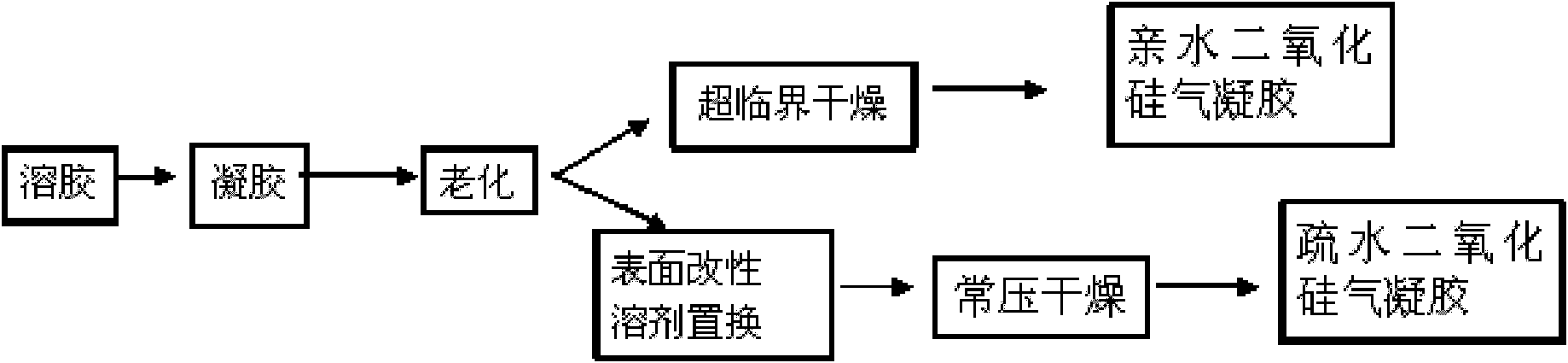

Preparation method of nanometer aerogel heat-insulation coating

A technology of nano-airgel and thermal insulation coatings, applied in the direction of polyester coatings, epoxy resin coatings, polyurea/polyurethane coatings, etc., can solve the problems of poor thermal insulation effect and ineffective inhibition of heat conduction, etc., to reduce the contact area, Effect of reducing heat transfer and increasing heat conduction path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of a kind of nano-airgel thermal insulation coating described in embodiment 1 of the present invention comprises the following steps:

[0028] 1) Mix and hydrolyze tetraethyl orthosilicate, 1% hydrochloric acid solution, absolute ethanol and water for 12 hours, and the weight-number ratio of the above-mentioned components is 1:0.1:6:0.5;

[0029] 2) After the step 1) is hydrolyzed, add 1% ammonia solution in mass concentration, the ratio of the liquid after hydrolysis to the ammonia solution by weight is 1:0.1-0.2, and react for 18-48 hours to obtain silica gel ;

[0030] 3) Place the silica gel produced in step 2) in absolute ethanol for aging treatment for 12-36 hours;

[0031] 4) Put the silica gel after the aging treatment in step 3) into a mixture of trimethylchlorosilane and n-pentane for modification, the ratio of the mixture is 1:5-50, every 24-48 hours Replace the mixture once, repeat this process 3-5 times;

[0032] 5) Dry the silica ...

Embodiment 2

[0035] The preparation method of a kind of nano-airgel thermal insulation coating described in embodiment 2 of the present invention, comprises the following steps:

[0036] 1) Mix and hydrolyze tetraethyl orthosilicate, 1% hydrochloric acid solution, absolute ethanol and water for 12 hours, and the weight-number ratio of the above-mentioned components is 1:0.1:6:0.5;

[0037] 2) After step 1) is hydrolyzed, add 1% ammonia solution in mass concentration, the ratio of parts by weight of the liquid after hydrolysis to the ammonia solution is 1:0.1-0.2, and silica gel is obtained after 18-48 hours;

[0038] 3) Put the silica gel produced in step 2) in absolute ethanol for aging treatment for 12-36 hours;

[0039] 4) Put the silica gel after the aging treatment in step 3) into a mixture of trimethylchlorosilane and n-hexane for modification, the weight ratio of the mixture is 1:5-100, every 24-48 Replace the mixture every hour, repeat this process 3-5 times;

[0040] 5) Drying t...

Embodiment 3

[0043] A kind of preparation method of nano-airgel thermal insulation coating described in embodiment 3 of the present invention, comprises the following steps:

[0044] 1) Mix and hydrolyze tetraethyl orthosilicate, 1% oxalic acid solution, absolute ethanol and water for 24 hours, and the weight ratio of the above components is 1:0.5:6:0.5;

[0045] 2) After step 1) is hydrolyzed, add 1% ammonia solution in mass concentration, the ratio of parts by weight of liquid after hydrolysis to ammonia solution is 1:0.1-0.2, and obtain silica gel after 18-48 hours;

[0046] 3) Put the silica gel produced in step 2) in absolute ethanol for aging treatment for 12-36 hours;

[0047] 4) Put the silica gel after aging treatment in step 3) into a mixture of trimethylchlorosilane and n-hexane for modification, the weight ratio of the mixture is 1:5-100, every 24-48 Replace the mixture every hour, repeat this process 3-5 times;

[0048] 5) Dry the modified silica gel in step 4) at 20-90°C fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com