Negative plate of battery, preparation method thereof and battery comprising negative plate

A negative plate and battery technology, applied to battery electrodes, lead-acid battery electrodes, lead-acid batteries, etc., can solve the problems of long charging time, short battery cycle life, poor starting performance at low temperature, etc., to inhibit crystal growth and improve Large current discharge capability, effect of improving cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0025] According to a typical embodiment of the present invention, a battery is provided. The battery includes the aforementioned negative plate. The positive plate can be completed by the positive plate manufacturing process of the traditional lead-acid battery. The finished battery can be obtained by internalizing the green electrode plate and the assembled battery, or the green electrode plate can be externalized to form a mature electrode plate and then assembled into a finished battery. Preferably, the aforementioned battery is a lead-carbon super battery.

[0026] According to a typical implementation of the present invention, the preparation method of the above-mentioned negative electrode plate includes the following steps: 1) mixing the active material of the battery, the capacitor material and the conductive steric resistance agent uniformly, and then adding water and sulfuric acid solution to prepare the negative electrode lead of the battery paste; 2) apply the l...

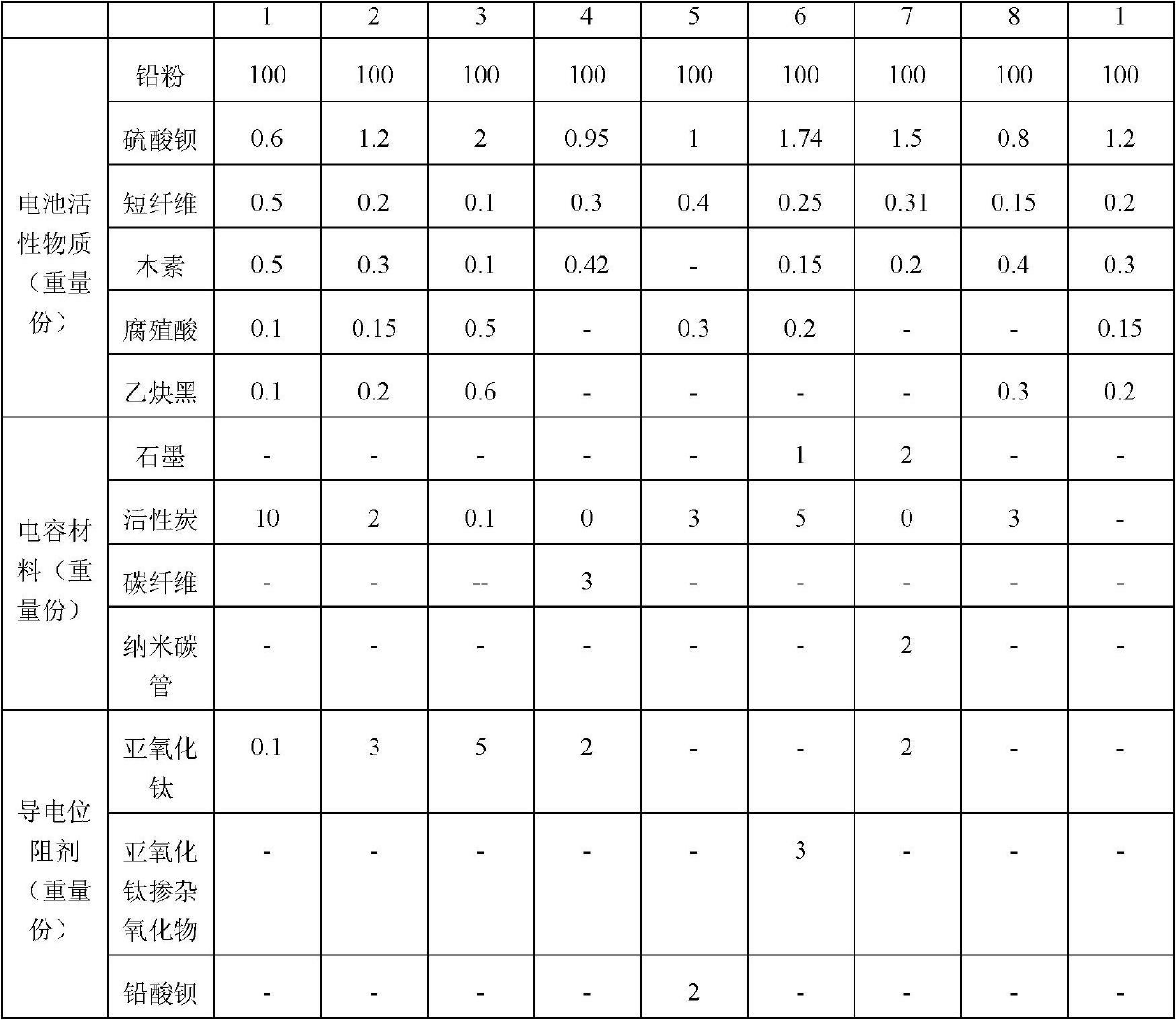

Embodiment l

[0029] The content of each component of the negative electrode in this example is shown in Table 1. After mixing the battery active material component, the capacitor material component, and the conductive steric hindrance agent component evenly, add water and sulfuric acid respectively and stir in a paste mixing machine to make a lead paste. The prepared lead paste is coated on the grid, cured at 60°C and 98% relative humidity, dried at 70°C to obtain a raw electrode plate, and the green electrode plate is formed to obtain a negative mature electrode plate for a battery.

[0030] The positive plate in this embodiment is made by the traditional method of making the positive plate of the lead-acid battery, and the positive plate and the negative plate of the battery are assembled into a battery for performance testing.

[0031] In this embodiment, after high content of activated carbon is added, the negative electrode has good capacitive characteristics. When a large current is c...

Embodiment 2

[0034] The content of each component of the negative electrode in this example is shown in Table 1. After mixing the battery active material component, the capacitor material component, and the conductive steric hindrance agent component evenly, add water and sulfuric acid respectively and stir in a paste mixing machine to make a lead paste. The prepared lead paste is coated on the grid, cured at 60°C and 98% relative humidity, dried at 70°C to obtain a raw electrode plate, and the green electrode plate is formed to obtain a negative mature electrode plate for a battery. The positive plate in this embodiment is made by the traditional method of making the positive plate of the lead-acid battery, and the positive plate and the negative plate of the battery are assembled into a battery for performance testing.

[0035] In this embodiment, the addition of activated carbon makes the negative electrode have good capacitance characteristics. When high-current charge and discharge are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com