Negative electrode of lithium ionic secondary battery and battery thereof

A secondary battery and lithium ion technology, applied in secondary batteries, battery electrodes, active material electrodes, etc., can solve the problems of increasing the specific surface area of graphite, reducing the reversible capacity and capacity of graphite, destroying the structure of graphite, etc., and achieve high current discharge The effect of excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

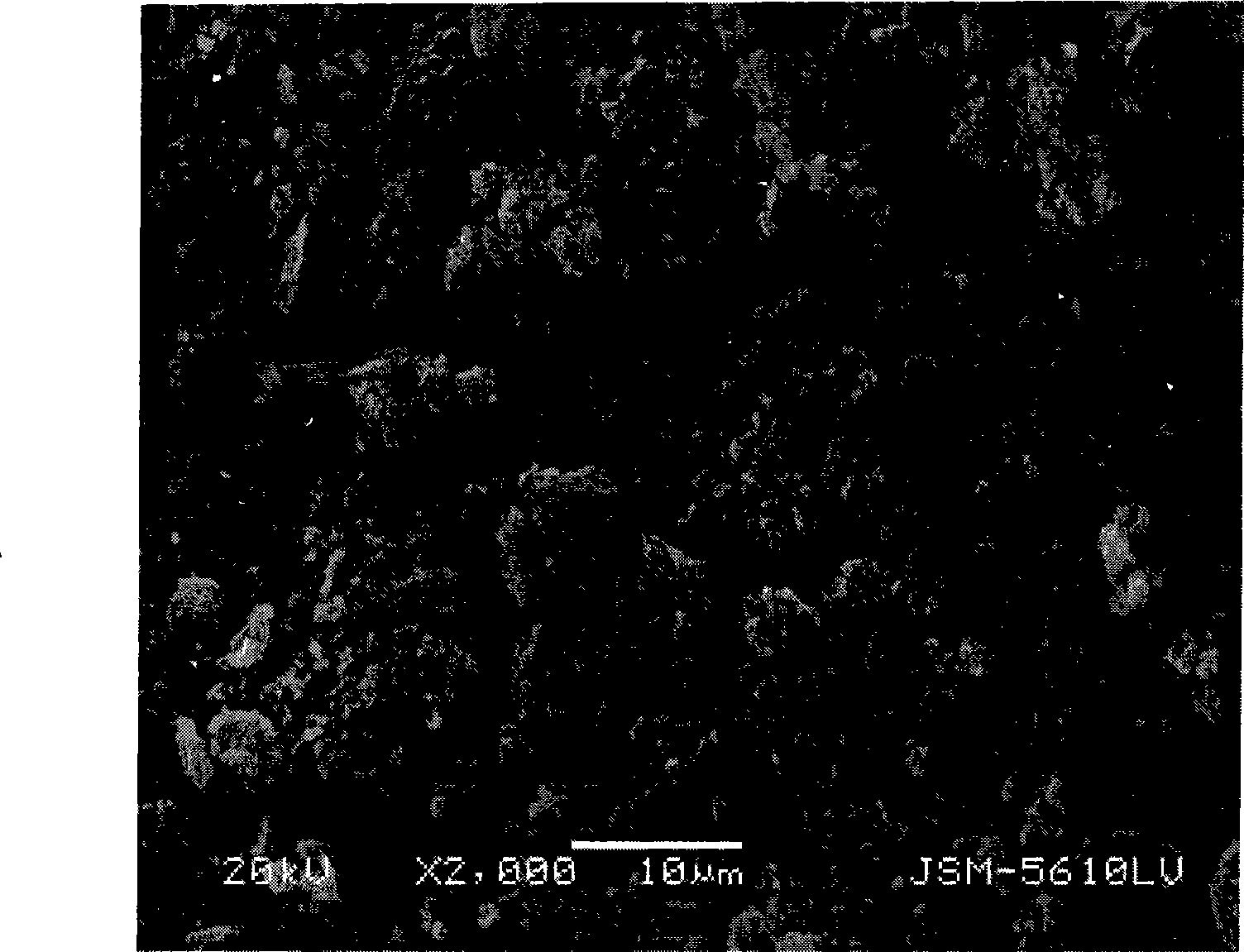

Image

Examples

Embodiment 1

[0024] 2 kilograms of natural graphite with an average particle size of 1.0 microns, a corrected value of d002 between crystallite layers, and a specific surface area of 13.6 square meters per gram is the first graphite; The natural graphite with a correction value of 0.3364 nanometers and a specific surface area of 4.5 square meters per gram is the second graphite; after mixing the two, add 50 g of phase deposited carbon fiber (VGCF) and mix thoroughly. Graphite A is obtained.

[0025] 970 grams of graphite A and 30 grams of styrene-butadiene rubber (SBR) were mixed. Add 1500 ml of water and stir evenly to make negative electrode slurry, apply it evenly on both sides of 12 micron copper foil with a pulper, heat and dry under vacuum at 125°C for 1 hour, roll, and cut into pieces to obtain 790mm (length) × 57.5 mm (width)×85 μm (thickness) negative electrode, each negative electrode contains 5.1-5.2 grams of graphite to obtain the negative electrode A1.

Embodiment 2

[0027] The coating agent is petroleum pitch, and the first graphite and the second graphite are respectively coated to obtain the coated first graphite and the coated second graphite, wherein the coated graphite is exactly the same as the graphite used in the example 1 . The coating agent petroleum pitch is dissolved in the solvent toluene in a certain proportion, and the total amount of petroleum pitch and graphite is mixed in a weight percentage of 100:8, of which graphite is 100, petroleum pitch is 8, and then cracked under inert gas conditions at 1100°C to cladding.

[0028] 2 kilograms of coated first graphite with an average particle size of 1.0 microns, a corrected value of d002 of the crystallite interlayer distance of 0.3375 nanometers, and a specific surface area of 10.5 square meters per gram after coating; 8 kilograms of coated first graphite with an average particle size of 9.5 microns, Coated second graphite with a corrected value of d002 of crystallite layer ...

Embodiment 3-4

[0037] According to the method for coating lithium ion secondary battery negative electrode active material according to the method of embodiment 1, the difference is that the particle diameter of the graphite value that is coated is D 50 , interlayer distance d002 value of crystallite, specific surface area, the relative weight ratio between graphite, the ratio of conductive agent to the total weight of graphite, see Table 1 for details.

[0038] Table 1

[0039]

[0040] The weight ratio of the second graphite to the first graphite 80:20 80:20 70:30 95:5

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com