Graphene composite electrode material and preparation method thereof, lead-carbon battery negative electrode lead plaster and preparation method thereof as well as lead-carbon battery

A graphene composite and electrode material technology, applied in lead-acid batteries, battery electrodes, circuits, etc., can solve problems such as difficulty in meeting the requirements of electric vehicles and energy storage backup power sources, poor cycle performance of lead-carbon batteries, and short negative electrode cycle life, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

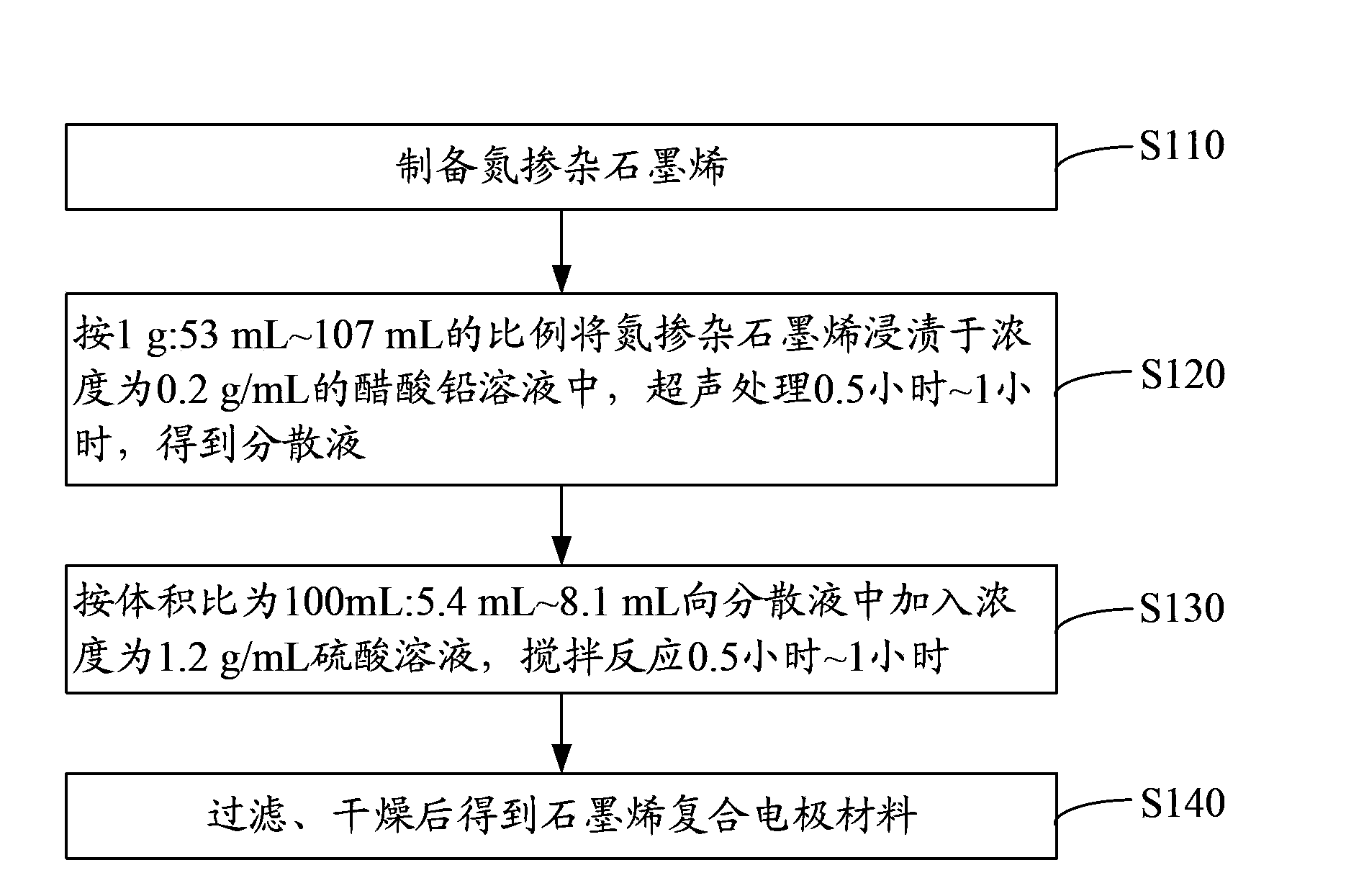

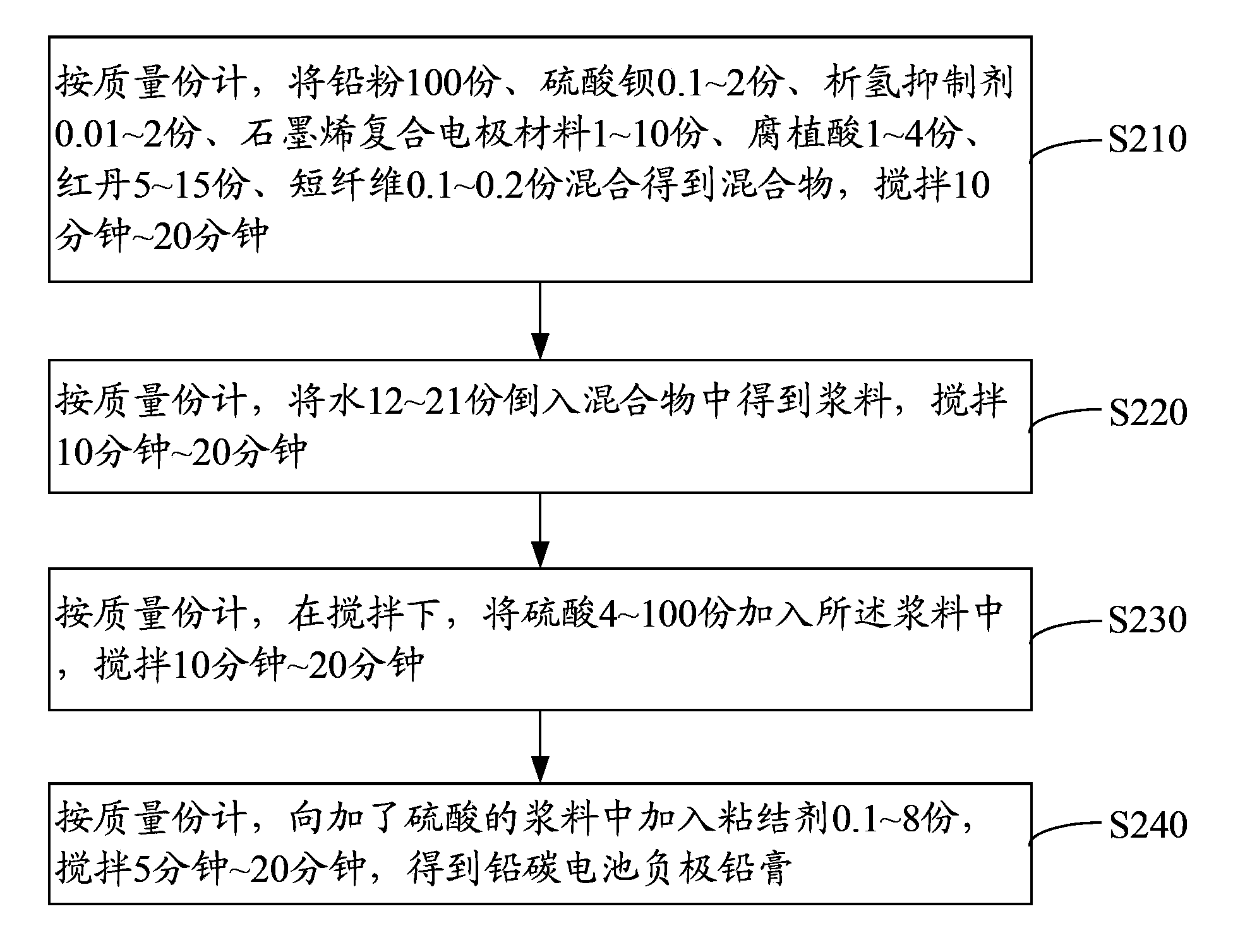

[0053] see figure 1 , the preparation method of the graphene composite electrode material of an embodiment, comprises the steps:

[0054] Step S110: preparing nitrogen-doped graphene.

[0055] Place graphite oxide or graphene in an ammonia atmosphere, heat up to 500°C-700°C at a heating rate of 5-15°C / min, react for 0.5-1 hour, and obtain nitrogen-doped graphene after cooling.

[0056] Graphite oxide or graphene can be placed in a horse boiling furnace, and ammonia gas is passed into the horse boiling furnace, and then the temperature is raised to 500°C~700°C for reaction. The flow rate of ammonia is preferably 400mL / min to ensure that graphite oxide or graphene is in full contact with ammonia.

[0057] In other embodiments, graphite oxide or graphene can also be combined with urea (CN 2 h 4 O), ammonium carbonate ((NH 4 ) 2 CO 3 ), ammonium bicarbonate (NH 4 HCO 3 ), ammonium acetate (CH 3 COONH 4 ) and melamine (C 3 h 6 N 6 ) to obtain a mixture, heat the mixtu...

Embodiment 1

[0107] (1) Preparation of nitrogen-doped graphene

[0108] Graphene was put into a horse boiling furnace protected by ammonia gas, the flow rate of ammonia gas was 400mL / min, and the temperature was raised to 500°C at a heating rate of 5°C / min, reacted for 1 hour, and nitrogen-doped graphene was obtained after cooling.

[0109] (2) Preparation of graphene composite electrode material

[0110] Nitrogen-doped graphene is immersed in the lead acetate solution that concentration is 0.2g / mL by the ratio of 1g:107mL, ultrasonic treatment is 0.5 hour, obtains dispersion liquid; It is 100mL:5.4mL to add concentration to dispersion liquid by volume ratio is 1.2 g / mL sulfuric acid solution, stirred and reacted for 0.5 hours to obtain a reaction solution, filtered the reaction solution, and vacuum-dried the filter residue at 60°C for 5 hours to obtain a graphene composite electrode material. The graphene composite electrode material includes nitrogen-doped graphene and adsorption Lead s...

Embodiment 2

[0120] (1) Preparation of nitrogen-doped graphene

[0121] Mix graphene and urea at a mass ratio of 1:1 and put it into a horse boiling furnace, raise the temperature to 700°C at a heating rate of 15°C / min, react for 0.5 hours, and obtain nitrogen-doped graphene after cooling.

[0122] (2) Preparation of graphene composite electrode material

[0123] Immerse nitrogen-doped graphene in a lead acetate solution with a concentration of 0.2g / mL at a ratio of 1g:53mL, and ultrasonically treat it for 1 hour to obtain a dispersion; add a concentration of 1.2 g / mL sulfuric acid solution, stirred and reacted for 1 hour to obtain a reaction solution, filtered the reaction solution, and vacuum-dried the filter residue at 100°C for 2 hours to obtain a graphene composite electrode material. The graphene composite electrode material includes nitrogen-doped graphene and adsorption Lead sulfate between nitrogen-doped graphene sheets, the mass ratio of nitrogen-doped graphene to lead sulfate i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com