Cobalt-covered lithium ion cell anode material precursor as well as preparation method and application

A technology for lithium-ion batteries and positive electrode materials, applied to battery electrodes, circuits, electrical components, etc., to achieve the effect of increased rate performance and good electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

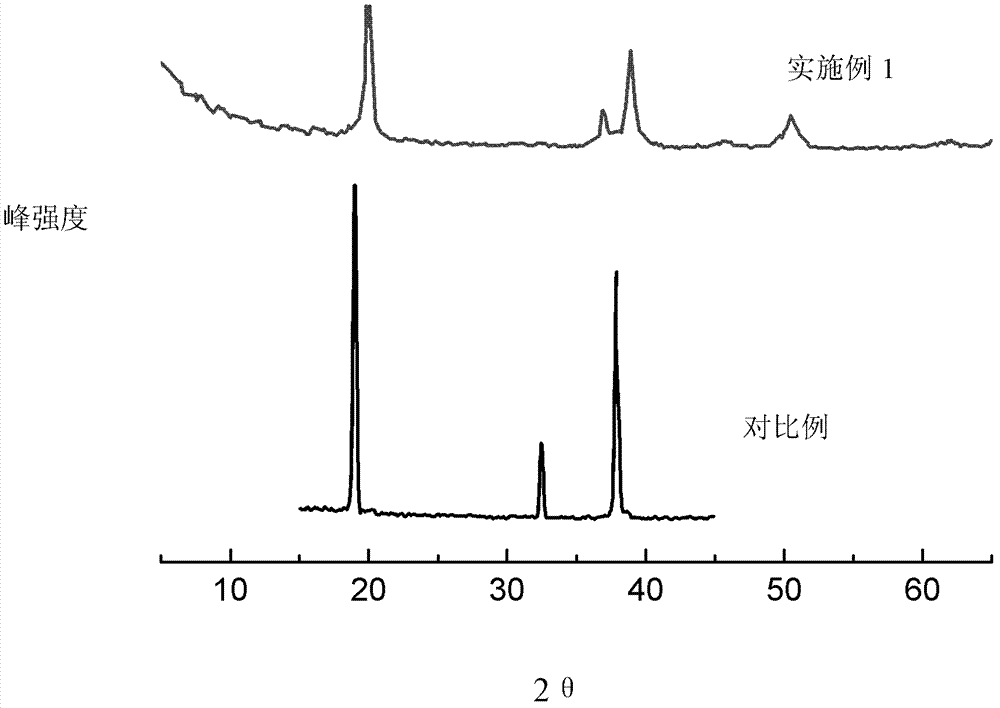

[0031] Embodiment 1: surface coating tricobalt tetroxide LiNi 1 / 3 co 1 / 3 mn 1 / 3 o 2 Preparation of cathode material

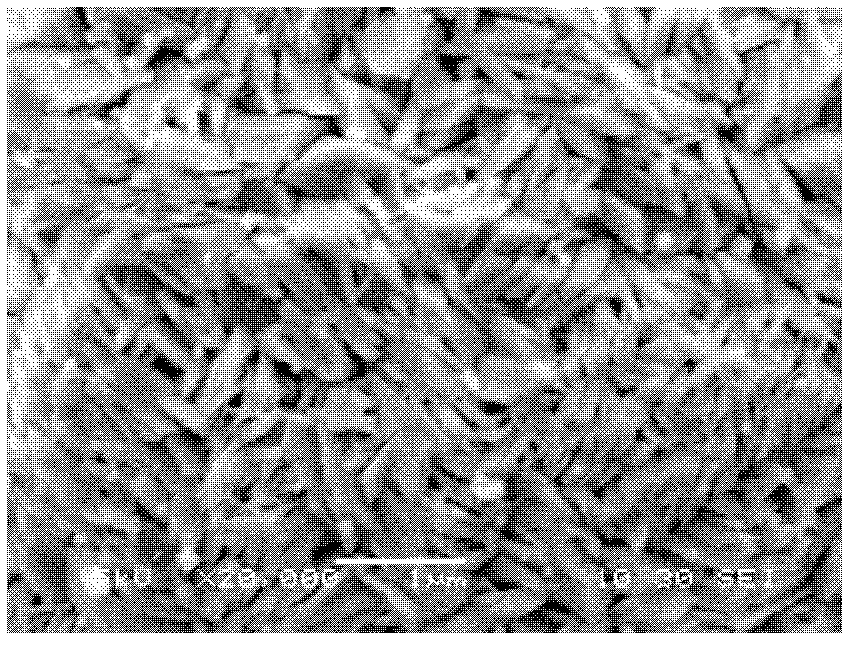

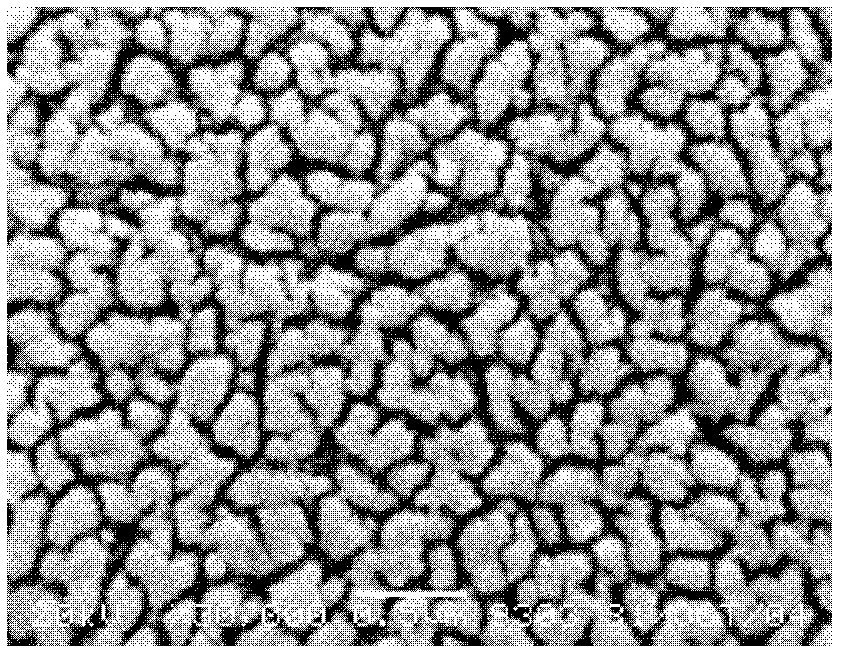

[0032]Nickel sulfate, cobalt sulfate, and manganese sulfate were prepared in a molar ratio (1:1:1) to prepare 50 L of salt solution with a concentration of 1.8 mol / L. The prepared solution was injected into a reaction kettle with a rotation speed of 250 rps through a metering pump at a rate of 0.4 L / h, and the temperature of the reaction kettle was kept at 50° C. At the same time, inject 20wt% ammonia water and 8mol / L NaOH solution, adjust the flow rate of the alkali solution, and keep the pH value stable between 10-12 through the pH tester. When the salt solution is completely injected into the reactor, the precursor preparation reaction is completed. . After the reaction is completed, the solid-liquid mixture is filtered through the filter, and after washing to neutrality, the filtered solid part is re-added to the reactor, and 1L of the prepared 1mol / L ...

Embodiment 2

[0036] Embodiment 2, adopt the same step as embodiment 1 to prepare the LiNi of surface coating tricobalt tetroxide 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material differs in that the oxidizing agent is sodium persulfate.

Embodiment 3

[0037] Example 3, using the same steps as in Example 1 to prepare LiNi coated with tricobalt tetroxide on the surface 1 / 3 co 1 / 3 mn 1 / 3 o 2 The positive electrode material is different in that the concentration of sodium hydroxide is 20wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com