Preparation method of MXene nanofiltration membrane

A nanofiltration membrane and nanosheet technology, which is applied in the field of preparation of new MXene nanofiltration membranes, can solve the problem that MXenes do not have a two-dimensional sheet structure under etching conditions, and achieve good retention performance and increase water flux.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

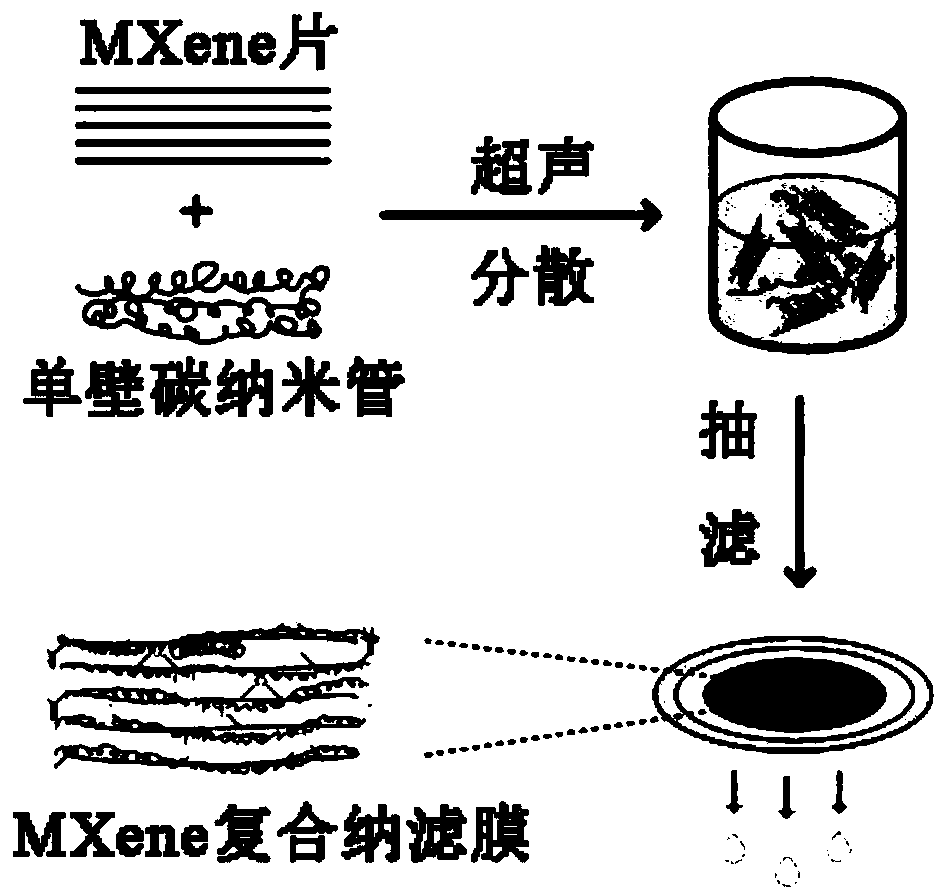

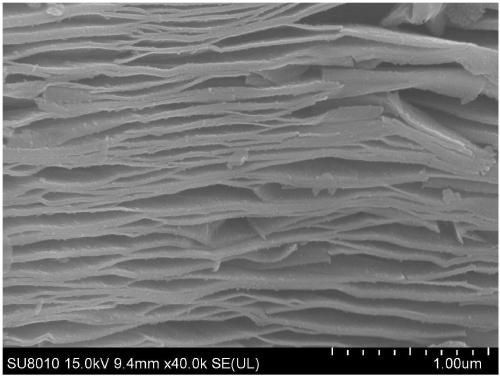

[0030] Ti 3 CNT x / CNT nanofiltration membrane preparation

[0031] Take 1g Ti 3 Al(C,N) 2 Soak the powder in 100ml of aqueous solution containing 0.5g of ammonium hydrofluoride, stir for 72h, and after centrifugal drying, take 0.1g of dried MXene powder and put it into a tube furnace for water vapor stripping. The water content of the gas is 10vol%, and the water vapor heating temperature is 500 degrees, heat treatment time is 1h. The powder after heat treatment and stripping is dried and set aside. Afterwards, take 0.2 g of purchased single-walled carbon nanotubes (Aladdin’s reagent) (2nm in diameter, 0.3-5 μm in length) and place them in 50ml of water for ultrasonic dispersion. After the dispersion is complete, add 1 g of stripped MXene powder, continue ultrasonic dispersion, and finally pass The prepared solution is suction-filtered on a ceramic substrate to form a film by suction filtration.

[0032] Membrane flux test is carried out under 0.1Mpa pressure, prepare 1...

Embodiment 2

[0034] Zr 3 C 2 T x / CNT nanofiltration membrane preparation

[0035] Take 1g Zr 3 al 3 C 2 Soak the powder in 100ml of aqueous solution containing 0.5g of ammonium hydrofluoride, stir for 72h, and after centrifugal drying, take 0.1g of dried MXene powder and put it into a tube furnace for water vapor stripping. The water content of the gas is 10vol%, and the water vapor heating temperature is 500 degrees, heat treatment time is 10h. The powder after heat treatment and stripping is dried and set aside. Afterwards, take 0.2 g of purchased single-walled carbon nanotubes (Aladdin’s reagent) (2nm in diameter, 0.3-5 μm in length) and place them in 50ml of water for ultrasonic dispersion. After the dispersion is complete, add 1 g of stripped MXene powder, continue ultrasonic dispersion, and finally pass The prepared solution is suction-filtered on a ceramic substrate to form a film by suction filtration.

[0036] Membrane flux test is carried out under 0.1Mpa pressure, prepa...

Embodiment 3

[0038] Ti 4 N 3 T x / CNT nanofiltration membrane preparation

[0039] Take 1g Ti 4 AlN 3Soak the powder in 100ml of aqueous solution containing 0.5g of ammonium hydrofluoride, stir for 72h, and after centrifugal drying, take 0.1g of dried MXene powder and put it into a tube furnace for water vapor stripping. The water content of the gas is 10vol%, and the water vapor heating temperature is 500 degrees, heat treatment time is 5h. The powder after heat treatment and stripping is dried and set aside. Afterwards, take 0.2 g of purchased single-walled carbon nanotubes (Aladdin’s reagent) (2nm in diameter, 0.3-5 μm in length) and place them in 50ml of water for ultrasonic dispersion. After the dispersion is complete, add 1 g of stripped MXene powder, continue ultrasonic dispersion, and finally pass The prepared solution is suction-filtered on a ceramic substrate to form a film by suction filtration.

[0040] Membrane flux test is carried out under 0.1Mpa pressure, prepare 1g ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com