3D printing weather-resistant nylon powder composite material and preparation method thereof

A nylon powder and 3D printing technology, which is applied in the field of weather-resistant nylon powder composite materials for 3D printing and its preparation, can solve the problems of not meeting the requirements of product accuracy and strength, affecting the accuracy and strength of 3D printing products, and uneven distribution of stirring and mixing. , to achieve the effect of not easy delamination and powder removal, narrow spherical particle distribution, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

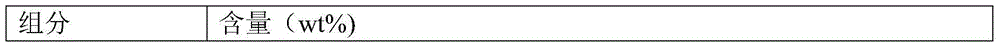

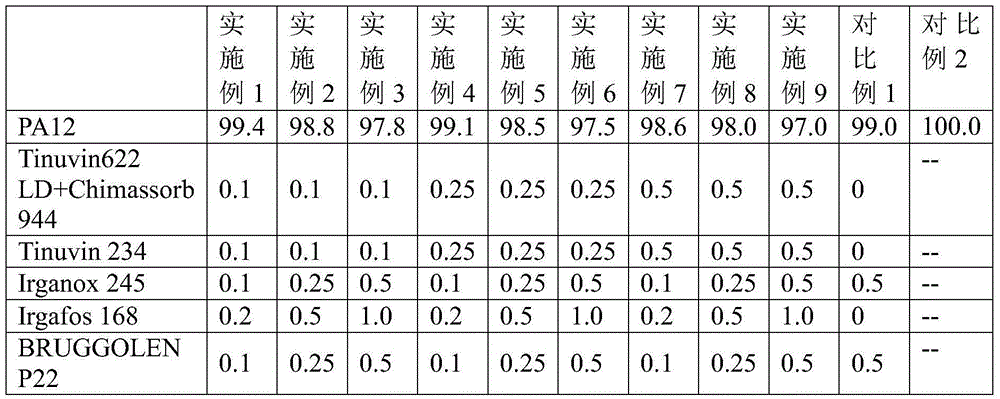

Examples

preparation example Construction

[0049] The preparation method of comparative example 1 in the above table is as follows:

[0050] (1) Take PA12 according to the weight ratio of the formula;

[0051] (2) Put PA12 and trifluoroethanol in a nitrogen-filled airtight container, and stir continuously to form a nylon solution; the amount of trifluoroethanol solvent is the quality of nylon resin: solvent volume=1:1~1:5;

[0052] (3) Transport the solution to the spray dryer through a peristaltic pump, and carry out atomization, drying, powder collection and formic acid recovery and reuse under the protection of nitrogen; the air inlet temperature is 125±2°C, and the air outlet temperature is 85±2°C °C °C, oxygen concentration ≤1.5%.

[0053] (4) Place the collected powder in a vacuum dryer, dry at room temperature for 3 hours, and seal the package to obtain a weather-resistant nylon powder composite material for 3D printing.

[0054] Comparative example 2 in the above table is PA12 powder material for 3D printing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com