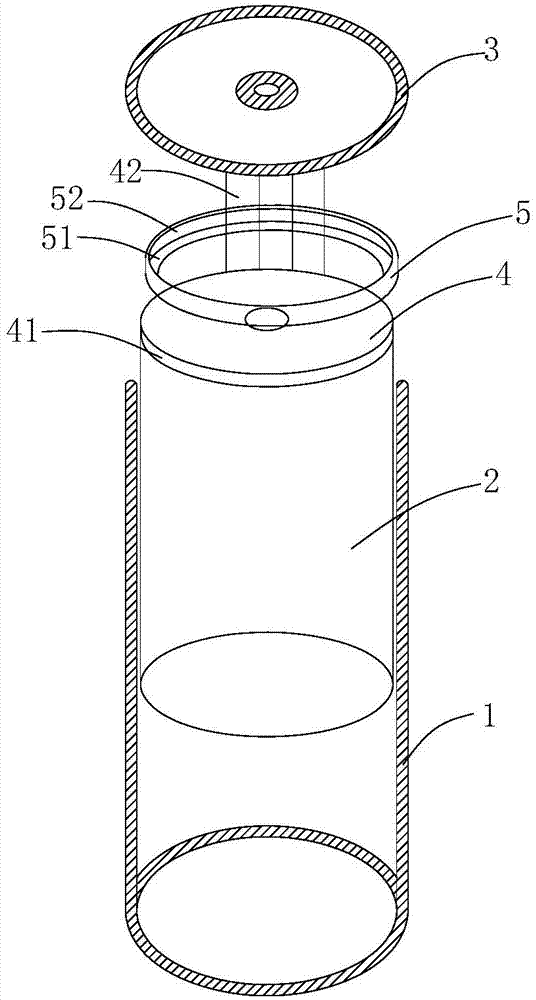

Nickel-hydrogen battery and manufacturing method thereof

The invention relates to a technology of nickel-hydrogen battery and manufacturing method, which is applied in the manufacture of nickel storage battery, alkaline storage battery, secondary battery, etc., and can solve the problems of hindering the high-current discharge performance of the battery and the large internal resistance of the battery, so as to improve the high-current discharge performance, The effect of protecting the environment and improving the charging efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

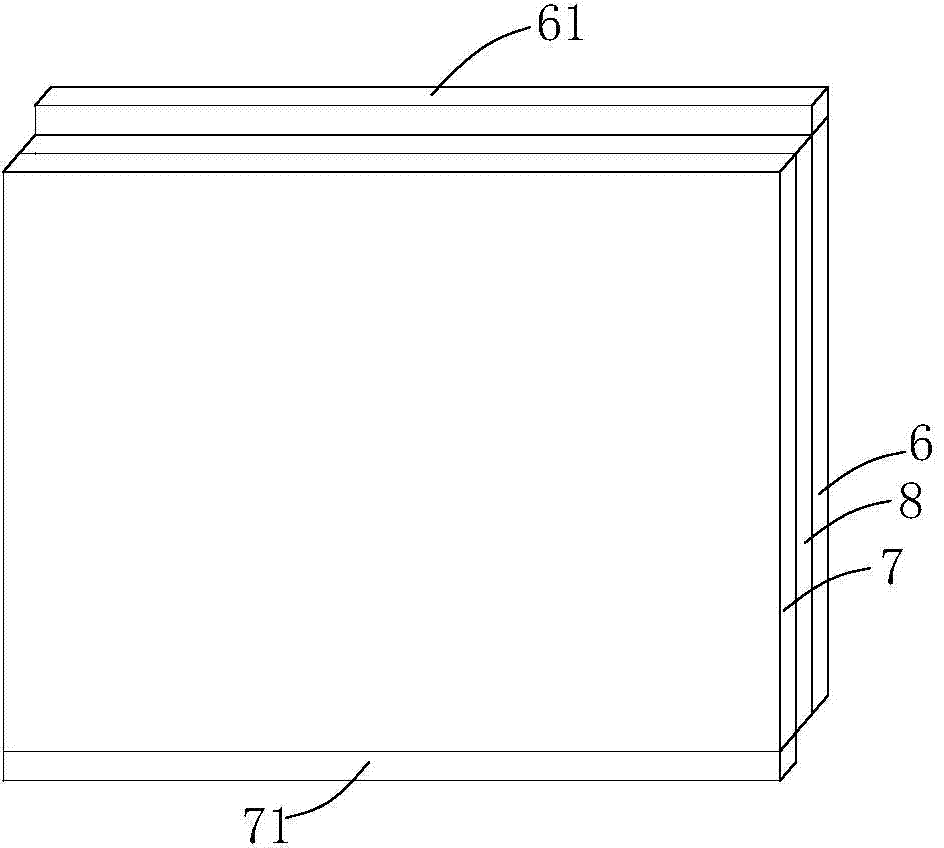

Embodiment 1

[0108] Hunan Jintianfu Cobalt Nickel is selected as the positive electrode active material, 89 wide nickel foam is selected as the positive electrode substrate, and a groove is pressed in the middle part of the whole 89 wide nickel foam to form a reserved non-coated positive electrode material cropping area. Then, except for the cutting area, the positive electrode material is evenly coated on the whole piece of 89 wide foamed nickel, and the whole piece of 89 wide foamed nickel is pressed. Finally, from the middle part of the reserved area not coated with positive electrode material, the pressed whole piece of 89 wide foamed nickel is divided into two, so as to obtain two positive plates made of 89 wide nickel foamed at one time, and Both positive electrode sheets are formed with edge portions; cobalt-coated nickel, calcium oxide, yttrium oxide and polytetrafluoroethylene are mixed uniformly with 90, 3, 1 and 3 parts by weight respectively to obtain 6.55g positive electrode m...

Embodiment 2

[0111] Example 2: AA1500 conventional Ni-MH battery

[0112] Hunan Jintianfu Cobalt Nickel is selected as the positive electrode active material, 89 wide nickel foam is selected as the positive electrode substrate, and a groove is pressed in the middle part of the whole 89 wide nickel foam to form a reserved non-coated positive electrode material cropping area. Then, except for the cutting area, the positive electrode material is evenly coated on the whole piece of 89 wide foamed nickel, and the whole piece of 89 wide foamed nickel is pressed. Finally, from the middle part of the reserved area not coated with positive electrode material, the pressed whole piece of 89 wide foamed nickel is divided into two, so as to obtain two positive plates made of 89 wide nickel foamed at one time, and Both positive electrode sheets are formed with edge portions; cobalt-coated nickel, calcium oxide, yttrium oxide and polytetrafluoroethylene are mixed uniformly with 98, 2, 3 and 2 parts by w...

Embodiment 3

[0115] Example 3: D9000 conventional Ni-MH battery

[0116] Hunan Jintianfu Cobalt Nickel is selected as the positive electrode active material, 99 wide nickel foam is selected as the positive electrode substrate, and a groove is pressed in the middle part of the whole 99 wide nickel foam to form a reserved non-coated positive electrode material cropping area. Then, except for the cutting area, the positive electrode material is evenly coated on the whole piece of 99 wide foamed nickel, and the whole piece of 99 wide foamed nickel is pressed. Finally, from the middle part of the reserved area where the positive electrode material is not coated, the pressed whole piece of 99 wide foamed nickel is divided into two, so as to obtain two positive plates made of 99 wide nickel foamed at one time, and Both positive electrode sheets are formed with edge portions; cobalt-coated nickel, calcium oxide, yttrium oxide and polytetrafluoroethylene are mixed uniformly with 80, 1, 1 and 3 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com