Patents

Literature

125results about How to "Reduces electrochemical polarization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Modified method for lithium ion cell negative electrode material

InactiveCN1812168AGood battery performanceImprove battery performanceElectrode manufacturing processesSecondary cellsModified methodCarbon source

This invention relates to a kind of improving method of lithium ionic cell cathode materials. The cathode materials in need of improving are mixed evenly with catalyst which has 0.1úÑ-10úÑ weight percent of cathode materials. The materials are then put into reaction furnace, which uses hydrocarbon as carbon source. The cathode materials are mixed with buffer gas according to 1í†(0-10) volume ratio. Then the mixture are reacted in reaction furnace at 600-1300íµ for 1-900 minutes. A kind of improved composite cathode materials, at the surface of which in-situ grows nanometer carbon fibrin / carbon tube, are gained. The improved materials have good cell kinetic ability, circulating ability, charge-discharge capacity and consistency with electrolyte.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Lead acid battery taking graphene as additive

ActiveCN102244300AImprove electronic conductivityIncrease the speed of chargingLead-acid accumulatorsCell electrodesEngineeringGraphene

The invention discloses a lead acid battery taking graphene as an additive, and relates to a lead acid battery technology. The lead acid battery comprises a battery shell, a positive plate grid, a negative plate grid, a partition board and electrolyte, wherein the positive and negative plate grids are positioned in the battery shell; the partition board is positioned between the positive and negative plate grids; and the electrolyte is filled into the shell. The lead acid battery is characterized in that: the positive plate grid is manufactured by coating cathode lead paste and performing curing, drying and formation; the negative plate grid is manufactured by coating anode lead paste and performing the curing, the drying and the formation; and the cathode lead paste or the anode lead paste or both take the graphene as the additive. The lead acid battery provided by the invention takes the graphene material as the additive, can be rapidly charged and discharged, and simultaneously has high capacity and relatively longer charging and discharging circulation service life.

Owner:JIESHOU HUAYU POWER SUPPLY

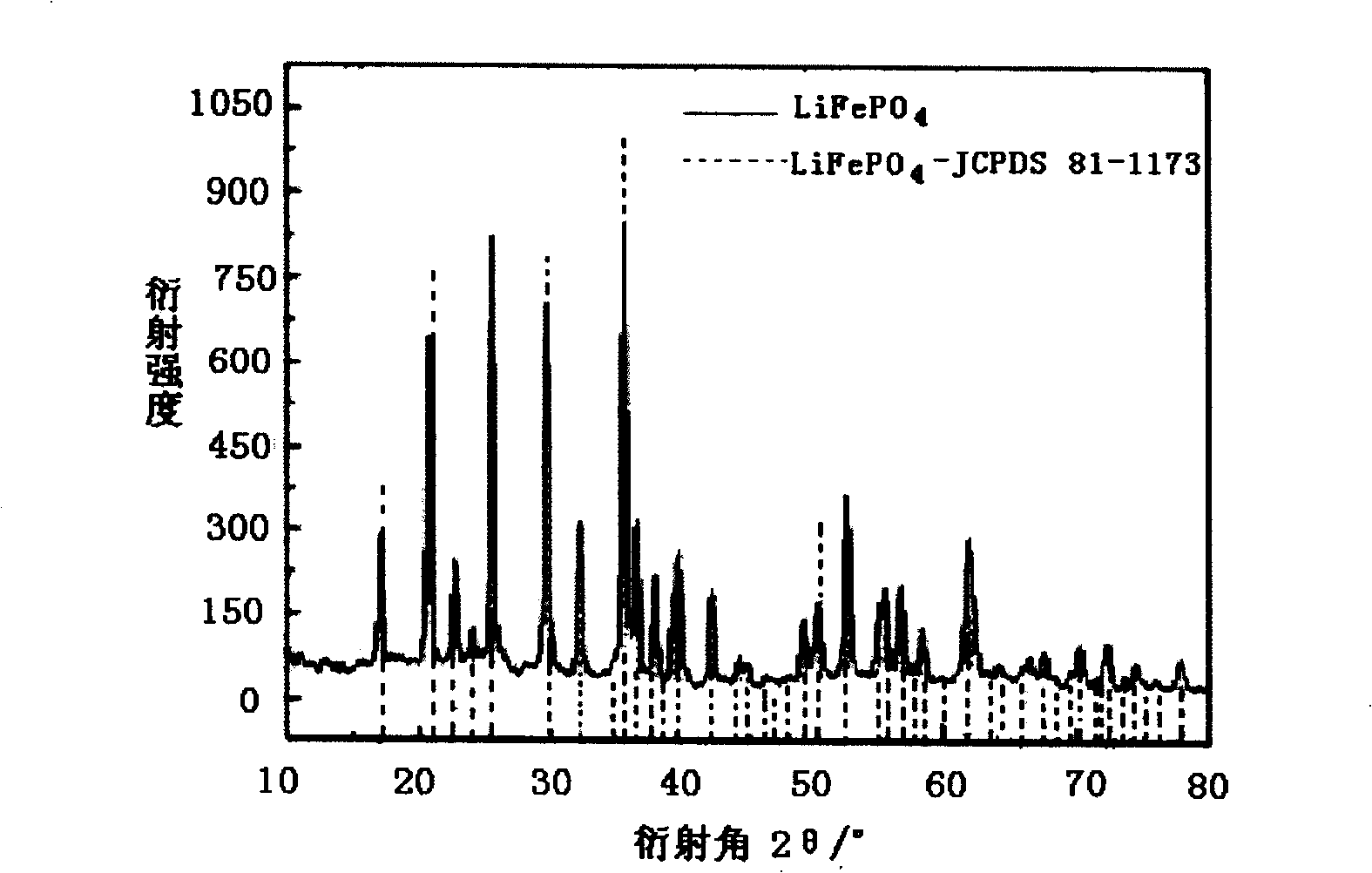

Positive electrode material of lithium ion cell and its preparation method

InactiveCN101339988ASolve the control puzzleWell mixedElectrode manufacturing processesPhosphorus compoundsPhosphateCopper nitrate

The invention discloses an electrode material of a lithium-ion battery and a preparation method thereof. The electrode material is lithium iron phosphate (LiFePO4) with the surface coated with nano-copper and is prepared by using the following method: water solution of ferrous phosphate and lithium phosphate is evenly mixed according to a chemical formula, and is added with a stabilizer OP-10 water solution for mixing and stirring, the mixed solution is controlled at a certain temperature for precipitation, and then the precipitate is filtered, rinsed and aired. Heat treatment is carried out for an aired precursor obtained from the previous step at high temperature, therefore a lithium iron phosphate semi-finished product is obtained. The problem of the imperfect particle size of the lithium iron phosphate is solved by controlling the process conditions. Copper nitrate solution is mixed with the lithium iron phosphate semi-finished product and is added with vitamin C for reducing to obtain the copper; metal copper is evenly clad on the surface of the lithium iron phosphate particles. The preparation method has simple operational procedure; the lithium-ion battery anode material of the prepared lithium-ion battery electrode material has high ionic conductivity and electron conductivity, the 1C initial specific capacity is not less than 162mAh / g and the lC tap density is not less than 1.5g / cm<3>.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

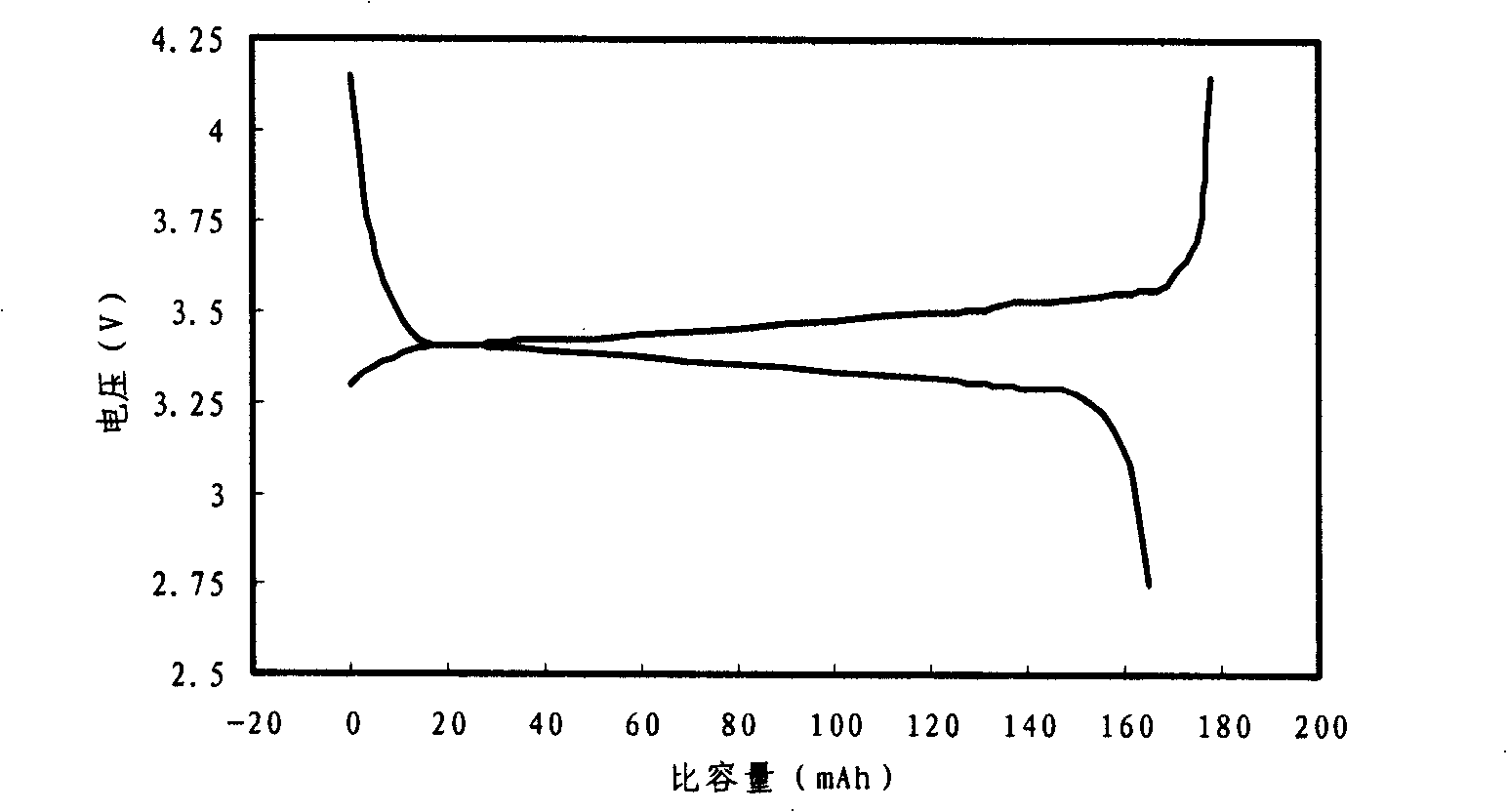

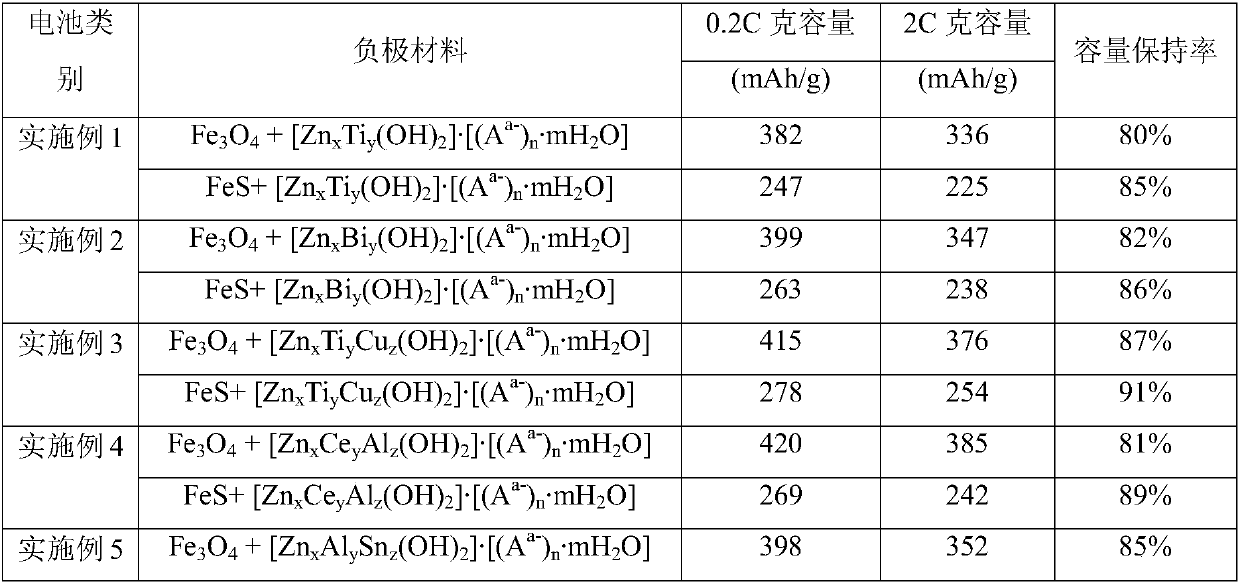

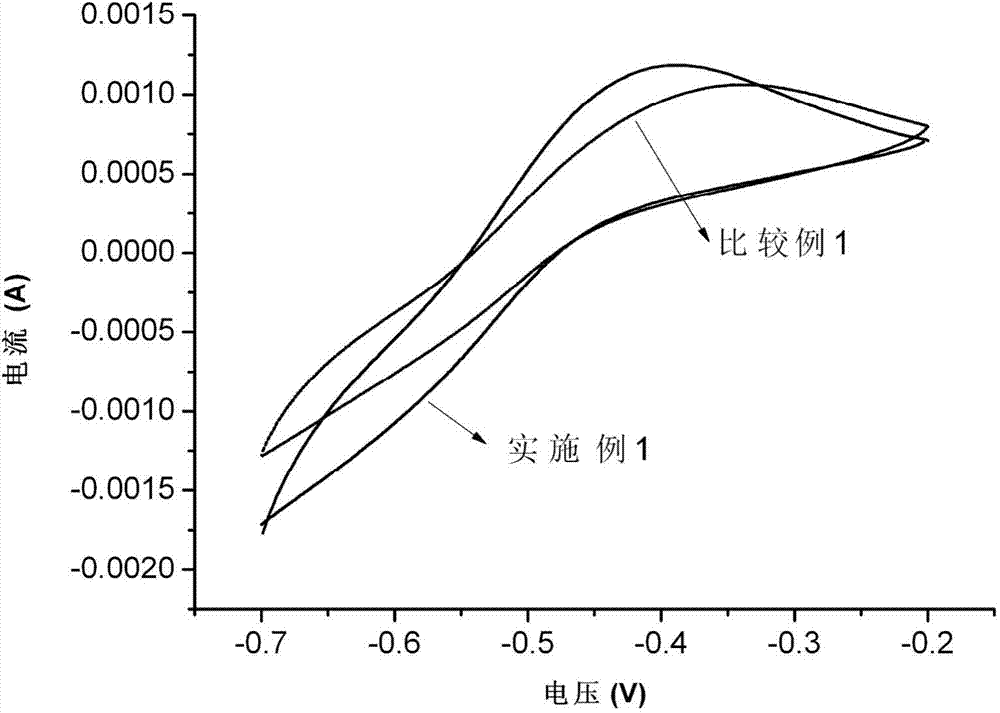

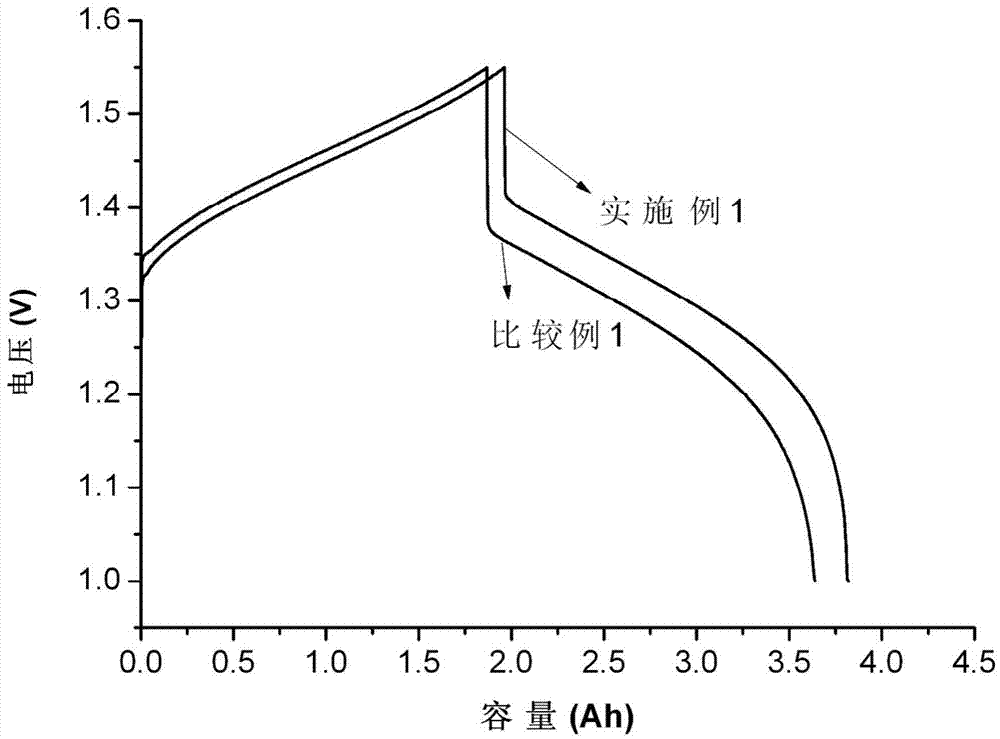

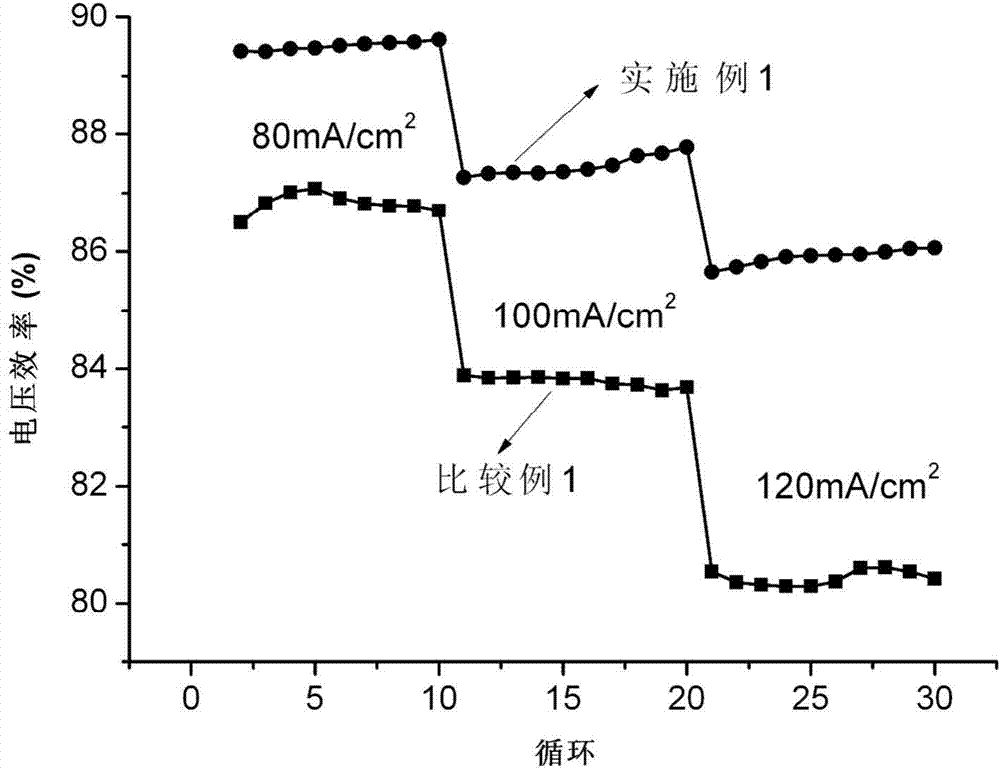

Negative plate of secondary nickel-iron battery, preparation method of negative plate and secondary nickel-iron battery of using negative plate

InactiveCN107681118AExcellent rate performanceImprove cycle performanceCell electrodesNickel accumulatorsEngineeringZinc

The invention discloses a negative plate of a secondary nickel-iron battery, a preparation method of the negative plate and a secondary nickel-iron battery of using the negative plate and belongs to the technical field of negative electrode materials for secondary nickel-iron batteries. According to the main points of the technical scheme, a negative active material in the negative plate of the secondary nickel-iron battery comprises an additive zinc-based multilayered hydroxide [ZnxMyM'z(OH)2].[(A<a->)n.mH2O]. The invention further particularly discloses a preparation method of the negative plate of the secondary nickel-iron battery and the secondary nickel-iron battery of using the negative plate. By adopting the novel negative plate of the secondary nickel-iron battery, the energy density and the rate capability of the secondary nickel-iron battery can be greatly improved and the cycle life of the secondary nickel-iron battery can be greatly prolonged.

Owner:HENAN NORMAL UNIV

Double-function negative electrode and applications of double-function negative electrode as all-vanadium flow battery negative electrode

ActiveCN104518221AReduces electrochemical polarizationIncrease working current densityMaterial nanotechnologyCell electrodesFormateCharge transfer resistance

The invention relates to an all-vanadium flow battery double-function negative electrode, wherein a carbon material is adopted as a substrate, a Bi-containing electro-catalyst is modified on the surface of the substrate, the Bi-containing electro-catalyst is one or more than two selected from a Bi elementary substance, Bi2O3, a Bi halide and a Bi metal salt, the Bi halide is bismuth fluoride, bismuth trichloride, bismuth bromide, or bismuth iodide, and the Bi metal salt is bismuth sulfate, bismuth nitrate, bismuth phosphate, bismuth formate or bismuth acetate. According to the present invention, the electrode is suitable for the negative electrode of the all-vanadium flow battery, the electrocatalysis activity and the electrochemical reversibility of the electrode material on the V<2+> / V<3+> oxidation reduction reaction can be substantially improved, and the charge transfer resistance can be reduced; and the high hydrogen evolution overpotential is provided so as to inhibit the occurrence of the hydrogen evolution reaction and prolong the service life of the battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

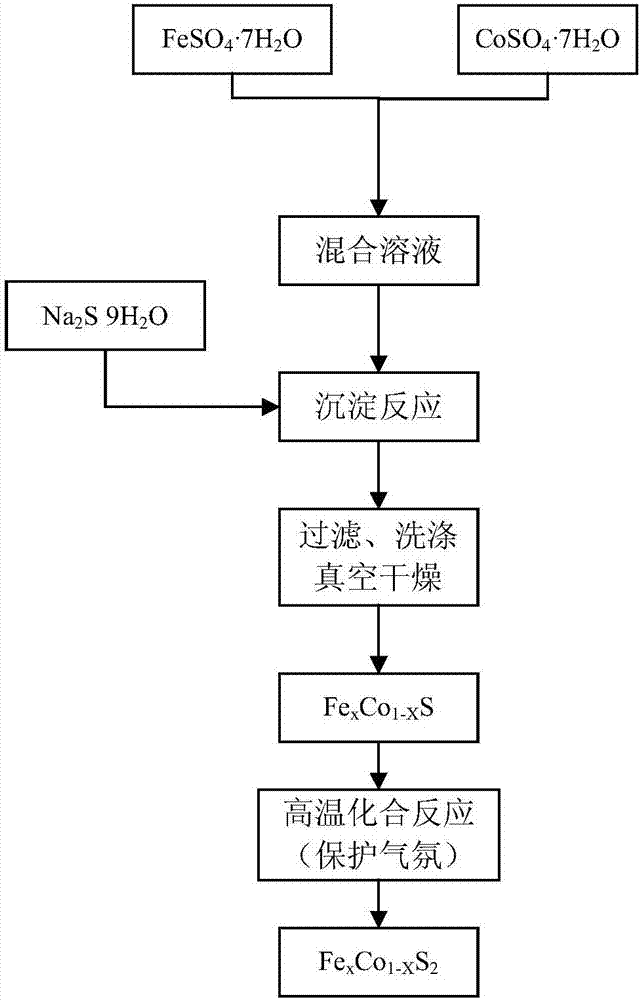

Positive electrode material Fe<x>Co<1-x>S<2> powder of thermal battery and preparation method for powder

ActiveCN107026256ALarge specific surface areaReduce current densityPrimary cell electrodesThermal stabilityThermal Battery

The invention provides positive electrode material Fe<x>Co<1-x>S<2> powder of a thermal battery and preparation method for the powder. In the Fe<x>Co<1-x>S<2> powder, x is greater than 0 and less than 1. The positive electrode material Fe<x>Co<1-x>S<2> powder of the thermal battery is prepared by combination of advantages of two kinds of positive electrode materials of CoS<2> and FeS<2> by a method in combination of chemical deposition and high-temperature solid-phase reaction. The positive electrode material Fe<x>Co<1-x>S<2> powder of the thermal battery has the advantages of high capacity and high voltage platform of the FeS<2>, as well as the advantages of low electrical resistivity and thermal stability of CoS<2>, and is a novel positive electrode material of the thermal battery.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Energy-saving anode for non-ferrous metal electrodeposition

An energy saving anode used in electro-deposition of nonferrous metal is characterized in that the energy saving anode used in electro-deposition of nonferrous metal comprises a metal-conductive base-plate and at least one block of composite structure which is compounded by a metal layer with porous structure, wherein the structure is frame type, sandwich type and slab lattice type. The energy saving anode not only can effectively reduce true current density of the anode in electro-deposition of the nonferrous metal, reduce overpotential for oxygen evolution of the anode and lower energy consumption, but also can reduce the quality of the anode, reduce the creep deformation and the deformation of the anode, form a more dense oxydic film on the surface, reduce the corrosion rate of the anode, extend the service length of the anode and improve the quality of the cathode products. The energy saving anode can make a full use of the existing anode without changing the structure of the groove and have no effect to the process flow, and the energy saving anode has low preparing cost and low investment.

Owner:CENT SOUTH UNIV

High-strength heatproof glassware

The invention relates to the technical field of glass and provides a high-strength heatproof glassware. The glassware comprises, by weight, 298 kg of an amorphous quartz granule, 7 kg of potassium phosphotungstate, 2.05 kg of zirconium silicate, 50 kg of potash feldspar, 1.7 kg of leucite, 3 kg of sodium nitrate, 1.36 kg of kyanite, 0.015 kg of graphene, 0.0055 kg of nanometer selenium powder, 0.020 kg of cerium oxide, 3.5 kg of sodium fluosilicate, 130 kg of cullet and 0.5 kg of aluminum hydroxide. According to the invention, since the amorphous quartz granule is used as a main material, a good molding effect and good glossiness are obtained; through addition of the component--graphene, electrochemical polarization among active substance particles is reduced, and the strength of the glassware is greatly improved due to structural strength and networking of graphene; a prepared glass is safe and reliable to use and has improved surface glossiness, an improved reflection effect and a beautiful color.

Owner:ANHUI FENGYANG HUAIHE GLASS

Lithium-salt-modified lithium ion battery anode material and preparation method thereof

InactiveCN104393235AIncrease the diffusion coefficientIncrease high currentCell electrodesDischarge efficiencyMicro nano

The invention relates to a lithium-salt-modified lithium ion battery anode material and a preparation method thereof. A dipping solid-phase technology is employed to distribute lithium ion in a lithium-containing compound in a graphite anode material, so that the lithium-modified lithium ion battery lithium-rich multi-channel type graphite anode material is obtained. The provided lithium ion battery anode material has the advantages of high initial charge / discharge efficiency, good cycling stability and the like. Additionally, the preparation method can be performed in air, the preparation process is simple, small-molecular gaseous oxides generated through high-temperature decomposition of a lithium salt compound or a mixture is capable of breaking through micro-nano channels in an anode carbon particle and clearing away obstacles in the channels in a diffusion and exhausting process, rapid channels for diffusion of lithium ion are provided, the diffusion coefficient of lithium ion in the anode material is improved, electrochemical polarization is reduced, and the heavy-current high-efficiency charge / discharge performance of the lithium ion battery is improved.

Owner:天津锦美碳材科技发展有限公司

Method for making lead-acid battery pole plate

InactiveCN101841033AHigh bonding strengthTight jointElectrode carriers/collectorsLead-acid accumulator electrodesLead alloyAfter treatment

The invention relates to a method for making a lead-acid battery pole plate, which is characterized by comprising the following steps: adopting a foamy carbon with a three-dimensional structure as a skeleton, and electroplating lead or lead alloy on the skeleton to obtain a grid; coating active materials on the grid, and solidifying and drying the grid; and casting a lead or lead-alloy frame on the grid subjected to solidification and drying to obtain the lead-acid battery pole plate. The lead-acid battery pole plate is environment-friendly, can greatly reduce the lead consumption and significantly reduce the weight of the battery pole plate, and can three-dimensionally contact the active materials so as to make the current and potential distributed more uniformly on the battery pole plate, thereby reducing the electrochemical polarization and polarization resistance on the surface of the battery, facilitating the transformation of the active materials, and improving the utilization ratio and specific energy of the active materials. The lead-acid battery pole plate prepared by the method adopts the lead or lead-alloy frame, can facilitate process after-treatment, and has good process processability.

Owner:WUHAN INTEPOWER CO LTD

Rapidly discharged/charged high power lithium ion battery and manufacturing method thereof

ActiveCN108306013ATake advantage ofHigh tap densityFinal product manufactureElectrode carriers/collectorsManganateCarbon nanotube

The invention discloses a rapidly discharged / charged high power lithium ion battery and a manufacturing method thereof. The positive current collector comprises an aluminum foil and a conductive coating. The negative current collector comprises a copper foil and a conductive coating. The diaphragm is a PE material, which is bidirectionally and synchronously stretched, and ceramic oxide is paintedon the surface of the PE material. The anode paste comprises following components in parts by weight: 10 to 35 parts of lithium cobaltate, lithium nickelate, lithium manganate, lithium iron phosphate,lithium manganese phosphate, lithium iron manganese phosphate, or lithium vanadium phosphate, 62 to 81 parts of nickel cobalt lithium manganate, 1 to 3 parts of Ketjen black or carbon nanotube, and 1to 3 parts of graphene or Super-P and modified 1,3-polyvinylidene fluoride. The cathode paste comprises following components in parts by weight: 55 to 75 parts of artificial graphite or meso-phase carbon micro beads, 20.5 to 36 parts of soft carbon or hard carbon, 1 to 2 parts of CMC, 2 to 4 parts of Super-P, and 1.5 to 3 parts of styrene butadiene rubber SBR or polystyrene-acrylate. The providedlithium ion battery can continuously discharge or charge (30C). The 30C constant current charge capacity can account for 70% or more of 1C capacity, and the 30C discharge capacity can account for 90%or more of 1C capacity.

Owner:FENGFAN

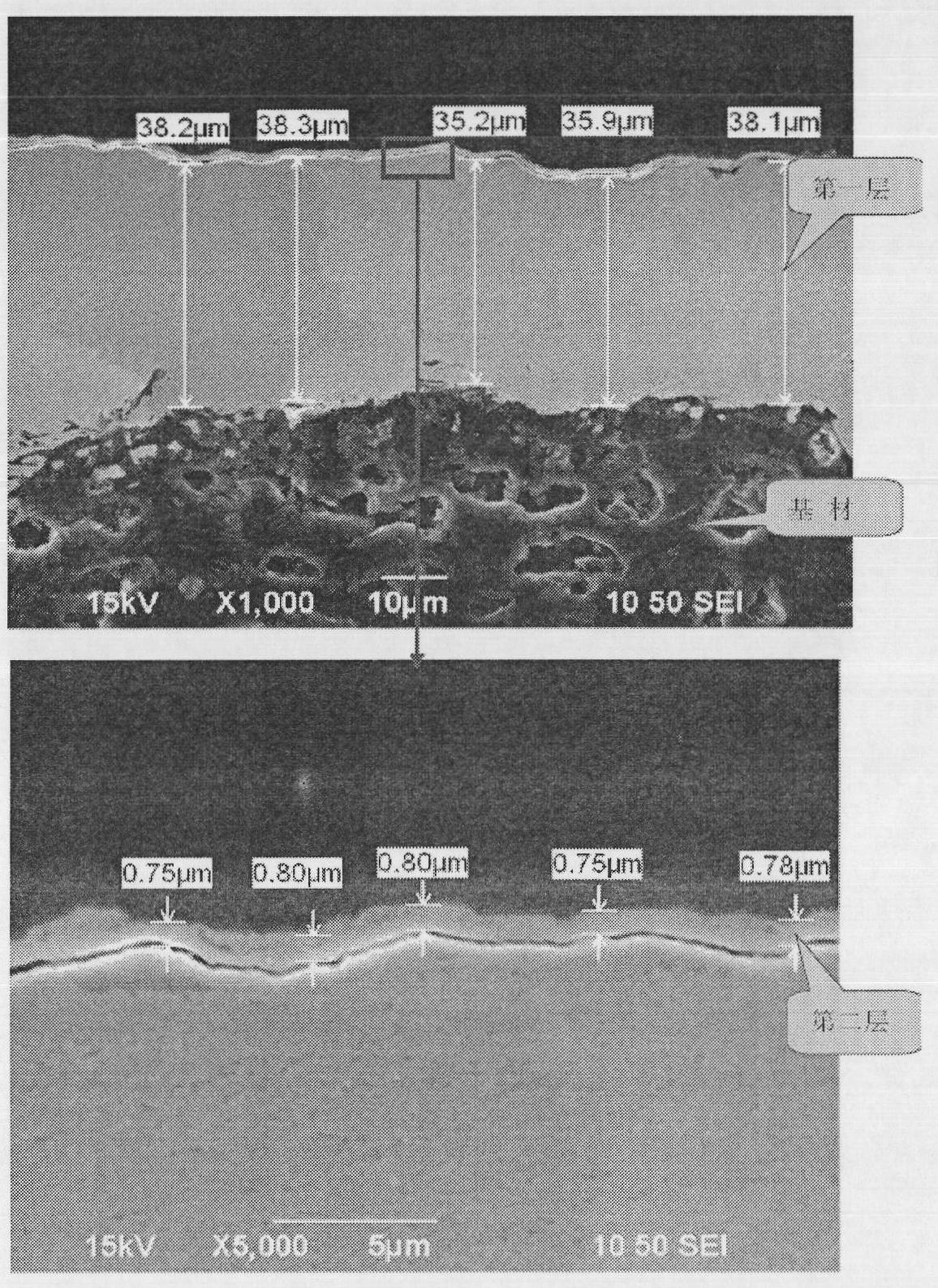

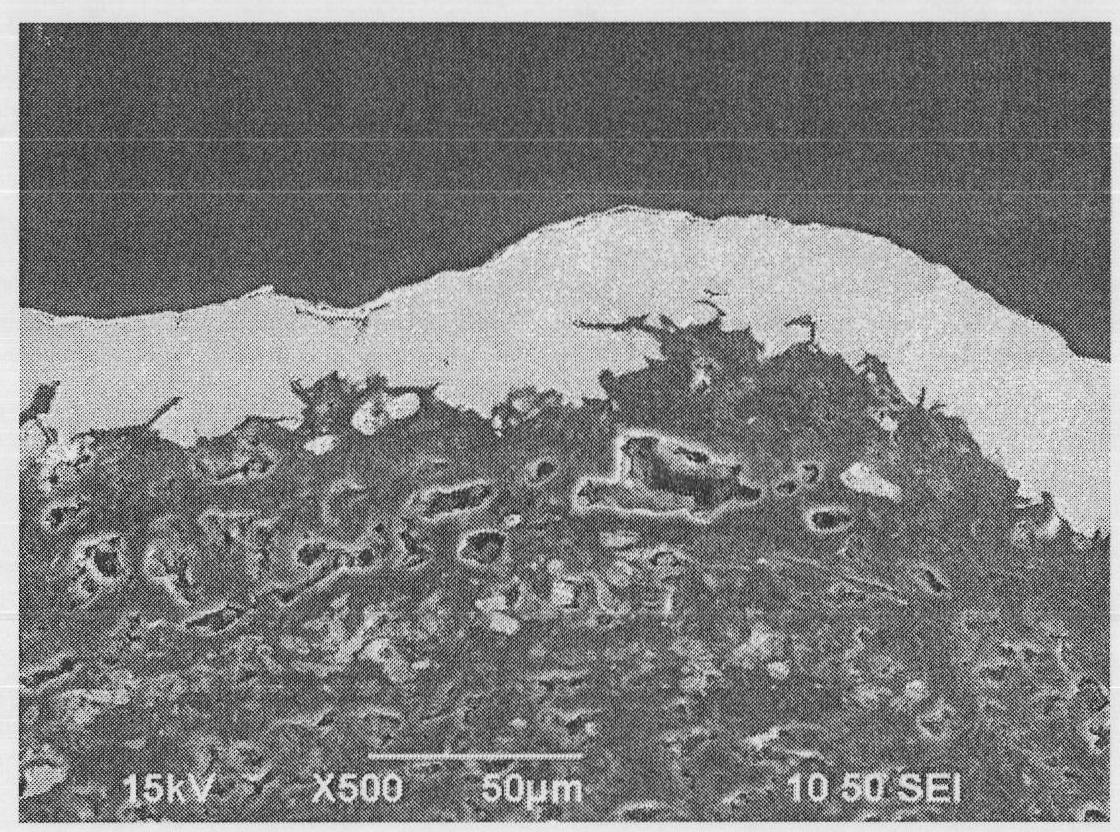

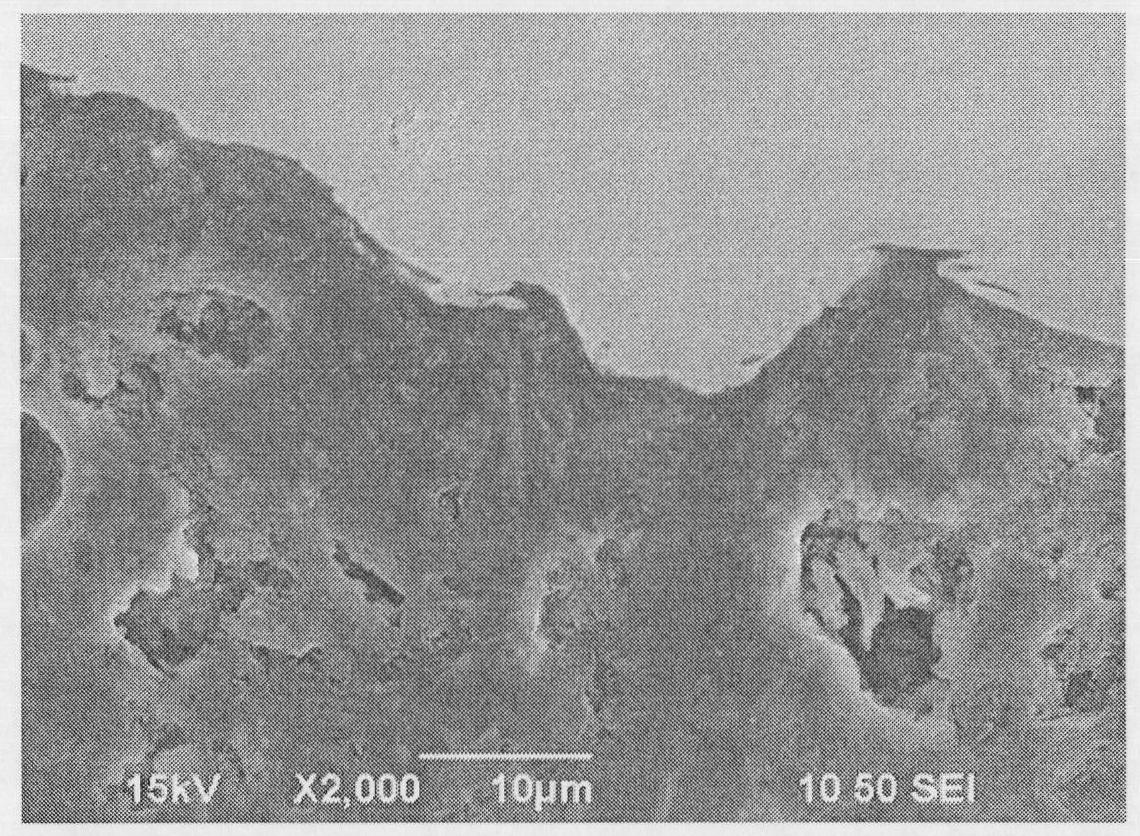

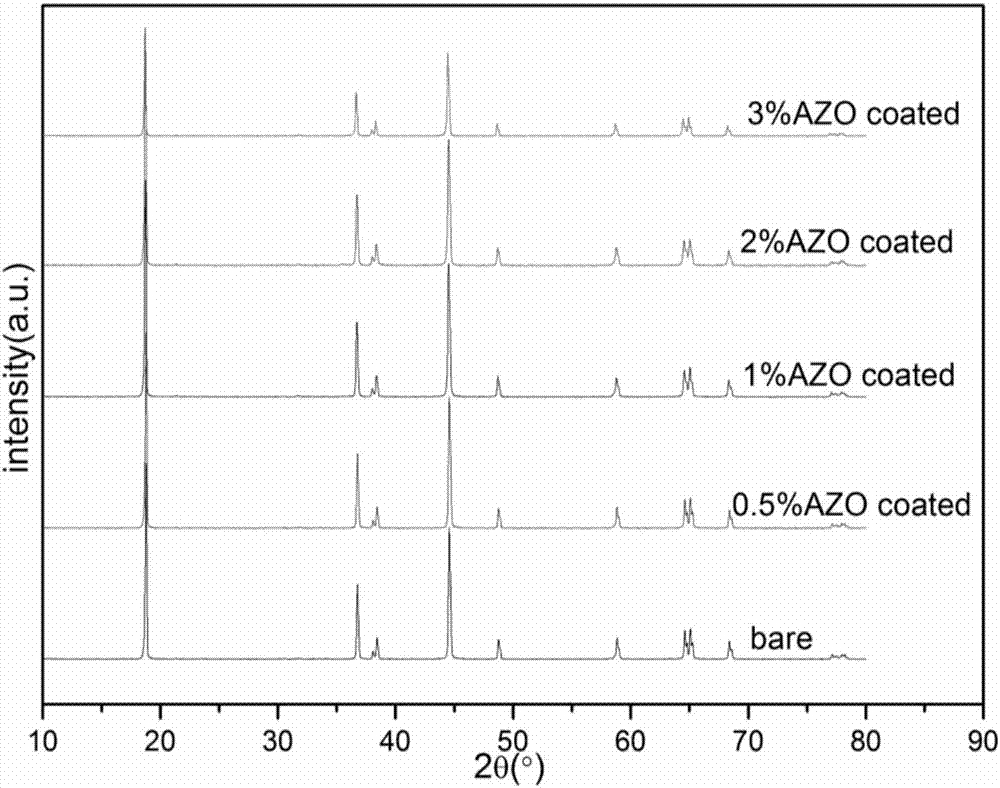

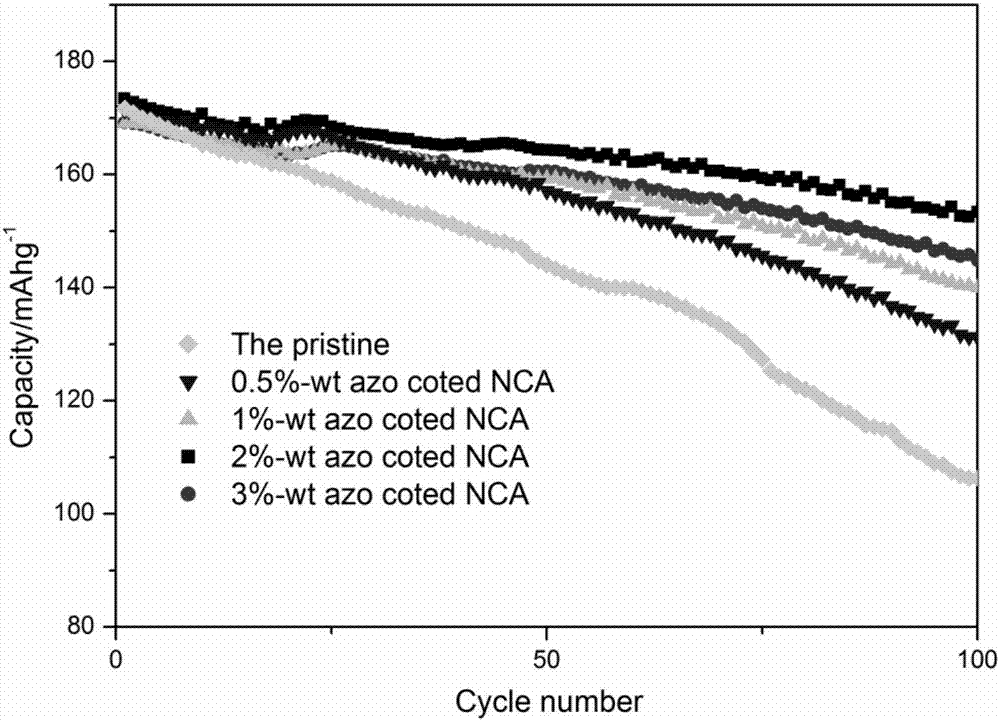

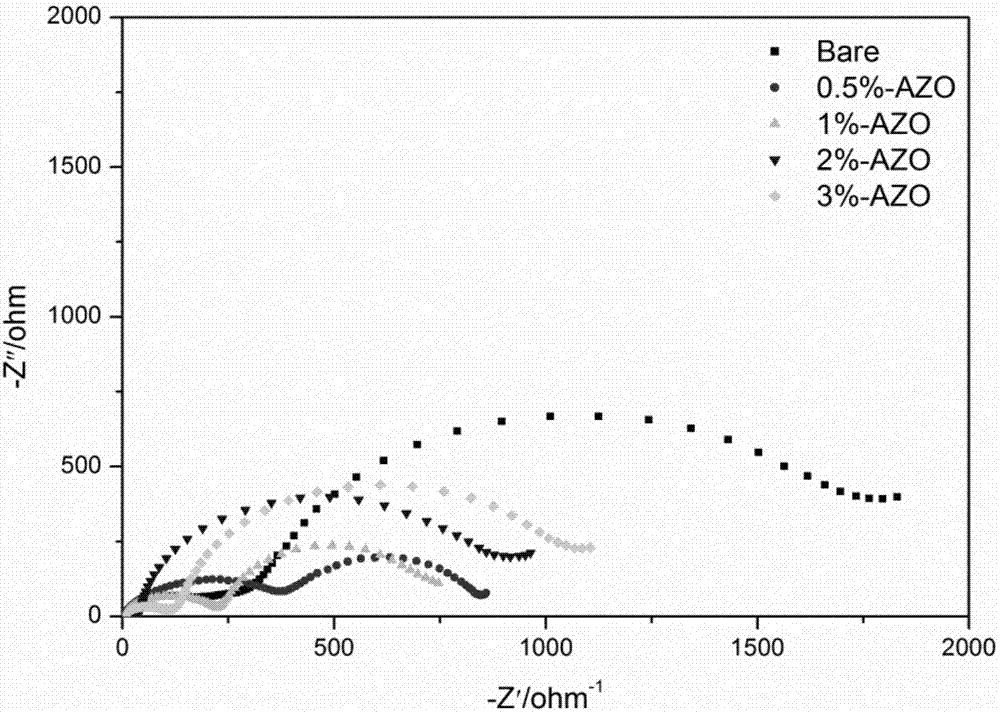

Aluminum doped nano-zinc oxide coated NCA positive material and preparation method thereof

InactiveCN106865496AImprove cycle performanceImproved magnification performanceMaterial nanotechnologyCell electrodesElectronic transmissionOrganic solvent

The invention relates to an aluminum doped nano-zinc oxide coated NCA positive material and a preparation method thereof. The preparation method includes: using an organic solvent to prepare a sol containing a aluminum source and a zinc source, adding NCA to acquire the NCA coated with the sol, performing drying and calcinations to acquire the aluminum doped nano-zinc oxide coated NCA positive material. The NCA is coated with an aluminum doped nano-zinc oxide film, the structural stability of the NCA is improved in a circulation process, aluminum doped zinc oxide semiconductors have excellent electronic transmission performance, impedance among material particles can be effectively reduced, and the circulation performance of the material can be improved.

Owner:CENT SOUTH UNIV

Positive paste of rapid-charge and rapid-discharge type high-power lithium ion battery and manufacturing method

ActiveCN108258207AHigh tap densityIncrease compaction densityCell electrodesPolyvinylidene fluorideCarbon nanotube

The invention discloses a positive paste of a rapid-charge and rapid-discharge type high-power lithium ion battery and a manufacturing method. The positive paste comprises 10 to 35 parts of an activesubstance A, 62 to 81 parts of an active substance B, 1 to 3 parts of a conductive agent A, 1 to 3 parts of a conductive agent B and 1 to 3 parts of an adhesive A, wherein the active substance A is lithium cobalt oxide LiCoO2, lithium nickelate LiNiO2, lithium manganate LiMn2O4, lithium iron phosphate LiFePO4, lithium manganese phosphate LiMnPO4, manganese lithium iron phosphate LiFexMn1-xPO4 or lithium vanadium phosphate Li3V2(PO4)3; the active substance B is lithium nickel-cobalt manganate LiNixCo1-x-yMnyO2, wherein x+y is smaller than 1; the conductive agent A is a Ketjen Black or carbon nanotube; the conductive agent B is graphene or Super-P; and the adhesive A is modified polyvinylidene fluoride PVDF. By adopting the lithium ion battery, high power, rapid charge and rapid discharge can be met, and the service life is long.

Owner:FENGFAN

Novel fuel cell manufacturing method based on graphene thermoelectric management layer

ActiveCN105047963AReduce output capacityStable lifeCell electrodesFinal product manufactureConvex structureElectrochemical response

The invention discloses a novel fuel cell manufacturing method based on a graphene thermoelectric management layer. The method comprises the following steps: forming a micron-grade concave-convex structure on a proton exchange membrane; preparing a catalytic layer on the surface of the proton exchange membrane with the concave-convex structure; preparing the thermoelectric management layer on the surface of the catalytic layer; preparing a diffusion layer on the surface of the thermoelectric management layer; and manufacturing a single cell in a flow field fixture. The thermoelectric management layer based on graphene has ultrahigh electronic conductivity and ultrahigh heat conductivity, so that electrons generated in an electrochemical reaction process of the fuel cell catalytic layer and required electrons can be exported and imported rapidly; electrochemical polarization and ohmic polarization are reduced; and the output performance is enhanced. Moreover, a large amount of waste heat generated by a catalyst can be discharged rapidly, and a stable electrochemical reaction is maintained. Meanwhile, the temperature and an electric field in the catalytic layer can be balanced, and the service life is prolonged. Moreover, a manufacturing process is simple and controllable, and suitable for industrial production.

Owner:广东喜玛拉雅氢能科技有限公司

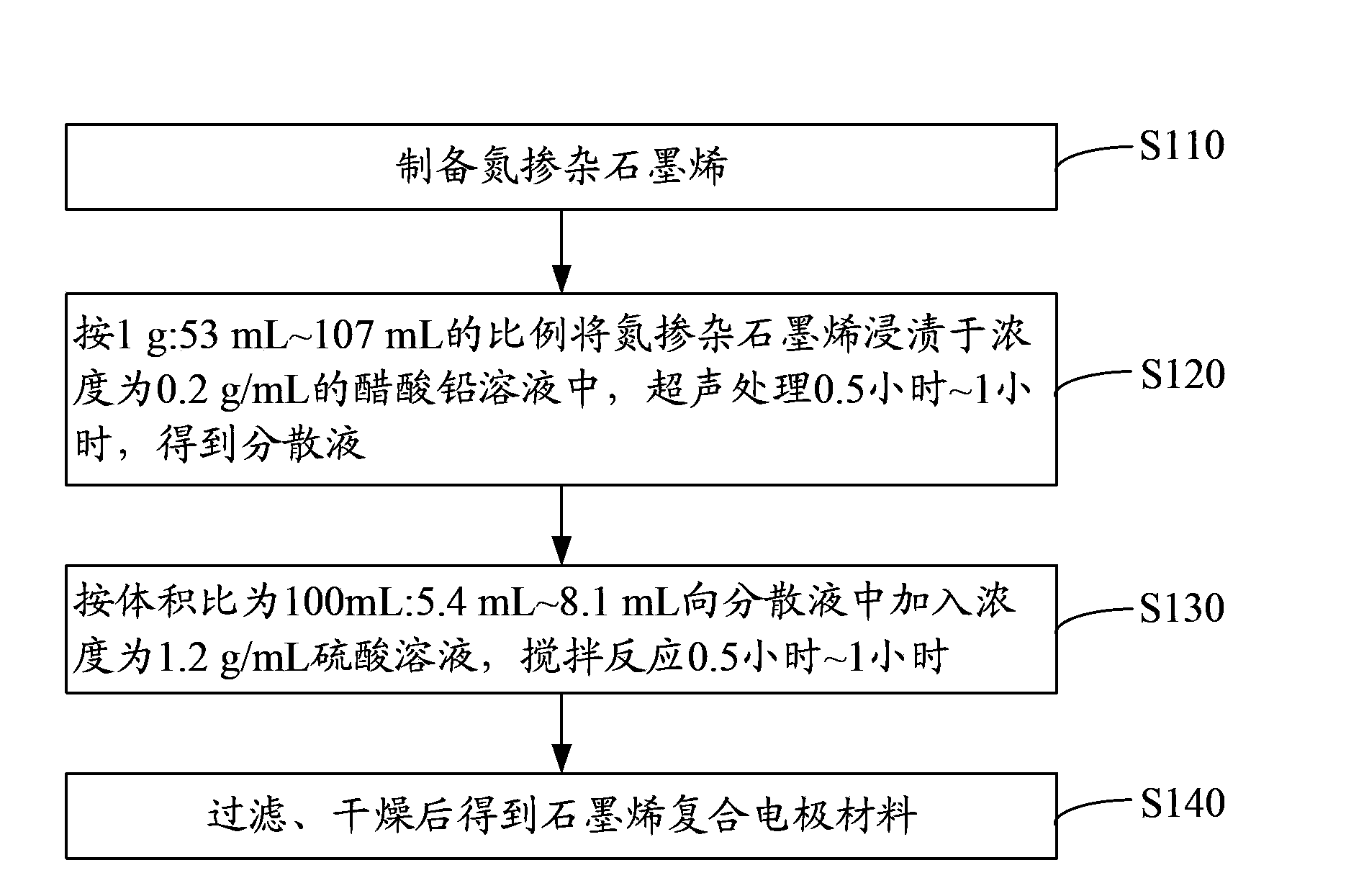

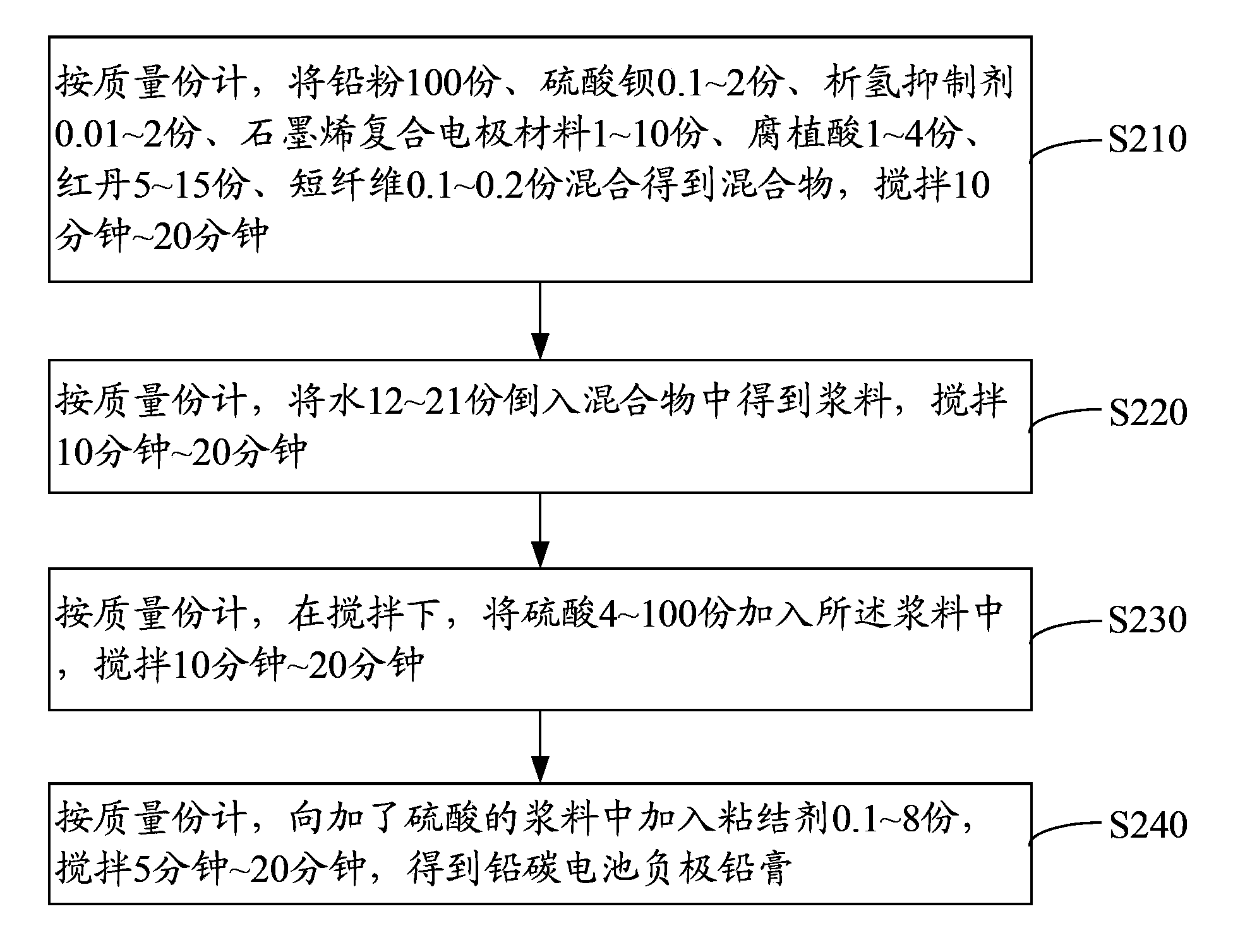

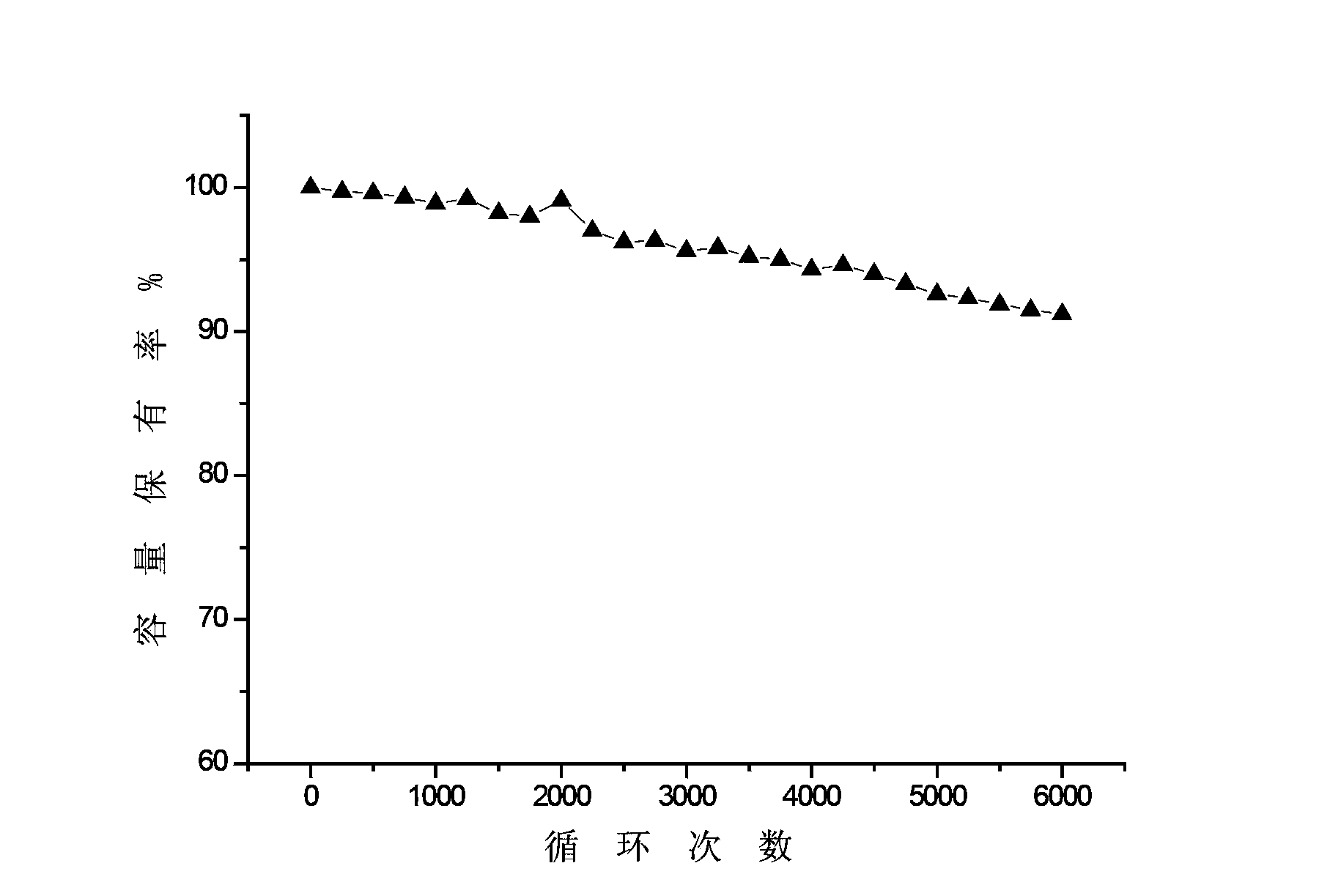

Graphene composite electrode material and preparation method thereof, lead-carbon battery negative electrode lead plaster and preparation method thereof as well as lead-carbon battery

InactiveCN103682357AIncrease layer spacingReduces electrochemical polarizationLead-acid accumulatorsCell electrodesComposite electrodeNitrogen

The invention provides a graphene composite electrode material. The graphene composite electrode material comprises nitrogen-doped graphene and lead sulfate adsorbed between nitrogen-doped graphene sheet layers; the mass ratio of the nitrogen-doped graphene to the lead sulfate is 1:(10-20). When the graphene composite electrode material is applied to a negative electrode of a lead-carbon battery, the nitrogen-doped graphene is a non-polarity material and can be well compatible with electrolyte-sulfuric acid of the lead-carbon battery, so that reduction of the electrochemical polarization of the negative electrode is facilitated. The interlayer spacing of the nitrogen-doped graphene is large so that the specific surface area is large and the nitrogen-doped graphene is suitable for being used as a growing point of a lead sulfate crystalline grain under a large-power condition; the sulfation of the negative electrode under the large-power condition is reduced so that the cycle life of the negative electrode is prolonged and the cycle performance of the lead-carbon battery is improved. The invention further provides a preparation method of the graphene composite electrode material, lead-carbon battery negative electrode lead plaster and a preparation method thereof, and the lead-carbon battery.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

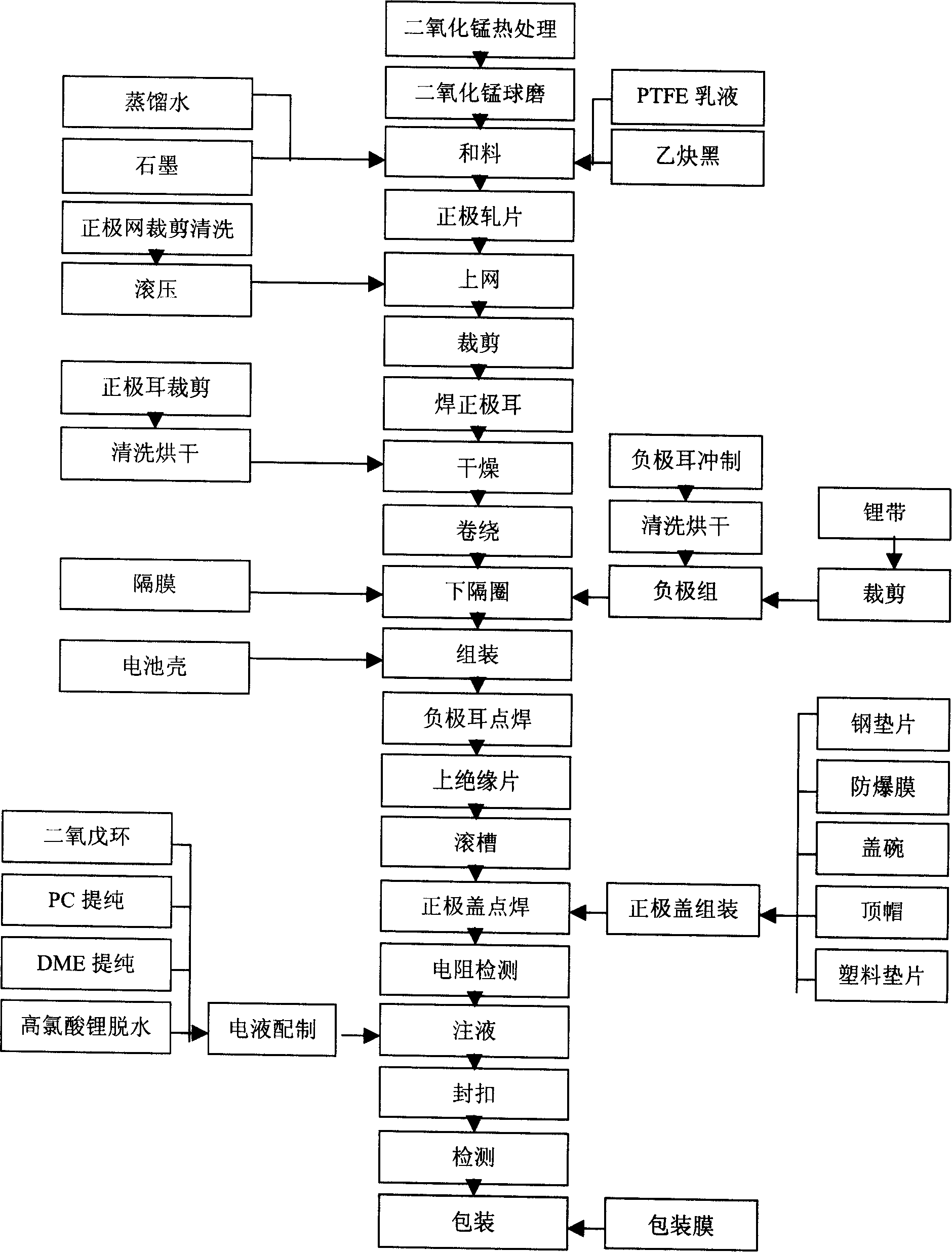

Electrolytic manganese dioxide for doped modified lithium manganese dioxide buttery

InactiveCN1619865AImprove electrochemical activityReduces electrochemical polarizationCell electrodesLi-accumulatorsLithiumElectrolysis

This invention refers to cell industrial material, a doping modified electrolytic manganese dioxide containing gamma-MnO2 for lithium manganese dioxide cell, which is doped with any kind or more than any two kinds among 0.3-12.5 % of V2O5, 0.12-10.0 % of SiO2 and 0.01-6.0 % of Bi2O3 through mixing calcinations to obtain said material which can raise manganese dioxide electrochemistry activity, reduce electrochemical polarization and raise discharge capacity of cell.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

WS2/CNTs modified diaphragm of lithium-sulfur battery and preparation method of WS2/CNTs modified diaphragm

ActiveCN111916640ALight weightImprove conductivityLi-accumulatorsCell component detailsLithium–sulfur batteryElectrical battery

The invention belongs to the technical field of new energy materials and devices, and particularly relates to a WS2 / CNTs modified diaphragm of a lithium-sulfur battery and a preparation method of theWS2 / CNTs modified diaphragm. The WS2 / CNTs modified diaphragm comprises a diaphragm matrix and a modified layer laid on the surface of one side of the diaphragm matrix, wherein the modified layer is composed of a WS2 / CNTs composite material. Hydroxylated CNTs serve as a carrier, CTAB serves as a surfactant, TAA and WCl6 serve as an S source and a W source respectively, a WS2 / CNTs composite materialis prepared through a one-step hydrothermal method, the WS2 / CNTs composite material is subjected to suction filtration on the surface of one side of a commercial battery diaphragm base body, and themodified diaphragm for the lithium-sulfur battery is obtained. The WS2 / CNTs modified diaphragm can effectively solve the shuttle effect problem of the lithium-sulfur battery and improve the specific capacity, coulombic efficiency and cycle life of the battery while ensuring the electrochemical reaction activity of the lithium-sulfur battery and the smooth penetration of lithium ions, and meanwhile, the overall mass of the modified layer is relatively light, so that the overall energy density of the lithium-sulfur battery is not influenced.

Owner:HEFEI UNIV OF TECH

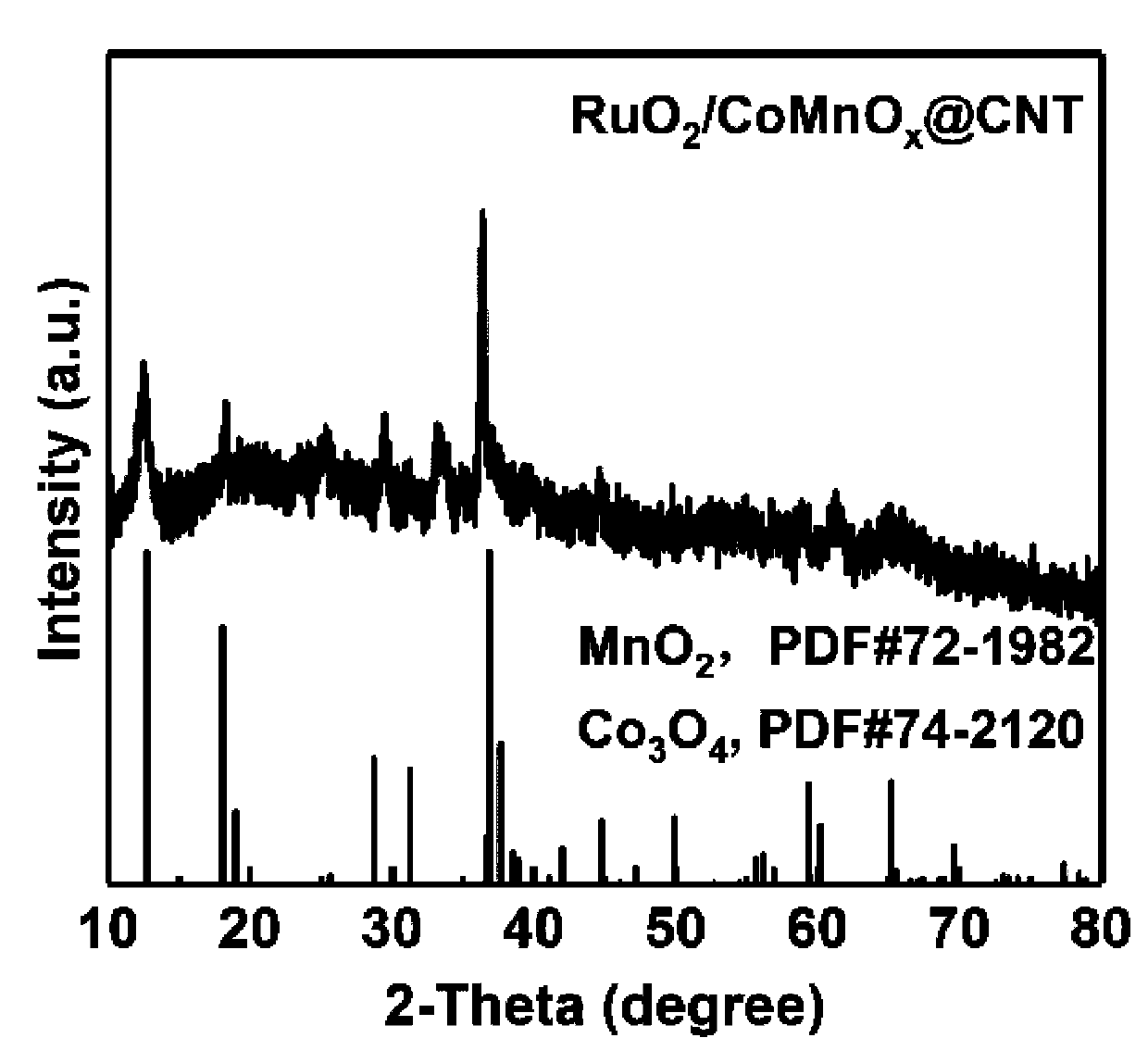

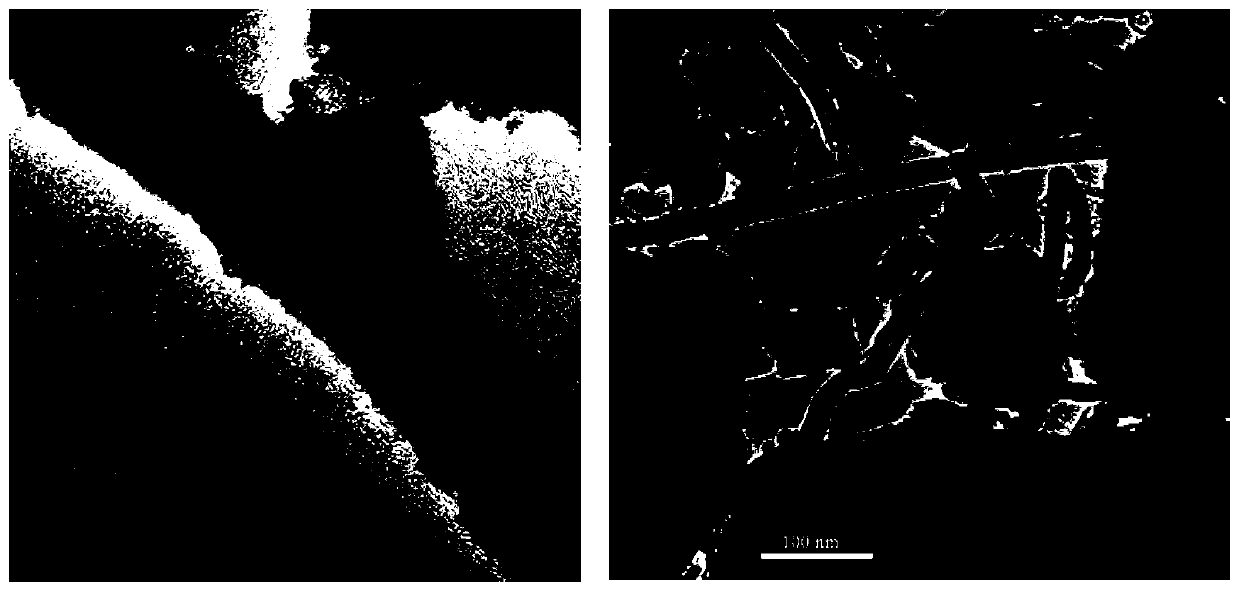

Carbon-supported noble metal oxide bifunctional catalyst and preparation method and application thereof

ActiveCN109786769AHelp with storageStable voltageFuel and secondary cellsCell electrodesDischarge efficiencyState of art

The invention discloses a carbon-supported noble metal oxide bifunctional catalyst and a preparation method and application thereof. The chemical expression of the carbon-supported noble metal oxide bifunctional catalyst is RuO<2> / CoMnO<x>@CNT; wherein Co is present in the form of Co<3>O<4>, Mn is present in the form of MnO<2>, and the content of Ru therein is 12 to 14% by weight. Through the invention, the problem that the cycle life of the lithium-oxygen battery is low caused by the unicity of the structural function of the cathode catalyst of the lithium-oxygen battery and the problems of poor charging and discharging efficiency, severe electrode polarization and bad cycle performance caused by incomplete deposition and decomposition of lithium peroxide in the prior art are solved.

Owner:XIAMEN UNIV

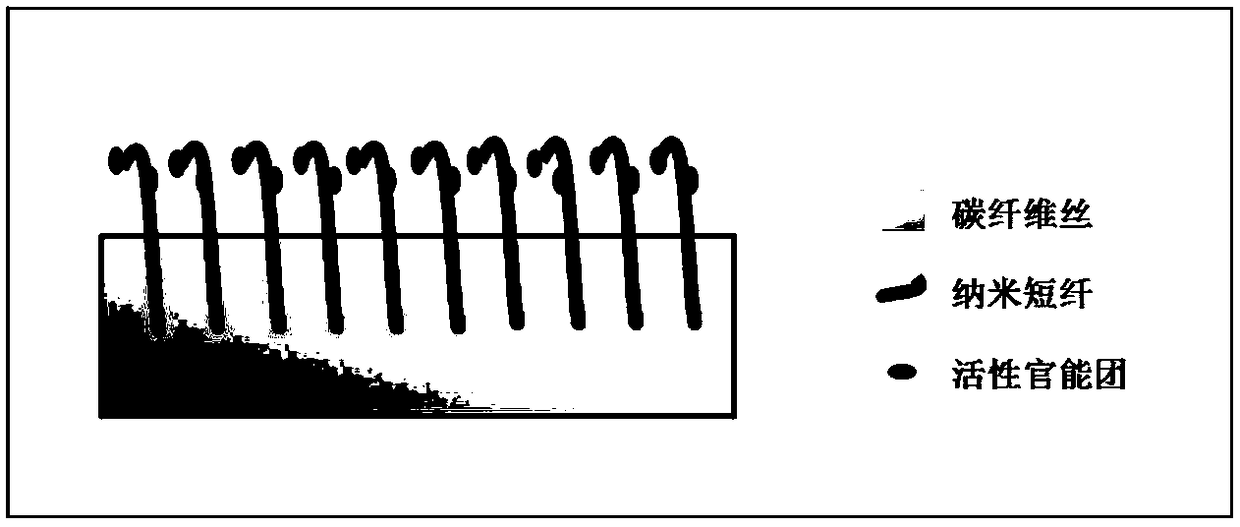

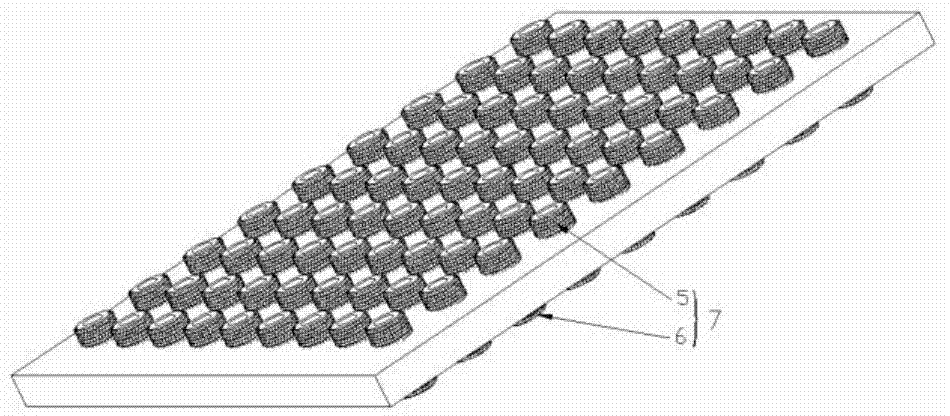

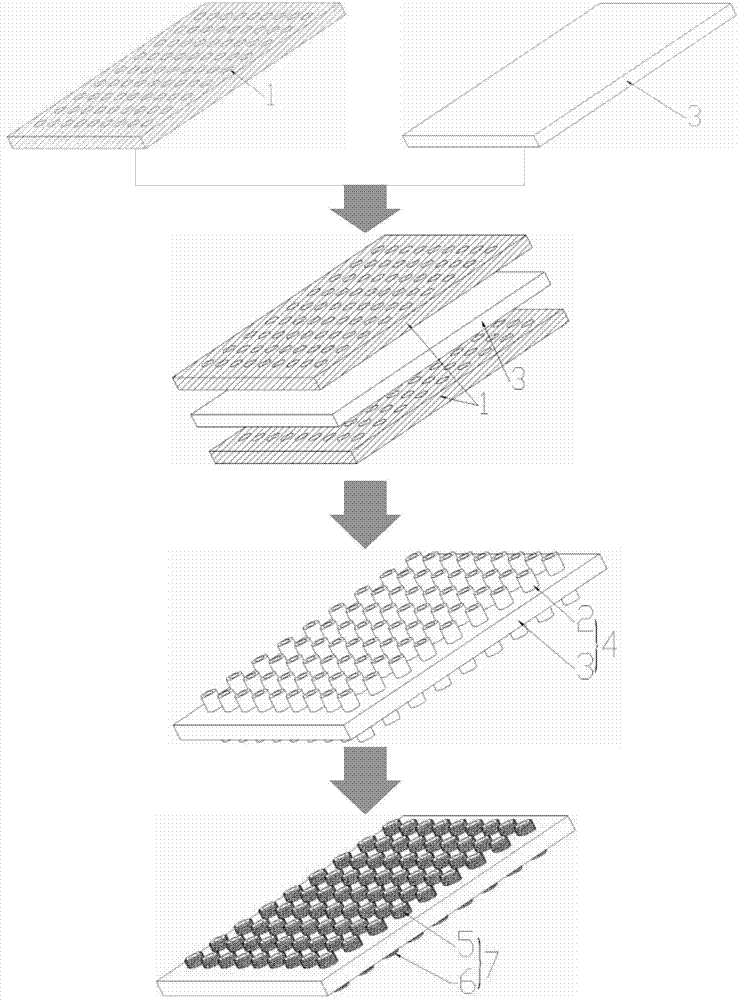

A method for constructing seed tree effect of high specific surface carbon fiber mat and application thereof

InactiveCN109216710ALarge specific surface areaEasy to realize engineering preparationCell electrodesRegenerative fuel cellsFiberCarbon fibers

The invention relates to the field of chemical power supply and electrochemical catalysis, in particular to a method for constructing seed tree effect of high specific surface carbon fiber mat and application thereof. In the post-treatment process of carbon fiber mat, carbon fiber mat composite electrode with high specific surface area was formed by bonding, growth and deposition of typical nano-functional materials on the surface of carbon fiber mat. Like trees planted on the surface of carbon fiber, these nano-functional materials can not only directly increase the surface area of carbon fiber mat composite electrode, but also improve the wettability of carbon fiber mat and thereby increase its electrochemical surface area. The invention mainly utilizes the tree planting effect of the typical nano functional material to make the prepared carbon fiber felt composite electrode have high electrochemical surface area, and the electrode is used as the positive electrode material and the negative electrode material of the vanadium battery, so that the electrochemical polarization in the reaction process of the vanadium battery can be greatly reduced, and the charging and discharging performance of the vanadium battery can be further improved.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

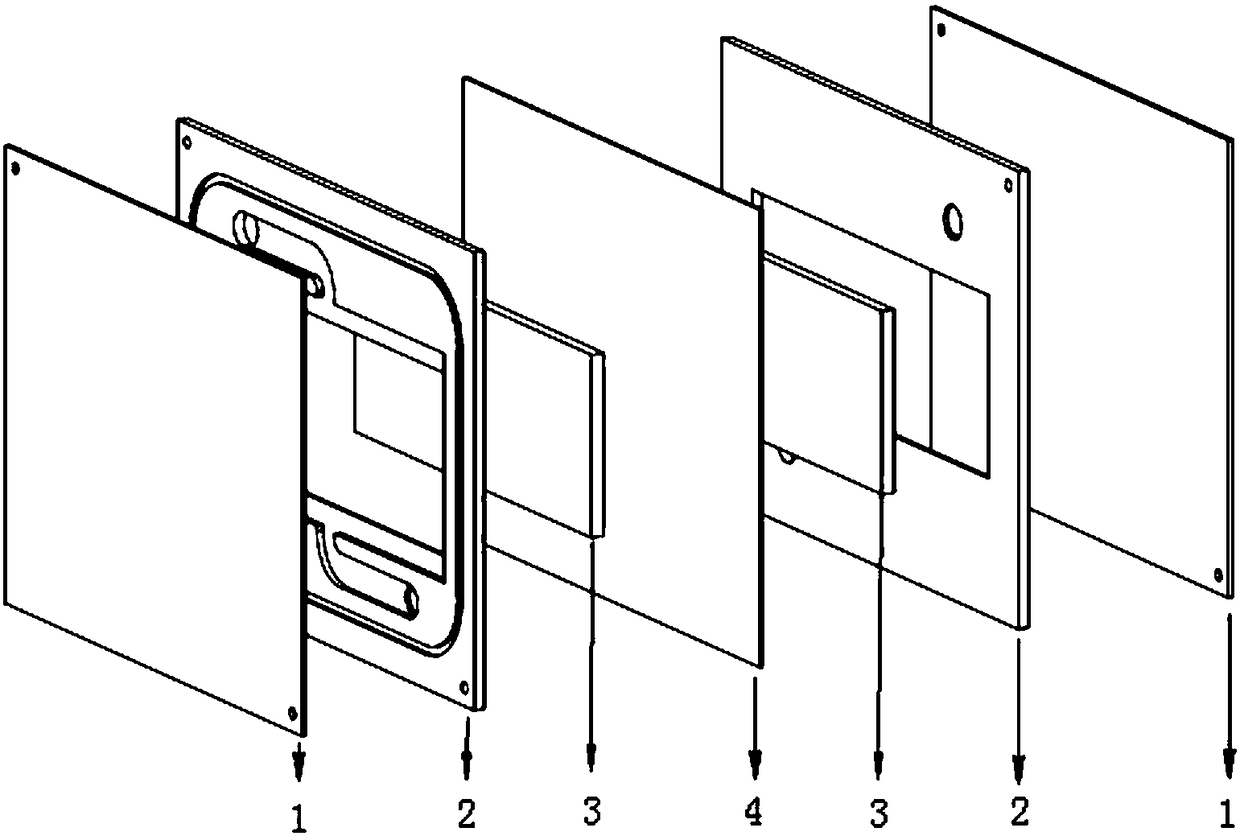

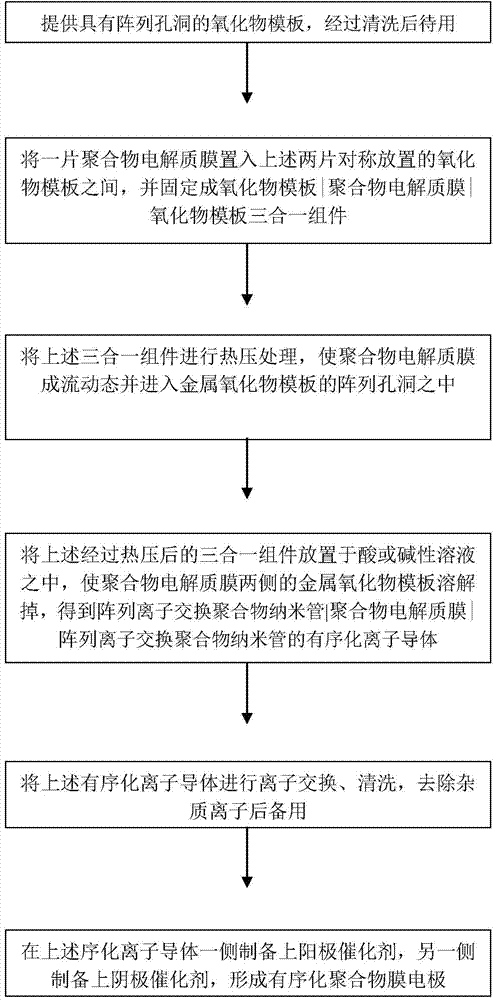

Preparation method of self-humidifying ordered polymer membrane electrode

ActiveCN103887521ARealize self-humidification energy conversionIncrease the three-phase reaction interfaceCell electrodesFuel cellsElectrochemical responseConcentration polarization

The invention discloses a preparation method of a self-humidifying ordered polymer membrane electrode, belonging to the technical field of membrane electrode preparation. An ordered ion exchange polymer nanotube array prepared through the method is fused together with a polymer membrane and is provided with highly ordered ion, electron and gas mass transfer channels, and electrochemical three-phase reaction interfaces are distributed in the outer surfaces of polymer nanotubes with water storage functions, so that a high-efficiency energy conversion process can be carried out in a self-humidifying manner. A catalyst in a nanoparticle or microparticle state is bonded on the surface of the ion exchange polymer nanotube array to form a catalysis layer and is relatively high in specific surface area and catalytic activity, so that the three-phase reaction interfaces of the membrane electrode are greatly added, the electrochemical polarization, the ohmic polarization and the concentration polarization of the electrode are reduced, the energy conversion efficiency is improved, and the reaction speed is increased. According to the preparation method, a membrane electrochemical reactor system is expected to be remarkably simplified, the energy conversion efficiency and the stability are improved, and the operation life is prolonged.

Owner:国鸿氢能科技(嘉兴)股份有限公司

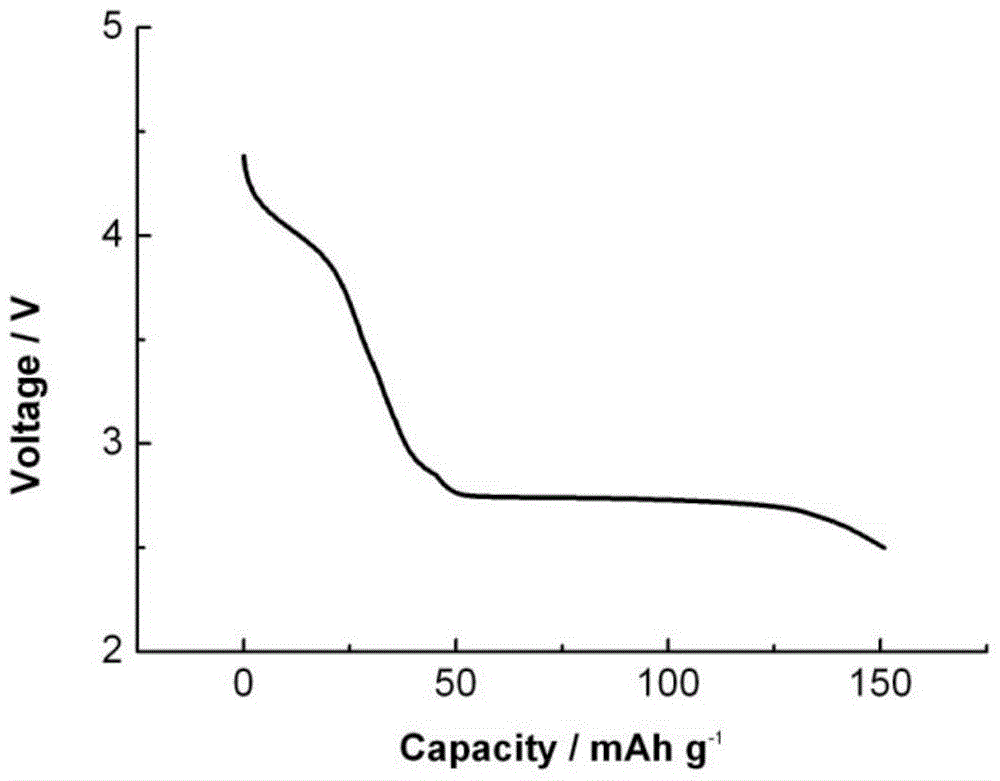

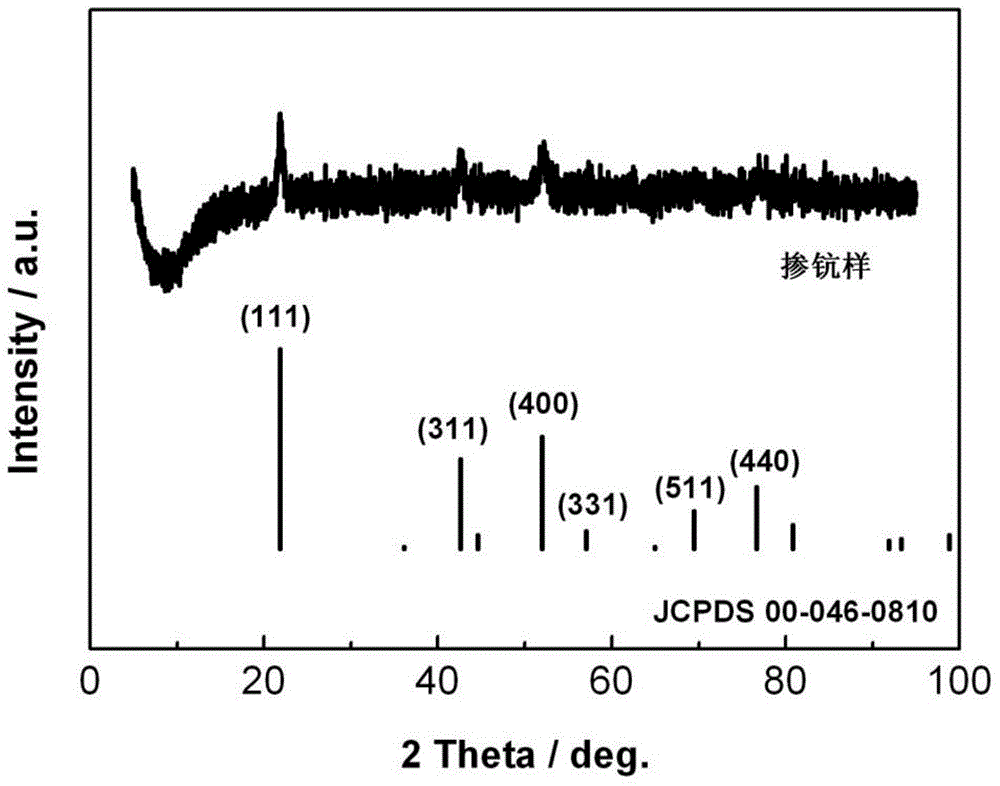

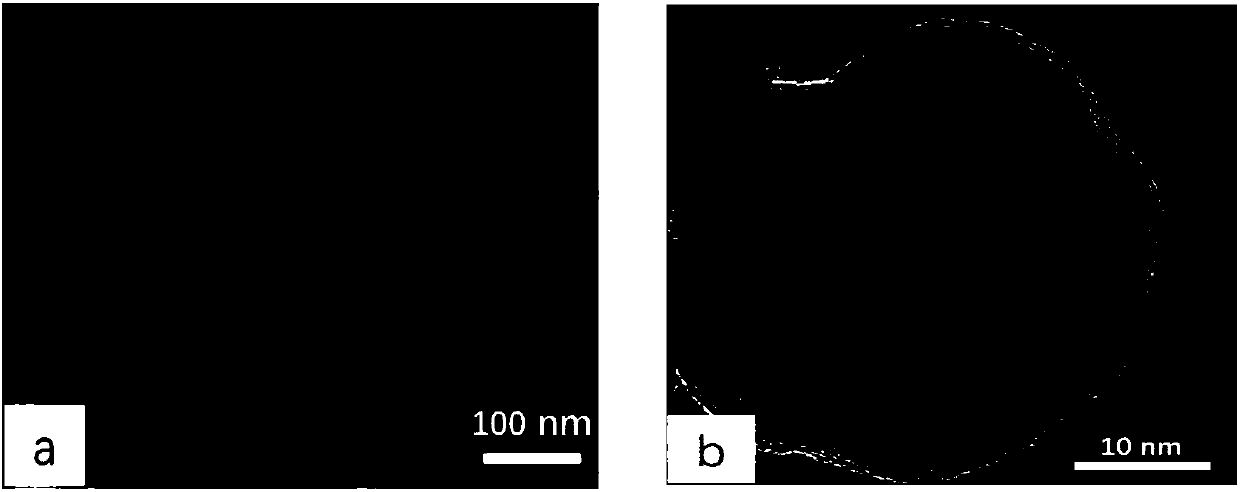

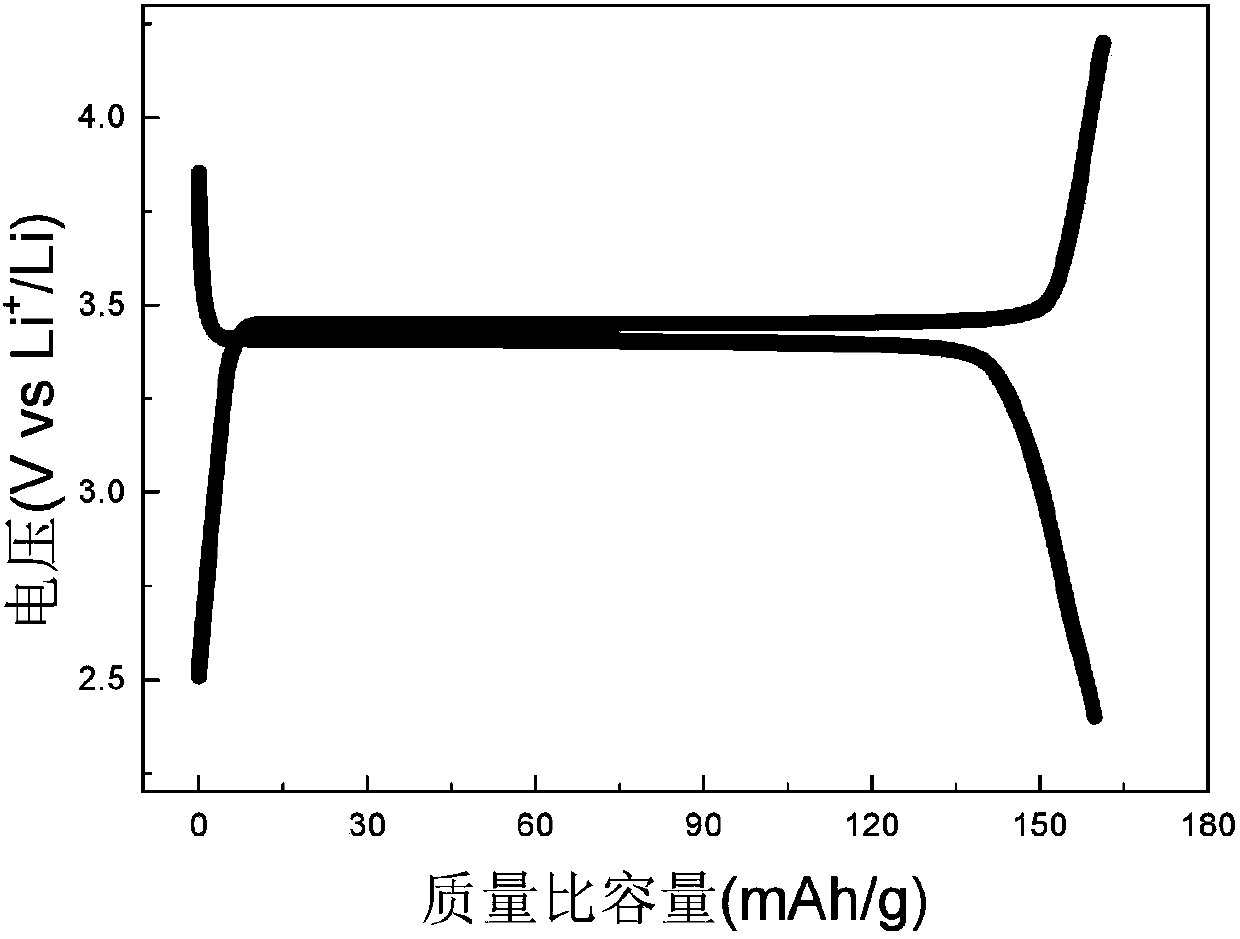

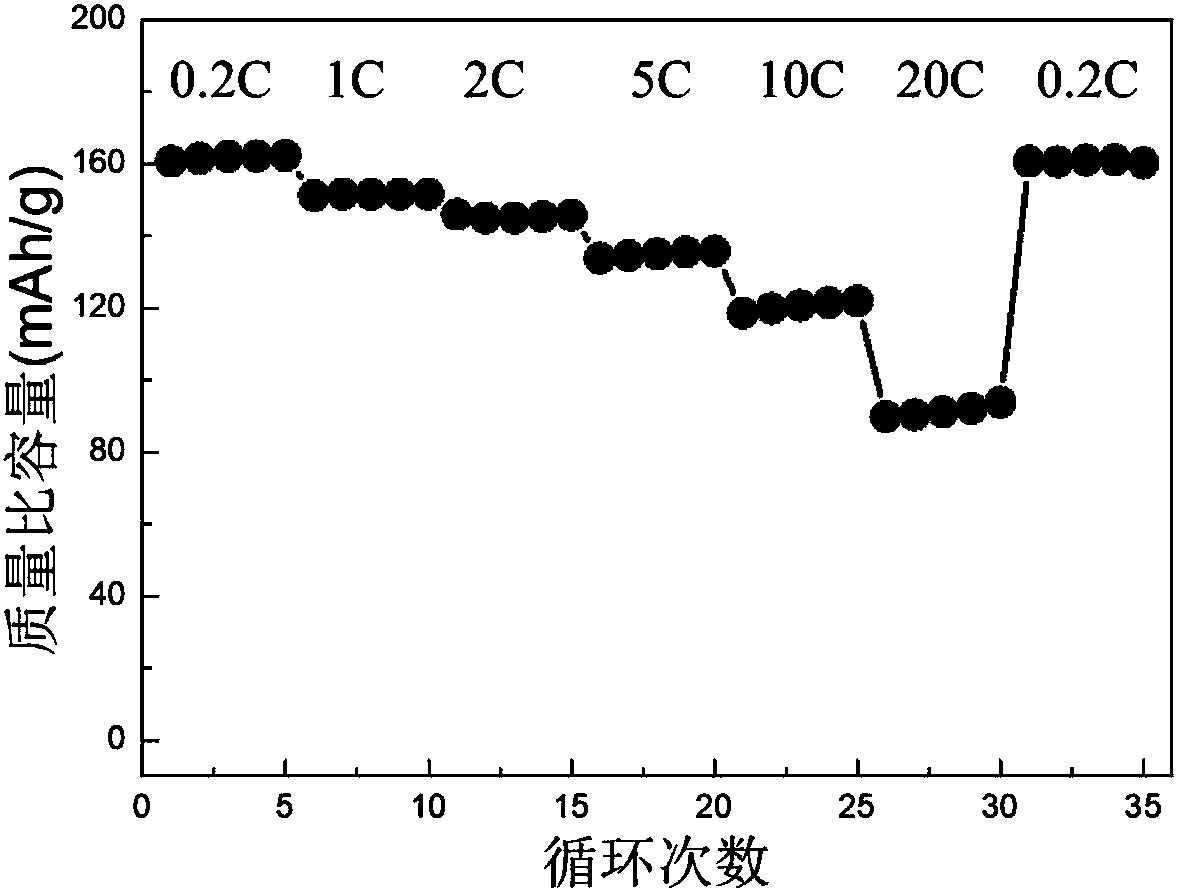

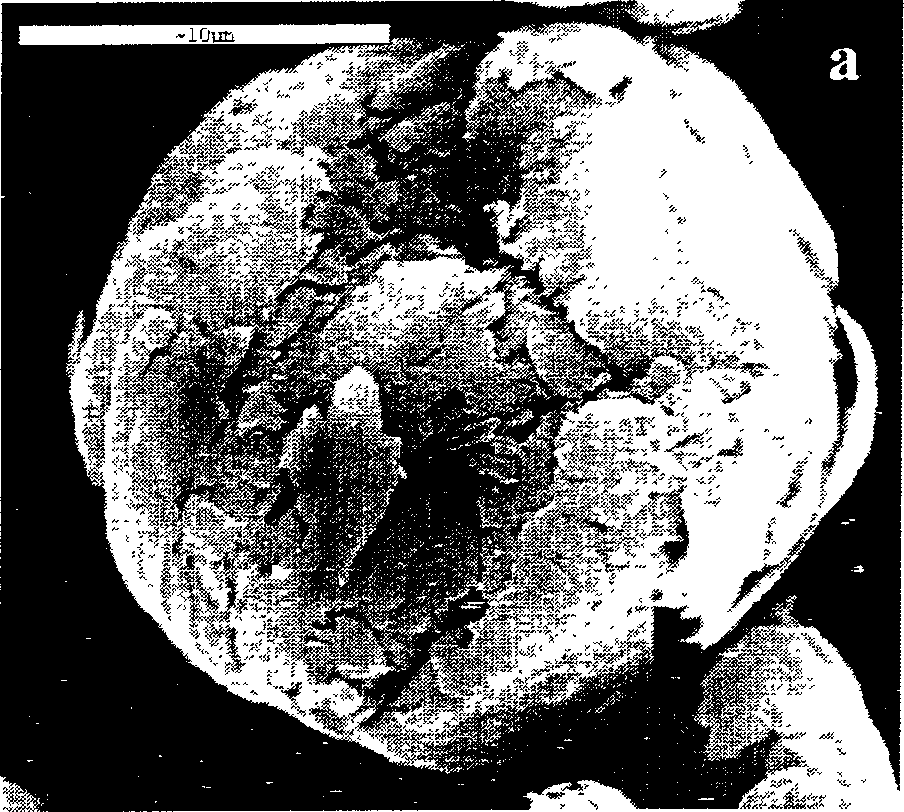

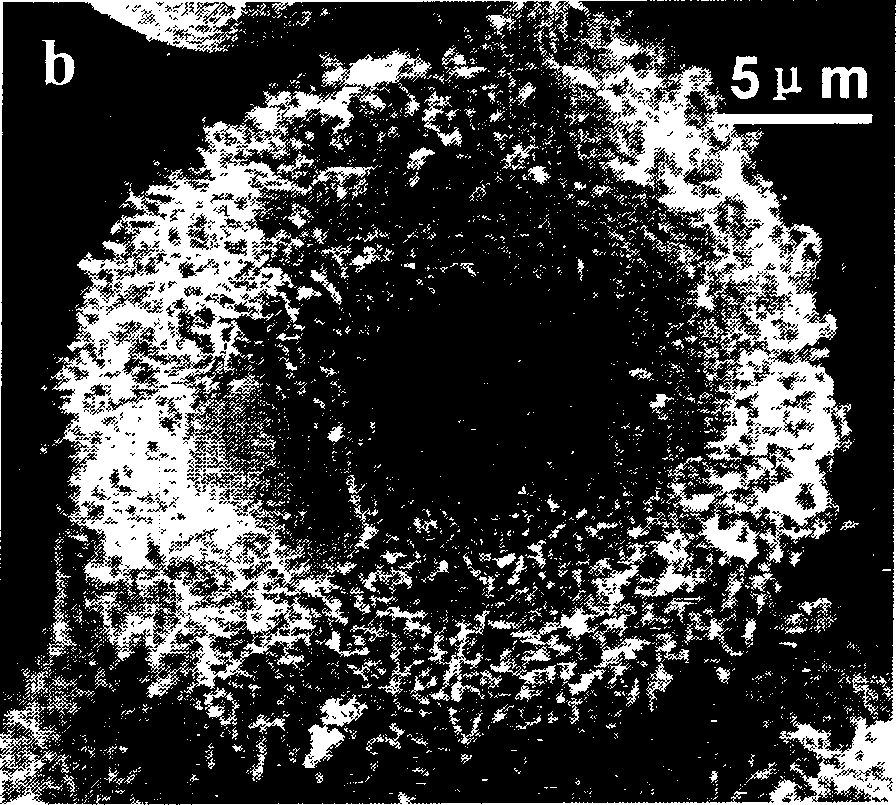

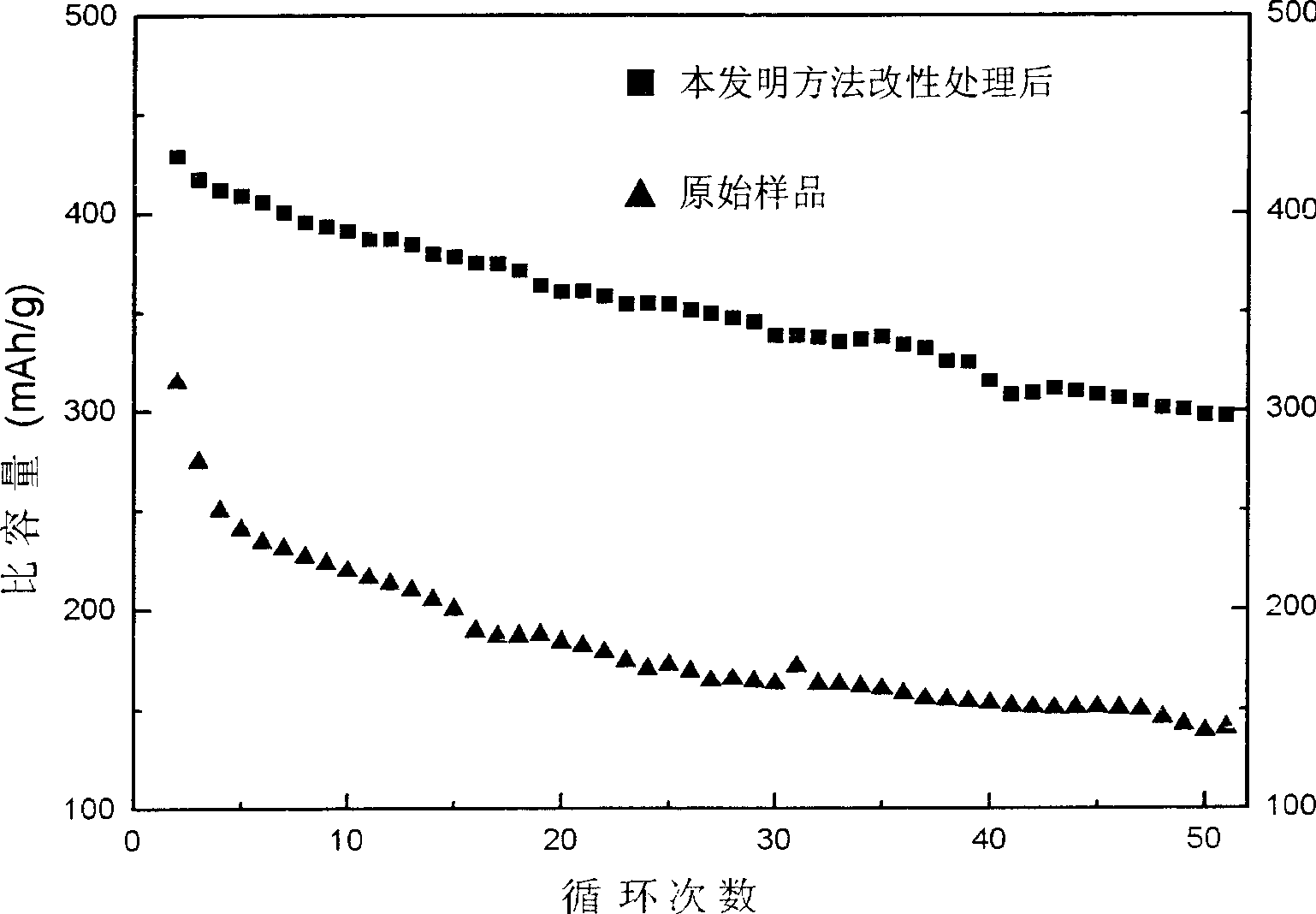

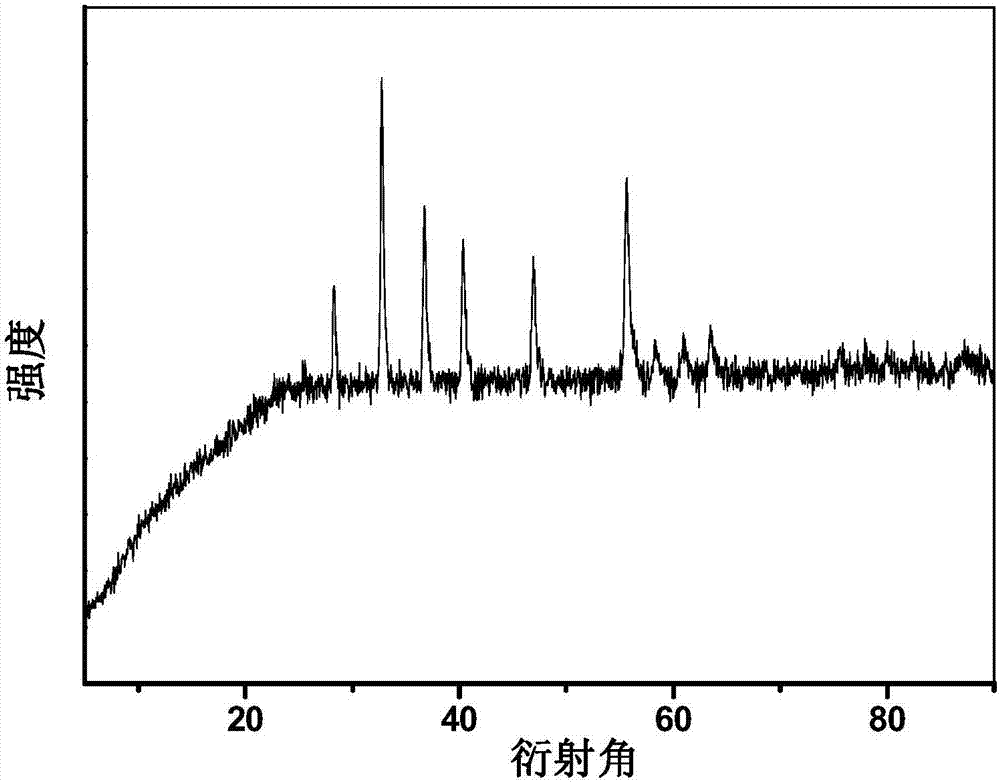

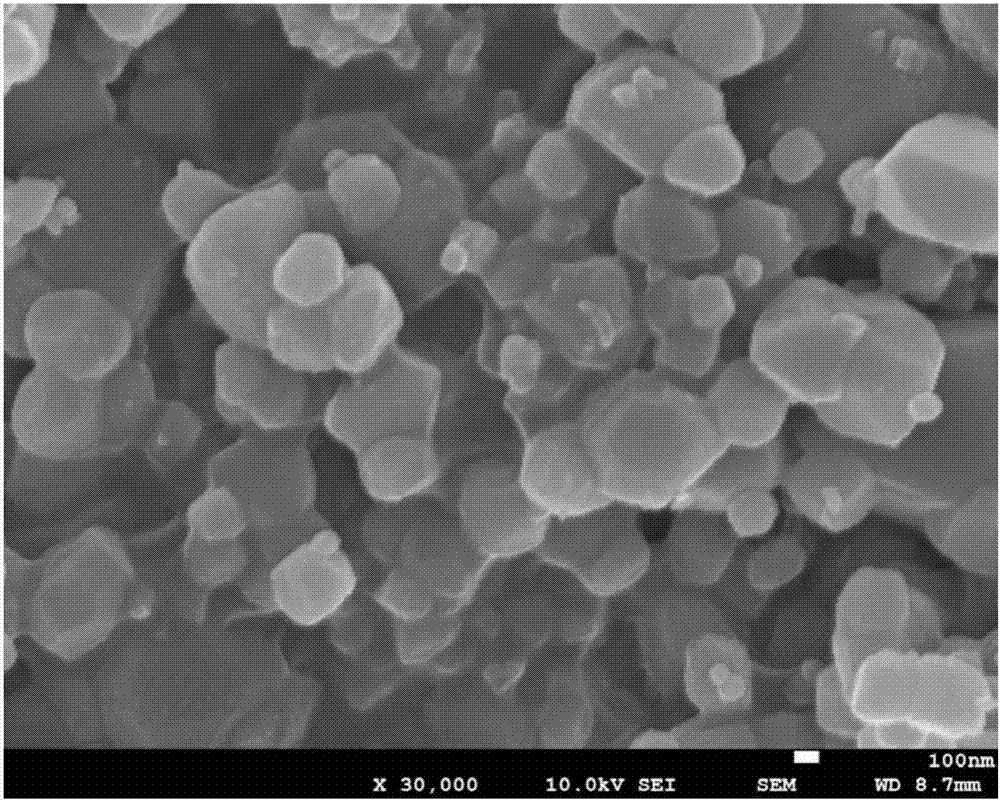

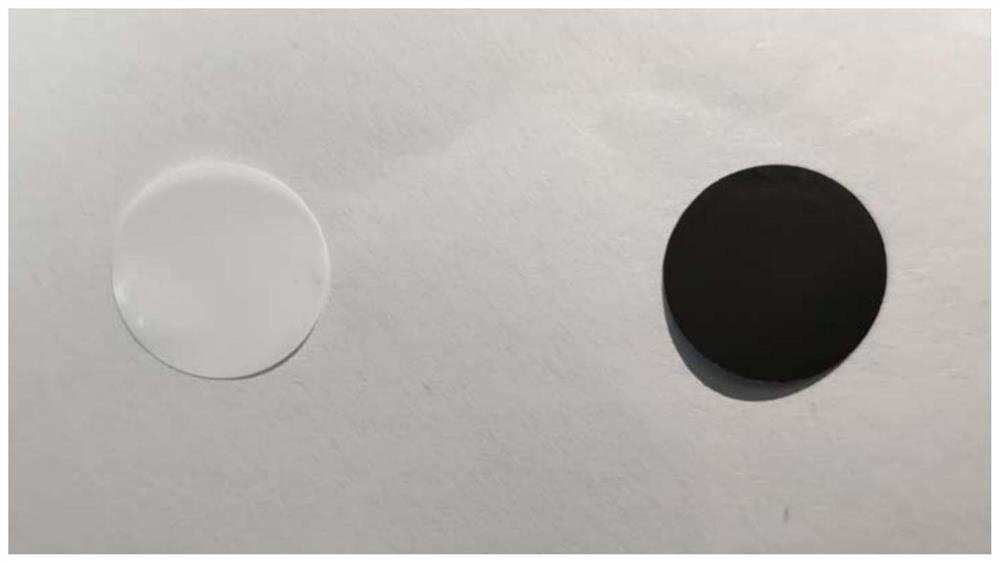

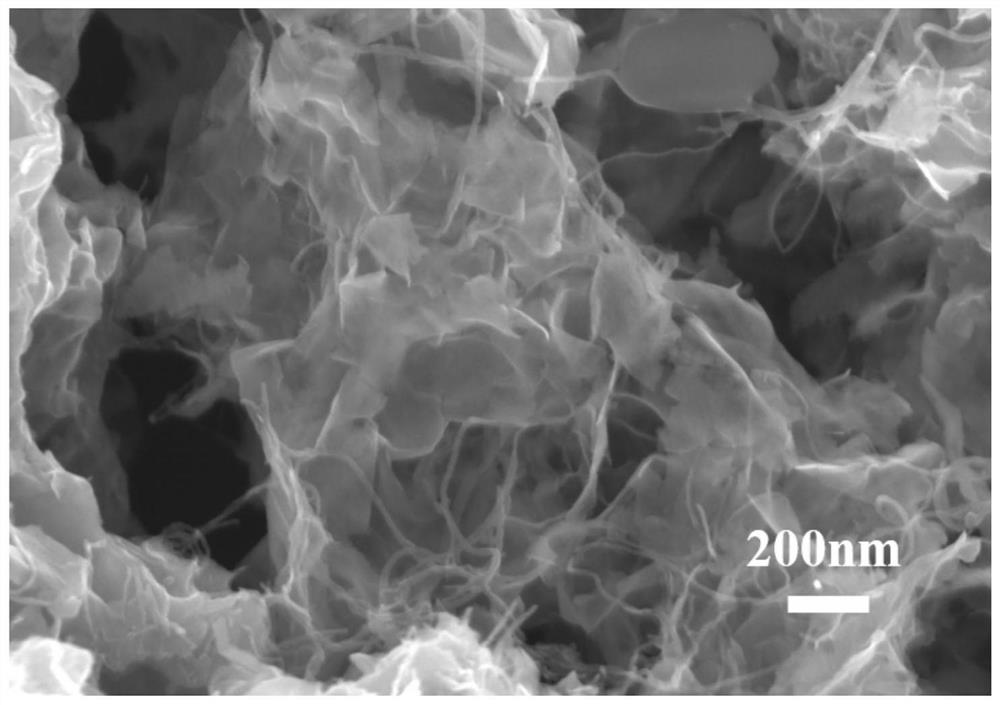

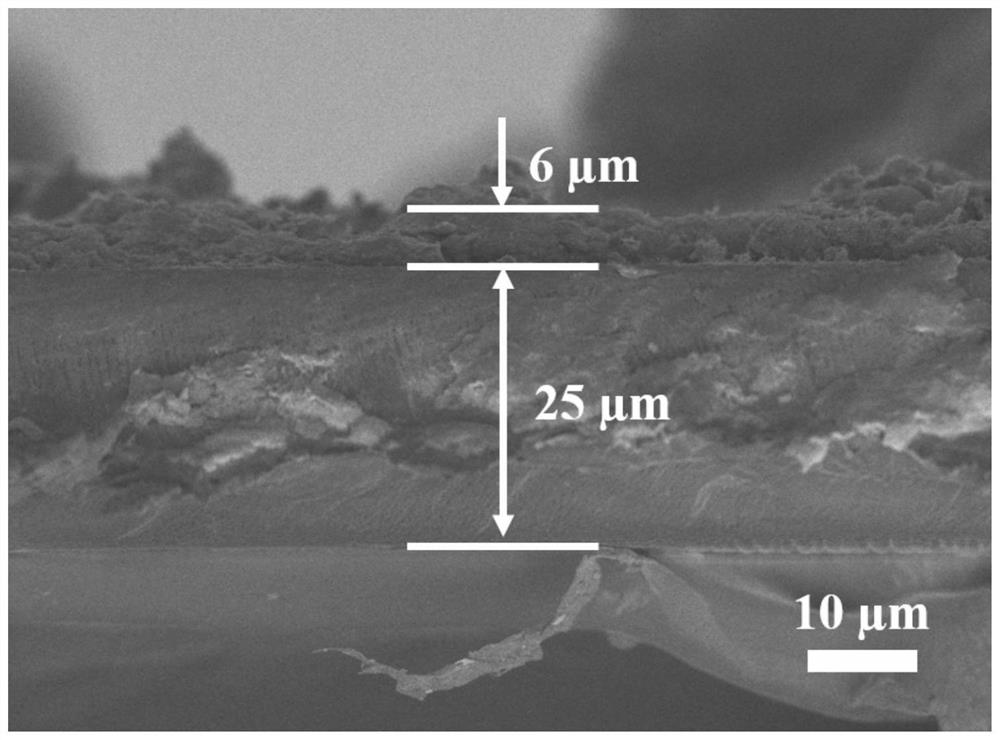

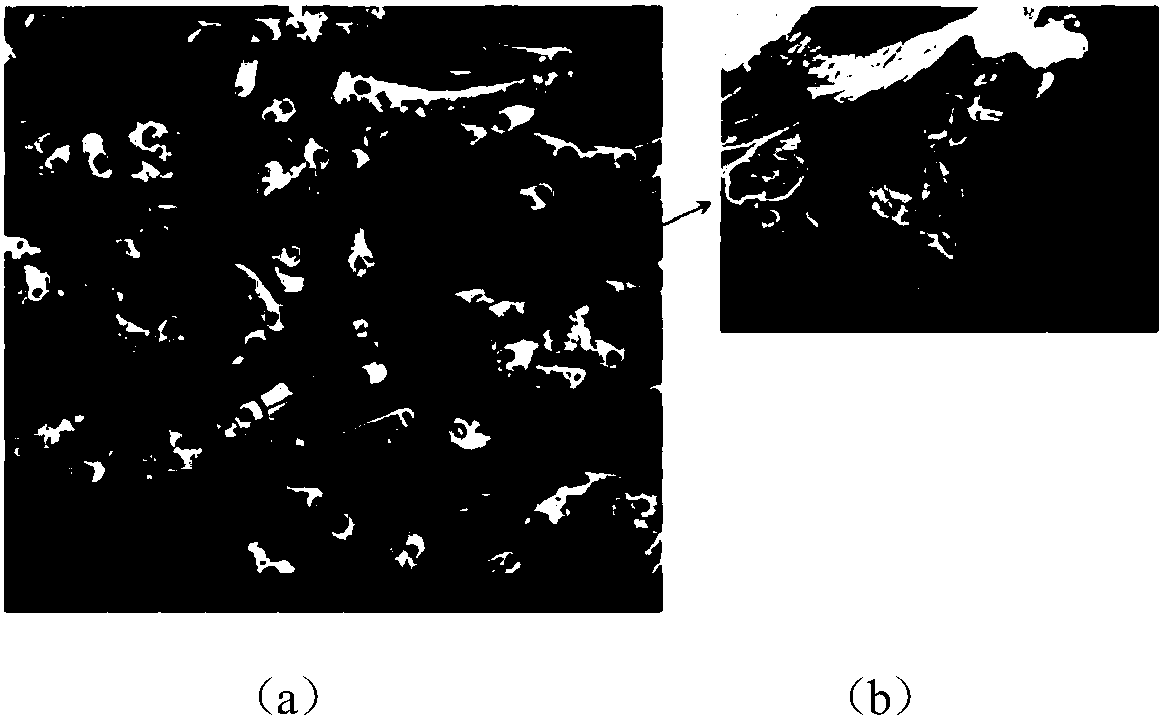

Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same

ActiveCN107706367AImprove Capacitive PerformanceImprove conductivityAlkaline accumulatorsCell electrodesGramSpinel

The invention discloses an alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and a battery employing the same, and belongs to the technical field of a secondary battery negative electrode material. The alkali secondary battery negative electrode material comprises a spinel-structure composite ferrite [Cu<x>Zn<y>Ni<z>Fe2O4] or a composite material comprising the spinel-structure composite ferrite [Cu<x>Zn<y>Ni<z>Fe2O4] and a carbon material, wherein x is more than or equal to 0.5 but less than or equal to 0.95, y is more than 0 but less than 0.5, z is more than 0 but less than 0.5, and (x+y+z) is equal to 1. The invention also discloses a preparation method of the alkali secondary battery negative electrode material and application of the alkali secondary battery negative electrode material in an alkali secondary battery negative pole plate. The discharging gram capacity of the negative material prepared by the method reaches 530mAh / g at 0.2C, and the discharging gram capacity at 5C reaches 480mAh / g; and the alkali secondary battery prepared by employing the negative electrode material has the advantages of low cost, high rate performance and long cycle lifetime.

Owner:HENAN NORMAL UNIV

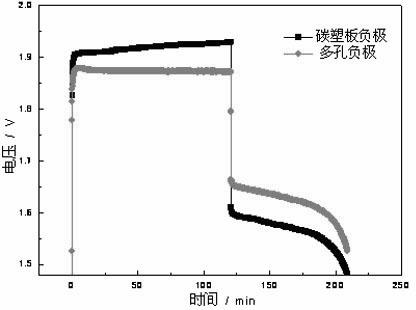

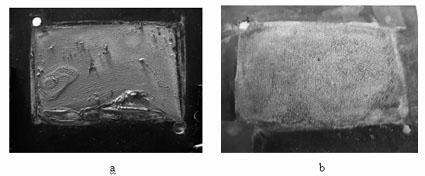

Negative electrode of zinc-bromine flow battery for energy storage and manufacture method thereof

InactiveCN102569832AIncrease contact areaReduces electrochemical polarizationCell electrodesElectrolytic agentElectrical battery

The invention relates to a negative electrode of a zinc-bromine flow battery for energy storage and a manufacture method of the negative electrode. The electrode comprises a carbon plastic composite material plate, and a porous layer having high specific surface area and adhered onto one side surface of the carbon plastic composite material plate. The porous layer is composed of a binding agent and a porous material, wherein the binding agent is selected from chlorinated polypropylene or chlorinated polyethylene; the porous material includes active carbon, carbon-supported metal, graphite or carbon black, with a weight ratio of (1 to 5): (1 to 15); the loading amount of the porous material on the carbon plastic composite material plate is 0.5mg / cm<2> to 10mg / cm<2>. The negative electrode adopting the porous carbon plastic composite material with high specific surface area can increase the contact area between electrolyte and the electrode and suppress electrochemical polarization of zinc deposition and dissolving of the negative electrode, and has higher conductivity, thereby greatly improving battery performance.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Preparation method of vanadium battery negative electrode solution

InactiveCN103199292AImprove reversibilityReduces electrochemical polarizationRegenerative fuel cellsIonToluene

The invention provides a preparation method of a vanadium battery negative electrode solution. The preparation method comprises the following steps of: (1) mixing vanadic oxide, oxalic acid and sulfuric acid in a ratio; (2) adding sulfuric acid to the mixture obtained in the step (1), heating so that the vanadic oxide is fully dissolved, and boiling for 45-60 minutes, to obtain a vanadyl sulfate solution; (3) electrifying the vanadyl sulfate solution to remove excessive oxalic acid and obtain a mixture of trivalent vanadium ions and bivalent vanadium ions; (4) adding an appropriate amount of bivalent vanadium oxide electrolyte to the mixture obtained in the step (3) to remove the bivalent vanadium ions and obtain the vanadium battery negative electrode solution; and (5) adding toluene sulfonic acid to the vanadium battery negative electrode solution as the catalyst. The preparation method has the advantages that through adding the toluene sulfonic acid to the vanadium battery negative electrode solution as the catalyst, the reversibility of the electrode process is improved, the electrochemical polarization is reduced, the vanadium battery energy efficiency is increased, and the viscosity of the negative electrode solution is reduced.

Owner:朴宁

EFB start-stop battery positive and negative electrode with high charging acceptance capacity and preparation method thereof

ActiveCN109037597AImprove corrosion resistanceReduce voltage dropLead-acid accumulatorsElectrode carriers/collectorsFiberCarbon fibers

The invention relates to an EFB start-stop battery positive and negative electrode with high charge acceptance capacity and a preparation method thereof, belongs to the technical field of EFB start-stop batteries, and mainly solves the problem that the high-temperature life of a battery is reduced due to carbon fibers contained in existing lead paste. The main features are as follows: an anode lead paste formula includes 0.2% -- 0.4% of expanded graphite, 0.08% - 0.12% of short fiber, 0.1% - 0.3% of metal sulfate additive, 0.6% - 1.0% of 4BS seed, 9% - 12% of pure water, 8% - 10% of 1.38 g / cm3sulfuric acid solution and the balance of lead powder; a cathode lead paste formula includes 0.1 to 0.2 percent of carbon nanotube slurry, 0.1 to 0.2 percent of carbon black A, 0.02 to 0.06 percent of carbon black B, 0.08 to 0.12 percent of short fiber, 0.15 to 0.25 percent of organic additive A, 0.08 to 0.12 percent of organic additive B, 0.5 to 0.8 percent of nanometer barium sulfate, 8 to 10 percent of pure water, 8 to 10 percent of 1.38 g / cm3 sulfuric acid solution and the balance of lead powder. The invention has the characteristics of greatly improving battery charging acceptance capacity and further prolonging the battery life, and is mainly used for EFB starting and stopping batteries with high charging acceptance capacity.

Owner:CAMEL GRP XIANGYANG BATTERY

Preparation method of trivalent scandium or chromium-doped spinel-type lithium-rich lithium manganate cathode material

ActiveCN103606669ALow costReduces electrochemical polarizationCell electrodesChemistryLithium ion intercalation

The invention relates to a preparation method of a trivalent scandium or chromium-doped spinel-type lithium-rich lithium manganate cathode material. The preparation method is characterized in that 1, lithium, manganese, and scandium or chromium compounds are weighed according to a lithium-manganese-doping ion mole ratio of x: y: z, and x is greater than or equal to 0.97 and less than or equal to 1.08, y is greater than or equal to 1.05 and less than or equal to 1.20 and z is greater than or equal to 0.05 and less than or equal to 0.17; 2, the weighed compounds are mixed, a wet grinding medium is added into the mixture so that a predecessor 1 is obtained, and the predecessor 1 is dried to form a predecessor 2; and 3, the trivalent scandium or chromium-doped spinel-type lithium-rich lithium manganate anode material is obtained by a two-stage sintering method. The preparation method has a low raw material cost, reduces electrochemical polarization of lithium ion embedding and removal by doping, improves heavy current discharge performances and lays a good foundation for industrialization.

Owner:FUJIAN NORMAL UNIV

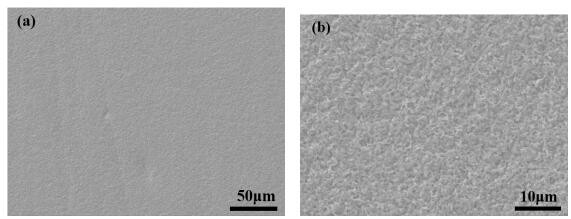

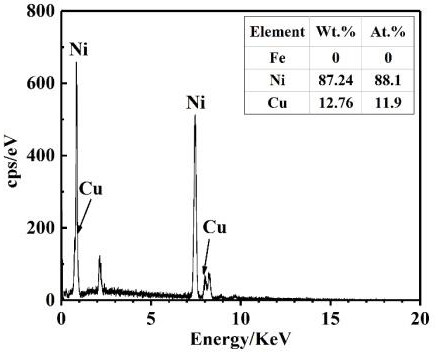

Method for preparing nickel-copper alloy plating layer on surface of carbon steel

The invention discloses a method for preparing a nickel-copper alloy plating layer on the surface of carbon steel. The method specifically comprises the following steps: (1) pretreatment, wherein a carbon steel workpiece is pretreated to obtain a carbon steel base material for later use; (2) preparation of an electroplating solution, wherein nickel sulfate, copper sulfate, trisodium citrate, boric acid, an additive and a brightener are dissolved in deionized water to prepare the electroplating solution for later use, and the concentrations of nickel sulfate, copper sulfate, trisodium citrate, boric acid, the additive and the brightener in the electroplating solution are 170-200 g / L, 5-20 g / L, 60-100 g / L, 10-25 g / L, 0.05-1 g / L and 0.1-1 g / L respectively; and (3) preparation of the nickel-copper alloy plating layer, wherein the carbon steel base material is immersed into the electroplating solution, the carbon steel base material serves as a cathode, one of monel alloy, pure nickel, graphite and pure copper serves as an anode, and electroplating deposition is conducted on the carbon steel base material to form the nickel-copper alloy plating layer. The nickel-copper alloy plating layer prepared through the method not only can effectively solve the problem of corrosion of a fluorine-making electrolytic cell made of carbon steel, but also has good thermal conductivity and strong binding force with the carbon steel base material.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

Staged formation method for lead-acid storage battery

ActiveCN107591580ALess heat productionReduces electrochemical polarizationFinal product manufactureSecondary cells charging/dischargingEngineeringSecondary stage

The invention discloses a staged formation method for a lead-acid storage battery, and belongs to the technical field of production of lead-acid storage batteries. The staged formation method comprises the following stages: 1, charging the storage battery until the voltage reaches 2.75-2.9 V / bar, and discharging the storage battery to reach a final voltage; 2, carrying out positive and negative pulse formation charging until the voltage of the storage battery reaches 2.75-2.9 V / bar, discharging the storage battery to reach the final voltage, and repeating the process multiple times; 3, carrying out positive and negative pulse formation charging step by step in an amplitude decreasing manner until the electrolyte density of the storage battery reaches a preset standard, and discharging thestorage battery to reach the final voltage; and 4, charging the storage battery until the voltage of the storage battery is stable. The method shortens the formation time to 44 h and improves the formation efficiency by 50% or more. A formed pole plate has a compact structure and a good strength, and the 100% DOD cycle life of the battery is 450 times or more, and is 20% or more longer than the life of common batteries.

Owner:TIANNENG BATTERY GROUP

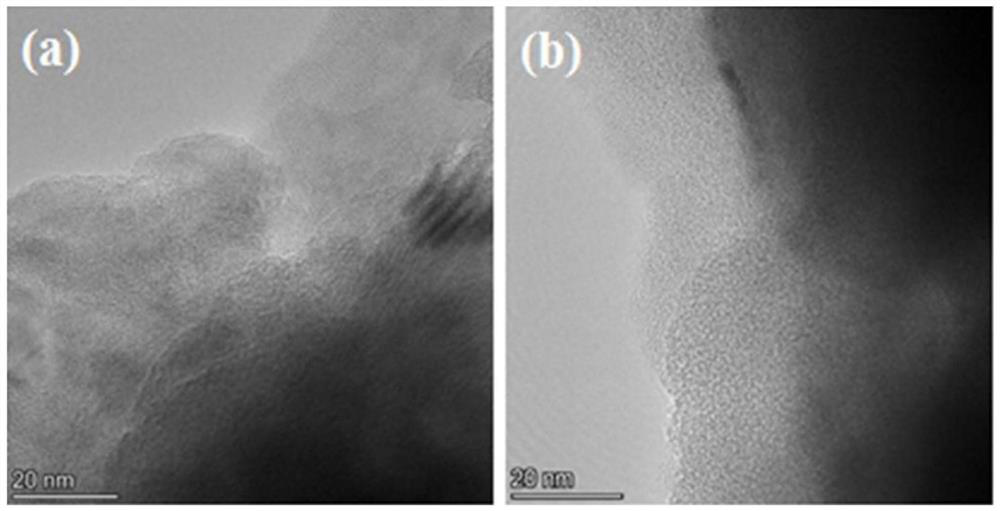

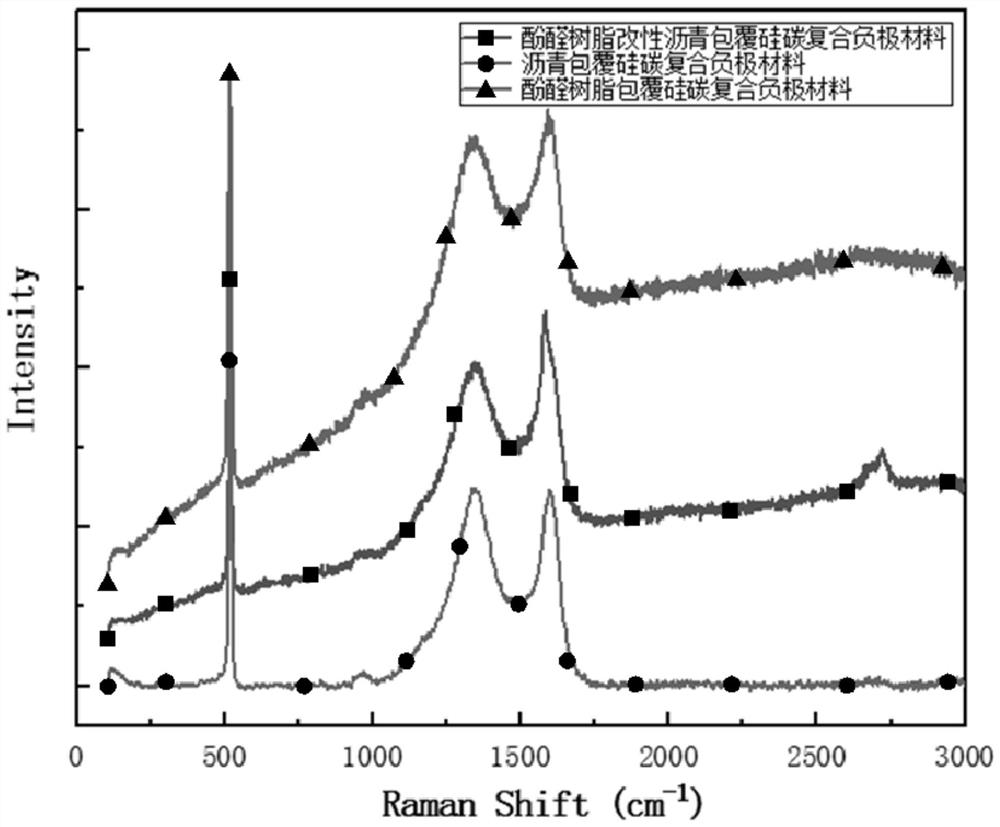

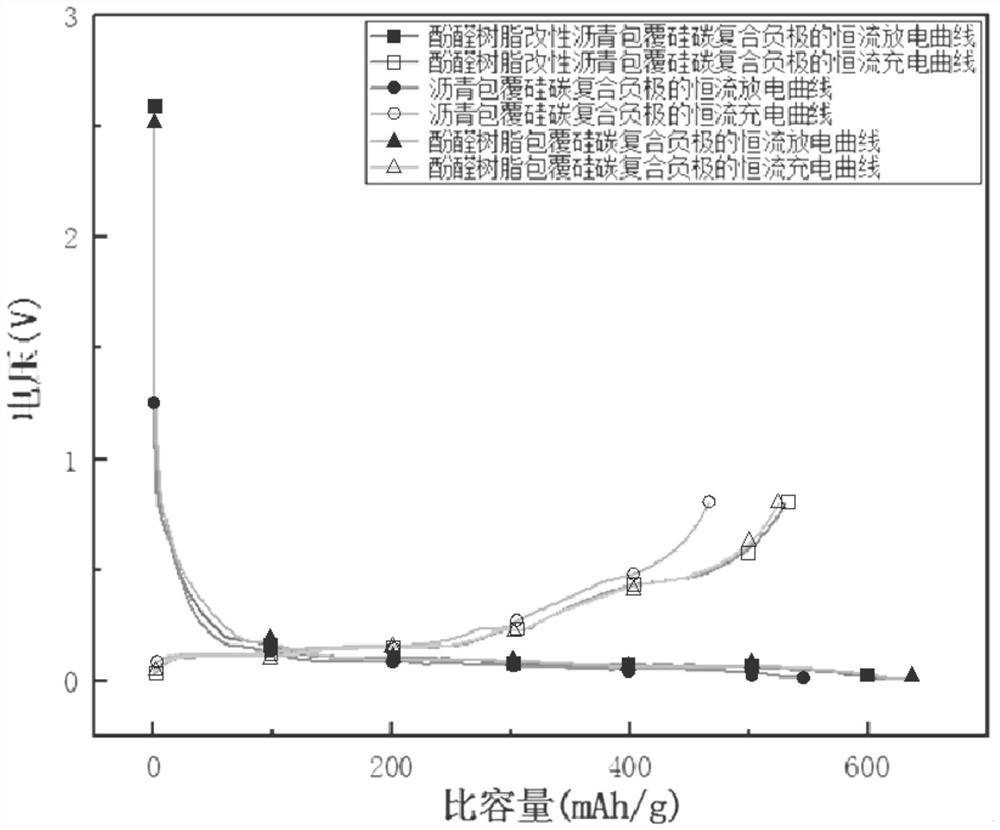

Modification method for coating silicon-carbon composite negative electrode material interface with modified asphalt

PendingCN112768644AHigh carbon residue rateHigh first rateSecondary cellsNegative electrodesCarbon compositesBattery capacity

The invention relates to the technical field of lithium battery materials, and in particular relates to a modification method for coating a silicon-carbon composite negative electrode material interface with modified asphalt. The asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing specially selected phenolic resin, so that the silicon-carbon composite negative electrode material with high rate performance and high first rate is prepared. And a compact nano carbon coating layer with low pore defect degree is formed, so that the defects such as cracks and holes on the surfaces of nano silicon and graphite can be effectively repaired, irreversible consumption of a large number of active lithium ions in the charging and discharging process of a battery is avoided, and irreversible reduction of the battery capacity is remarkably reduced. Therefore, the asphalt-coated silicon-carbon composite negative electrode material is subjected to interface modification by utilizing the mutual synergistic effect of the phenolic resin and the asphalt, the capacity diving condition during high-current charging and discharging of the battery is obviously delayed, and the rate capability and coulombic efficiency of the material are improved.

Owner:西安英纳吉科技有限公司

Method for synthesizing graphene/carbon-coated lithium iron phosphate small-scale nanometer composite material by aniline polymerization confinement effect

InactiveCN110444740AInhibit growthPromote circulationCell electrodesSecondary cellsPhosphateCharge discharge

A method for synthesizing a graphene / carbon-coated lithium iron phosphate small-scale nanometer composite material by an aniline polymerization confinement effect belongs to the field of lithium ion batteries and aims to solve the problems that an existing lithium iron phosphate is small in active area and poor in electronic conductivity and the large-rate charge-discharge requirement is difficultto met. During the synthesis process, aniline is catalyzed and polymerized by ferric ions absorbed onto a graphene oxide surface in advance, the aniline reacts with phosphate radical to generate ironphosphate precipitant, two sets of reaction are simultaneously performed, the generated polyaniline wraps iron phosphate particle, the phosphate radical is prevented from being contacted with the ferric ions, the iron phosphate particle is prevented from being grown by the confinement effect, so that a small-scale nanometer precursor is obtained, a lithium source is introduced, and sintering is performed to prepare the graphene / carbon-coated lithium iron phosphate small-scale nanometer composite material. The grain size of the iron phosphate particle in the composite is smaller than 40 nanometers, carbon-coated lithium iron phosphate is anchored onto the graphene surface to form a sandwiched layer structure of an amorphous carbon layer / lithium iron phosphate / graphene layer, and the graphene / carbon-coated lithium iron phosphate small-scale nanometer composite material has favorable cycle property.

Owner:HARBIN INST OF TECH

Lead acid battery taking graphene as additive

ActiveCN102244300BImprove electronic conductivityIncrease the speed of chargingLead-acid accumulatorsCell electrodesEngineeringGraphene

The invention discloses a lead acid battery taking graphene as an additive, and relates to a lead acid battery technology. The lead acid battery comprises a battery shell, a positive plate grid, a negative plate grid, a partition board and electrolyte, wherein the positive and negative plate grids are positioned in the battery shell; the partition board is positioned between the positive and negative plate grids; and the electrolyte is filled into the shell. The lead acid battery is characterized in that: the positive plate grid is manufactured by coating cathode lead paste and performing curing, drying and formation; the negative plate grid is manufactured by coating anode lead paste and performing the curing, the drying and the formation; and the cathode lead paste or the anode lead paste or both take the graphene as the additive. The lead acid battery provided by the invention takes the graphene material as the additive, can be rapidly charged and discharged, and simultaneously has high capacity and relatively longer charging and discharging circulation service life.

Owner:JIESHOU HUAYU POWER SUPPLY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same](https://images-eureka.patsnap.com/patent_img/a89d3c1f-67f6-4d9b-a6ee-ea8bd496d05a/170831140701.png)

![Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same](https://images-eureka.patsnap.com/patent_img/a89d3c1f-67f6-4d9b-a6ee-ea8bd496d05a/170831140707.png)

![Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same Alkali secondary battery negative electrode material [Cu<x>Zn<y>Ni<z>Fe2O4] and battery employing same](https://images-eureka.patsnap.com/patent_img/a89d3c1f-67f6-4d9b-a6ee-ea8bd496d05a/170831140713.png)