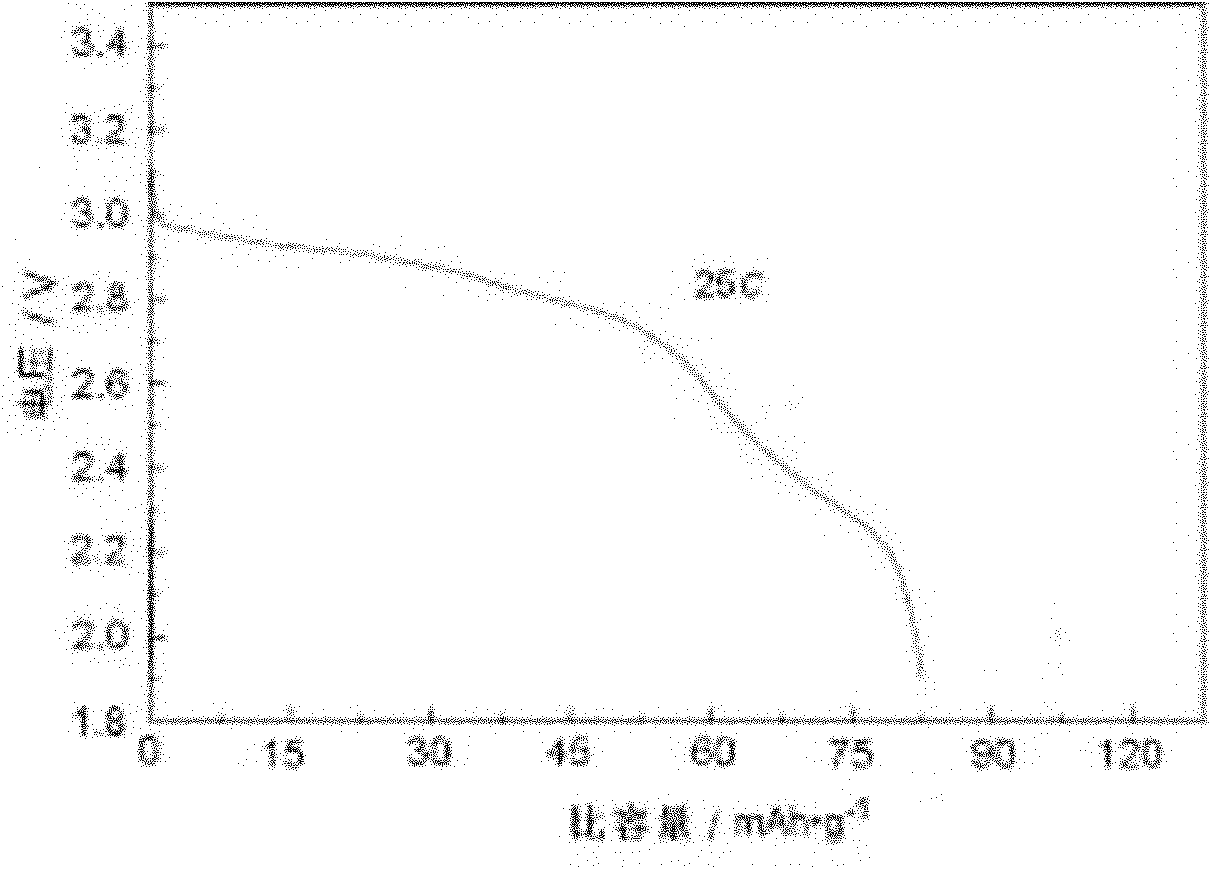

High magnification polymer lithium ion power battery and preparation method thereof

InactiveCN102130363AImprove material performanceSimple processSecondary cellsNon-aqueous electrolyte accumulator electrodesAdhesiveALUMINUM PHOSPHATE

The invention discloses a high magnification polymer lithium ion power battery and a preparation method thereof, and belongs to the field of lithium ion power batteries. Compared with the conventional batteries (1-10C), the discharge current of the battery is greatly promoted; and the magnification discharge can reach 20 to 25C. Aluminum phosphate (AlPO4) is coated on the surface of a high-voltage lithium ion anode material (LiNi0.5Mn1.5O4) in the anode; the anode mixture contains 78 to 92 percent of active substance, 4 to 11 percent of conductive agent and 4 to 11 percent of adhesive in percentage by weight; and the cathode contains 78 to 92 percent of surface cracked carbon coated lithium titanate, 4 to 11 percent of conductive agent and 4 to 11 percent of adhesive. The battery 2C, 8C and 25C discharge specific capacities of the lithium ion battery are 130mAh / g, 120mAh / g and 83.5mAh / g. The power battery can be used for various high-capacity high magnification discharge equipment such as electric vehicles, unmanned machines, power sources for submarines and the like.

Owner:BEIJING SHENZHOU YUANWANG TECH

Samarium-containing praseodymium and neodymium-free hydrogen storage alloy for nickel-hydrogen power battery

The invention discloses a samarium-containing praseodymium and neodymium-free hydrogen storage alloy for a nickel-hydrogen power battery. The hydrogen storage alloy is characterized in that the atomic ratio of the composition is La(1-x-y)CexSmyNiaCobMncAldMe, wherein M is one or two of Fe, Cu and B; and x is 0.20-0.70, y is 0.01-0.30, a is 3.30-4.20, b is 0.10-0.70, c is 0.40-0.65, d is 0.10-0.35 and e is 0.05-0.30. The samarium-containing praseodymium and neodymium-free hydrogen storage alloy for a nickel-hydrogen power battery disclosed by the invention does not contain relatively expensive rare earth elements such as praseodymium, neodymium and the like and thus reduces the production cost, and also has the performance such as easy activation, high discharge voltage and capacity, good high-current discharge and the like.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS +1

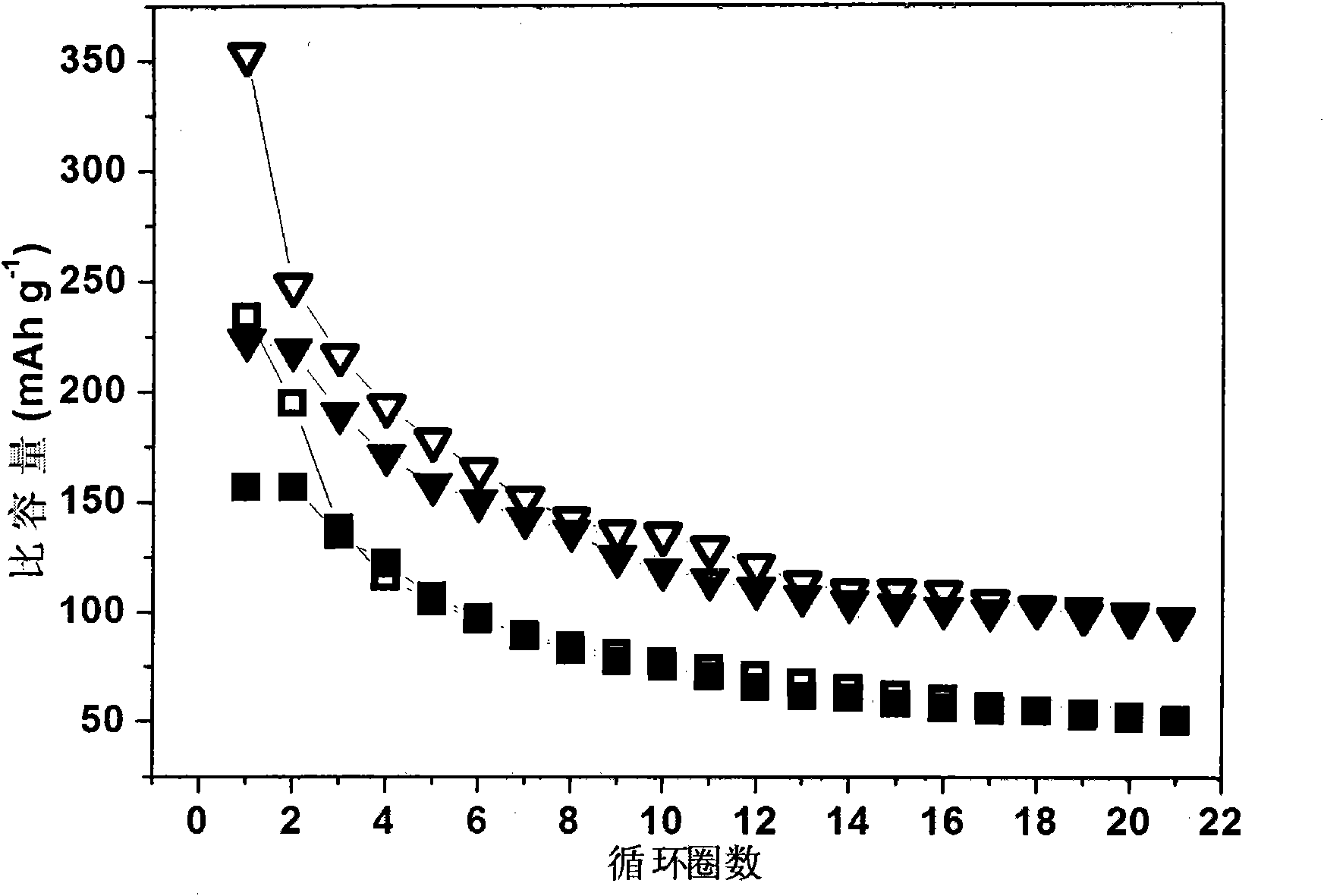

Method for preparing cathode electrode material of nanobelt-type lithium ion battery

InactiveCN102013482AInhibit swellingHigh reversible capacityCell electrodesNanotechnologyLithium-ion batteryElectron

The invention discloses a method for preparing a cathode electrode material of a nanobelt-type lithium ion battery, belonging to the technical field of energy. The method comprises the following steps: preparing a MoO3 nanobelt by using a hydrothermal method, evenly blending the MoO3 nanobelt and MgCl2 solution and stirring; then performing hydrothermal treatment once again; and utilizing Mg to dope the MoO3 nanobelt. By using the method, the specific area of MoO3 is greatly improved, the transmission speeds of electrons and ions are increased, and the embedding and abjection of lithium ions are promoted, thus improving the large-current discharging performance of the material of the battery; after Mg is doped, due to the polarization of Mg, the crystal face of MoO3 is contracted, therebyinhibiting the expansion of the material during charging and discharging; meanwhile, due to the doping of Mg, Li-O keys are weaken, the interface resistance is reduced, the mobility of the lithium ions is improved and the reversible capacity and cycling performance of the material are improved; and in addition, the preparation method provided by the invention has the characteristic of simple flow, small energy consumption and the like, and is beneficial to large-scale preparation and production.

Owner:TSINGHUA UNIV

Method for preparing iron disulfide/carbon composite positive electrode material for disposable lithium battery and method for assembling button battery by using positive electrode material

The invention relates to a method for preparing an iron disulfide / carbon composite positive electrode material for a disposable lithium battery. According to the method, carbon covers the surfaces of iron disulfide particles, the mass percentage of iron disulfide is 75-99.5%, and the mass percentage of carbon is 0.5-25%. The method comprises the following specific steps: mixing pyrite and a carbon source substance according to the mass ratio of (75-95): (5-60), dispersing into a dispersing agent, and carrying out ball milling for 1-10 hours, so as to obtain a mixed paste material; drying the obtained mixed paste material for 1-10 hours in a vacuum drying oven at the temperature of 80-150 DEG C, heating the dried precursor material to the temperature of 300-500 DEG C under the protection of inert gas, maintaining for 1-8 hours, then, cooling to room temperature, and sifting, thereby obtaining the iron disulfide / carbon composite positive electrode material for the disposable lithium battery.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

Composite cathode material for thermal battery suitable for long-time terminal heavy current discharge

ActiveCN108039468AReduce capacity lossImprove conductivityDeferred-action cellsCell electrodesIonCarbon nanotube

The invention discloses a composite cathode material for a thermal battery suitable for long-time terminal heavy current discharge. The composite cathode material is characterized by being prepared from the following components by mass fraction: 30 to 50 percent of CoS2, 30 to 50 percent of NiS2, 1 to 3 percent of Li2O, 15 to 30 percent of an ion conductive agent and 0.5 to 2 percent of an electronic conductor. By adding a NiS2 cathode material, elemental nickel with high conductivity is generated by the NiS2 cathode material in the self-discharge process, and further the later conductivity ofan electrode material is improved; secondly, the conductivity of the whole composite cathode material is improved without affecting the output capacity of the composite cathode material due to the addition of a small amount of a carbon nanotube electronic conductor with high conductivity; and finally, due to the addition of the ion conductive agent, the migration rate of Li<+> in the electrode reaction process is improved and the concentration polarization in the reaction process is reduced.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

Battery anode, preparation method thereof and lithium ion battery using the same

ActiveCN103456918AIncrease capacityPromote circulationSecondary cellsNon-aqueous electrolyte accumulator electrodesLithium iron phosphateOlivine

The invention provides a battery anode, its preparation method and a lithium ion battery using the same. The battery anode includes a conductive substrate and an anode material coated on the conductive substrate. The anode material comprises an anode active material, a conductive agent and a binder. The anode active material contains, based on its total weight, 5wt%-20wt% of layered nickel cobalt lithium aluminate and 80wt%-95wt% of olivine type lithium iron phosphate. The battery anode has the advantages of high capacity and cycling stability.

Owner:BYD CO LTD

Preparation method of positive electrode paste for lithium fluorocarbon battery with carbon nanotube as conductive agent

InactiveCN109962240ALower internal resistanceImprove high-current discharge performanceElectrode manufacturing processesNon-aqueous electrolyte cellsLow speedAdhesive

The invention relates to a preparation method of positive electrode paste for a lithium fluorocarbon battery with a carbon nanotube as a conductive agent, and belongs to the technical field of lithiumprimary batteries. According to the preparation method of the positive electrode paste for the lithium fluorocarbon battery with the carbon nanotube as the conductive agent, the conductive adhesive containing the carbon nanotube is used as the conductive agent, the mass ratio of the positive electrode material, the conductive agent and the adhesive of the positive electrode paste is 90-97.5: 6-0.5: 4-2, the paste solvent is deionized water or N-methyl pyrrolidone and the paste solid content is 30-50wt%. The preparation process is that firstly the paste solid powder is stirred and mixed in a mixer, the solvent is added, the paste solid powder is stirred at a low speed of 30-70 revolutions per minute and dispersed at a high speed of 2000-5500 revolutions per minute, and the stirring time is5-8 hours; after 3 to 5 hours of stirring, carbon nanotube conductive adhesive is added; and a binder is added and stirred for 30 to 60 minutes so as to obtain the positive electrode paste for the lithium fluorocarbon battery. The method has the advantages of simple operation and convenience and rapidity and is suitable for large-scale production and greatly improves the electrochemical performance of the lithium fluorocarbon battery such as high current discharge capacity and energy density.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST

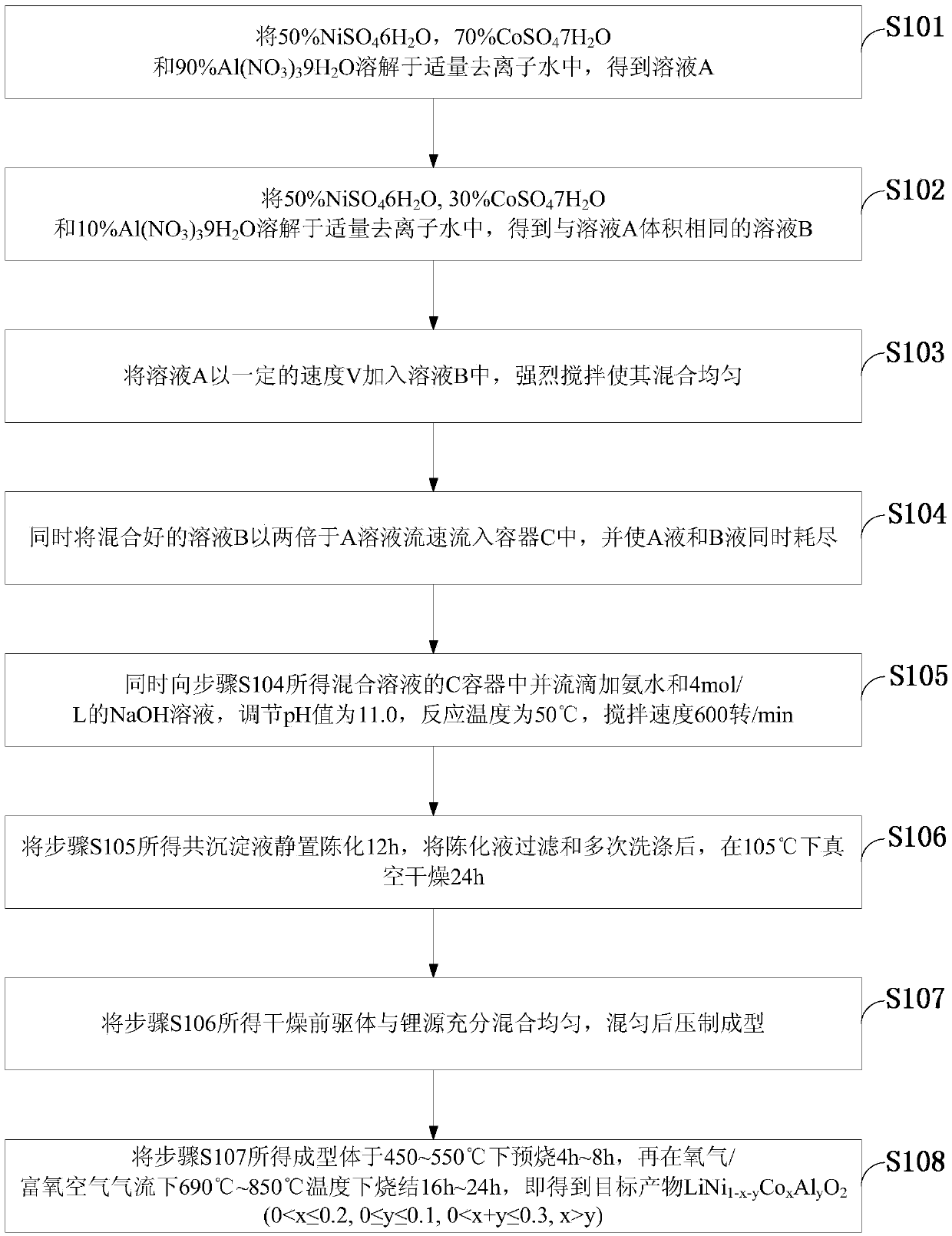

Positive electrode material of high-capacity lithium ion battery and preparation method of positive electrode material

InactiveCN105514373AHigh discharge specific capacityExcellent cycle stabilityCell electrodesSecondary cellsLithium electrodeLarge capacity

The invention discloses a positive electrode material of a high-capacity lithium ion battery and a preparation method of the positive electrode material. The preparation method comprises the following steps: dissolving raw materials into de-ionized water to prepare a mixed solution A and a mixed solution B, which have the same volume and different concentrations; adding a sodium hydroxide solution and an ammonia water solution into a container C in a parallel flow manner to be subjected to co-precipitation, so as to prepare a co-precipitate Ni1-x-yCoxAly(OH)2+y precursor; after ageing, filtering, washing and drying the prepared co-precipitate precursor, uniformly mixing the co-precipitate precursor with a lithium source; pressing and molding mixed materials, putting the mixture into a pipe furnace for presintering, and sintering the mixture in an oxygen / oxygen-enriching air airflow to obtain a target product. The positive electrode material of the lithium ion battery, provided by the invention, has no impure phases and has high crystallization quality; the product has a uniformly-distributed grain diameter and a regular spherical shape, and has a very high specific discharge capacity and relatively excellent circulating stability; the positive electrode material can meet high-energy density and high-power charging and discharging requirements, a process is simple and a manufacturing cost is relatively low.

Owner:SICHUAN FUHUA NEW ENERGY HIGH TECH CO LTD

Positive electrode active material and non-aqueous electrolyte secondary cell

ActiveCN1658415AInhibition lowering potentialInhibits breakdown of electrolytesNon-aqueous electrolyte accumulatorsFinal product manufactureDecompositionComposite oxide

A non-aqueous electrolyte secondary cell having superior high temperature-operation properties and excellent large current-discharge properties is provided. The non-aqueous electrolyte secondary cell has a positive electrode composed of a positive electrode collector and positive electrode active material layers formed thereon. A positive electrode active material contained in the above layer is formed of a first composite oxide and a second composite oxide mixed therewith. The first composite oxide is formed of grains of a first lithium transition metal composite oxide containing at least nickel as a transition metal and a cover layer formed on at least part of the surface of each of the grains for suppressing decomposition of an electrolyte caused by the first lithium transition metal composite oxide. The second composite oxide is composed of grains of a second lithium transition metal composite oxide.

Owner:MURATA MFG CO LTD

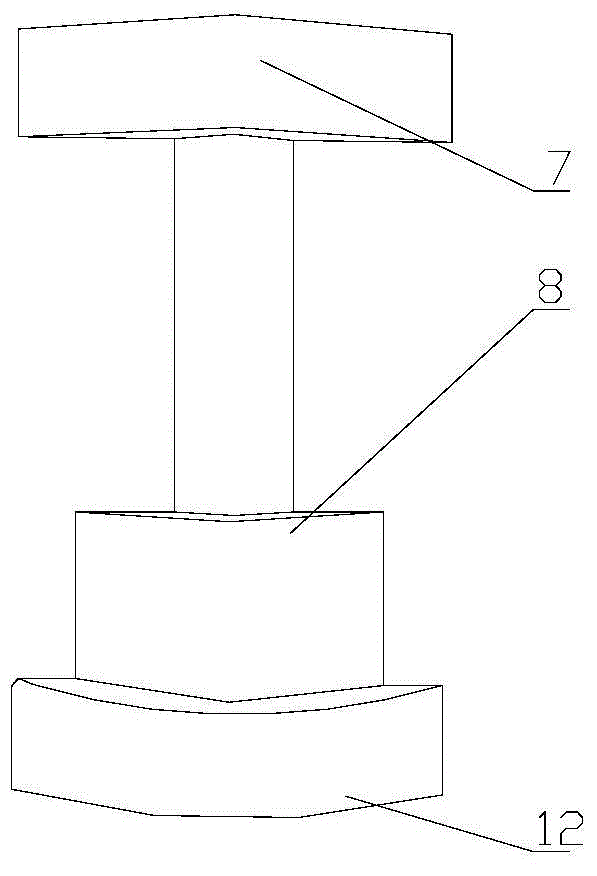

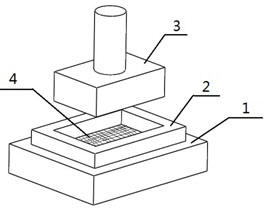

Manufacturing equipment and manufacturing method for electrode of power type lithium ion battery

InactiveCN102694149ANot easy to fall offSuppress and correct deformationCell electrodesSolventCurrent collector

The invention discloses manufacturing equipment and a manufacturing method for an electrode of a power type lithium ion battery. The manufacturing equipment comprises a vibration disk, a foam metal die, an electrode solid-state filler powder box and foam metal, wherein the foam metal die is arranged on the vibrating disk; the electrode solid-state filler powder box is arranged above the foam metal die; and the foam metal is arranged in the foam metal die. The foam metal with the characteristics of high electric conductivity, high thermal conductivity, large specific surface area, uniform and small through holes and the like is adopted as a current collector, and a skeleton structure of the foam metal is inserted into powdery active substances for pressurization to obtain an electrode plate with strong binding force, so that the active substances difficultly fall, the electric conductivity of the active substances of the electrode is effectively improved, internal resistance is lowered, heat produced by the battery is reduced, radiation is facilitated, and the service life of the battery is prolonged; and in addition, a solid-state active substance is used for directly filling the foam metal without an aqueous solution or a non-aqueous solvent, so that the obtained electrode plate is not required to be baked to remove the solvent, the manufacture period of the battery is shortened, energy consumption is reduced, and production cost is saved.

Owner:广州贝特缪斯能源科技有限公司

A phosphate Fe, lithium and aluminum shell column battery and its making technology

InactiveCN101188310ALarge capacityIncrease capacityFinal product manufactureSmall-sized cells cases/jacketsPhosphateEngineering

The invention relates to an iron phosphate lithium aluminum shell cylindrical battery and the manufacture process thereof, and belongs to the field of lithium ion power batteries. The invention comprises a shell, a positive plate, a negative plate, electrolyte and a septum. The positive plate and the negative plate respectively comprise positive and negative fluid collecting bodies and positive and negative sizing agent, and the positive and negative sizing agent are coated on the positive and the negative fluid collecting bodies. The shell is an aluminum shell. Positive materials adopt iron phosphate lithium; the positive fluid collecting body adopts aluminum foil; electric conduction agent adopts one or two mixtures of superconductive carbon soot and electric conduction graphite; positive material caking agent selects polyvinylidene fluoride. Negative materials adopt native graphite or artificial graphite; the negative fluid collecting body adopts copper foil; the electric conduction agent selects one or two mixtures of the superconductive carbon soot and the electric conduction graphite; negative material caking agent selects the polyvinylidene fluoride or sodium carboxymethyl cellulose and perbunan. The positive plate, the negative plate and the septum are made into a columniform winding core through the winding of multilayer cascades. The invention not only has big capacity, but also can discharge in a great multiplying power.

Owner:山东海霸电池有限公司

Dual-foamed iron-nickel battery and production method thereof

ActiveCN103022575APrevent easy powder removalIncrease profitFinal product manufactureAlkaline accumulator electrodesPolyolefinNickel substrate

The invention discloses a dual-foamed iron-nickel battery and a production method thereof. The technical scheme adopted by the invention is as follows: the dual-foamed iron-nickel battery comprises a container with electrolyte, and an anode and a cathode which are arranged inside the container, wherein the anode is a foamed nickel electrode; the foamed nickel electrode comprises a foamed nickel substrate, active slurry coated inside the foamed nickel substrate, and a nickel-plated stainless steel woven wire mesh or a porous nickel-plated steel sheet which is adhered to the two sides of the nickel electrode; the cathode is a foamed iron electrode; the foamed iron electrode comprises a foamed substrate and active slurry coated inside the foamed substrate; the foamed substrate can be foamed nickel, foamed copper or foamed iron; the anode and the cathode adopt combined lamination structures; and a polyolefin diaphragm is arranged between the anode and the cathode. The invention further discloses the production method of the iron-nickel battery. The dual-foamed iron-nickel battery is high in capacity, strong in high-current discharging capability, long in service life and simple in production.

Owner:河南创力新能源科技股份有限公司

1.5V cylinder lithium pyrite battery with anode collection fluid of stephanoporate metal

InactiveCN101299459AInhibit swellingImprove high-current discharge performanceElectrode carriers/collectorsOrganic electrolyte cellsFiberMetallic lithium

A 1.5V column lithium iron disulphide cell with the porous metal as the anode current collector, includes a case, wherein the upper of the case is a combination nut cap, and an anode and a cathode are arranged in the case; the case is filled with the electrolyte; a septum is arranged between the anode composed of a current collector and an anode material and the cathode. The cathode is the metallic lithium, the lithium aluminum alloy or the lithium silicon alloy. The electrolyte is the solution in which lithium salt is dissolved in the ethylene carbonate, characterized in that, the anode current collector is the porous metal, selected from one of foaming nickel, fiber nickel, foaming copper, foaming aluminum, weaved aluminum mesh, weaved copper mesh, weaved stainless steel mesh, weaved nickel mesh. The invention causes the active material fully to contact with the current collector, advances the utilance of the active material, refrains expansion of the anode in the cell discharging process, reduces the falling of the active material, reinforces the discharging ability of the large current of the cell, advances the discharging capacity of the cell, simplifies the production technology of the cell, which is suitable for the large-scale industrialization production.

Owner:SHANDONG SHENGONGHAITE ELECTRONICS TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com