Under-voltage protection method of high-voltage half-bridge driving chip and high-voltage half-bridge circuit

A half-bridge drive chip and half-bridge drive technology, which are applied in the undervoltage protection of high-voltage half-bridge drive chips and high-voltage half-bridge circuits, can solve the problems of being unable to do so, wasting the power of the bootstrap capacitor, and reducing the charging efficiency of the bootstrap capacitor, etc. problems, to achieve the effect of improving charging efficiency and reducing complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

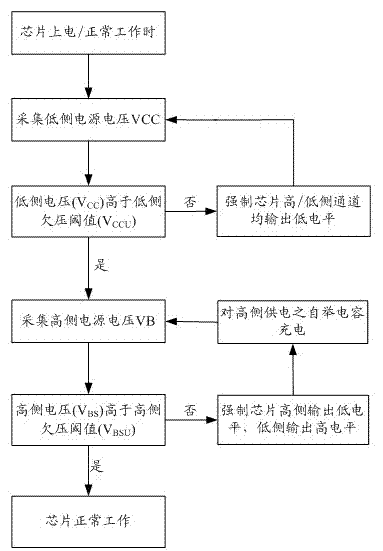

[0033] An undervoltage protection method for a high-voltage half-bridge driver chip, comprising the following steps:

[0034] S1) Power on the high-voltage half-bridge driver chip, so that the high-voltage half-bridge driver chip is in a working state,

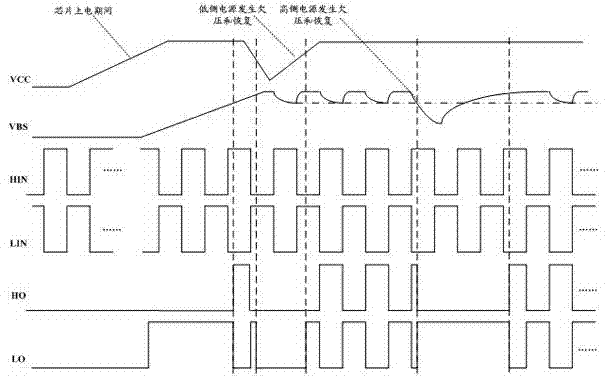

[0035] S2) Collect the low-side power supply voltage VCC. If the low-side power supply voltage VCC is lower than the set low-side undervoltage threshold, and the low-side undervoltage threshold is VCCU, the high-side channel and low-side channel of the high-voltage half-bridge are forced to drive the chip. All channels output zero level, thereby turning off the upper power transistor M1 and the lower power transistor M2 in the half bridge driven by the high-voltage half-bridge driver chip. If the low-side power supply voltage is higher than the low-side undervoltage threshold, the following one is performed: step;

[0036] S3) Collect the high-side power supply voltage VB, and compare the high-side power supply voltage and th...

Embodiment 2

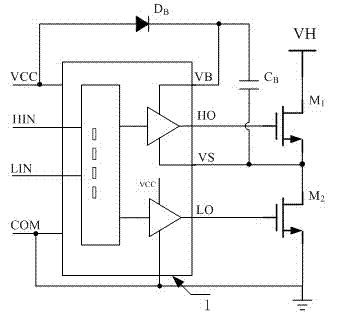

[0039] A high-voltage half-bridge circuit, comprising a high-voltage half-bridge drive circuit 1, the high-side output terminal HO and the low-side output terminal LO of the high-voltage half-bridge drive circuit 1 are respectively connected with an upper power tube M1 and a lower power tube M2, and the high-side The output terminal HO and the low-side output terminal LO are respectively connected to the gate terminals of the upper power transistor M1 and the lower power transistor M2, and the source terminal of the upper power transistor M1 and the drain terminal of the lower power transistor M2 are connected and connected to the high-voltage half-bridge drive circuit The high-side ground VS of 1 is connected, the drain terminal of the upper power transistor M1 is connected to the bus voltage VH, the source terminal of the lower power transistor M2 is connected to the low-side ground COM, and the low-side power supply terminal VCC of the high-voltage half-bridge drive circuit 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com