Patents

Literature

229results about How to "High initial capacity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

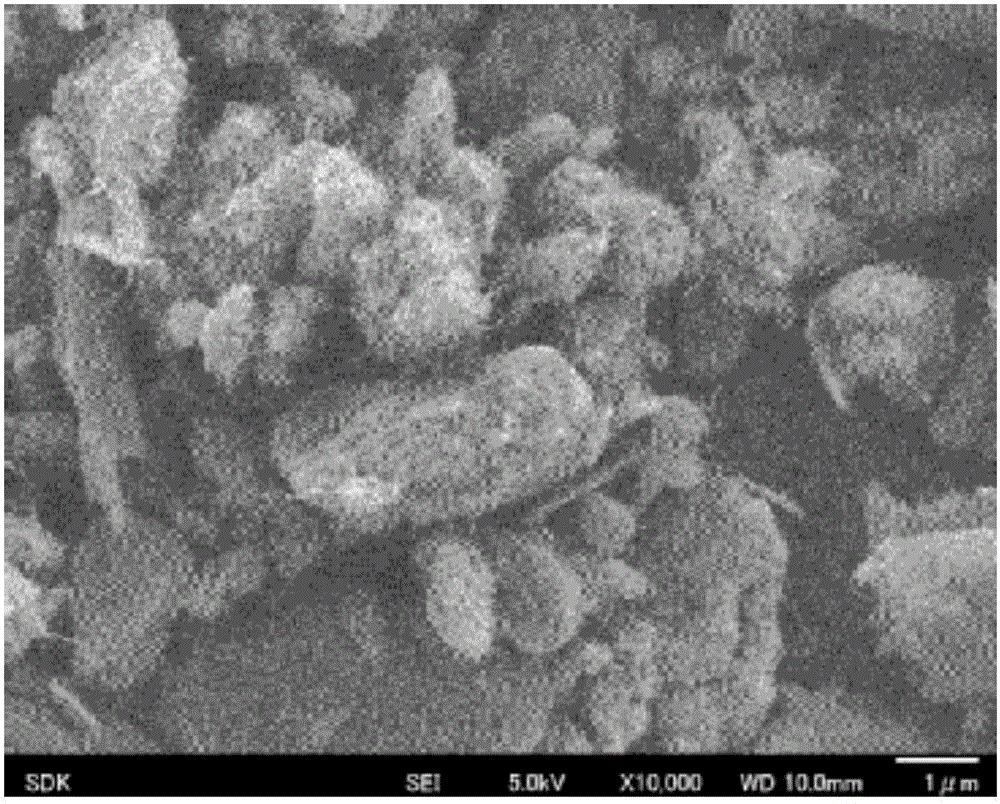

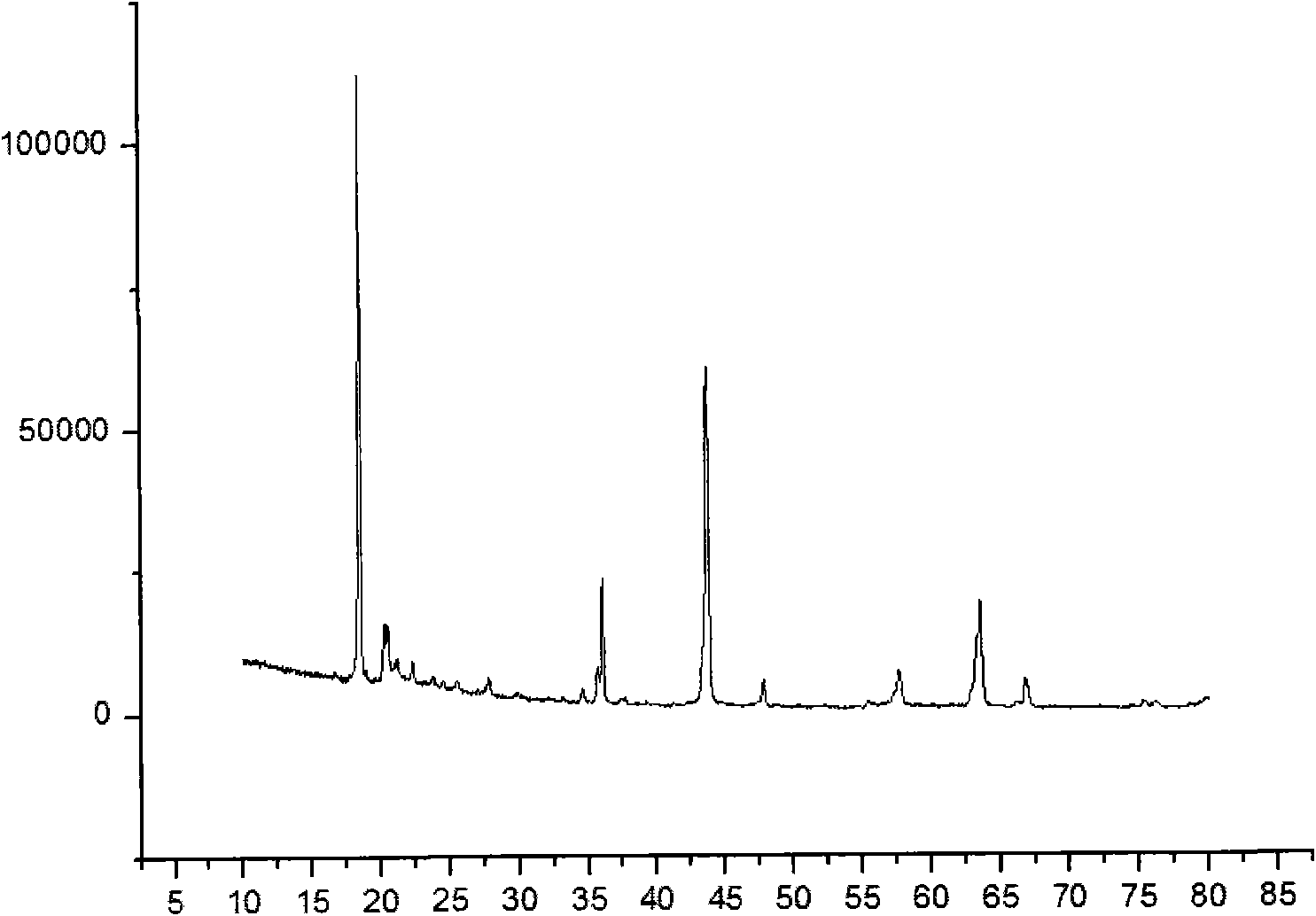

Negative active material for rechargeable lithium battery, and method of preparing the same

ActiveUS20090075173A1High initial capacityImprove initial efficiencyMaterial nanotechnologyElectrode thermal treatmentFree energiesEngineering

An negative active material for a rechargeable lithium battery includes a nano-composite including a Si phase, a SiO2 phase, and a metal oxide phase of formulation MyO, where M is a metal with an oxidation number x, a free energy of oxygen-bond formation ranging from −900 kJ / mol to −2000 kJ / mol, x, and x·y=2. The negative active material for a rechargeable lithium battery according to the present invention can improve initial capacity, initial efficiency, and cycle-life characteristics by suppressing its initial irreversible reaction.

Owner:SAMSUNG SDI CO LTD +1

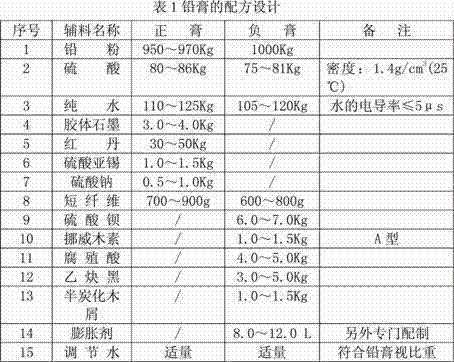

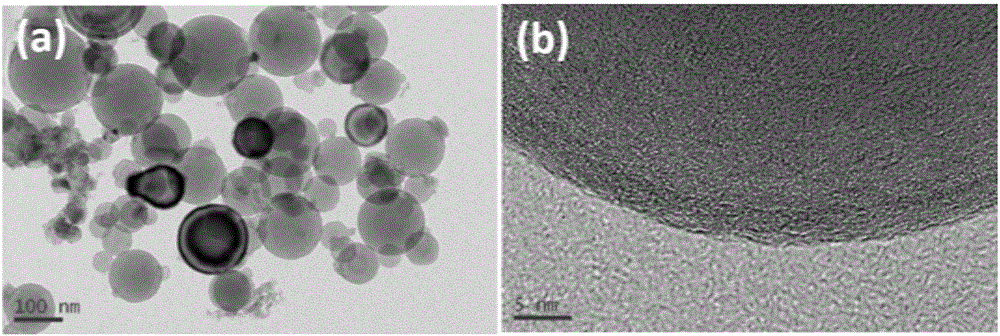

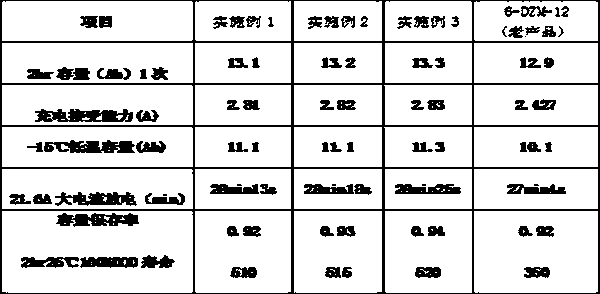

Positive lead plaster for lead-acid storage battery and preparation method of positive lead plaster

ActiveCN103762358APromote formationReduce the difficulty of formationCell electrodesPolyesterSulfuric acid

The invention discloses positive lead plaster for a lead-acid storage battery and a preparation method of the positive lead plaster. The positive lead plaster is characterized by consisting of the following raw materials by weight percent: 7 to 10 percent of 1.4g / ml dilute sulfuric acid, 8 to 12 percent of deionized water, 5 to 20 percent of red lead, 0.1 to 0.4 percent of colloid graphite, 0.1 to 0.3 percent of stannous sulfate, 0.1 to 0.3 percent of anhydrous sodium sulfate, 0.2 to 0.5 percent of 4BS, 0.1 to 0.3 percent of diantimony trioxide, 0.05 to 0.2 percent of polyester short fibers, and the balance being lead powder. After the lead plaster which is prepared by utilizing the formula and the preparation method is prepared into the storage battery, the storage battery has the characteristics of high primary capacity, long service life, good low-temperature performance and good charging capacity.

Owner:江苏海宝电池科技有限公司

Formula and preparation method of high energy storage lead-acid battery lead paste

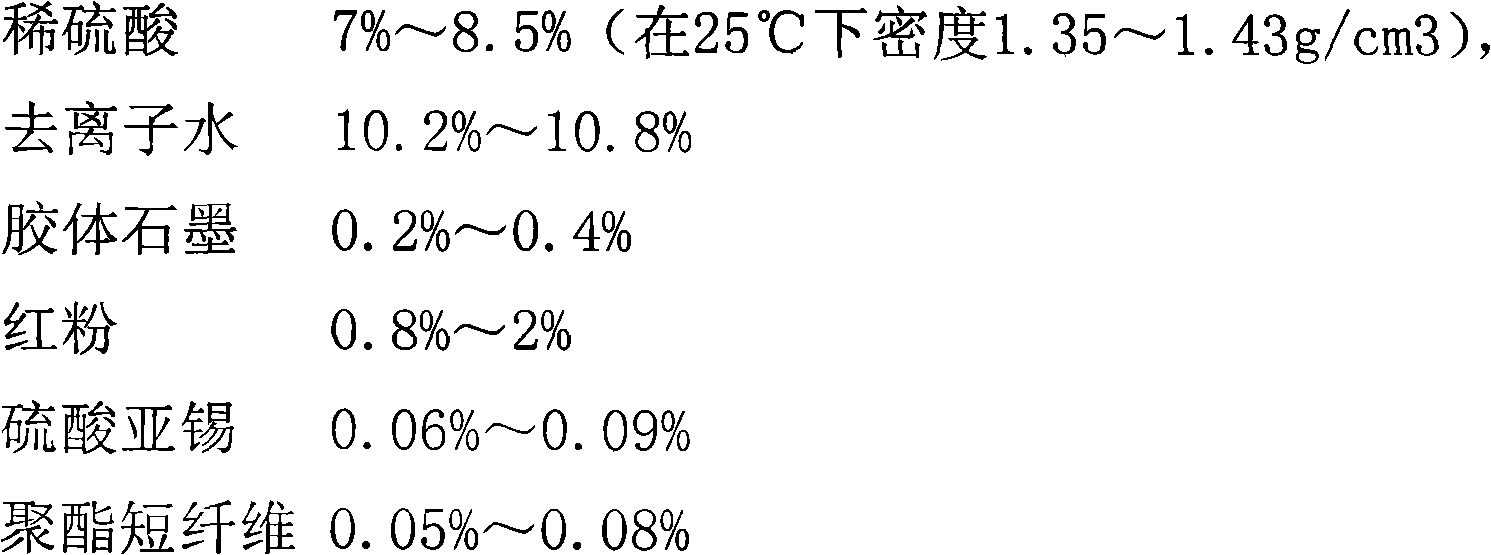

ActiveCN102354751AImprove charging efficiencyHigh initial capacityLead-acid accumulator electrodesFiberPolyester

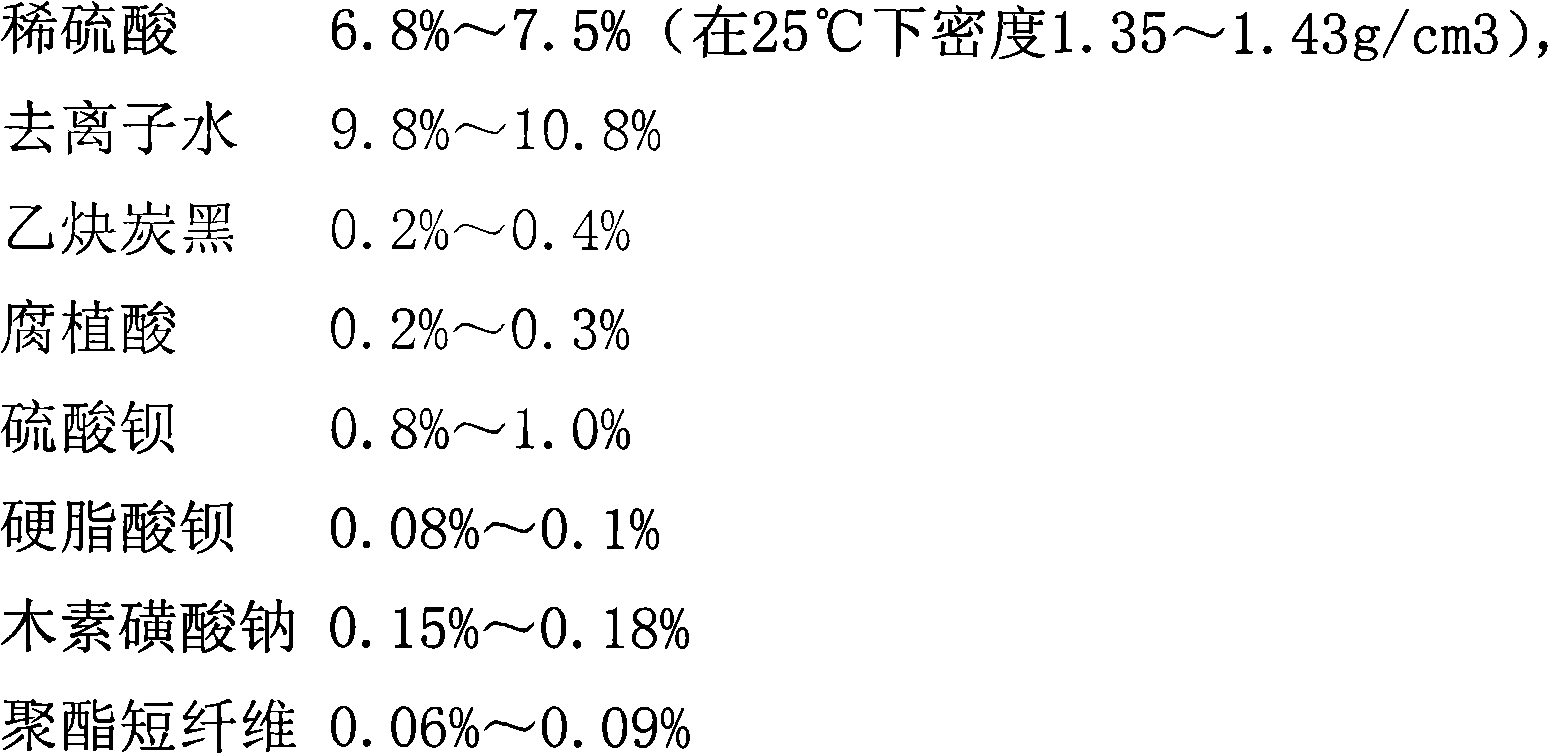

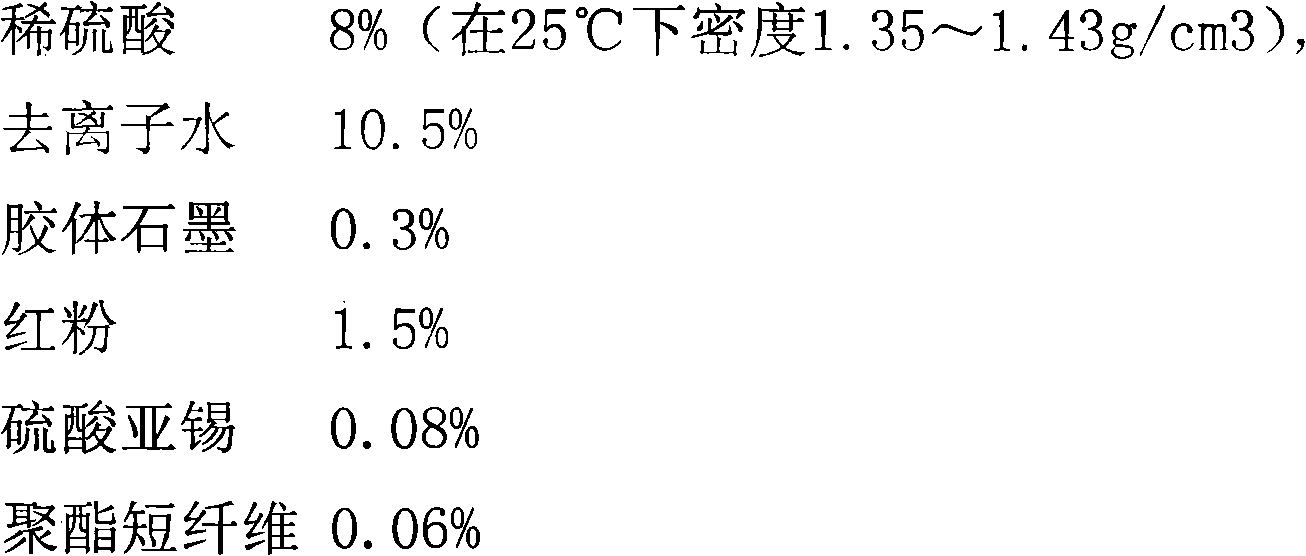

The invention provides a formula and preparation method of a high energy storage lead-acid battery lead paste and relates to the technical field of lead-acid batteries. The formula of a positive plate lead paste comprises the following raw materials: 7-8.5% of dilute sulphuric acid, 10.2-10.8% of deionized water, 0.2-0.4% of colloidal graphite, 0.8-2% of red powder, 0.06-0.09% of stannous sulfate, 0.05-0.08% of polyester staple fiber and the balance of lead powder; the formula of a negative plate lead paste comprises the following raw materials: 6.8-7.5% of dilute sulphuric acid, 9.8-10.8% of deionized water, 0.2-0.4% of acetylene black, 0.2-0.3% of humic acid, 0.8-1.0% of barium sulfate, 0.08-0.1% of barium stearate, 0.15-0.18% of sodium lignosulphonate, 0.06-0.09% of polyester staple fiber and the balance of lead powder. The battery prepared by the lead paste has the advantages of high initial capacity and long cycle life; and the overdischarge resistance and charge acceptance of the battery are higher than the standard requirements.

Owner:TIANNENG BATTERY GROUP +4

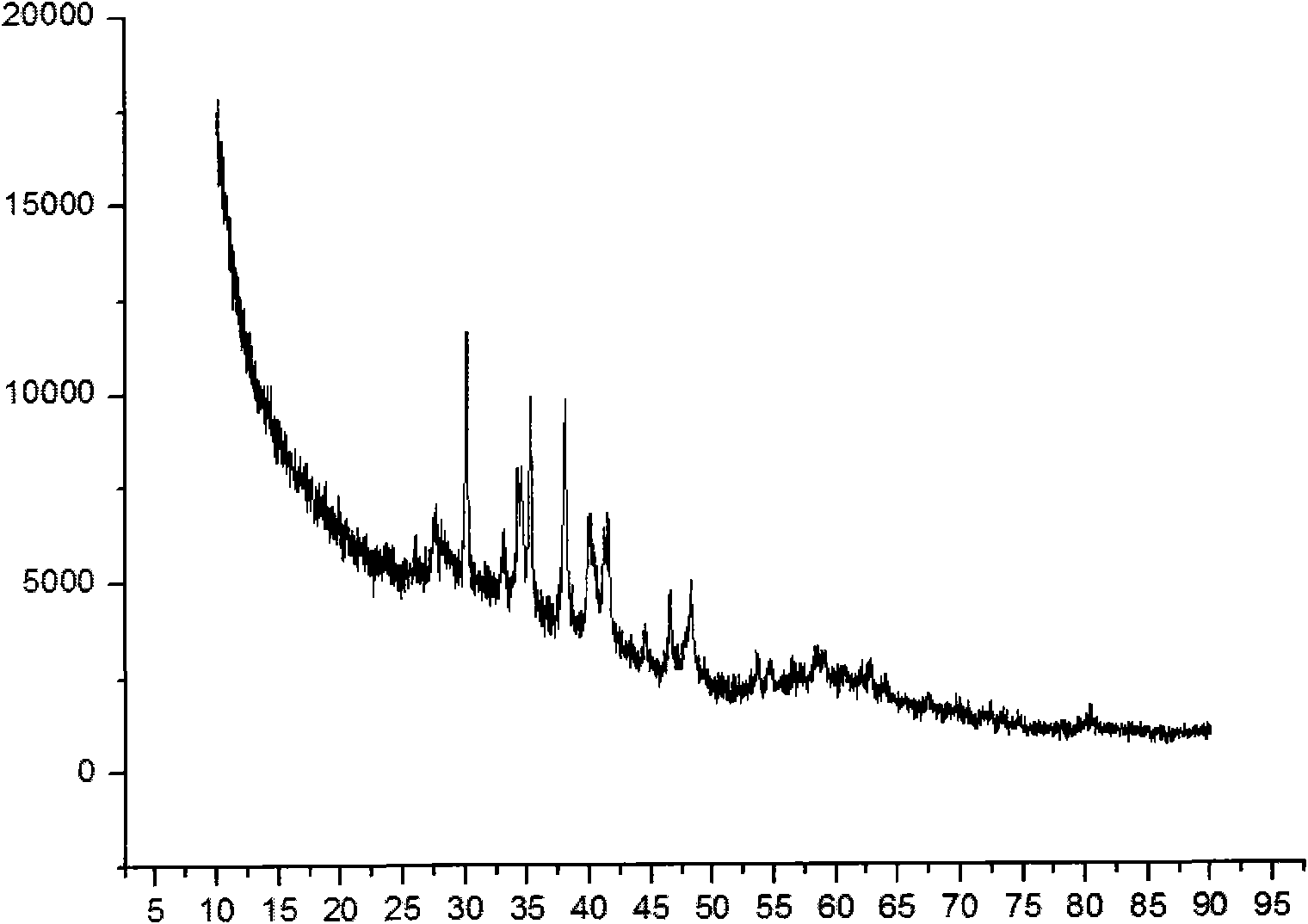

Negative active material for rechargeable lithium battery, and method of preparing the same

InactiveUS20090136847A1High initial capacityImprove initial efficiencyMaterial nanotechnologyActive material electrodesMaterials scienceLithium battery

A negative active material for a rechargeable lithium battery with a composite phase particle has a chemical formula, SiOx, where 0<x<1. The material comprises a first crystalline phase of Si nano-grains, and a second phase of non-crystalline SiO2, where the composite phase particle has a Si-phase peak of 150 to 480 cm−1 according to Raman spectroscopic analysis.

Owner:SAMSUNG SDI CO LTD +1

Method for internal chemical reaction in battery via charging five times and discharging four times

ActiveCN102437380AReduce the temperatureEnsure the amount of acidFinal product manufactureSecondary cells charging/dischargingSulfuric acidElectrical and Electronics engineering

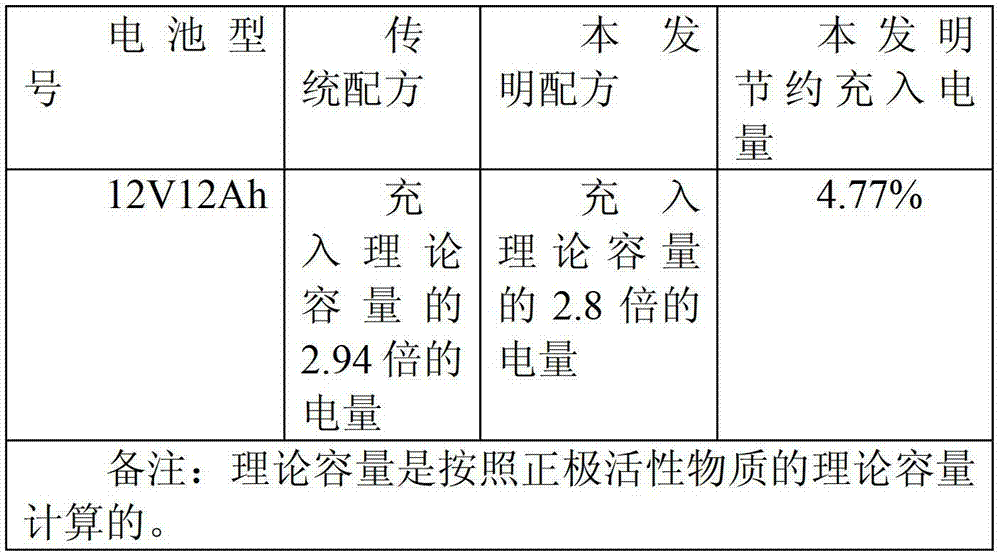

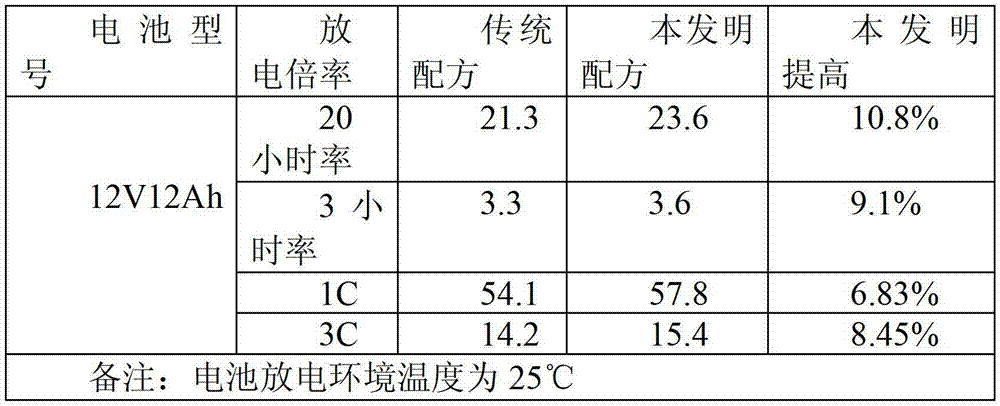

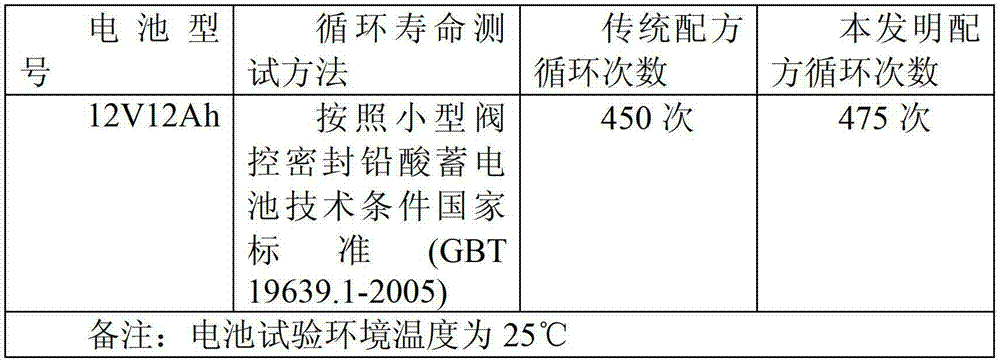

The invention discloses a method for internal chemical reaction in a battery via charging five times and discharging four times, belonging to the technical field of a battery. The battery is of a 12V12Ah type. The method adopts nine stages with charging five times and discharging four times, and comprises the following steps: immediately placing the battery in cooling water for cooling after acid is added, keeping the battery static for 2 plus 0.5 hours so that pole plates and separators are completely impregnated in sulfuric acid, powering for chemical reaction when the temperature of the battery is reduced to 30-40 DEG C, controlling the water temperature during the chemical reaction so that the temperature of the chemical reaction is no higher than 50 DEG C, starting the internal chemical reaction of the battery, charging a plurality of times with alternating current during the internal chemical reaction, and keeping the battery static for a certain period each time after charging. When the internal chemical reaction in the method is adopted for the battery, the initial capacity of the battery can be increased by 4.1-9.1 percent, the rate of utilization of active substances of the battery can also be increased, and the difference of PbO2 contents inside and outside the finished pole plates can be reduced from 17.1 percent to 5.6-7.6 percent after charging.

Owner:HENAN CHAOWEI POWER SUPPLY

Lead plaster for low temperature resistant lead storage battery for electric scooter and preparation method of lead plaster

ActiveCN103779557AInhibition of \"shrinkage\"Inhibit \"passivation\"Cell electrodesFiberElectrical battery

The invention relates to a lead plaster for a low temperature resistant lead storage battery for an electric scooter and a preparation method of the lead plaster. The lead plaster comprises an anode lead plaster and a cathode lead plaster, wherein the anode lead plaster comprises the following components in parts by weight: 950-970 parts of lead powder, 80-86 parts of 1.3-1.4g / cm<3> sulfuric acid, 110-125 parts of pure water, 3.0-4.0 parts of colloidal graphite, 30-50 parts of red lead, 1.0-1.5 parts of tin sulfate, 0.5-1.0 part of sodium sulfate and 0.7-0.9 part of short fiber; the cathode lead plaster comprises the following components in parts by weight: 1000 parts of lead powder, 75-81 parts of 1.3-1.4g / cm<3> sulfuric acid, 105-120 parts of pure water, 0.6-0.8 part of short fiber, 6.0-7.0 parts of barium sulfate, 1.0-1.5 parts of Norway lignin, 4.0-5.0 parts of humic acid, 3.0-5.0 parts of acetylene black and 1.0-1.5 parts of semi-carbonized saw dust. According to the lead plaster and the preparation method thereof, the acceptance performance when the battery is charged at low temperature is improved and the discharge capacity is increased; the lead plaster disclosed by the invention is applicable to low-temperature environment and is especially suitable for northeast and northwest regions in China.

Owner:河北超威电源有限公司

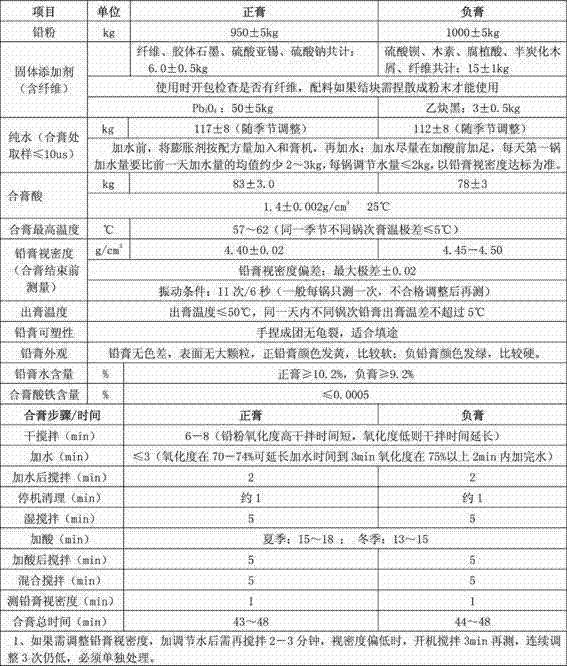

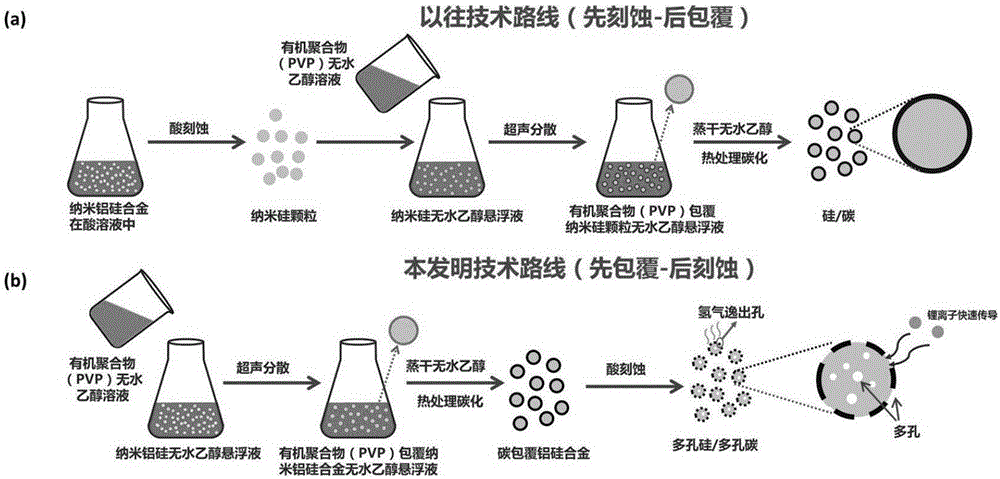

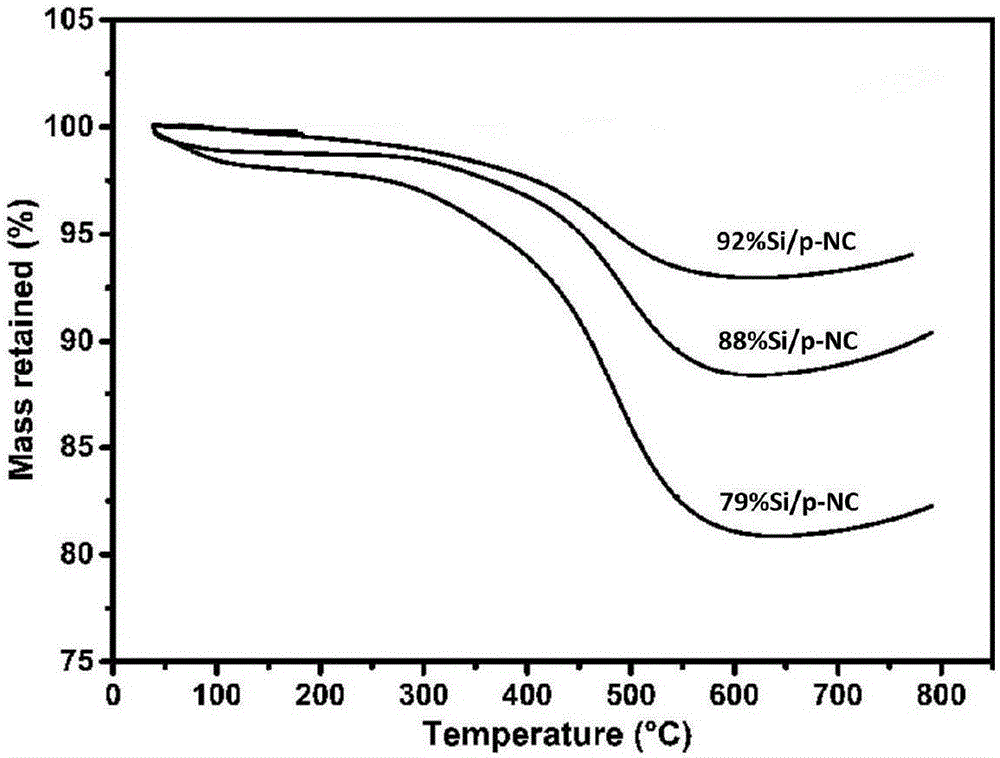

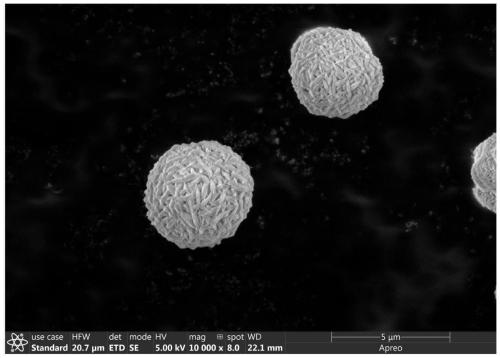

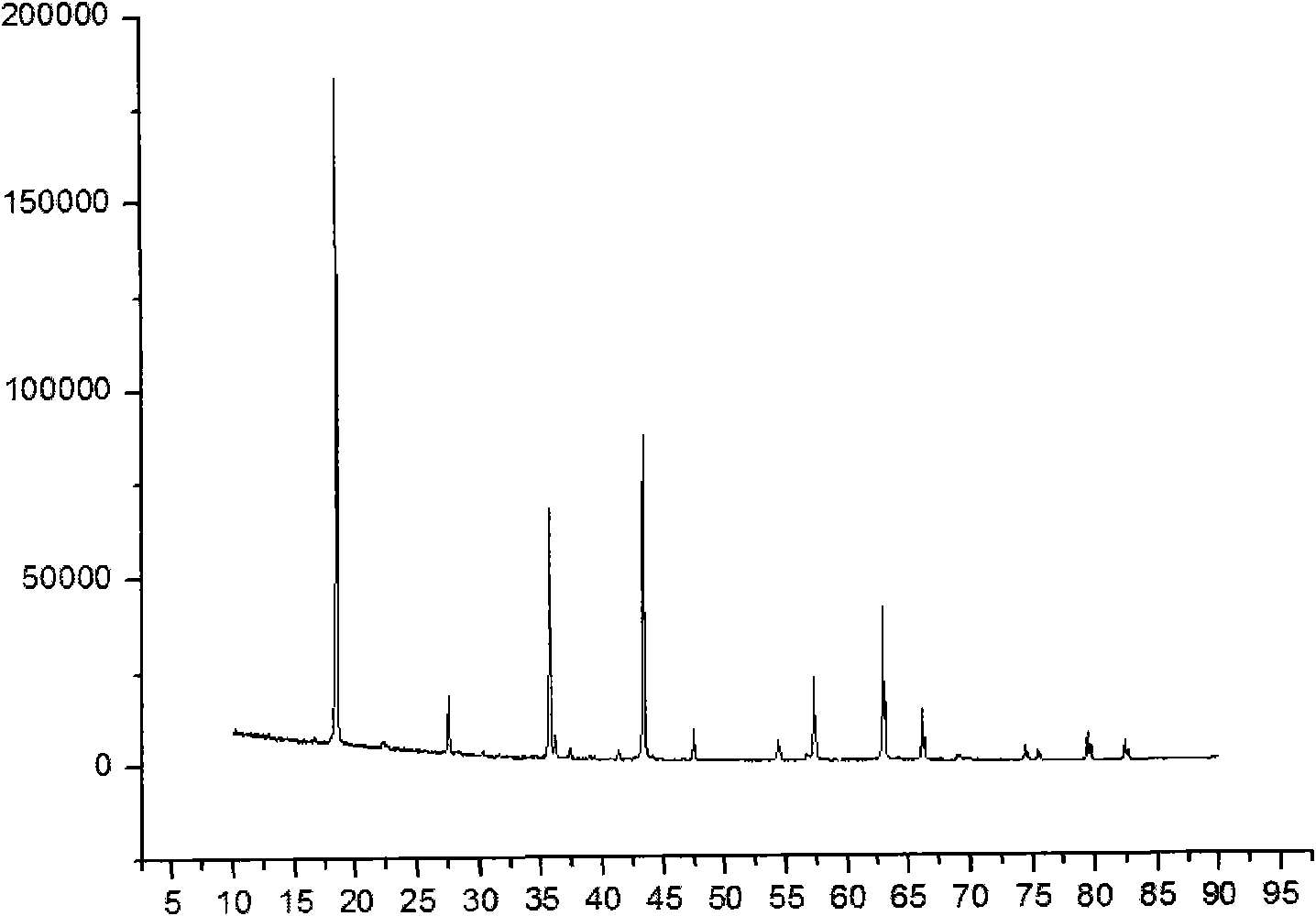

Nano silicon/porous carbon composite anode material of lithium ion batteries as well as preparation method and application of composite anode material

The invention discloses a nano silicon / porous carbon composite anode material of lithium ion batteries as well as a preparation method and an application of the composite anode material. The composite anode material is a core-shell structure material consisting of a porous nano silicon particle core and a porous carbon layer shell. The preparation method of the composite anode material comprises the steps as follows: carbonization treatment is performed after an organic polymer layer is coated on the surface of aluminum-silicon alloy powder, aluminum is removed by performing acid etching on a carbonization product, pore forming is performed on a carbon layer, and thus the nano silicon / porous carbon composite anode material is obtained. The preparation method is simple and low in cost, the mass production requirement is met, and the prepared composite anode material can be used for preparing the lithium ion battery and shows high capacity and excellent cycle and rate performance.

Owner:CENT SOUTH UNIV

Lead-acid storage battery lead paste and preparation method thereof

InactiveCN107230777AIncrease the speed of chargingIncrease the discharge speedLead-acid accumulator electrodesFiberPolyester

The invention discloses a lead-acid storage battery lead paste, comprising a positive lead paste and a negative lead paste, wherein the positive lead paste comprises the following components: regenerated lead powder, red lead, polytetrafluoroethylene, ultra-fine tetrabasic lead sulfate, sodium perborate, graphite, polyester staple fiber, glass fiber, antimonous oxide, dilute sulfuric acid and deionized water; and the negative lead paste comprises the following components: regenerated lead powder, red lead, barium sulfate, barium stearate, sodium lignosulfonate, humic acid, semi-carbonized wood chips, polyester staple fiber, modified graphene, dilute sulfuric acid and deionized water. According to the lead-acid storage battery lead paste disclosed by the invention, the problem of poor over-discharge performance and charge acceptance capability of a storage battery can be improved, and the service life of the storage battery can be prolonged.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

Electrode plate solidification technology for lead-acid battery

ActiveCN103943831AIncreased floating charge lifeHigh initial capacityElectrode thermal treatmentLead-acid accumulator electrodesFloating chargeThermal insulation

The invention relates to an electrode plate solidification technology for lead-acid battery. The solidification technology comprises a moisture retention phase, a thermal insulation solidification phase, and a drying phase. In the moisture retention phase, a low-temperature solidification treatment is carried out at first, the temperature in the low-temperature solidification treatment is 40 to 45 DEG C, then a high-temperature solidification treatment is carried out, and the temperature in the high temperature solidification treatment is 75 to 85 DEG C. In the thermal insulation solidification phase, the relative humidity is gradually reduced during the solidification process. Electrode plates that are produced through the solidification technology are assembled into batteries. The floating charging resistant performance of the battery is prominently improved, and thus the service life of the battery is prolonged. The primary capacity of the battery is large, and the service life is 5 years or more. The electrode plate solidification technology is an ideal solidification mode for lead-acid battery for communication.

Owner:CHAOWEI POWER CO LTD

Method for container formation of lead-acid storage battery

ActiveCN102983366AImprove cycle lifeHigh initial capacityFinal product manufactureSecondary cells charging/dischargingWater bathsPower flow

The invention discloses a method for container formation of a lead-acid storage battery. The method comprises the following steps of: placing a lead-acid storage battery filled with electrolyte into a circulating water bath, cooling to 40 DEG C below, conducting charging and discharging, wherein the specific charging and discharging processes include eight charging processes and two discharging processes. According to the method, by adding a second-stage and a fifth-stage charging currents, the charging efficiency is improved, the container formation time of the battery is shortened, and the initial-stage capacity and recycling life of the battery can also be increased and prolonged, so that the method has great significances for the production of the storage battery.

Owner:ZHEJIANG TIANNENG POWER ENERGY

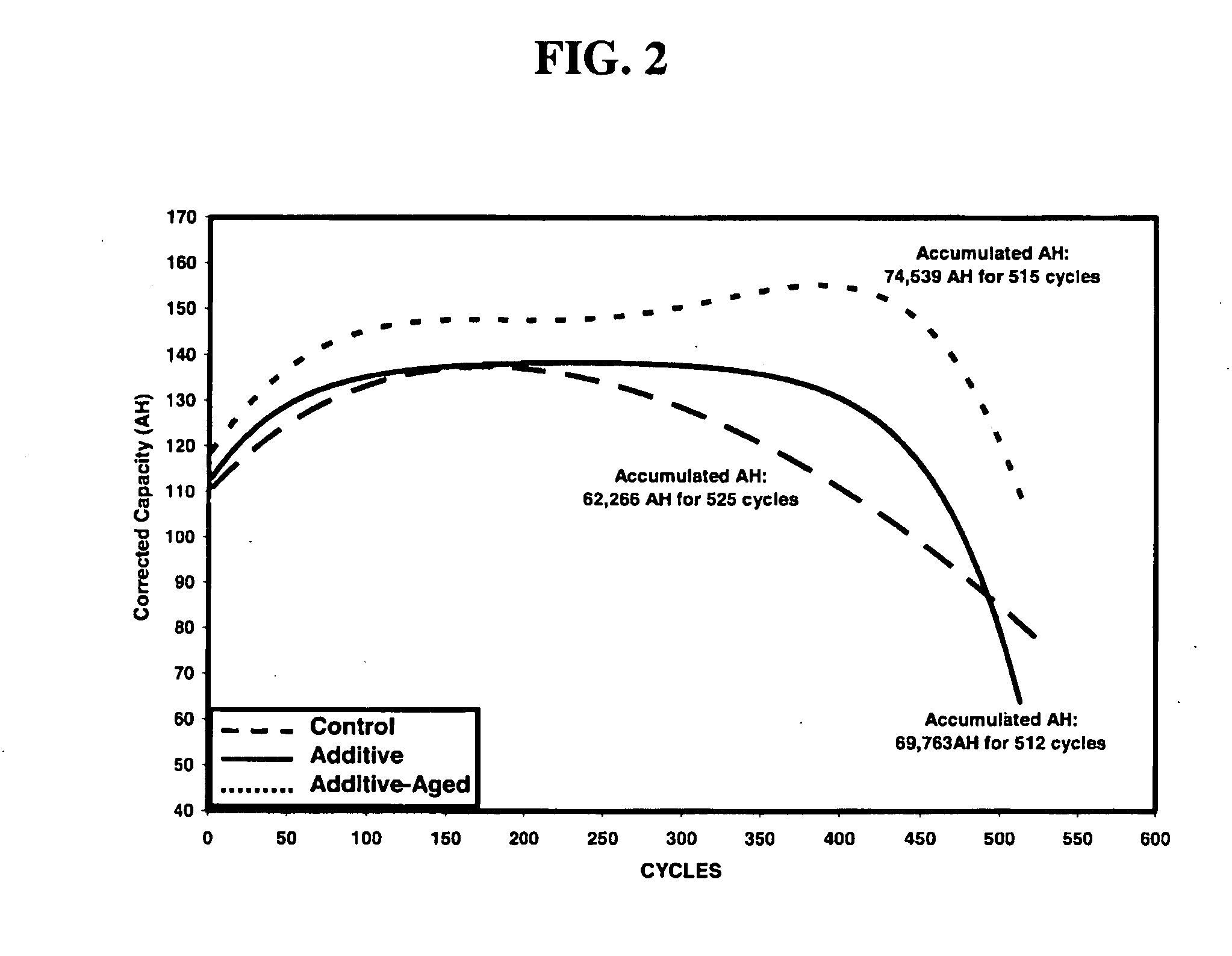

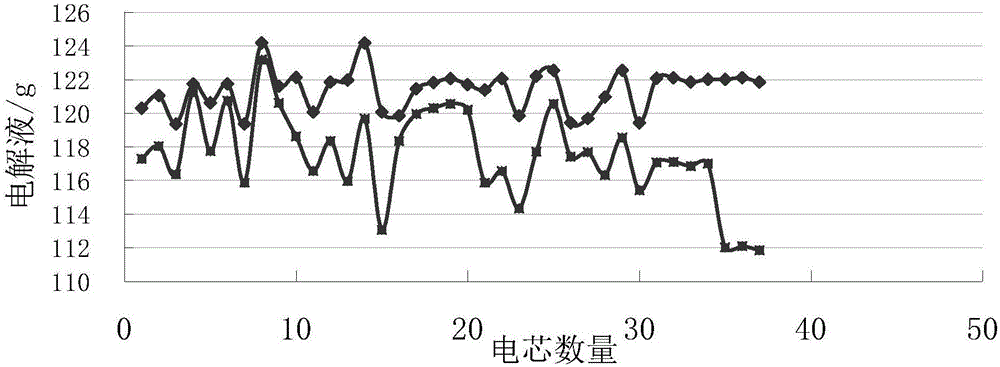

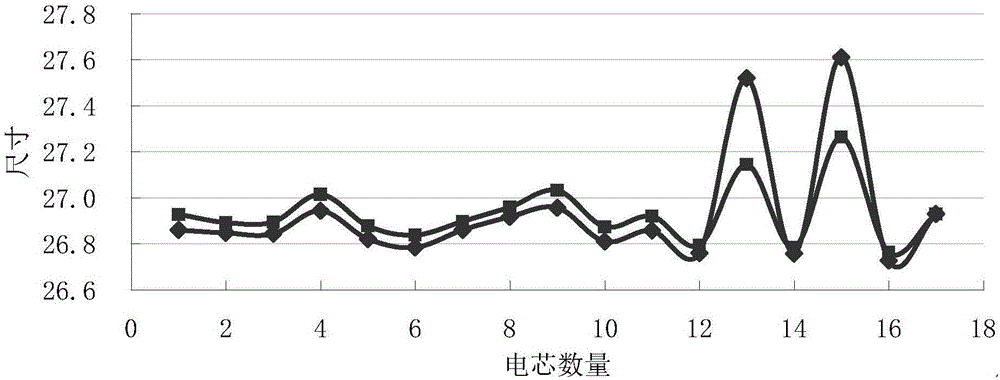

Matching and sorting method for lead-acid storage batteries

ActiveCN103560278AImprove cycle lifeImprove uniformitySecondary cells charging/dischargingLead-acid accumulators constructionState of artCharge discharge

The invention provides a matching and sorting method for lead-acid storage batteries and aims to solve the problems in the prior art that the consistency of storage batteries in a storage battery pack is poor and the service life is short. According to the matching and sorting method, sorted storage battery plates are assembled and sorted storage batteries with similar capacities and open-circuit voltage are matched to form one group by adopting a quantitative acid adding manner. The cycle life of the storage battery pack is obviously prolonged, the initial capacity of the storage battery pack is improved by 5%, and the charging receiving capability and the low-temperature performance of the storage battery pack are obviously enhanced. According to the matching and sorting method, the defects that the cycle life of the batteries is short and the consistency of the storage battery pack is poor are overcome; the batteries are suitable for being subjected to charge-discharge cycles under various environment temperatures so that the cycle life of the batteries is prolonged to be more than 500 times.

Owner:CHAOWEI POWER CO LTD

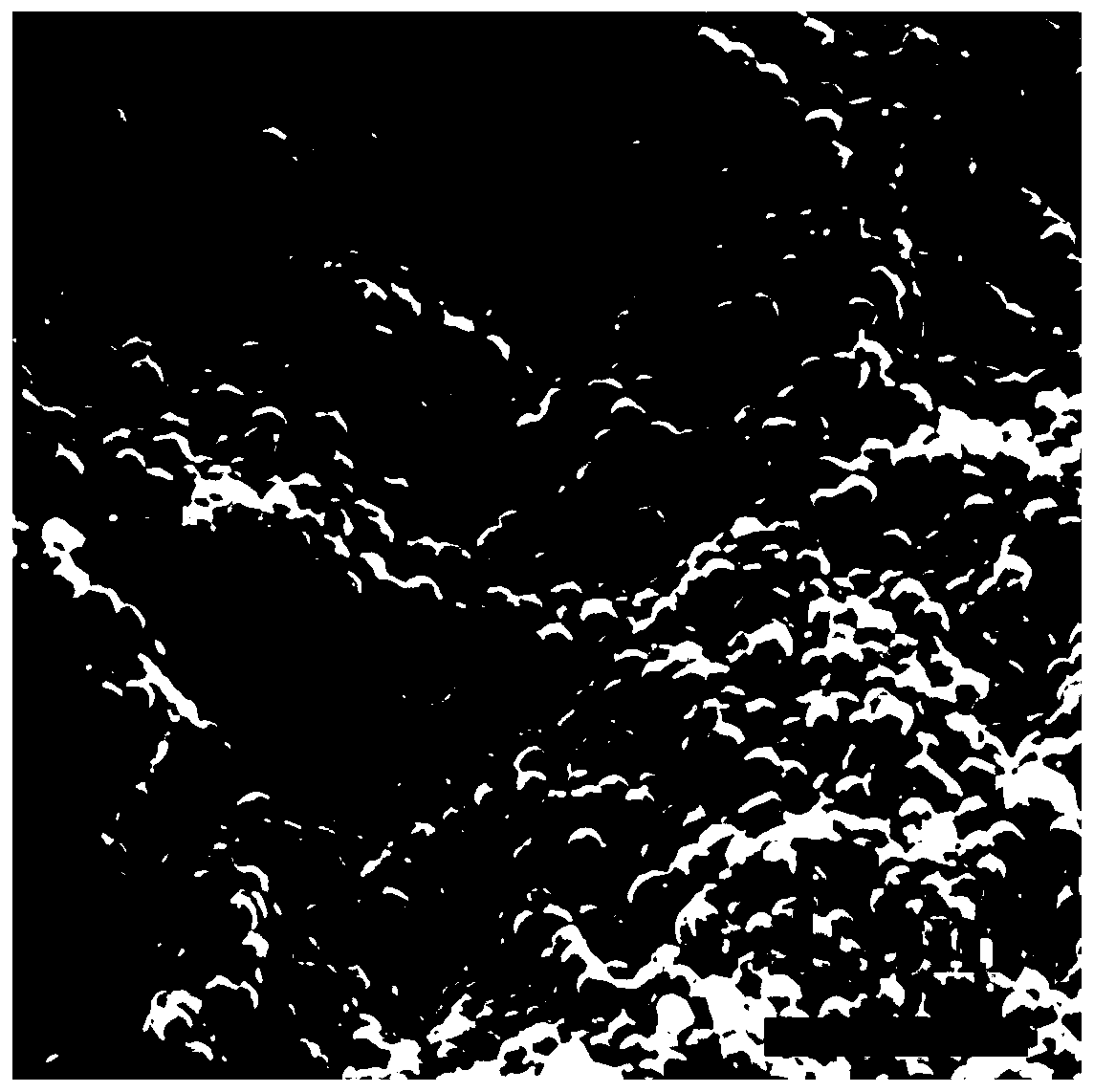

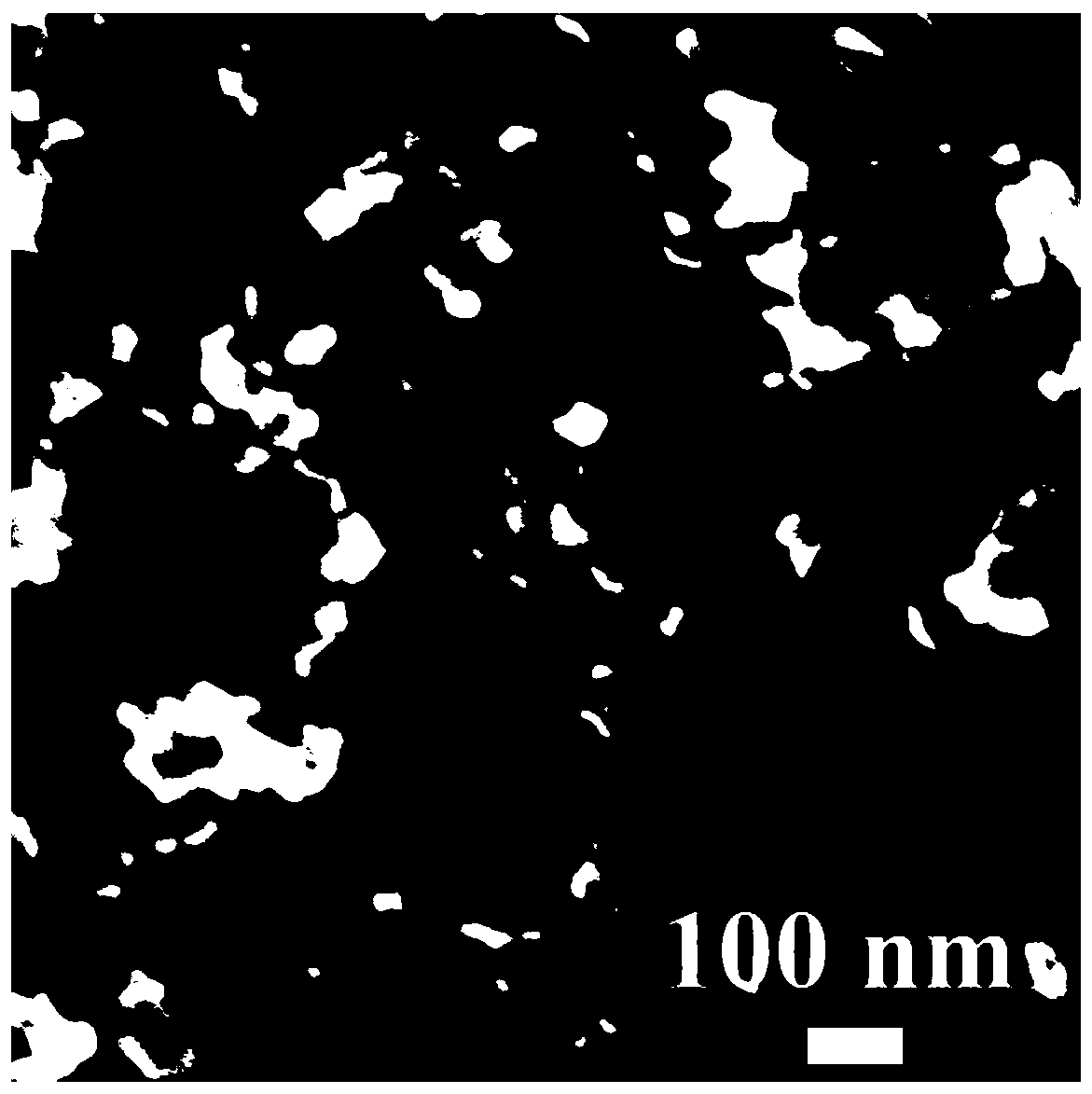

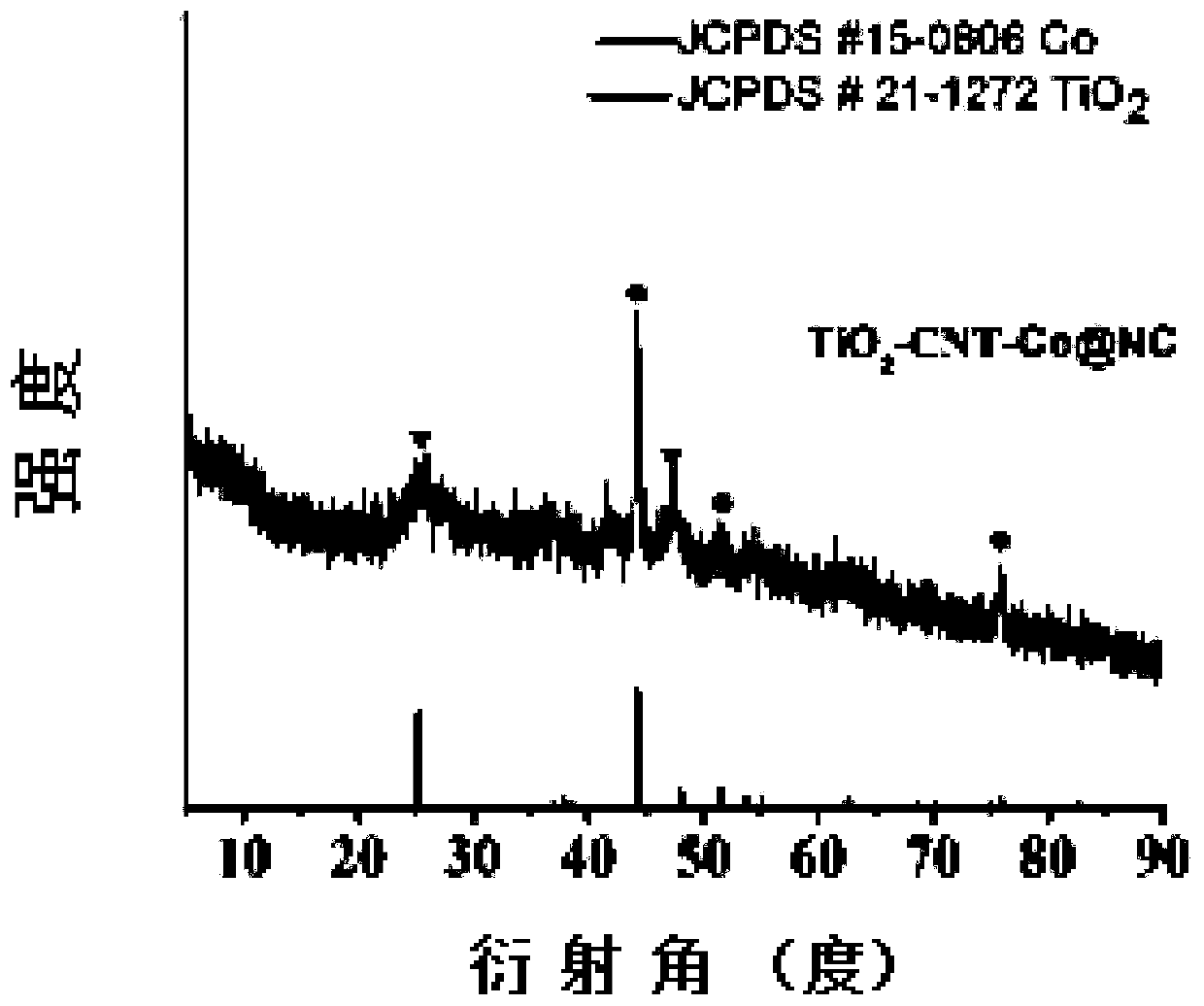

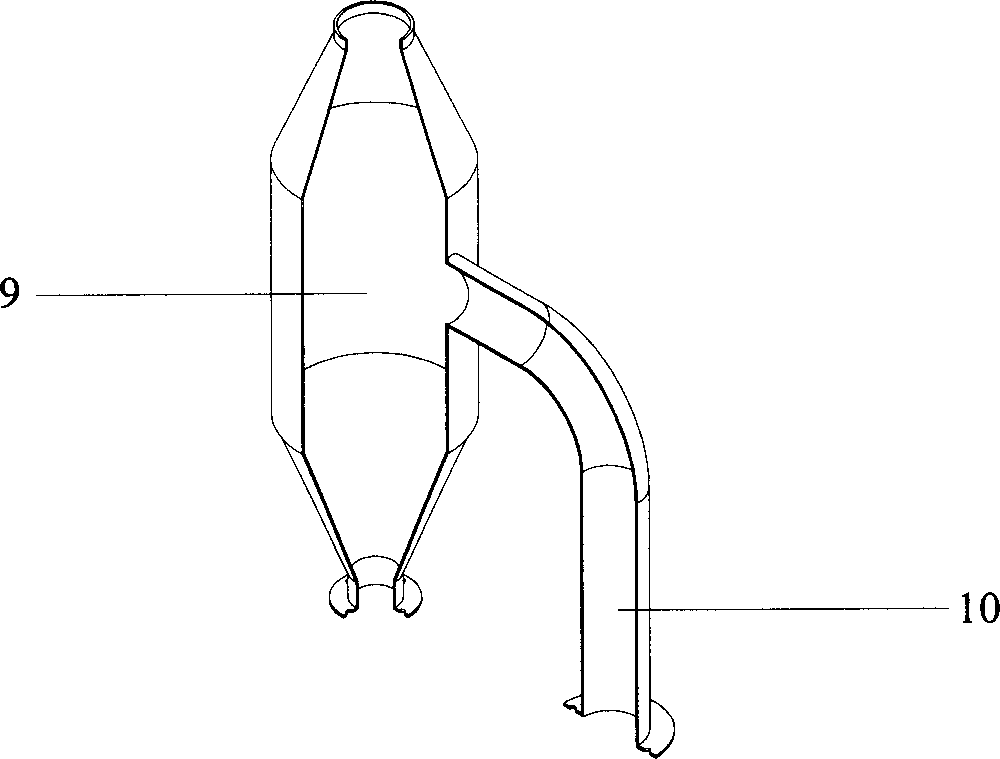

Method for preparing lithium-sulfur battery cathode material

ActiveCN110190262AHighlight substantiveImprove adsorption capacityPositive electrodesLi-accumulatorsMolecular sieveLithium–sulfur battery

The invention relates to a method for preparing a lithium-sulfur battery cathode material, which relates to an electrode consisting of active materials. The method comprises the following steps of: firstly, preparing a multi-metal imidazole type molecular sieve framework TiO2-Co-ZIF-8 growing in a three-dimensional ordered titanium dioxide framework, then obtaining cobalt nano-particles TiO2-CNT-Co@NC coated with porous N-doped carbon and serially loaded on the three-dimensional ordered titanium dioxide framework through in-situ growth, and compounding the nano-particles and the with sublimedsulfur powder to obtain the S / TiO2-CNT-Co@NC lithium-sulfur battery cathode material. The method for preparing a lithium-sulfur battery cathode material overcomes the defects of low utilization rate of active substances, poor conductivity and shuttle effect in the prepared cathode material of the lithium-sulfur battery in the prior art.

Owner:HEBEI UNIV OF TECH

Positive lead paste of lead-acid storage battery

The invention discloses a positive lead paste of a lead-acid storage battery. The positive lead paste is composed of the following raw materials by mass percent: 6.8-10% of 1.4 g / cm<3> sulfuric acid, 9-11% of de-ionized water, 5-16% of red lead, 0.05-0.06% of short fiber, 0.10-015% of carbon fibers, 0.1-0.3% of silicon dioxide, 0.1-0.4% of anisotropic graphite, 0.05-0.28% of stannous sulfate and the balance of lead powder. The positive lead paste of the lead-acid storage battery is characterized in that various positive active materials such as anisotropic graphite, stannous sulfate, silicon dioxide and red lead are added on the basis of a certain content of water and acids in the positive lead paste material so that the porosity of the positive plate is improved and the early-stage capacity and the vimetric specific energy of the lead-acid storage battery are enhanced; and as a result, the formation efficiency of batteries is improved.

Owner:CHAOWEI POWER CO LTD

Anode active material for lithium secondary battery and manufacturing method thereof

InactiveUS20050282070A1High initial capacityHigh reversible capacityElectrode manufacturing processesNitrogen-metal/silicon/boron binary compoundsSilicon nitrideIndium

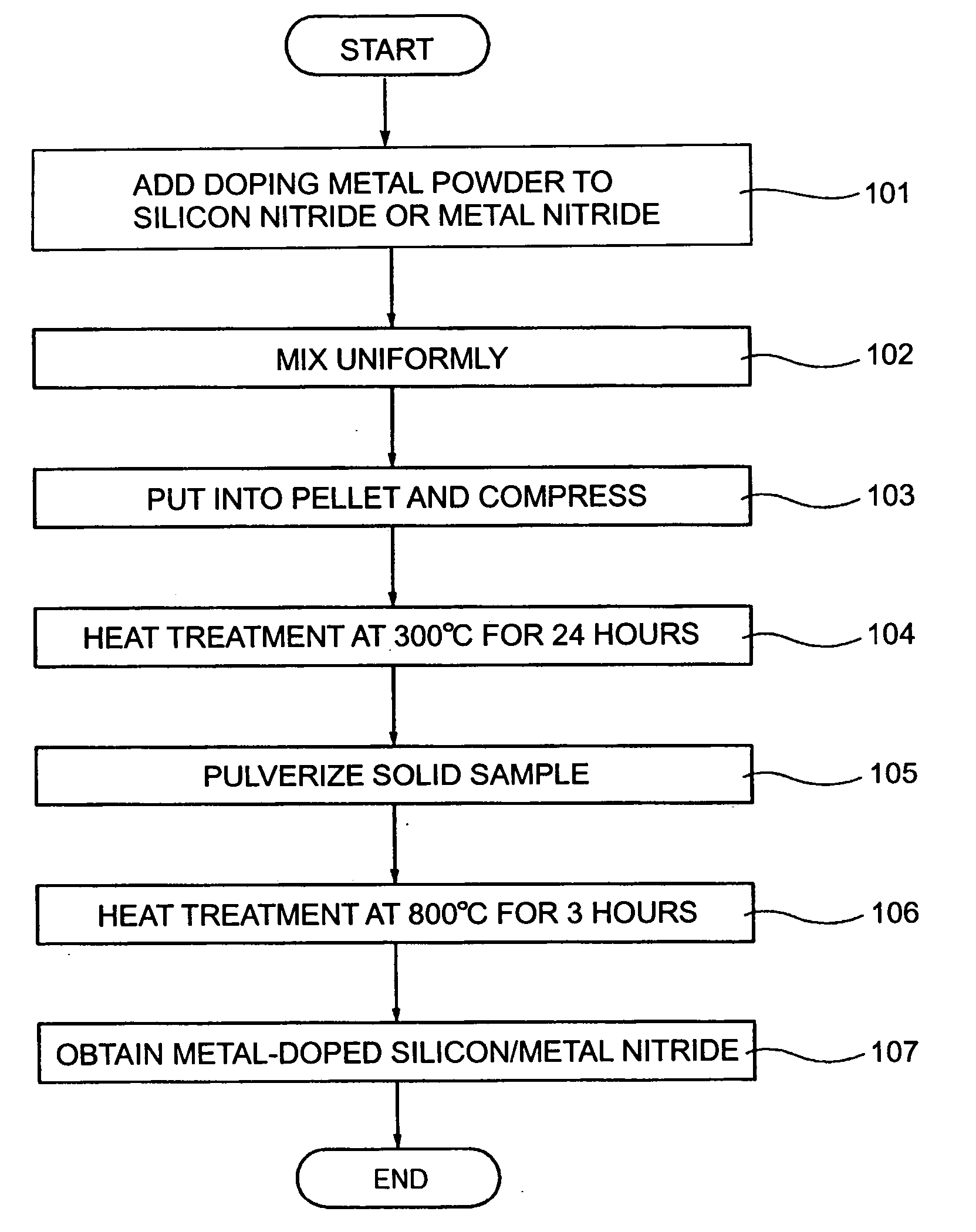

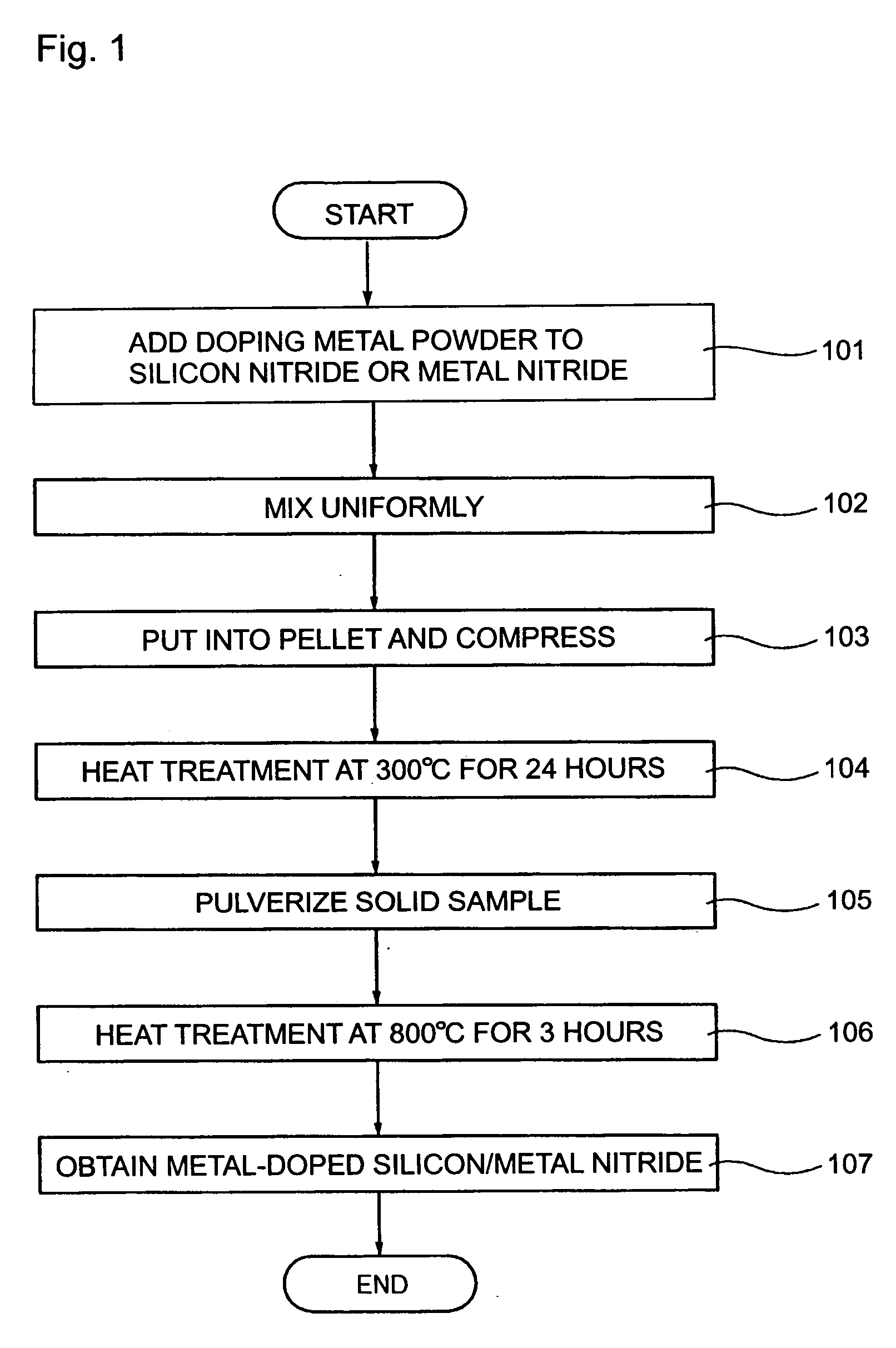

An anode active material for a lithium secondary battery, wherein a nitride compound containing silicon or metal such as copper, tin, germanium, indium and zinc is doped with second metal such as ferrum, cobalt, nickel and copper. To obtain the anode active material, a predetermined amount of metal nitride or silicon nitride is added to a second metal powder and then mixed uniformly. The mixture powder is filled into a container, and then a pressure is applied thereto to obtain a solid sample. The solid sample is heat-treated and pulverized into fine powder. The fine powder is heat-treated to obtain the metal nitride or the silicon nitride doped with the second metal.

Owner:KOREA ELECTROTECH RES INST

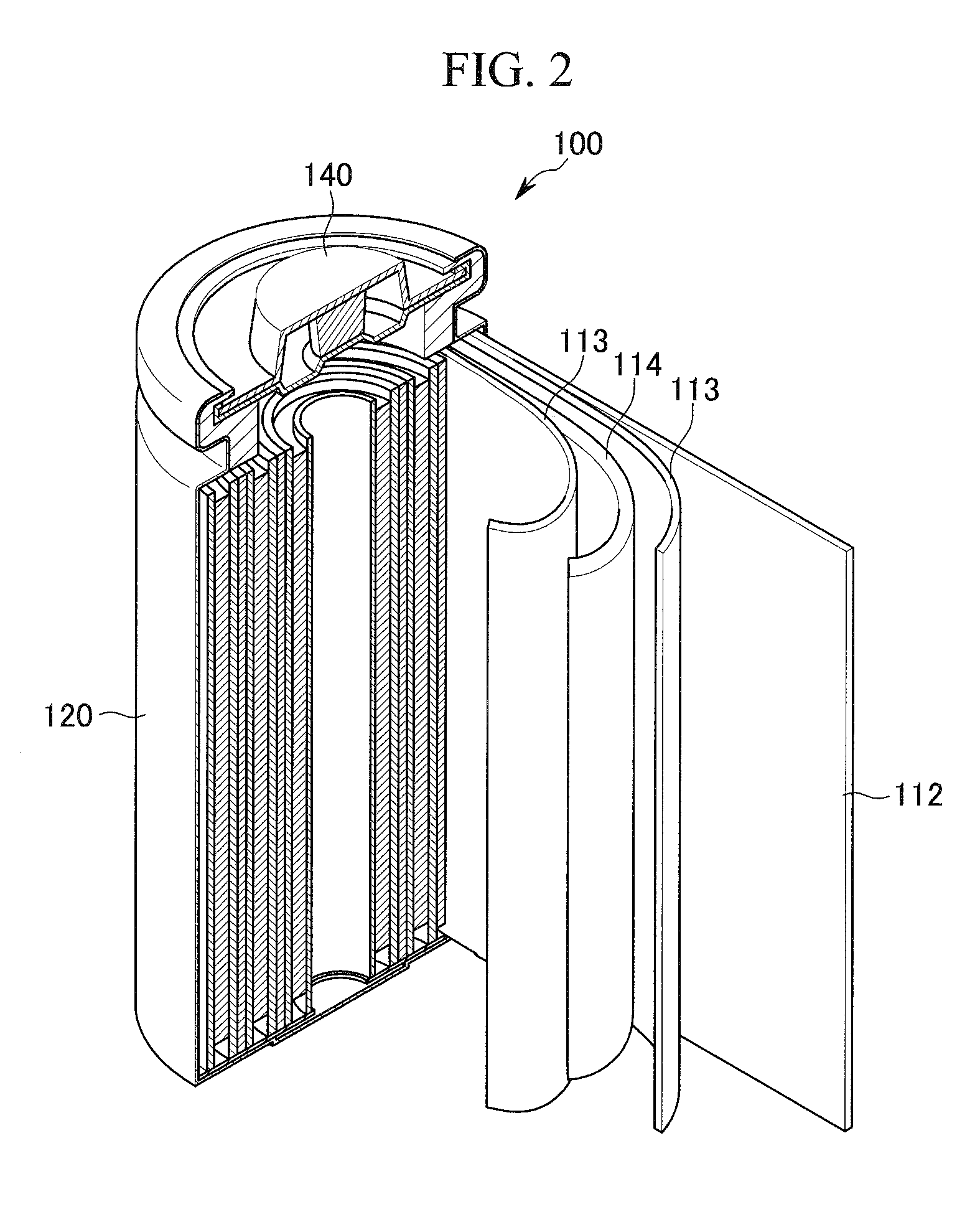

Lithium ion secondary battery

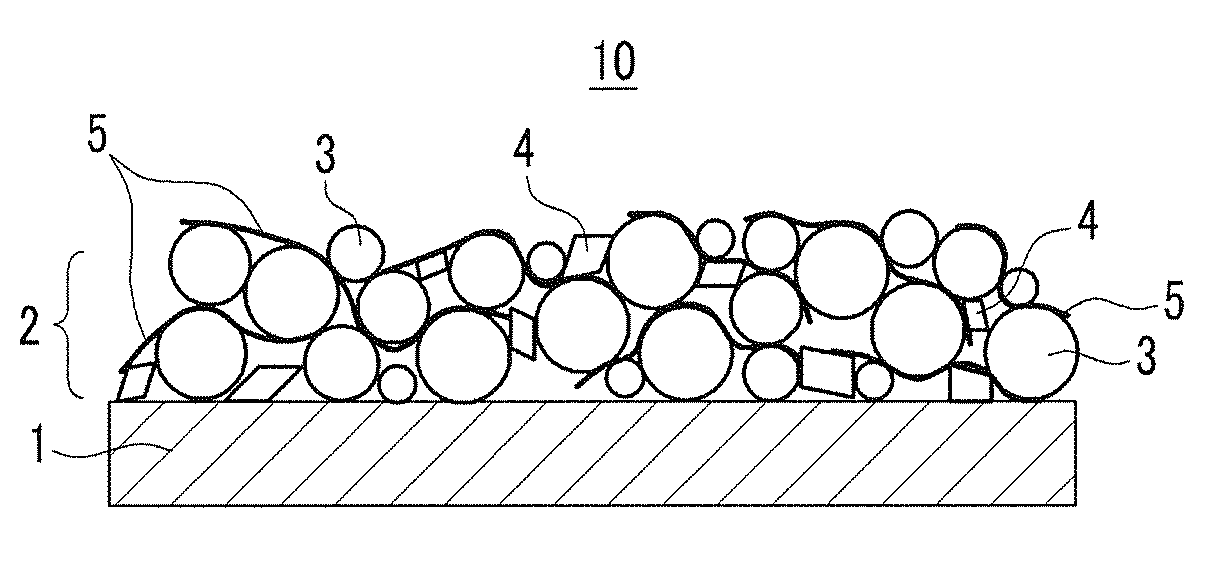

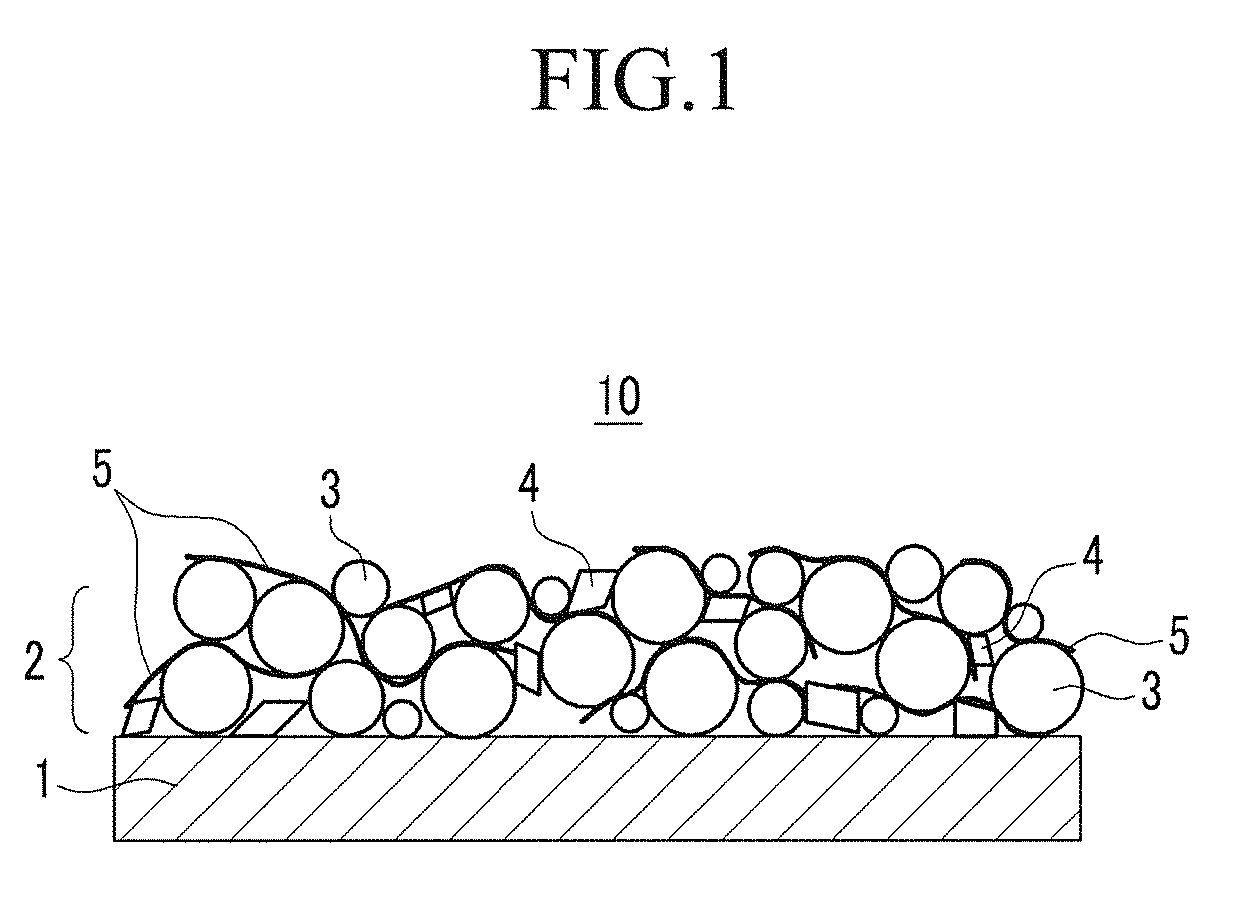

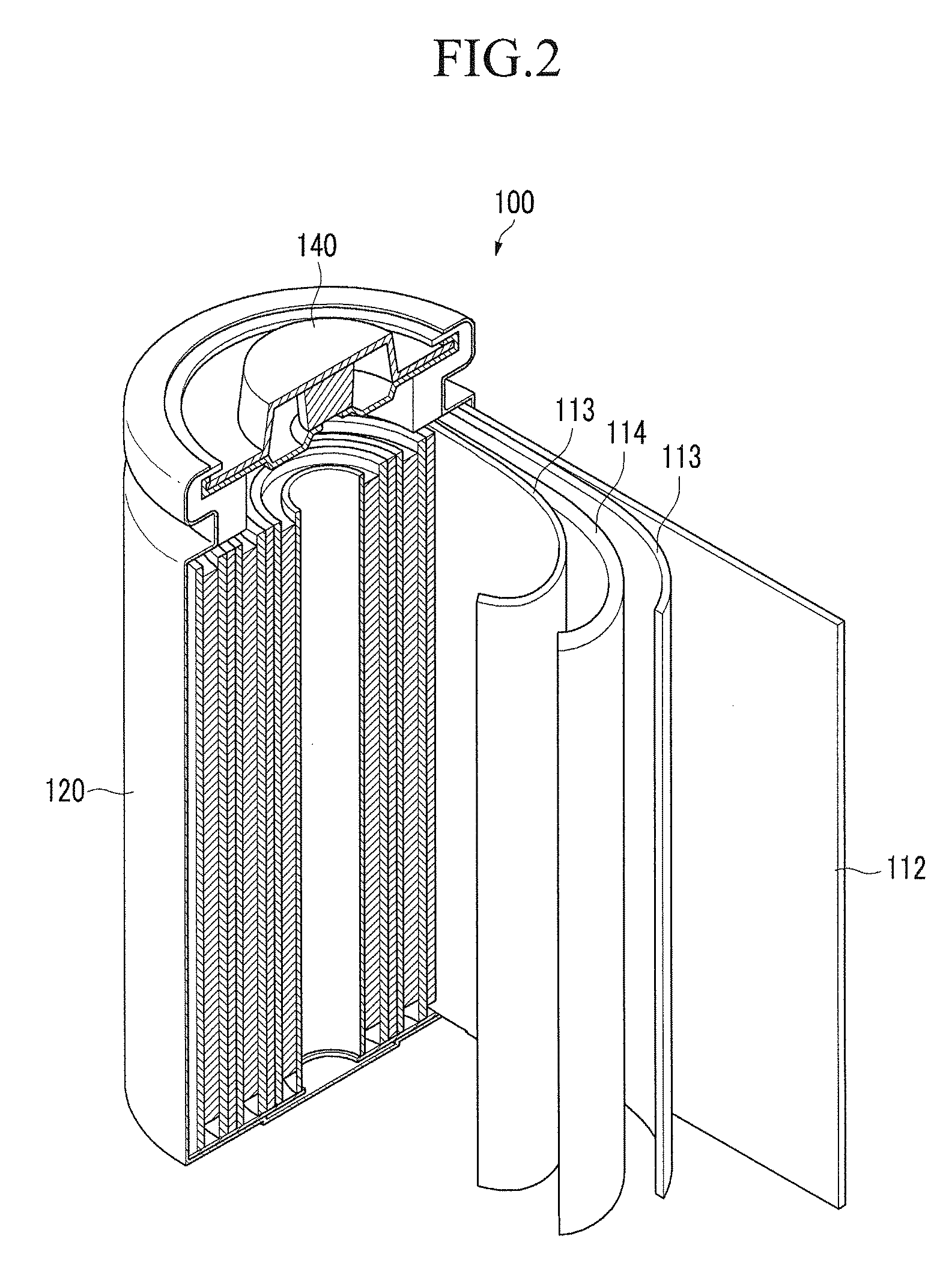

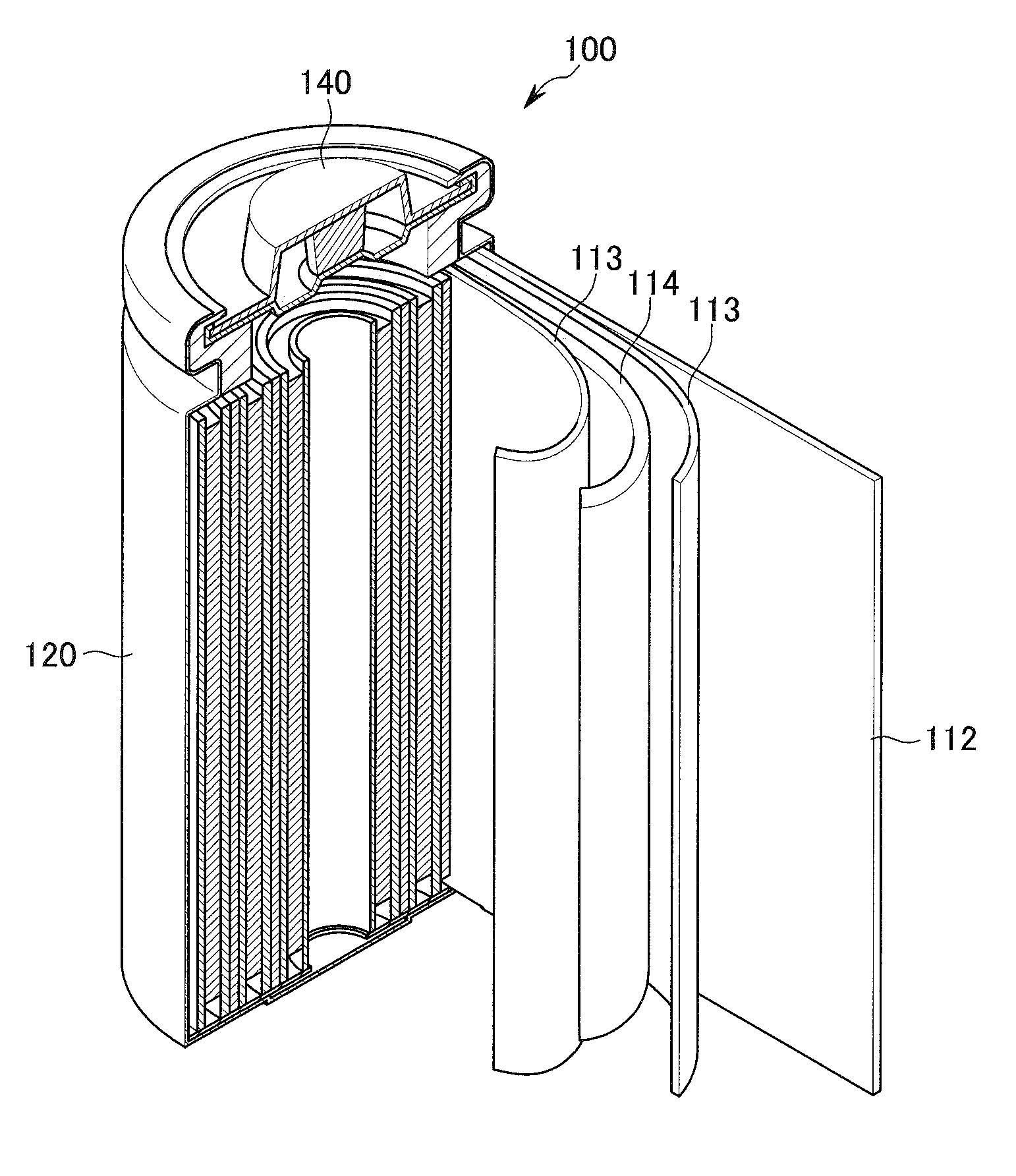

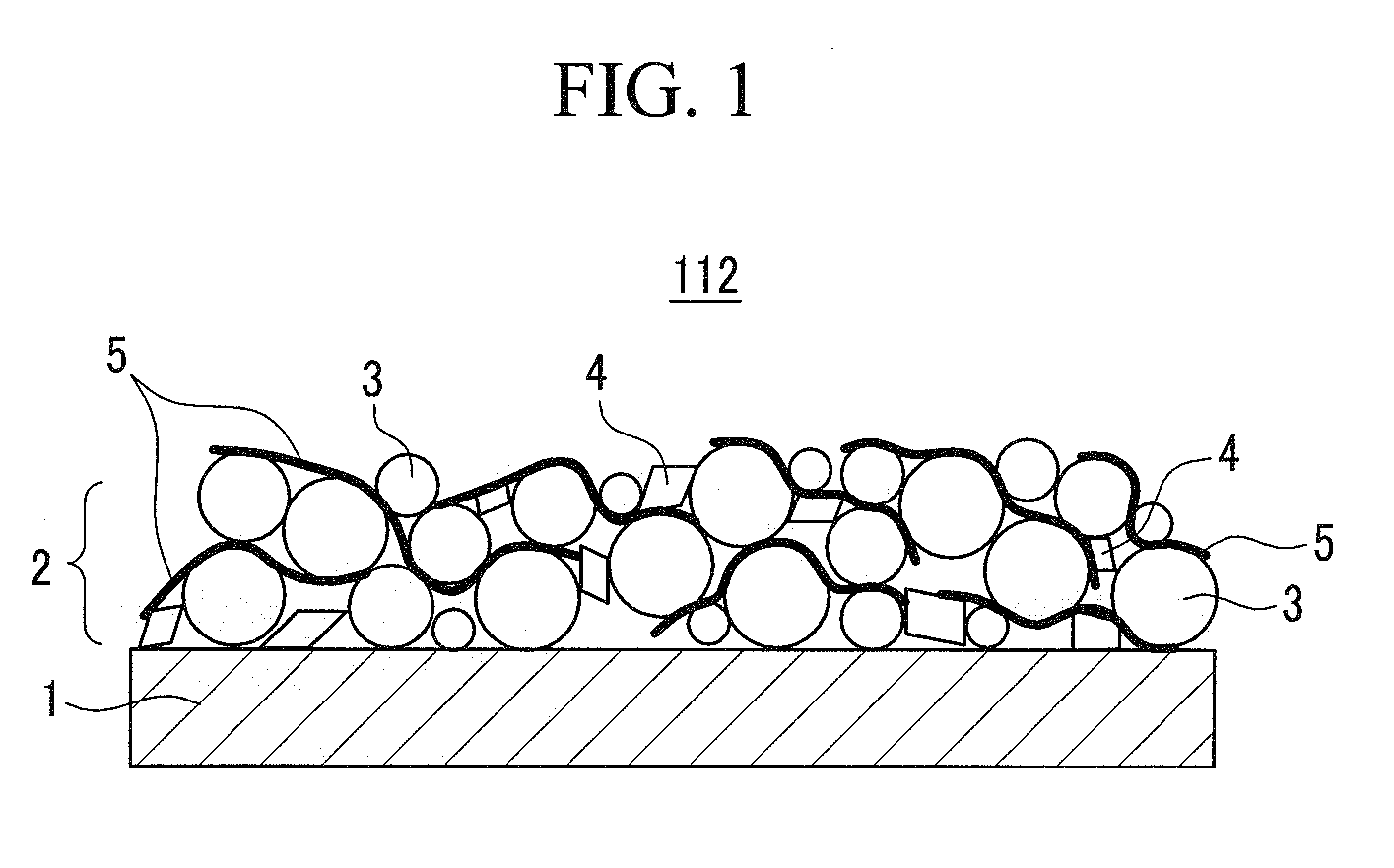

ActiveCN104396060AIncrease capacityHigh densityMaterial nanotechnologyHybrid capacitor electrodesLithiumAlloy

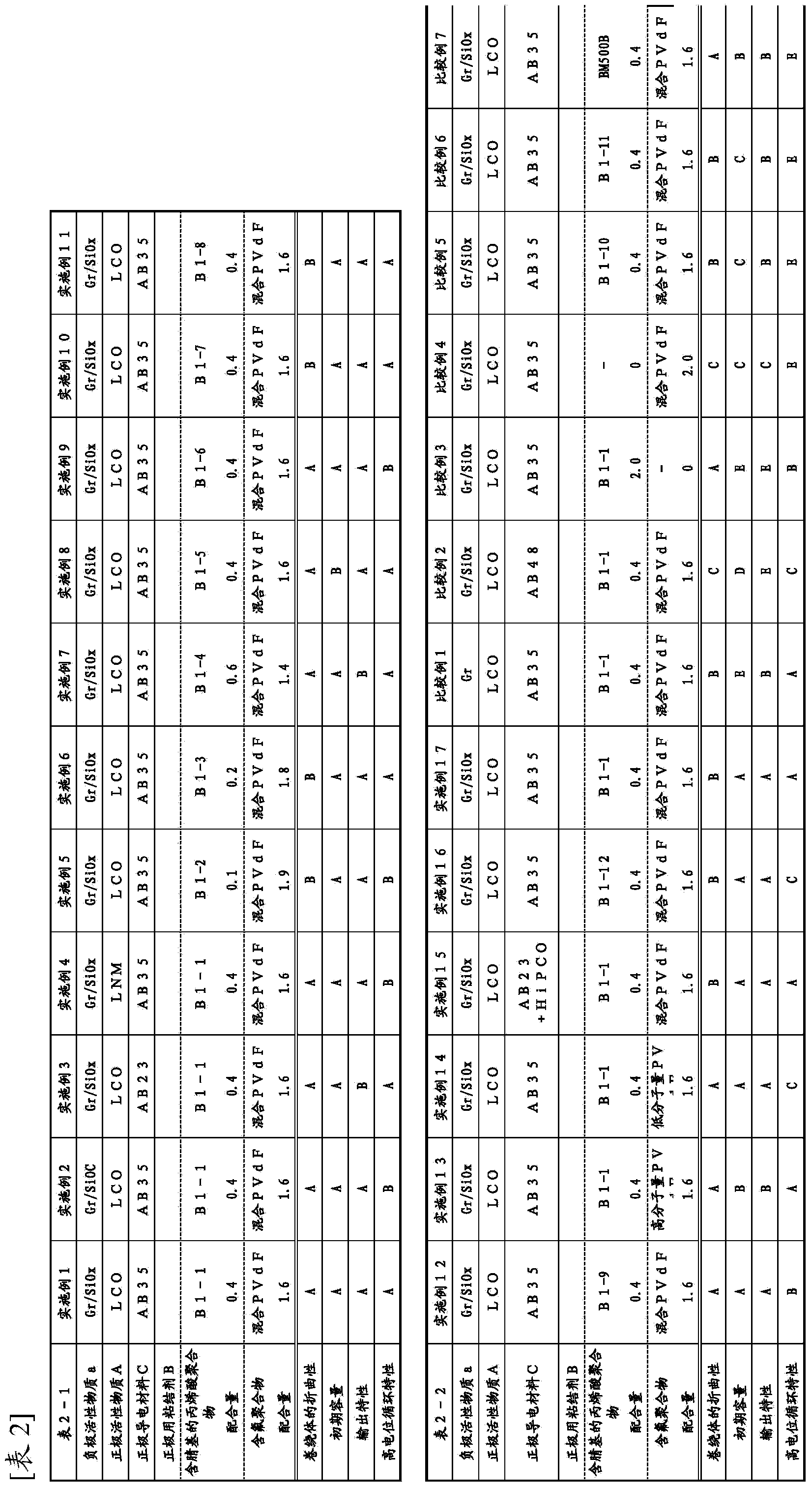

[Problem] To provide a high-capacity lithium ion secondary battery which is flexible and has excellent high potential cycle characteristics, while being prevented from the occurrence of cracks in an electrode layer when bent. [Solution] A lithium ion secondary battery of the present invention is characterized by comprising a negative electrode, a positive electrode and a nonaqueous electrolyte solution, and is also characterized in that: the negative electrode contains an alloy-based active material; the positive electrode contains a positive electrode active material, a binder for positive electrodes, and a conductive material; the binder for positive electrodes contains a nitrile group-containing acrylic polymer and a fluorine-containing polymer; the nitrile group-containing acrylic polymer has a swelling degree of three times or less with respect to the nonaqueous electrolyte solution and a THF insoluble fraction of 30% by mass or less; and the conductive material has particle diameters of 5-40 nm.

Owner:ZEON CORP

High-performance lead-acid storage battery and machining-assembling process thereof

ActiveCN105789711AHigh strengthIt is less difficult to formFinal product manufactureLead-acid accumulators constructionPolyesterFiber

The invention discloses a high-performance lead-acid storage battery. The high-performance lead-acid storage battery comprises a shell, a positive plate, a negative plate, a baffle plate and electrolyte, wherein the positive plate, the negative plate and the baffle plate are arranged inside the shell; the electrolyte is injected into the shell; the positive plate comprises a positive grid and positive lead plaster which coats front and back sides of the positive grid; the positive lead plaster is prepared from the following components by weight: 1.1kg of antimonous oxide, 0.95kg of stannous mono-sulphate, 1.96kg of graphite, 0.66kg of polyester staple fiber, 100kg of pure water, 80kg of sulfuric acid, 1000kg of lead powder and 0.35kg of tetrabasic lead sulfate; the negative plate comprises a negative grid and negative lead plaster which covers the front and back sides of the negative grid; the negative lead plaster is prepared from the following components by weight: 202kg of graphite, 1.8kg of lignin, 7kg of barium sulfate, 0.65kg of polyester staple fiber, 2.2kg of humic acid, 110kg of pure water, 78kg of sulfuric acid, 1000kg of lead powder and 0.23kg of tetrabasic lead sulfate.

Owner:ANHUI HUASEN POWER SUPPLY

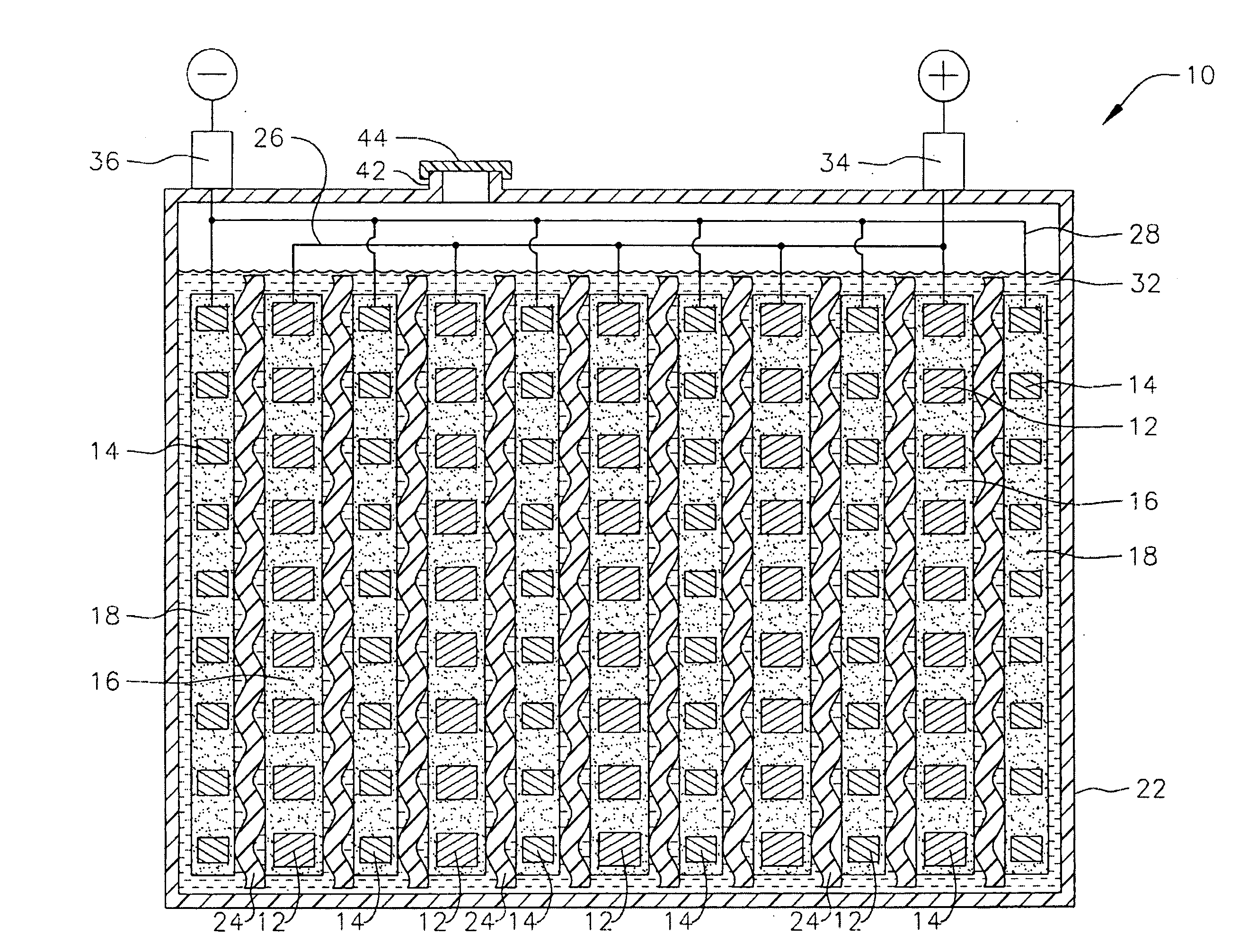

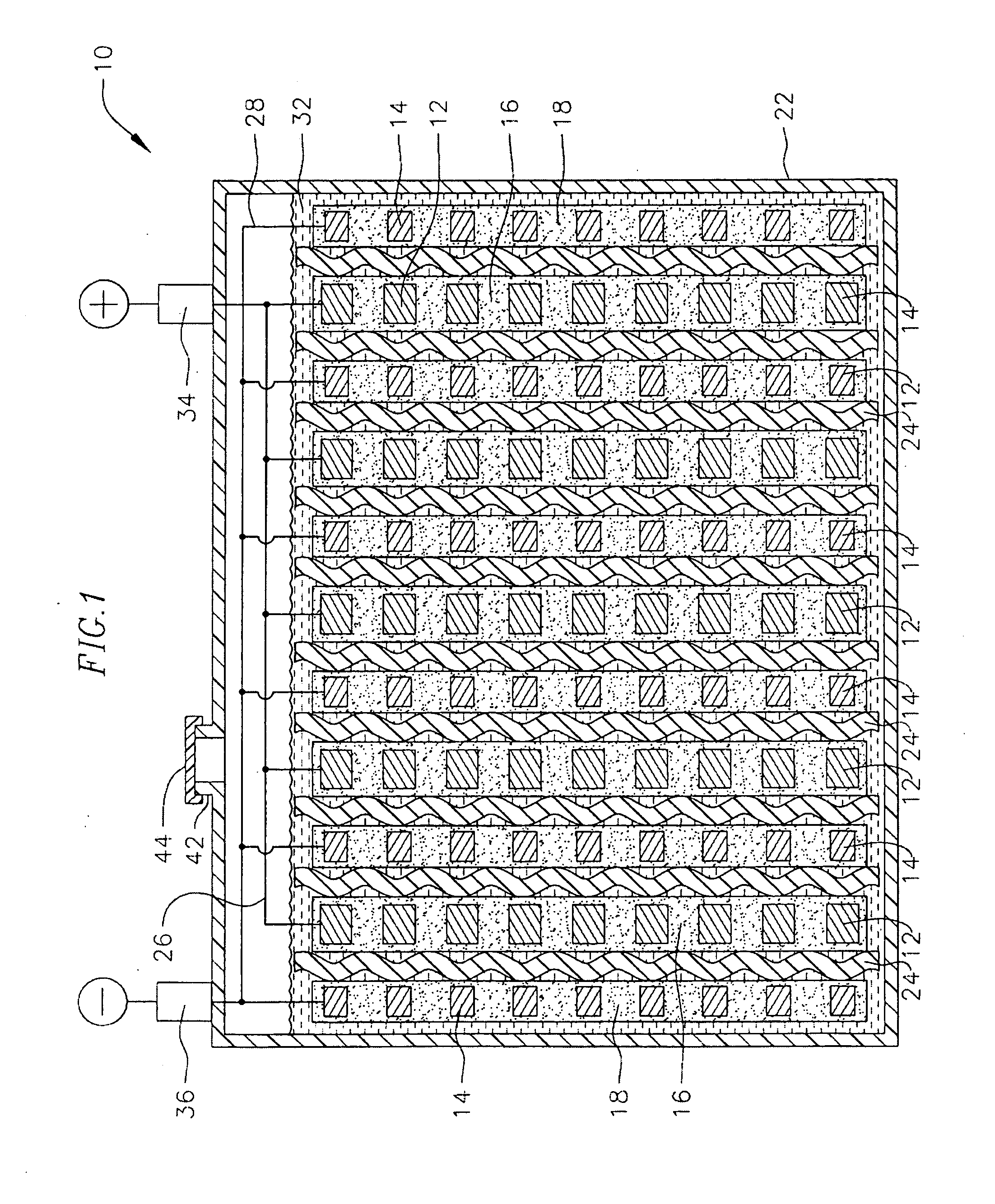

Flooded lead-acid battery and method of making the same

ActiveUS20090253041A1Excellent mechanical propertiesIncrease costLiquid surface applicatorsLead-acid accumulatorsSulfateLead oxide

Positive active material pastes for flooded deep discharge lead-acid batteries, methods of making the same and lead-acid batteries including the same are provided. The positive active material paste includes lead oxide, a sulfate additive, and an aqueous acid. The positive active material paste contains from about 0.1 to about 1.0 wt % of the sulfate additive. Batteries using such positive active material pastes exhibit greatly improved performance over batteries with conventional positive active material pastes.

Owner:TROJAN BATTERY

A method of inhibiting gas generation in battery formation and a lithium ion battery formed by adopting the method

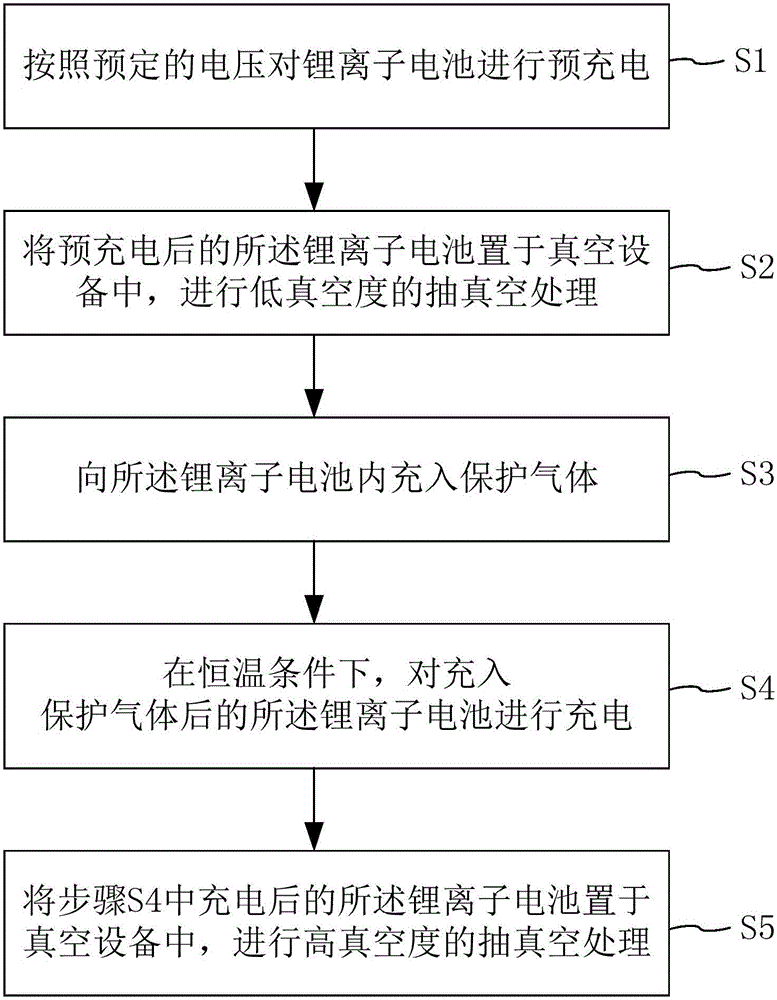

InactiveCN106505250AInhibit decomposition gas productionHigh initial capacityFinal product manufactureSecondary cells charging/dischargingDecompositionElectrochemistry

A method of inhibiting gas generation in battery formation and a lithium ion battery formed by adopting the method are disclosed. The method includes S1) pre-charging the lithium ion battery according to a preset voltage, S2) putting the pre-charged lithium ion battery into a vacuum device and performing vacuumizing treatment with a low vacuum degree, S3) feeding a protective gas into the lithium ion battery, S4) charging the lithium ion battery at a constant temperature after the protective gas is fed, and S5) putting the lithium ion battery charged in the step S4) into the vacuum device and performing vacuumizing treatment with a high vacuum degree. Gas generation due to electrolyte decomposition in a formation process of the lithium ion battery is effectively inhibited by the method, thus effectively avoiding a ballooning phenomenon, and providing safety for lithium ion battery production and application. In addition, the initial capacity of the battery is increased, the battery interface internal resistance is reduced, electrochemical performance stability of the battery is effectively improved and the cyclic life of the battery is greatly prolonged.

Owner:SHENZHEN TOPBAND

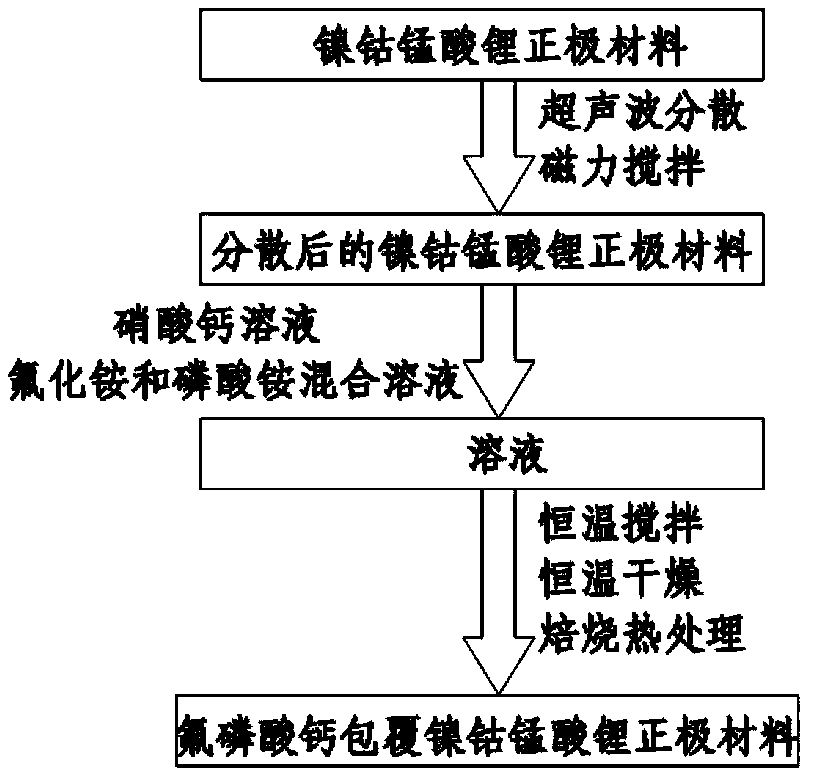

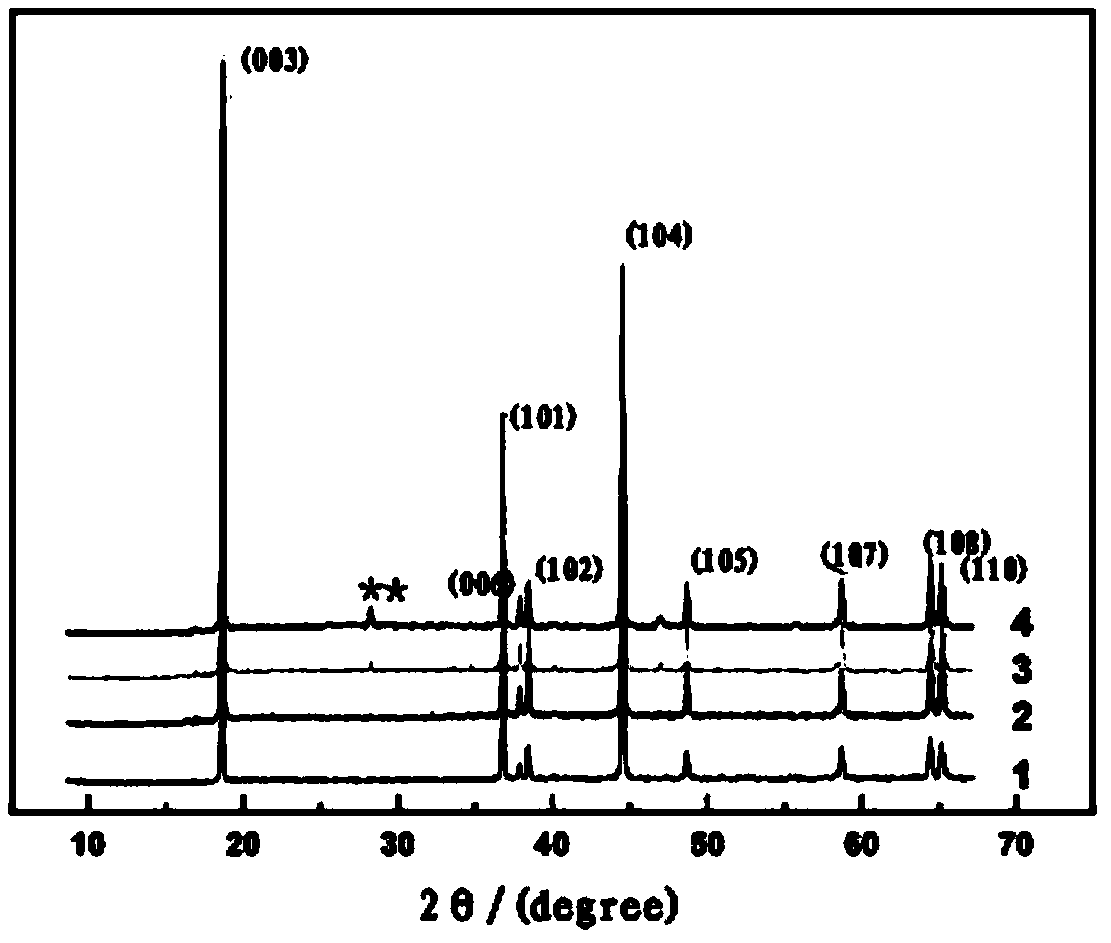

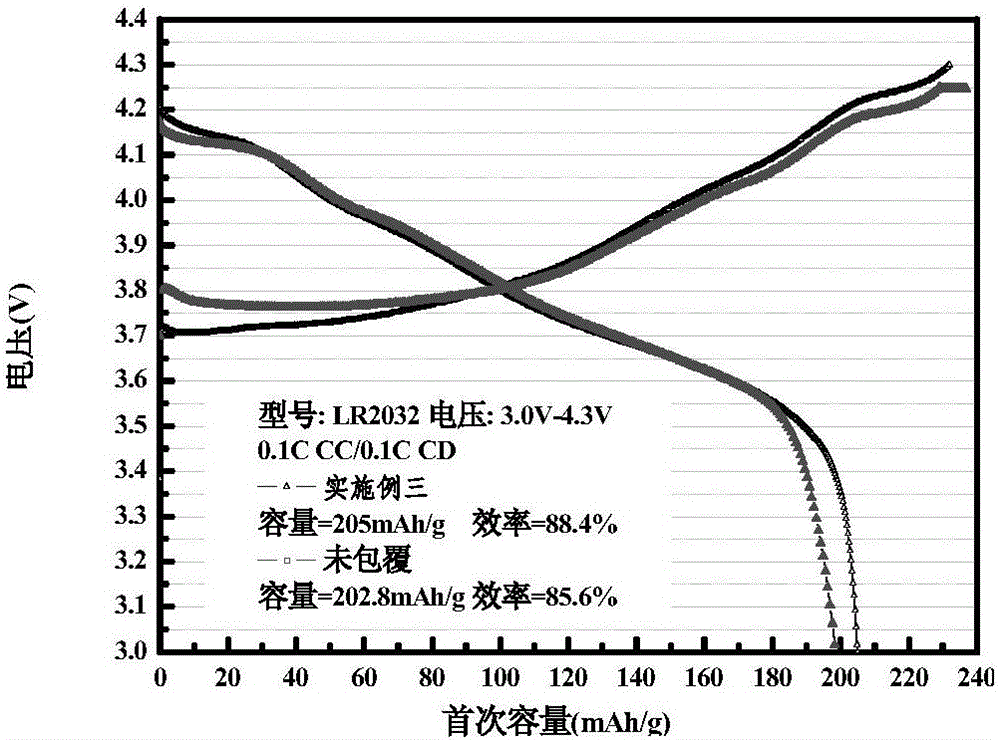

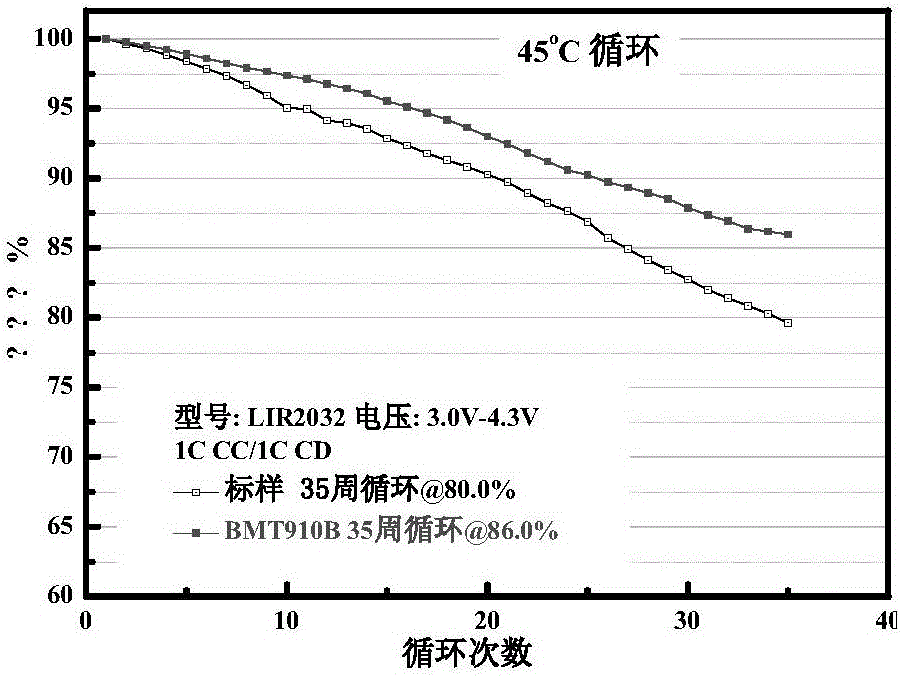

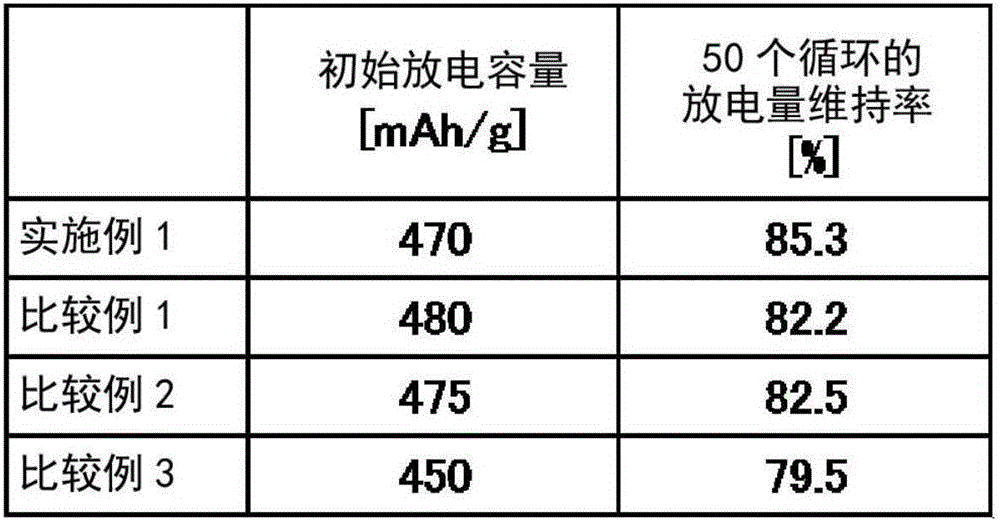

Method for coating nickel cobalt lithium manganate positive-electrode material with calcium fluophosphate

InactiveCN103367723AHigh initial capacityGood capacity retentionCell electrodesCharge dischargeSolvent

The invention provides a method for coating a nickel cobalt lithium manganate positive-electrode material with calcium fluophosphate. The method comprises the following steps: a) dissolving the nickel cobalt lithium manganate positive-electrode material in deionized water for dispersion; b) first adding calcium nitrate solution and then adding ammonium fluoride solution into the nickel cobalt lithium manganate positive-electrode material dispersed by the step a), with the molar ratio of the calcium nitrate solution to the ammonium fluoride solution being 1:2, and reacting to produce the calcium fluophosphate; c) stirring a suspension liquid obtained in the step b) for 2-4 hours at the temperature of 75-85 DEG C, evaporating the suspension liquid to dryness, and thermostatically drying for 12 hours at the temperature of 120 DEG C; d) putting the dried material of the step c) into a muffle furnace for baking heat treatment, and then naturally cooling to obtain the calcium fluophosphate coated nickel cobalt lithium manganate positive-electrode material. According to the method, the nickel cobalt lithium manganate positive-electrode material is coated with the calcium fluophosphate, higher initial capacity of the nickel cobalt lithium manganate positive-electrode material itself can be maintained, dissolving in electrolyte of transition metals in the nickel cobalt lithium manganate positive-electrode material during a charge-discharge cycle process can be inhibited, and capacity retention rate of the nickel cobalt lithium manganate positive-electrode material can be improved.

Owner:SHENZHEN JIALINENG TECH CO LTD

Formulation and solidifying process for anode lead plaster of long and narrow type valve controlled sealed lead acid accumulator

InactiveCN1482696AHigh initial capacityInhibit sheddingLead-acid accumulator electrodesFiberHermetic seal

A elongated valve control hermetic sealing lead-acid storage battery lead grease formulation and solidification process, wherein the percentages by weight of each ingredient in the lead grease formula are, lead powder 65-80%, red lead 8úÑí½ 20úÑ, short fibers 0.07úÑí½ 0.15úÑ, sulfuric acid 5úÑí½ 10úÑ, water 5úÑí½ 10úÑ, the high temperature and high moisture process is used for solidification, with a temperature of 70-85 degree C., and a moistness over 95%, the curing time is 20h - 30 h, the invention can guarantee both the initial capacity and the cycle life of the battery.

Owner:江苏隆源双登电源有限公司

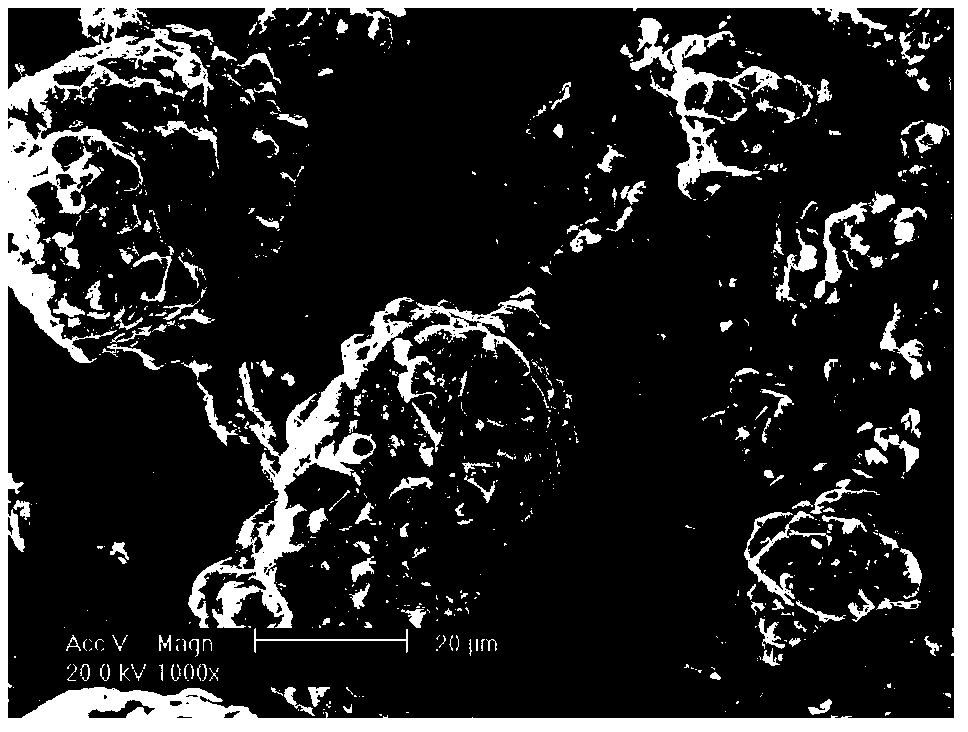

High-performance power accumulator and preparation method thereof

ActiveCN103413976AImprove adsorption capacityIncrease profitLead-acid accumulatorsLead-acid accumulator electrodesLead dioxideElectrical battery

The invention discloses a high-performance power accumulator and a preparation method thereof. Graphite is substituted by a novel conductive agent, namely, polyaniline, in the lead paste of a positive plate; the conductivity of a mixture of the polyaniline and lead dioxide is improved by 12.5 times; acetylene black is substituted by a novel conductive agent, namely, super carbon black, in the lead paste of a negative plate, the specific surface area of the super carbon black is 130-190m<2> / g, and the adsorption is high. During preparation, water is firstly added, then an additive is added, the water and the additive are mixed and then lead powder is added, while the original steps of adding the additive firstly, adding the lead powder, adding the water and then stirring are changed, so that the additive is well dispersed. According to the high-performance power accumulator and the preparation method thereof, the utilization rate of an active material is effectively improved, the consistency of the battery is improved, the discharge depth of the battery is great, and the cycle life is long.

Owner:TIANNENG GRP JIANGSU TECH

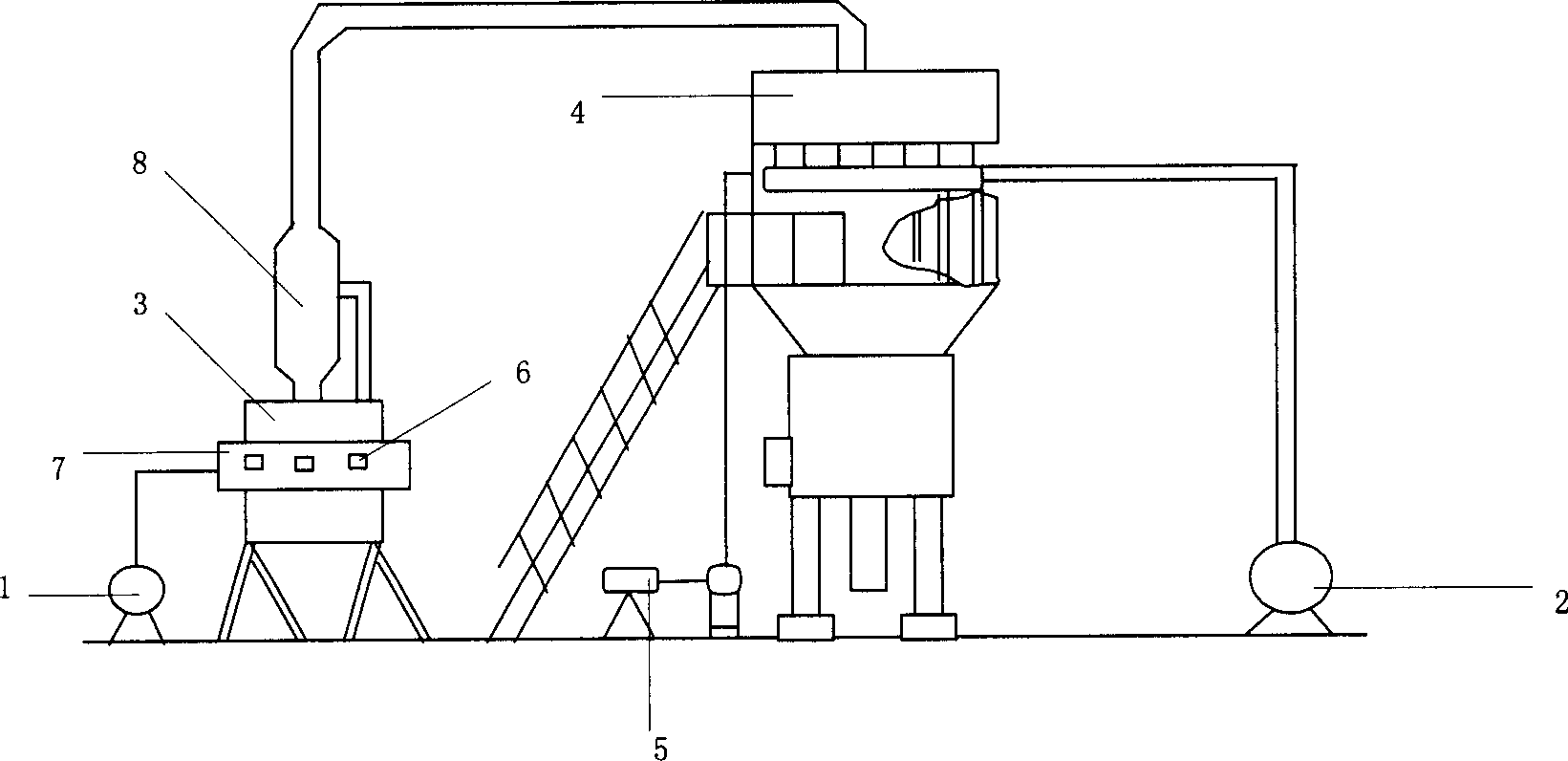

Cyclic utilization method and apparatus of lead dioxide from storage cells

InactiveCN1805208AEasy to obtainLow costWaste accumulators reclaimingBattery recyclingLead dioxideAir volume

The invention relates to a cycle utilization method and relative device of accumulator lead dioxide. It comprises: drying the anode plate in the temperature of 80-100Deg. C; when the water content is less than 10wt%, taking out anode plate and separating the plate grid with lead pastern; milling the lead pastern on the milling breaker into PbO2 powder; controlling the wind content of wind nozzle of positive fan and passive fan to form micro passive pressure in the milling breaker; collecting the PbO2 powder into powder collector; adding lead powder which is 4.5-5.0wt% of collected PbO2 powder. The invention can utilize the waste accumulator electrode plate which can improve the initial capacity and improve the cycle service life of accumulator.

Owner:赵恒祥

Lead-acid storage battery cathode diachylon made of high-activity carbon material and preparation method of lead-acid storage battery cathode diachylon

InactiveCN107863521AThe electrochemical reaction is smoothImprove adsorption capacityMaterial nanotechnologyLead-acid accumulatorsFiberPorosity

The invention discloses lead-acid storage battery cathode diachylon made of a high-activity carbon material and a preparation method of the lead-acid storage battery cathode diachylon. The preparationmethod comprises the following steps: (1) dispersing 0.2-0.8g of short carbon fibers into deionized water; (2) grinding 500g of lead oxide and 1.5-4.0g of the high-activity carbon material for 4-6min, sequentially adding 3.5-5g of barium sulfate, 0.5-1g of lignin, 3.5-5.5g of TiO2, 0.5-1.5g of humic acid and the dispersed short carbon fibers into the mixture of the lead oxide and the high-activity carbon material, and stirring the mixture for 10-12min; (3) adding 40-43g of sulfuric acid with the density of 1.4g / cm<3> drop by drop, and regulating the consistency of the diachylon with 50-65g ofdeionized water, so that the apparent density of the diachylon is 4.3-44g / cm<3>. According to the cathode diachylon, the porosity and the acid absorption value of a cathode plate can be increased, sothat sulfate ions can be diffused favorably, and the active surface area of an electrode is increased. Therefore, the chemical reaction of the electrode is performed more smoothly, and the cycle lifeof a lead-acid storage battery is prolonged.

Owner:HENAN CHAOWEI POWER SUPPLY

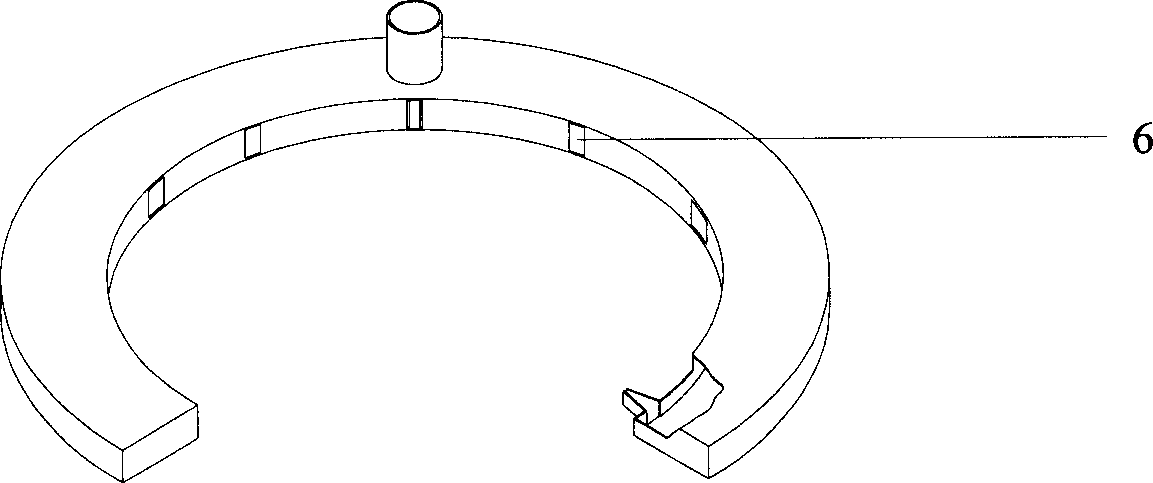

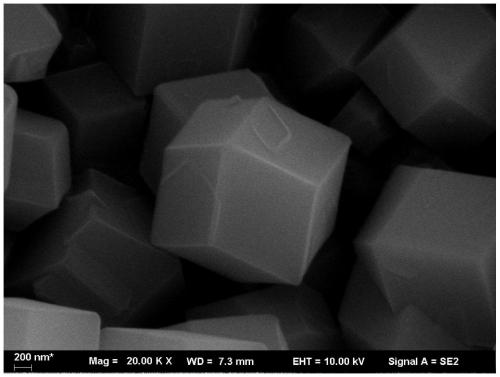

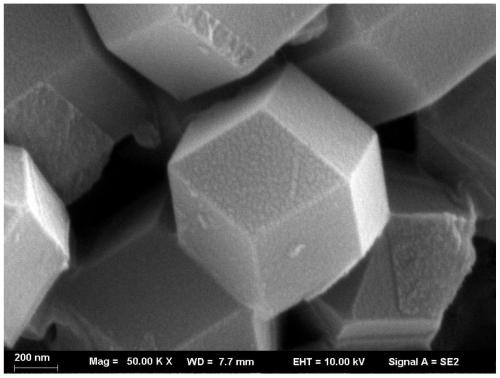

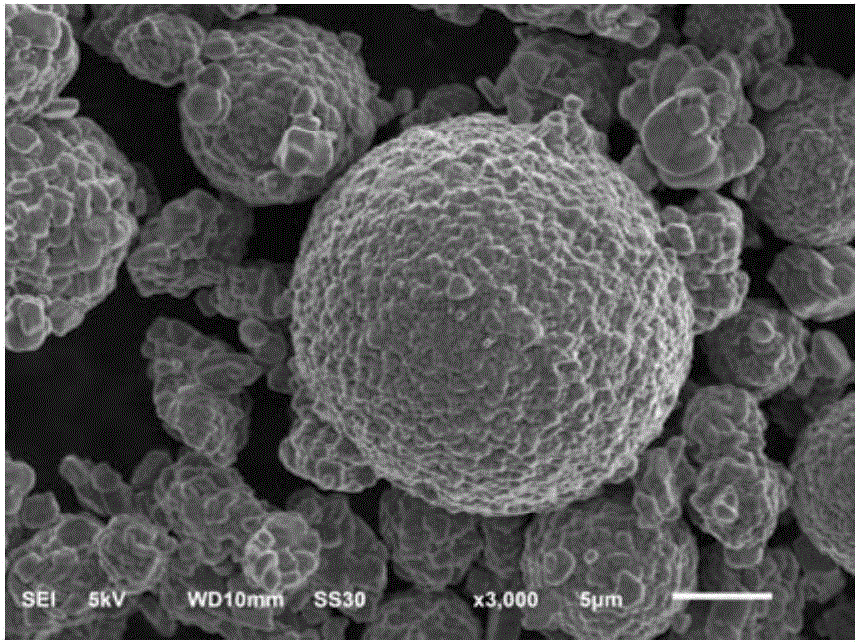

High-nickel ternary precursor with core-shell structure, preparation method of high-nickel ternary precursor, and hollow doped high-nickel ternary positive electrode material

ActiveCN111525113ATailorableHave diversityCell electrodesSecondary cellsOctahedronMetal-organic framework

The invention relates to the field of lithium ion battery materials, in particular to a high-nickel ternary precursor with a core-shell structure, a preparation method of the high-nickel ternary precursor and a hollow doped high-nickel ternary positive electrode material. The precursor is of a core-shell structure, an inner core is of a boron-doped octahedral structure Zn-MOF, and an outer shell is of a nickel-rich ternary precursor NixCoyMnz(OH)2. The preparation method comprises the following two steps: step 1, synthesizing octahedral structure Zn-MOF (metal organic framework) through coprecipitation, and soaking the octahedral structure Zn-MOF in a boric acid solution to obtain boron-doped MOF; and step 2, coating a high-nickel ternary precursor material on the basis to form the high-nickel ternary precursor with the core-shell structure. The high-nickel ternary precursor with the core-shell structure is prepared by adopting a simple and efficient method, and a foundation is laid for a cathode material prepared in the later period to have higher initial capacity and cycling stability; the product synthesized by adopting a coprecipitation method is uniform in component, good in sphericity degree and good in reproducibility, and has good economic value and application prospect.

Owner:ZHUJI PAWA NEW ENERGY

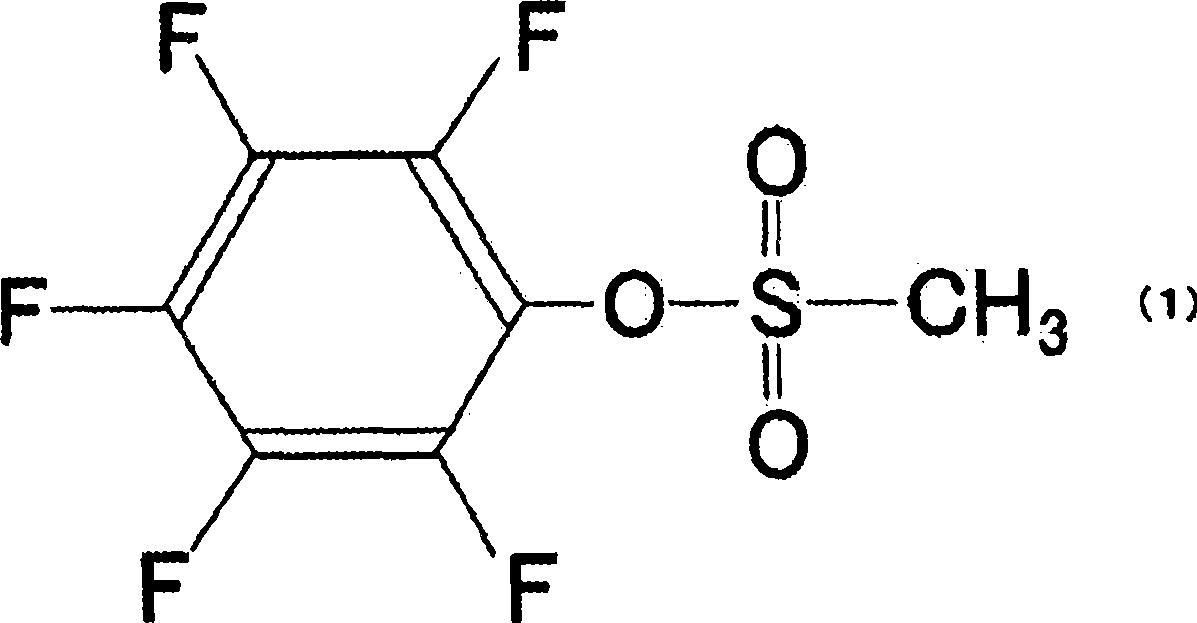

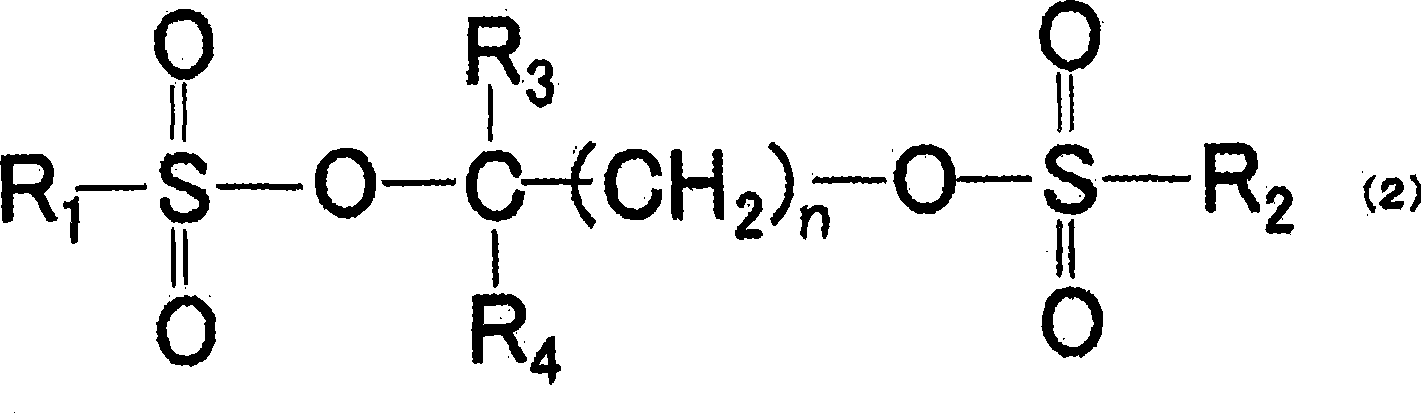

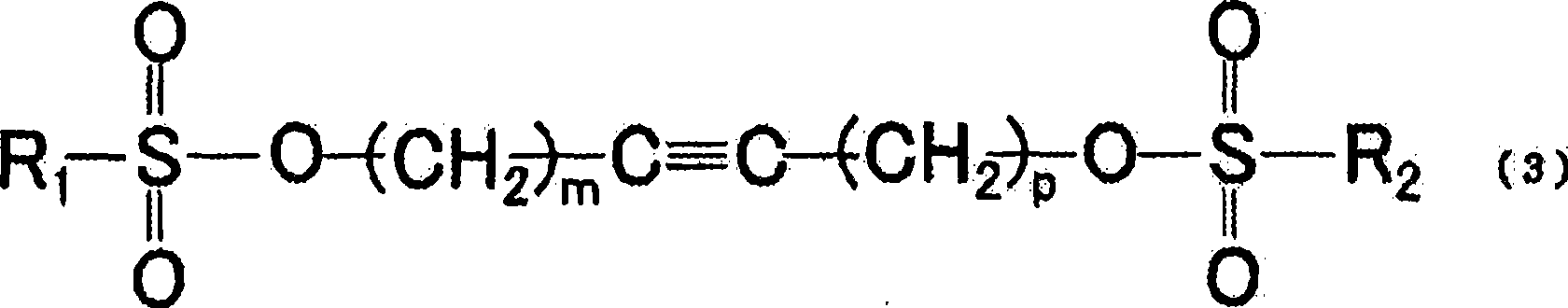

Non-aqueous electrolyte secondary battery

ActiveCN101453041AHigh initial capacityExcellent cycle characteristicsLi-accumulatorsNon aqueous electrolytesSulfonic acid ester

Owner:PANASONIC ENERGY CO LTD +1

Ce1-xZrxO2 nano solid solution homogenate modified lithium ion battery anode material and preparation method thereof

ActiveCN106058241AHigh initial capacityExcellent rate performanceCell electrodesSecondary cellsSolid phasesLithium electrode

The invention belongs to the technical field of lithium ion battery material manufacturing process and discloses a Ce1-xZrxO2 nano solid solution homogenate modified lithium ion battery anode material and a preparation method thereof. A LiNixCoyM(1-x-y)O2 material preparation process includes: forming a coating of a nanoscale metal oxide according to a homogeneous precipitation method, wherein the nanoscale metal oxide refers to Ce1-xZrxO2 nano solid solution; after coating is finished, drying the coating, heating to 200-1000 DEG C at a heating temperature of 1-5DEG C / min, keeping the temperature for 2-20h, and naturally cooling to obtain the Ce1-xZrxO2 nano solid solution homogenate modified LiNixCoyM(1-x-y)O2 material. The prepared LiNixCoyM(1-x-y)O2 material has excellent high-temperature cycle performance and electrochemical interface stability. Compared with a traditional solid-phase method, the modification method is high in uniformity and reliability.

Owner:TIANJIN B&M SCI & TECH

Negative electrode active material for lithium-ion secondary cell

InactiveCN105900269AHigh initial capacityGood capacity retentionElectrode thermal treatmentLi-accumulatorsLithiumSurface layer

A negative electrode active material for a lithium-ion secondary cell, comprising: (A) a flaked graphitic carbon material in which the IG / ID(G value) is 5.2-100 and the aspect ratio and the area of the optical structure satisfy the relationships 1.5<=AOP<=6 and 0.2*D50<=(SOP*AOP)1 / 2<2*D50 for a 50% diameter D50[mu]m; a composite material (B) obtained by dispersing silicon-containing particles (b2) having an oxygen content of 1-18% by mass and a surface layer comprising SiOx (0<x<=2) in an assembly of carbon nanotubes (b1) having an aspect ratio of 100-1000, at least 90% of the silicon-containing particles (b2) (expressed in terms of quantity) having a primary particle diameter of 200 nm or less; and a carbonaceous carbon material (C) covering at least some of the surface of the silicon-containing particles (b2).

Owner:SHOWA DENKO KK +1

Method for preparing lithium titanate cathode material for lithium ion power batteries

InactiveCN101967009AImprove electrochemical performanceHigh initial capacityTitanium compoundsTitanium dioxidePower battery

The invention discloses a method for preparing a lithium titanate cathode material for lithium ion power batteries, which is characterized by: mixing nano titanium dioxide or metatitanic acid doped with Zr, Sn and Ni and solution of lithium hydroxide in a Li to Ti molar ratio of 1.16:1 for performing a hydro-thermal reaction at 150 to 200 DEG C and under a pressure of 0.4 to 1.4MPa for 24 to 38 hours; performing spray drying and globulation; and calcining at 700 to 900 DEG C in a high-temperature furnace for 10 to 20 hours, and obtaining a lithium titanate with a spinel structure.

Owner:CHINA NAT OFFSHORE OIL CORP +1

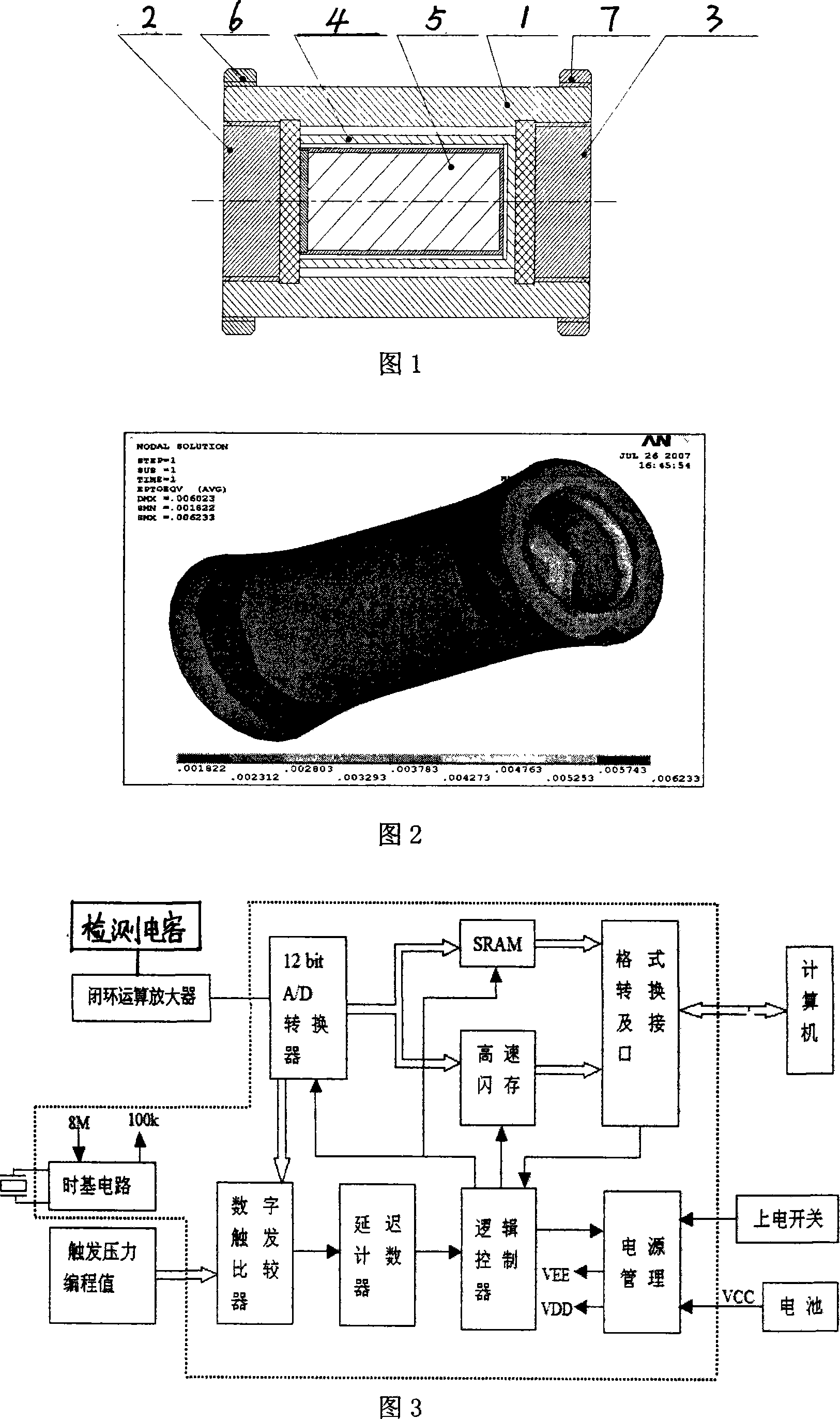

Minisize condenser type sensing, bearing structure integrated electric voltage detector

InactiveCN101201229AStructural integrationCompact structureWeapon testingFluid pressure measurement using capacitance variationCapacitanceEngineering

The invention relates to an electronic pressure gauge for pressure measurement, in particular to an electronic pressure gauge integrated with micro capacitance sensor and bearing structure. The pressure gauge solves the problem that pressure sensors of the current electronic pressure gauges have quite large size, so that the overall size of the electronic pressure gauges are too large, and the pressure gauges cannot be used in occasions with limited space. The electronic pressure gauge integrated with micro capacitance sensor and bearing structure includes a cylindrical dynamic plate made of elastic metal material and as a shell, and a cylindrical fixed plate which is fixed in the center of the cylindrical dynamic plate and forms a detection capacitance with the cylindrical dynamic plate; a measuring circuit connected with the output of the detection capacitance consisting of the cylindrical fixed plate and the cylindrical dynamic plate is arranged in the cylindrical fixed plate. The invention has the advantages of simple structure, small size, wide scope of application, low manufacturing cost, etc.

Owner:ZHONGBEI UNIV

Winter paste mixing process for container formation battery plate

ActiveCN103943892AGood initial capacityExtend your lifeFinal product manufactureCell electrodesElectrical batteryCell fabrication

The invention relates to the lead battery manufacturing field, in particular to a winter paste mixing process for a container formation battery plate. The process specifically includes the steps of: adding corresponding materials into a lead powder measuring hopper, a sulfuric acid measuring barrel and a water measuring barrel respectively according to the formula measurement; adding auxiliary materials into a paste mixing pot according to the formula measurement, then adding well measured lead powder into the paste mixing pot during continuous stirring, then further conducting dry stirring for 8-10min; adding water into the paste mixing pot in the continuous stirring process, and keeping the adding process duration at 1-2min, then conducting stirring for another 5-7min, adding all the water according to a use amount, and when the environment temperature is lower than or equal to 20DEG C, pre-heating the water to 30-50DEG C; adding well measured acid into the paste mixing pot in the continuous stirring process, and keeping the adding process last for 13-15min, and when the environmental temperature is lower than or equal to 20DEG C, pre-heating sulfuric acid to 20-40DEG C; at the same time controlling the temperature in the paste mixing pot lower than or equal to 60DEG C; at the end of acid adding, further conducting stirring for 10-25min, testing the diachylon apparent density, and discharging the diachylon from the pot when the apparent density reaches the standard.

Owner:CHAOWEI POWER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com