Preparation method of emulsion antioxidant

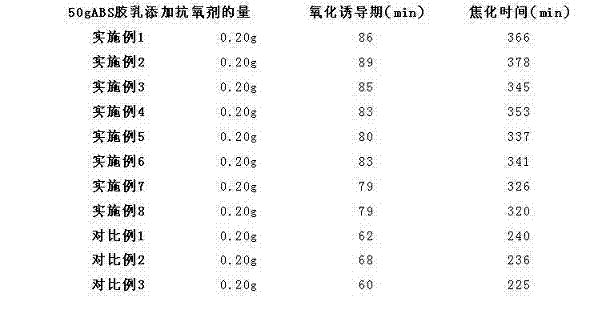

An antioxidant and emulsion-type technology, which is applied in the field of preparation of emulsion-type antioxidants, can solve problems such as uneven dispersion of antioxidants, polymer color stains, and poor anti-oxidation effect of ABS powder, and achieve improved color stability Sexuality and high temperature thermal stability, the effect of emulsion stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

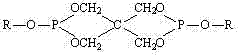

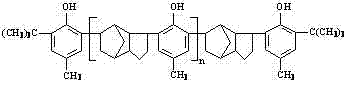

[0060] Mix 40g of Wingstay-L, 40g of dinonylbenzene pentaerythritol diphosphite, and 20g of DTDTP to form a composite antioxidant. Mix the composite antioxidant with 20g of KN4008 and 4g of isomeric alcohol ether, add it to a beaker, and heat it to 50°C. Stir and melt evenly, homogeneously pre-emulsify under high-speed shearing machine for 10-15min, and lower the temperature to 30°C for later use; mix and dissolve 28g 25% potassium abietate and 85g deionized water, and slowly add it under high shear to prepare In the good oil phase, homogeneously pre-emulsify for 15-20 minutes under a high-speed shearing machine after adding; after emulsification, slowly reduce the shear rate, and lower the temperature to 25-30 °C at a low shear rate to obtain an emulsion-type antioxidant agent. pH=9.3, average particle size is 380nm, viscosity is 660CPS.

Embodiment 2

[0062] Mix 40g Wingstay-L, 25g trinonylphenyl phosphite (TNPP), 30g DTDTP to form a composite antioxidant, mix the composite antioxidant with 25g KN4008, 6g isomeric alcohol ether, add it to a beaker, and heat to 100 ℃, stir and melt evenly, homogeneously pre-emulsify under high-speed shearing machine for 10-15min, and lower the temperature to 80℃ for later use; mix and dissolve 26g 25% potassium abietate and 85g deionized water, and slowly Add to the prepared oil phase, after adding, homogeneously pre-emulsify under high-speed shearing machine for 15-20min; after emulsification, slowly reduce the shear speed, and lower the temperature to 25-30°C at low shear speed to obtain emulsion type Antioxidant. pH=9.1, average particle size is 430nm, viscosity is 710CPS.

Embodiment 3

[0064] Mix 40g of Wingstay-L, 10g of dinonylbenzene pentaerythritol diphosphite, and 45g of DTDTP to form a composite antioxidant, mix the composite antioxidant with 32g of KN4008, and 12g of isomeric alcohol ether, add it to a beaker, and heat it to 120°C. Stir and melt evenly, homogeneously pre-emulsify under high-speed shearing machine for 10-15min, and lower the temperature to 80°C for later use; mix and dissolve 24g 25% potassium abietate and 80g deionized water, and slowly add it under high shear to prepare In the good oil phase, homogeneously pre-emulsify for 15-20 minutes under a high-speed shearing machine after adding; after emulsification, slowly reduce the shear rate, and lower the temperature to 25-30 °C at a low shear rate to obtain an emulsion-type antioxidant agent. pH=10.2, average particle size is 410nm, viscosity is 700CPS.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com