Production of substantially spherical metal powers

A metal powder and metal technology, which is applied in the field of preparation of basically spherical metal powder, can solve the problems of high cost of titanium parts and limited application of titanium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

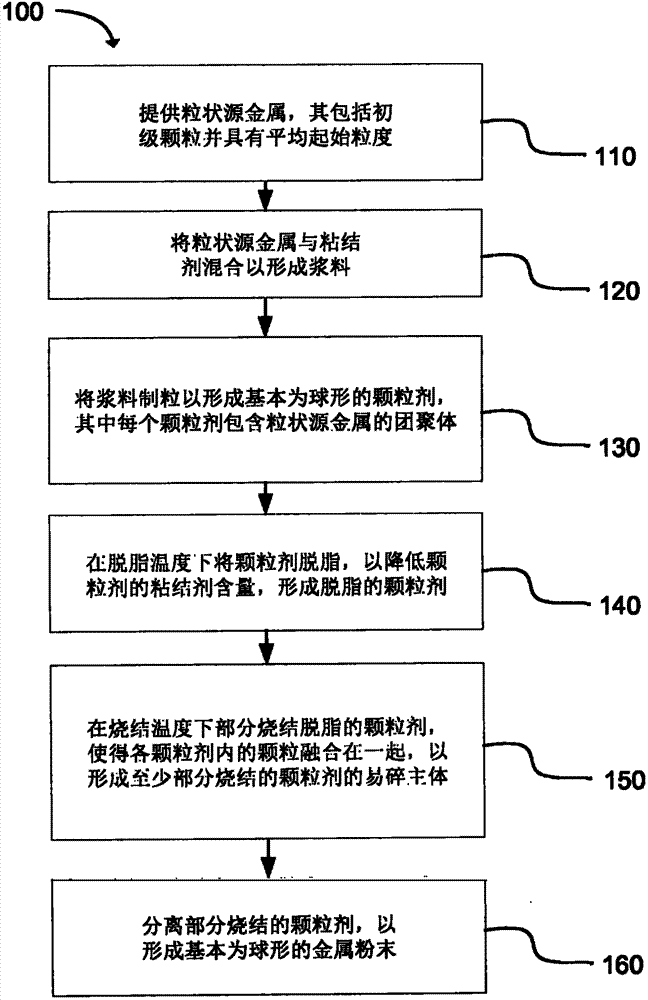

Method used

Image

Examples

example 1

[0082] Example 1: Preparation of TiH with UGS 2

[0083] The preparation of TiO is given below 2 powder, and use magnesium to reduce TiO 2 to generate TiH 2 instance of . The ready-to-use UGS with an average particle size greater than 200 μm was ball milled to expose the encapsulated Si and facilitate re-leaching. Ground UGS can easily be several microns in size, eg 1 to 5 microns. Next, 100 g of ground UGS was pre-leached at 100° C. for 2 hours with an alkaline solution containing 200 g / L NaOH, and the volume-to-mass ratio was controlled to be 2:1. After pre-leaching, the slurry was subjected to solid / liquid separation and about 100 grams of residual solids were dried to prepare it for firing treatment. Then, 100 grams of pre-leach residue was mixed with 150 grams of commercial NaOH solid using a tumbler for 30 minutes and the mixture was charged to an Inconel reactor. The reactor was placed in a top loading box furnace. Heat the furnace and track the temperature ...

example 2

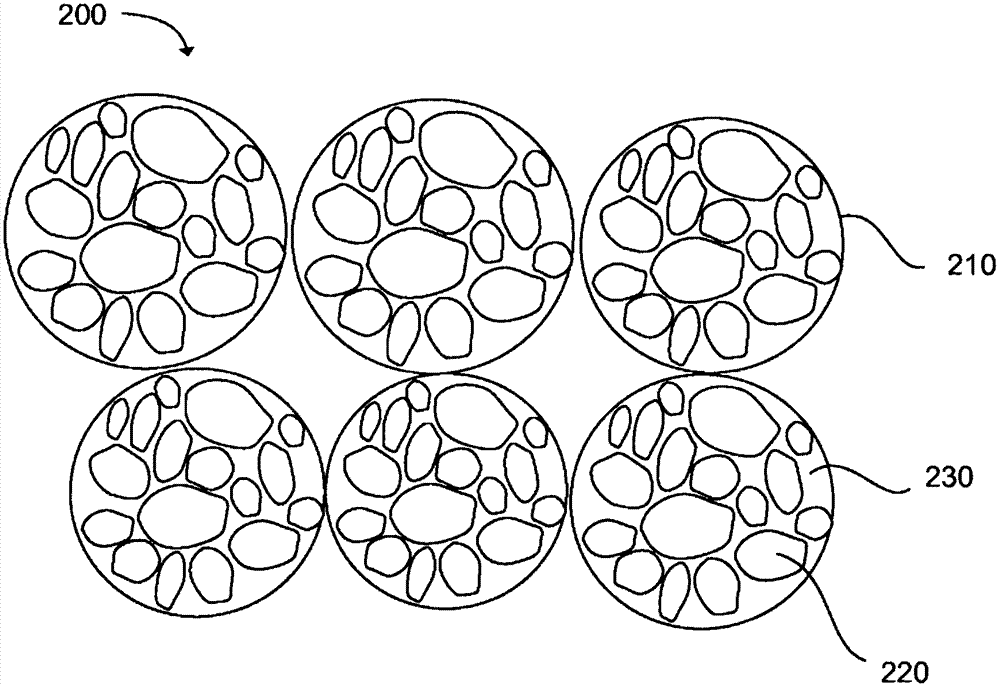

[0085] Example 2: Preparation of spray-dried TiH 2 Granules

[0086] Fine TiH 2 Granules are prepared by mixing the granules with a binder and solvent, and spray drying the mixture to form spherical granules. Figure 7 is spherical TiH 2 SEM photographs of the granules. The granules have a size of about 40 microns to about 100 microns.

example 3

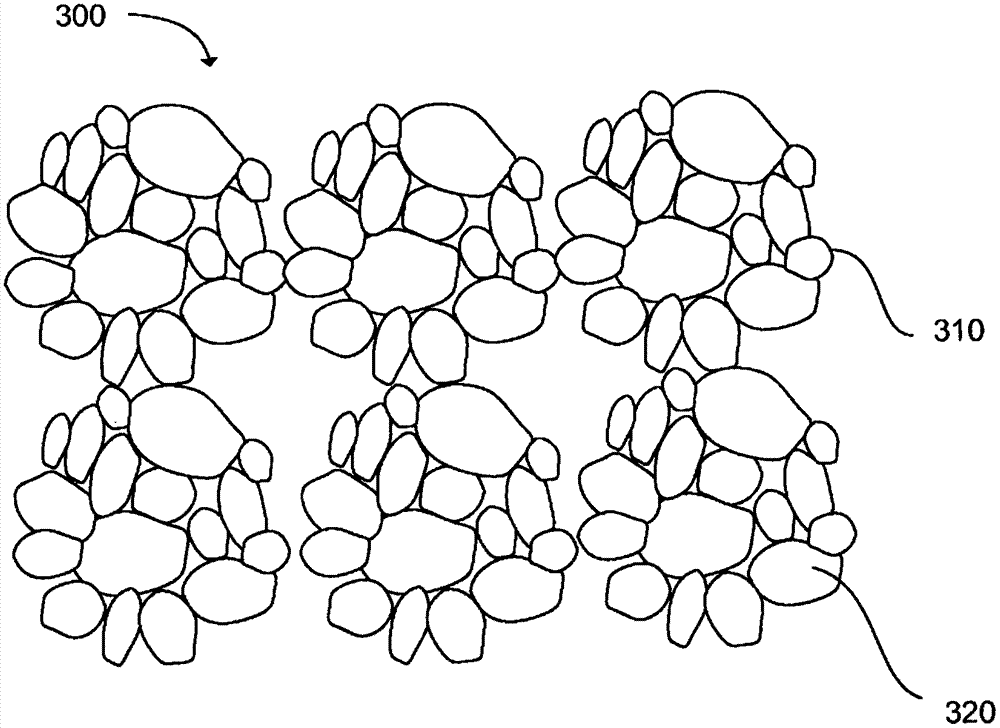

[0087] Example 3: Preparation of Partially Sintered Granules

[0088] Fine TiH 2 Granules are prepared by mixing the granules with a binder and solvent, and spray drying the mixture to form spherical granules. The granules were degreased with flowing argon in a tube furnace at a temperature range of 250-400°C for 9 hours. After the debinding phase, the temperature was raised to 700 °C and held for 30 min for dehydrogenation and partial sintering in the same tube furnace. Figure 8 is the SEM picture of partially sintered granules.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com