Sodium ion doped high-nickel ternary lithium battery positive electrode material and preparation method

A ternary lithium battery and positive electrode material technology, applied in the field of lithium ion materials, can solve the problems of lithium ion capacity reduction, achieve the effect of improving cycle stability, improving stability, and facilitating diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

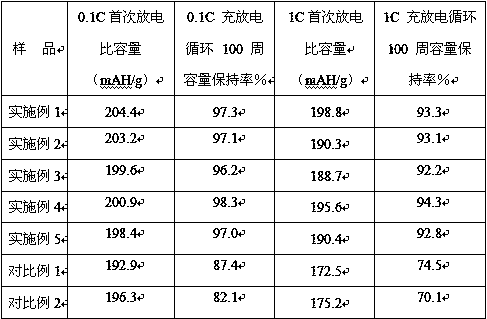

Examples

Embodiment 1

[0030] (1) Nickel chloride, cobalt chloride, manganese chloride, lithium oxide and sodium peroxide are used as raw materials, and 0.8 parts of nickel chloride, 0.1 part of cobalt chloride, 0.1 part of manganese chloride, and 0.485 parts are weighed according to the molar ratio Lithium oxide and 0.015 parts of sodium peroxide;

[0031] (2) Add the nickel salt, cobalt salt, and manganese salt into the phosphoric acid solution with an appropriate pH value of 3, add an appropriate amount of sodium hydroxide to adjust the pH value to 10, set the stirring speed to 800 rpm, and obtain NCM coprecipitation under high-speed stirring The dispersion liquid is then filtered, and the treatment conditions are such that the drying temperature is 50°C and the ambient pressure is 300 Pa, and the low-temperature drying is obtained to obtain the 811-type NCM precursor;

[0032] (3) The 811-type NCM precursor was added to a ball mill for grinding, and the temperature was kept at 60°C during the gr...

Embodiment 2

[0035] (1) Using nickel nitrate, cobalt nitrate, manganese nitrate, lithium oxide and sodium peroxide as raw materials, weigh 0.8 part of nickel salt, 0.1 part of cobalt salt, 0.1 part of manganese salt, 0.485 part of lithium oxide and 0.015 part of peroxide sodium oxide;

[0036] (2) Add an appropriate amount of nickel salt, cobalt salt, and manganese salt to hydrochloric acid solution with a pH value of 3, add an appropriate amount of alkaline solution sodium carbonate to adjust the pH value to 11, set the stirring speed to 600 rpm, and obtain NCM under high-speed stirring The co-precipitation dispersion is then filtered, and the treatment conditions are such that the drying temperature is 55°C and the ambient pressure is 30Pa and dried at a low temperature to obtain the 811-type NCM precursor;

[0037] (3) The 811-type NCM precursor was added to a ball mill for grinding, and the temperature was kept at 80°C during the grinding process to obtain a precursor powder with a par...

Embodiment 3

[0040] (1) Using nickel bromide, cobalt bromide, manganese bromide, lithium oxide and sodium peroxide as raw materials, weigh 0.8 parts of nickel salt, 0.1 part of cobalt salt, 0.1 part of manganese salt, 0.485 parts of lithium oxide and 0.015 part sodium peroxide;

[0041] (2) Add an appropriate amount of nickel salt, cobalt salt, and manganese salt into the mixed solution of sulfuric acid, hydrochloric acid, and nitric acid with an appropriate pH value of 3, respectively, add an appropriate amount of potassium hydroxide to adjust the pH value to 12, set the stirring speed to 300 rpm, and stir at a high speed The NCM co-precipitation dispersion was obtained under the following conditions, and then filtered, and the treatment conditions were that the drying temperature was 55 ° C, and the ambient pressure was 180 Pa. Drying at low temperature to obtain the 811-type NCM precursor;

[0042] (3) The 811-type NCM precursor was added to a ball mill for grinding, and the temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com