Square power lithium ion battery cell and manufacturing method thereof

A lithium-ion battery and lithium-ion technology, applied in the manufacture of electrolyte batteries, non-aqueous electrolyte batteries, and final product manufacturing, can solve the problem of inconvenient connection between tabs and polar terminals, affecting the high-current discharge performance of large-capacity power batteries, Positive and negative ear short circuit and other problems, to achieve the effect of good high-current discharge performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

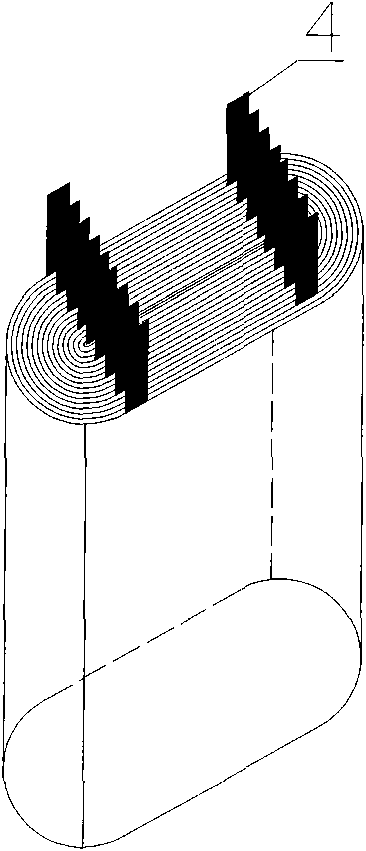

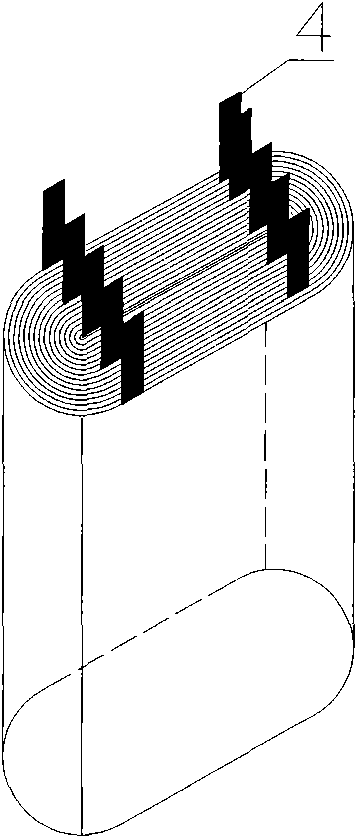

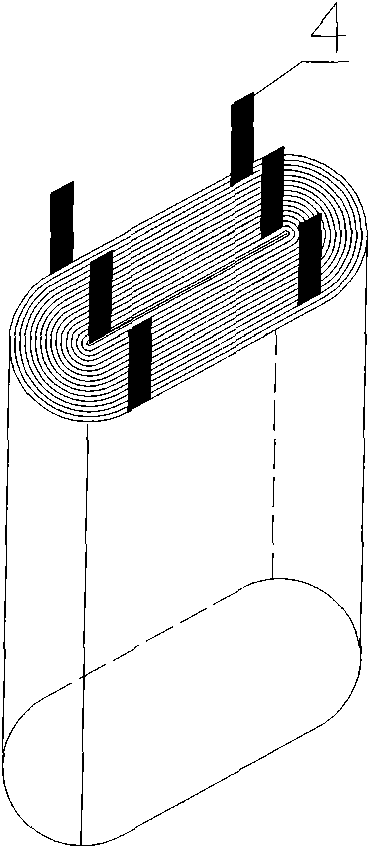

[0033] like figure 1 , figure 2 , image 3 As shown, a square power lithium-ion battery cell includes a positive electrode sheet, a diaphragm, a negative electrode sheet, a positive electrode ear and a negative electrode ear, the positive electrode ear is connected to the positive electrode sheet, and the negative electrode ear is connected to the negative electrode sheet. The square power lithium-ion battery cell is formed by winding the positive electrode sheet, separator, and negative electrode sheet around the winding needle. After winding, the upper and lower sides of the winding needle have positive and negative electrode ears. One end of the body, the negative tab is located at the other end of the cell body, and the positive tab and the negative tab are located on the same side of the cell body.

[0034] The power lithium-ion battery cell in the embodiment of the present invention can be provided with more than one positive pole lug and more than one negative pole l...

Embodiment 2

[0048] like figure 1 and Figure 5 As shown, when the number of winding turns e of the tab installation cycle is equal to 1, that is, the tab 4 is installed once for each winding of the battery cell, and the provided tab 4 includes two positive tabs and two negative tabs. The battery cell is composed of a positive electrode sheet, a diaphragm, and a negative electrode sheet that are stacked in sequence and then wound. Each winding round, the battery cell forms two layers of positive electrode sheets and two layers of negative electrode sheets. Each layer is provided with a positive tab, and each layer of the negative sheet in the winding core is provided with a negative tab.

[0049] Take the positive tab and the positive tab as an example: the positive tab of the first layer is located at the starting end of the winding, the positive tab of the second layer is close to the end of the first winding, and the positive tab of the second layer is connected to the positive tab of ...

Embodiment 3

[0061] like figure 2 , Image 6 As shown, when the number of winding turns e of the tab installation cycle is equal to 2, that is, the tab 4 is installed every two turns of the battery cell, and the provided tab 4 includes two positive tabs and two negative tabs. The battery cells are formed by stacking positive plates, separators, and negative plates in sequence and then winding them.

[0062] Take the positive tab and the positive tab as an example: the positive tab of the first layer is located at the starting end of the winding, the positive tab of the fourth layer is close to the end of the second winding, the positive tab of the fourth layer is connected to the positive tab of the first layer The ears are in the same tab setting period, and the tab spacing is L1. The positive tab of the fifth layer is located at the starting end of the third coil, which is the starting end of the second tab setting cycle, and the positive tab of the fourth layer is located at the begin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com