Patents

Literature

162results about How to "Good high current discharge performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

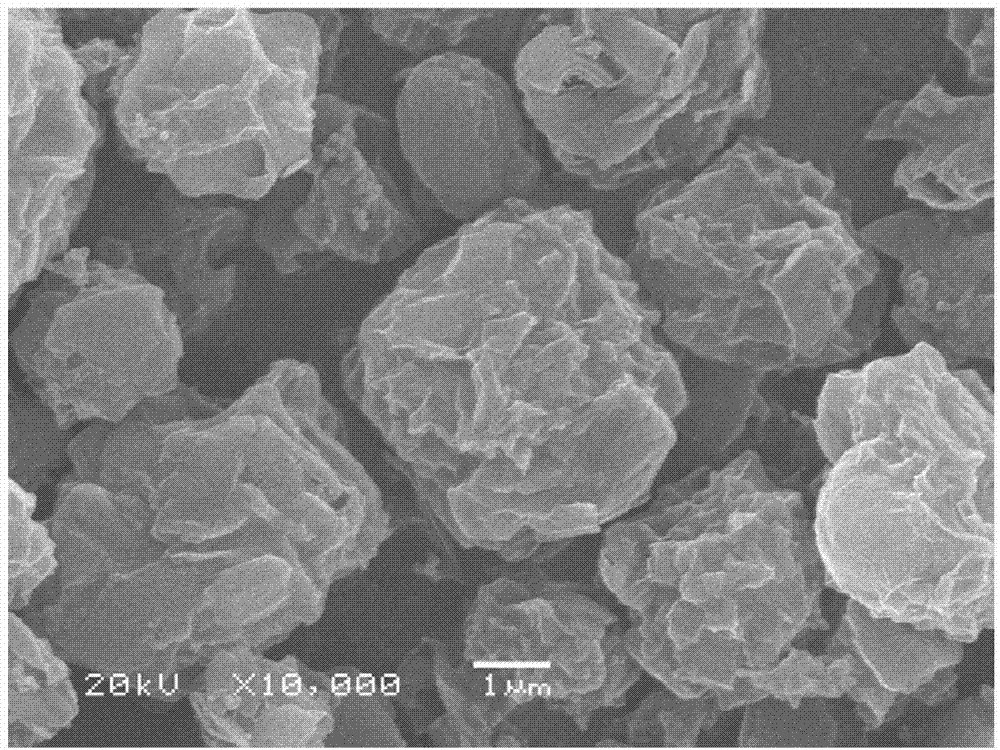

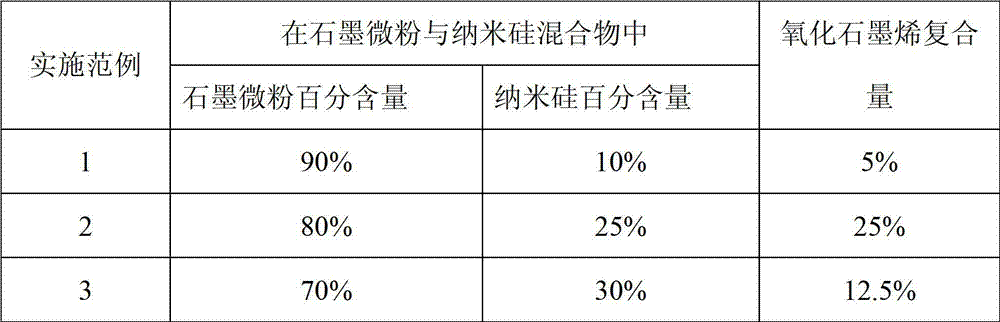

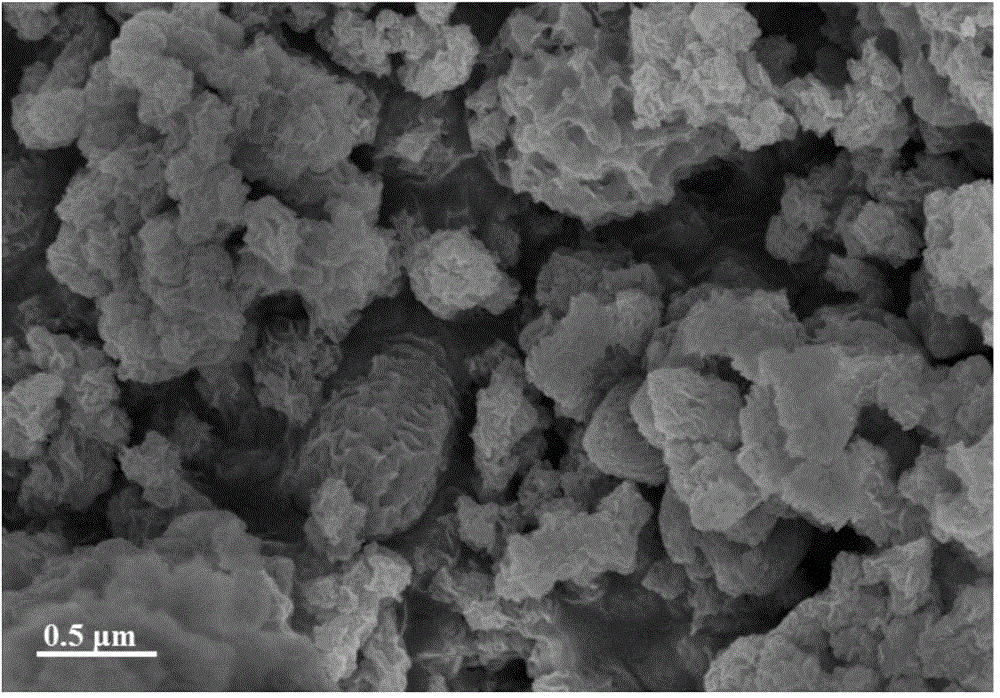

Preparation method of silicon and carbon-coated graphene composite cathode material

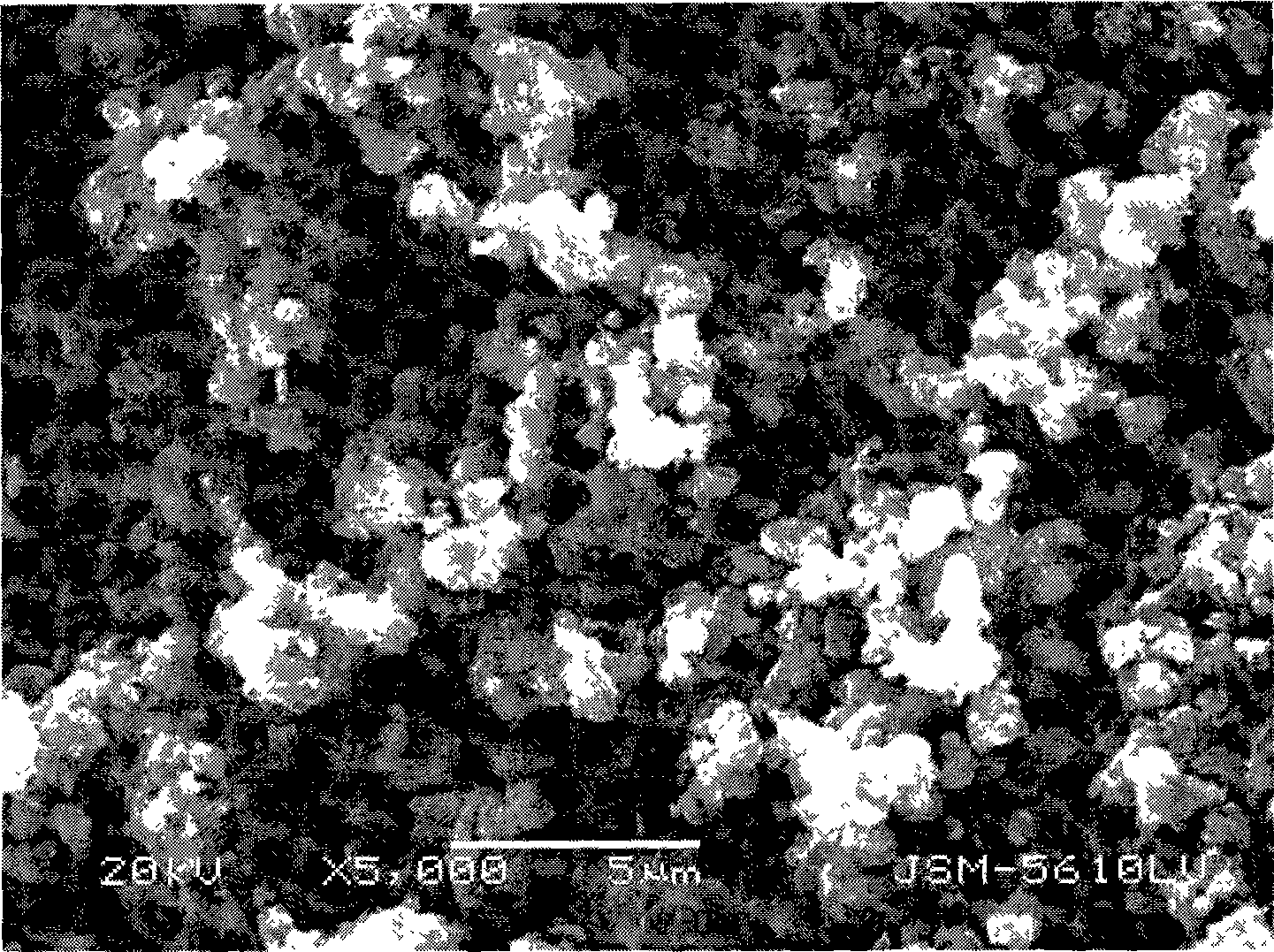

ActiveCN103050666ARealize in situ restorationThe preparation process is simple, convenient and practicalMaterial nanotechnologyCell electrodesCarbon coatedStructural stability

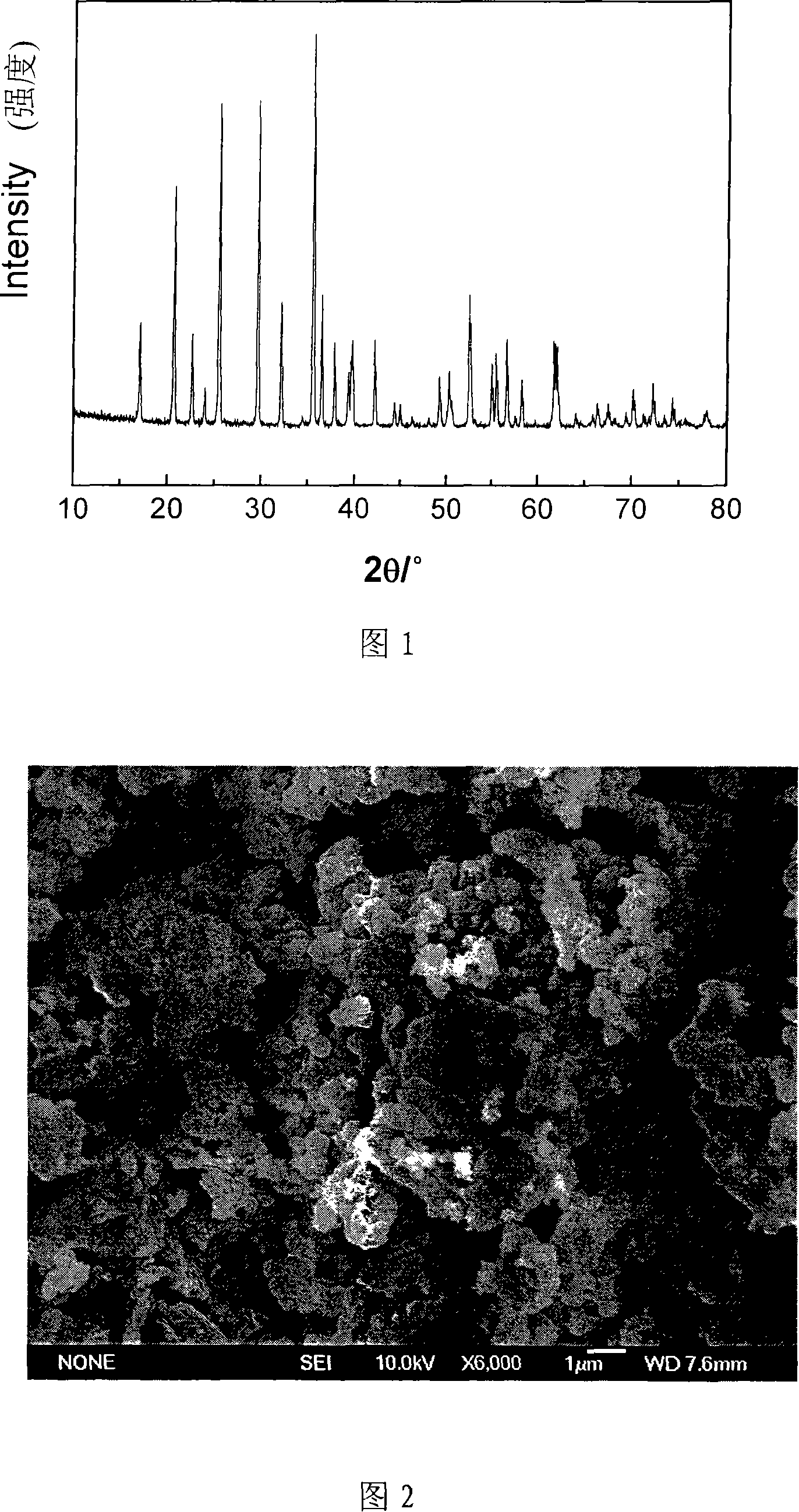

The invention discloses a preparation method of a silicon and carbon-coated graphene composite cathode material. The technical problem to be solved is to enhance the electronic conductivity of the silicon-based cathode material, buffer the volume effect produced in the process of deintercalation of the lithium in the silicon-based cathode material and enhance the structure stability in the circulation process of the material at the same time. The material is prepared by using a spray drying-thermally decomposing treatment process in the invention. The preparation method comprises the following steps of: evenly dispersing nano silicon and graphite micro powder in a dispersion solution of oxidized graphene, carrying out thermal treatment under an inert protection atmosphere after spray drying, subsequently cooling along a furnace to obtain the silicon and carbon-coated graphene composite cathode material. The extra binder does not need to add in the process of manufacturing balls in the invention and the outer oxidized graphene is thermally reduced in situ to graphene in the thermal treatment process of the composite precursor, so that the process is simple and easy to operate; and the practical degree is high. The prepared composite material has the advantages of great reversible capacity, designable capacity, good cycling performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

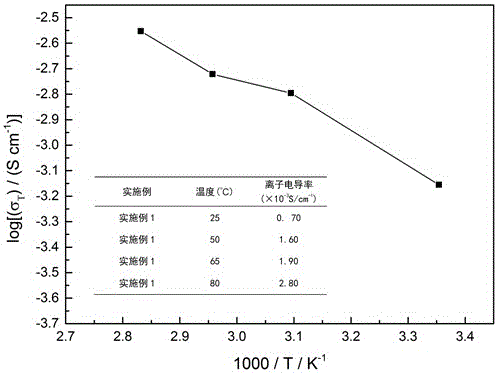

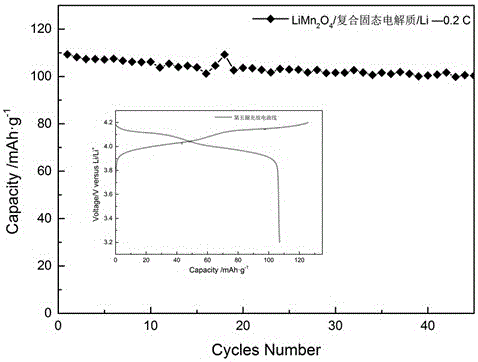

Composite solid polymer electrolyte and preparing method and application thereof

InactiveCN106299471AHigh mechanical strengthImprove thermal stabilitySolid electrolytesSecondary cellsPolymer electrolytesElectrical battery

The invention discloses a composite solid polymer electrolyte and a preparing method and application thereof. The composite solid polymer electrolyte is prepared from a gadoleic acid ester monomer, a porous supporting matrix, lithium salt, an additive and an initiator, wherein the mass ratio of the gadoleic acid ester monomer to the additive is (1-10):1, the lithium salt accounts for 5-30% of the total mass of the gadoleic acid ester monomer and the additive, and the mass ratio of the initiator to the gadoleic acid ester monomer is (1-10):100. The composite solid polymer electrolyte prepared with the method has the advantages of being large in ion conductivity, high in mechanical strength, easy to form, stable in interface contact, high in electrochemical stability and easy to prepare and can be used for forming solid lithium ion secondary batteries, and the prepared solid lithium ion secondary batteries are high in safety, energy density and production efficiency.

Owner:HARBIN INST OF TECH +1

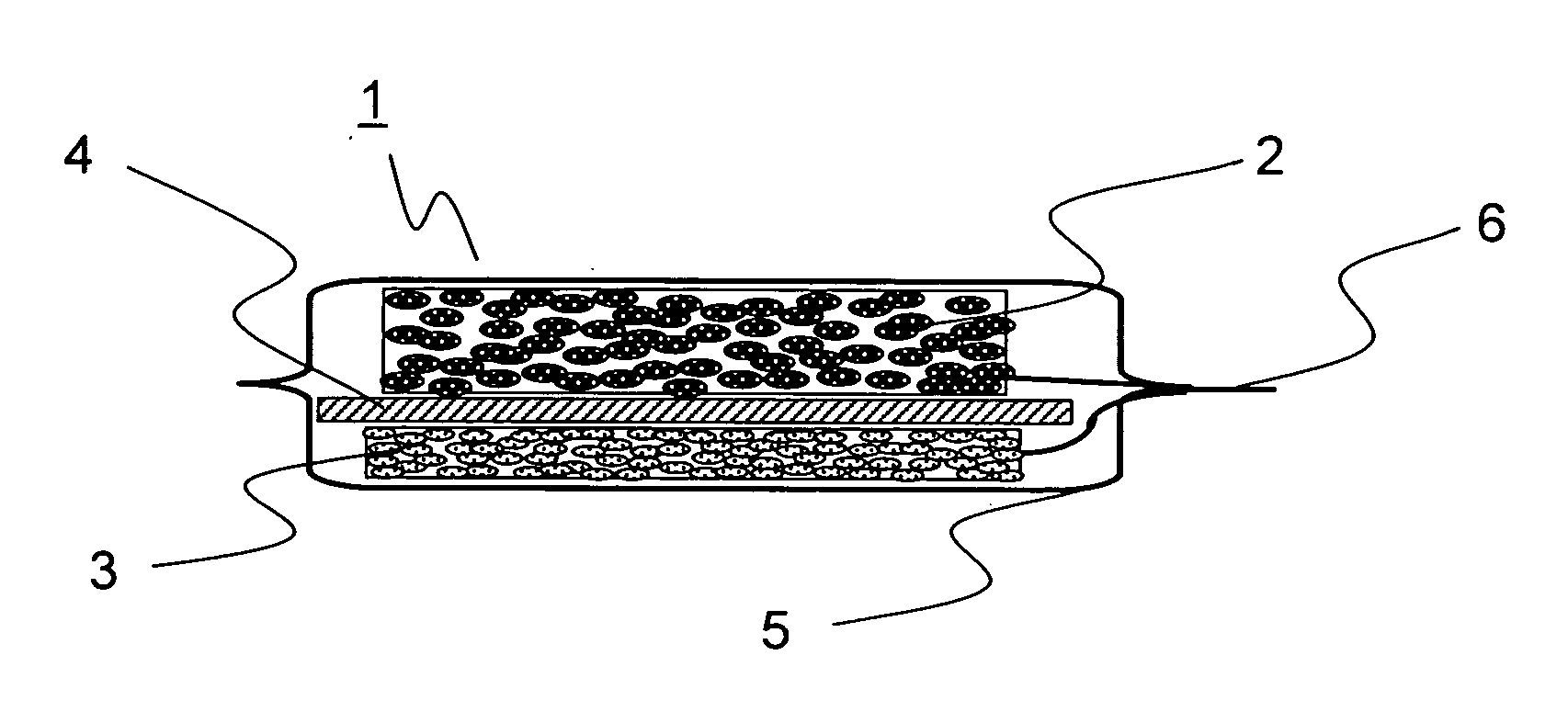

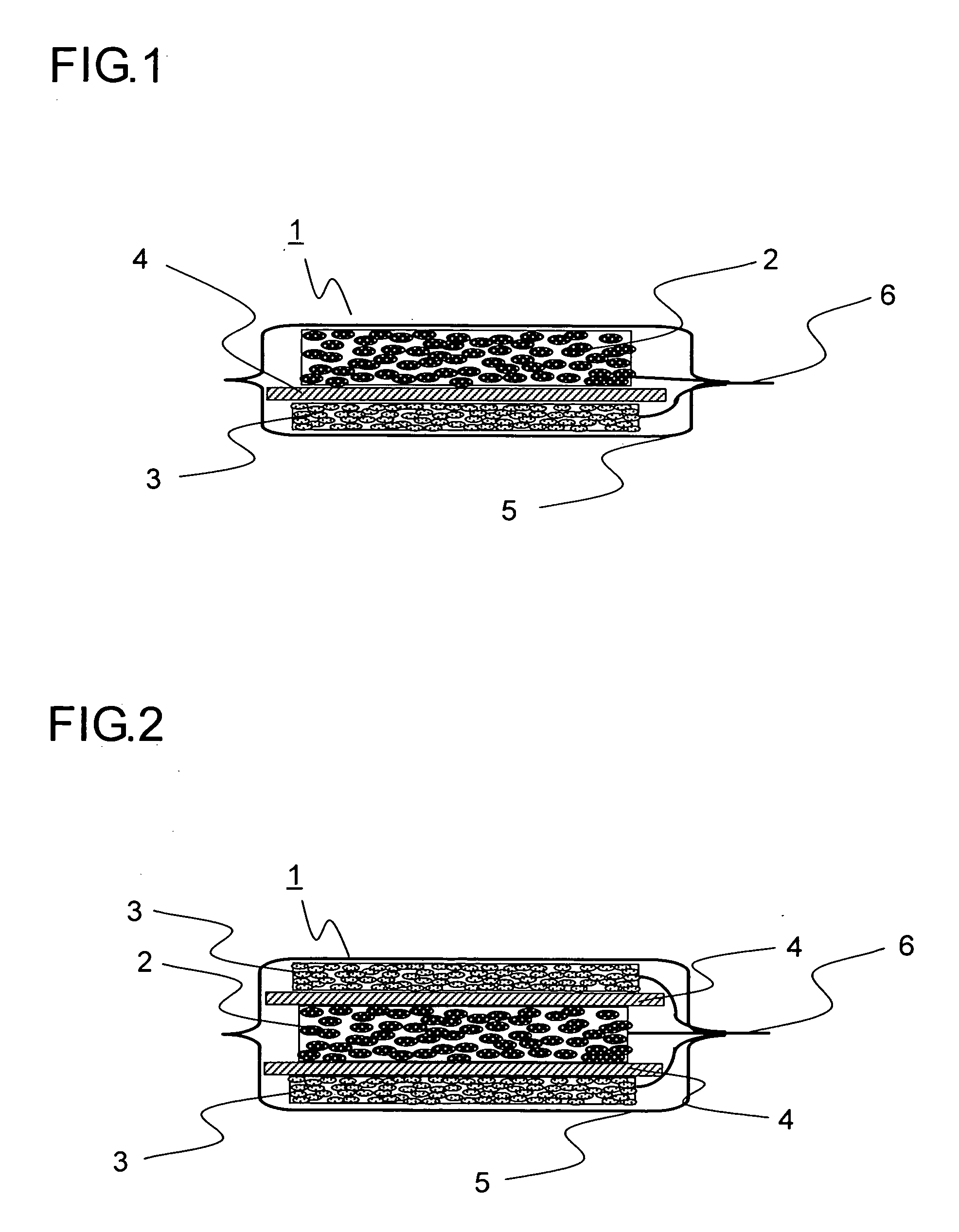

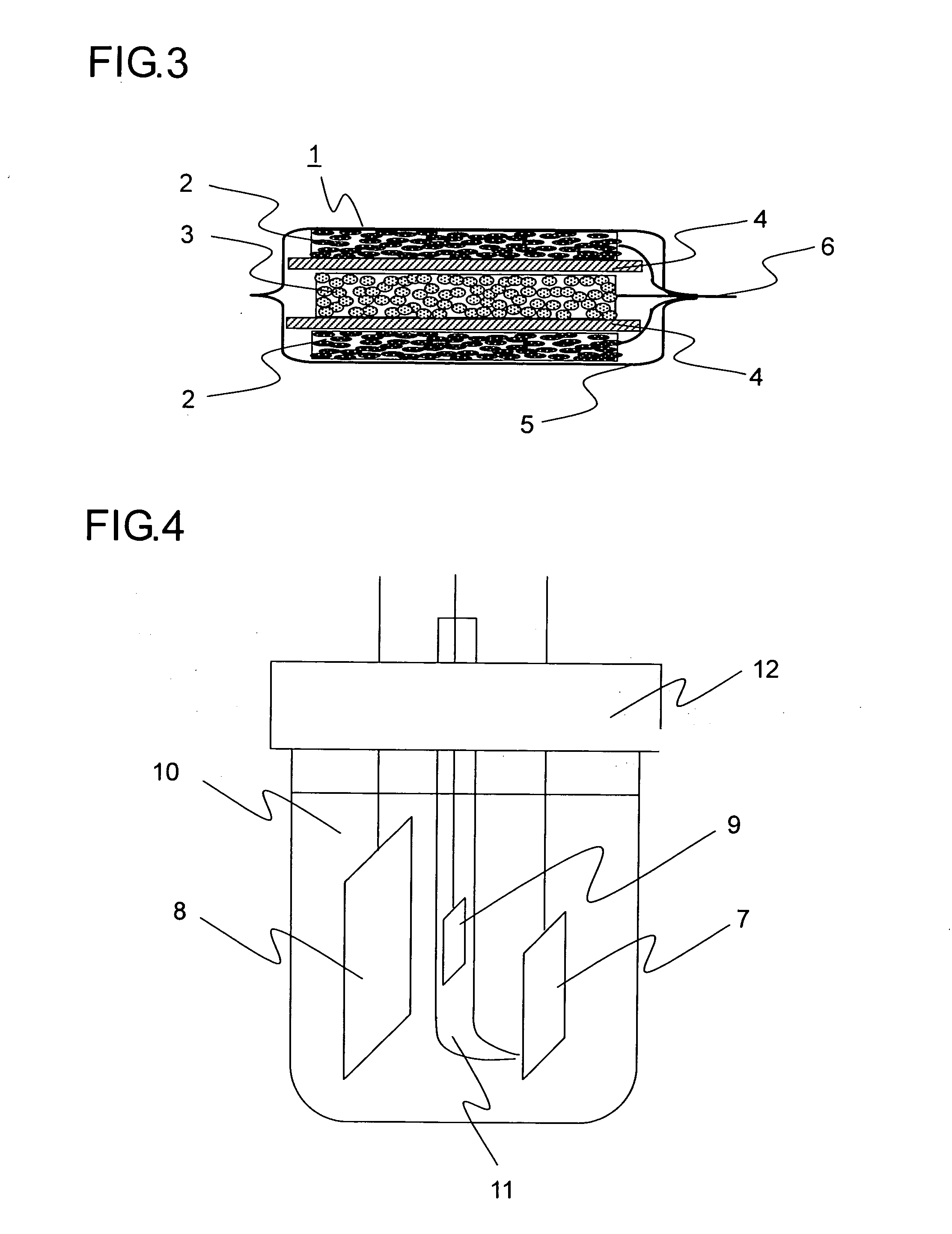

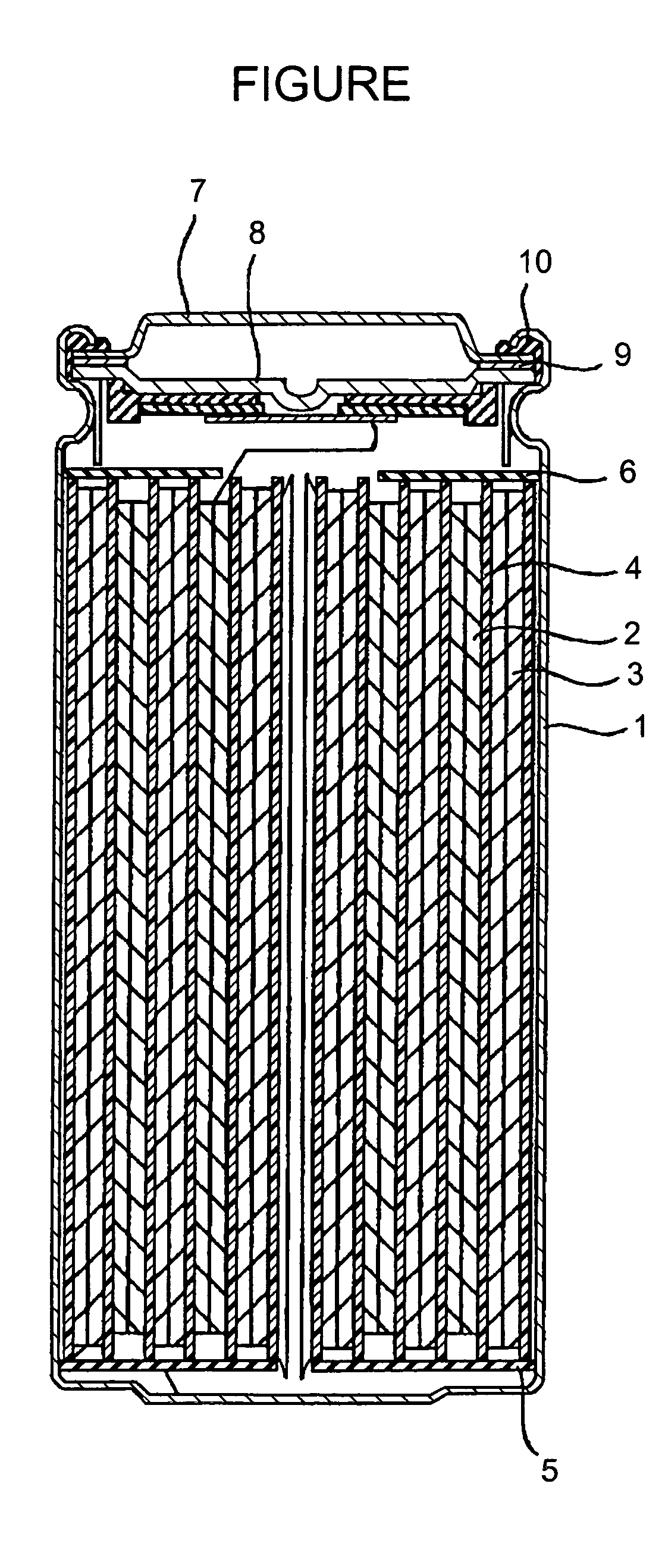

Lithium-ion secondary battery and manufacturing method thereof

InactiveUS20070003837A1Reduce manufacturing costSimple procedureElectrode thermal treatmentFinal product manufactureLithiumFiber

In a lithium-ion secondary battery of the present invention, the electrical resistivity of the mixture of a positive electrode active material, an electrically conductive member, and a binder is 0.1 Ωcm or more but 1 Ωcm or less. The positive and negative electrodes each have an electrical capacity of 10 mAh or more but 50 mAh or less per volume of a rectangular parallelepiped that has a 1 cm2 square base on a face of the electrode of one polarity facing the electrode of the other polarity and that has a height equal to the thickness of the electrode of the one polarity at the square base. Used as the negative electrode thereof is a negative electrode formed by sintering graphite powder, non-graphitizing carbon, and fibrous powder retained in the pores of a porous metal structure in an inert gas atmosphere at a temperature of between 600 and 1000° C.

Owner:SHARP KK

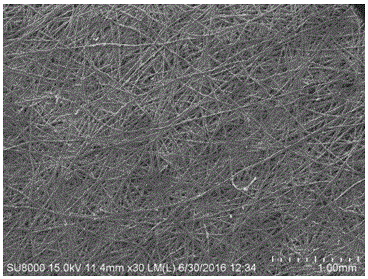

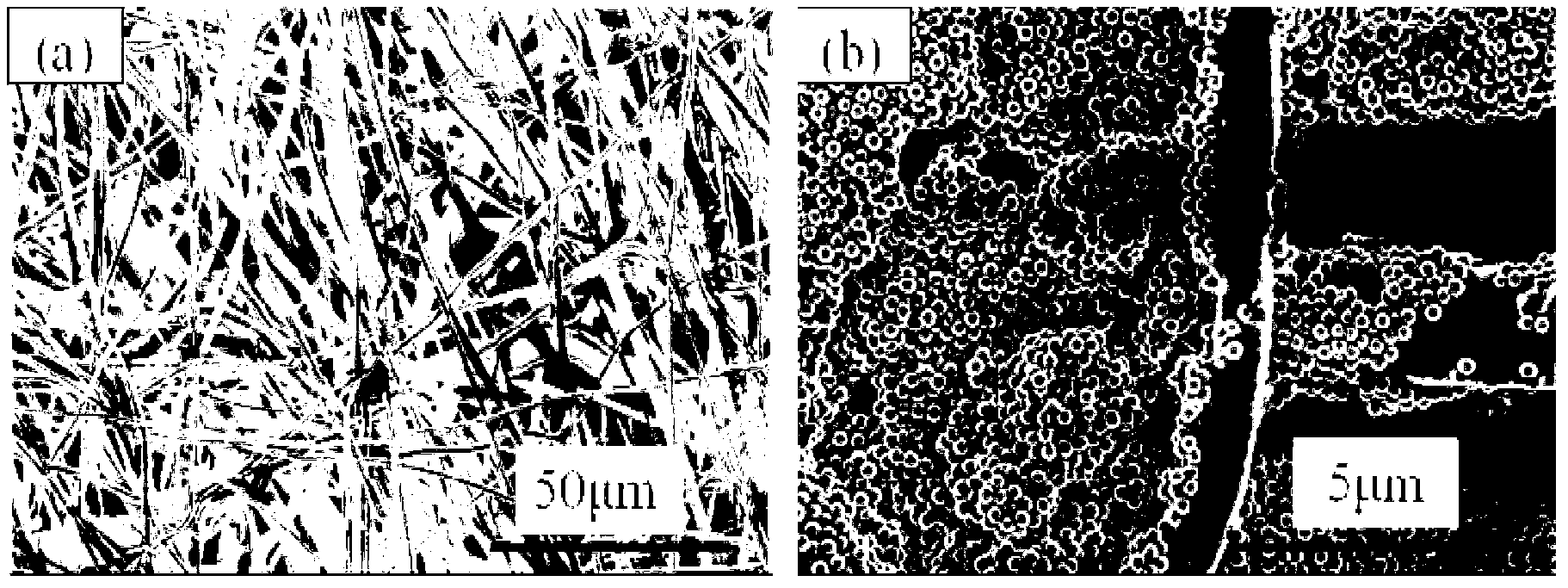

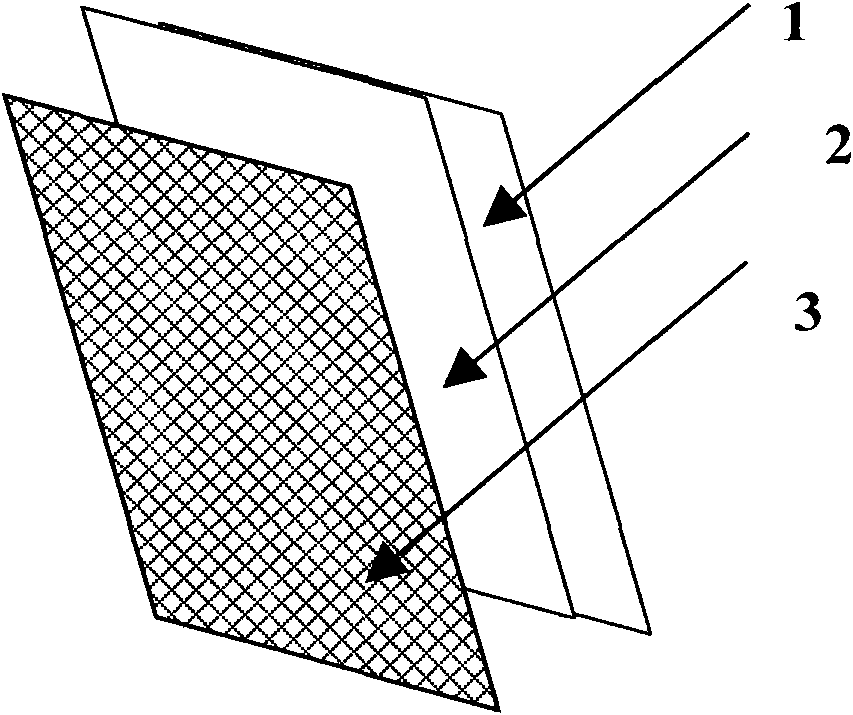

High-performance flexible composite nonwoven fabric membrane for lithium ion battery, as well as preparation method and application of membrane

InactiveCN103296240AGood flexibilityGood high current discharge performanceCell component detailsAdhesiveCharge discharge

The invention discloses a high-performance flexible composite nonwoven fabric membrane for a lithium ion battery, as well as a preparation method and an application of the membrane, which belongs to the technical field of a lithium-ion battery membrane material. The prepared composite nonwoven fabric membrane is formed by coating functional serous fluid with thermally curable or optically curable functional groups onto a substrate membrane containing an active functional group, thermally curing or optically curing the substrate membrane, removing a pore-forming agent, and hot pressing and drying the substrate. The prepared composite nonwoven fabric membrane is good in flexibility. The composite nonwoven fabric membrane has good ion electric conductivity and hot shrinkage resistance, can bear the large-current discharge, and also can improve the safety performance of the battery. Since no fluorine-containing adhesive is used in a preparation process, nano particles or nano optical fibers are connected with the substrate membrane through a chemical key, the nano particles or the nano fibers are bonded together through the chemical key and free from dropping off in the charging-discharging cycle, the stability of the coating is enhanced, and the cycling performance of the battery can be improved. The prepared flexible composite nonwoven fabric membrane is used as a membrane assembly of the lithium ion battery.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

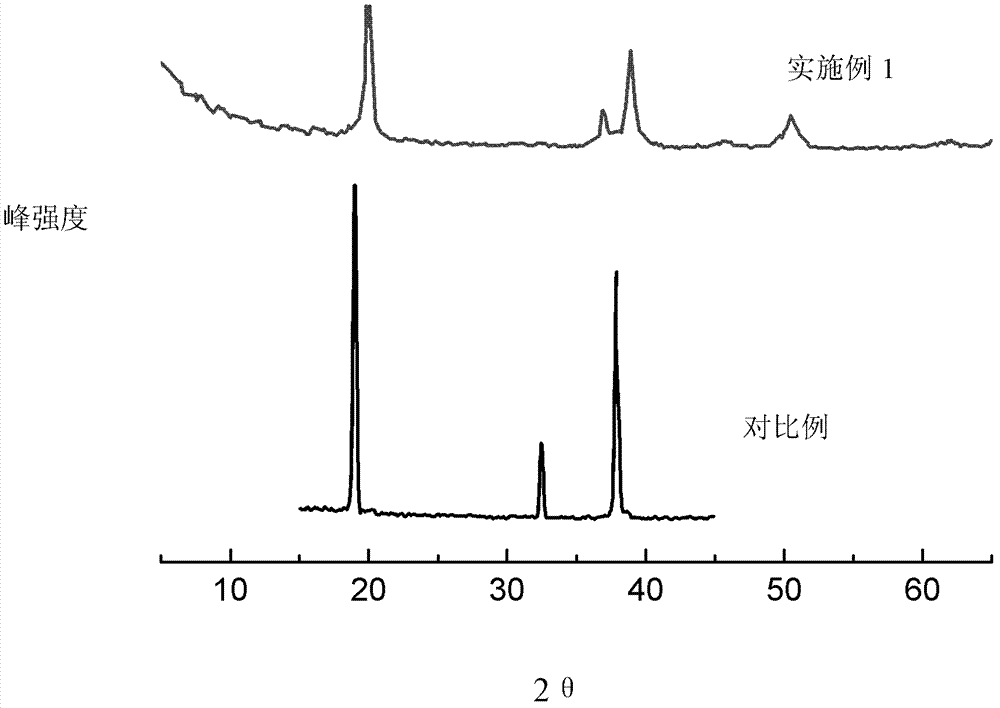

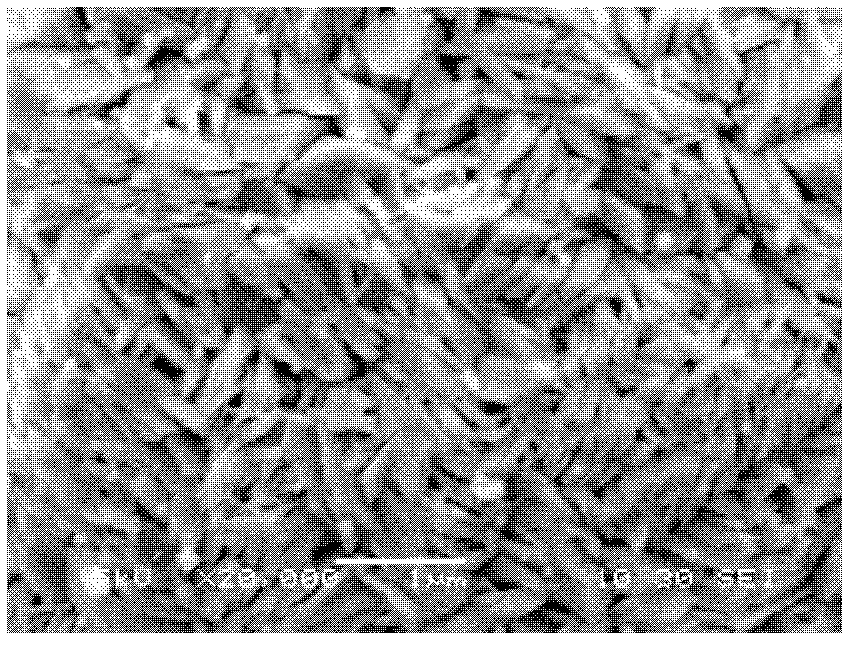

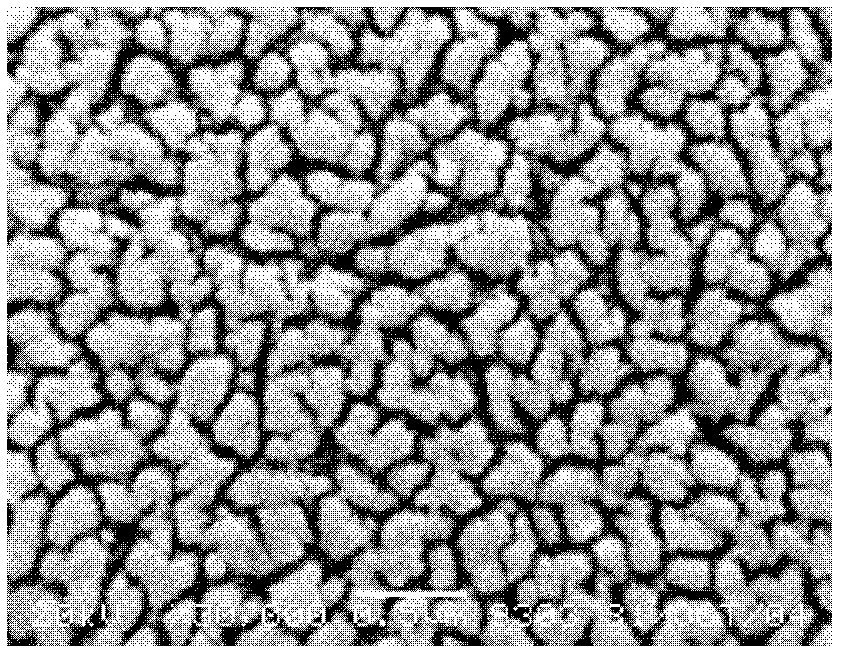

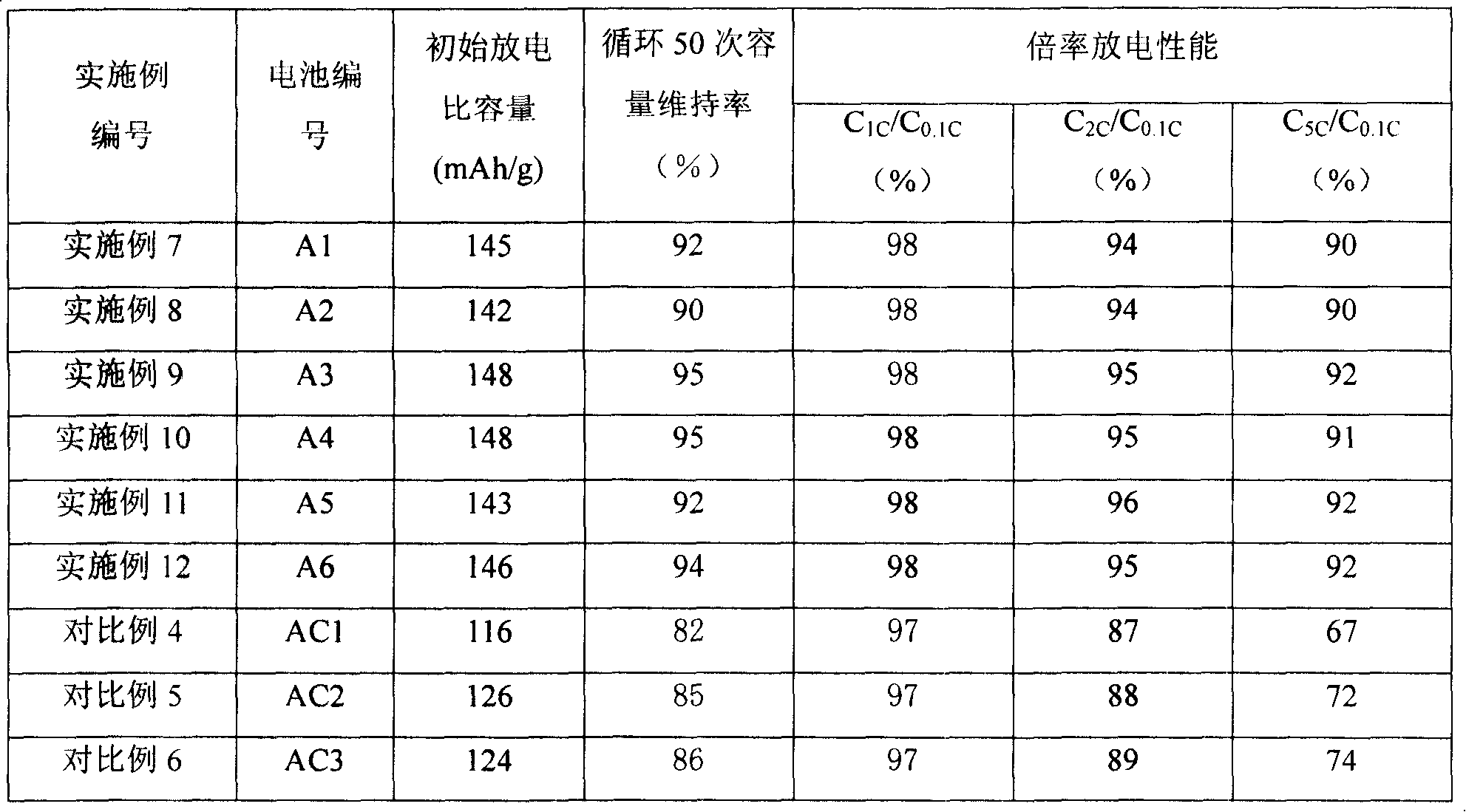

Lithium ion battery phosphatic composite cathode material and preparation method thereof

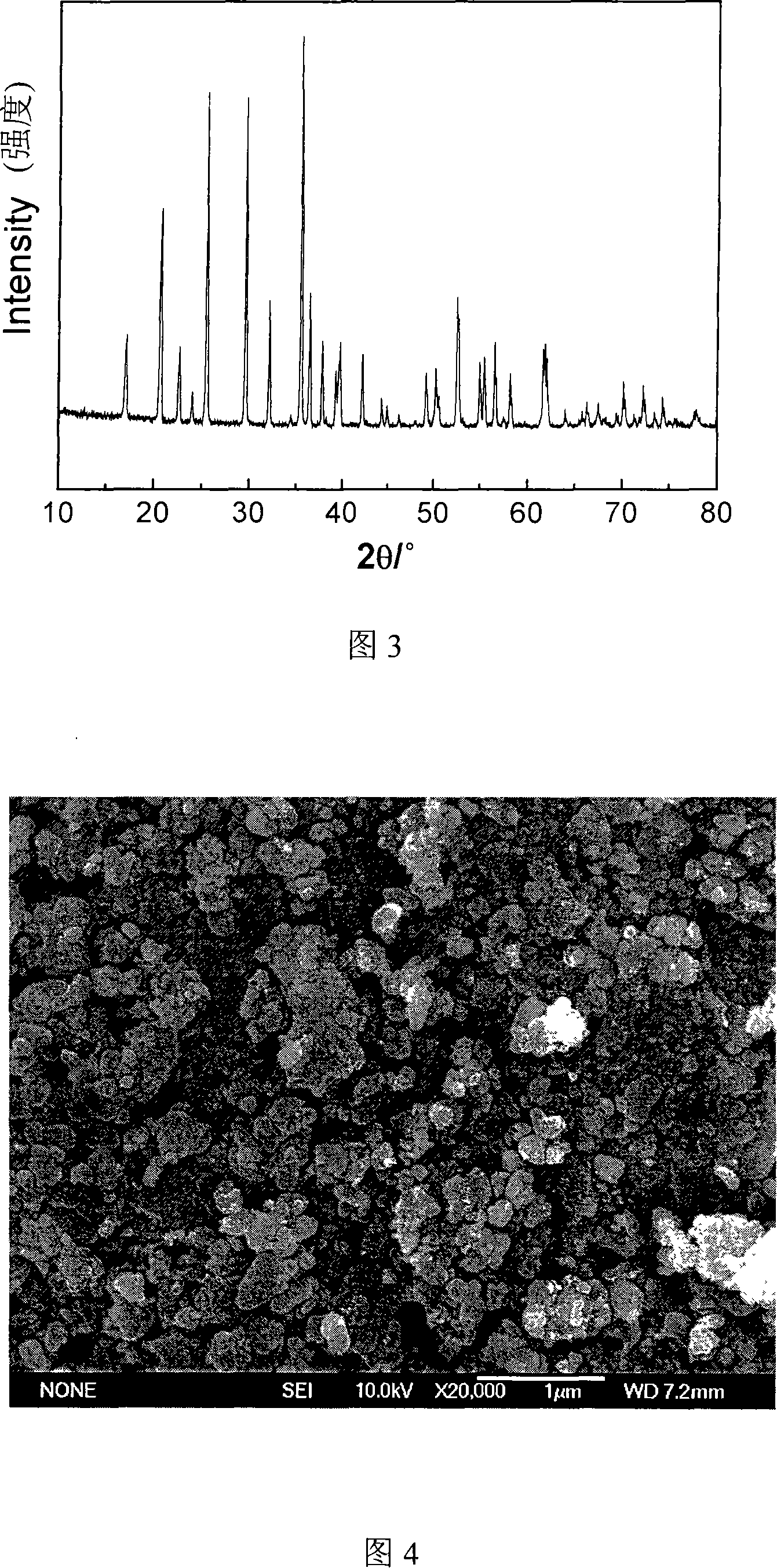

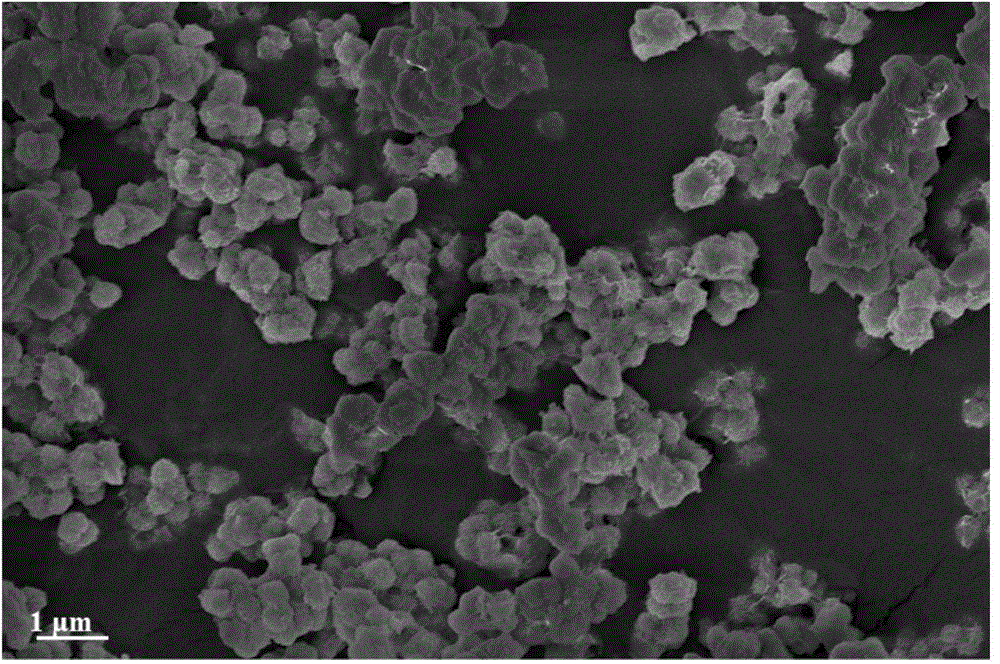

ActiveCN102244263AEasy to processImprove electrochemical performanceCell electrodesMicro structurePhosphoric acid

The invention discloses a lithium ion battery phosphatic composite cathode material and a preparation method thereof. The composite material is a multinuclear core shell structure composed of a plurality of cores and a housing layer, the cores are lithium iron phosphate particles wrapped by lithium vanadium phosphate and the housing layer is amorphous carbon. Preparation of the lithium iron phosphate particles wrapped by lithium vanadium phosphate comprises the following steps: preparing precursor sol with a sol gel method, adding lithium iron phosphate powder to disperse uniformly, carrying out spray drying on the above mixture, calcining the above resultant in inert gas, and followed by cooling and grinding to obtain the lithium iron phosphate particles wrapped by lithium vanadium phosphate. Preparation of the composite cathode material comprises the following steps: dissolving a carbon source compound into deionized water, adding core materials, dispersing the above resultant uniformly, carrying out second spray drying, calcining the above resultant in inert gas, and followed by cooling to obtain the composite cathode material. The composite material prepared in the invention has good electronic conduction performance, good ionic conduction performance and excellent electrochemistry performance. Because of existence of lithium vanadium phosphate, energetic density of a material is raised. Because of the multinuclear core shell structure like nano / micro structures, the composite material has good processing performance, and tap density of the material is greatly raised.

Owner:CENT SOUTH UNIV

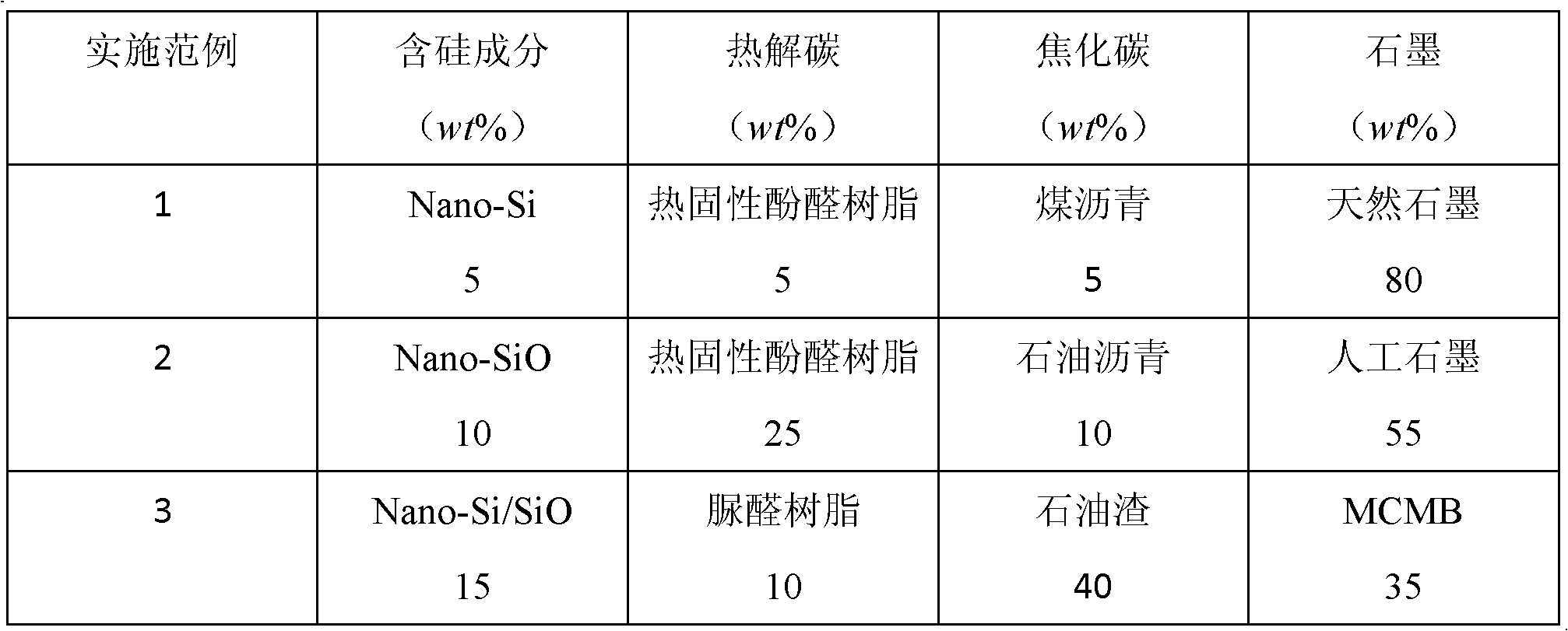

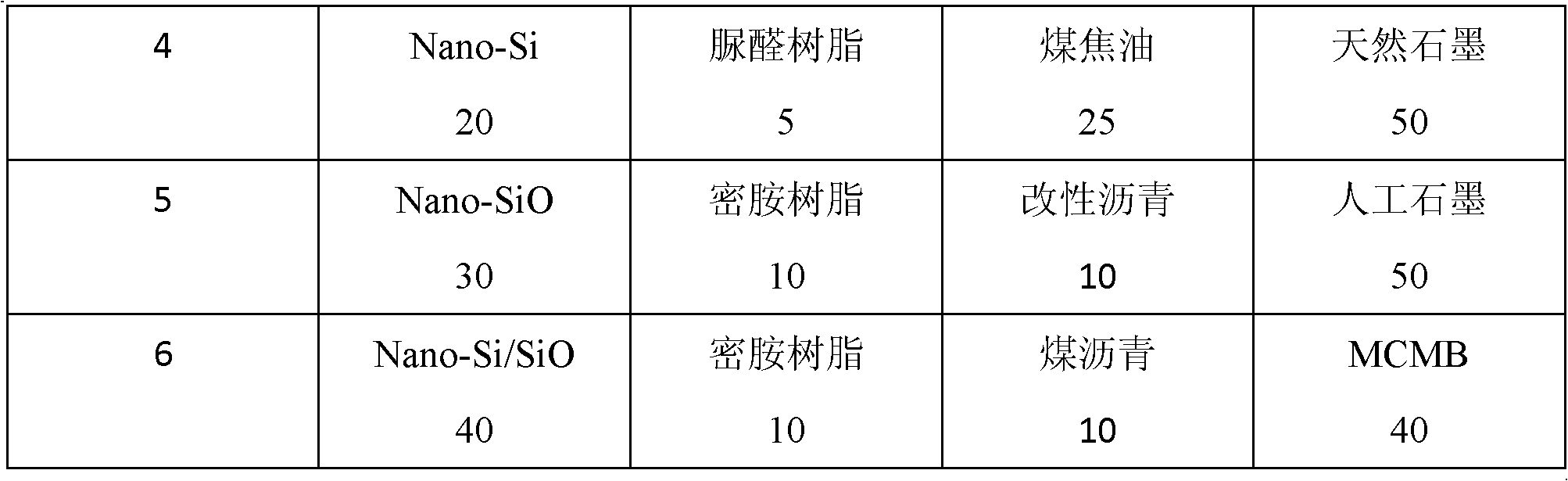

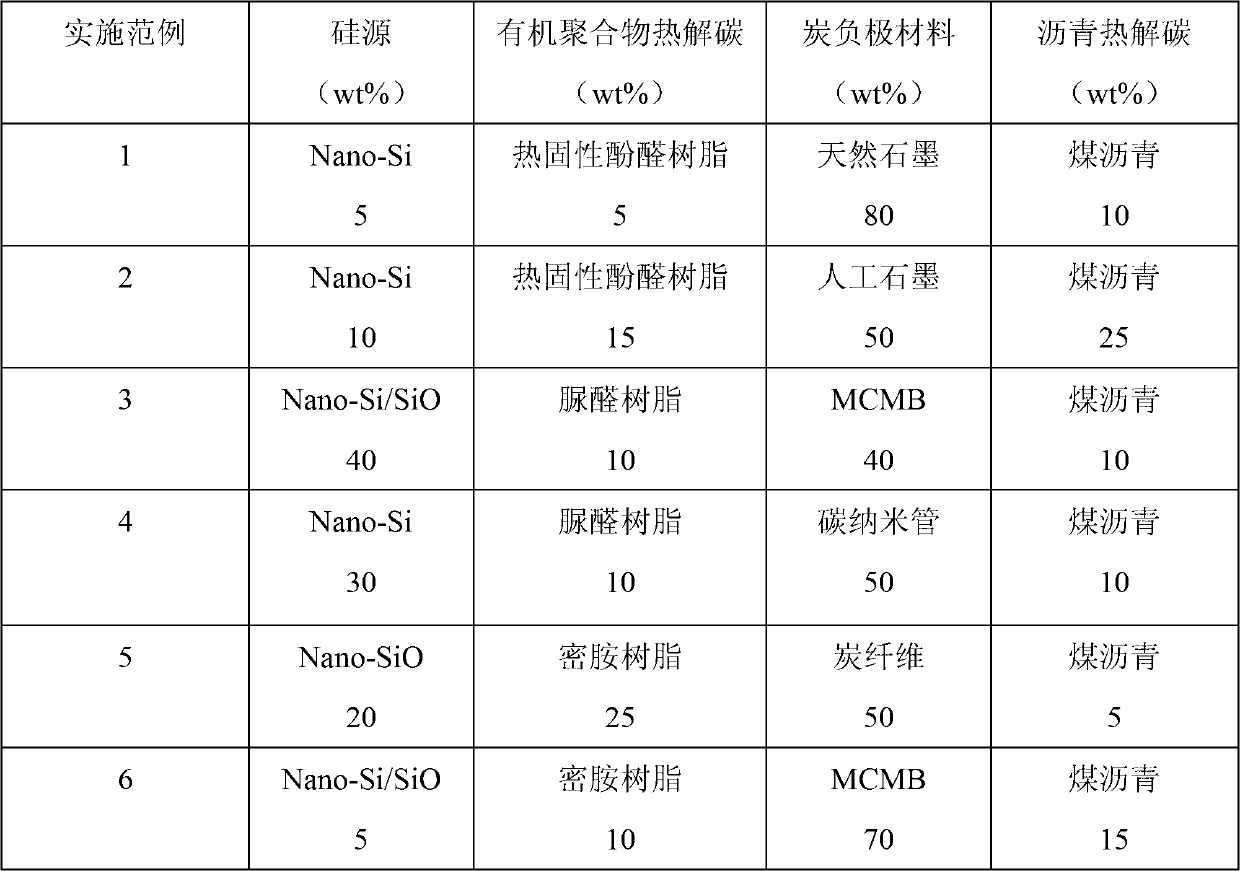

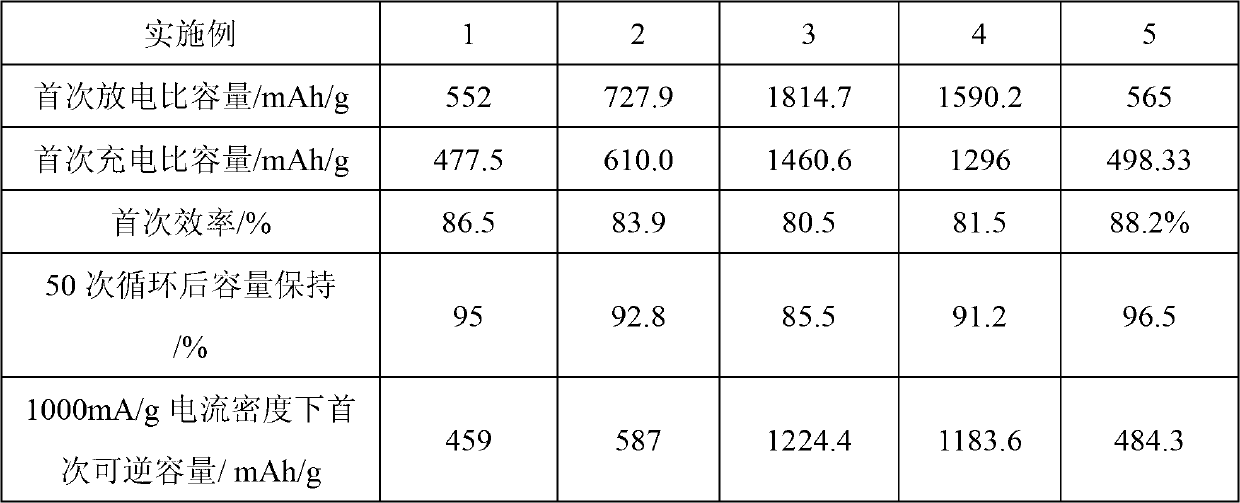

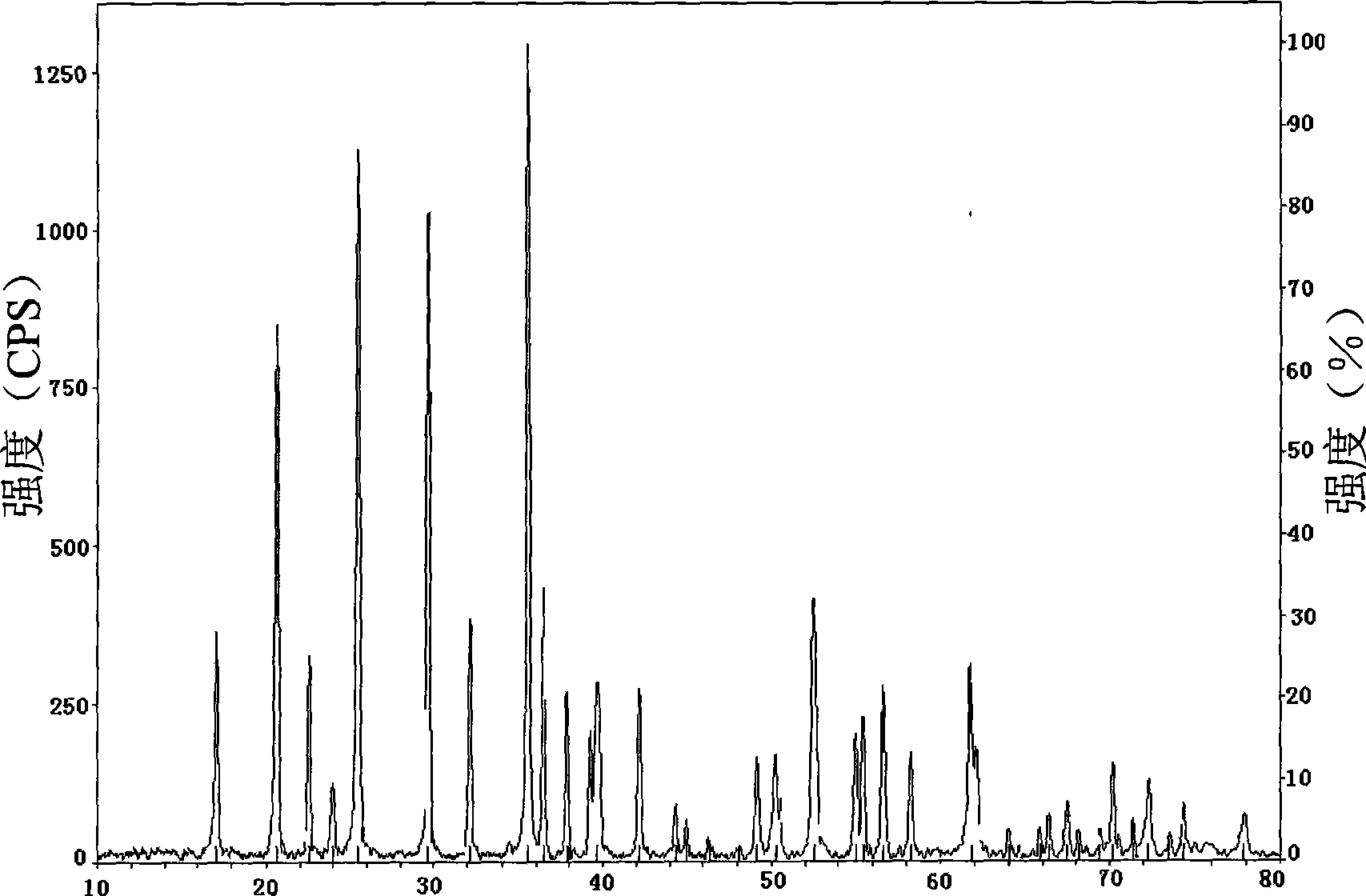

Preparation method for composite cathode material of lithium ion battery

The invention discloses a preparation method for a composite cathode material of a lithium ion battery by means of spray drying pyrolysis treatment. The preparation method includes the steps: dissolving a first type of binder organic carbon source into solvent of a proper quantity, adding a silicon source, a second type of binder and a dispersing agent, dispersing uniformly, adding graphite, dispersing for a certain time, subjecting uniformly dispersed suspension to spray drying, and using the first type of binder organic carbon source to bond the silicon source, the graphite and the second type of binder particles into spherical or spherical-like forms to obtain a composite precursor; and transferring the precursor into a shielding atmosphere for sintering, heating the second type of binder to a certain temperature to be melted into a liquid crystal state, bonding the particle silicon source and the graphite into cores, subjecting the organic carbon source to pyrolysis at the high temperature to form a coating, and furnace cooling to obtain the carbon-silicon composite cathode material of the lithium ion battery. The preparation method is simple, easy in implementation and high in practicality. The carbon-silicon composite prepared by the method has the advantages of high reversible capacity, designable capacity, high circulating performance and high-current discharging performance, high tap density and the like.

Owner:CENT SOUTH UNIV

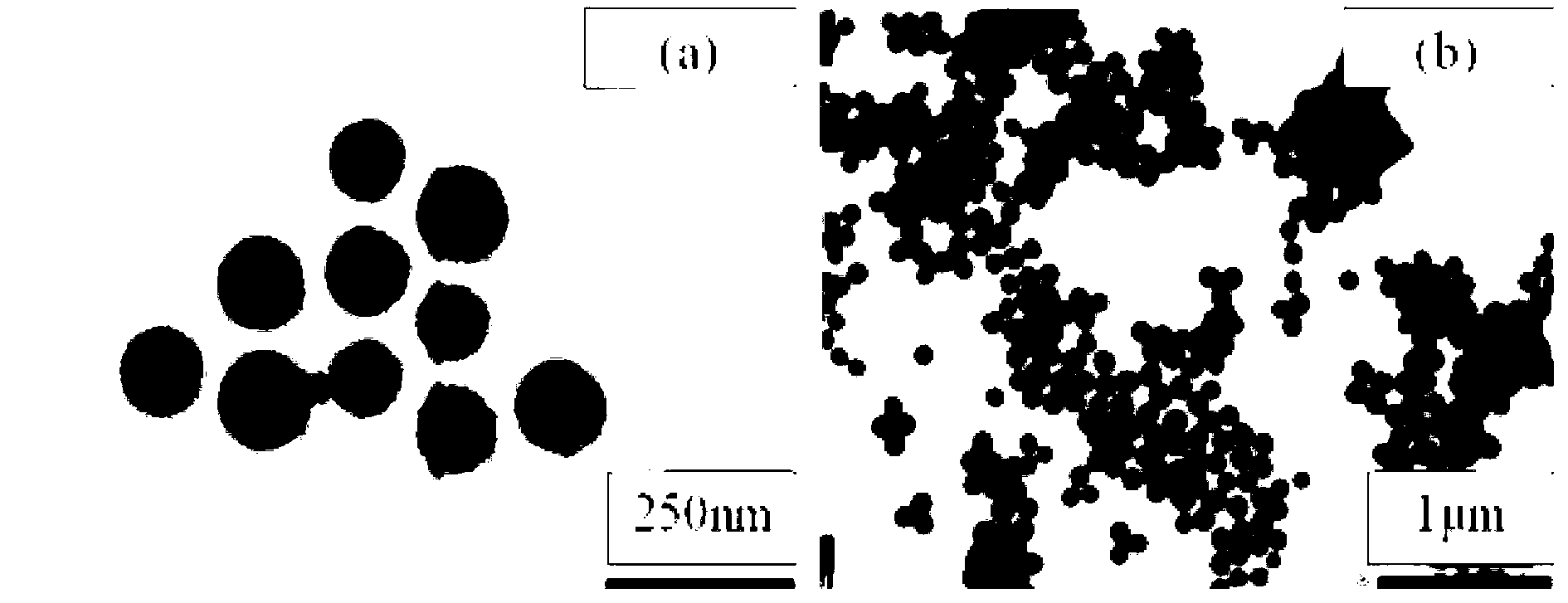

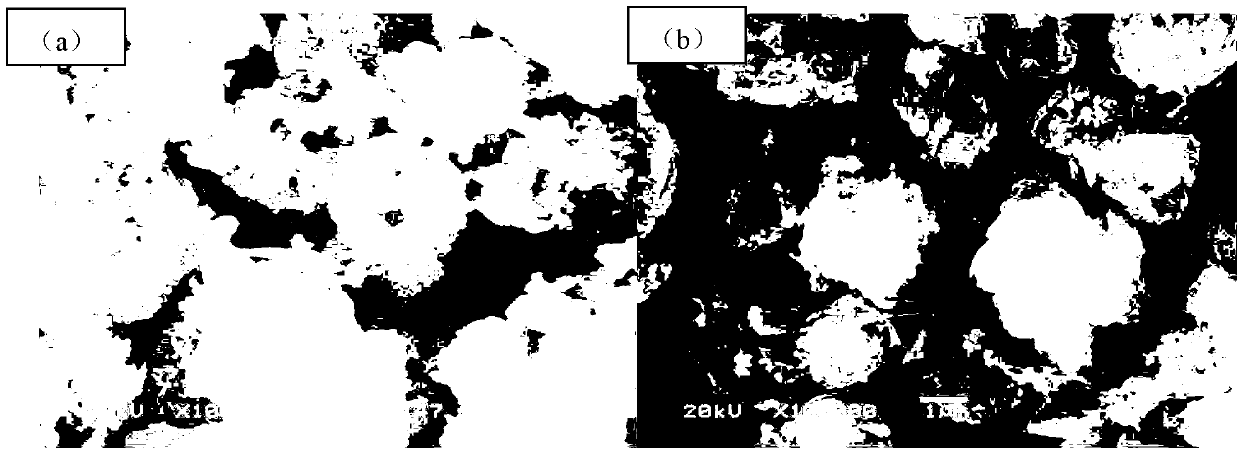

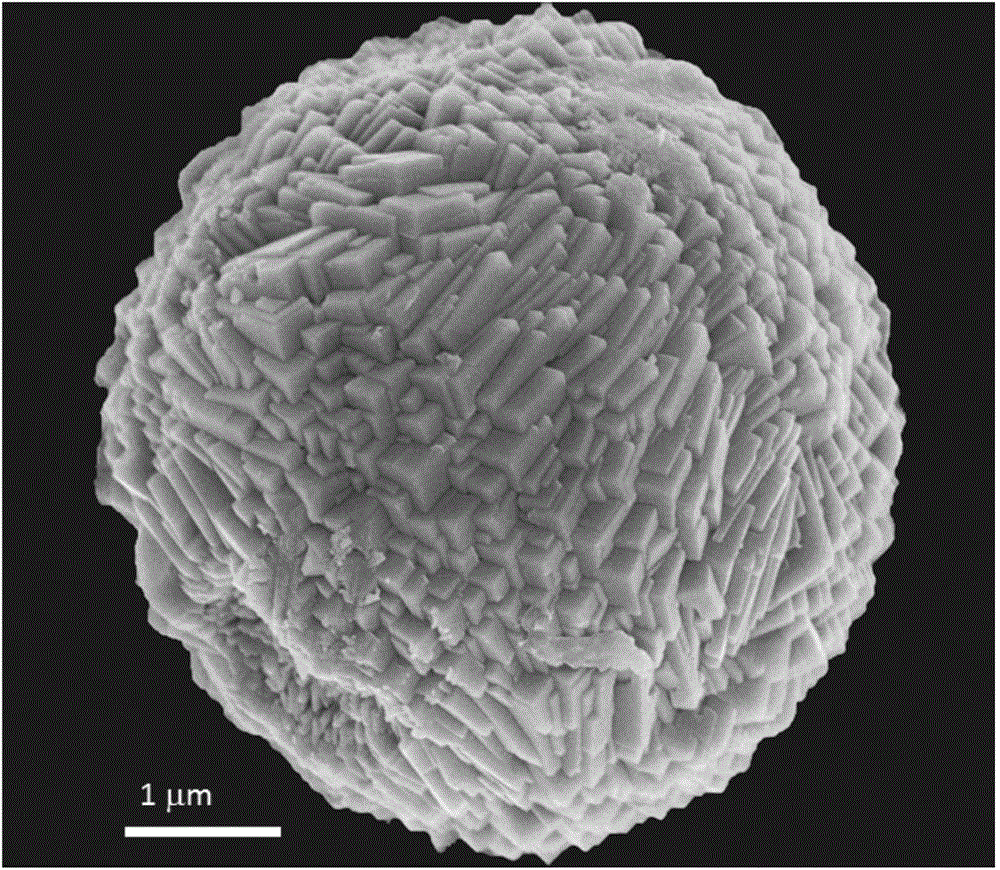

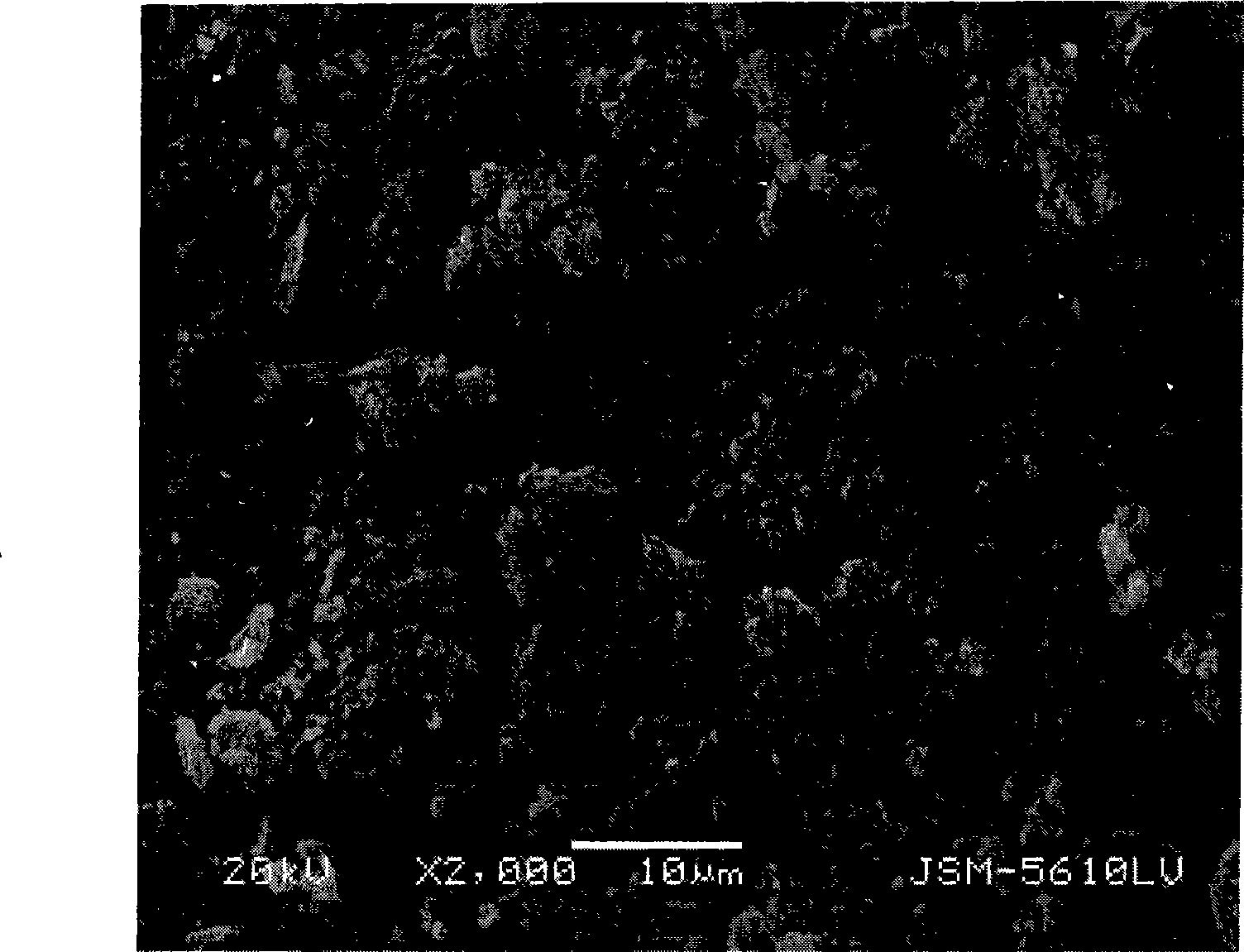

Multi-core core-shell-structure silicon carbon composite negative pole material and preparation method thereof

The invention relates to a multi-core core-shell-structure silicon carbon composite negative pole material and a preparation method thereof. The preparation method comprises the following steps: 1. preparation method of high-dispersivity multi-core porous spheres; 2. preparation of high-dispersivity asphalt suspension; and 3. preparation of multi-core core-shell-structure silicon carbon composite negative pole material: adding the porous spheres prepared in the step 1 into the high-dispersivity asphalt suspension prepared in the step 2, carrying out ultrasonic dispersion, heating and drying by distillation while intensely stirring to remove the solvent, transferring the powder particles into a protective atmosphere, and holding at low temperature so that the asphalt liquid enters the inside of the porous spheres to enhance the binding strength between the silicon source and the conducting carbon mesh, carry out secondary coating on the silicon source, overcome the defects in the coating in the step 1 and enhance the capacity performance of the silicon; and carrying out high-heat treatment. The invention is simple and easy to implement, and has the advantage of high practicality. The prepared silicon carbon composite material has the advantages of high reversible capacity, designable capacity, favorable cycle performance, favorable heavy-current discharge capacity, high tap density and the like.

Owner:CENT SOUTH UNIV

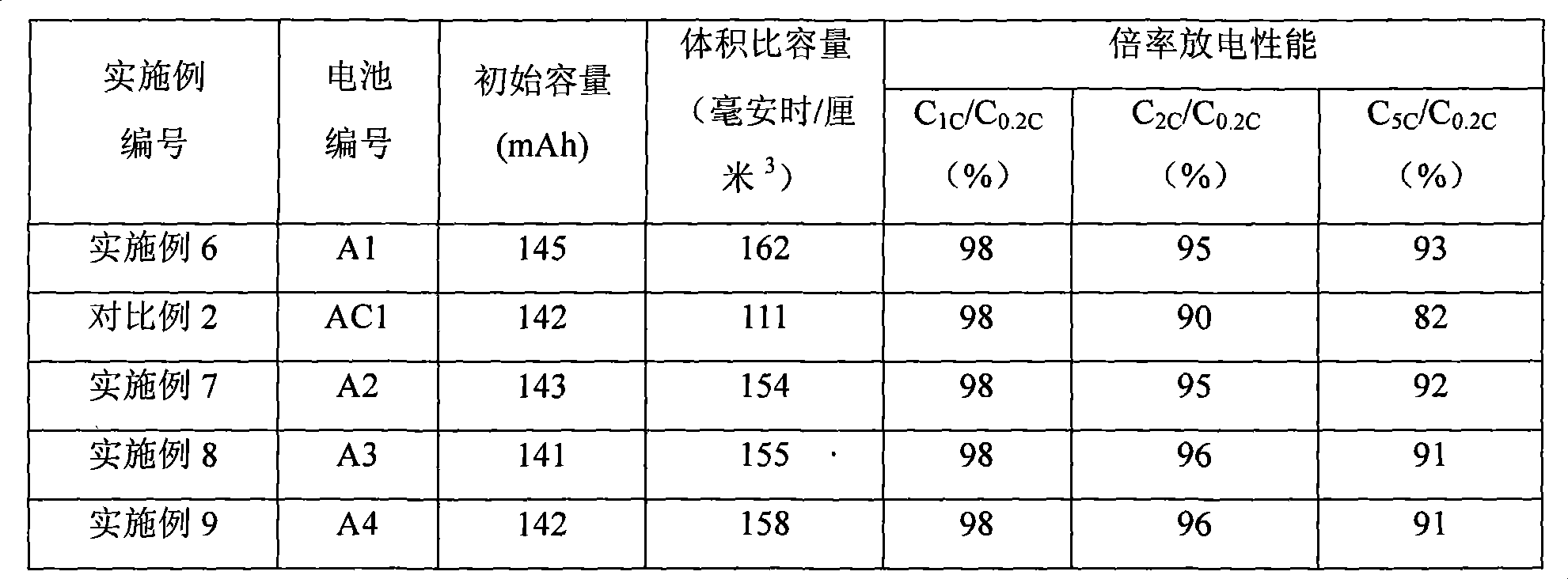

Preparing method of anode active material lithium iron phosphate for lithium ionic secondary cell

ActiveCN101399343AEasy to crushImprove high current charge and discharge performanceElectrode manufacturing processesSecondary cellsLithium iron phosphateBall mill

The invention provides a preparation method of lithium iron phosphate of a lithium-ion secondary battery positive electrode active material, the method comprises: a ferrous source compound, a phosphorus source compound, a lithium source compound and a carbon source compound are mixed, the first sintering is carried out on the obtained mixture under the protection atmosphere, products in the first sintering are ball-milled and dried, the second sintering is further carried out to obtain the lithium iron phosphate, wherein, the method further comprises the heating of the mixture at the temperature of 60-250 DEG C under the oxidation atmosphere before the first sintering or after the first sintering. The lithium iron phosphate which is obtained by adopting the method can have both high volume specific capacity and excellent high-current discharge performance.

Owner:TAICANG RONGCHI MOTOR

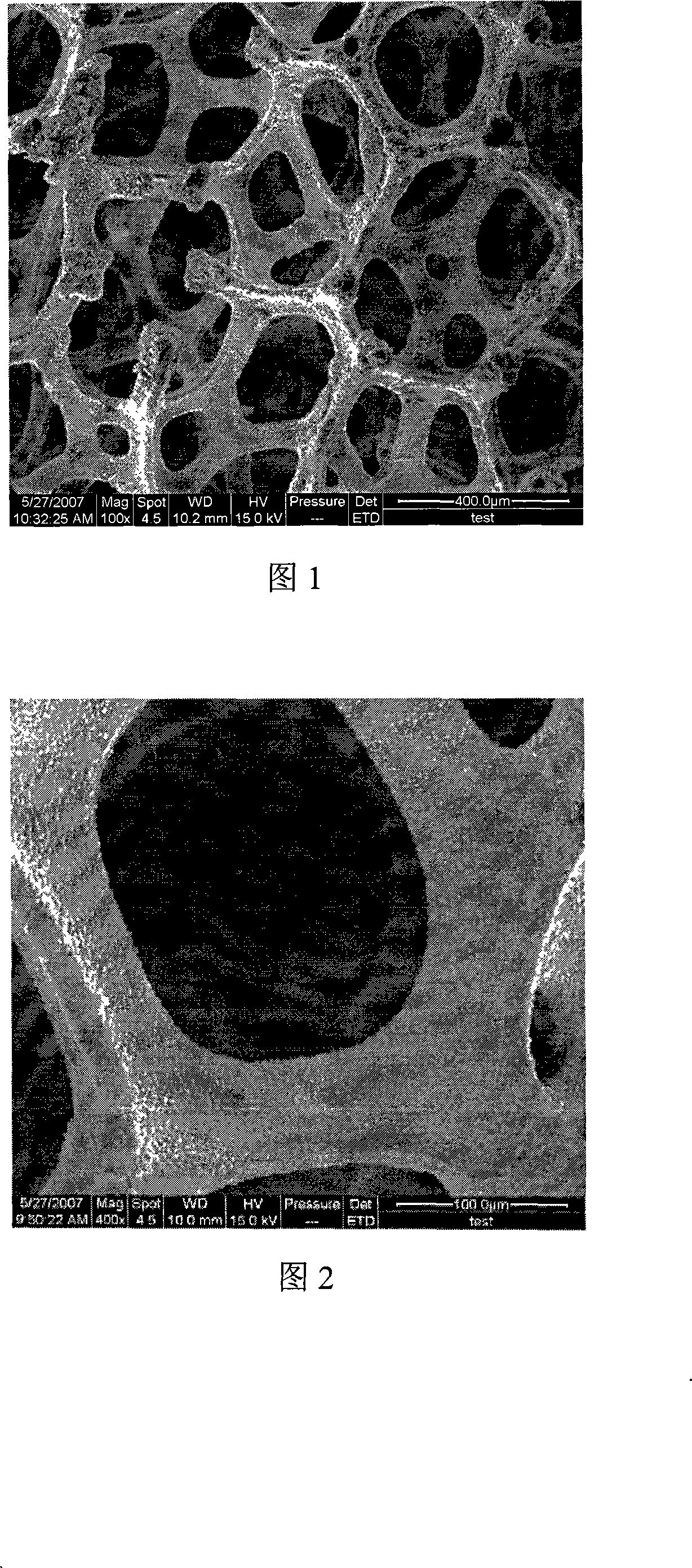

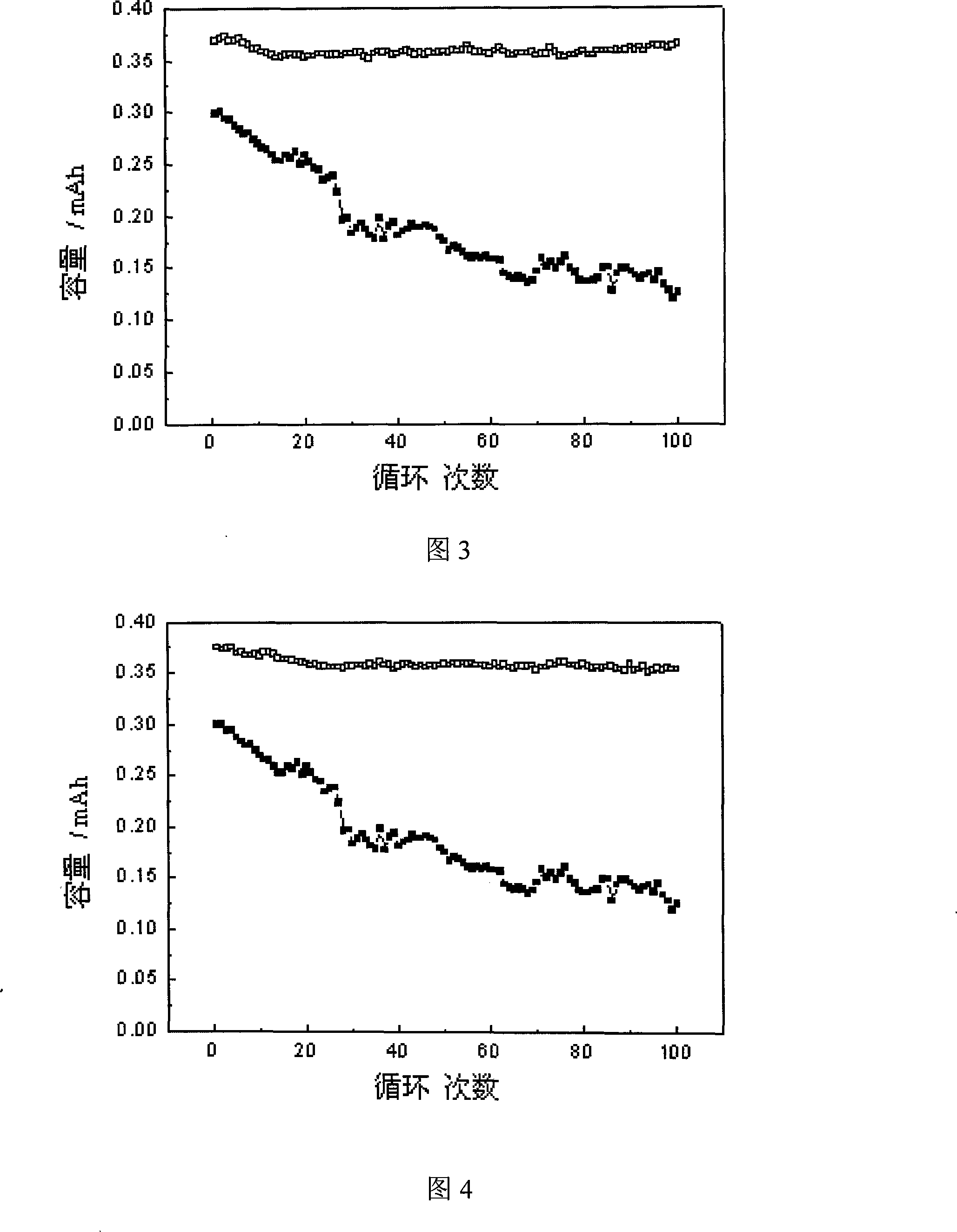

Spume lithium cathode of lithium metal secondary batteries and method for producing the same

InactiveCN101162772AImprove securityImprove cycle performanceElectrode manufacturing processesElectrode carriers/collectorsLithium metalMetal substrate

A foam lithium cathode of a lithium metal secondary battery and a method for preparing the same relate to a lithium metal secondary battery cathode and a method for preparing the same. The present invention solves the problems that the prior lithium metal secondary battery cathode material with lithium foil metal as the main material has poor cyclicity and safety. The foam lithium cathode consists of a foam metal substrate and a lithium deposit layer deposited on the surface of the foam metal substrate. The preparation method comprises the following procedures: the surface of the foam metal substrate is treated and then lithium is electrodeposited or plated lithium is vaporized. With the foam lithium material as the cathode of the lithium metal secondary battery, the real area of the cathode is large and the real current density of charge and discharge is small; no dendritic crystal and no dead lithium are produced easily; in a three-dimensional foam structure, the dendritic crystal grows in the inner side of the foam, thereby reducing the occurrence of short circuit and improving the safety and the cyclicity of the lithium metal secondary battery.

Owner:严格集团股份有限公司

Cobalt-covered lithium ion cell anode material precursor as well as preparation method and application

InactiveCN103359795AImprove performanceImproved magnification performanceCell electrodesManganese oxides/hydroxidesPower batteryLithium

The invention relates to a cobalt-covered compound polybasic lithium ion cell anode material precursor as well a as preparation method and application. The precursor has the following formula: NixCoy+zMn1-x-y(OH)2, wherein x is more than 0 and less than 0.8, y is more than 0 and less than 0.5 and z is more than 0 and less than 0.05; the precursor is formed by a core part and a nano cobaltosic oxide layer covering the surface of the core; the molecular formula of the core part is as follows: NikConMn1-k-n(OH)2, wherein k is more than 0 and less than 0.8 ad n is more than 0 and less than 0.5. According to the precursor disclosed by the invention, the outer surface of the core part is covered with one layer of nano cobalt hydroxide through a nano technology; and a covering layer is formed by uniformly growing in a liquid phase so that the very good and dense covering layer is formed on a spherical surface. Then, a strong oxidant is added under a strong alkali environment so that the cobalt hydroxide is oxidized into cobalt hydroxyl cobalt oxide and a cobaltosic oxide covering layer is formed on the surface of the material in a following sintering process. The cobaltosic oxide has the very good electronic conduction capability so that the heavy load discharge performance of the material is greatly improved and the material can be more suitable for the requirements of a power battery.

Owner:协鑫动力新材料(盐城)有限公司

Cathode diachylon used for power-type lead-acid storage battery and manufacture method thereof

InactiveCN102088088AStrong maneuverabilityHigh viscosityLead-acid accumulator electrodesIonActivated carbon

The invention discloses cathode diachylon used for a power-type lead-acid storage battery, comprising the following components: 100kg of lead powder, 0.10-0.12kg of short fiber, 0.40-0.60kg of humic acid, 0.12-0.30kg of sodium lignin sulfonate, 1.00-2.00kg of acetylene black, 1.00-1.50kg of conduction graphite, 2.00-3.00kg of activated carbon, 0.60-1.00kg of barium sulphate, 15000-22000g of deionized water and 7200-6000ml of sulfuric acid with the concentration of 1.30-1.40g / cm<3>(25 DEG C). The cathode diachylon has the beneficial effect that the power-type battery produced by the cathode diachylon has the advantages of high specific energy and good large current discharging capability, the low-temperature volume and cycle life are obviously improved.

Owner:SHANDONG SACRED SUN POWER SOURCES

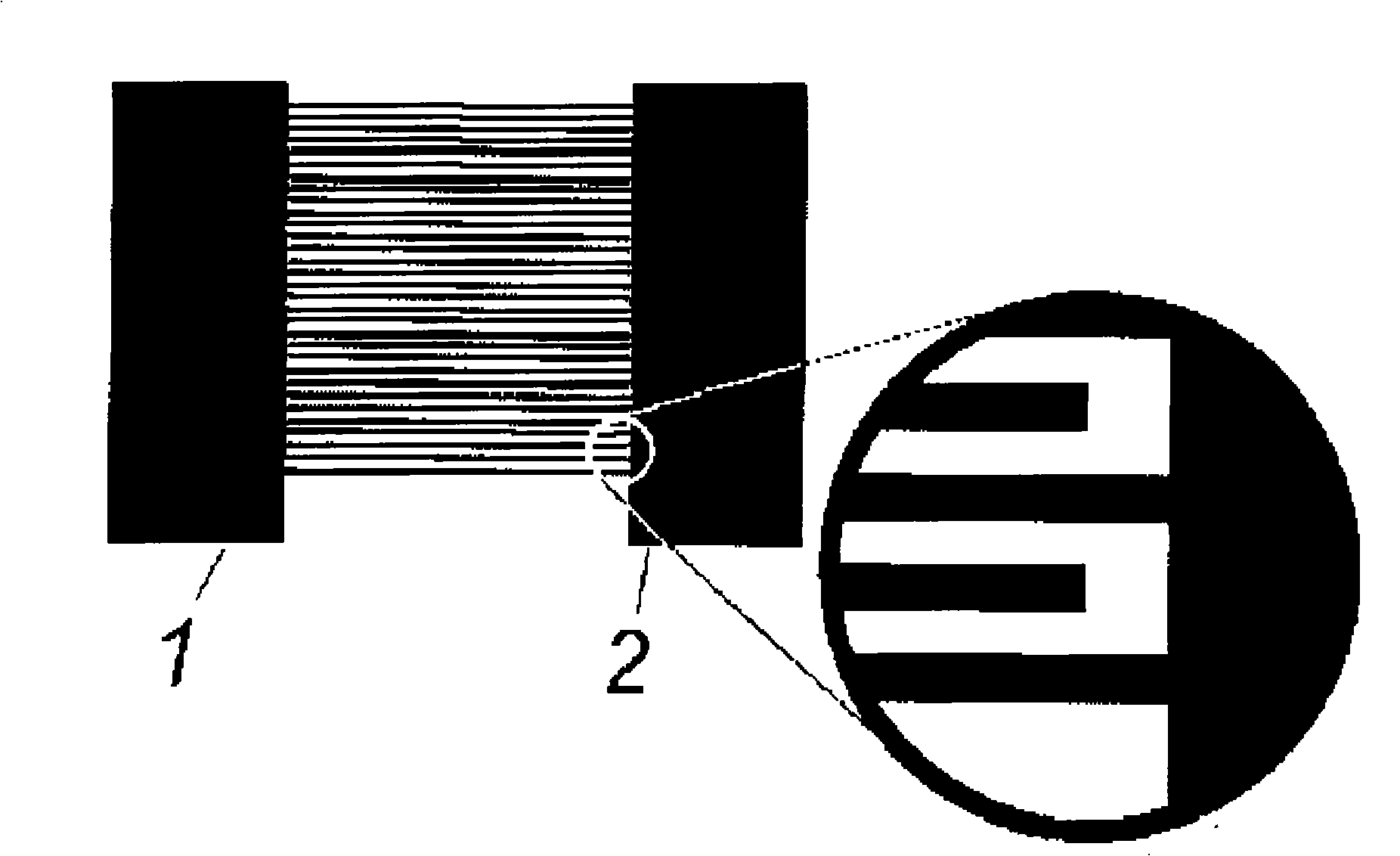

Poly-pyrrole minisize super capacitor based on MEMS technique and method for manufacturing the same

InactiveCN101325130AGood high current discharge performanceIncrease energy densityCapacitor electrolytes/absorbentsSecondary cellsSilicon matrixSolid state electrolyte

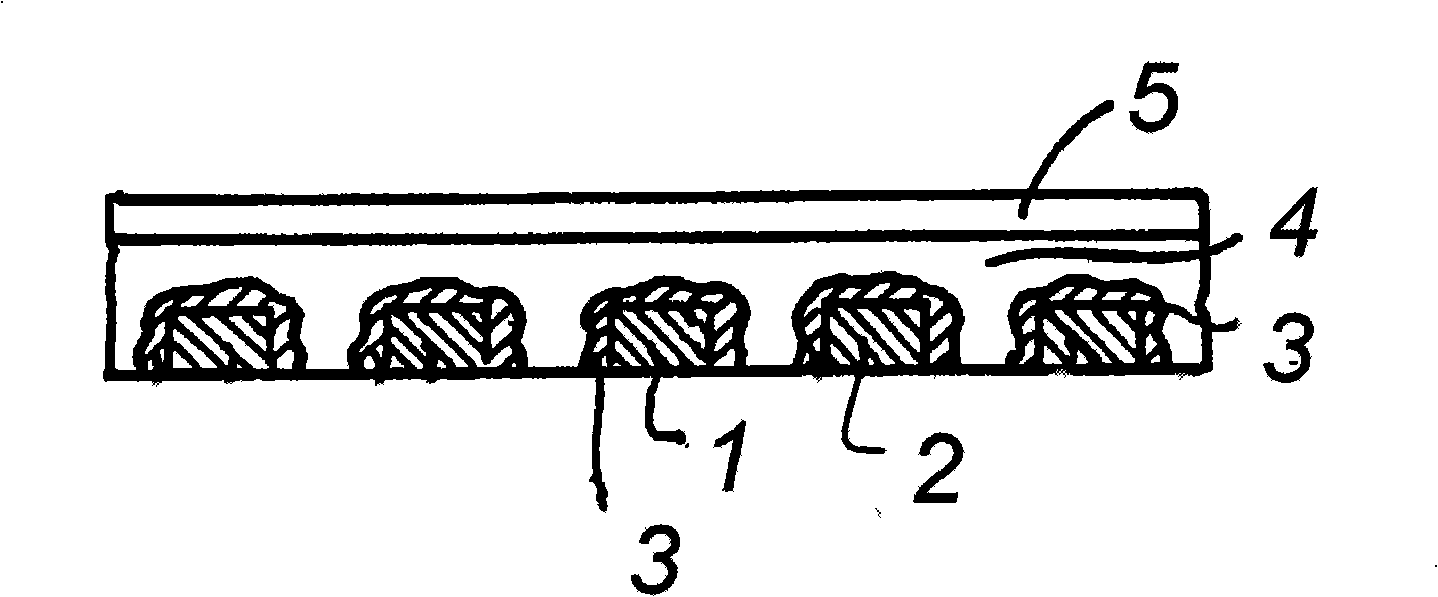

The invention discloses a polypyrrole minitype super capacitor in the range of the capacitor manufacturing technology based on MEMS technology and the preparation method thereof. The polypyrrole minitype super capacitor adopts the structure that a metal comb two-dimensional plane structure as a current collector is prepared on the surface of the silicon matrix by utilizing the micro-machining technology; a comb-shaped polypyrrole active electrode is prepared on the surface of the current collector by adopting the method of polypyrrole substance being prepared by the electric precipitation method; a layer of gel solid electrolyte is covered on the surface of the comb-shaped polypyrrole electrode and between a positive electrode and a negative electrode; and a layer of polyimide material is covered on the surface of the structure to accomplish the encapsulation of the minitype super capacitor. The MEMS-based manufacturing technology has the characteristic that the process is simple, and is suitable for mass manufacture. The minitype super capacitor has the advantages of small volume, high energy storage and stable performance, and is widely applicable to micro-robot electronic intelligence systems, chemical sensors, battlefield friend-or-foe identification devices, distributed type battlefield sensors and other fields.

Owner:TSINGHUA UNIV

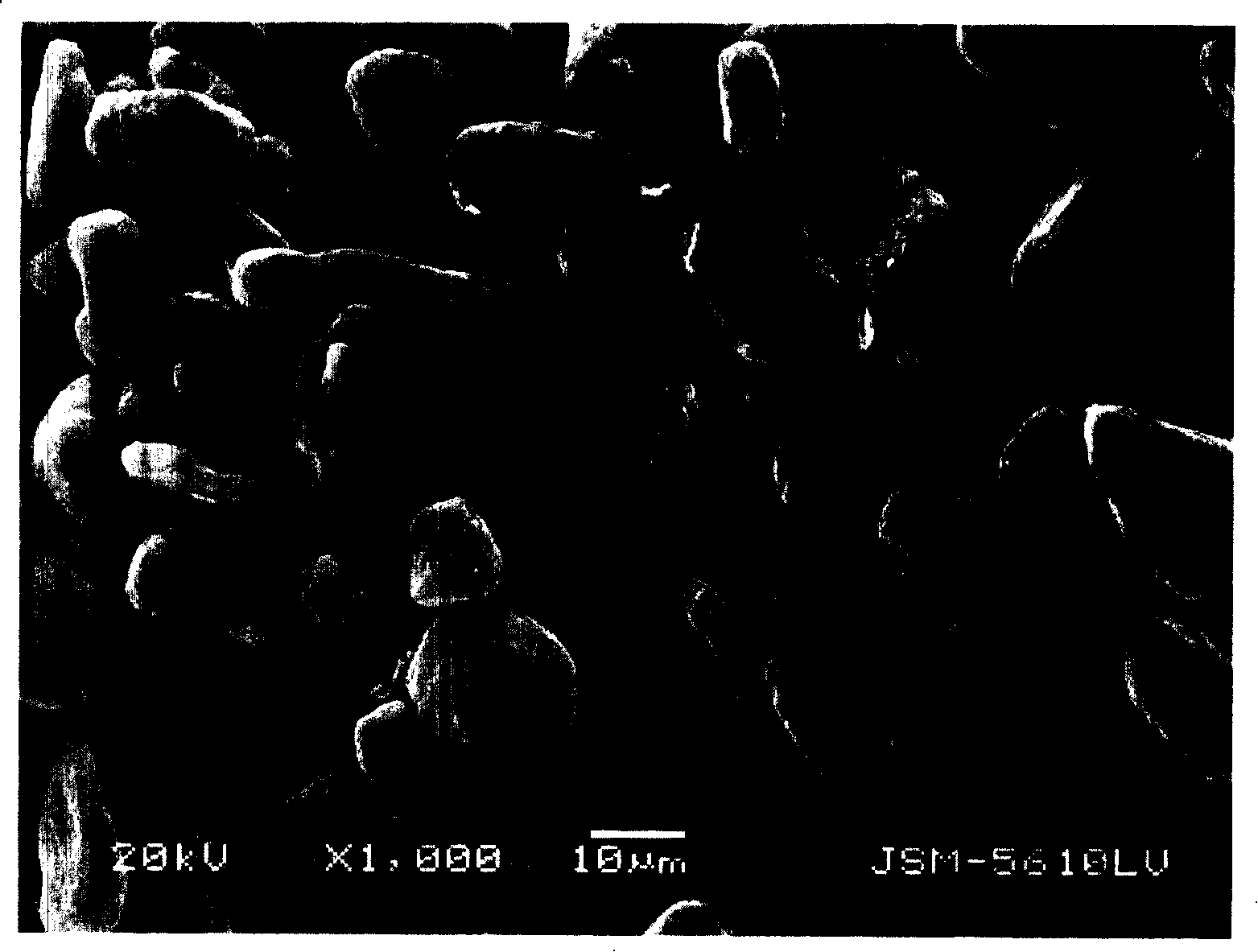

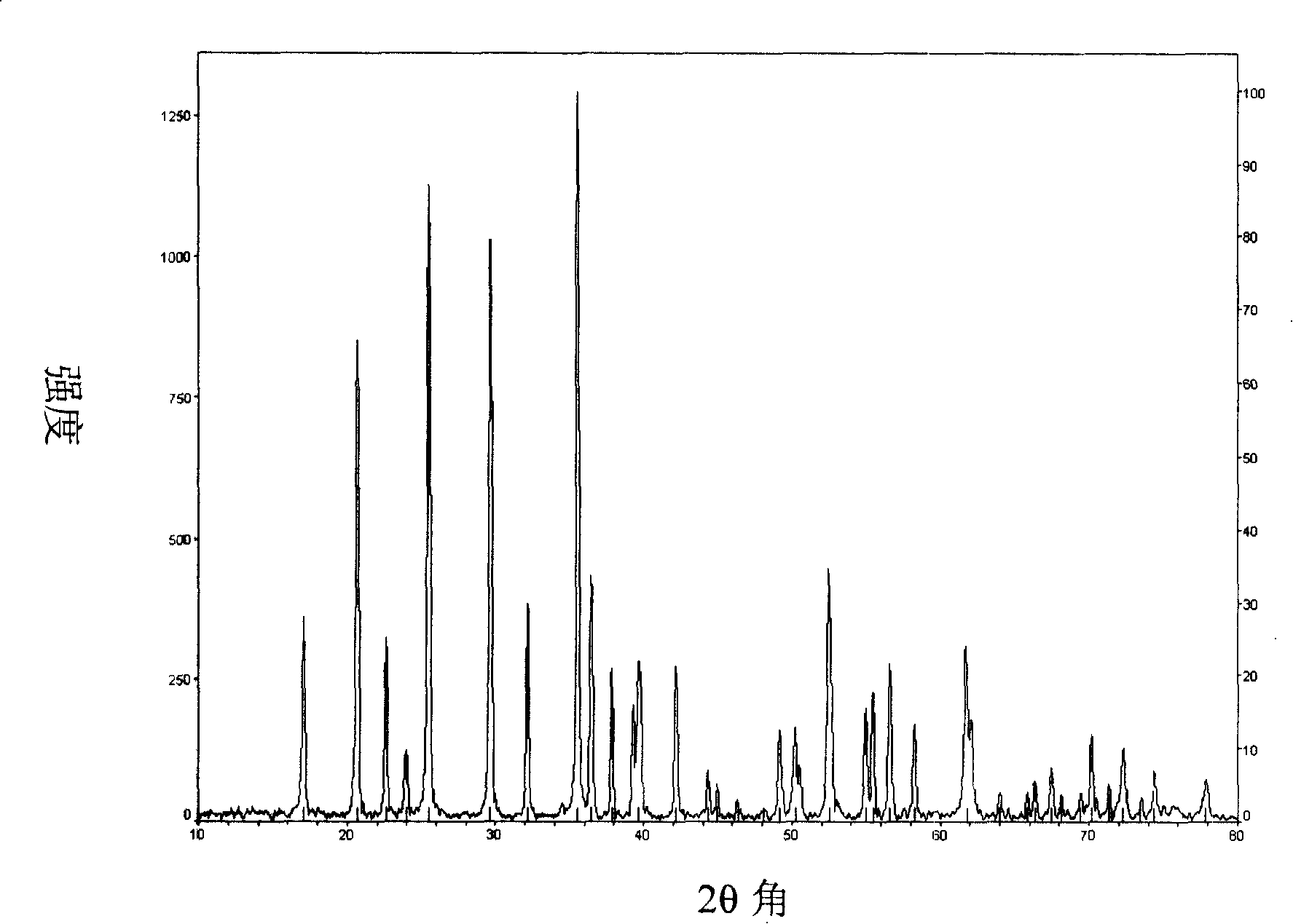

Anode material lanthanum or Ac adulterated LiFePO4 of lithium ion secondary battery and its making method

InactiveCN101150191AHigh charge and discharge capacityPromote crystallizationCell electrodesPhosphorus compoundsPhosphateVolumetric Mass Density

This invention relates to FeLiPO4 doped with La or Ac, positive material of Li ionic secondary cells and its preparation method characterizing that the formula is: LiMxFe1-xPO4 (M is La or Ac, 0.01<-x<-0.05) in the structure of olivine, the preparation includes the following steps: taking Li compound, Fe, phosphate, La or Ac as the raw materials to add them into a ball mill for wet mill then putting them into N2 and H2 mixed atmosphere for pre-calcining, then wet-grinding them and drying them and then ball-milling them, then putting them into N2 and H2 mixed atmosphere for secondary calcining to get the invented positive material. Advantages: fine crystalizatin, conduction performance of ions is good and discharge performance of heavy current is good, tap density is great and the problem of easy oxidation of Fe2+ is solved.

Owner:TIANJIN B&M SCI & TECH

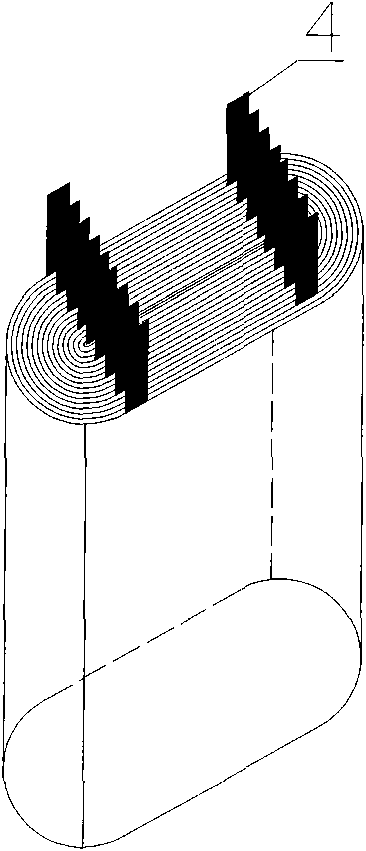

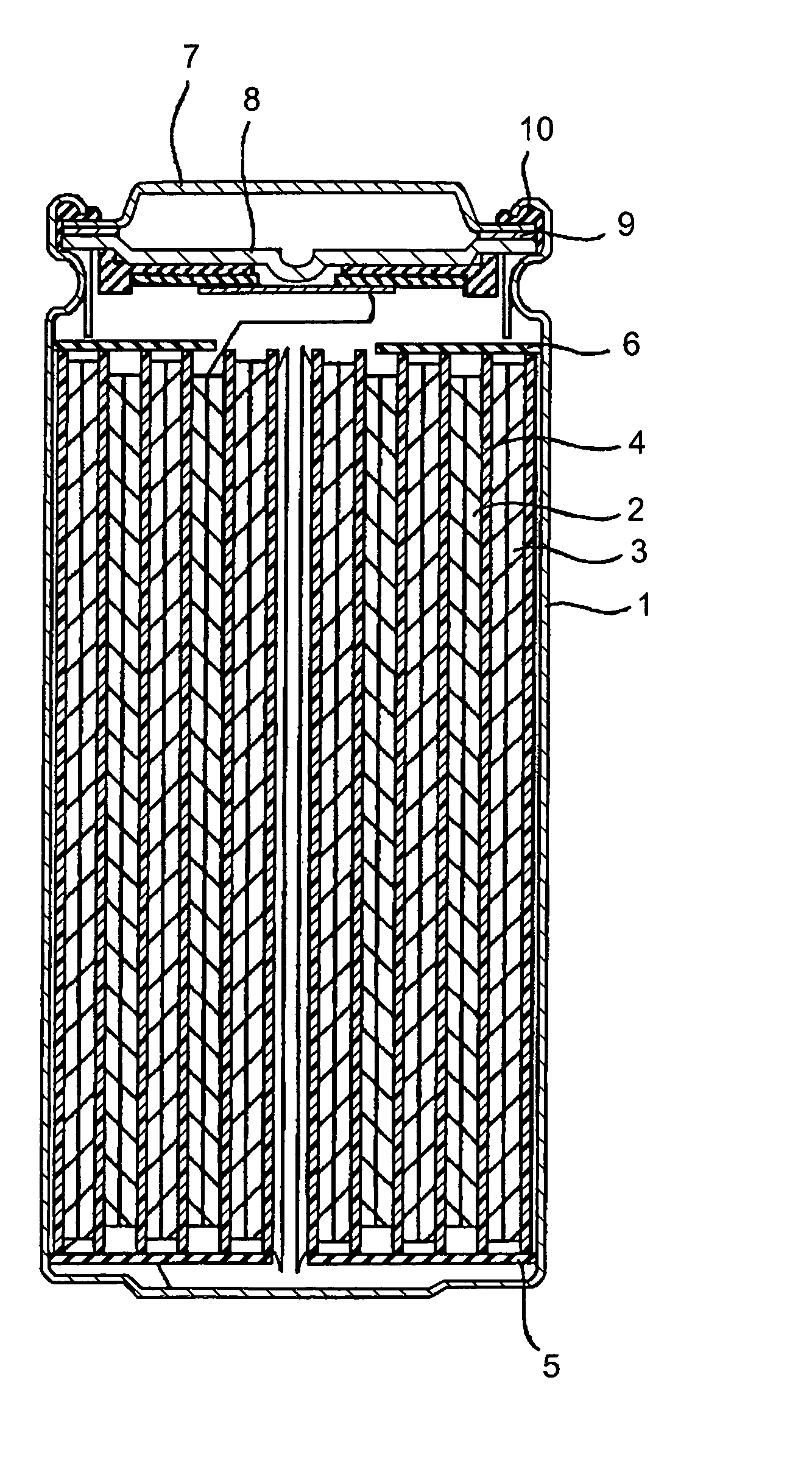

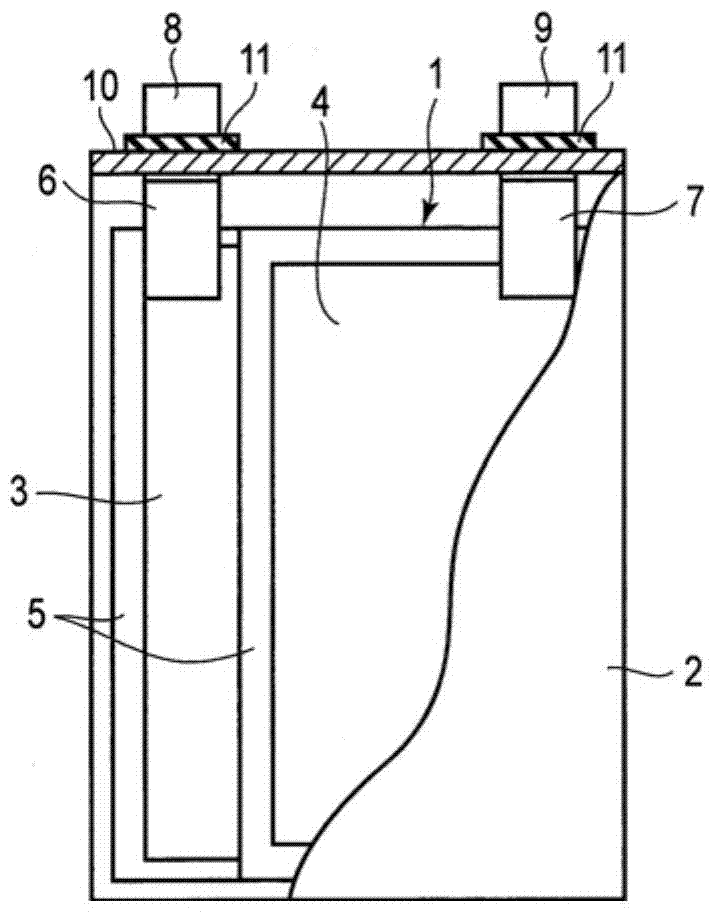

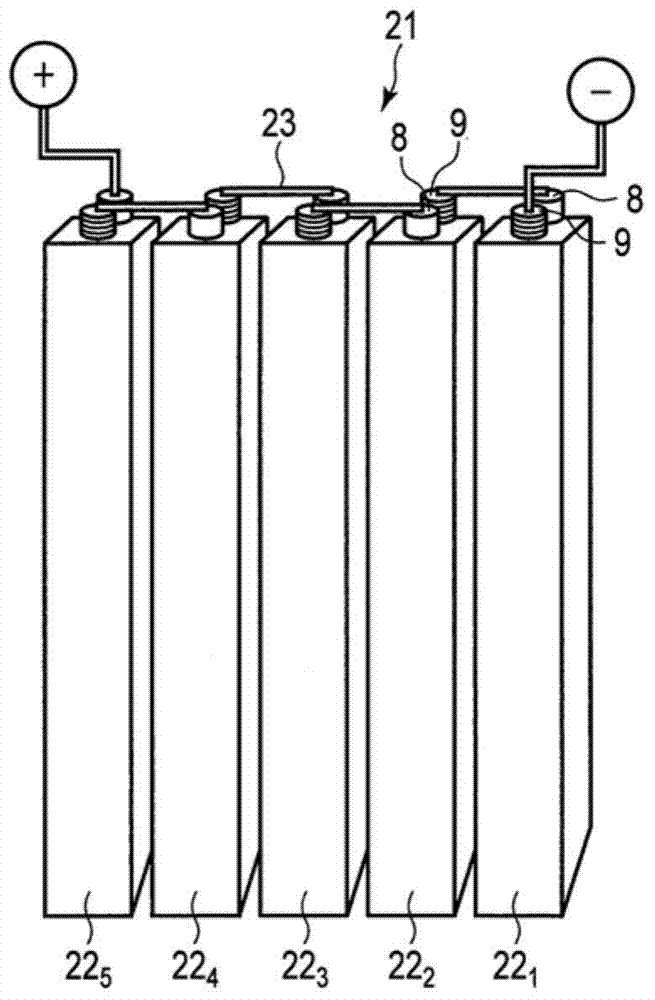

Square power lithium ion battery cell and manufacturing method thereof

InactiveCN101950816AEasy to operateGood high current discharge performanceFinal product manufactureElectrolyte accumulators manufacturePower flowLaser cutting

The invention discloses a square power lithium ion battery cell and a manufacturing method thereof, belonging to the field of lithium ion battery manufacturing. The square power lithium ion battery cell comprises a positive plate, a diaphragm, a negative plate, a positive lug and a negative lug; the square power lithium ion battery cell is formed by winding the positive plate, the diaphragm and the negative plate around a coiling needle; the upper side and the lower side of the coiling needle after coiled are both provided with the negative lug and the positive lug; the positive lug is positioned on one end of the battery cell body; the negative lug is positioned on the other end of the battery cell body; the positive lug and the negative lug are positioned on the same side of the battery cell body; and the negative lug and the positive lug are reserved by laser cutting. The method comprises: reserving a non-coated area for a pole piece coating coat; cutting the reserved lug by laser cutting according to the preset lug interval; and successively stacking and coiling the positive plate, the diaphragm and the negative plate into the battery cell. The square power lithium ion battery cell of the invention has tidy lug arrangement and can realize the large current discharging performance of the battery.

Owner:CHERY AUTOMOBILE CO LTD

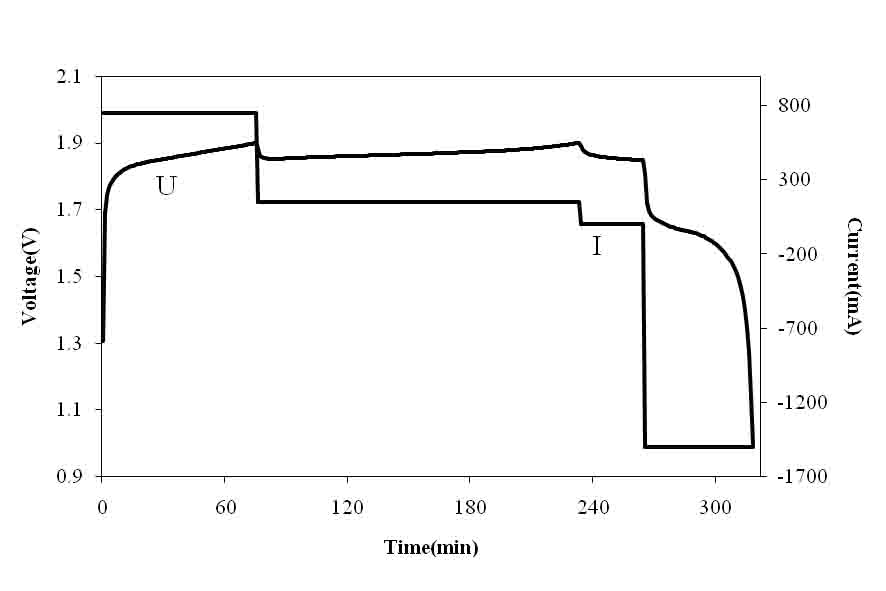

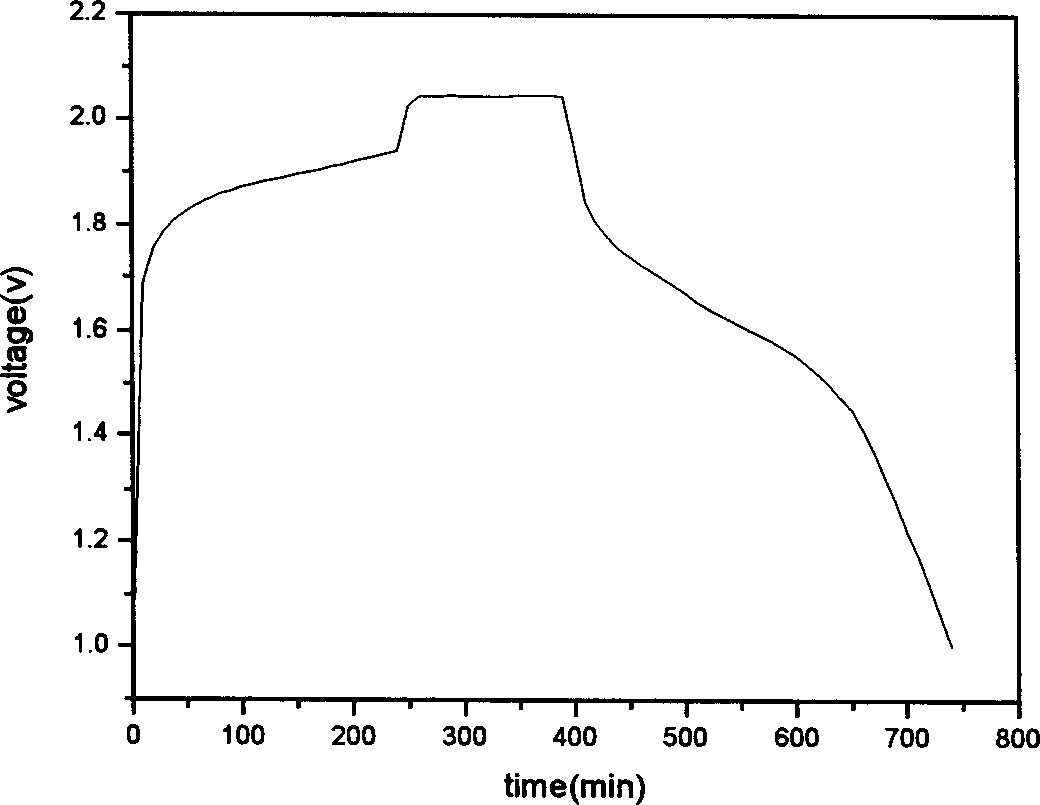

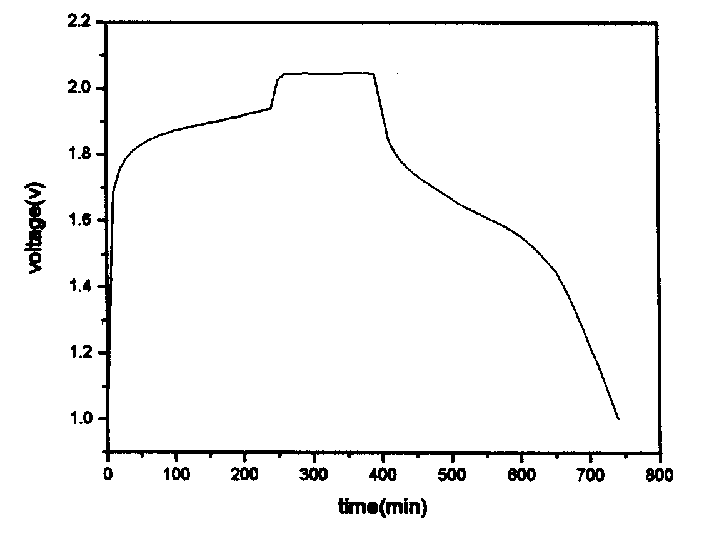

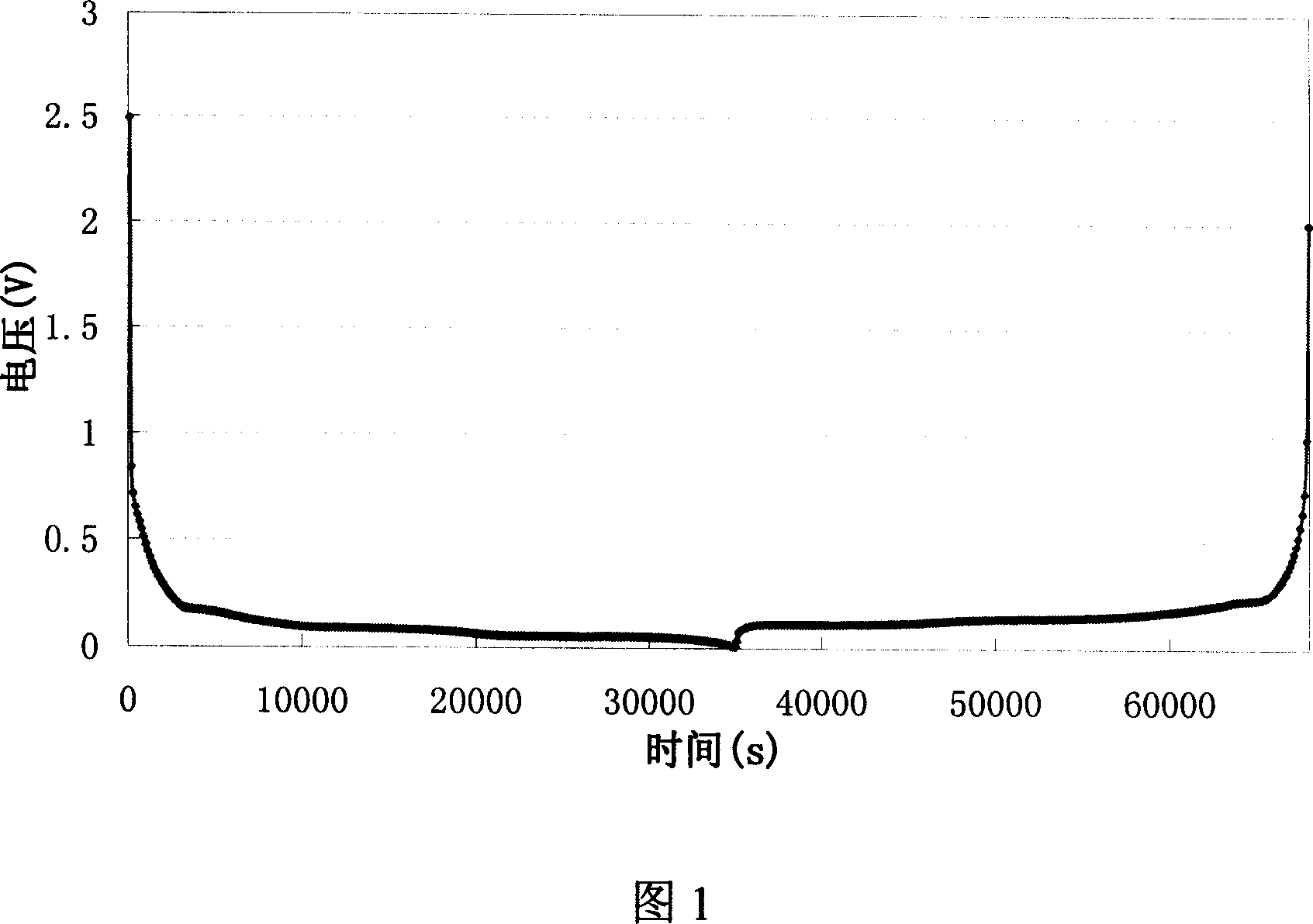

Nickel-zinc secondary battery and preparation method thereof

ActiveCN102024994AHigh discharge platformImprove performanceFinal product manufactureElectrode carriers/collectorsElectrolytic agentBattery cell

The invention relates to a nickel-zinc secondary battery and a preparation method thereof. The technical scheme is that: the preparation method comprises the following steps of: mixing 85 to 99 weight percent of anode active substance, 0.5 to 10 weight percent of anode additive and 0.5 to 5 weight percent of anode bonding agent uniformly; adding water into the mixture to prepare paste; coating the paste on an anode conductive matrix; drying, performing roll forming and slicing to obtain an anode plate; mixing 75 to 99 weight percent of cathode active substance, 0.5 to 20 weight percent of cathode additive and 0.5 to 5 weight percent of cathode bonding agent uniformly; adding water into the mixture to prepare paste; coating the paste on a cathode conductive matrix; drying, performing roll forming and slicing to obtain a cathode plate; separating the anode plate from the cathode plate by using diaphragm paper; winding the separated anode plate and cathode plate to be a cylindrical shape; sleeving the cylindrical object into a battery case; injecting electrolyte, wherein the anode plate is connected with an anode cap by a lug and the cathode plate contacts with the battery case; and sealing the battery to form the nickel-zinc secondary battery. The nickel-zinc secondary battery prepared by the method has a long cycle life, a high discharging platform and high specific energy.

Owner:LIAONING JIUYI ENERGY TECH

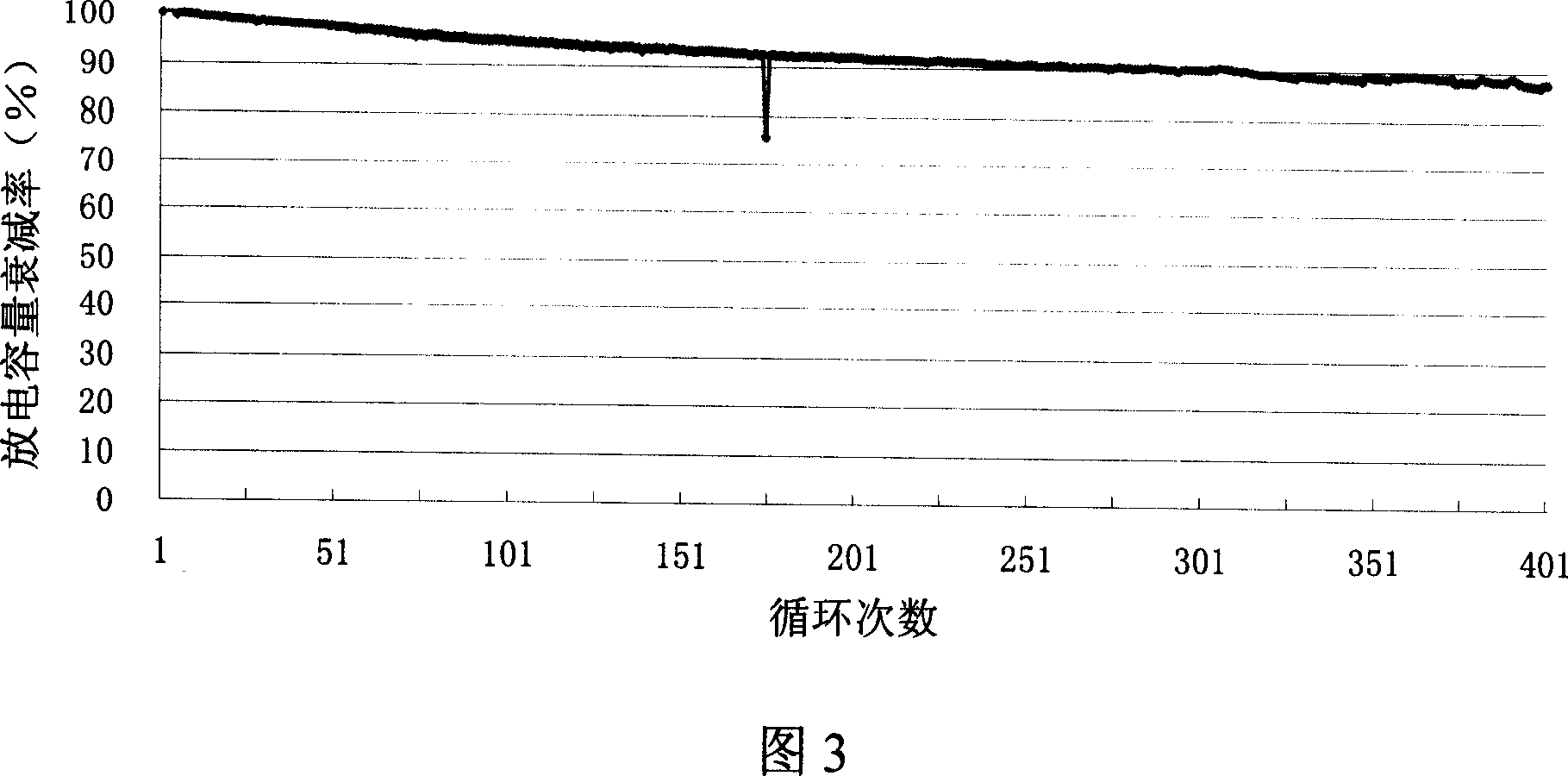

High-multiplying power lithium ion battery and preparation method thereof

InactiveCN105591055ASimple structural designImprove interface propertiesFinal product manufactureCell component detailsPorosityCooking & baking

The invention discloses a high-multiplying power lithium ion battery and a preparation method thereof. The lithium ion battery comprises a cathode plate, an anode plate, a composite diaphragm and an electrolyte solution, and the surfaces of the diaphragm are coated with composite conductive layers; each composite conductive layer is composed of a bonding agent, a conductive agent and micropores; the cathode plate and the anode plate are each of a full-tab structure. The preparation method comprises the steps that the diaphragm coated with the composite conductive layers, the cathode plate and the anode plate are subjected to a winding process to prepare a wound core, and the wound core is subjected to the processes of packaging, baking, liquid injecting, hot-cold pressing, forming and capacity grading to prepare the high-multiplying power lithium ion battery. According to the high-multiplying power lithium ion battery and the preparation method thereof, by improving the characteristics of the interfaces between the diaphragm and cathode and anode membranes and optimizing the structural design of the battery, the bonding performance of the contact interfaces between the diaphragm and the cathode and anode plates is improved, the lithium ion transfer resistance between the different interfaces is decreased, the electronic conductivity of the cathode and anode plates is enhanced, the porosity and the air permeability of the composite diaphragm are improved, wetting of the electrolyte solution to the diaphragm is improved, the retaining capacity of the electrolyte solution in the battery is improved, the high-multiplying power performance of the lithium ion battery is greatly improved, the high-multiplying power discharge capacity retention rate is increased by 10% or above compared with the prior art, and the high-multiplying power lithium ion battery is suitable for industrialized production.

Owner:CENT SOUTH UNIV

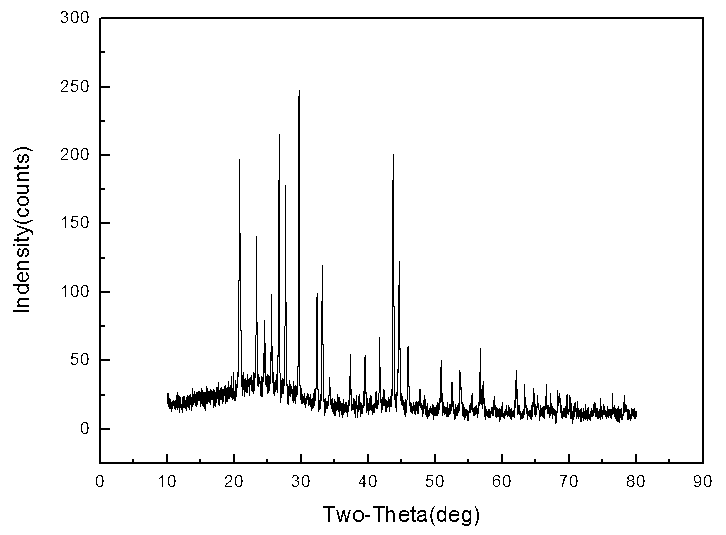

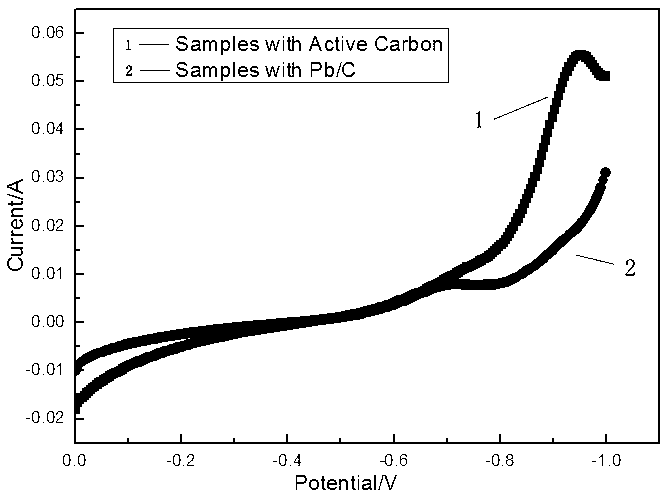

Lead/carbon composite for storage battery and preparation method of lead/carbon composite material

ActiveCN103137955AIncrease the proportionAvoid uneven mixingCell electrodesCarbon compositesCharge current

The invention discloses a lead / carbon composite for a storage battery. The lead / carbon composite is prepared from the following raw materials in percent by weight: 85-99.9 percent of lead-salt solution and 0.1-15 percent of conductive carbon material, wherein the lead salt solution is prepared from a soluble lead salt and deionized water, and the mol concentration of the lead salt solution is 0.1-0.8M. The invention also discloses a preparation method of the lead / carbon composite for the storage battery. The lead / carbon composite is substantially a conductive carbon material modified by lead oxide. Lead has the characteristics of low resistivity, high plasticity and high hydrogen evolution overpotential. The characteristics of the lead ensure that the hydrogen evolution overpotential of the carbon material after modified by PbO in a lead-acid battery is remarkably increased; and meanwhile the charging current occupied by partial hydrogen evolution reaction in a charging process is reduced, and the charging efficiency is increased.

Owner:SHENZHEN CENT POWER TECH

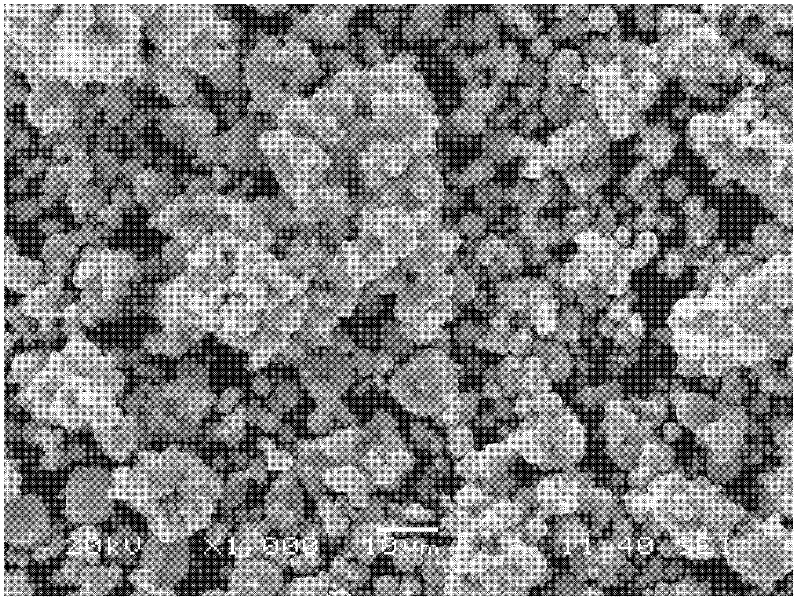

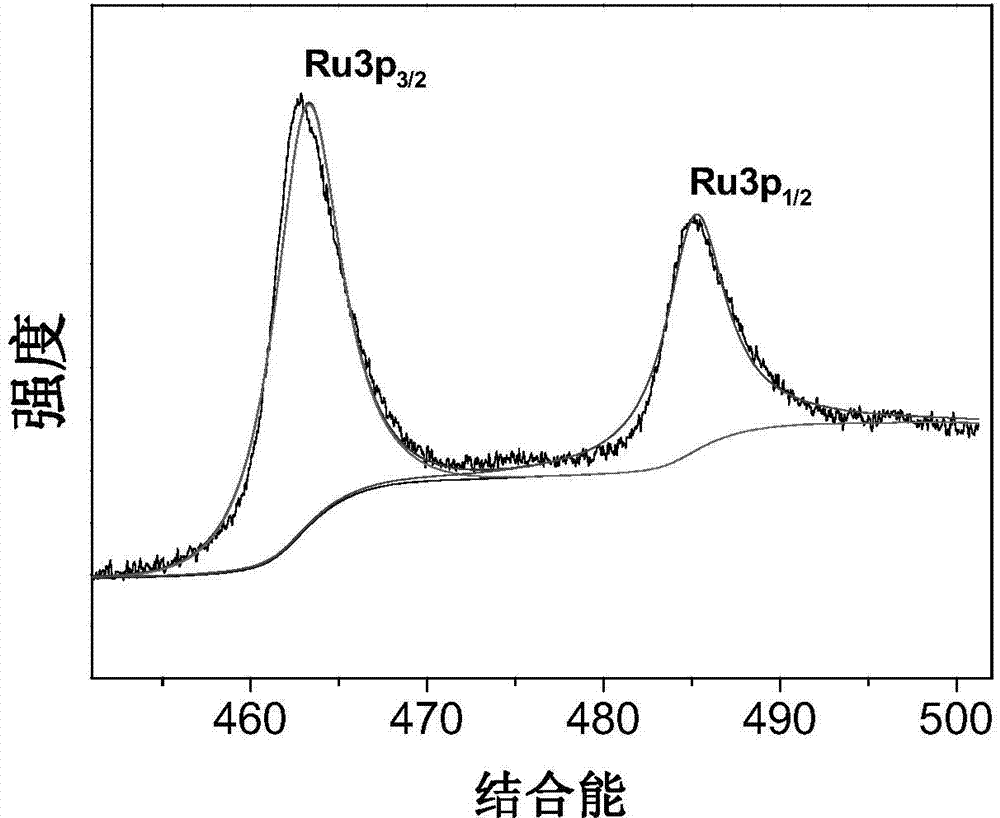

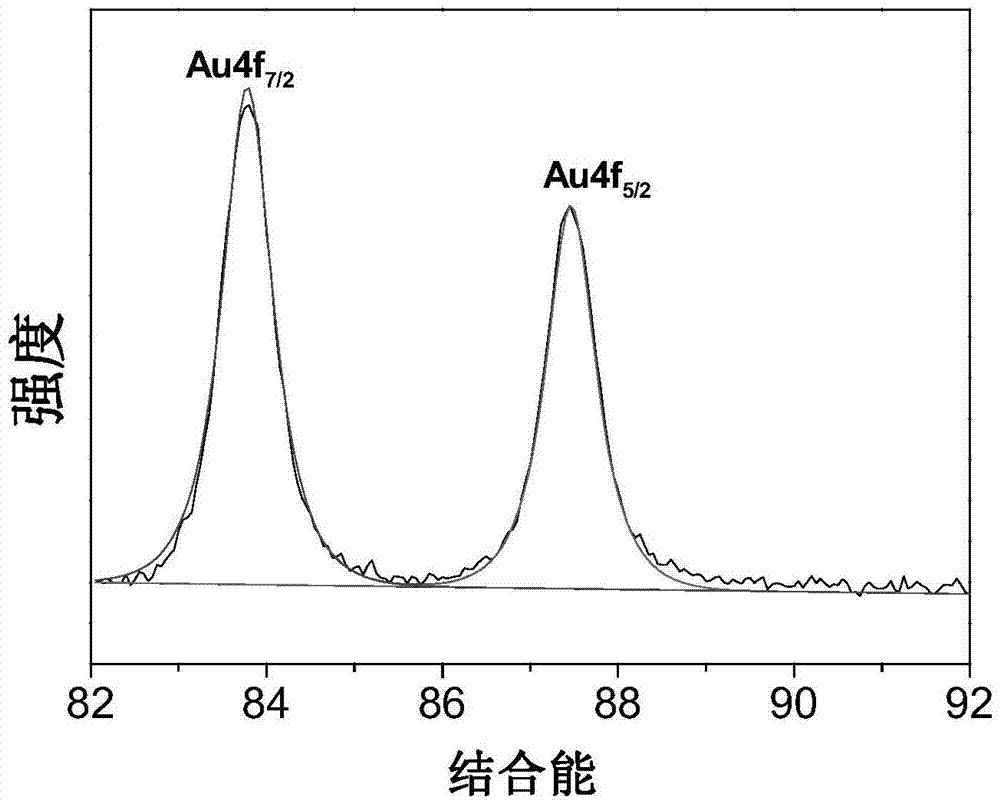

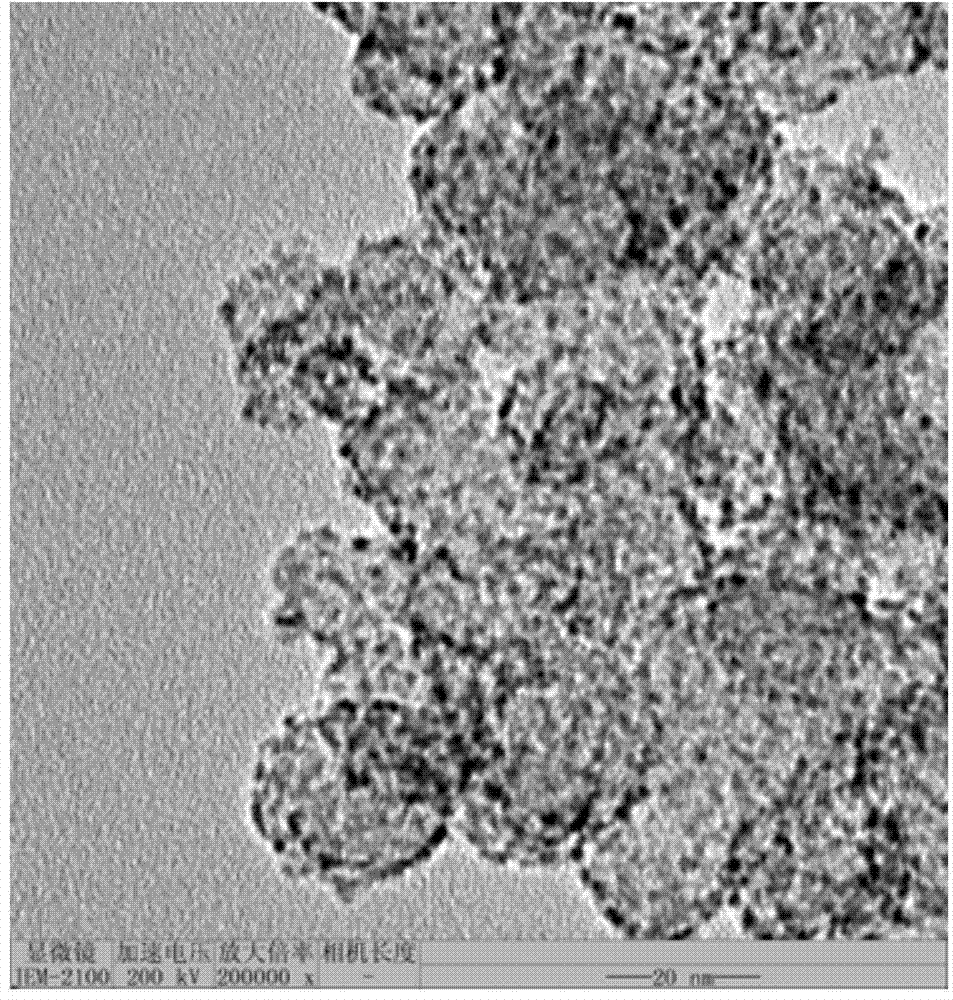

Ruthenium dioxide-based composite nano-material and preparation method thereof

ActiveCN104124071AEvenly dispersedImprove electrochemical performanceMaterial nanotechnologyHybrid capacitor electrodesCarbon compositesBULK ACTIVE INGREDIENT

The invention discloses ruthenium dioxide-based composite nano-material and a preparation method thereof. The preparation method includes that dispersing carbon matrix in water, adding ruthenium source and oxidized metal source, regulating the pH value of the solution, after stirring to adsorb, performing oil bath reaction, centrifuging, washing, and roasting in an inert atmosphere to obtain the composite nano-material. The preparation method is easy to operate, high in yield, low in cost and environmental friendly, and the prepared ruthenium dioxide / metal nano-particle / carbon composite nano-material is featured with small active ingredient size, large specific surface area and uniform dispersion. The ruthenium dioxide is hydrous ruthenium dioxide which belongs to good reversible charging / discharging active substances, and the metal nano-particle is easy to adsorb protons and transmit electrons to improve the electro-chemical performance of the ruthenium dioxide / metal nano-particle / carbon composite nano-material. The ruthenium dioxide / metal nano-particle / carbon composite nano-material can be used as super-capacitor electrode material and has excellent electro-chemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

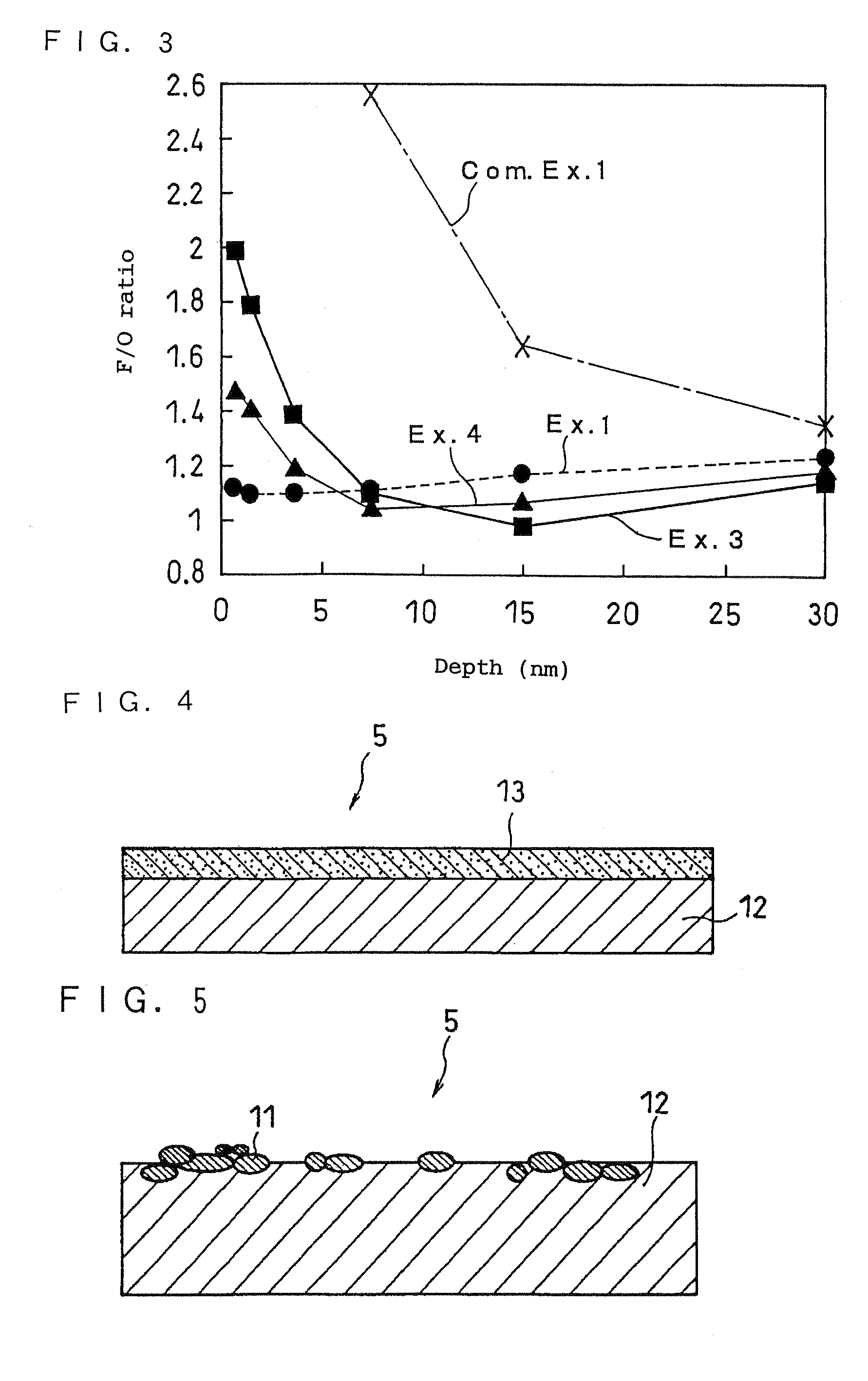

Positive electrode active material and non-aqueous electrolyte secondary cell

ActiveUS20050181279A1Reduces ionic conductivityImprove the immunityNon-aqueous electrolyte accumulatorsFinal product manufactureDecompositionComposite oxide

A non-aqueous electrolyte secondary cell having superior high temperature-operation properties and excellent large current-discharge properties is provided. The non-aqueous electrolyte secondary cell has a positive electrode composed of a positive electrode collector and positive electrode active material layers formed thereon. A positive electrode active material contained in the above layer is formed of a first composite oxide and a second composite oxide mixed therewith. The first composite oxide is formed of grains of a first lithium transition metal composite oxide containing at least nickel as a transition metal and a cover layer formed on at least part of the surface of each of the grains for suppressing decomposition of an electrolyte caused by the first lithium transition metal composite oxide. The second composite oxide is composed of grains of a second lithium transition metal composite oxide.

Owner:MURATA MFG CO LTD

Zinc-nickel secondary cell and preparation method thereof

InactiveCN1434534ASimple processQuality controllableFinal product manufactureAlkaline accumulators manufactureCapacitanceElectrolytic agent

This invention relates to a preparation method for ZnNi secondary cell and the cell prepared by the said method which is to isolate the positive and negative plates by diaphragm paper to be put into cell shell after being laminated and winded and fill in electrolyte, the positive plate contacts with the shell of positive collector, the negative is connected with the negative cap in weld via conductive terminal, finally go on with sealing, packing and storage, with the advantags of high voltage, large discharge capacitance, long circulation life, small internal resistance, excellent large current discharging performance.

Owner:SOUTH CHINA UNIV OF TECH

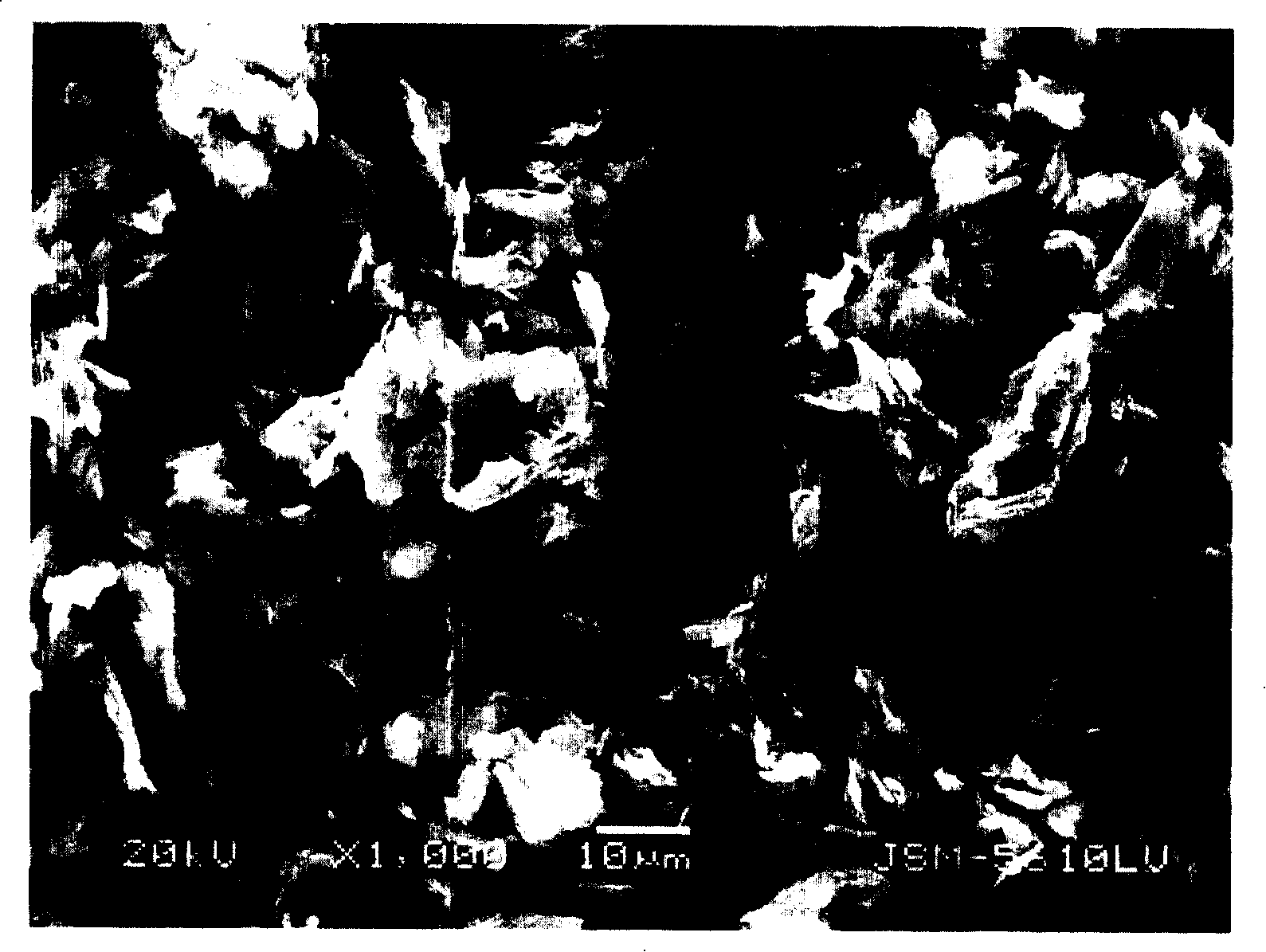

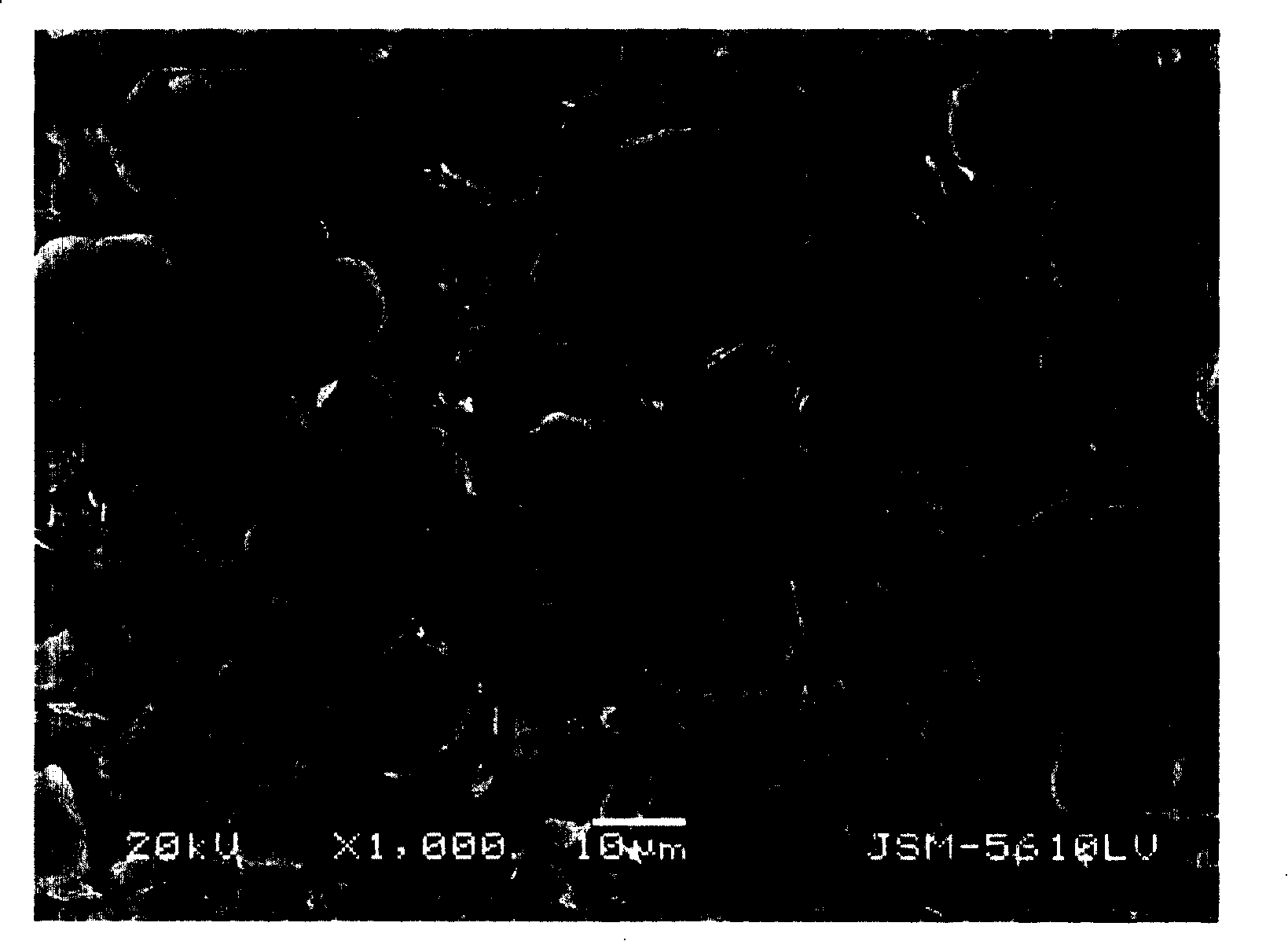

Battery cathode and lithium ion secondary battery comprising same

ActiveCN101192662AInhibition of structural changesImprove cycle performanceElectrode manufacturing processesSecondary cellsAdhesiveElectrical battery

The invention relates to a cathode of a lithium ion secondary battery, comprising a current collector and cathode material smeared over and / or filled in the current collector. The cathode material comprises cathode active substance and cathode adhesive. The cathode active substance is the mixture of a natural graphite and an artificial graphite, wherein, the natural graphite is the natural graphite with a ball shape, the artificial graphite is the artificial graphite with a micro granule scaly shape, the particle diameter of the natural graphite with the ball shape is longer than that of the artificial graphite with the micro granule scaly shape, the difference in value of the median diameter D50 between the natural graphite with the ball shape and the artificial graphite with the micro granule scaly shape is 4-25 microns; the median diameter D50 of the artificial graphite with the micro granule scaly shape is 0. 3-6 microns; the proportion by weight between the natural graphite with the ball shape and the artificial graphite with the micro granule scaly shape is 1:0.05-0.2. The lithium ion secondary battery provided by the invention has good circle performance and discharging performance with a large rate and safety performance under the condition of high capacity.

Owner:BYD CO LTD

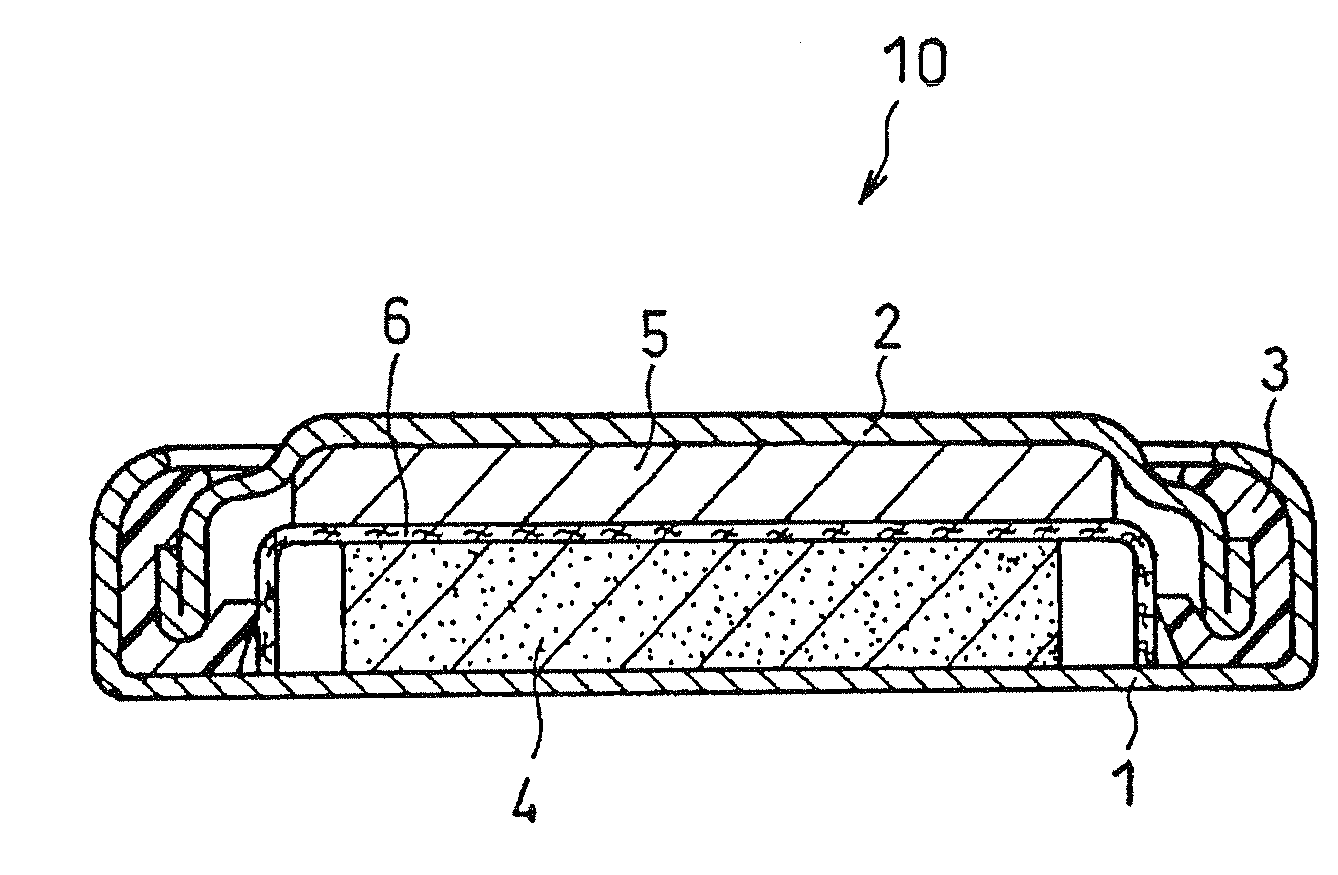

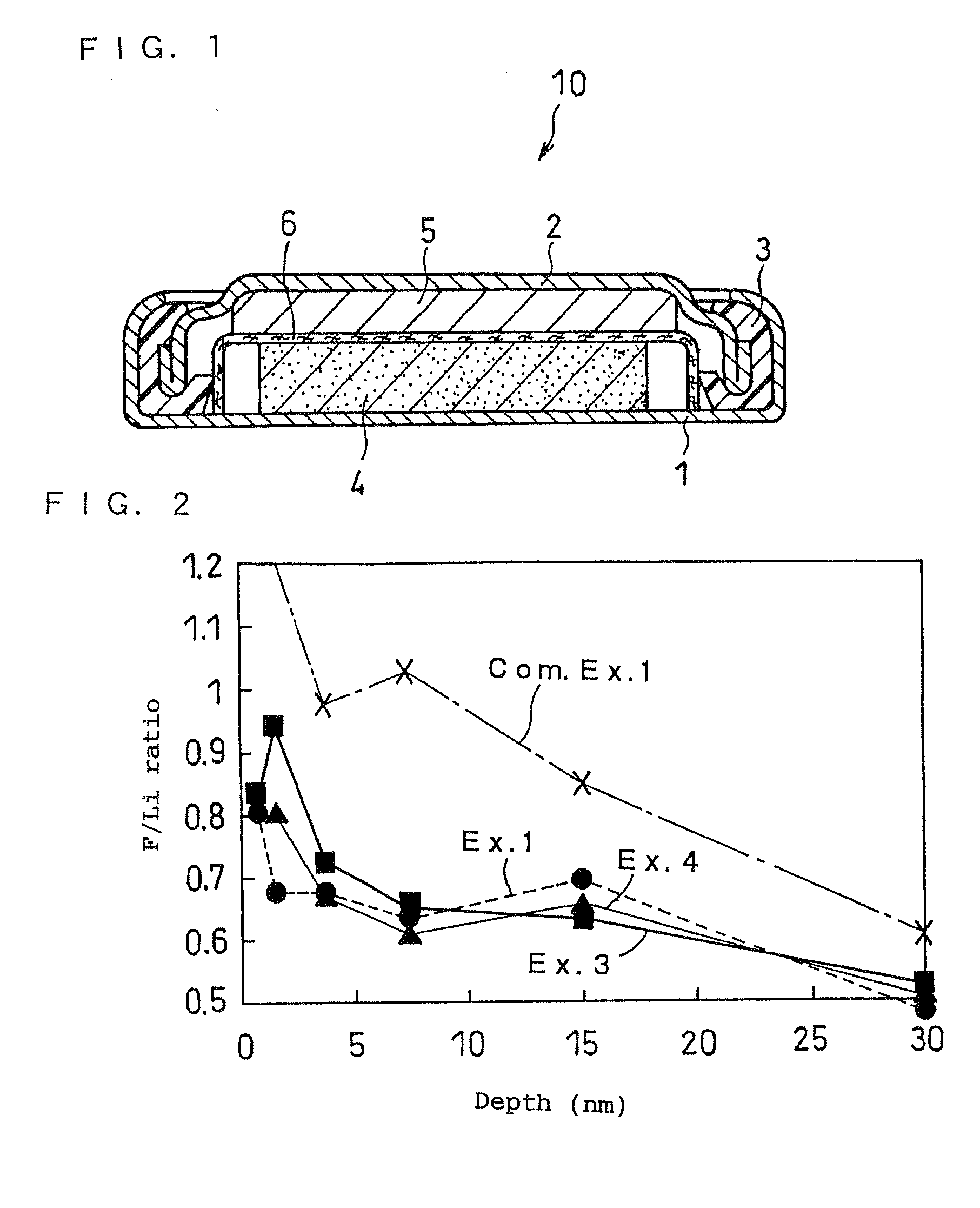

Lithium Primary Battery and Manufacturing Method Therefor

ActiveUS20090123844A1Increase internal resistanceImprove high-current discharge performanceElectrode manufacturing processesElectrode carriers/collectorsSurface layerLithium metal

A lithium primary battery including a positive electrode, a negative electrode, an organic electrolyte, and a separator interposed between the positive electrode and the negative electrode: the negative electrode including a negative electrode active material; the negative electrode active material being at least one selected from the group consisting of lithium metal and a lithium alloy; at least a surface layer portion of the negative electrode including a composite of amorphous carbon material and the negative electrode active material; and the surface layer portion facing the positive electrode with the separator interposed therebetween.

Owner:PANASONIC CORP

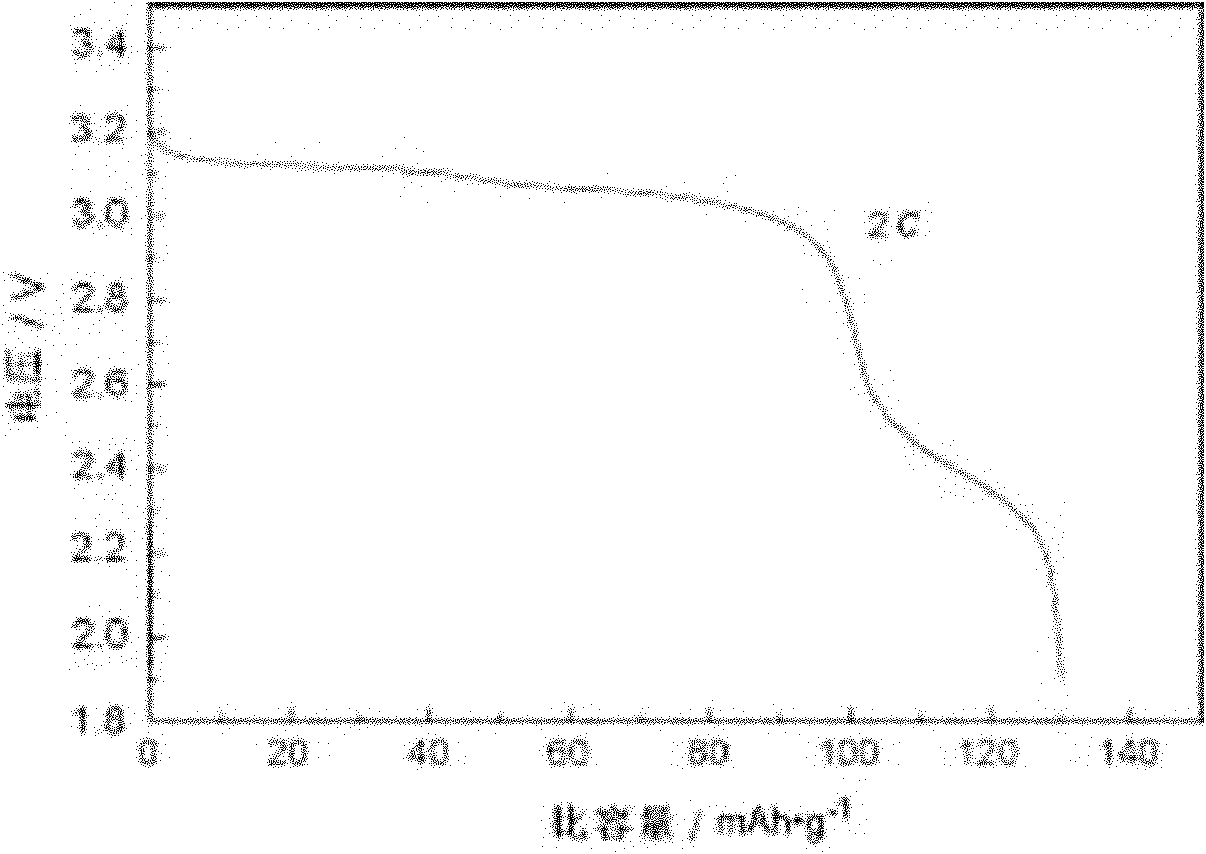

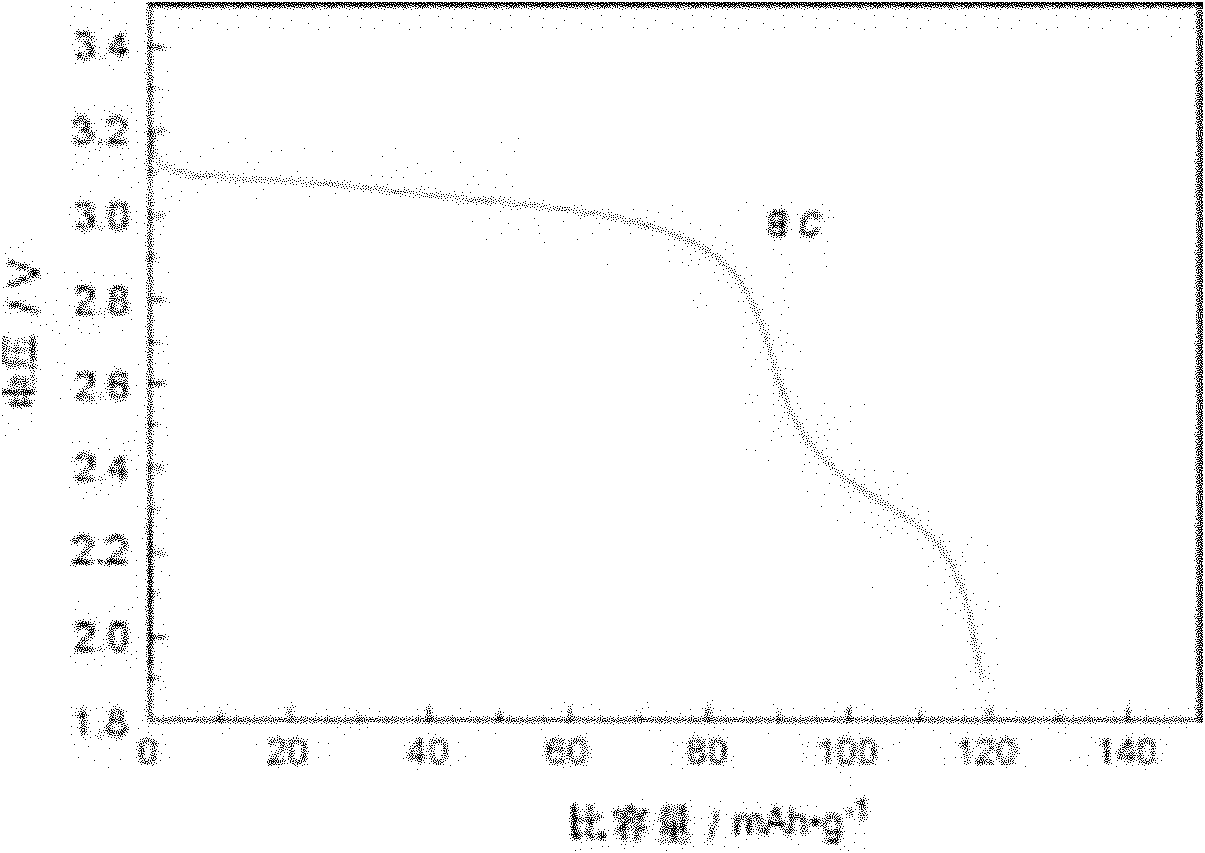

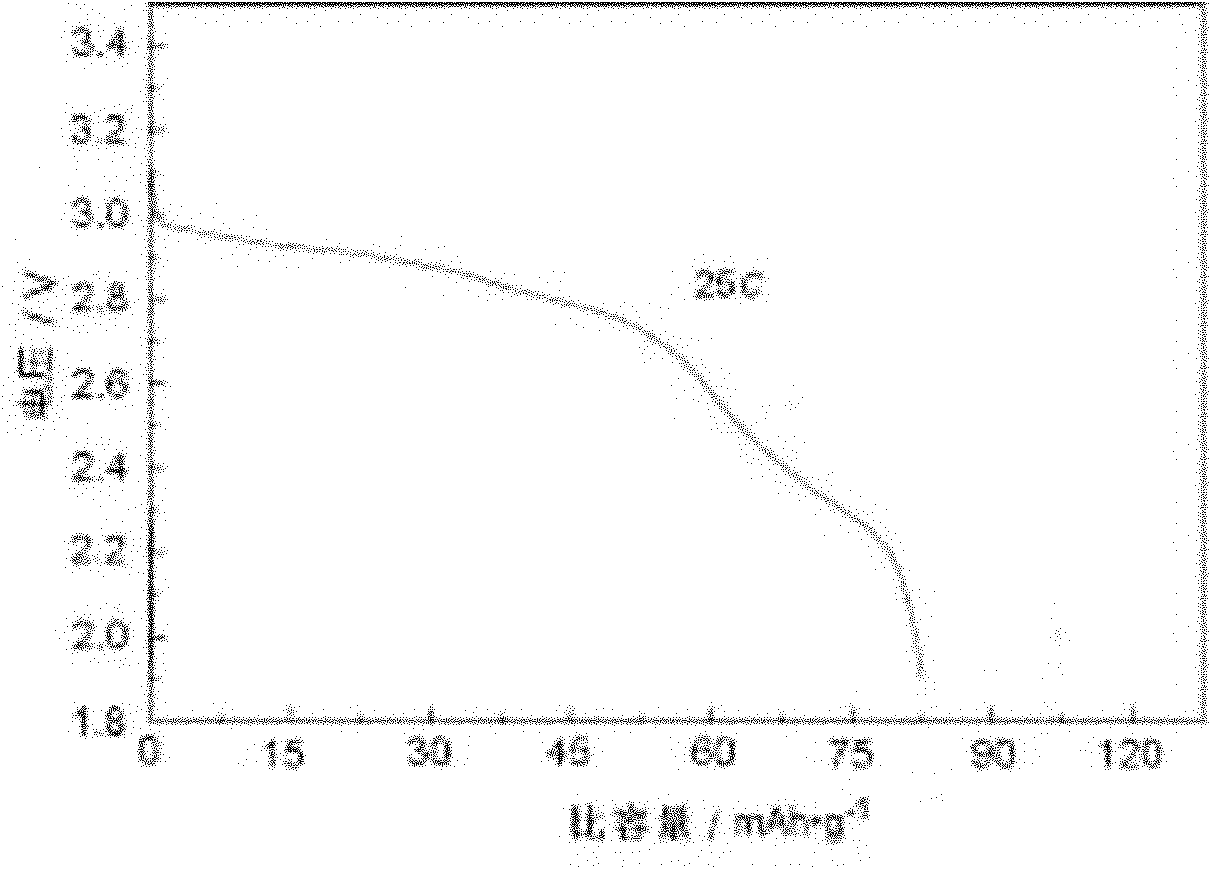

High magnification polymer lithium ion power battery and preparation method thereof

InactiveCN102130363AImprove material performanceSimple processSecondary cellsNon-aqueous electrolyte accumulator electrodesAdhesiveALUMINUM PHOSPHATE

The invention discloses a high magnification polymer lithium ion power battery and a preparation method thereof, and belongs to the field of lithium ion power batteries. Compared with the conventional batteries (1-10C), the discharge current of the battery is greatly promoted; and the magnification discharge can reach 20 to 25C. Aluminum phosphate (AlPO4) is coated on the surface of a high-voltage lithium ion anode material (LiNi0.5Mn1.5O4) in the anode; the anode mixture contains 78 to 92 percent of active substance, 4 to 11 percent of conductive agent and 4 to 11 percent of adhesive in percentage by weight; and the cathode contains 78 to 92 percent of surface cracked carbon coated lithium titanate, 4 to 11 percent of conductive agent and 4 to 11 percent of adhesive. The battery 2C, 8C and 25C discharge specific capacities of the lithium ion battery are 130mAh / g, 120mAh / g and 83.5mAh / g. The power battery can be used for various high-capacity high magnification discharge equipment such as electric vehicles, unmanned machines, power sources for submarines and the like.

Owner:BEIJING SHENZHOU YUANWANG TECH

Active material, nonaqueous electrolyte battery, and battery pack

InactiveCN104282899AIncrease capacityGood high current discharge performanceNegative electrodesLi-accumulatorsComposite oxideBattery pack

According to one embodiment, there is provided an active material including monoclinic niobium titanium composite oxide particles and a carbon material layer. The monoclinic niobium titanium composite oxide particles can absorb and release Li ions or Na ions and satisfy Formula (1) below. The carbon material layer covers at least a part of surfaces of the niobium titanium composite oxide particles and satisfies Formula (2) below: 0.5≰(α / β)≰2 (1) 0≰(γ / σ)≰0.1 (2)

Owner:KK TOSHIBA

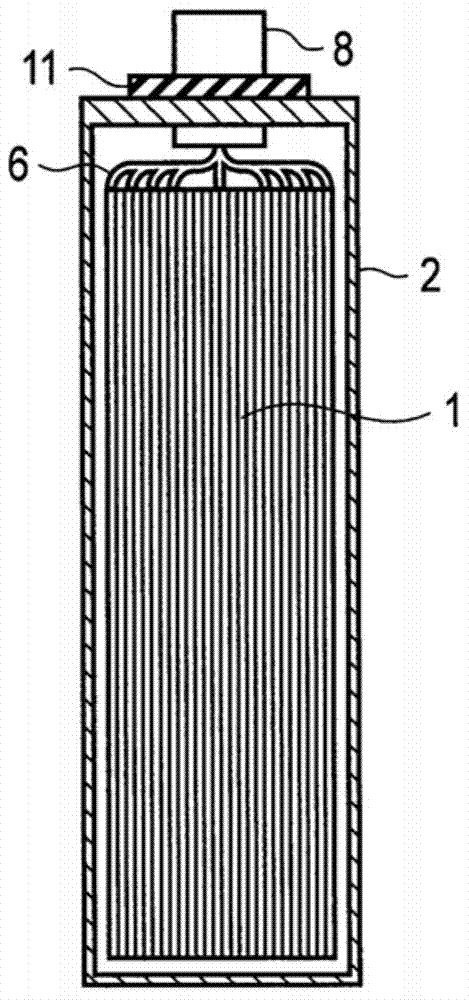

Nickel-hydrogen battery and manufacturing method thereof

InactiveCN104218264AImprove charging efficiencyGood high current discharge performanceFinal product manufactureCell component detailsEngineeringNickel–hydrogen battery

The invention discloses a manufacturing method of a nickel-hydrogen battery. The manufacturing method comprises a positive plate manufacturing process, a negative plate manufacturing process, a rolling process, a placement process, an electrolyte injection process and a seal process. A diaphragm is arranged between a positive plate and a negative plate. A turnup edge of the positive plate stretches out of the upper end of the diaphragm and a raised part of a negative plate stretches out of the lower end of the diaphragm so that the plates are rolled together to form a cell. The upper end of the cell is connected to a battery cap by a current collector disc. The nickel-hydrogen battery comprises the positive plate, the negative plate, the diaphragm sandwiched between the positive plate and the negative plate, the battery cap and a battery case. The turnup edge of the positive plate stretches out of the upper end of the diaphragm and is bent by pressing to reach to the upper end surface of the cell. The upper end of the cell is electrically connected to the battery cap by the current collector disc. The manufacturing method is convenient for operation and batch production. The nickel-hydrogen battery has high charging efficiency, good heavy current discharge performances and excellent dynamic performances.

Owner:SHENZHEN BETTERPOWER BATTERY

Preparation method of artificial graphite charcoal negative electrode material and prepared artificial graphite charcoal negative electrode material

The preparation process of artificial graphite charcoal as negative pole material includes the following steps: 1. adding artificial graphite powder and asphalt in the weight ratio of 1.5-19 to 1 while stirring, stirring for further 0.5-3 hr, and adding reaction assistant in 4-20 wt% of graphite powder and asphalt within 10-50 min; 2. heating to 500-600 deg.c in 4-10 hr and pumping out the light component in the first 1-2 hr; 3. maintaining at 500-600 deg.c for 3-8 hr while pumping out the heavy components and reaction assistant; 4. cooling to room temperature and 5. graphitizing. The present invention has environment friendship and high yield, and the prepared artificial graphite charcoal as negative pole material has the advantages of common artificial graphite, the density near that of natural graphite and lowered specific surface area.

Owner:福建杉杉科技有限公司

Hollow porous spherical mixed oxide for lithium ion battery negative electrode and preparation method of hollow porous spherical mixed oxide

ActiveCN104466108AEasy to prepareConducive to industrial mass productionCell electrodesNanotechnologyManganeseSpherical shaped

The invention relates to hollow porous spherical mixed oxide for a lithium ion battery negative electrode and a preparation method of the hollow porous spherical mixed oxide. The material is a uniform nano-mixture of Mn2O3 and NiMn2O4, and a specific chemical formula is NixMn<1-x>O<1.5-0.5x> (x is more than 0 and less than 1 / 3). The preparation method of the hollow porous spherical mixed oxide comprises the steps that based on complexing action of ammonia water and nickel ions, the precipitation speed of nickel carbonate is reduced, so that a spherical structure of the manganese carbonate cannot be destroyed by the nickel carbonate and has a certain modification function on a spherical structure of the manganese carbonate to form a uniform spherical mixture (NixMn<1-x>CO3, x is more than 0 and less than 1 / 3) of the nickel carbonate and the manganese carbonate; the prepared hollow porous spherical mixed oxide for the lithium ion battery negative electrode is obtained by using a high-temperature segmental roasting process. Compared with the prior art, the method is easy to operate and suitable for industrial large batch production; by utilizing the hollow porous spherical mixed oxide, the large-current charging / discharging performance of the lithium ion battery negative electrode can be effectively improved, and the and the cycle life of the lithium ion battery negative electrode can be effectively prolonged.

Owner:SHANGHAI JIAO TONG UNIV

Preparation method for lithium ion secondary battery positive pole active substance lithium iron phosphate

InactiveCN101209824AEvenly dispersedImprove uniformityCell electrodesPhosphorus compoundsLithium iron phosphateLithium compound

The invention relates to a preparation method of lithium iron phosphate, an active substance applied in the anode of lithium-ion secondary batteries. The method comprises that a mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered and cooled to get a sintering product; wherein, the iron compound is ferric iron compound; the sintering method comprises the step: the mixture that contains lithium compound, iron compound, phosphorus compound and carbon source additive is sintered at a first constant sintering temperature, then a mixture of the product acquired at the first sintering temperature and the carbon source additive is sintered at a second constant sintering temperature, and the second sintering temperature is at least 80 DEG C higher than the first sintering temperature. Batteries made of the lithium iron phosphate acquired by the method of the invention have both high capacity and good discharge performance at high current.

Owner:海宁市盐官工业投资有限公司

Negative electrode of lithium ionic secondary battery and battery thereof

ActiveCN101453007AGood high current discharge performanceActive material electrodesSecondary cellsLithiumGraphite

The invention provides a lithium ion secondary cell cathode and a cell. The lithium ion secondary cell cathode comprises a conductive agent, graphite, a caking agent and a current collecting body; the graphite is formed by mixing first graphite and second graphite by weight percentage of 5-30 to 95-70; the average particle diameter of the first graphite is between 0.5 and 2 mu m; the average particle diameter of the second graphite is between 4 and 12 mu m, wherein the graphite is coated-type graphite coated with a coating agent; and the coating agent is 1 to 20 weight percent of gross weight of the graphite. The average particle diameter of the first coated-type graphite is between 0.8 and 2.3 mu m; and the average particle diameter of the second coated-type graphite is between 5 and 13 mu m. The provided cathode has excellent large-current discharging performance and is in particular suitable for application of a power cell.

Owner:BYD CO LTD

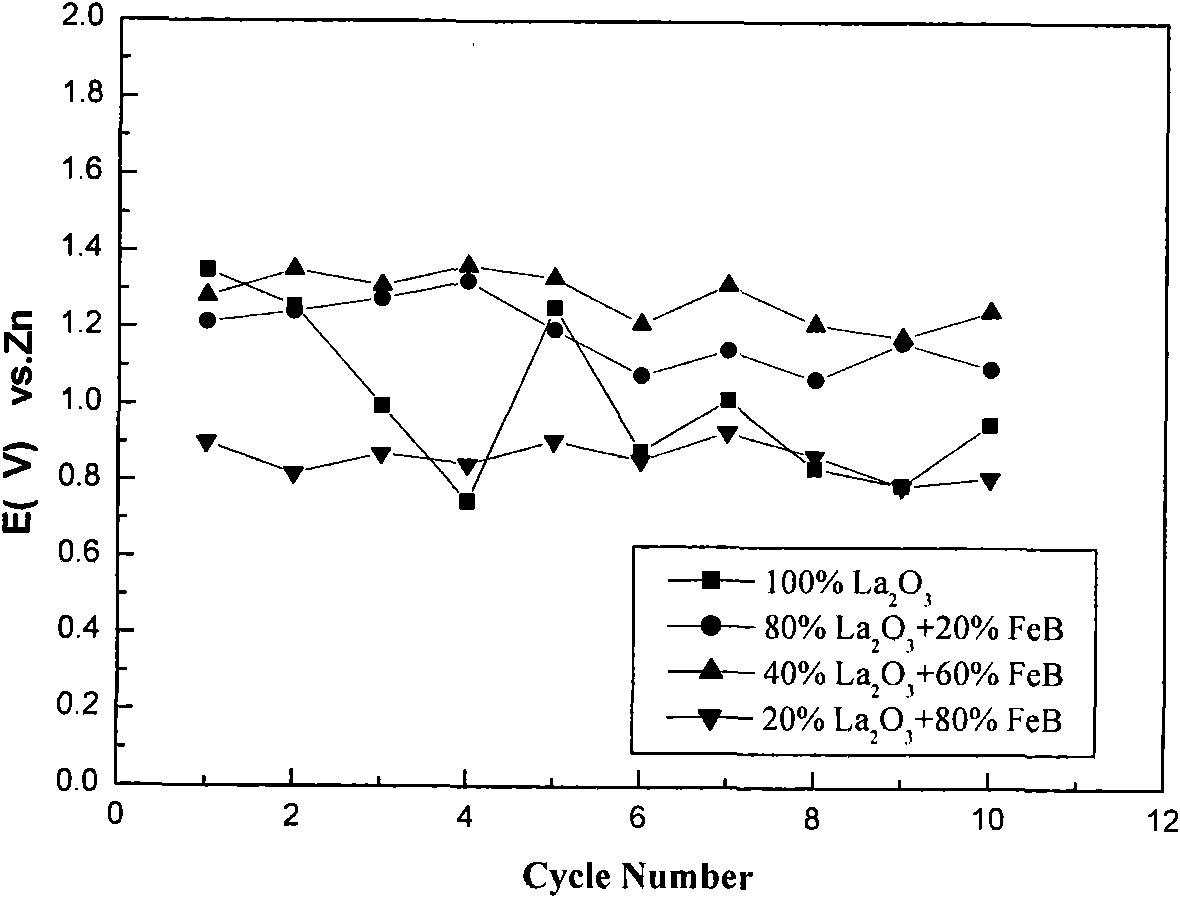

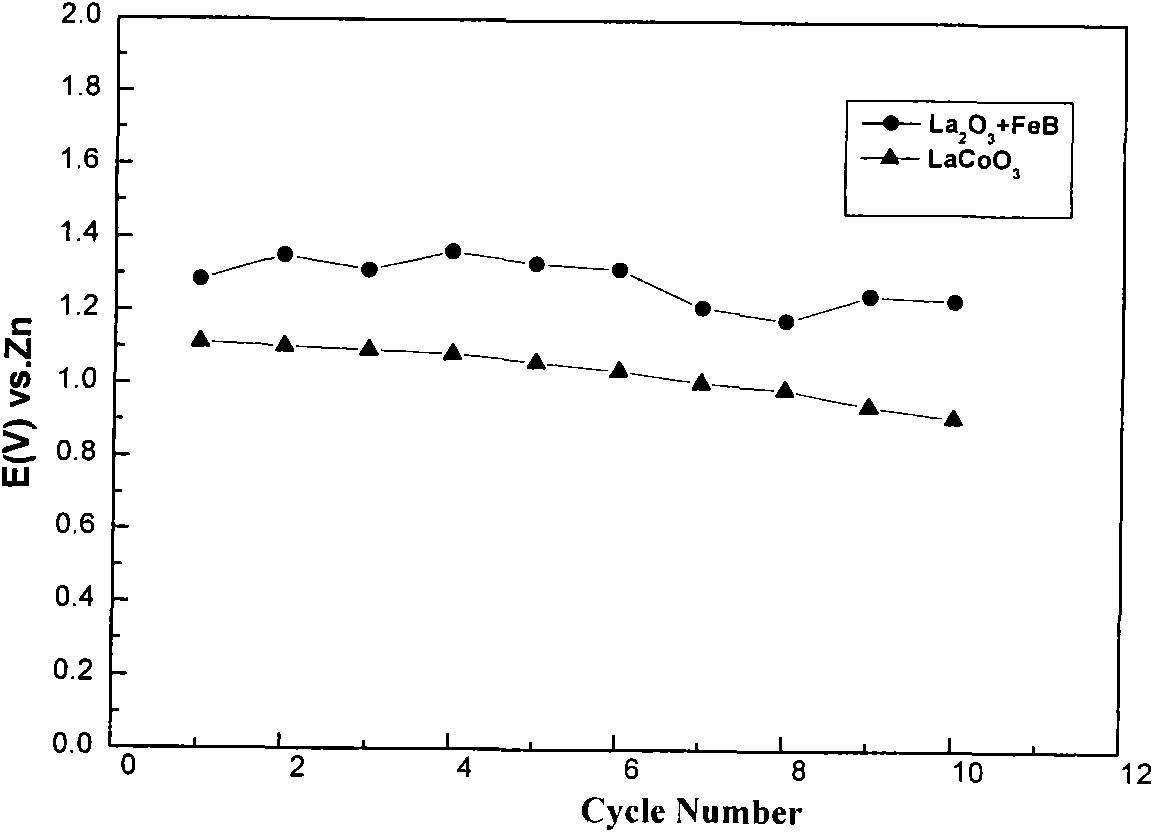

Combined double-effect oxygen catalyst and electrode and battery containing same

InactiveCN101820087AGood high current discharge performanceImprove voltage stabilityFuel and primary cellsCell electrodesAlloyOxygen

The invention relates to a combined double-effect oxygen catalyst and an electrode and a battery containing the same. The catalyst is a combination of a non-crystalline alloy and a bifunctional catalyst. The electrode comprises a gas diffusion layer, a catalyst layer and a current collector electrically contacted with the catalyst layer, and is characterized in that the catalyst included in the catalyst layer is the combined double-effect oxygen catalyst of the invention. The battery mainly comprises an air electrode, a membrane and an anode, wherein the air electrode adopts a double-effect oxygen electrode. The catalyst and the electrode have the advantages that the catalyst has high catalytic activity and the electrode prepared from the same is characterized by high stability for charging and discharging circulation performance, high heavy-current discharging performance, high working voltage, simple preparation process and low cost.

Owner:NAT ENG RES CENT OF RARE EARTH METALLURGY & FUNCTION MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com