High brightness electrode for super high pressure mercury lamp

A high-brightness, ultra-high-voltage technology, used in electrode system manufacturing, discharge tube/lamp manufacturing, gas discharge lamp components, etc. And the performance improvement of high current, fine discharge arc and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

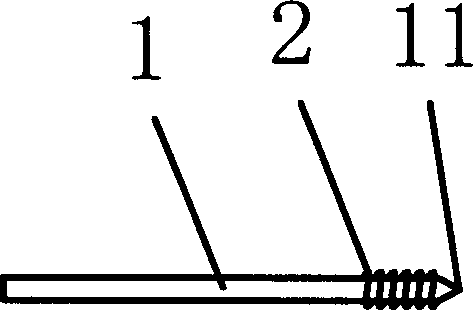

[0013] figure 1 It shows that a specific embodiment of the present invention is: a high-brightness electrode for an ultra-high pressure mercury lamp, comprising a rod-shaped tungsten electrode (1) and a coil (2) on the discharge end side of the rod-shaped tungsten electrode (1) The discharge end of the electrode (1) is a cone-shaped electrode tip (11), and the electrode tip (11) is formed by welding the discharge end with tungsten solder by means of argon arc welding.

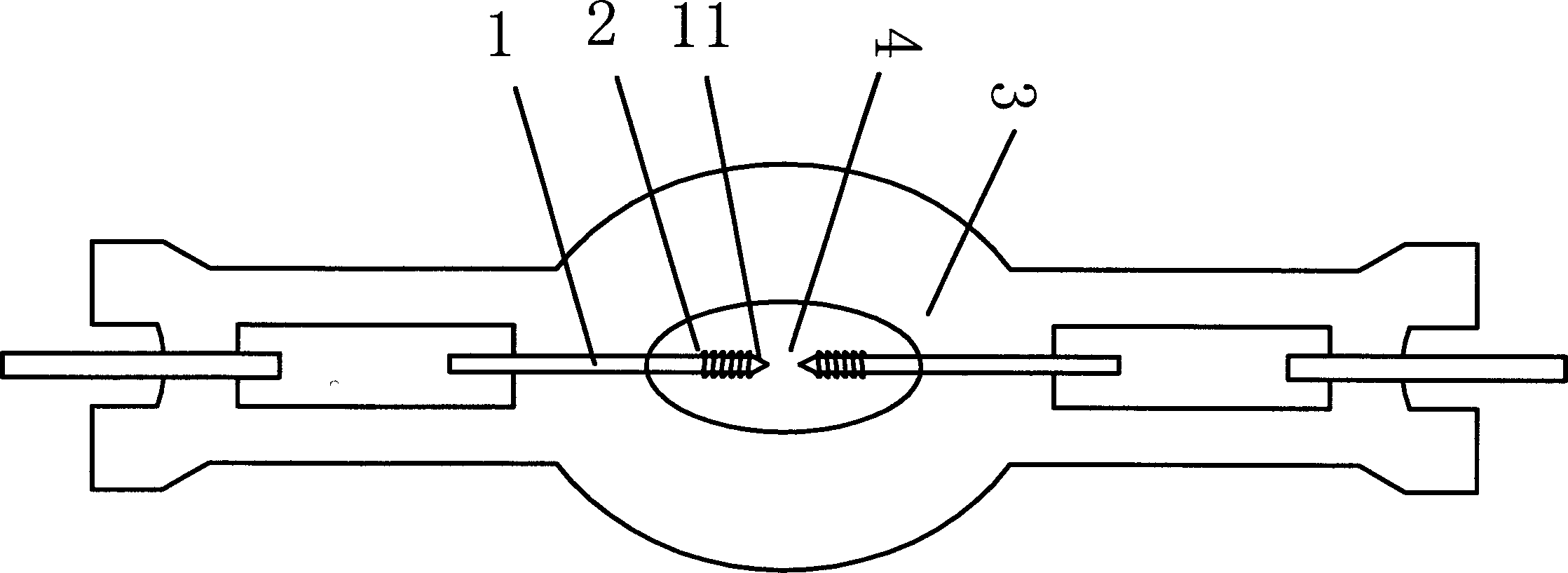

[0014] figure 2 Shown, during use, two electrodes 1 of the present invention are relatively fixed on both sides of the arc tube 3 by using the prior art, so that the pole tips of the two electrodes are opposite, and mercury, Argon and tungsten circulating gases are sufficient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com