Nylon with high color stability and preparation method thereof

A stability and color technology, applied in the field of nylon material reinforcement, can solve the problems of easy color change and high water absorption, and achieve the effect of improving color change, firm coloring and simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

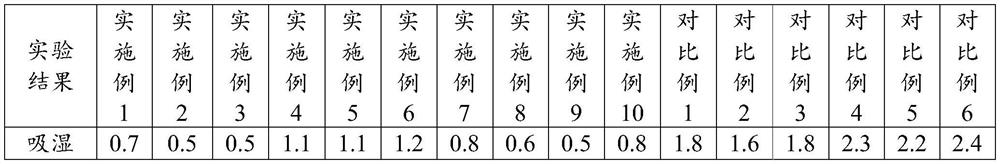

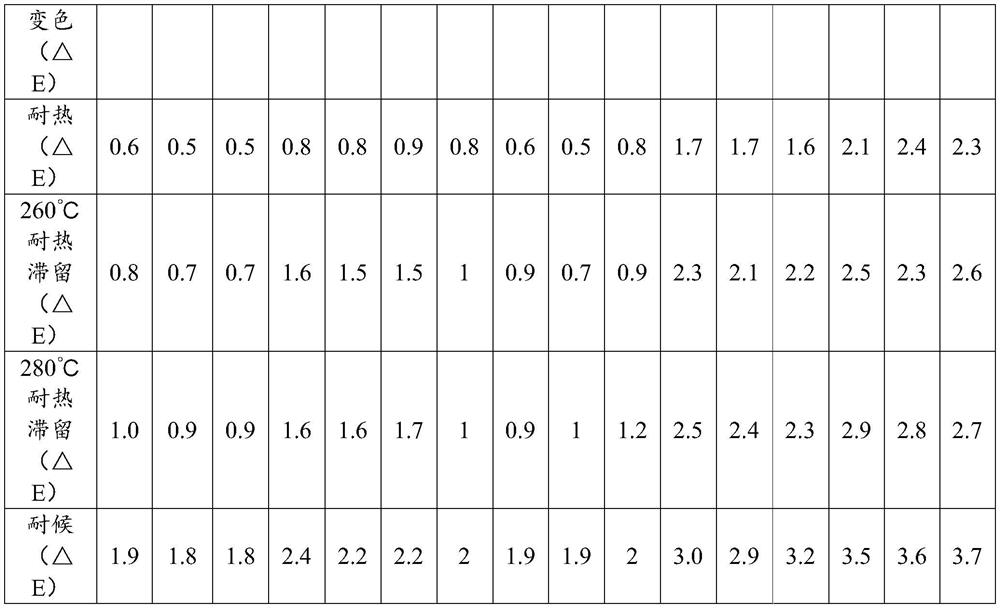

Examples

Embodiment 1~9

[0036] The embodiment of the nylon with high color stability of the present invention, the preparation method of described product, comprises the following steps:

[0037] After the dried components are uniformly mixed according to the proportion, they are placed in a twin-screw extruder, melted and blended at 230° C., extruded and granulated to obtain the nylon with high color stability.

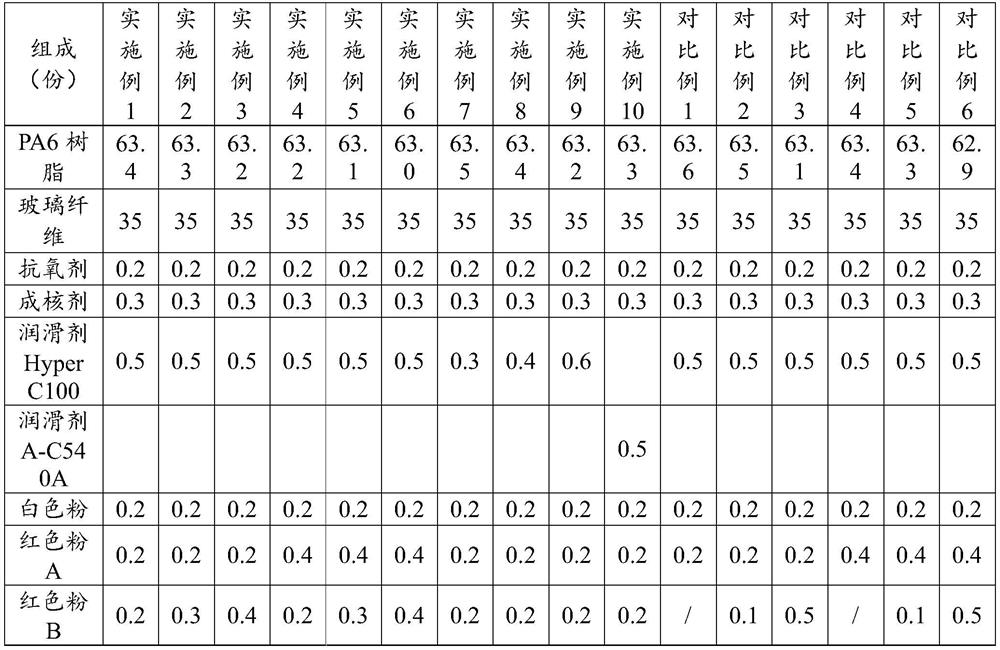

[0038] The raw materials used in each embodiment are as follows, and the proportioning ratio of the raw materials is shown in Table 1.

[0039] PA6 resin: high viscosity PA6 resin, grade HY-2800;

[0040] Glass fiber: chopped glass fiber, grade Chongqing glass fiber ECS301HP-3-H;

[0041] Antioxidant: Antioxidant 1098;

[0042] Nucleating agent: nucleating agent LICOMONT NAV101 PWD;

[0043] Lubricant: Wuhan hyperbranched HyperC100;

[0044] White powder: zinc sulfide;

[0045] Red powder A: Naphthalene red;

Embodiment 10

[0048] The difference between this embodiment and embodiment 9 is that the lubricant used is replaced by lubricant A-C540A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com