High-glossiness automobile black film and preparation method therefor

A black film, automotive technology, applied in the direction of pressure-sensitive film/sheet, film/sheet adhesive, non-polymer organic compound adhesive, etc., can solve the problem of poor stone impact resistance and scratch resistance, Problems such as poor shrinkage effect of the aluminum plate and low gloss of the black film can achieve the effect of prolonging the service life, improving the competitiveness of the vehicle, and having a good ventilation function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

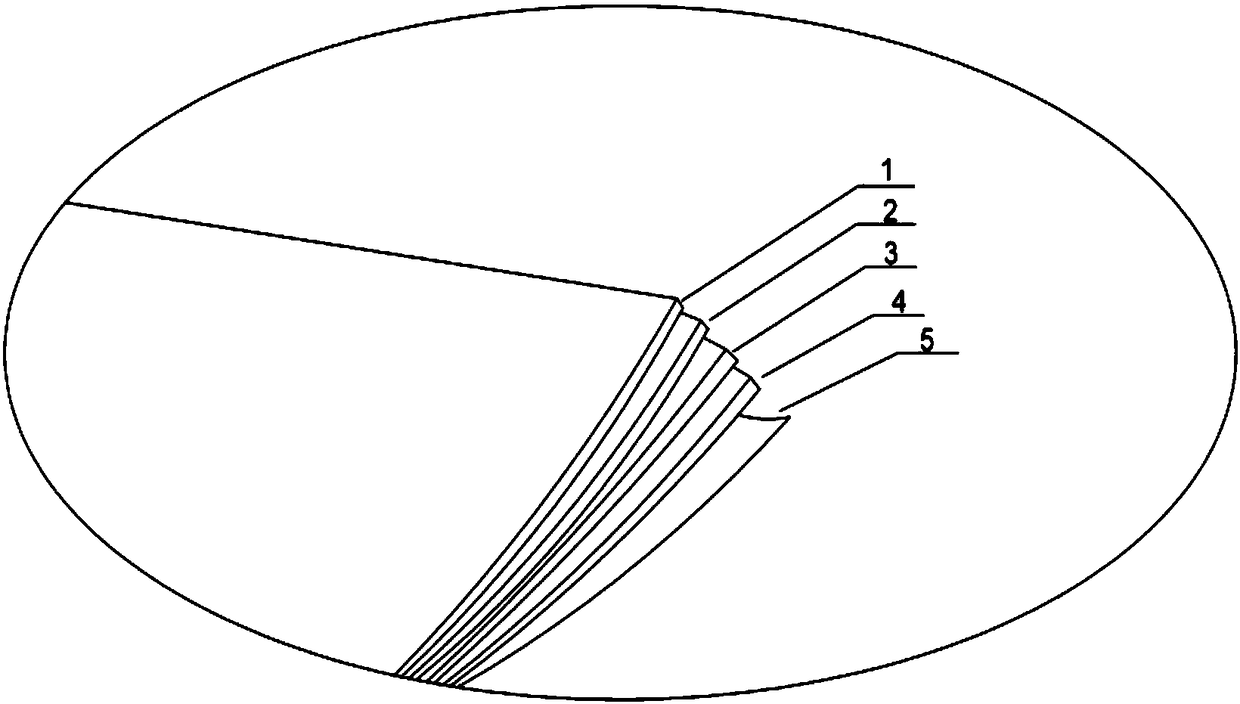

[0039] A high-gloss automotive black film, see figure 1 , from top to bottom is composed of positioning paper 1, glossy coating 2, PVC black film 3, acrylic pressure-sensitive adhesive 4 and release paper 5.

[0040] This positioning paper 1 is used for the temporary protection of the PVC black film 3.

[0041] The formula of this glossy coating 2 is made up of the material of following parts by weight: 43 parts of diethyl p-toluenesulfonyloxymethyl phosphonate, 2.7 parts of tin light stabilizer, 0.25 part of 8% zinc octanoate, propylene glycol methyl ether acetate 5.3 parts, polyisocyanate 29.5 parts, butyl cellulose acetate 8 parts and butanone 14 parts.

[0042] The formula of the acrylic pressure-sensitive adhesive 4 is composed of the following parts by weight: 6 parts of acrylic acid, 26 parts of ethyl acetate, 0.9 part of dibenzoyl peroxide, 41 parts of toluene, 27.5 parts of isooctyl acrylate and crosslinking agent 1.6 servings.

[0043] Wherein, the crosslinking ag...

Embodiment 2

[0056] The high gloss automobile black film of the present embodiment and preparation method thereof are similar to embodiment 1, and its difference is only in:

[0057] The formula of this glossy coating 2 is made up of the material of following parts by weight: 41 parts of diethyl p-toluenesulfonyloxymethylphosphonate, 3 parts of tin light stabilizer, 0.2 part of 8% zinc octanoate, propylene glycol methyl ether acetate 5.5 parts, polyisocyanate 28 parts, butyl cellulose acetate 6 parts and butanone 15 parts.

[0058] The formula of the acrylic pressure-sensitive adhesive 4 is made up of the following parts by weight: 5 parts of acrylic acid, 27 parts of ethyl acetate, 0.8 part of dibenzoyl peroxide, 42 parts of toluene, 25 parts of isooctyl acrylate and crosslinking agent 1.8 servings.

[0059] Wherein, the crosslinking agent is 3-methyltetrahydrothiazole-2-thione.

[0060] The difference between the preparation method of the high-gloss automotive black film provided in th...

Embodiment 3

[0063] The high gloss automobile black film of the present embodiment and preparation method thereof are similar to embodiment 1, and its difference is only in:

[0064] The formula of this glossy coating 2 is made up of the following material in parts by weight: 45 parts of diethyl p-toluenesulfonyloxymethylphosphonate, 2.5 parts of tin light stabilizer, 0.3 part of 8% zinc octanoate, propylene glycol methyl ether acetate 5 parts, polyisocyanate 31 parts, butyl cellulose acetate 9 parts and butanone 13 parts.

[0065] The formula of the acrylic pressure-sensitive adhesive 4 is composed of the following parts by weight: 7 parts of acrylic acid, 25 parts of ethyl acetate, 1 part of dibenzoyl peroxide, 40 parts of toluene, 30 parts of isooctyl acrylate and crosslinking agent 1.4 servings.

[0066] The difference between the preparation method of the high-gloss automotive black film provided in this embodiment and Example 1 is:

[0067] The heat preservation reaction time descr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com