Organic wastewater modified bentonite adsorbent and preparation method thereof

A technology of organic wastewater and bentonite, which is applied in chemical instruments and methods, adsorption water/sewage treatment, water pollutants, etc. Low cost, improved adsorption capacity, and the effect of increasing layer spacing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

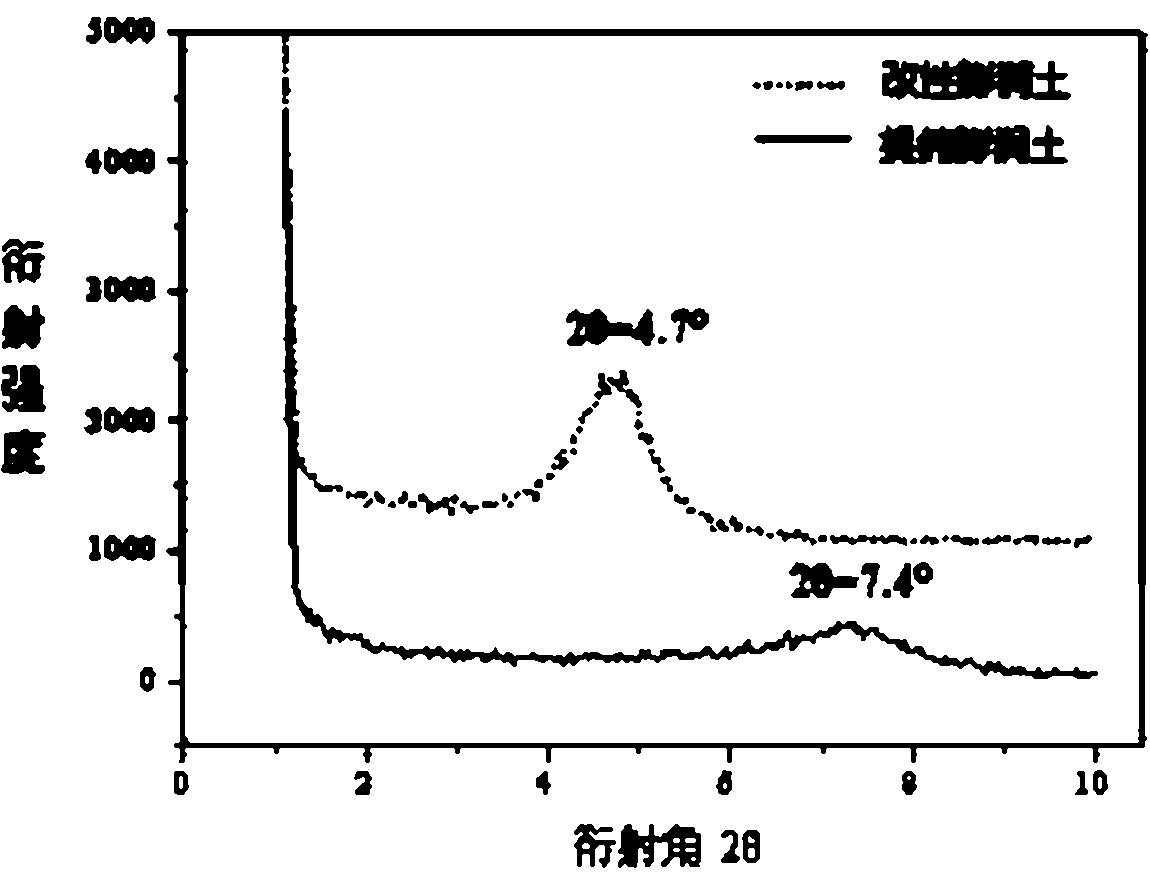

Image

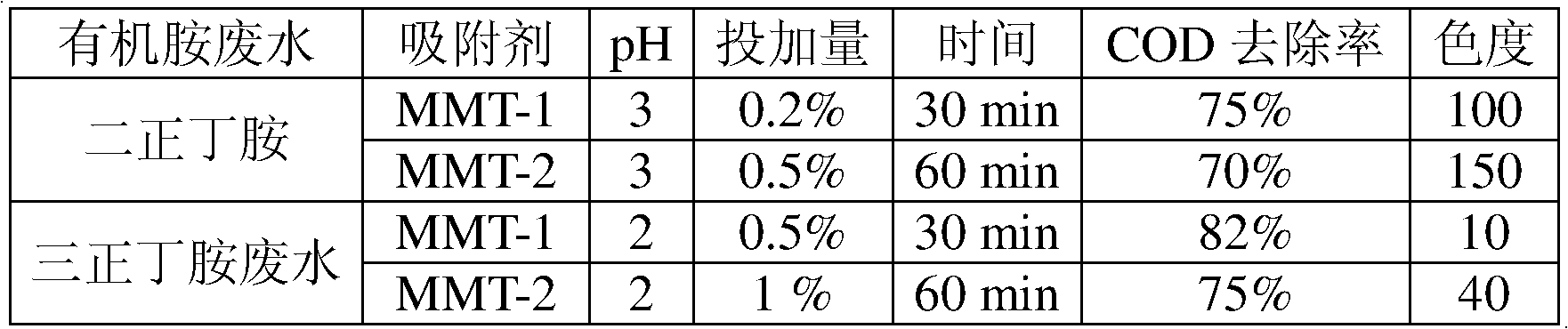

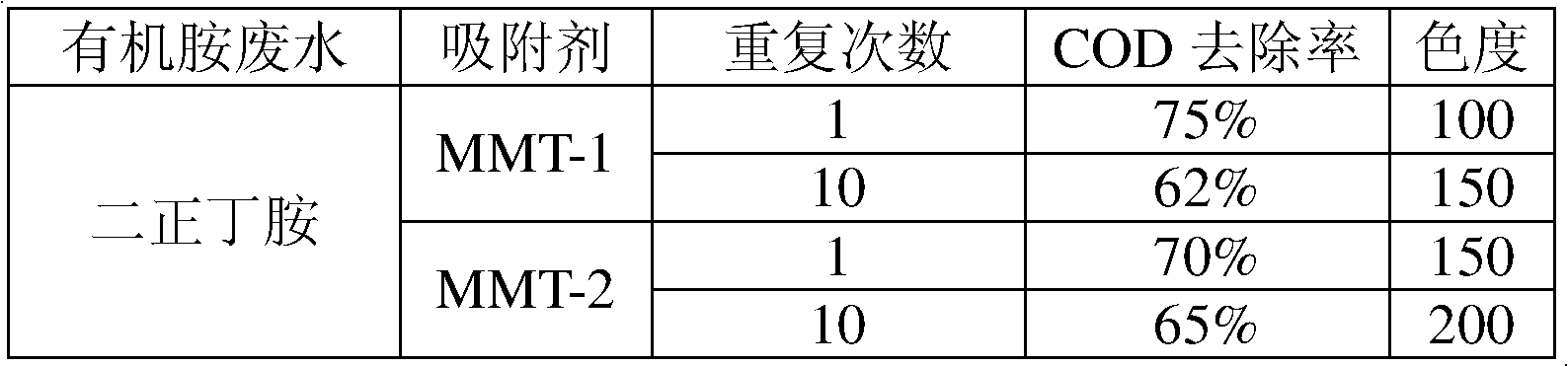

Examples

example 1

[0019] Example 1: Add 50g of sodium bentonite to 500mL of distilled water, keep the temperature in the water bath at 60°C, keep stirring for 24 hours, then let it stand for 6 hours, discard the sand at the bottom, and take the supernatant for suction filtration. The filtrate can be used for the next purification. Dry in an oven at 90°C, grind and pass through a 200-mesh sieve to obtain refined bentonite for future use.

[0020] Take 2L of pyrimidinol wastewater (the concentration of pyrimidinol is about 5000 mg / L), and adjust the pH to 2 with sulfuric acid with a concentration of 2 mol / L. Add 2g of refined bentonite powder, stir and react at room temperature for 1 hour, filter with suction, place in an oven and bake at 90°C for 5 hours, grind, then place in a muffle furnace and heat to 350°C at a heating rate of 40°C / min, then roast After 4 hours, a black-gray product was obtained after cooling down, the yield was 2.17 g, and the product number was MMT-1.

example 2

[0021] Example 2: Obtain purified bentonite according to the process in Example 1.

[0022] Take 10L of furanol wastewater (furanol concentration is about 5000mg / L), first use sulfuric acid with a concentration of 10mol / L to roughly adjust the pH, and then use sulfuric acid with a concentration of 2mol / L to adjust the pH to 3. Add 1g of refined bentonite powder, stir and react at room temperature for 2 hours, filter with suction, place in an oven and bake at 100°C for 5 hours, grind, then place in a muffle furnace and heat to 280°C at a heating rate of 40°C / min. After roasting for 2 hours, a black-gray product was obtained after cooling down. The yield was 1.02 g, and the product number was MMT-2.

example 3

[0023] Example 3: The organic waste water modified bentonite of the present invention is applied to the adsorption and roasting cycle test of pyrimidinol waste water: get the organic waste water modified bentonite obtained in the above example 1 as the adsorbent, and follow the waste water treatment process.

[0024] 1. Take 100mL of pyrimidinol wastewater, the initial concentration of pyrimidinol is 5000mg / L, the COD is 27000mg / L, and the chroma is 100 times;

[0025] 2. Adjust the pH to 3.0-5.0;

[0026] 3. Add organic bentonite to the wastewater, and the amount of adsorbent is 0.5g / 100mL water sample;

[0027] 4. Stir at room temperature for 15 minutes;

[0028] 5. Stand still for 15 minutes, take the supernatant and measure the concentration of residual pyrimidinol by liquid chromatography, the results show that the concentration of residual pyrimidinol is 500 mg / L, and the removal rate reaches 90%; use potassium dichromate microwave digestion method to analyze the remain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com