Patents

Literature

813results about How to "Good decolorization effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

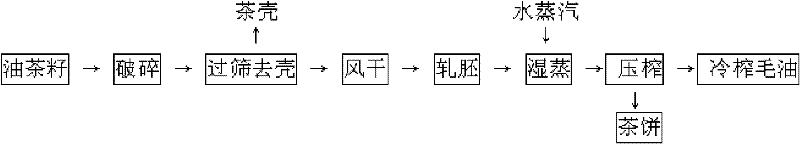

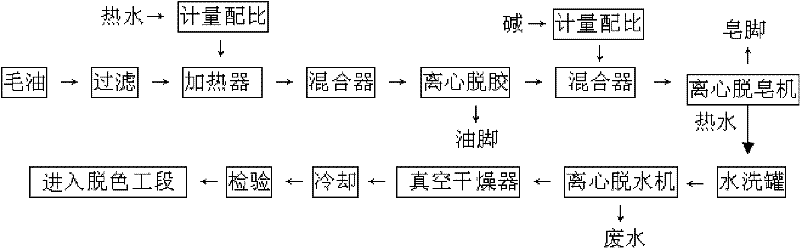

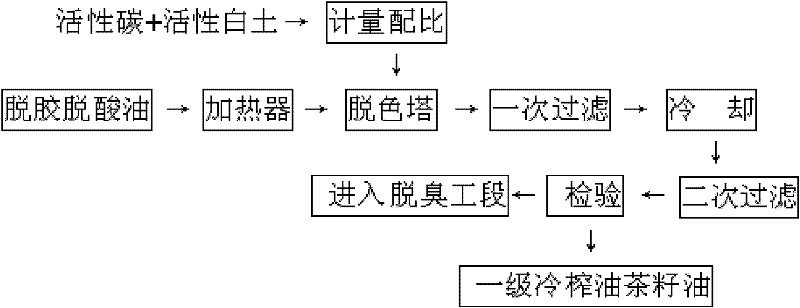

Low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil

InactiveCN102329690AAvoid it happening againEasy to dryFatty-oils/fats refiningFatty-oils/fats productionSocial benefitsActivated carbon

The invention discloses a low-temperature cold-pressing and bivariate continuous refining and processing method for oiltea camellia seed oil, which mainly comprises the following technical steps of squeezing, leaching, degumming, deacidifying, decoloring, deodorizing, winterizing, dewaxing and the like. In the method, the technology of low-temperature drying and low-temperature squeezing and the bivariate mixed decoloring technology of activated carbon and activated clay are adopted to adsorb and decolor oil, thereby preventing from generating harmful substances, such as benzopyrene, coking objects, carbide and the like, and improving the quality and the grade of the product. The method has good economic benefit and social benefit.

Owner:贵州大龙健康油脂有限公司

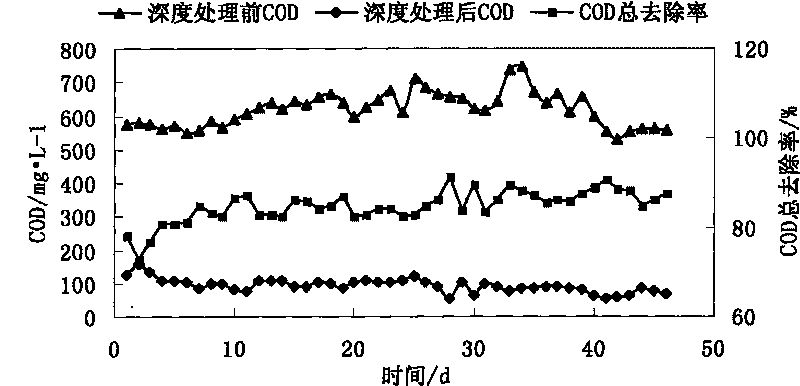

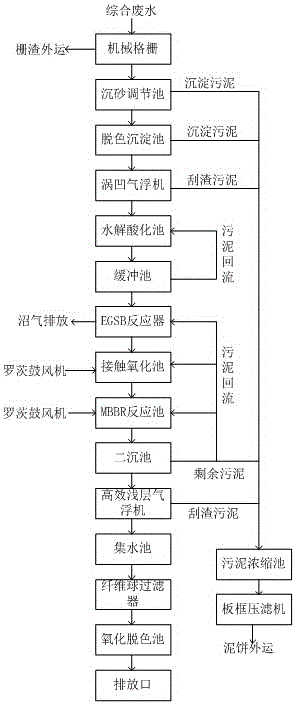

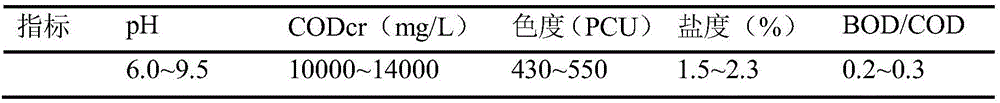

Advanced treating method of landfill leachate

InactiveCN101698550AImprove biodegradabilityReduce concentrationMultistage water/sewage treatmentWater/sewage treatment by neutralisationSludgeLitter

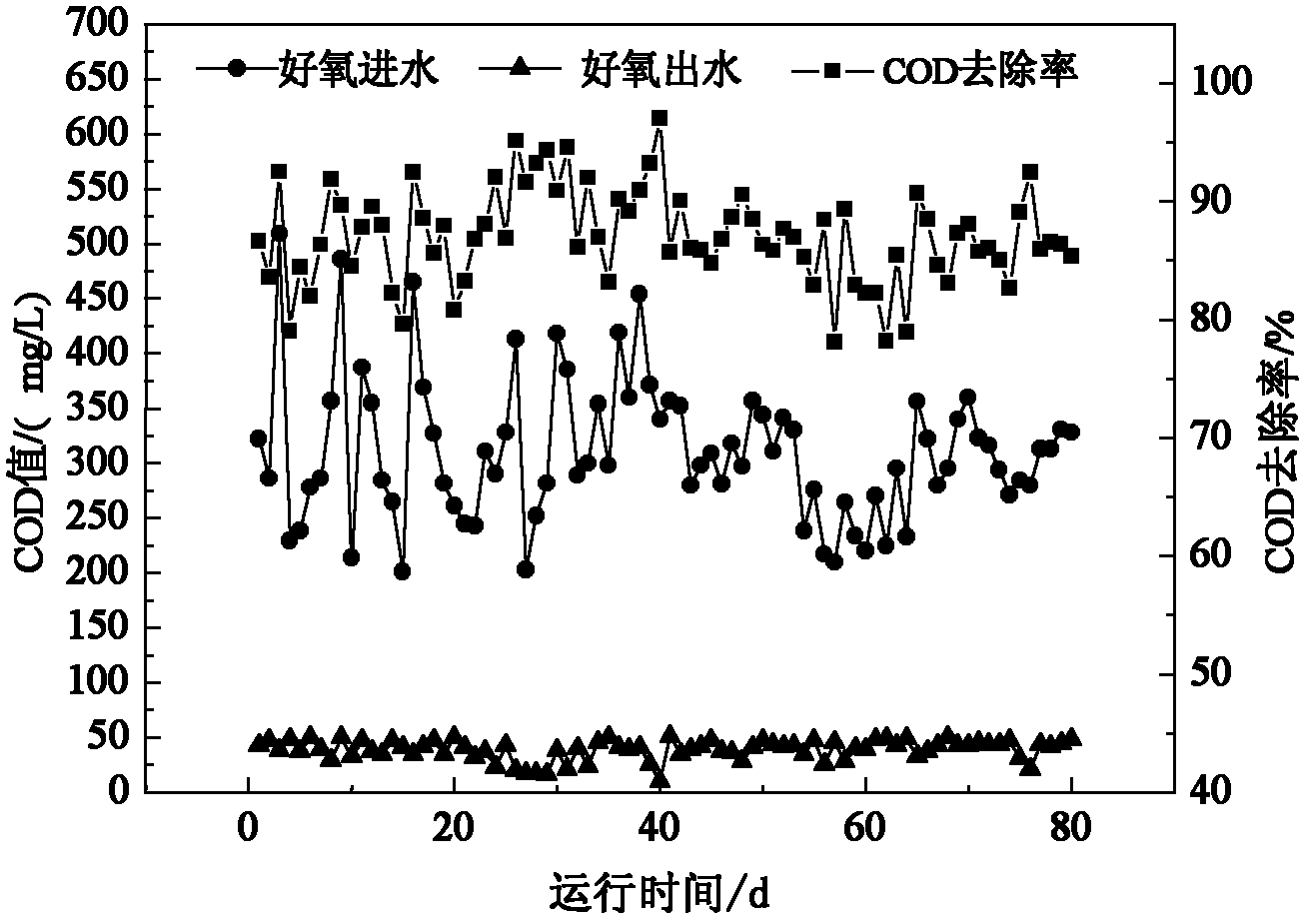

The invention discloses an advanced treating method of landfill leachate, which comprises the steps of: discharging eobiont-treated landfill leachate waste water into an adjusting pond; pumping the waste water in the adjusting pond into a polymeric ferrum reaction precipitation pond with a waste water metering pump to evenly mix polymeric ferrum agent with the waste water, and treating liquid supernatant which flows into an Fento oxidation pond by means of advanced oxidation after coagulating polymeric ferrum; leading the water to flow into a neutralization pond after the advanced oxidation to adjust the pH value of the waste water at 6-8, and adding PAM into the precipitation pond to carry out coagulation precipitation after neutralizing the waste water; and pumping liquid supernatant of the precipitation pond into a biological filler filter to carry out biological treatment, putting filler into the pond, sufficiently aerating to carry out aerobic treatment, and draining at the top of the pond through a water outlet weir, wherein the quality of the outlet water achieves landfill leachate state first-grade discharge standard. Sludge in the polymeric ferrum reaction pond and the precipitation pond can be directly transported to landfill areas to be landfilled after dehydration treatment.

Owner:SOUTH CHINA UNIV OF TECH

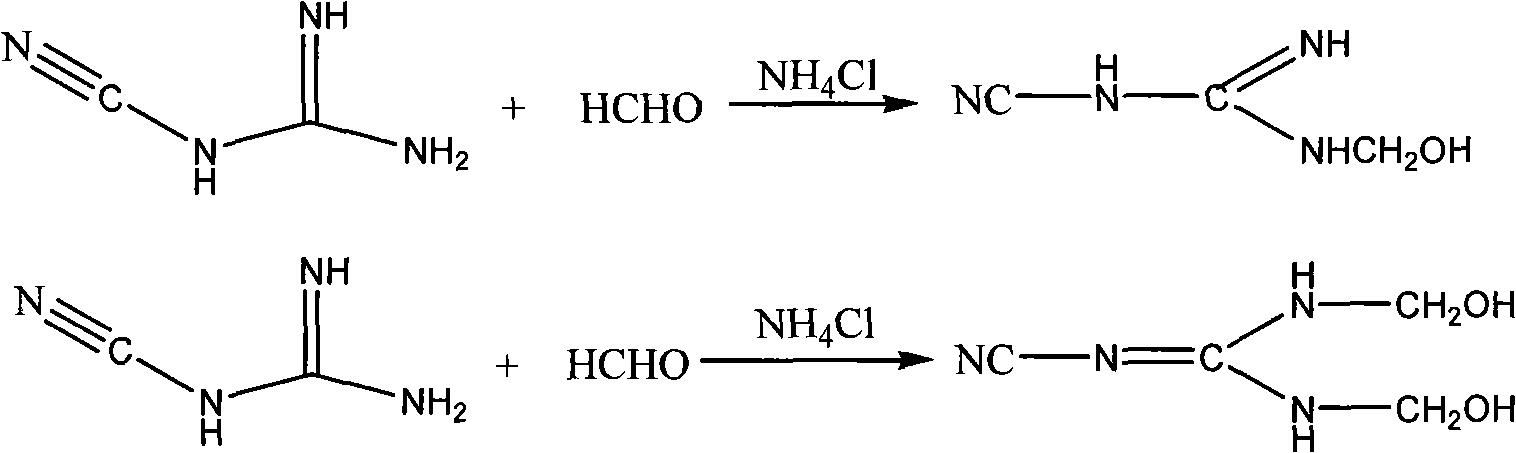

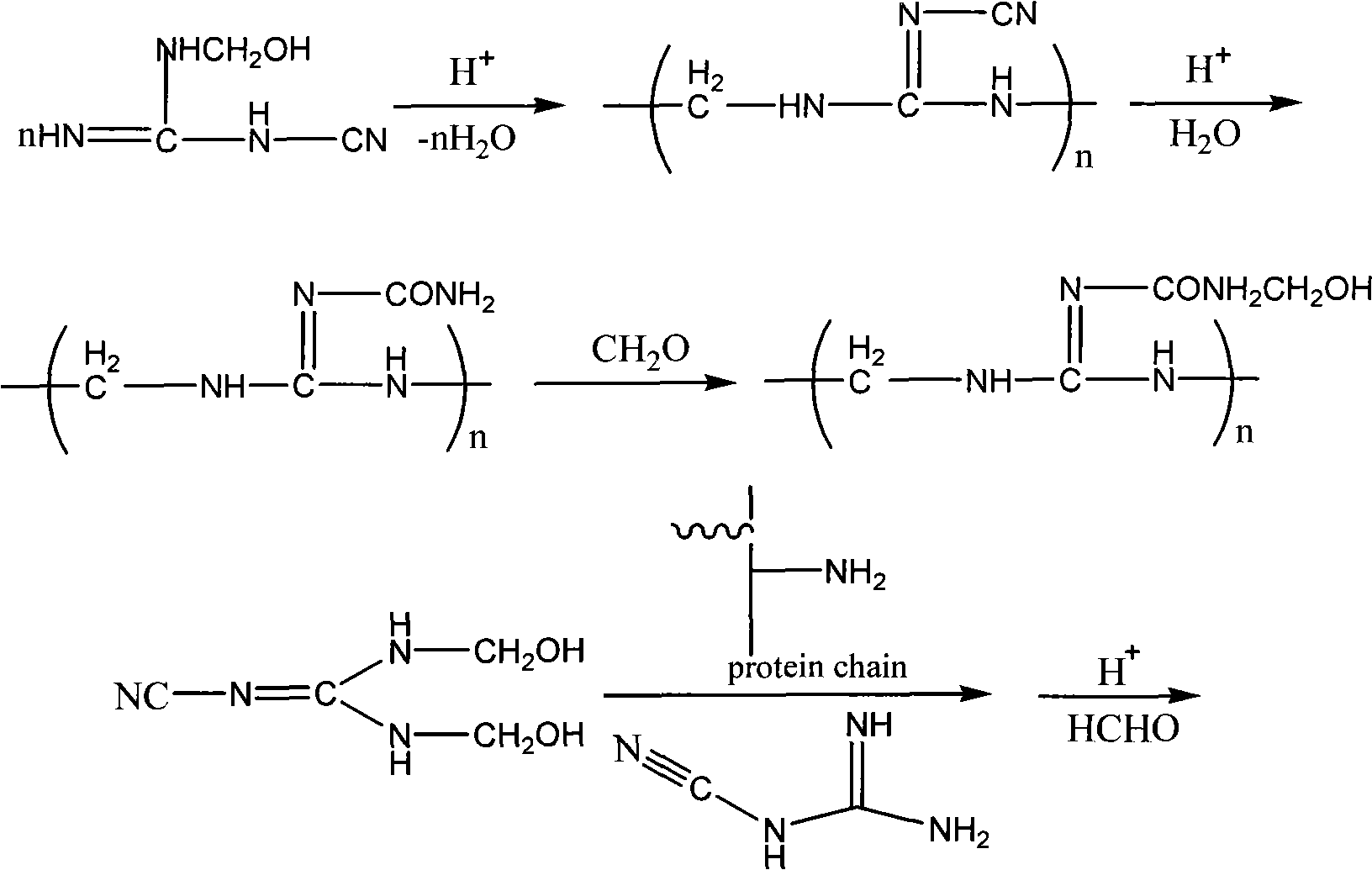

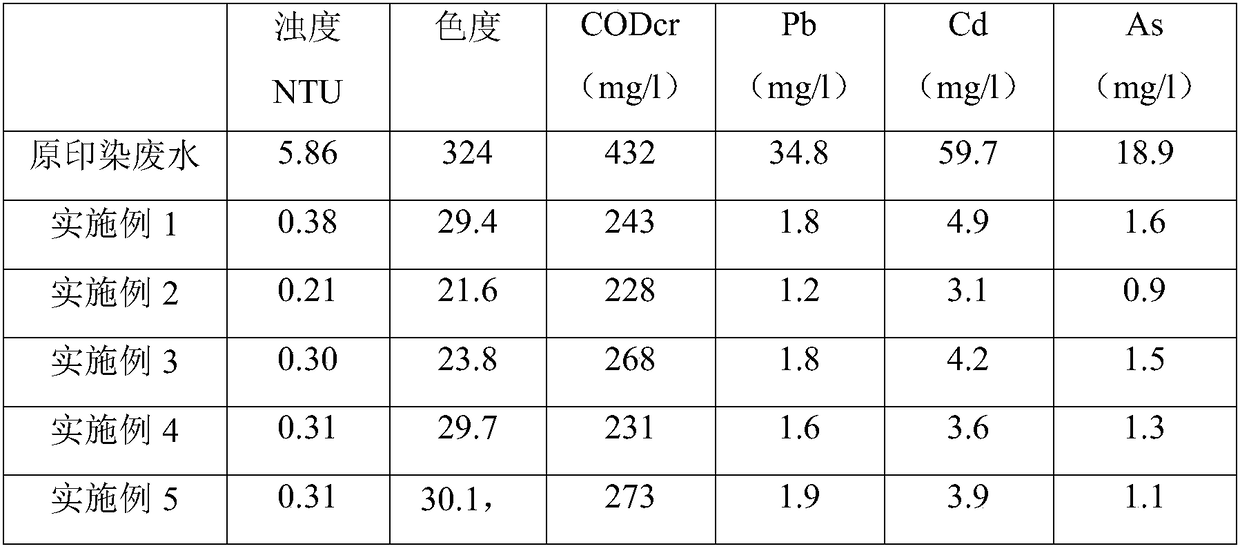

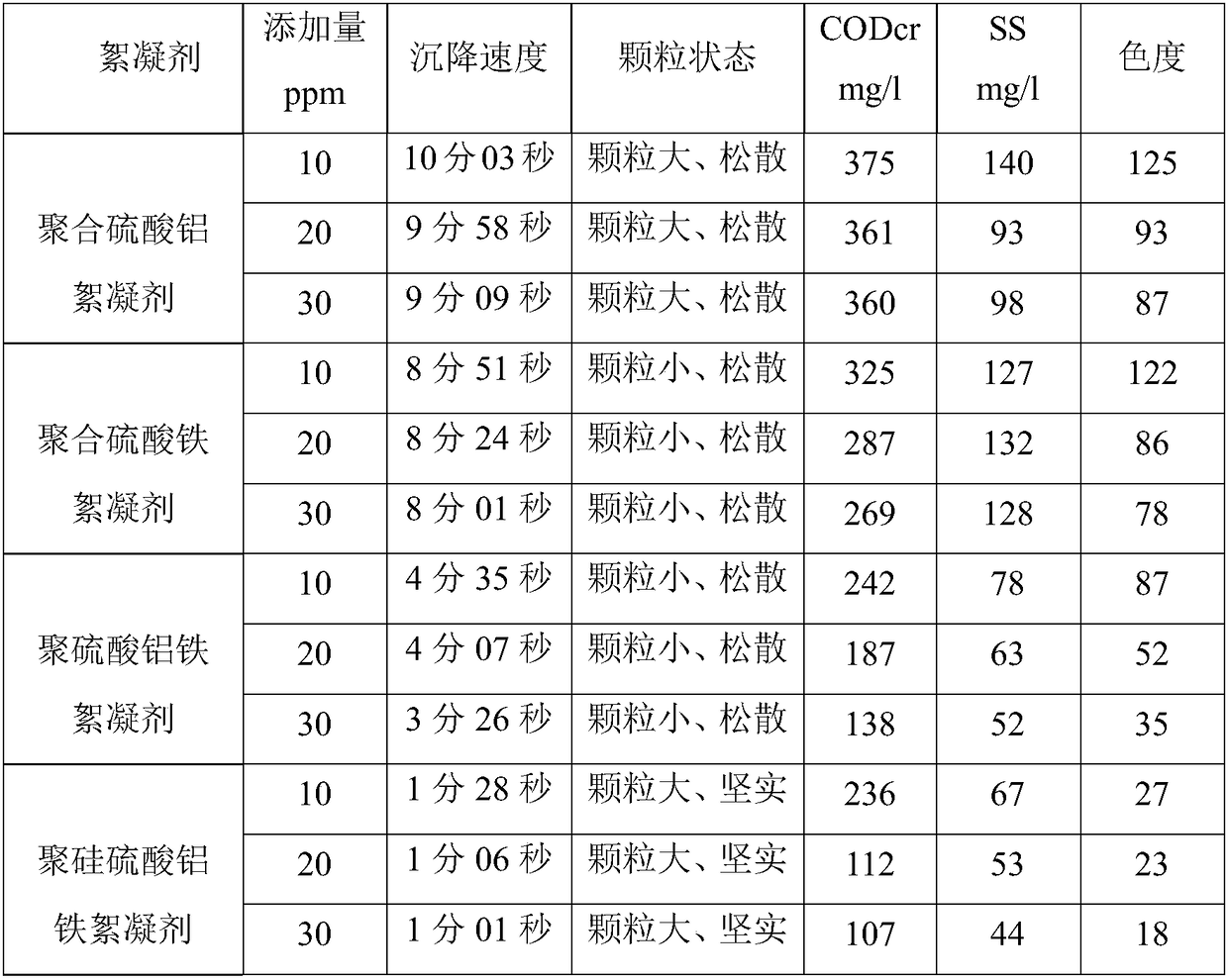

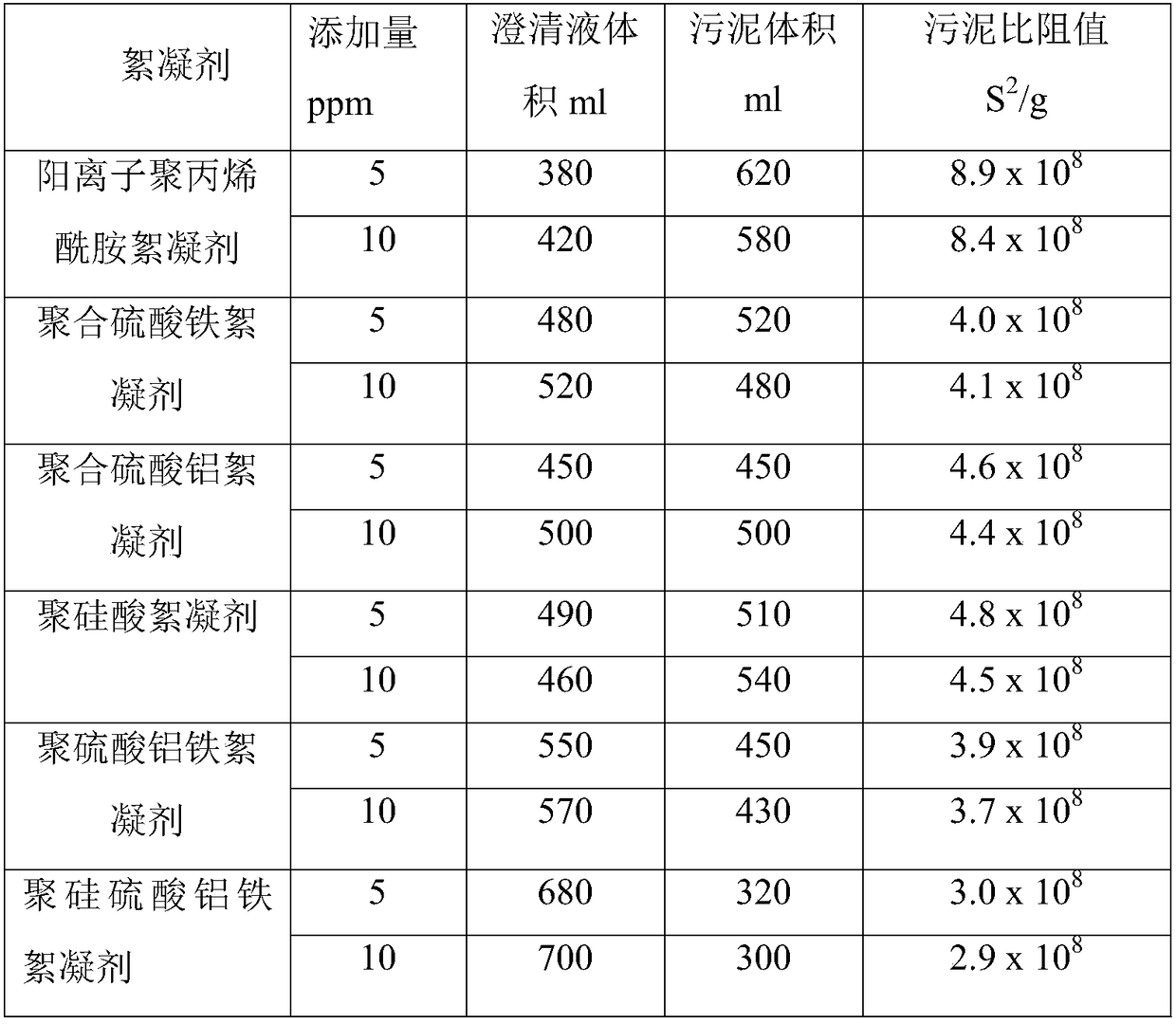

Decolorization flocculating agent for printing and dyeing waste water

InactiveCN101085688ADosage controlGood decolorization effectWater/sewage treatment by flocculation/precipitationRefluxAluminium chlorohydrate

The invention provides a method for preparing decolouring flocculating agent for printing and dyeing wastewater. It comprises following steps: adding 6- 9 units dicyandiamide, 4- 1 units urea, 20 -26 units formaldehyde and 3.5- 7.5 untis ammonium chloride into autoclave equipped with reflux condensing unit, reacting at 40 -50 Deg. C for 1- 2 hours, heating to 80- 85 Deg. C and reacting for another 1.5- 2 hours, adding 66.5- 56.5 units newly prepared polymeric aluminum chloride solution (Al2O3%=12), cooling to 40- 50 Deg. C and reacting for 0.5- 1 hour, curing 24 hours and getting final product. The invention is characterized by good decoloring and flocculating effect, simple device and process, and low production cost.

Owner:GUANGZHOU GELONG ENVIRONMENTAL PROTECTION TECH DEV

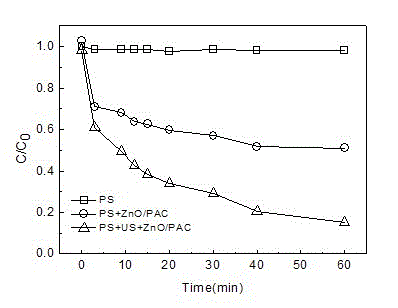

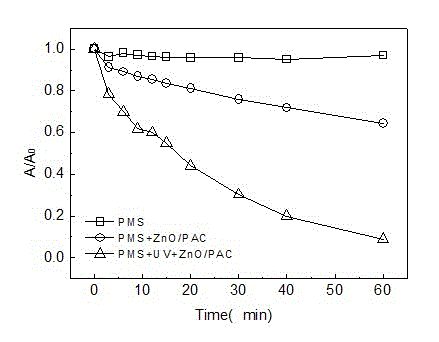

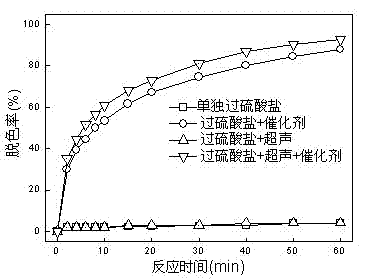

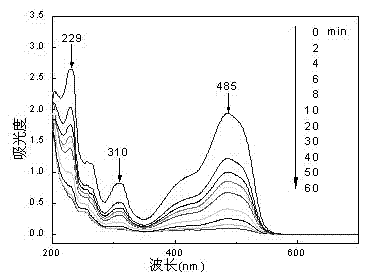

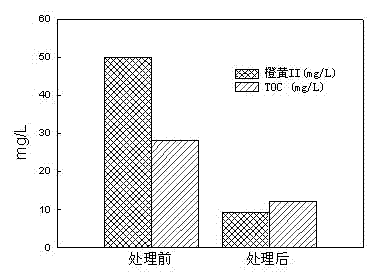

Active carbon loaded zinc oxide catalyst and application thereof in degradation of organic pollutant

InactiveCN102744055AEasy to prepareLow priceWater/sewage treatment by irradiationWater/sewage treatment with mechanical oscillationsPtru catalystPersulfate

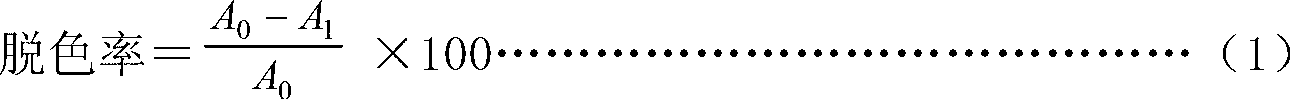

The invention relates to active carbon loaded zinc oxide catalyst and application thereof for treating organic wastewater after being combined with ultrasonic wave or ultraviolet light and persulfate. The catalyst can be combined with disulfate to treat the organic wastewater taking azo dye orange II as target pollutant, and decolorization rate can reach 68% in 60 minutes; and after the ultrasonic wave is jointly used, the decolorization rate can be increased to 92% in 60 minutes; meanwhile, the catalyst can be combined with peroxy-monosulfate to treat the organic wastewater taking azo dye reactive black 5 as target pollutant, and decolorization rate can reach 36% in 60 minutes; and after the ultraviolet light is jointly used, the decolorization rate can be increased to 91% in 60 minutes. The active carbon loaded zinc oxide catalyst is high in catalyzing efficiency and low in metal ion digestion. The active carbon loaded zinc oxide catalyst is combined with the ultrasonic wave or the ultraviolet light and the persulfate to treat organic pollutant in the wastewater, the treatment can be performed in a mild condition, and the treatment is simple to process, low in cost and good in treatment efficiency.

Owner:WUHAN UNIV

Cold pressing and refining method of camellia oil

InactiveCN104232292AImprove qualityDelicate and soft tasteFatty-oils/fats refiningFatty-oils/fats productionCamellia oleiferaHusk

The invention discloses a cold pressing and refining method of camellia oil. The cold pressing and refining method comprises the following operation steps: separating camellia seed kernels from camellia seed husks of camellia seeds, rolling into a material blank, further performing steaming, stir-frying and drying, and then feeding the material blank into a cold pressing machine for pressing; and further performing degumming, alkaline refining, washing with water, decolorization, deodorization and dewaxing to obtain finished camellia seed oil. The quality of the camellia oil processed by adopting the method in various items is better than that of hot pressed oil; furthermore, the camellia seed oil produced by the method disclosed by the invention has soft and fine taste and crystal and bright luster, and can be used for direct eating and cold mixing; a camellia seed oil product produced by the method has more stable quality in comparison with the prior art; tests prove that the benzopyrene content in the product can not be detected, the decoration effect is excellent, and the cake residual oil is reduced from original 10-12% to 7-9%.

Owner:JINPING SHIWEITIAN AGRI PROD CO LTD

Activated carbon loaded iron-cobalt oxide catalyst and application thereof in degrading organic pollutants

InactiveCN102500376AEasy to prepareLow priceWater/sewage treatment with mechanical oscillationsWater contaminantsActivated carbonPtru catalyst

The invention relates to an activated carbon loaded iron-cobalt oxide catalyst of which the components and content in weight percentage are that: 80.0 percent to 99.0 percent of activated carbon and 1.0 percent to 20.0 percent of iron-cobalt bi-metal oxide, wherein the cobalt and iron mole ratio is 1:1 to 1:19. The catalyst is integrated with ultrasonic wave and persulfate, and is used for treating organic wastewater. The catalyst and the persulfate are used for treating the organic wastewater with azo dye orange II as a target pollutant, and the decolorization rate reaches 74.5 percent within 30min; after the ultrasonic wave is added, the decolorization rate can be improved to 81.2 percent within 30min, and the total organic carbon (TOC) removal rate can reach 43.4 percent. The catalyst has the advantages of high catalytic efficiency and low metal ion dissolution rate. The catalyst is integrated with the ultrasonic wave and the activated persulfate to treat the organic pollutants in the wastewater, the treatment is carried out under milder conditions, the method is simple, the cost is low and the treatment effect is good.

Owner:WUHAN UNIV

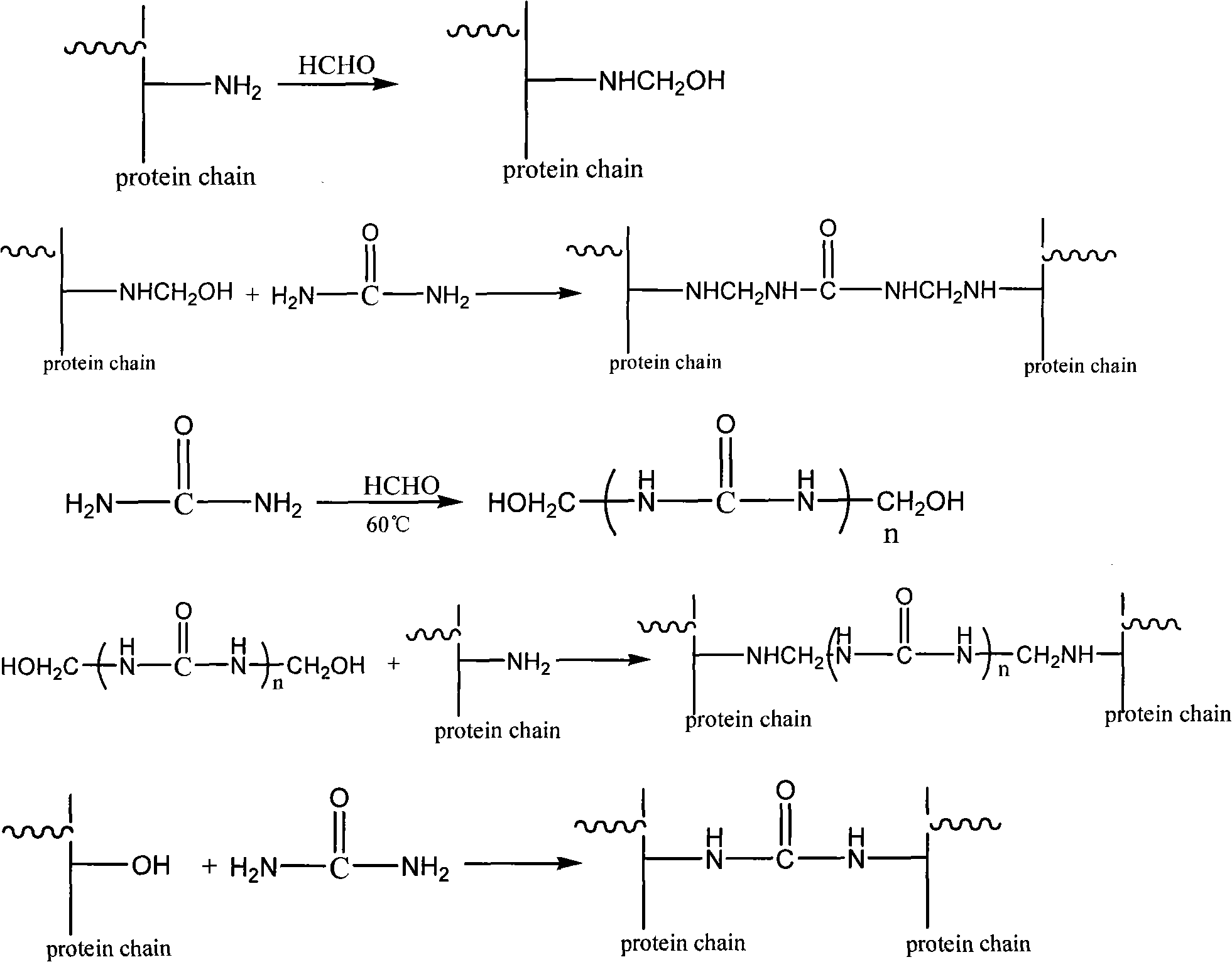

Protein flocculant for treating printing and dyeing wastewater

InactiveCN102115239AHigh decolorization rateReduce dosageWater/sewage treatment by flocculation/precipitationWater dischargeProtein molecules

The invention discloses a protein flocculant for treating printing and dyeing wastewater. The protein flocculant for treating the printing and dyeing wastewater is prepared from various animal protein powders originating from cheap waste animal pelts, hoofs, animal fur powders and bean pulps aiming at different groups in a protein molecule and a chemical modifier for reaction. The invention simultaneously provides a protein flocculant compound. The invention provides a simple and practicable method; and by utilizing the method, various dye waste waters discharged in printing and dyeing plants and dye production plants can be effectively treated, and the product cost is cheap.

Owner:中国中化股份有限公司 +1

Printing and dyeing waste water treatment process

InactiveCN106630472AEasy to handleEasy to trainSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsExisting TreatmentWastewater

The invention discloses a printing and dyeing waste water treatment process, and solves the problem the existing treatment effects of the printing and dyeing waste water are not good. The printing and dyeing waste water treatment process comprises the steps that 1, in the pretreatment process, impurities in the waste water are removed, and the decoloration process is conducted to a certain degree, and loads of subsequent treating processes are reduced; 2, in the biochemical treatment process, organic pollutants in waste water are degraded; 3, in the advanced treatment process, the impurities, the organic pollutants and chroma in the waste water are further removed. The problems in the prior art are well solved by the above scheme.

Owner:四川亿龙环保工程有限公司

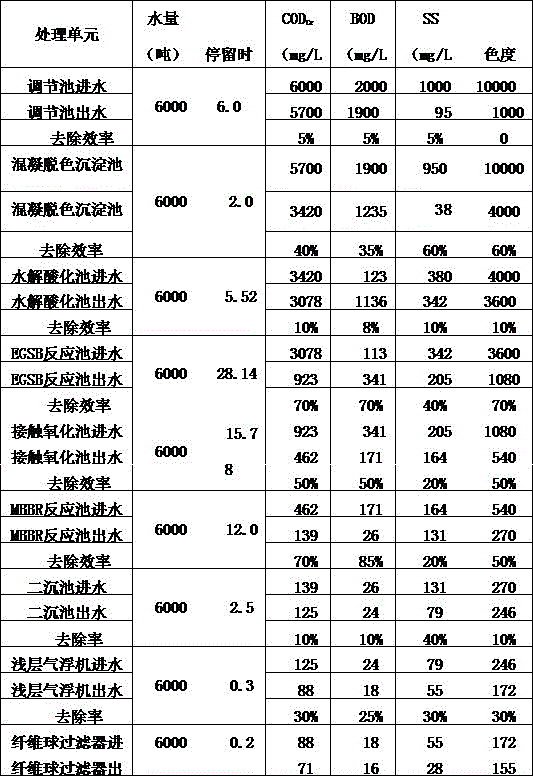

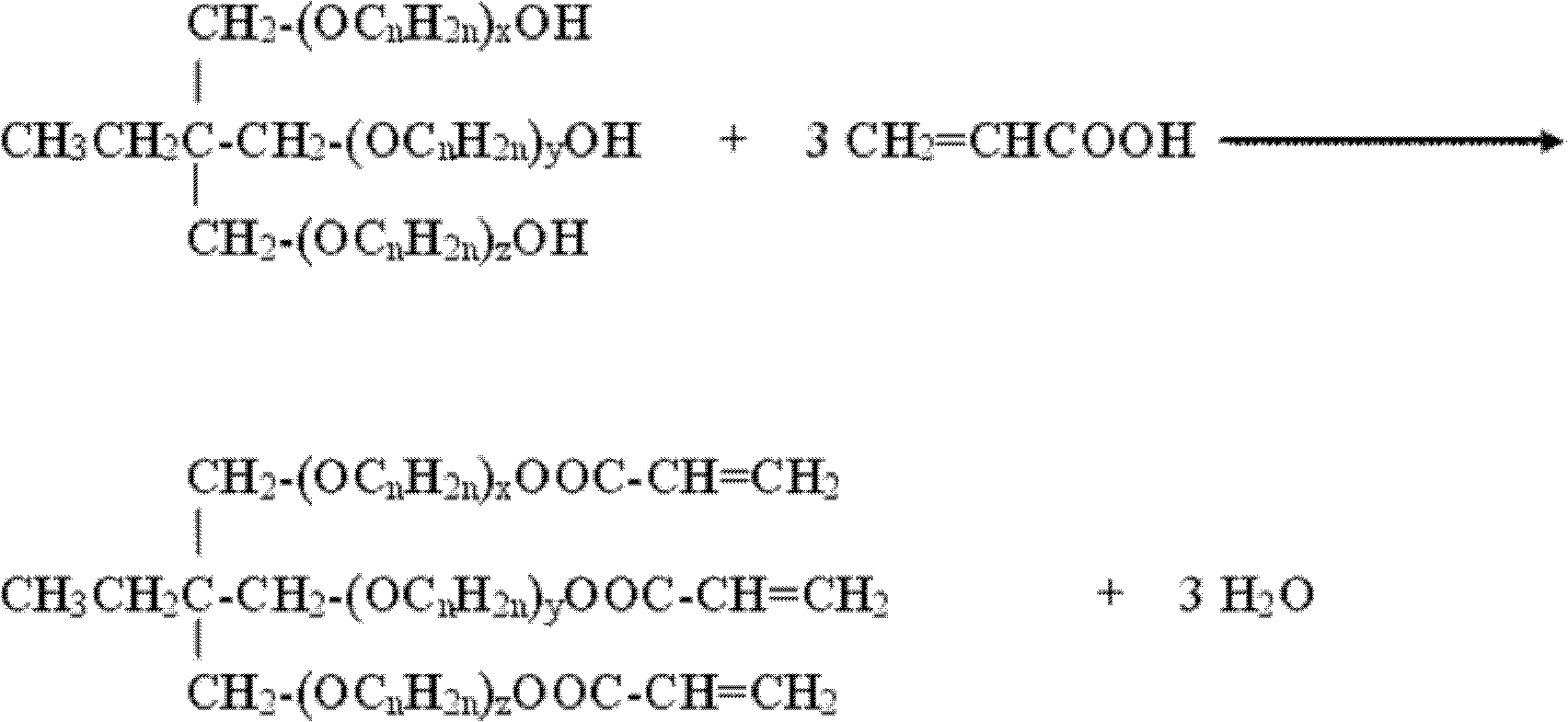

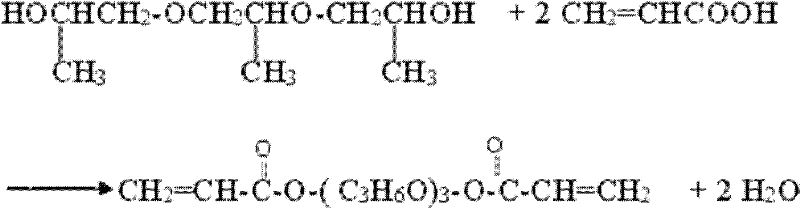

Clean production method of alkoxylation glycerol triacrylate

ActiveCN102503821ANo emissionsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSodium BentoniteAntioxidant

The invention belongs to the field of photocuring materials and relates to a clean production method of alkoxylation glycerol triacrylate. The method comprises the following steps that: (1) ethoxylation glycerol / propoxylation glycerol, acrylic acid, catalysts, solvents, polymerization inhibitors and antioxidants are subjected to esterification backflow dehydration; (2) soda flakes and a small quantity of water are added for neutralization; (3) magnesium polysilicate absorbing agents are added for absorbing salt generated during the neutralization; (4) the pressure reduction dehydration is carried out, and solvents are removed; (5) press filtering is carried out, and the magnesium polysilicate and the salt absorbed by the magnesium polysilicate are filtered away; (6) alkaline calcium bentonite and calcium bentonite are added, and decoloration, trace moisture removal and trace acid removal are carried out; (7) press filtering is carried out; and (8) product index detection is carried out. The method belongs to the high-yield clean production method of the ethoxylation glycerol triacrylate and propoxylation glycerol triacrylate and has the advantages that economic benefits and environment benefits are realized, and the problem of organic waste water pollution in the production process of the ethoxylation glycerol triacrylate and the propoxylation glycerol triacrylate is fundamentally solved.

Owner:JIANGSU LITIAN TECH

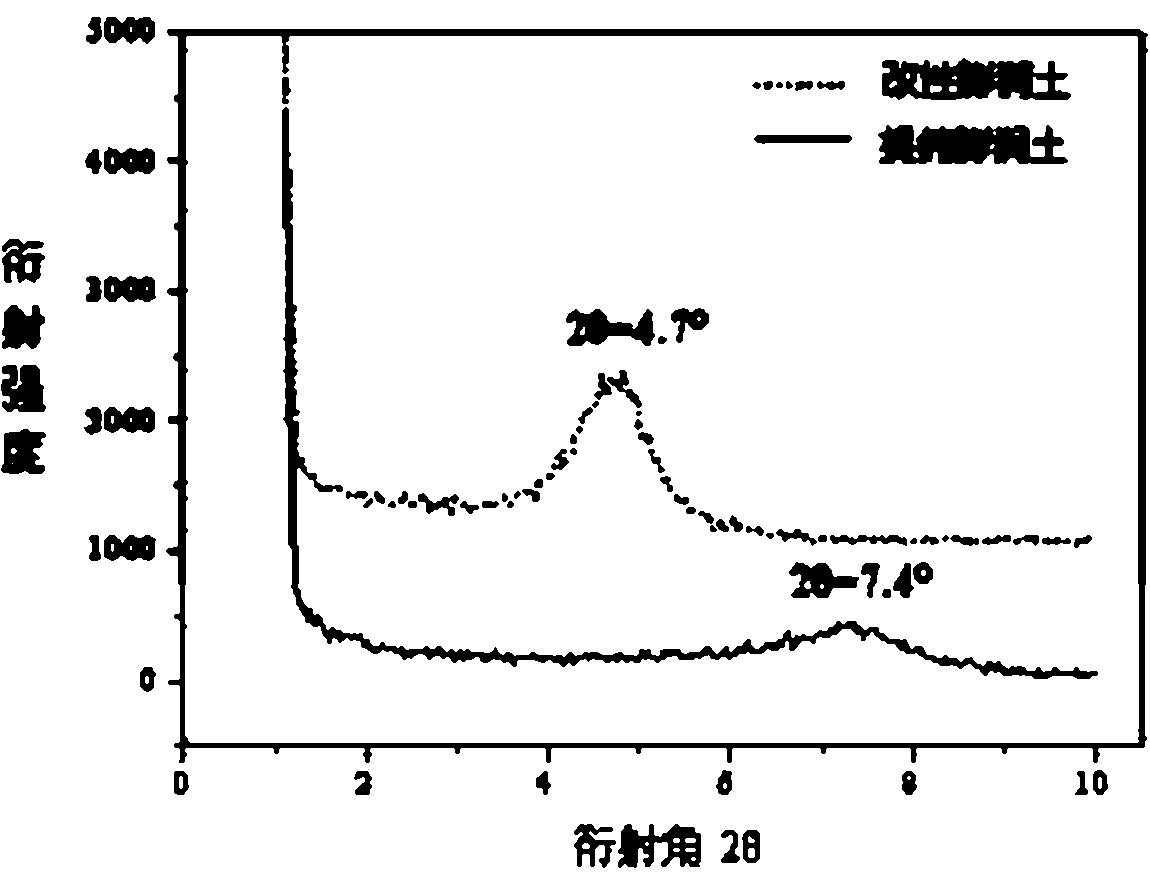

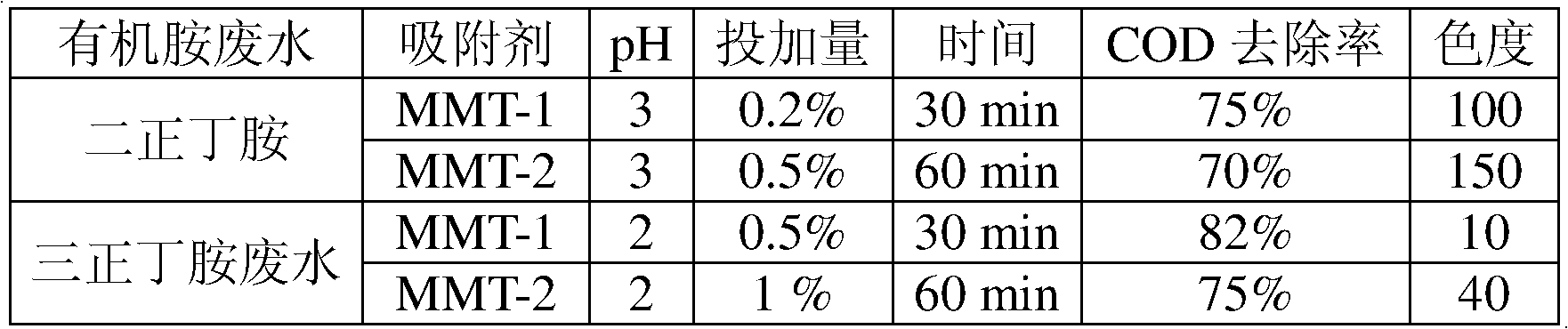

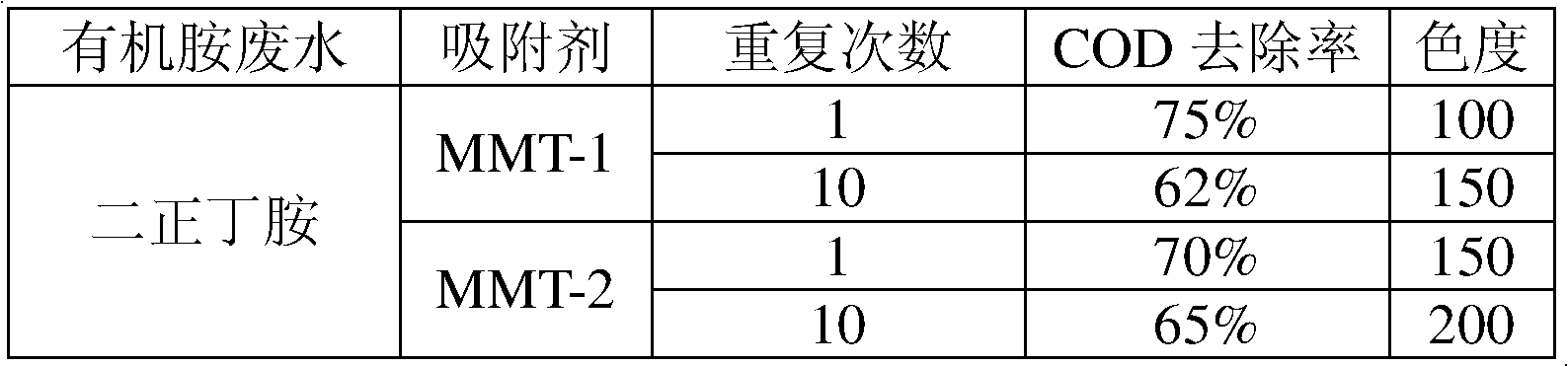

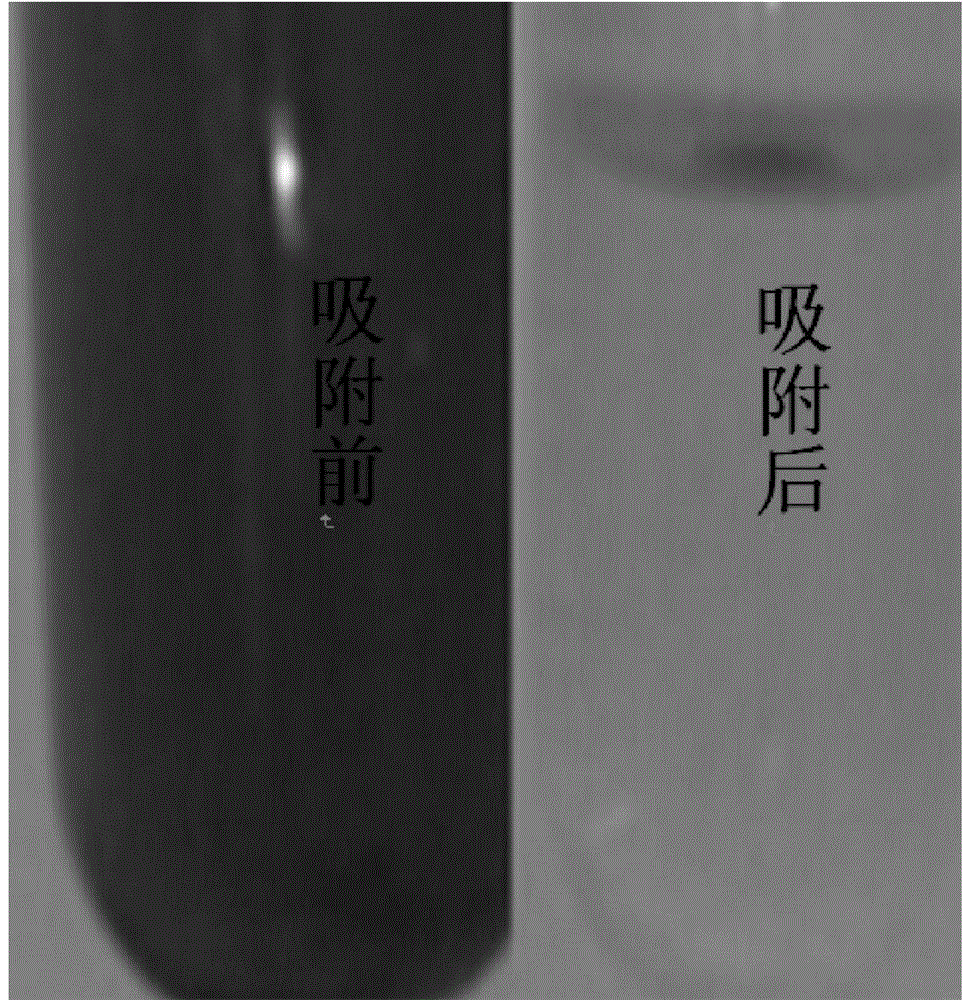

Organic wastewater modified bentonite adsorbent and preparation method thereof

InactiveCN102151544ADecolorization reachedIncrease the interlayer spacingOther chemical processesWater contaminantsSorbentWastewater

The invention discloses an organic wastewater modified bentonite absorbent and a preparation method of the absorbent. The preparation method comprises the following steps: taking organic amine type of pollutants in organic wastewater as modifying agents, taking purified bentonite powder as raw materials, adding the purified bentonite powder into the organic amine type of wastewater to agitate for 10-120 minutes at the normal temperature, and then filtering to obtain an organic wastewater modified bentonite filter cake; drying and grinding the organic wastewater modified bentonite filter cake under the condition of 90-105 DEG C to obtain organic wastewater modified bentonite, then placing the organic wastewater modified bentonite into a muffle furnace for roasting, and cooling to the normal temperature to obtain the organic wastewater modified bentonite adsorbent. The organic wastewater modified bentonite adsorbent and the preparation method have the advantages that firstly, the pollutants in the wastewater are taken as the modifying agents to realize the effect of treating the wastes with the wastes; secondly, the modification time is short; thirdly, the pollutant removal efficiency is high, and the decoloring effect is remarkable; fourthly, the solid-liquid separation is quick; and fifthly, the processing cost is low.

Owner:HUNAN CHEM RES INST

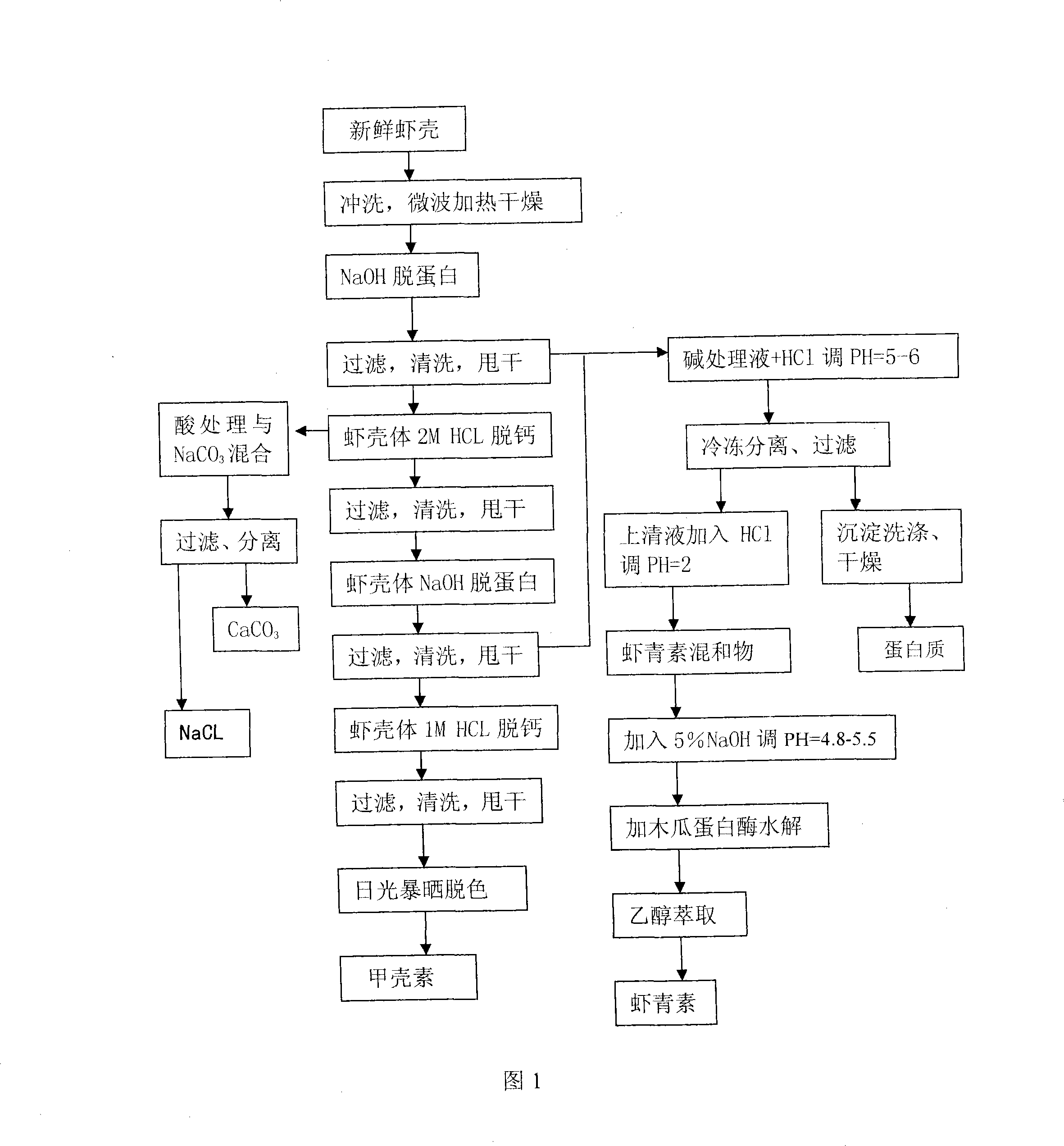

Low energy- wasting and environment protection method for extracting chitin as well as biologically active substance thereof from shrimp shell

InactiveCN101176549AImprove freshnessIncrease profitCalcium/strontium/barium carbonatesOrganic chemistryShrimpMicrowave oven

The invention relates to a low-consumption and environment-protection method for extracting chitin and bioactive substances from shrimp shell, which comprises the steps that: the fresh shrimp shell is arranged in a microwave oven for heating, then is arranged in the NaOH solution and boiled for 1 to 2 hours, then is immersed in the HCI solution for immersion; the shrimp shell is treated again with the NaOH solution, and is arranged in the sunshine and heavily sunned for decoloration after immersed in the HCI solution, thus the chitin product is obtained; when protein powder is extracted, protein is separated from the alkali treatment solution through the physical process of freezing and thawing; and when astaxanthin product is extracted, papain is adopted for degradation, then astaxanthin is obtained through ethanol extraction. The invention has the advantages of high material utilization ratio of shrimp shell, less acid and alkali consumption, less dosage of organic solvent, complete separation of various useful substances in shrimp shell, high purity of the obtained product, no discharge of waste acid, waste alkali and harmful organic solvent during reaction process, and effective use of various treatment solutions generated during reaction.

Owner:湖北东方天琪生物工程股份有限公司

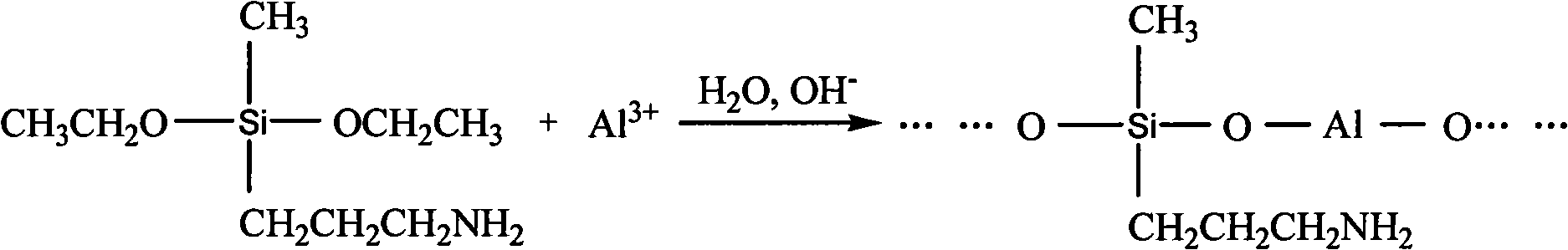

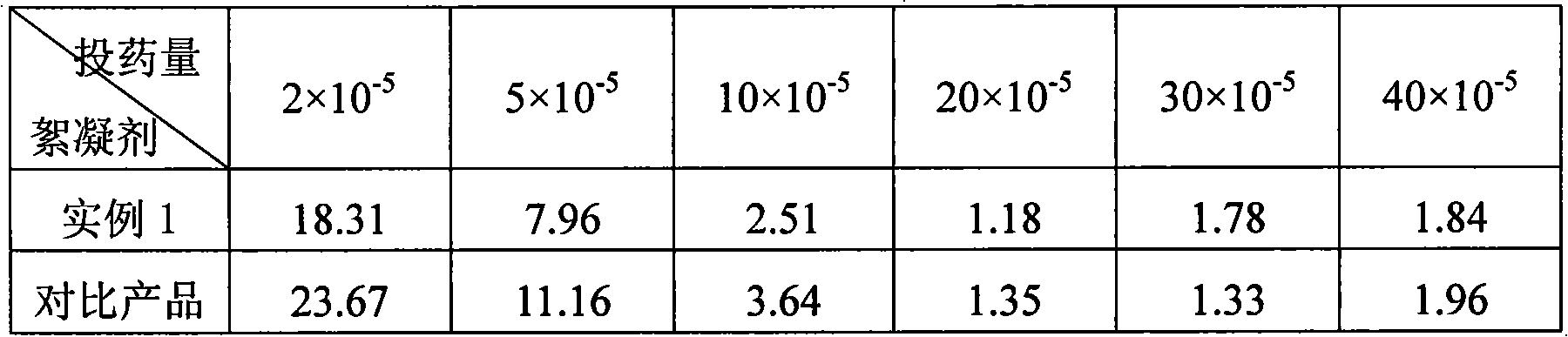

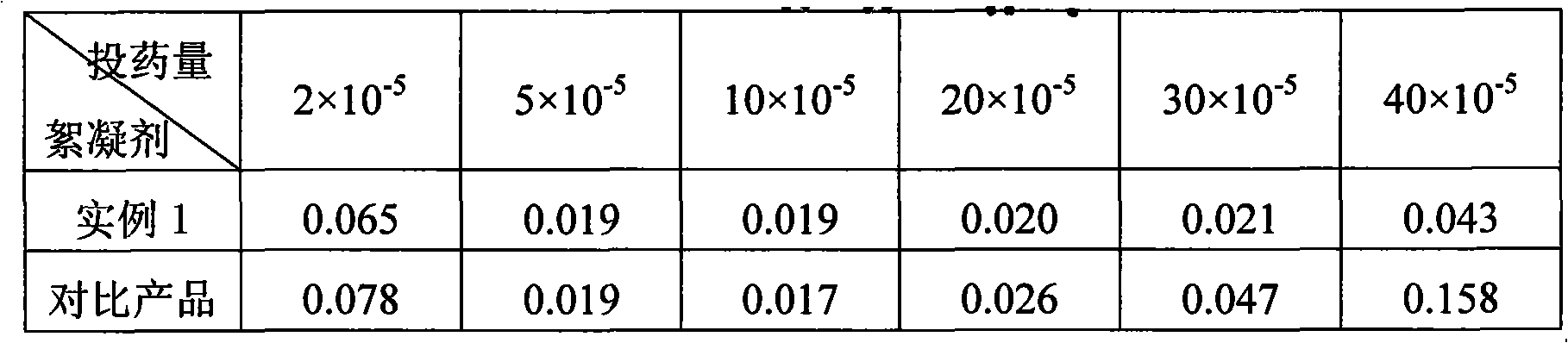

Covalent bond type inorganic organic composite flocculant, preparation process and use thereof

ActiveCN101298347AAchieve compositeGood decolorization effectWater/sewage treatment by flocculation/precipitationSimple Organic CompoundsAluminium chloride

The invention relates to a covalent bond type inorganic / organic compound flocculant, a production technique and an application thereof. The invention adopts Gamma-APDES (gamma-Aminopropylmethyldiethoxysilane) and aluminum chloride solution as the raw materials to produce the covalent bond type inorganic / organic compound flocculant by gradually dripping alkaline. The a covalent bond type inorganic / organic compound flocculant, the production technique and the application thereof have the advantages that the inorganic constituent and the organic constituent in the flocculant are bonded by covalent bond, which has good stability, good turbidity removal and decoloration effect and wider optimal dosing range. The covalent bond type inorganic / organic compound flocculant can be used for the water purification and the turbidity removal, decoloration, deoiling and solid-liquid separation during the wastewater treatment.

Owner:PEKING UNIV

Silicone rubber pyrolysis recycling process

InactiveCN104017366AHigh hardnessImprove recycling efficiencyPlastic recyclingMechanical material recoveryPolymer scienceSilicone rubber

The invention discloses a silicone rubber pyrolysis recycling process. According to the technical scheme disclosed by the invention, the process is characterized by comprising the following steps: smashing organic silicone wastes; carrying out pyrolysis, polymerization rearrangement as well as decoloration and odor removal on the organic silicone wastes; and processing a finished product so as to obtain a simethicone product. The process is relatively high in recycling efficiency and realizes reduction in environmental pollution.

Owner:任炳陵

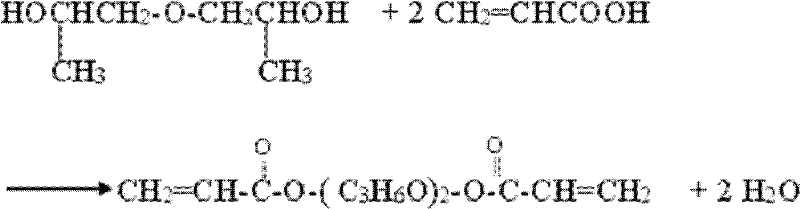

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolDipropylene glycol diacrylate

The invention which belongs to the light-cured material field relates to a clean production method of DPGDA or TPGDA. The method concretely comprises the following steps: 1, carrying out esterification reflux dehydration on dipropylene glycol / tripropylene glycol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; 2, adding sodium hydroxide and a small amount of water to neutralize; 3, adding a magnesium polysilicate adsorbent to adsorb a salt generated through neutralization; 4, carrying out reduced pressure dehydration and desolventization; 5, press-filtering to filter out magnesium polysilicate and the salt absorbed thereby; 6, adding alkaline calcium bentonit and calcium oxide to decolor, remove trace water and remove trace acids; 7, press-filtering; and 8, carrying out product index detection. The clean production method of the DPGDA or the TPGDA of the invention, which has the advantages of high yield, economic benefit possessing and environmental benefit possessing, fundamentally solves an organic wastewater pollution problem in the production process of the DPGDA or the TPGDA.

Owner:JIANGSU LITIAN TECH

Compound water treatment agent based on ferrate and preparation method of compound water treatment agent

ActiveCN105923735AHigh yieldIncrease profitWater treatment compoundsWater/sewage treatment by flocculation/precipitationSludgePotassium hydroxide

The invention discloses a compound water treatment agent based on ferrate and a preparation method of the compound water treatment agent, and belongs to the field of industrial wastewater treatment. The compound water treatment agent is prepared from the following raw materials: 18-20 parts of sodium hydroxide, 15-20 parts of potassium hydroxide, 10-15 parts of sodium hypochlorite, 15-18 parts of ferric nitrate, 1-3 parts of copper chloride, 30-35 parts of ethylene diamine tetraacetic acid and 18-20 parts of calcium chloride. The prepared water treatment agent is good in stability and high in oxidability, has the characteristics that the oxidizing capacity is continuous, the decolourising property is good, the pH application range is wide, the added amounts of acid, base and chemicals are small, sludge is unlikely to float and the content of ferric salt in the sludge is relatively low, and has adsorption and flocculent precipitation performance, so that the heavy metals such as Cd, Cr and Pb in industrial wastewater can be effectively removed, and the biodegradability of the wastewater is greatly improved.

Owner:NANJING UNIV

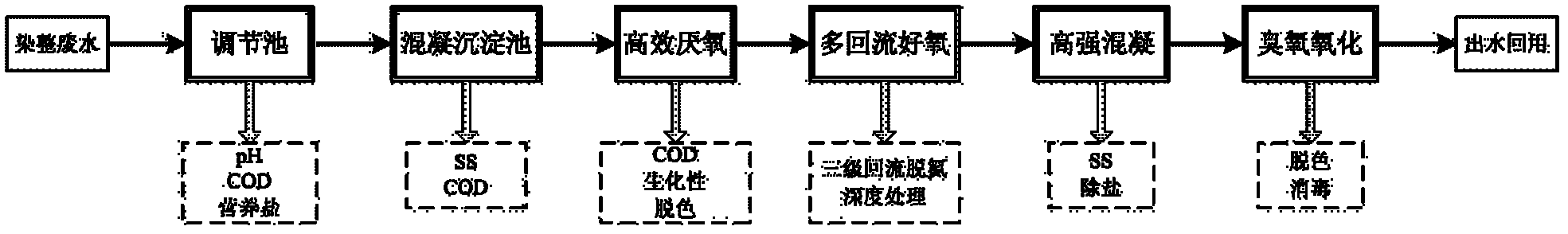

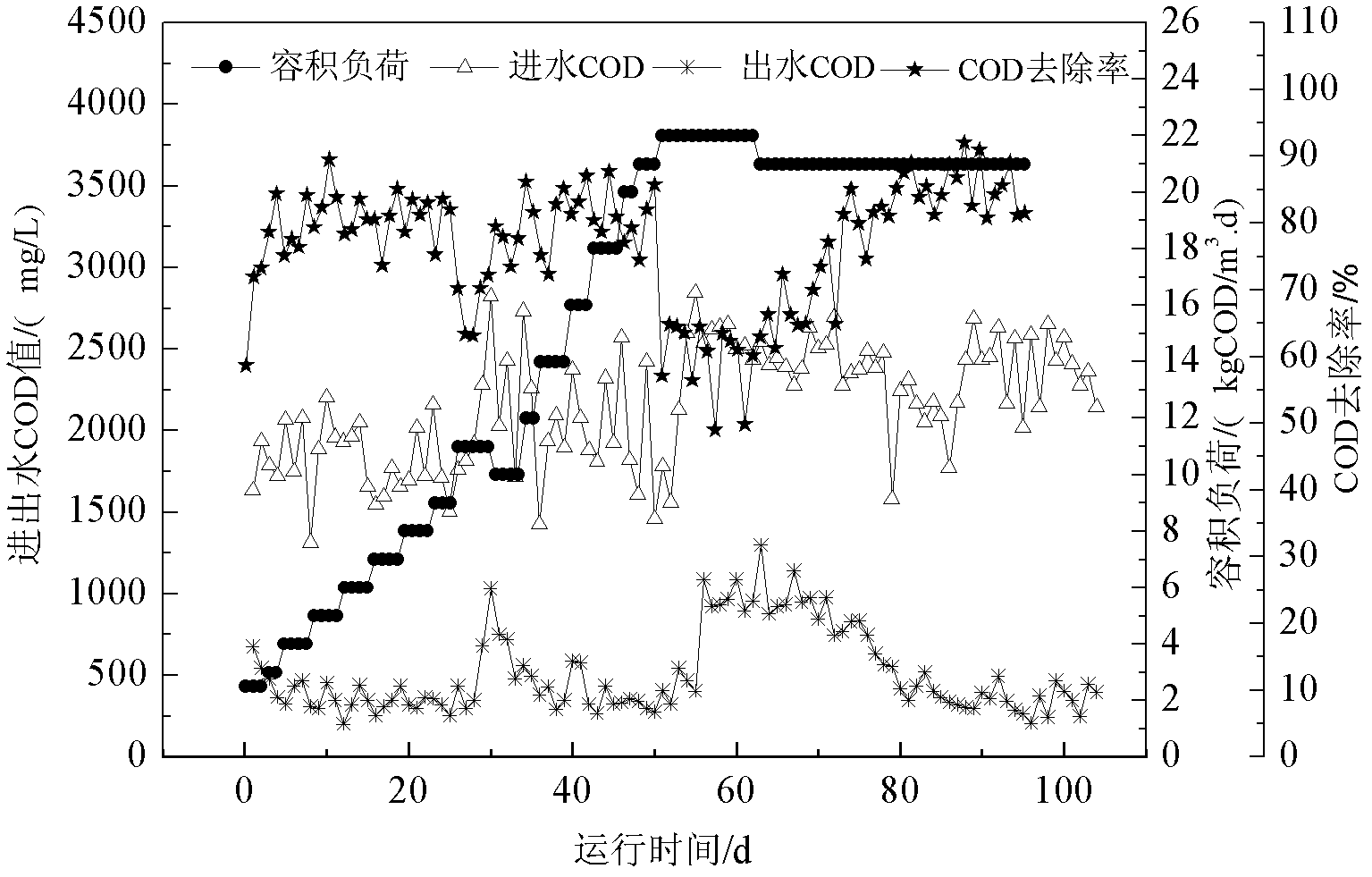

Method for recycling textile dyeing and finishing wastewater

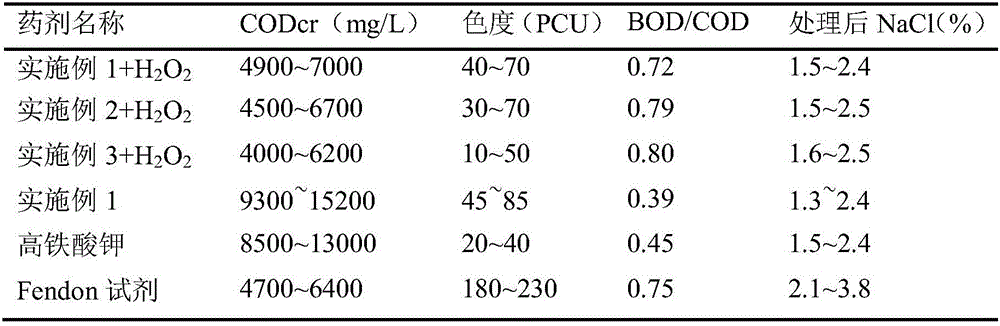

ActiveCN102190412AGood effect of energy saving and emission reductionTargetedTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentAerobic treatment systemWater quality

The invention discloses a method for recycling textile dyeing and finishing wastewater, which comprises the following steps of: regulating the pH of the textile dyeing and finishing wastewater in a regulating tank to be 7.0 by using acidic solution, performing coagulative precipitation in a coagulative precipitation tank by using an inorganic flocculating agent, and performing anaerobic treatmentin a high-efficiency anaerobic reactor; performing anaerobic / anoxic and aerobic circulation treatment in a multi-stage circulation aerobic treatment system, wherein the multi-stage circulation aerobic treatment system consists of anaerobic / anoxic reaction tanks A and aerobic reaction tanks O in an A-O-A-O-A-O-A staggered series connection mode; performing coagulative precipitation in a high-efficiency air floatation coagulative precipitation tank; and performing ozone oxidation and disinfection in an ozone oxidation tank to obtain recycled water. Compared with the conventional physical-chemical method, the technology has the advantages that: operating cost is obviously reduced, and over 30 percent of economic benefit is achieved. The quality of the treated water is high, and 70 percent ofrecycling rate can be achieved.

Owner:JIANGSU SHANGDA WATER AFFAIR

Paenibacillus and application thereof to environmental engineering

InactiveCN101870958AImprove fermentation yieldEasy to pick upBacteriaMicroorganism based processesIonChemistry

Owner:THE INST OF MICROBIOLOGY XINJIANG ACADEMY OF AGRI SCI

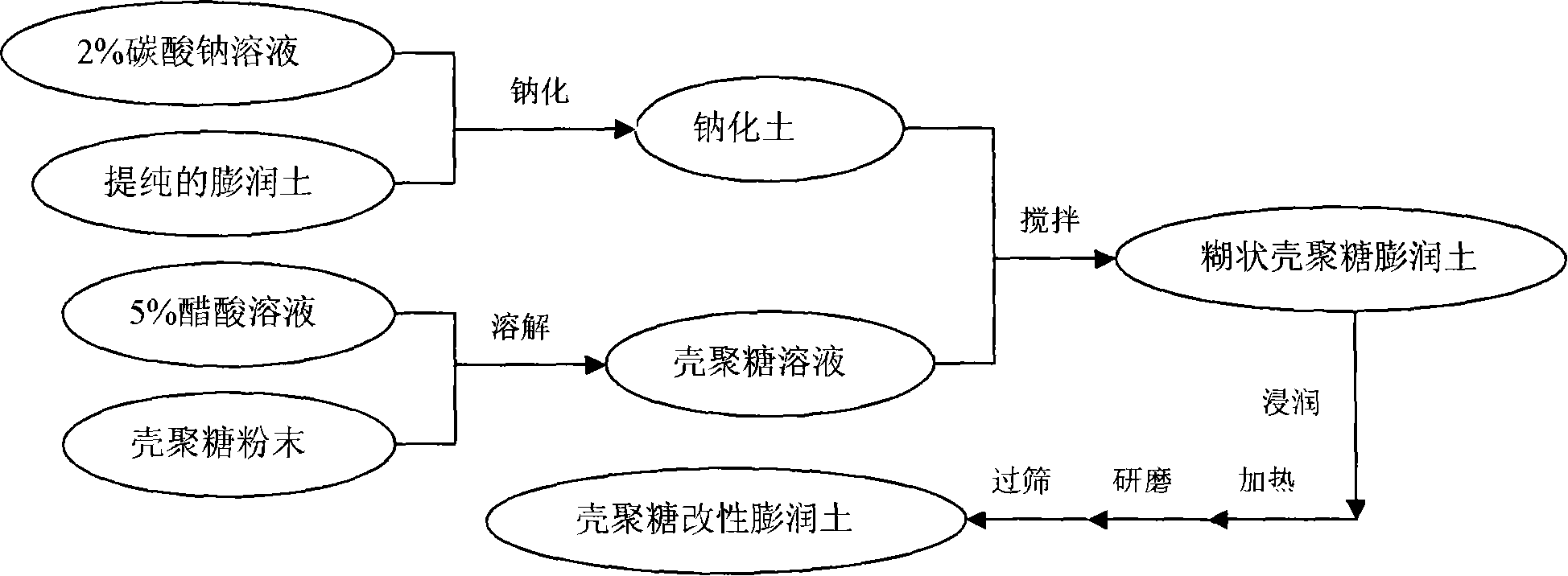

Environment-friendly modified bentonite and preparation method thereof

The invention discloses an environment-friendly modified alta-mud and making method, which comprises the following steps: adopting natural polysaccharide without toxicity and harm such as chitosan as modifier to modify sodium-based alta-mud; disposing original mud; allocating chitosan acetic solution; weighing 50-60ml chitosan solution with density at 0. 5-1. 0% and diacetyl degree at 90%; allocating 50g alta-mud into paste-shaped material; stewing; infiltrate the alta-mud completely; placing the paste-shaped material into microwave oven; heating to dry; grinding finely; sieving in the screen at 0. 16mm; obtaining the product with low price, good property and environment friendly without any polluting; fitting for disposing industrial waste water, manufacturing drug and food industry.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY +1

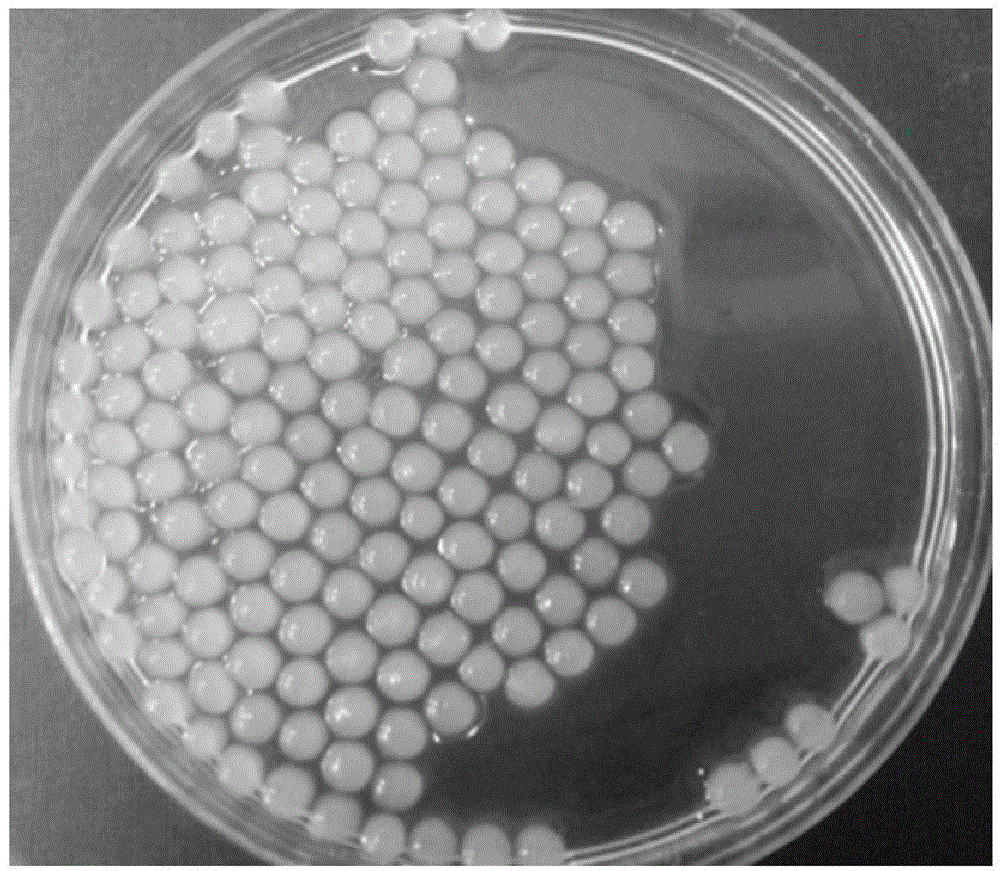

Cellulose/chitosan composite pellet as well as preparation method and application thereof

InactiveCN104530449AWide variety of sourcesNo pollution in the processIon-exchange process apparatusOther chemical processesCelluloseSmoked Plum

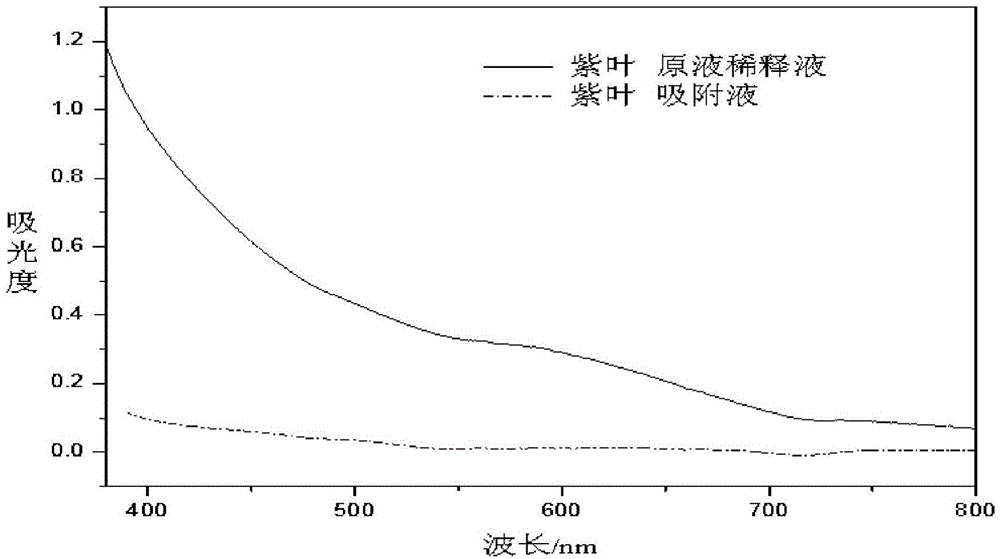

The invention belongs to the field of natural high polymer material preparation and application, discloses a cellulose / chitosan composite pellet as well as a preparation method thereof and an application thereof in traditional liquid medicine discoloring. The preparation method for the cellulose / chitosan composite pellet comprises the following steps: by taking an ionic liquid as a solvent, respectively dissolving the cellulose and the chitosan into the solvent, heating and stirring until the cellulose and the chitosan are completely dissolved; then, mixing a cellulose dissolved solution with a chitosan dissolved solution, heating and cross-linking until the mixed solution is changed into a light yellow and uniform liquid; dropwise adding the mixed solution into a coagulating bath drop by drop, thereby obtaining a gel-state composite pellet; soaking the gel-state composite pellet, taking out and washing the soaked gel-state composite pellet to obtain a product cellulose / chitosan composite pellet. The preparation method disclosed by the invention is cheap in whole reaction process, easy to perform and environmentally friendly; the obtained cellulose / chitosan composite pellet has a good adsorption effect on pigments in an aqueous extract solution of Chinese herbal medicines such as purple leaves, momordica grosvenori, smoked plums and honeysuckles, and has a wide application prospect in the purifying field of the Chinese herbal medicine liquid.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing high-quality fine lacquer wax product

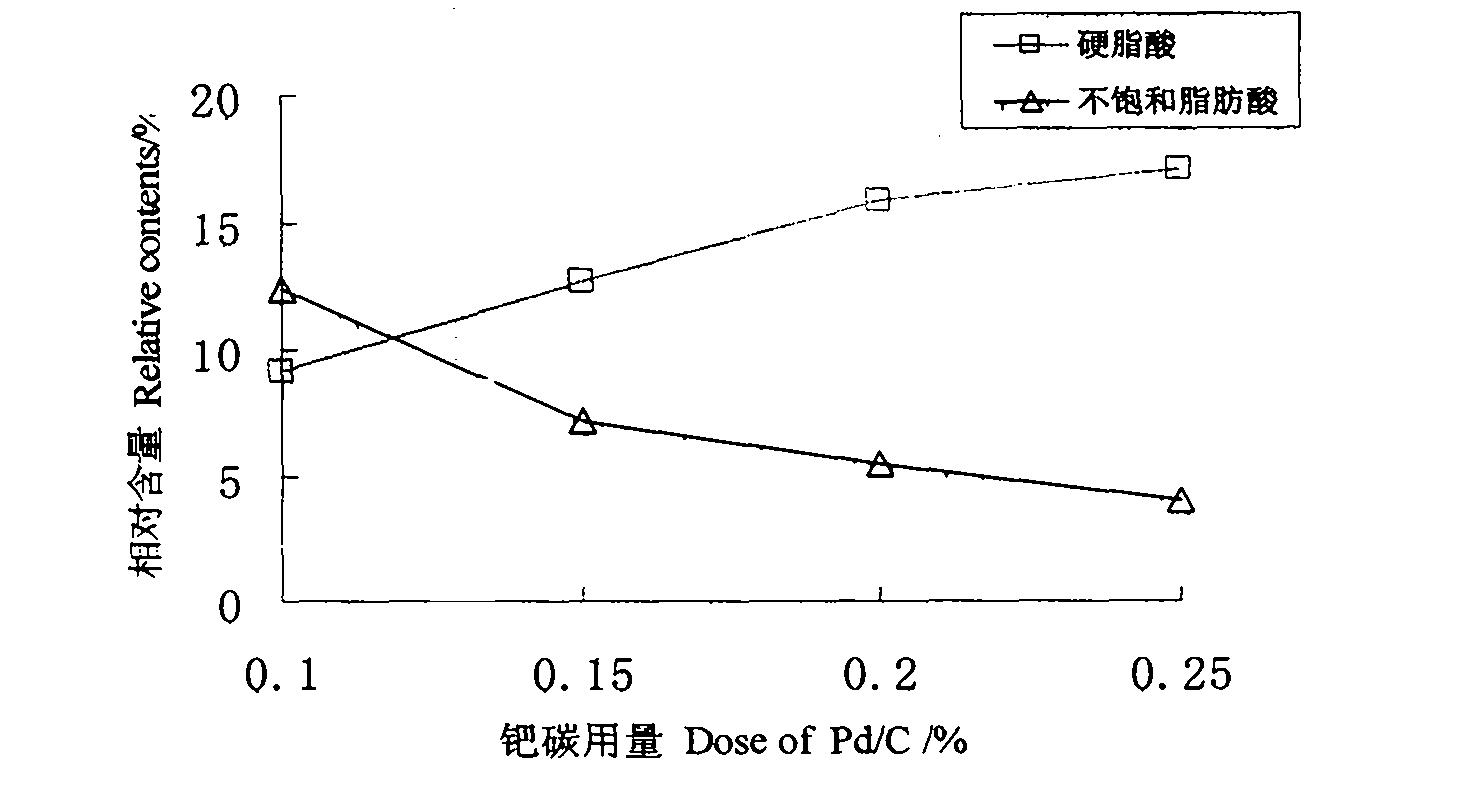

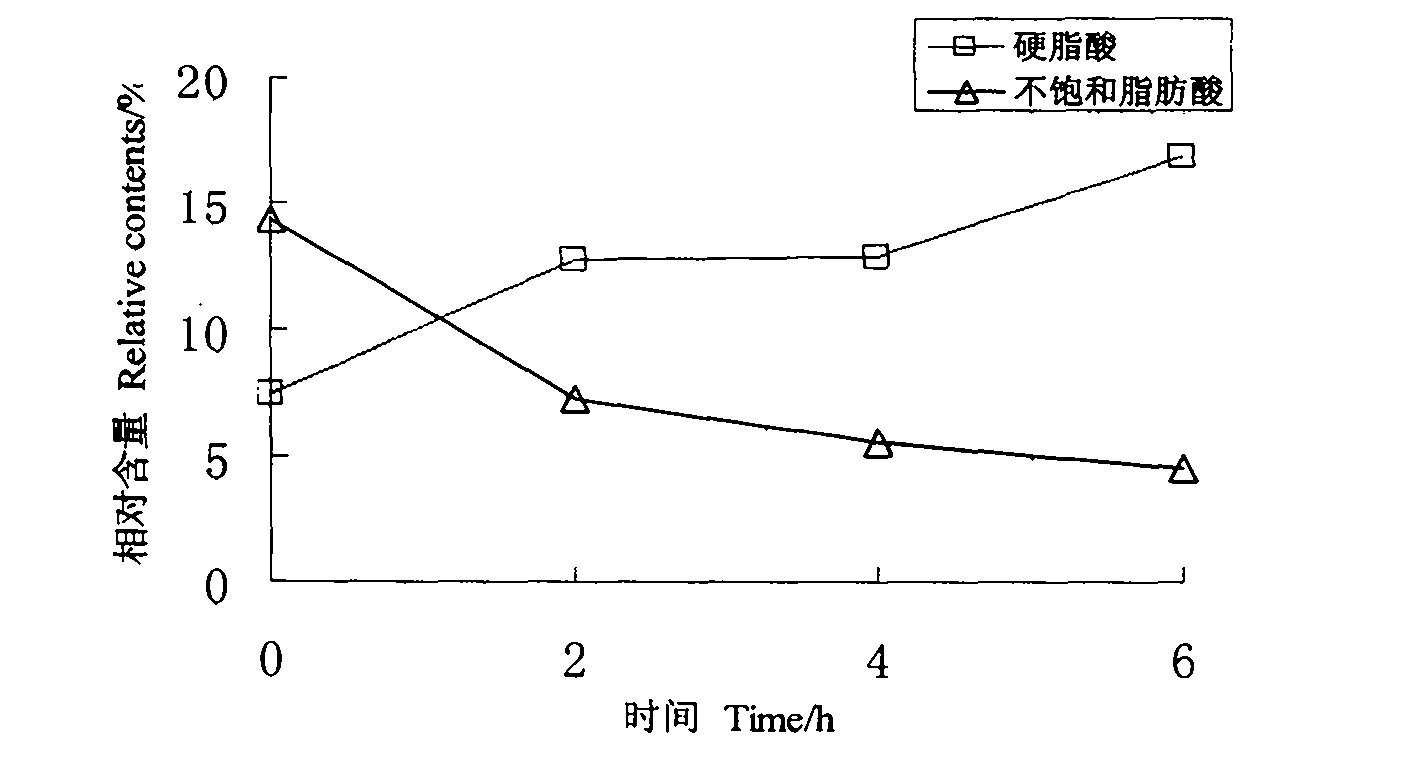

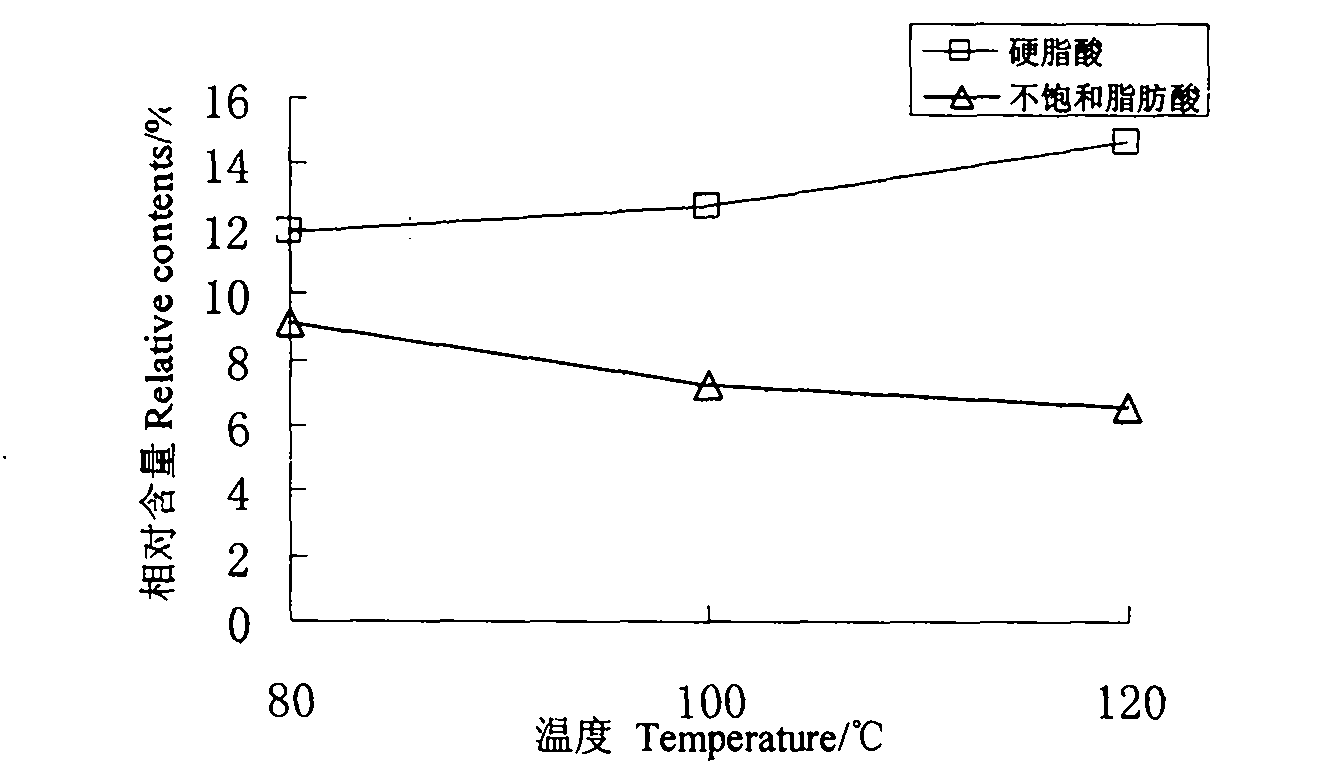

ActiveCN102329693APrevent mildewReduce moisture contentFatty substance recovery/refiningFatty substance recoveryPalladium on carbonLacquer

The invention discloses a method for preparing high-quality fine lacquer wax product, which comprises the following steps of: firstly, microwave drying lacquer seeds, separating skin and cores, and lixiviating the skin and flesh part of the lacquer seeds by using a non-polar solvent to obtain rough lacquer wax; heating and uniformly mixing the lacquer wax and a certain proportion of Pd / C catalyst in a high-temperature high-pressure reactor, charging hydrogen gas and maintaining a certain hydrogen gas pressure for reaction; after the reaction is completed, and filtering and discoloring the product while hot to obtain highly saturated lacquer wax; and detecting the variation of fatty acid content in the lacquer wax, by using gas chromatography. The method is simple and convenient, and the problems of low lacquer wax melting point, easy rancidity and the like caused by high content of unsaturated fatty acid in rough lacquer wax can be effectively solved. The obtained hydrogenated fine lacquer wax product has similar physical and chemical properties to Star Cherry-A white wax processed by Japan Araki Wax Manufacturing Company and can be widely applied to the field of daily chemicals.

Owner:NANJING ZHONGSEN BIOLOGICAL TECH CO LTD

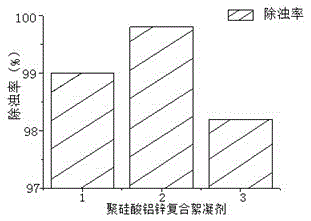

Aluminum-zinc polysilicate composite flocculating agent and application thereof

InactiveCN105984929AImprove adsorption bridging effectGood decolorization effectWater/sewage treatment by neutralisationWater/sewage treatment by flocculation/precipitationTurbiditySODIUM SILICATE SOLN

The invention discloses an aluminum-zinc polysilicate composite flocculating agent and application thereof. Sodium silicate solution and excessive sulfuric acid are mixed with each other to prepare polysilicate solution, zinc sulfate and aluminum sulfate solution, polyacrylamide, calcium hydroxide and sodium hypochlorite are sequentially added into the polysilicate solution, and reaction is carried out to obtain the aluminum-zinc polysilicate composite flocculating agent. The aluminum-zinc polysilicate composite flocculating agent and the application have the advantages that the aluminum-zinc polysilicate composite flocculating agent can be applied to the field of water treatment, accordingly, excellent effects of removing colors, turbidity and carbon can be realized, coagulated floc particles are large, the aluminum-zinc polysilicate composite flocculating agent is high in floc settling velocity, excellent net capturing effects can be realized, and the excellent effects of removing the colors and the turbidity can be realized; raw materials for the aluminum-zinc polysilicate composite flocculating agent can come from wide sources, the aluminum-zinc polysilicate composite flocculating agent is easy to prepare and can be widely applied to the field of wastewater from dyeing and printing and papermaking industries and the like and the field of advanced municipal sewage treatment, and the like.

Owner:NANJING UNIV +1

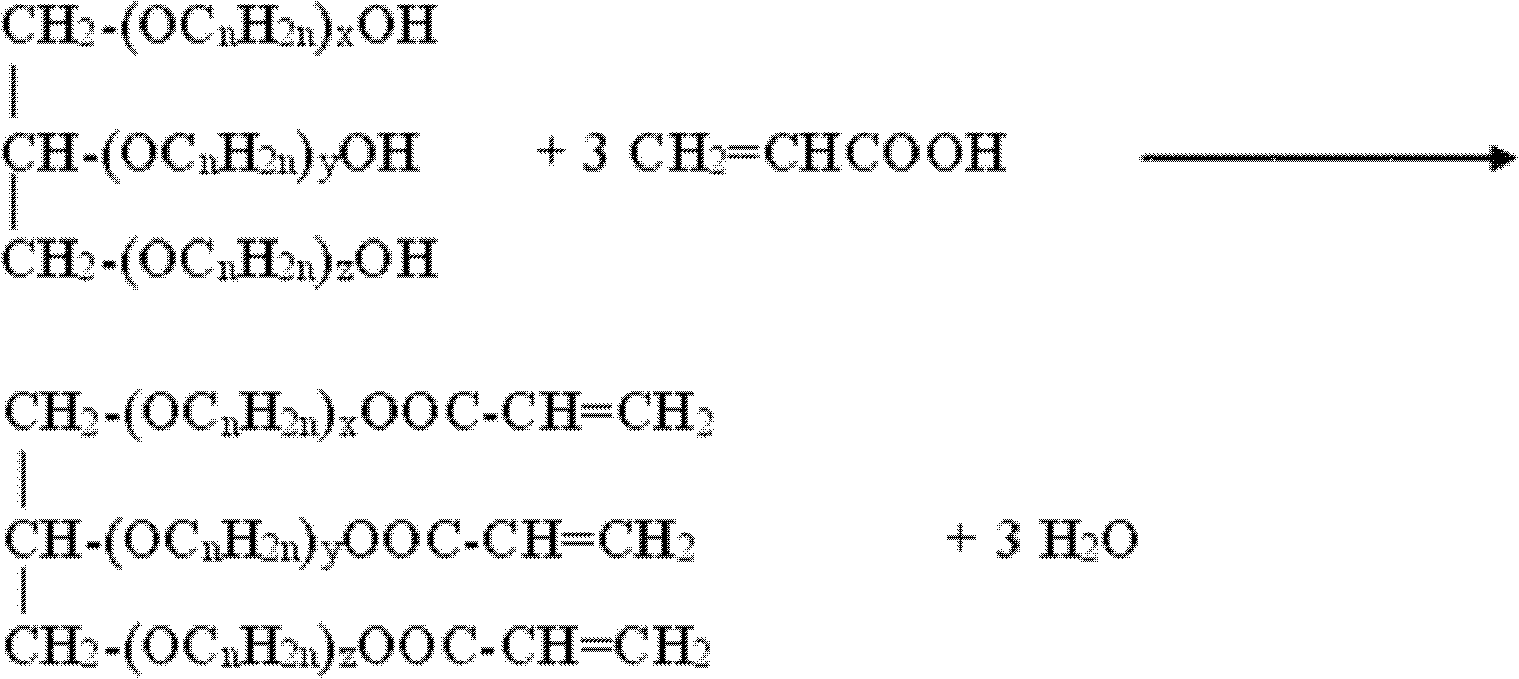

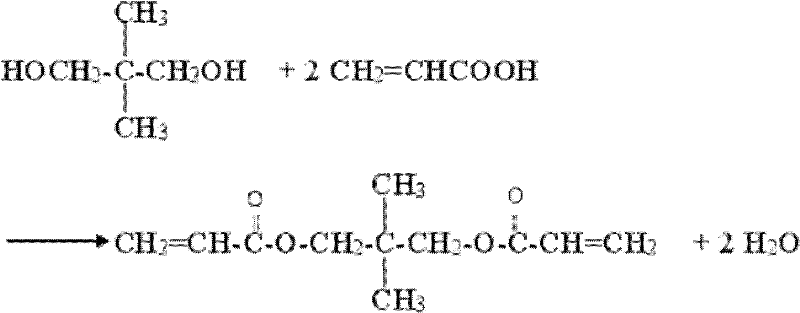

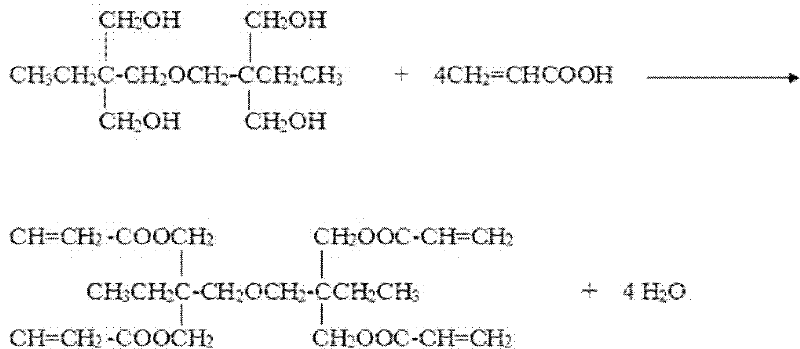

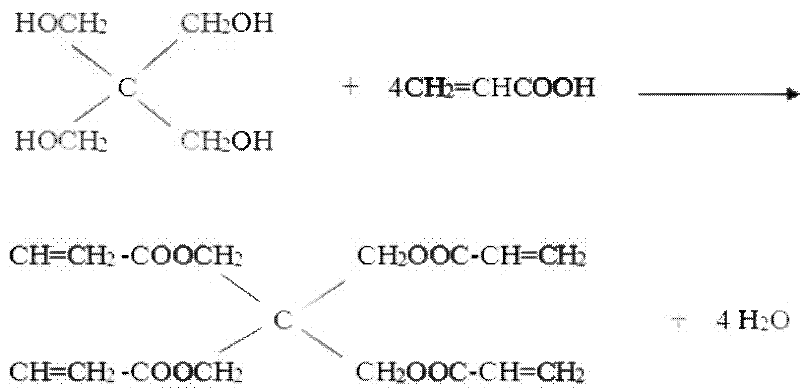

Cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester

ActiveCN102643197ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters separation/purificationSorbentSolvent

The invention belongs to the field of photo-curing material, and relates to a cleaning production method for di-trimethylolpropane tetra-acrylic ester or pentaerythritol tetra-acrylic ester. The method specifically comprises the following steps of: (1) dehydrating di-trimethylolpropane / pentaerythritol, crylic acid, catalyst, solvent, polymerization inhibitor and antioxygen by means of esterification and backflow; (2) adding sheet alkali and a small quantity of water to neutralize; (3) adding magnesium polysilicate adsorbent to adsorb and neutralize the generated salt; (4) dehydrating in a pressure reducing way, and removing solvent; (5) carrying out filter pressing, filtering out the magnesium polysilicate and salt adsorbed by the magnesium polysilicate; (6) adding alkaline calcium bentonite and calcium oxide, to remove color, trace moisture and trace acid; (7) carrying out filter pressing; and (8) detecting the indexes of a product. The invention belongs to a cleaning production method for the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester, which is good in economic benefit and environmental benefit, so that the problem of organic waste water pollution when the di-trimethylolpropane tetra-acrylic ester or the pentaerythritol tetra-acrylic ester is produced can be basically solved.

Owner:JIANGSU LITIAN TECH

Extraction method of morindea officinalis polysaccharide

The invention provides an extraction method of morindea officinalis polysaccharide, belonging to the technical field of traditional Chinese medicines and solving the problems that in the existing morindea officinalis polysaccharide extraction method, the extraction method has complicated process steps and a poor protein removal effect, and the yield and purity of the obtained morindea officinalispolysaccharide are low. The extraction method of morindea officinalis polysaccharide in the invention comprises the following steps of: drying morindea officinalis rhizome and then smashing to 40-80 meshes; adding a chloroform / methanol mixed solvent in morindea officinalis powder for carrying out reflux extraction; carrying out alcohol extraction on a filter cake obtained by filtration and then adding water for lixiviation; subsequently, filtering and concentrating a filtrate, carrying out alcohol precipitation on a concentrated liquid and then filtering so as to obtain the crude morindea officinalis polysaccharide; adding the crude morindea officinalis polysaccharide into a n-butanol / trichloroacetic acid mixed solvent for processing, and entering a chromatographic column for elution; andcarrying out concentration, alcohol precipitation, filtration and drying on an effluent liquid so as to obtain the morindea officinalis polysaccharide. The extraction method of the morindea officinalis polysaccharide in the invention has a simple process and a good protein removal effect, and the extracted morindea officinalis polysaccharide has less impurities and high yield and purity.

Owner:朱孟勇

Preparation method of amino acid modified attapulgite clay palm oil decolorizing agent

ActiveCN103357377AGood decolorization effectImprove bindingOther chemical processesFatty-oils/fats refiningImpurityPalm oil

The invention discloses a preparation method of an amino acid modified attapulgite clay palm oil decolorizing agent. The preparation method comprises: inorganic acid activating treatment of attapulgite clay, amino acid modification of the attapulgite clay, after a certain reaction time filtering and impurity removing, solid-liquid separation, drying and baking, and crushing and sieving, and obtaining of the amino acid modified attapulgite clay palm oil decolorizing agent. The amino acid modified attapulgite clay palm oil decolorizing agent prepared by the preparation method not only has good decolorizing effect, but also can prevent the palm oil oxidation deterioration during storage, and improve the storage security.

Owner:中国科学院兰州化学物理研究所盱眙凹土应用技术研发中心

Ampholytic modified grafted starch flocculant

InactiveCN102250291AGood decolorization effectWater/sewage treatment by flocculation/precipitationFlocculationGraft reaction

The invention discloses an ampholytic modified grafted starch flocculant. The flocculant is characterized in that the preparation method comprises the following steps: under the action of an initiator, starch is used to perform a grafting reaction with an acrylic or vinyl sulfonate monomer the mass of which is 0.05-5 times that of starch to obtain an anionic starch graft polymer, and then the anionic starch graft polymer reacts with a cationic monomer the mass of which is 0.05-5 times that of starch to prepare the flocculant. The ampholytic modified grafted starch flocculant not only has the functions of coagulation and flocculation, but also has the decoloring effect and can be widely used in the industries such as petroleum, coal, sewage treatment, sludge dehydration and papermaking. In addition, the preparation method of the flocculant has the advantages of simple method, high productivity and the like.

Owner:何善媛

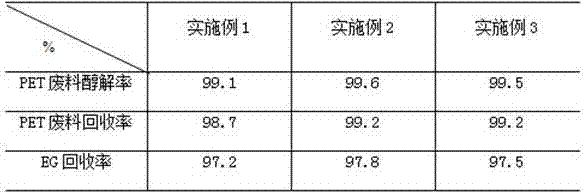

Polyethylene terephthalate waste recovery process

InactiveCN107266664AHigh reaction depolymerization rateImprove responseOrganic compound preparationPlastic recyclingPolyesterDepolymerization

Relating to the resource regeneration field, the invention discloses a polyethylene terephthalate (PET) waste recovery process, and solves the recovery problem of colored PET waste. The method includes the steps of: S1. crushing, cleaning and drying PET waste; S2. adding the treated PET waste, EG and a catalyst into a reaction kettle, carrying out depolymerization reaction completely at a constant temperature of 170-210DEG C; S3. performing cooling to 125-145DEG C, and conducting hot filtration to obtain primary filtrate and unreacted PET; S4. distilling the primary filtrate to obtain EG; S5. adding a solvent into the distilled liquid, and performing hot filtration to obtain secondary filtrate and an oligomer of BHET; S6. adding a decolorizing agent into the secondary filtrate, and conducting hot filtration to obtain tertiary filtrate; S7. subjecting the tertiary filtrate to cooling crystallization to precipitate needle crystals, conducting filtration to obtain monomer BHET, and performing drying at 60DEG C; S8. conducting polycondensation under a low vacuum condition, and carrying out final polycondensation under a high vacuum condition; and S9. carrying out strip casting, cooling, grain cutting and drying, thus finally obtaining the PET particle product.

Owner:宜兴市创新精细化工有限公司

Corn silk polysaccharide separation and decoloring method

The invention relates to a corn silk polysaccharide separation and decoloring method, which is characterized in that the method comprises the following steps: crushing corn silks, then mixing the corn silks with water in a mass ratio of 1: 10 to 1: 15, adding cellulase with the corn silk mass of 1.0-1.5%, and regulating to a 45 DEG C of constant-temperature water bath with the pH value of 4.5-5.5; filtering polysaccharide leaching liquor after enzymolysis, centrifugating, taking liquid supernatant for vacuum concentration, and removing protein; adding powdered activated carbon into a polysaccharide solution after the removal of protein and the 45 DEG C of constant-temperature water bath; after centrifugation, taking the liquid supernatant, utilizing a microporous filter membrane for sucking filtration for one time to three times, and removing the activated carbon residue; adding anhydrous ethanol or methanol into the decolored silk polysaccharide solution, and centrifugating after uniform mixing; drying precipitation in a vacuum mode to obtain corn silk polysaccharide. The method can decolor pigment in the solution in corn silk polysaccharide separation and extraction, so the effect is obvious, the pigment removal rate can reach 85-90%, and the polysaccharide retention rate can reach more than 83%. The process is simple. At the same time, the method effectively removes the activated carbon left over in the decolored polysaccharide solution and maintains the purity of the polysaccharide color of the corn silk polysaccharide.

Owner:BOHAI UNIV

Method for preparing polysilicate ferro-aluminum sulfate composite flocculant from red mud waste

InactiveCN108083345AHigh molecular weightGood flocculation effectIron sulfatesWater/sewage treatment by flocculation/precipitationRed mudSilicon oxide

The invention discloses a method for preparing a polysilicate ferro-aluminum sulfate composite flocculant from red mud waste. The method comprises the following steps: (1) putting red mud waste and anactivating agent into a muffle furnace to be roasted and grinding the red mud waste to obtain activated red mud powder; (2) putting an oxidizing agent and the activated red mud powder into a sulfuricacid solution to react; (3) adding adjusting salt to adjust a molar ratio of Fe to Al to Si in the solution as 1 to 1 to (0.2 to 0.7), utilizing a pH conditioning agent to adjust a pH of the solutionto 1 to 6; (4) adding a stabilizer to react and filtering to obtain the polysilicate ferro-aluminum sulfate composite flocculant. By means of the method disclosed by the invention, ferric oxide, aluminum oxide and silicon oxide in the red mud waste are effectively utilized to prepare the polysilicate ferro-aluminum sulfate composite flocculant; not only are the problems that the waste red mud occupies a lot of land and pollutes underground water are solved, but also the waste red mud can be resourcefully utilized, production cost is low, added value of products is high, and a novel way for comprehensively utilizing the red mud waste is provided.

Owner:SUN YAT SEN UNIV

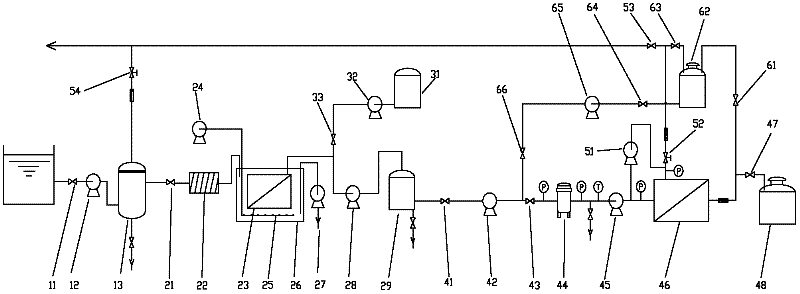

A regenerated water manufacturing device and method based on electrolysis and double-membrane technology

InactiveCN102260013AImprove water qualityTo achieve the purpose of cleaner productionWater/sewage treatmentMultistage water/sewage treatmentWater basedWater quality

Provided is an apparatus for producing reclaimed water based on electrolysis and double membrane technologies. The apparatus is disposed with an electrolysis system, an MBR system and a reverse osmosis system. Further provided is a method for producing reclaimed water using the apparatus, comprising the following steps: retrieving biochemical sewage through a water pump (12) and inputting the biochemical sewage into an electrolysis apparatus (13) of the electrolysis system to be electrolyzed, then enabling the sewage to enter an MBR reaction tank (26) through a grid (22) to obtain primary reclaimed water, pumping the primary reclaimed water into the reverse osmosis system with a high pressure pump (45) to separate dialysis water and concentrated water, enabling the dialysis water to enter a reclaimed water storage tank (48) to obtain ultrapure reclaimed water, enabling a part of the concentrated water to flow back for cyclic membrane filtering and separation, enabling a part of the concentrated water to flow back to enter an electrolysis procedure for cyclic use, and discharging the rest part of the concentrated water.

Owner:BOYING XIAMEN SCI & TECH

Decoloring carclazyte produced from ledikite and turface mixed layer clay as well as production method and application of decoloring carclazyte

InactiveCN103007876ANo pollution in the processReduce manufacturing costOther chemical processesFatty-oils/fats refiningChemical treatmentWastewater

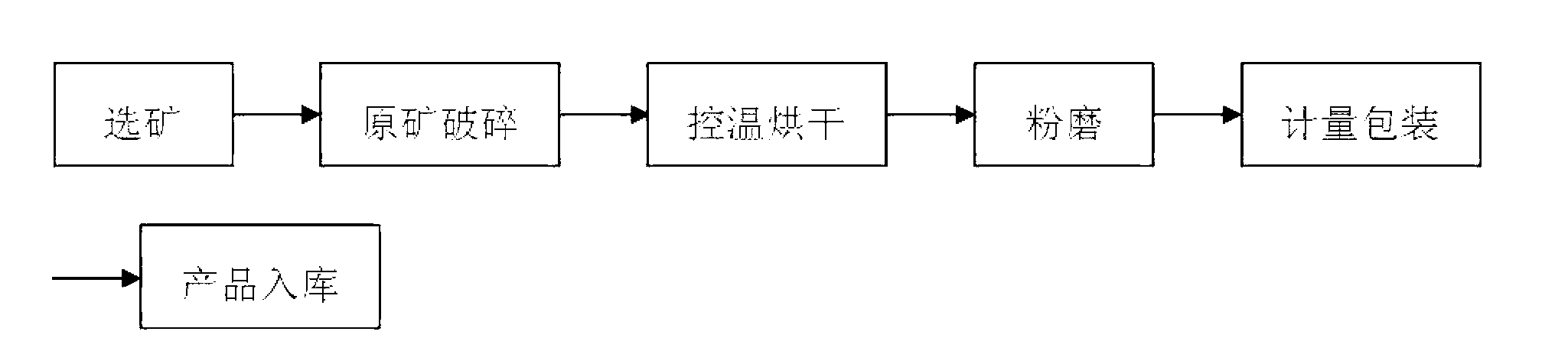

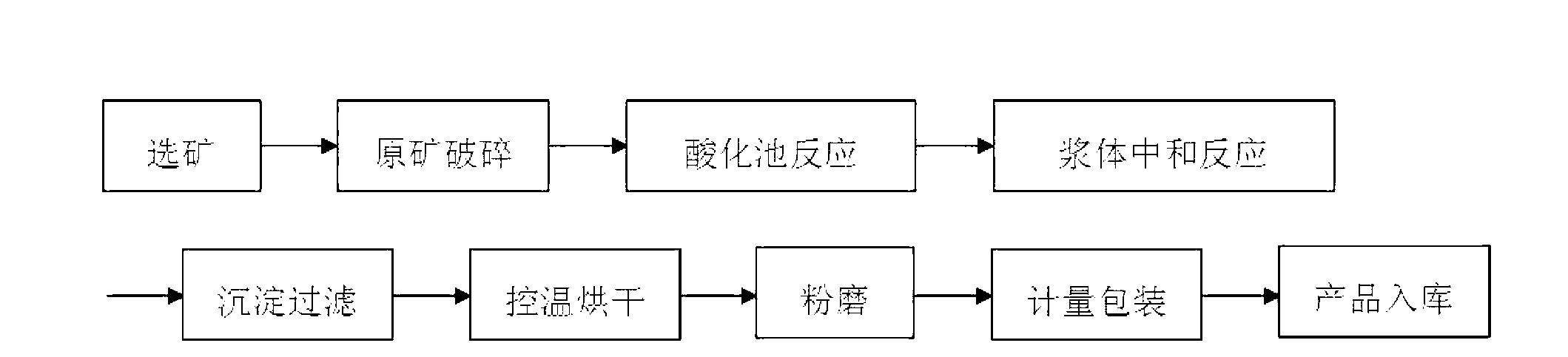

The invention discloses decoloring carclazyte produced from ledikite and turface mixed layer clay as well as a production method and application of the decoloring carclazyte. The inventor selects and uses the novel material (namely the ledikite and turface mixed layer clay) as the main raw material and respectively adopts a dry process and a wet process to carry out appropriate physical and chemical treatments of the ledikite and turface mixed layer clay to prepare the decoloring carclazyte which can be used as a decolorizing agent. The product is low in production cost, simple in production technology and free of acid waste water pollution in production process, ensures clean and beautiful production environment, has high adsorptive capacity and good decoloring effect, is a new source for high-quality and excellent decolorizing agent products, and can be widely applied to the fields such as grease, chemicals engineering and environmental protection.

Owner:上思县文德矿业科技咨询服务有限公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com