Composite antioxidant for polyurethane fiber

A composite antioxidant and polyurethane technology, applied in the field of composite antioxidants, can solve the problems of inability to meet the anti-yellowing effect of spandex, unstable fiber physical properties, etc., and achieve the effect of improving anti-yellowing and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Mix 1mol ether polyol (PTMEG; molecular weight 2000±100) with 2mol diisocyanate (MDI), react at 80-90°C to form a polymer with isocyanate at the end, then cool to about 55°C, and then add N, N -Dimethylacetamide (DMAc) is made into a solution containing 45% solid content, and then ethylenediamine and cyclohexanediamine are added as chain extenders, and diethylamine is used as a capping agent. At this time, polyurethane resin The content is about 36%, and the viscosity is about 2200 poise (poise; 40°C).

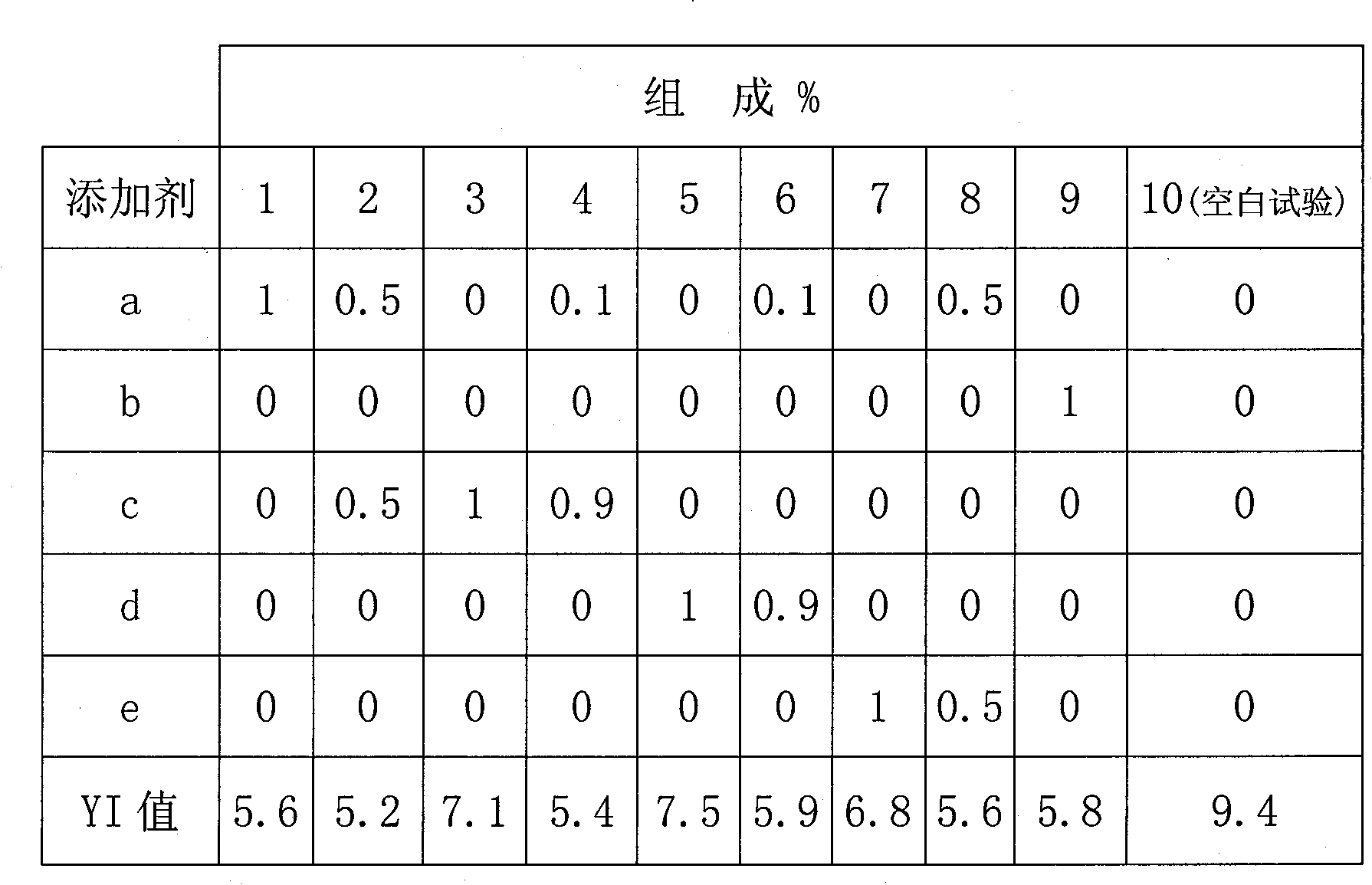

[0018] Divide the viscous liquid into several parts and add the additives shown in Table 1 respectively, mix and dissolve, and then apply it on a flat glass to form a film, and measure its YI value in an oven at 100°C for 30 hours. The test results are shown in Table 1; it can be seen from Table 1 that the two-component antioxidants such as 2 and 4 are significantly better than the single components 1 and 3, and the two-component compositions 6 and 4 are also significan...

Embodiment 2

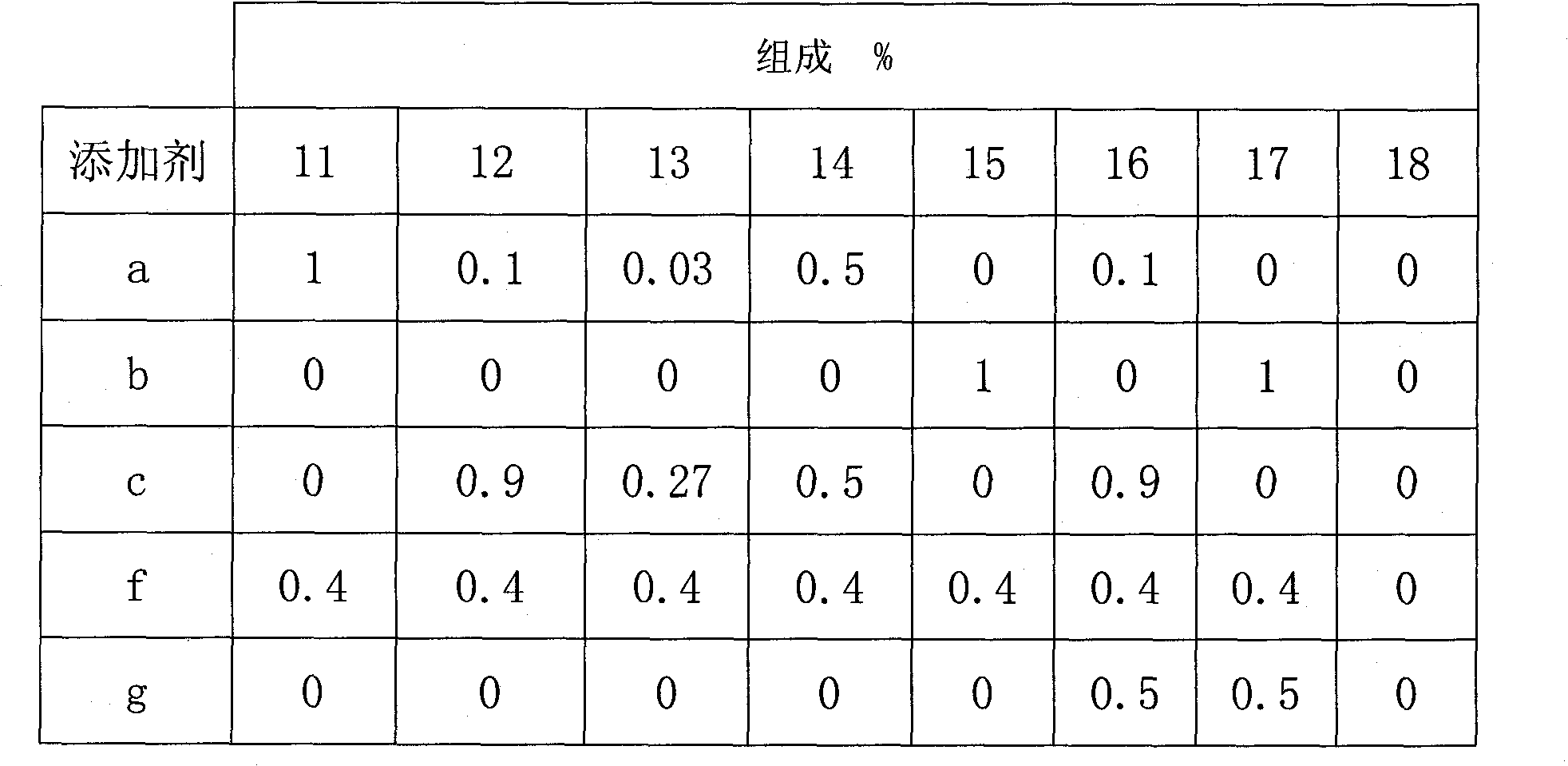

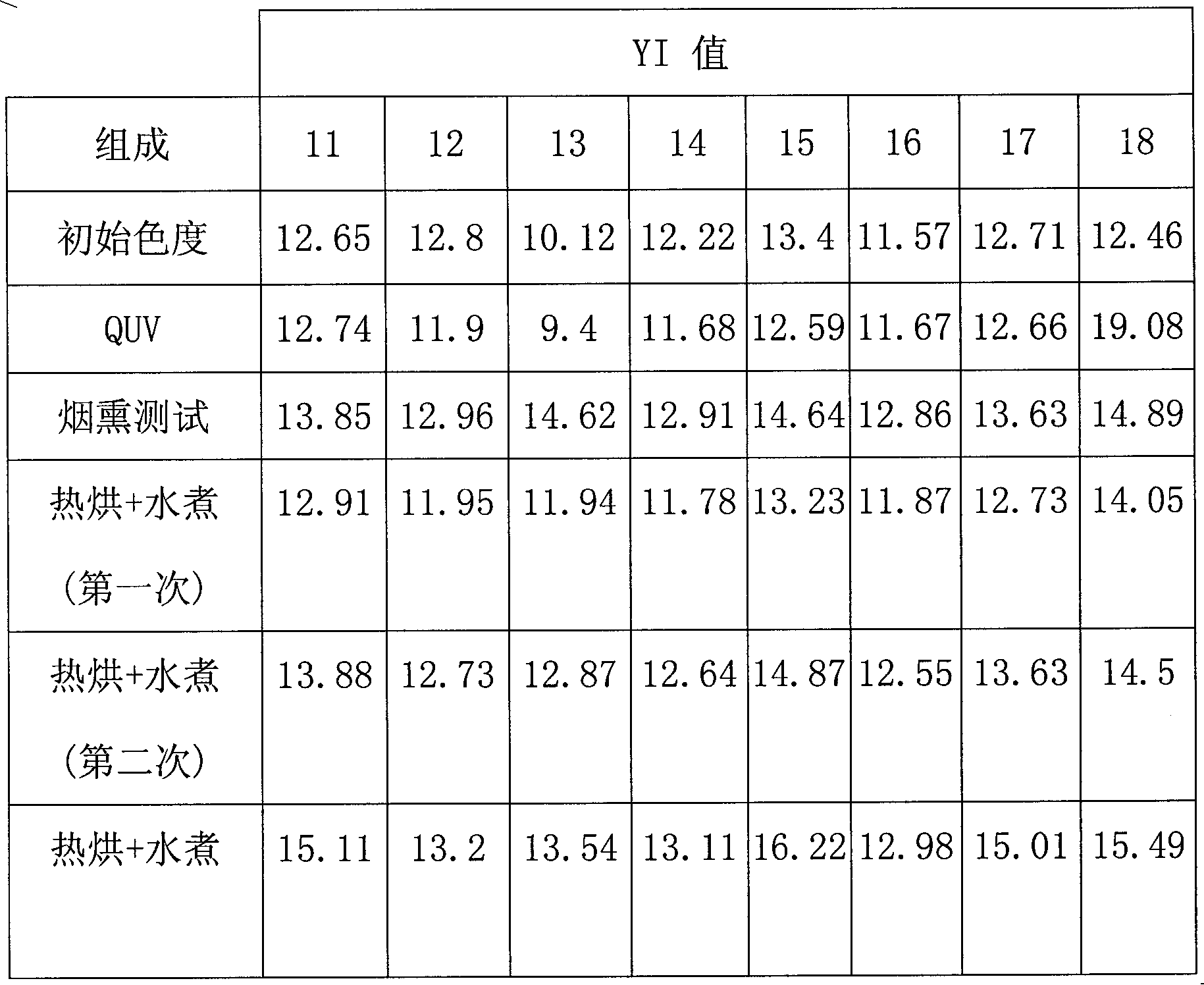

[0027] Take 100 parts of thermoplastic polyurethane resin (TPU product name: S-195AL; provided by Taiwan Kunzhong Company) and dry it in an oven for 5 hours. Injection pressure: 120kgf / cm 2), the size of the test piece was made into a circular test piece (diameter 50mm, thickness 2mm), and the weather resistance (QUV; 12 hours), smoke (50°C; 16 hours) and heat drying (150°C; 30 minutes) and Yellowing index (YI) of boiling (95°C; 1 hour). The test results are shown in Table 3; as can be seen from Table 3, the weather resistance, smoke resistance, cycle temperature resistance and hydrolysis resistance of the two-component formulations of the present invention such as 12, 13 and 14 are significantly better than those of the single components 11 and 15; the composition 16 is also relatively Better than composition 17.

[0028] Table 2:

[0029]

[0030] a=1,3,5-trimethyl-2,4,6-tris(3,5-di-tert-butyl-4-hydroxybenzyl)benzene

[0031] b=Triethylene glycol bis[3-(3-tert-butyl-5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com