UV oil solid color paint

A solid-color, oil-based technology, applied in the field of coatings, can solve the problems of large color difference, flexibility, unsatisfactory wettability, color migration, etc., and achieve the effect of reducing stress shrinkage, improving flexibility, and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below.

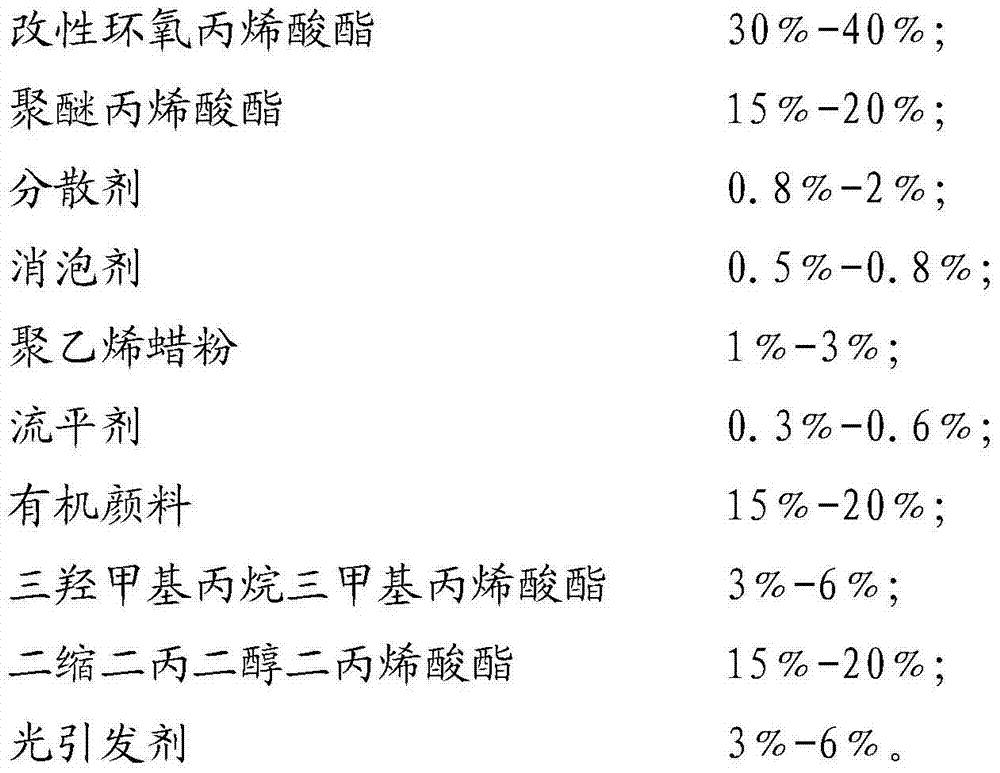

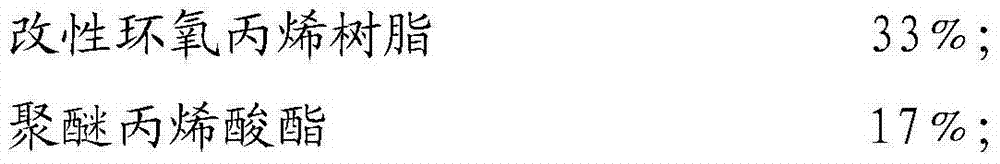

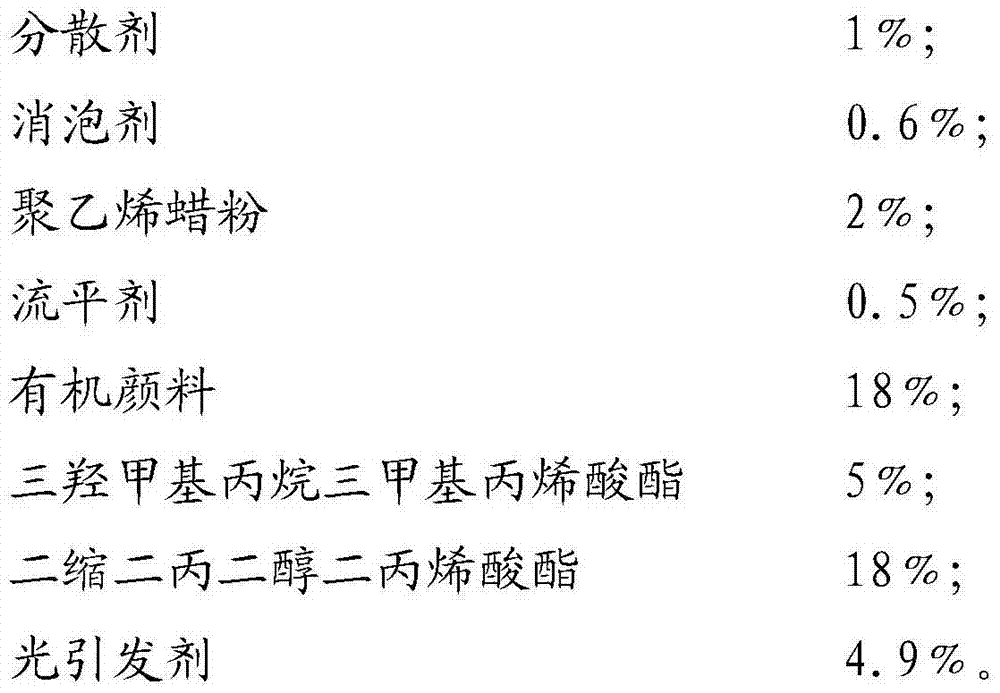

[0018] The embodiment of the present invention UV oily solid color paint, is made up of following components by mass percentage:

[0019] Epoxy resin 33%; polyether acrylate 17%; dispersant 1%; defoamer 0.6%; polyethylene wax powder 2%; leveling agent 0.5%; organic pigment 18%; trimethylolpropane trimethyl Acrylate 5%; Dipropylene glycol diacrylate 18%; Photoinitiator 4.9%;

[0020] The dispersant is one of the following substances: commercially available block polymer dispersants such as BYK-163 and BYK-161 from BYK, Germany, and EFKA4056 from Ciba.

[0021] The defoamer is one of the following substances: commercially available silicone defoamers such as BYK-141 from BYK and EFKA2022 from Ciba.

[0022] The leveling agent is one of the following substances: commercially available photosensitive-responsive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com