Patents

Literature

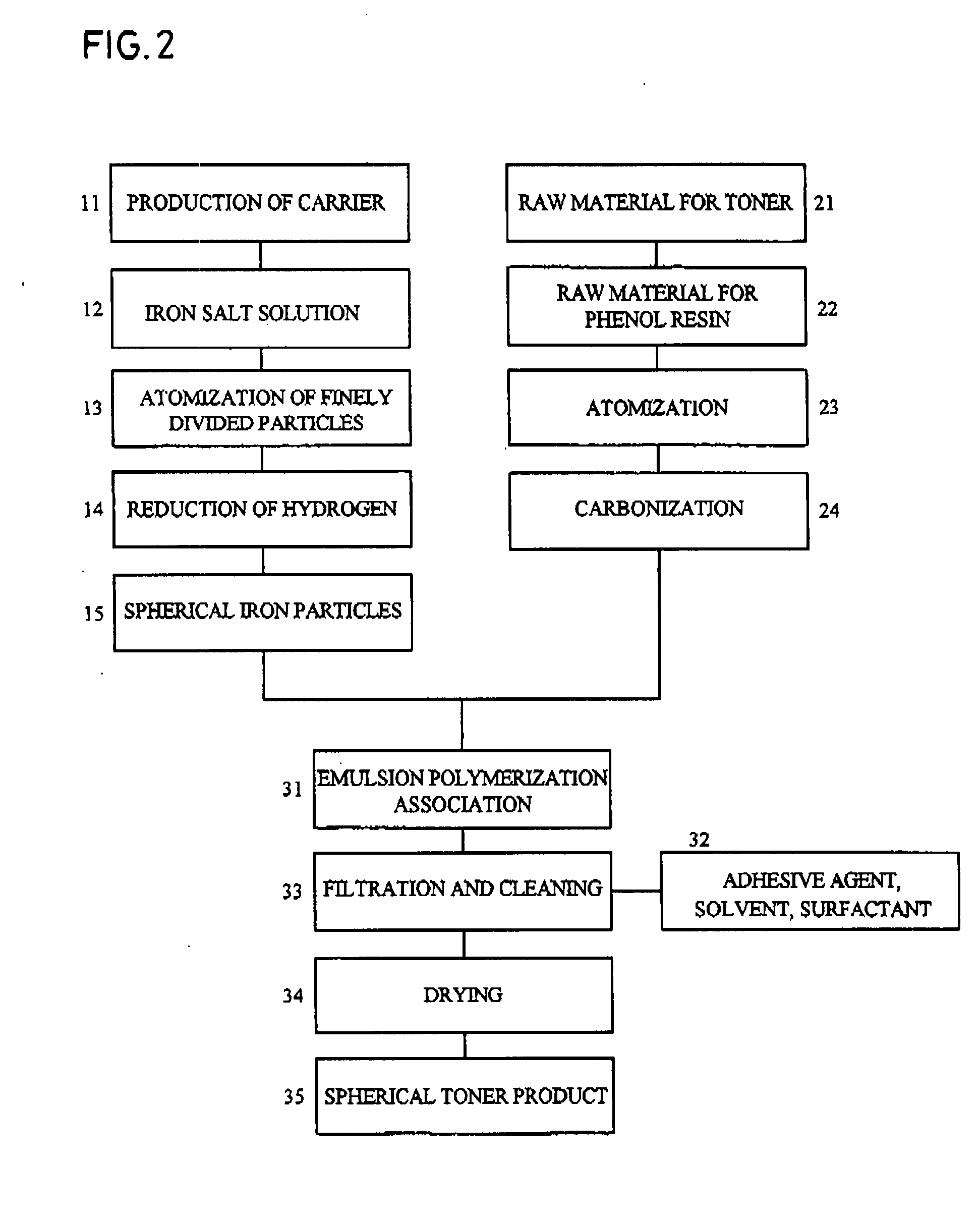

198 results about "Spherical granule" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Martian spherules, spherical granules of material found on the surface of the planet Mars; Granule (geology), a specified particle size of 2–4 millimetres (-1 to -2 on the φ scale) Granule, in pharmaceutical terms, small particles gathered into a larger, permanent aggregate in which the original particles can still be identified

Engineering shape of polymeric micro- and nanoparticles

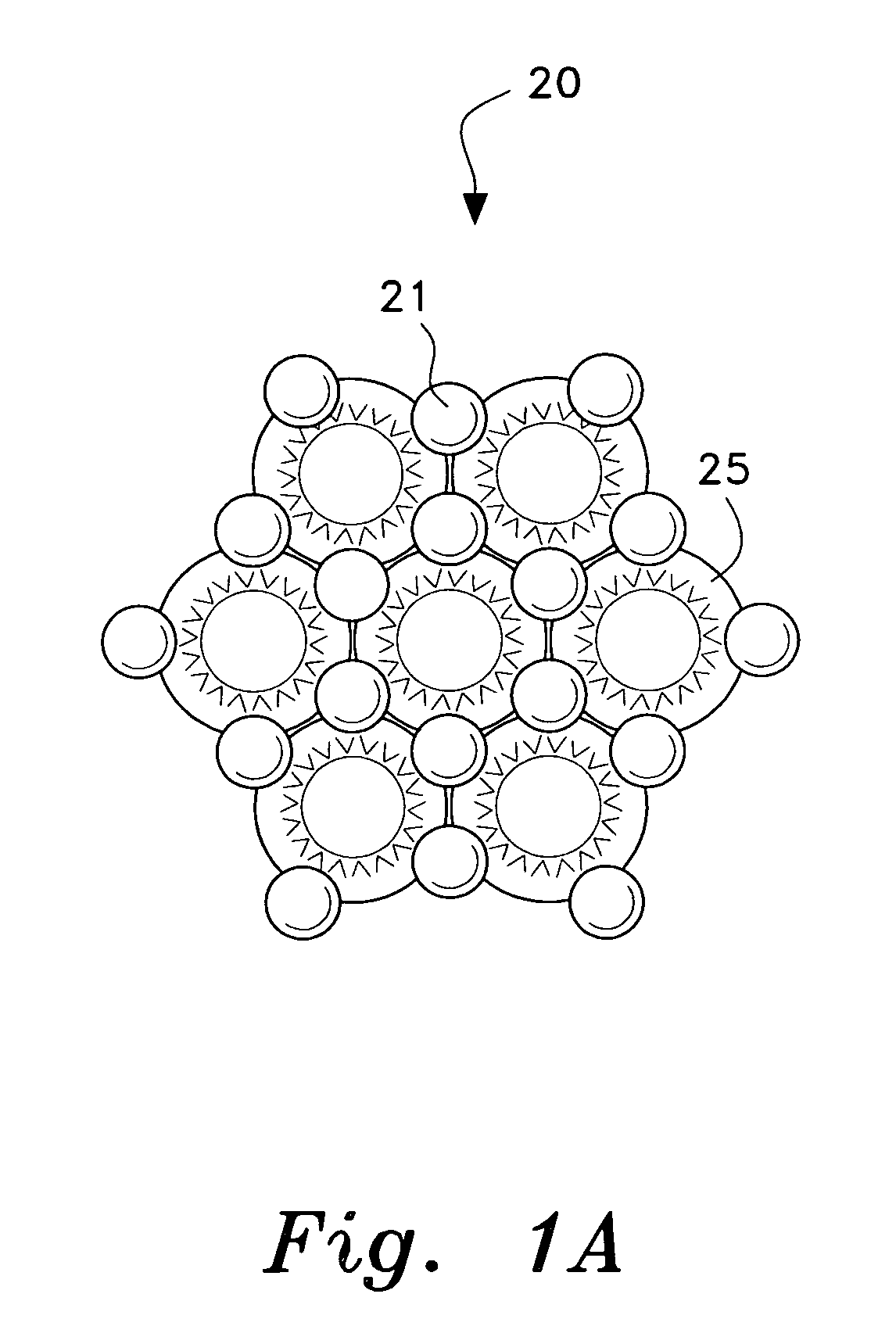

InactiveUS20080112886A1Produced in advanceMicromachined deliveryGranular deliveryPhagocytic CellSpherical granule

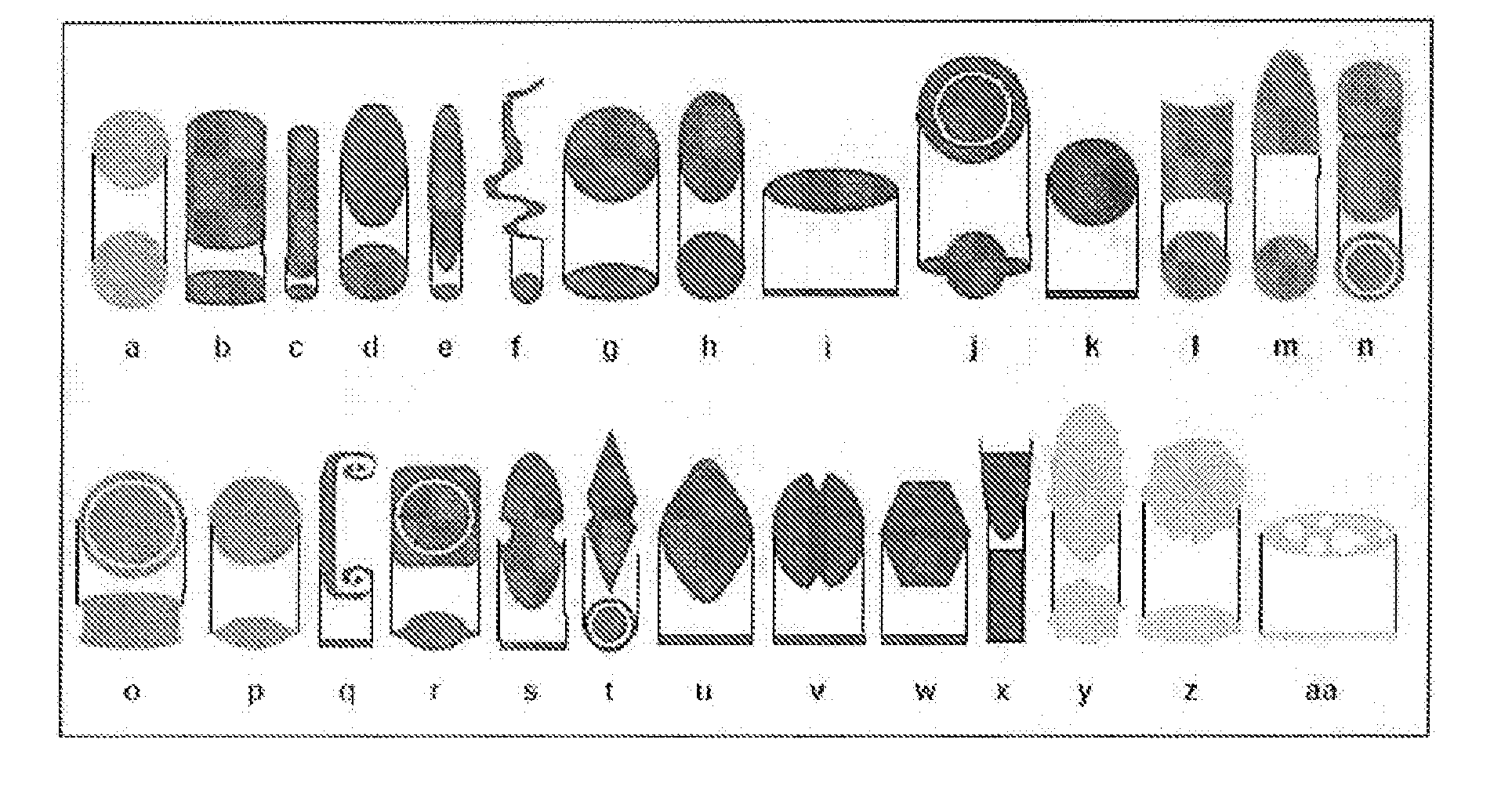

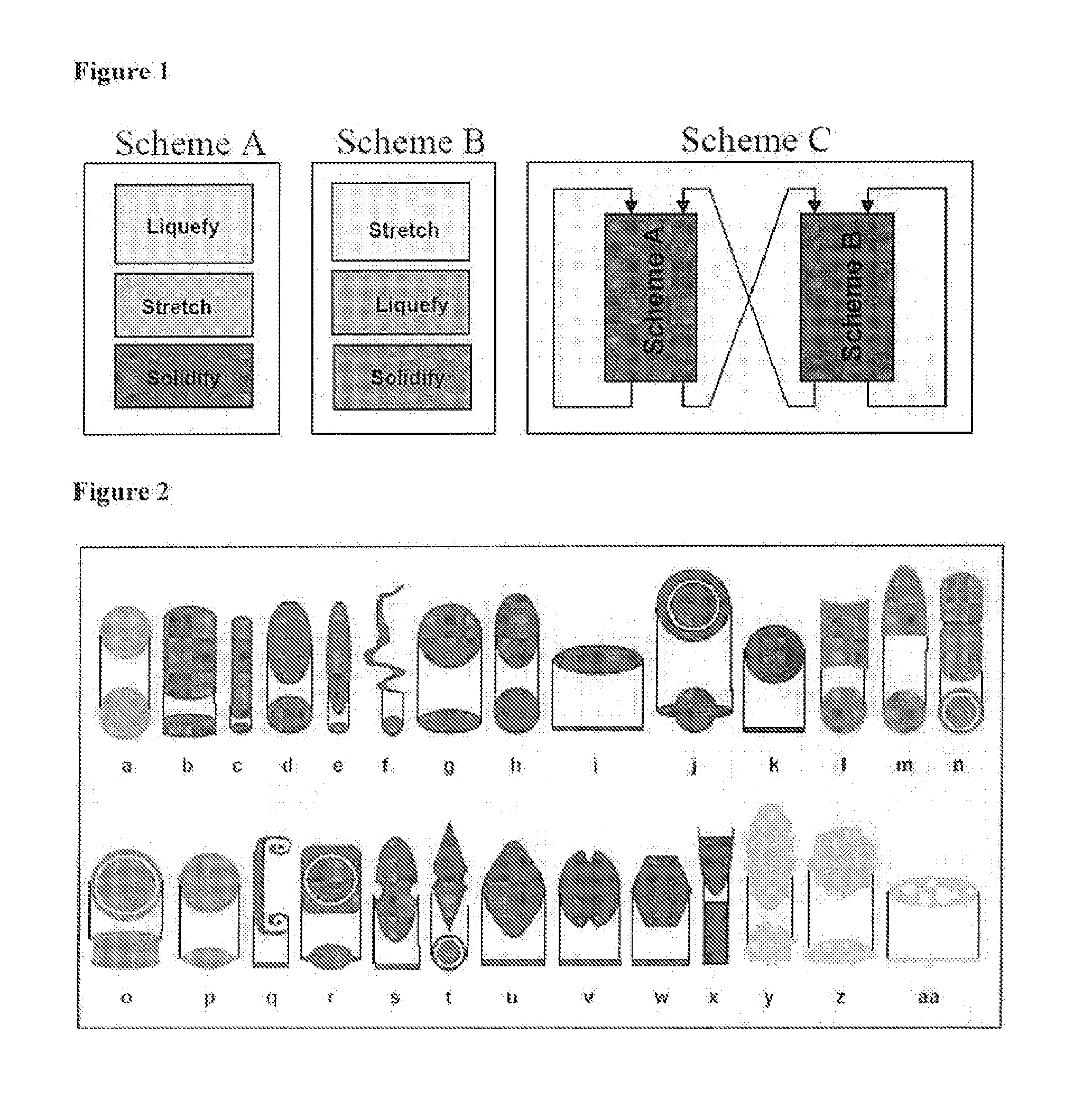

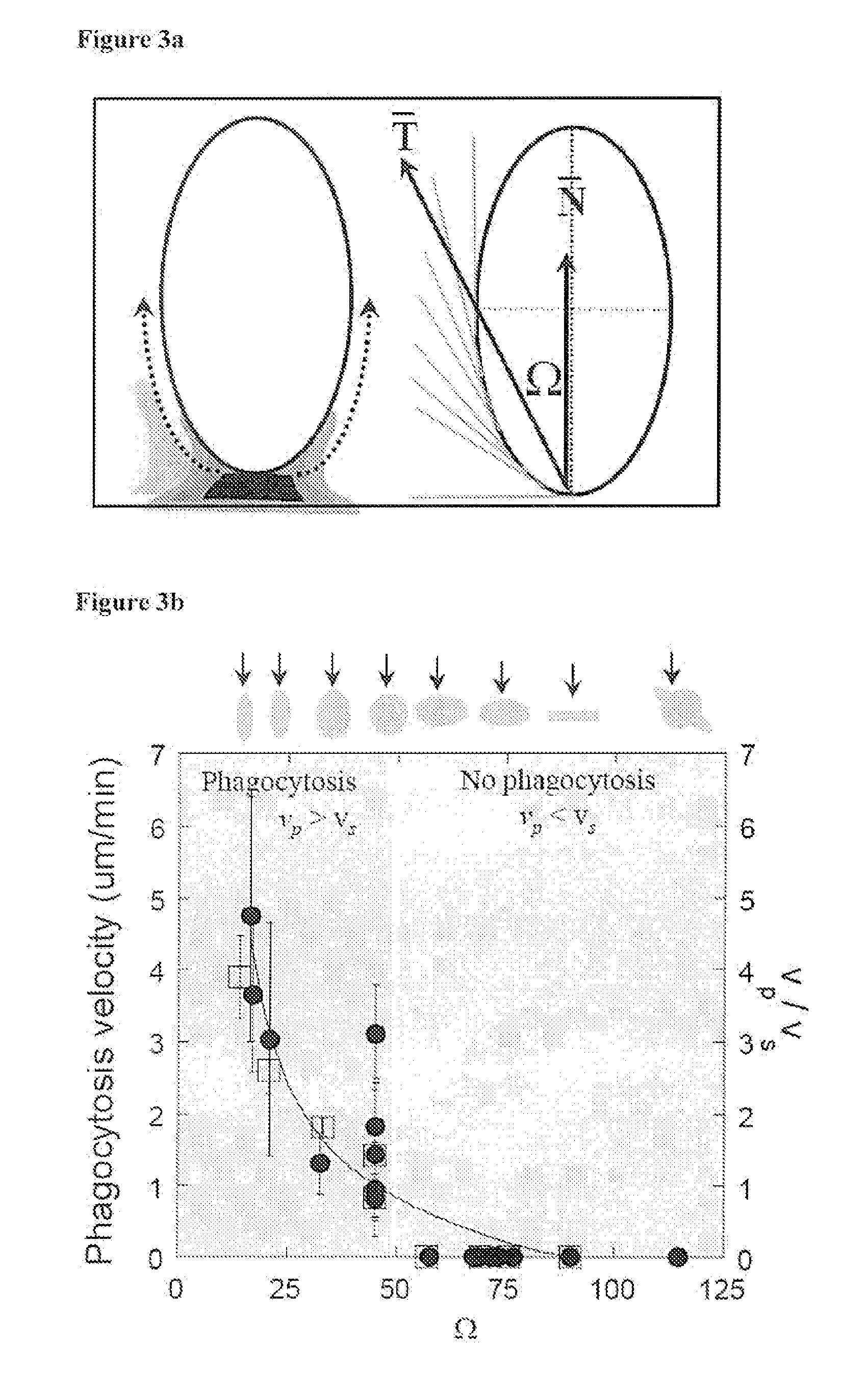

Compositions containing polymeric micro- and nanoparticles with non-spherical shapes and methods for making and using such particles are described herein. The particles have a size range from an average diameter of about Compositions containing polymeric micro- and nanoparticles with non-spherical shapes and methods for making and using such particles are described herein. The particles have one or more dimensions ranging from about 5 nm to about 100 μm, preferably about 100 nm to 10 μm. The particles can have any of a wide variety of non-spherical shapes. The particles are generally formed by manipulation of spherical particles embedded in a polymeric film. A wide variety of resulting shapes can be made. The resulting shape is a function of whether the films are manipulated in a first and / or second dimension, and the processes used to liquefy the microparticles. Variations of the method of manufacture may be used to generate particles having the desired shapes in large, reproducible quantities. The resulting non-spherical shaped particles can be used to alter uptake by phagocytic cells and thereby clearance by the reticuloendothelial system.

Owner:RGT UNIV OF CALIFORNIA

Preparation method of ceramic granules

InactiveCN102060562ALow water absorptionHigh compressive strengthCeramicwareSpherical granuleDiiron Trioxide

The invention relates to a preparation method of ceramic granules, which comprises the following steps: drying and crushing coal ash, kaolin, ferric oxide and basic magnesium carbonate into powder after wet grinding; carrying out the biscuit firing treatment on the powder to prepare biscuit-firing granules after spherical granules are prepared; preparing microcrystal glass powder by utilizing an Li-Al-Si system; pouring the prepared microcrystal glass powder into a granulator to be stirred; preparing the biscuit-firing granules packaged by the microcrystal glass powder after the surface of the biscuit-firing granules is completely packaged by the microcrystal glass powder; placing the biscuit-firing granules packaged by the microcrystal glass powder into the granulator; adding the powder;preparing the ceramic granules to be treated through the biscuit firing after the biscuit-firing granules packaged by the microcrystal glass powder are completely packaged by the powder; and preparing the ceramic granules after the ceramic granules to be treated through the biscuit firing are placed into a muffle furnace to be sintered and crushed. In the invention, a packaging method is adopted to prepare the ceramic granules, the inner layer of the prepared ceramic granules is completely packaged by the glass powder, and the gas of the inner layer is prevented from discharging in the sintering course so that the inner layer is in a loose porous structure, thereby greatly reducing the water absorption rate of the ceramic granules and decreasing the specific gravity.

Owner:SHAANXI UNIV OF SCI & TECH +1

Preparation method of nanometer aerogel heat-insulation coating

InactiveCN102079949AReduce heat transferReduce contact areaSilicaPolyurea/polyurethane coatingsSupercritical dryingSolid particle

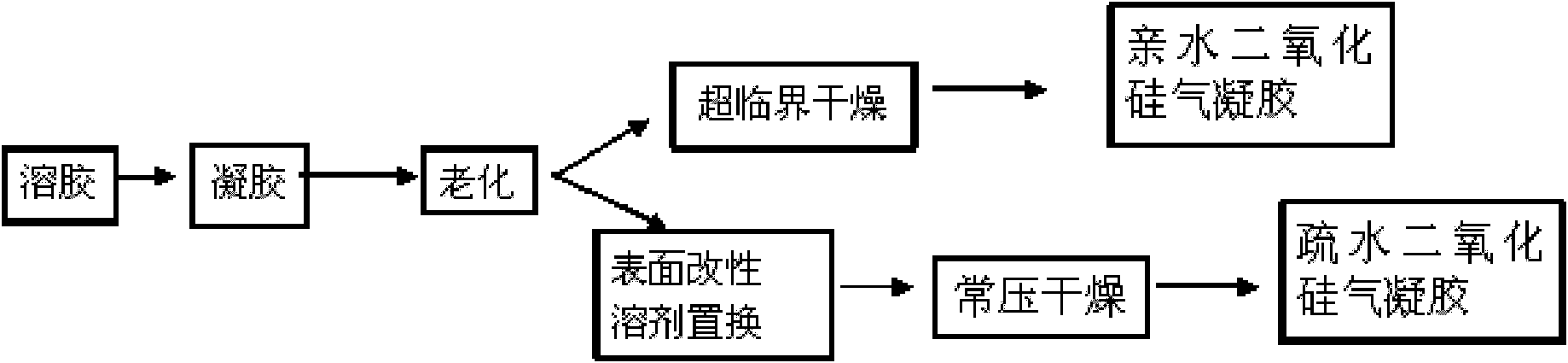

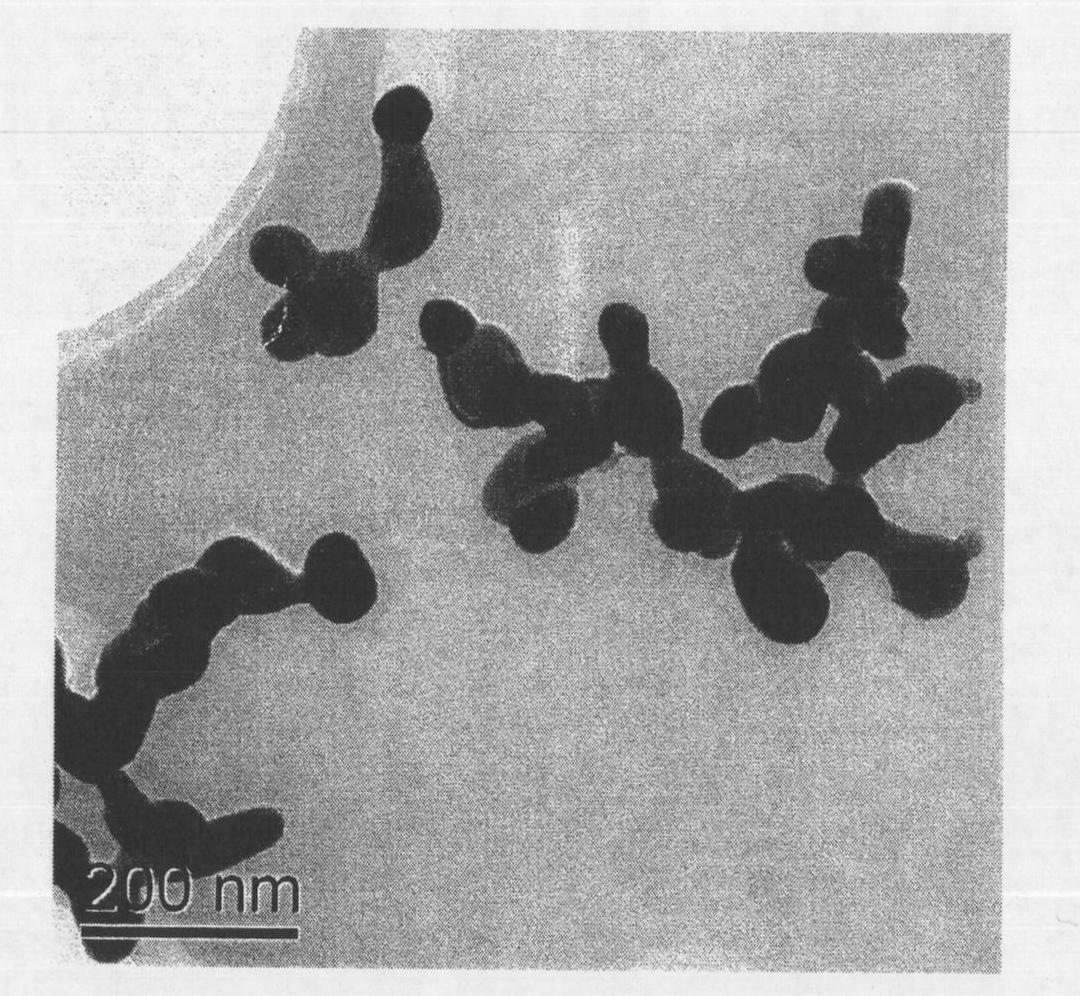

The invention relates to a preparation method of nanometer aerogel heat-insulation coating, which comprises the following steps: dissolving aerogel, solidifying the aerogel, aging, replacing by a surface modification solvent, drying at normal pressure and preparing lyophobic silicon dioxide aerogel; or supercritically drying and preparing hydrophilic silicon dioxide aerogel. The preparation method provided by the invention has the beneficial effects that the aperture of the silicon dioxide aerogel prepared by adopting the method provided by the invention is in nanometer-level distribution, and the main aperture of the silicon dioxide aerogel is10nm and is less than the free path of an air molecular movement, thereby greatly reducing the heat transfer generated by a gas molecular heat movement; the aerogel in the invention is in a network structure formed by overlapping the spherical granules of nanometer silicon dioxide, thereby reducing the contact area of solid granules, increasing the heat transfer path and further achieving the effects of heat maintenance and heat insulation; and lyophobic and hydrophilic type silicon dioxide aerogel can be prepared according to different drying processes to be used by matching organic or inorganic coatings.

Owner:李志

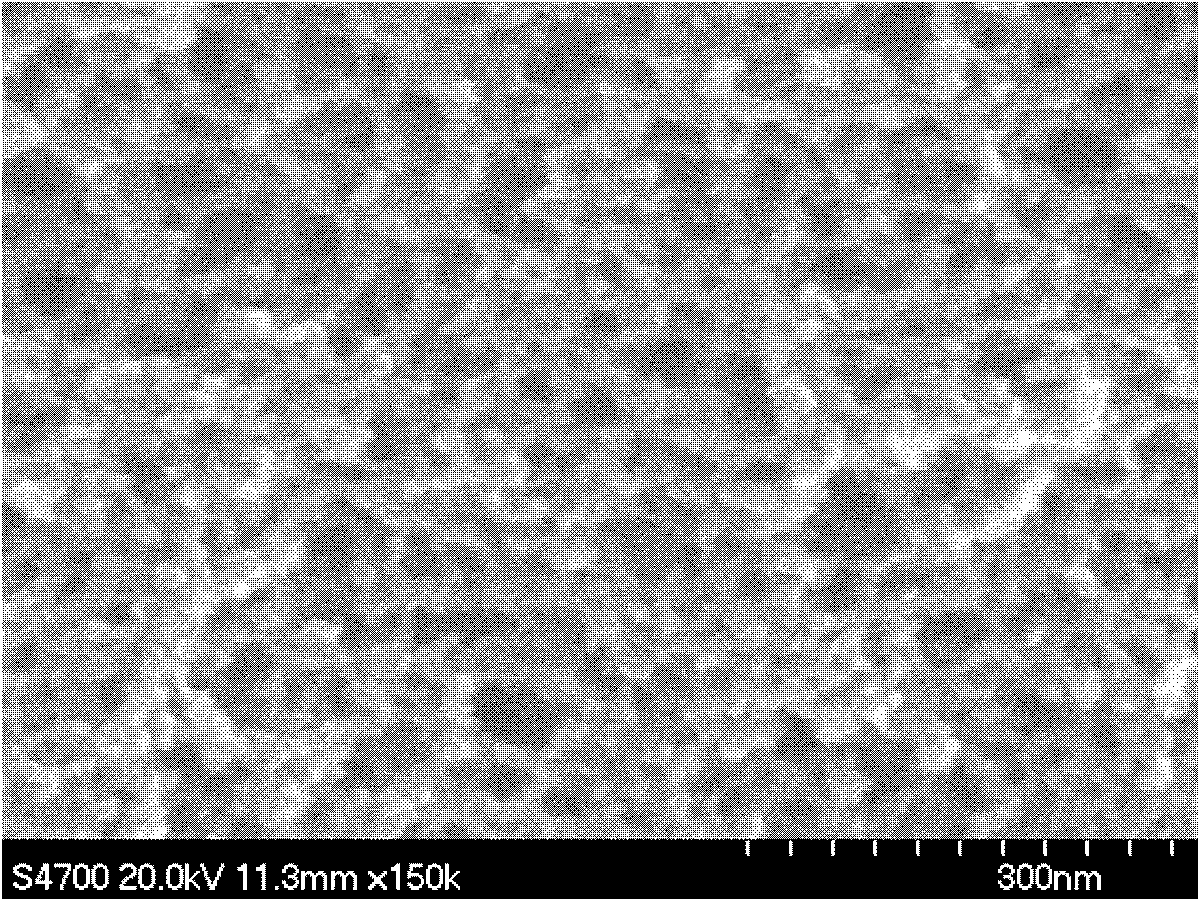

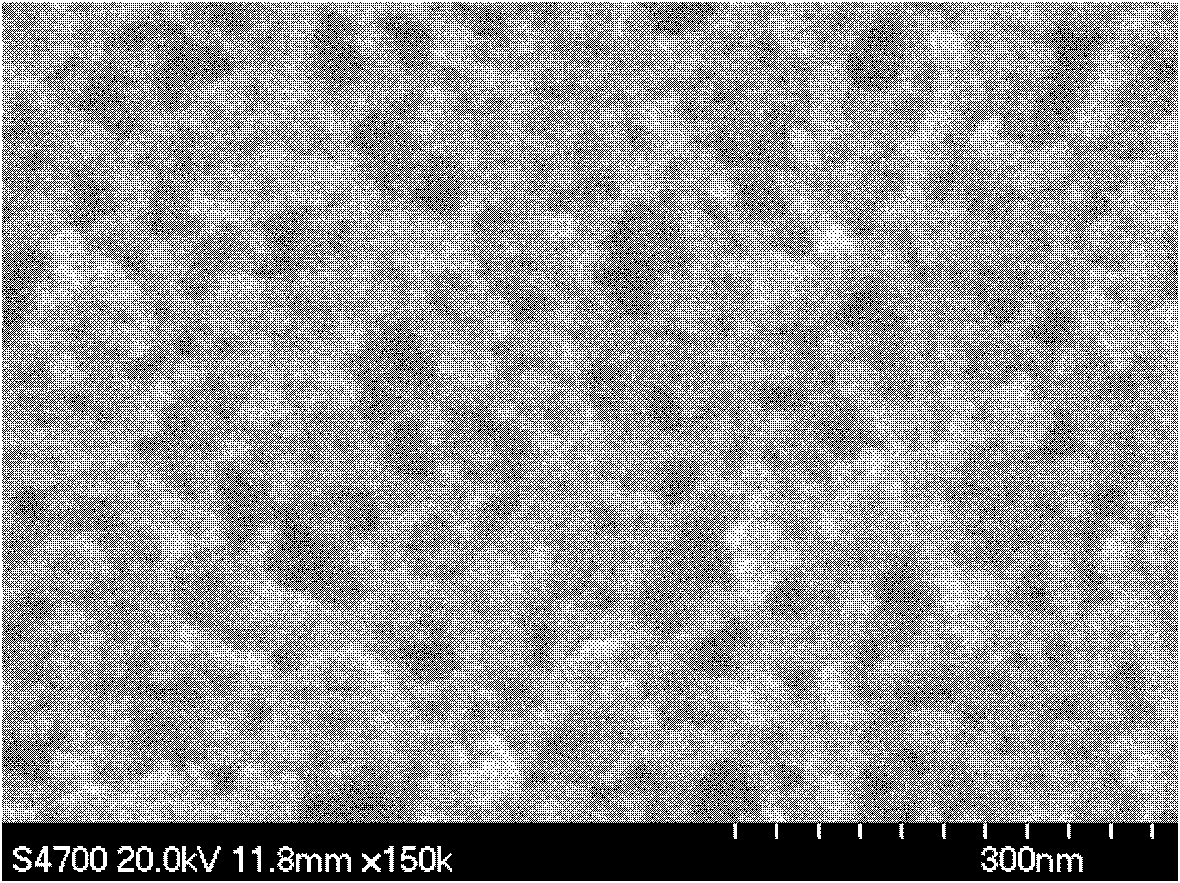

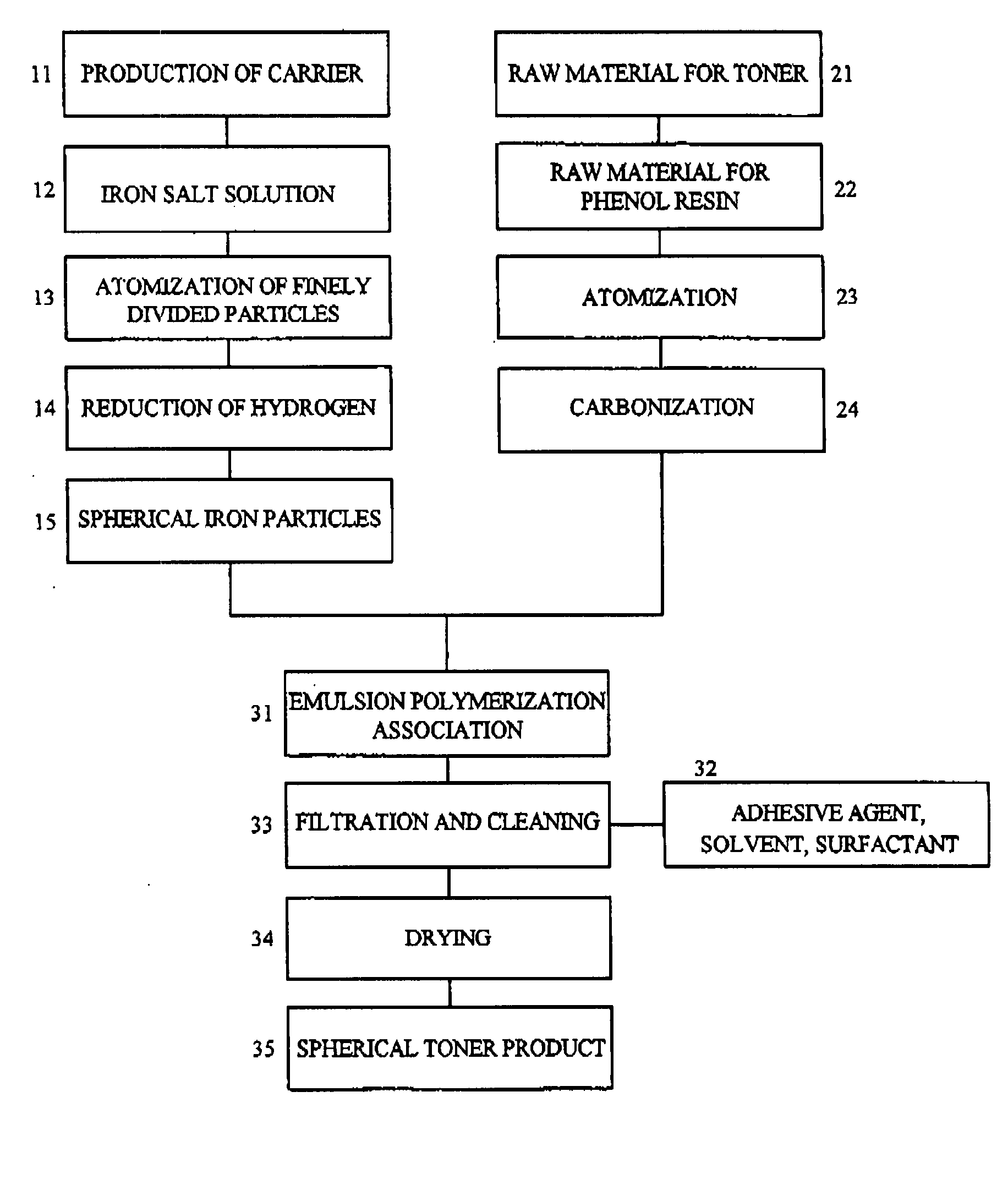

Spherical particles having nanometer size, crystalline structure, and good sphericity and method for producing

InactiveUS20080038555A1Maintain good propertiesPrevent oxidationSynthetic resin layered productsMetal-working apparatusSpherical granuleCrystal structure

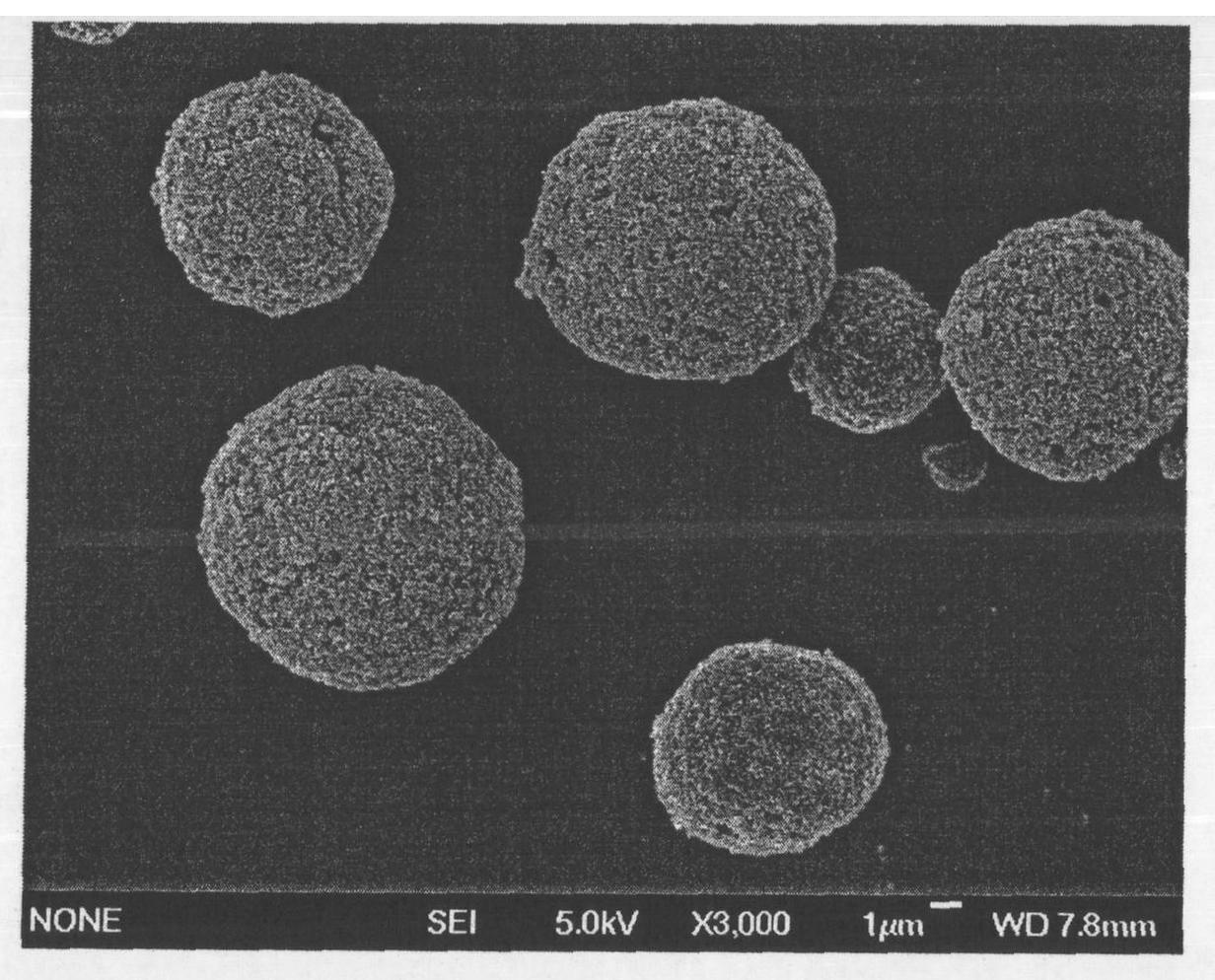

There is provided nanometer-size spherical particles. The particles of the present invention are made of at least one selected from the group consisting of a metal, an alloy, and a metal compound. The particles include one or both of a polycrystalline region and a single-crystalline region. The particles have a particle size of less than 1 μm; and a sphericity of −10% to +10%.

Owner:NAPRA

Method for making nitrogenous and complex fertilizers in highly homogenized spherical granule form starting from urea formaldehyde liquid resins and the fertilizer made thereby

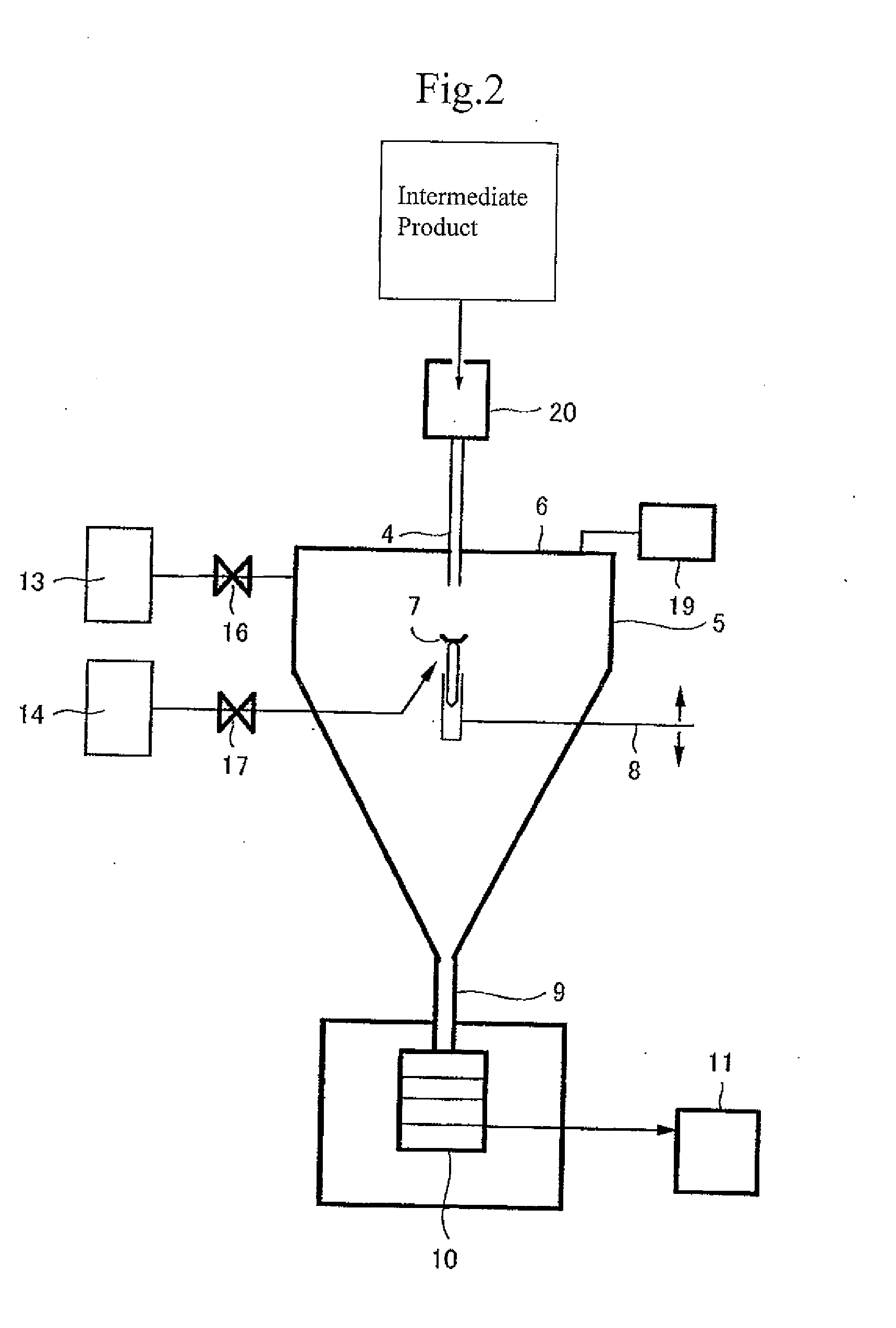

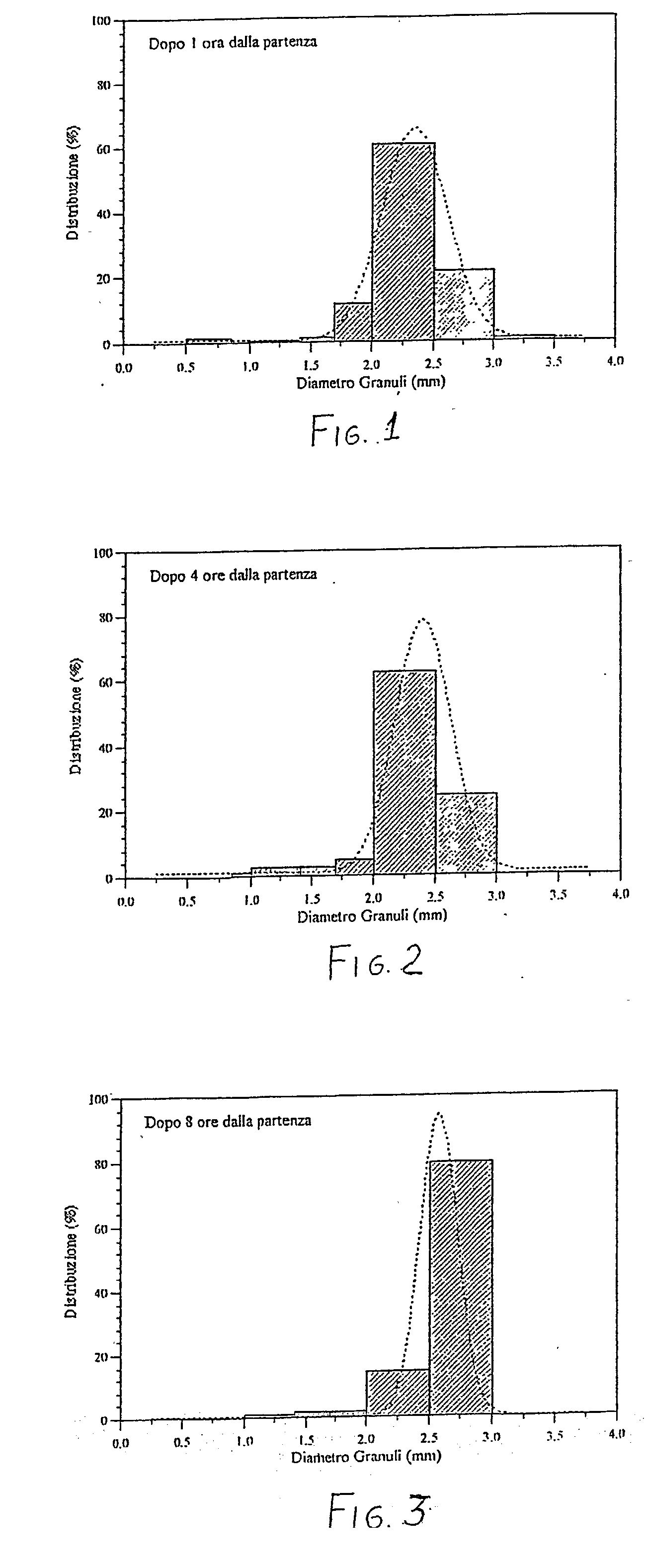

InactiveUS20030154754A1Easily and accurately controlSafe and reliableSolid/semi-solid fertilisersUrea compound fertilisersSpherical granuleNitrogen

The present invention relates to a method for making nitrogenous and complex fertilizers, in granule form, suitable for slowly releasing nitrogen, comprising the steps of preparing an aqueous urea / formaldehyde dispersion with a molar ratio from 0.8:1 to 2:1, adding an aqueous catalyzer solution in a weight ratio from 0.1 to 4%, controlling the pH of the aqueous dispersion to hold it within a range from 4.0 to 7.0, and supplying the aqueous dispersion to a recirculating granulating device, as a growth seed.

Owner:COSTA GIANCARLO +1

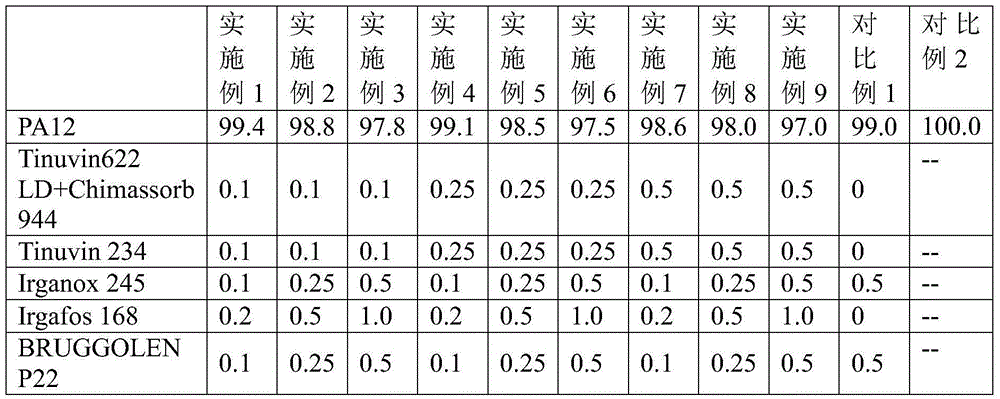

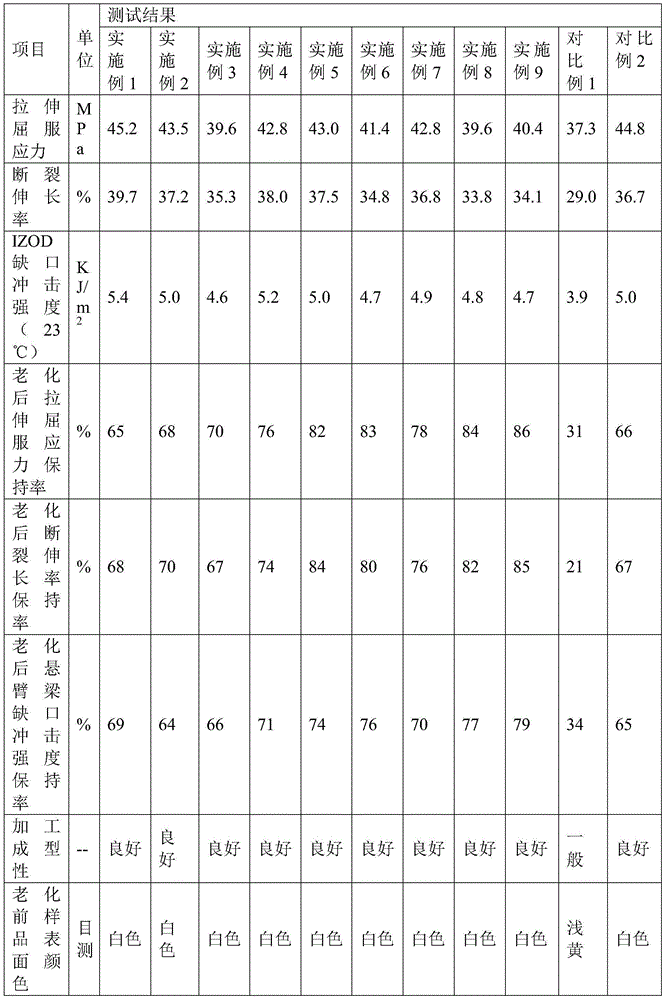

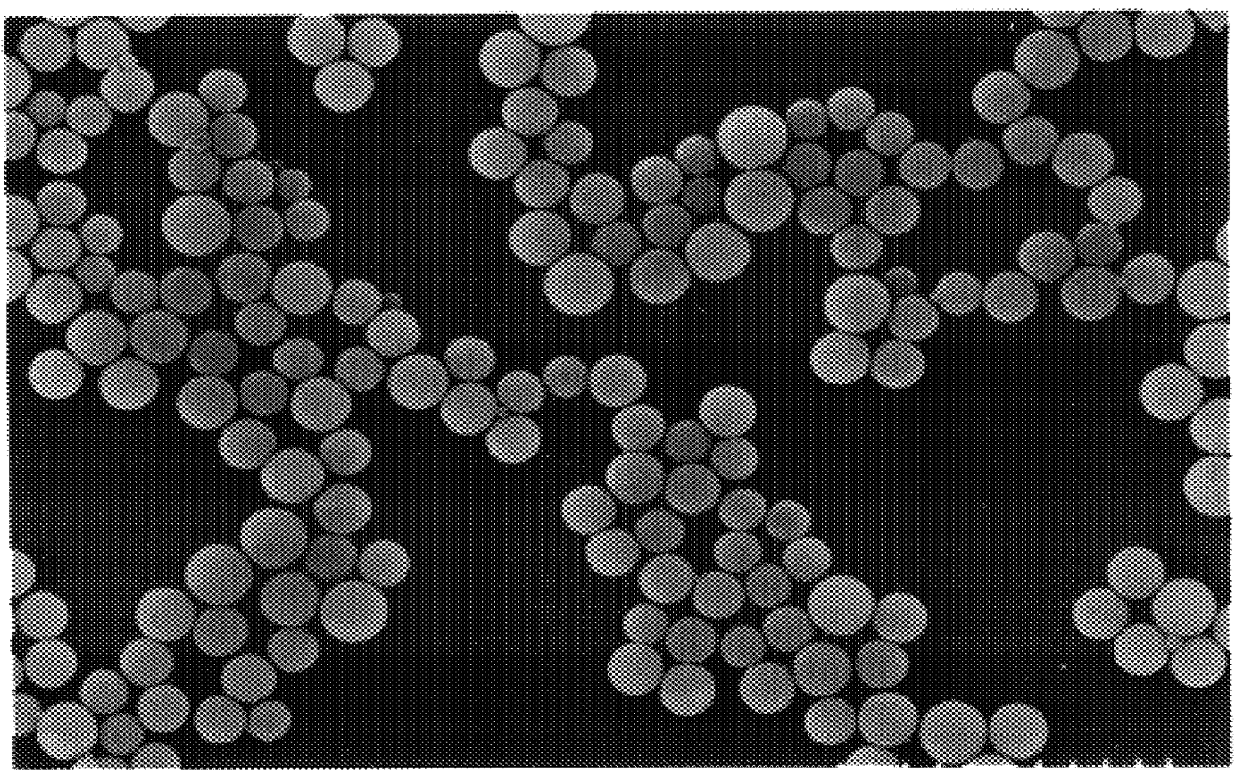

3D printing weather-resistant nylon powder composite material and preparation method thereof

The invention discloses a 3D printing weather-resistant nylon powder composite material and a preparation method thereof. The 3D printing weather-resistant nylon powder composite material is characterized by being prepared from the following components in percentage by mass: 97-99.4wt% of nylon, 0.1-0.5wt% of a hindered amine light stabilizer, 0.1-0.5wt% of an ultraviolet light absorber, 0.1-0.5wt% of a hindered phenol antioxidant, 0.2-1.0wt% of a phosphite ester antioxidant and 0.1-0.5wt% of other additives, wherein the other additives comprise one or combination of multiple components of a dispersing agent, a nucleating agent and a lubricant. With the combination of the hindered amine light stabilizer, the ultraviolet light absorber, the hindered phenol antioxidant and the phosphite ester antioxidant, the 3D printing weather-resistant nylon powder composite material prepared through spray-drying is excellent in weather resistance and small in mechanical property change before and after being modified, can be recycled and reused for multiple times, is narrow in spherical granule distribution, good in flowing property, free of layering or powder dropping, and moreover is high in preparation efficiency, small in energy consumption and simple and easy to process.

Owner:QINGDAO UNIV OF SCI & TECH +2

Production of active carbon with Chinese chestnut

Production of active carbon from Chinese chestnut shell as raw materials is carried out by collecting dust on Chinese chestnut shell, drying at 105-140 Deg C., grinding into fines with grain size <0.053mm, blending with 0.15-0.45mol zinc chloride solution, obtaining granule with 4-5mm diameter or normalized spherical granule, drying, transferring into carbonizing furnace, carbonizing without oxygen and at 380-680 Deg C. for 200-240mins, transferring into vertical activating furnace, activating at 550-650 Deg C. and 0.08-0.15Mpa for 30-45mins, washing and removing zinc for activated products by HCl solution with pH 2-2.5 and 85-95 Deg C., solid-liquid separating, washing to neutralization with water, drying solid materials, grinding and grading, and obtaining crushed active carbon or granular active carbon or spherical activate carbon.

Owner:WUHAN UNIV OF TECH

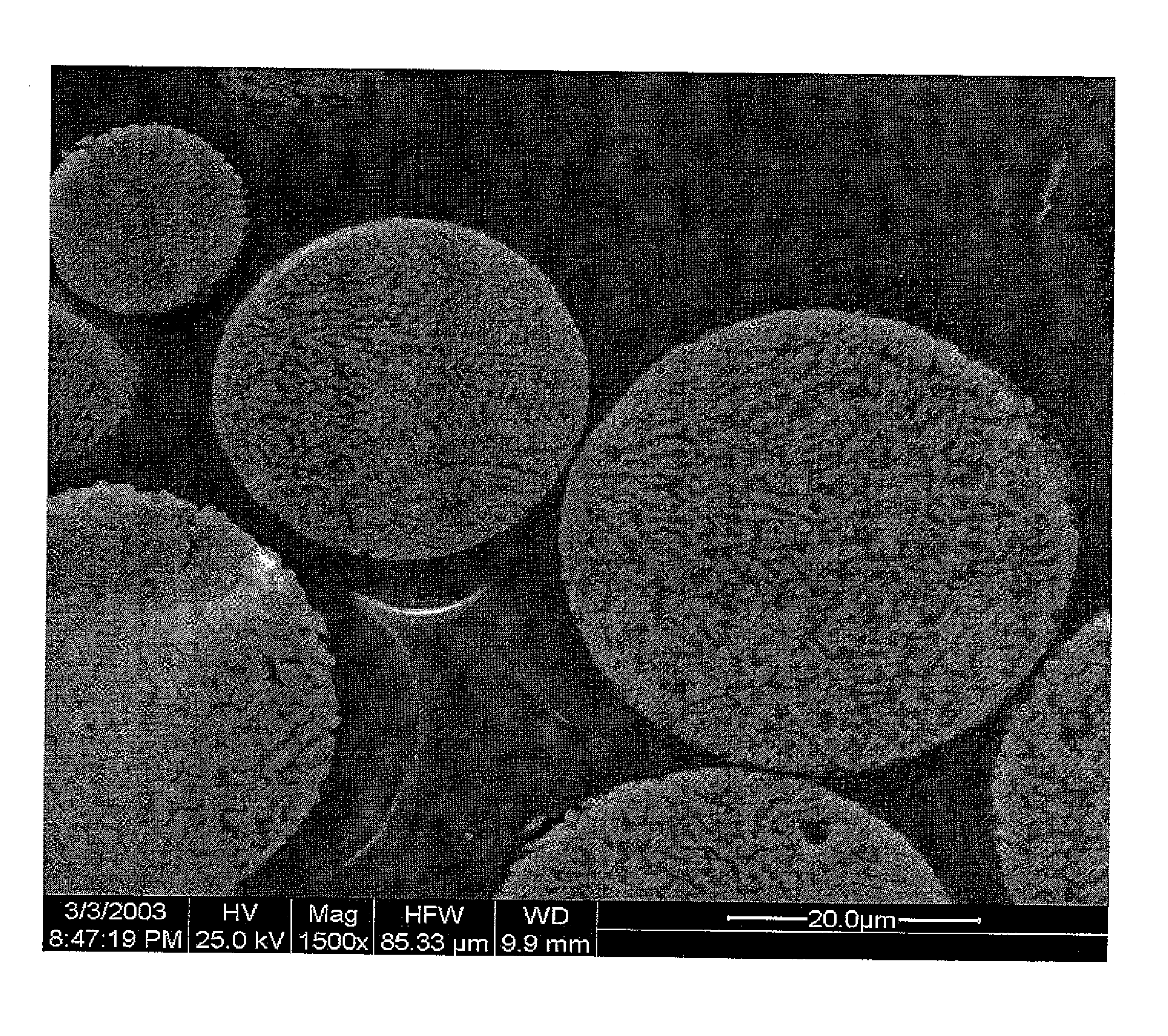

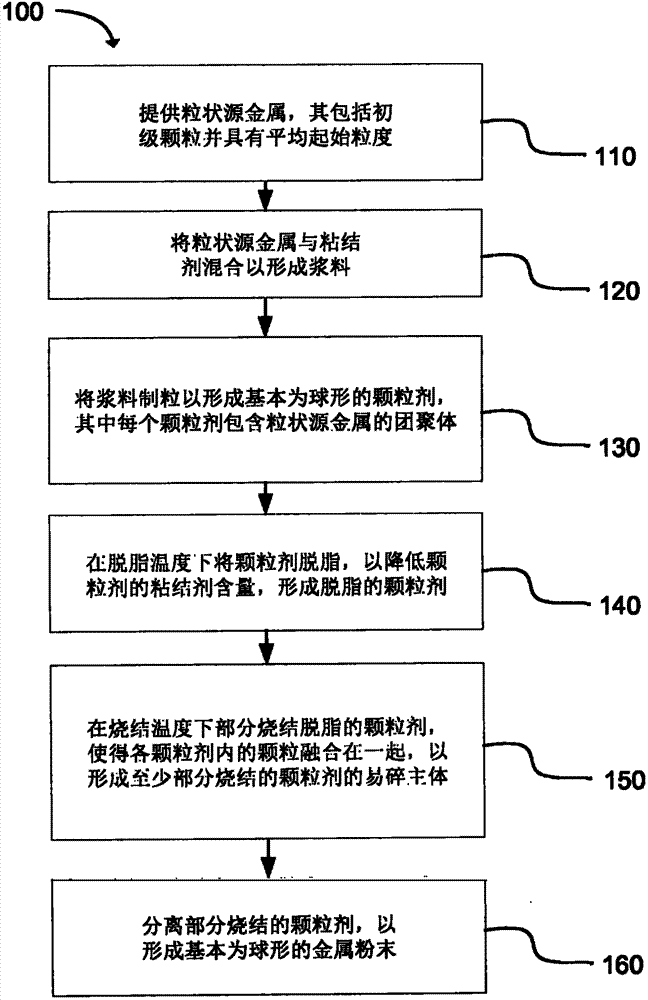

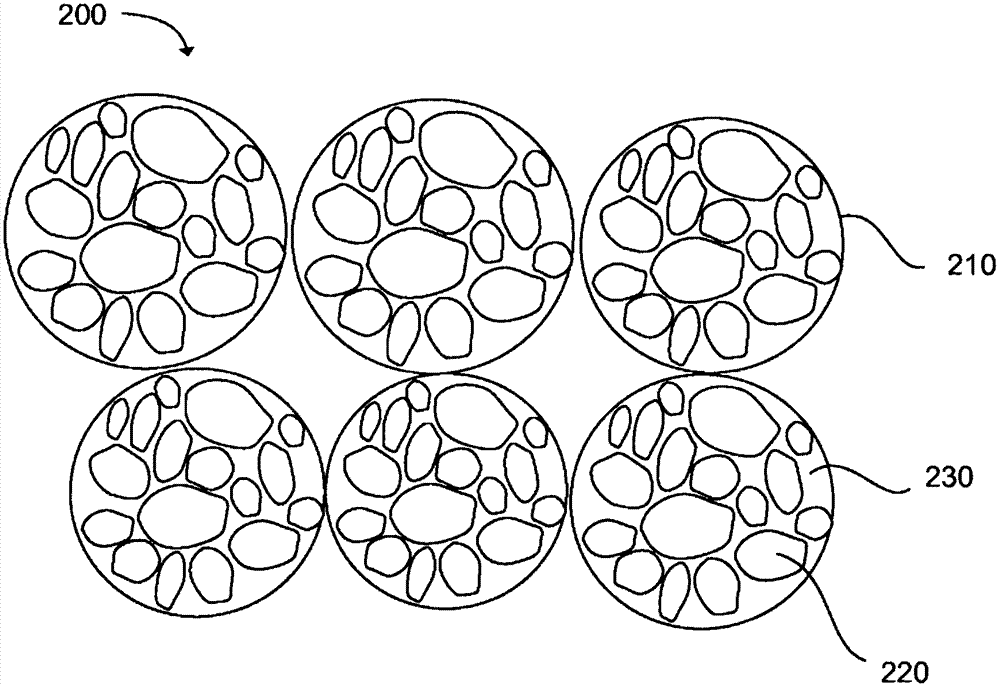

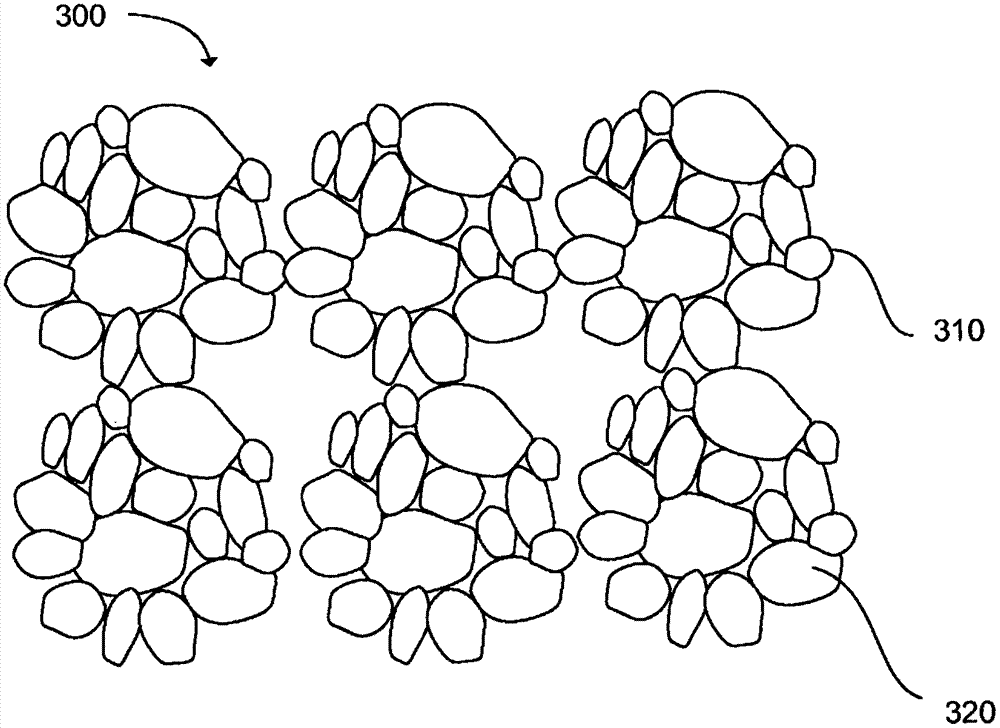

Production of substantially spherical metal powers

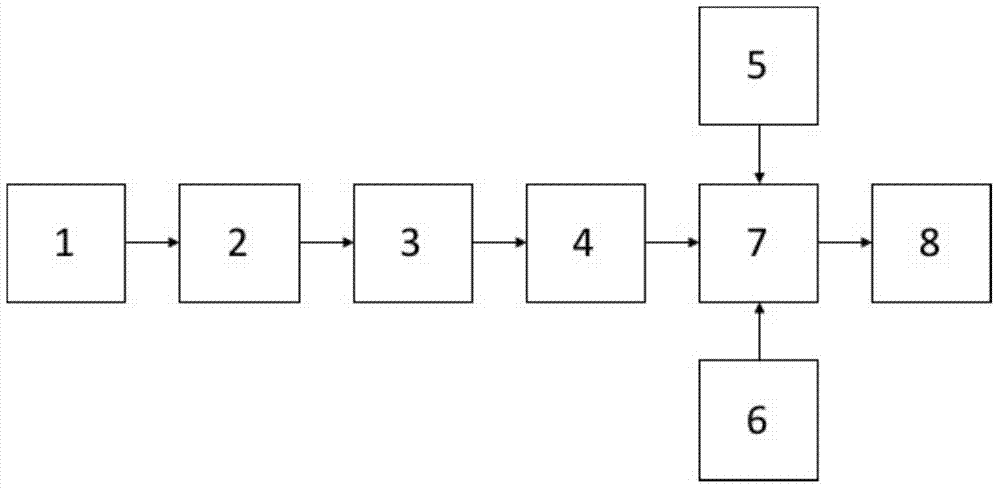

A method (100) for producing a substantially spherical metal powder is described. A particulate source metal includes a primary particulate and has an average starting particle size (110). The particulate source metal is optionally ball milled and mixed with a binder in a solvent to form a slurry (120). The slurry is granulated to form substantially spherical granules (130), wherein each granule comprises an agglomeration of particulate source metal in the binder. The granules are debinded (140) at a debinding temperature to remove the binder from the granules forming debinded granules. The debinded granules are at least partially sintered (150) at a sintering temperature such that particles within each granule fuse together to form partially or fully sintered solid granules. The granules can then be optionally recovered to form a substantially spherical metal powder (160).

Owner:UNIV OF UTAH RES FOUND

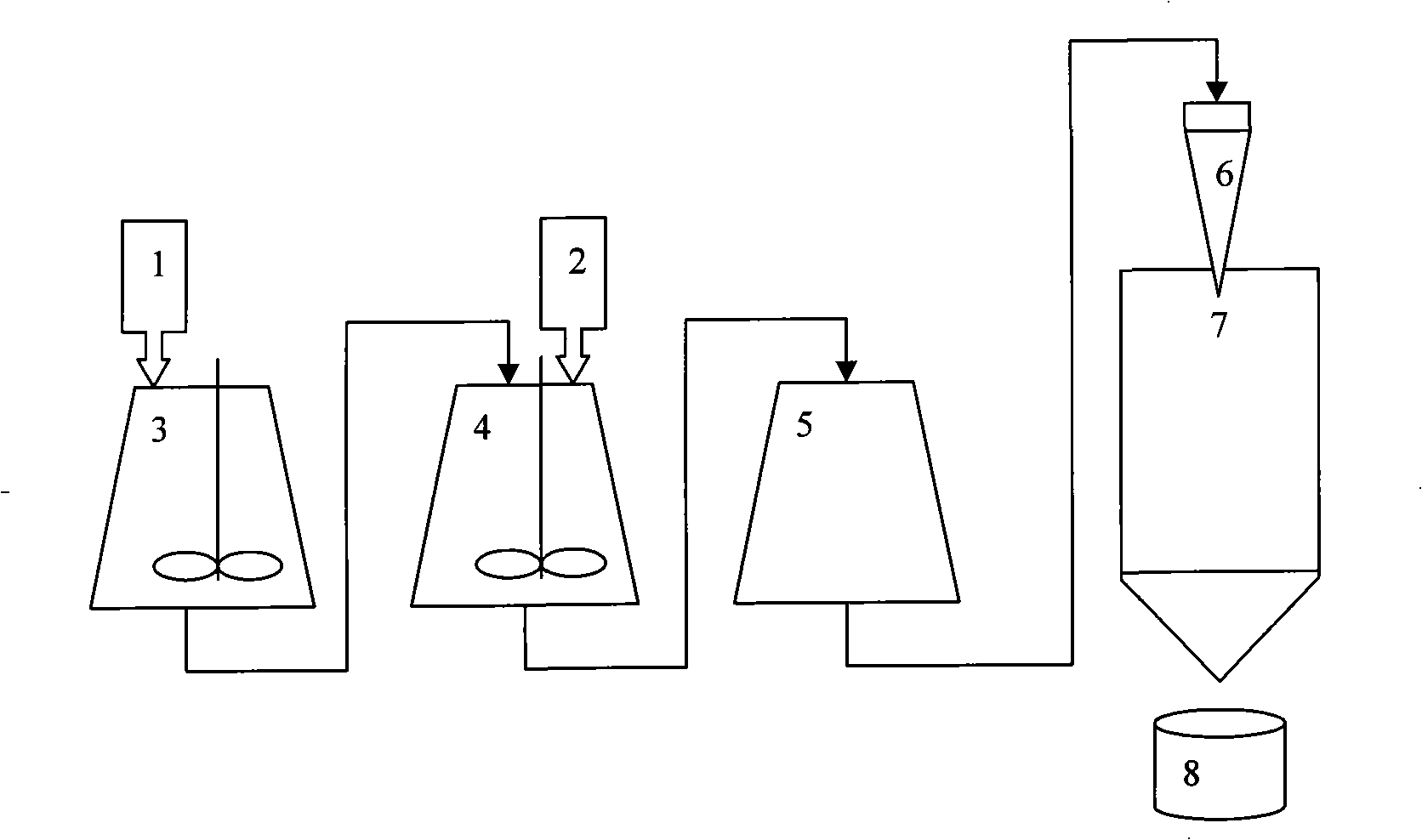

A preparing method of a lightweight ceramsite biological filter material

InactiveCN106396725ALow true densityLarge specific surface areaTreatment involving filtrationFiltration separationSpherical granuleClay minerals

The invention relates to a preparing method of a lightweight ceramsite biological filter material. The filter material is prepared by subjecting clay mineral, a lightweight material, a pore forming agent and a binder which are adopted as raw materials to high-temperature calcinating, wherein the lightweight material adopts an inorganic material the true density of which is about 0.23 g / cm<3>. The method includes (1) a step of raw material preparation, namely a step of inner core matching, outer shell matching and glue preparing, namely a step of mixing the clay, the lightweight material and the pore forming agent, mixing the clay and the pore forming agent, and mixing the binder and water, respectively, (2) a step of granulation, namely a step of feeding the inner core matching material into a granulating machine, granulating to obtain inner core granules, feeding the outer shell matching material into the granulating machine, and granulating to obtain spherical granules, with the glue being sprayed at the same time of feeding of the outer shell matching material, (3) a step of drying, namely a step of drying the spherical granules to remove water, and (4) a step of calcinating, namely a step of calcinating the dried spherical granules to obtain the lightweight ceramsite biological filter material.

Owner:清水源(上海)环保科技有限公司

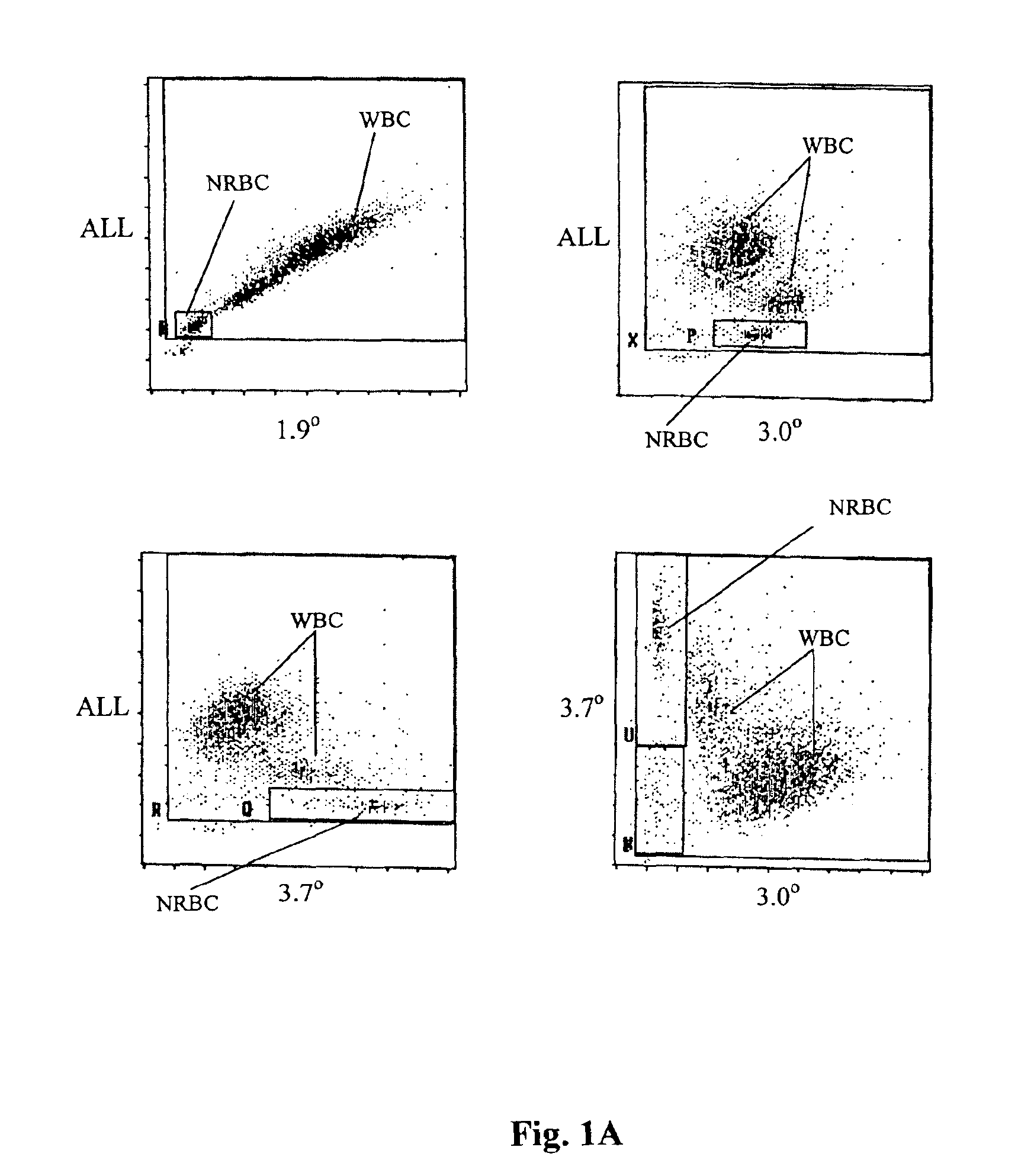

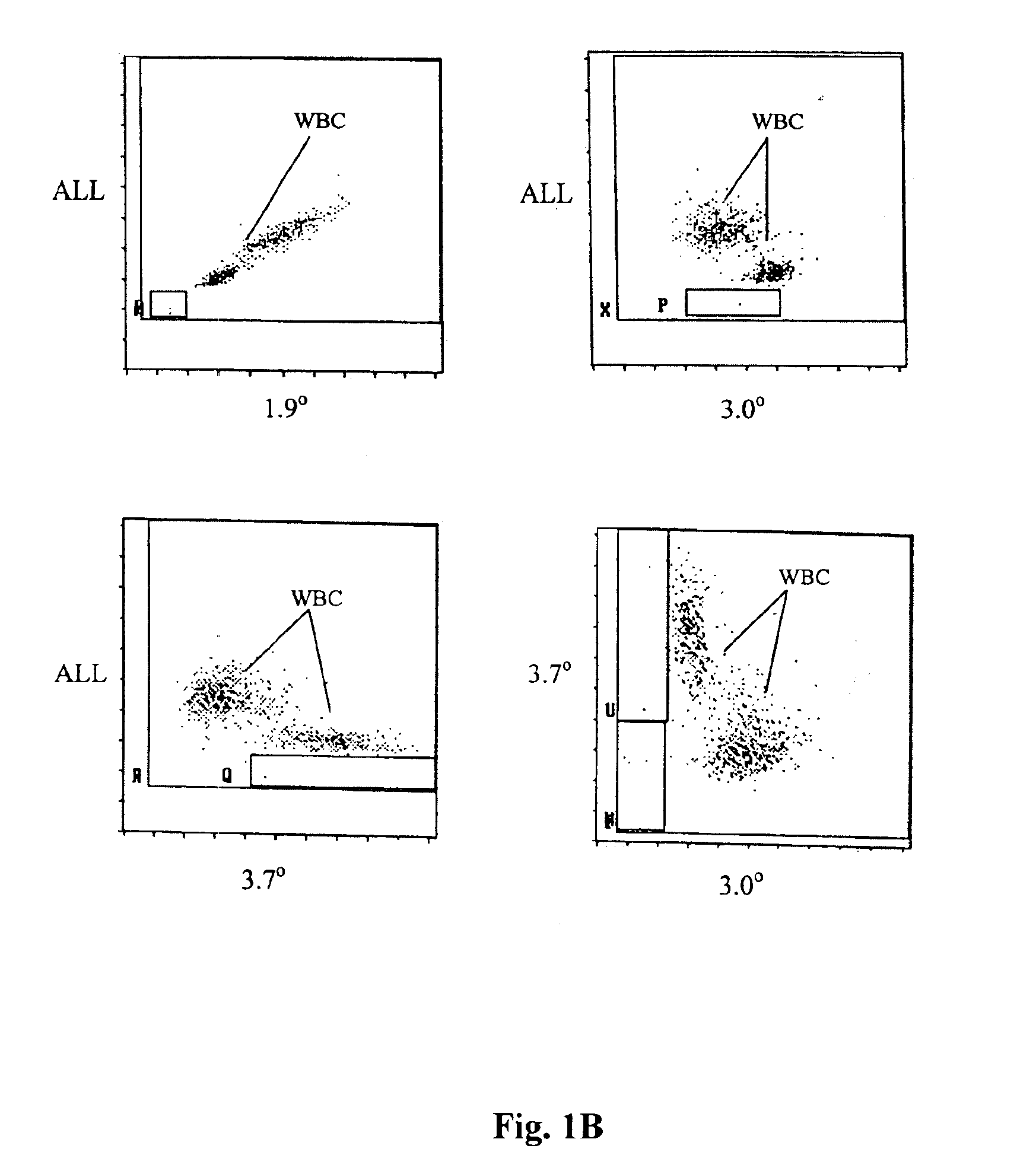

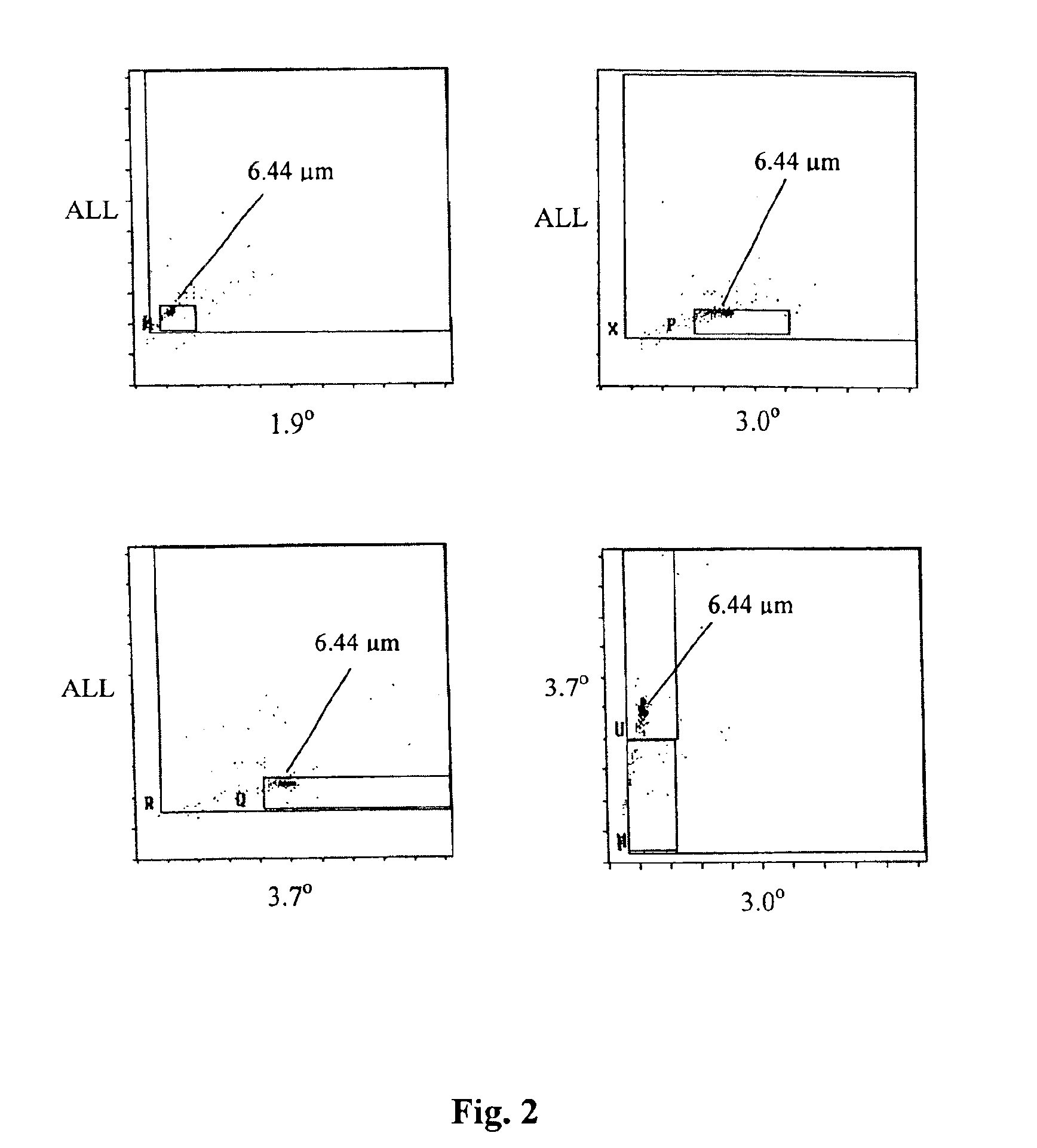

Reference control for optical measurement of nucleated red blood cells of a blood sample

ActiveUS6962817B2Dead animal preservationAnalysis by subjecting material to chemical reactionSpherical granuleOptical property

Reference control compositions and the method of use are disclosed for measurement of nucleated red blood cells, which includes one set of synthetic spherical particles having a mean particle diameter ranging from 6.2 μm to 6.8 μm and a refractive index from 1.58 to 1.62 monodispersed in an aqueous suspension medium. The synthetic spherical particles have optical properties simulating optical properties of nucleated red blood cells as measured by optical measurements. The reference control composition can further include a second set of the synthetic spherical particles having optical properties simulating optical properties of white blood cells. Further disclosed is a reference control system which includes a series of reference control compositions, each having an amount of one type of synthetic spherical particles which have optical properties simulating the optical properties of nucleated red blood cells having a specific cell maturity.

Owner:BECKMAN COULTER INC

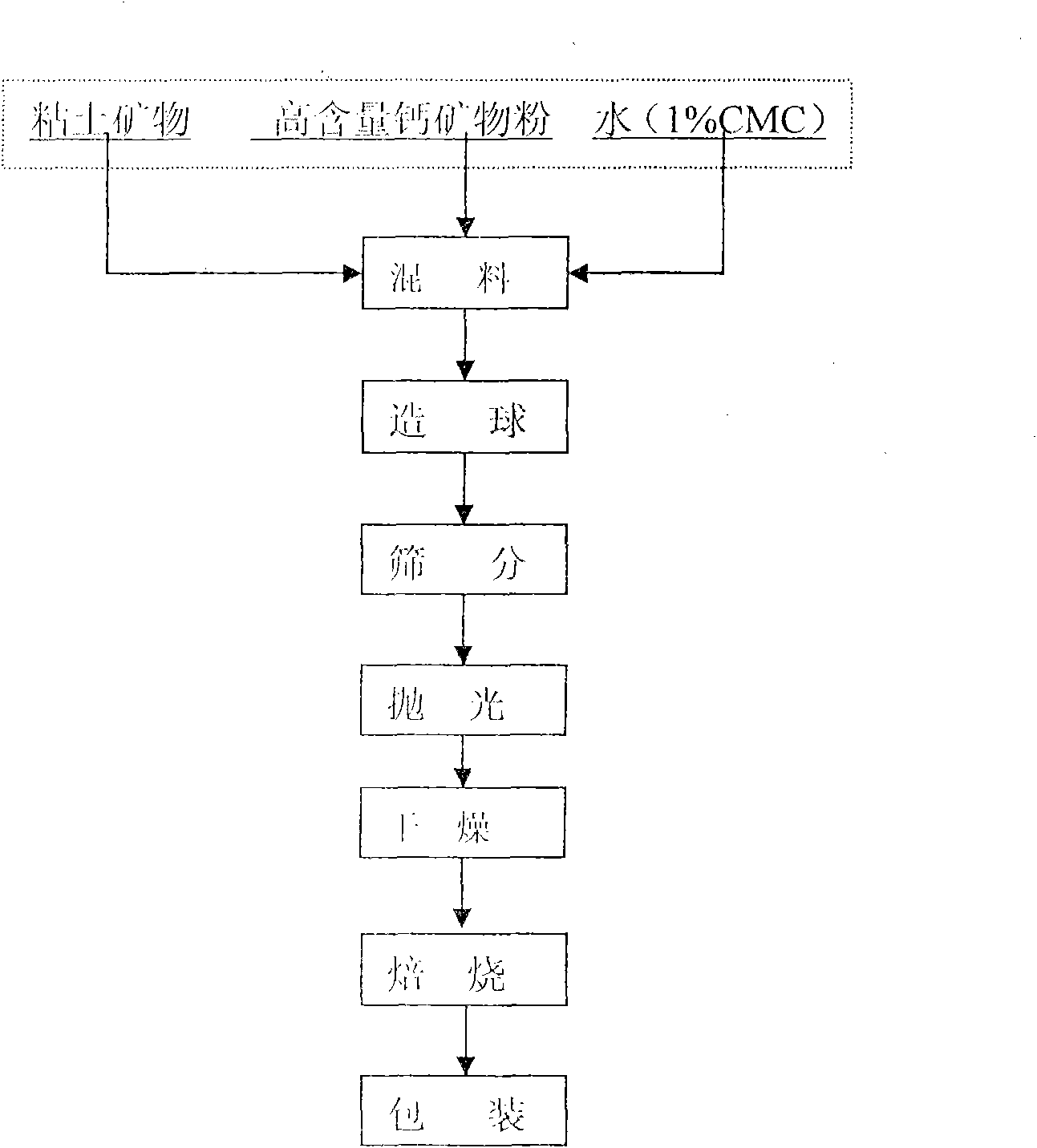

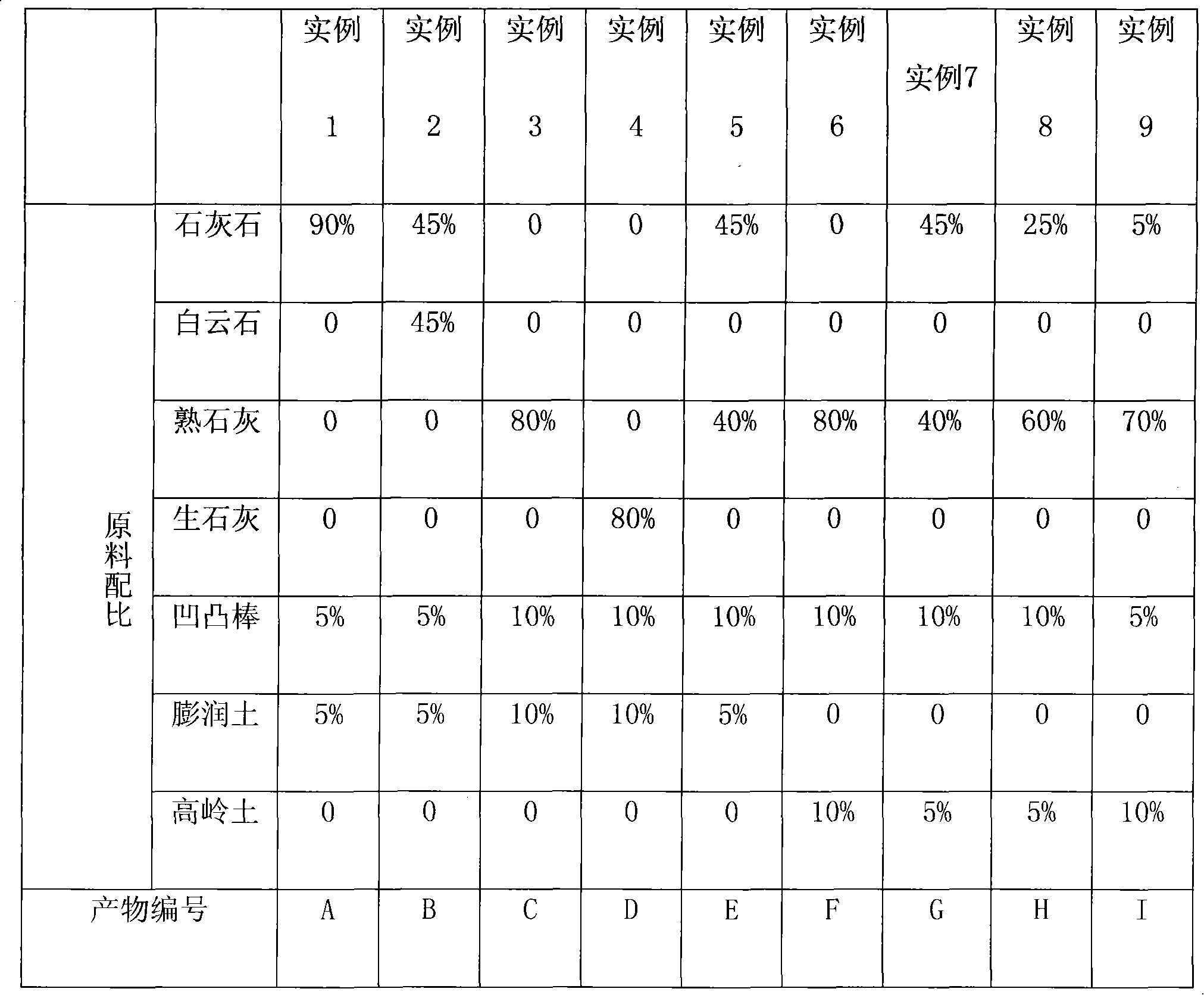

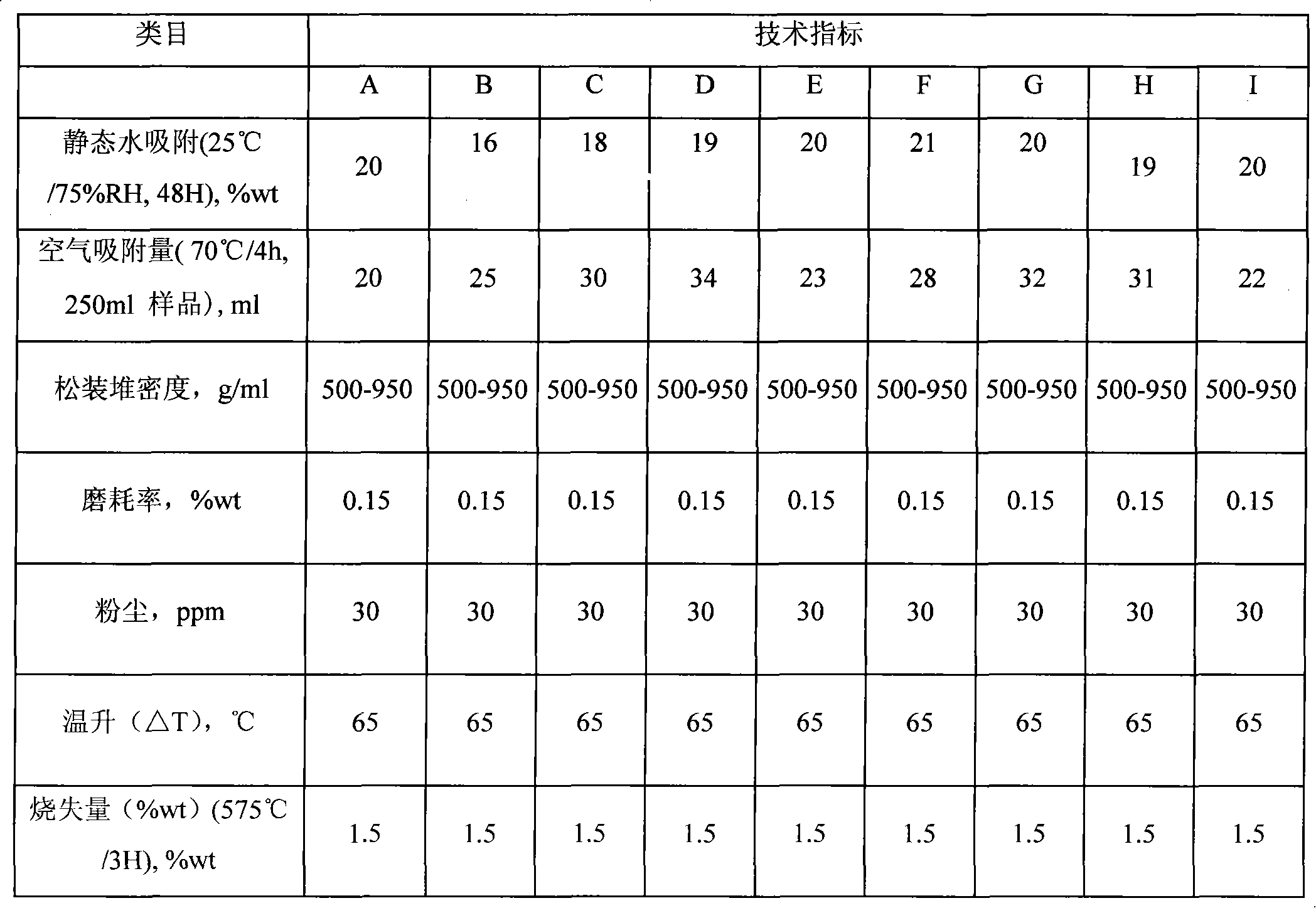

Spherical calcium oxide adsorbent and preparation method thereof

InactiveCN101628221AImprove water absorptionReduce manufacturing costOther chemical processesClay mineralsSorbent

The invention discloses a spherical calcium oxide adsorbent and a preparation method thereof. High-content calcium oxide mineral and clay mineral are used as main raw materials, and the materials are mixed according to the following mixture ratio (in percentage by weight): 50 to 95 percent of the high-content calcium oxide mineral, and 10 to 50 percent of the clay mineral. The preparation method comprises the following steps: mixing the two minerals, molding the mixture in a spherical granulator by using 0 to 1 percent CMC water solution as assistant, screening out spherical granules with certain granularity range by using a two-layer sieve, and further drying, roasting and packing the spherical granules to obtain the spherical calcium oxide adsorbent. The spherical calcium oxide adsorbent comprises the following chemical components: 40 to 90 percent of calcium oxide, 0 to 50 percent of magnesium oxide, 5 to 30 percent of silicon dioxide, 5 to 30 percent of aluminum oxide, and 0 to 30 percent of sodium oxide. The adsorbent has good selective adsorption property and abrasion-resistant property, can be used as a drying agent in the hollow glass industry, can adsorb acid gases such as hydrogen sulfide, hydrogen chloride, sulfur dioxide, chlorine and the like, and can purify industrial waste gases.

Owner:郑州天祥无机材料有限公司 +1

Preparation method of fly ash ceramic membrane

InactiveCN109173748ALow costImprove throughputSemi-permeable membranesSpherical granuleCeramic membrane

The invention discloses a preparation method of a fly ash ceramic membrane. The preparation method comprises: (1) preparation of a support body: uniformly mixing spherical granule fly ash, a binder and a small amount of water and carrying out molding, drying and sintering, and (2) coating of the support body with a coating liquid prepared from the spherical granule fly ash, drying and sintering. The fly ash ceramic membrane realizes a low production cost, has pure water flux obviously higher than that of other inorganic membranes, has obvious anti-pollution properties and can be used for the fields of particle filtration and cold sterilization.

Owner:TANGSHAN KAILUAN CHEM TECH CO LTD

Spherical Ultrafine Particles and Process for Producing the Same

InactiveUS20080107902A1Improve efficiencyLow costMetal-working apparatusCarbon preparation/purificationSpherical granuleSpherical shaped

The method of the present invention can 1) produce spherical and scaly ultrafine particles without pulverization, 2) obtain spherical ultrafine particles having a sharp spherical particle diameter distribution without requiring a sieving step, 3) produce spherical ultrafine particles extremely approximating a true circle and possessing a particle diameter of 100 nm˜50,000 nm allowing selection of a size suitable for the particular purpose of use and 4) produce spherical ultrafine particles on a commercial scale at low cost. There is also provided spherical ultrafine particles produced by the above production process. The spherical ultrafine particles of the present invention are characterized by a form having circularity of 0.9 to 1.0 and a particle diameter of 0.01 μm to 10 μm without pulverization. The spherical ultrafine particles can be produced by the method of the present invention using as a nozzle a base having special through holes and hole density. In this base nozzle, the through holes have a diameter of 0.05 μm˜50 μm, a through hole aspect ratio of 5 to 200 and a hole density of 100 to 7,000 / cm2.

Owner:OPTNICS PRECISION

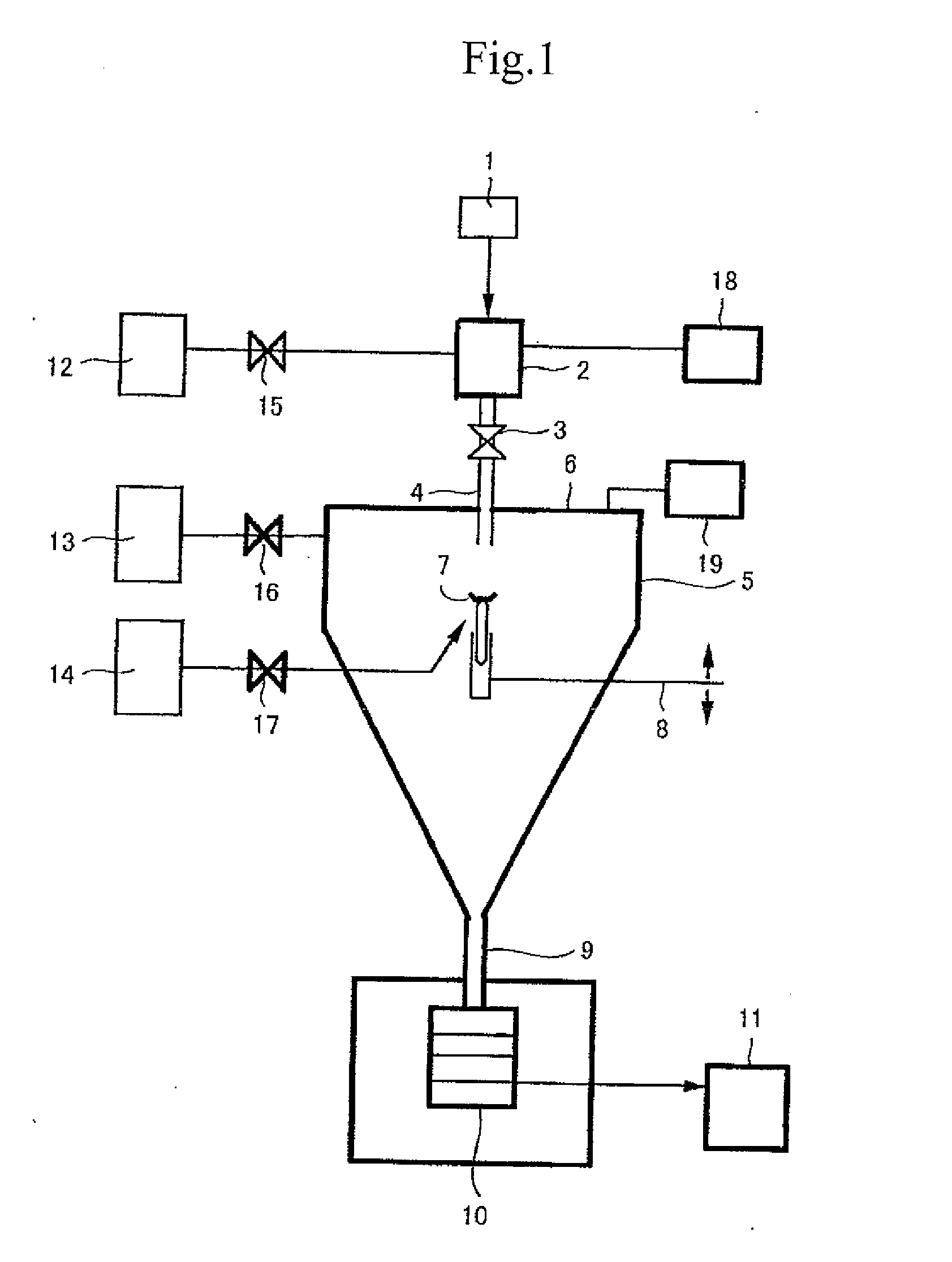

Method for preparing rare earth doped yttrium aluminum garnet transparent ceramics by utilizing spray granulation modified powder

The invention relates to a method for preparing rare earth doped yttrium aluminum garnet transparent ceramics by utilizing spray granulation modified powder. The method is characterized in that an alcohol-water system is adopted as a solvent and comprises the following steps: preparing rare earth doped Re to yttrium aluminum garnet(YAG) powder through a coprecipitation method; modifying the powder by adopting a spray granulation process; carrying out the molding through the mode combining dry pressing and cold isostatic pressing; preparing the rare earth doped Re to YAG transparent ceramics through degreasing, vacuum sintering, annealing treatment, plane grinding and polishing; modifying the powder through a spray granulation process, namely carrying out the ball grinding on the prepared Re to YAG transparent ceramics, a ball grinding medium and surfactants such as a sintering auxiliary, an adhesive, a plasticizer, a dispersant and the like; carrying out the twice granulation on the slurry obtained by the ball grinding through a spray drying method, and preparing powder after being modified into solid spherical granules or similar spherical granules. The modified powder has good dispersity, enhances the fluidity of the powder, is easy to mold, has the granule-stage proportion, greatly enhances the density of the biscuit and is beneficial to sintering at the later stage..

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

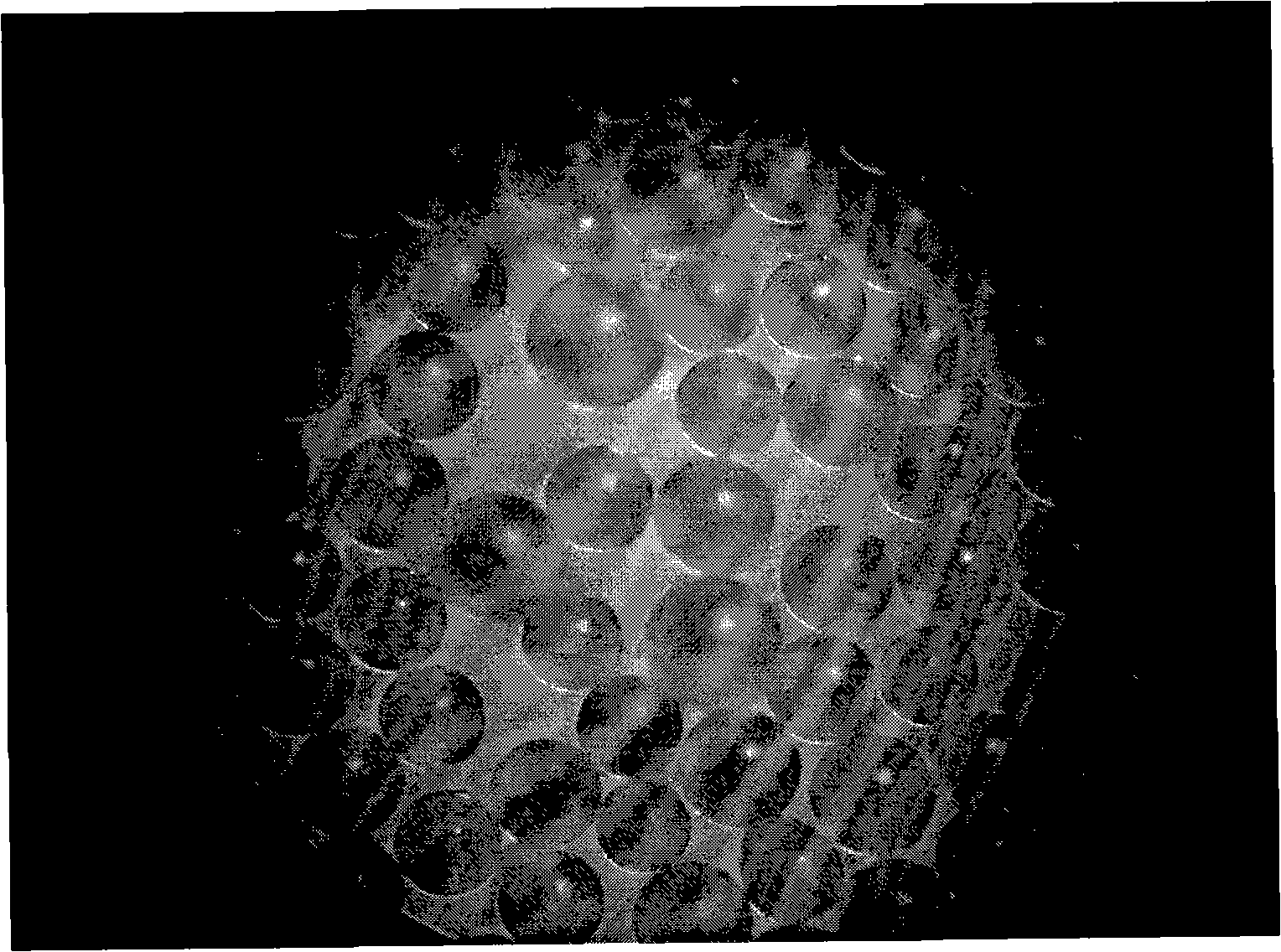

Spherical granule bacteria cellulose and preparing method thereof and special culture medium

InactiveCN101586134AImprove mechanizationHigh degree of automationMicroorganism based processesFermentationPollutionCulture mediums

The invention discloses a spherical granule bacteria cellulose and preparing method thereof and special culture medium. The culture medium provided by the invention comprises carbon, nitrogen source, inorganic salt and growth factor, also comprises coconut water with percentage by volume 0%-80% and carbon source concentration 1-30g / L. The preparing method of spherical bacteria cellulose provided by the invention is to place the production bacterium of bacteria cellulose in the culture medium to oscillate for fermenting or in the fermentation cylinder to ventilate for cultivating. The spherical bacteria cellulose of the invention can be directly applied to the food processing without the cutting operations. The oscillation fermentation needs less nutrition, and is suitable for fermentation cylinder ventilated cultivation, the pollution probability is small, the product yield rate is high, the cellulose product is not traditional film sheets-shaped, and is a bran-new spherical granule-shaped, stabbed spherical or star flower-shaped, the harvesting and the rinsing are easy, especially without extra cutting operations, the spherical granule sizes can be regulated according to the fermentation condition and time.

Owner:HAINAN UNIVERSITY

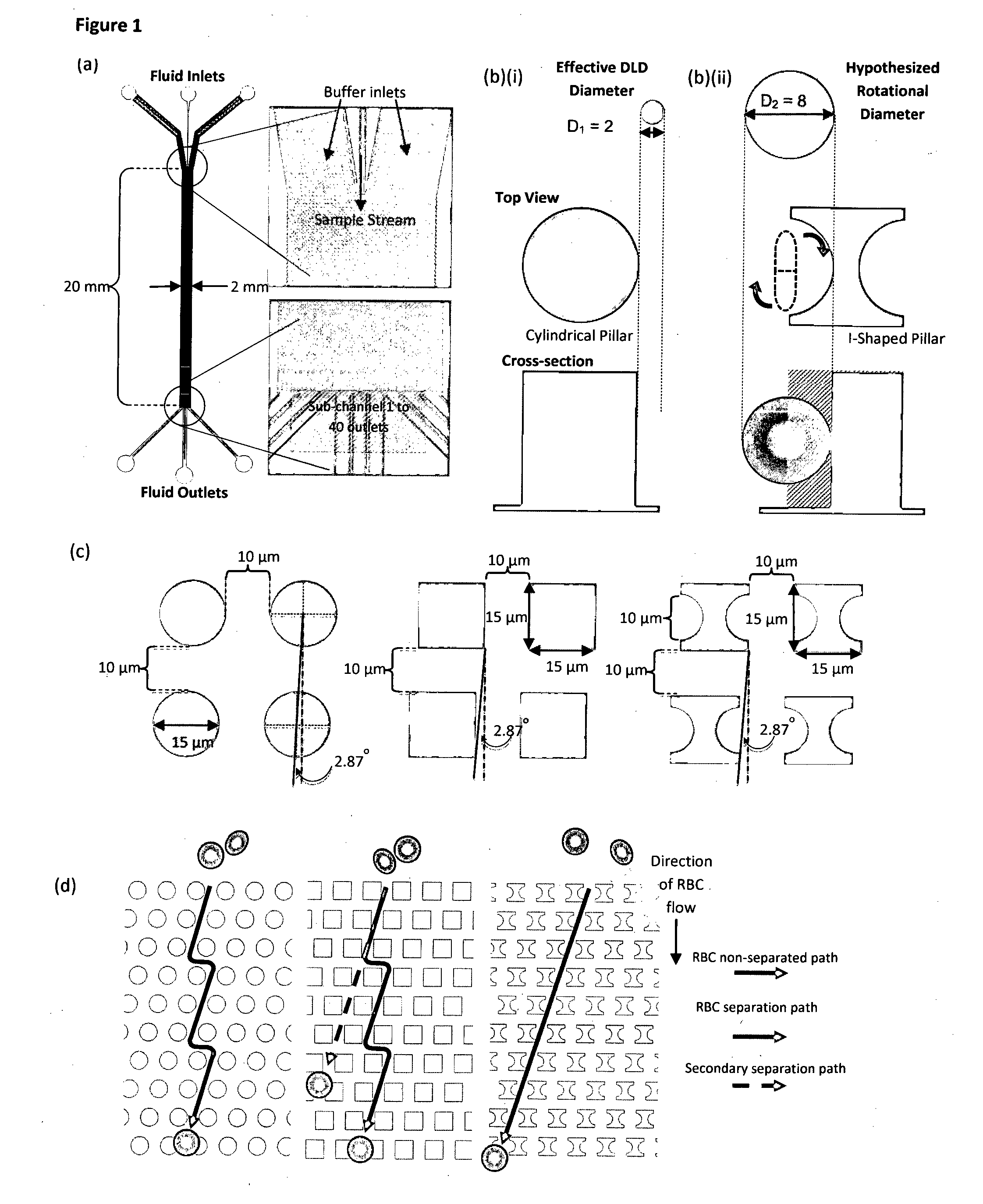

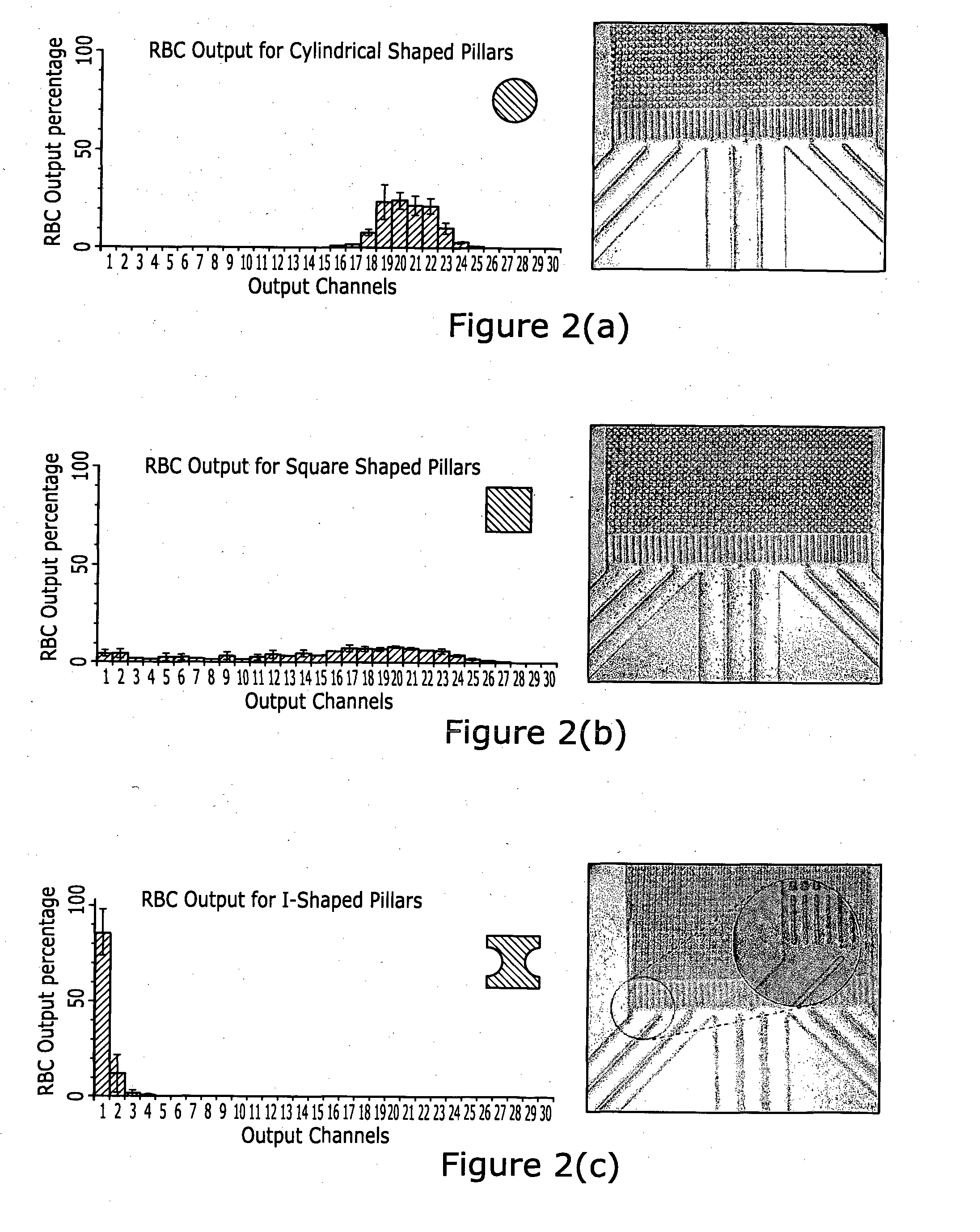

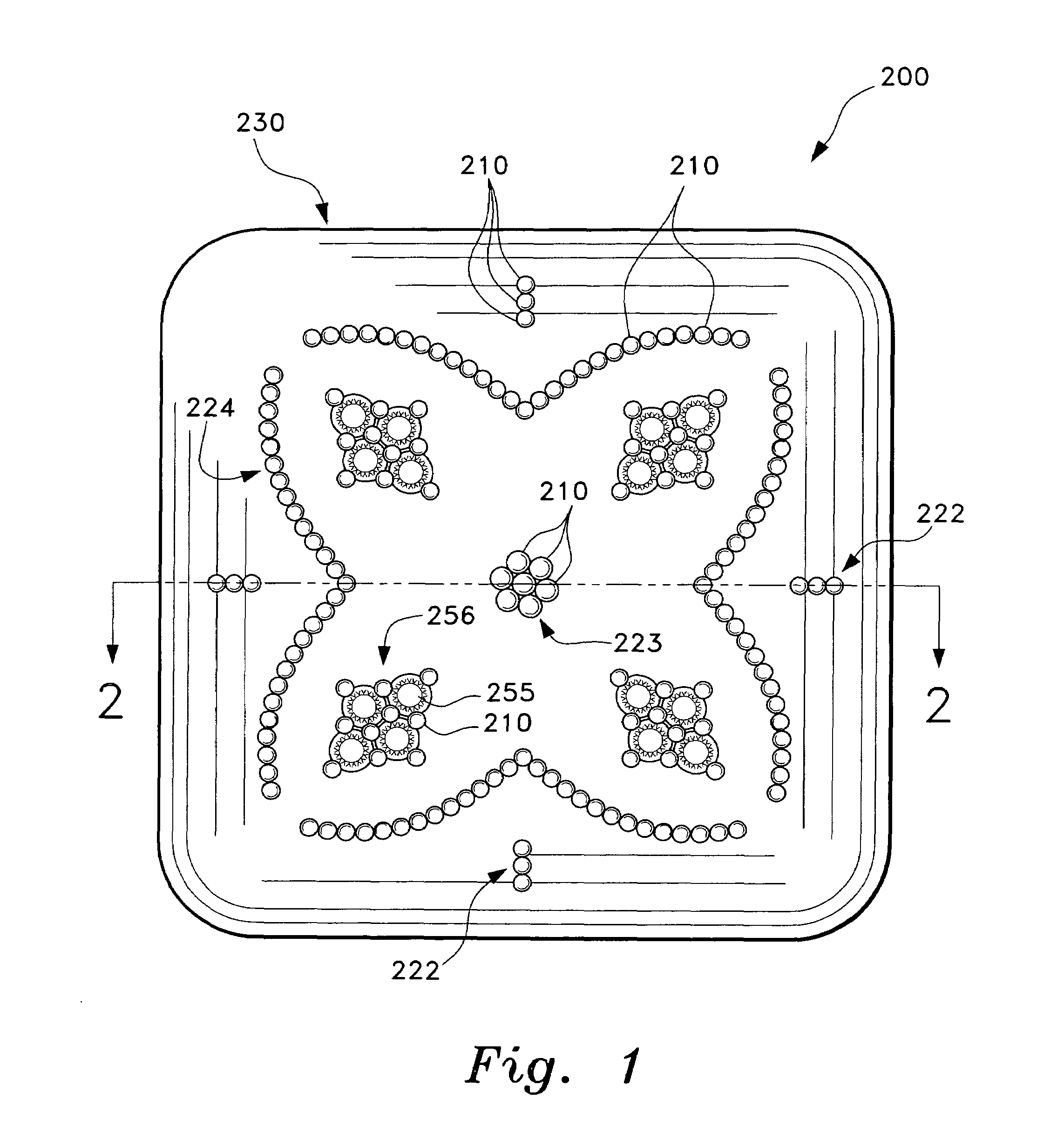

Microdevices for separation of non-spherical particles and applications thereof

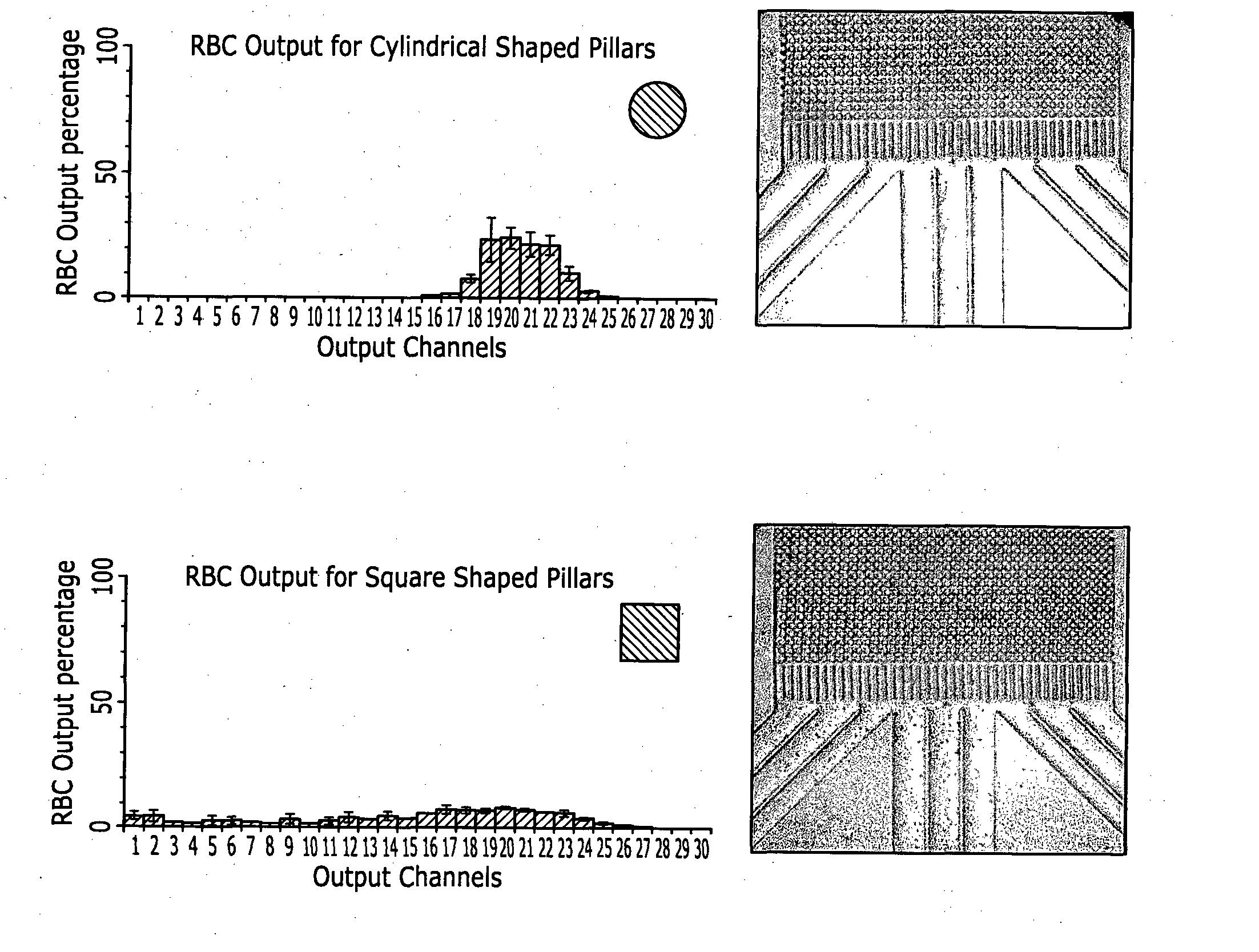

InactiveUS20150362413A1Quick checkFast analysisPreparing sample for investigationLaboratory glasswaresSpherical granuleAbutment

The invention concerns at least one pillar in, or for use in, a microfluidic device wherein said pillar comprises, in cross-section, at least one particle abutment surface and an adjacent space that indents said pillar, or an adjacent groove that indents said pillar, to accommodate said particle; a plurality of such pillars arranged in an array; a method for separating particles in a fluid using said pillar, array or said device; and a diagnostic method involving the separation of particles from a fluid using said pillar, array or said device.

Owner:NAT UNIV OF SINGAPORE

Environmentally-friendly natural multielement rock fertilizer

The invention relates to an environmentally-friendly natural multielement rock fertilizer, comprising the following components in percentage by weight: 45%-55% of quartzdiorite powder with particles being less than or equal to 200 meshes, 22%-25% of phosphoric metamorphic rock powder, 16%-18% of potassium-rich shale powder, 5%-8% of dolomite powder, 2%-4% of salt solution with the mass concentration of NaCl being 1%-3%. A preparation method comprises the following steps of: weighing the quartzdiorite powder, the phosphoric metamorphic rock powder, the potassium-rich shale powder and the dolomite powder, arranging the materials into a stirrer for mixing uniformly, spraying salt solution with the mass concentration of NaCl being 1%-3% into powder bodies mixed uniformly, preparing into spherical granules by a granulator, roasting the granules by a roaster, putting the granules into an electromagnetic field for carrying out magnetizing treatment, and preparing the environmentally-friendlynatural multielement rock fertilizer disclosed by the invention. By adopting the environmentally-friendly natural multielement rock fertilizer, the yield of crops is increased, the quality of the crops is improved, the soil structure is improved, and safe eating of the crops is ensured.

Owner:吴才来

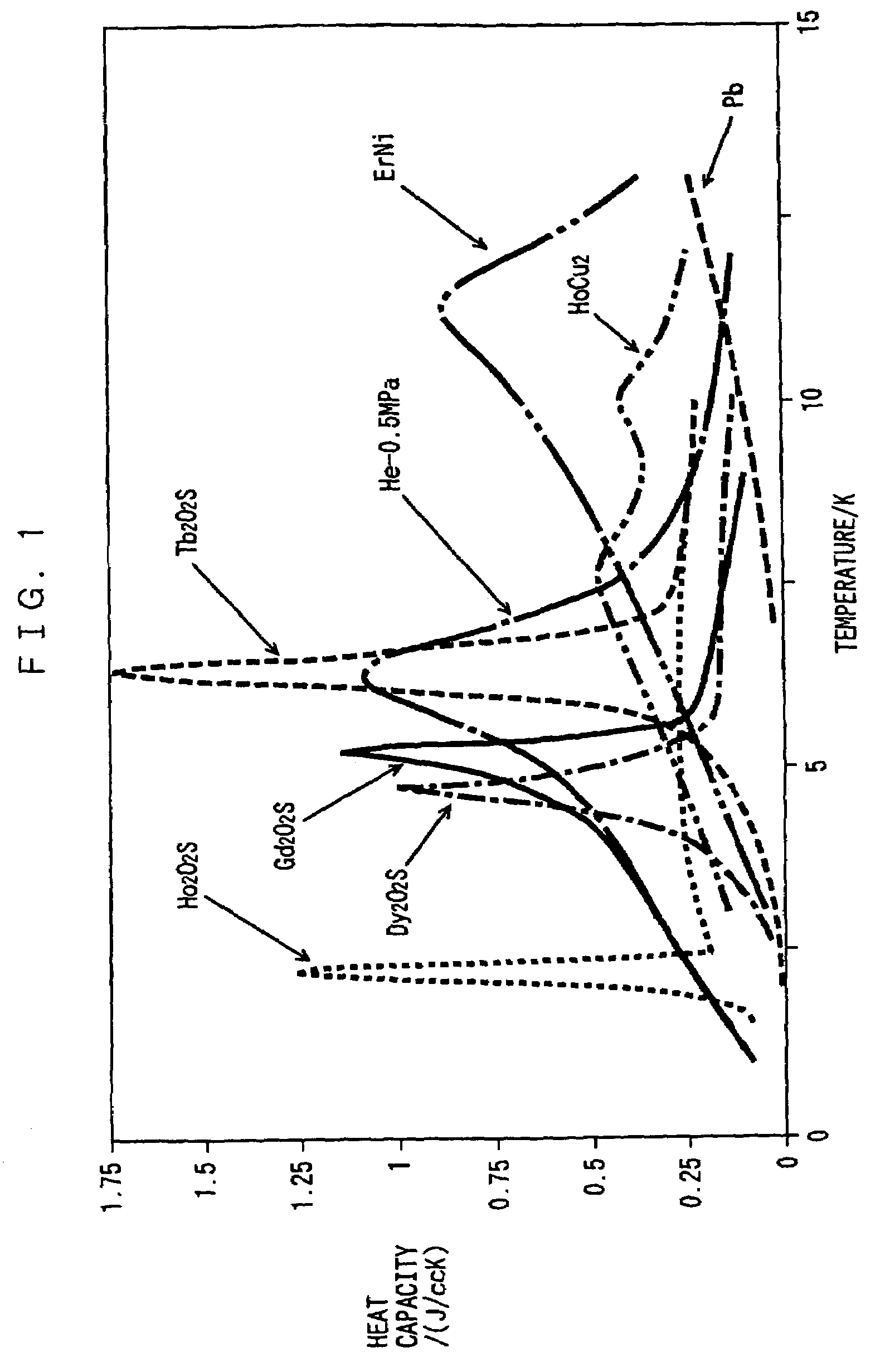

Rare earth metal oxysulfide regenerative material and regenerator

InactiveUS7226543B2Large heat capacityIncreased durabilityRare earth metal sulfidesOther chemical processesMischmetalSpherical granule

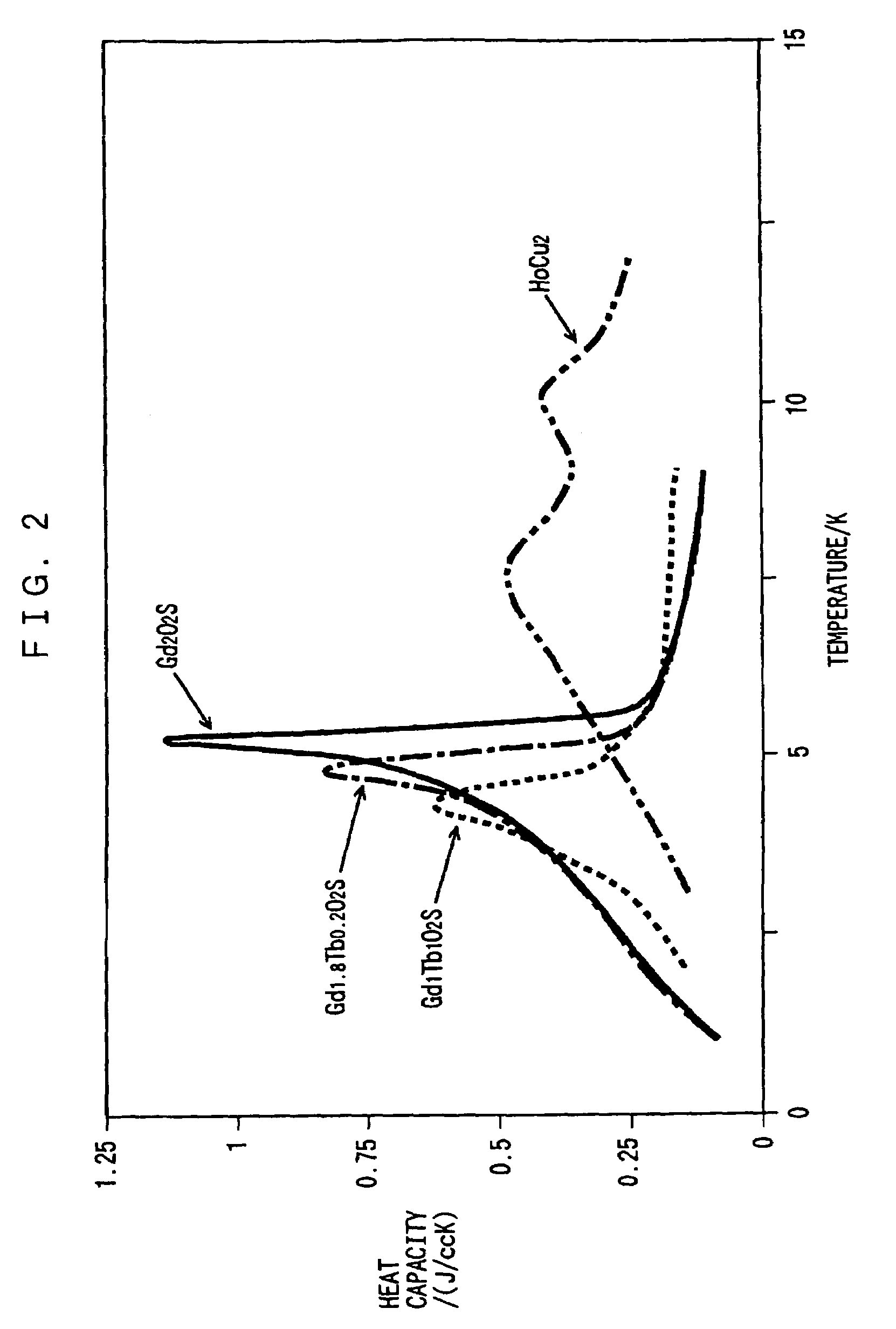

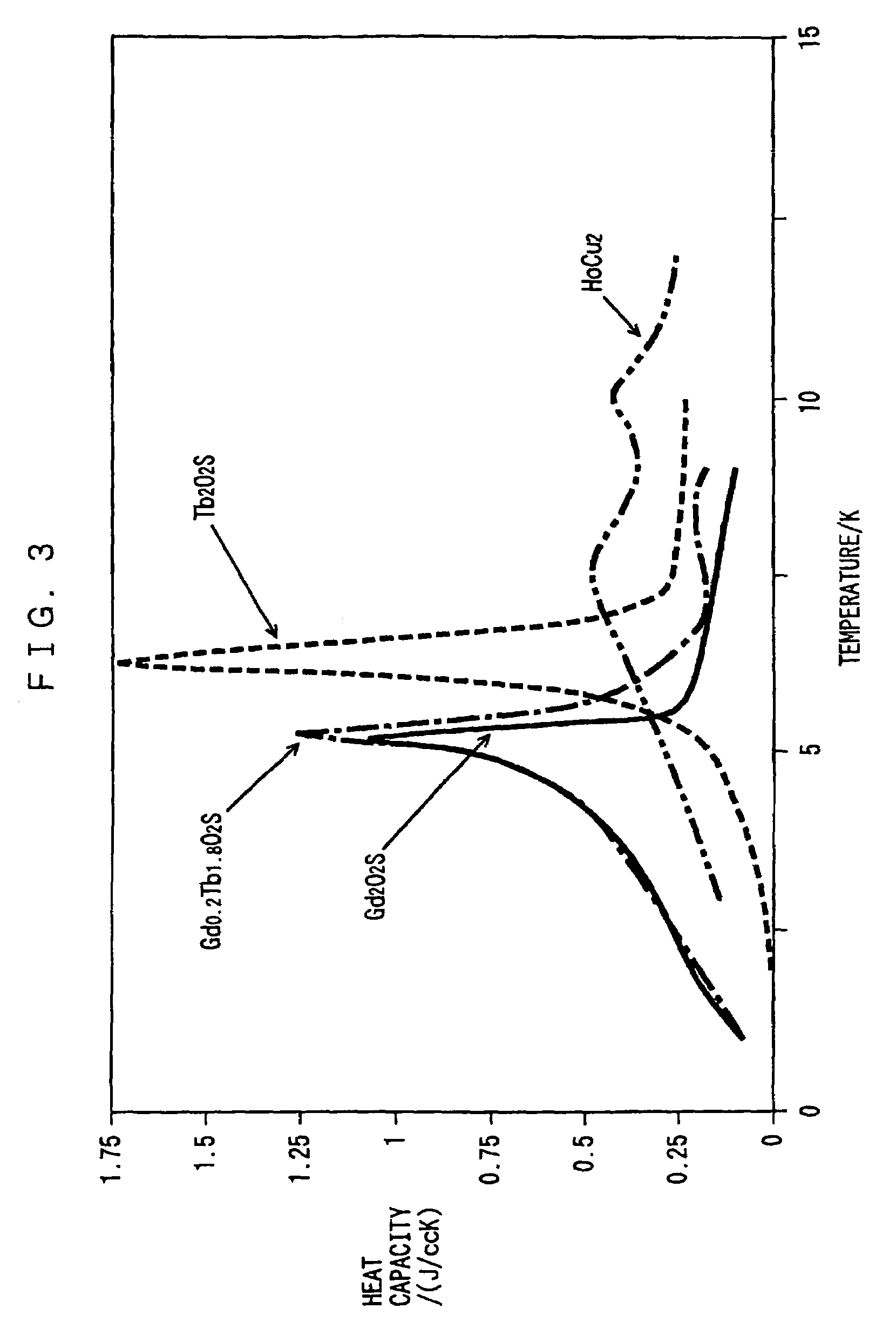

A rare earth metal oxysulfide represented by a general formula R2O2S (R denotes one kind or two or more kinds of rare earth elements to be selected from a group of La, Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu, as wells as Y) is formed into spherical granules. The mean particle size of the granules is 0.05–1 mm and their relative density is 96% or over. The granules are used as a regenerative material at the liquid helium temperature.

Owner:KONOSHIMA CHEMICAL CO LTD

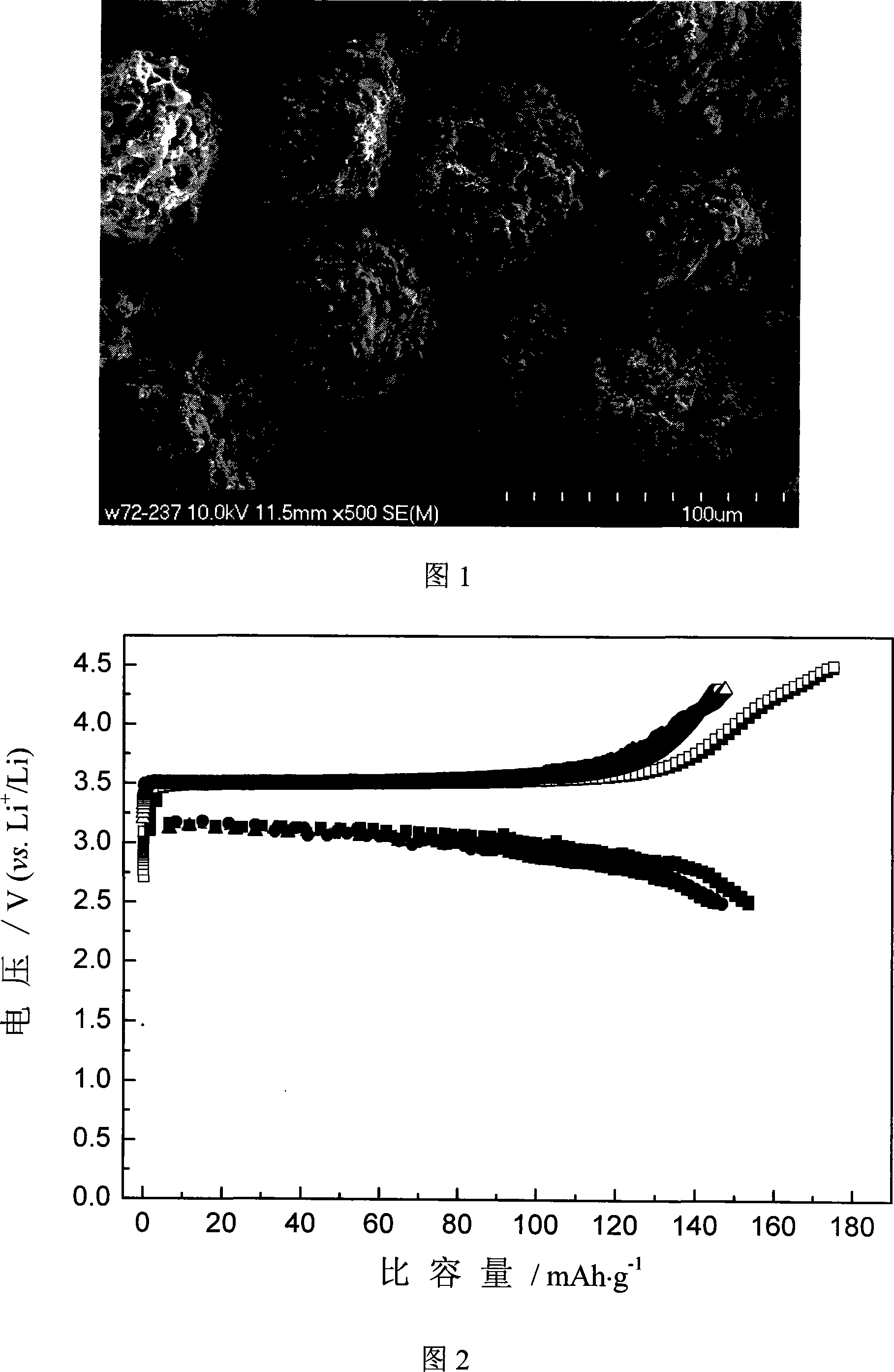

Composite material of round LiFePO4 / C in honeycomb structure, and preparation method

InactiveCN101093888AShorten the solid phase diffusion pathImprove electronic conductivityElectrode manufacturing processesChemical/physical/physico-chemical processesSucrosePhosphate

The invention solves safety issue existed in anode material of lithium ion battery currently. The issue limits lithium ion battery to be applied to electric automobile. The disclosed product is prepared from NH4FePO4.H2O, Li2CO3 and glucose or cane sugar. Mol ratio between NH4FePO4.H2O and Li2CO3 is 2:1. Mass ratio between C in glucose or cane sugar and LiFePO4 is 1:10-30. NH4FePO4.H2O is prepared from ferrous sulfate, phosphoric acid and ammonia according to mol ratio. Using ultrasonic controlled crystallization process prepares precursor, and using solid state sintering at high temperature prepares composite material. Electrolyte with cellular structure (CS) in the invention can penetrate to inside spherical granules of lithium ferrous phosphate with CS so as to shorten path of solid phase diffusion for lithium ions and to be in favor of charge and discharge in large scaling factor. The anode material is suitable to electric automobile. The method is easy of operation.

Owner:HARBIN INST OF TECH

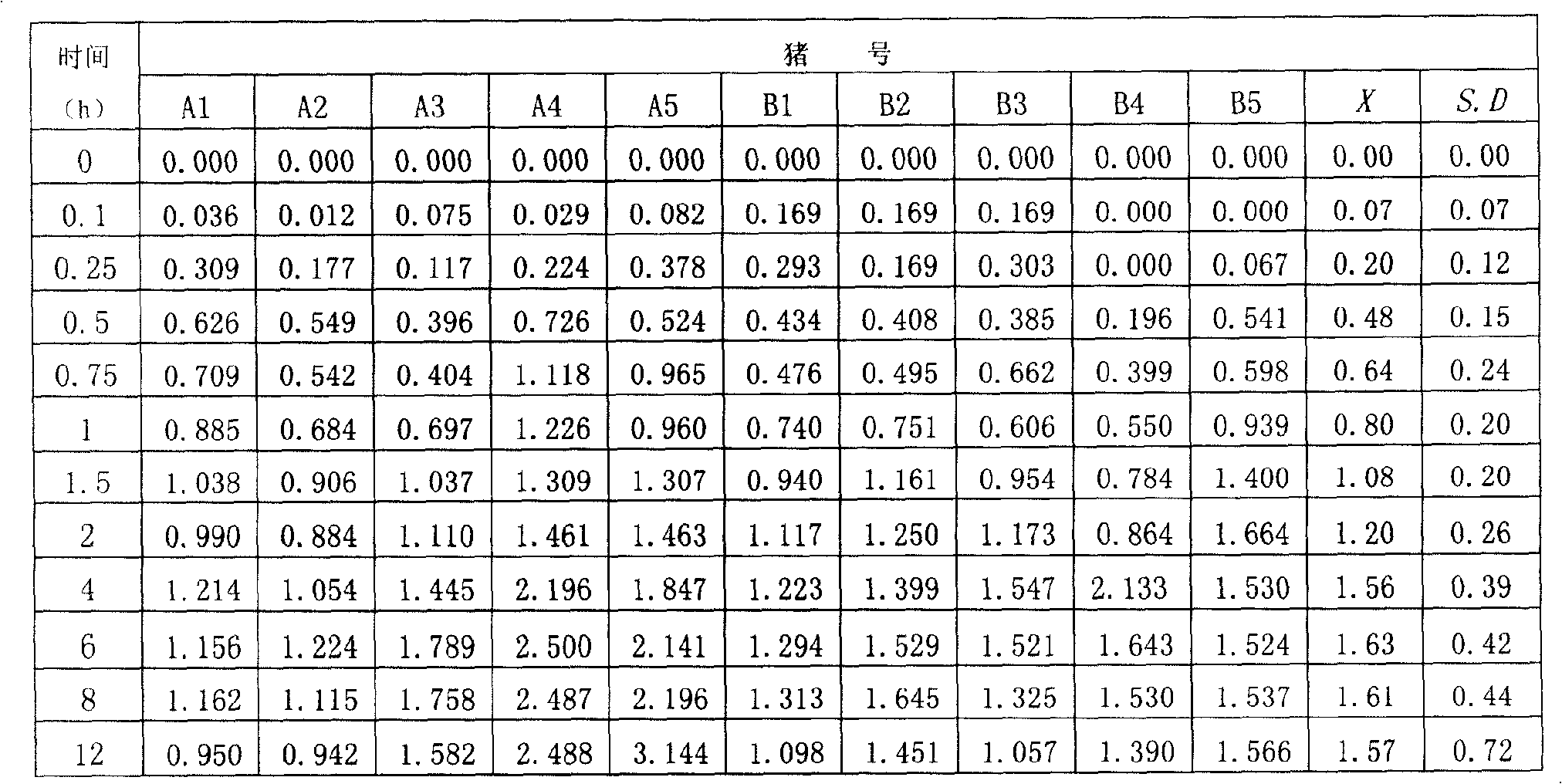

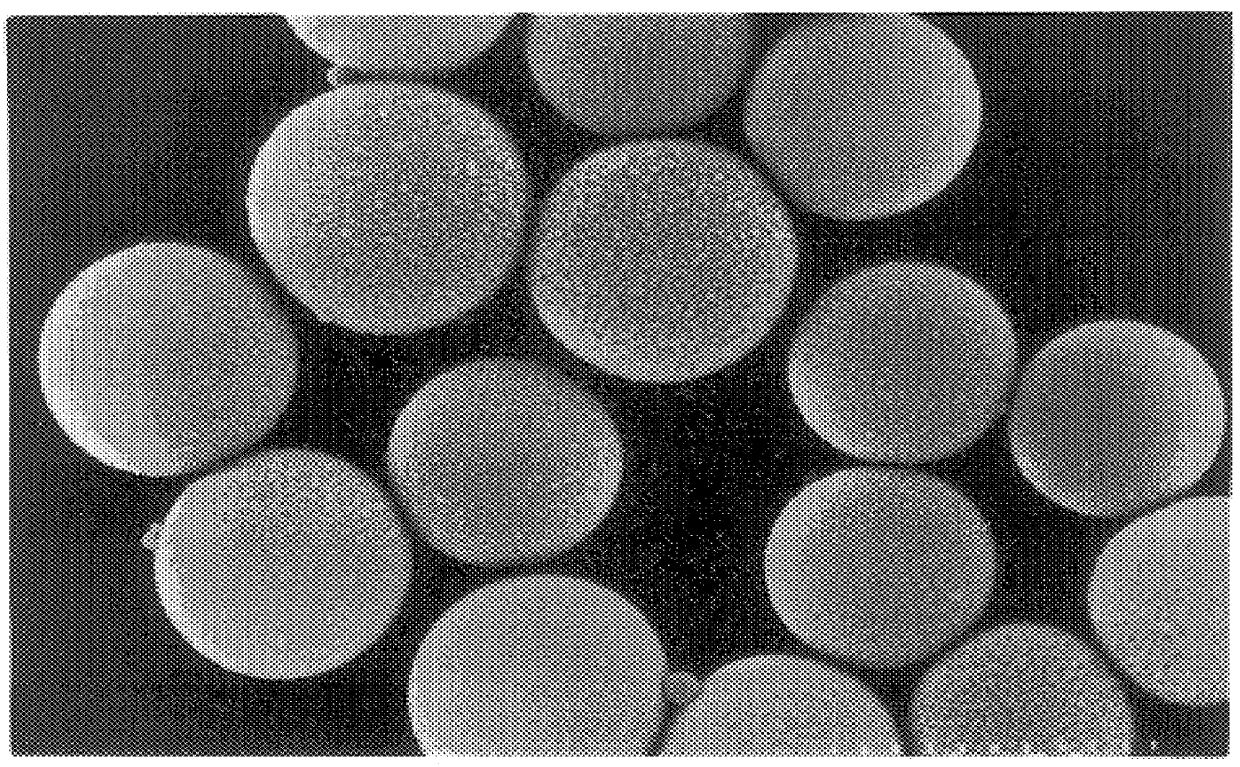

Preparation of Enrofloxacin microcapsule and method of preparing the same

ActiveCN101273980AMask bitternessEasy to prepareAntibacterial agentsOrganic active ingredientsSpherical granuleWax

The invention discloses an enrofloxacin microcapsule preparation and a preparation method thereof. The enrofloxacin microcapsule preparation is prepared by 5 percent to 90 percent of enrofloxacin raw material and 95 to 10 percent of accessories, and the accessory is one of the followings or a mixture mixed by a plurality of the followings: 12 to 18 carbon fatty acid, calcium stearate monoglycerol ester, stearyl alcohol, saturated triglyceride, glycerol monoester, paraffin, animal wax, vegetable wax and fat powder, etc.. The appearance of the enrofloxacin microcapsule preparation is a white or light yellow spherical granule, the dispersion performance is good, the used accessory is safe, and the enrofloxacin microcapsule preparation has no toxicity or side effects for livestock and poultry and has a gradual release in stomach and intestine, thus maintaining the durability of the efficacy.

Owner:GUANGDONG HINAPHARM PHARMA CO LTD

Method for measuring the flow of fluids

InactiveUS6118519ALack of signalVolume/mass flow measurementFull-field flow measurementParticulatesSpherical granule

The disclosed method of measuring the flow of a fluid with a porous particulate ceramic tracer and an optical instrument is characterized in that spherical particles having diameters in the range of 0.5 to 150 mu m are used as the tracer. Inasmuch as the tracer particles for flow measurement are spherical, the sectional area of scattered light to be detected by an optical sensor means is constant regardless of the orientation of particles. Furthermore, spherical particles have no surface irregularities that might cause concatenation so that individual particles are not agglomerated in tracking a fluid flow, thus contributing to improved measurement accuracy.

Owner:OSAKA GAS CO LTD

Nanometer pore light-weight corundum refractory aggregate and preparation method thereof

The invention relates to a nanometer pore light-weight corundum refractory aggregate and a preparation method thereof. The technical scheme of the preparation method is that 1 to 15 mass parts of water-soluble salts are dissolved into 15 to 25 mass parts of water to obtain a mixed solution; then, 85 to 99 mass parts of industrial aluminum oxide micro powder is put into a rotating pelletizer; under the rotation condition, the mixed solution is uniformly sprayed onto the industrial aluminum micro powder; the rotating pelletizer rotates until the industrial aluminum oxide micro powder totally forms spherical particles; then, the spherical particles are dried for 12 to 36 hours under the condition of 110 to 200 DEG C; the heat insulation is performed for 1 to 8 hours under the conditions of 1750 to 1950 DEG C, and thus the nanometer pore light-weight corundum refractory aggregate is obtained. The preparation method of the nanometer pore light-weight corundum refractory aggregate has the advantages that the cost is low; the process is simple; the prepared nanometer pore light-weight corundum refractory aggregate has the characteristics that the apparent porosity is low; a great number of nanoscale intracrystalline closed opening air pores are contained; the heat conductivity is lower; the molten slag erosion resistant capability is high.

Owner:WUHAN UNIV OF SCI & TECH +1

Multi-dimensional composite energy active material and preparation method thereof

ActiveCN101891264AHigh energyHigh energy activityWater/sewage treatment by substance additionWater/sewage treatment by sorptionSpherical granuleNanoparticle

The invention discloses a multi-dimensional composite energy active material and a preparation method thereof. The material is composed of Muyu stone, tourmaline, medical stone, germanite, parmesan rock, igneous rock and ceramic clay. The preparation method of the multi-dimensional composite energy active material comprises the following steps: firstly, immersing parmesan rock powders with edible ethylic acid and then carrying out calcination, wherein the parmesan rock powders are crushed into nanometer grains; then carrying out high-speed stir and even mixing on the immersed parmesan rock powders and the balance of the nanometer grains of components and forming ball grains; finally, sintering the formed ball grains for 2-4 hours at the temperature of 800-1200 DEG C and carrying out disinfection by ultraviolet light and sterile packaging to obtain the material. The multi-dimensional composite energy active material in the invention can be applied to various water purification machines, water-quality filters and health cups. The drinking water treated by the material in the invention is no pollution, is rich in multi-mineral substances, has pH value in the range of 7.2-8.5, is microcluster water, has negative potential stability and qualifies with standards of high-quality drinking water.

Owner:上海沃泉科技有限公司

Brucite granular fertilizer and its preparation method

InactiveCN1785914AReduce pollutionNo wasteMagnesium fertilisersFertiliser formsSpherical granuleWater soluble

The present invention relates to a brucite granule fertilizer and its preparation method. Said preparation method includes the following steps: mixing brucite, natural magnesium sulfate and light calcined magnesium, using water or 5% (mass) of citric acid solution as binding agent, mixing all the materials, granulating drying and packaging so as to obtain spherical granules whose diameter is 2-4mm, in which water content is less than or equal to 1%, hardness is 1.5-4kg / sq.cm, disintegration rate is greater than or equal to 90%, citric-soluble MgO mass content is 53-62% and water-soluble MgO mass content is 3-5%.

Owner:大连爱思凯矿产有限公司

Powdery potassium chloride granulation method taking synthesised urea resin as binder

ActiveCN104744164ASimple processReduce manufacturing costFertilizer mixturesPotassiumMoisture absorption

The invention provides a powdery potassium chloride granulation method taking synthesised urea resin as a binder. The powdery potassium chloride granulation method comprises the following steps: by taking the reaction product, namely urea resin of urea and formaldehyde solution as a powdery potassium chloride binder, slowly and uniformly spraying the urea resin on the mixture of powdery potassium chloride and auxiliary substances to enable the mixture to become spherical fertilizer granules, discharging and then sieving the fertilizer granules with sizes of 2-5mm, feeding the sieved fertilizer granules into a drying system and drying, so as to obtain spherical granules with smooth surfaces and a high hardness. The urea resin binder suspension used in the powdery potassium chloride granulation method provided by the invention is high in binding property and capable of providing a part of controlled-release nitrogen; the spherical granular potassium chloride produced by the synthesised binder is high in strength, smooth in surface, good in moisture absorption resistance, low in production cost, and good in storage, transport, sowing and fertilizing performances; the powdery potassium chloride granulation method is especially suitable for preparation for film-coated controlled-release potassium chloride.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

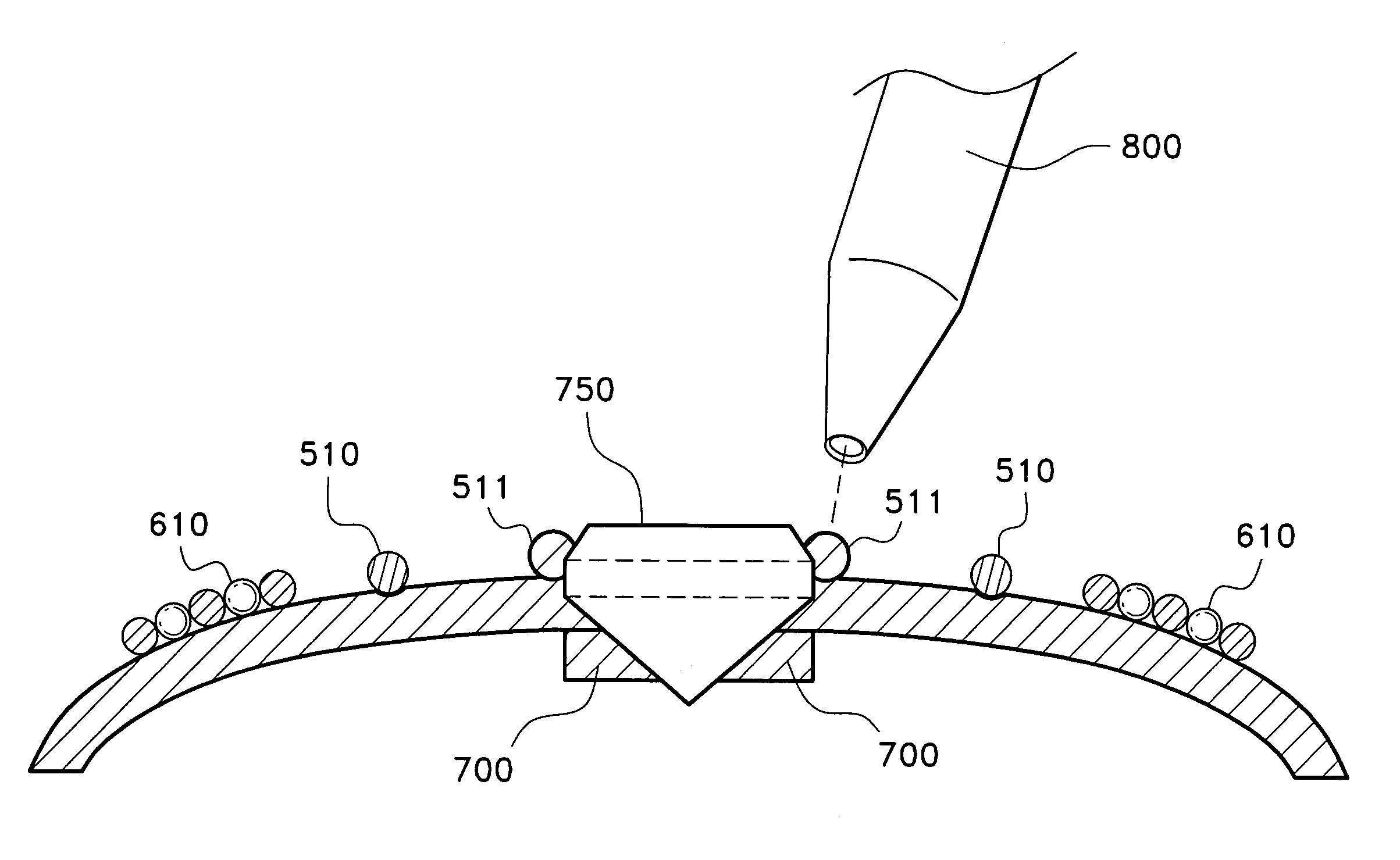

Method for metal ornamentation

InactiveUS7419083B1Placed in the indentations easily and preciselyImprove bindingLamination ancillary operationsDecorative surface effectsSpherical granuleAdhesive

A method for metal ornamentation, particularly for making granulated metal ornaments, is used to arrange single and single line granulated arrangements or patterns and to set gemstones within a workpiece. The method places pre-formed spherical granules in seats defined on a surface of the workpiece. The seats permit the granules to stay in position on the workpiece and allow adhesive to cover more contact surface area between the granules and the workpiece. Since the amount of fusion will increase due to the increased contact area, the granules are strong enough to be used to set gemstones. In addition, this method facilitates using small round stones in lieu of metal granules to form unique granulated patterns.

Owner:CHENG ANGELA

Nanometer metal/carbon composite material as well as preparation method and application thereof

The invention discloses a nanometer metal / carbon composite material as well as a preparation method and application thereof. According to the nanometer composite material, amorphous carbon spheres serve as a skeleton, metal elements are embedded in a carbon layer uniformly, and spherical granules with the granularity of 100 to 500 nm are formed. The amorphous carbon sphere has a loose and porous structure, the specific surface area is between 300 m<2> / g and 1000 m<2> / g, and the grain diameter of the quantum metal elements is between 3 nm and 10 nm. The porous structures in the amorphous carbonspheres provide a large amount of active sites and are favorable for performing oxygen adsorption and precipitation kinetics reaction; meanwhile, the metal elements embedded in the carbon layer can improve the catalytic activity of carbon material oxygen precipitation. The nanometer composite material shows high catalytic activity when serving as a catalyst, has the characteristics of low cost and excellent catalytic property relative to the existing method for preparing the catalyst, and is suitable for large-scale marketization application.

Owner:CENT SOUTH UNIV

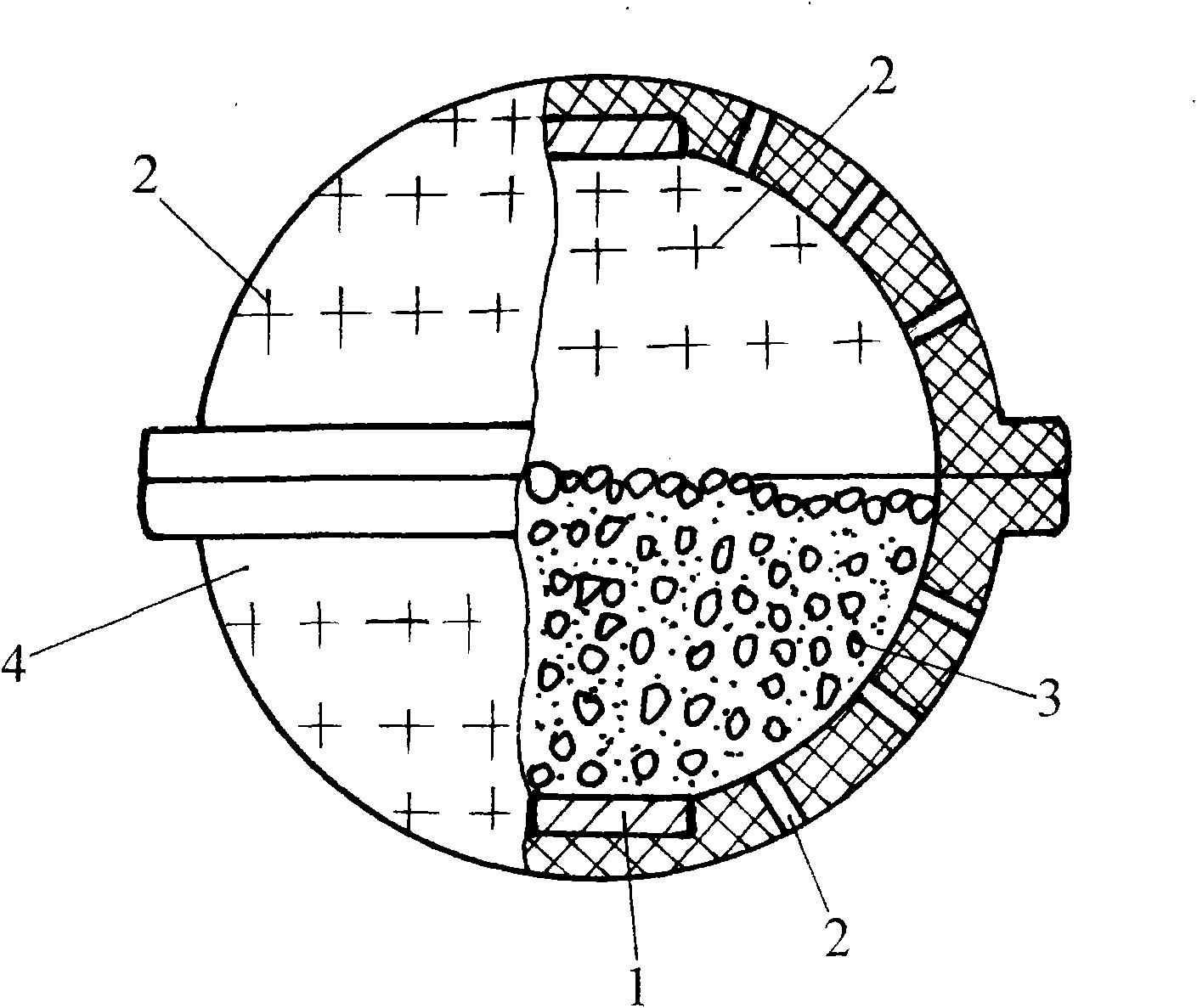

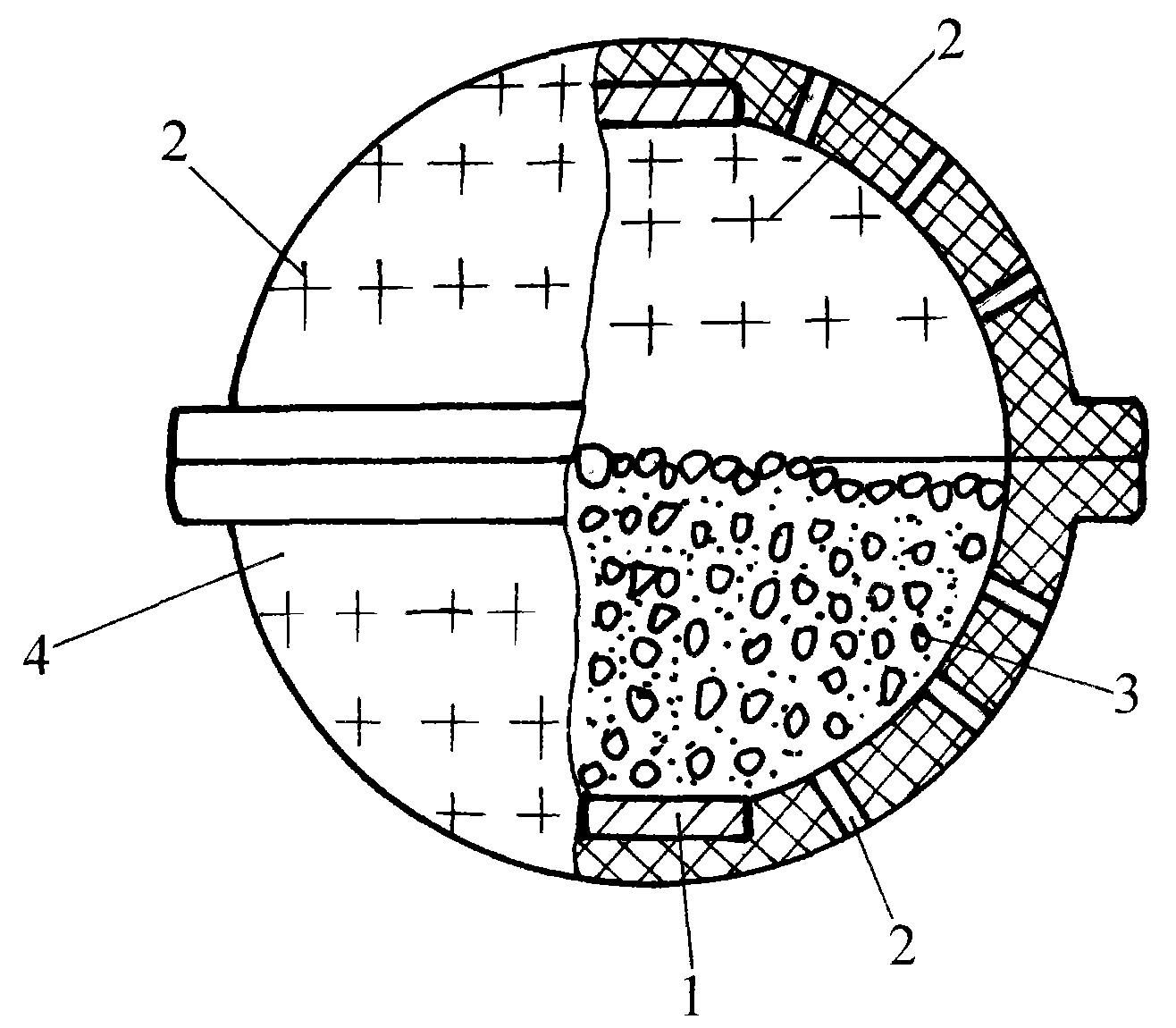

Mixture for fabrication of fireproof high-strength spherical granules and the method of their manufacture

InactiveUS20060058173A1Physical/chemical process catalystsAluminium silicatesSpherical granuleKaolin clay

The inventive method for producing refractory high-strength spherical granules consists in separately presintering kaolin and bauxite in a rotational furnace, jointly sintering said components in order to produce a charging material, granulating, drying and screening said charging material, sintering said granules in the rotational furnace and screening the sintered granules. Said sintered kaoline is produced by sintering at a temperature ranging from 1400 to 1500 DEG C. so far as a water absorption of 5% is attained for kaoline containing 40-45 mass % and a free quartz in a quantity equal to or greater than 60 mass %. The Al2O3:SiO2 ratio in the charging material is equal to 1:1 at the following charging material component ratio: 36-67 mass % sintered kaolin and the rest being sintered bauxite.

Owner:OTKRYTOE AKTSIONERNOE OBSHCHESTVO BOROVICHSKIJ KOMB OGNEUPOROV

Manufacture of strong, lightweight carrier granules

Method for manufacturing carrier granules. The method forms a mixture comprising fibers, mineral filler, and binder. The mixture contains 32-48 weight-% wood fibers having a bulk density of less than 20 pounds per cubic foot, at least 35 weight-% of which fibers are retained on a 50-Mesh U.S. Sieve Series screen. The fibers have a moisture content of less than 15 weight-%. The mixture also contains 52-65 weight-% mineral filler having a moisture content of less than 12 weight-%. In addition, the mixture contains 3-7 weight-% binder. The mixture is agglomerated by conditioning and agglomerating it in a pin mixer to form small particles followed by agglomerating it in a disc or pan pelletizer to form substantially spherical granules. The method then dries the granules to a moisture content of less than about 5 weight-%, and screens the granules to select granules that pass through a 10-Mesh U.S. Pat. No. Sieve Series screen but are retained on a 40-Mesh U.S. Pat. No. Sieve Series screen. The carrier granules have a bulk density of less than 40 pounds per cubic foot and a Resistance to Attrition of at least 95%.

Owner:THE ANDERSONS

Washing ball with bleaching and sterilizing functions

InactiveCN101818108ATo achieve the purpose of decontaminationConserve waterDetergent materialsInorganic non-surface-active detergent compositionsSpherical granuleHazardous substance

The invention discloses a washing ball with bleaching and sterilizing functions. The washing ball is prepared by preparing spherical granules by mixing 1 to 5 parts of ceramic powder, 2 to 3 parts of negative ion powder, 2 to 3 parts of far infrared powder, 3 to 5 parts of medical stone powder, 2 to 5 parts of antibacterial powder, 1 to 4 parts of Tourmaline and 1 to 6 parts of clay powder, preparing a slow-release granular washing aggregate by calcining the spherical granules at the high temperature, and filling the aggregate in the washing ball. The washing ball is formed by butting two hemispherical shells, the circumference of the hemispherical shell is provided with regularly arranged osmosis holes, and a strong magnet of no lower than 1,800 gausses is arranged inside the dome end parts of the hemispherical shells respectively. The slow-release granular aggregate is prepared from natural raw materials and has no toxic or harmful substance components, so the washing ball has the advantages of no pollution and convenient use. In addition, the washing ball has incomparable sterilizing function compared with other washing articles.

Owner:苏少娟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com