Patents

Literature

152results about How to "Increase the discharge speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

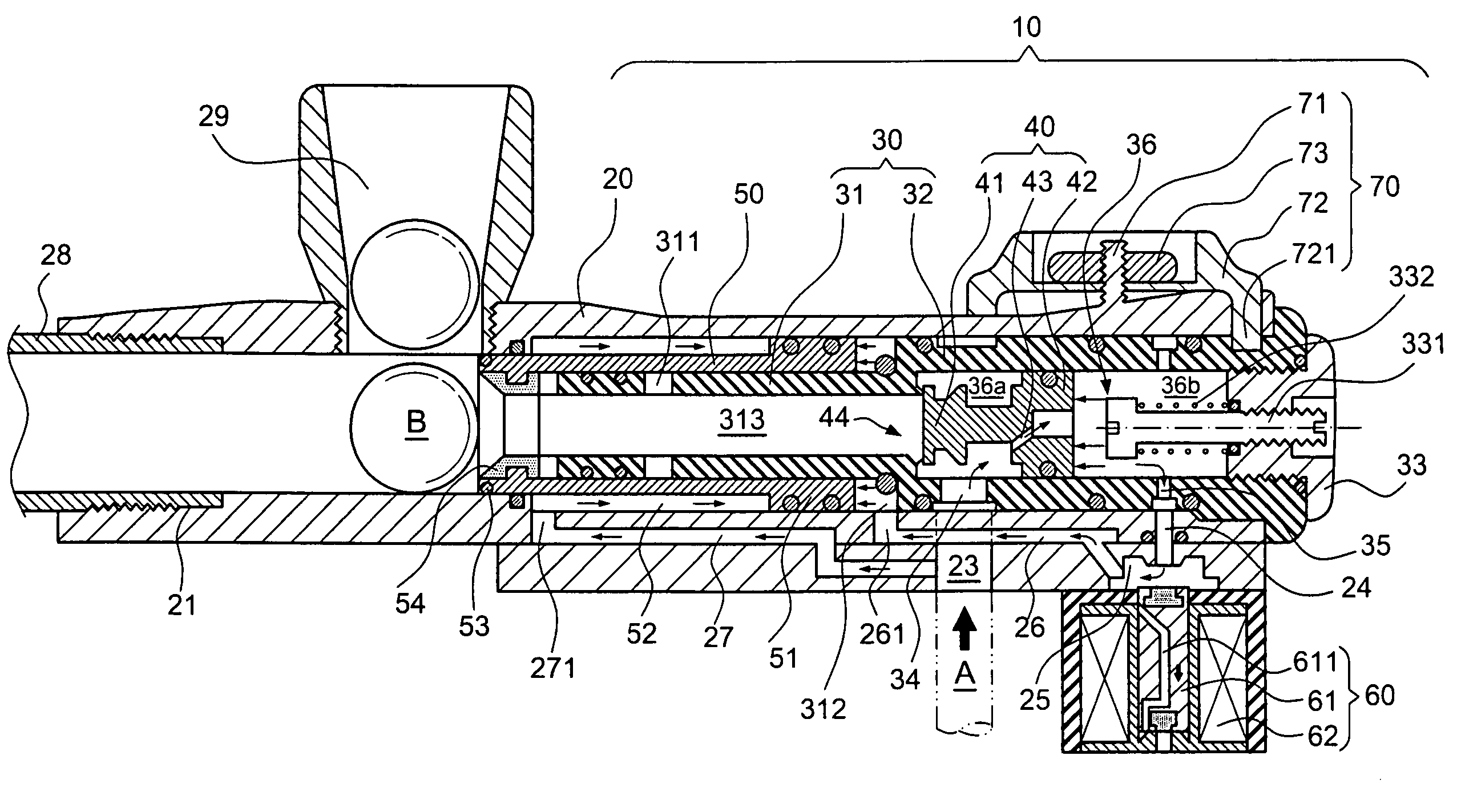

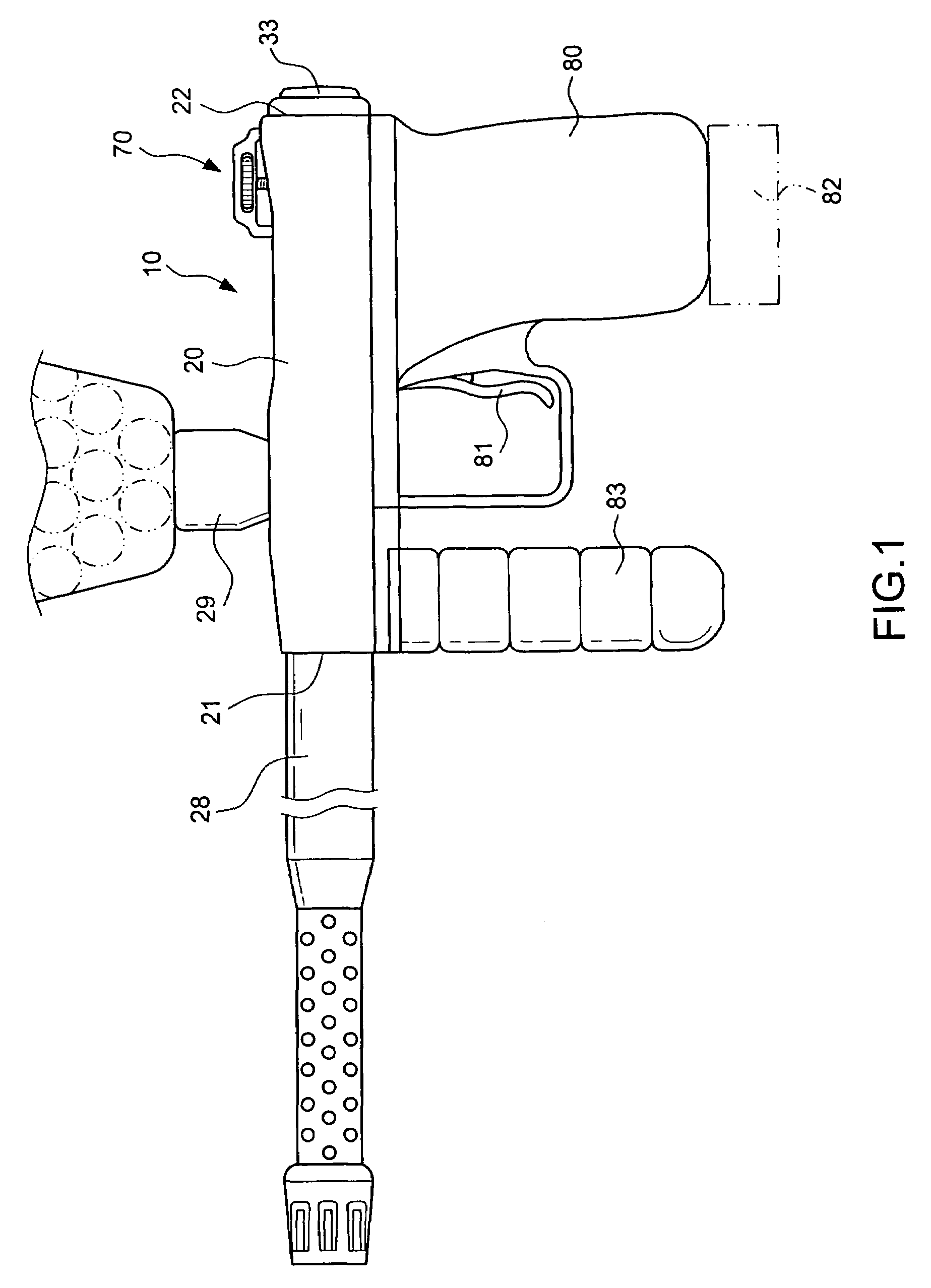

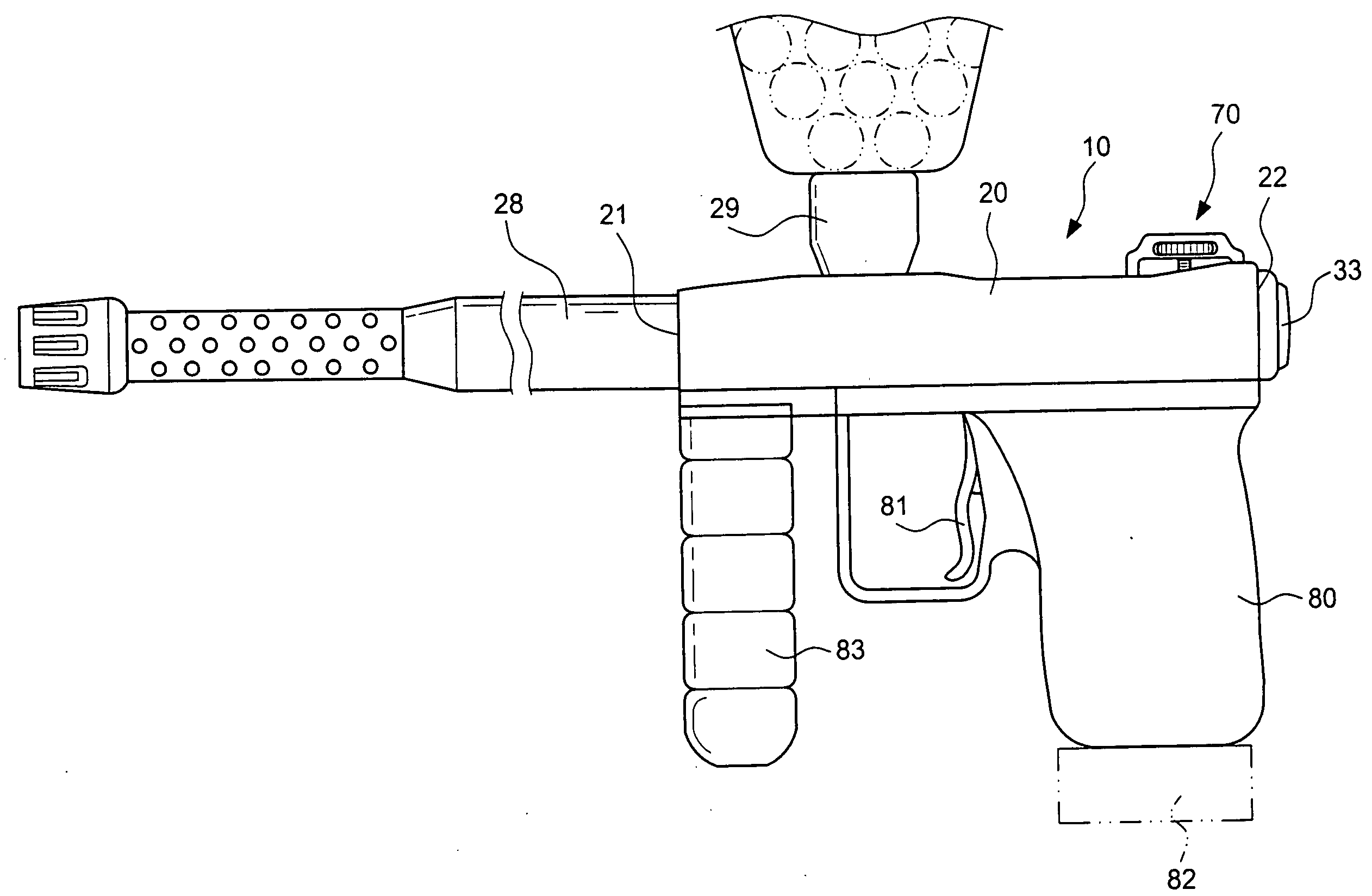

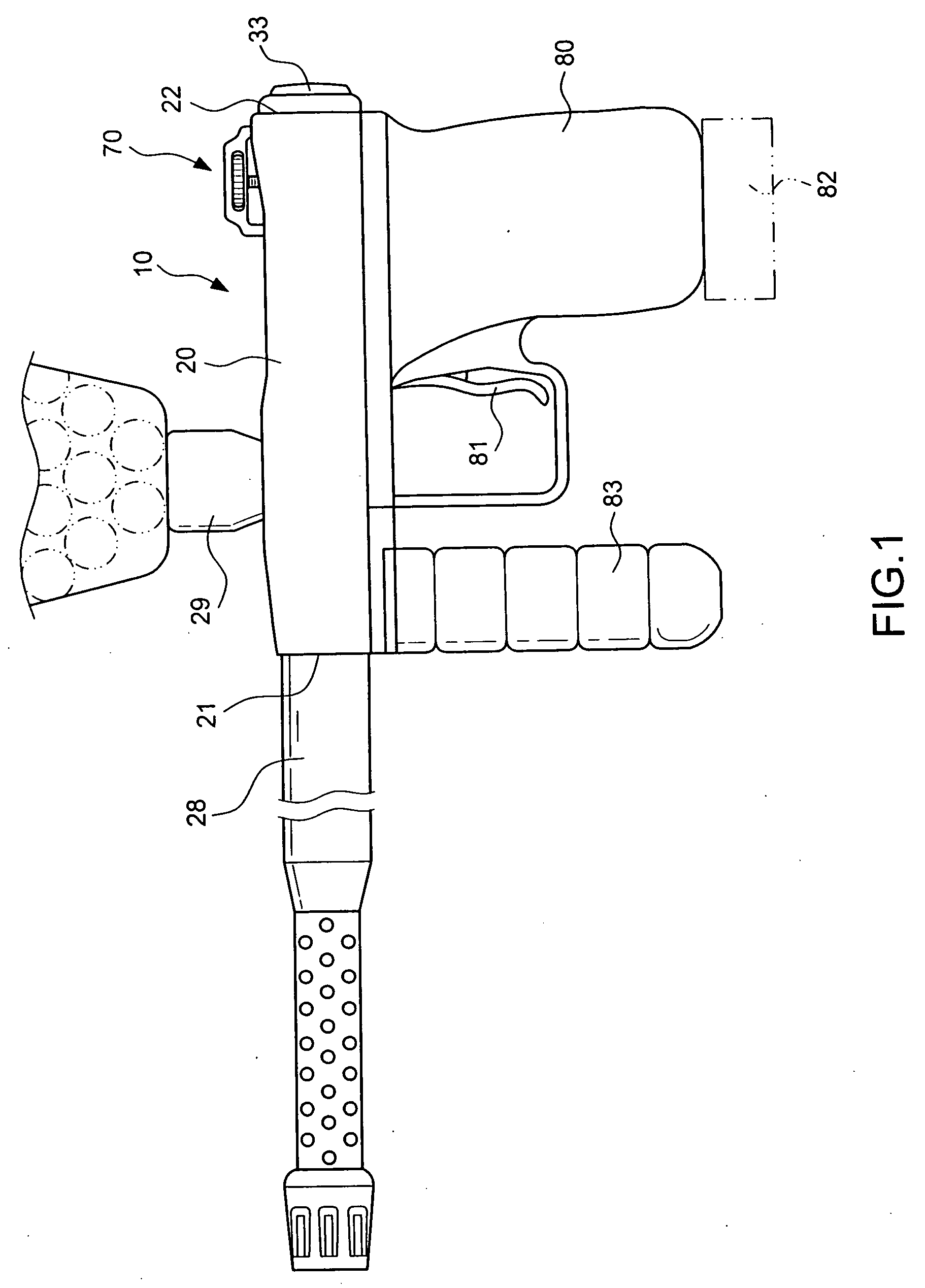

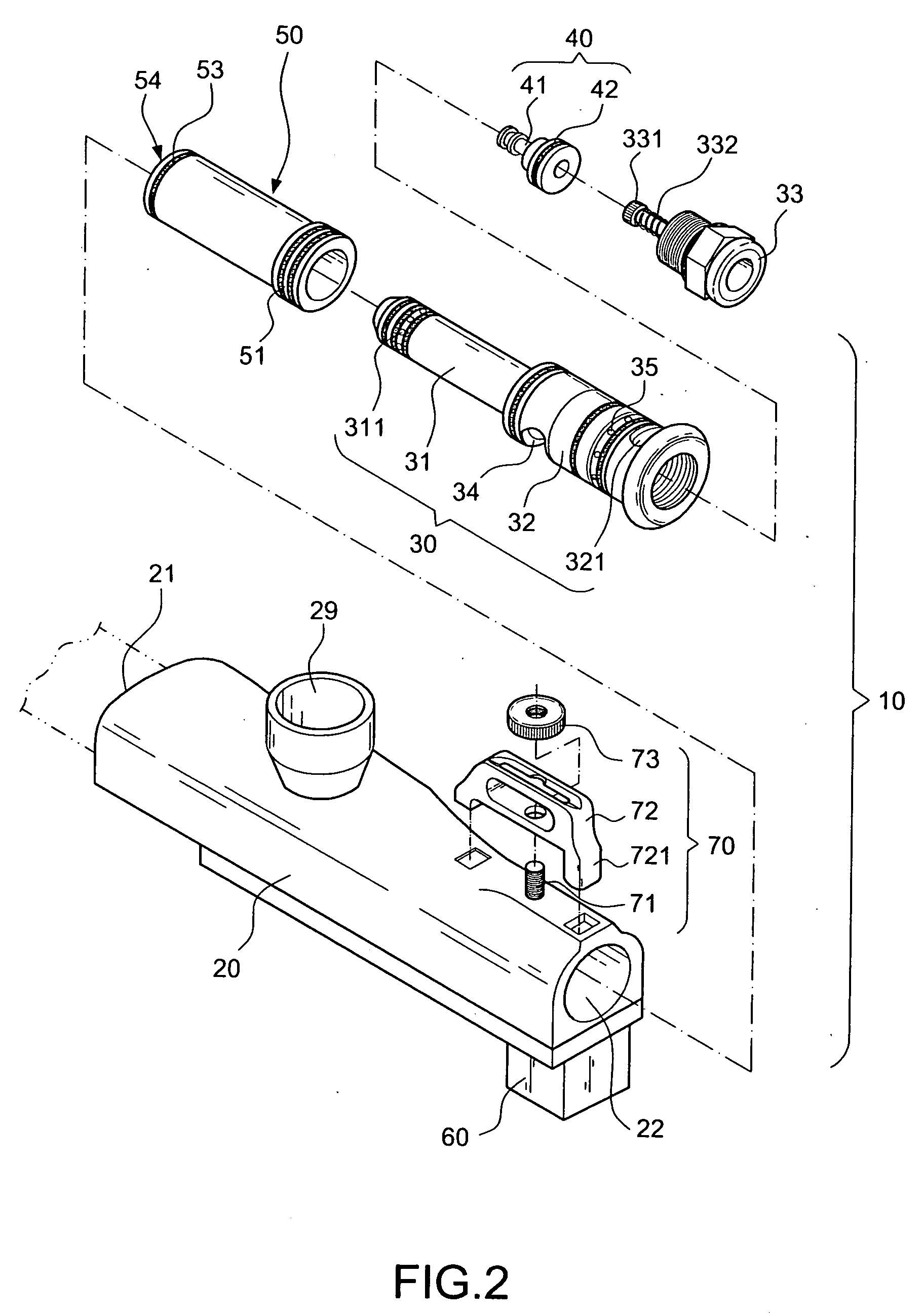

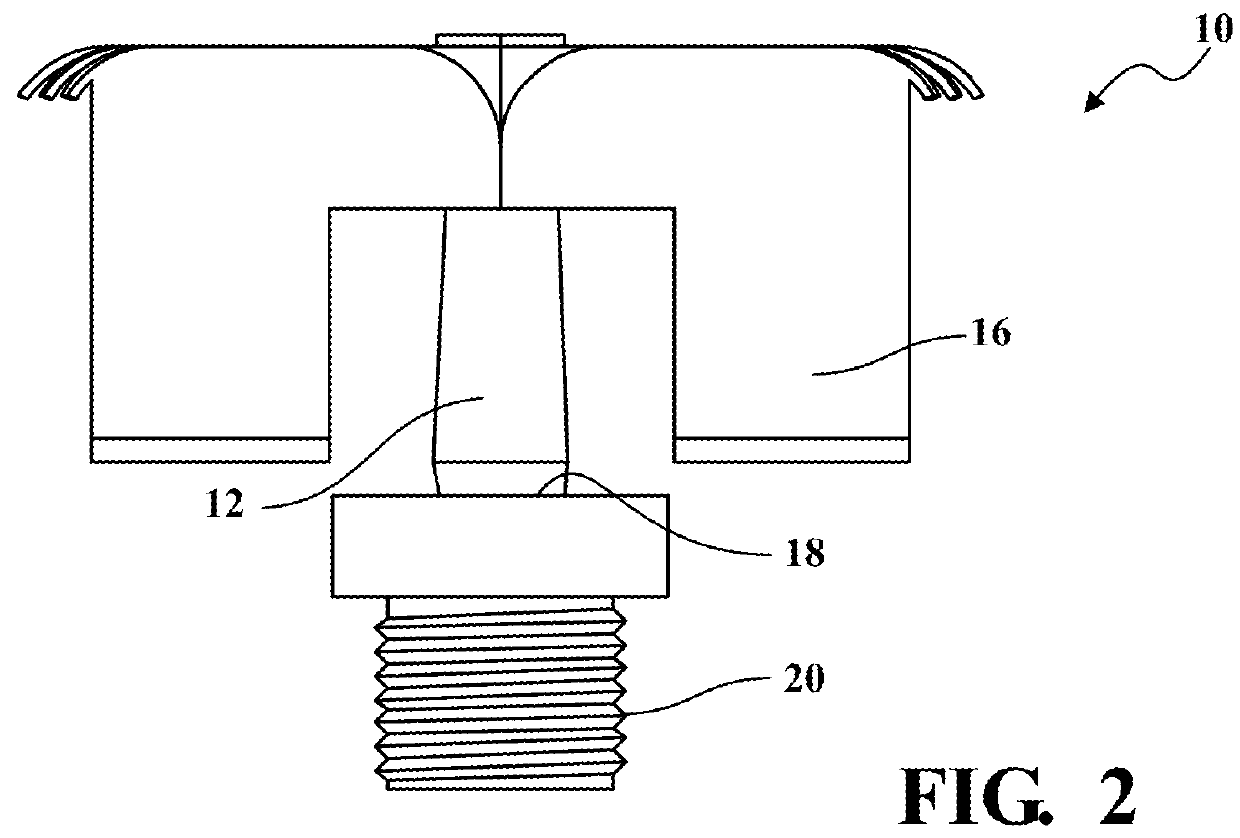

Pneumatic pusher

ActiveUS7527049B2Low failure rateIncrease the discharge speedCompressed gas gunsLiquid spraying apparatusReciprocating motionPneumatics

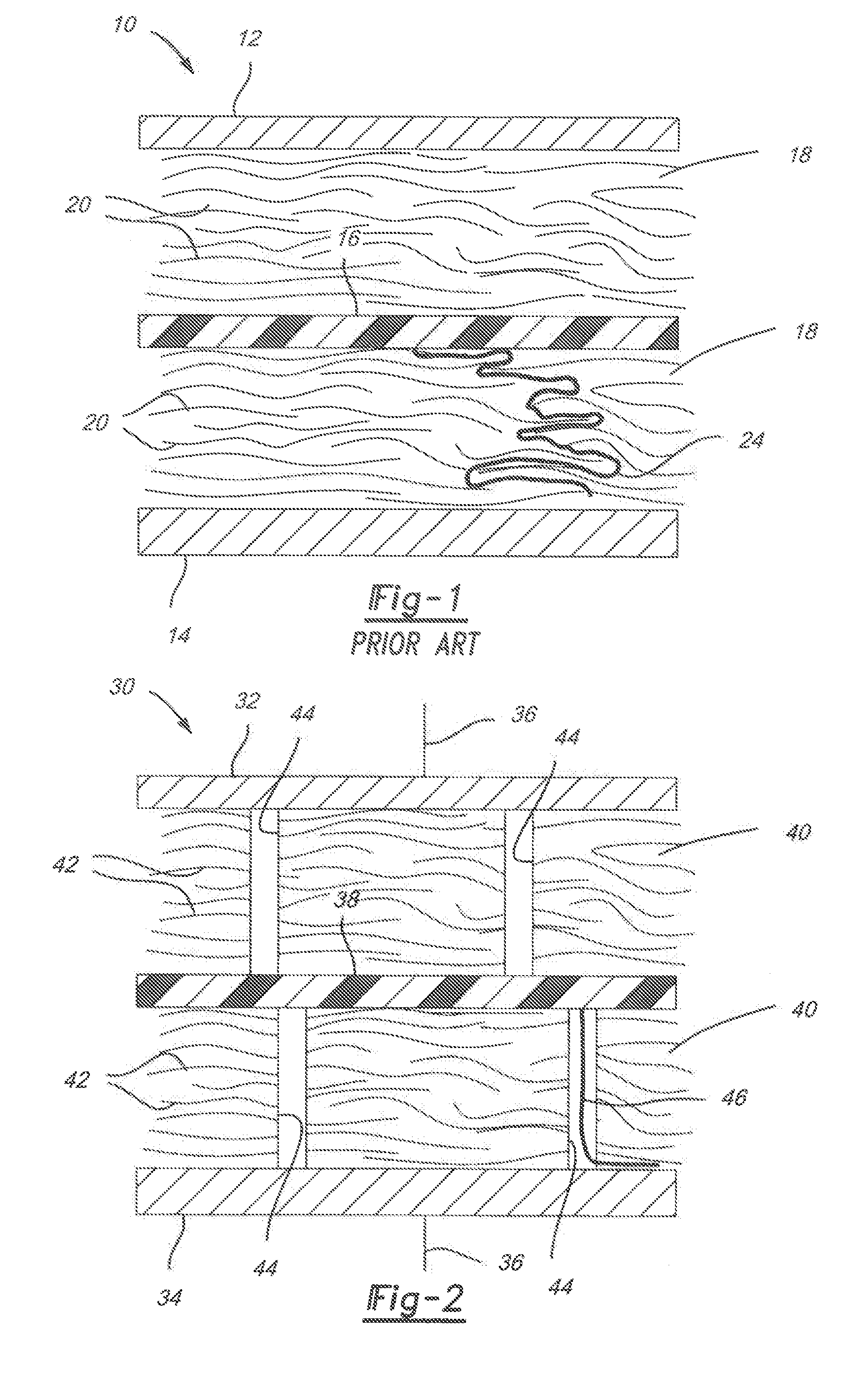

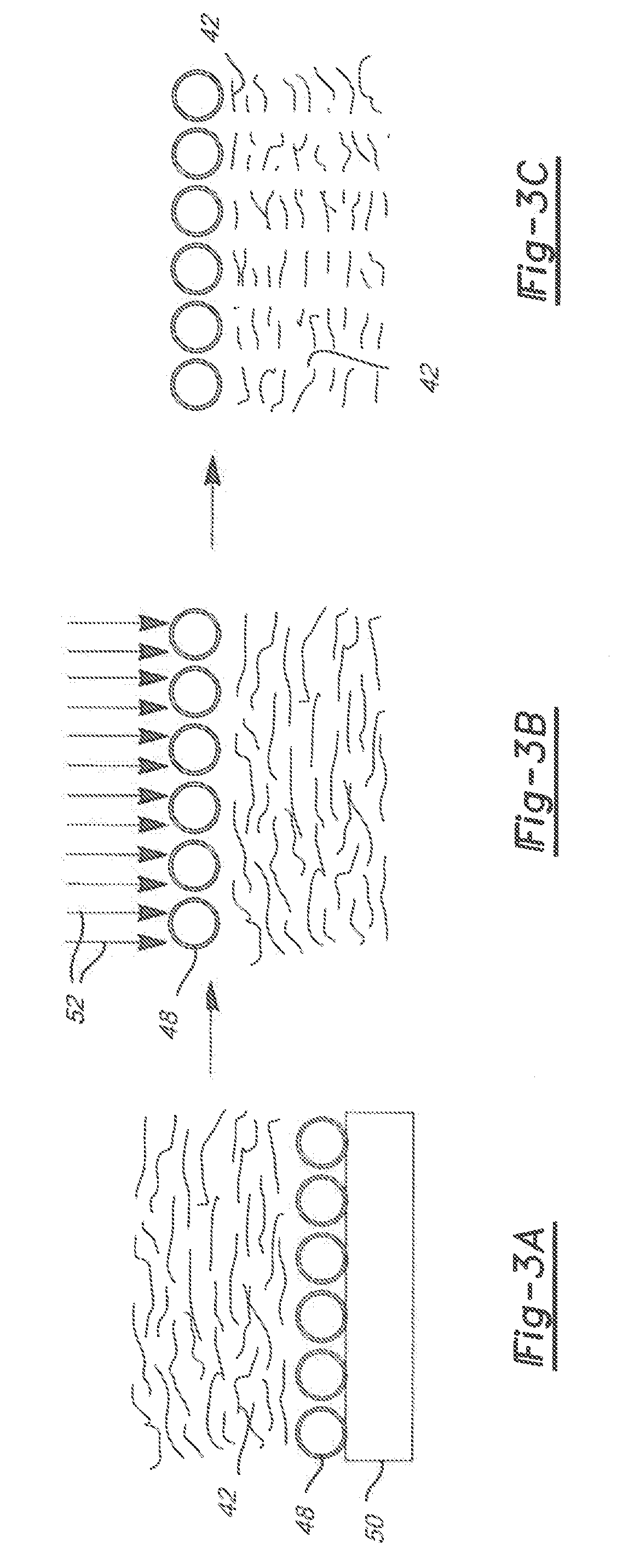

A pneumatic pusher having a main body, a flow-guiding body, a moving body, and a delivery tube. The flow-guiding body includes a front tube with a smaller diameter and a rear tube with a larger diameter. The delivery tube is mounted on the front tube in such a way that the outer wall of the delivery tube and the inner wall of the main body define a return pressure chamber. A first gas-distributing channel extending from a first air outlet at one side of the main body leads directly to the inner side of the delivery tube. The side of the first air inlet of the main body communicates with a second gas-distributing channel. The second gas-distributing channel includes an exit located at one side of the return pressure chamber of the delivery tube. The air pressure provided through the second gas-distributing channel serves as cushioning force in pushing the delivery tube outwardly. When the moving plunger blocks the gas distributing chamber in such a way that the gas is stopped to be injected through the first gas distributing channel into the pushing chamber for bringing the delivery tube forward, the gas pressure injected through the second gas distributing channel into the return pressure chamber acts as inward return force for the delivery tube. Therefore, the reciprocating movement of the delivery tube on the front tube can be completely done by the airflow.

Owner:SHENG CHIH SHENG

Lead acid battery taking graphene as additive

ActiveCN102244300AImprove electronic conductivityIncrease the speed of chargingLead-acid accumulatorsCell electrodesEngineeringGraphene

The invention discloses a lead acid battery taking graphene as an additive, and relates to a lead acid battery technology. The lead acid battery comprises a battery shell, a positive plate grid, a negative plate grid, a partition board and electrolyte, wherein the positive and negative plate grids are positioned in the battery shell; the partition board is positioned between the positive and negative plate grids; and the electrolyte is filled into the shell. The lead acid battery is characterized in that: the positive plate grid is manufactured by coating cathode lead paste and performing curing, drying and formation; the negative plate grid is manufactured by coating anode lead paste and performing the curing, the drying and the formation; and the cathode lead paste or the anode lead paste or both take the graphene as the additive. The lead acid battery provided by the invention takes the graphene material as the additive, can be rapidly charged and discharged, and simultaneously has high capacity and relatively longer charging and discharging circulation service life.

Owner:JIESHOU HUAYU POWER SUPPLY

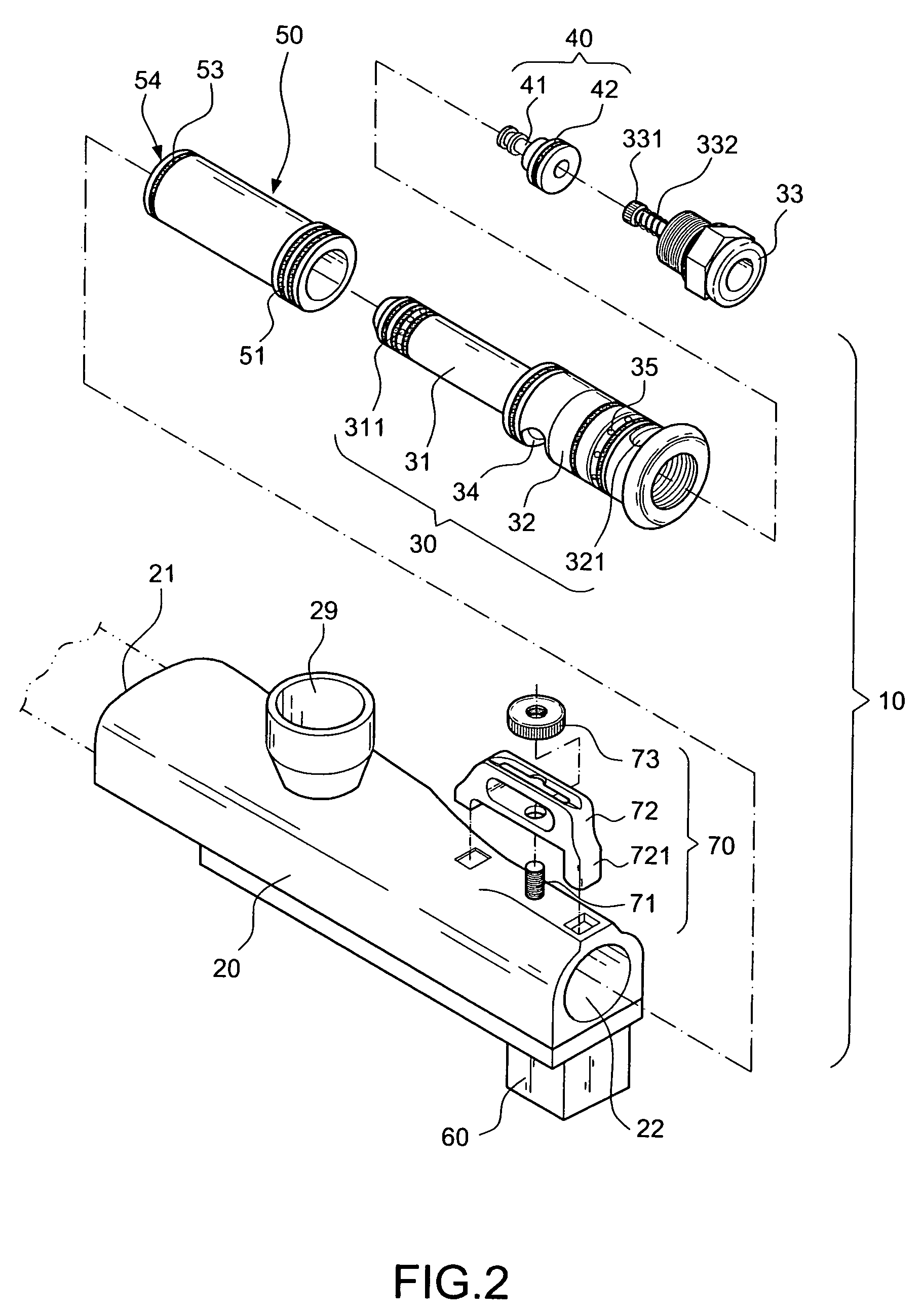

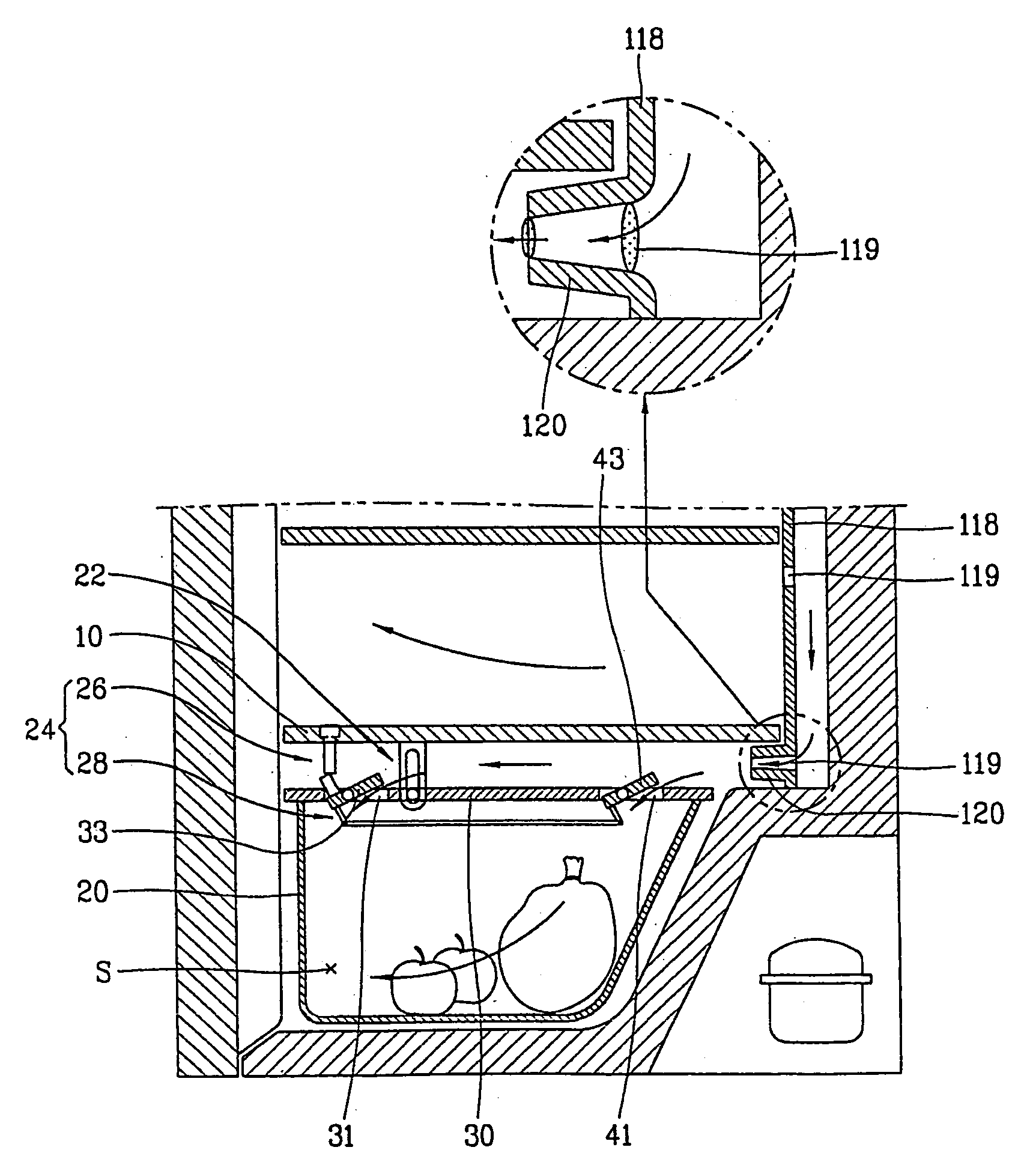

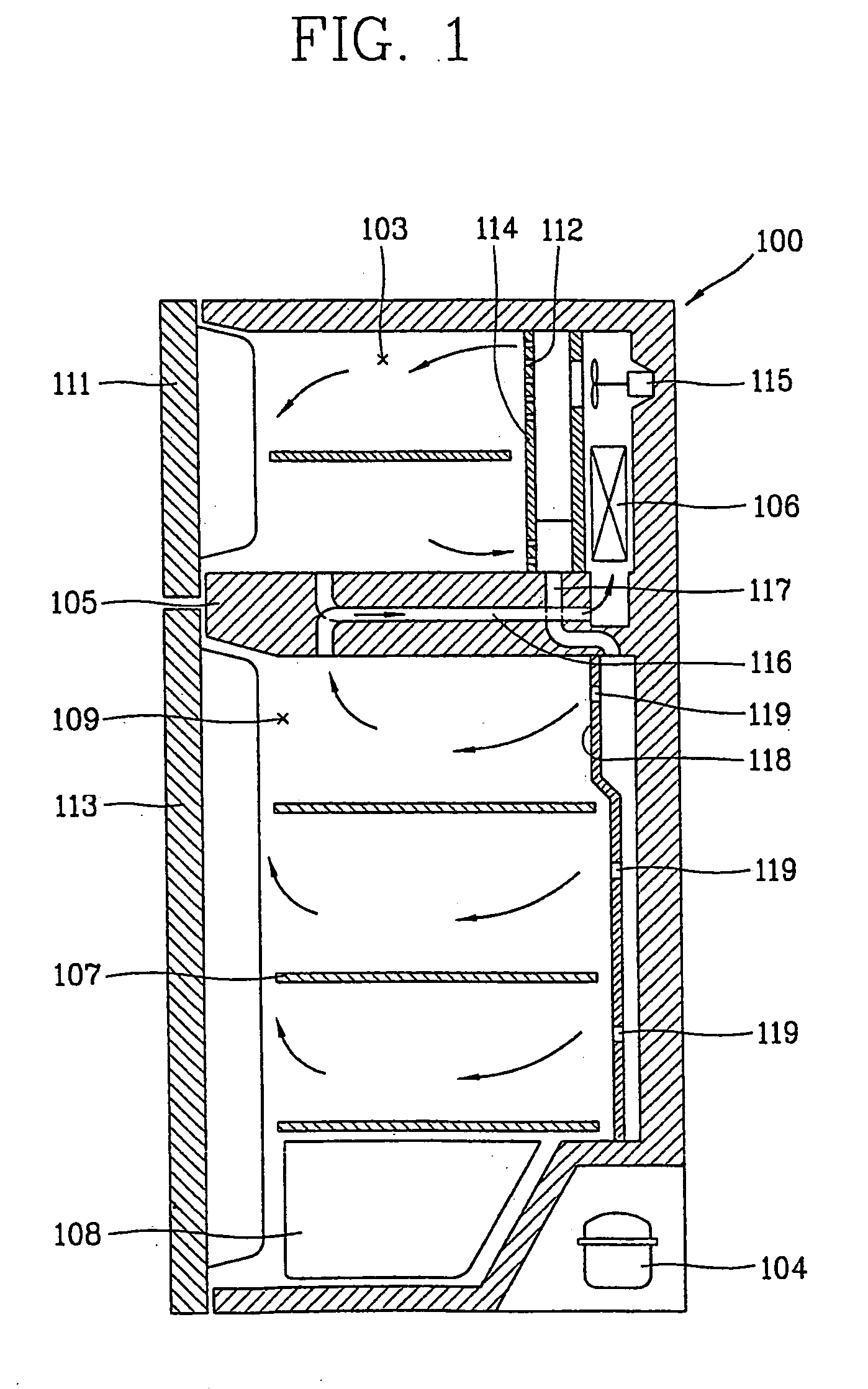

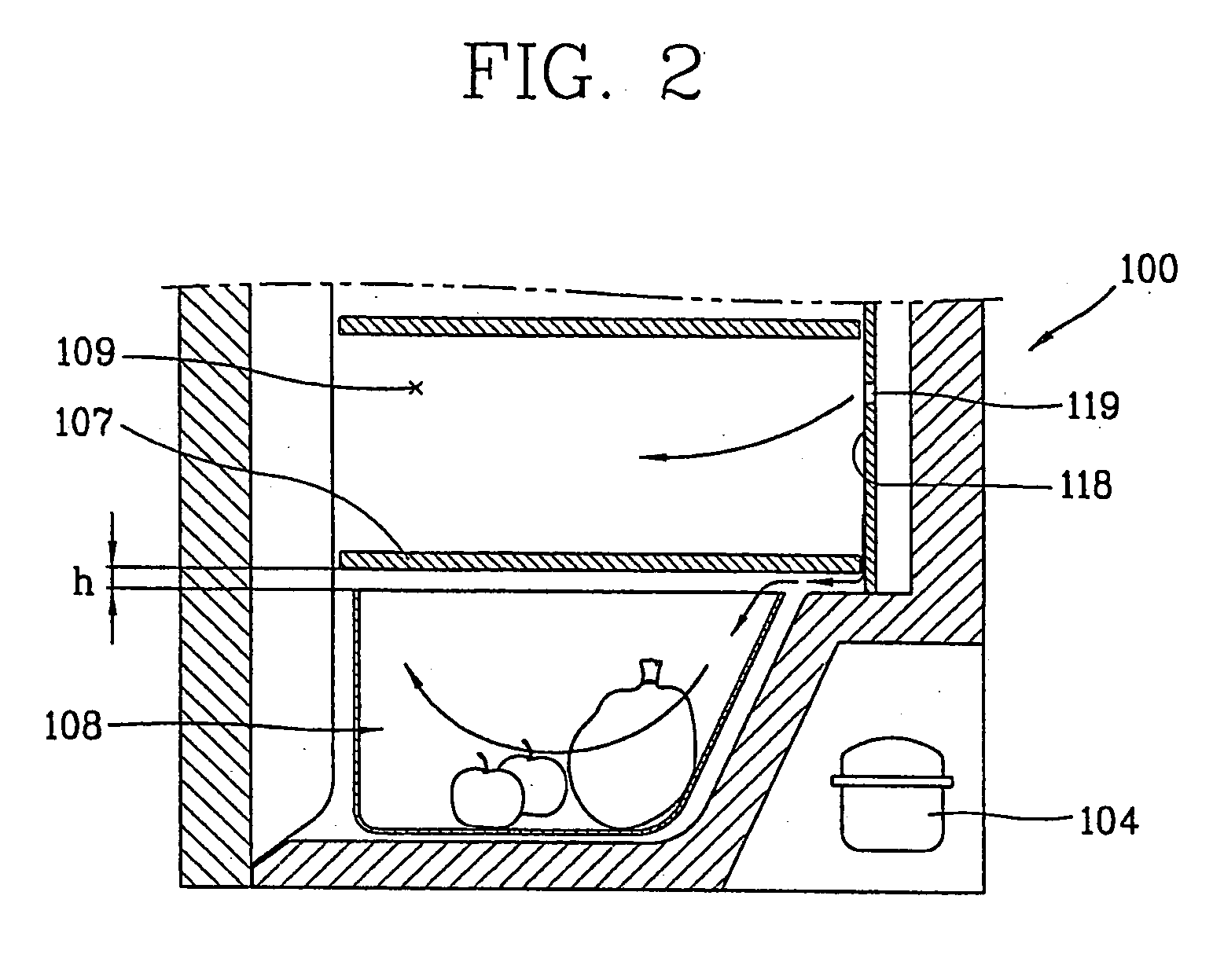

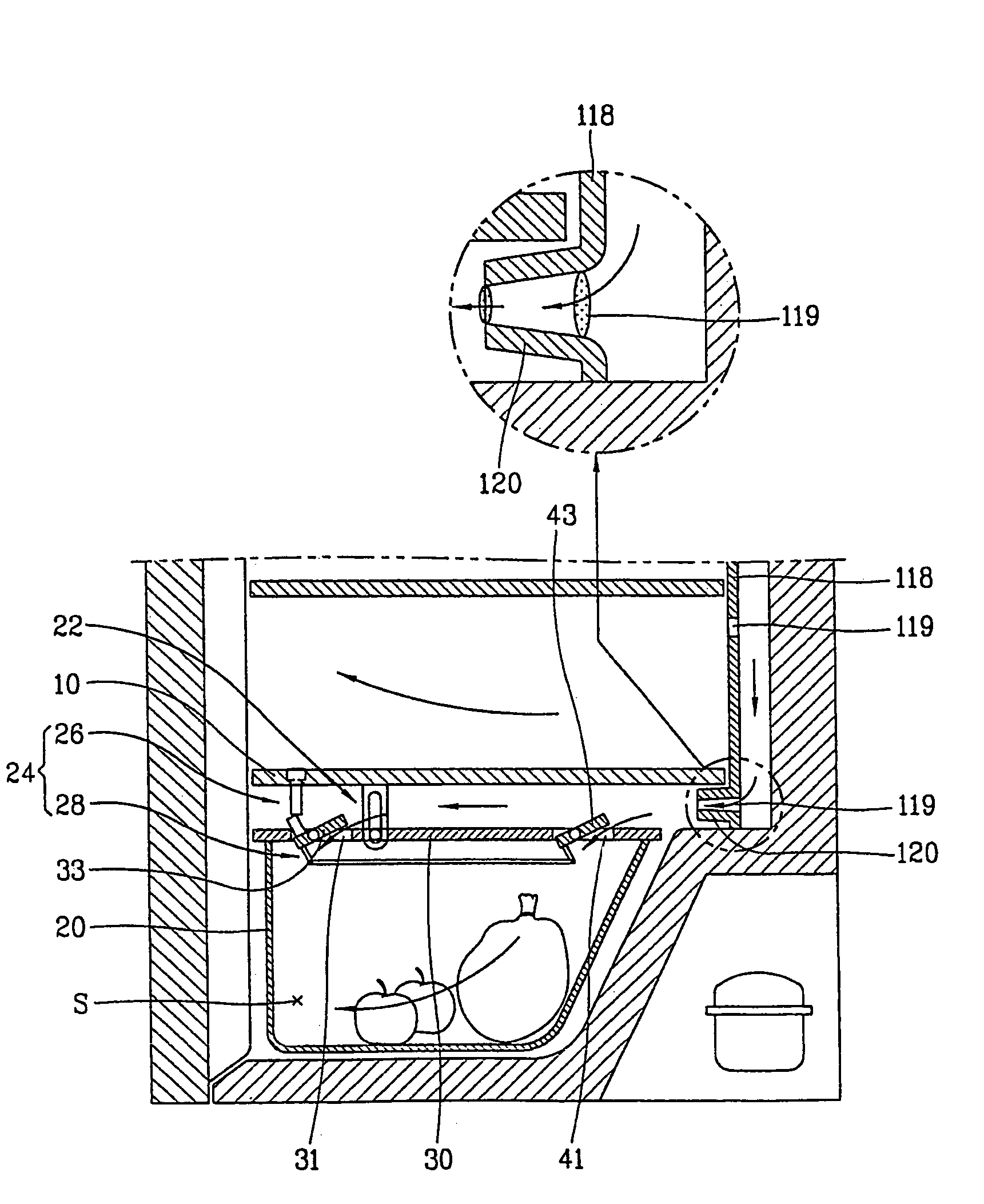

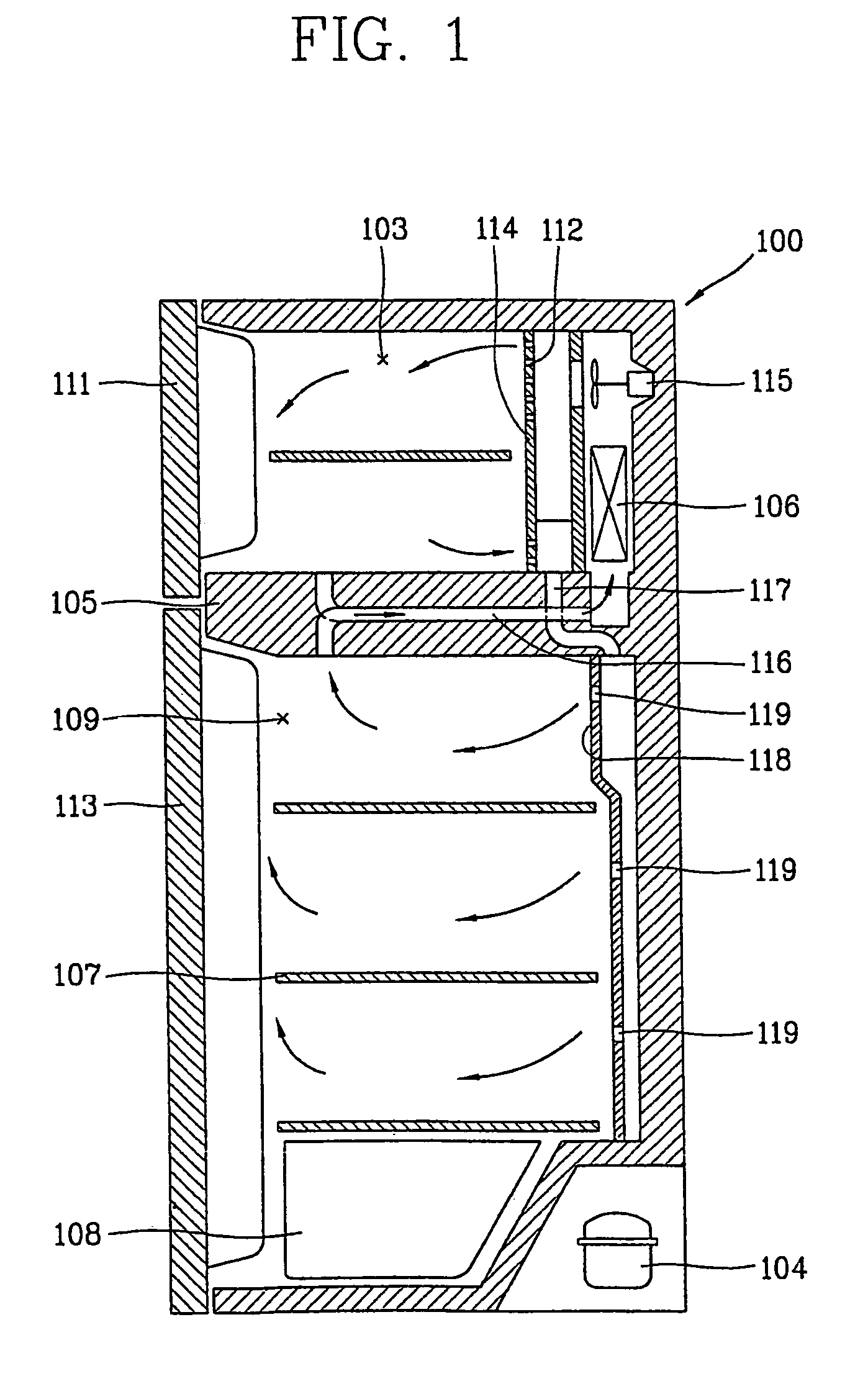

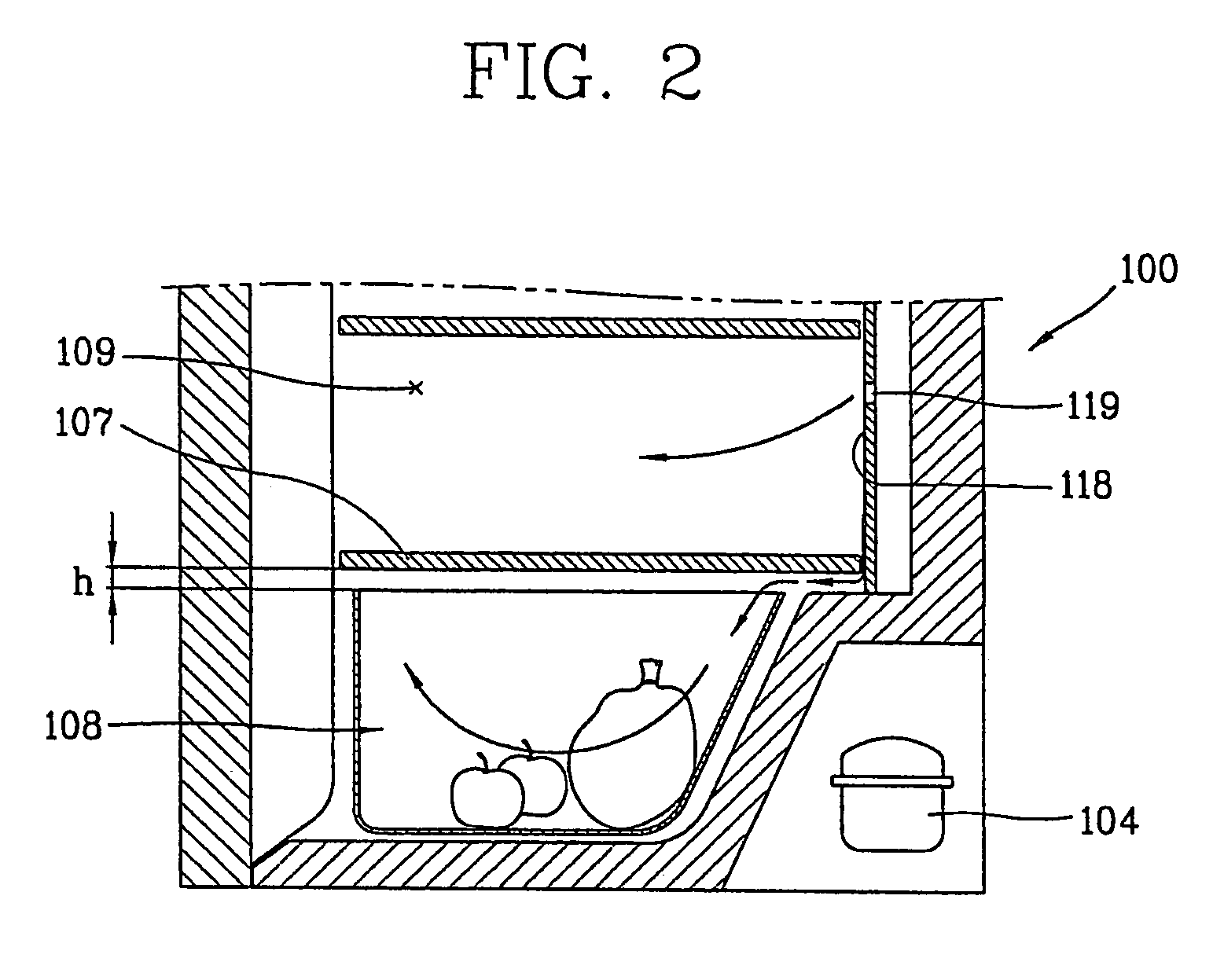

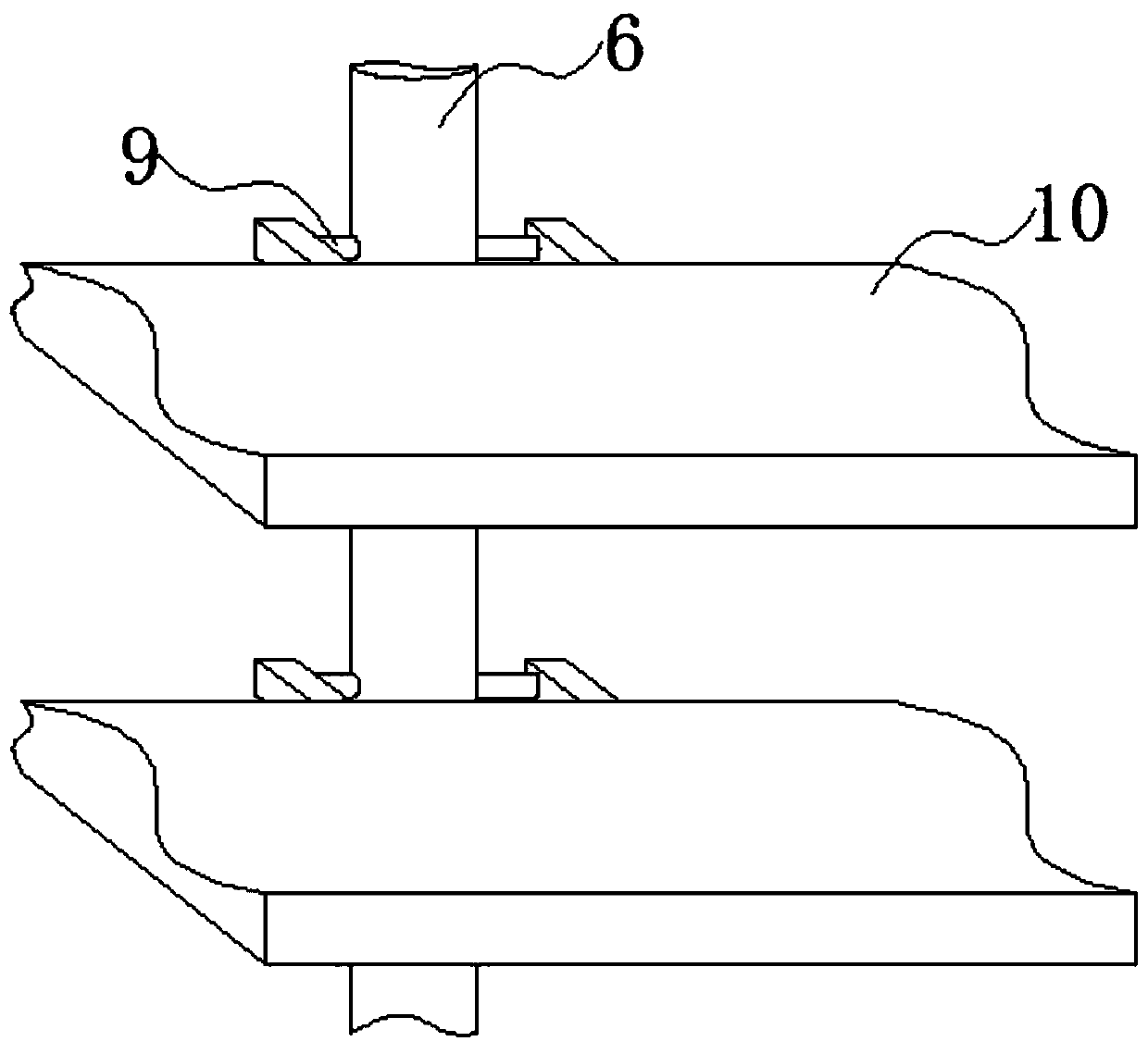

Vegetable room for refrigerator

InactiveUS20060005567A1Increase the discharge speedAvoid introducingDomestic refrigeratorsRefrigeration componentsEngineeringMechanical engineering

Owner:LG ELECTRONICS INC

Lead-acid storage battery lead paste and preparation method thereof

InactiveCN107230777AIncrease the speed of chargingIncrease the discharge speedLead-acid accumulator electrodesFiberPolyester

The invention discloses a lead-acid storage battery lead paste, comprising a positive lead paste and a negative lead paste, wherein the positive lead paste comprises the following components: regenerated lead powder, red lead, polytetrafluoroethylene, ultra-fine tetrabasic lead sulfate, sodium perborate, graphite, polyester staple fiber, glass fiber, antimonous oxide, dilute sulfuric acid and deionized water; and the negative lead paste comprises the following components: regenerated lead powder, red lead, barium sulfate, barium stearate, sodium lignosulfonate, humic acid, semi-carbonized wood chips, polyester staple fiber, modified graphene, dilute sulfuric acid and deionized water. According to the lead-acid storage battery lead paste disclosed by the invention, the problem of poor over-discharge performance and charge acceptance capability of a storage battery can be improved, and the service life of the storage battery can be prolonged.

Owner:HEFEI SHANGQIANG ELECTRIC TECH CO LTD

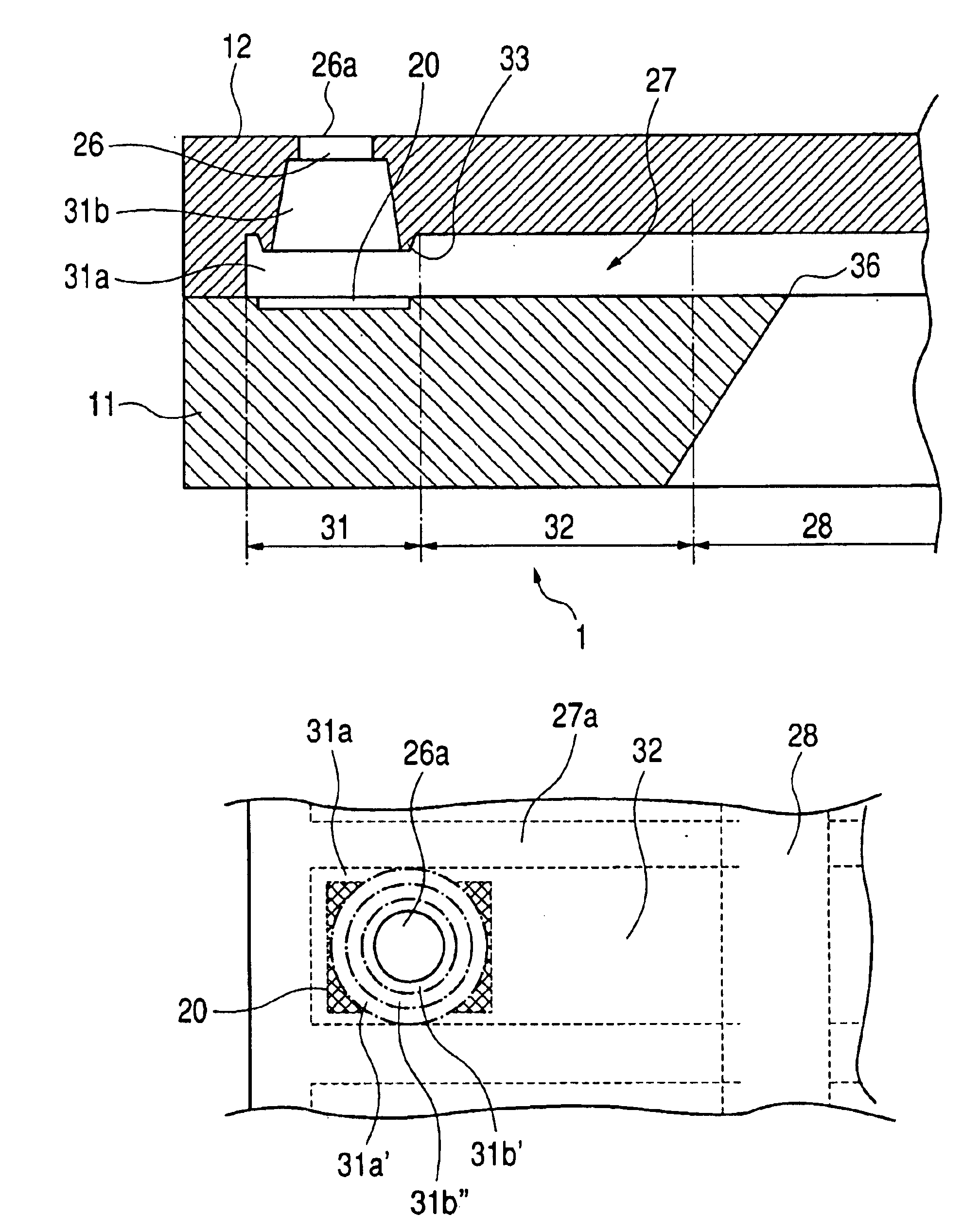

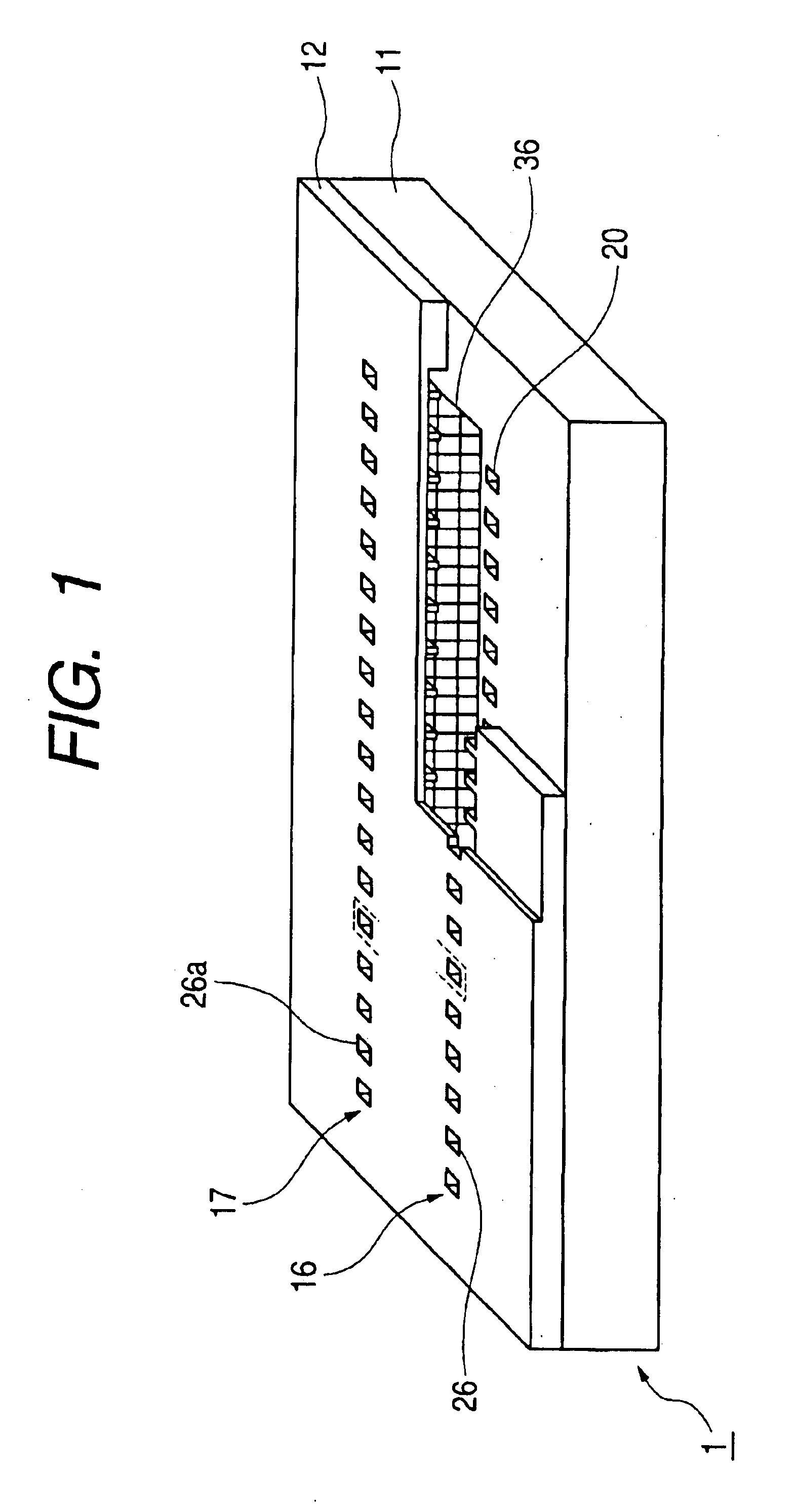

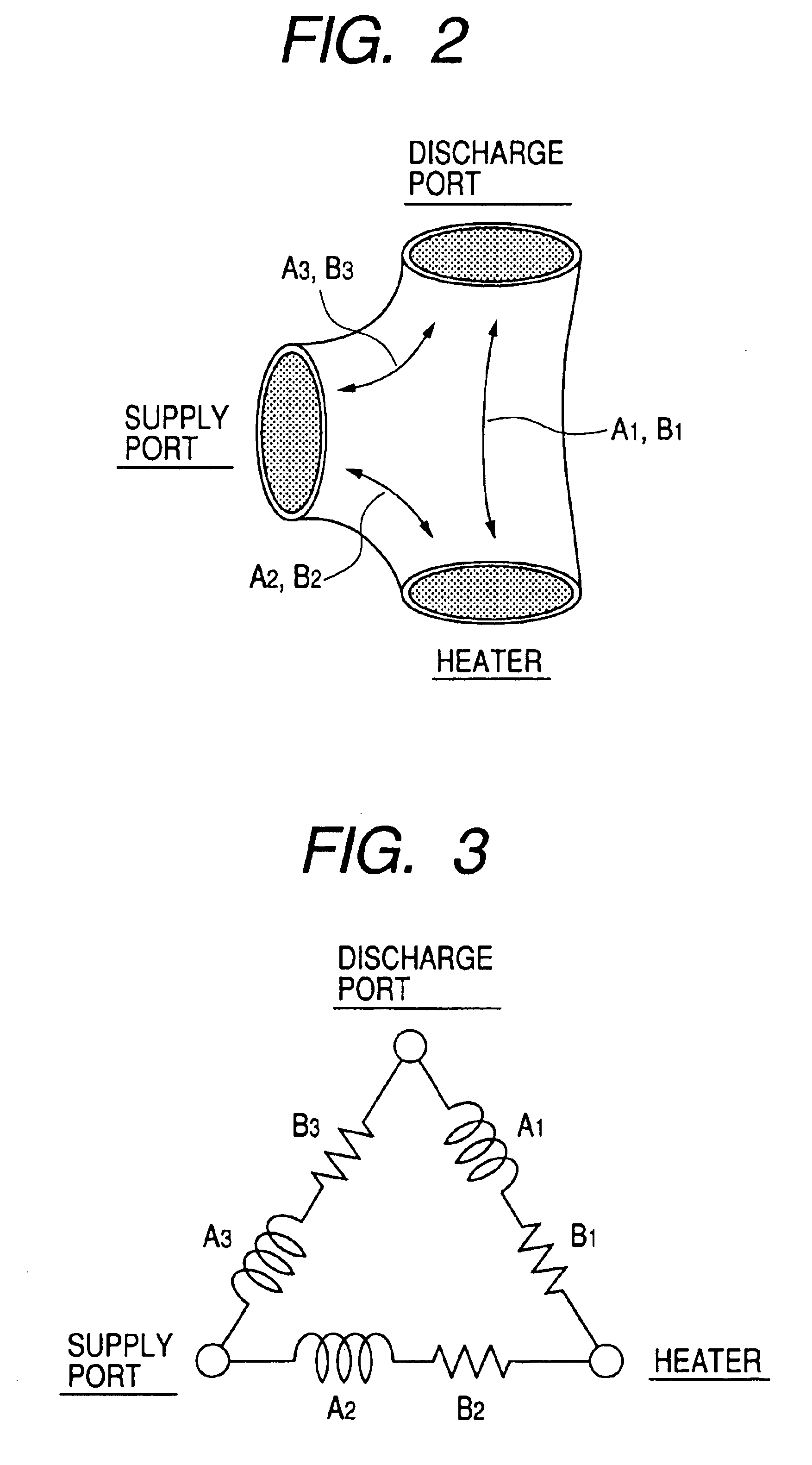

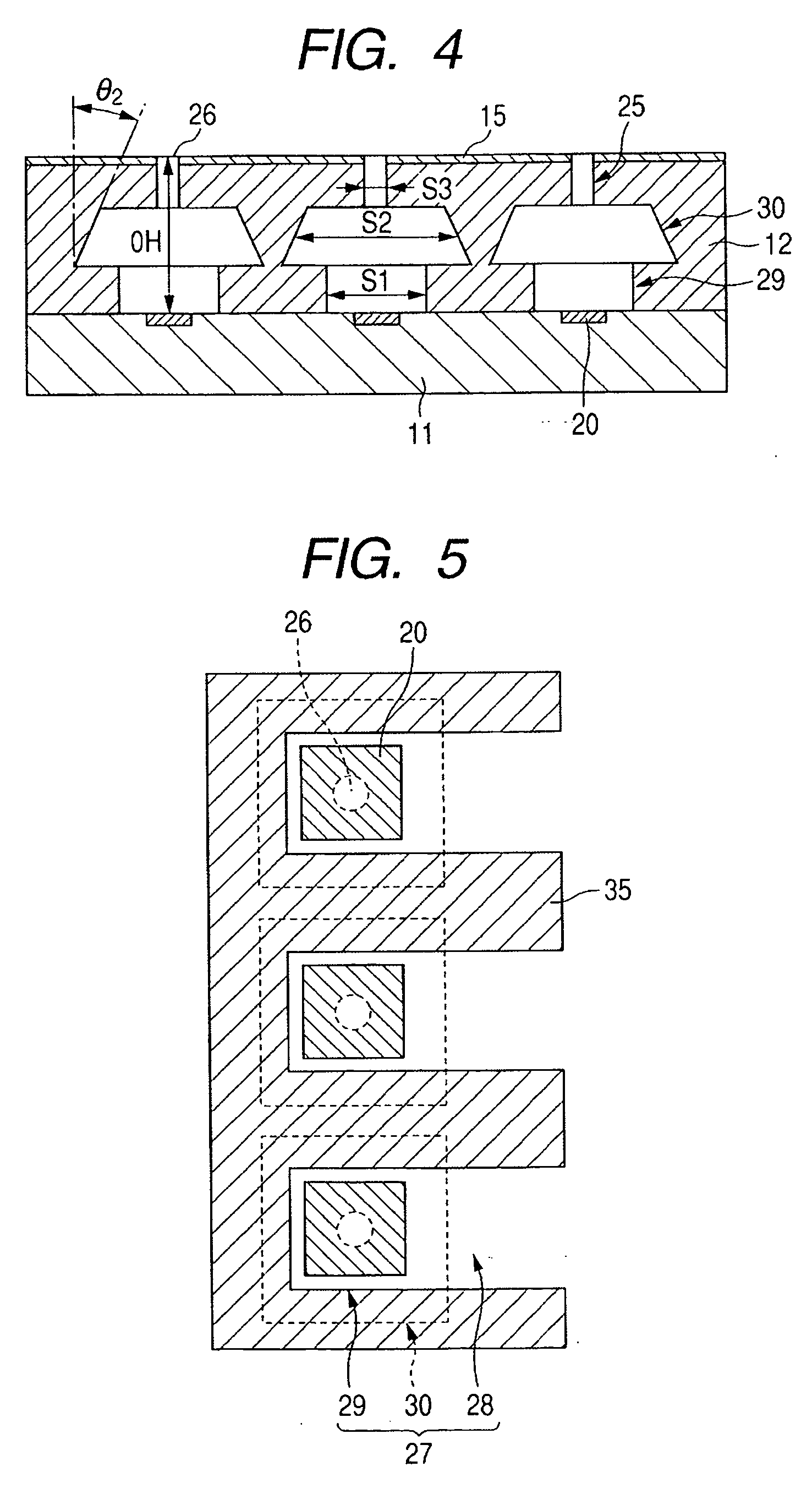

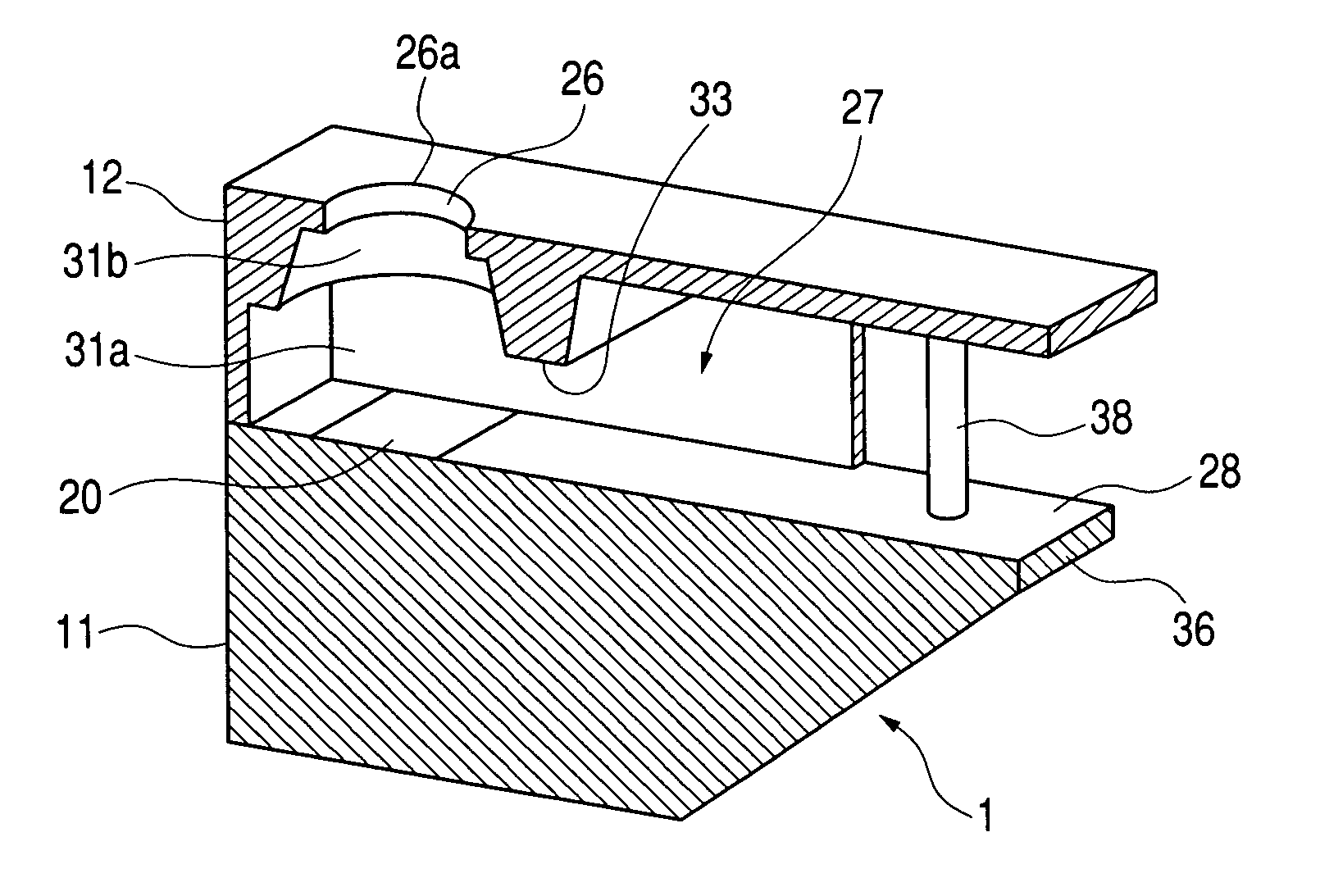

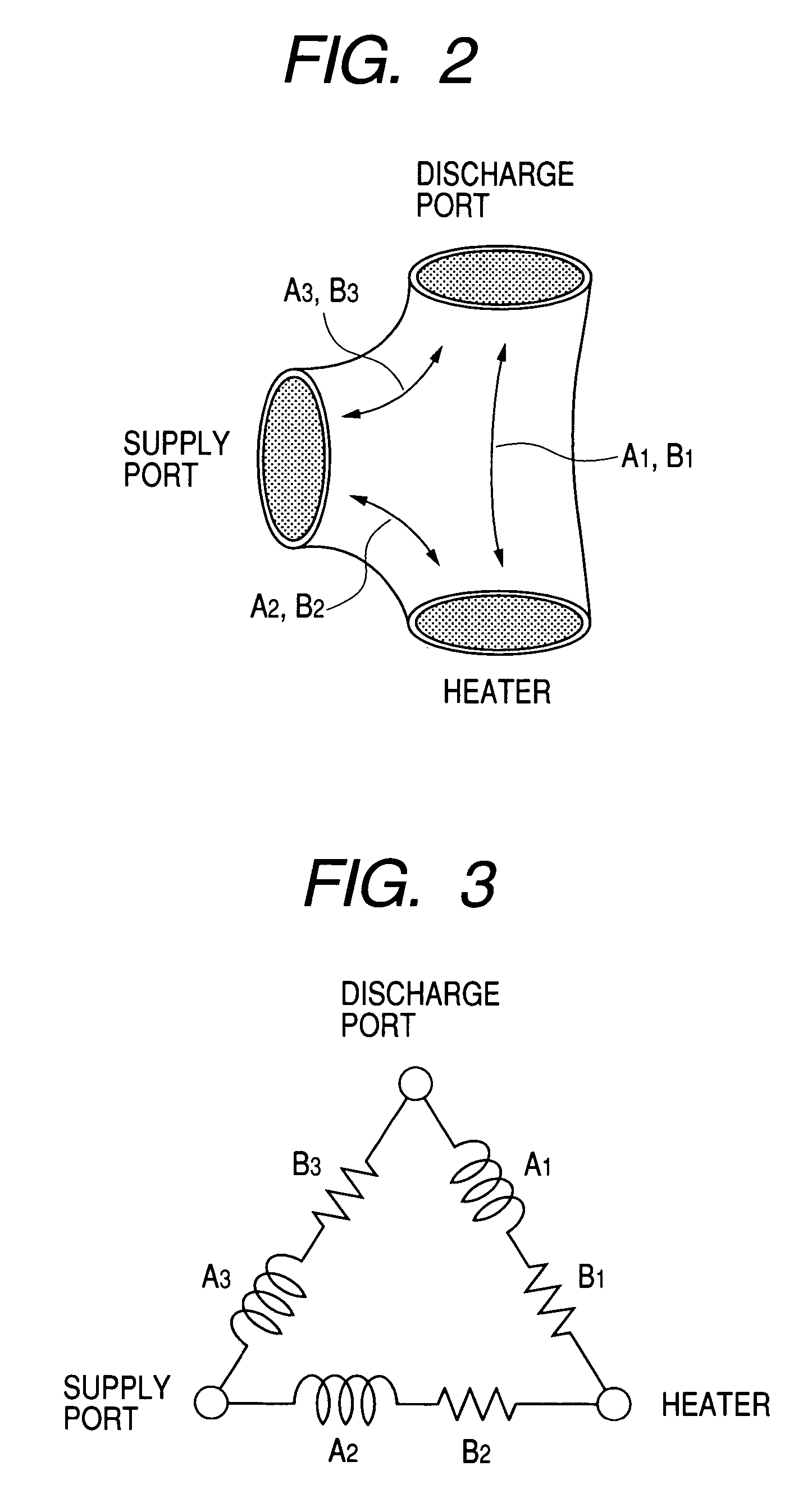

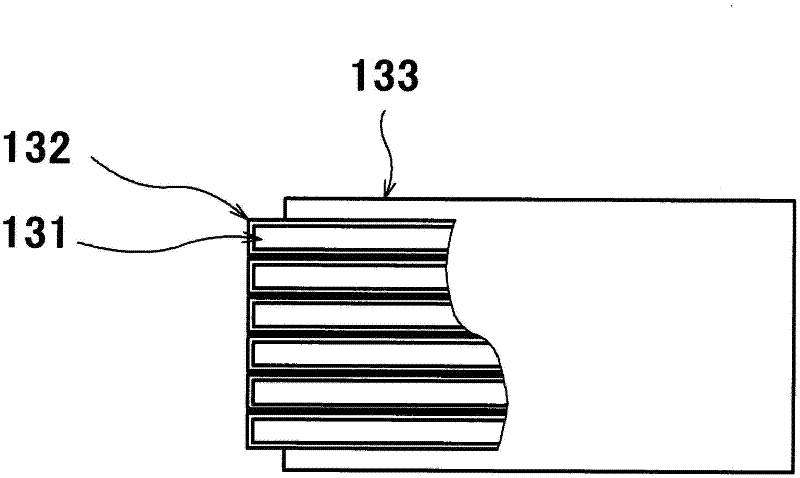

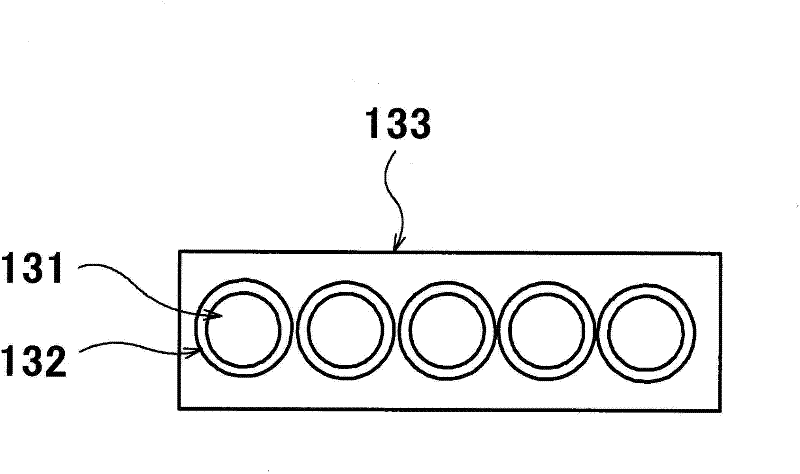

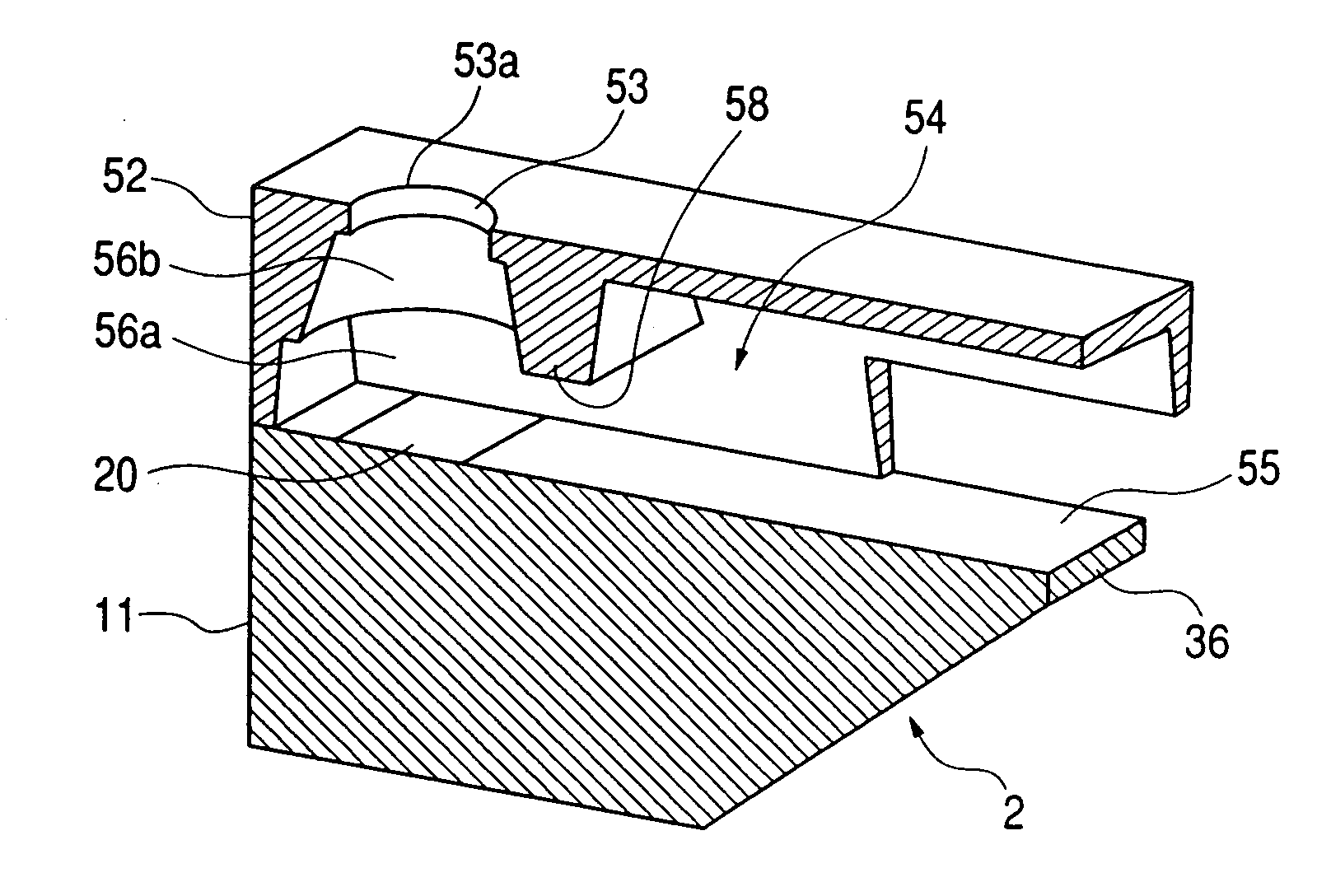

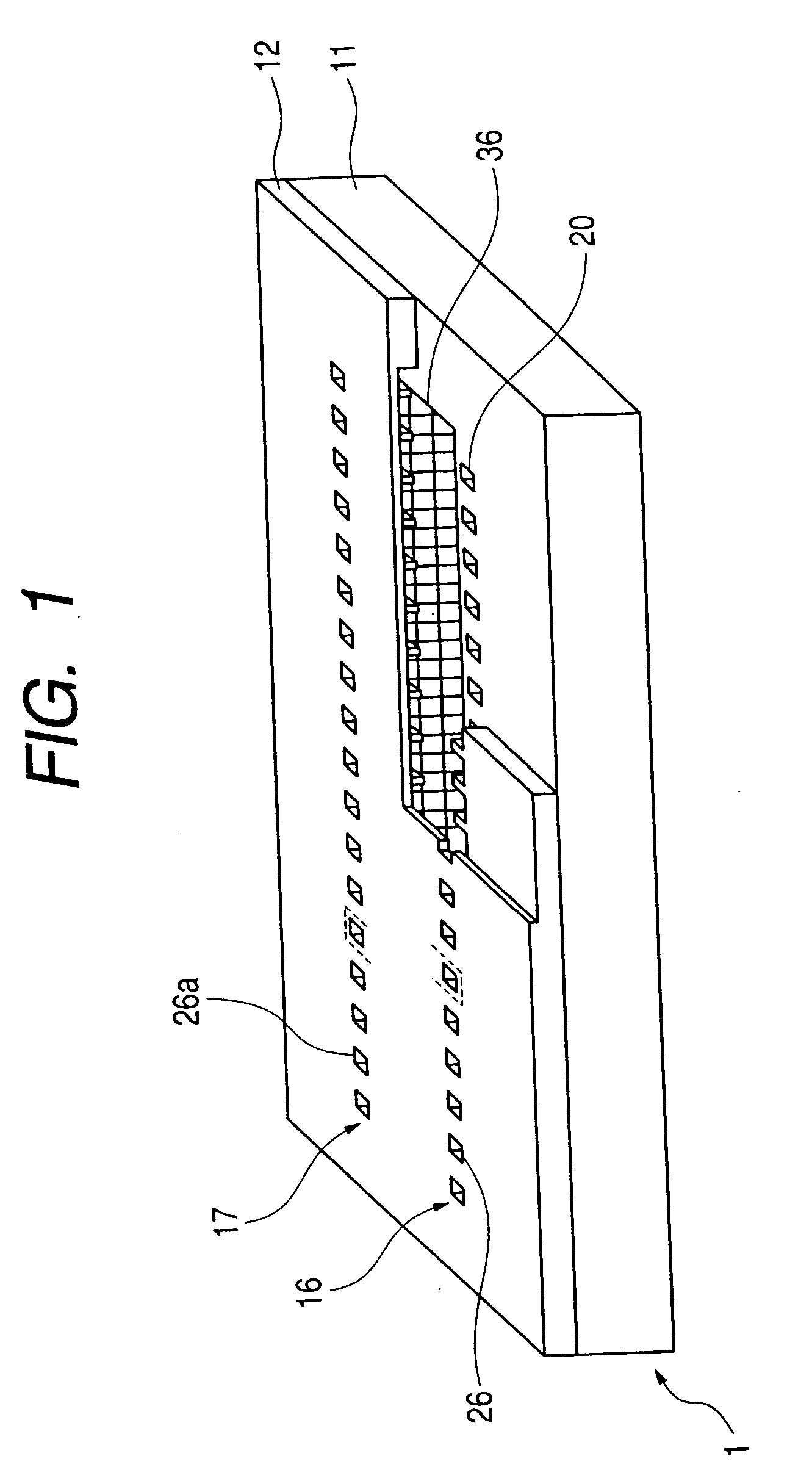

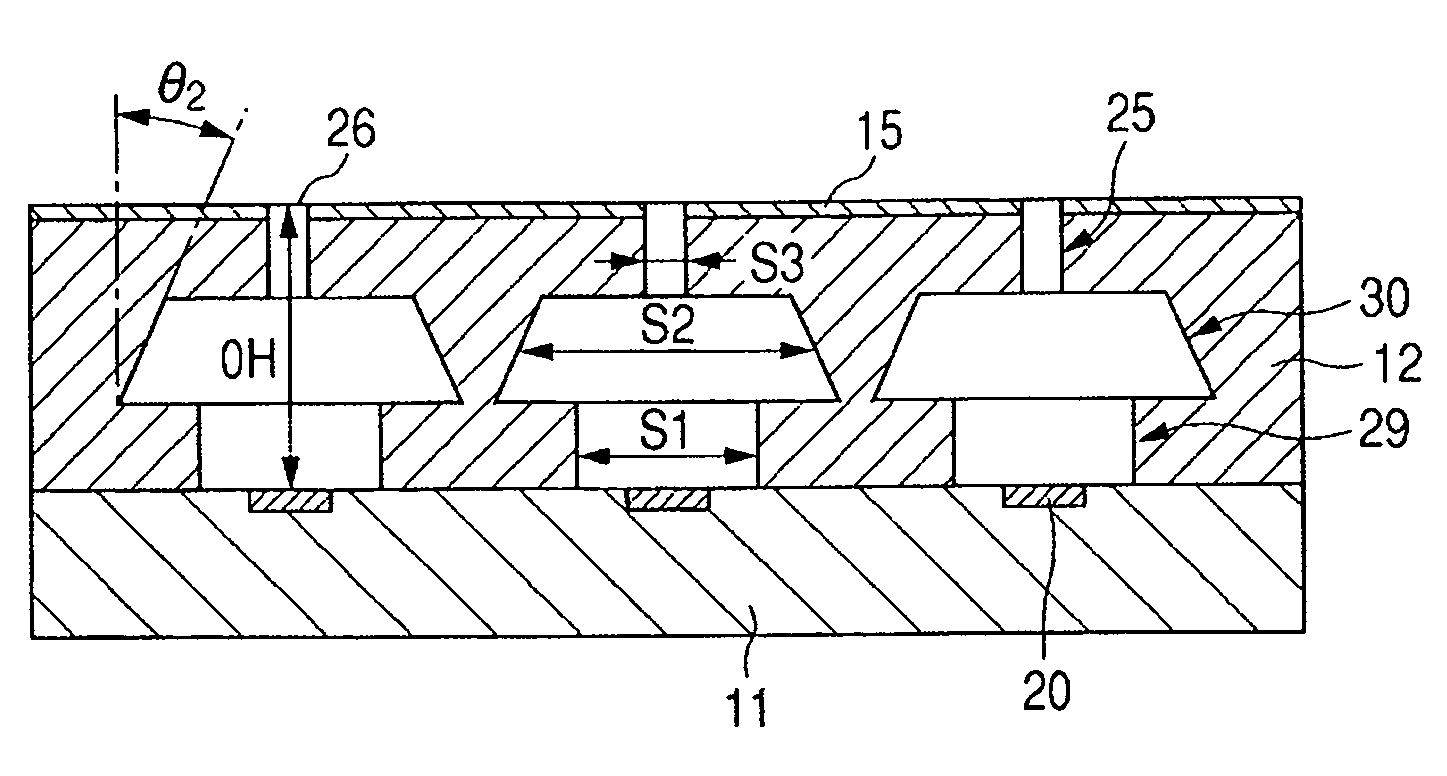

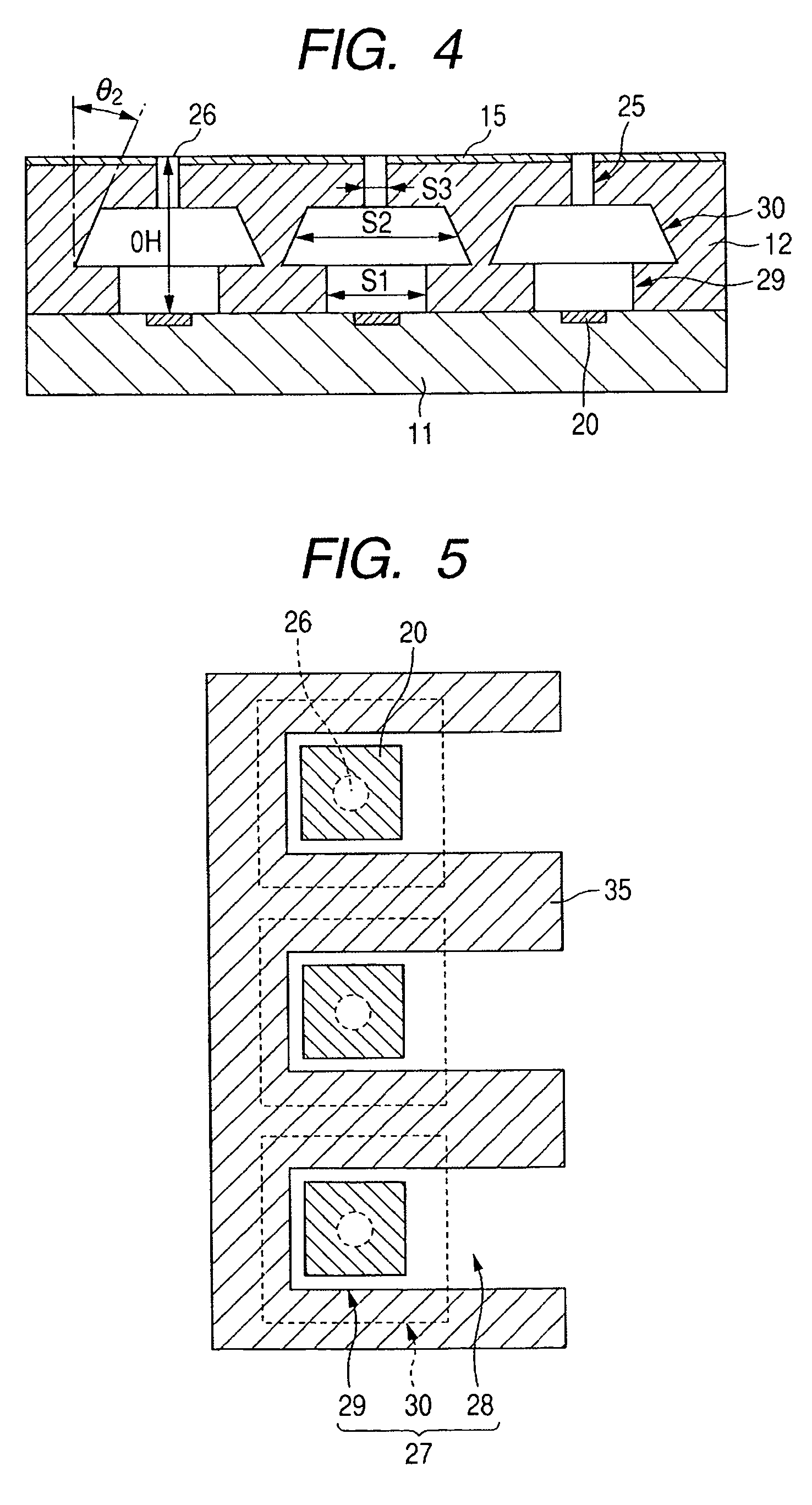

Liquid discharge head and method for manufacturing recording head

A liquid discharge head includes a first bubbling chamber, a second bubbling chamber arranged thereon, and a discharge port portion communicated with the second bubbling chamber with a difference in level. The sidewalls of the second bubbling chamber contract in the direction toward the discharge port at an inclination of 10 to 45°. On the circumferential portion of the upper face of the first bubbling chamber in contact with an opening communicated with the second bubbling chamber, an extrusion is formed continuously to surround the opening, in the direction toward the main surface of the element base plate.

Owner:CANON KK

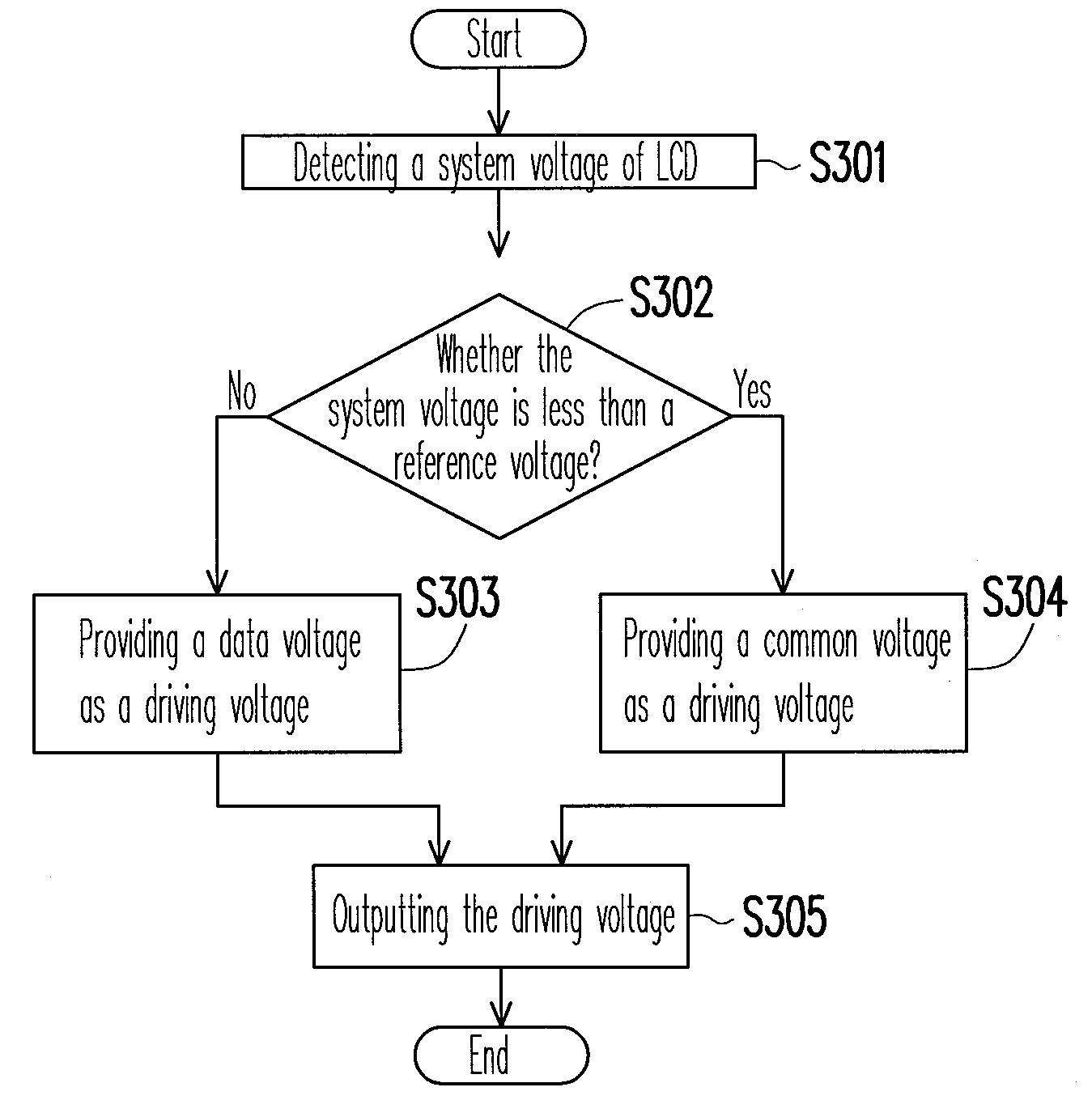

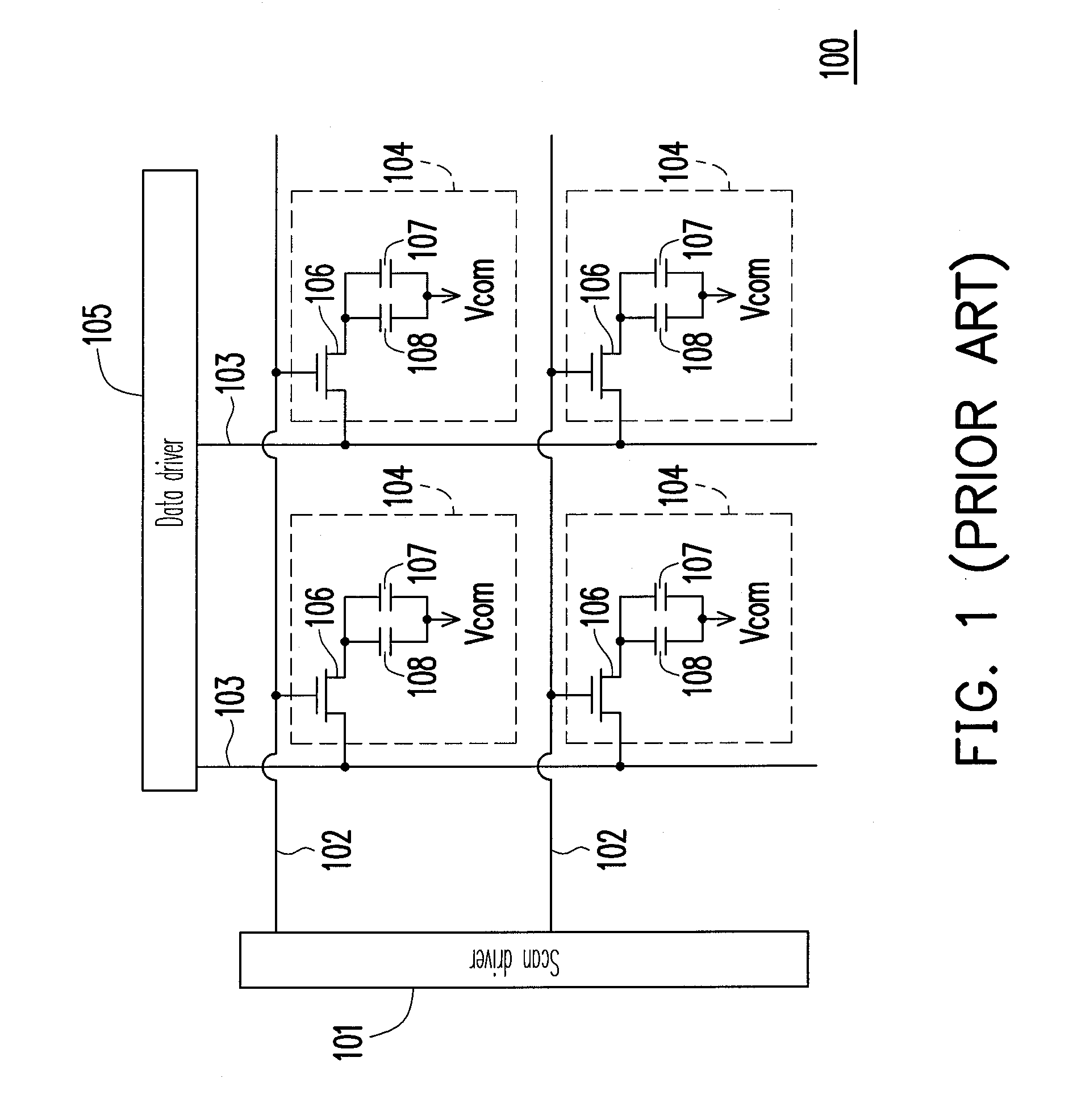

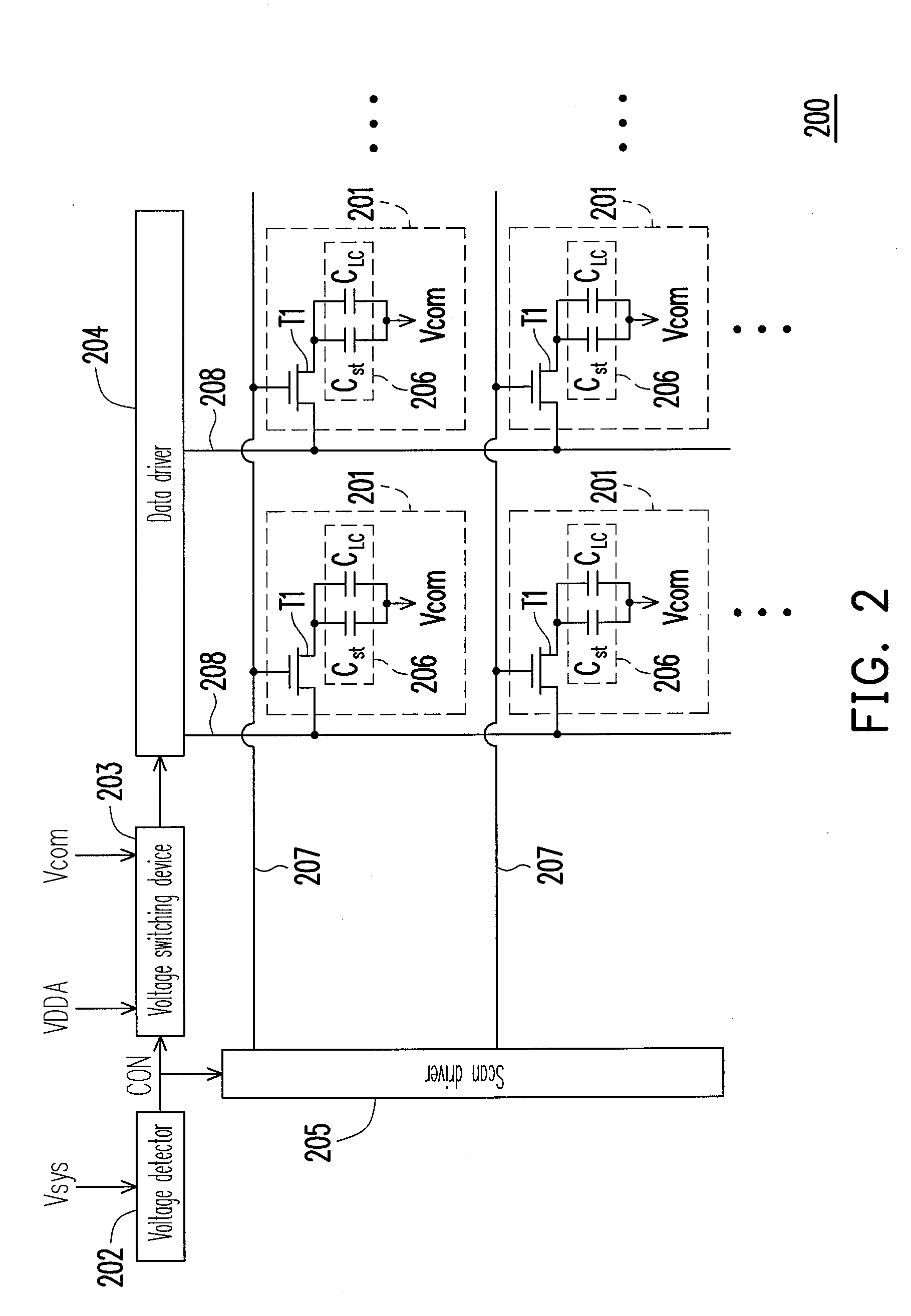

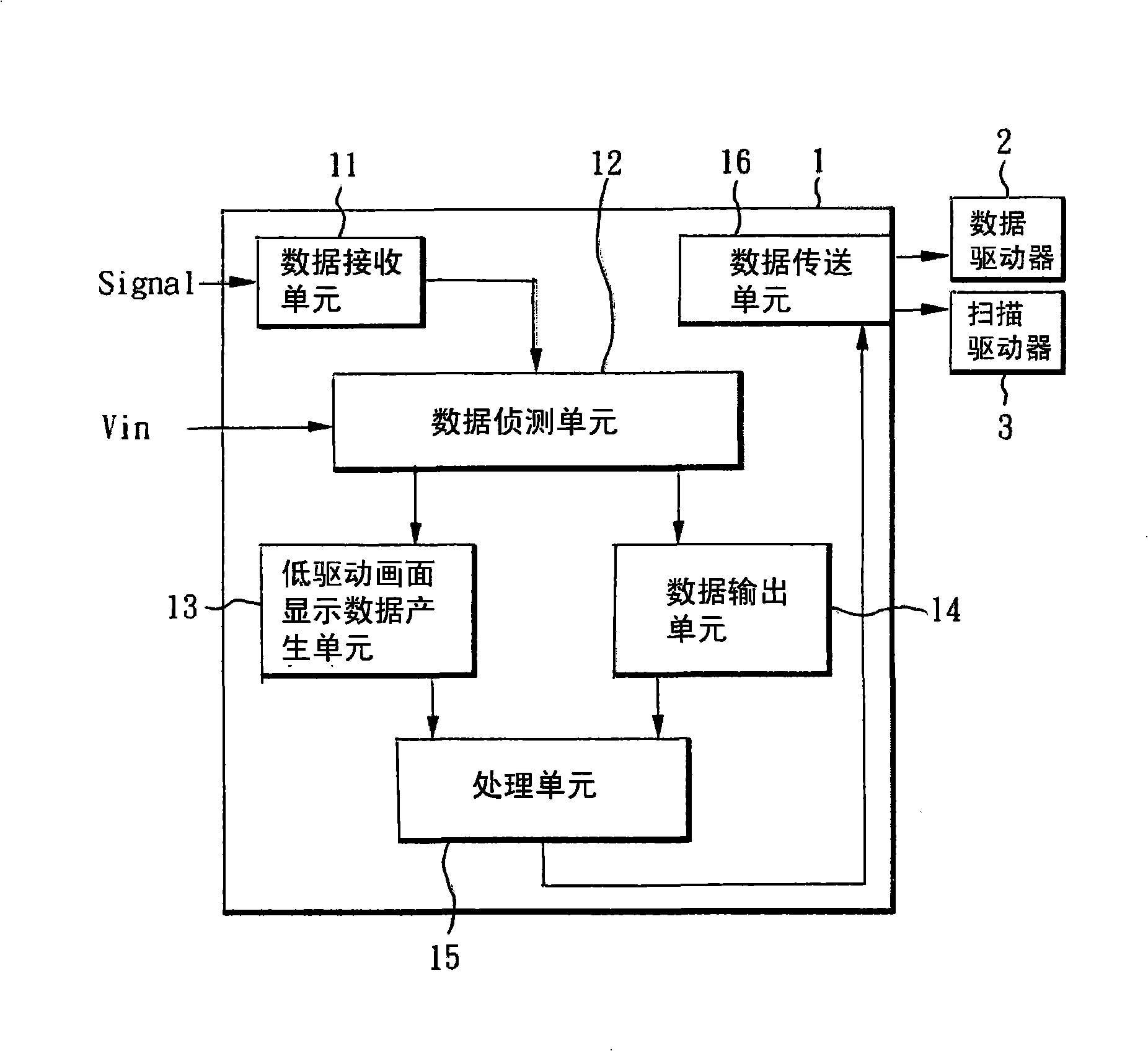

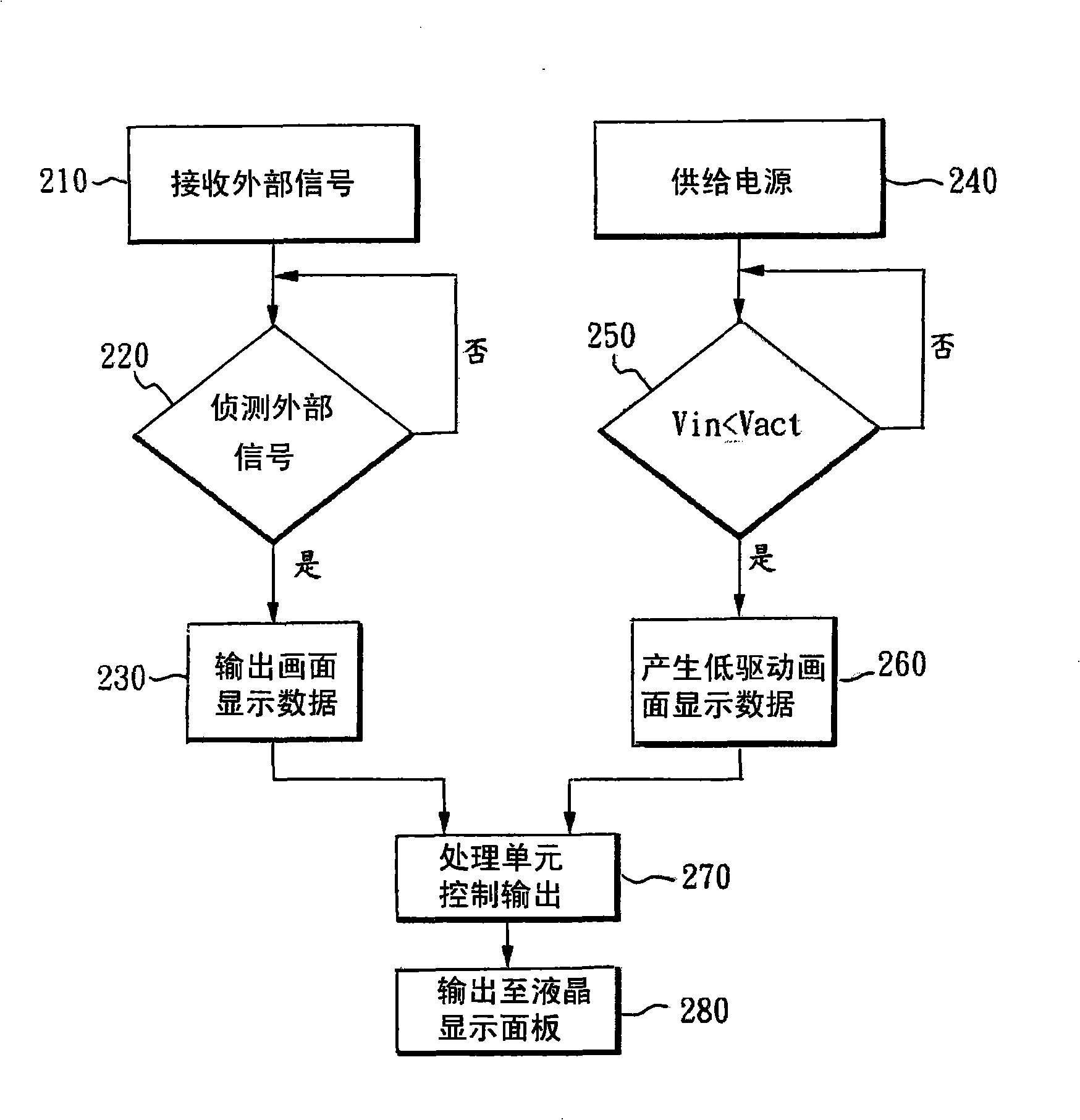

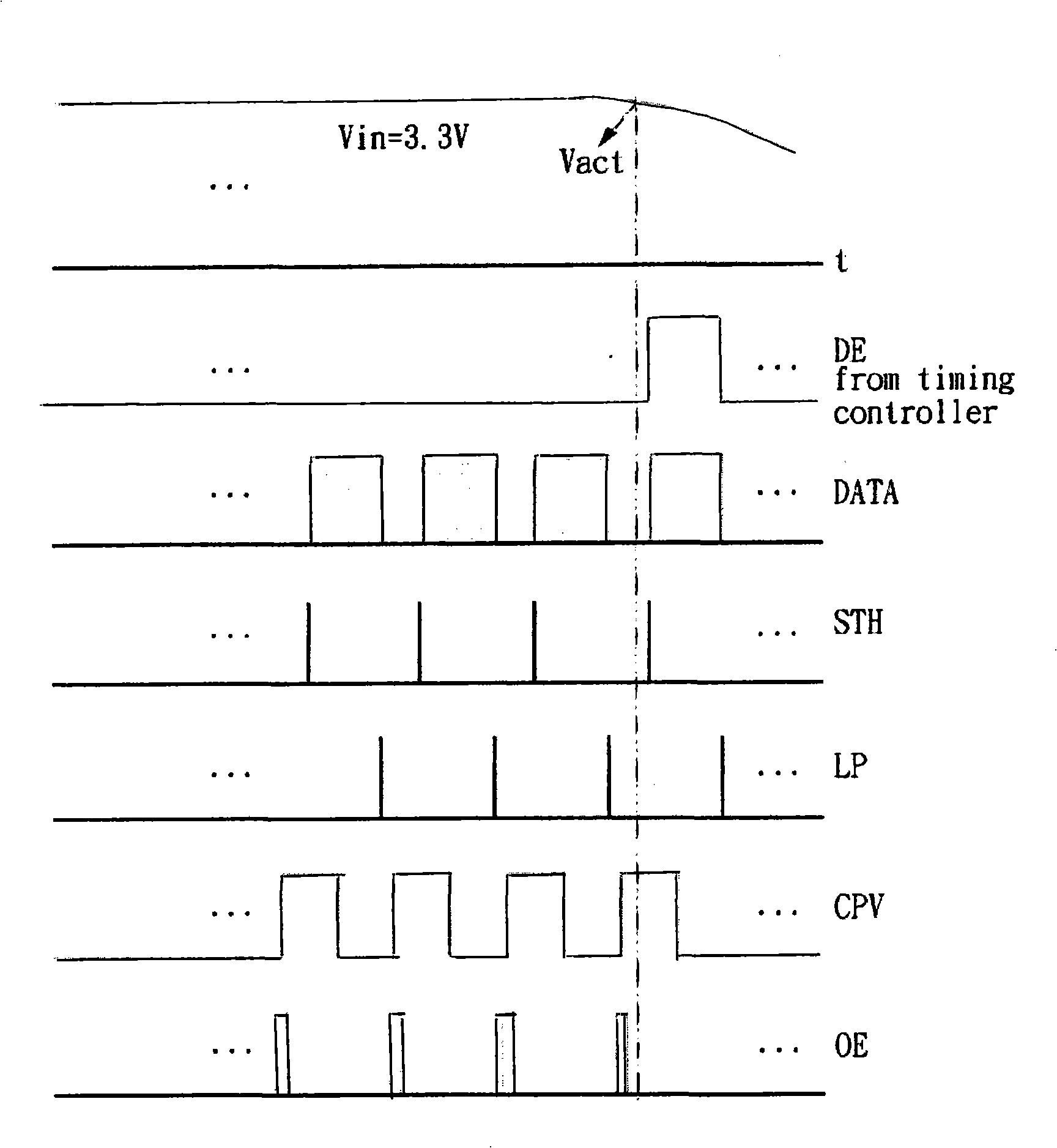

Apparatus and method for eliminating image sticking of liquid crystal display

InactiveUS20090231259A1Increase the discharge speedRemoving image stickingStatic indicating devicesLiquid-crystal displayControl signal

An apparatus and a method for eliminating an image sticking of a liquid crystal display (LCD) are provided. The image sticking occurs when the LCD is turned off. The LCD includes a data driver and a number of pixels coupled to a common voltage. The apparatus includes a voltage detector and a voltage switching device. The voltage detector detects a system voltage of the LCD and outputs a control signal according to the system voltage. The voltage switching device is coupled to the voltage detector for selectively providing a data voltage or the common voltage as a driving voltage of the data driver according to the control signal. The voltage switching device is controlled by the control signal to provide the common voltage to the data driver when the system voltage is less than a reference voltage.

Owner:CHUNGHWA PICTURE TUBES LTD

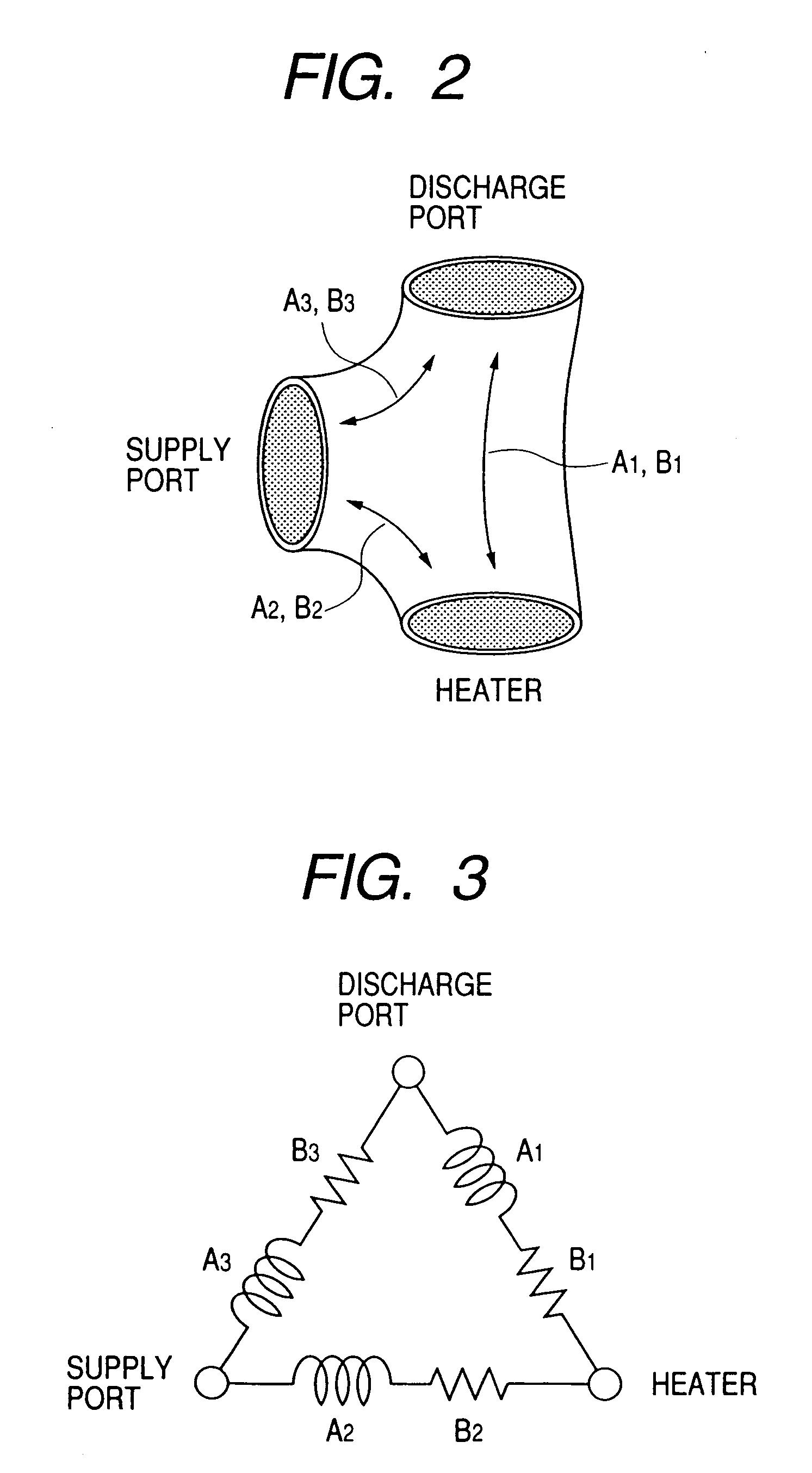

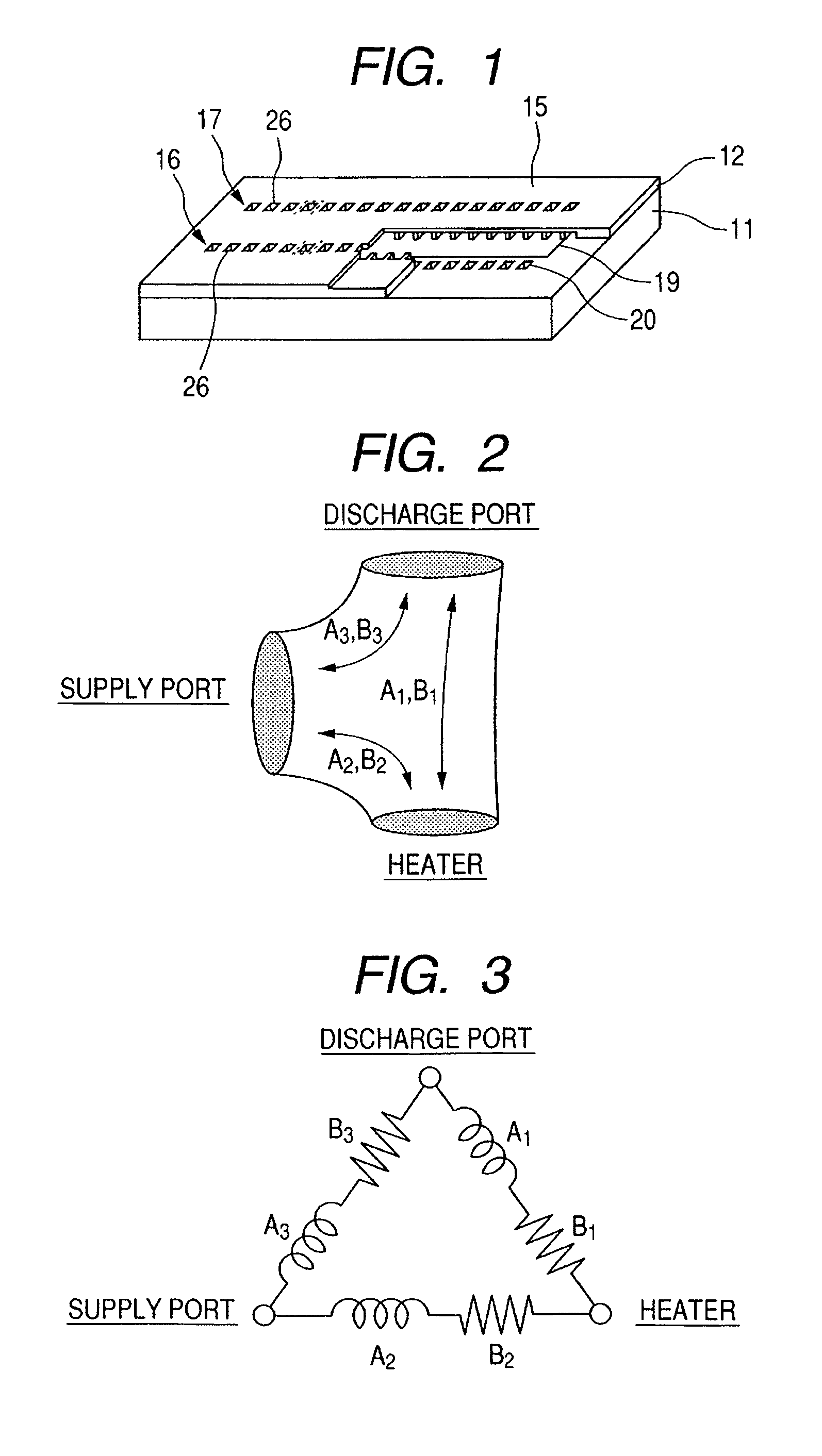

Liquid discharge head and method of manufacturing the same

InactiveUS20060114295A1Improve discharge stabilityEnhance liquid dischargePrintingDischarge efficiencyBubble chamber

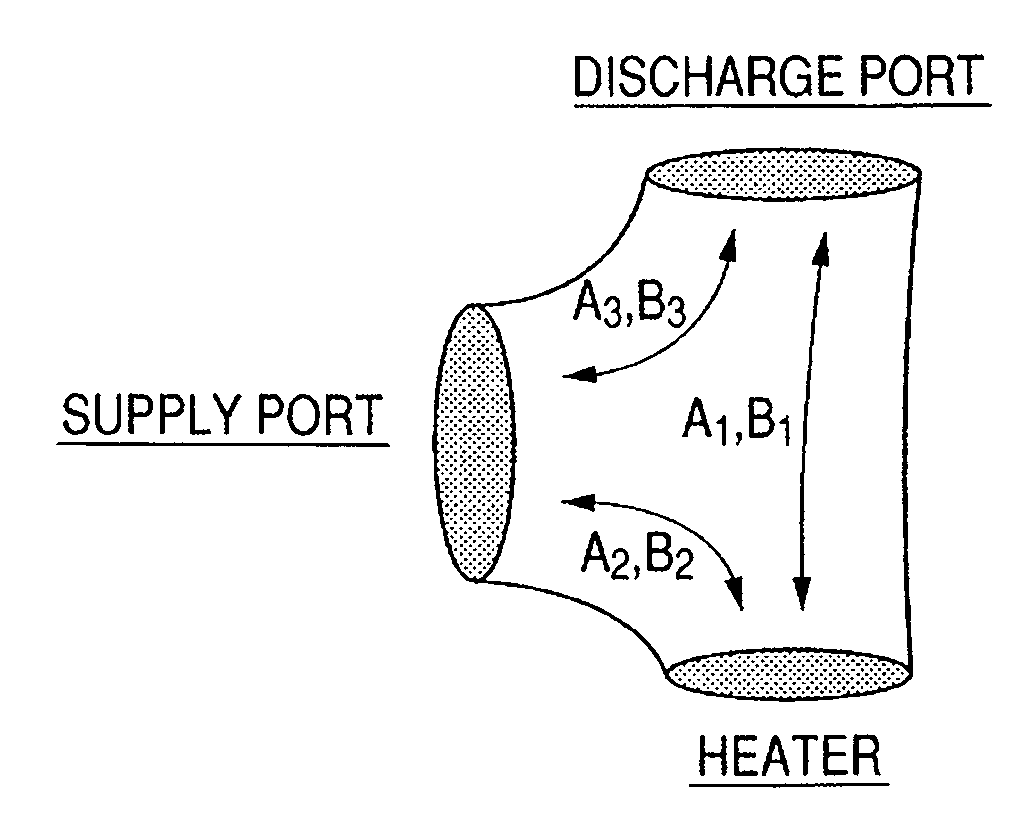

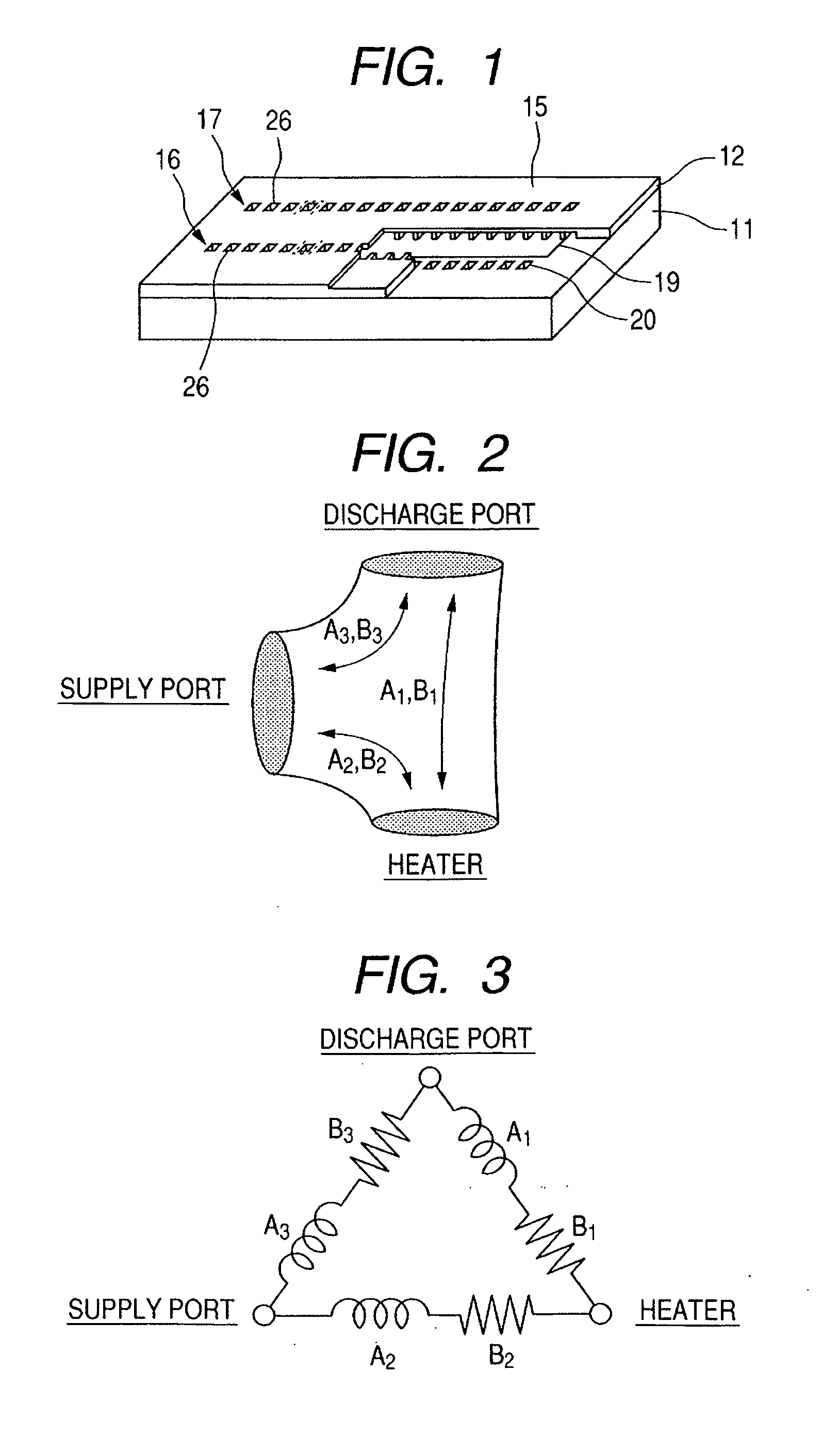

According to the present invention, a discharge speed of liquid droplets is increased, a discharge amount of liquid droplets is stabilized, and a discharge efficiency of the liquid droplets is enhanced. A bubbling chamber has: a first bubbling chamber which is connected to a supply path while a main surface of an element substrate is a bottom surface and in which bubbles are generated in ink by a heater; and a second bubbling chamber connected to the first bubbling chamber. Moreover, a nozzle has a discharge port portion including a discharge port connected to the second bubbling chamber. Assuming that an average sectional area of the first bubbling chamber is S1, an average sectional area of the second bubbling chamber is S2, and an average sectional area of the discharge port portion is S3 in a section parallel to the main surface of the element substrate, the nozzle satisfies a relation of S2>S1>S3.

Owner:KOHLER CO +1

Pneumatic pusher

ActiveUS20070119988A1Low failure rateIncrease the discharge speedCompressed gas gunsLiquid spraying apparatusReciprocating motionEngineering

A pneumatic pusher having a main body, a flow-guiding body, a moving body, and a delivery tube. The flow-guiding body includes a front tube with a smaller diameter and a rear tube with a larger diameter. The delivery tube is mounted on the front tube in such a way that the outer wall of the delivery tube and the inner wall of the main body define a return pressure chamber. A first gas-distributing channel extending from a first air outlet at one side of the main body leads directly to the inner side of the delivery tube. The side of the first air inlet of the main body communicates with a second gas-distributing channel. The second gas-distributing channel includes an exit located at one side of the return pressure chamber of the delivery tube. The air pressure provided through the second gas-distributing channel serves as cushioning force in pushing the delivery tube outwardly. When the moving plunger blocks the gas distributing chamber in such a way that the gas is stopped to be injected through the first gas distributing channel into the pushing chamber for bringing the delivery tube forward, the gas pressure injected through the second gas distributing channel into the return pressure chamber acts as inward return force for the delivery tube. Therefore, the reciprocating movement of the delivery tube on the front tube can be completely done by the airflow.

Owner:SHENG CHIH SHENG

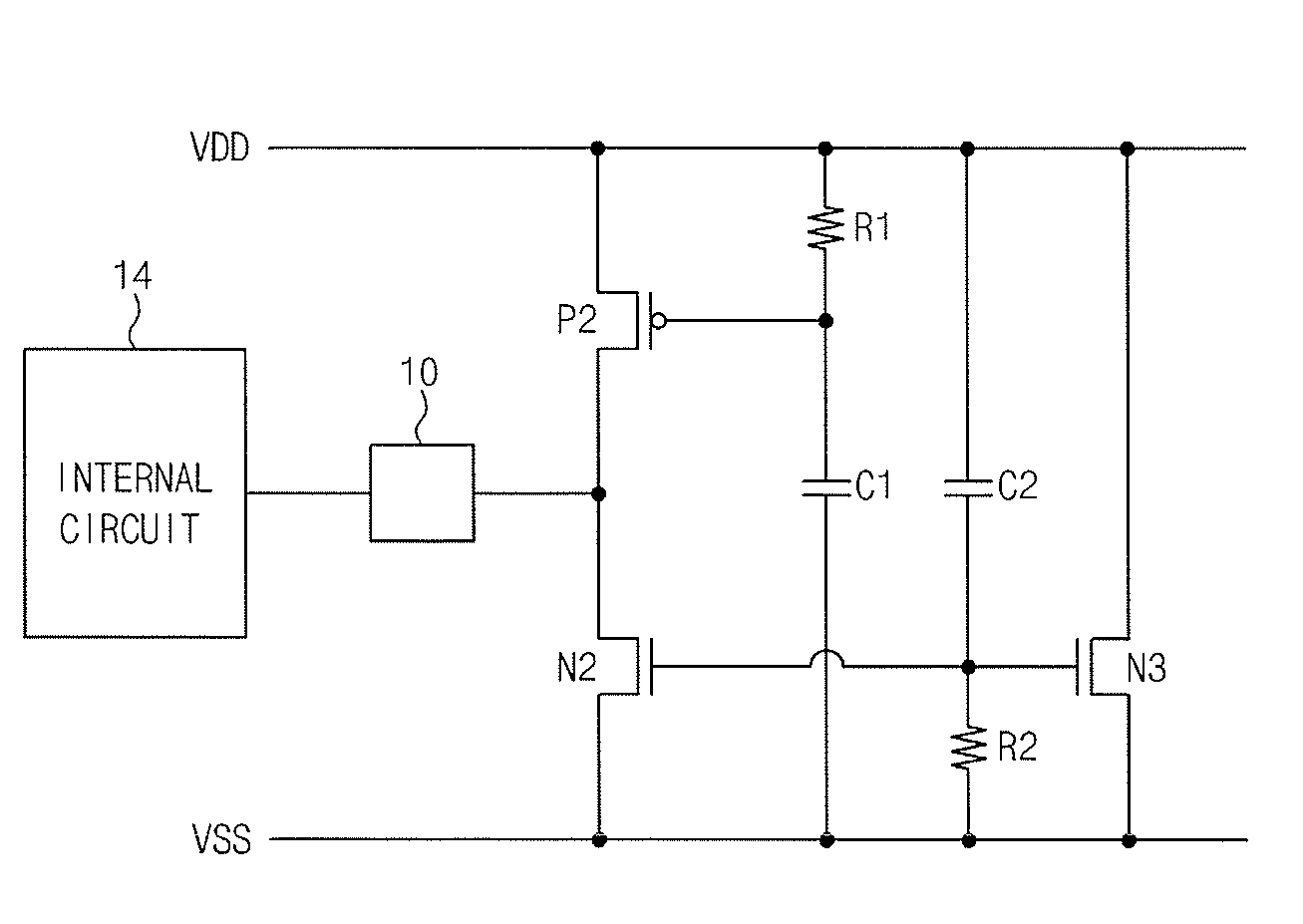

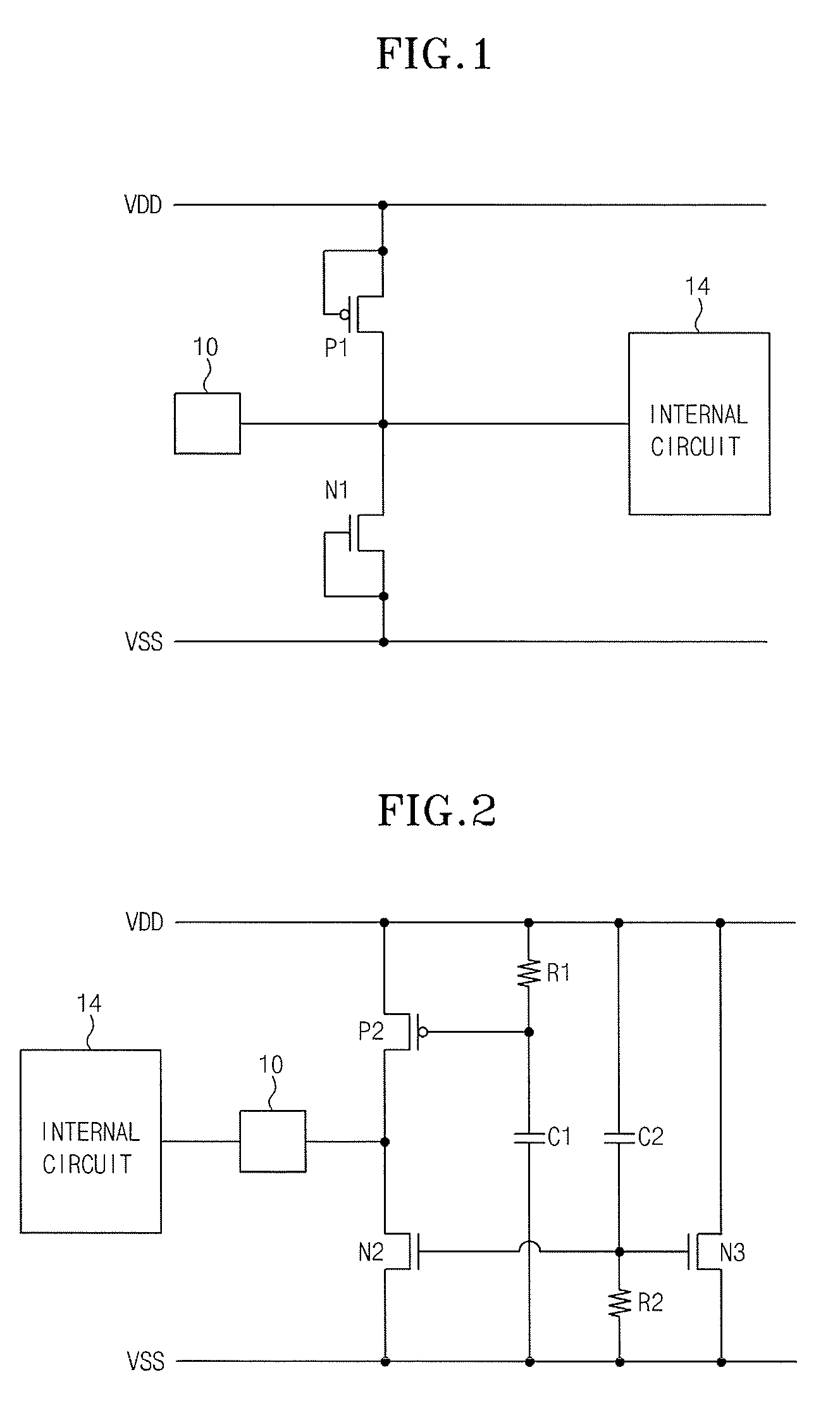

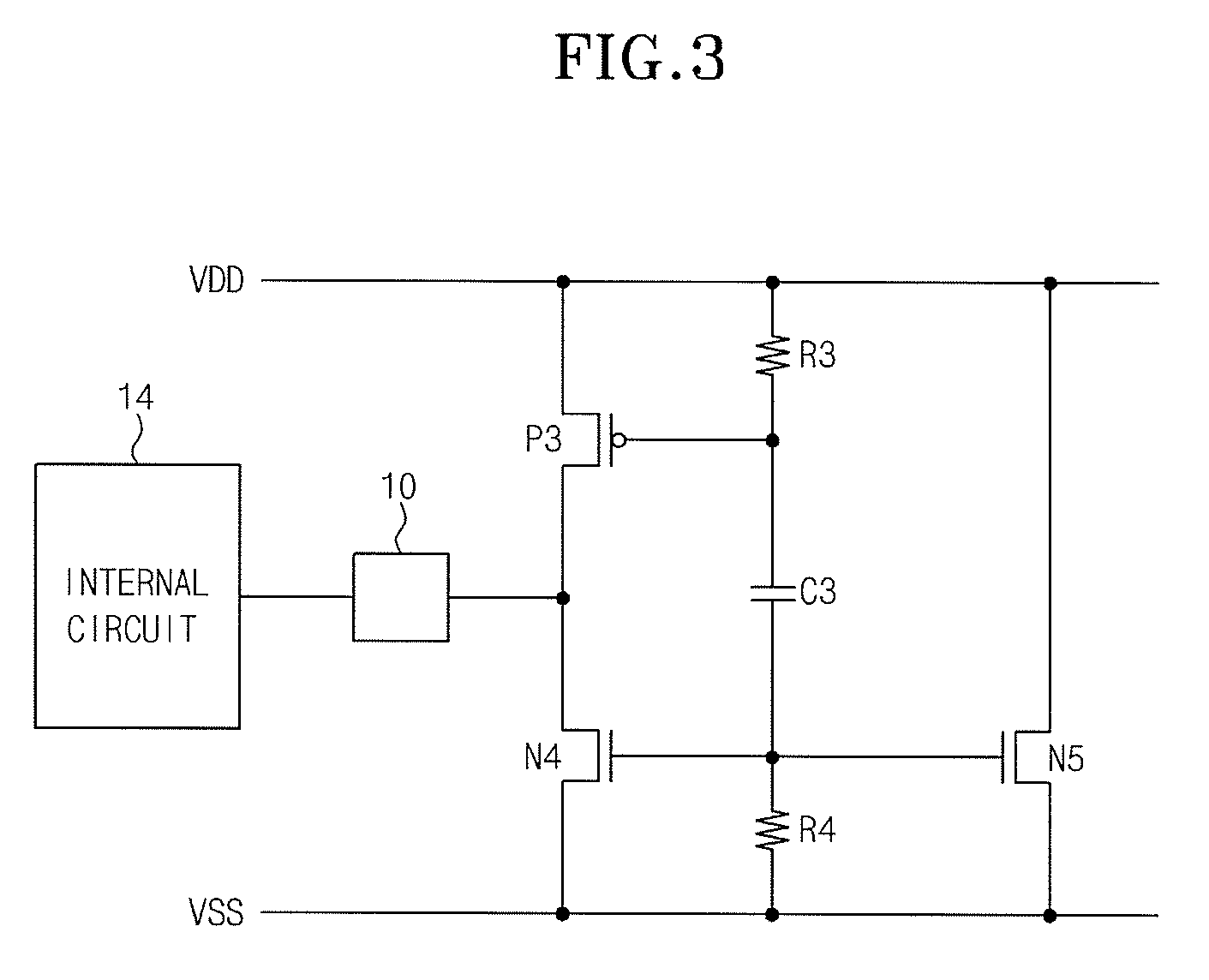

Electrostatic discharge protection circuit having multiple discharge paths

InactiveUS20080197415A1Enhance electrostatic discharge speedEnhance electrostatic discharge performanceTransistorSemiconductor/solid-state device detailsEngineeringSemiconductor

The present invention relates to an electrostatic discharge protection circuit of a semiconductor memory device to protect an internal circuit from static electricity. The electrostatic discharge protection circuit includes a first trigger unit which provides a first trigger voltage in response to static electricity transferred from at least one of a first and second voltage line. A second trigger unit provides a second trigger voltage by the static electricity in response to the first trigger voltage. An electrostatic discharge protection unit configures an electrostatic discharge path among the first voltage line, the second voltage line and an input / output pad in response the first and second trigger voltages. The electrostatic discharge speed of the electrostatic discharge protection unit is enhanced by the first and second trigger voltages.

Owner:SK HYNIX INC

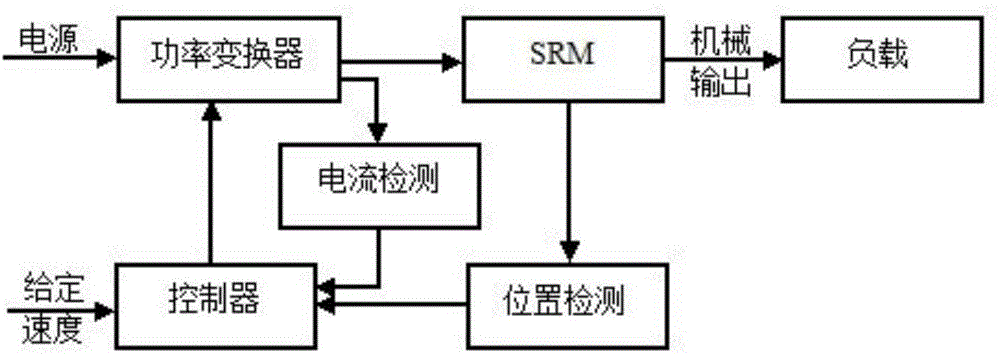

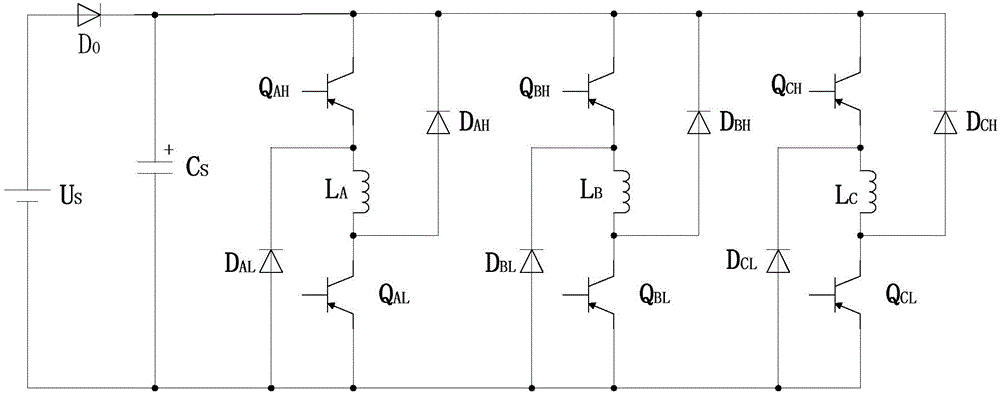

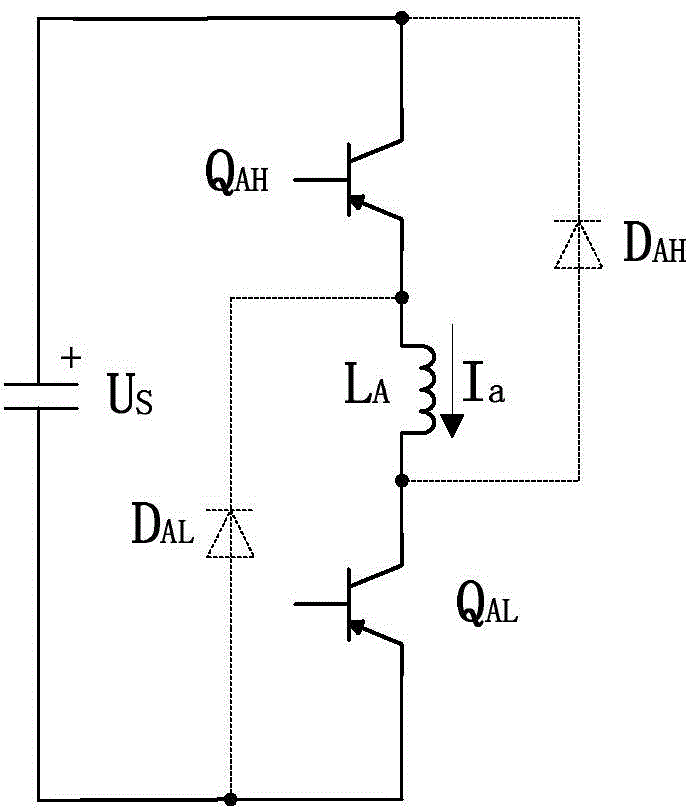

Three-level motor power converter achieving quick demagnetization

InactiveCN105322838AFall fastShorten the timeTorque ripple controlSingle motor speed/torque controlPhase currentsCapacitance

The invention discloses a three-level motor power converter achieving quick demagnetization, and the converter comprises an upper DC power supply, a lower DC power supply, a three-phase winding, an upper three-phase power device, a low three-phase power device, a filtering capacitor, an energy storage capacitor, and six freewheel diodes. Compared with the topological structure of a conventional three-phase switching magnetic resistance motor power converter, the converter is additionally provided with the upper DC power supply, adjusts the voltage of the upper DC power supply to be greater than the exciting voltage of the lower DC power supply thorough a voltage adjuster, enables the decrease speed of a phase current at a follow current stage to be increased, increases the discharge speed of a phase winding, prolongs the time when the current of the phase winding maintains the maximum effective value while eliminating a braking torque, increases the output power of a system, and reduces the torque ripple.

Owner:NANJING UNIV OF TECH

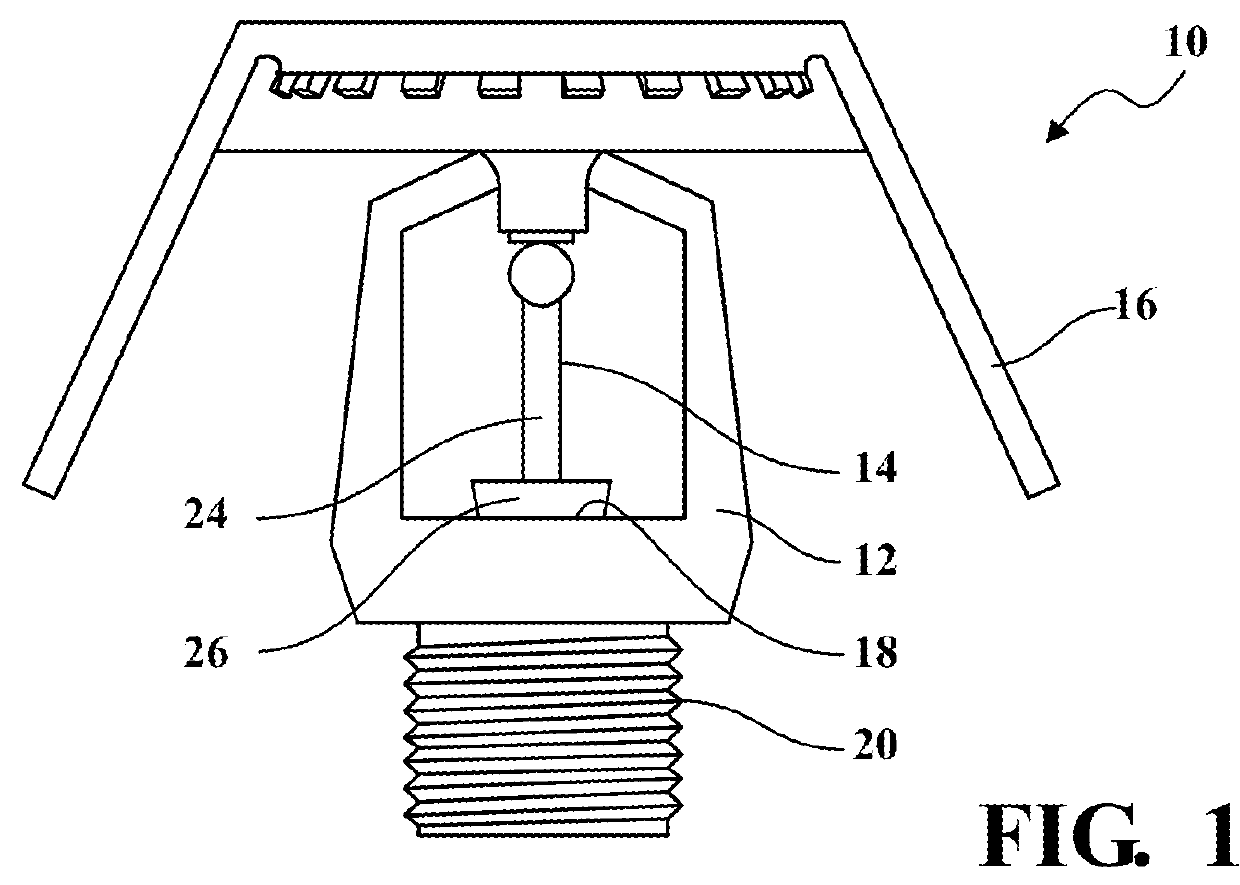

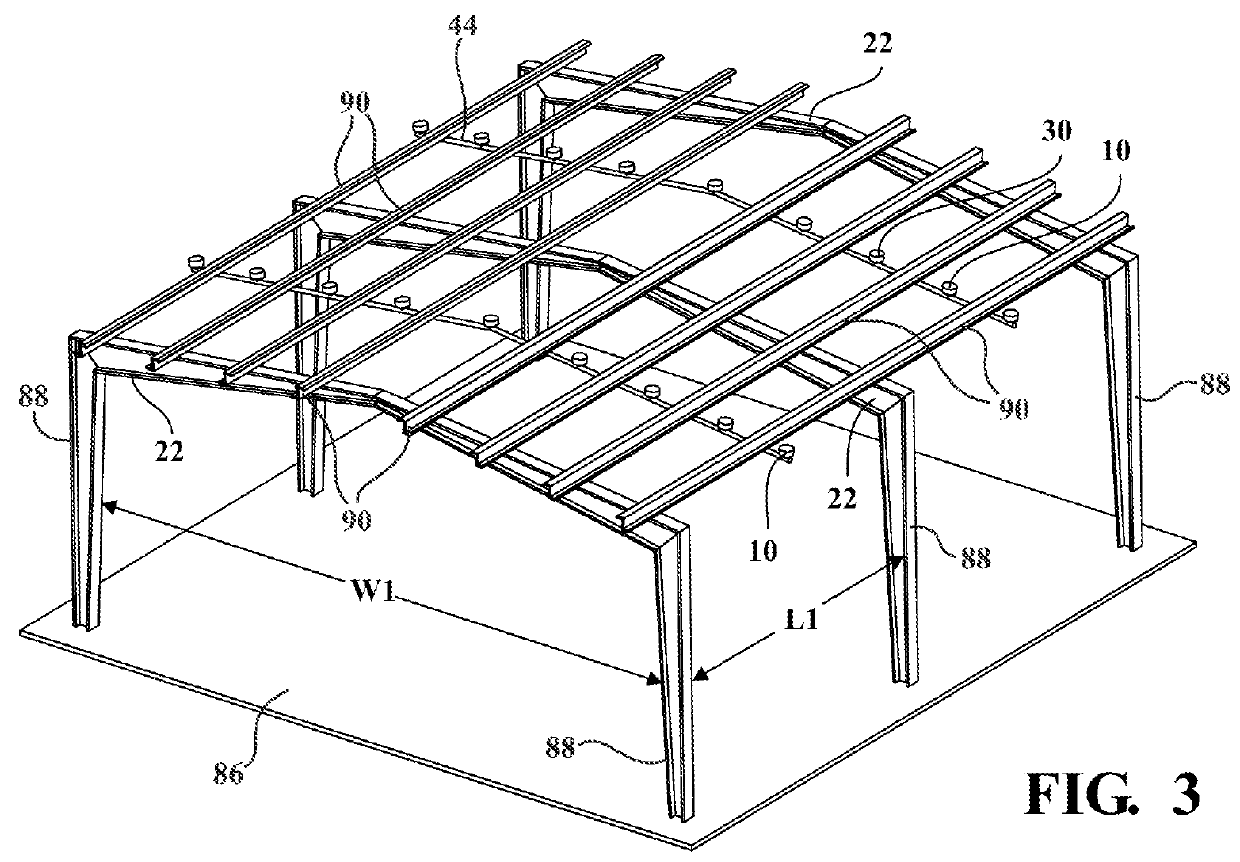

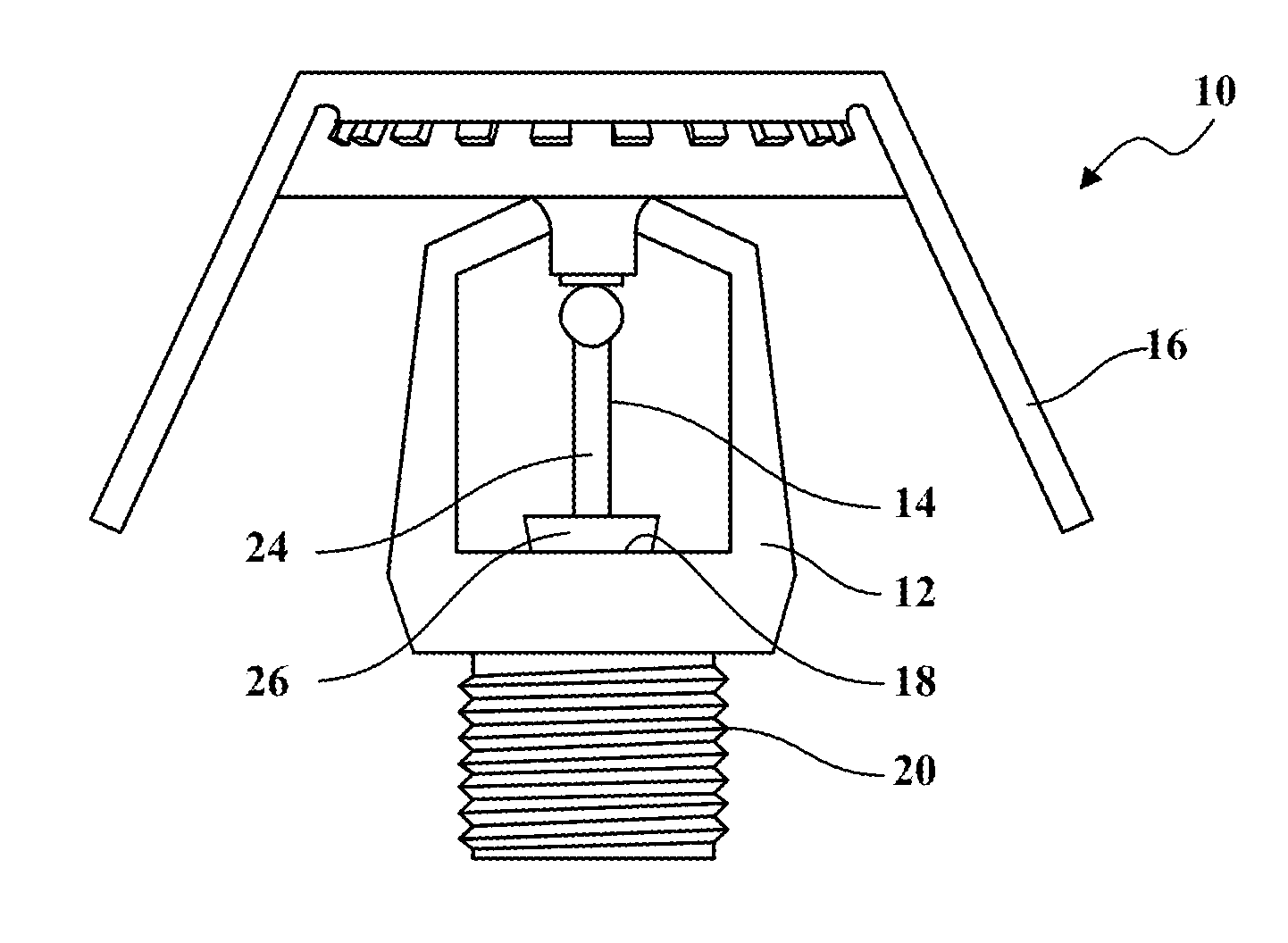

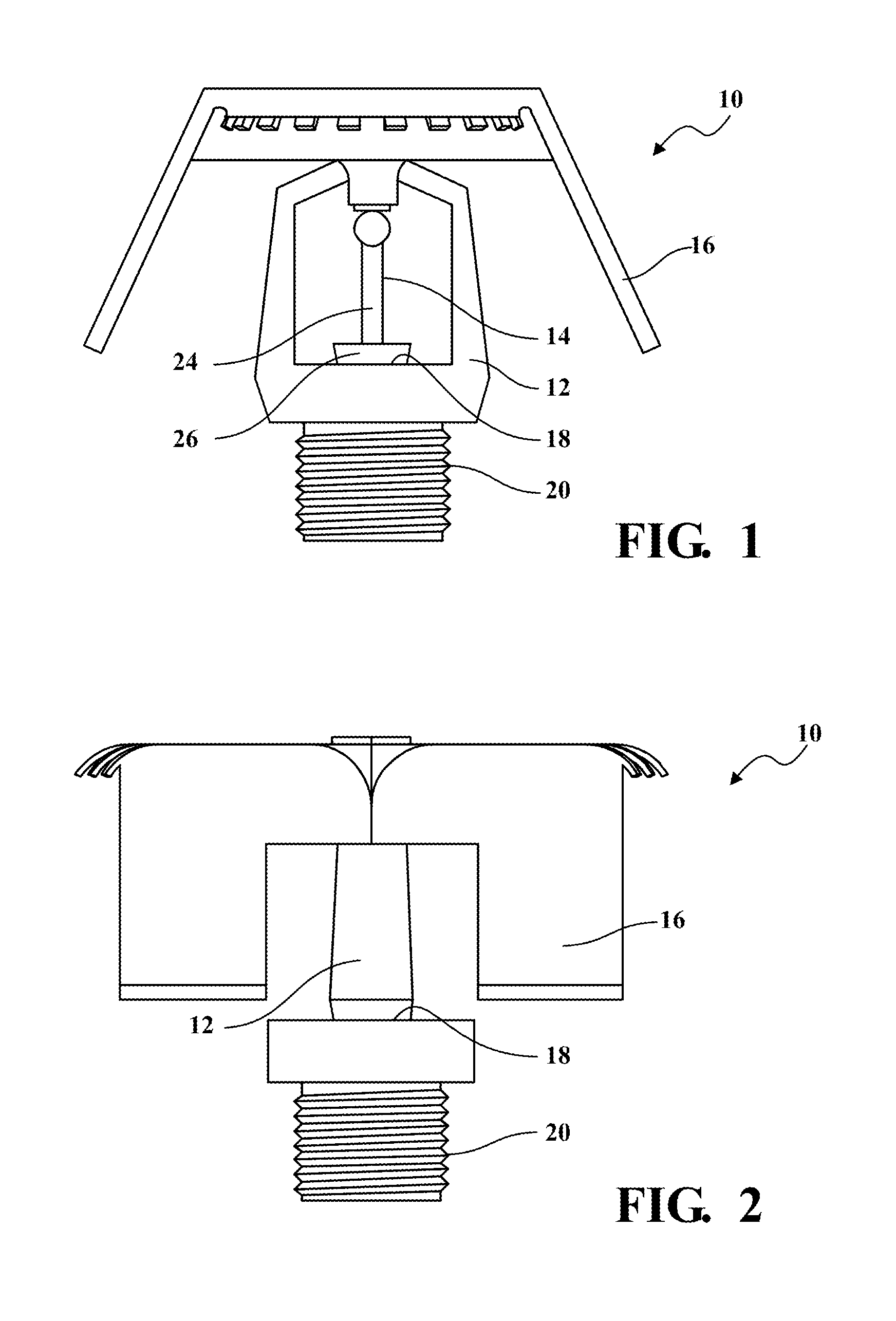

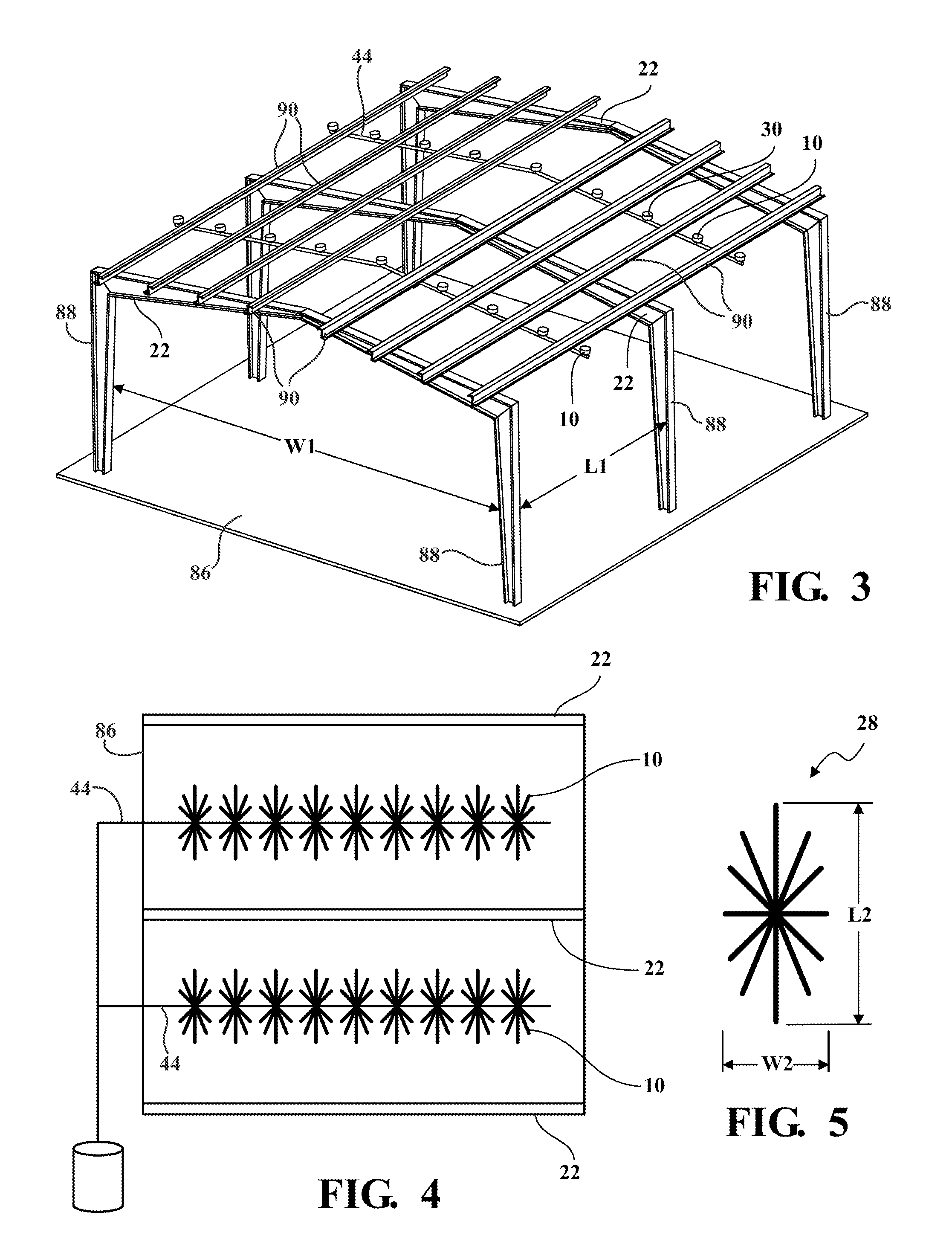

Fire sprinkler with flue-penetrating non-circular spray pattern

ActiveUS9381386B2Evenly dispersedNot be excessively suppliedSpray nozzlesFire rescueFire sprinklerEngineering

Owner:FIREBIRD SPRINKLER COMPANY

Liquid discharge head and method for manufacturing such head

InactiveUS7048358B2Improve discharge efficiencyIncrease the discharge speedPrintingBubble chamberEngineering

Owner:CANON KK

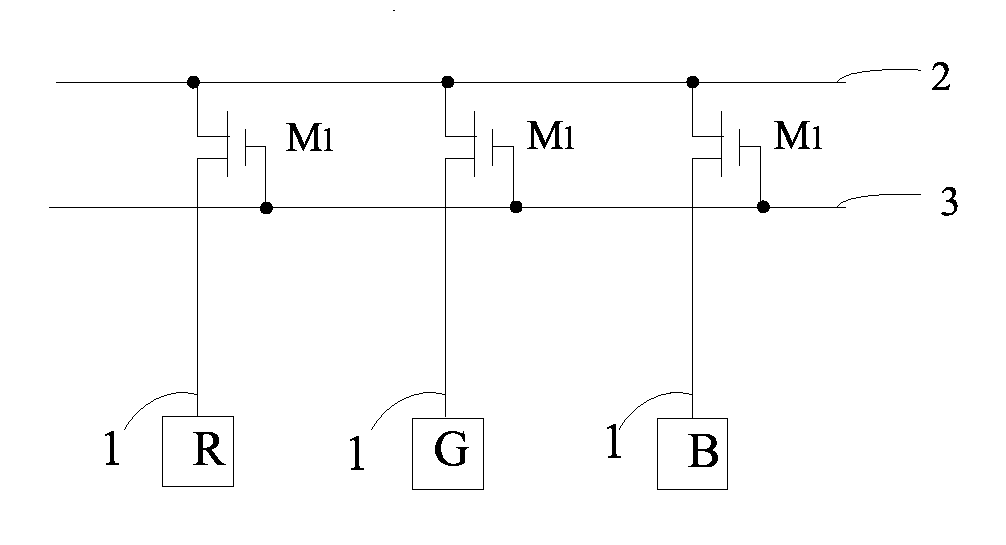

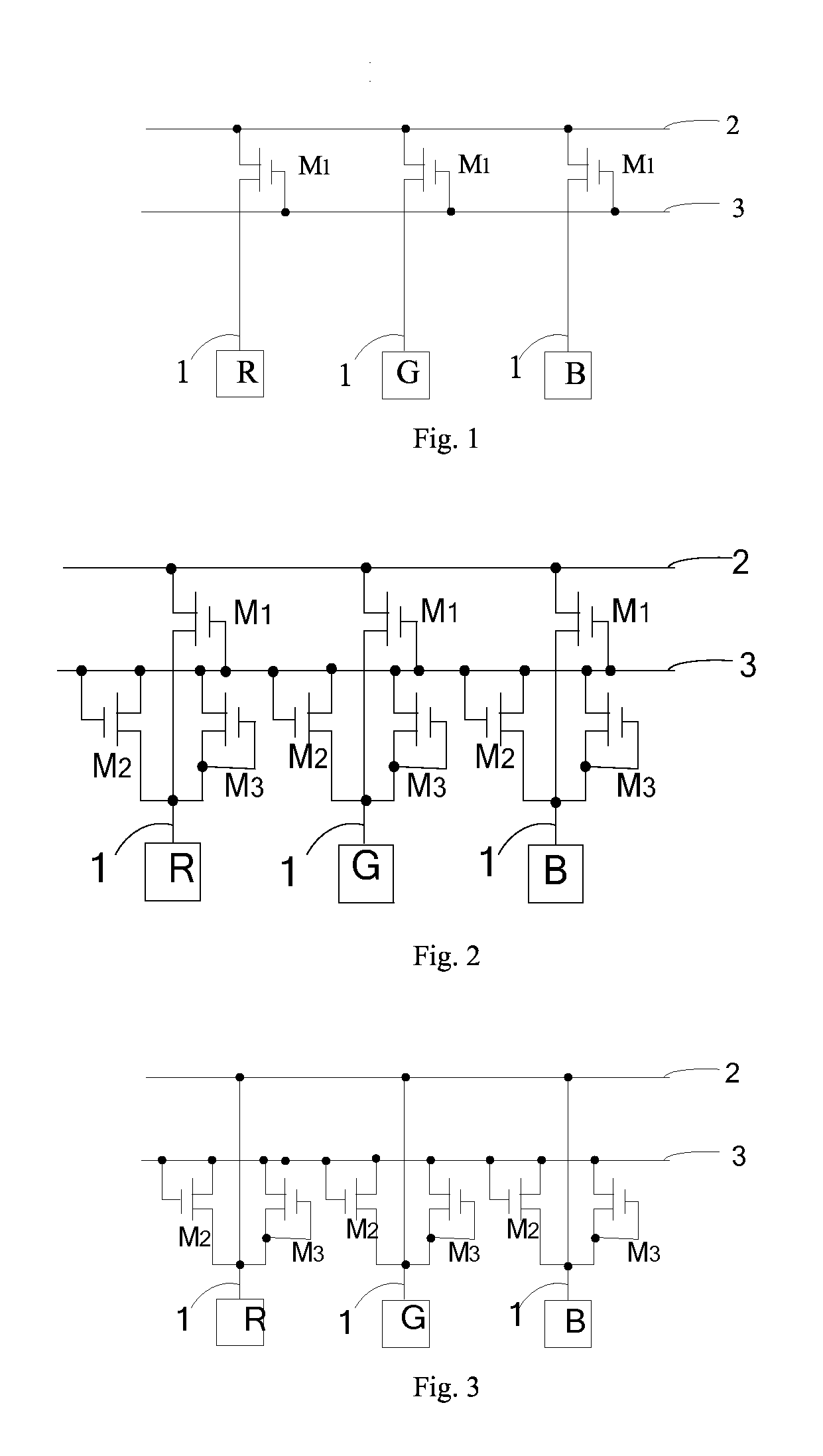

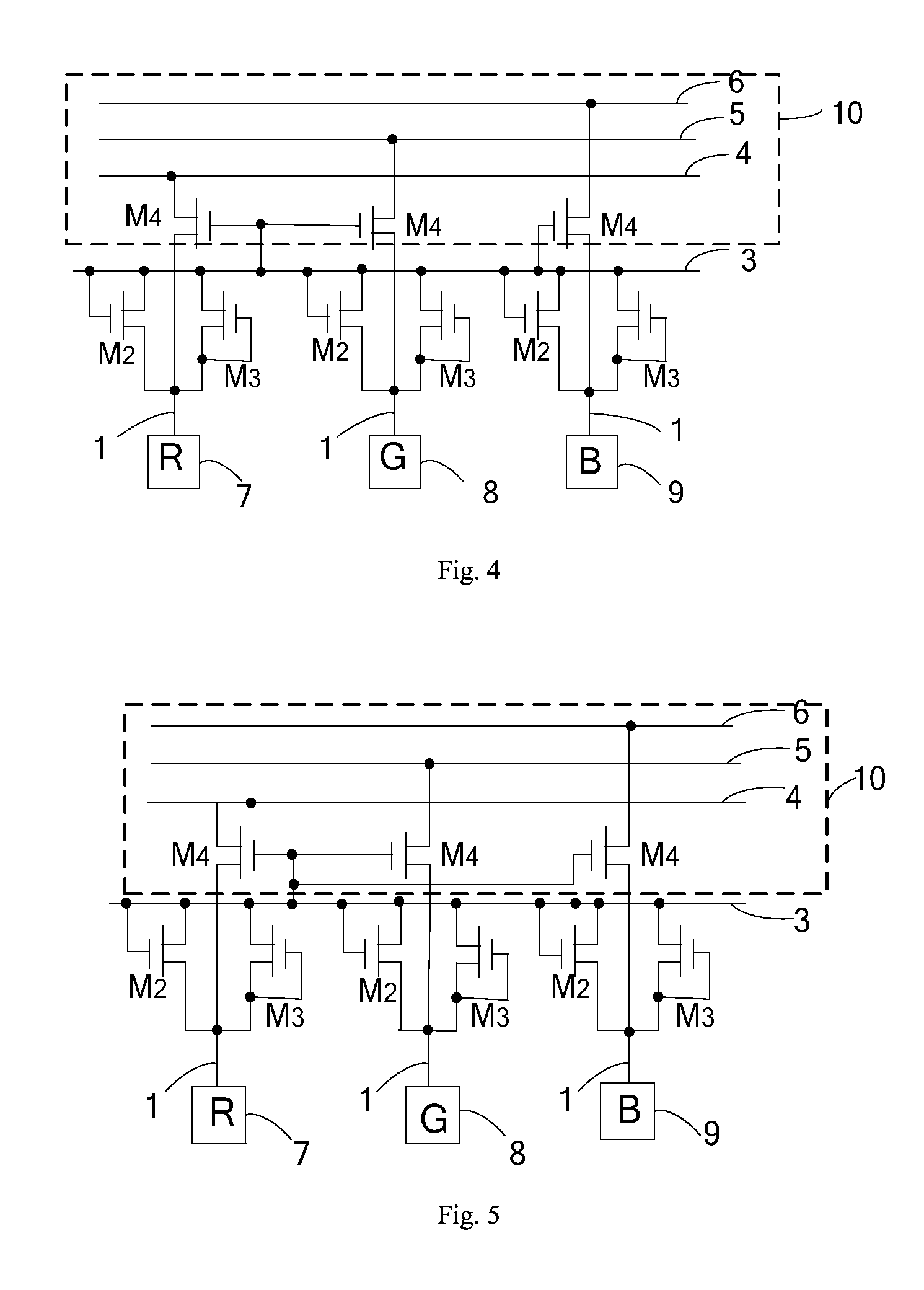

Array Substrate and Display Panel

ActiveUS20150325188A1Reduce generationSimple structureStatic indicating devicesNon-linear opticsCapacitanceEngineering

The present invention provides an array substrate and a display panel. The array substrate comprises a plurality of data lines and a plurality of common electrode lines, wherein, the array substrate further comprises at least one discharge unit, each discharge unit corresponds to one of the plurality of data lines and is connected between the corresponding data line and one of the plurality of common electrode lines, and each discharge unit can selectively conduct the data line to the common electrode line connected thereto. The display panel comprises the array substrate. In the present invention, the discharge unit can selectively conduct the data line connected thereto to the common electrode line connected thereto, to enable fast discharge of the storage capacitance and reduce occurrence of afterimage phenomenon.

Owner:BOE TECH GRP CO LTD +1

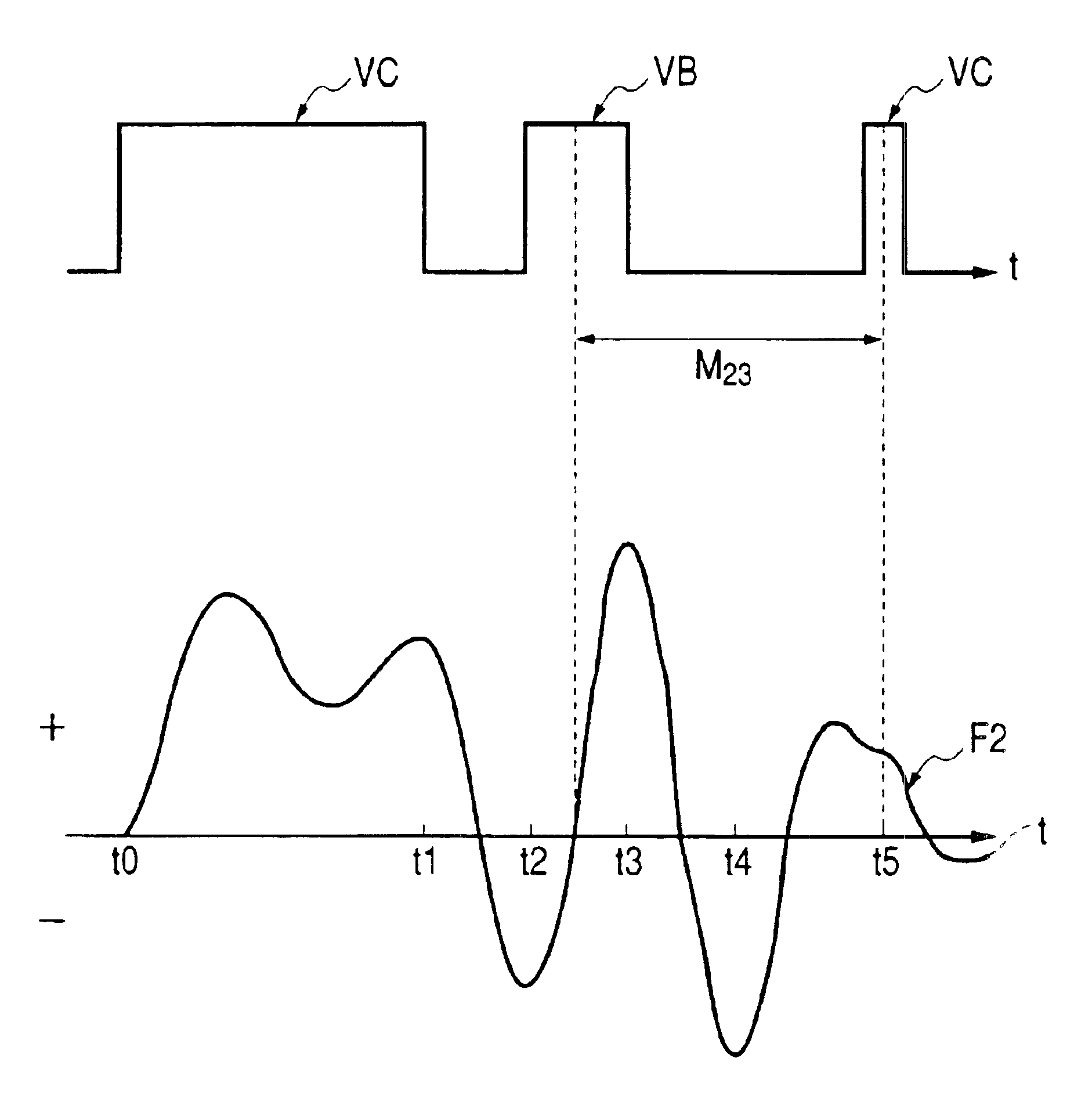

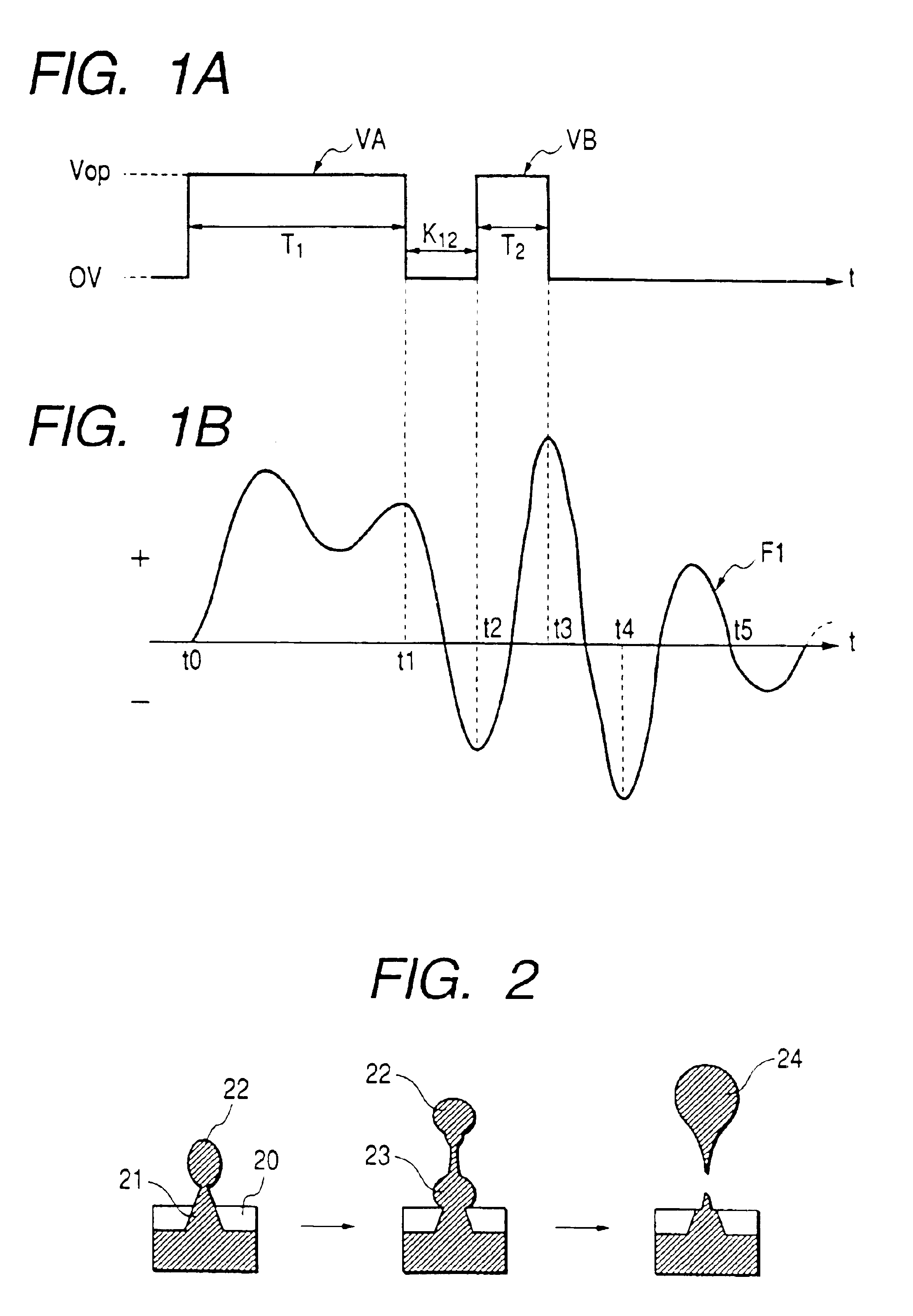

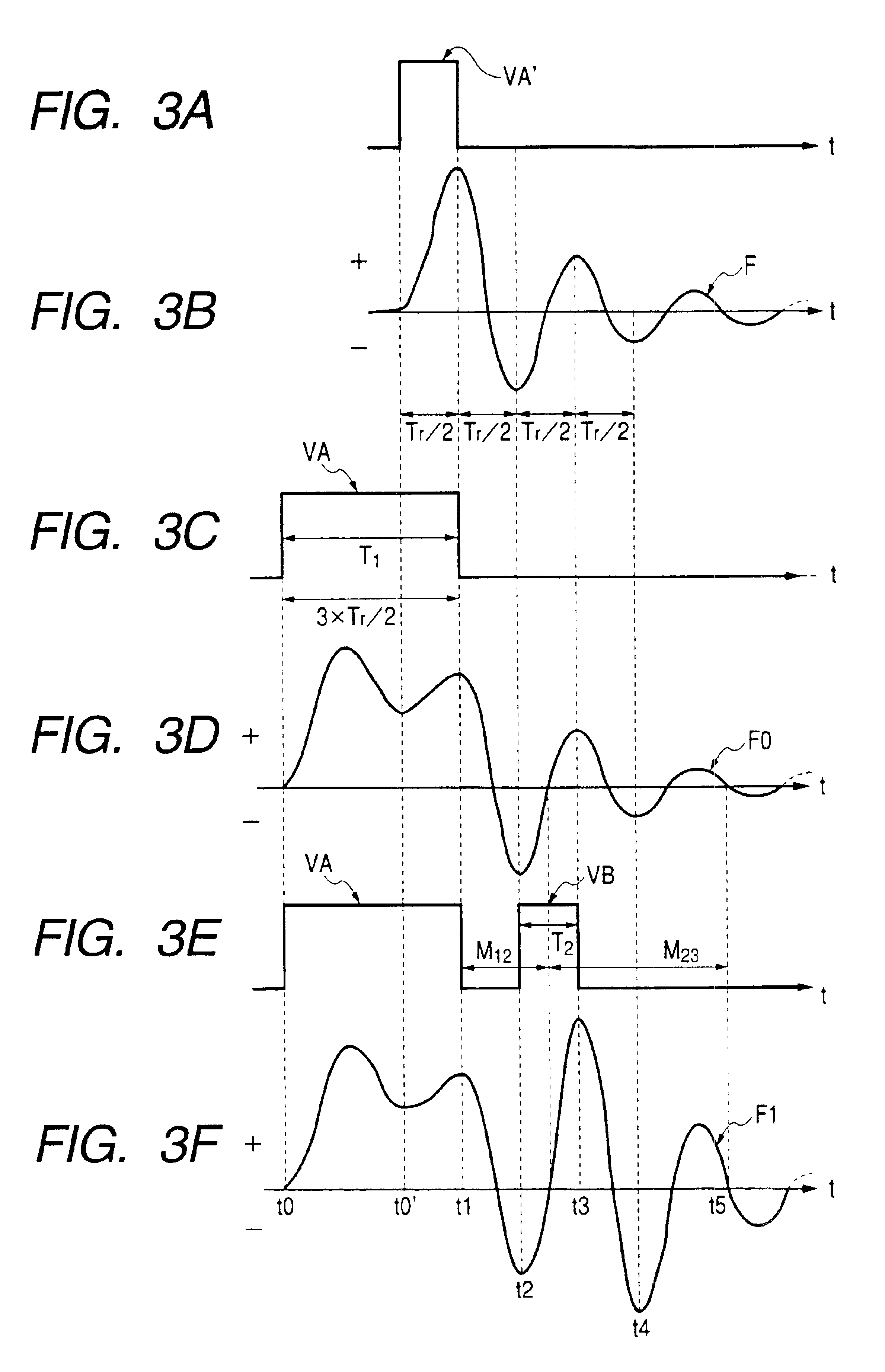

Driving method and apparatus for liquid discharge head

InactiveUS6851780B2Improve accuracyIncrease volumeInking apparatusOther printing apparatusResting timeRest time

In order that the volume of a liquid drop can increase and the drop can reach with high precision even if the distance between a head nozzle and a plotted base is short, there is provided a driving method for a liquid discharge head including: a discharge port for discharging liquid; a pressure-applying portion communicating with the discharge port, for applying a pressure for discharge to the liquid; and a pressure generating device for generating the pressure, the method including a step of applying a first discharge pulse for discharging liquid and a second discharge pulse for discharging liquid to the pressure generating device in a sequential manner in response to an instruction of one-dot discharge, in which the pulse width of the first discharge pulse, the pulse width of the second discharge pulse, and a rest time between the first discharge pulse and the second discharge pulse are determined so that a first liquid discharged in response to the first discharge pulse has a volume equal to or greater than that of a second liquid discharged in response to the second discharge pulse and the discharge speed of the first liquid is lower than the discharge speed of the second liquid.

Owner:CANON KK

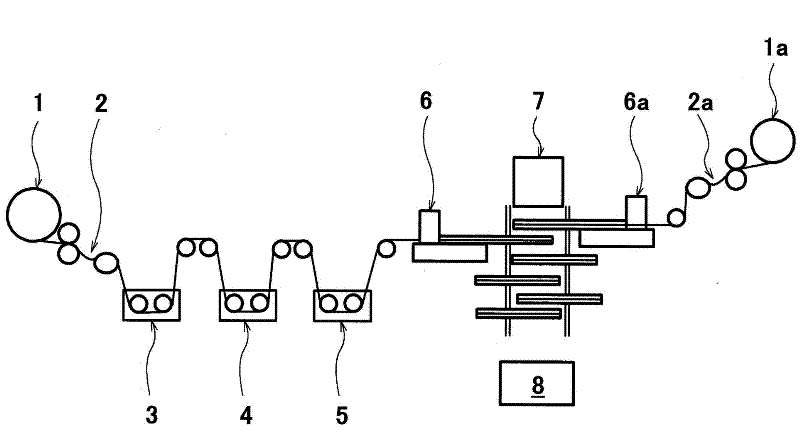

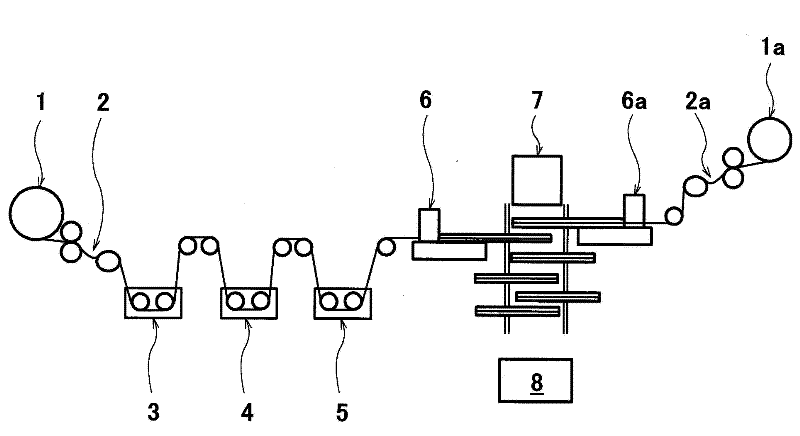

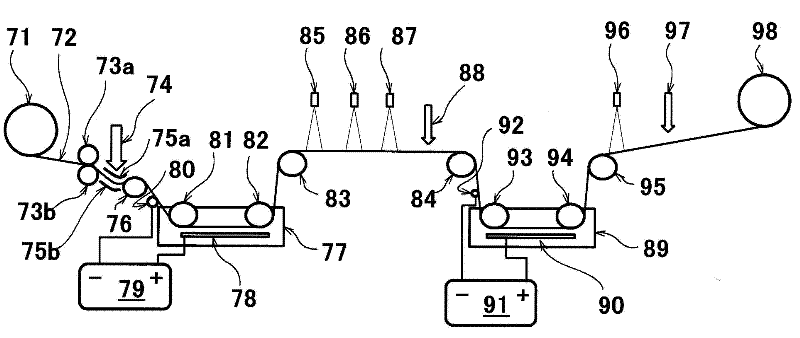

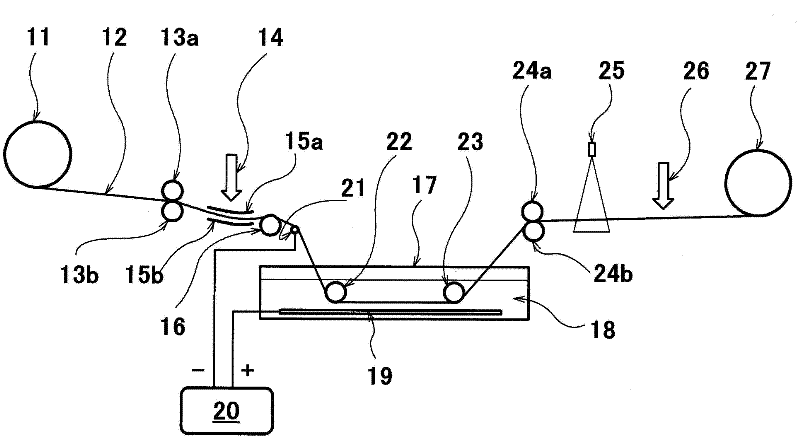

Fiber electrode and fiber cell, and method for producing same, facility for producing fiber electrode and fiber cell

InactiveCN102473903AEfficient manufacturingIncrease surface areaMicroscopic fiber electrodesHybrid capacitor electrodesFiber bundleSingle fibre

Disclosed is a method for efficiently producing a plurality of fiber electrodes simultaneously from a plurality of fibers, which takes advantage of the advantages that fiber electrodes conventionally have. The method for producing fiber electrodes has steps (2,2a) for opening a bundle of fibrous material, steps (3,4,5) for obtaining a fiber cathode or a fiber anode by means of forming a cathode active material coat layer or an anode active material coat layer on each monofilament obtained by means of opening, and steps (6,6a) for forming a separator coat layer on the abovementioned fiber cathode or fiber anode.

Owner:KAWASAKI HEAVY IND LTD +1

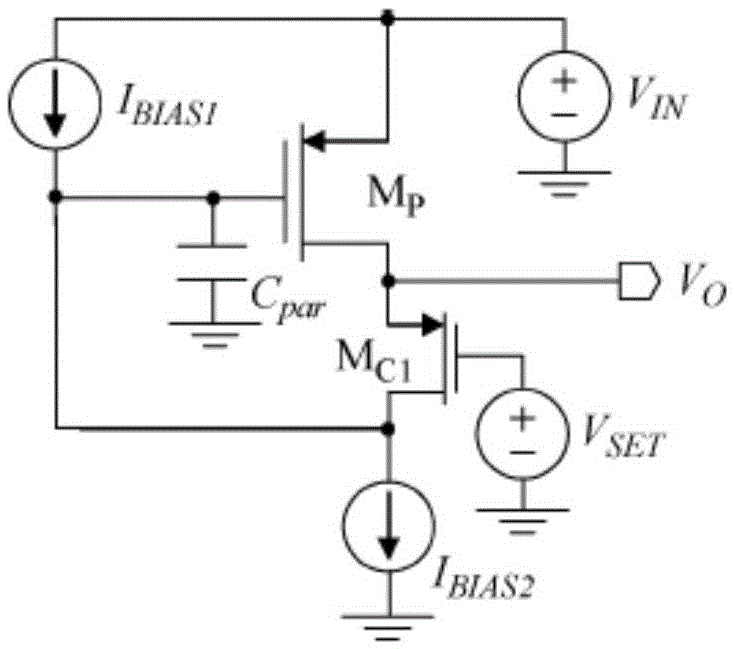

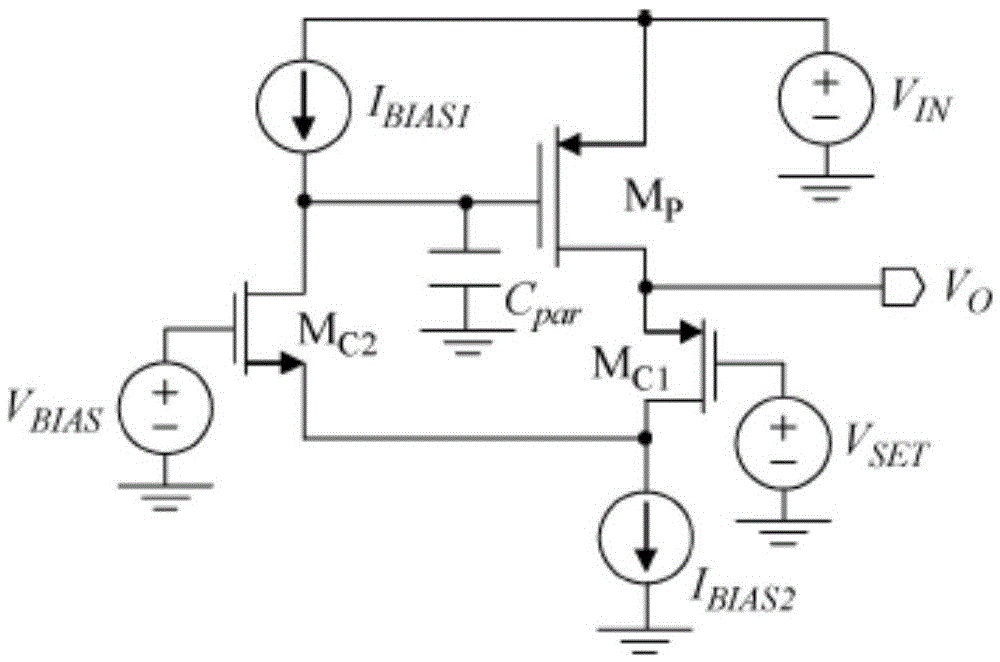

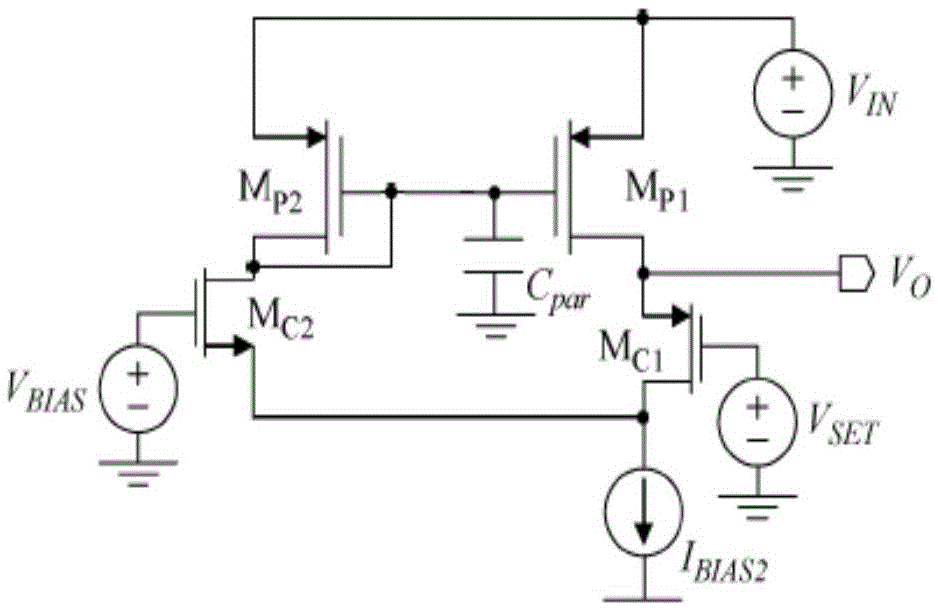

Low-dropout linear regulator

InactiveCN105549672AIncrease conversion rateEnhanced gate drive capabilityElectric variable regulationCapacitanceLinear regulator

The invention provides a low-dropout linear regulator. A turnover source voltage follower serves as an error amplification circuit in a loop and can induct changes of output voltage of a power output tube drain, when the output voltage changes, the error amplification circuit will provide corresponding error voltage to control a power tube grid driving circuit, the power tube grid driving circuit has the effect of increasing grid charging speed or discharging speed of a power output tube according to the error voltage to improve the converting speed of the power output tube, and the grid driving capacity of the power output tube is improved; as output resistance of the power tube grid driving circuit is extremely low, the power tube grid driving circuit can push a pole of a power output tube grid to a position with higher frequency, and a main pole of the loop is located at an output pole. The low-dropout linear regulator has fast transient response, stable loop bandwidth is provided by a simple compensation technology, and no ESR limit exists in off-chip capacitor selection.

Owner:OMNIVISION TECH (SHANGHAI) CO LTD

Liquid discharge head and method for manufacturing such head

ActiveUS20060098051A1Suppress pressure lossIncrease discharge speedPrintingEngineeringBubble chamber

The present invention provides a liquid discharge head and a method for manufacturing such a head, in which a discharging speed of a liquid droplet can be increased, a discharging amount of the liquid droplet can be stabilized and discharging efficiency of the liquid droplet can be enhanced. The liquid discharge head comprises a heater, an element substrate on which the heater is provided, a nozzle including a discharge port portion having a discharge port for discharging the liquid droplet and a bubbling chamber and a supply path for supplying the liquid to the bubbling chamber and a supply chamber for supplying the liquid to the nozzle and an orifice substrate and, the bubbling chamber includes a first bubbling chamber and a second bubbling chamber above the first bubbling chamber and the discharge port portion is communicated with the second bulling chamber via a stepped portion and a side wall of the second bubbling chamber is converged toward the discharge port with inclination of 10 to 45 degrees and the nozzle is provided with a control portion comprised of a stepped portion in the flow path in the vicinity of the bubbling chamber and a maximum height of the flow path is smaller than a height up to a lower surface of the discharge port portion.

Owner:CANON KK

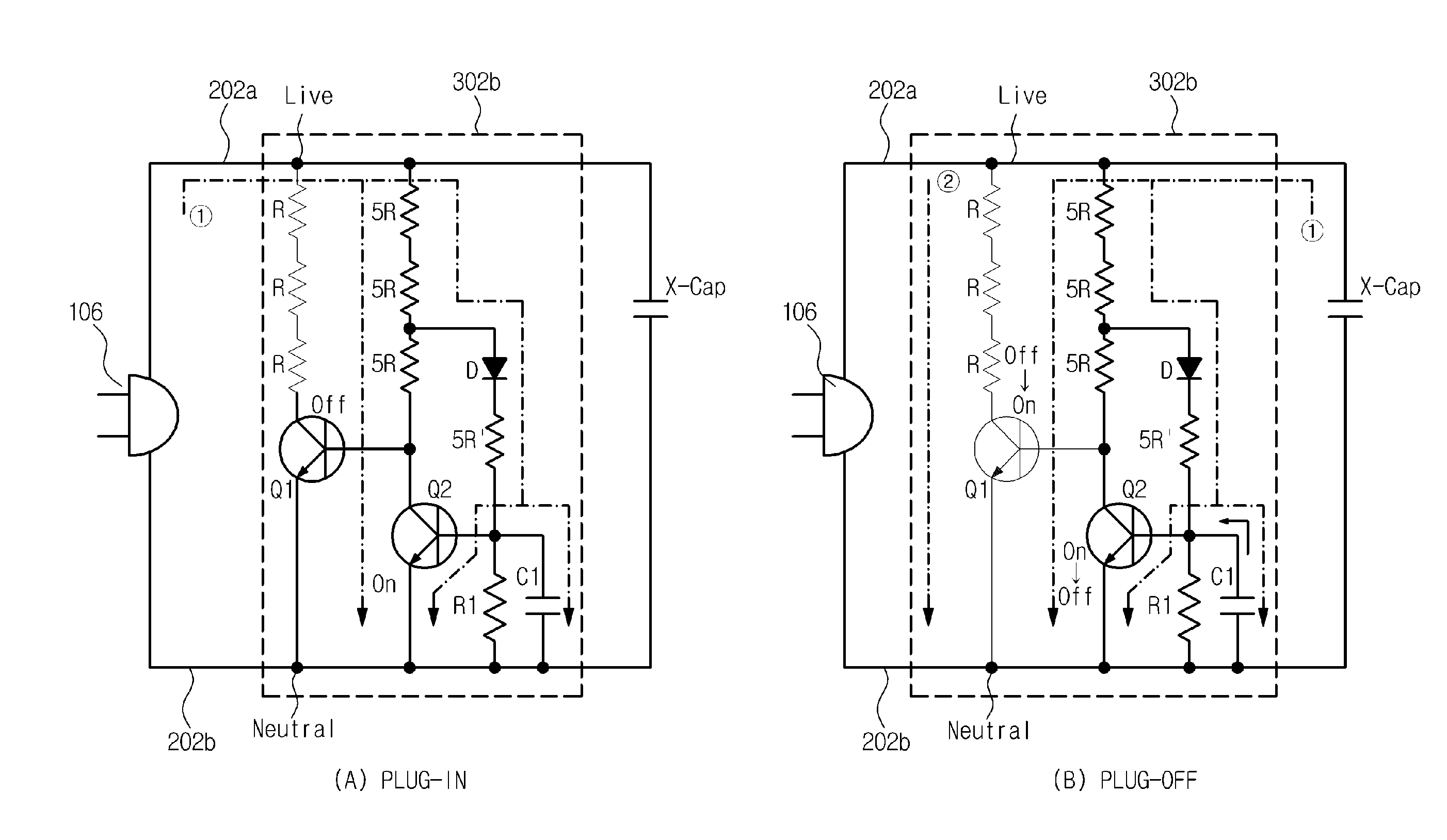

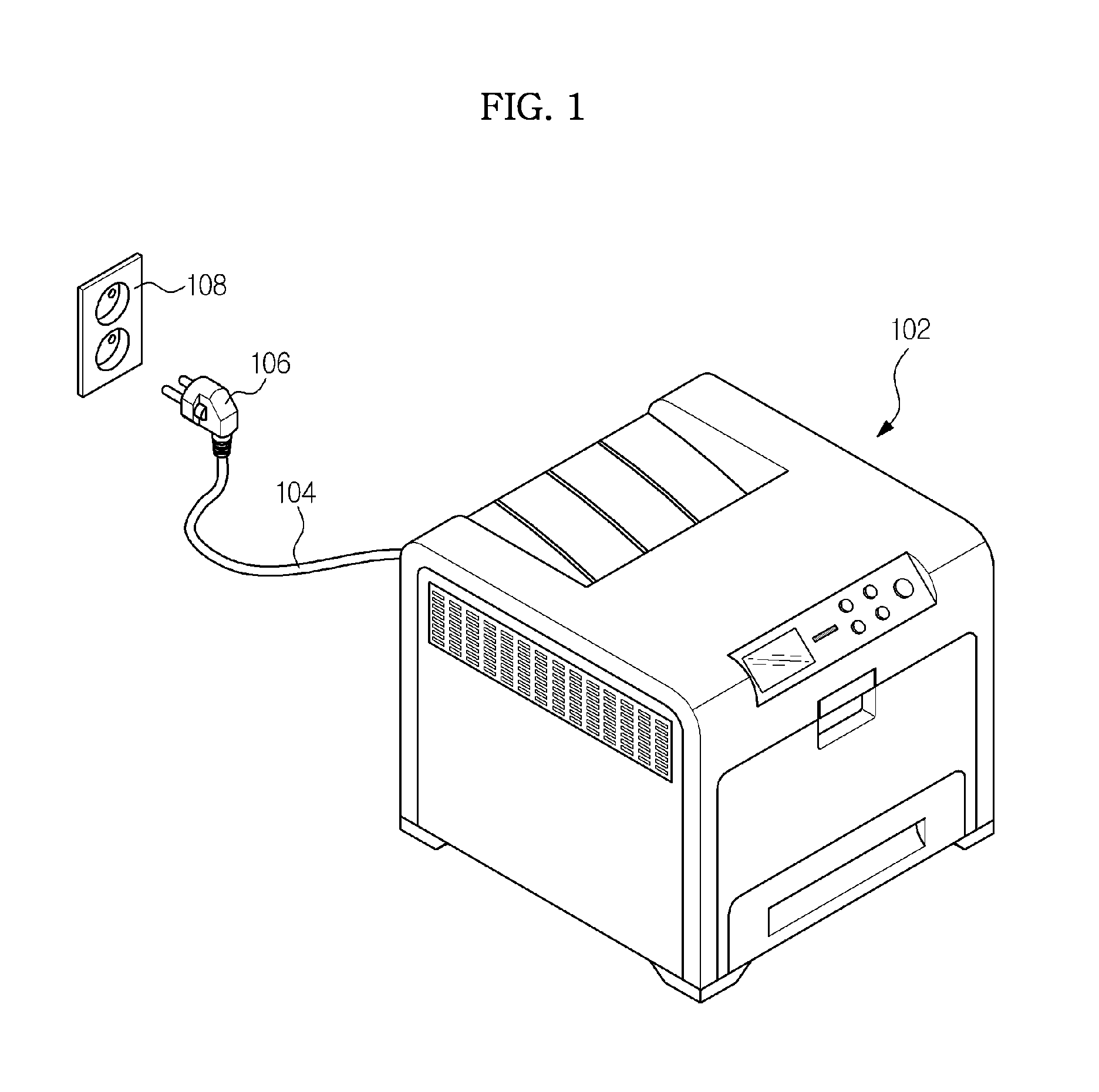

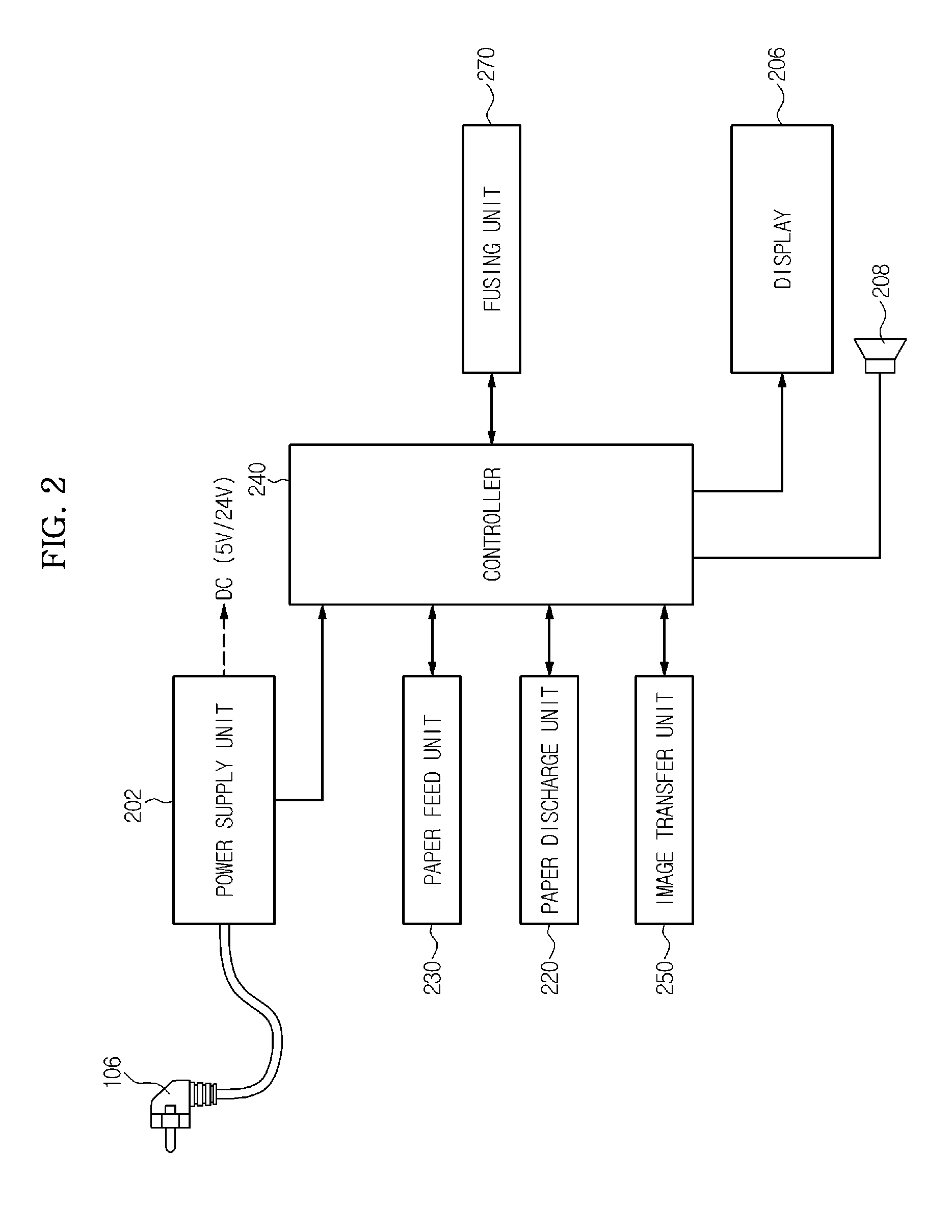

Discharging circuit, image forming apparatus having the discharging circuit, and power supply unit

ActiveUS20140062421A1Increase the discharge speedMinimize powerPower network operation systems integrationElectric powerElectricityPower flow

A discharge circuit, an image forming apparatus having the discharge circuit, and a power-supply unit are disclosed to minimize a standby power generated in a standby mode and improve a discharging speed of a capacitor charged with electricity by the AC power in a power off mode. The discharge circuit connected between AC power input lines receiving an AC power includes a first resistor and a first switch element connected in series between the AC power lines, and a second resistor and a second switch element which are connected in series between the AC power lines, turn off the first switching element upon receiving an electric current during supply of the AC power, and turn on the first switching element in response to cutoff of the AC power to discharge the first capacitor.

Owner:HEWLETT PACKARD DEV CO LP

Liquid discharge head and method of manufacturing the same

InactiveUS7513601B2Increase the discharge speedThe total amount is stablePrintingDischarge efficiencyBubble chamber

With the liquid discharge head, a discharge speed of liquid droplets is increased, a discharge amount of liquid droplets is stabilized, and a discharge efficiency of the liquid droplets is enhanced. A bubbling chamber has a first bubbling chamber which is connected to a supply path with a main surface of an element substrate forming a bottom surface thereof and in which bubbles are generated in ink by a heater, and a second bubbling chamber connected to the first bubbling chamber. Moreover, a nozzle has a discharge port portion including a discharge port connected to the second bubbling chamber. Assuming that an average sectional area of the first bubbling chamber is S1, an average sectional area of the second bubbling chamber is S2, and an average sectional area of the discharge port portion is S3 in sections parallel to the main surface of the element substrate, the nozzle satisfies a relation of S2>S1>S3.

Owner:KOHLER CO +1

Vegetable room for refrigerator

InactiveUS7624593B2Avoid introducingSmooth circulationDomestic refrigeratorsRefrigeration componentsEngineeringRefrigerated temperature

Owner:LG ELECTRONICS INC

Time schedule controller and method for processing and controlling display signal

InactiveCN101494027AIncrease the discharge speedShorten discharge timeStatic indicating devicesCapacitanceTime schedule

The invention relates to a time schedule controller and a display signal processing control method thereof, which detects the input external signals to judge whether the time schedule controller is stopped so as to send low driving scene display data to a liquid-crystal display panel in advance when the time schedule controller is stopped, cause the power discharge rates of a liquid-crystal capacitor and a storage capacitor of the liquid-crystal display panel to be increased and shorten the power discharge rate of residual electric charge, thus lowering the occurrence possibility of tides.

Owner:CHUNGHWA PICTURE TUBES LTD

Fire sprinkler with flue-penetrating non-circular spray pattern

A fire sprinkler of the preferred embodiments includes a frame, a trigger, and a deflector. The frame defines a duct to exhaust the flow of a fire suppressing or extinguishing substance, and includes a fastener to fasten the frame to a supply line. The trigger blocks the flow of the fire suppressing or extinguishing substance through the duct during a first mode, and permits the flow of the fire suppressing or extinguishing substance during a second mode. The deflector redirects the flow of the fire suppressing or extinguishing substance into a coverage area. The deflector also at least partially shields the trigger from the dispersal of a fire suppressing or extinguishing substance from an adjacent fire sprinkler and prevents a failure of the trigger.

Owner:FIREBIRD SPRINKLER COMPANY

Electrical storage device provided with fiber electrodes, and method for producing same

InactiveCN102473905AIncrease surface areaReduce distanceLarge-sized flat cells/batteriesHybrid capacitor electrodesFiberMaterials science

Disclosed is a highly efficient electrical storage device, which uses a fiber cathode and a fiber anode, and in which lithium ions are intercalated. Further disclosed is a method for producing such an electrical storage device. The electrical storage device is provided with: a fiber cathode wherein a cathode active material coat layer containing a transition metal oxide represented by chemical formula 1 (Li1-xAx)aMbXcOd (in chemical formula 1, A is at least one alkali metal chosen from the group consisting of Na, K, Rb, and Cs; M is at least one transition metal chosen from the group consisting of Ti, V, Cr, Mn, Fe, Co, Ni, Cu, Nb, Mo, Ru, Pd, Ag, Ta, W, Ce, Pr, Sm, Eu, and Pb; X is at least one representative element chosen from the group consisting of B, Al, Si, P, S, Ga, and Ge; and 0<a=6, 1=b=5, 0=c=4, 0<d=12, 0=a / b=4, 0=x=0.5) is formed on the surface of a conductive fiber; a fiber anode wherein an anode active material coat layer is formed on the surface of a conductive fiber; a separator; and an electrolyte.

Owner:KAWASAKI JUKOGYO KK +1

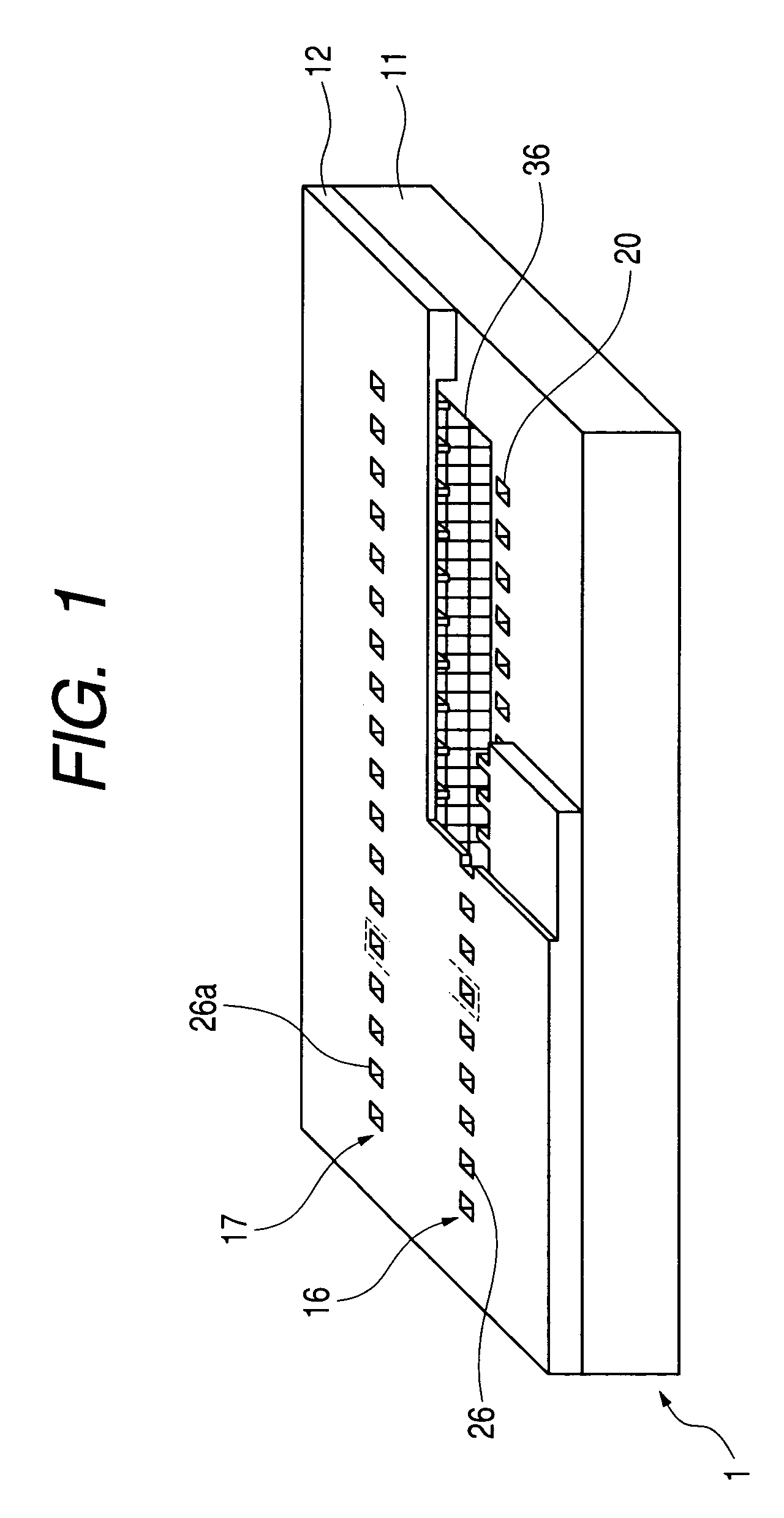

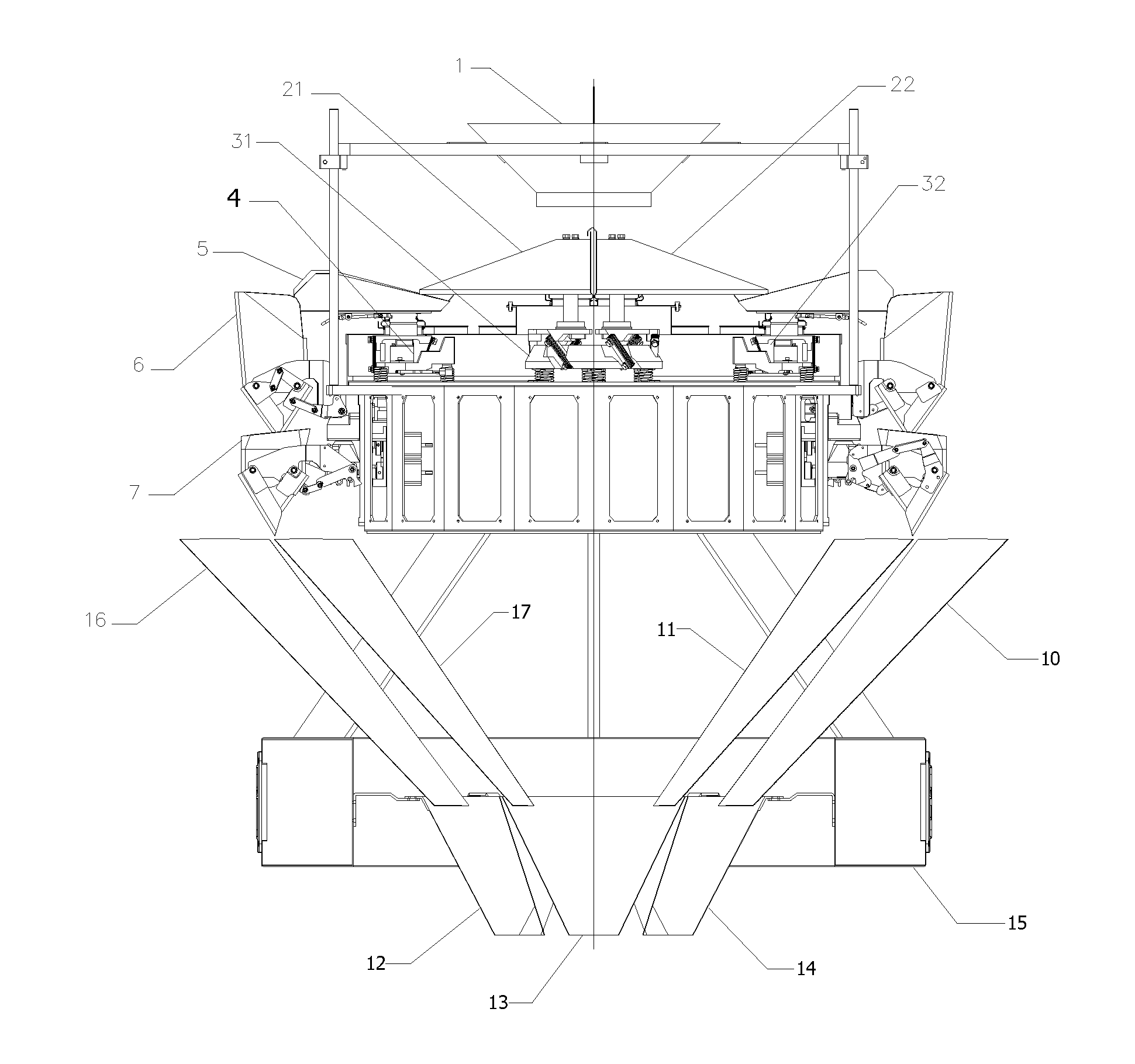

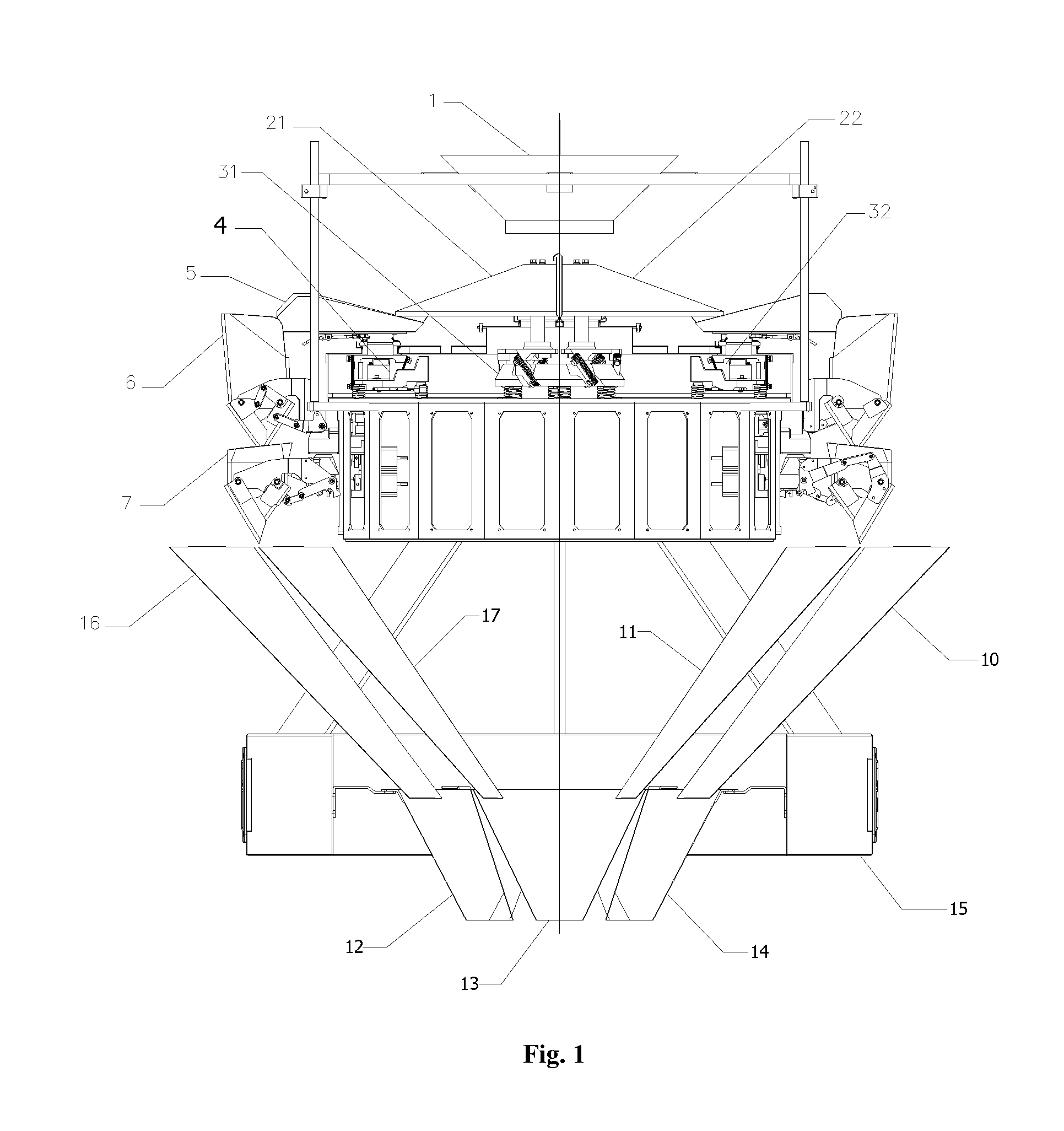

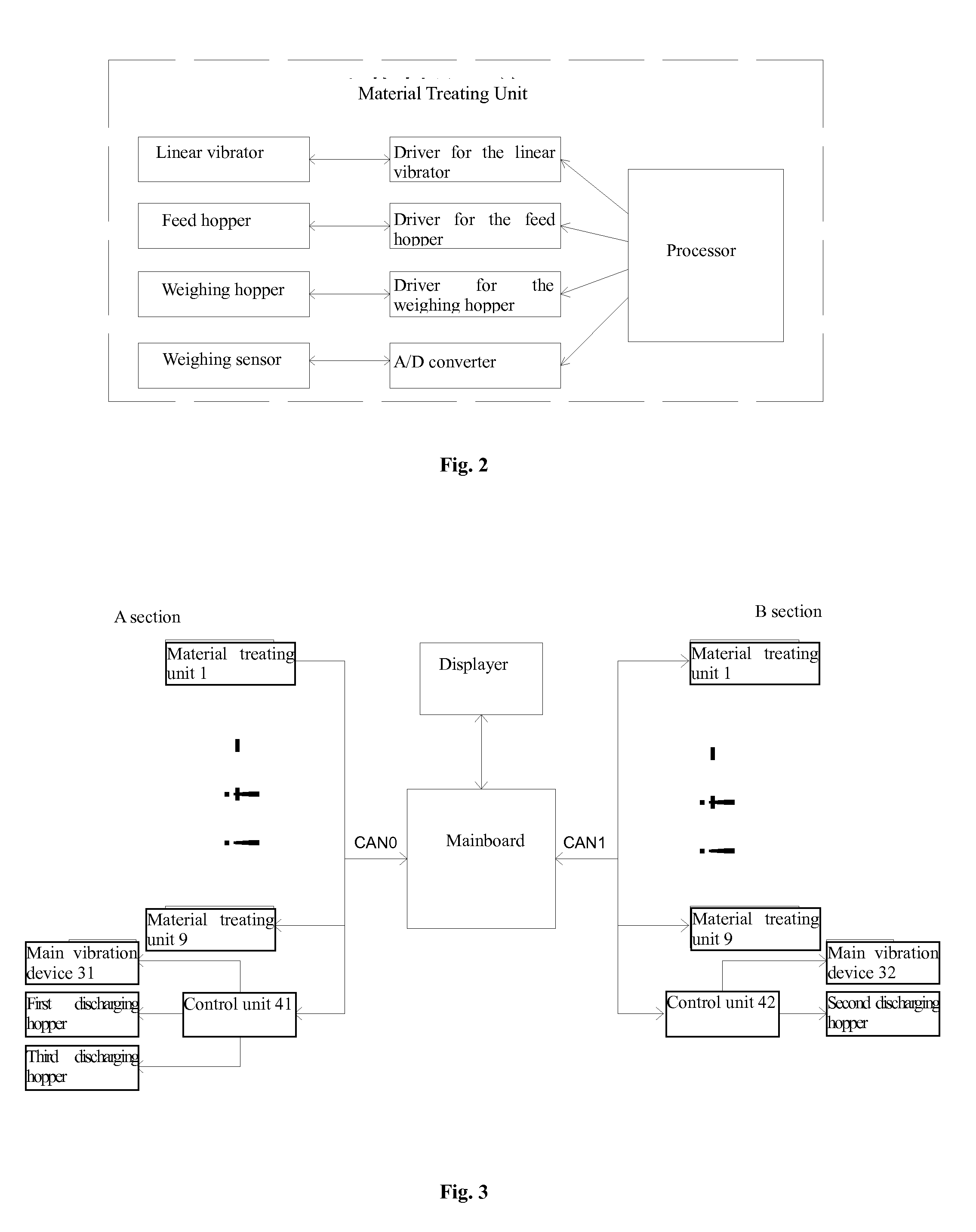

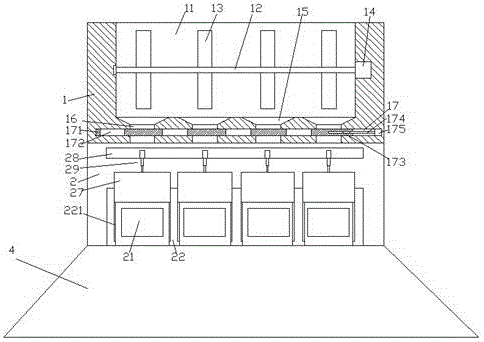

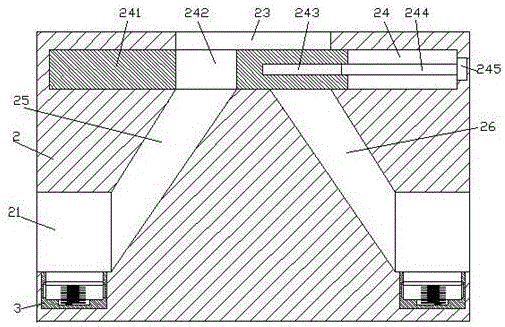

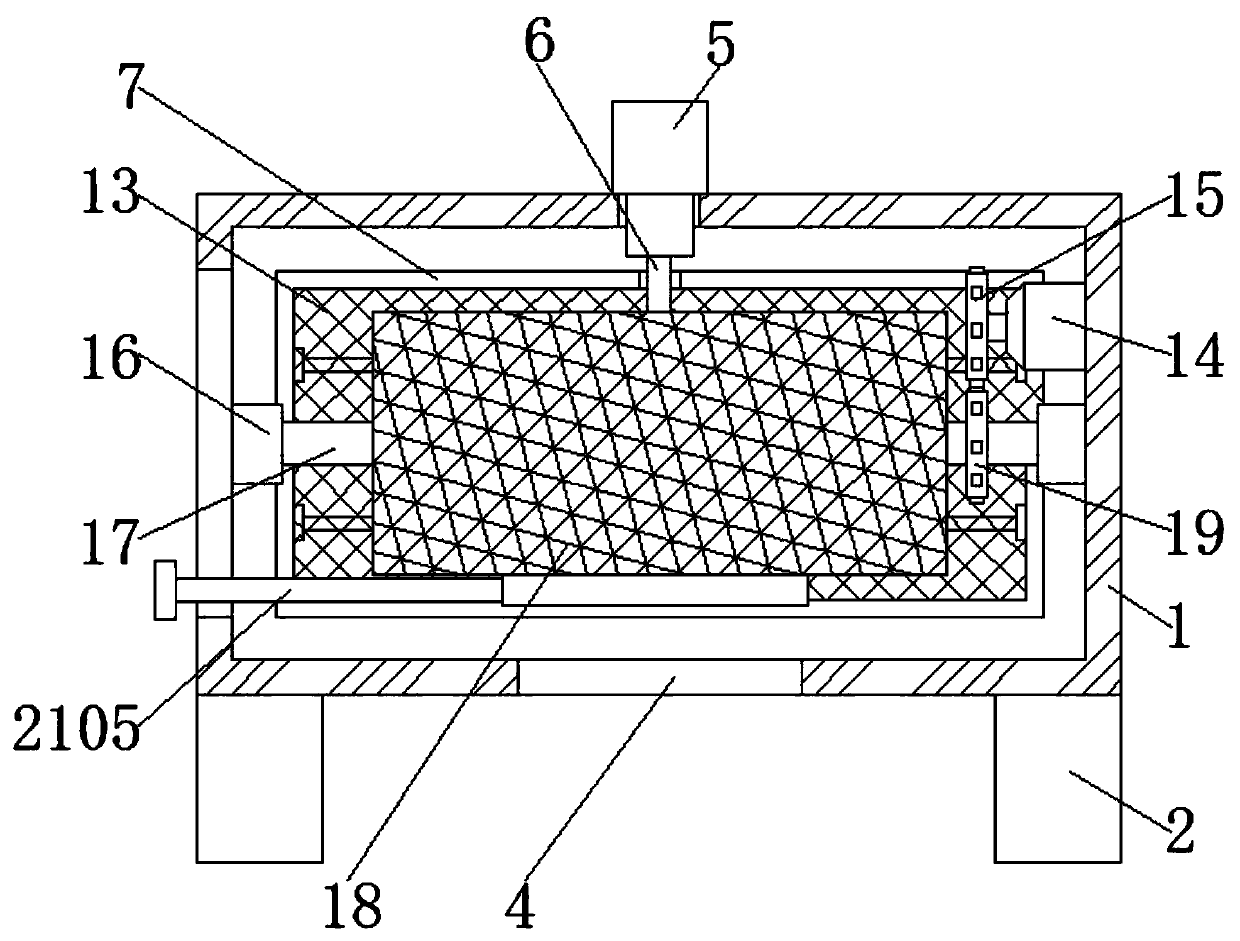

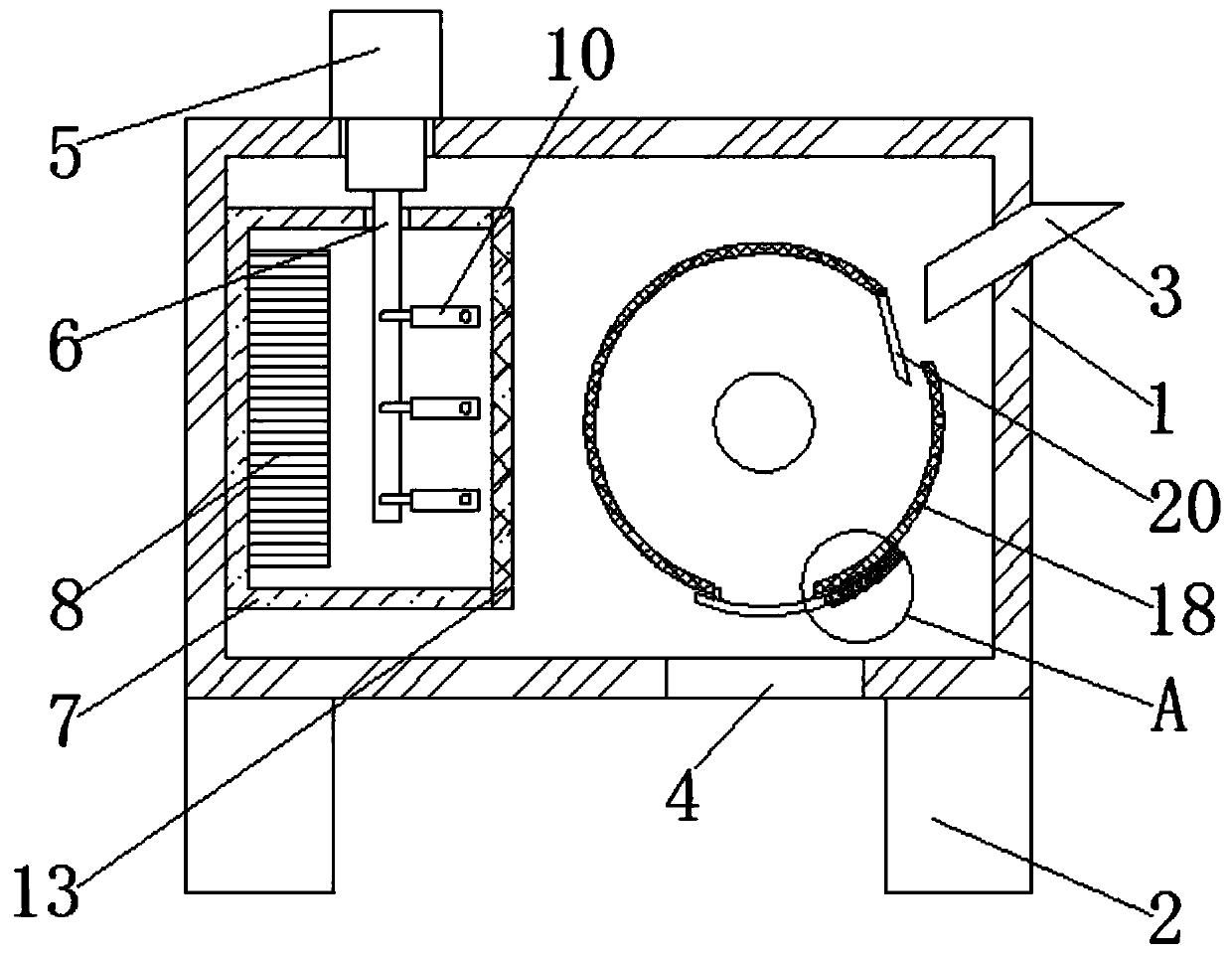

Combination weighing device and operating method thereof

ActiveUS20120103703A1Improve efficiencyData transfer speed is fastSolid materialWeighing apparatus for materials with special property/formControl signalEngineering

A combination weighing device and an operating method thereof are disclosed. The device comprises N material treating units, a mainboard, chutes (10, 11, 16, 17) and discharging hoppers (12, 13, 14), wherein the material treating units are used for receiving materials, outputting the weight value of materials and discharging materials according to the discharging control signal from the mainboard; the mainboard is used for selecting materials by combinatorial calculation based on the present-period weight value during every period and outputting the discharging control signal to weighing hoppers (7); the chutes (10, 11, 16, 17) are used for collecting the materials through a discharging route, discharging the materials to the discharging hoppers (12, 13, 14), after a discharging route is determined; the discharging hoppers (12, 13, 14) are used to separately collect materials discharged from the chutes (10, 11, 16, 17) during the same weighing period and send the materials to a packing machine; each material treating unit comprises a linear vibrator (5), a feed hopper (6), a weighing hoper (7), a weighing sensor used to weigh the materials in the weighing hoper (7), a processor and a A / D converter which is connected with the weighing sensor and the processor, N material treating units are connected with the mainboard signal together by two data receiving and delivering communication converters of the mainboard.

Owner:GUANGODNG HIGH DREAM INTELLECTUALIZED MACHINERY

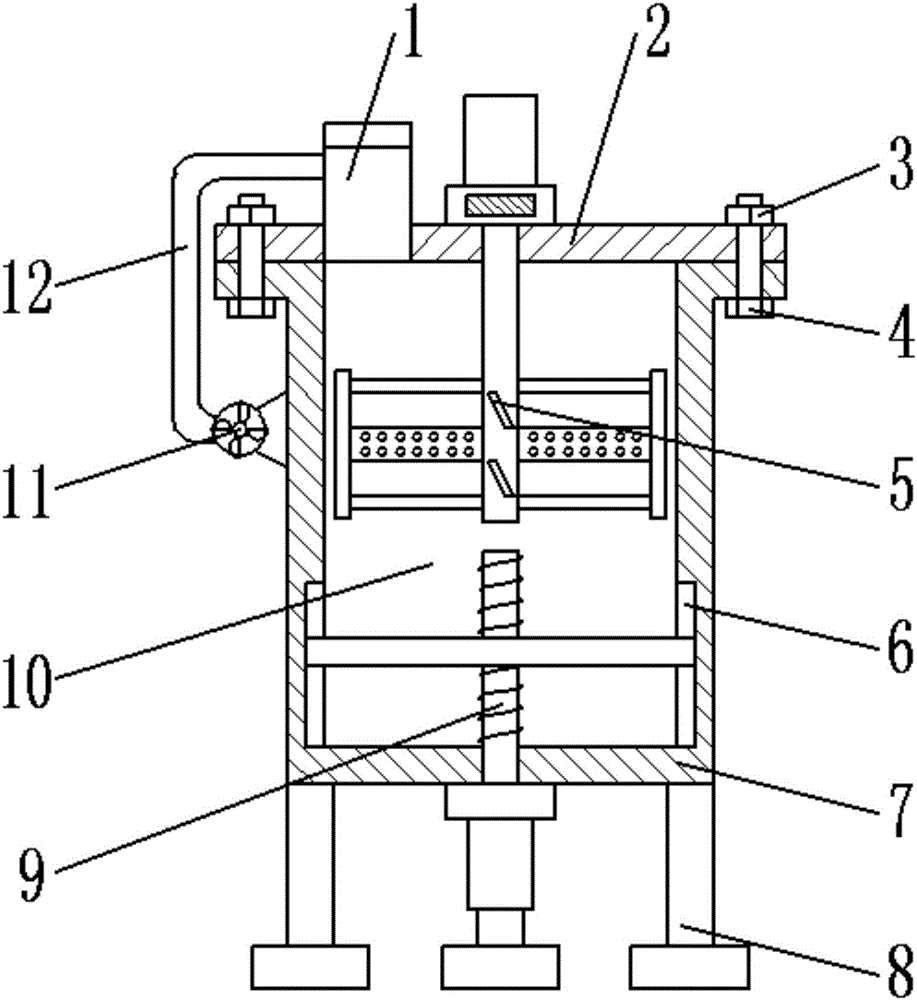

Even-stirring equipment

InactiveCN106823889AAutomatic control onAutomatic control offTransportation and packagingRotary stirring mixersEngineeringAutomatic testing

The invention discloses even-stirring equipment which comprises an even-stirring part, an output part arranged at the bottom of the even-stirring part and a boss part arranged at the bottom of the output part. The boss part is of a hollow structure, a balancing weight is embedded in the inner bottom of the boss part, an accommodating cavity is arranged in the even-stirring part, multiple sets of bucket troughs are arranged in the bottom of the accommodating cavity, a port is arranged in the bottom of each bucket trough, a first sliding connecting groove penetrating the port and extending leftwards and rightwards is arranged in the port, a first sliding connection part is arranged in the first sliding connection groove, an output hole is arranged in the first sliding connection part, a first spiral thread hole is arranged in the left side of the first sliding connection part, a first spiral rod is connected in the first spiral thread hole in spiral thread fitness, the first spiral rod is connected with a first electrical rotating machine, multiple sets of collecting zones are evenly arranged on the outer surface of the front and rear sides of the output part, a connection slot matched with the bottom of each port is arranged in the output part, a first chamfer groove and a second chamfer groove are arranged on front and rear sides of the bottom of each connection slot, and the bottom tail of the first chamfer groove is communicated with the collecting part on the front side of the output part. The even-stirring equipment is simple in structure, reasonable in design, convenient in operation, capable of realizing automatic stirring and automatic discharging and transferring and even in stirring, stirring efficiency is improved, supply requirements are met, and use cost is low.

Owner:王裕迪

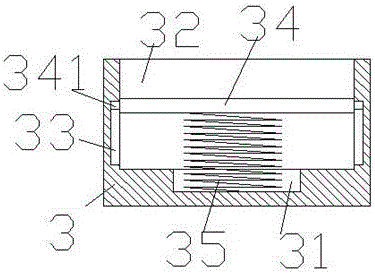

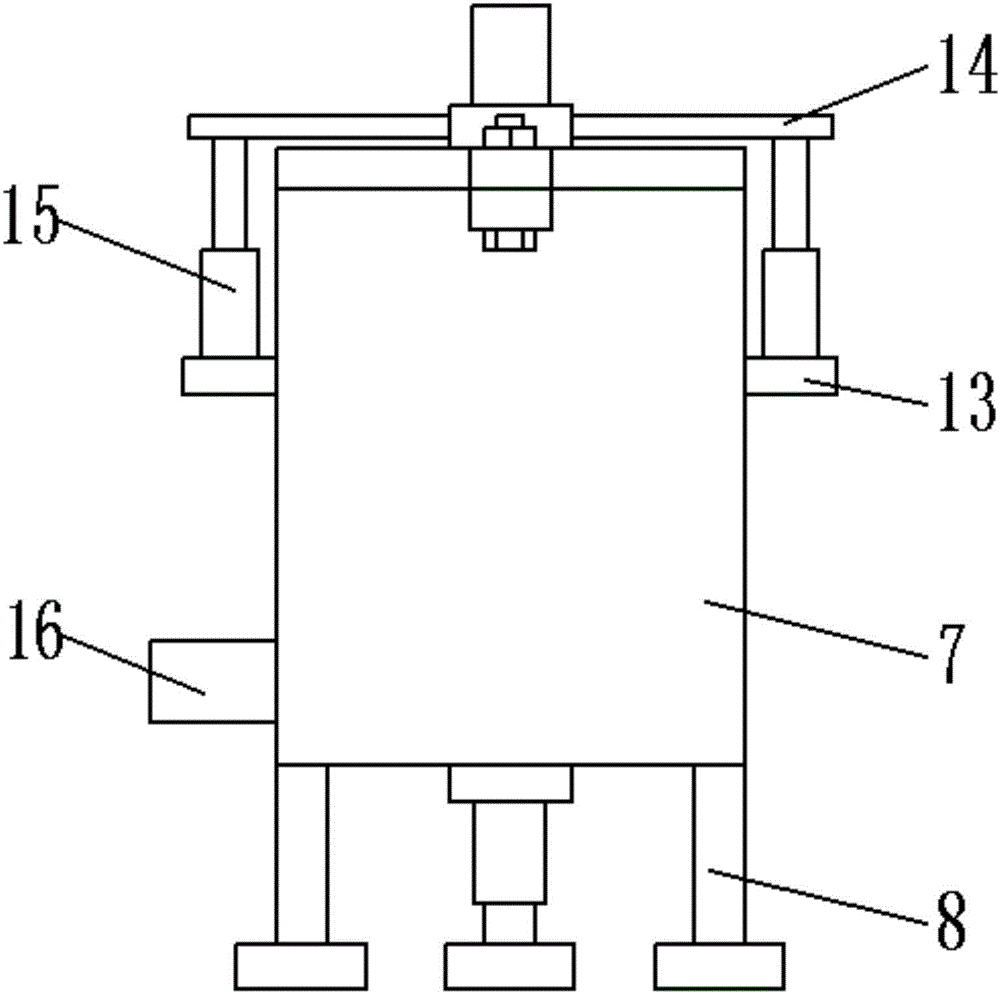

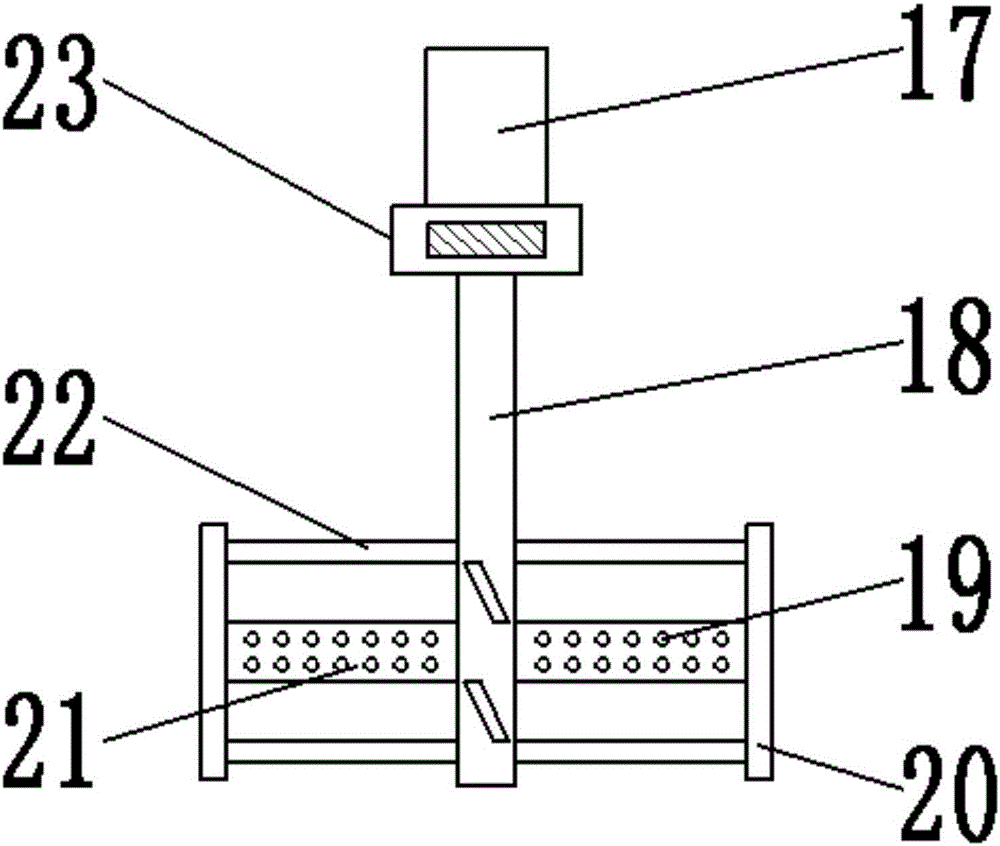

Coating stirring and mixing equipment with double stirring devices

InactiveCN106310996AIncrease the discharge speedAchieve horizontal mixingRotary stirring mixersTransportation and packagingMetallic LeadCoating

The invention provides coating stirring and mixing equipment with double stirring devices. The coating stirring and mixing equipment comprises a tank body and an upper cover. A stirring cavity is formed in the tank body, and the upper cover is arranged on a top opening. A feed pipe is arranged on the upper cover. The feed pipe is provided with a sealing cover. The side wall of the feed pipe is communicated with one end of a pressurizing pipe, and the other end of the pressurizing pipe is connected with a pressurizing pump. The first stirring device and the second stirring device are arranged in the stirring cavity. The first stirring device is composed of a first motor, a stirring shaft, a stirring blade and a scraper plate. The second stirring device is arranged at the bottom of the tank body and composed of a second motor, a thread lead screw and a stirring plate. Through the arrangement of the pressurizing pump, air is blown in the feed pipe through the pressurizing pipe to pressurize materials, and the discharge speed of the materials can be increased during discharge. The second stirring device is matched with the first stirring device to efficiently stir and mix the materials, and the stirring and mixing speed can be increased.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

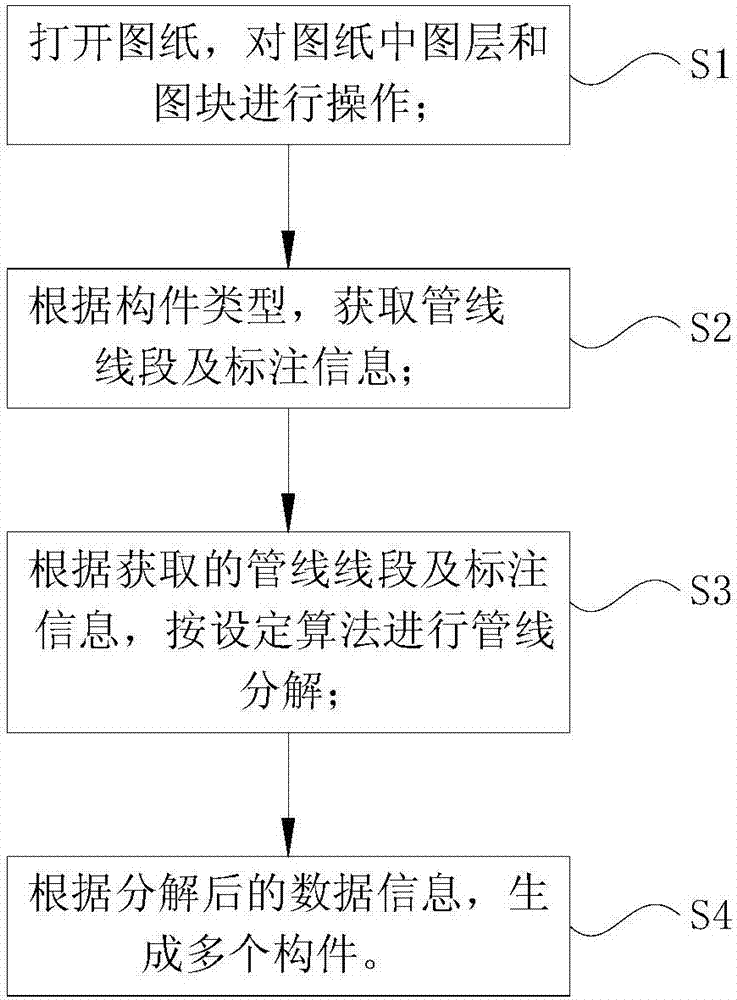

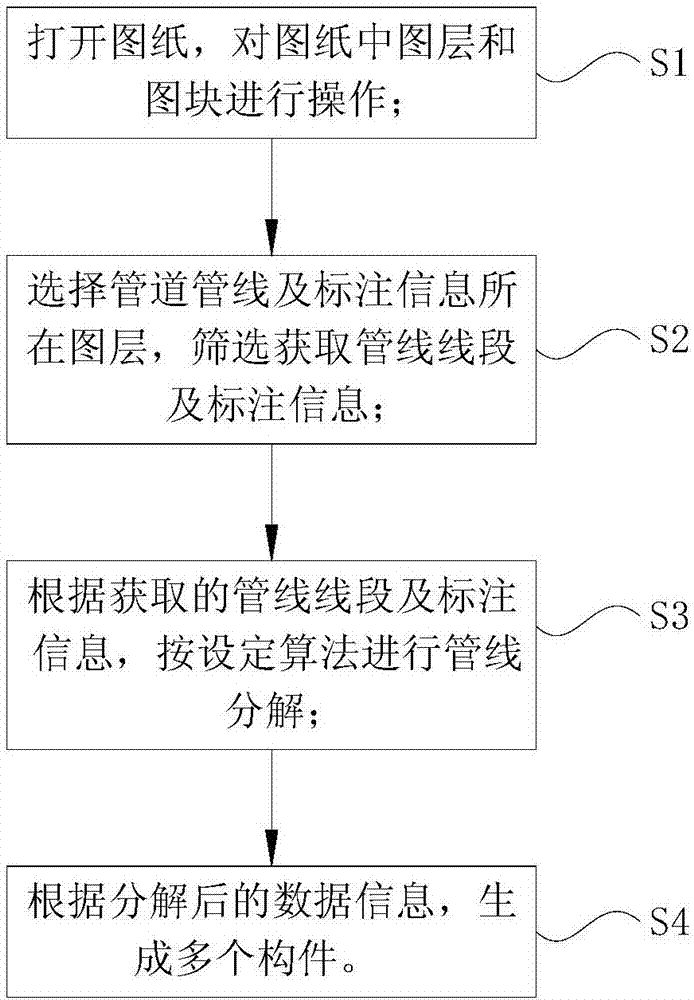

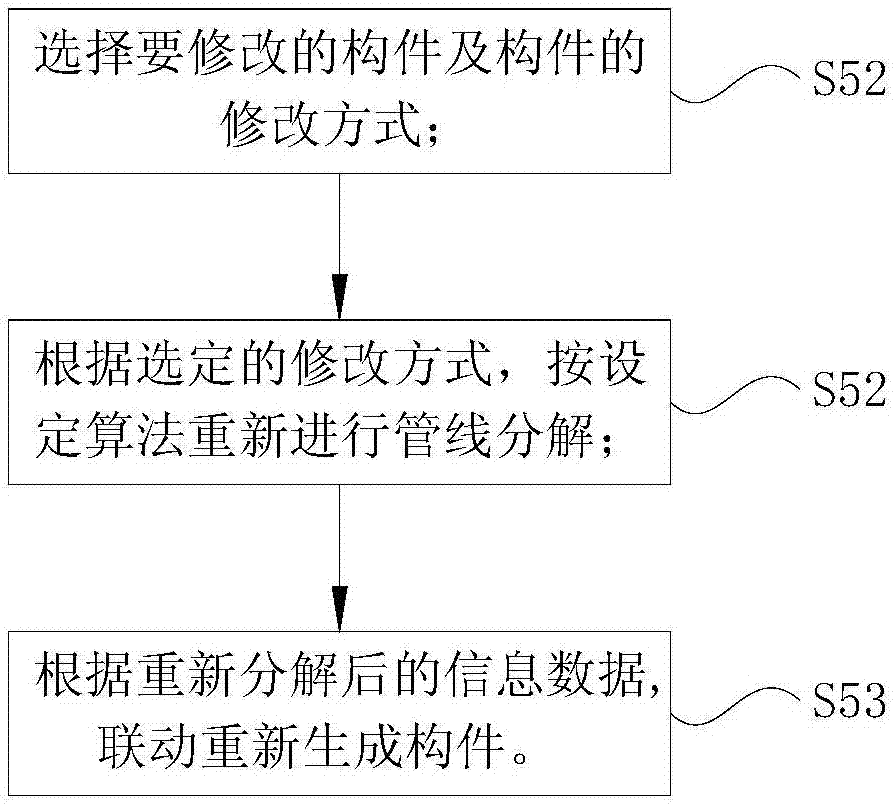

Automatic layout method of building pipeline system

ActiveCN107169203AReduce in quantityLower performance requirementsGeometric CADSpecial data processing applicationsParallel computingLine segment

The invention provides an automatic layout method of a building pipeline system. The layout method comprises following steps: S1. unfolding graphing paper to manipulate layers and blocks in the graphing paper for easy identification and retrieval of pipelines and annotations for pipelines required layout operation; S2. obtaining pipeline segments and annotations from the operated graphing paper; S3. performing pipeline resolving according to a set algorithm according to the obtained pipeline segments and annotations; S4. automatically generating multiple components having attributes, methods and being responding to specific events according to the resolved data; a building information model is formed by combining the components, that is, the automatic layout of pipeline system is completed. By means of the method of the invention, the layout is accelerated; the number of personnel for layout is reduced; the accuracy of layout is increased; the capacity requirement for the layout workers is reduced; the layout is more reasonable and raw material is saved; there is less error in the layout graphs so that the method is easy to be accepted by all parties with less divergence and the work progress is accelerated.

Owner:CHONGQING ERAN ELECTROMECHANICAL EQUIP ENG CO LTD

Supercapacitor

ActiveUS20160268059A1Increase working frequencyReduced ionic impedanceHybrid capacitor separatorsHybrid capacitor electrodesElectricityFluid electrolytes

A supercapacitor or electrochemical capacitor includes spaced apart electrodes which are separated from each other by a separator made of an electrically insulating material. Each electrode is formed of carbonaceous material and capable of being impregnated with a liquid electrolyte. Metal current collectors are provided on the sides of the electrodes opposite from the separator. The electrodes have holes or elongated orifices extending through the electrodes to reduce ionic impedance in order to produce faster charging and discharging of the device.

Owner:UNITED STATES OF AMERICA THE AS REPRESENTED BY THE SEC OF THE ARMY

Novel energy-saving malt drying device

ActiveCN109945608AImprove uniformityEnsure comprehensive deliveryDrying gas arrangementsDrying chambers/containersMotor driveMalt Grain

The invention discloses a novel energy-saving malt drying device which comprises a tank. Support legs are fixedly connected to four corners of the bottom part of the tank; and a feeding pipe communicates to the front side of the tank. According to the novel energy-saving malt drying device provided by the invention, through the cooperative use of a motor, a drying cylinder, an electric telescopicrod, a blade and a limiting mechanism, the motor drives the driving cylinder to rotate so as to turn over malt, so that the degree of uniformity in drying the malt is improved; the electric telescopicrod drives the blade to deflect up and down so as to adjust the wind direction, so that the comprehensive transmission of heat is ensured; the limiting mechanism is used for limiting a discharge holeand can be opened when discharging is required, so that discharging can be carried out conveniently, and the problems that an existing malt drying device does not have a function on uniformly dryingthe malt when being used for drying the malt, and is inconvenient to discharge after drying and poor in blade adjusting ability are solved; and the novel energy-saving malt drying device has the advantages of uniformity in drying, adjustability in wind direction and convenience in in discharging, and is worth popularizing.

Owner:JIANSU JINSHAN BEER RAW MATERIAL CO LTD

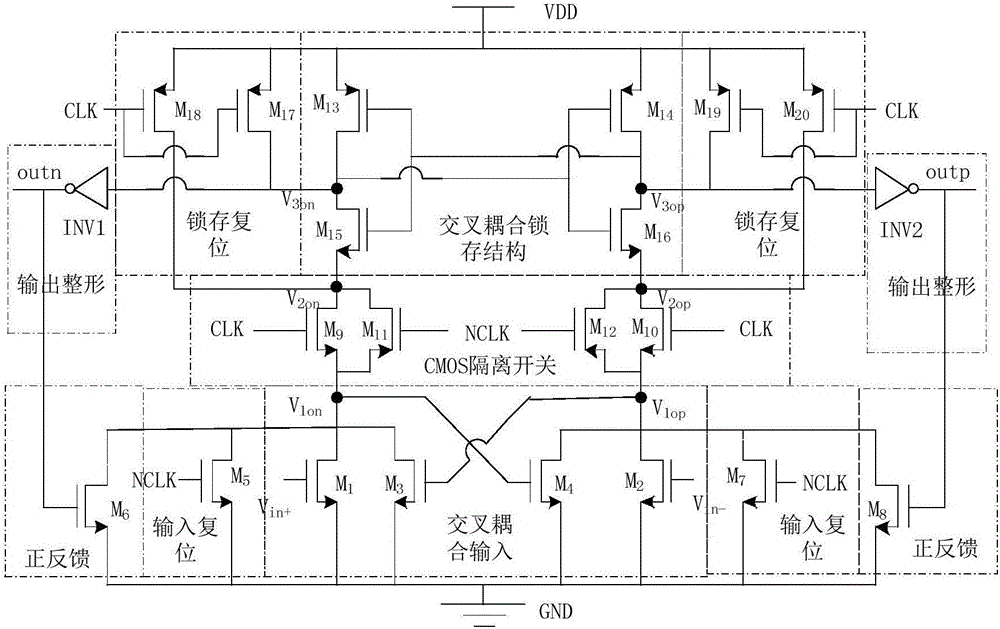

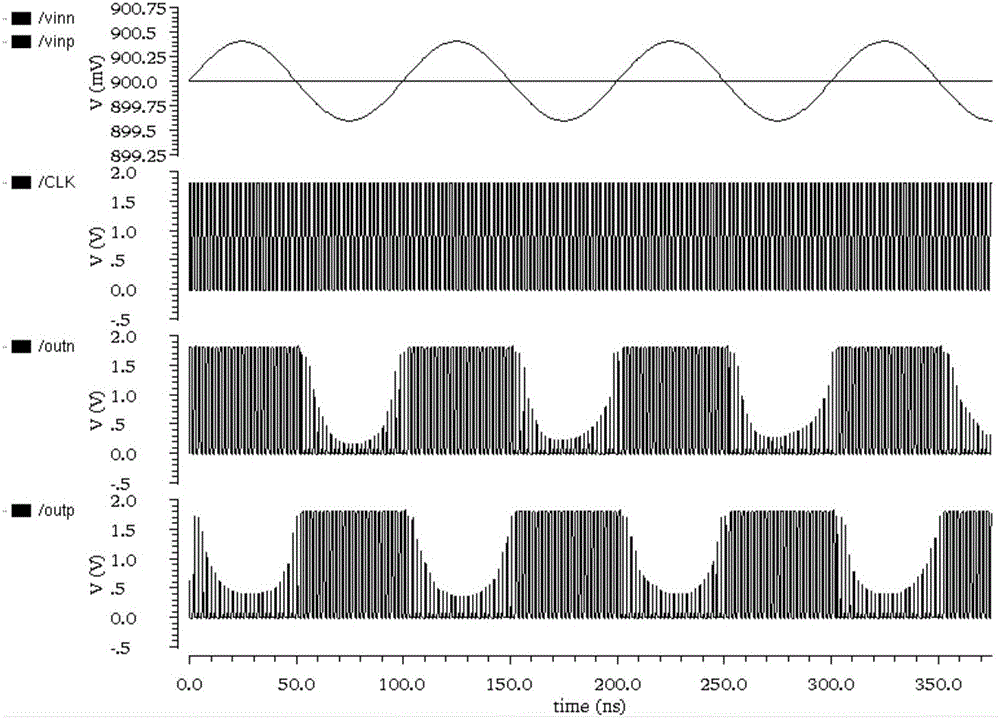

Positive feedback isolating dynamic latch comparator

ActiveCN106026996AHigh precisionSuppresses the effects of kickback noiseMultiple input and output pulse circuitsCMOSCoupling

The invention discloses a positive feedback isolating dynamic latch comparator. The comparer comprises a cross coupling input unit, an input reset unit, a CMOS isolating switch unit, a cross coupling latch structure unit, a latch reset unit, an output shaping unit and a positive feedback unit. The cross coupling input unit converts an input voltage signal into a current. The cross coupling latch structure unit and the latch reset unit finish comparison functions. The CMOS isolating switch unit isolates the cross coupling input unit and the cross coupling latch structure unit at a reset stage, thereby reducing the influence of kickback noises. The input reset unit resets the output end of the cross coupling input unit at the reset stage. The positive feedback unit is controlled by the output of the output shaping unit and amplifies the current at a comparison stage. CLK and NCLK are two non-overlap clocks and provide a time sequence for the whole dynamic latch comparator. According to the comparer, the speed and precision of the dynamic latch comparator can be remarkably improved, and the power consumption is reduced.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com