Combined double-effect oxygen catalyst and electrode and battery containing same

A technology of oxygen catalyst and bifunctional catalyst, applied in the field of electrochemical energy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] This example mainly illustrates the electrochemical performance of the air electrode prepared by using different types of combined catalysts described in the present invention. The air electrode is composed of a catalytic layer, a gas diffusion layer and a nickel mesh, and the structure schematic diagram is shown in figure 1 . The catalytic layer wherein is prepared according to the following process: take by weight respectively 48% VulcanXC72 and 12% PTFE emulsion, dissolve in distilled water, process 30min in a magnetic stirrer, after the two are mixed, and then place them in a magnetic stirrer Treat in the medium for 30 minutes, then put it into ultrasonic treatment for 10 minutes, and finally put it in an oven and dry it at 250 ° C for 2 hours. After cooling naturally, crush it, and then add the weight percentage to account for 16%. The representative ones described in the content of the present invention are different. Types of combined catalysts, including the co...

Embodiment 2

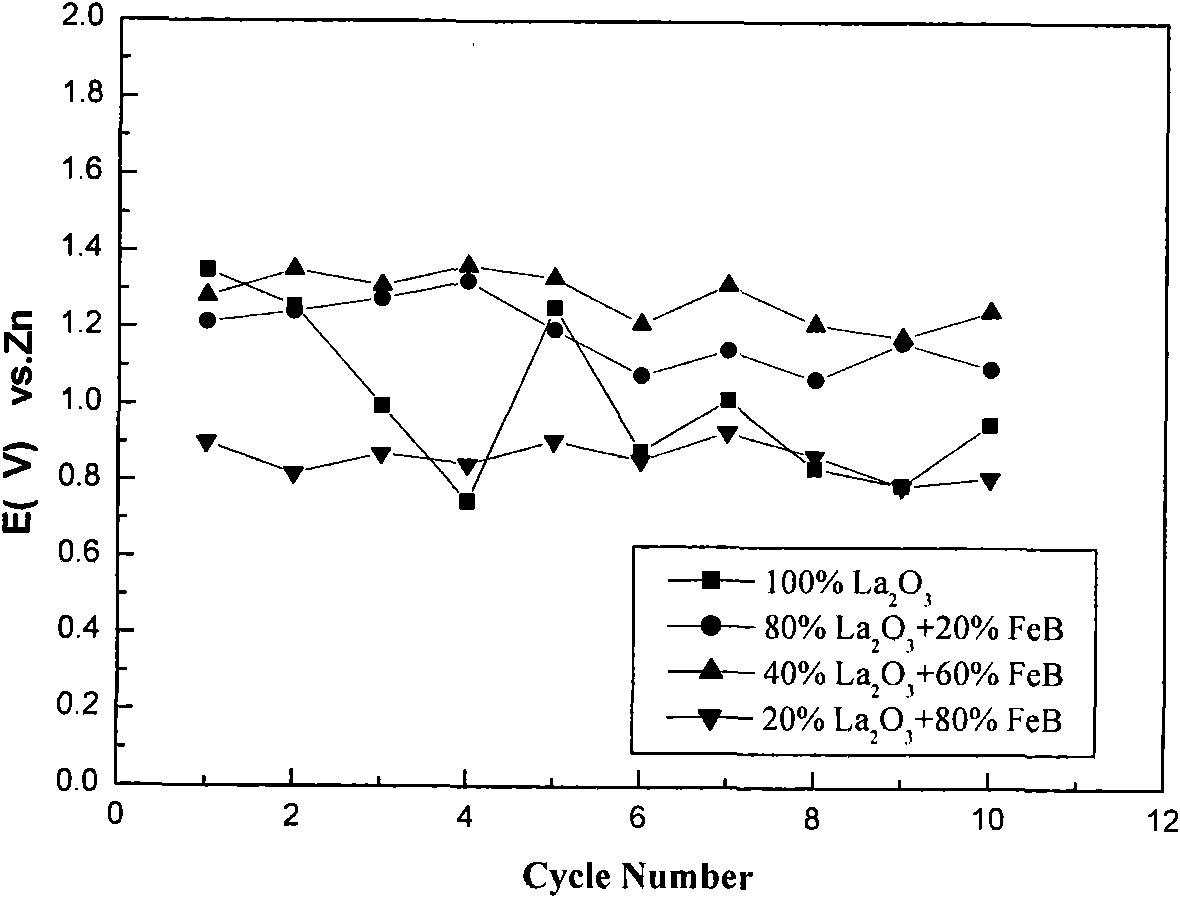

[0032] This example mainly illustrates the performance of a combined catalyst formed by combining two kinds of catalysts in different proportions. The air electrode was prepared according to the method in Example 1, and four catalyst combinations with different proportions were selected, which were 100% La 2 o 3 , 80% La 2 o 3 and 20% FeB, 40% La 2 o 3 and 60% FeB, 20% La 2 o 3 And 80% FeB, test condition is also identical with embodiment 1, according to 20mA / cm 2 The charging and discharging current cycle is 10 times, and the cycle discharge curve is shown in figure 2 .

[0033] It can be seen from the figure that the performance of the air electrode with different catalyst combinations is very different. The curve without FeB fluctuates greatly, while the curve with FeB is relatively flat. completely use La 2 o 3 The data of the catalyst fluctuates greatly, indicating that it is not stable enough, but the maximum discharge voltage is higher; the addition of 20% F...

Embodiment 3

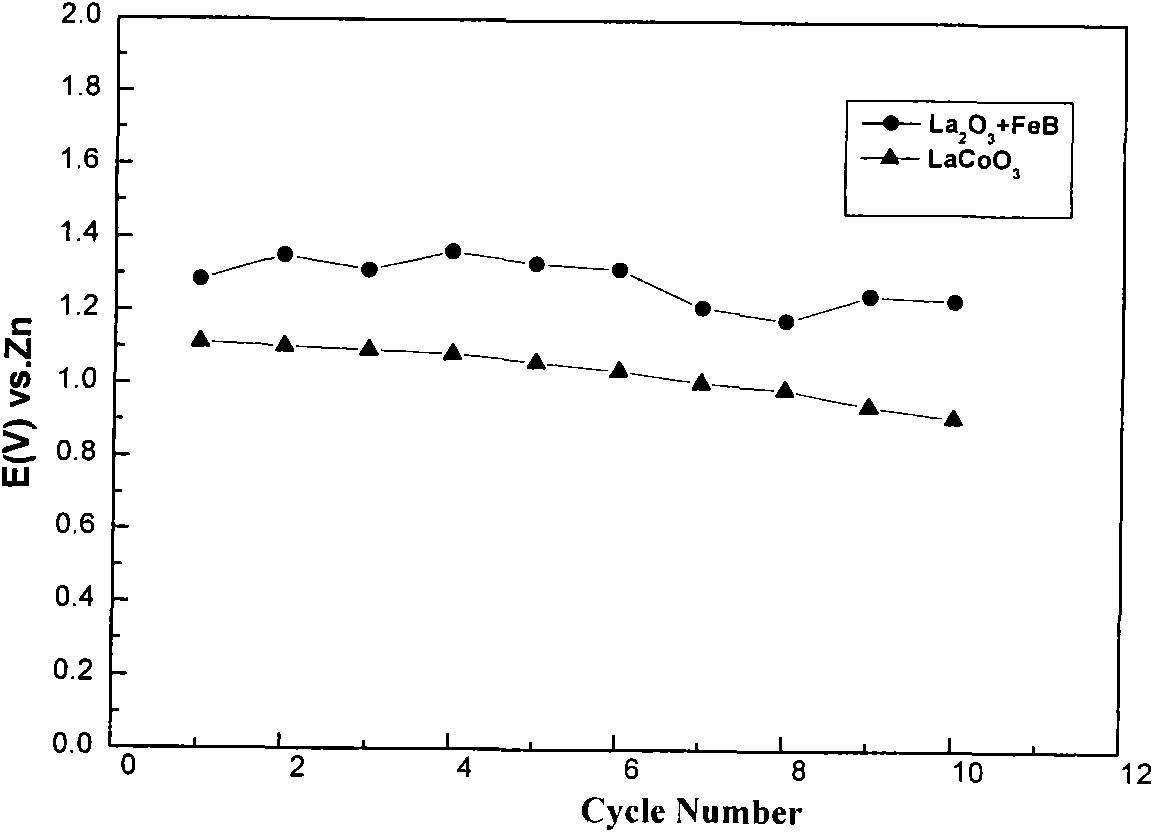

[0035] This example visually illustrates the charge-discharge cycle stability performance of the air electrode prepared with the optimized combination of catalysts. The air electrode was prepared according to the method in Example 1, and the test conditions were exactly the same as in Example 1. According to 20mA / cm 2 The charging and discharging current cycles 10 times, the test results are shown in image 3 .

[0036] As can be seen from the figure, the use of perovskite LaCoO 3 The air electrode made of catalyst has a low initial discharge voltage, less than 1.2V (vs. Zn), and the discharge voltage shows a downward trend as the charge-discharge cycle proceeds. While using the optimized combined catalyst of the present invention, the curve as a whole is using LaCoO 3 type catalyst, the discharge voltage is significantly higher than that of LaCoO 3 , the discharge voltage is still around 1.3V after 10 charge-discharge cycles, which is significantly better than that of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com