Patents

Literature

34results about How to "Improve discoloration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164AImprove the lubrication effectImprove rust resistanceLubricant compositionWater basedCombustion

The invention discloses anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid. The anticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is prepared from the following components in percentage by mass: 5 to 10 parts of base oil, 5 to 15 parts of an oiliness agent, 10 to 25 parts of organic amine, 5 to 15 parts of a synthetic rust inhibitor, 15 to 25 parts of a functional polyether surfactant, 0.2 to 3 parts of an extreme pressure additive, 3 to 8 parts of a solubilizer, 0.1 to 2 parts of a metal corrosion inhibitor, 0.1 to 2 parts of a magnesium alloy anti-fading agent, 0.1 to 2 parts of a bactericide, 0.1 to 1 part of an antifoaming agent, 0.1 to 10 parts of a pH regulator and 15 to 30 parts of water. The nticorrosive, anti-fading and environmentally-friendly water-based magnesium alloy cutting fluid is outstanding in ticorrosive and lubricating and has water resisting performances, and is high in cleaning and cooling effects, and effectively reduces the major technical problems such as corrosion, oxidative combustion, fading of magnesium alloy, demulsification and layering of the cutting fluid in the magnesium alloy processing process; the pH ranges from 9 to 11, and therefore, the demand of magnesium alloy cutting process can be met well.

Owner:苏州禾川化学技术服务有限公司

Base tri element colour sublimed fastness balancing type dispersion gray dye mixture

ActiveCN1861699AHigh fastness to sublimationImprove yieldOrganic dyesDyeing processFiberColor changes

A basic trichromatic sublimed firmness balanced dispersed grey dyestuff mixture is based on the sublimed firmness of the dispersed blue 2BLN to design a basic trichromatic dyestuff. The three are mixed to get a dispersed grey dyestuff mixture. The sublimed firmness of the dispersed blue 2BLN is three grades; the dispersed red and the yellow are also the three grades, so they can reach the balance. In the dying of the middle light colored Dacron and the plus material, the color changed problem can be solved leading by the dyestuff subliming inconsistently.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

Bentonite-loaded nano silver antibacterial agent and preparation method thereof

The invention discloses a bentonite-loaded nano silver antibacterial agent and a preparation method thereof. The preparation method comprises the following steps: carrying out acid treatment on bentonite to obtain acidification-modified bentonite; putting the acidification-modified bentonite into a dispersion stabilizer sodium polyphosphate water solution; adding a silver-ammonia solution and carrying out an illumination reaction to insert compound powder composed of nano silver and silver ammino ions into a bentonite sheet layer, so as to obtain the bentonite-loaded nano silver antibacterial agent. The grain diameter of the antibacterial agent compound powder prepared by the invention is 0.1-5 microns and the silver content is 0.1-15wt%; a bacteriostasis circle to colon bacillus and staphylococcus aureus is more than or equal to 10mm and the minimal inhibitory concentration is 10-200 micrograms / milliliter; the bentonite-loaded nano silver antibacterial agent is suitable for being used for preparing antibacterial plastic, antibacterial textiles, domestic chemical antibacterial materials and the like.

Owner:朱岳

Disperse yellow dye mixture with promoted fastness to sublimation

ActiveCN1884392ASolve the problem of serious shade changeBalanced sublimation fastnessOrganic dyesDyeing processFiberDisperse yellow

Owner:WUJIANG LVZHOU DYESTUFF CHEM

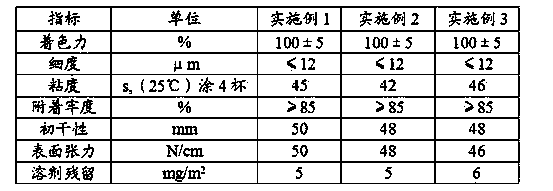

Benzene and ketone free high temperature resistant table printing ink

The invention discloses a benzene and ketone free high temperature resistant table printing ink. The benzene and ketone free high temperature resistant table printing ink comprises, by mass, 25-40 parts of a polyurethane resin, 10-15 parts of polyethylene vinyl acetate, 30-45 parts of an ester alcohol solvent, 0.6-1 part of propylene glycol methyl ether acetate, 5-15 parts of a pigment, 0.3-0.6 parts of a dispersant, 0.3-0.6 parts of polyethylene wax powder, 0.8-1.5 parts of an adhesion promoter, 0.8-1.5 parts of an antistatic agent, 5-10 parts of a delustering agent, 0.3-0.6 parts of an antifoaming agent, 0.3-0.8 parts of a high temperature resistant assistant, and 1-2 parts of a curing agent. The adoption of a double liquid design increases the hardness and the adhesion of an ink film, effectively prevents offsetting or ink falling, realizes excellent high temperature and boiling resistances, and increases the shelf life of the printing ink.

Owner:SUZHOU ZHONGYA INK

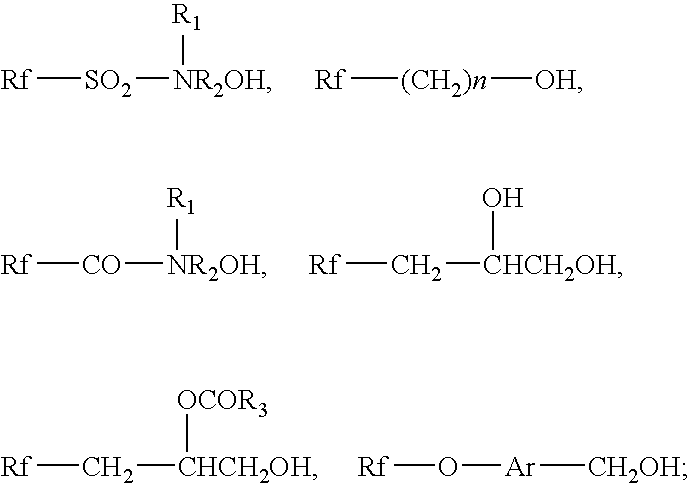

Solvent-based fluorinated water and oil repellent and process for producing the same

InactiveUS20050178996A1Easy to waterExcellent oil repellencyPhysical treatmentLiquid repellent fibresPolymer scienceCross linker

This invention discloses a solvent-based fluorinated water and oil repellent and process for producing the same. Said fluorinated water and oil repellent comprises 20˜50% (w / w) blocked polyfluorourethane compound and 50˜80% (w / w) solvent; its reaction agents include fluoroalcohol compound, diisocyanate or polymeric isocyanate compound, cross-linking agent, blocking agent, and solvent. The process for synthesizing the blocked polyfluorourethane is by bulk polymerization.

Owner:JINEX CORP

Colorfast nitro-colored paint

The invention relates to the technical field of paint, especially to a nitro-colored paint, which is composed of the following components by weight: 23-42.5% of a solvent; 10-20% of 1 / 4s nitrocotton; 4-7% of 1 / 2s nitrocotton; 5.5-10% of maleic resin; 12-20% of soybean oil modified alkyd resin; 1-6% of polyethylene wax powder; 1-3% of a segmented copolymer type dispersing agent containing pigment affinity groups; 3-5% of toner; 1-3% of a plasticizer; and 0.2-0.5% of a leveling agent. According to the invention, a high dosage of polyethylene wax is added to improve the smoothness and surface hardness of a paint film, and the fading phenomenon caused by friction can be effectively reduced. In addition, by making use of the superstrong wetting and dispersion properties of the high molecular weight dispersing agent with polyfunctional groups and multi-adsorptive groups on the organic toner, the packaging of the toner by a paint base is substantially reinforced. Thus, the fading phenomenon caused by wiping is also greatly improved.

Owner:广东千叶松化工有限公司

Preparation method of anionic acrylic acid resin retanning agent

ActiveCN105924564AImprove discolorationImprove retanning effectTanning treatmentPolymer scienceBenzoyl peroxide

The invention discloses a preparation method of an acrylic acid resin retanning agent. At present, acrylic acid resin retanning agents which can simultaneously overcome the defects of pastel shade and plastic feeling are all imported products, and the leather making cost is greatly increased. The preparation method is characterized by comprising the steps that a mixed monomer and a benzoyl peroxide solution are synchronously dropwise added to a mixed solution of ethylene glycol monomethyl ether and water at a constant speed for 2 h to 3 h, and heat preservation is conducted for 1 h to 2 h after dropwise adding is completed, wherein the temperature of the mixed solution ranges from 75 DEG C to 80 DEG C; the temperature in a polymeric kettle is cooled to 30 DEG C to 40 DEG C, ammonia water of which the mass percent ranges from 20%-30% is used for regulating the pH of the system to range from 6.0 to 7.0, and the acrylic acid resin retanning agent is obtained. The prepared acrylic acid resin retanning agent can obviously improve the pastel shade effect in the dyeing process of crust leather, and the plastic feeling of leather is greatly reduced.

Owner:传化智联股份有限公司 +1

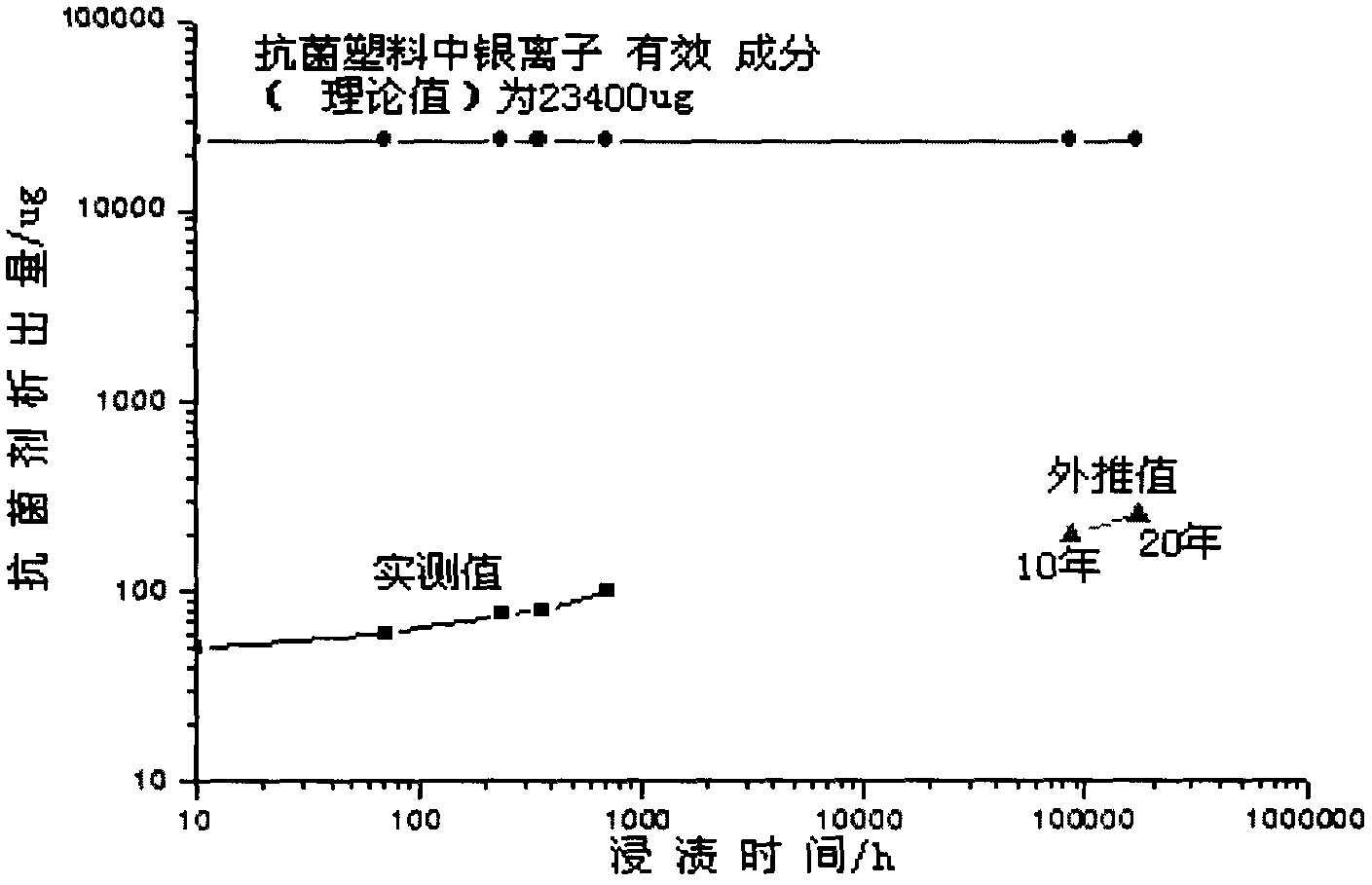

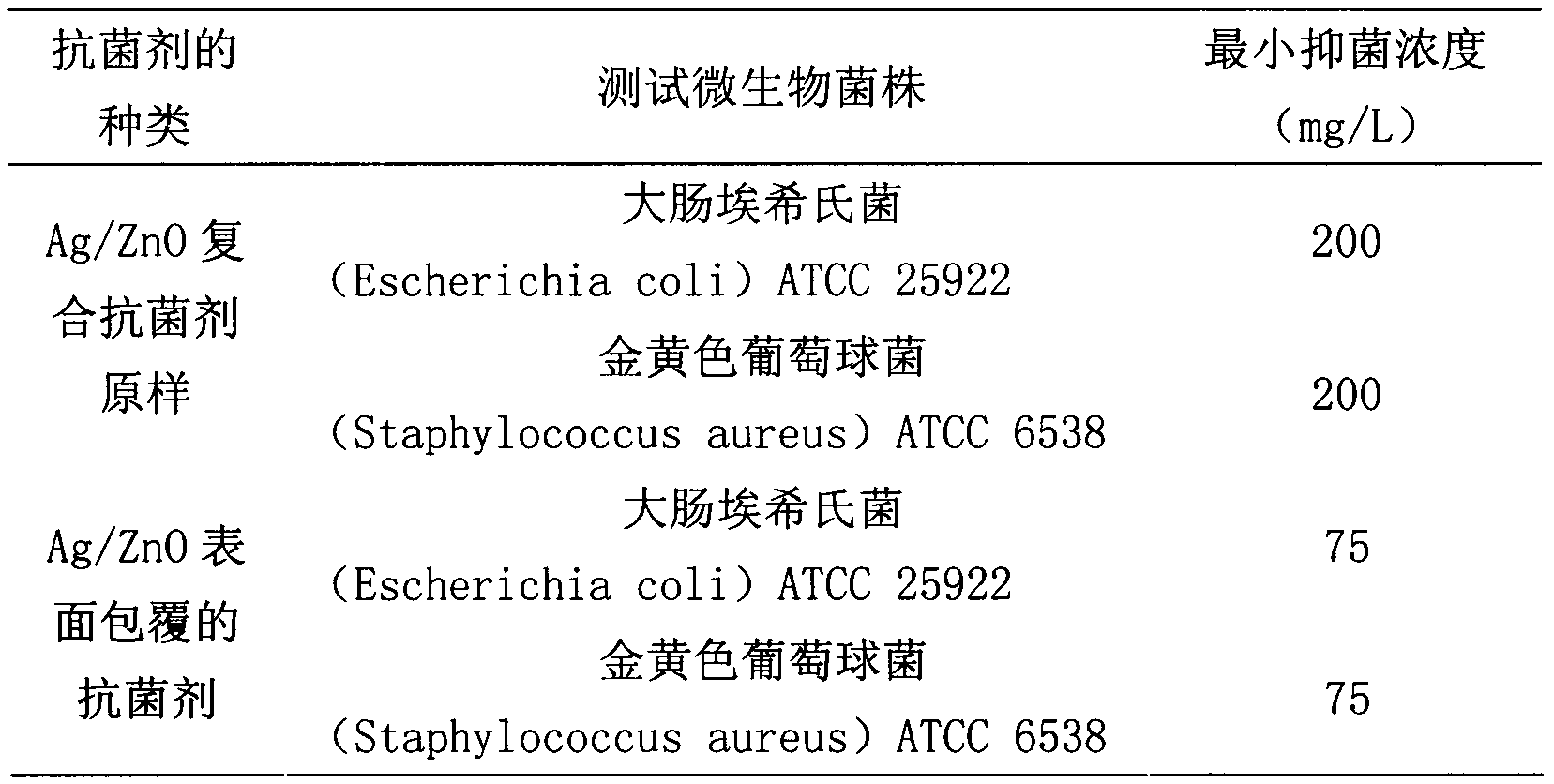

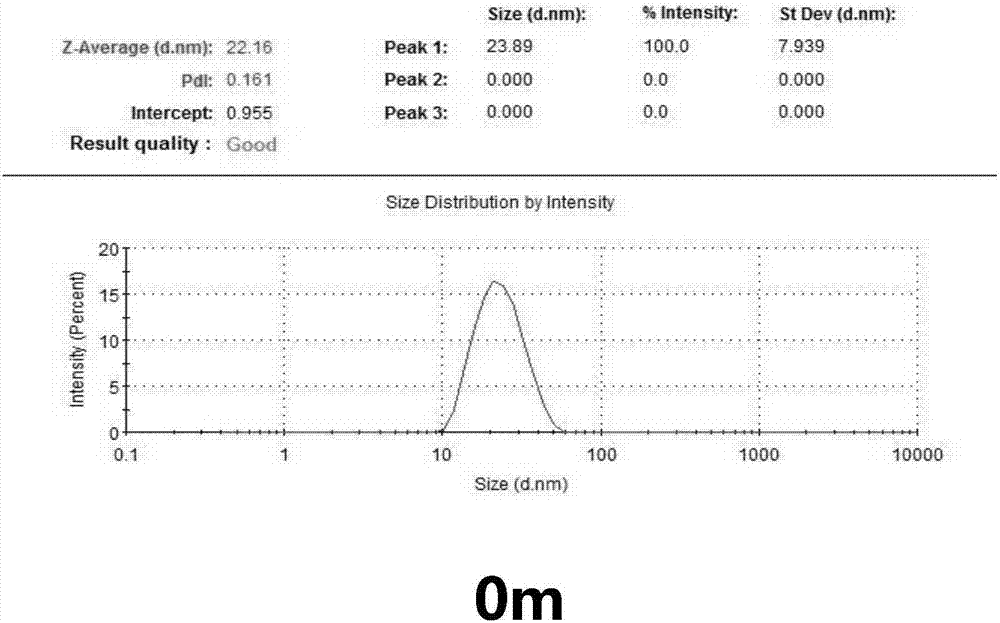

Technology for preparing surface-coated modified Ag/ZnO nano composite antibacterial agent

The invention provides a technology for preparing a surface-coated modified Ag / ZnO nano composite antibacterial agent. The technology comprises the following steps: (1) adding sodium hexametaphoshpate serving as a dispersing agent into distilled water; (2) adding nano ZnO powder into the solution; (3) performing washing and filtering, and then drying the material in a constant-temperature drying oven at the temperature of 80-120 DEG C for 3-4 hours; (4) putting the material into a box type resistance furnace for roasting at the temperature of 600-800 DEG C for 2-4 hours; (5) taking out the material and grinding the material into raw powder of an Ag / ZnO nano composite antibacterial agent, adding the raw powder of the Ag / ZnO antibacterial agent into the distilled water, then adding a sodium laurate coating agent according to the mass ratio of the raw powder and the sodium laurate of 500 to 1, adjusting the pH value of the solution to 5-6, controlling the temperature of a water bath, and mechanically stirring the materials under the temperature range of 25-40 DEG C for 1-2 hours, filtering and drying the materials to obtain the surface-coated modified Ag / ZnO nano composite antibacterial agent. The surface-coated modified Ag / ZnO nano composite antibacterial agent disclosed by the invention is high in antibacterial performance and has a long-time antibacterial characteristic.

Owner:NANTONG VOCATIONAL COLLEGE

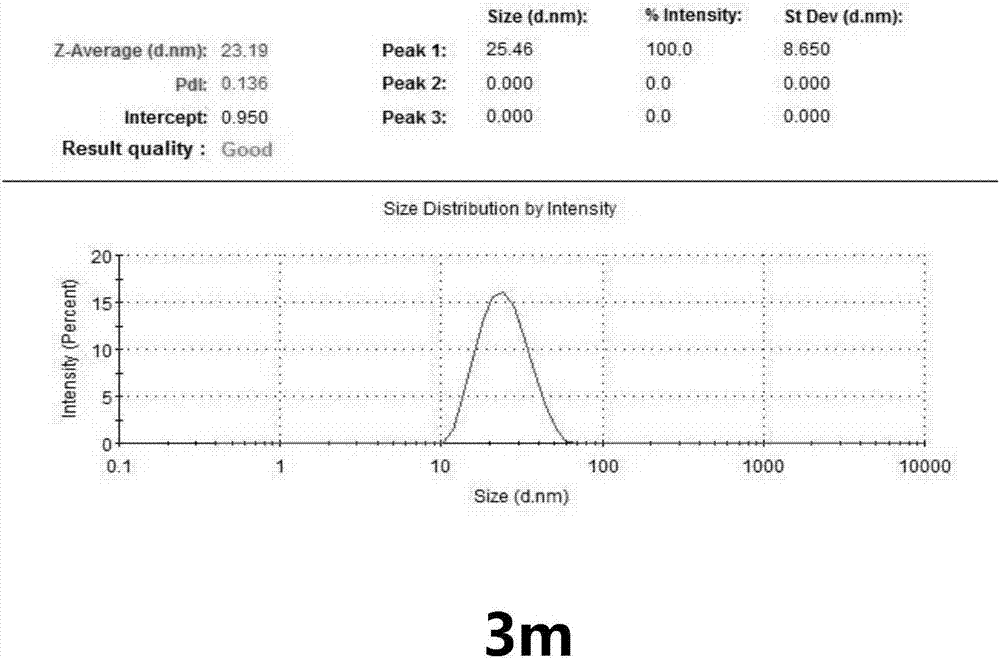

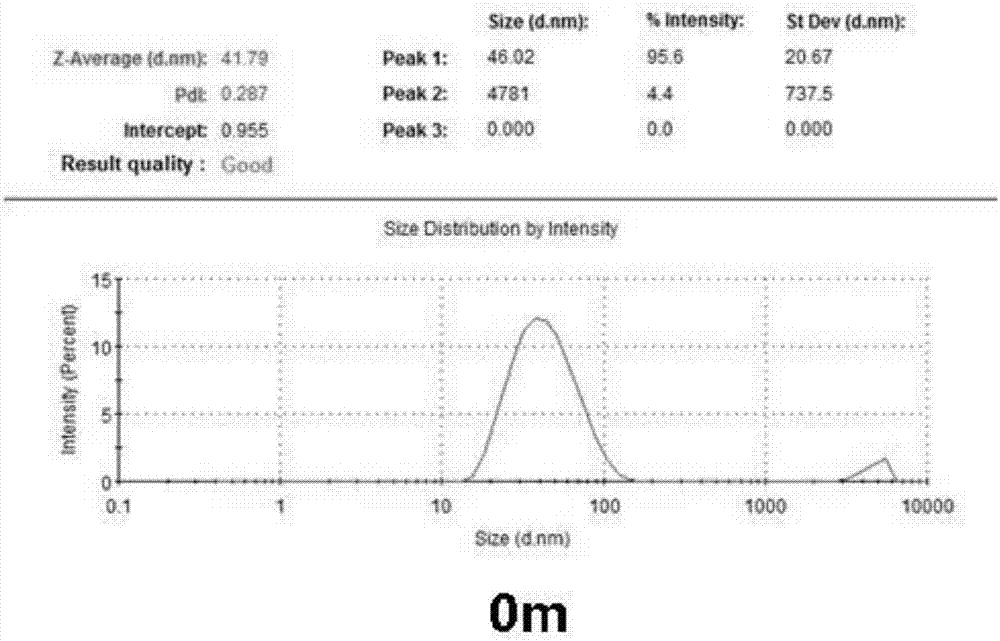

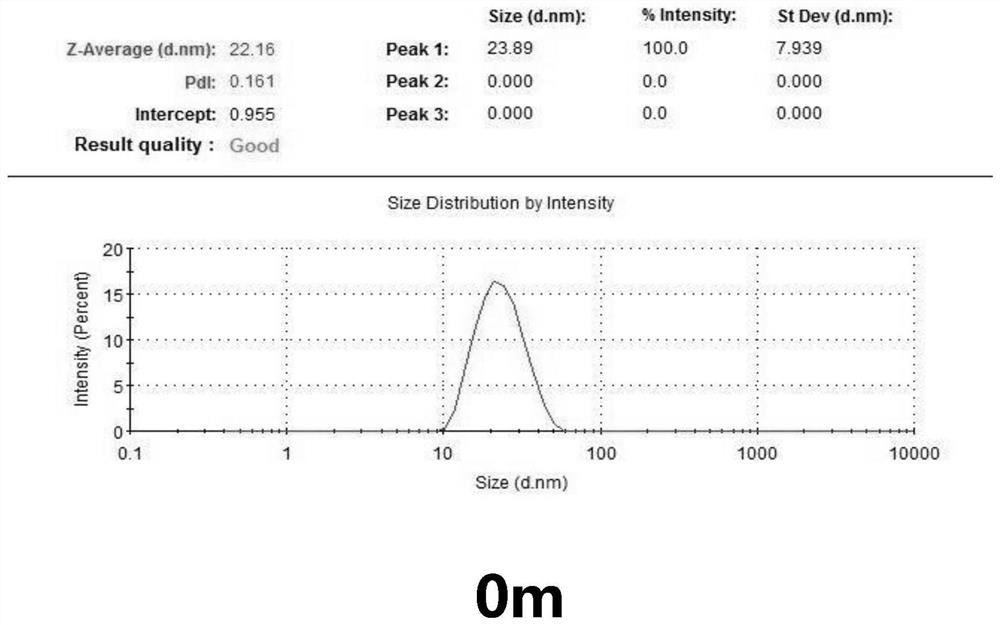

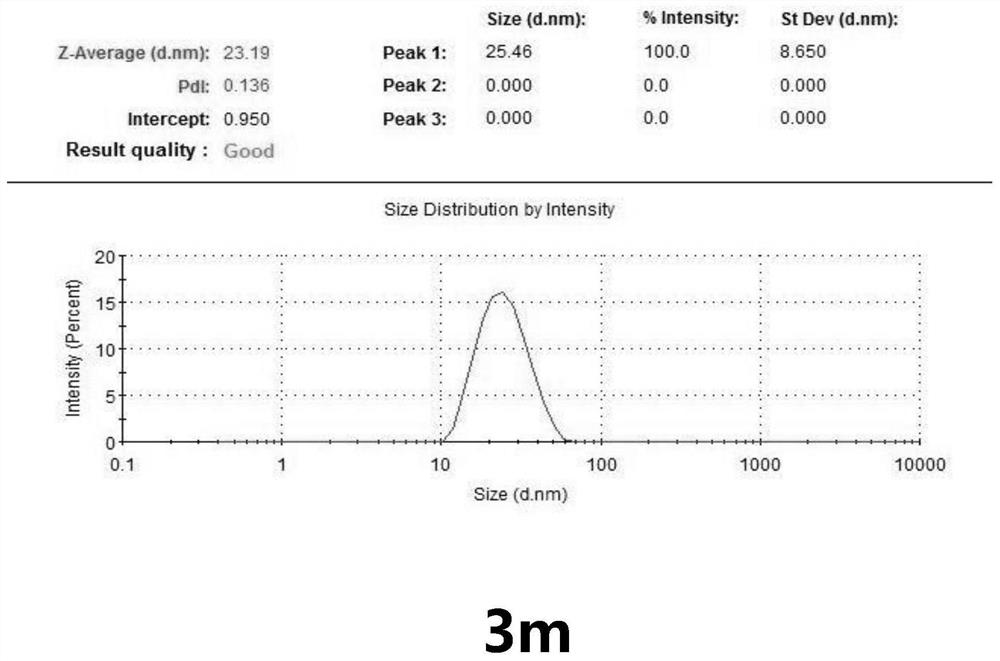

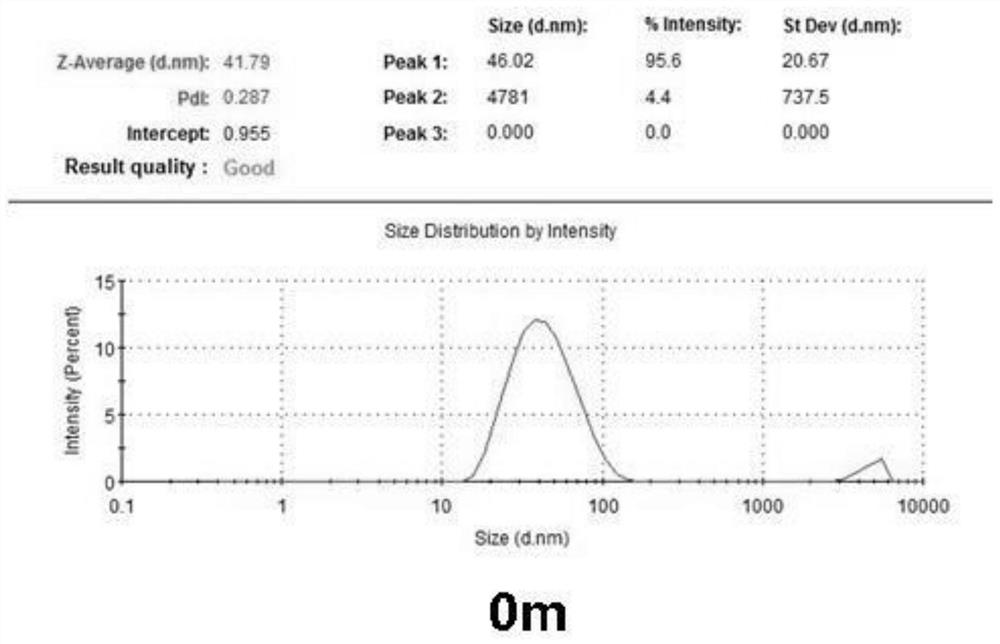

Composite antioxidant self-microemulsion as well as preparation method and application of microemulsion

ActiveCN107875034AImprove solubilityImprove discolorationCosmetic preparationsHydroxy compound active ingredientsAntioxidantOil phase

The invention discloses a composite antioxidant self-microemulsion as well as a preparation method and application of the microemulsion, belonging to the field of preparations. The composite antioxidant self-microemulsion contains the following components in percentage by weight: 1%-4% of an oil phase, 10%-60% of a surfactant, 2%-50% of a cosurfactant and 1%-20% of a compound antioxidant, whereinthe compound antioxidant is a mixture of vitamin E, ferulic acid and resveratrol. Vitamin E, ferulic acid and resveratrol have different antioxidant mechanisms, are mutually complemented and repairedand are compounded, so that an anti-oxidation synergistic interaction effect can be achieved. By optimizing a self-microemulsion system, a proper oil phase, a proper mixed surfactant and a proper cosurfactant are screened and are utilized for dissolving vitamin E, ferulic acid and resveratrol in the compound antioxidant; and by regulating the proportion of the self-microemulsion system, the microemulsion with a particle size smaller than 70nm is obtained, the functional components of the microemulsion can be easily transdermally absorbed, and a very good anti-oxidation effect is achieved.

Owner:GUANGDONG PHARMA UNIV

Halogen flame-retardant high-temperature nylon composition and preparation method thereof

The invention belongs to the field of polymer composite materials, and discloses a halogen flame-retardant high-temperature nylon composition and a preparation method thereof. The composition comprises the following components in parts by weight: 40 to 65 parts of high-temperature nylon, 15 to 25 parts of halogen flame retardant, 2 to 10 parts of zinc stannate, 0 to 40 parts of glass fibre and 0.5 to 2 parts of other processing agents; the halogen flame-retardant high-temperature nylon composition is prepared by the following steps of adding the raw materials in a high-speed mixer, stirring for 3 to 5min in the high-speed mixer; adding the uniformly mixed materials in a charging hole of a twin-screw extruder; performing melt extrusion on the materials through the twin-screw extruder. The composition provided by the invention has balanced mechanical property, is light in color and easy to dye.

Owner:HEFEI GENIUS NEW MATERIALS

Preparation method of anti-cracking instant frozen streamed bread

InactiveCN101755880APromote formationPromote growthDough treatmentPreservation by coolingSteamed breadChemistry

The invention provides a preparation method of anti-cracking instant frozen streamed bread. In order to achieve the purpose, the invention adopts the following technical scheme: 1 to 10 percent of DHC-F7301 modified starch and 1 to 10 percent of DATEM emulsifier are added into flour to be mixed uniformly. The technical scheme of the invention can prevent the steamed bread from cracking, reduce the return rate, improve the product preservation, warranty and shelf life, so as to reduce the production cost.

Owner:河南省淇县永达食业有限公司

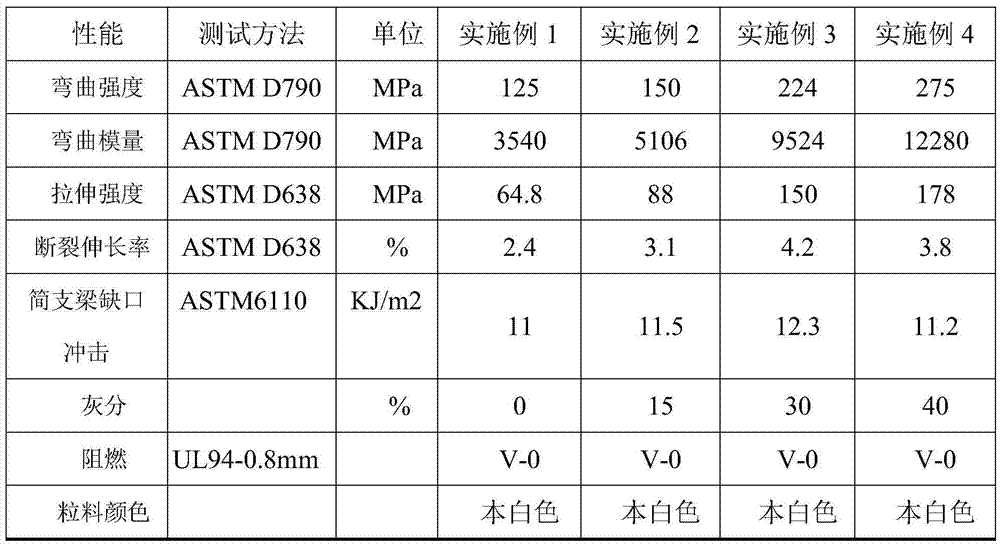

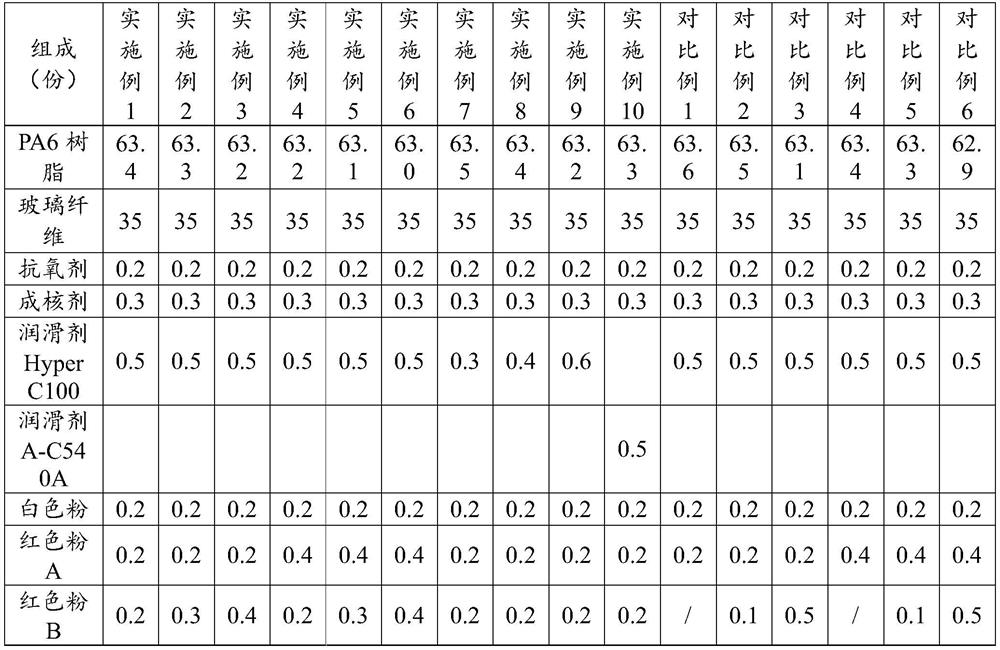

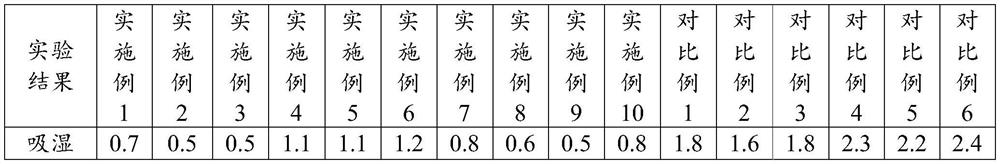

Nylon with high color stability and preparation method thereof

The invention discloses nylon with high color stability and a preparation method thereof, and belongs to the field of nylon material reinforcement. According to the nylon product disclosed by the invention, after the glass fiber is introduced as a reinforcing component, the product is modified by taking the cerium sulfide with a specific content as a pigment, so that the obtained nylon is firm in coloring, and the color change condition after moisture absorption is obviously improved; meanwhile, all the components have a synergistic effect, so that the heat resistance, the weather resistance and the stability of the obtained nylon are effectively enhanced, and the comprehensive performance is excellent. The invention also discloses the preparation method of the nylon, the preparation method is simple in operation steps, and industrial large-scale products can be realized.

Owner:KINGFA SCI & TECH CO LTD +1

Poly formaldehyde resin composition

The present invention relates to a polyoxymethylene composition that is excellent in heat stability and mold properties (mold release and mold cycle) and can be melt and held in a molding machine with the improved prevention of the resin from color change. The present invention provides the polyoxymethylene composition comprising: a polyoxymethylene; (a) 0.01-3.0% by weight (in the composition, hereinafter likewise) of a steric-hindered phenolic antioxidant; (b) 0.01-1.0% by weight of a compound selected from oxides or carboxylic acid salts of an alkali earth metal; and (c) 0.01-1.0% by weight of an ester of a polyhydric alcohol selected from propylene glycol, trimethylol propane and pentaerythritol and a higher fatty acid (C8-C29).

Owner:POLYPLASTICS CO LTD

Preparation method of nano titanium dioxide modified polyacrylate coating agent with core-shell structure

The invention relates to a preparation method of a nano titanium dioxide modified polyacrylate coating agent with a core-shell structure. Firstly, an aluminum zirconium coupling agent and nano titanium dioxide are added to deionized water, and the mixture is stirred for a refluxing reaction for 30 min; deionized water, an emulsifier, an acrylate monomer and a nano titanium dioxide dispersion liquid are added to a reaction kettle, and the mixture is heated to 55-58 DEG C and stirred at a high speed to form an emulsified liquid; deionized water, the acrylate monomer and an emulsifier are added to an emulsification kettle and stirred at a high speed to form a pre-emulsified liquid; an initiator is dissolved in deionized water, and an initiator solution is prepared; after the temperature of the reaction kettle is increased to 65-68 DEG C, the initiator solution is added, and a thermal insulation reaction is performed for 1 h; the pre-emulsified liquid, crosslinking monomers and the remaining initiator water solution are dropwise added within 2 h, the mixture is subjected to a thermal insulation reaction at the temperature of 80 DEG C for 1 h after the pre-emulsified liquid, crosslinking monomers and the remaining initiator water solution are dropwise added, and cooling and filtration are performed.

Owner:绍兴博凯科技信息咨询有限公司

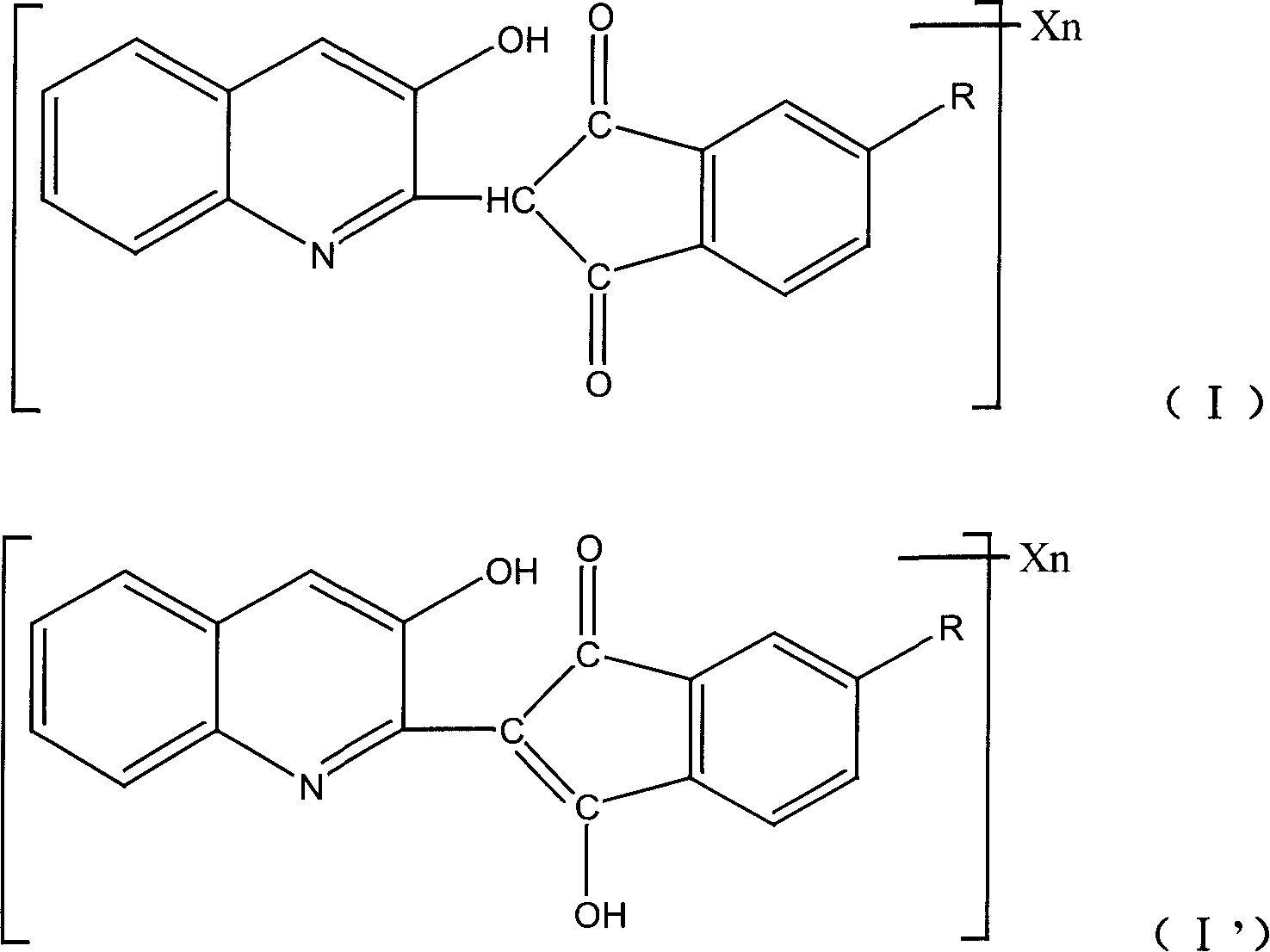

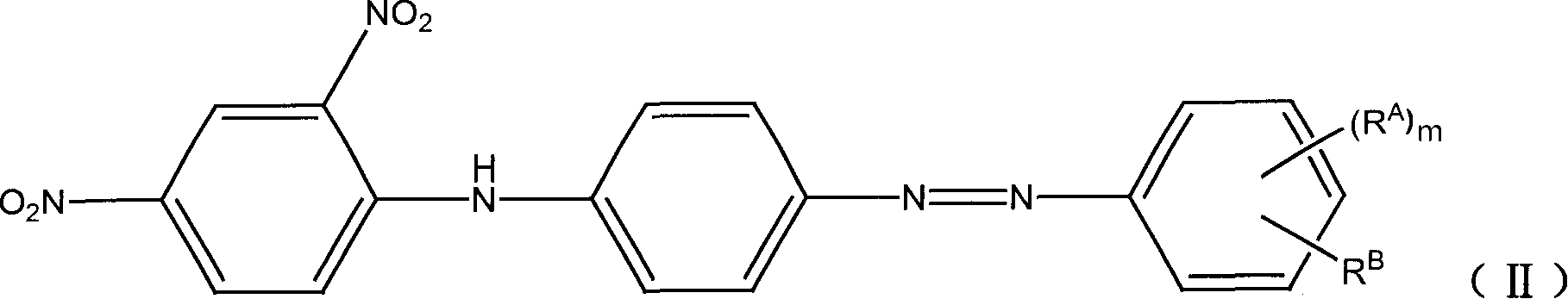

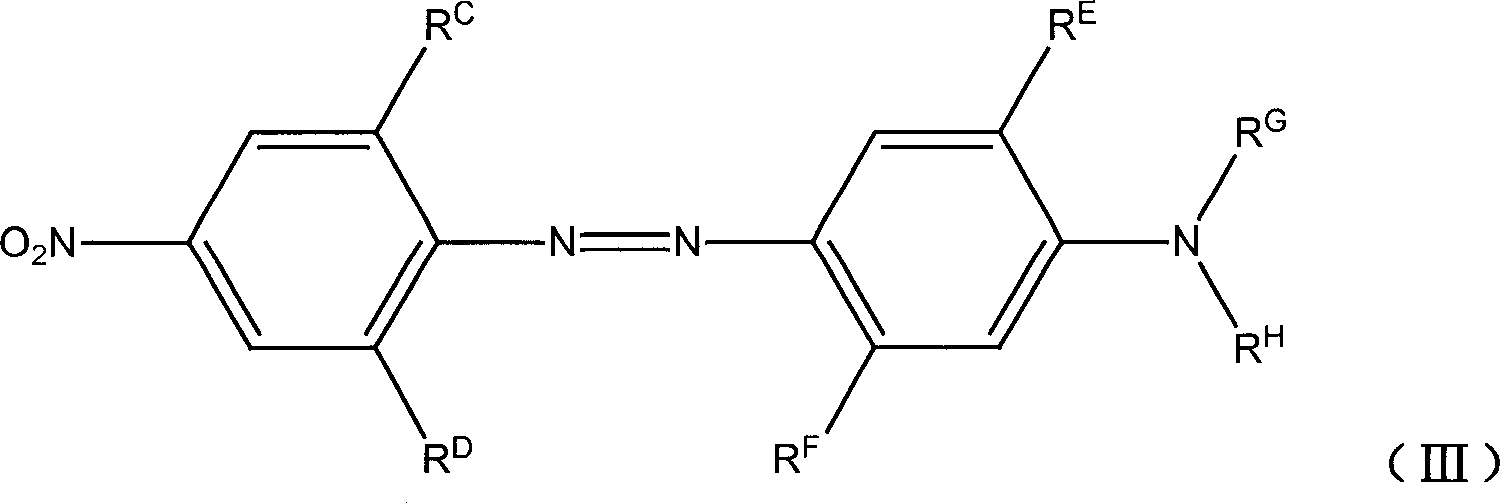

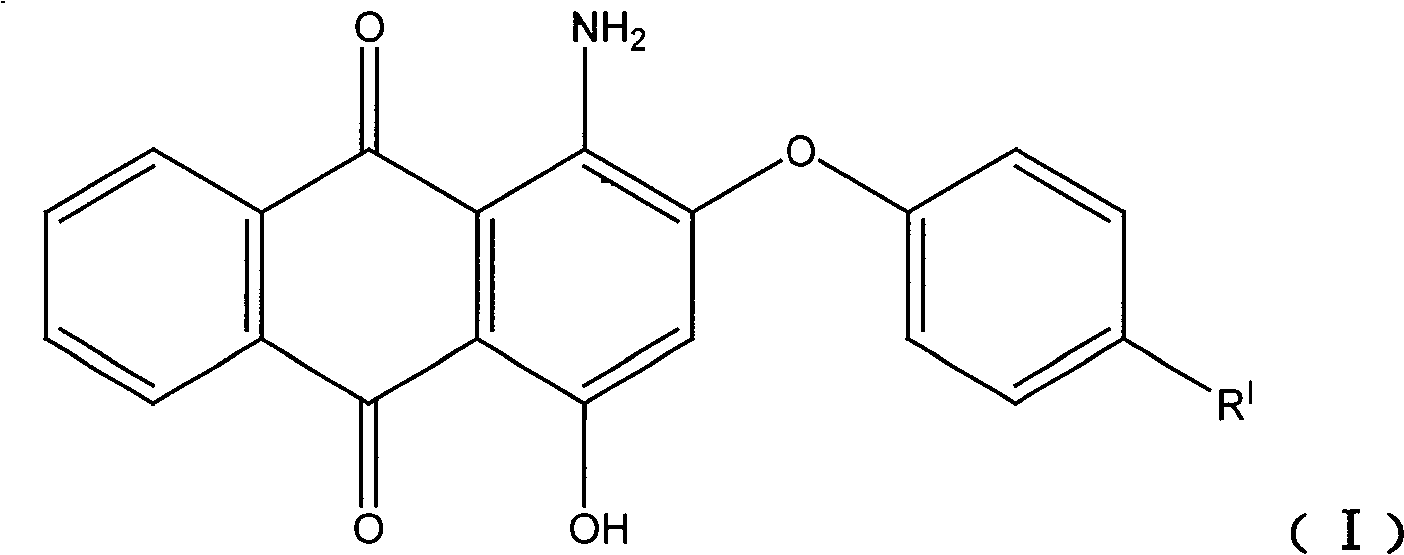

Sublimation fastness improved dispersion red dyes mixture

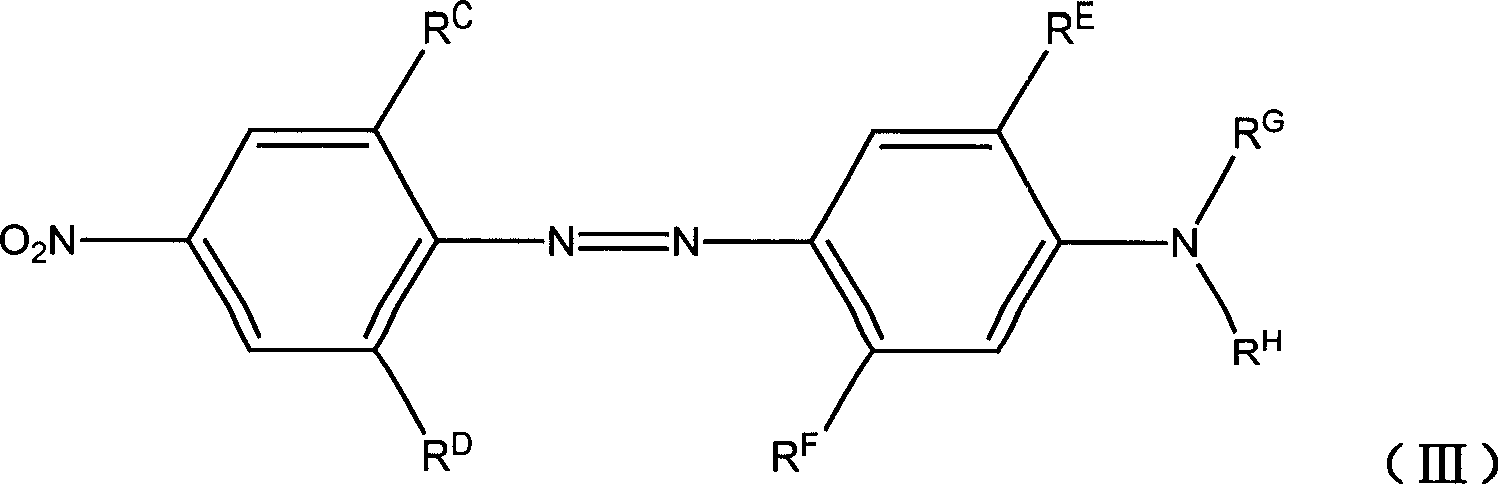

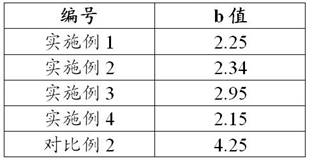

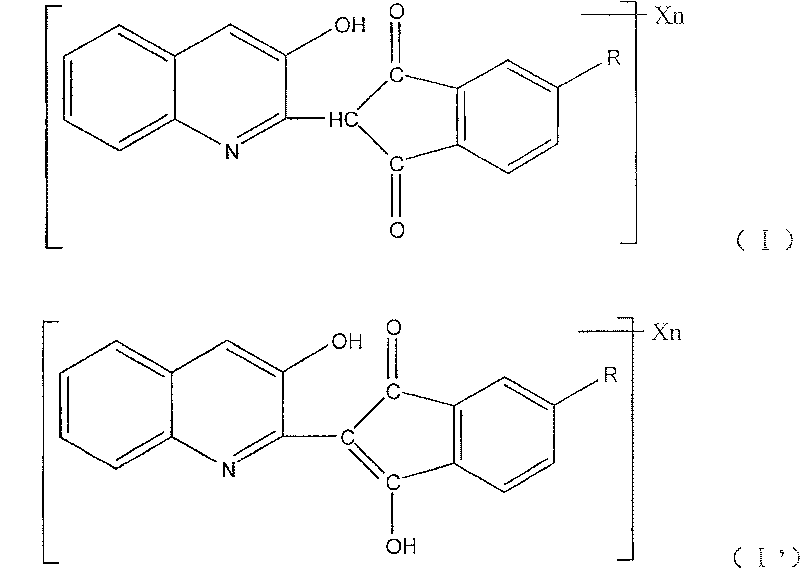

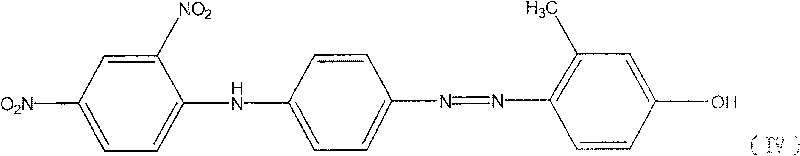

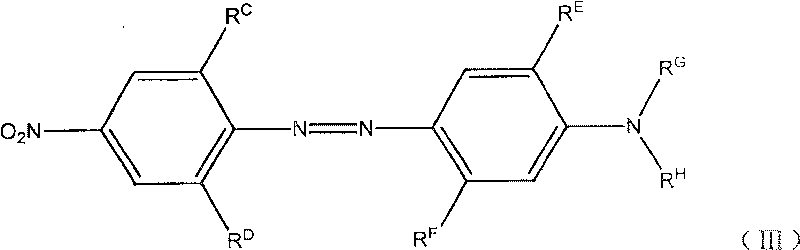

ActiveCN100422271CSolve the problem of serious shade changeImprove discolorationOrganic dyesFiberTints and shades

The disperse red dye mixture with raised sublimation fastness consists of dye in the chemical general expression as shown in 5-95 wt%, and C.I. disperse red 343, C.I. disperse red 92 or C.I. disperse red 146 in 5-95 wt%. The disperse red dye mixture has sublimation fastness raised to Level 3, and may be compounded with disperse blue 2BLN and disperse yellow in the same sublimation fastness to form various kinds of marketable dyes with balanced sublimation fastness. It may be also used directly in dyeing.

Owner:WUJIANG LVZHOU DYESTUFF CHEM

Fur retanning technology for preventing leather fading

ActiveCN108774650AComfortable touchClear grainTanning treatmentPre-tanning chemical treatmentOrganic acidBoron containing

The invention relates to the field of leather processing, in particular to a fur retanning technology for preventing leather fading. Pollution-free leather with few defects is subjected to water removal treatment; by mass percent, 100-120 parts of leather and 200-300 parts of water are added in a drum, 0.6-1.8 parts of acid proteinase and 0.5-1.4 parts of polyethoxylated fatty alcohols are added,organic acid is used for adjusting the solution pH value to 2-5.5, and 150-200 parts of water and 0.5-1.5 parts of dye are added; and after rotation is conducted for 10-20 min, 2-8 parts of glyoxal, 0.3-0.8 part of tween 80, 1.5-5 parts of protein filler and 3-8 parts of a boron-containing fading preventing retanning agent are added, uniform dissolving is conducted after rotation is conducted for10-20 min, the temperature is controlled to range from 40 DEG C to 50 DEG C, and after rotation is conducted for 80-120 min and water is drained, the retanning procedure can be finished.

Owner:嘉兴宏远汽车座椅股份有限公司

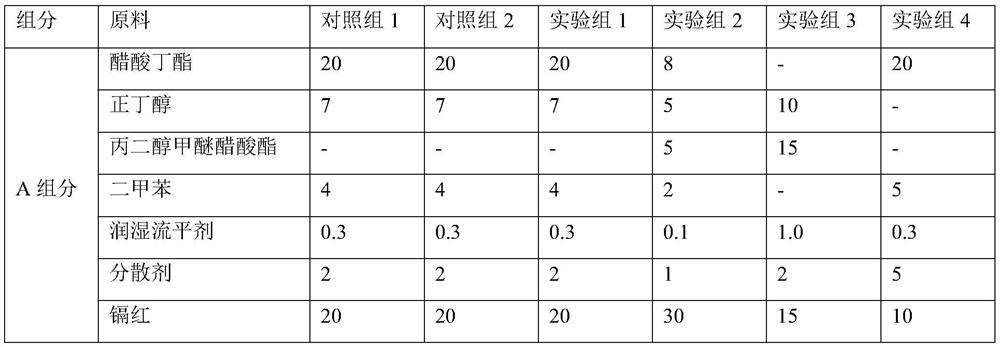

High-temperature-resistant coating and preparation method thereof

InactiveCN111995949AImprove discolorationReduce organic contentFireproof paintsMaterials scienceOrganosilicon

The invention relates to a high-temperature-resistant coating and a preparation method thereof. The high-temperature-resistant coating is prepared from two components, namely a component A and a component B, wherein the component A comprises organic silicon resin, cadmium red, a dispersing agent, an auxiliary agent and a solvent, and the above raw materials are mixed and dispersed to obtain the component A, and the mass content of inorganic components in the organic silicon resin is not lower than 60%; the component B is alcohol-soluble silica sol; and the component A and the component B are mixed to form the high-temperature-resistant coating. The high-temperature-resistant paint disclosed by the invention is low in substrate pretreatment requirement and outstanding in high-temperature resistance, solves the problem of discoloration of the cadmium red pigment at a high temperature to a great extent, and has wide application prospects.

Owner:陈子辉 +1

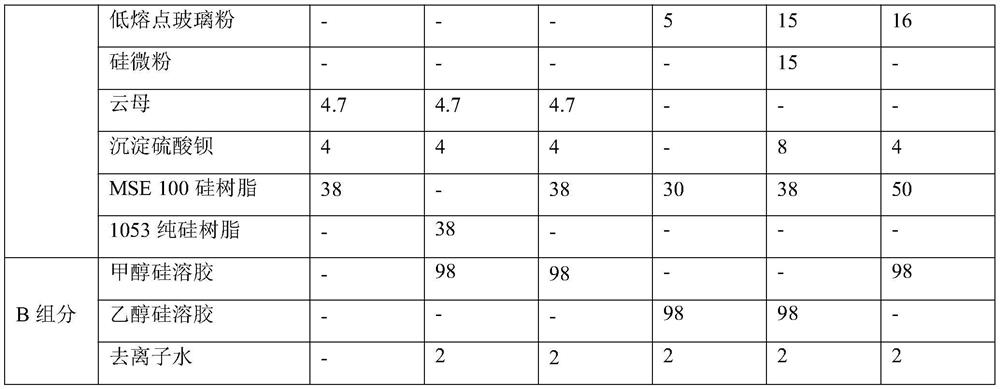

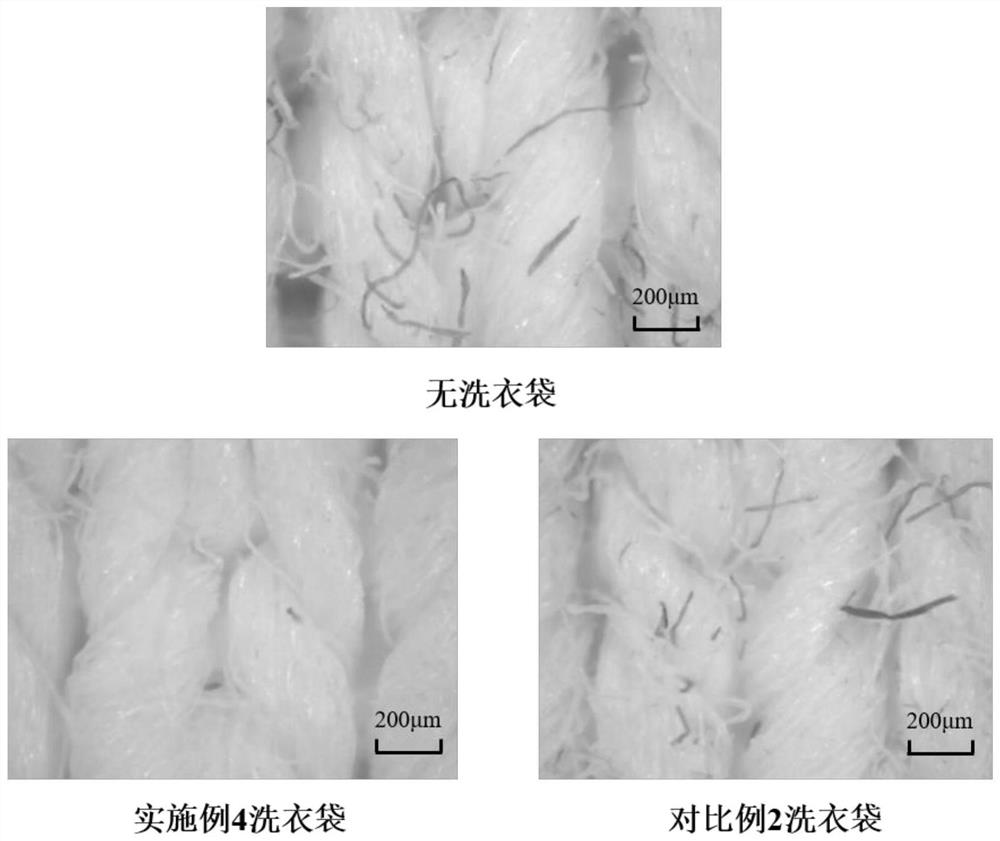

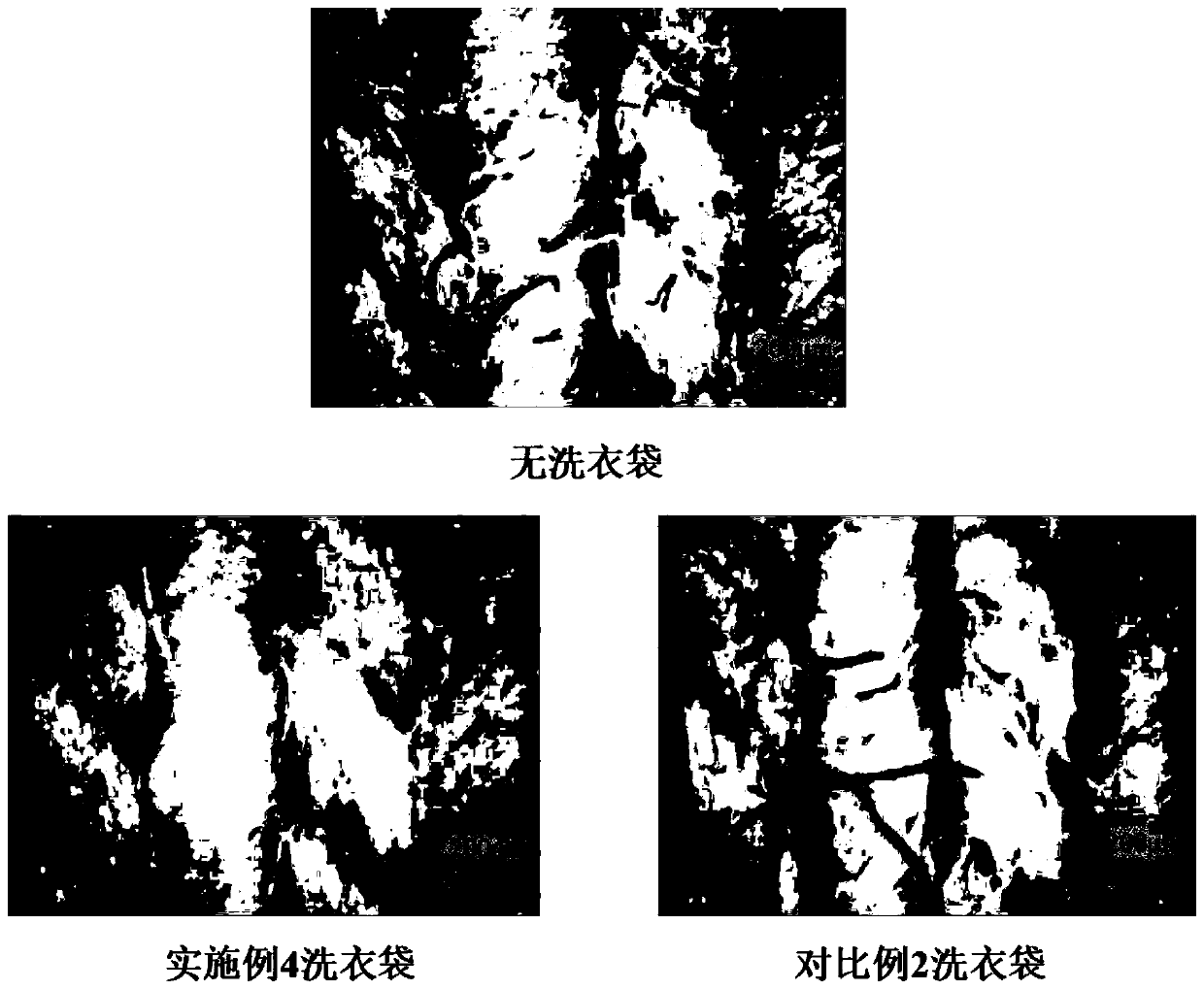

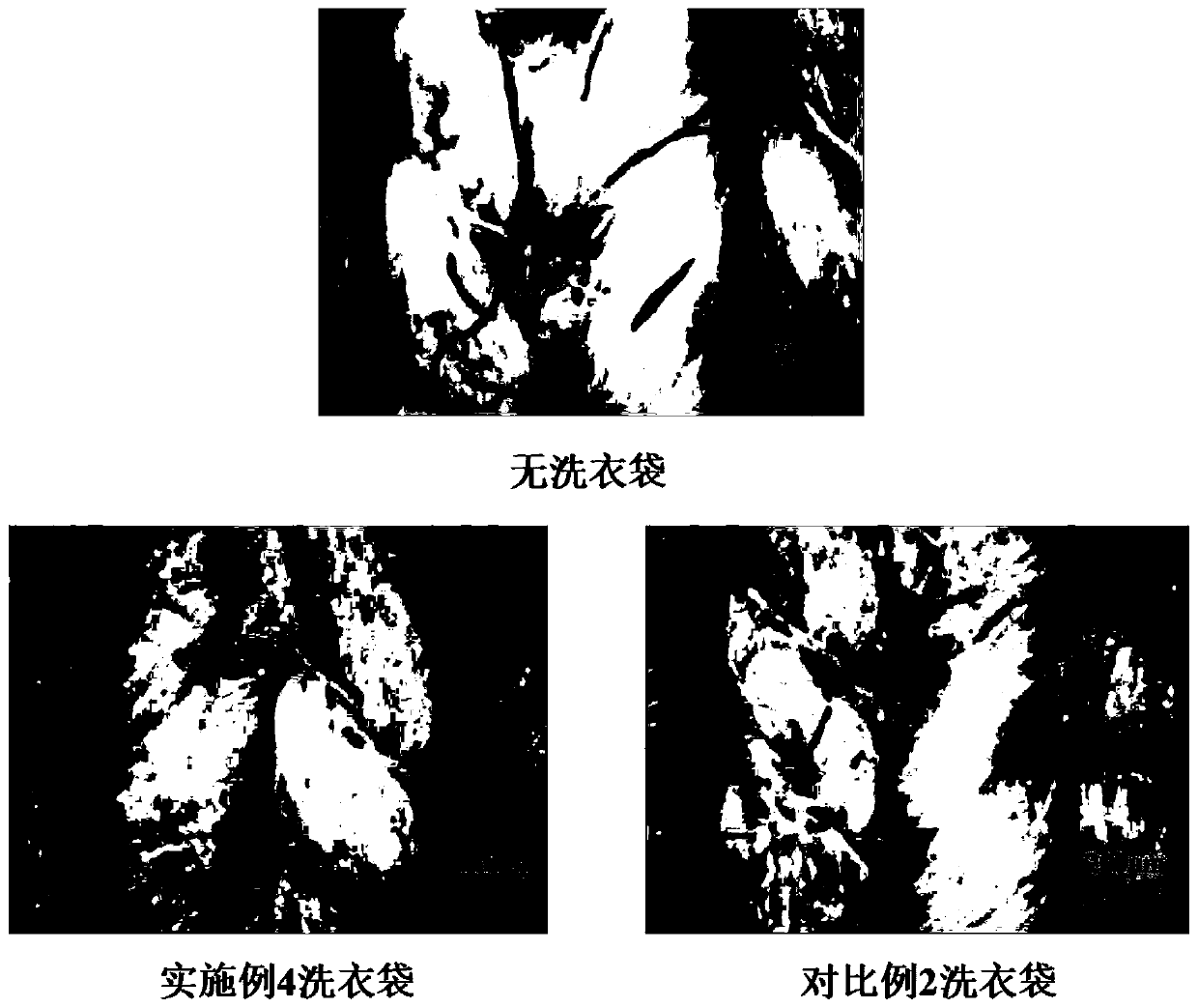

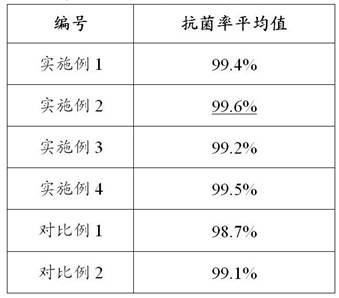

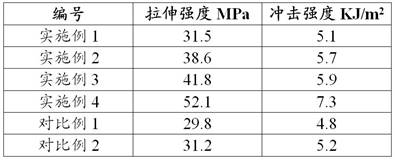

Discoloration-resistant laundry bag mesh bag and laundry bag

ActiveCN110952297BIncrease pollutionImprove the discoloration of shufflingIroning apparatusTextiles and paperFiberProcess engineering

The invention discloses an anti-discoloration laundry bag mesh bag and a laundry bag. The average pore size of this anti-tarnish laundry bag mesh bag is ≤117μm. At the same time, a laundry bag comprising the laundry bag net bag is also disclosed. The laundry bag of the invention can improve the contamination of other clothes by shedding fibers and dyes when the clothes are mixed and washed, thereby improving the discoloration of clothes of different colors after mixed washing, and the laundry bag can be used repeatedly.

Owner:GUANGZHOU BLUE MOON IND

An anti-corrosion, anti-discoloration and environment-friendly water-based magnesium alloy cutting fluid

InactiveCN104498164BGood anti-tarnishImprove corrosion resistanceLubricant compositionWater basedCooling effect

The invention discloses an anti-corrosion, anti-discoloration and environment-friendly water-based magnesium alloy cutting fluid, which comprises the following components by weight percentage: 5-10 parts of base oil, 5-15 parts of oily agent, 10-25 parts of organic 5-15 parts of rust agent, 15-25 parts of functional polyether surfactant, 0.2-3 parts of extreme pressure additive, 3-8 parts of solubilizer, 0.1-2 parts of metal corrosion inhibitor, 0.1-2 parts of magnesium alloy anti-discoloration agent 0.1-2 parts of fungicide, 0.1-1 part of defoamer, 0.1-10 parts of pH regulator, and 15-30 parts of water. The invention has excellent anti-corrosion, lubricating and anti-hard water capabilities, good cleaning and cooling effects, and effectively improves several major problems in the process of magnesium alloy processing, such as corrosion, oxidative combustion, discoloration of magnesium alloys, and demulsification and delamination of cutting fluids. The technical problem is that the pH value is between 9-11, which better meets the requirements of the magnesium alloy cutting process.

Owner:苏州禾川化学技术服务有限公司

A kind of composite antioxidant self-microemulsion and its preparation method and application

ActiveCN107875034BImprove solubilityImprove discolorationCosmetic preparationsHydroxy compound active ingredientsAntioxidantActive agent

The invention discloses a composite antioxidant self-microemulsion as well as a preparation method and application of the microemulsion, belonging to the field of preparations. The composite antioxidant self-microemulsion contains the following components in percentage by weight: 1%-4% of an oil phase, 10%-60% of a surfactant, 2%-50% of a cosurfactant and 1%-20% of a compound antioxidant, whereinthe compound antioxidant is a mixture of vitamin E, ferulic acid and resveratrol. Vitamin E, ferulic acid and resveratrol have different antioxidant mechanisms, are mutually complemented and repairedand are compounded, so that an anti-oxidation synergistic interaction effect can be achieved. By optimizing a self-microemulsion system, a proper oil phase, a proper mixed surfactant and a proper cosurfactant are screened and are utilized for dissolving vitamin E, ferulic acid and resveratrol in the compound antioxidant; and by regulating the proportion of the self-microemulsion system, the microemulsion with a particle size smaller than 70nm is obtained, the functional components of the microemulsion can be easily transdermally absorbed, and a very good anti-oxidation effect is achieved.

Owner:GUANGDONG PHARMA UNIV

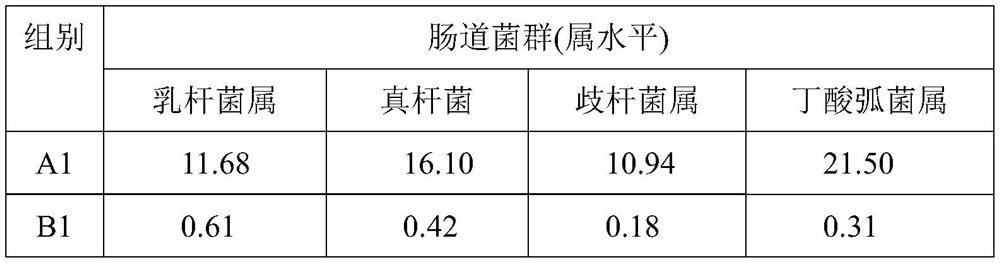

Production method of black garlic rich in amino acid

InactiveCN112293699AHighly effective therapeuticEfficient functionFood freezingFood dryingBiotechnologyMaillard reaction

The invention discloses a production method of black garlic rich in amino acid. The production method comprises the following steps of: selecting; soaking; freezing pretreatment; fermentation liquor preparation; fermentation; and drying. According to the method, garlic is frozen through freezing pretreatment to destroy the cell structure, promote enzymatic reaction and promote the increase of thecontent of S-allylcysteine; Maillard reaction is influenced by histidine to promote browning; the black garlic fermented by lactobacillus bulgaricus can significantly improve the oxidation resistanceof the black garlic, can reduce the fasting blood glucose level of type 2 diabetes mellitus and improve the intestinal flora of a human body, and has the characteristic of promoting health in diabetesmellitus treatment; and therefore, the requirements of vast consumers for health can be met, and wide market application value is achieved.

Owner:江苏福多美生物科技有限公司

Preparation method of anti-cracking quick-frozen steamed bread

InactiveCN105495083APromote formationPromote frost crackingFood preparationQuick FreezeSteamed bread

The invention provides a preparation method of anti-cracking quick-frozen steamed bread. In the method, 1-10% of DHC-F7301 modified starch and 1-10% of DATffl emulsifier are added to flour with uniform mixing. By means of the technical scheme, the steamed bread is prevented from cracking, is reduced in rejected rate, is improved in shelf life and fresh-keeping time, and is reduced in production cost.

Owner:QINGDAO SEIICHI INTPROP SERVICE CO LTD

Composition of night cream

PendingCN114246820AImprove discolorationPromote oxidationCosmetic preparationsToilet preparationsBiotechnologyEthylhexyl palmitate

The invention relates to the technical field of cosmetics, in particular to a night cream composition. The invention relates to an anti-allergy shampoo, which is prepared from the following ingredients in percentage by mass: 25 to 55 percent of water, 2 to 12 percent of butanediol, 0.5 to 4.5 percent of undecylenoyl phenylalanine, 1 to 10 percent of alpha-arbutin, 1 to 8 percent of nicotinamide, 0.2 to 2.5 percent of 3-o-ethyl ascorbic acid, 0.5 to 6 percent of tranexamic acid, 0.5 to 7.5 percent of azelaic acid, 0 to 7.5 percent of paeonia lactiflora extracts, 1 to 8 percent of ethylhexyl palmitate, 0.5 to 4.5 percent of cetostearyl alcohol, 1 to 7.5 percent of simmondsia chinensis seed oil, 0.5 to 8.5 percent of polydimethylsiloxane and 1 to 12 percent of squalane. 0.5 to 7.5 percent of isononyl isononanoate; the whitening and freckle-removing composition has excellent whitening and freckle-removing effects, has a very good effect of reducing melanin deposition, and greatly improves the problems that common whitening and freckle-removing whitening cosmetics are easy to discolor and oxidize.

Owner:广州有容生物科技有限公司

Anti-discoloration mesh bag of laundry bag and laundry bag

ActiveCN110952297AIncrease pollutionImprove the discoloration of shufflingIroning apparatusTextiles and paperProcess engineeringLaundry

The invention discloses an anti-discoloration mesh bag of a laundry bag and the laundry bag. The average pore size of the anti-discoloration mesh bag of the laundry bag is smaller than or equal to 117[mu]m. Meanwhile, the invention also discloses the laundry bag comprising the net bag of the laundry bag. The laundry bag disclosed by the invention can be used for relieving contamination of fallenfibers and dyes on other clothes when clothes are washed together, so that the color change condition of clothes after clothes with different colors are washed together can be avoided, and the laundrybag can be repeatedly used.

Owner:GUANGZHOU BLUE MOON IND

Flower color protecting agent

InactiveCN108719277AImprove discolorationGood color protectionDead plant preservationColor changesCitric acid

The invention discloses a flower color protecting agent, which is prepared from the following raw materials in parts by weight: 5 to 8 parts of citric acid, 2 to 3 parts of sodium chloride, 10 to 15 parts of pine needle extracts, 0.5 to 1 part of sodium carboxymethylcellulose, 7 to 10 parts of sodium alginate and 280 to 300 parts of water. When the flower color protecting agent provided by the invention is used in the dry flower preparation process, the color change phenomenon of the flowers can be effectively alleviated; the color and luster differences between the dry flowers and the fresh flowers can be reduced; the grade of the dry flower products is obviously improved.

Owner:安徽爱情谷旅游开发有限公司

A kind of preparation method of fluorescent acid color-fixing agent and obtained color-fixing agent

ActiveCN106702790BHigh color fastnessImprove discolorationDyeing processRoom temperatureColor changes

The invention discloses a preparation method of a novel fluorescent acidic color fixing agent and the prepared color fixing agent. During preparation, the method comprises the following steps: carrying out mixing, heating and stirring treatment on bisphenol S and a dimethylacetamide solution, then adding hexamethyldisilazane, cooling to 70 DEG C, and carrying out stirring treatment, wherein the mass ratio of the bisphenol S to hexamethyldisilazane is (25 to 35): (2 to 6), and the volume ratio of the hexamethyldisilazane to the dimethylacetamide solution is 1: (10 to 12); then adding an acrylic acid solution, and carrying out stirring treatment at the temperature of 65 DEG C, wherein the volume ratio of the hexamethyldisilazane to the acrylic acid solution is 1: (10 to 11); then dripping a glycol dimethyl ether solution, carrying out stirring treatment at the temperature of 60 DEG C, wherein the adding amount of the glycol dimethyl ether solution is 33 to 35 percent of the mass of the bisphenol S, and cooling to room temperature to obtain the novel fluorescent acidic color fixing agent. The novel fluorescent acidic color fixing agent disclosed by the invention can greatly improve the color fastness of a fluorescent dye, so as to obviously improve the color change. The preparation method is simple, and the preparation process is fast, high in controllability and high in yield, and favorable for popularization and application.

Owner:江西德盛精细化学品有限公司

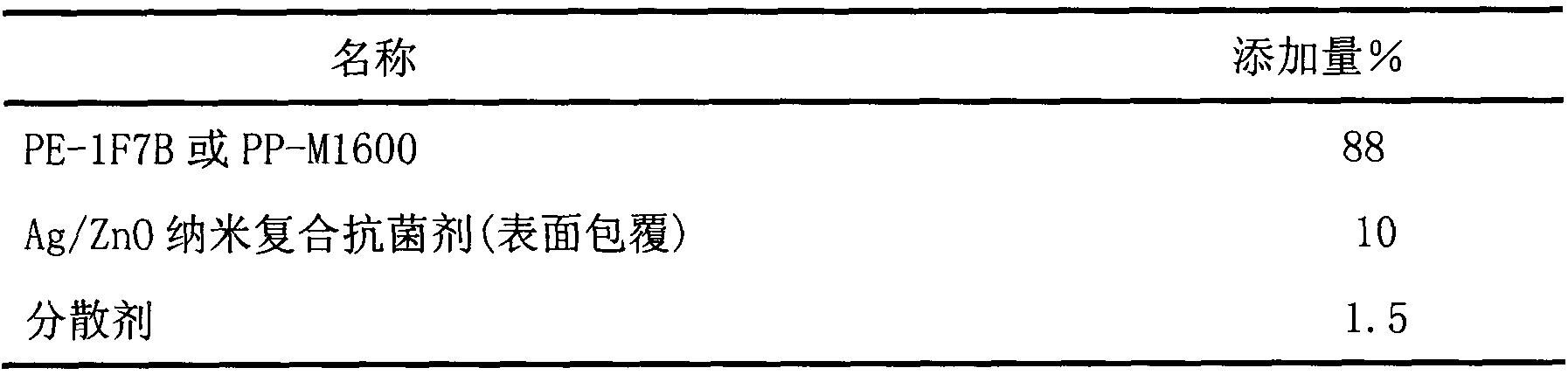

Silver ion antibacterial compatibilizer masterbatch suitable for inorganic filler modified pp

The invention provides an antimicrobial compatibilizer masterbatch suitable for the production of downstream inorganic filler modified PP and its preparation method and application. Through the adjustment of the preparation process parameters, the compatibility of inorganic fillers in the production of downstream filler modified PP plastics can be solved at the same time. The problem of antibacterial properties and the uniformity of antibacterial content, as well as the discoloration problem caused by the silver ion antibacterial agent in the compatibilizer masterbatch; the inorganic filler modified PP can be used in the production of vehicle plastic parts.

Owner:NINGBO NENGZHIGUANG NEW MATERIALS TECH

Disperse yellow dye mixture with promoted fastness to sublimation

ActiveCN1884392BSolve the problem of serious shade changeBalanced sublimation fastnessOrganic dyesDyeing processFiberDisperse yellow

Owner:WUJIANG LVZHOU DYESTUFF CHEM

A fur retanning process for preventing leather from discoloration

ActiveCN108774650BComfortable touchClear grainTanning treatmentPre-tanning chemical treatmentOrganic acidEnvironmental engineering

The invention relates to the field of leather processing, in particular to a fur retanning technology for preventing leather fading. Pollution-free leather with few defects is subjected to water removal treatment; by mass percent, 100-120 parts of leather and 200-300 parts of water are added in a drum, 0.6-1.8 parts of acid proteinase and 0.5-1.4 parts of polyethoxylated fatty alcohols are added,organic acid is used for adjusting the solution pH value to 2-5.5, and 150-200 parts of water and 0.5-1.5 parts of dye are added; and after rotation is conducted for 10-20 min, 2-8 parts of glyoxal, 0.3-0.8 part of tween 80, 1.5-5 parts of protein filler and 3-8 parts of a boron-containing fading preventing retanning agent are added, uniform dissolving is conducted after rotation is conducted for10-20 min, the temperature is controlled to range from 40 DEG C to 50 DEG C, and after rotation is conducted for 80-120 min and water is drained, the retanning procedure can be finished.

Owner:嘉兴宏远汽车座椅股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com