Patents

Literature

103 results about "Dipropylene glycol diacrylate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

DPGDA (Dipropylene Glycol Diacrylate) is a difunctional reactive diluent that polymerizes when exposed to sources of free radicals.

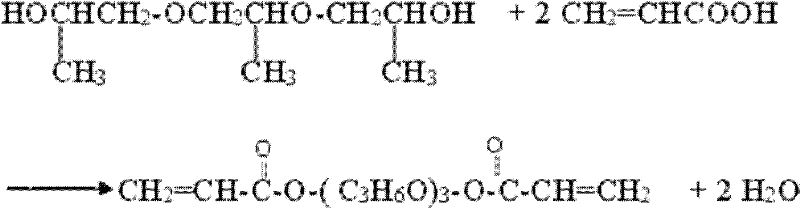

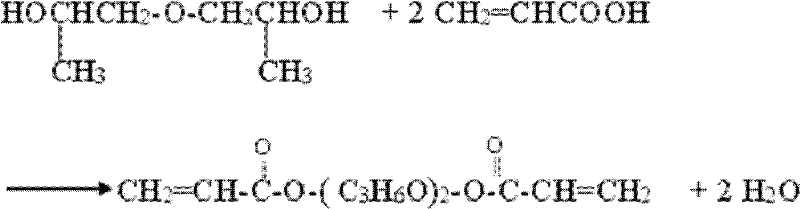

Clean production method of dipropylene glycol diacrylate (DPGDA) or tripropylene glycol diacrylate (TPGDA)

ActiveCN102491896ANo processing costsGreen and Clean Production MethodsOrganic compound preparationCarboxylic acid esters preparationTripropylene glycolDipropylene glycol diacrylate

The invention which belongs to the light-cured material field relates to a clean production method of DPGDA or TPGDA. The method concretely comprises the following steps: 1, carrying out esterification reflux dehydration on dipropylene glycol / tripropylene glycol, acrylic acid, a catalyst, a solvent, a polymerization inhibitor and an antioxidant; 2, adding sodium hydroxide and a small amount of water to neutralize; 3, adding a magnesium polysilicate adsorbent to adsorb a salt generated through neutralization; 4, carrying out reduced pressure dehydration and desolventization; 5, press-filtering to filter out magnesium polysilicate and the salt absorbed thereby; 6, adding alkaline calcium bentonit and calcium oxide to decolor, remove trace water and remove trace acids; 7, press-filtering; and 8, carrying out product index detection. The clean production method of the DPGDA or the TPGDA of the invention, which has the advantages of high yield, economic benefit possessing and environmental benefit possessing, fundamentally solves an organic wastewater pollution problem in the production process of the DPGDA or the TPGDA.

Owner:JIANGSU LITIAN TECH

UV film-pressed yellowing-resistant topcoat gloss paint

ActiveCN103289456ADry fastImprove the decorative effectPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycolPolymer science

The invention provides an UV (Ultra Violet) film-pressed yellowing-resistant topcoat gloss paint, comprising the following components by weight percent: 35%-45% of functional monomer, 17%-23% of polyurethane acrylate, 26%-40% of epoxy acrylic resin, 0.2-0.3% of defoamer, 0.4%-0.6% of flatting agent and 5%-7% of photoinitiator. The functional monomer is a mixture of hydroxyethyl methacrylate, dipropylene glycol diacrylate, tripropylene glycol diacrylate and trimethylolpropane triacrylate. The UV film-pressed yellowing-resistant topcoat gloss paint provided by the invention is good in adhesive force, excellent in resistance to yellowing, low cost, simple and flexible to operate, high in drying speed, free of waste and high in production efficiency.

Owner:上海展辰涂料有限公司 +1

Dust-proof antimicrobial fireproof UV (ultraviolet) photocuring paint and preparation method thereof

InactiveCN103805034AReduce surface tensionGood dispersionFireproof paintsAntifouling/underwater paintsEpoxyAcrylic resin

The invention relates to a dust-proof antimicrobial fireproof UV (ultraviolet) photocuring paint which is prepared from the following raw materials in parts by weight: 8-12 parts of dipropanediol diacrylate, 26-32 parts of silicon oil modified epoxy acrylic resin, 15-20 parts of butyl acrylate, 3-5 parts of vanillin, 2-4 parts of nano chitosan, 2-4 parts of aluminum hydroxide, 7-10 parts of styrene, 1-2 parts of photoinitiator, 2-4 parts of phenyl trichlorosilane, 3-4 parts of assistant and 4-6 parts of triglycidyl cyanurate. The UV (ultraviolet) photocuring paint has the advantages of low surface tension and high dust and dirt resistance; by adding the nano chitosan, the UV paint has antimicrobial effect; by adding the aluminum hydroxide, the paint is dispersed stably and can not easily settle, and the fire resistance is enhanced; and the paint also has excellent water resistance, and is safe and environment-friendly. The assistant enhances the dispersivity of the paint, so that the UV (ultraviolet) photocuring paint has favorable leveling property and the coating formed by the paint is smooth and bright.

Owner:WUHU BAOYI AMUSEMENT EQUIP

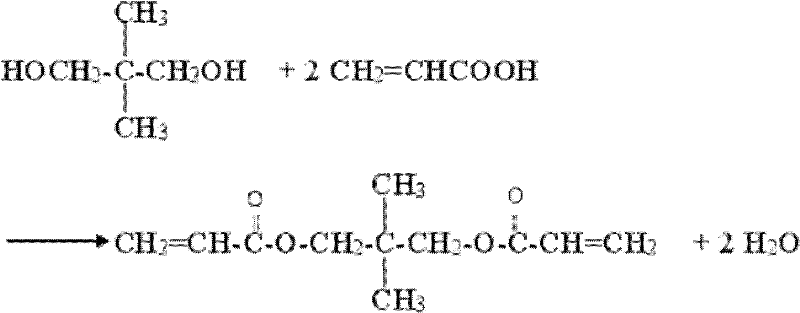

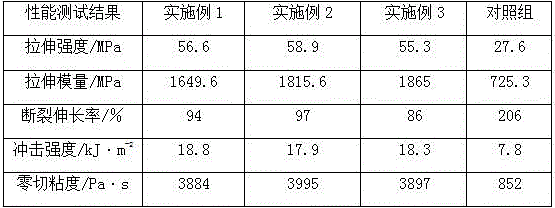

Polymer material used for 3D printing and preparation method thereof

InactiveCN105732915AHigh tensile strengthHigh tensile modulusAdditive manufacturing apparatusPolymer sciencePerformance index

The invention relates to a polymer material used for 3D printing. The polymer material comprises polyurethane acrylate, epoxy resin, ethyl cellulose, polyethylene wax, wollastonite powder, hydrogenated abietinol, epoxy acrylate, 2-hydroxy-4-methoxybenzophenone, trioctyl trimellitate, dipropylene glycol diacrylate, benzidine, polyoxyethylene laurate, nano-nickel oxide, poly(butyl acrylate), trimesic acid, isodecyl acrylate, barium stearate and calcium stearate. The prepared material has higher tensile strength and tensile modulus, retains good toughness, has good performance indexes, such as elongation at break and impact strength, not only has rather high toughness but also has higher heat resistance and good usability.

Owner:王璐

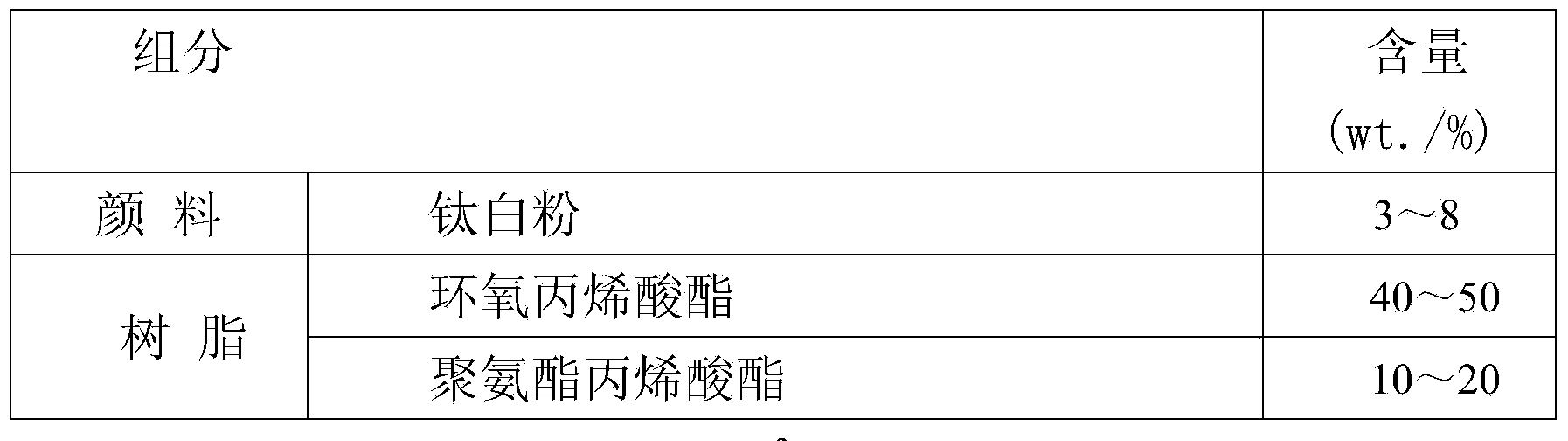

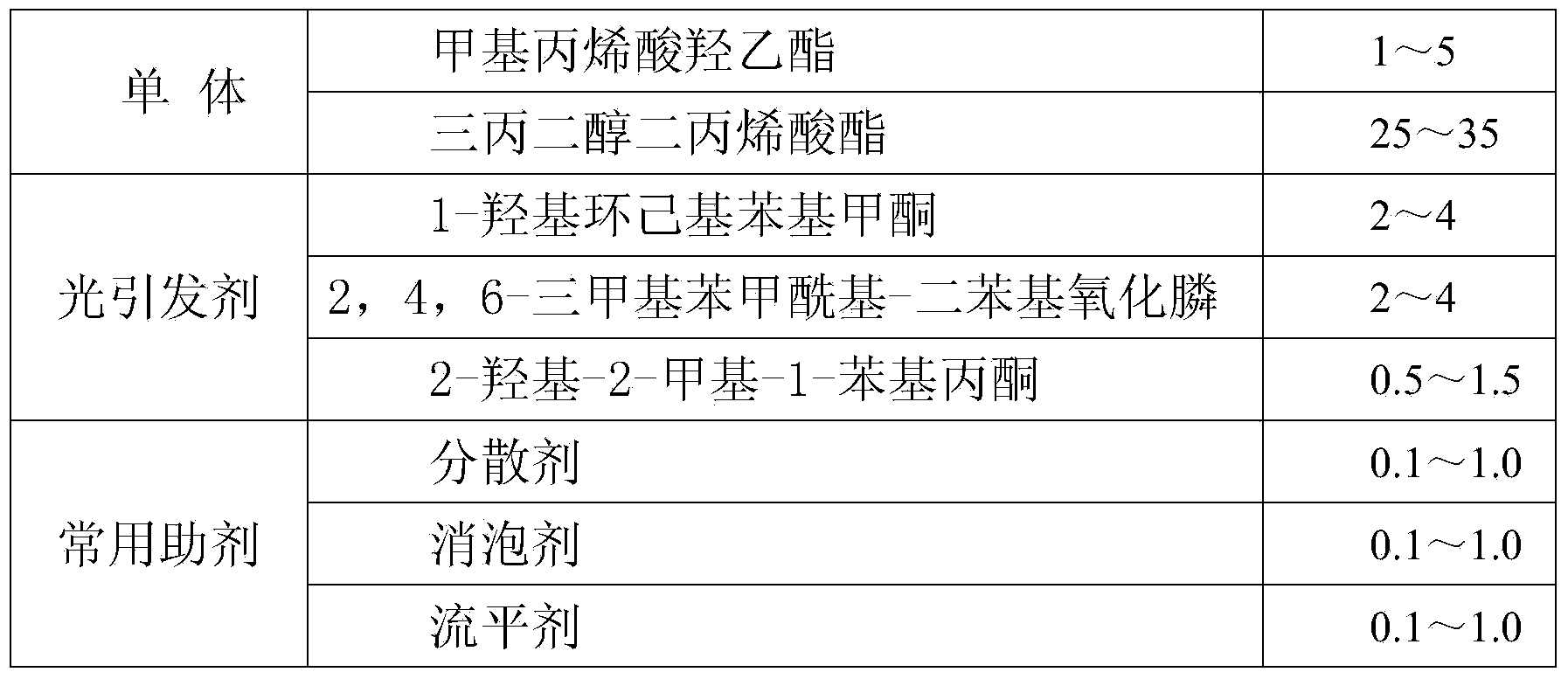

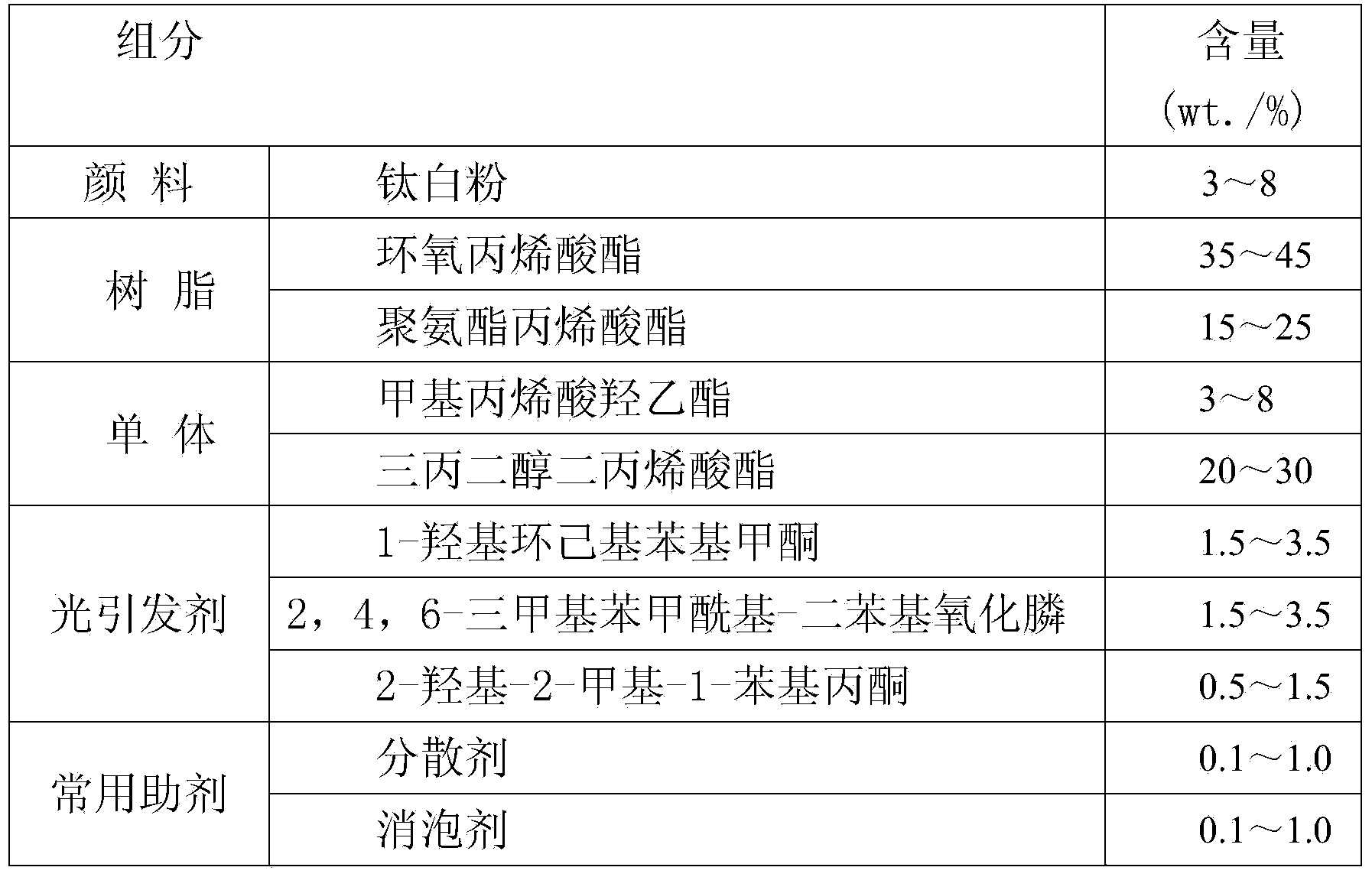

White ultraviolet curing finishing coat

ActiveCN103709906AFast curingIncrease productivityPolyurea/polyurethane coatingsEpoxy resin coatingsTripropylene glycol(Hydroxyethyl)methacrylate

The invention discloses a white ultraviolet curing finishing coat which consists of the following components by weight percent: 50-70 percent of resin, 23-40 percent of an acrylate compound monomer, 4.5-9.5 percent of a photo-initiator and 0.3-3.0 percent of an aid, wherein the resin is a mixture consisting of epoxy acrylate and urethane acrylate; the acrylate compound monomer is one or a mixture of two of hydroxyethyl methylacrylate, tripropylene glycol diacrylate, 1,6-hexanediol diacrylate, dipropylene glycol diacrylate and trimethylolpropane triacrylate. The white ultraviolet curing finishing coat can be sprayed instead of the conventional solvent based coating, and has the advantages of high curing speed, high production efficiency, lower plate production cost, energy saving, carbon reduction and the like.

Owner:东周化学工业(昆山)有限公司

Scratch-resistant BOPP (biaxially-oriented polypropylene) film and preparation method thereof

ActiveCN109897283AImprove adhesionImprove scratch resistancePolyurea/polyurethane coatingsDipropylene glycol diacrylateUltraviolet

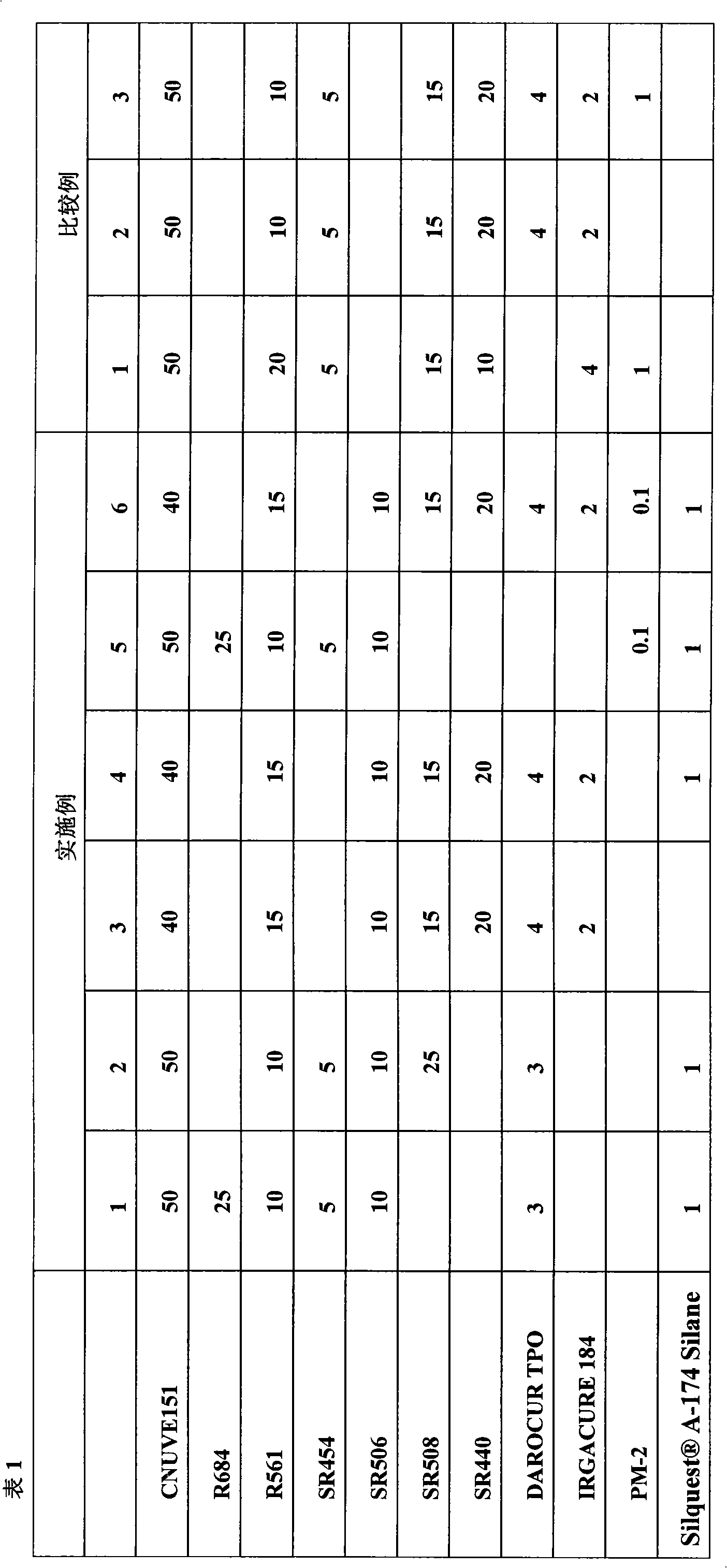

The invention discloses a scratch-resistant BOPP (biaxially-oriented polypropylene) film and a preparation method thereof, and belongs to the technical field of packaging. The scratch-resistant BOPP film comprises a BOPP film substrate and a scratch-resistant coating, the surface of the BOPP film substrate subjected to corona treatment is coated with scratch-resistant paint to form the scratch-resistant coating by ultraviolet curing, and the scratch-resistant paint comprises, by weight, 40-70 parts of aliphatic polyurethane acrylate hexaacrylate, 10-25 parts of dipropylene glycol diacrylate, 2-10 parts of photoinitiators 1173, 5-15 parts of KH-550 modified nano-silica, 0.1-0.5 part of defoaming agents and 0.1-0.5 part of wetting agents. The preparation method is simple, and the prepared scratch-resistant BOPP film has excellent scratch resistance and long service life.

Owner:SHANGHAI PUDONG HUANGGONG PRINTING

Waterproof wear-resistant polyurethane acrylate oil paint for copper sculpture

InactiveCN104194612AStrong adhesionLong lasting colorAnti-corrosive paintsPolyurea/polyurethane coatingsXylylenePolymer science

The invention relates to oil paint and particularly relates to waterproof wear-resistant polyurethane acrylate oil paint for a copper sculpture. The oil paint is prepared from the following raw materials in parts by weight: 12-15 parts of amino resin, 3-4 parts of boron nitride, 1-2 parts of molybdenum disulfide, 3-4 parts of shell powder, 2-3 parts of citric acid, 1-2 parts of stannous mono-sulphate, 2-3 parts of dicyclopentadiene, 35-40 parts of polyurethane acrylate, 10-12 parts of dipropylene glycol diacrylate, 3-5 parts of allyl glycidyl ether, 1-2 parts of 4-methyl guaiacol, 0.19-0.21 part of an accelerant TT, 5-6 parts of zinc stearate, 4-8 parts of N220 carbon black, 6-9 parts of diamino diphenyl sulfone, 1-2 parts of tributyl tin chloride, 5-6 parts of auxiliaries, 10-12 parts of xylene and 10-12 parts of butyl acetate. The oil paint provided by the invention is strong in adhesive force, bright and full in film, hard and wear-resistant, lasting in color retention, water-permeation-resistant, weatherproof and aging-resistant, long in service life and relatively simple in production process, and can be widely applied to protecting various copper sculpture artware.

Owner:TONNGLING YUANCHENG ART PROD

Aldehyde removing, antibacterial and negative ion integrated ultraviolet light curable coating material and preparation process thereof

InactiveCN106433443AGood dealdehyde effectContinuous and effective degradationAntifouling/underwater paintsPaints with biocidesAcrylic resinDipropylene glycol diacrylate

The invention discloses an aldehyde removing, antibacterial and negative ion integrated ultraviolet light curable coating material and a preparation process thereof, wherein the aldehyde removing, antibacterial and negative ion integrated ultraviolet light curable coating material comprises, by mass, 20-30% of a special acrylic resin, 20-30% of a polyurethane acrylate, 20-30% of dipropylene glycol diacrylate, 3-8% of trimethylolpropane triacrylate, 5-8% of an organic aldehyde removing aid, 2-5% of an inorganic aldehyde removing aid, 1-3% of an antibacterial aid, 5-8% of a negative ion ionizer, 3-5% of a photoinitiator, 1-3% of a coating material aid, and 5-10% of a filler. According to the present invention, the aldehyde removing, antibacterial and negative ion integrated ultraviolet light curable coating material integrates the three effects of aldehyde removing, antibacterial effect and negative ion releasing, has advantages of environmental protection, high efficiency, high hardness, good wear resistance and good scratch resistance, and further has the aldehyde removing, antibacterial and negative ion releasing integrated synergistic air purifying function.

Owner:HUNAN BANFERT NEW MATERIALS TECH

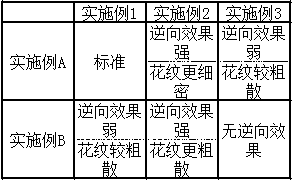

Large-on-line gravure UV reverse ink on gold and silver card paper material

The invention relates to the field of polymer materials, and discloses a large-on-line gravure UV reverse ink on a gold and silver card paper material, which comprises, by weight, the following components: 10-25% of fatty acid-modified epoxy acrylate; 5%-15% of aliphatic urethane acrylate; 10%-20% of trimethylolpropane triacrylate; 30%-45% of dipropylene glycol diacrylate; 4%-6% of hydrogen abstraction photoinitiator, 1%-3% of cleavage photoinitiator; 10%-15% of amine initiator; 0.1%-0.5% of polymerization inhibitor; 0.1%-3.5% of auxiliary agent. The invention also discloses a preparation method and an application method thereof. The UV reverse ink has the advantages of good reverse effect, good adhesive force and good fluidity, and can meet the requirements of high-speed printing and decorating ink.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Hydrographic transfer printing ink and preparation method thereof

InactiveCN106046927ALow energy and environmental protectionInksDipropylene glycol diacrylateAcrylic resin

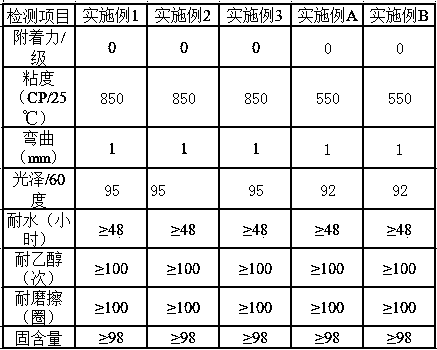

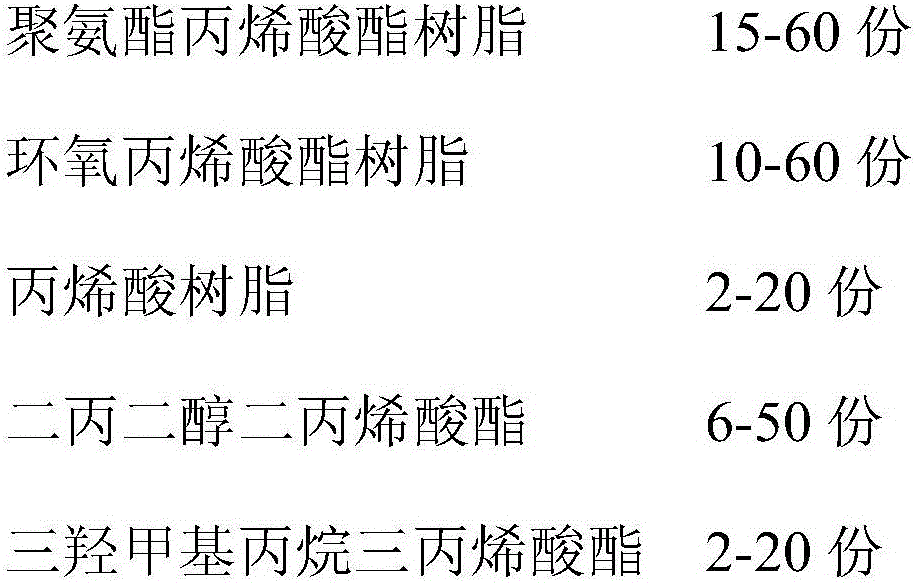

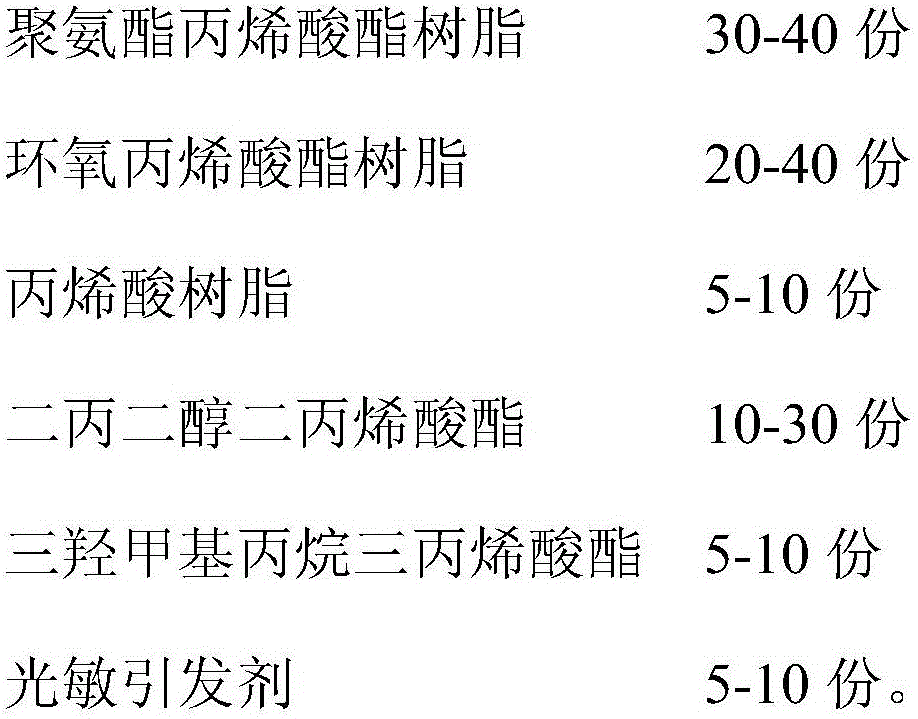

The invention provides hydrographic transfer printing LED curing series printing ink and a preparation method. The printing ink is mainly prepared from, by weight, 15-60 parts of polyurethane acrylic resin, 10-60 parts of epoxy acrylic resin, 2-20 parts of acrylic resin, 6-50 parts of dipropylene glycol diacrylate, 2-20 parts of trimethylolpropane triacrylate and 2-20 parts of photosensitized initiator. The ingredients are added in sequence according to weight parts, stirred regularly at a fixed speed and finally ground through a three-roller machine, stirring is conducted, and the printing oil is obtained. The printing ink meets the requirements of clients for surface decoration of ceramics, glass wine bottles, cosmetic bottles and the like.

Owner:永修县利君科技有限公司

Method for preparing acrylic ester-styrene butadiene styrene (SBS) copolymer

The invention discloses a method for preparing an acrylic ester-styrene butadiene styrene (SBS) copolymer. The method comprises a step of performing graft modification on SBS in a solvent N-class A pyrrolidone (NMP) by using the SBS triblock copolymer as a matrix and methyl methacrylate (MMA), dipropylene glycol diacrylate ester (DPGDA) as a mixed monomer. An ester group and a carboxyl group are introduced into the SBS, so that the polarity of the SBS is increased, and the method is high in binding performance for the SBS subjected to graft modification and the polarity material.

Owner:QINGDAO SAMUELS INDAL & COMML

Glass reinforced plastic composite coating material with good anti-corrosion effect and preparation method thereof

InactiveCN103773090AGood physical propertiesImprove mechanical propertiesAnti-corrosive paintsEpoxyDipropylene glycol diacrylate

The invention discloses a glass reinforced plastic composite coating material with a good anti-corrosion effect. The glass reinforced plastic composite coating material is characterized by being prepared from the following raw materials in parts by weight: 30-34 parts of E-12 epoxy resin, 9-12 parts of styrene, 6-10 parts of alpha-methyl styrene, 12-14 parts of organic silicon resin, 2-3 parts of polytetrafluoroethylene, 1-2 parts of silane coupling agent KH-550, 2-5 parts of tetrabutylammonium bromide, 15-18 parts of dipropylene glycol diacrylate, 25-29 parts of chopped fiber glass, 5-8 parts of ceramic powder, 10-13 parts of methyl ethyl ketone peroxide, 2-4 parts of KJP-1002 epoxy resin curing agent, 3-5 parts of vaseline, 2-5 parts of tetrabutyl ammonium bromide, 2-4 parts of dipropylene glycol acrylate and 1-2 parts of additive. The glass reinforced plastic composite coating material has good physical performance and mechanical performance due to addition of the additive; the glass reinforced plastic composite coating material has a good anti-corrosion effect and is light in weight, non-toxic, low in cost and suitable for industrial production; a production technology is simple.

Owner:WUHU BAOYI AMUSEMENT EQUIP

UV-curable adhesive composition for compact discs

InactiveCN101857776AExcellent heat and humidity resistanceImprove aging resistanceRecord information storageOrganic non-macromolecular adhesiveIsooctyl acrylateDipropylene glycol diacrylate

The invention provides a UV-curable adhesive composition for compact discs, which consists of bisphenol epoxy acrylate (A), acrylate compound (B) and photopolymerization initiator (C), wherein the acrylate compound (B) consists of iso-Bornyl acryl (B-1) and at least one of the following acrylate compounds: phenoxyethyl acrylate (B-2), tricyclodecane dihydroxymethyl diacrylate (B-3), ethoxylated trihydroxymethyl tricrylate (B-4), dipropylene glycol diacrylate (B-5) and enthyl hexyl acrylate (B-6). The composition can be utilized to bond two compact disc substrates together to produce a bonded compact disc.

Owner:上海拓引数码技术有限公司

UV (ultraviolet) white coating system, preparation method and coating process

ActiveCN108410328AImprove adhesionImprove the level ofPolyurea/polyurethane coatingsEpoxy resin coatingsPolyester(Hydroxyethyl)methacrylate

The invention provides a UV (ultraviolet) white coating system, composed of UV high-adhesion base varnish, UV ultra-white base coat and UV ultra-white top coat. The UV high-adhesion base varnish has afilm-forming base made with modified epoxy acrylate, difunctional aliphatic polyurethane, a pure acrylate, 1,6-hexanediol diacrylate, and hydroxyethyl methylacrylate; the UV ultra-white base coat hasa film-forming base made with modified epoxy acrylate, difunctional polyester acrylate, a pure acrylate, 1,6-hexanediol diacrylate, and dipropylene glycol diacrylate; the UV ultra-white top coat hasa film-forming base made with modified epoxy acrylate, difunctional aliphatic polyurethane, a pure acrylate, trimethylolpropane triacrylate, and dipropylene glycol diacrylate. A white coating layer ofgood adhesion, leveling property, high L value and low b value is formed by: performing multiple coating with the combination of UV base coat and UV top coat having different functions, and forming films respectively via UA.

Owner:QINGDAO ZHANCHEN NEW MATERIAL +1

Photo-curable printing ink

InactiveCN104744999AImprove performanceImprove the decorative effectInksDipropylene glycol diacrylatePrinting ink

The invention relates to the technical field of printing inks, and concretely relates to a photo-curable printing ink. The printing ink comprises, by weight, 30-60 parts of pure acrylate, 5-8 parts of 2-isopropylthioxanthone, 4-6 parts of 4-phenylbenzophenone, 30-32 parts of dipropylene glycol diacrylate, 8-12 parts of a pigment, and 2-5 parts of an assistant. The photo-curable printing ink provided by the invention has the advantages of beautiful decoration and ideal performances.

Owner:田建频

Heat-resistant PLA (Polylactic Acid) anti-electrostatic composite material and preparation method thereof

InactiveCN105907060AImprove thermal stabilityImprove impact resistanceCross-linkDipropylene glycol diacrylate

The invention discloses a heat-resistant PLA (Polylactic Acid) anti-electrostatic composite material. The heat-resistant PLA anti-electrostatic composite material is prepared from the following raw materials in parts by mass: 100 parts of polylactic acid (PLA), 5-15 parts of anti-electrostatic additives, 25-40 parts of heat resistance modifier, 1-2 parts of a reinforcing agent, i.e., active zinc oxide powder, 3-8 parts of a cross-linking agent, i.e., dipropylene glycol diacrylate and 2-5 parts of glyceryl monostearate. The invention simultaneously discloses a preparation method for the heat-resistant PLA anti-electrostatic composite material. According to the heat-resistant PLA anti-electrostatic composite material and the preparation method thereof, the heat resistance modifier is used for carrying out heat resistance modification on the PLA in a manner of being matched with other assistants, so that the thermal stability and impact resistance of the PLA are effectively improved, and meanwhile, the mechanical strength of PLA products is effectively improved; through modifying the anti-electrostatic additives, the compatible compounding of the anti-electrostatic additives, i.e., acetylene black and graphite with the PLA is better facilitated, and good anti-electrostatic performance is obtained.

Owner:JIN BAOLI TECH SUZHOU

LED-UV (Light Emitting Diode-Ultraviolet) curing nano-coating for woodenware and preparation method thereof

ActiveCN107513344AHigh solid contentLow viscosityPolyurea/polyurethane coatingsPolyester coatingsPolyesterDipropylene glycol diacrylate

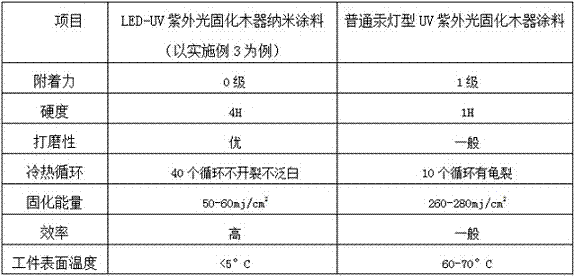

The invention discloses LED-UV (Light Emitting Diode-Ultraviolet) curing nano-coating for woodenware and a preparation method thereof. The LED-UV curing nano-coating for the woodenware is prepared from the following raw materials in percentage by weight: 25 percent to 30 percent of polyurethane acrylate formed by crossly linking pentaerythritol triacrylate and polyisocynate, 10 percent to 15 percent of fatty acid modified polyester acrylate resin, 20 percent to 25 percent of ethoxylated modified trimethylolpropane triacrylate, 10 percent to 20 percent of dipropylene glycol diacrylate, 0.2 percent to 1.0 percent of a wetting dispersant, 10 percent to 15 percent of nano barium sulfate powder, 2 percent to 5 percent of a UV curing monomer dispersion solution of nano wear-resisting particles, 2 percent to 4 percent of a hydrogen abstraction type photoinitiator, 1 percent to 3 percent of active amine, 2 percent to 4 percent of a cracking type photoinitiator, 0.2 percent to 0.5 percent of a leveling agent, 0.2 percent to 0.5 percent of a de-foaming agent and 0.1 percent to 0.3 percent of a polymerization inhibitor. The ultraviolet curing coating disclosed by the invention can reach a needed curing degree only through 50mj / cm<2> to 60mj / cm<2> of LED-UV energy, so that the energy needed by coating curing is greatly reduced, the construction efficiency is improved and the possibility of causing quality defects in woodenware surface coating construction is reduced.

Owner:SHANDONG UNIV +1

3D printing floor

ActiveCN105419306AEasy constructionGood chemical resistanceAdditive manufacturing apparatusPolymer scienceDipropylene glycol diacrylate

The invention relates to a 3D printing floor. The 3D printing floor comprises the following components, by weight, 30-35 parts of polyurethane resin, 10-20 parts of epoxy acrylate, 15-20 parts of 1,6-hexanediol diacrylate, 10-15 parts of dipropylene glycol diacrylate, 2.5-3.0 parts of photoinitiator 127, 10-15 parts of talcum powder, 0.5-1.0 part of bentonite, 0.4-0.6 part of defoaming agent, 0.3-0.5 part of dispersant and 1-8 parts of color paste. The construction technology time is shortened greatly, and problems of materials and technology processes are solved through a new technology. The3D printing floor is presented on the ground through a 3D printer, which is simple and rapid, and the performances of the original materials are not changed.

Owner:浙江西塘实业有限公司

UV (Ultraviolet light) snowflake printing ink

InactiveCN110183899AShorten drying timeImprove printing efficiencyInksDipropylene glycol diacrylateUltraviolet lights

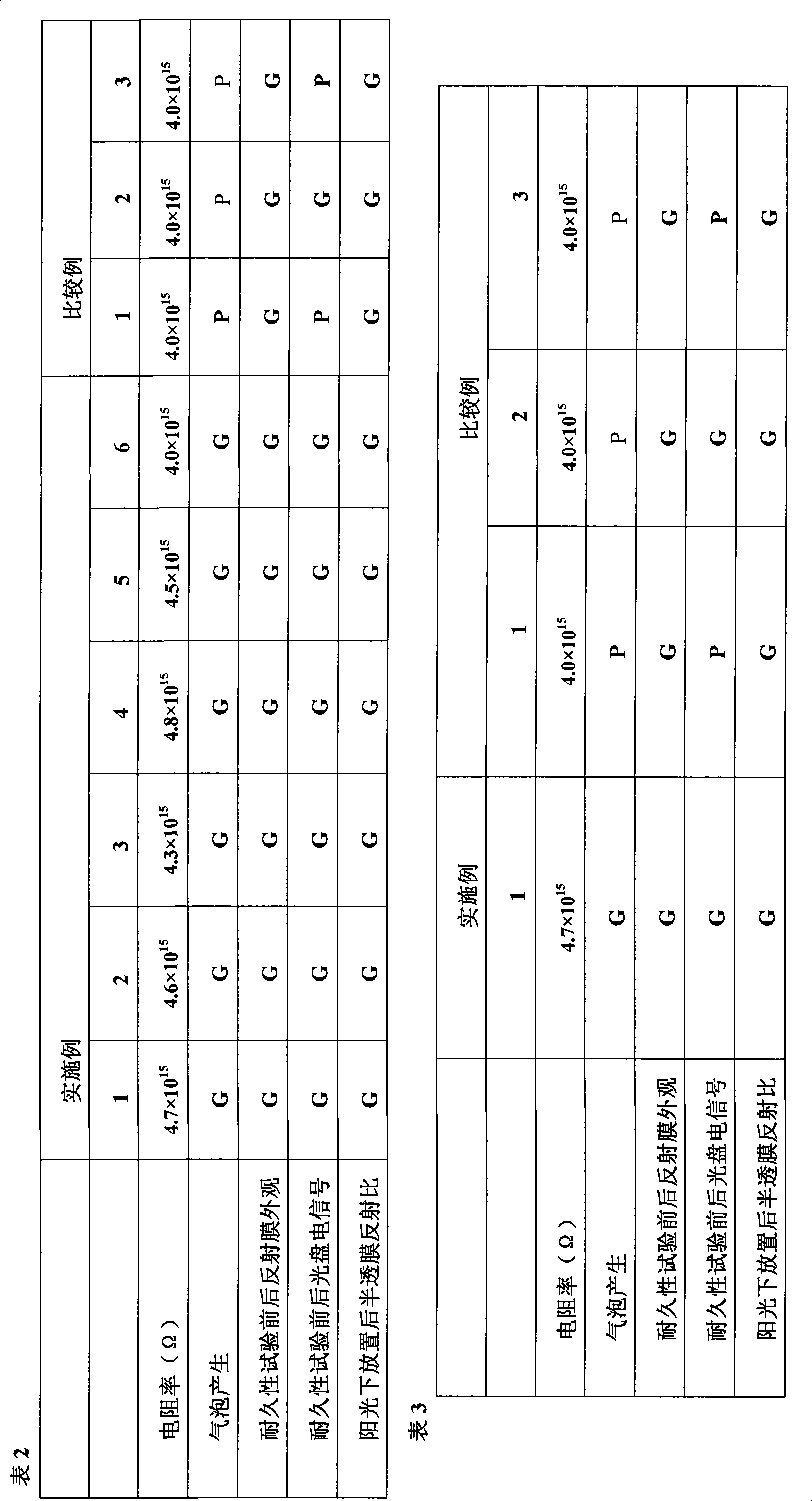

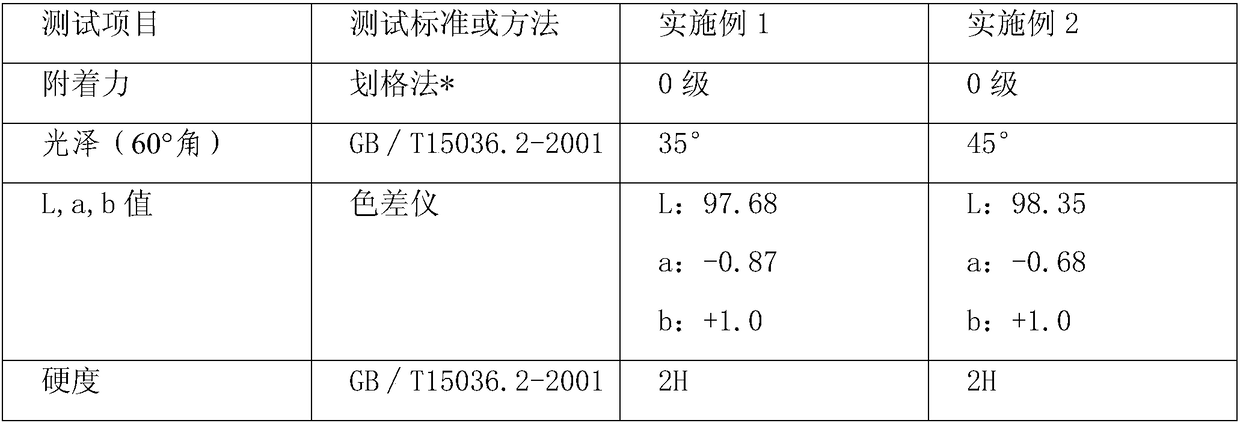

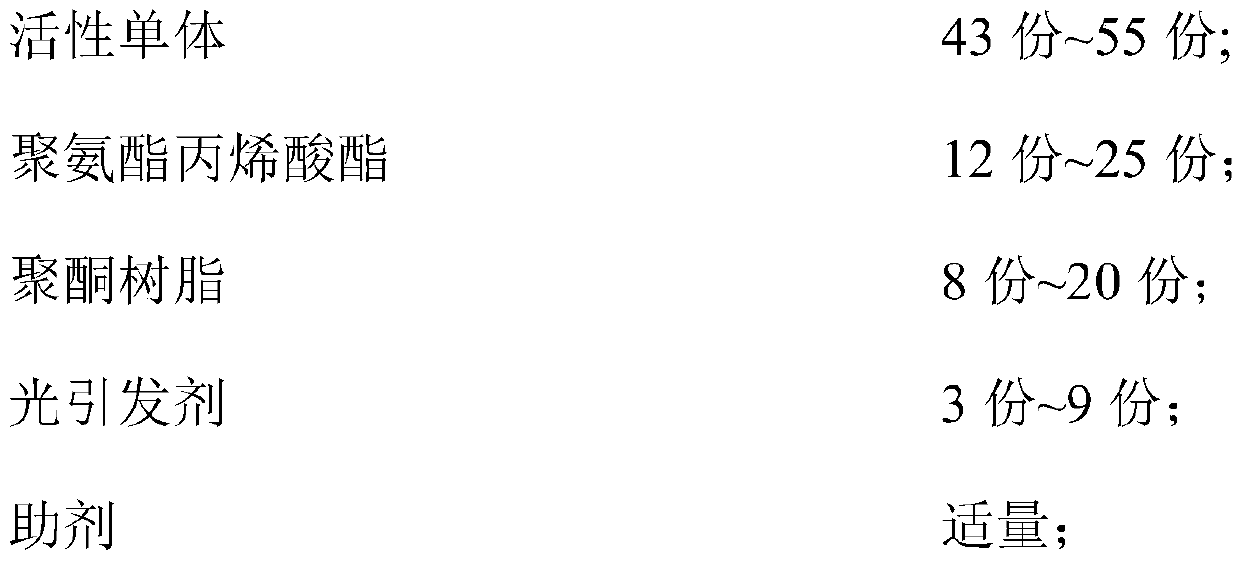

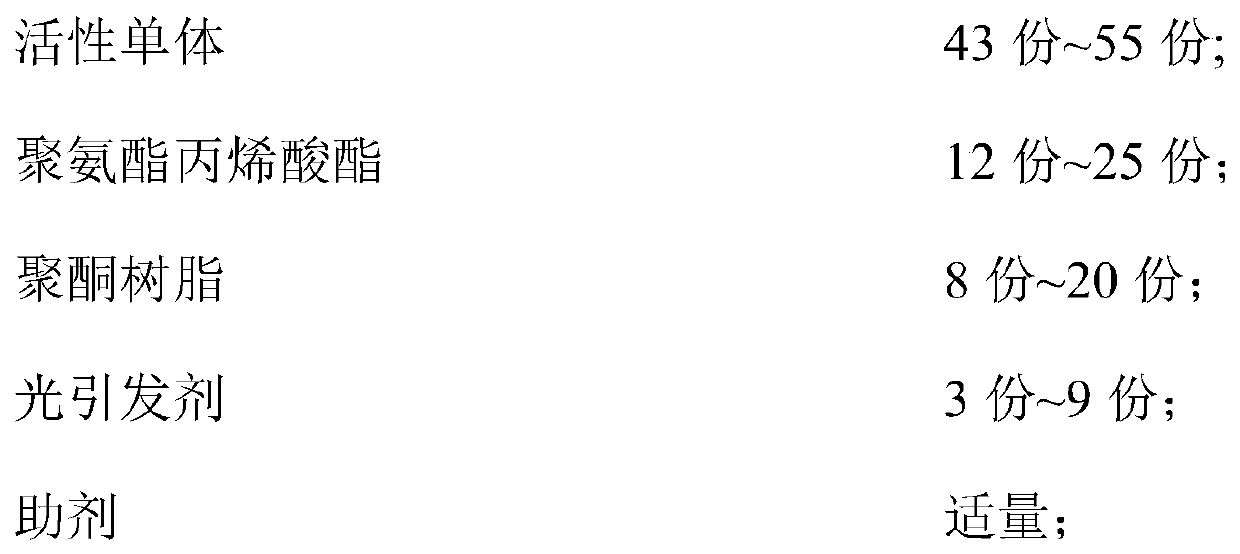

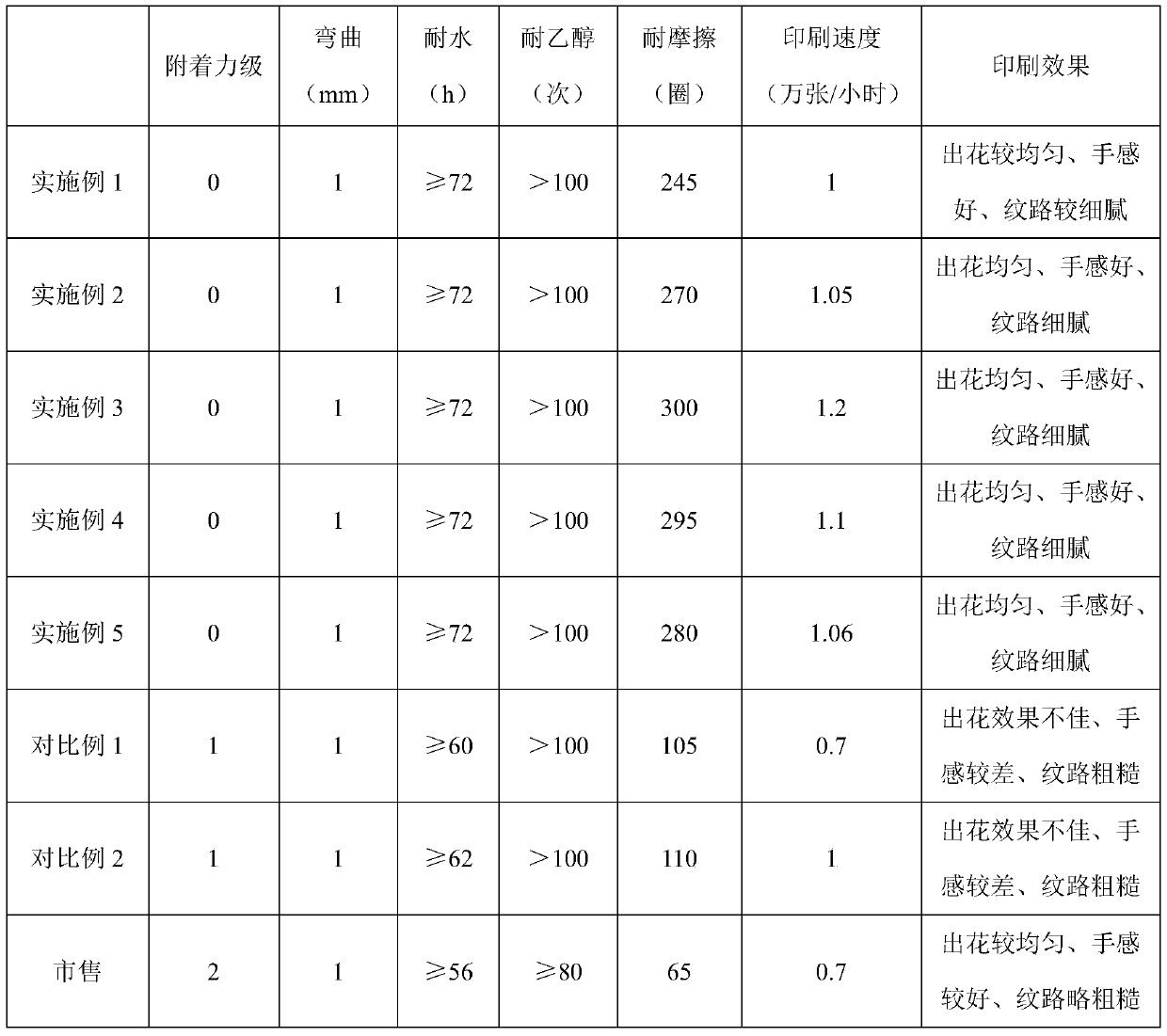

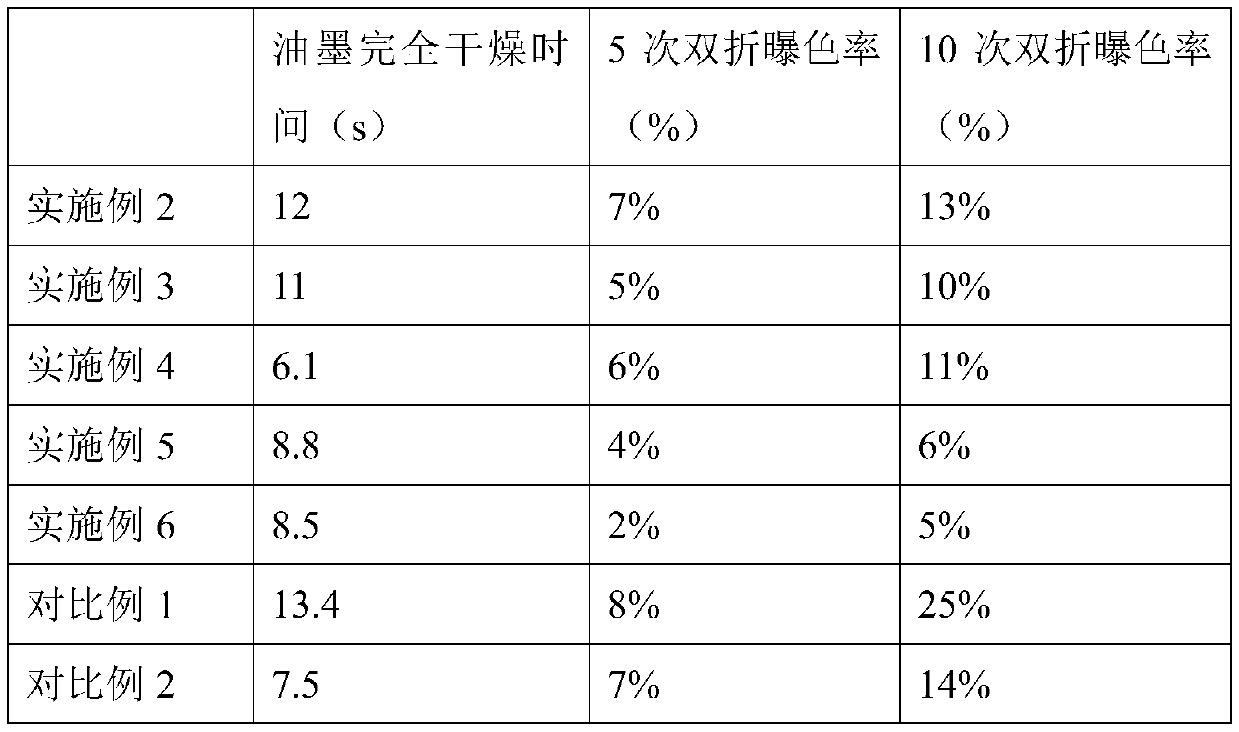

The invention relates to UV (Ultraviolet light) snowflake printing ink. The UV snowflake printing ink is prepared from the following components in parts by weight: 43-55 parts of an active monomer, 12-25 parts of polyurethane acrylate, 8-20 parts of polyketone resin, 3-9 parts of a photoinitiator and appropriate amount of an additive; the active monomer is selected from one or more of bifunctionalgroup acrylic ester and trifunctional group acrylic ester. Under illumination of UV, the photoinitiator is dissociated into free radicals to promote the crosslinked polymerization of the active monomer, the polyurethane acrylate and the polyketone resin, and special texture is generated; through regulating and controlling the component content of a dipropylene glycol diacrylate monomer, the polyurethane acrylate, the polyketone resin, the photoinitiator and the additive, the drying time of the UV snowflake printing ink is shortened to be within 2 s; the drying speed can keep up with the speedof online gravure; the UV snowflake printing ink is applicable to rotary gravure online printing; the printing speed can reach 10,000 pieces / hour or above; the printing efficiency of the snowflake printing ink is greatly improved; the printing cost is lowered.

Owner:湖南省浩彩新材料科技有限公司

UV photo-curable ink

InactiveCN105733351AFast curingStrong adhesionInksDipropylene glycol diacrylateHexanediol diacrylate

The present invention relates to the technical field of chemical materials, and particularly relates to an UV photo-curable ink. The UV photo-curable ink comprises the following components by weight: 15 to 27 parts of aliphatic-modified epoxy acrylate resin; 23 to 30 parts of dipropylene glycol diacrylate; 2 to 11 parts of a dye; 5 to 10 parts of a photoinitiator; 2 to 12 parts of an accelerator; 10 to 19 parts of epoxy acrylate resin; 8 to 17 parts of 1,6-hexanediol diacrylate; 2 to 10 parts of trimethylolpropane triacrylate and 3 to 10 parts of a defoamer. Object of the present invention is to provide a fast-curing strong-adhesion UV photo-curable ink.

Owner:田建频

Curing method of nanocrystalline magnetic core

ActiveCN112309703AReduce internal stressImprove performanceTransformers/inductances magnetic coresOrganic non-macromolecular adhesiveDipropylene glycol diacrylatePhenyl group

The invention discloses a curing method of a nanocrystalline magnetic core, and belongs to the technical field of magnetic core material preparation. The method comprises the following steps: firstly,mixing 40-60 parts of polyurethane modified epoxy resin, 15-30 parts of bisphenol A epoxy acrylate, 8-15 parts of dipropylene glycol diacrylate, 2-4 parts of 1-hydroxycyclohexyl phenyl ketone, 0.2-1part of an antifoaming agent, 0.3-1.5 parts of a wetting agent and 0.5-1.5 parts of a leveling agent, and uniformly stirring to form a glue solution; then, soaking the nanocrystalline magnetic core subjected to heat treatment in the glue solution, wherein the soaking time is 30-60s; and finally, airing the impregnated magnetic core till that there is no residual glue solution on a surface, and then curing the impregnated magnetic core through a UV photocuring instrument, wherein a curing temperature ranges from 25 DEG C to 30 DEG C, and the curing time ranges from 5s to 15s. The method is easyto operate and low in cost, a stress borne by the cured magnetic core can be greatly reduced, and the cured magnetic core can keep good performance.

Owner:FUYANG NORMAL UNIVERSITY +1

Laser paper printing ink and preparation method thereof

The invention relates to laser paper printing ink and a preparation method thereof. The laser paper printing ink comprises the following ingredients (by weight): 15-20 parts of waterborne acrylic resin, 10-20 parts of waterborne polyurethane resin, 10-18 parts of dipropylene glycol diacrylate, 15-20 parts of a pigment, 6-10 parts of nanometer titanium dioxide, 2-4 parts of nano-zinc oxide, 8-10 parts of a filler, 14-20 parts of a reactive diluent, 3-5 parts of a photoinitiator, 1-3 parts of a photosensitizer, and 0.1-0.2 part of an auxiliary agent. The invention is beneficial for the ink to adhere to the surface of a printed material by the surface tension at the initial stage of drying; and in the drying process of the printing ink which is thoroughly adhered to the surface of the printedmaterial by solvent volatilization and penetration into the printed material, the formed net structure can make the solvent to be volatilized at a proper drying rate. In addition, due to high viscosity, cohesiveness of the printing ink penetrating through the printed material can be improved, and the color exposure problem is reduced.

Owner:宜昌金兴新材料有限公司

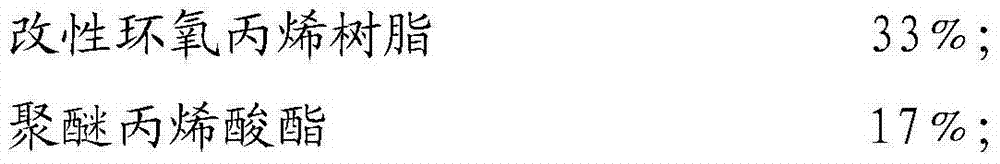

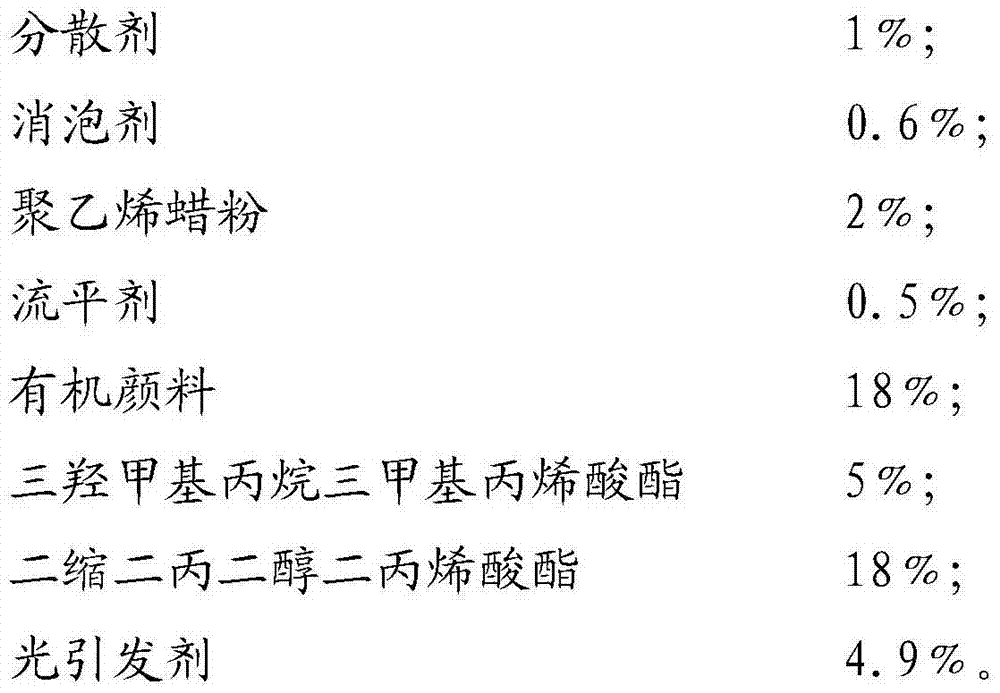

UV oil solid color paint

ActiveCN103709904AGood flexibilityImprove adhesionPolyether coatingsEpoxy resin coatingsEpoxyPolymer science

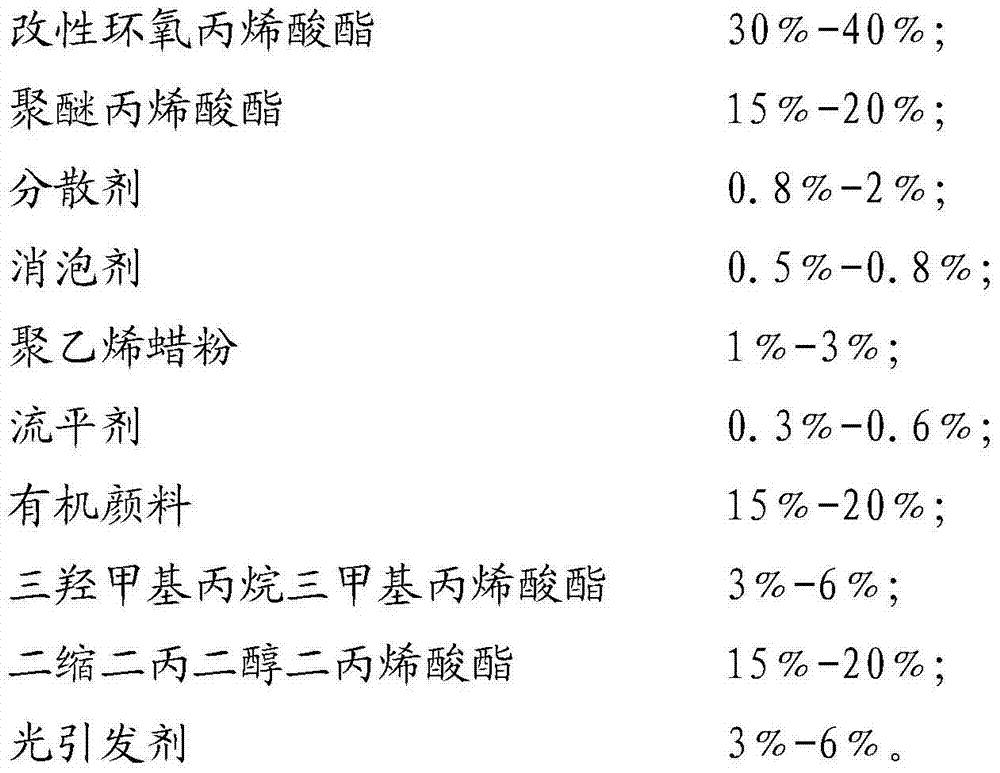

The invention relates to the technical field of paint and especially relates to UV oil solid color paint. The UV oil solid color paint comprises, by mass, 30-40% of epoxy resin, 15-20 parts of polyether-type acrylate, 0.8-2% of a dispersant, 0.5-0.8% of an antifoaming agent, 1-3% of polyethylene wax powder, 0.3-0.6% of a flatting agent, 15-20% of an organic pigment, 3-6% of trimethylol-propane trimethacrylate, 15-20% of dipropylene glycol diacrylate and 3-6% of a photoinitiator. Through use of the polyether-type acrylate, problems of use of single epoxy resin are solved, paint film performance complementation is realized, paint film flexibility is improved, adhesion is improved, residual acrylic acid ester groups in the photocured paint film are reduced, and aging resistance and yellowing resistance are improved.

Owner:广东千叶松化工有限公司

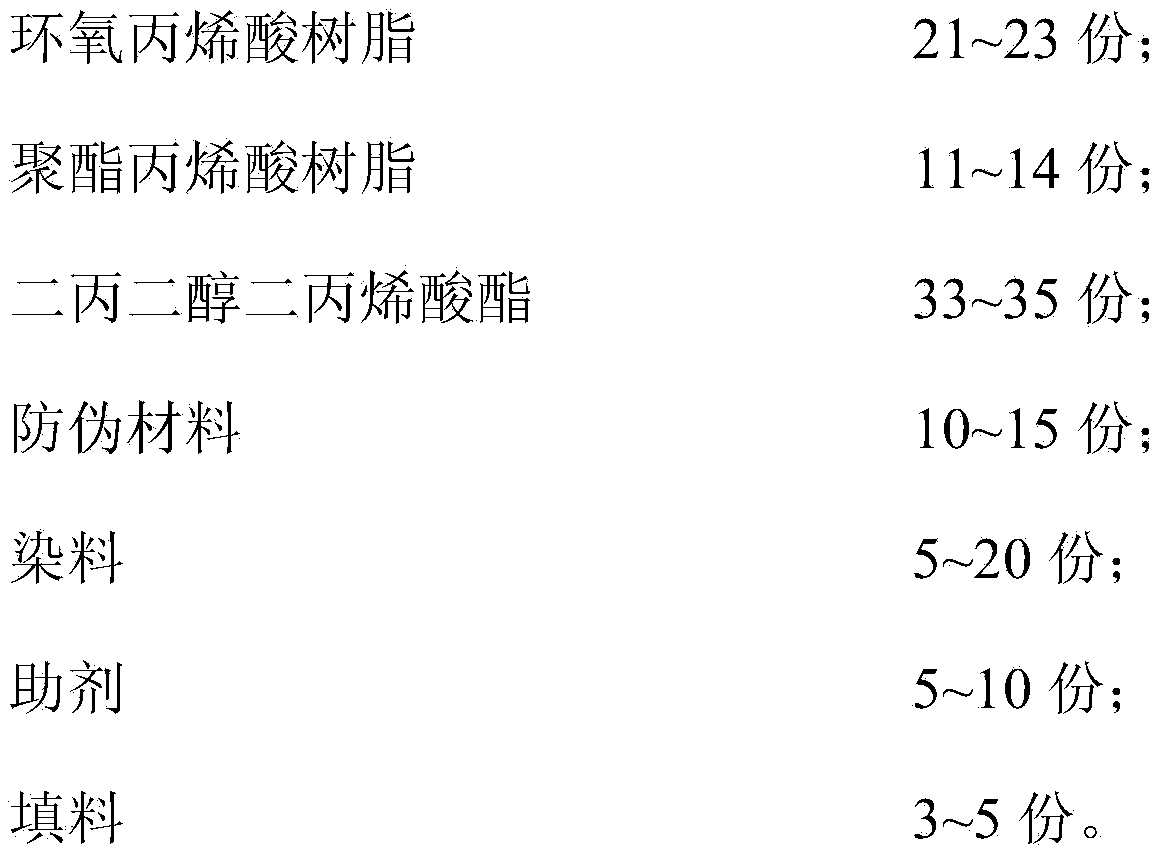

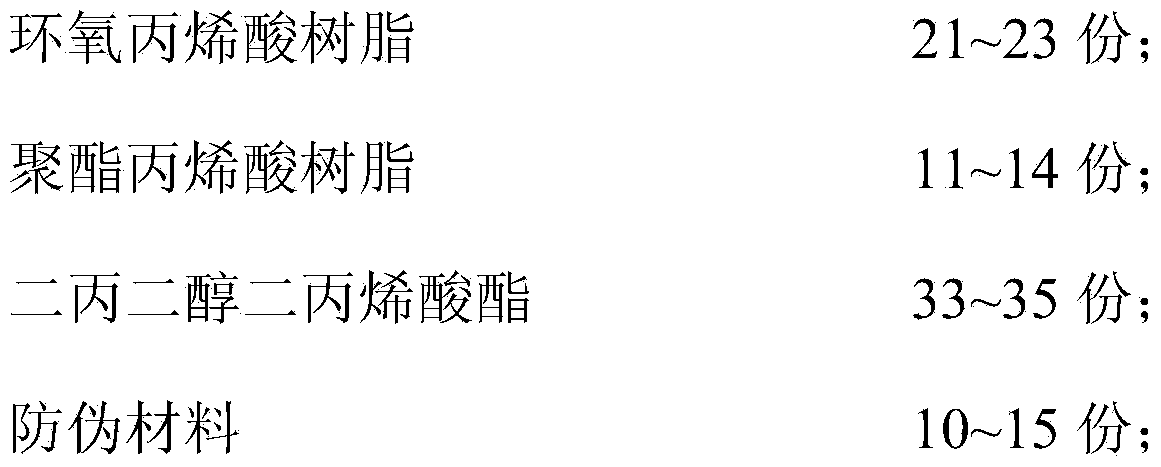

Anti-forgery ink

InactiveCN103627251AReduce manufacturing costIncrease productivityInksAcrylic resinDipropylene glycol diacrylate

The invention discloses anti-forgery ink which consists of the following components in parts by mass: 21-23 parts of epoxy acrylic resin, 11-14 parts of polyether acrylic resin, 33-35 parts of dipropylene glycol diacrylate, 10-15 parts of anti-forgery material, 5-20 parts of dye, 5-10 parts of auxiliary and 3-5 parts of filler. The production cost of the anti-forgery ink disclosed by the invention is low, the production efficiency is high, instant drying can be realized, and the anti-forgery ink is not easy to copy and has high anti-forgery capability grade.

Owner:张家港任发化工材料有限公司

Active energy ray-curable inkjet ink composition

The disclosure relates to an active energy ray-curable inkjet ink composition comprising at least a monomer and a pigment, wherein the monomer comprises at least 2-(2-vinyloxyethoxy)ethyl acrylate and dipropylene glycol diacrylate. A content of 2-(2-vinyloxyethoxy)ethyl acrylate is 36 to 65% by weight in a total weight of the ink. A content of dipropylene glycol diacrylate is 31 to 63% by weight in the total weight of the ink. A content of the pigment is 1 to c % by weight in the total weight of the ink, wherein the c is the pigment concentration at which the average absorbance at 320-380 nm in 2,000-fold dilution of the ink composition with dipropylene glycol diacrylate is 1.

Owner:TOYO INK SC HOLD CO LTD +1

Ultraviolet curing printing ink for silk-screen printing and preparation method thereof

The invention discloses ultraviolet curing printing ink for silk-screen printing. The ultraviolet curing printing ink is characterized by being prepared by the following raw material in parts by weight: 1 to 3 parts of organic pigment, 12 to 15 parts of trimethylolpropane triacrylate, 9 to 12 parts of 1,6-hexanediol diacrylate, 2 to 4 parts of magnesium aluminate spinel powder, 10 to 12 parts of dipropylene glycol diacrylate, 1 to 2 parts of trimethylolpropane, 1 to 2 parts of phenyl glycidyl ether, 6 to 9 parts of propylene glycol methyl ether acetate, 4 to 6 parts of 184 photoinitiator, 3 to 4 parts of an accelerant DM, 1 to 2 parts of a crosslinking agent TAC, 1 to 2 parts of cobalt naphthenate, 1 to 2 parts of zirconium fluoride and 4 to 5 parts of an additive. The ultraviolet curing printing ink improves the toughness of printing ink, enables the printing ink to be uniformly distributed, maintains the stability of the printing ink, has good toughness, guarantees good adhesive force of overprinted ink films, avoids defects of cracking and falling off of the ink films, is high in curing speed, saves energy consumption, and is relatively environmentally friendly.

Owner:GUANGDONG GAOYI PACKAGING & PRINTING CO LTD

Thermosensitive color-changing microcapsule UV (Ultraviolet) photo-cured printing ink and preparation method thereof

The invention discloses thermosensitive color-changing microcapsule UV (Ultraviolet) photo-cured printing ink and a preparation method thereof, and belongs to the technical field of printing ink. The thermosensitive color-changing microcapsule UV photo-cured printing ink is prepared from the following raw materials in parts by weight: 22 to 60 parts of epoxy acrylate, 15 to 25 parts of color developing microcapsule, 15 to 25 parts of polyester acrylate, 10 to 15 parts of dipropylene glycol diacrylate, 5 to 10 parts of trimethylolpropane triacrylate, 5 to 10 parts of acrylic acid-4-polyhydroxybutyrate, 0.5 to 3 parts of benzil dimethyl ketal, 1 to 5 parts of dispersing agent, 1 to 5 parts of hollow glass beads and 1 to 3 parts of UV varnish. The thermosensitive color-changing microcapsule UV photo-cured printing ink is cured by UV, and has the advantages of high drying speed, good fixing effect, clear meshes, water resistance, solvent resistance, abrasion resistance and the like, is almost zero in VOCs (Volatile Organic Compounds) emission, is environment-friendly, and has a wide application range and a higher application value.

Owner:GUANGDONG ZHUANGLI COLOR PRINTING

Degradable gravure UV anti-counterfeiting ink and application thereof to gold and silver cardboards

ActiveCN106590174APromote degradationGood directional discoloration effectInksCardboardDipropylene glycol diacrylate

The invention discloses degradable gravure UV anti-counterfeiting ink. The degradable gravure UV anti-counterfeiting ink comprises, by weight percentage, 20-30% of epoxidized soybean oil acrylate, 10-20% of optical-variable pigment, 15-25% of dipropylene glycol diacrylate, 20-30% of 2-phenoxyethyl acrylate, 2-5% of BP photo-initiator, 3-6% of ITX photo-initiator, 8-10% of amine initiator and 1-3% of auxiliaries. The prepared single-component gravure UV anti-counterfeiting ink has the advantages that the ink is free of solvent during use, no toxic gas is discharged, the ink is environmentally friendly, free of pollution and good in tinting power and fluidity, the color changing performance of the ink along with angle change is high, and the requirements of the anti-counterfeiting ink can be satisfied.

Owner:HUIZHOU PERFECT CHEM IND CO LTD

Anti-cracking UV spray coating white gloss varnish and preparation method of same

InactiveCN110938369AImprove crack resistanceGood yellowing resistancePolyurea/polyurethane coatingsEpoxy resin coatingsPolymer scienceO-Phosphoric Acid

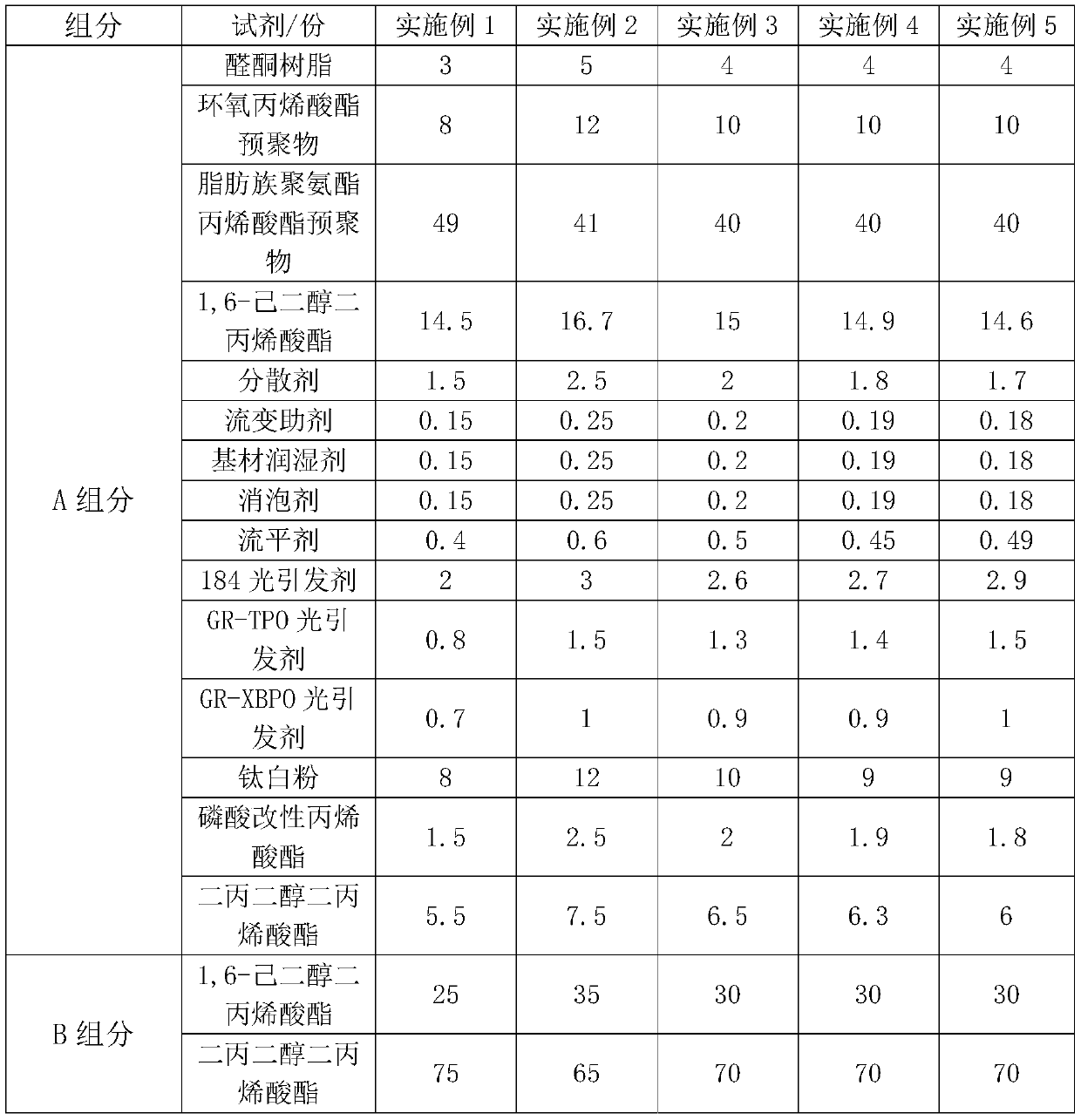

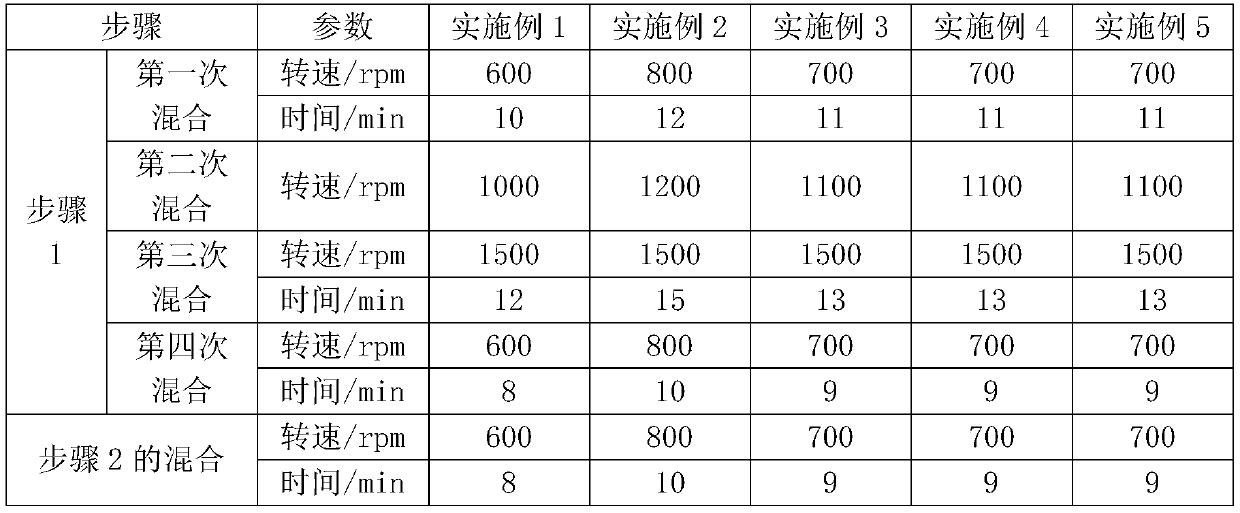

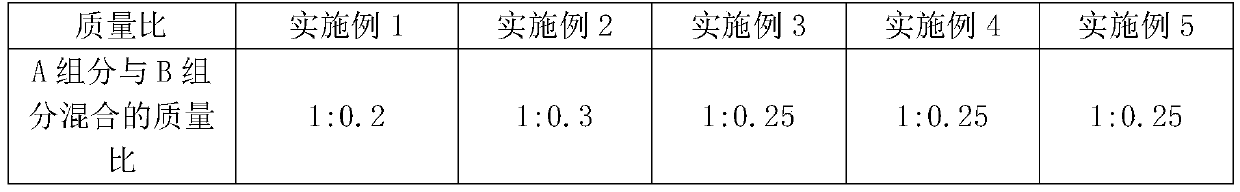

The invention discloses an anti-cracking UV spray coating white gloss varnish which includes, in an independent packaged manner, a component A and a component B, wherein the component A is composed of, by weight, 3-5 parts of aldehyde ketone resin, 8-12 parts of epoxy acrylate prepolymer, 41-49 parts of aliphatic polyurethane acrylate prepolymer, 14.5-16.7 parts of 1,6-hexanediol diacrylate, 1.5-2.5 parts of a dispersant, 0.15-0.25 parts of a rheological additive, 0.15-0.25 parts of a base material wetting agent, 0.15-0.25 parts of a defoamer, 0.4-0.6 parts of a leveling agent, 3.6-5.5 parts of a photoinitiator, 8-12 parts of titanium dioxide, 1.5-2.5 parts of phosphoric acid modified acrylate, and 5.5-7.5 parts of dipropylene glycol diacrylate; the component B is composed of, by weight, 25-35 parts of 1,6-hexanediol diacrylate and 65-75 parts of dipropylene glycol diacrylate. The mass ratio of the component A to the component B is 1:0.2-0.3. The UV spray coating white gloss varnish has excellent anti-cracking effect.

Owner:SHANGHAI BADES CHEM NEW MATERIAL CO LTD

UV matte white finish paint on melamine board and preparation of UV matte white finish paint

InactiveCN114437631ASmall smellImprove drynessEpoxy resin coatingsPolymer scienceDipropylene glycol diacrylate

The invention discloses UV matte white finish paint on a melamine board and preparation of the UV matte white finish paint. The UV matte white finish paint is prepared from modified UV adhesive force resin, modified UV acrylic resin, modified epoxy acrylic resin, dipropylene glycol diacrylate (DPGDA), hydroxyethyl methylacrylate (HEMA), an acrylic copolymer dispersing agent, a rheological additive, a base material wetting agent, a non-silicon defoaming agent, a fluorocarbon modified polymer leveling agent, a 184 photoinitiator, a GR-TPO photoinitiator and fumed silica. A component A is composed of imported rutile titanium dioxide, matting powder, a cellulose acetate butyrate solution (20% cellulose acetate butyrate and 80% butyl acetate) and butyl acetate, and a component B is composed of butyl acetate, butyl acetate and propylene glycol methyl ether acetate. During construction, the component A and the component B are uniformly mixed in proportion. Detection and trial prove that in the construction process, the UV matte white finish is low in odor, good in paint film dryness, good in whiteness, high in fullness, uniform in gloss, fine and smooth in hand feeling, high in hardness, good in water resistance and chemical resistance and good in yellowing resistance. The paint is suitable for coating melamine boards in furniture.

Owner:CHENGDU ZHANCHEN PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com