Patents

Literature

68results about How to "Improve anti-yellowing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

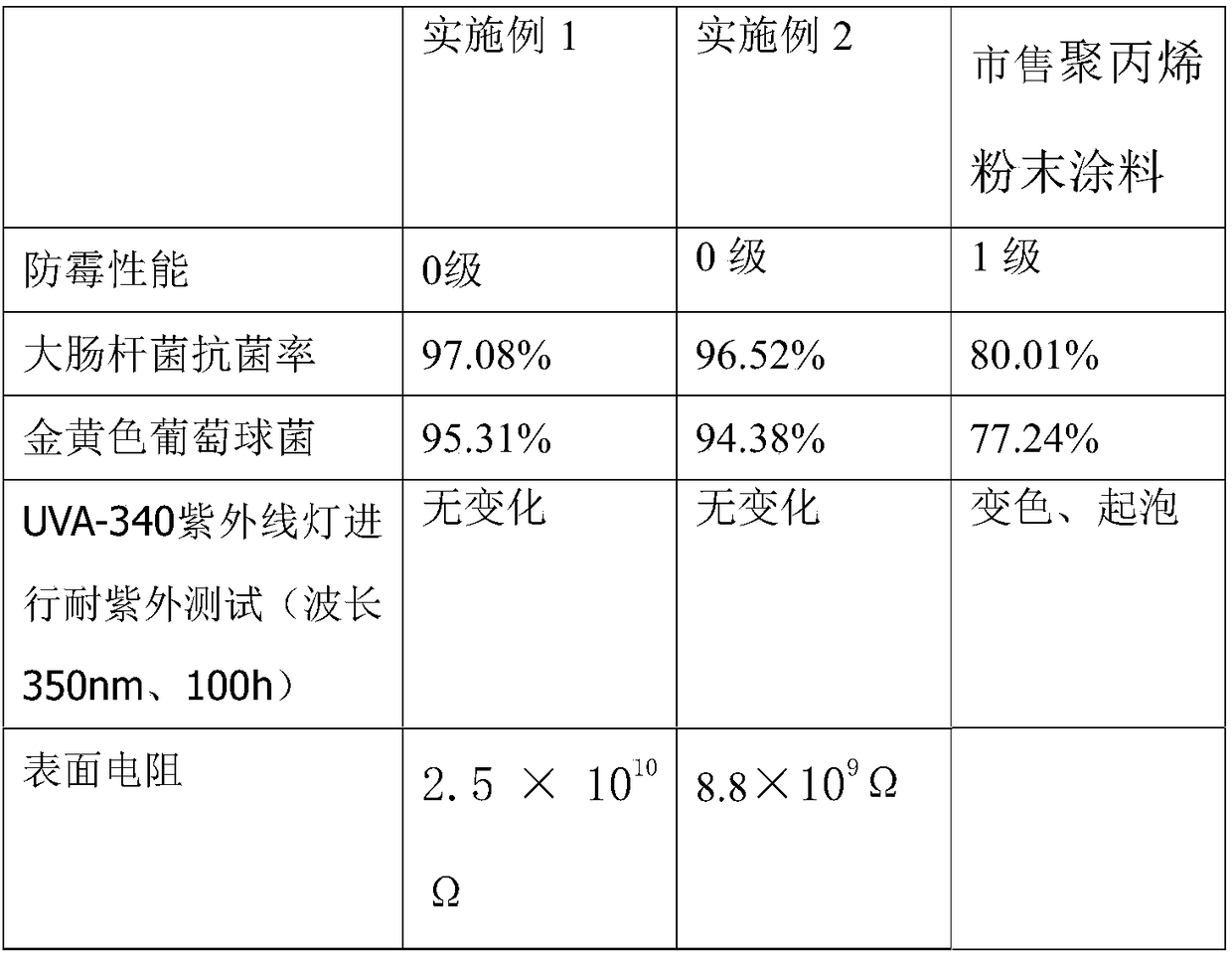

High weather-proof and corrosion-resistant powder paint for satellite earth antenna and preparation method thereof

ActiveCN102898933AGood electrificationShort curing timePowdery paintsPolyester coatingsAcrylic resinPolyester resin

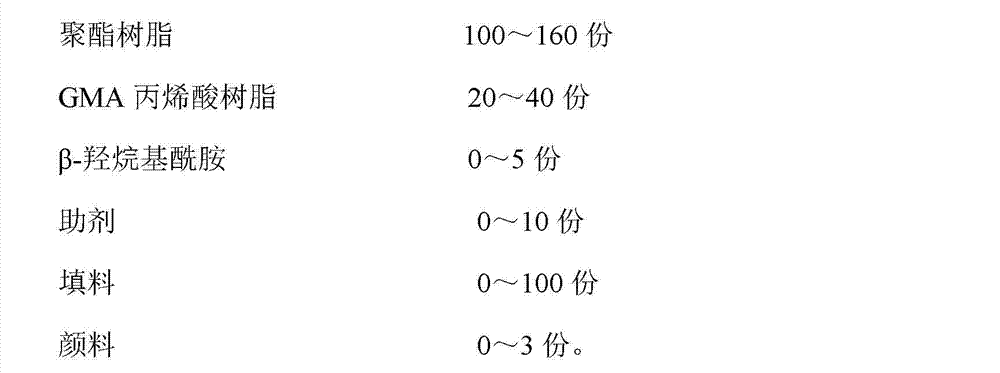

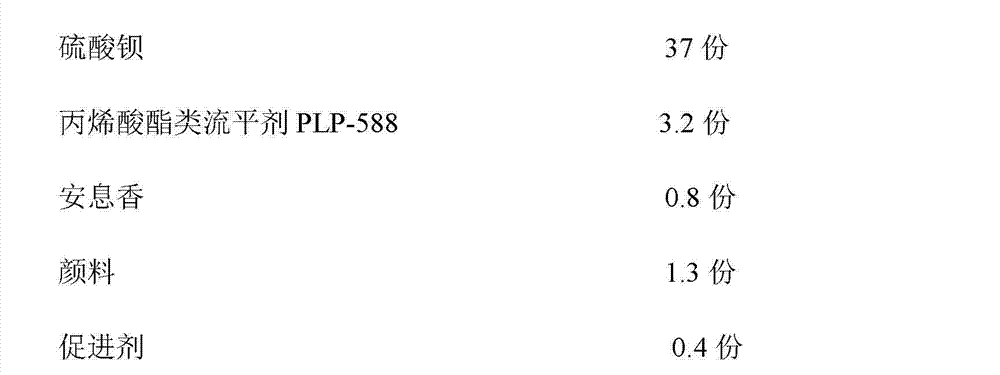

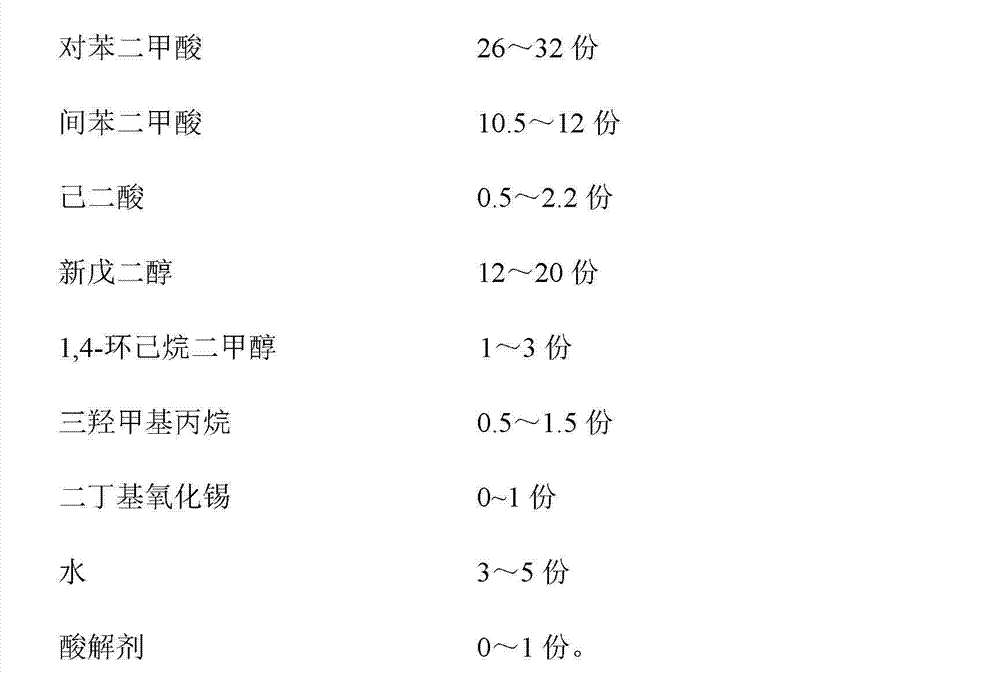

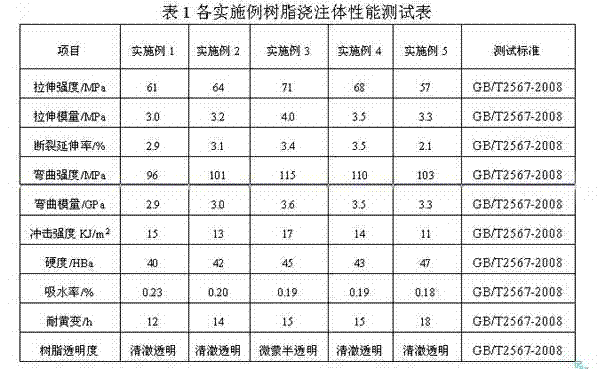

The invention discloses a high weather-proof and corrosion-resistant powder paint for a satellite earth antenna. The paint comprises, by weight, 100-150 parts of polyester resin, 20-40 parts of GMA acrylic resin, 0-5 parts of beta-hydroxyalkylamide, 0-10 parts of assistants, 0-100 parts of paddings and 0-3 parts of pigments. The invention further discloses a preparation method for the powder paint. A coating after being coated by the paint and curing is good in mechanical properties, super-weather-proof, salt mist resistant, and provided with stable low gloss area.

Owner:GUANGZHOU KINTE IND

Mono-acid blocked unsaturated polyester resin and preparation method for same

The invention belongs to the technical field of unsaturated polyester resin, and particularly relates to a mono-acid blocked unsaturated polyester resin, formed by using dibasic alcohol, saturated dibasic acid, unsaturated dibasic acid, a monobasic acid blocking agent and a diluting agent as raw materials, and then performing condensation polymerization; and the raw materials comprise, in parts by weight, (1) 19-28 parts of dibasic alcohol, (2) 10-25 parts of saturated dibasic acid, (3) 15-27 parts of unsaturated dibasic acid, (4) 1-7 parts of monobasic acid blocking agent, and (5) 28-37 parts of diluting agent. The invention further provides a preparation method for the mono-acid blocked unsaturated polyester resin. The product obtained by the preparation method provided by the invention is better in compatibility, better in hydrolytic stability and higher in hardness compared with common unsaturated resin, as well as high in strength.

Owner:湖州红剑聚合物有限公司

Polyurethane dull white paint for woodenware

The present invention is one kind of dull white finishing polyurethane paint for wood ware. The present invention features that the dull white finishing paint is compounded with three components, including the component A comprising modified alkyd resin, titanium white powder, nitro cotton, etc.; the component B comprising n-butyrate and HDI-90; and component C comprising n-butyrate and toluene. The dull white finishing paint has excellent yellowing resistance, powerful adhesion, high hardness, high wear resistance, good leveling property, and high environment protecting property.

Owner:GUANGDONG BADESE CHEM

Yellowing resistant liquid optical adhesive

ActiveCN103382381APromote uniform dispersionImprove uniformityPolyureas/polyurethane adhesivesPrepolymerPhotoinitiator

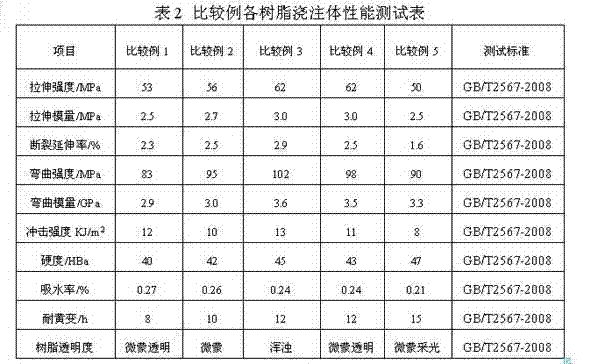

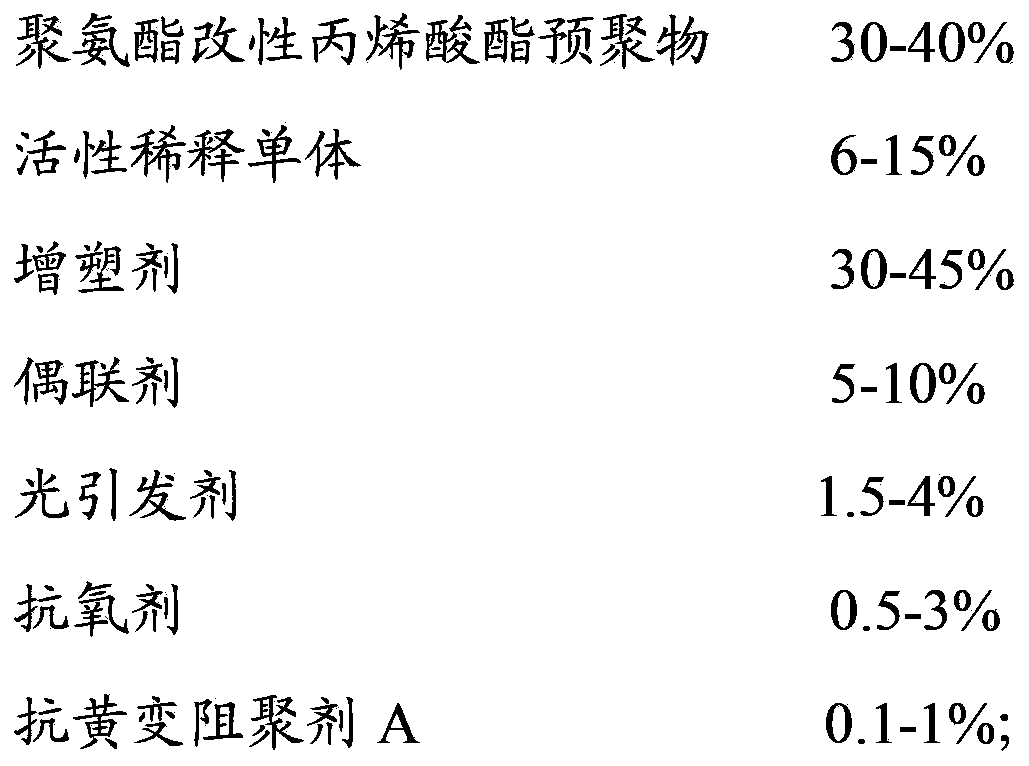

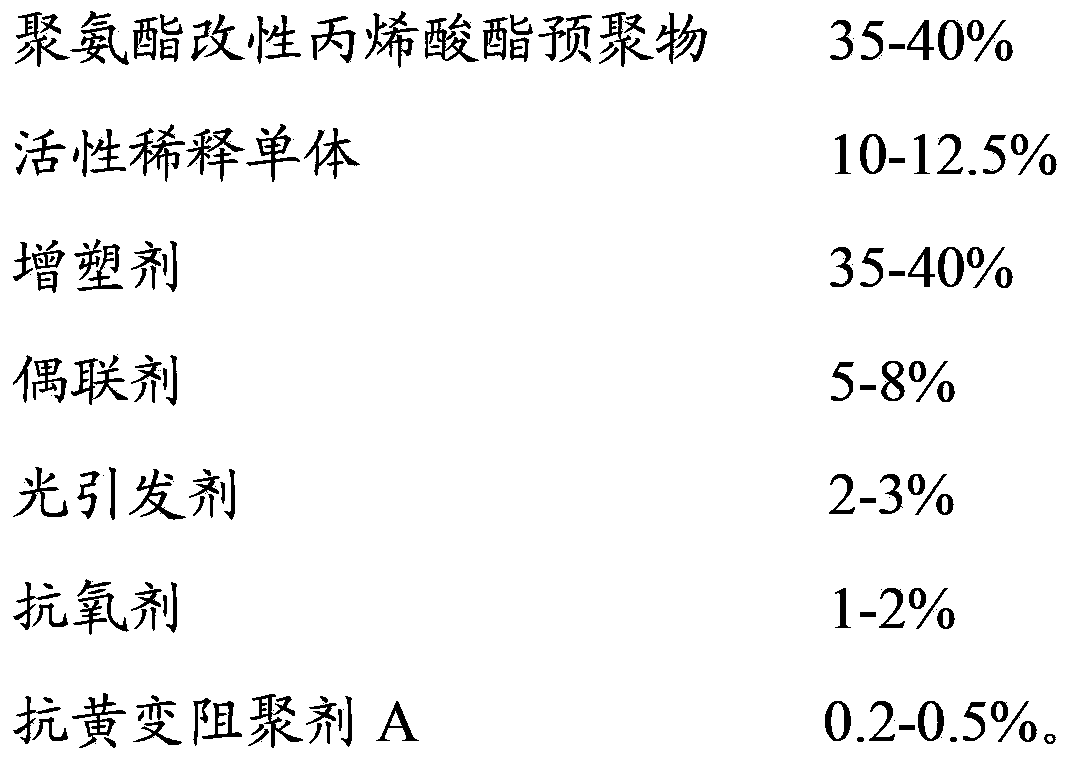

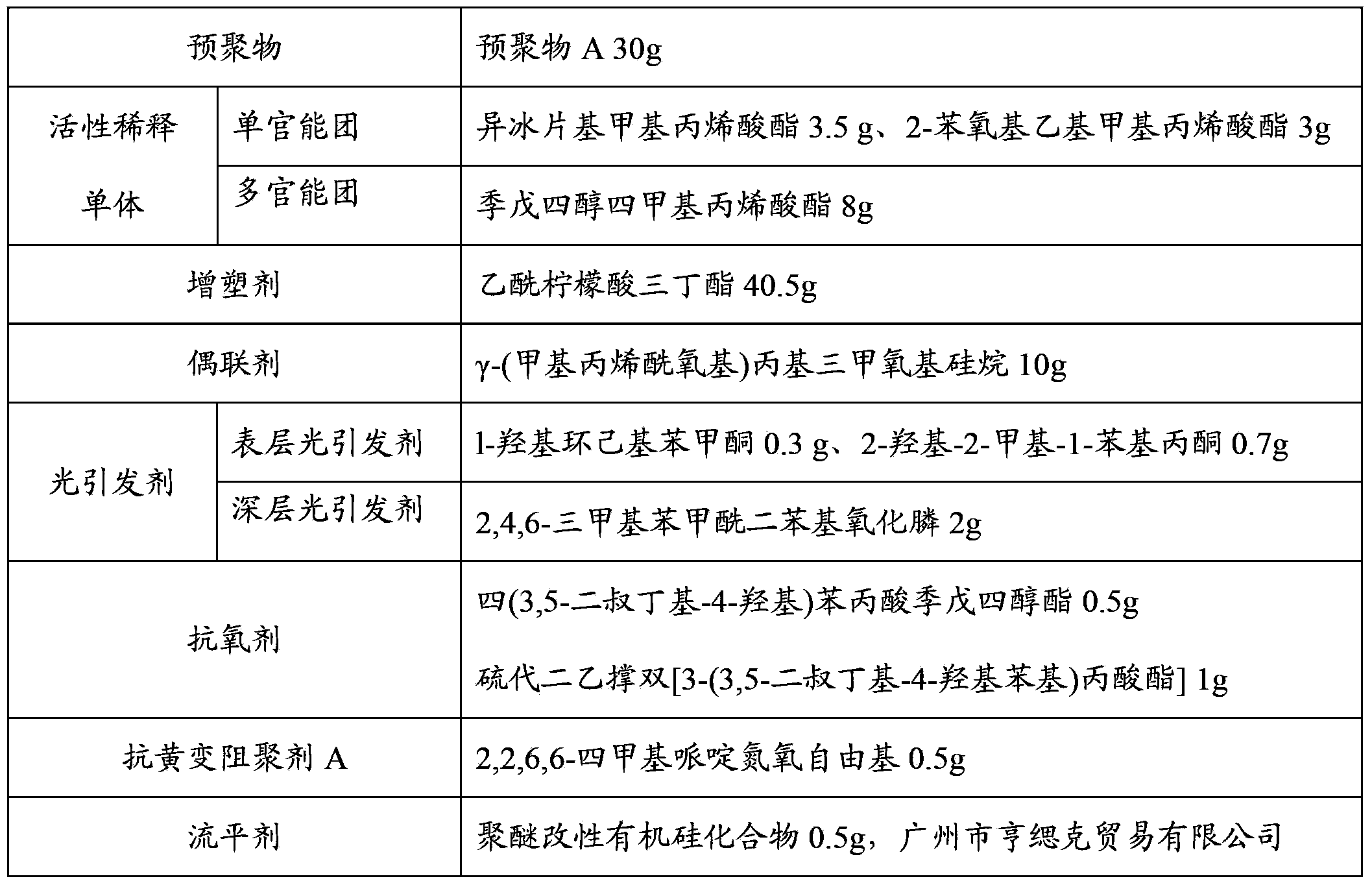

The invention belongs to the technical field of adhesive materials and discloses yellowing resistant liquid optical adhesive. The yellowing resistant liquid optical adhesive comprises the following components of, by mass, 30 to 40% of polyurethane modified acrylate pre-polymers, 6 to 15% of active diluent monomers, 30 to 45% of plasticizers, 5 to 10% of coupling agents, 1.5 to 4% of photoinitiators, 0.5 to 3% of antioxidants and 0.1 to 1% of yellowing resistant polymerization inhibitor A. The yellowing resistant liquid optical adhesive has the advantages of enabling the light transmittance to be larger than 99% and being high in refractive index, yellowing resistant and remarkable in ageing resistance effect due to the synergistic effect of yellowing resistant polyurethane modified acrylates and the monomers, the plasticizers, the coupling agents, the photoinitiators, the antioxidants and the like.

Owner:SHENZHEN ANLI NEW MATERIALS

Moisture permeation and water proofing fabric, and preparation process thereof

InactiveCN102619092ASolve the weakness that it is easy to expand when exposed to waterGood moisture permeabilityFibre treatmentCoated surfaceMoisture permeation

The present invention discloses a moisture permeation and water proofing fabric, and a preparation process thereof. According to the fabric, a prime coat comprises: a polyurethane resin, butanone, toluene, water, 1,6-diisocyanatohexane and N-methylethanolamine; a first surface coating and a second surface coating comprise a polyurethane resin, butanone, toluene, water and N-methylethanolamine. The preparation process comprises: mixing 1,6-diisocyanatohexane and a main resin; mixing water and butanone to form a solvent; adding the solvent to the main resin mixing solution in at least 6 times; filtering the resulting mixed solution with a nylon net to obtain a filtered main resin solution; carrying out a deaeration treatment to form a prime coat slurry; blending a surface coating slurry with a matching solution viscosity of 3500-6000 mpas; coating the prime coat slurry on the surface of the base cloth to form the prime coat, and drying; coating the surface coating slurry on the surface of the prime coat in 2 times to form the surface coatings, and drying. In the prior art, micropores in the hydrophilic moisture permeation processing coating fabric are not uniform, and are easily expanded when contacting the water. With the present invention, the disadvantages in the prior art are solved, and the moisture permeation performance of the fabric is improved.

Owner:KUNSHAN HUAYANG NEW MATERIAL

Method for preparing water-borne functional polyurethane elastic emulsion

InactiveCN101798453AHigh strengthGood weather resistancePolyurea/polyurethane coatingsPolyurethane dispersionWeather resistance

The invention relates to a polyurethane emulsion synthesizing technology and aims to provide a method for preparing water-borne functional polyurethane elastic emulsion. The method comprises the following steps: slowly adding mixed solution of tetrabutyl titanate and absolute ethyl alcohol into acid aqueous solution with stirring to obtain hydrated titanium ion solution; slowly adding the hydrated titanium ion solution into newly prepared water-borne polyurethane dispersion under the conditions of stirring and temperature rise to obtain titanium dioxide nanoparticle in-situ modified water-borne polyurethane dispersion after reaction for a period of time; and complexing the titanium dioxide nanoparticle in-situ modified water-borne polyurethane dispersion and silicone-acrylic emulsion in a certain proportion, and uniformly stirring the mixture to obtain the water-borne functional polyurethane elastic emulsion. The method of the invention solves the problems of easy agglomeration and difficult dispersion in nano powder modification, and endows polyurethane (paint) with higher strength and weather resistance at the same time. In addition, performance, such as water resistance and yellowing resistance, can be further enhanced by adding a proper amount of silicone-acrylic emulsion into the polyurethane dispersion.

Owner:ZHEJIANG UNIV

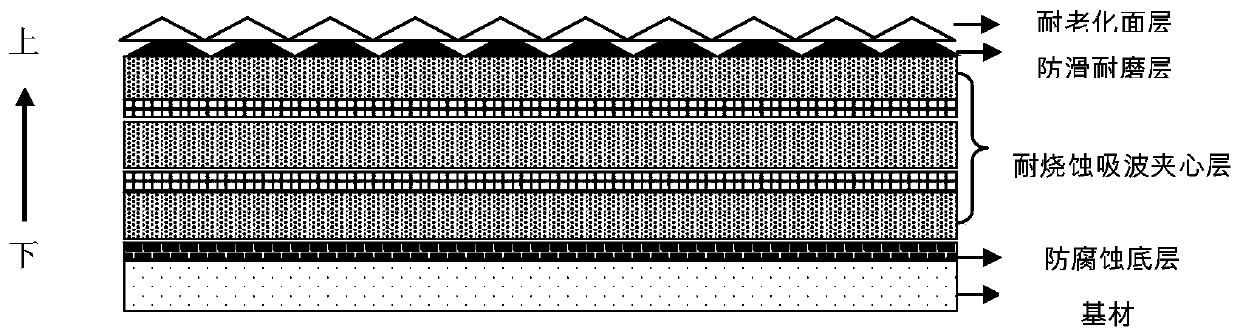

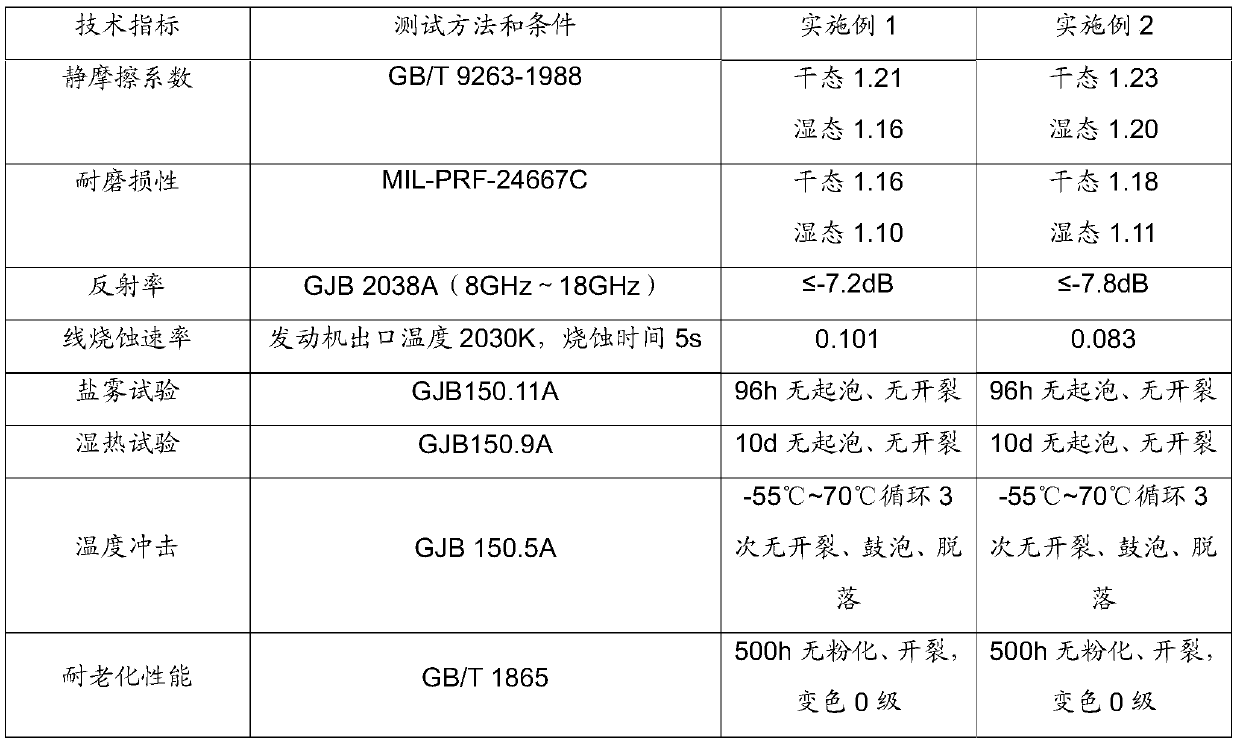

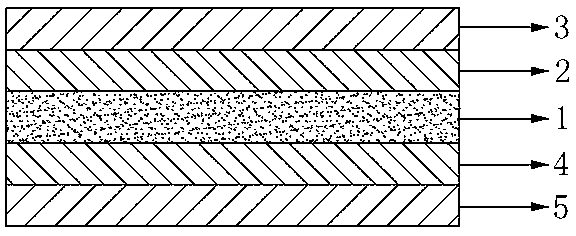

Ablation-resistant, wave-absorbing, antiskid and wear-resistant composite coating and preparation method thereof

ActiveCN110885583AThe need for multifunctional integrationReduced viewing distanceFireproof paintsAnti-corrosive paintsStatic friction coefficientComposite coating

The invention provides an ablation-resistant, wave-absorbing, antiskid and wear-resistant composite coating and a preparation method thereof, and belongs to the field of special functional coatings. The composite coating comprises an anticorrosion bottom layer, an ablation-resistant wave-absorbing sandwich layer, an antiskid and wear-resistant layer and an anti-aging surface layer, and the composite coating is designed through collaborative matching of interlayer thickness to form a multifunctional compatible integrated coating. Compared traditional antiskid coatings, the coating of the invention has the following advantages: the process is simple, the reflectivity of the composite coating is smaller than or equal to -7 dB in a frequency band of 8-18 GHz, the composite coating has a low linear ablation rate and a good anti-aging performance, the static friction coefficient before and after abrasion is larger than or equal to 1.10, the composite coating can pass GJB150 environment testassessment, and the coating design scheme has remarkable technical advancement.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Modified unsaturated polyester resin excellent in ageing resistance and preparation method thereof

The invention discloses a modified unsaturated polyester resin excellent in ageing resistance. The modified unsaturated polyester resin comprises the following raw materials: cis-butenedioic anhydride, phthalic anhydride, maleic anhydride, terephthalic acid, ethylene glycol, propylene glycol, diethylene glycol, rosin, propoxylated bisphenol A, hydroquinone, styrene, linseed oil, cobalt isooctanoate, methyl ethyl ketone peroxide, organic montmorillonite, nano titanium dioxide, nano zinc oxide, an aluminate coupling agent, a polymerization inhibitor, a modified ultraviolet absorber, a catalyst, an air-drying additive and an antioxidant B215. The invention also provides a preparation method of the modified unsaturated polyester resin excellent in ageing resistance. The unsaturated polyester resin prepared by the invention is excellent in ageing resistance.

Owner:滁州常源新材料有限公司

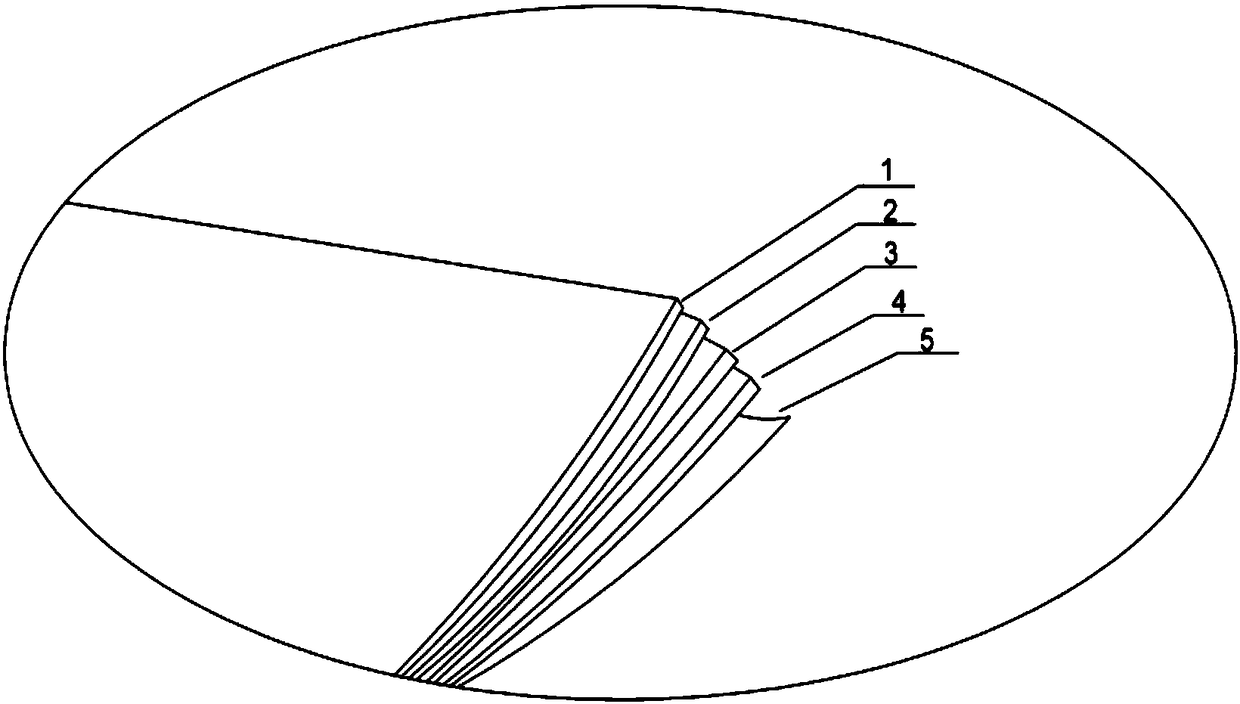

Brightening and anti-scraping protective film capable of being used for car paint or electronic product

PendingCN109233669AStrong adhesionImprove anti-agingFilm/foil adhesivesTectorial membraneAcrylic resin

The invention discloses a brightening and anti-scraping protective film capable of being used for car paint or an electronic product, and relates to the technical field of protective films. The brightening and anti-scraping protective film comprises a base material layer, wherein the upper surface of the base material layer is coated with a self-repair layer; a protective film layer is arranged onthe upper surface of the self-repair layer; the lower surface of the base material layer is coated with an acrylic acid glue layer; the lower surface of the acrylic acid glue layer is adhered with arelease film layer; the base material layer is selected from an aliphatic-series TPU material or a TPV material or a TPU and PVC composite material which is directly tape-cast by multiple layers in acomposite mode; and the self-repair layer is formed by acrylic resin, and is added with an ultraviolet-light absorber and a light stabilizer. The brightening and anti-scraping protective film integrates functions of scraping and ageing resistance, dirt resistance and brightening, good repair effect and the like, can realize the effects of enabling the car to be ageing-resistant, improving new carvalue-holding degree and the like while used on car paint, also can be used for car interior protection, can replace a relatively conventional paint protective film and a paint crystal-coating process, has service life of ten years or more, further can be used to the electronic product field, and achieves a good anti-scraping effect.

Owner:HENGSHAN JIACHENG NEW MATERIAL

Physical modification treatment method of polyurethane foam cotton or foam

The invention discloses a physical modification treatment method of polyurethane foam cotton or foam. The method comprises the following steps of: preparing an organic acid buffer solution, wherein the organic acid buffer solution is obtained by mixing an organic acid and salts thereof with water, and the pH value is between 3 and 7; heating the organic acid buffer solution to 25-40 DEG C; soaking the polyurethane foam cotton or foam in the organic acid buffer solution for 1-20 minutes; and then drying the polyurethane foam cotton or foam. The polyurethane foam cotton or foam treated by the method can improve the physical properties of yellowing resistance, phenolic yellowing resistance and the like.

Owner:YUANHE IND

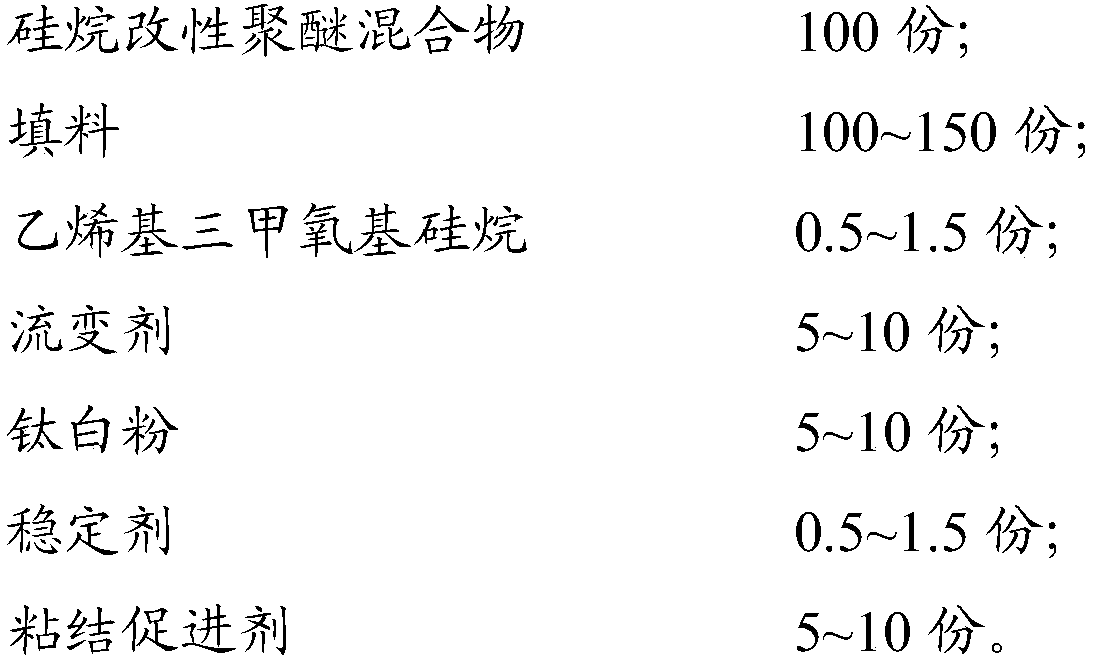

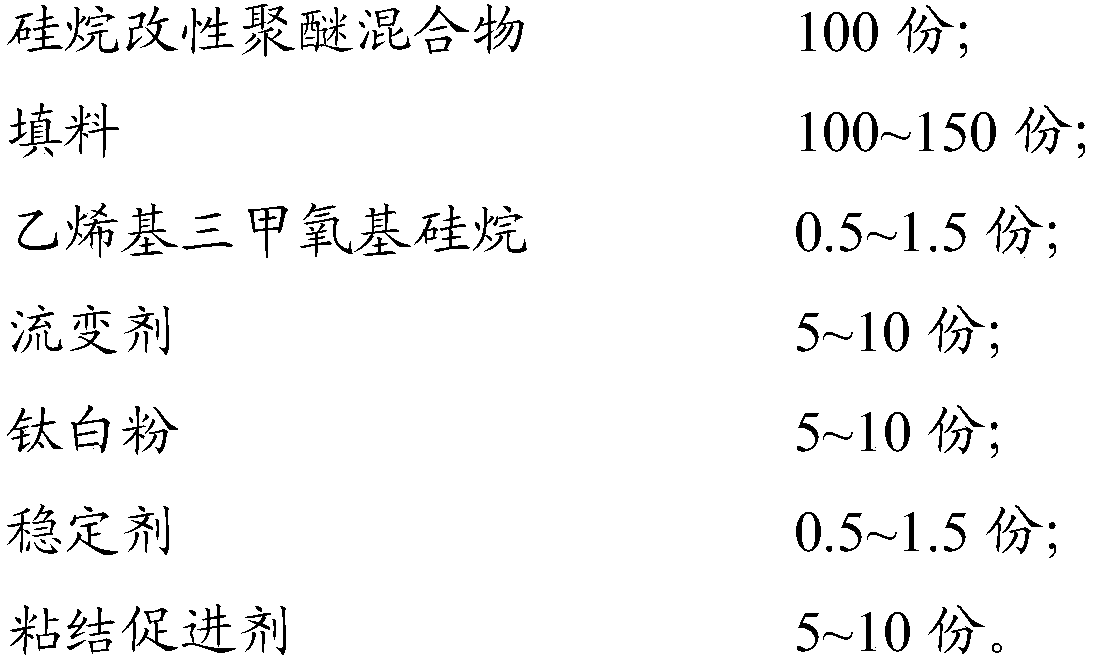

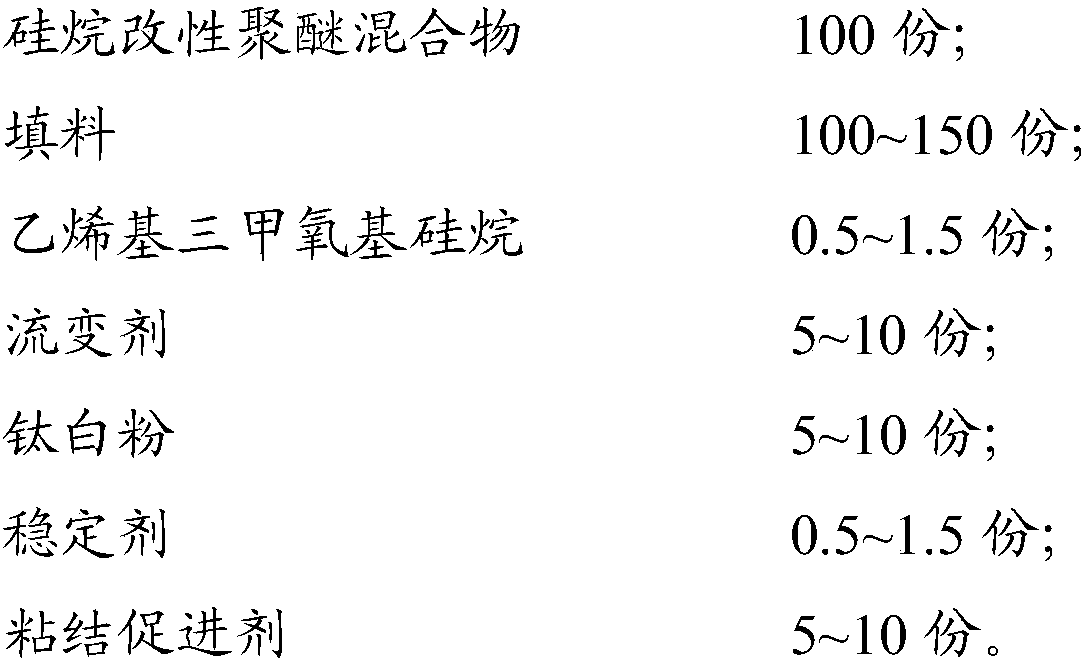

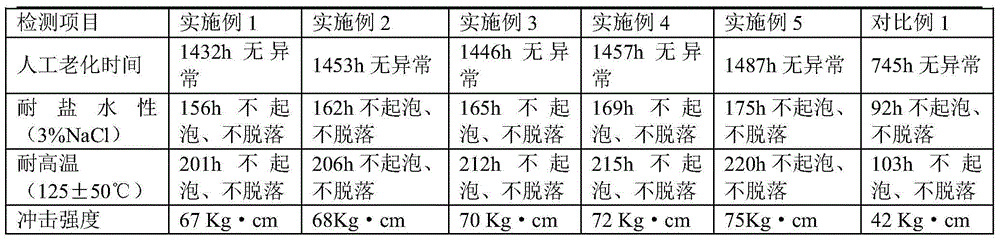

Mould-proof sealant and preparation method thereof

InactiveCN107603550AGood storage stabilityOvercome the defect of poor anti-mildew effectNon-macromolecular adhesive additivesPolyether adhesivesSilicone sealantTitanium dioxide

The invention discloses mould-proof sealant and a preparation method thereof. The mould-proof sealant is prepared from the following raw materials in parts by weight: 100 parts of a silane modified polyether mixture, 100-150 parts of filler, 0.5-1.5 parts of vinyl trimethoxy silane, 5-10 parts of a rheological agent, 5-10 parts of titanium dioxide, 0.5-1.5 parts of a stabilizer and 5-10 parts of acaking accelerator. The mould-proof sealant prepared from the silane modified polyether mixture, the filler, the vinyl trimethoxy silane, the rheological agent, light titanium dioxide, the stabilizerand the caking accelerator has high storage stability and can overcome the defect of the traditional mould-proof silicone sealant that mould-proof effect is poor; after being cured, the product has brightness like ceramic glaze, mould-proof, antipollution and anti-yellowing properties are greatly improved, and the mould-proof sealant is applicable to pointing of ground and wall surface, edge closing of an internal corner and edge closing beautifying of a closestool, a kitchen top, a shower room partition wall, a balcony and a windowsill of top-grade home space, public houses and business places, so that home space sanitation dead angles are thoroughly cleaned.

Owner:SHANDONG YONGAN ADHESIVE IND

Anticorrosive paint for stainless steel decorating plate and preparation method of anticorrosive paint

InactiveCN104877483AImprove protectionImprove rust resistanceCoatingsPolyvinyl alcoholDiethyltoluene diamine

The invention relates to anticorrosive paint for a stainless steel decorating plate and a preparation method of the anticorrosive paint. The anticorrosive paint comprises the following components in parts by mass: 33-34 parts of white latex, 2-10 parts of iron oxide red, 1-4 parts of chromium oxide green, 0.3-1.5 parts of mica magnesium oxide, 5-15 parts of aluminum triphosphate, 2-8 parts of zinc chromate, 1-7 parts of polyvinyl acetal, 0.8-4 parts of zinc oxide, 6-18 parts of zirconia, 1-5 parts of cobalt naphthenate, 0.5-1.8 parts of polyvinyl siloxane, 0.7-2.2 parts of tripropylene glycol diacrylate, 0.1-0.6 part of diethyl methyl benzene diamine, 1-5 parts of sodium nitrite, 0.3-1.6 parts of phenolic resin and 12-24 parts of purified water. The anticorrosive paint has not only an excellent anticorrosive function, but also the properties of relatively high impact resistance, flexibility, hardness, water resistance and the like.

Owner:SUZHOU DEXIANG DECORATION ENG

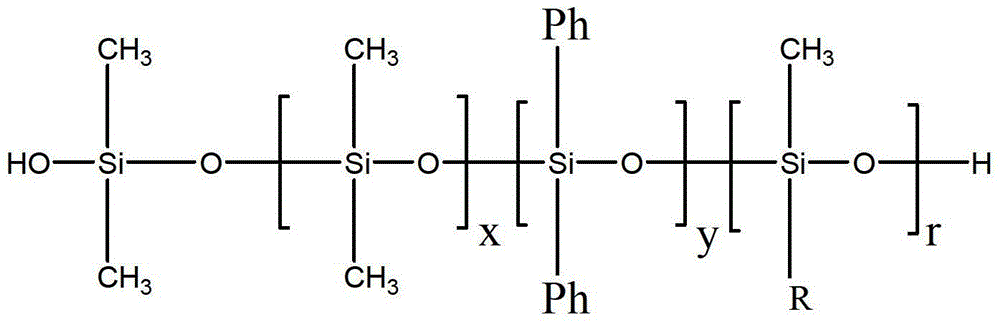

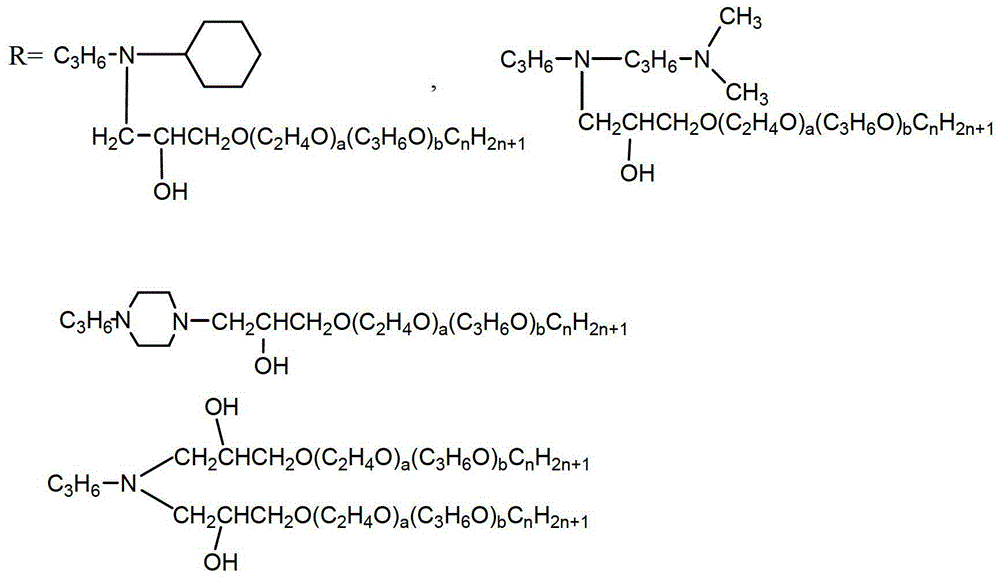

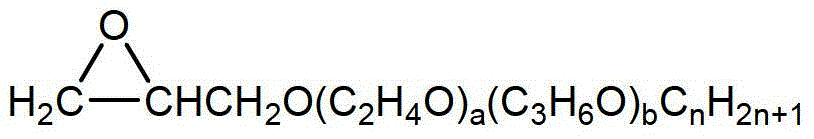

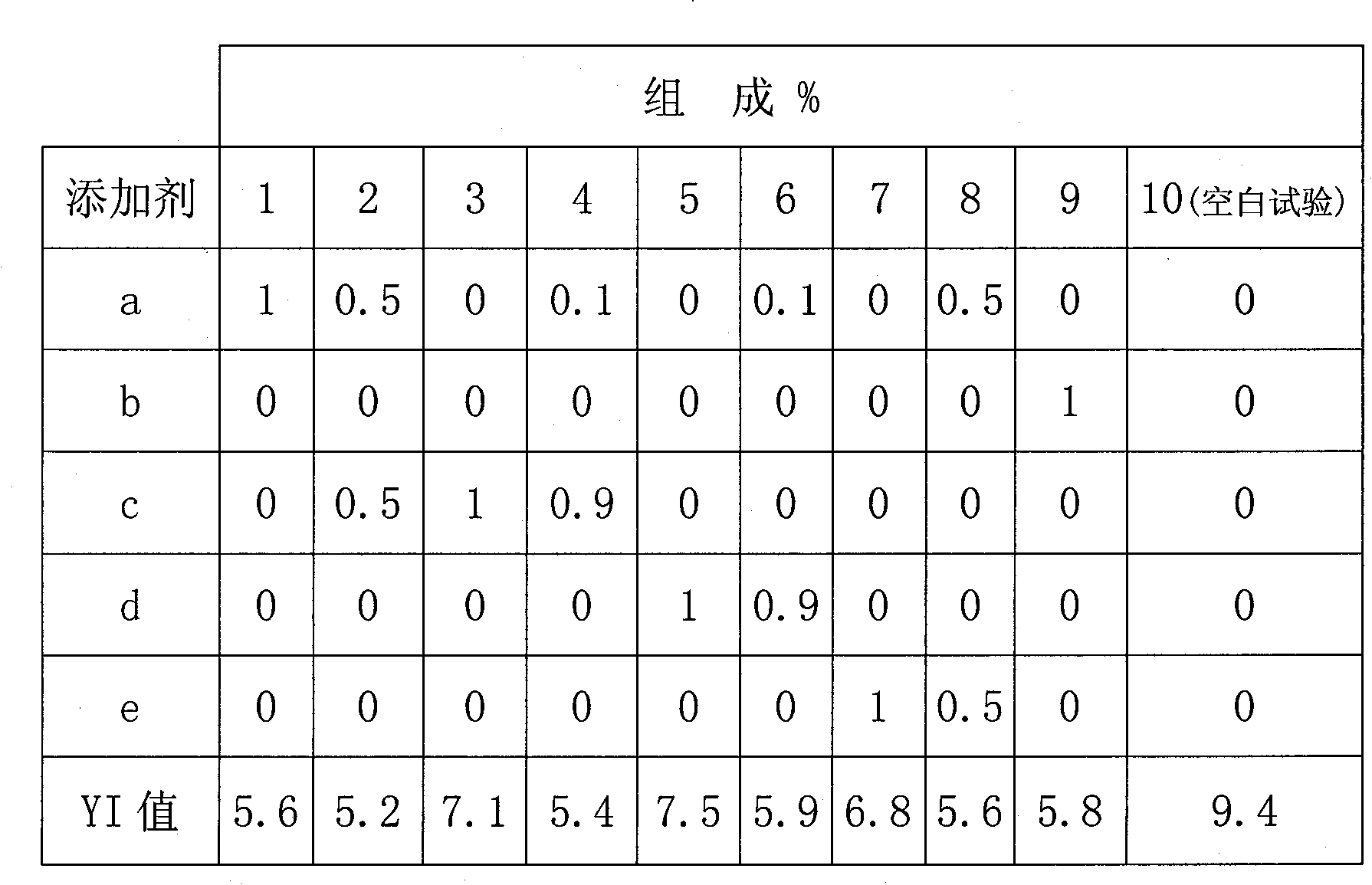

Hydroxyl-terminated phenyl amino polyether modified silicone oil

The invention discloses a hydroxyl-terminated phenyl amino polyether modified silicone oil. According to the invention, polyether modified amino silane is firstly prepared from amino silane and alkyl epoxy polyether, and then the hydroxyl-terminated phenyl amino polyether modified silicone oil is prepared from polyether modified amino silane, phenylsilane and octamethylcyclotetrasiloxane in the presence of a catalyst. Compared with the prior art, alkyl phenyl silane, polyether modified amino silane and octamethylcyclotetrasiloxane are synthesized into a brand-new hydroxyl-terminated phenyl polyether modified silicone oil through a polymerization balanced reaction. The microemulsion type softener emulsified by the silicone oil is soft and smooth in hand feel and excellent in yellowing resistance and temperature resistance when used for finishing textiles; the product is good in stability of shear force, centrifugal force, electrolyte, hard water and the like, and is particularly suitable for surface treatment of polyester fibers.

Owner:黄山市强力化工有限公司

Composite antioxidant for polyurethane fiber

InactiveCN101775204AImprove anti-yellowing and thermal stabilityImprove anti-yellowingMonocomponent synthetic polymer artificial filamentArtifical filament manufactureChemistryBenzene

The invention discloses a composite antioxidant for polyurethane fiber; the composite antioxidant takes 1, 3, 5-trimethyl-2, 4, 6-3 (3,5-di-tert-butyl-4-hydroxy benzyl) benzene as the main material, comprises one or two types of mixed pentaerythritol-4 (3-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate, 3 (3,5-di-tert-butyl-4-hydroxy benzyl) isocyanurate and Beta-(3,5-di-tert-butyl-4-Hydroxy-phenyl) propionic acid ester 18 and is added into polyurethane to improve the thermal stability of the polyurethane; the composite antioxidant comprises the following components in ratio by weight: the ratio of the 1,3,5-trimethyl-2,4,6-3 (3,5-di-tert-butyl-4-hydroxy benzyl) benzene to the sum of the other component or to the other two components is: 1 to 90:99 to 10; and the addition is 0.01 to 5.0 percent of the weight of the polyurethane. The use of the composite antioxidant for polyurethane fiber can greatly improve the yellowing resistance and the thermal stability of the polyurethane fiber.

Owner:迪比喜化学贸易(上海)有限公司

Aqueous marble-imitated colorful paint and preparation construction method therefor

InactiveCN105419542AGood alkali resistanceGood chemical resistanceAnti-corrosive paintsEmulsionPreservative

The invention relates to aqueous marble-imitated colorful paint. The comprises the following ingredients, by weight, 200-300 parts of deionized water, 3.5-5.5 parts of hydroxyethyl cellulose, 10-15 parts of heavy calcium carbonate, 0.5-2.0 parts of wetting agent, 1.5-2.5 parts of antifoaming agent, 10-20 parts of propylene glycol, 8.5-10.5 parts of glycol, 17.5-20.5 parts of film forming auxiliary agent, 2.5-5.5 parts of polyurethane thickening agent, 350-450 parts of silicone acrylic emulsion, 2.5-4.5 parts of leveling agent, 0.1-0.4 part of drier, 2.0-3.0 parts of anti-sedimentation agent, 2.0-3.0 parts of antiseptic and 150-200 parts of color slices. The aqueous marble-imitated colorful paint is advantaged by excellent acid resistance, alkali resistance and chemical resistance, high ultraviolet resistance, super durability, anti-yellowing and water white resistance.

Owner:青建集团股份公司

Anti-yellowing colorful explosion-proof membrane

PendingCN109161353AStrong adhesionImprove anti-yellowingFilm/foil adhesive primer layersPressure sensitive film/foil adhesivesTectorial membraneUltraviolet

An anti-yellowing colorful explosion-proof membrane relates to the technical field of printed explosion-proof membranes, and comprises a base material layer, wherein the base material layer is prepared from an optically-grade PET membrane or a PC membrane or a PMMA membrane, the bottom surface of the base material layer is provided with a printable hardening layer in a spin-coating manner, the printable hardening layer is subjected to spin-coating and rolling-pressing by a roller with the peripheral surface provided with textures, and a dyeing aid is added on the printable hardening layer, sothat the wire drawing and texture as well as color change can be achieved, the top surface of the base material layer is coated with an adhesive layer, an ultraviolet absorber and a stabilizing agentare added in the adhesive layer, and the top surface of the adhesive layer is compounded with a protective membrane layer. The invention relates to the anti-yellowing colorful explosion-proof membranewhich can be applied in the back cover of a 5G mobile phone; and the membrane can be directly silk-screened on the surface, operation procedures, such as slicing and UV transferring, are omitted, theproduction efficiency is high, and the anti-yellowing effect is good.

Owner:HENGSHAN JIACHENG NEW MATERIAL

Anti-storage yellowing agent for nylon and preparation method of anti- storage yellowing agent

ActiveCN108004768APrevent phenol yellowingImprove qualityLight resistant fibresEnvironmental resistanceAlcohol

The invention discloses a anti- storage yellowing agent for nylon and a preparation method of the anti- storage yellowing agent. The anti- storage yellowing agent comprises the following components bymass percent: 20-40% of linear alkyl benzenesulphonate, 10-25% of hydramine compound, 10-20% of an alcohol cosolvent, 1-3% of an anionic surfactant, 2-5% of a nonionic surfactant, 0.05-0.1% of a preservative and the balance of deionized water. The linear alkyl benzenesulphonate and the hydramine compound are combined to be taken as the raw materials, the compound synergetic effect of the raw materials is achieved while the effects of the linear alkyl benzenesulphonate and the hydramine compound are produced, and the anti- storage yellowing agent has an excellent anti-yellowing effect. The phenolic yellowing in the processes of storage, transportation and use of a nylon fiber product is prevented, the quality and the value of the nylon fiber product are improved, the raw materials meet theenvironmental requirement, belong to the environment-friendly products, are non-toxic, harmless and non-irritant, are environmentally friendly, and are pollution-free, the raw materials are basicallyuniversal raw materials, so that the pressure of the material inventory of a company is alleviated, and the production cost of the product is lowered.

Owner:广州先盈生物科技有限公司

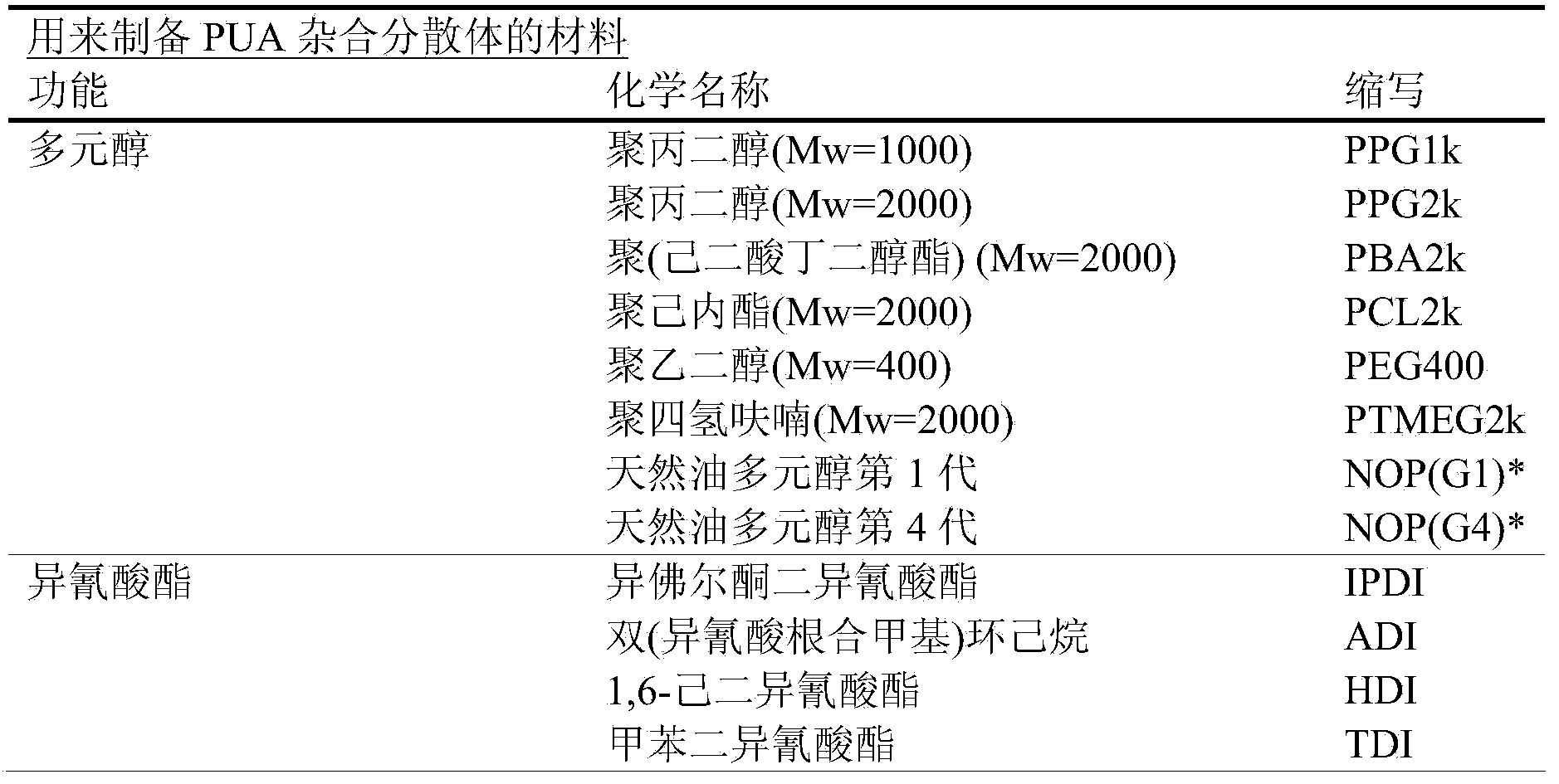

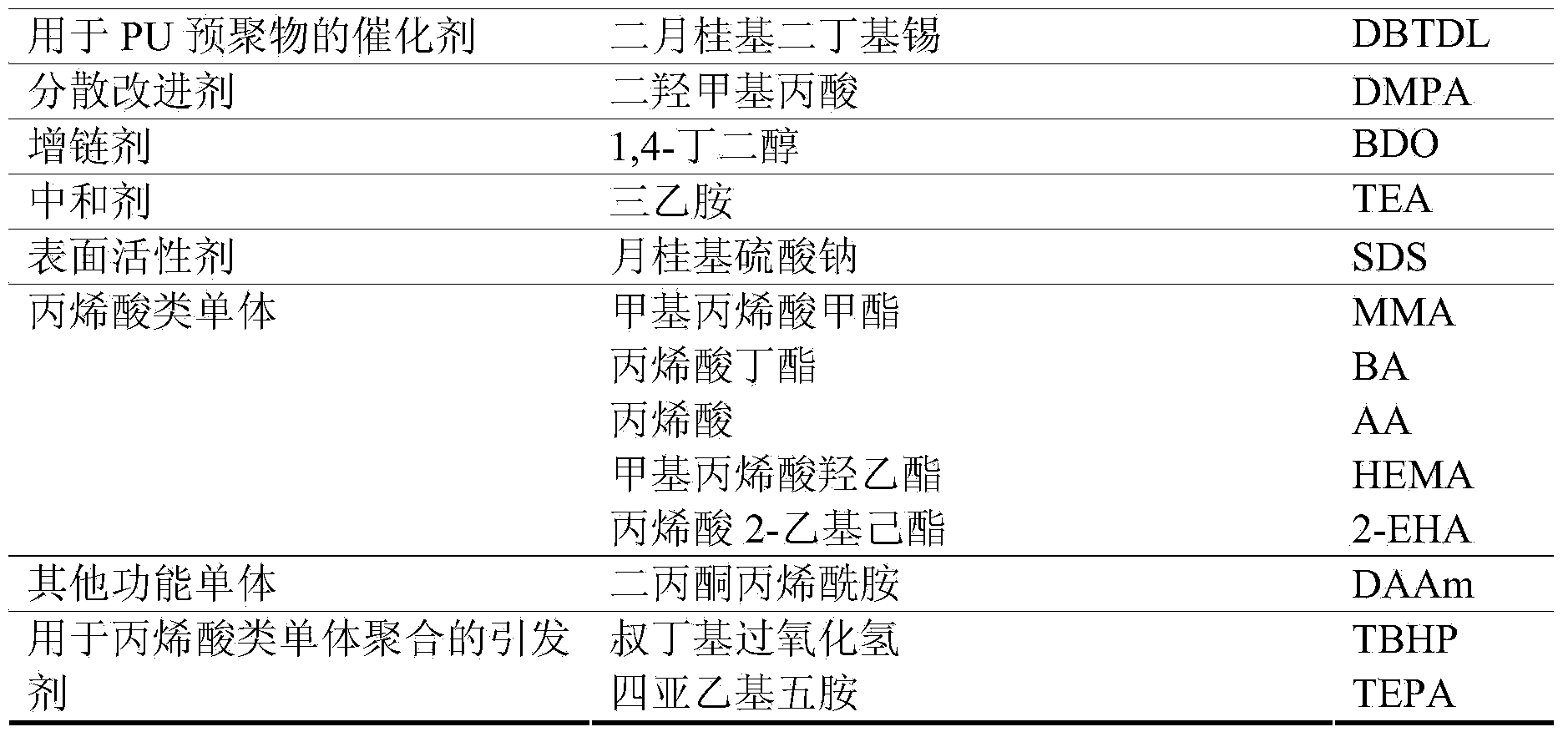

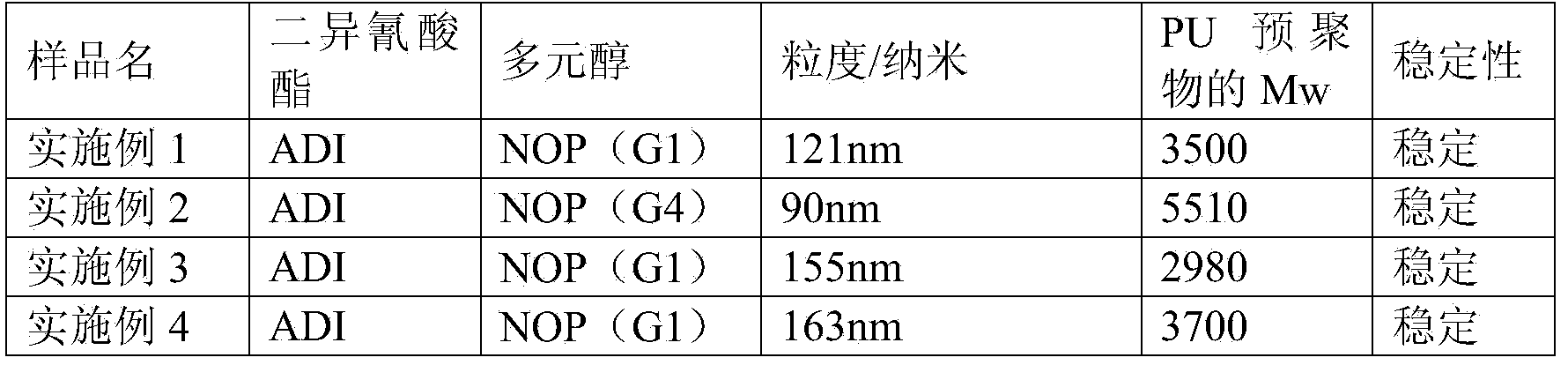

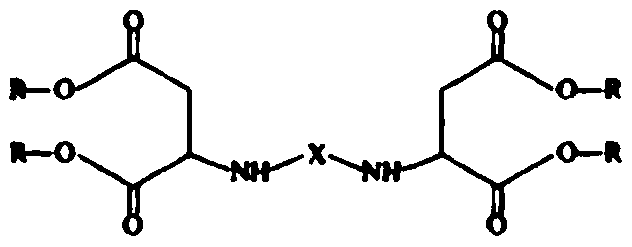

Process for preparing polyurethane/acrylic hybrid dispersions

InactiveCN103958558AImprove performanceCannabis DurabilityPolyurea/polyurethane coatingsCoatingPolyurethane

The present invention provides a new process for making polyurethane / acrylic (PUA) hybrid dispersions, specifically, it relates to a chemical hybrid method for preparing stable, super durable and water whitening resistant PUA hybrid dispersions. The present invention further provides a PUA hybrid dispersion prepared according to the above process and a coating composition comprising the PUA hybrid dispersion.

Owner:DOW GLOBAL TECH LLC +1

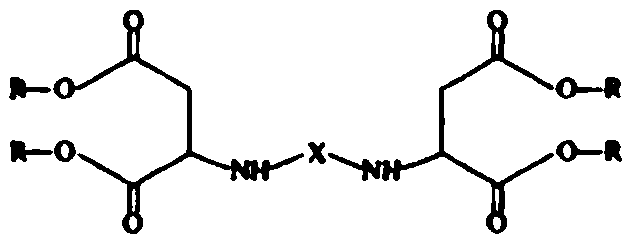

Aspartate polyurea adhesive and preparation method thereof

InactiveCN110256996AStrong adhesionReduce reactivityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesCarbamatePolyurethane adhesive

The invention discloses an aspartate polyurea adhesive, relates to the technical field of adhesive preparation and mainly aims to solve the problems that the adhesive strength, the appearance or the sealing performance of a conventional polyurethane adhesive are affected as an adhesive layer or surface has multiple fine bubbles caused by wet vapor. The aspartate polyurea adhesive disclosed by the invention is formed by mixing of a component A and a component B in a mass ratio of 100:(10-1000), wherein the component A comprises a polyaspartic ester; and the component B comprises an aliphatic or alicyclic diisocyanate monomer, dimer or trimer or a prepolymer of the monomer, dimer or trimer. The invention further discloses a preparation method of the aspartate polyurea adhesive. Compared with a common polyurethane adhesive, the aspartate polyurea adhesive disclosed by the invention is not sensitive to wet vapor and is excellent in property such as corrosion resistance and yellowing resistance, and a polyurea structure generated through a reaction has good adherence to a substrate when being compared with a carbamate structure.

Owner:上海汉司实业有限公司

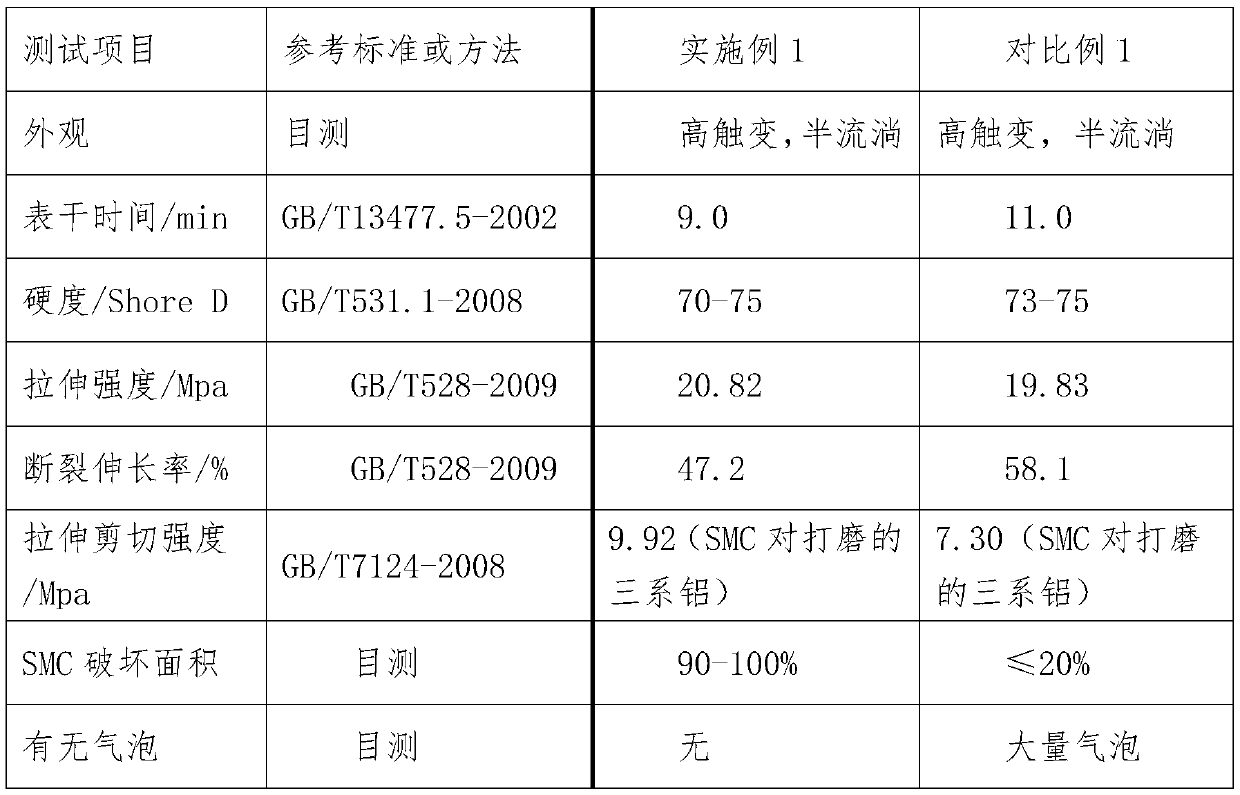

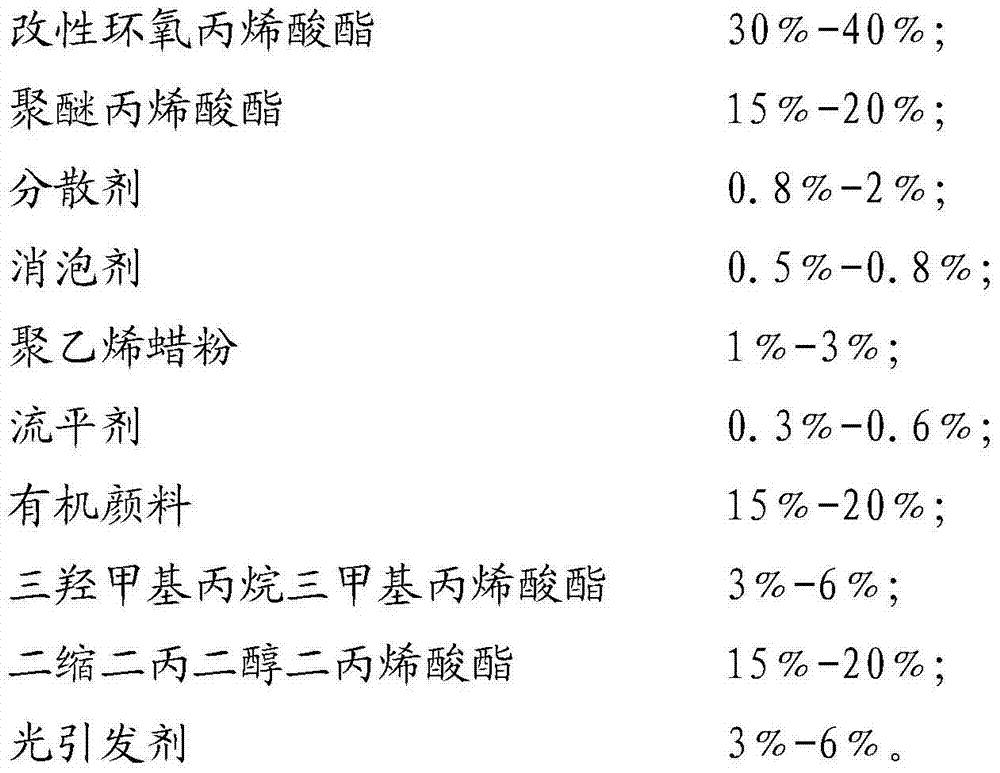

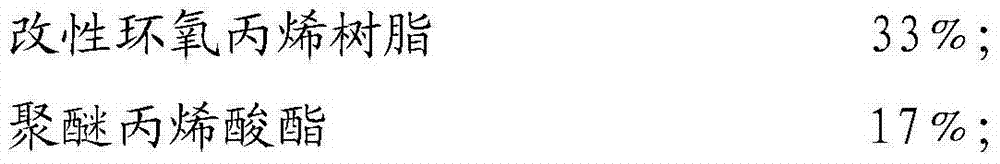

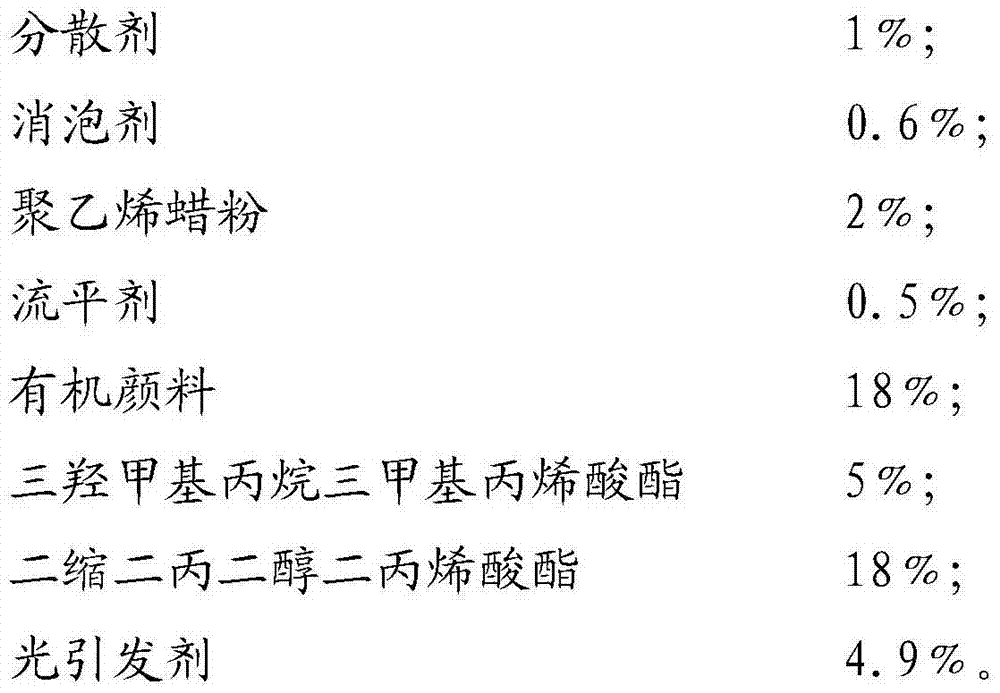

UV oil solid color paint

ActiveCN103709904AGood flexibilityImprove adhesionPolyether coatingsEpoxy resin coatingsEpoxyPolymer science

The invention relates to the technical field of paint and especially relates to UV oil solid color paint. The UV oil solid color paint comprises, by mass, 30-40% of epoxy resin, 15-20 parts of polyether-type acrylate, 0.8-2% of a dispersant, 0.5-0.8% of an antifoaming agent, 1-3% of polyethylene wax powder, 0.3-0.6% of a flatting agent, 15-20% of an organic pigment, 3-6% of trimethylol-propane trimethacrylate, 15-20% of dipropylene glycol diacrylate and 3-6% of a photoinitiator. Through use of the polyether-type acrylate, problems of use of single epoxy resin are solved, paint film performance complementation is realized, paint film flexibility is improved, adhesion is improved, residual acrylic acid ester groups in the photocured paint film are reduced, and aging resistance and yellowing resistance are improved.

Owner:广东千叶松化工有限公司

Multifunctional cellulose fiber based on graphene oxide/nano zinc oxide

InactiveCN107630349AGood antibacterialImproves UV resistanceBiochemical fibre treatmentVegetal fibresCellulose fiberNano zinc oxide

The invention discloses a multifunctional cellulose fiber based on graphene oxide / nano zinc oxide and a preparation method thereof. The method includes: impregnating cationic cellulose fiber in an anionic zinc oxide solution system and a cationic zinc oxide solution system in order for self-assembly, and finally wrapping the outermost layer of cellulose fiber with a layer of graphene oxide to obtain multifunctional cellulose fiber based on graphene oxide / nano zinc oxide. Nano zinc oxide undergoes layer-by-layer self-assembly by electrostatic attraction, endows cellulose fiber with excellent antibacterial, anti-ultraviolet, anti-wrinkle, anti-yellowing, washing resistance and other properties. Graphene oxide wrapping effectively improves the biosafety of inorganic nanomaterials. The invention applies electrostatic layer-by-layer self-assembly technology, nano-zinc oxide and graphene oxide in the textile field, is conducive to overcoming the current situation of single variety, low technical content and low added value of products in textile industry, and is of important significance for realizing transformation and upgrading and sustainable development of the textile industry.

Owner:赵兵

Polyurethane dull white paint for woodenware

The present invention is one kind of dull white finishing polyurethane paint for wood ware. The present invention features that the dull white finishing paint is compounded with three components, including the component A comprising modified alkyd resin, titanium white powder, nitro cotton, etc.; the component B comprising n-butyrate and HDI-90; and component C comprising n-butyrate and toluene. The dull white finishing paint has excellent yellowing resistance, powerful adhesion, high hardness, high wear resistance, good leveling property, and high environment protecting property.

Owner:GUANGDONG BADESE CHEM

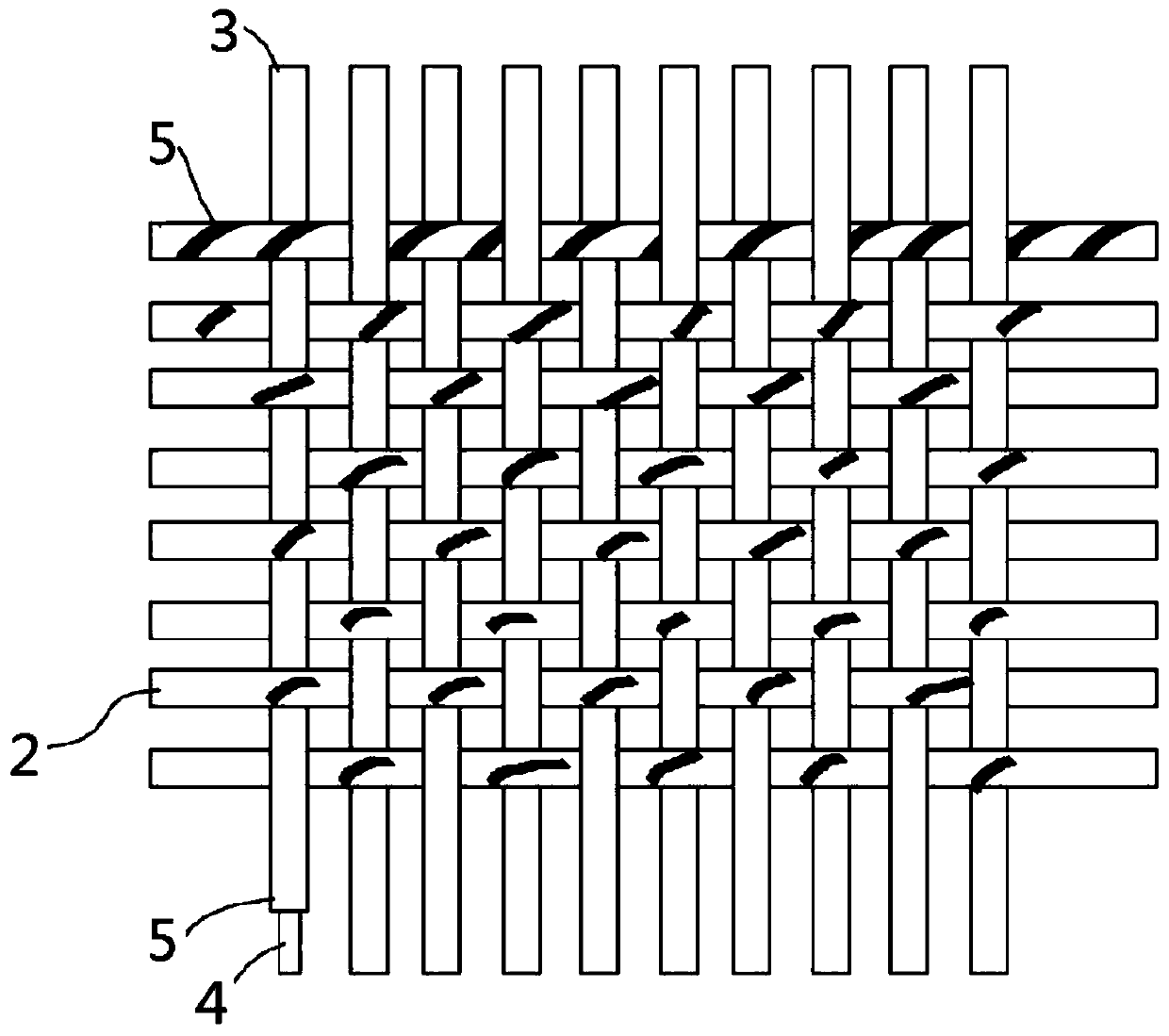

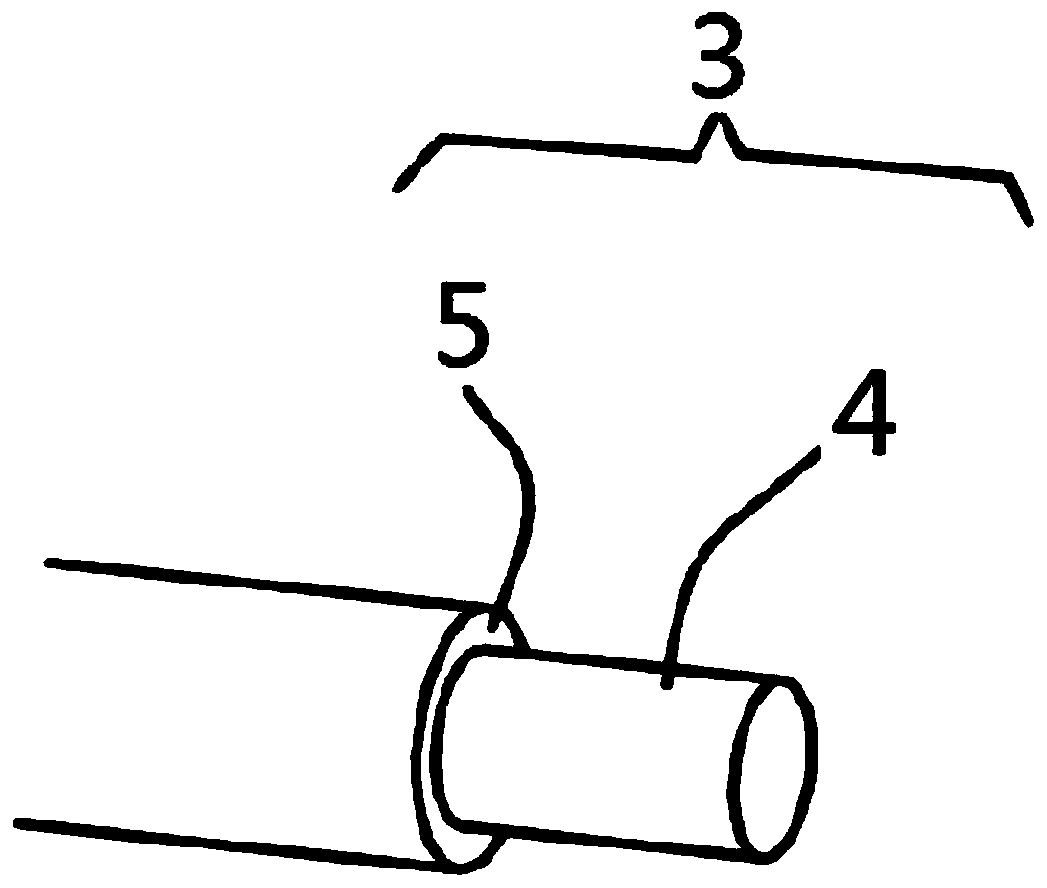

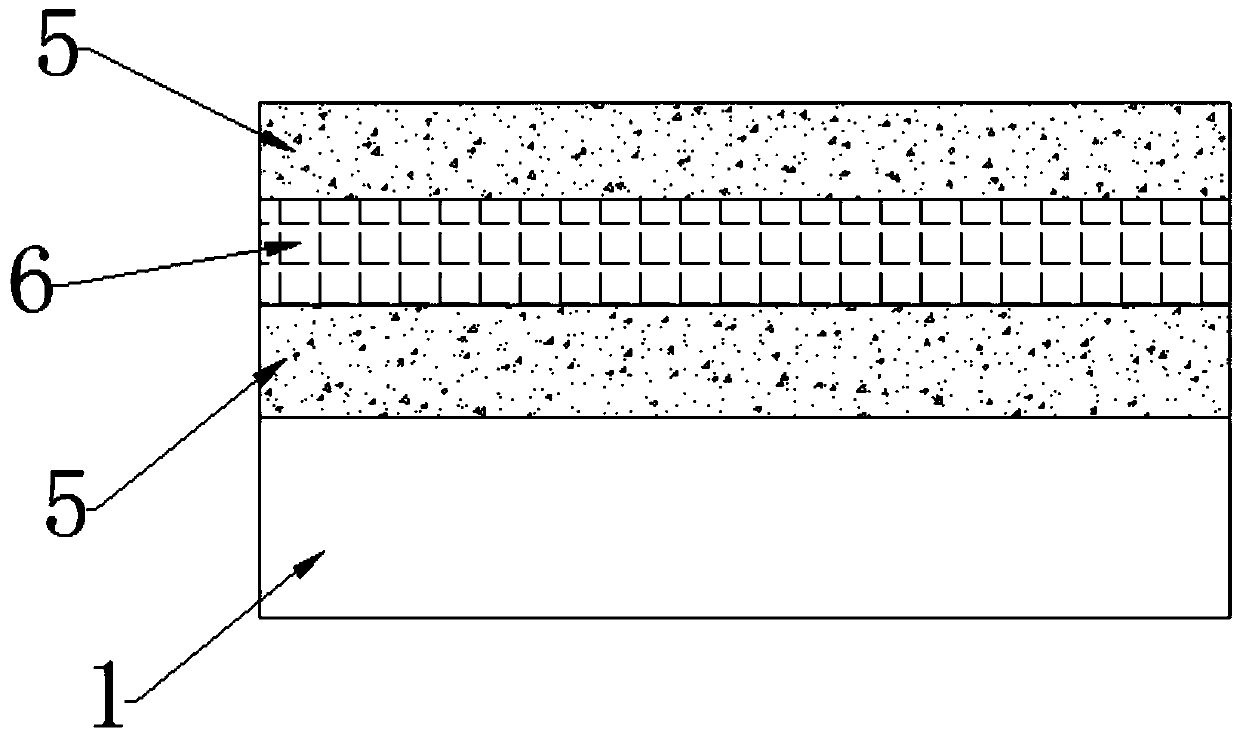

Safety lining cloth with excellent moisture transferring and heat conducting performance and production process thereof

InactiveCN110284333AImprove cooling effectGuaranteed breathabilityGarment special featuresFibre typesSurface layerHeat conducting

The invention discloses safety lining cloth with excellent moisture transferring and heat conducting performance and a production process thereof. The safety lining cloth comprises base layer safety lining cloth, wherein the base layer safety lining cloth is formed through plain weave of warp and weft yarns, the weft yarn is an elastic monofilament, the outer surface of the monofilament is also covered with a composite adhesive layer, and the composite adhesive layer comprises 70-80 parts of a hot melt adhesive, 5-10 parts of Teflon and 3-5 parts of nano-graphene oxide; the safety lining cloth also comprises hygroscopic fiber cloth arranged at the upper side face of the base layer safety lining cloth, wherein the lower side face of the hygroscopic fiber cloth is bonded with the base layer safety lining cloth through the composite adhesive layer on the upper side face of the base layer safety lining cloth, and the upper side face of the hygroscopic fiber cloth is also provided with a point-shaped or strip-shaped or grid-shaped composite adhesive layer. The lining cloth has the excellent moisture transferring, sweat discharging and heat conducting performance, the process comprises preparation of a composite adhesive, yarn making, preparation of the base layer safety lining cloth, improvement of moisture absorbing and transferring and heat conducting performance of the base layer safety lining cloth, preparation of an initial safety lining cloth product and surface layer sizing, the process is simple, and the practicability is strong.

Owner:张家港市杨舍镇美捷配饰设计工作室

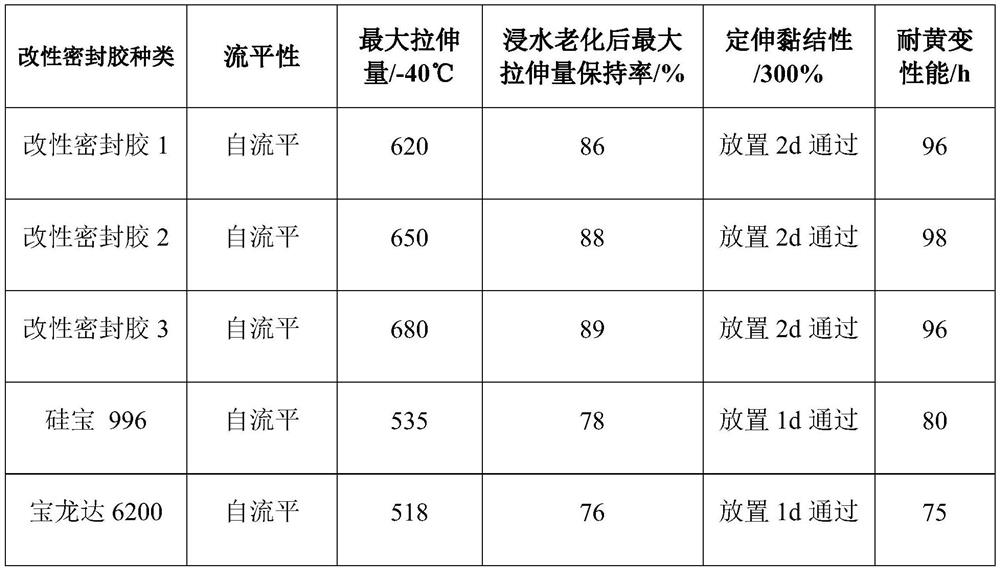

Modified silicone sealant for asphalt pavement crack treatment and preparation method thereof

ActiveCN112226197AUniform and stable dispersionGood compatibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesRubber materialPolymer science

The invention provides a modified silicone sealant for asphalt pavement crack treatment, which comprises the following components in parts by weight: 10-30 parts of modified polyurethane prepolymer, 10-30 parts of modified acrylic resin prepolymer, 50-70 parts of silicone sealant, 2-4 parts of dimethyl silicone oil, 3-8 parts of coupling agent, 2-4 parts of hydroxyl radical scavenger and 2-4 partsof cross-linking agent. The compatibility between the modified polyurethane prepolymer, the modified acrylic acid prepolymer and the silicone sealant is better, so that the polyurethane prepolymer and the acrylic acid prepolymer can be better modified and added into the silicone sealant, and the polyurethane prepolymer and the acrylic acid prepolymer can be uniformly and stably dispersed in a reaction system; and the binding force between the rubber materials is improved, so that the elongation, the low-temperature tensile strength and the storage stability of the rubber body are improved, and the modified silicone sealant provided by the invention can be effectively used for treating asphalt pavement cracks.

Owner:CHONGQING ZONJO RENEWABLE RESOURCES DEV CO LTD

Preparation method and application of polyamino vinyl silicone oil

InactiveCN112961355AGood flexibilityHigh viscosityLight resistant fibresGrip property fibresDisiloxanePolymer science

The invention belongs to the technical field of organic silicon material preparation, and particularly relates to a preparation method and application of polyamino vinyl silicone oil. The preparation method comprises the following steps: 1) under the condition of inert gas, adding a basic catalyst and a siloxane ring body, heating while stirring, reacting for a period of time, then adding a polyamino silane coupling agent and tetramethyl divinyl disiloxane, and continuously reacting for a period of time; and 2) performing heating and continuously performing reacting for a period of time to obtain a semitransparent viscous liquid. The invention solves the problems that in the prior art, an amino silicon oil preparation method is numerous in operation steps and high in manufacturing cost, and softness and yellowing resistance cannot be achieved at the same time.

Owner:山东特龙谱新材料有限公司

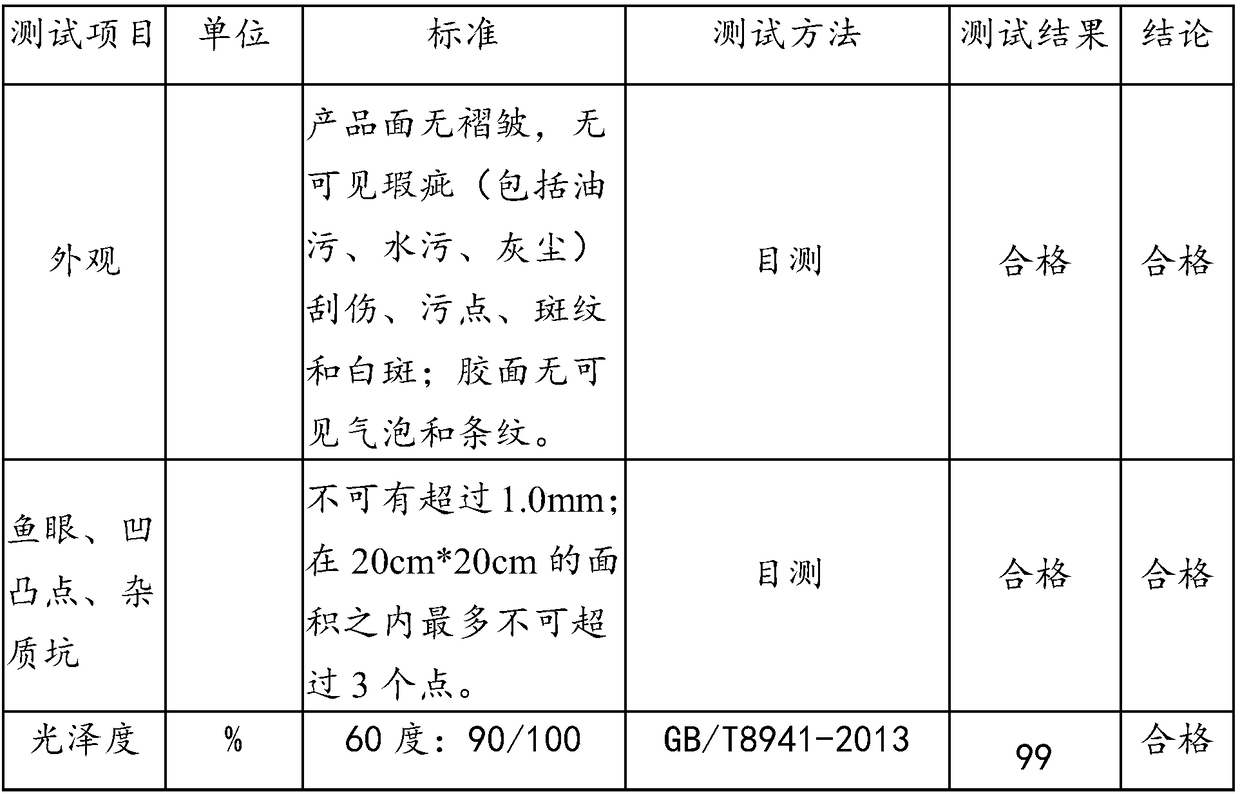

High-glossiness automobile black film and preparation method therefor

InactiveCN108410387AHigh glossIncrease the beauty of the bodyOrganic non-macromolecular adhesiveCoatingsDiethyl methylphosphonatePropylene glycol methyl ether acetate

The invention belongs to the technical field of automobile decoration and particularly discloses a high-glossiness automobile black film and a preparation method therefor. The high-glossiness automobile black film comprises locating paper, a bright coating, a PVC black film, an acrylic pressure-sensitive adhesive and release paper sequentially from top to bottom. A formula of the bright coating isprepared from the following matters in parts by weight: 41-45 parts of diethyl p-toluenesulfonyloxymethylphosphonate, 2.5-3.0 parts of tin photostabilizer, 0.2-0.3 part of 8% zinc caprylate, 5-5.5 parts of propylene glycol methyl ether acetate, 28-31 parts of polyisocyanate, 6-9 parts of butyl acetate cellulose and 13-15 parts of butanone. According to the high-glossiness automobile black film, the glossiness is 90% or more and is close to a mirror face effect, so that the attractiveness of an automobile body is improved, and the vehicle competitiveness is improved; and the weather resistanceand acid / base resistance are good, the scratch resistance, scrub resistance, stone impact resistance and water gun impact resistance are greatly improved, and the service life of the high-glossinessautomobile black film is prolonged.

Owner:安徽中胶工业材料有限公司

Fabric antibacterial softener and preparation method thereof

InactiveCN110578251AImprove smoothnessImprove antistatic performanceBiochemical fibre treatmentGrip property fibresEugenolStatic performance

The invention discloses a fabric antibacterial softener and a preparation method thereof. The softener is prepared from, by weight, 10-15 parts of amino-silicone oil, 10-15 parts of ester-based quaternary ammonium salt, 1-3 parts of propyl paraben, 1-3 parts of carboxymethyl chitosan silver, 2-5 parts of eugenol and 150-200 parts of deionized water. The method includes the steps that the deionizedwater is heated to 40 DEG C, the amino silicone oil and the ester-based quaternary ammonium salt are added for constant-temperature stirring for 15 minutes, the propyl paraben, the carboxymethyl chitosan silver and the eugenol are added for stirring for 20 minutes, the materials are sufficiently mixed, and the softener is prepared. The ester-based quaternary ammonium salt serves as a cationic surfactant and excellent smoothness, anti-static performance, yellowing resistance, easy biodegradation and environmental friendliness, so that the product not only has excellent softness, but also has good antistatic property; the product has an excellent antibacterial effect, and the preparation method is simple and easy to apply and popularize.

Owner:广州市沙索化工科技有限公司

Preparation method of antistatic powder coating material

InactiveCN108912855AImprove surface activityImprove dispersion compatibilityAntifouling/underwater paintsPaints with biocidesMethyl carbonateStearic acid

The invention discloses a preparation method of an antistatic powder coating material, comprising the following steps: firstly dispersing acetylene black by using a dimethyl carbonate solution of oleic acid diethanolamide, then esterifying stearic acid and triethanolamine under the action of a catalyst. dispersing obtained ester amine in an amide solution, and reacting ester amine with dimethyl carbonate to obtain an antistatic solution containing quaternary ammonium salt. The preparation method has the advantages of not only effectively improving the antistatic effect, but also improving thesurface activity of the acetylene black, thus enhancing the dispersion compatibility of the acetylene black in a polypropylene matrix, improving the uniform stability of the finished coating material,improving the antibacterial and anti-yellowing properties and the like of the finished coating material by the reaction, and enhancing the finished product quality.

Owner:合肥拖油瓶信息科技有限公司

Electricity conductive cloth electroplating post-treatment method

The present invention discloses an electricity conductive cloth electroplating post-treatment method, which comprises the following steps: coating and drying through extruding, wherein an electricity conductive cloth is dip-coated in a yellowing resistance polyurethane slurry and extruded; carrying out drying curing shaping, wherein the electricity conductive cloth is subjected to drying curing shaping; and winding, wherein the electricity conductive cloth is subjected to winding packaging. The post-treatment method of the present invention has the following characteristics that: a process is simple, batch production is easily achieved, no wastewater is generated during the production process, and the method is an environment protection process. The electricity conductive cloth treated by the method of the present invention has advantages of strong metal adhesion, excellent wear resistance, yellowing resistance, good anti-fingerprint discoloration property, and the like.

Owner:SHENZHEN FRD SCI & TECH

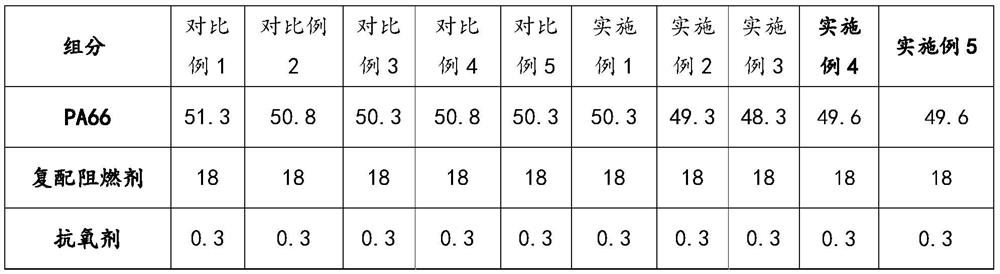

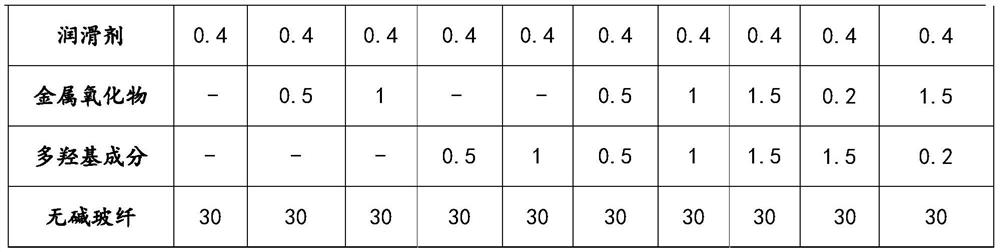

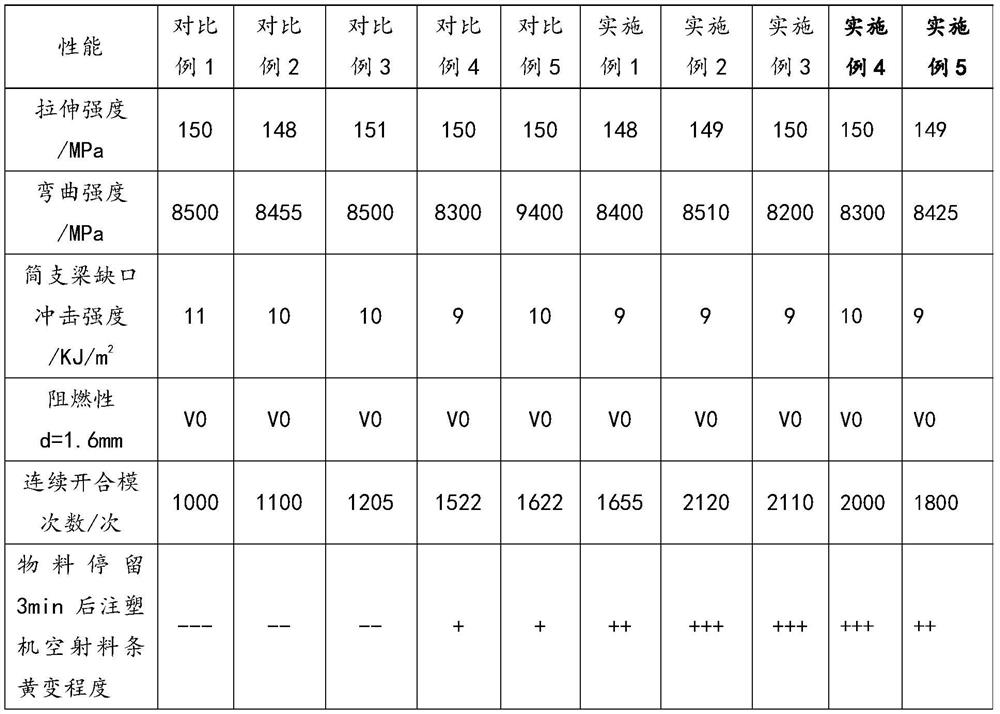

Anti-yellowing low-mold-scale halogen-free flame-retardant polyamide composite material and preparation method thereof

PendingCN114874616AImprove flame retardant performanceGood mechanical propertiesPolymer sciencePolyamide

The invention relates to the technical field of flame-retardant high polymer materials, in particular to an anti-yellowing low-mold-scale halogen-free flame-retardant polyamide composite material and a preparation method thereof. The polyamide composite material comprises the following components: polyamide resin, a compound halogen-free flame retardant, a metal oxide, a polyhydroxy component and other auxiliaries, the compound halogen-free flame retardant is prepared from alkyl phosphinate, melamine polyphosphate and zinc borate; the ratio of the polyamide resin to the compound halogen-free flame retardant to the metal oxide to the polyhydroxy component in parts by weight is (40-60): (15-25): (0.2-1.5): (0.2-1.5). The anti-yellowing low-mold-scale halogen-free flame-retardant polyamide composite material provided by the invention has high flame retardant property and good mechanical property, and also has excellent anti-yellowing and low-mold-scale characteristics.

Owner:JINYOUNG XIAMEN ADVANCED MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com