Patents

Literature

913 results about "Dipropylene glycol monomethyl ether acetate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propylene glycol methyl ether acetate (PGMEA, 1-methoxy-2-propanol acetate) is a P-type glycol ether used in inks, coatings, and cleaners. It is sold by Dow Chemical under the name Dowanol PMA and by Shell Chemical under the name methyl proxitol acetate.

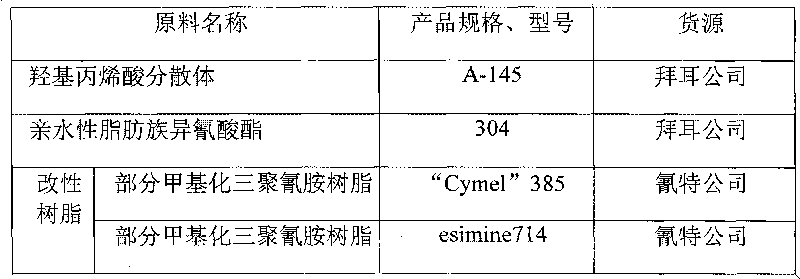

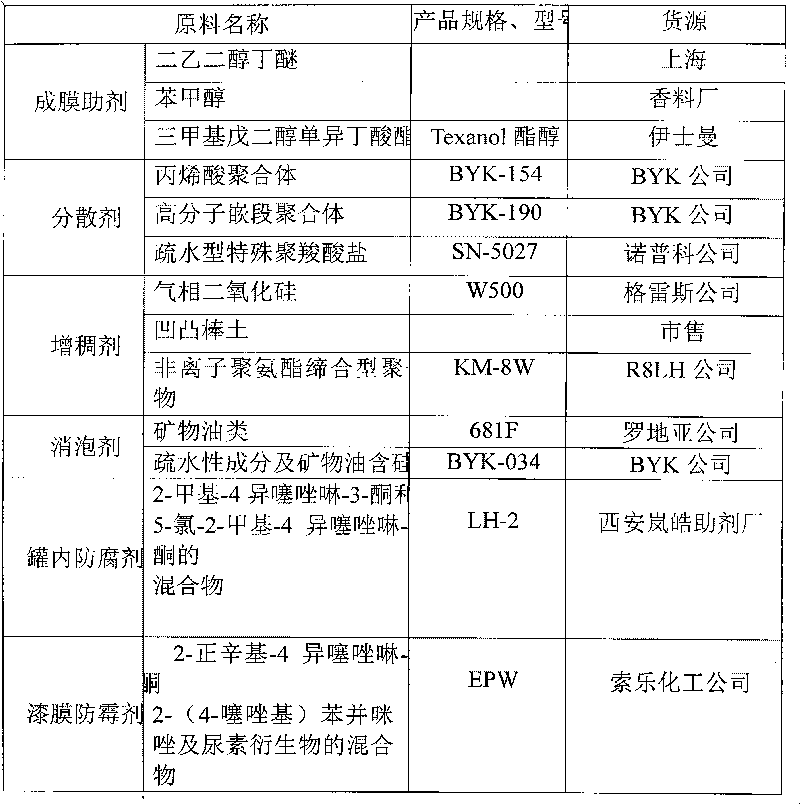

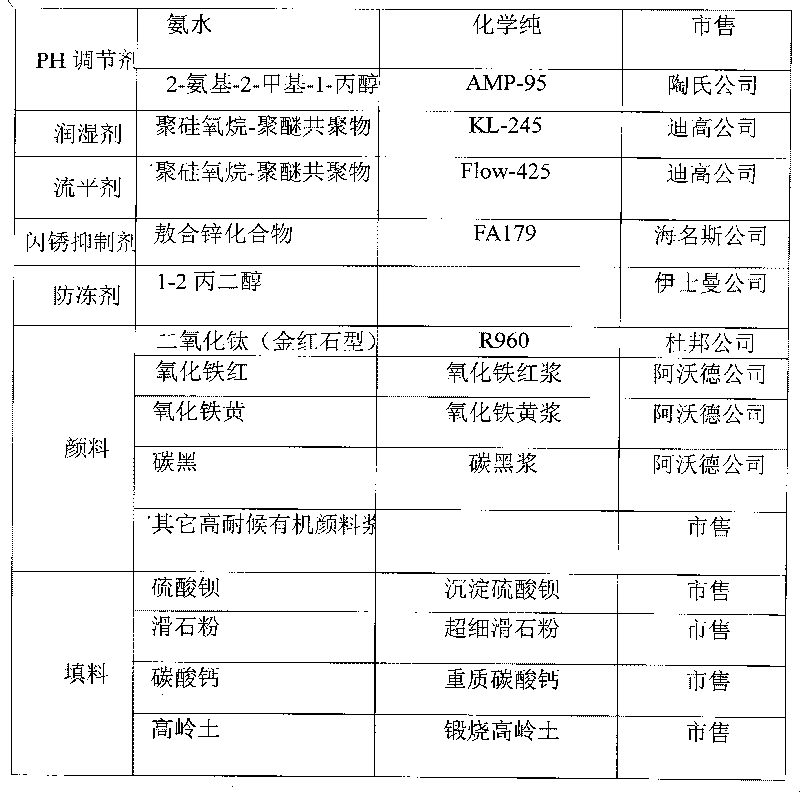

Water-based two-pack polyurethane preservative coating and preparation method thereof

ActiveCN101701128AHigh glossGood chemical resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsWater basedDipropylene glycol monomethyl ether acetate

The invention relates to the preservative coating technology, in particular to a water-based two-pack polyurethane preservative coating and a preparation method thereof. The water-based two-pack polyurethane preservative coating comprises two parts, namely paint vehicle and curing agent, wherein the paint vehicle is prepared from water-based hydroxylated acrylic dispersion, modified resin, pigment, filler, additive and water, the curing agent part comprises hydrophilic aliphatic isocyanate, dodecyl ester and propylene glycol methyl ether acetate. When using the coating of the invention, the weight ratio of the paint vehicle to the curing agent is 74-85:15-26 and the coating can solve the defects of the existing preservative coating.

Owner:JIANGSU LANLING POLYMER MATERIAL CO LTD

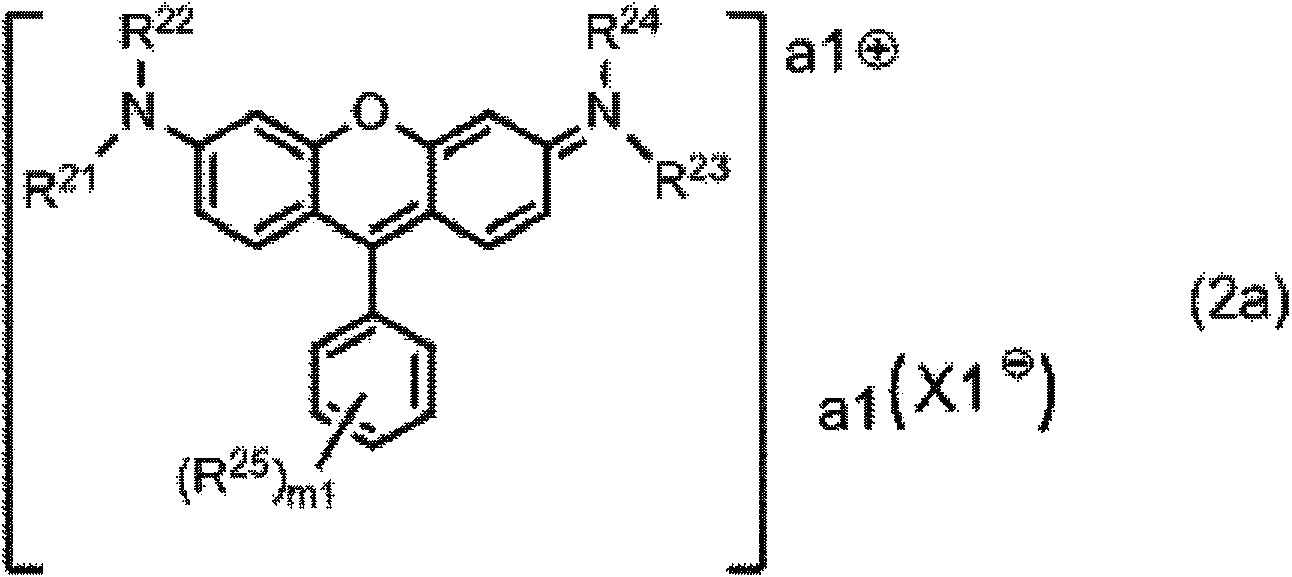

Ink composition and color filter including the same

An ink composition comprising dipropylene glycol monomethyl ether acetate (DPMA). For example, an ink composition for a color filter includes a binder material, a monomer material, a polymerization initiator, a pigment dispersion, and a solvent including dipropylene glycol monomethyl ether acetate (DPMA).

Owner:SAMSUNG ELECTRONICS CO LTD

Polyurethane matt varnish for benzene-free odor-less furniture

ActiveCN101684388AImprove mechanical propertiesGood gloss and color retentionPolyurea/polyurethane coatingsCyclohexanoneFoaming agent

The invention provides a polyurethane matt varnish for benzene-free odor-less furniture, which is composed of a main agent, a curing agent and a diluent. The main agent comprises 66.5-75.5% of hydroxyacrylic resin, 16.0-25.0% of solvent, 0.1-0.3% of defoarming agent, 0.05-0.1% of flatting agent, 0.1-0.5% of anti-settling agent, 0.1-0.5% of dispersing agent, and 4-8% of delustering agent; the curing agent comprises40.0-50.0% of toluene diisocyanate tripolymer, 20.0-30.0% of toluene diisocyanate-trimethylolpropane affixture, and 20.0-30.0% of butyl acetate; the diluent comprises 60.0-70.0% of butyl acetate, 15.0-20.0% of cyclohexanone, and 15.0-25.0% of propylene glycol methyl ether acetate. The product of the invention is favorable for construction, and no odor exists after the construction of the previous night.

Owner:上海展辰涂料有限公司 +1

Environment protective polyurethanes hammer paint

ActiveCN101353550AGood solvent resistanceGood acid and alkali resistancePolyurea/polyurethane coatingsOleoresinDimethyl siloxane

The invention discloses an environmental-protection polyurethane hammer paint which is applied to wood surface decoration and protection and consists of a component A, a component B and a component C; when in use, the component A, the component B and the component C can be evenly mixed by the weight ratio that component A: component B: component C is equal to 1: 0.4 to 0.6: 0.5 to 0.6; wherein, the component A consists of: short oil alkyd resin, 40 to 60 parts; long oleoresin, 2 to 5 parts; dispersing agent, 0.2 to 0.5 part; anti-sedimentation agent, 0.4 to 0.9 part; propylene glycol ether acetate 3 to 6 part; divalent ester 1 to 3 parts; pigment, 0 to 30 parts; defoamers, 0.2 to 0.5 part; leveling agent, 0.2 to 0.7 part; non-floating-type aluminum paste, 1 to 5 parts; n-butyl acetate 5 to 15 parts, polydimethylsiloxane, 0.1 to 0.5 part; the component B consists of the following materials by weight ratio: HDI trimer poly isocyanate: HDI-TDI trimer: n-butyl acetate is equal to 2 to 4: 3 to 5: 1 to 4; the component C consists of the following materials by weight ratio: n-butyl acetate: propylene glycol methyl ether acetate is equal to 7 to 9: 1 to 3. The invention has the advantagesof: 1. good paint film solvent resistance and acid and alkaline resistance, bright color, clear texture, and good hammer effective; 2. high paint film hardness and wide application range, not only being applicable to wood surface, but also being applicable to metal surface decoration and protection; and 3. triphenyl-free, low VOC, and high solid content, and meeting the requirements on environmental protection.

Owner:GUANGDONG SANVO CHEM IND TECH

Aqueous dull finishing coat, preparation method and use method thereof

InactiveCN101717603AGood chemical resistanceHigh hardnessPolyurea/polyurethane coatingsDefoaming AgentsMaterials science

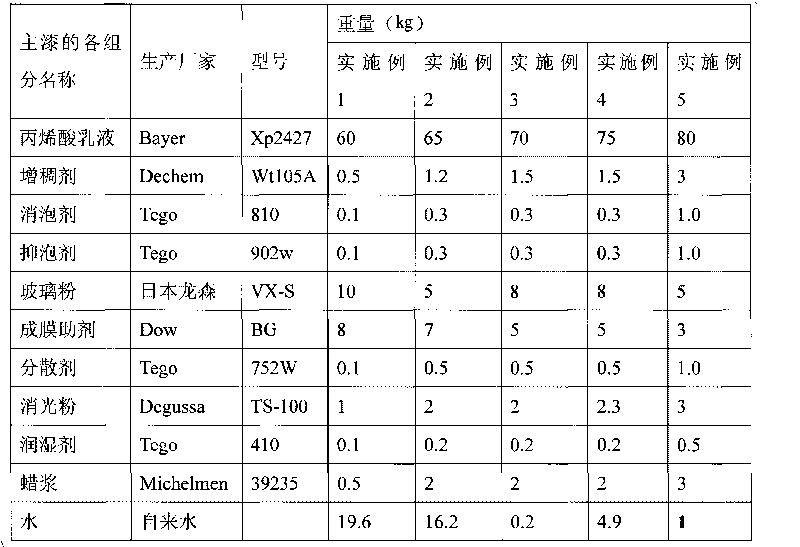

The invention relates to an aqueous dull finishing coat with scratch resistance, a preparation method and a use method thereof. Main varnish is prepared from the following components in parts by weight: 60-80 parts of acrylic acid emulsion, 0.5-3 parts of thickening agent, 0.1-1.0 part of defoaming agent, 5-10 parts of glass powder, 0.1-1.0 part of foam inhibitor, 3-8 parts of filming auxiliary agent, 0.1-1.0 part of dispersant, 0.1-0.5 part of wetting agent, 1.0-3.0 parts of extinction powder, 0.5-3.0 parts of wax pulp and 1-20 parts of water; a curing agent of the aqueous dull finishing coat is mixed by 80 parts by weight of aliphatic polyisocyanate and 20 parts by weight of propylene glycol methyl ether acetate; and the ratio of curing agent NCO to main varnish OH is 2.5. The main varnish is prepared by the steps of adding the acrylic acid emulsion into a container, adding the thickening agent, the defoaming agent, the foam inhibitor and the dispersant under stirring, and dispersing at 500RPM for 5-8 minutes till being uniform; afterwards, after adding the extinction powder, the glass powder and the wax pulp under stirring, dispersing at 1000RPM for 15 minutes till the fineness is not more than 25mum; and then, adding the wetting agent, the filming auxiliary agent and the water, dispersing at 500RPM for 10 minutes till being uniform and filtering by a sieve with 100 meshes so as to obtain the aqueous dull finishing coat. The aqueous dull finishing coat is used by mixing in the weight mixture ratio of the main varnish to the curing agent to tap water being 100:50:20. A varnish film has very good hardness, toughness, scratch resistance, abrasion resistance and weather resistance, can be recoated without blanching and has especially good chemical resistance.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

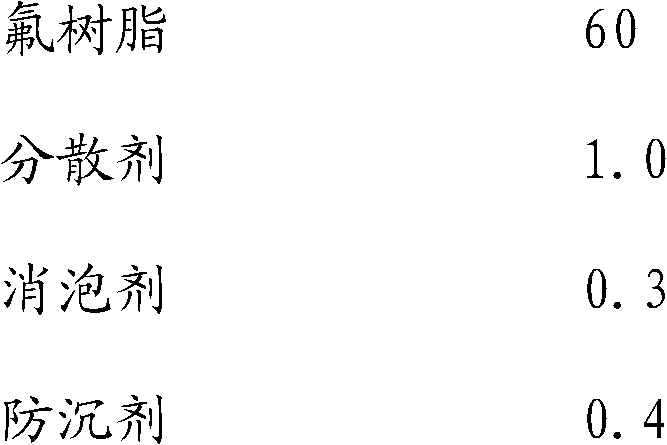

Elastic heat-insulation fluorocarbon coating and preparation method and use method thereof

InactiveCN102492338AGood weather resistanceGood gloss and color retentionReflecting/signal paintsButyl acetateTitanium

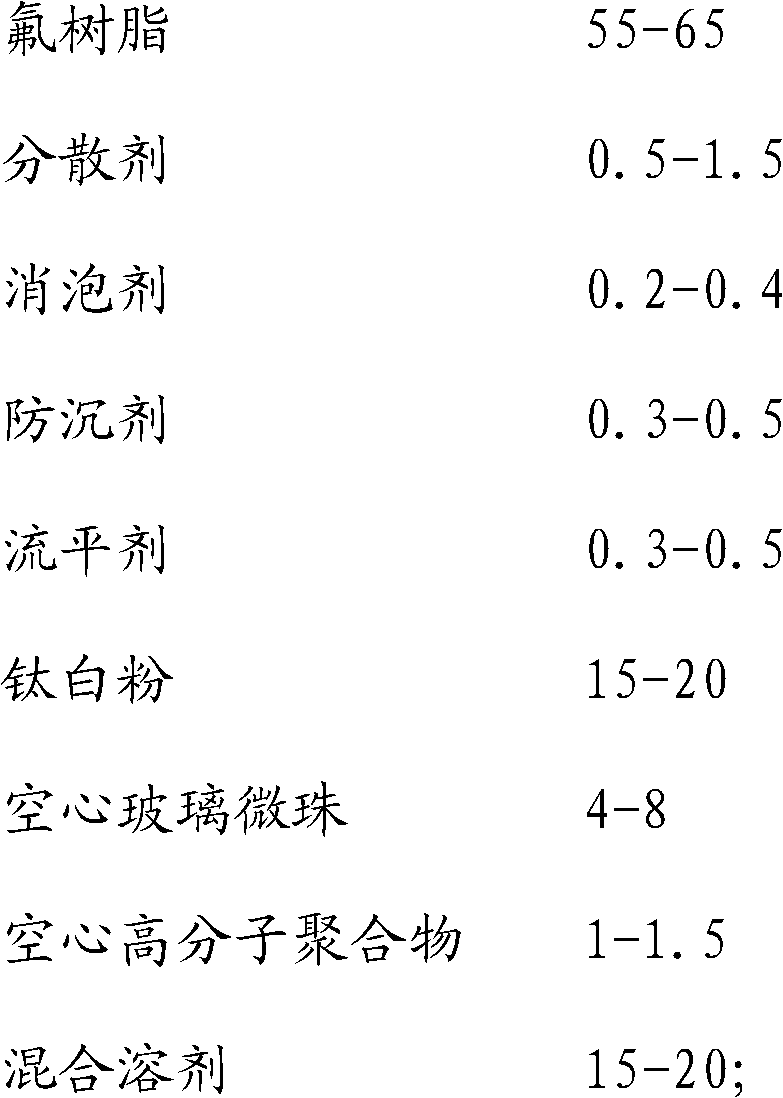

An elastic heat-insulation fluorocarbon coating consists of a host and curing agent. The host is prepared by the following components, by weight, 55 to 65 parts of fluororesin, 0.5 to 1.5 parts of dispersant, 0.2 to 0.4 part of defoamer, 0.3 to 0.5 part of anti-settling agent, 0.3 to 0.5 part of flatting agent, 15 to 20 parts of titanium white, 4 to 8 parts of hollow glass microballs, 1 to 1.5 parts of hollow macromolecular polymer and 15 to 20 parts of mixed solvent. The curing agent is manufactured by the following components, by weight, 90 parts of E405 to 80T, 5 parts of butyl acetate and 5 parts of propylene glycol methyl ether acetate. The weight proportion of the host and the curing agent can be calculated according to the hydroxyl value of the fluororesin and the NCO (isocyanate) content of the curing agent, namely OH / NCO=1:(1.05 to 1.15). The elastic heat-insulation fluorocarbon coating has the advantages of excellent weatherability, stain resistance, washability, decoration performance, excellent normal-temperature and low-temperature elasticity, capability of resisting to fine fissures, improved heat insulation effect and benefits to transport and settlement.

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

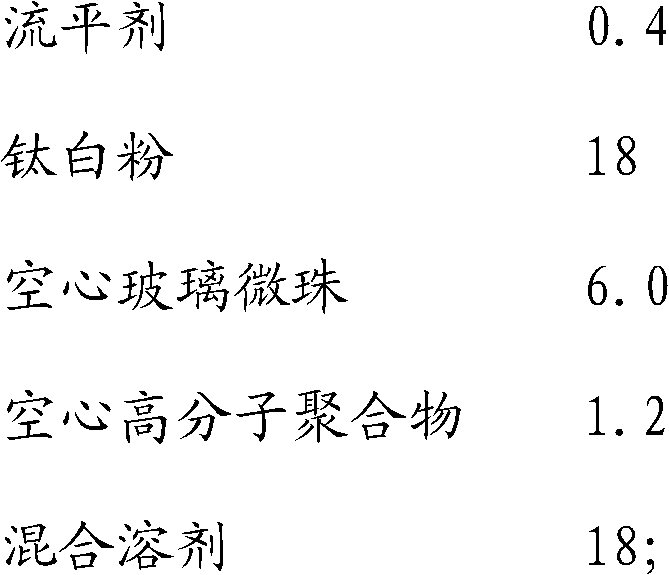

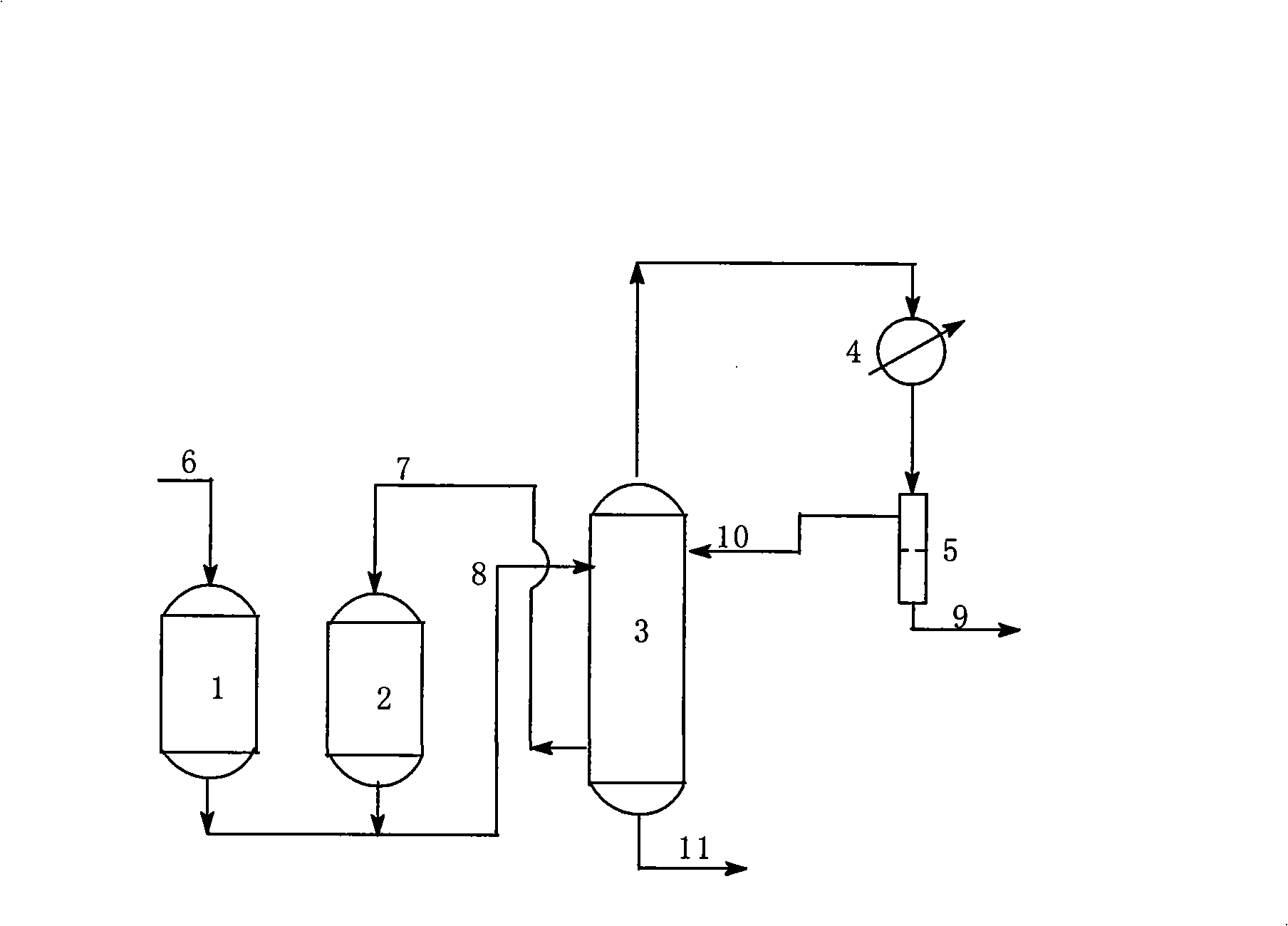

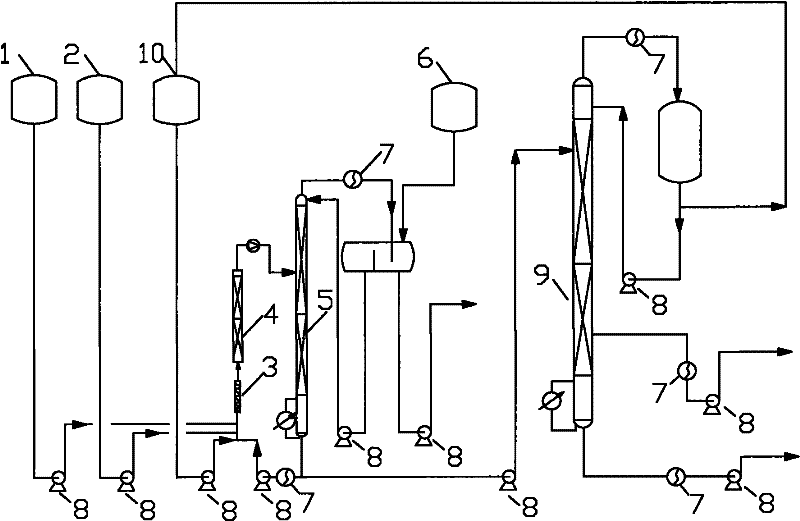

Method for producing propylene glycol methyl ether acetate

ActiveCN101693661AImprove reaction efficiencyPositive responseOrganic compound preparationCarboxylic acid esters preparationAcetic acidGas phase

The invention relates to a method for producing propylene glycol methyl ether acetate. The method is characterized in that a reactive kettle made of an acid-resisting material is applied to a reactive fractionating tower and the front passage of a material kettle on the lower part of the reactive fractionating tower; under the existence of a catalyst, when the number of moles of propylene glycol methyl ether is excessive compared with that of the acetic acid, the esterification is carried out concentratively in the reactive kettle; the obtained product and the unreacted material are evaporated and pass an acid catcher so that the acidic catalyst with a high boiling point is collected in liquid phase; the material of gas phase enters the reactive fractionating tower through a material inlet; an entrainer is added at the upper part of the reactive fractionating towel so as to remove the water in the material by azeotropy; under the action of the layered solid acid catalyst, the residual acetic acid in the material continues to react at the reaction section of the lower part of the material inlet of the reactive fractionating towel so that the material finally dropped in the material kettle of the reactive fractionating towel has no acidic compositions, thus avoiding the corrosion on the equipment in the subsequent separating and refining process; and the obtained product has low acidity and completely meets the requirement of the product standard.

Owner:JIANGSU BAICHUAN GAOKE NEW MATERIAL CO LTD +1

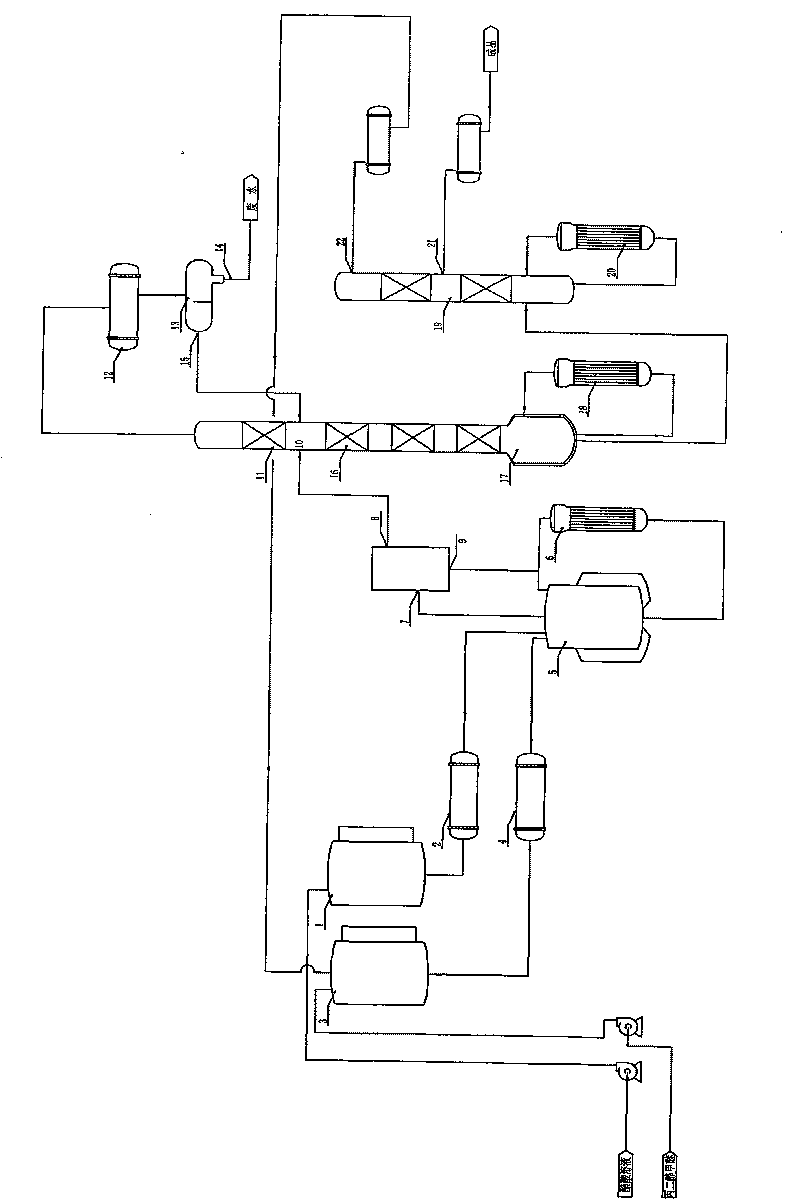

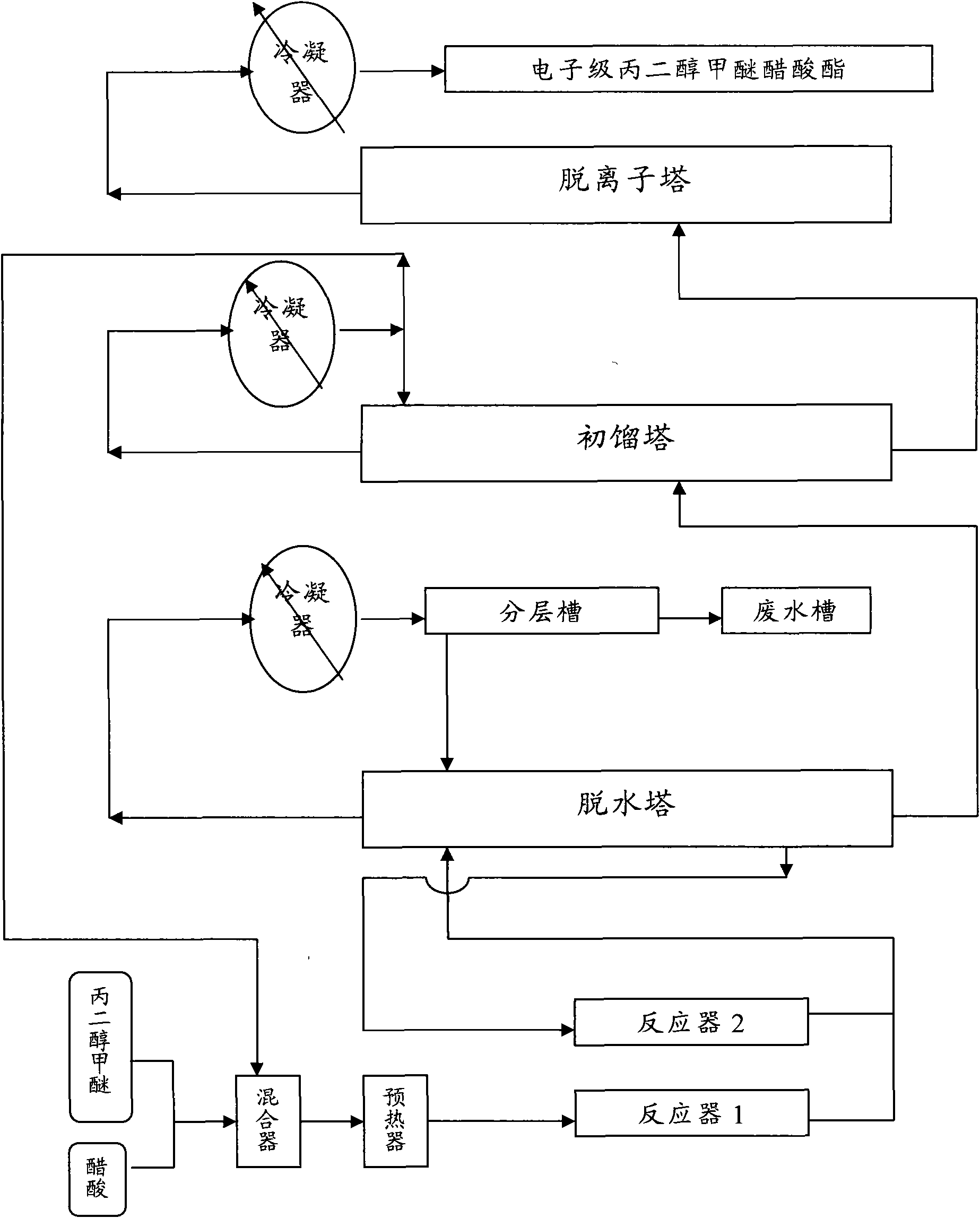

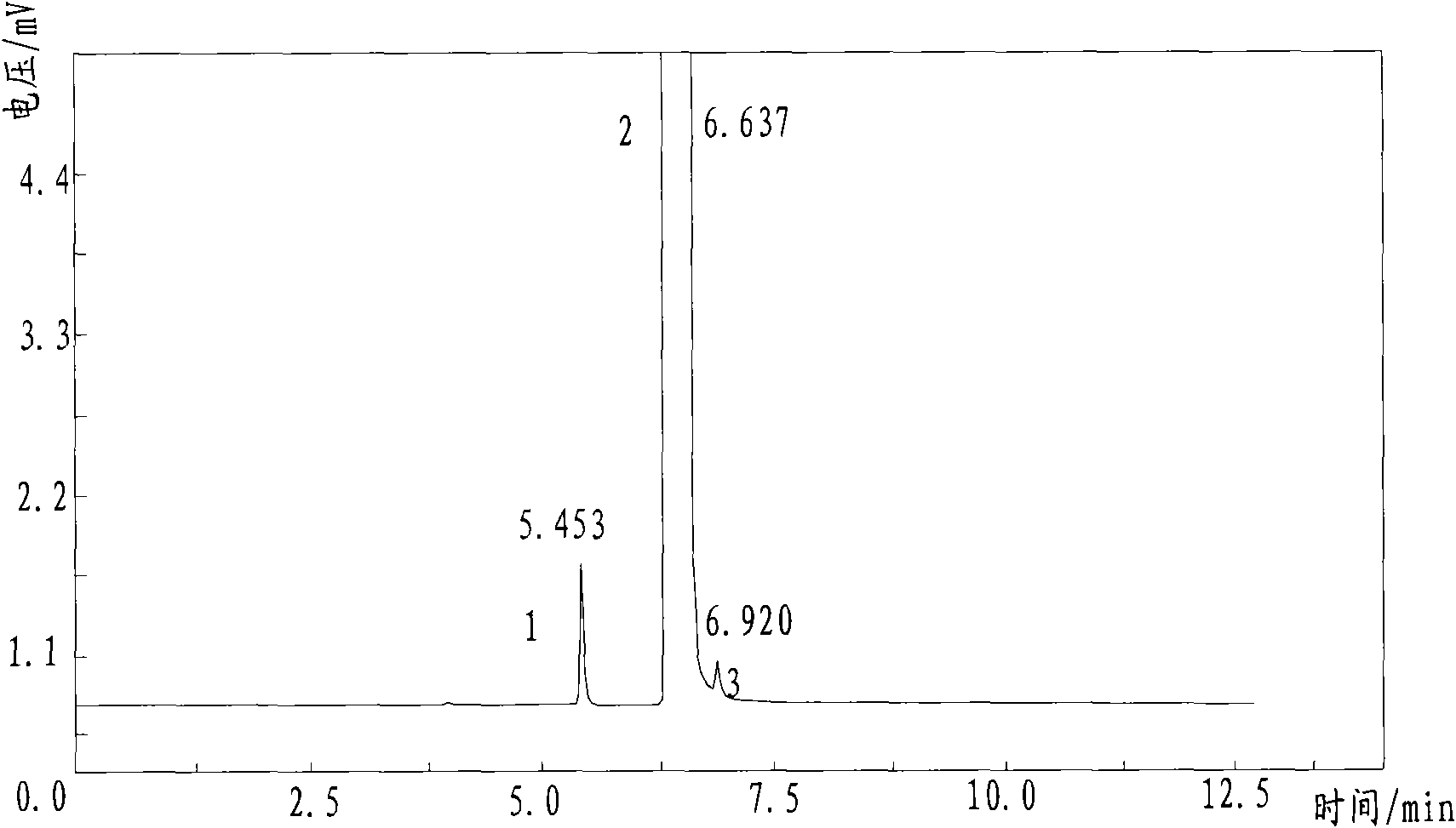

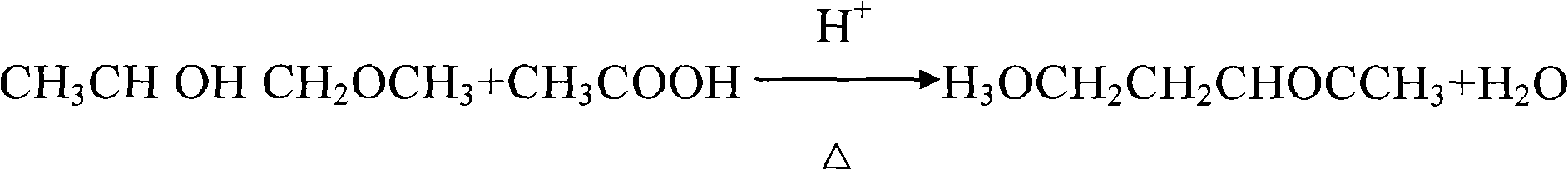

Method for preparing 1-Methoxy-2-propyl acetate by continuous esterification reaction

ActiveCN101337885ARealize industrial productionEmission reductionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidFixed bed

The invention discloses a process for preparing propylene glycol methyl ether acetate by continuous esterification reaction, which adopts propylene glycol methyl ether and acetic acid as the raw materials. The process is characterized in that a solid acid catalyst is adopted to carry out two-section fixed bed continuous esterification reaction at the esterification temperature of 70 to 150 DEG C; water generated in the sterification reaction is removed by azeotropic distillation; and the result of the esterification reaction is rectified to remove and recover unreacted propylene glycol methyl ether and acetic acid to obtain propylene glycol methyl ether acetate. The method can achieve continuous production of propylene glycol methyl ether acetate, and has the advantages of simple operation manner, greatly improved production efficiency of propylene glycol methyl ether acetate, lowered production cost, reduced emission of solid contaminants and wastewater, and excellent large-scale industrial application value.

Owner:江苏德纳化学股份有限公司

Halogen-free low temperature solidified silver paste and preparation method thereof

InactiveCN101950596AReduce pollutionSuitable process conditionsNon-conductive material with dispersed conductive materialCable/conductor manufactureLow temperature curingEthylene glycol monoethyl ether acetate

The invention provides a halogen-free low temperature solidified silver paste, which comprises the following raw materials in percentage by mass: 40 to 50 percent of conductive powder, 37 to 46 percent of solvents, 8 to 20 percent of high polymer resin and 1 to 3 percent of additives, wherein the conductive powder is a mixture of flake silver powder and silver coated nickel powder; the solvent is one or more of DBE, diethylene glycol monoethyl ether acetate, propylene glycol methyl ether acetate and ethylene glycol monoethyl ether acetate; the high polymer resin is one or more of polyester resins and polyurethane resins; and the additives comprise one or more of coupling agents, thickening agents and leveling agents. In the halogen-free low temperature solidified silver paste of the invention, the conductive powder is successfully used for replacing silver powder, which not only can reduce the cost, but also satisfies European safety standards, and reduces environment pollution.

Owner:IRICO

Alkaline paint remover

InactiveCN106497213AImprove working environmentNo pollution in the processChemical paints/ink removersLacquerPolyethylene glycol

The invention relates to an alkaline paint remover. The alkaline paint remover comprises the following components in percentage by weight: 8%-10% of sodium hydroxide, 13%-15% of propylene glycol methyl ether acetate, 5%-10% of ethylene glycol monobutyl ether, 0.5%-1% of sorbitol, 13%-17% of benzyl alcohol, 10%-13% of absolute ethyl alcohol, 3%-5% of polyethylene glycol and 30%-47.5% of deionized water. The alkaline paint remover is a medicament for removing various paints, powdered coatings and the like, is suitable for removing metal surface coatings of steel, copper, aluminum and various alloy components, and is high in utilization rate; after the paint removal is finished, residual paint residue is fished out, and the alkaline paint remover is covered with a lid and is sealed, so that the alkaline paint remover can be repeatedly used; and furthermore, the alkaline paint remover can be contained by virtue of containers made of stainless steel, PVC and the like, is wide in selection range and low in cost, does not contain phenol, dichloromethane, phosphorus or various heavy metals, meets the requirements of European Union WEEE&RoHS instructions and has good odor, so that the working environment of operators can be effectively improved, the environmental protection is realized, and the pollution is avoided.

Owner:粟飞

Coating composition with ceramic imitation effect

ActiveCN102585633AWear-resistantGood mechanical propertiesPolyurea/polyurethane coatingsSpecial surfacesXylyleneEthylic acid

The invention mainly relates to the field of paint coating, in particular to a coating composition with a ceramic imitation effect. The coating comprises primer coating, middle coating and top coating. The top coating mainly comprises a main agent and a curing agent, wherein the main agent mainly comprises the following components: 5-10 parts of butyl acetate, 4-10 parts of xylene, 80-85 parts of acrylic polyol resin, 4-8 parts of propylene glycol methyl ether acetate, 0.5-2 parts of an organosilicon leveling agent, and 0.1-0.5 parts of an organosilicon antifoaming agent; and the curing agent mainly comprises the following components: 15-30 parts of butyl acetate, 15-30 parts of xylene, and 40-65 parts of an isocyanate curing agent. The coating composition provided by the invention can be used on prefabricates of plastic, glass or other materials, so that the prefabricates have a high ceramic imitation effect, and the ceramic imitating products not only have various advantages of ceramic products, but also reduces mining and use of organic soil and saves consumption of natural resources. In addition, the coating composition can be dissolved in soil, so as to reduce the pollution and destroy to the environment and reduce the harm to human bodies.

Owner:DONGGUAN SUNLAND TECH CO LTD

General adhesion promoter for paint and method of producing the same

The invention relates to an adhesive force accelerant for a universal coating and a preparation method thereof. The adhesive force accelerant consists of the following raw materials in weight percentage: 20 to 40 percent of epoxy resin, 10 to 30 percent of chlorinated polypropylene resin, 20 to 40 percent of propylene glycol methyl ether acetate, 10 to 20 percent of n-butyl alcohol, 2 to 5 percent of water and 5 to 20 percent of phosphoric acid. According to the proportion, the propylene glycol methyl ether acetate, the n-butyl alcohol and the water are sequentially added into a vessel, are started to stir and are added with the chlorinated polypropylene resin; and upon complete dissolve, the solution is added with the epoxy resin, is evenly stirred, is dripped with the phosphoric acid and is continuously stirred for 2 to 3 hours to obtain the adhesive force accelerant. The adhesive force accelerant has the advantages of strong universality, excellent intermiscibility, low cost, small use amount, simple production process and convenient use.

Owner:JINAN HUALIN CHEM

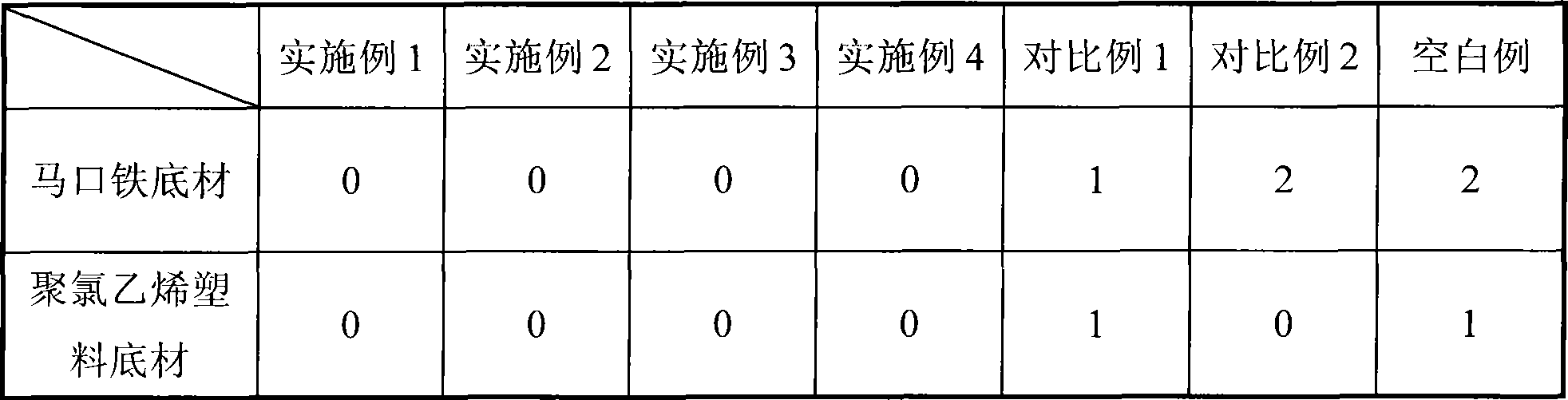

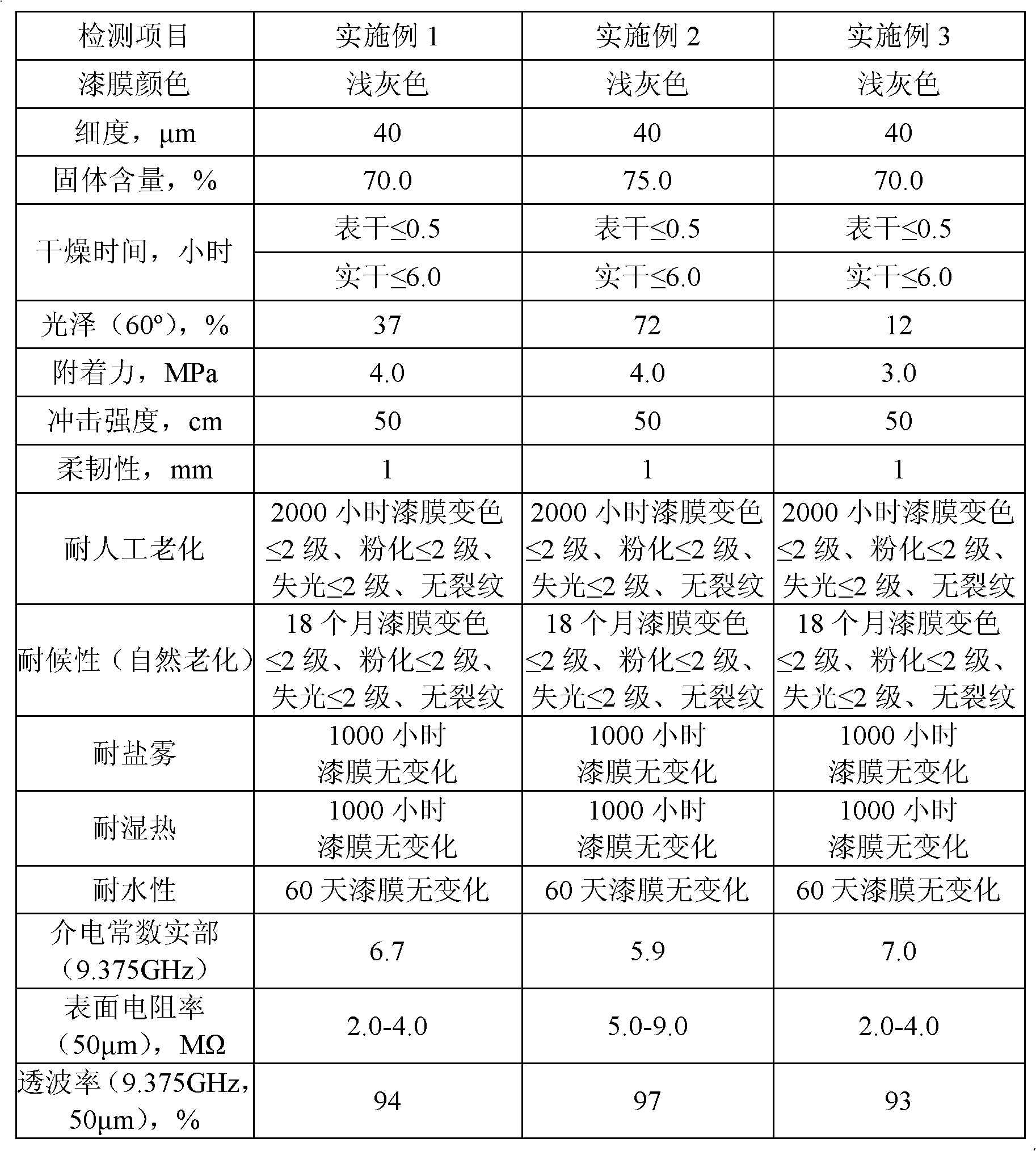

Light-color antistatic coating with high electromagnetic wave transmissivity and preparation method thereof

InactiveCN102127361AHigh wave transmittanceQuality improvementPolyurea/polyurethane coatingsElectrically-conductive paintsAging resistanceUltraviolet

The invention relates to a light-color antistatic coating with high electromagnetic wave transmissivity and a preparation method thereof and provides a light-color bi-component antistatic coating with high electromagnetic wave transmissivity, which consists of a component A and a component B in the weight ratio of 100:(8-10). The component A comprises the following components in parts by weight: 30-70 parts of hydroxyl fluorocarbon resin, 5-25 parts of mixed solvent, 30-70 parts of composite conductive powder, 0.5-1.5 parts of conductivity accelerator, 0.1-0.3 part of dispersant, 0.1-0.4 part of antifoaming agent, 0.5-1.5 parts of delustering agent, 0.5-1.5 parts of ultraviolet absorbent and 0.5-1.5 parts of catalyst. The component B comprises the following components in parts by weight: 70-80 parts of hexane diisocyanate tripolymer resin and 20-30 parts of propylene glycol methyl ether acetate. The invention also provides a preparation method of the coating. The light-color bi-component antistatic coating provided by the invention has the advantages of excellent field construction effect, contribution to improvement on coating quality of an antenna housing, low dielectric constant, high wave transmissivity, aging resistance, salt fog resistance, humidity resistance and the like.

Owner:NO 91872 TROOPS PLA

Environment-friendly electro-plated silver paint and preparation method thereof

InactiveCN103319966AMake up for the defects that cannot be partially electroplatedPromote environmental protectionCoatingsButyl acetateAcrylic resin

The invention relates to the technical field of paint and in particular relates to environment-friendly electro-plated sliver paint. The environment-friendly electro-plated sliver paint consists of modified acrylic resin, aluminum sliver paste, ethyl acetate, butyl acetate, propylene glycol methyl ether acetate and a flatting agent. A stirring device with rotation speed of 500 revolutions / minute-600 revolutions / minute is used for sufficiently and uniformly stirring for at least 20 minutes; the uniformly stirred electro-plated sliver paint is sprayed and roasted for 30 minutes at 65 DEG C-80 DEG C to obtain a paint film. The environment-friendly electro-plate sliver paint is energy-saving and environment-friendly, simple in spraying process, convenient to operate and provided with a spraying effect equal to that of an electro-plated product, and therefore, the environment-friendly electro-plated sliver paint is a substitute product of the conventional electro-plating process. Besides, the environment-friendly electro-plated sliver paint can be used for the products including a television, a washing machine, an air conditioner, a bicycle, an electric bicycle, a motorcycle, a small household appliance, hardware, plastic and the like.

Owner:CHANGZHOU HUASHI CHEM

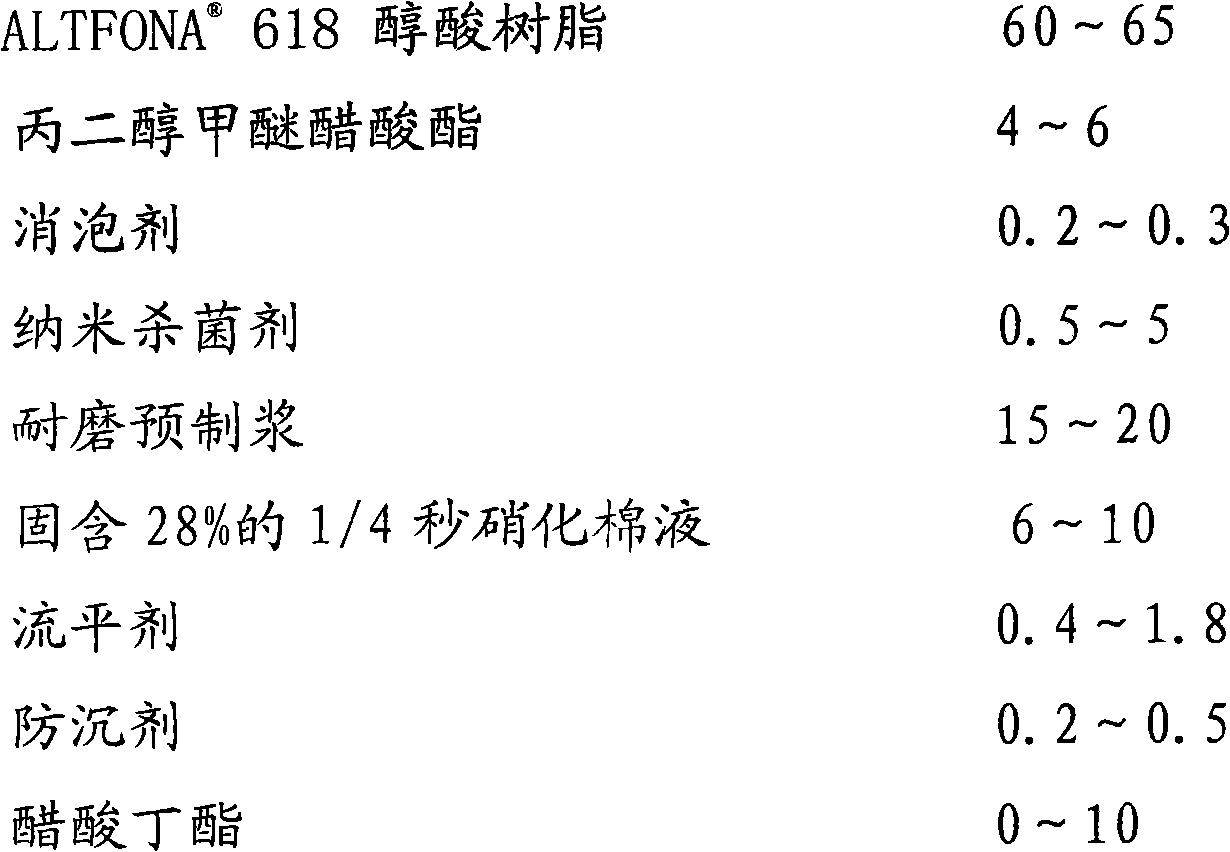

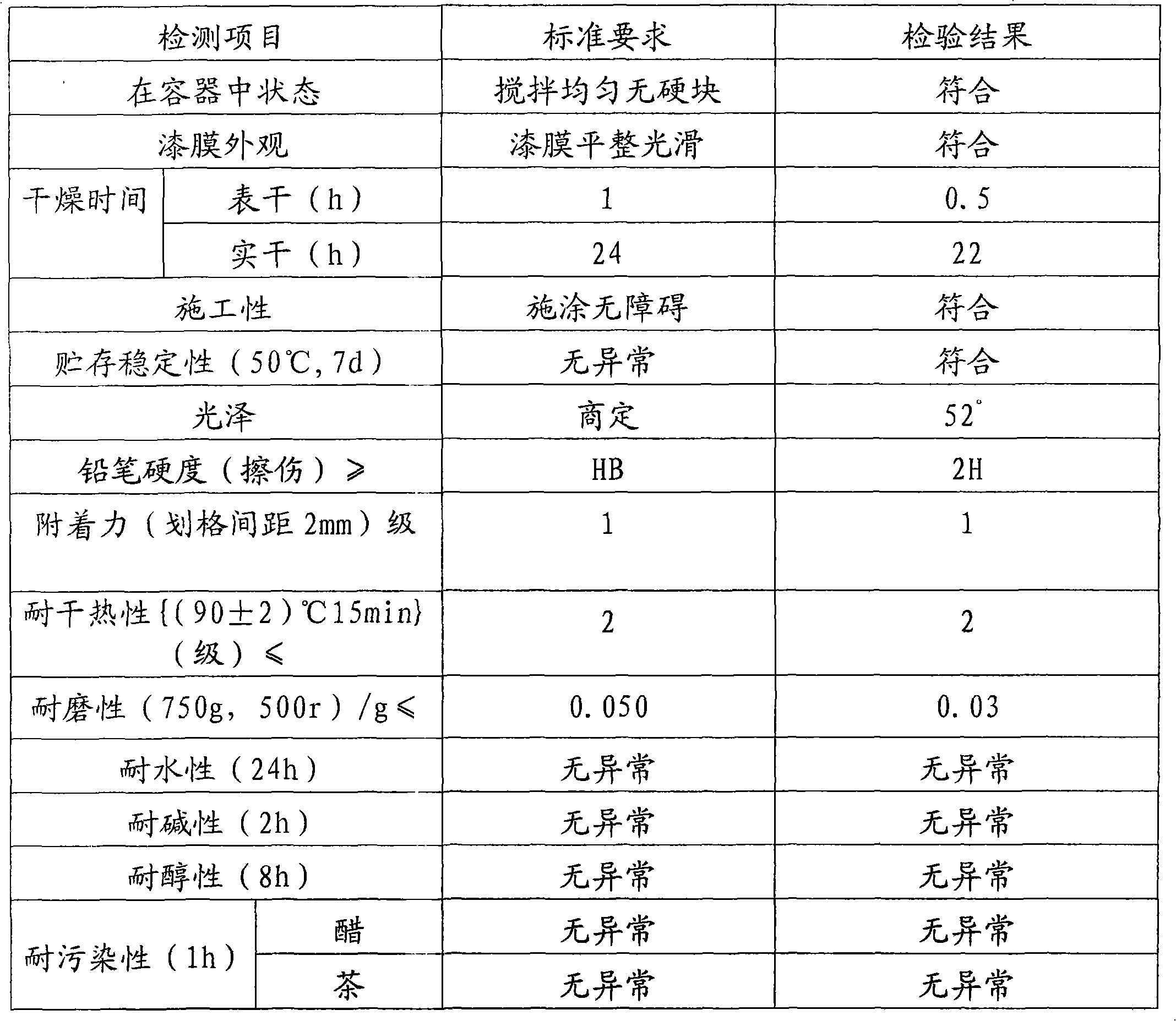

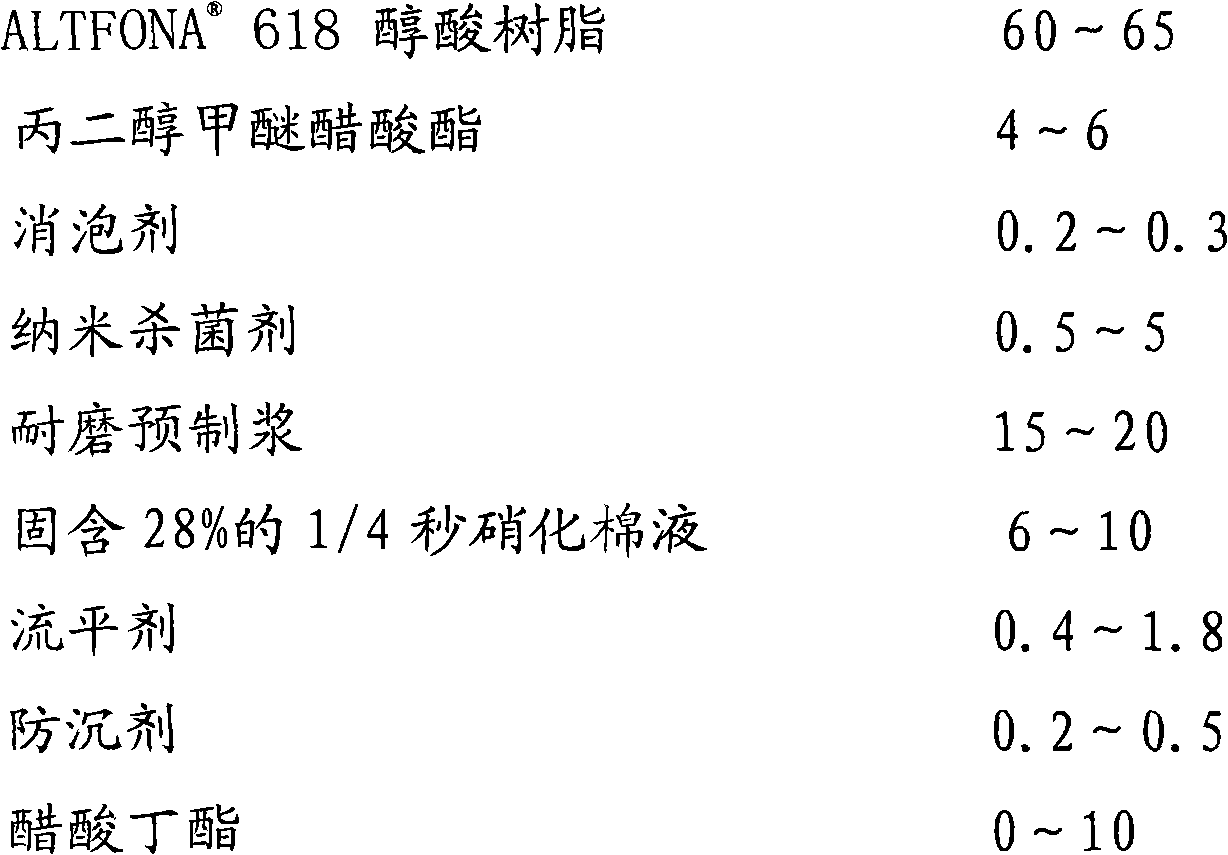

Sterilization and aldehyde-removal nanometer polyurethane paint

InactiveCN102634275AImprove the bactericidal effectImprove adhesionAntifouling/underwater paintsPaints with biocidesCyclohexanoneDecomposition

The invention discloses sterilization and aldehyde-removal nanometer polyurethane paint, which is composed of three components A, B and C. The component A is prepared by uniformly mixing alkyd resin 618, propylene glycol methyl ether acetate, a defoaming agent, a nanometer bactericide, wear-resisting prefabricated slurry, 1 / 4 second nitrocotton with a solid content being 28%, a leveling agent, an anti-settling agent and butyl acetate, the component B is prepared by uniformly mixing a tolylene diisocyanate (TDI) trimer, a TDI additive product and butyl acetate, and the component C is prepared by uniformly mixing propylene glycol methyl ether acetate, butyl acetate and cyclohexanone; and when the sterilization and aldehyde-removal nanometer polyurethane paint is used, the three components are uniformly mixed according to a weight ratio. Compared with similar products in the market, the sterilization and aldehyde-removal nanometer polyurethane paint disclosed by the invention has the function of removing formaldehyde in triple manners of absorption, decomposition and seal and has the advantages of favorable sterilization effect, good product adhesion force, scraping resistance, good application property and good tolerance.

Owner:GUANGDONG SANVO CHEM IND TECH

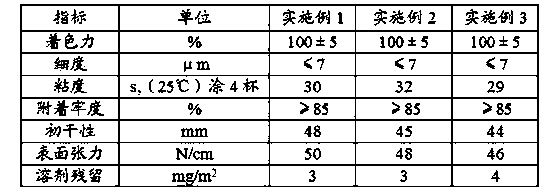

Novel environmentally-friendly high-speed gravure printing compound ink

ActiveCN103992690AImprove product qualityGood printing adaptabilityInksPolyethylene vinyl acetateDefoamer

The invention discloses a novel environmentally-friendly high-speed gravure printing compound ink. The ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-8 parts of a delustering liquid, 1-3 parts of delustring powder and 0.3-0.6 parts of an antifoaming agent. The ink has fine and uniform fineness, can adapt to a printing speed of 300m / min, and has the advantages of excellent light stability, excellent chemical drug resistance and no yellow stains.

Owner:SUZHOU ZHONGYA INK

High transparency scratch-resisting matt clear paint

ActiveCN103131321AImprove the decorative effectImprove protectionPolyurea/polyurethane coatingsPolymer scienceToluene diisocyanate

The invention discloses high transparency scratch-resisting matt clear paint which is composed of a host agent, a curing agent and a diluent agent. The host agent comprises 65.5 % - 75.5% of short oil alkyd resins, 16 % - 25 % of solvent, 0.1 % - 0.3 % of antifoaming agents, 0.1 % - 0.3 % of flatting agents, 0.1 % - 0.5 % of anti-settling agents, 0.1 % - 0.3 % of dispersing agents, 1 % - 3 % of scratch-resisting assistant agents, and 4 % - 8 % of delustering agents. The curing agent comprises 40 % - 50 % of toluene diisocynate (TDI) trimer, 10 % - 20 % of TDI- hexamethylene diisocyanate (HDI) mixed trimer, 20 % - 30 % of TDI- trimethylolpropane adduct, and 20 % - 30 % of butyl acetate. The diluent agent comprises 40 % - 50 % of butyl acetate, 20 % - 30 % of dimethylbenzene, and 20 % - 30 % of propylene glycol methyl ether acetate. The high transparency scratch-resisting matt clear paint is good in transparency and scratch-resisting performance, and is easy to process.

Owner:安徽名士达新材料有限公司

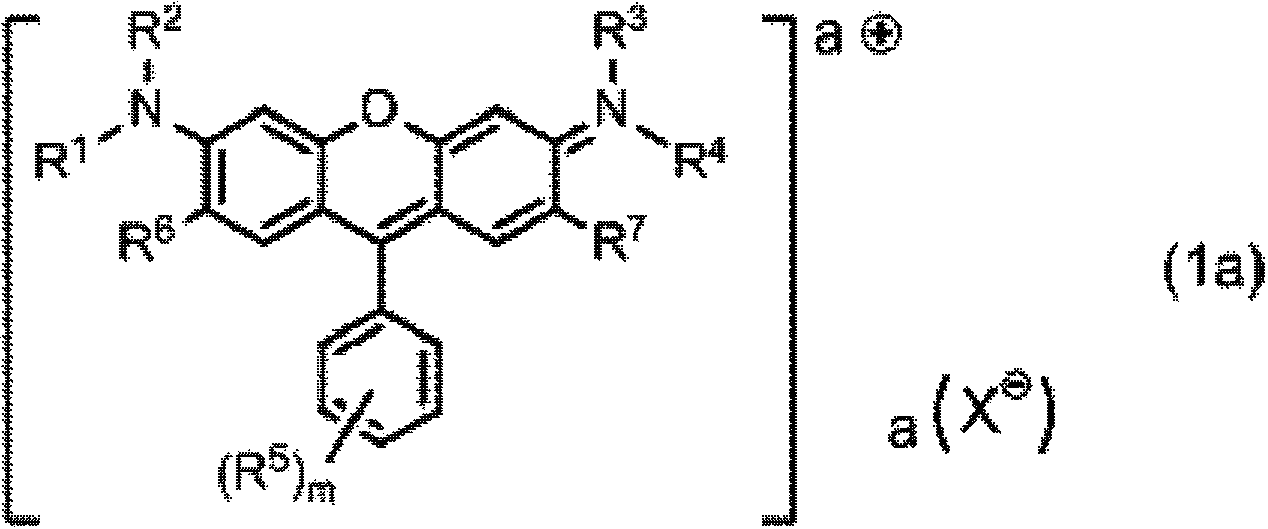

Colorant dispersion liquid

ActiveCN103360791AOptical filtersOrganic dyesDipropylene glycol monomethyl ether acetatePolymer chemistry

Owner:SUMITOMO CHEM CO LTD +1

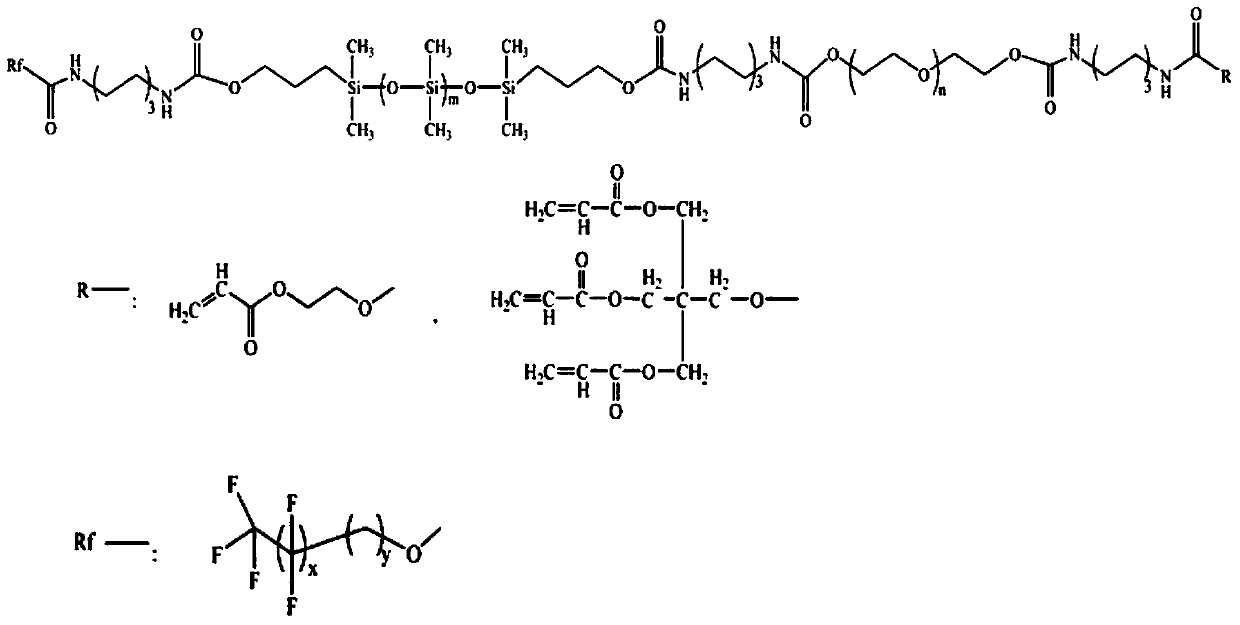

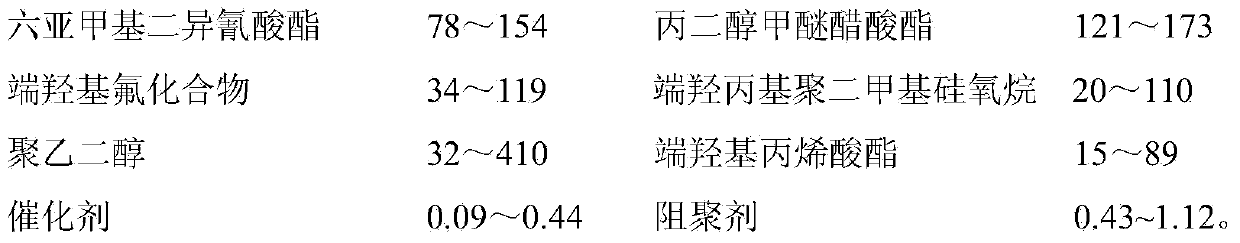

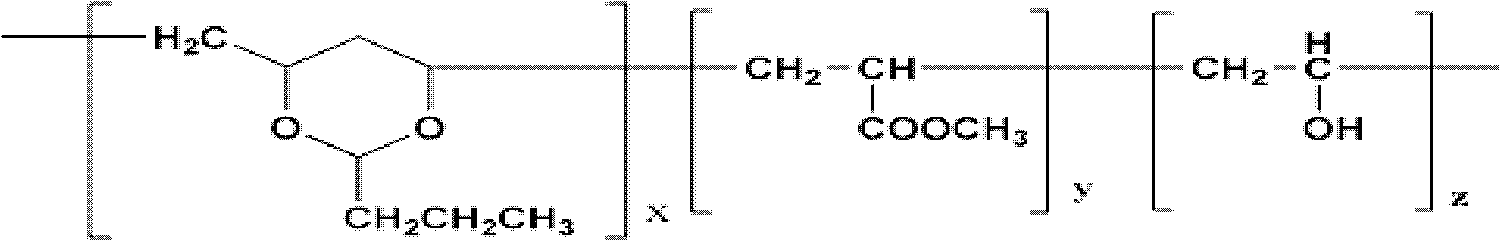

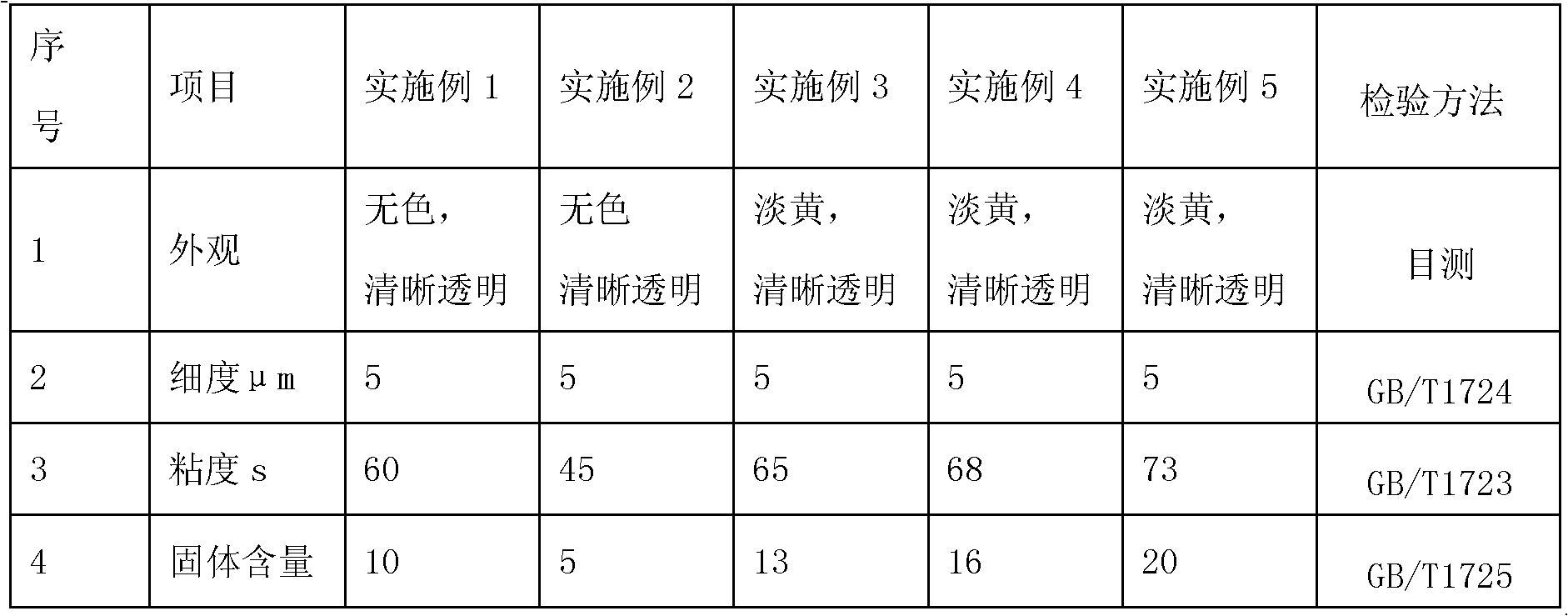

Urethane acrylate oligomer, preparation method of urethane acrylate oligomer, and coating prepared from urethane acrylate oligomer

ActiveCN103992460ASimple manufacturing methodEase of industrial productionPolyurea/polyurethane coatingsUltraviolet lightsPolyethylene glycol

The invention provides a urethane acrylate oligomer, which comprises the following components: hexamethylene diisocyanate, propylene glycol methyl ether acetate, a hydroxyl-terminated fluorine compound, hydroxypropyl-terminated polydimethylsiloxane, polyethylene glycol, hydroxyl-terminated acrylate, etc. According to the invention, silicon and fluorine are introduced in the urethane acrylate oligomer, so that the urethane acrylate oligomer has high hydrophilic angle; and in addition, by means of high hydrophilia provided by ethyoxyl in polyethylene glycol, the urethane acrylate oligomer has high pollution-resistant property. The invention further discloses a preparation method of the urethane acrylate oligomer, which is simple in process and convenient for industrialization production. The invention simultaneously discloses a coating comprising the urethane acrylate oligomer, which comprises urethane acrylate oligomer and the like; after the coating disclosed by the invention is cured by ultraviolet light, the hydrophilic angle of a paint film is up to 100-120 degrees; the coating has excellent pollution-resistant property; and stain of an oily pen can be wiped cleanly without any trace.

Owner:HUNAN BENAN YADA NEW MATERIALS

Bacteriostatic corrosion-resistant formaldehyde-removing laundry sheet and preparation method thereof

InactiveCN107022425AHas a smooth effectEasy to prepareInorganic/elemental detergent compounding agentsBiocideAlpha-olefinLaundry

The invention discloses a bacteriostatic corrosion-resistant formaldehyde-removing laundry sheet and a preparation method thereof. The laundry sheet is prepared from the following components in parts by mass: 5 to 12 parts of bonding agent, 2 to 15 parts of tea saponin, 8 to 13 parts of sodium alpha-olefin sulfonate, 0.1 to 0.3 part of preservative, 12 to 20 parts of filler, 0.2 to 0.3 part of lubricant, 2 to 3 parts of fabric softener, 5 to 8 parts of surfactant, 3 to 8 parts of washing aid, 0.6 to 1 part of plant aromatherapy extract, 0.2 to 0.5 part of chelating agent, 0.01 to 1.0 part of sodium hydroxide, 5 to 8 parts of propylene glycol methyl ether acetate and 30 to 35 parts of deionized water. By adopting the bacteriostatic corrosion-resistant formaldehyde-removing laundry sheet provided by the invention, breeding of bacteria can be effectively restrained, formaldehyde in clothes can be removed, a softening effect is achieved, and the generation of static electricity is effective prevented; the preparation method of the laundry sheet provided by the invention is simple, and is easy to implement.

Owner:诺圆环保科技(苏州)有限公司

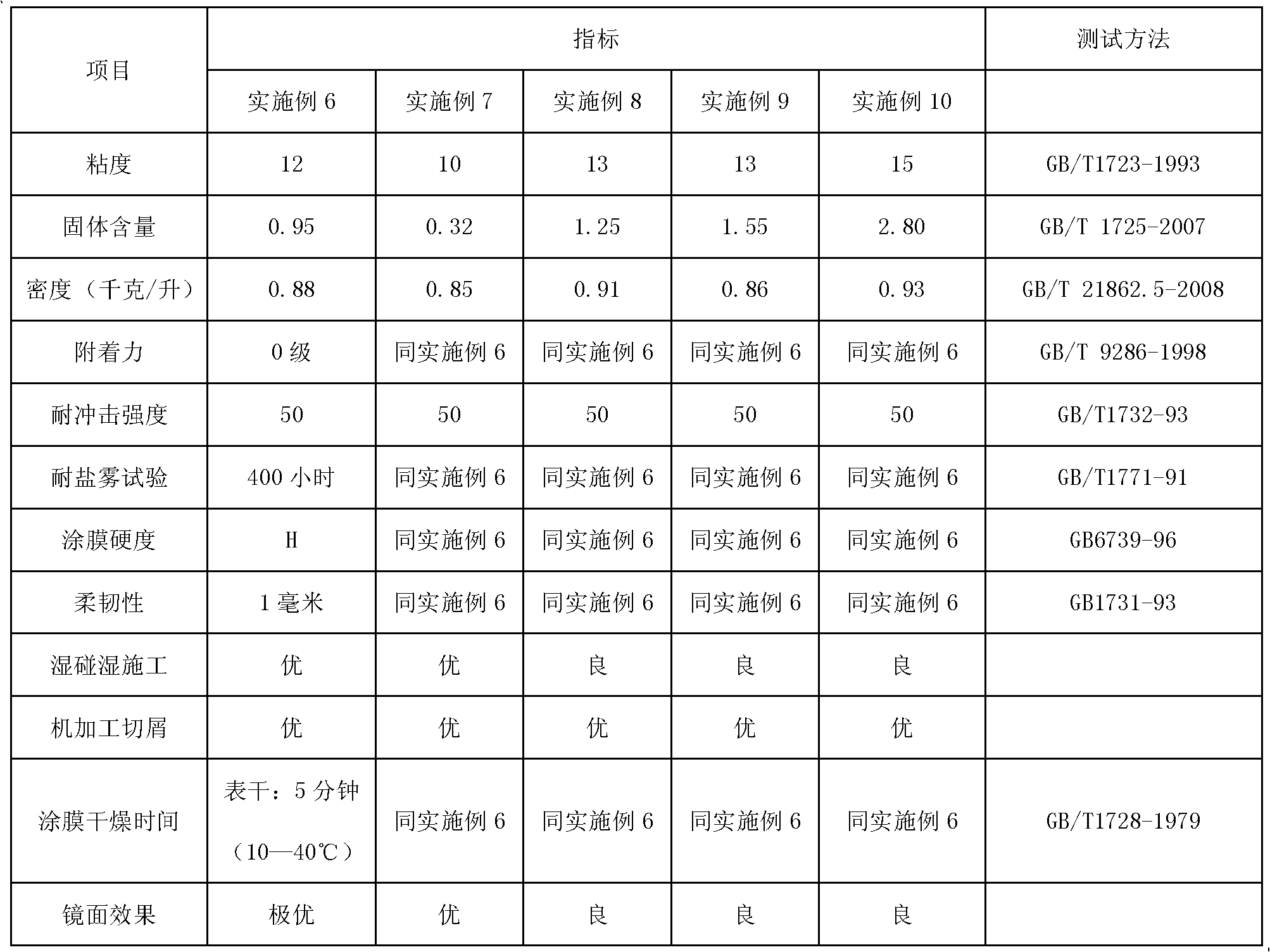

Mirror silver coating, mirror silver resin forming mirror silver coating, and preparation methods for mirror silver coating and mirror silver resin

InactiveCN102533014AGood anti-silver effectMatching adhesion is goodPaints with free metalsButyl acetateEther

The invention relates to a formula of a mirror silver coating, a mirror silver resin forming the mirror silver coating, and the preparation methods for the mirror silver coating and the mirror silver resin. According to the formula, the mirror silver coating consists of the following components in part by mass: 2 to 20 parts of mirror silver resin, 5 to 30 parts of butanol, 5 to 20 parts of isopropanol, 20 to 55 parts of acetic ether, 10 to 20 parts of butyl acetate, 5 to 30 parts of propylene glycol methyl ether acetate, and 0.5 to 3 parts of electroplating silver slurry; the mirror silver coating is high in decoration; compared with the conventional cyanogen-containing electroplating, the method for electroplating by using the mirror silver coating has the advantage that environment is polluted slightly; the selected raw materials have special structures and are low in cost, the mirror silver coating can replace a foreign product completely due to the performance, and the price of the mirror silver coating is more than 50 percent lower than that of an imported product; and the mirror silver coating has a super electroplating effect, is high in adhesion, and can meet the characteristics of a wet to wet spraying process; and a paint film can be machined and cut.

Owner:上海天地涂料有限公司

Benzene and ketone free high temperature resistant table printing ink

The invention discloses a benzene and ketone free high temperature resistant table printing ink. The benzene and ketone free high temperature resistant table printing ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-10 parts of a delustering agent, 0.3-0.6 parts of an antifoaming agent, 0.3-0.8 parts of a high temperature resistant assistant, and 1-2 parts of a curing agent. The adoption of a double liquid design increases the hardness and the adhesion of an ink film, effectively prevents offsetting or ink falling, realizes excellent high temperature and boiling resistances, and increases the shelf life of the printing ink.

Owner:SUZHOU ZHONGYA INK

High-fullness and shock-resistance polyurethane matte top-coat paint

The invention discloses high-fullness and shock-resistance polyurethane matte top-coat paint. Castor oil alkyd resin, 20% of chlorine vinegar resin, wax powder and matte powder are prepared to a component A; TDI addition curing agent L-75, TDI tripolymer curing agent 1451, HDI tripolymer curing agent HX-90B, dehydrated n-butyl acetate and xylene are prepared to a component B; n-butyl acetate, propylene glycol methyl ether acetate, acetic ether, ethylene glycol diacetate and xylene are prepared to a thinner component C during constructing; the paint is prepared by mixing the components A, B and C according to the weight ratio of 1: 0.5: (0.5-0.8). By using the characteristics of high solid content and good flexibility of the raw materials such as the castor oil alkyd resin and HDI diisocyanate, the paint of the invention improves the flexibility and the shock resistance of painted films, enables coated layers to have good transparency, high fullness and excellent flexibility and shock resistance, and is specifically suitable for coating wood artware and cane furniture.

Owner:GUANGDONG BADESE CHEM

Waterproof and anticorrosive paint special for marine ships

InactiveCN106318105AAccelerated corrosionImprove water resistanceRubber derivative coatingsAnti-corrosive paintsDimethylaniline N-oxideDefoamer

The invention discloses a waterproof and anticorrosive paint special for marine ships. The paint comprises 60-85wt% of a component A and 15-40wt% of a component B. The component A comprises the following raw materials: epoxy resin, chlorinated rubber, an ethylene chloride-vinyl acetate copolymer, organic fluorine modified acrylic resin, a silane coupling agent, zinc powder, mica powder, iron oxide red, ceramic micro-powder, molybdenum disulfide, propylene glycol butyl ether, propylene glycol methyl ether acetate, a dispersing agent, an organic silicon defoamer, a leveling agent, methyl isobutyl ketone and n-butanol; and the component B includes the following raw materials: poly 2, 3-dimethylaniline modified montmorillonite, a curing agent, ethyl acetate, and butyl acetate. The waterproof and anticorrosive paint special for marine ships provided by the invention has excellent waterproof performance and corrosion resistance, also has excellent impact resistance, abrasion resistance and weather resistance, has good comprehensive performance when used in ship engineering, and has long service life.

Owner:ANHUI KAILIN ADVANCED MATERIAL CO LTD

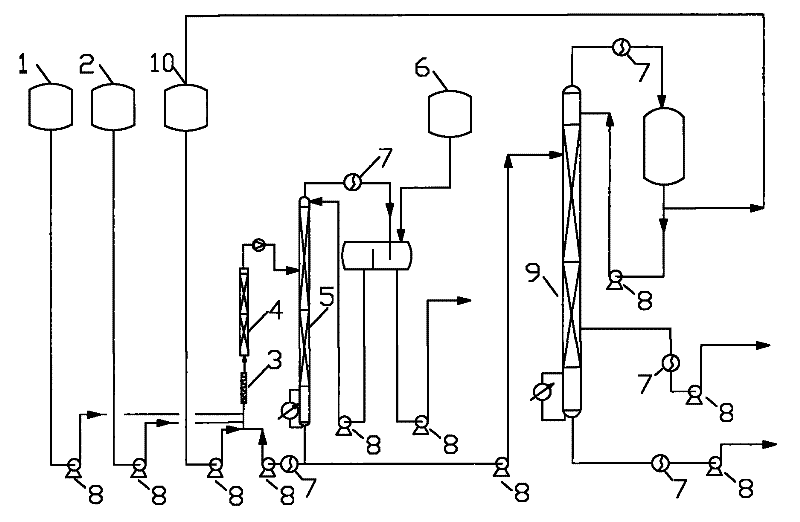

Preparation method of electronic grade propylene glycol methyl ether acetate

ActiveCN101993360ARealize continuous productionIncrease productivityOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsOperation modeCorrosion

The invention discloses a preparation method of electronic grade propylene glycol methyl ether acetate, and the method uses propylene glycol methyl ether and acetic acid as raw materials and adopts strong acidic cation resin catalyst to perform the esterification reaction. The method of the invention adopts the new technology of continuous production to realize the efficient industrial production of the electronic grade propylene glycol methyl ether acetate product; the operation mode is simple, the production efficiency is high, the discharge amounts of residue and wastewater can be reduced in the production process; the reaction product is not required to be neutralized with a large amount of alkali and washed with water; the catalyst has long service life, high catalytic activity and catalytic selectivity, good mechanical strength and no corrosion to the equipment; and the catalyst has the following advantages: the catalyst can be used repeatedly, be easy to separate from the reaction product, etc. The invention has good economic benefit and environmental benefit.

Owner:JIANGSU RUIJIA CHEM

Weather-resistant paint and preparation method thereof

ActiveCN104371472AImprove high temperature resistanceImprove corrosion resistanceAnti-corrosive paintsAcrylic resinSilanes

The invention discloses weather-resistant paint and a preparation method thereof. The weather-resistant paint is composed of, by weight, 20 parts of epoxy modified hydroxy acrylic resin, 20 parts of thermoplastic acrylic resin with weight-average molecular weight of 80000-85000, 20 parts of organic silicon modified acrylic resin, 10 parts of melamine resin, 7 parts of phenyl trichorosilane, 3 parts of vinyl trimethoxy silane, 10 parts of nano corundum powder, 7 parts of titanium dioxide, 5 parts of talcum powder, 0.5 part of defoamer, 0.5 part of flatting agent, 0.5 part of dispersant, 20 parts of ethylene glycol butyl ether and 15 parts of propylene glycol methyl ether acetate, wherein number-average molecular weight of the epoxy modified hydroxy acrylic resin is 10000-15000. Overall weatherability of a paint film is improved, and service life of the paint film is prolonged effectively.

Owner:佛山市顺德区容桂江裕化工五金有限公司

Anticorrosion environment-friendly building water-based coating material and preparation method thereof

InactiveCN105219138AWon't crackNo pollution in the processAnti-corrosive paintsWater basedTemperature resistance

The invention relates to an anticorrosion environment-friendly building water-based coating material and a preparation method thereof. The high-strength environment-friendly building water-based coating material contains raw materials such as graphene, hydroxypropyl methylcellulose, polyamide, magnesium phosphate, fatty acid sorbitan, polysorbate, sodium hexametaphosphate, organic silicon emulsion, epoxy silane modified silicon sol, cross-linked polyethylene, tert-butyl peroxybenzoate, sodium silicate, melamine polyphosphate, N-dodecyl mercaptan, pentaerythritol, alumina silicate fiber, silicon dioxide, 2,4,5,6-tetrachloro-3-benzenedicarbonitrile, propylene glycol monomethyl ether, propylene glycol methyl ether acetate, 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate, water-based polyurethane resin, acrylate, tung oil, titanium dioxide, polyvinyl alcohol, light calcium carbonate, talcum powder, titanium dioxide, silicon carbide, glass fibers, fluorine resin, water-based epoxy modified resin, styrene-acrylic emulsion and a siloxane defoaming agent. The anticorrosion environment-friendly building water-based coating material has high temperature resistance and corrosion resistance and is suitable for the coating requirements of various fields; moreover, the anticorrosion environment-friendly building water-based coating material contains no toxicity and organic solvents, has no pollution and also has the advantages of no fracturing of a coat, aging resistance, corrosion resistance and the like.

Owner:杨洋

Oil modified epoxy resin superstrong anticorrosive paint for coated aluminum foils

ActiveCN103275602AImprove hydrophobicityReduce adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyester

An oil modified epoxy resin superstrong anticorrosive paint for coated aluminum foils, belongs to a paint coated on a metal plate, and is manufactured through a conventional paint production process. The oil modified epoxy resin superstrong anticorrosive paint is characterized by comprising the components by weight: 20-30% of oil modified epoxy resin, 5-15% of oil soluble phenolic resin, 1-4% of HMMM resin, 0.2-0.8% of boron phosphate, 0.20-0.25% of polyester-imide, and the balance of solvent prepared from butylcellosolve, propylene glycol methyl ether acetate and dibasic ester. The paint is coated on the surface of an aluminum foil coiled material to become a superstrong anticorrosive aluminum foil coiled material, and after trials and tests, compared with the prior art, the oil modified epoxy resin superstrong anticorrosive paint has the beneficial effects as follows: after slat spray test determination, the corrosion evaluation grade of the coated aluminum foil coiled material of which the corrosion area is smaller than 0.01% reaches up to over highest grade 10, but the high corrosion-resistance hydrophilic coated aluminum foil in the prior art cannot reach the corrosion-resistance highest grade 10. The oil modified epoxy resin superstrong anticorrosive paint can be used for not only heat exchange parts but also oceaneering and ship surface decoration and protection.

Owner:ZHENJIANG WANYUAN ELECTRONICS

Self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating

InactiveCN106590385AGood gloss and color retentionThe advantage is: polyurethane resin has good heat resistanceAntifouling/underwater paintsPaints with biocidesDibenzoyl PeroxideOrganic inorganic

The invention discloses a self-cleaning antifouling organic-inorganic super-amphiphobic polymer coating which is prepared from the following raw materials: perfluoroalkyl ethanol, methyl isobutyl ketone, HDI trimer, methyl methacrylate, styrene, hydroxyethyl methacrylate, perfluorooctyl methacrylate, benzoyl peroxide, 25-28 parts of methanol silica sol, propylene glycol methyl ether acetate, titanium dioxide, sodium hexametaphosphate, ethyl orthosilicate, vinyl triethoxysilane, an appropriate amount of ammonia water, an appropriate amount of silane coupling agent KH570, an appropriate amount of methyl hydroxyl silicone oil, an appropriate amount of 10% dibutyltin dilaurate, a dispersant, a leveling agent, a defoamer, an appropriate amount of butyl acetate, an appropriate amount of anhydrous ethanol, and an appropriate amount of deionized water. The super-amphiphobic polymer coating provided by the invention is simple and feasible in preparation method, can be firmly combined with a variety of substrates, and has universality, good self-cleaning performance, dirt resistance, scrub resistance, corrosion resistance and other performance, and good application prospects.

Owner:TIANCHANG YINHU PAINT

Method for continuously synthesizing propylene glycol methyl ether acetate

InactiveCN102206153AEmission reductionEasy to operateOrganic compound preparationCarboxylic acid esters preparationAcetic acidDistillation

The invention relates to a method for continuously synthesizing propylene glycol methyl ether acetate. The method is characterized in that propylene glycol methyl ether and glacial acetic acid are taken as raw materials, an esterification is carried out in a fixed bed reactor which is filled with an acidic resin catalyst; the esterified reaction product is entered into a dewatered distillation tower for performing an azeotropic dehydration with an azeotropic desiccant, the dewatered materials are continuously extracted from a tower kettle of the dewatered distillation tower and backflowed to the fixed bed reactor for continuously performing the esterification, the cycle is established and then feeding of the raw materials is stopped until the esterification achieves a balance, thereby an equilibrium conversion rate can be reached; a continuous production is performed after the esterification is reached a balance, the fixed bed reactor is performed a continuous feeding, simultaneously, product of propylene glycol methyl ether acetate is continuously taken out of the tower kettle of the dewatered distillation tower. The invention has the advantages of simple operation, high production efficiency, less discharge of waste water and waste residue in process of production, environmental protection and low cost.

Owner:东莞市同舟化工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com