Patents

Literature

591results about How to "Reduce gas content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

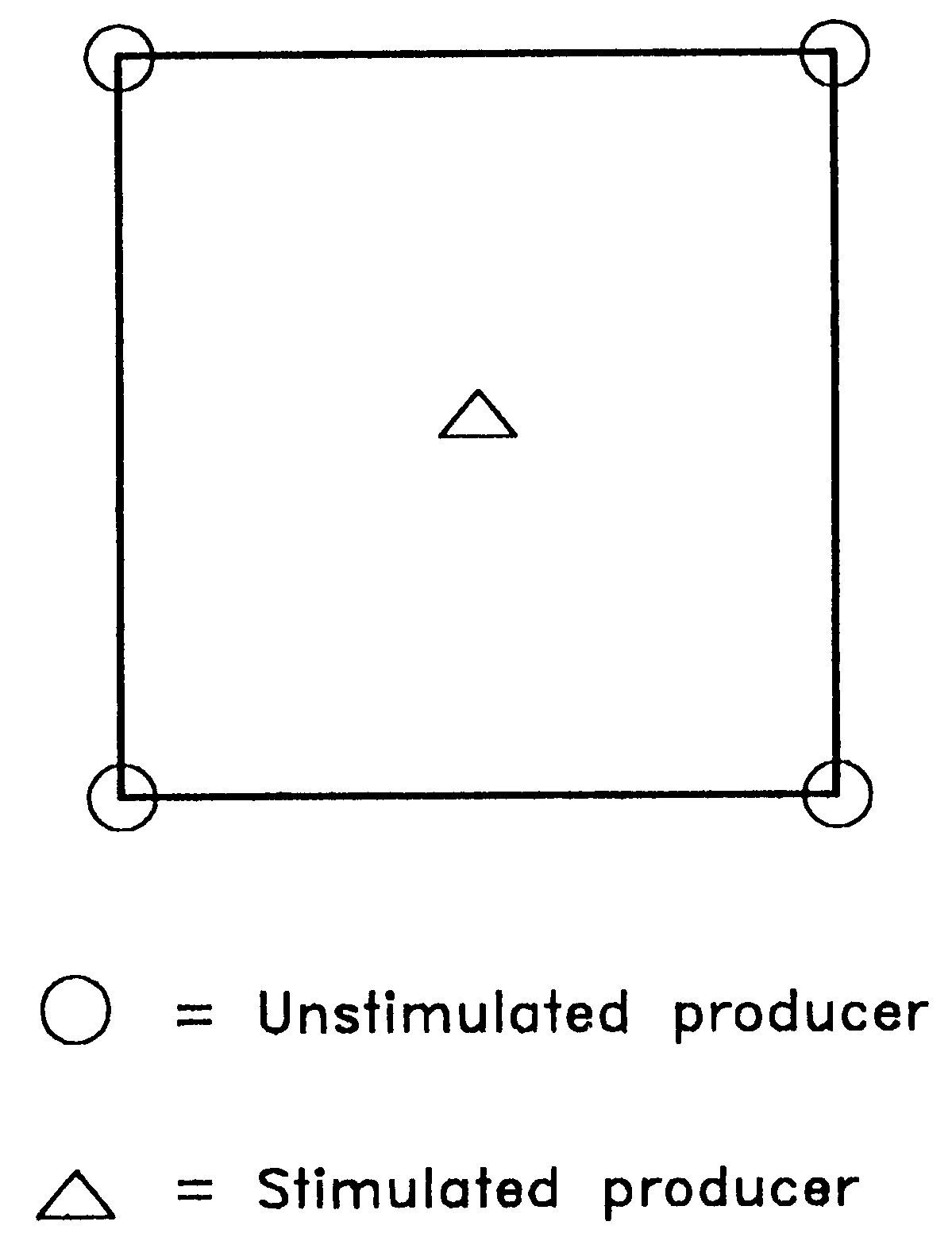

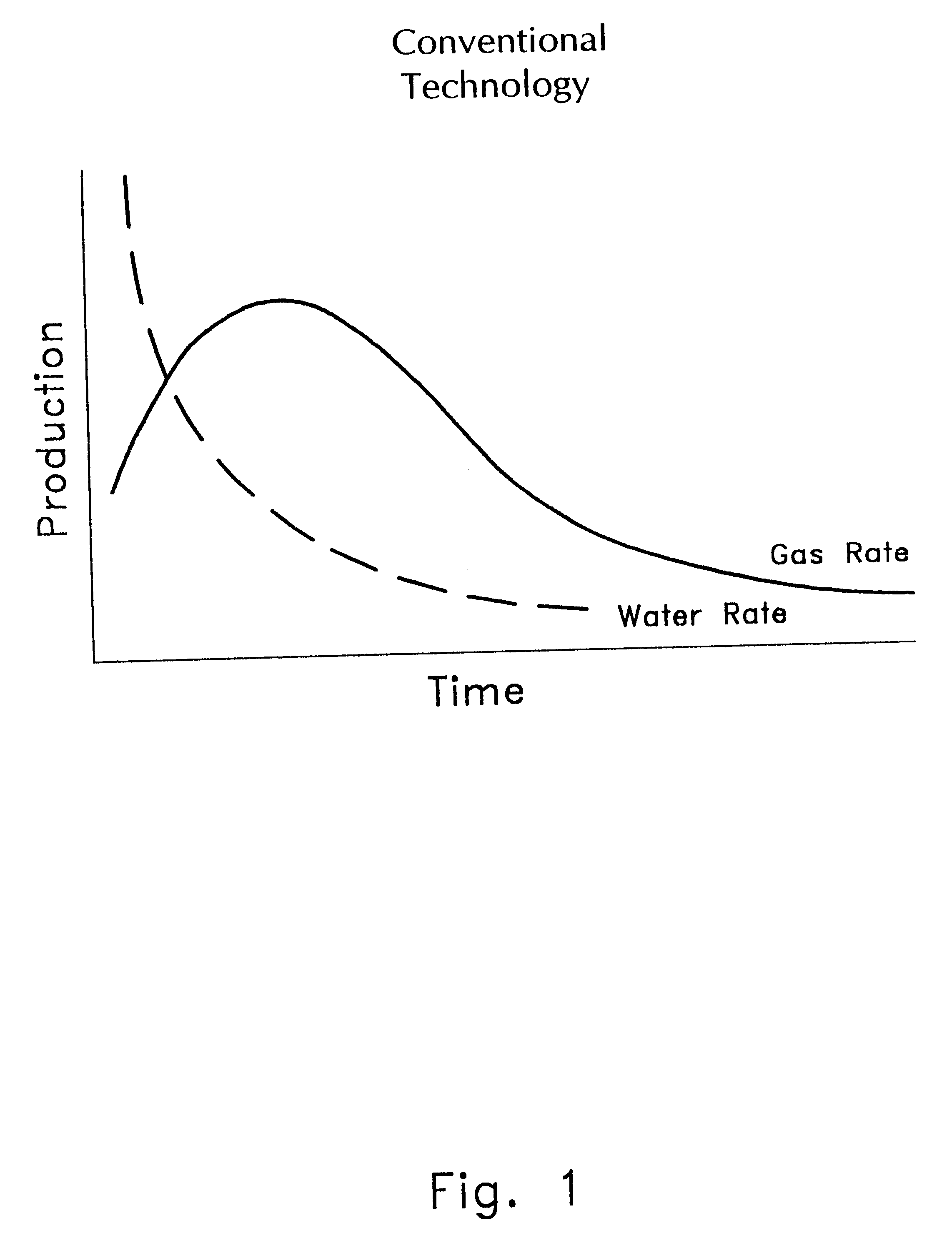

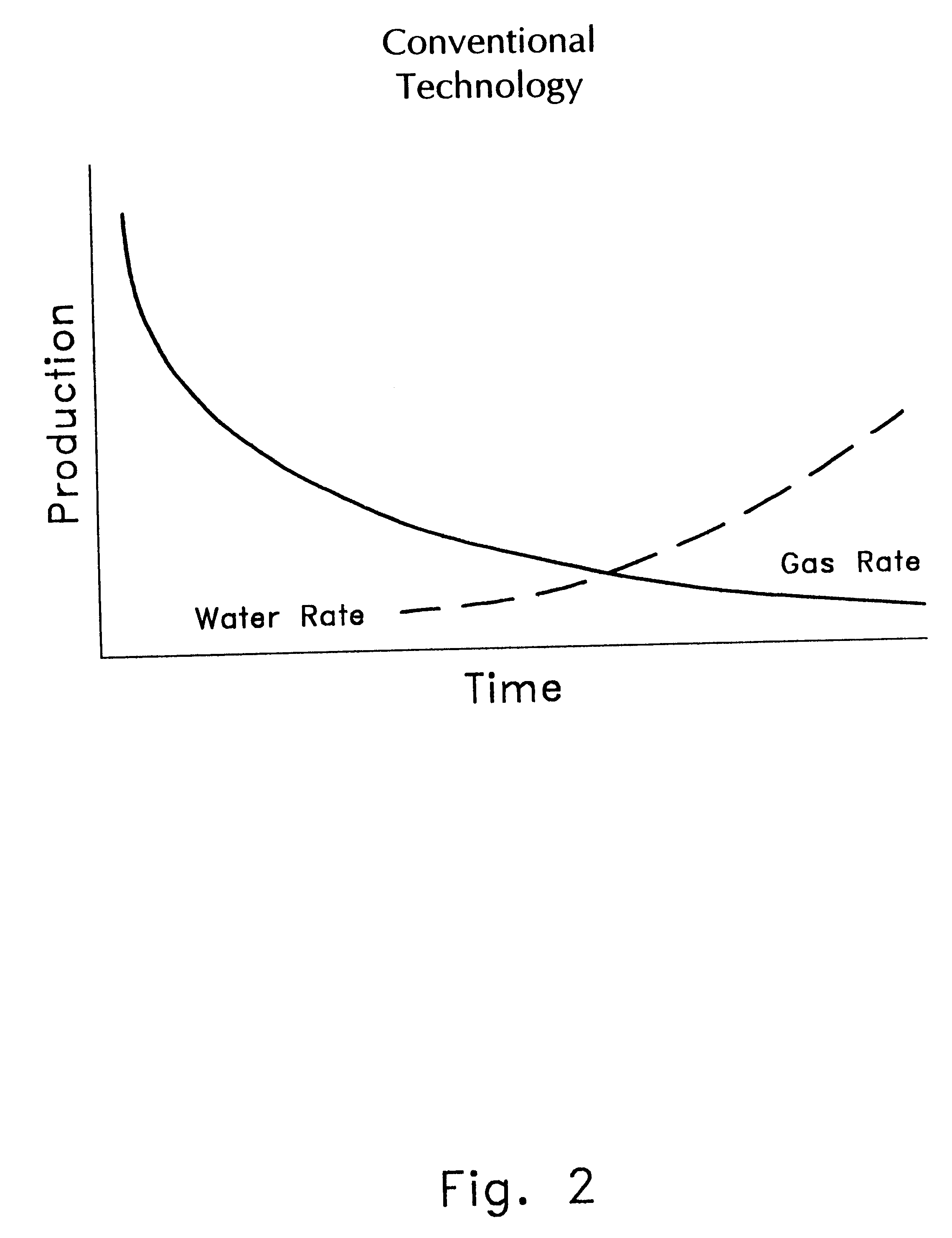

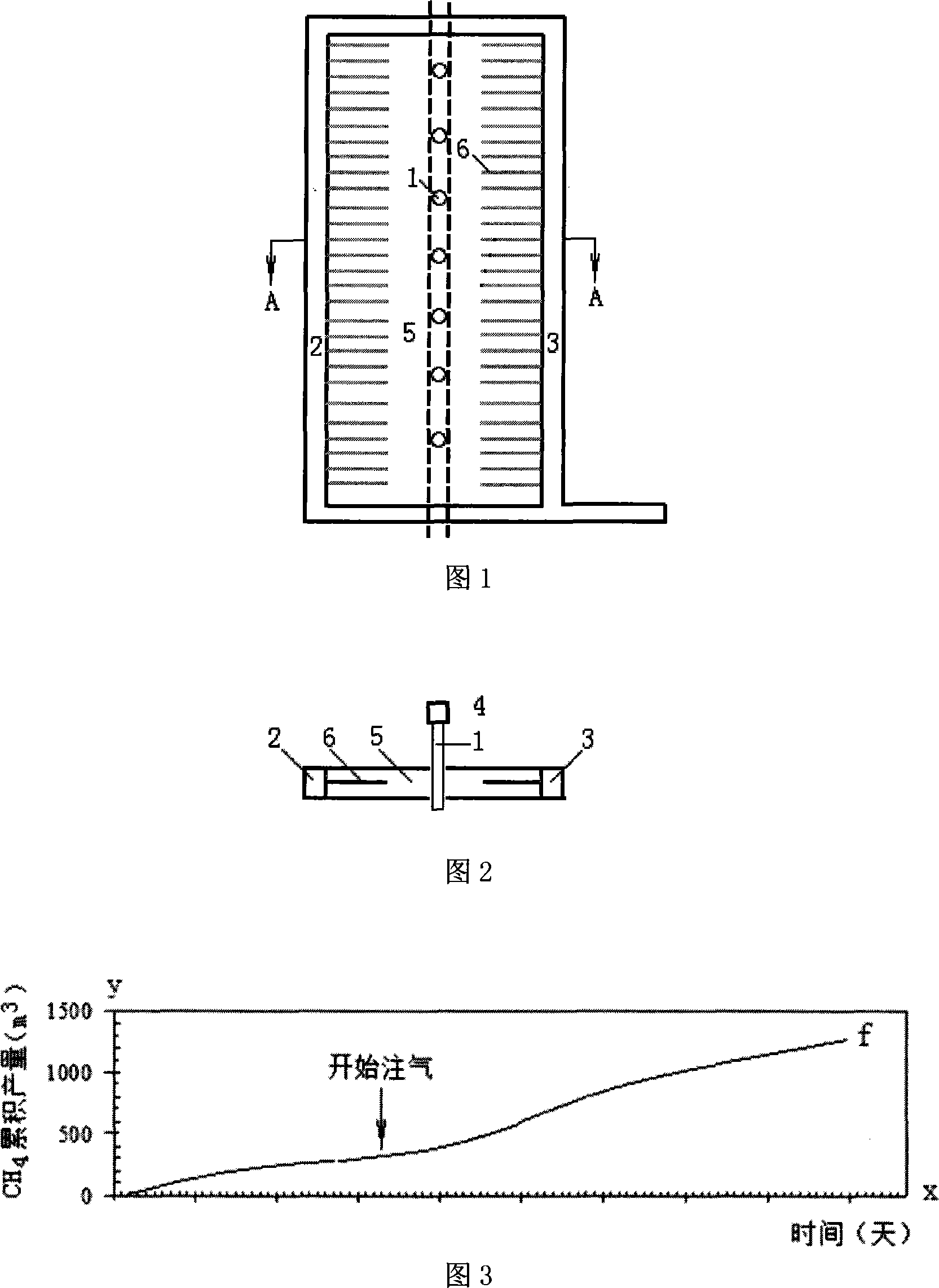

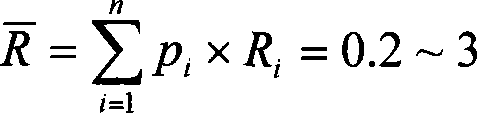

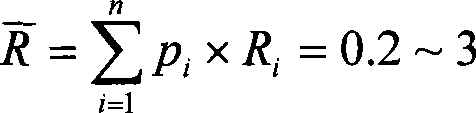

System for improving coalbed gas production

InactiveUS6244338B1Change in permeabilityPromote recoverySurveyDrilling rodsCoal matrixWater production

A method of stimulating coalbed methane production by injecting gas into a producer and subsequently placing the producer back on production is described. A decrease in water production may also result. The increase in gas production and decrease in water production may result from: (1) the displacement of water from the producer by gas; (2) the establishment of a mobile gas saturation at an extended distance into the coalbed, extending outward from the producer; and (3) the reduction in coalbed methane partial pressure between the coal matrix and the coal's cleat system.

Owner:THE UNIVERSITY OF WYOMING RESEARCH CORPORATION DBA WESTERN RESEARCH INSTITUTE

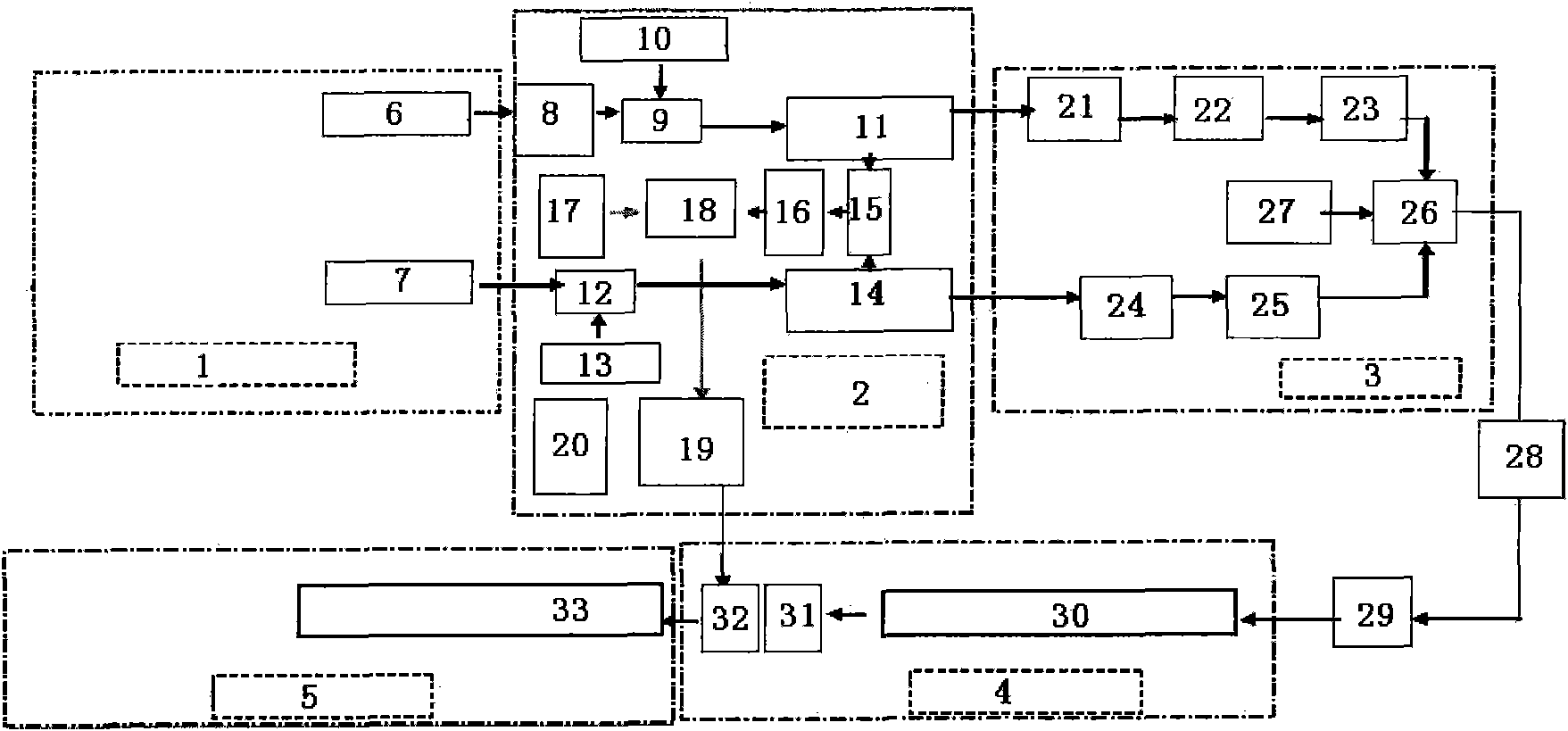

Method for preparing tobacco sheet and application thereof

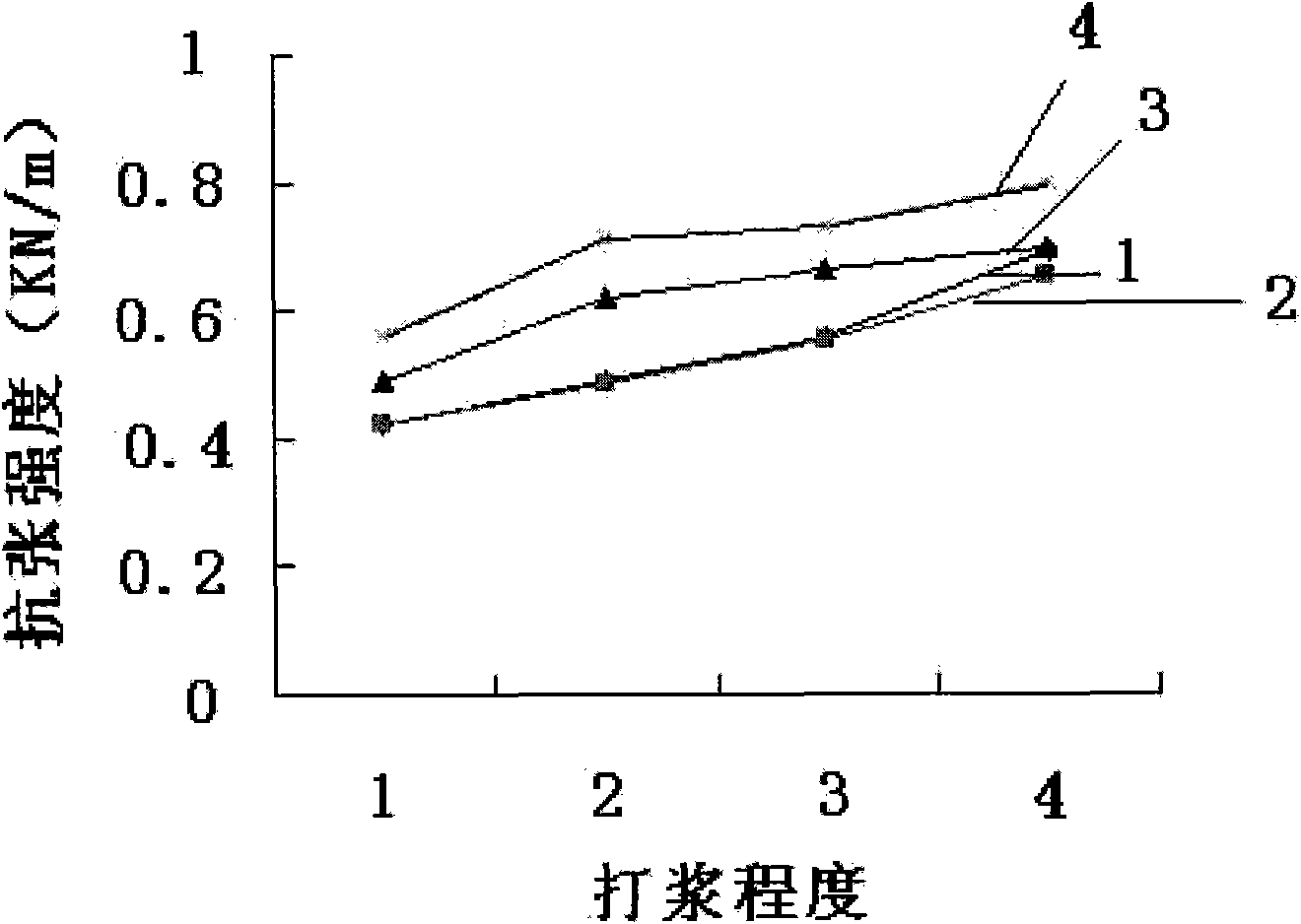

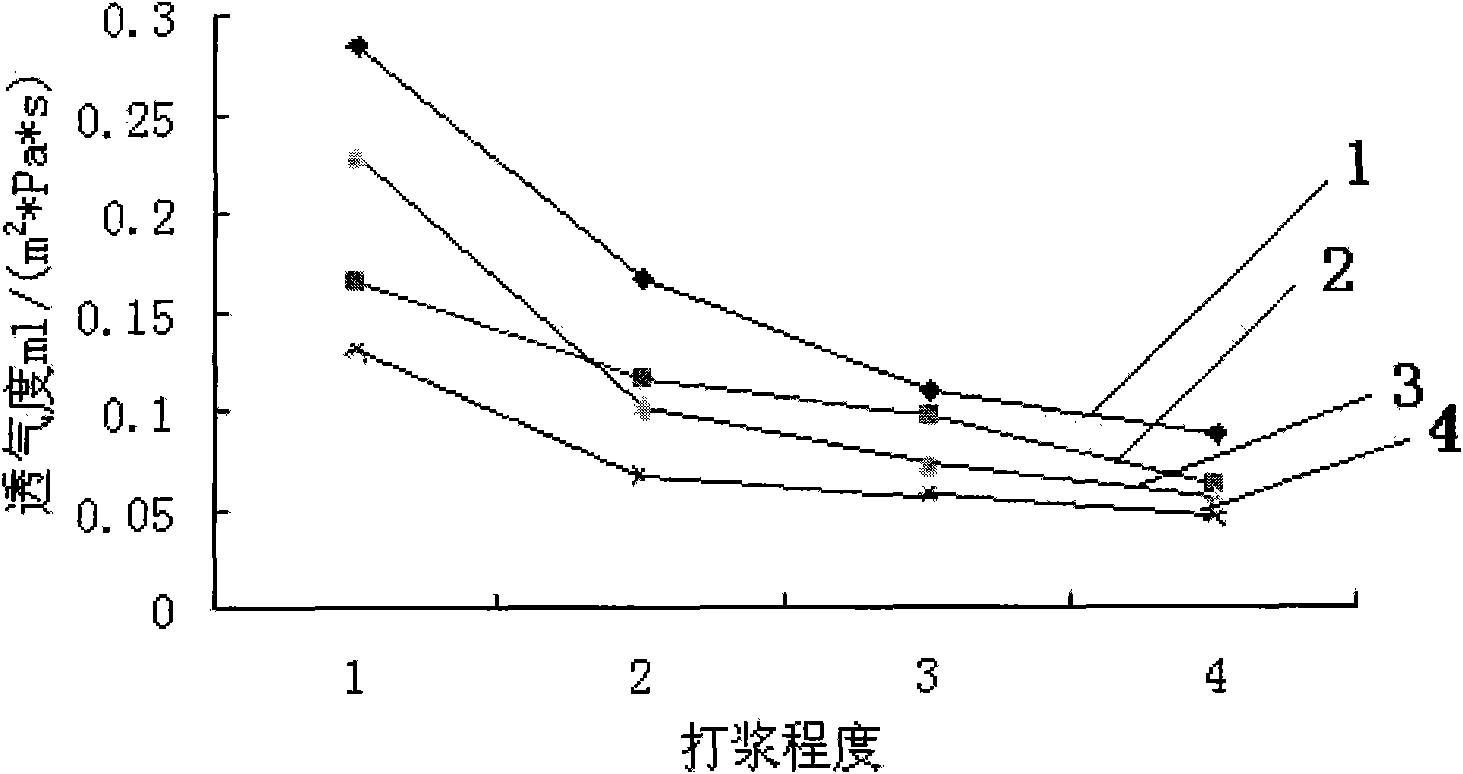

ActiveCN101637298AGood physical propertiesExtract completelyTobacco preparationTobacco treatmentMaillard reactionFiber

The invention discloses a method for preparing tobacco sheets and an application of the method. In the method, enzymolysis is implemented when the tobacco stalk and the tobacco powder are soaked, solid-liquid separation is implemented after extraction, the solids are made into fiber sheet substrates, liquid is made into concentrated solution by alcohol precipitation and concentration, the concentrated solution is made into coating liquid by maillard reaction and coated on the fiber sheet substrates, and the fiber sheet substrates are dried and cut into tobacco sheets. In the invention, the macromolecular compounds that influence the quality of the tobacco sheets are sufficiently degraded by enzymolysis, the content of the impure taste in the tobacco sheets is decreased, the internal quality of the tobacco sheets is improved, and better aroma is obtained by the technical solution that produces prospective aroma by the maillard reaction to provide a rich aroma for the tobacco sheets so as to obtain tobacco sheet products fitting different types of cigarette products and having better internal quality. The tobacco sheets prepared by the method have excellent compatibility and harmonywith the conventional raw materials of the cigarettes, and have the advantages of good cigarette taste, various and rich aromas and less impure taste.

Owner:CHINA TOBACCO GUANGDONG IND

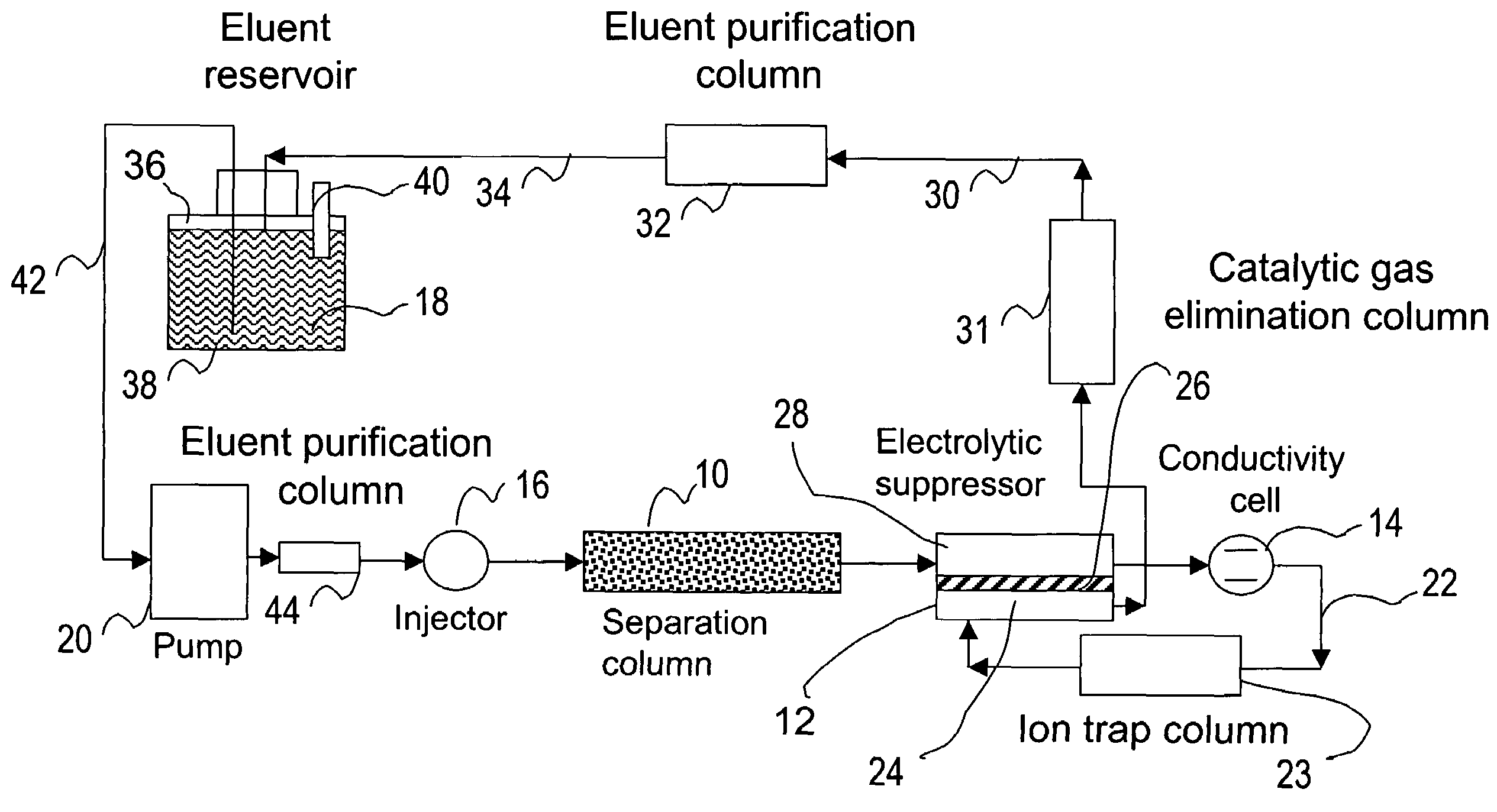

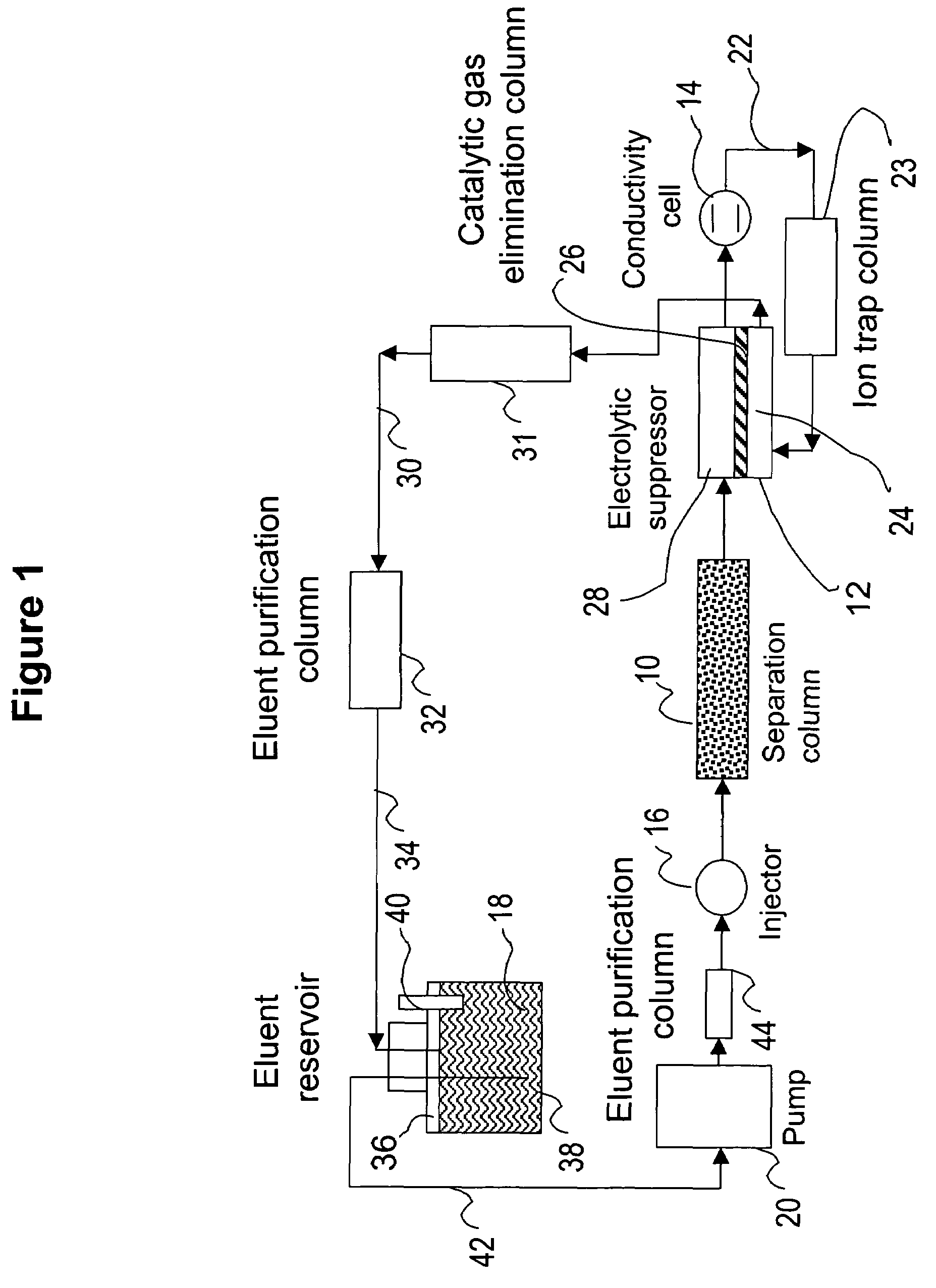

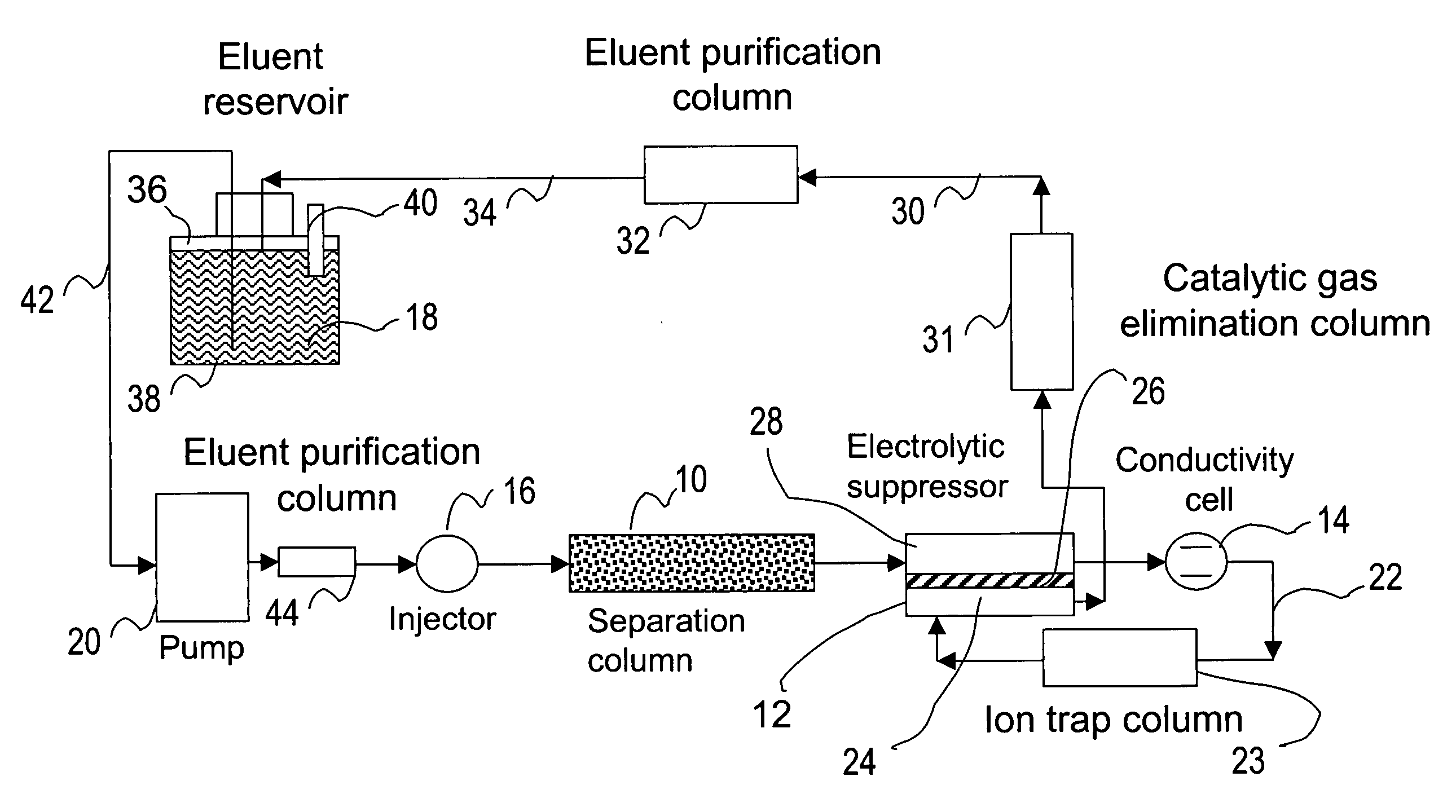

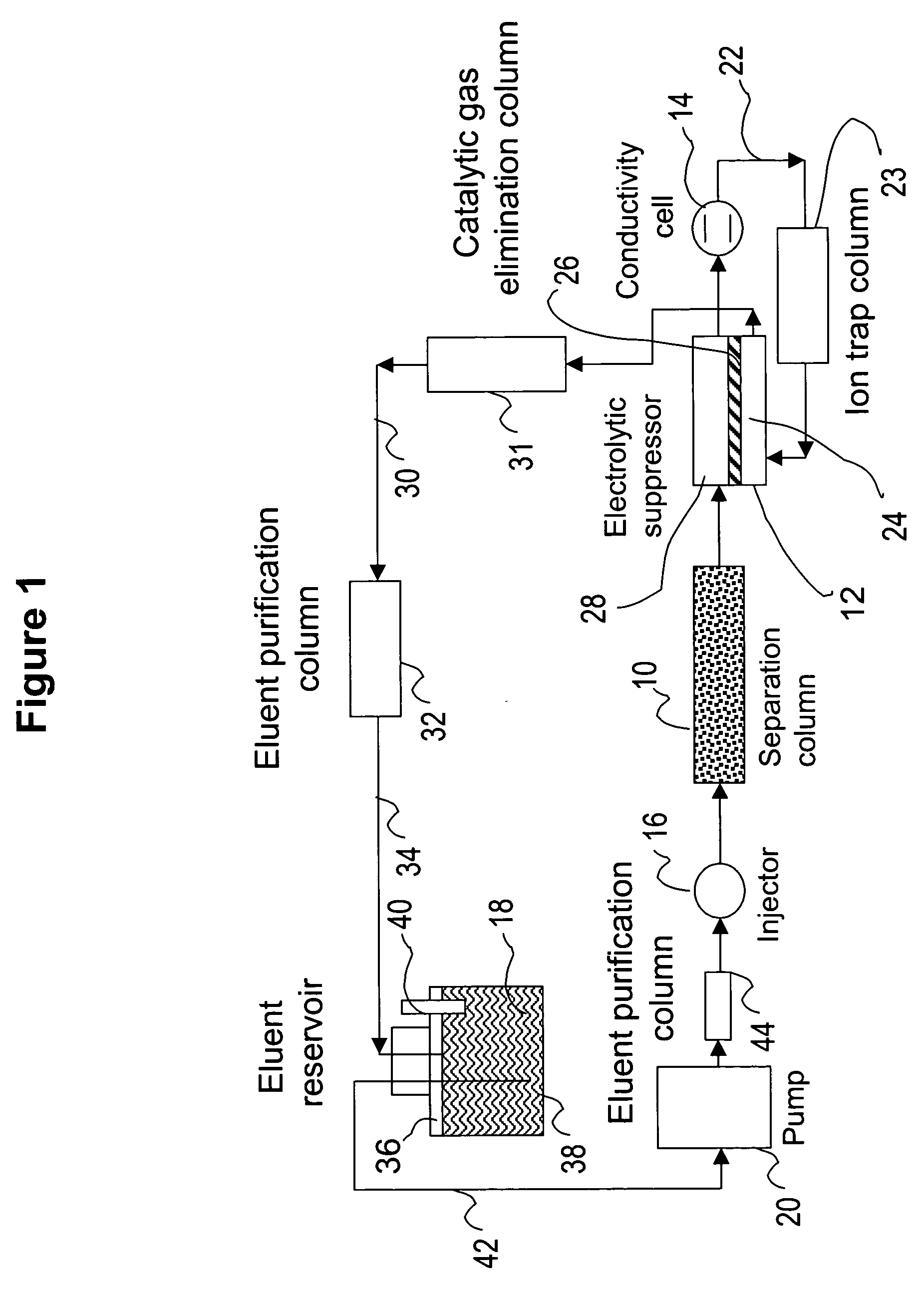

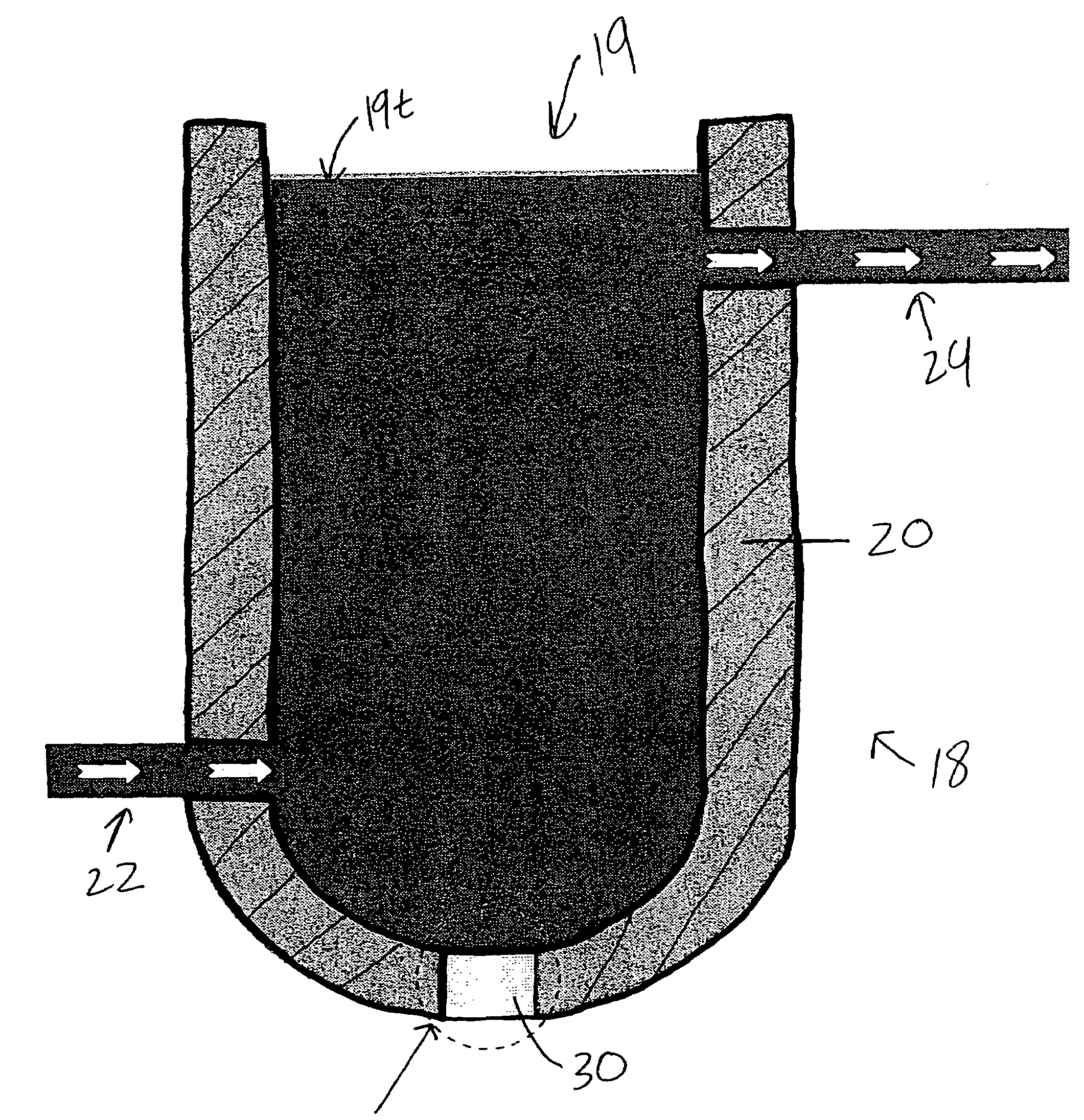

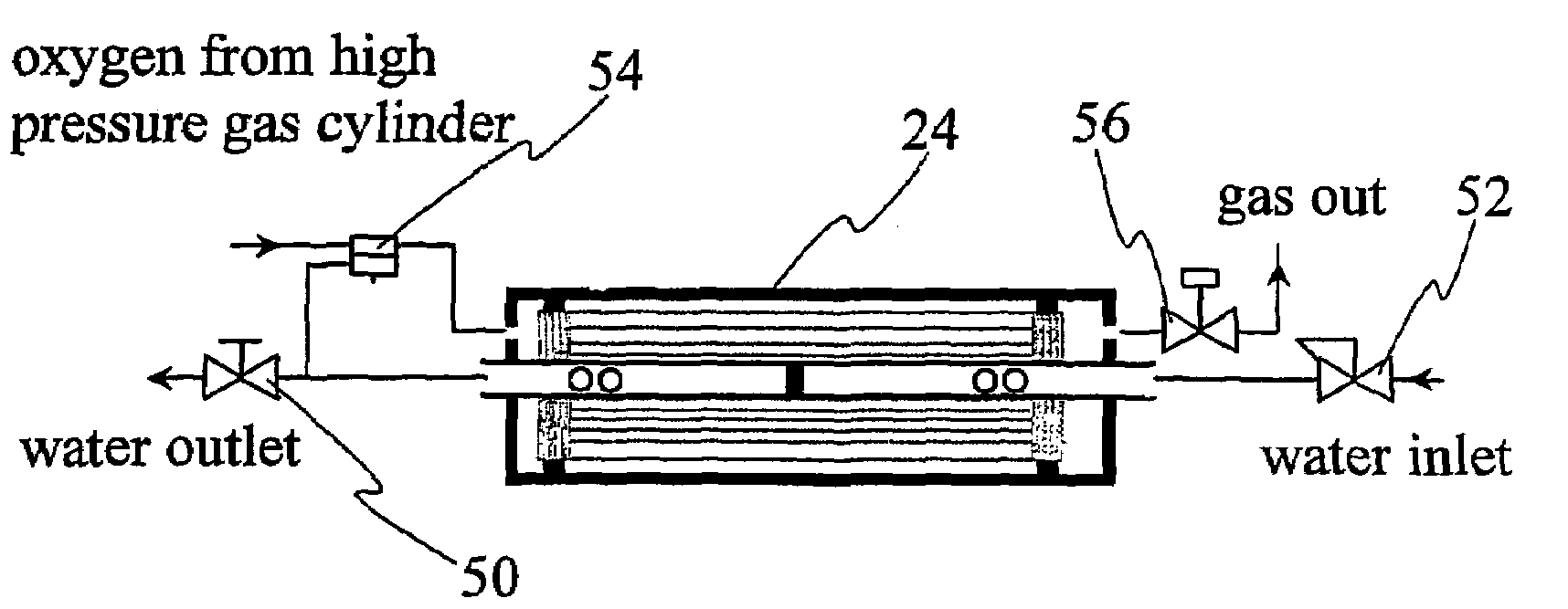

Ion chromatography system using catalytic gas elimination

ActiveUS7329346B2Reduce gas contentElectrolysis componentsWeather/light/corrosion resistanceHydrogenIon chromatography

A liquid chromatographic system is provided including catalytically combining hydrogen and oxygen gases in the chromatography eluent stream in a catalytic gas elimination chamber, to form water and thereby reduce the gas content in the eluent stream. Also, a liquid ion chromatographic system in which the effluent from the detector is recycled to a membrane suppressor and then is mixed with a source of eluent for recycle to the chromatographic column.

Owner:DIONEX CORP

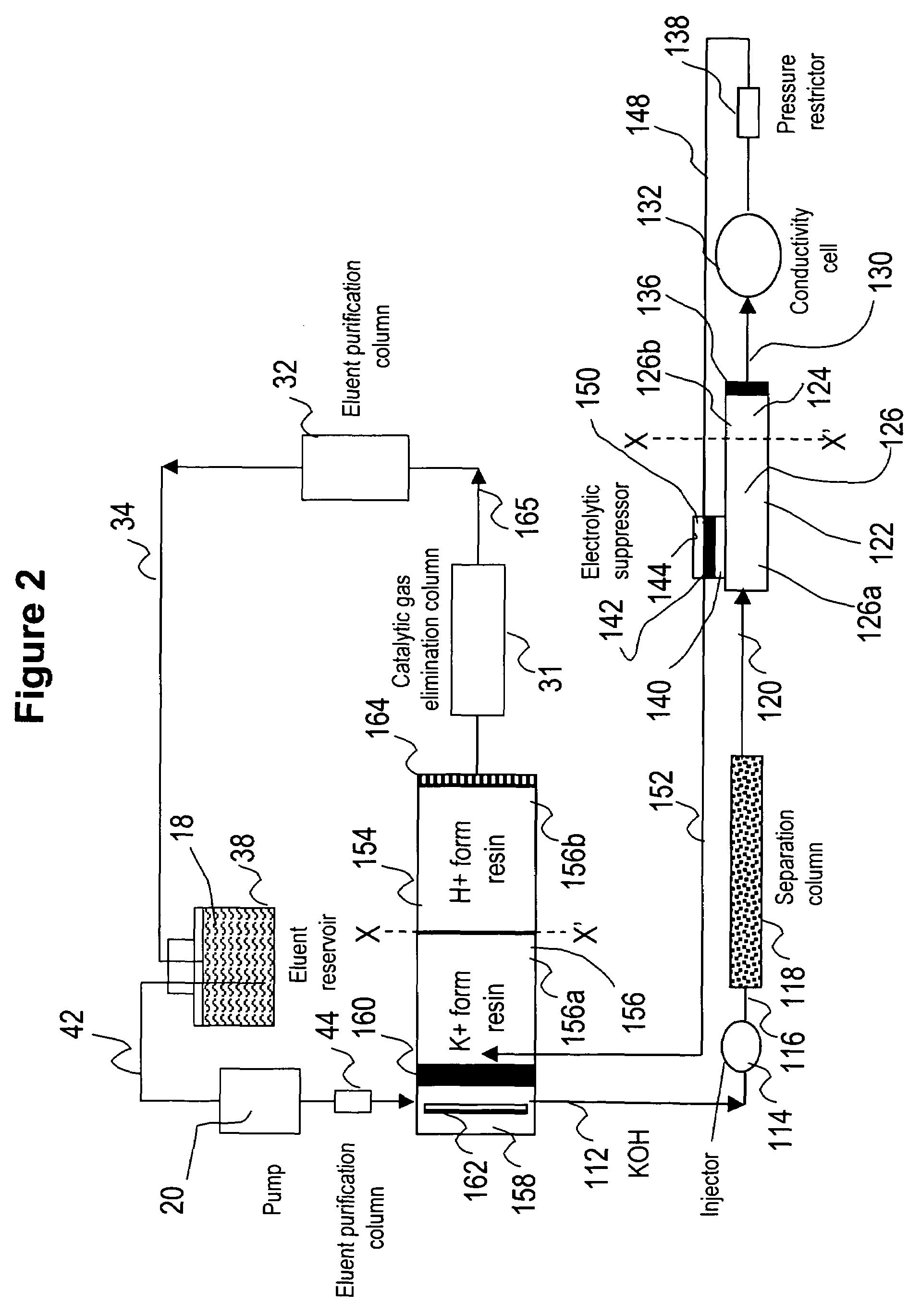

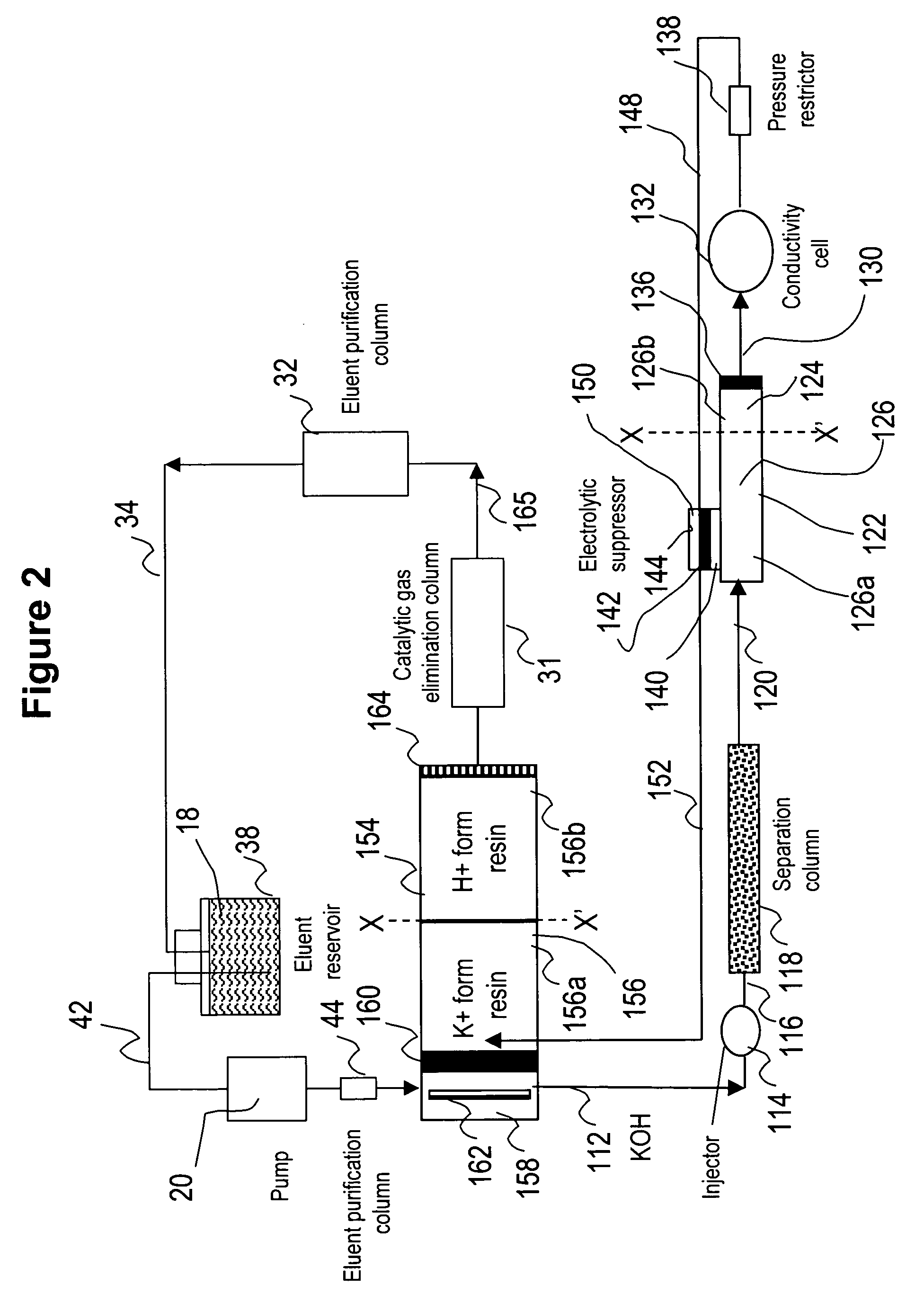

Ion chromatography system using catalytic gas elimination

ActiveUS20060186046A1Reduce gas contentElectrolysis componentsWeather/light/corrosion resistanceChromatographic columnIon

A liquid chromatographic system is provided including catalytically combining hydrogen and oxygen gases in the chromatography eluent stream in a catalytic gas elimination chamber, to form water and thereby reduce the gas content in the eluent stream. Also, a liquid ion chromatographic system in which the effluent from the detector is recycled to a membrane suppressor and then is mixed with a source of eluent for recycle to the chromatographic column.

Owner:DIONEX CORP

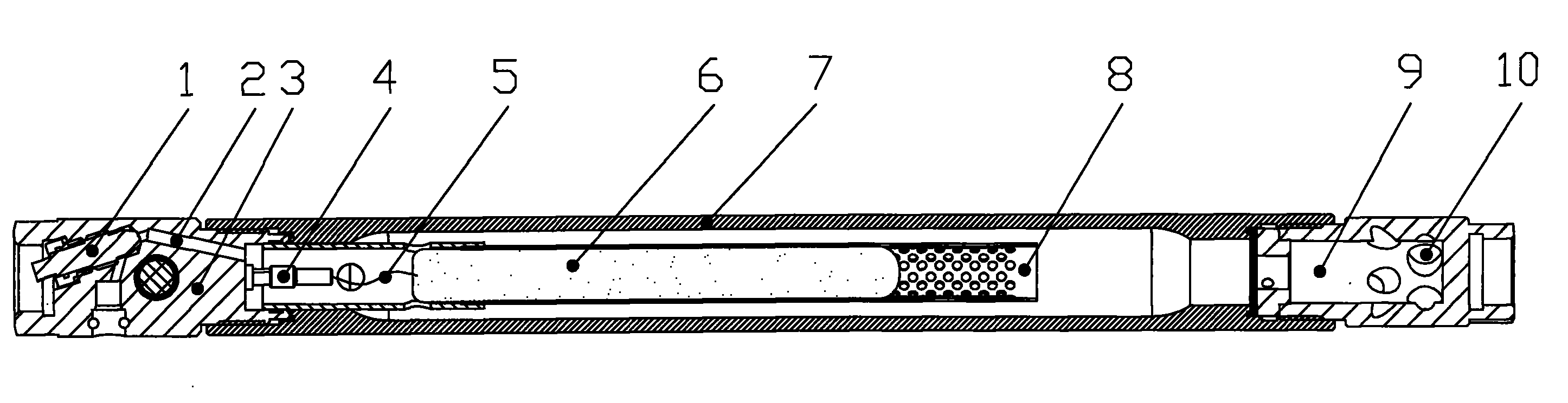

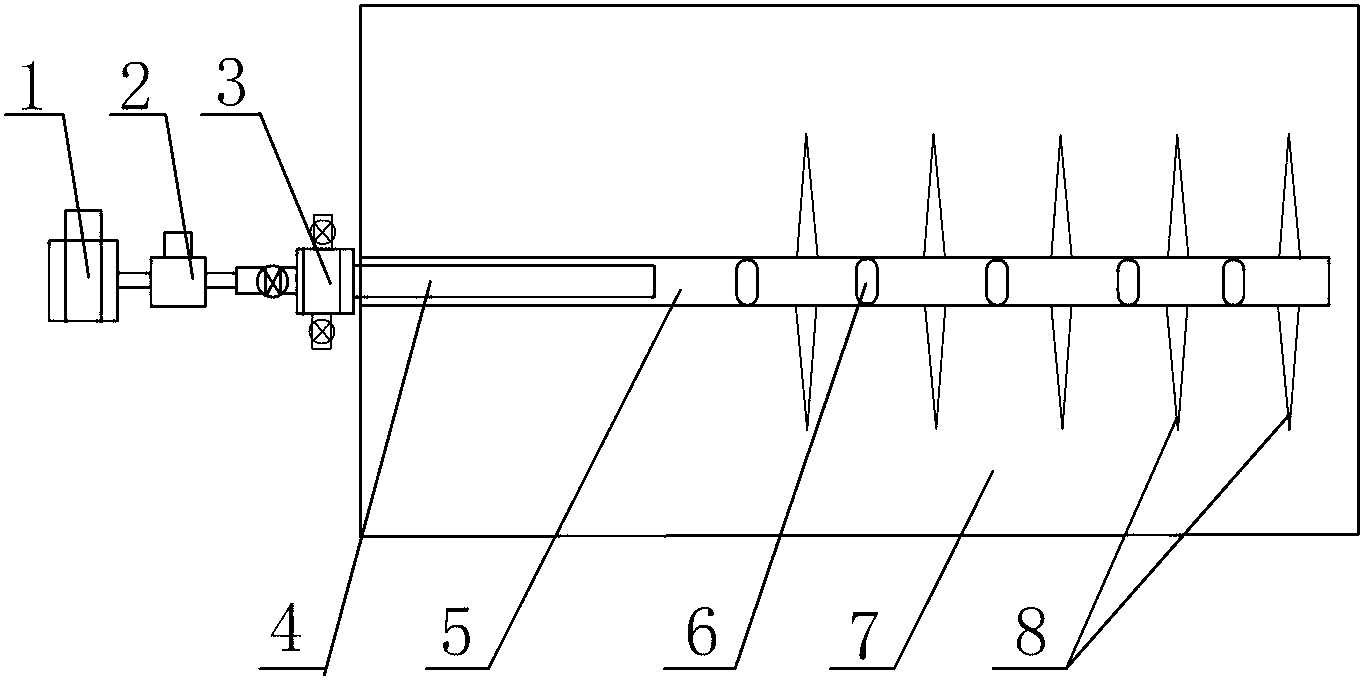

Coal seam pre-splitting method based on gas extraction

The invention relates to a coal seam pre-splitting method based on gas extraction, which adopts a 'CO2 gas extraction device' as a tool to blast and pre-split a pre-mined coal seam, so as to increase the crack of the coal seam, drive out gas absorbed on the coal seam and extract the gas. The method particularly comprises the following steps: drilling a hole on the working surface of a pre-mined coal seam, filling CO2 gas extraction device into the drilled hole, sealing the drilled hole, detonating the CO2 gas extraction device, releasing high-pressure CO2 gas for deep-hole impact and pre-splitting of the coal seam, taking out the CO2 gas extraction device, and connecting the drilled hole with a gas extraction system to extract gas. The pre-splitting method of the invention can greatly enhance the permeability of the coal seam, promote the gas dissociation in the coal seam, and improve the underground gas extraction efficiency of the coal mine.

Owner:山西锦浩诚科技有限公司

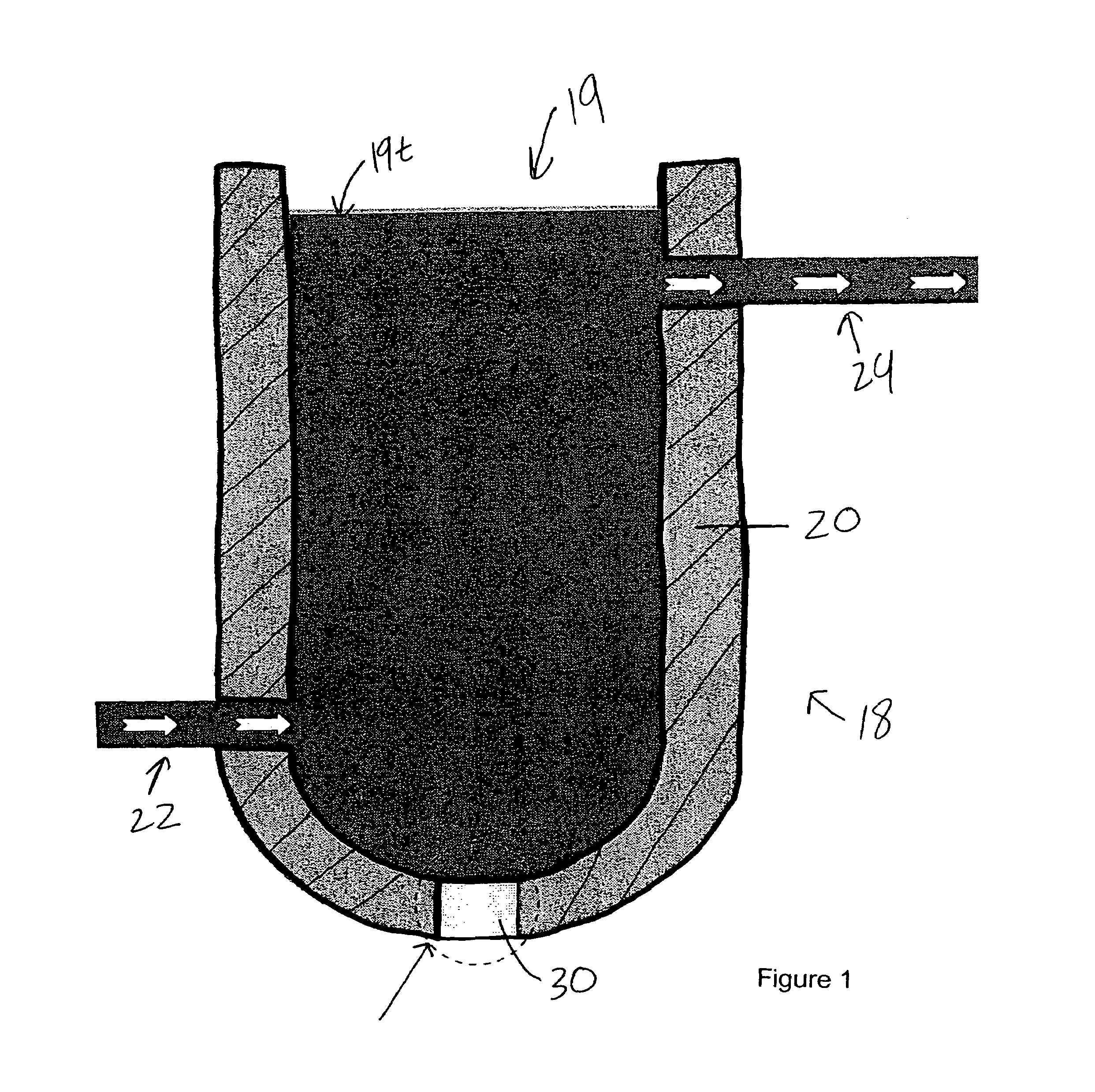

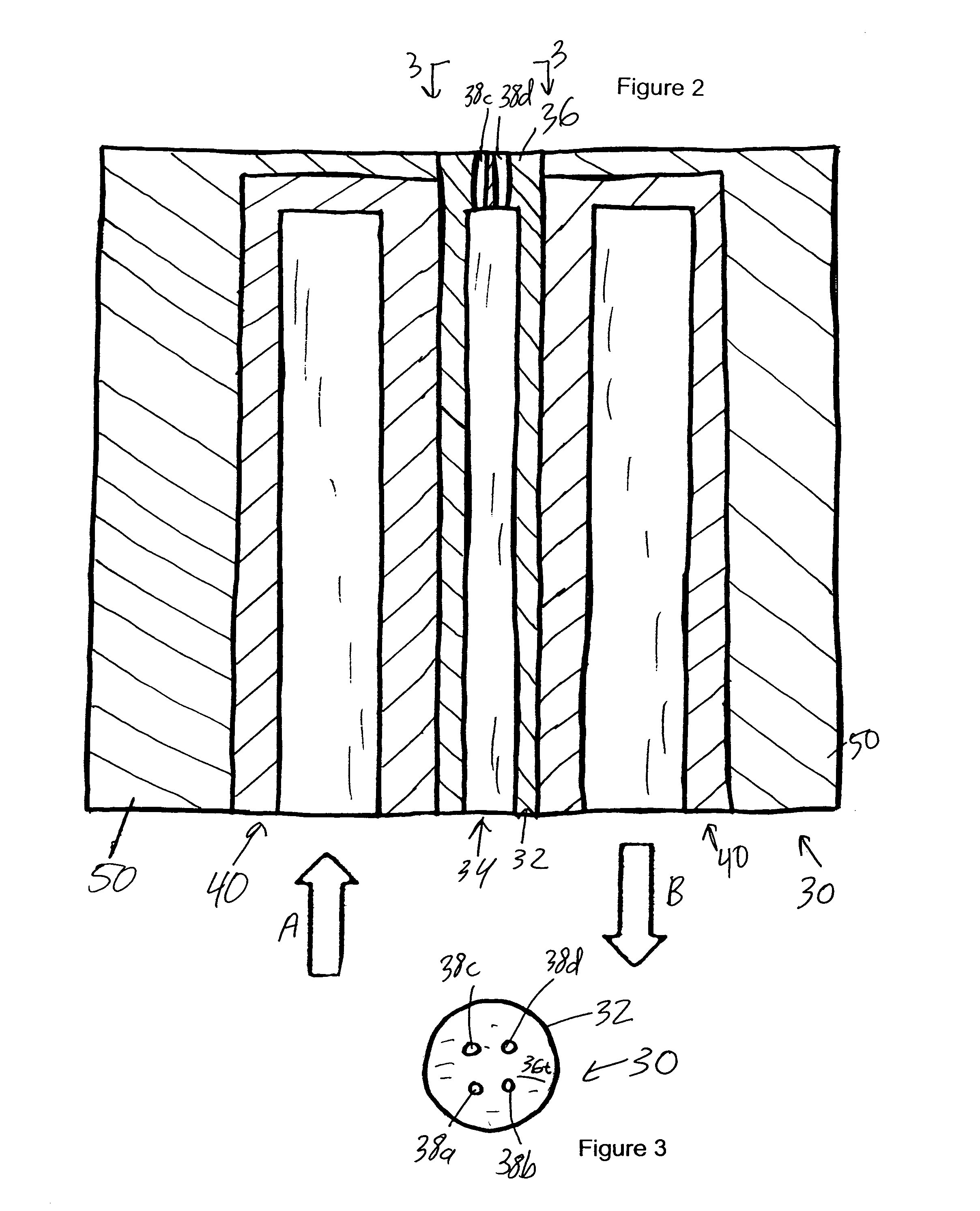

Degassing of molten alloys with the assistance of ultrasonic vibration

InactiveUS7682556B2Reduce gas contentReduce heat transferMelt-holding vesselsLiquid degasificationNitrogen gasCavitation bubble

An apparatus and method are disclosed in which ultrasonic vibration is used to assist the degassing of molten metals or metal alloys thereby reducing gas content in the molten metals or alloys. High-intensity ultrasonic vibration is applied to a radiator that creates cavitation bubbles, induces acoustic streaming in the melt, and breaks up purge gas (e.g., argon or nitrogen) which is intentionally introduced in a small amount into the melt in order to collect the cavitation bubbles and to make the cavitation bubbles survive in the melt. The molten metal or alloy in one version of the invention is an aluminum alloy. The ultrasonic vibrations create cavitation bubbles and break up the large purge gas bubbles into small bubbles and disperse the bubbles in the molten metal or alloy more uniformly, resulting in a fast and clean degassing.

Owner:UNIV OF TENNESSEE RES FOUND +1

Low premeability high gas soft thick coal layer remote pressure relief gas exhausting method

ActiveCN1534164AEliminate the danger of coal and gas outburstSafe and efficient miningGas removalCoalEnvironmental geology

A remotely pressure-releasing method for sucking and exhausting gas from the low-air-permeability high-gas soft and thick coal seam is disclosed. The coal seam, which is 70m under the coal seam to be gas-exhausted and has relative interbeam distance of 30-70 times, is first mined. Under the action of pressure release and subsidence, the cracks are generated in the coal seam and the gas penetrates through the cracks and then is exhausted via predrilled holes. After the coal seam is mined, a great deal of gas is flowing along the seam and then is sucked by said predrilled holes.

Owner:HUAINAN MINING IND GRP +1

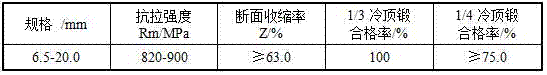

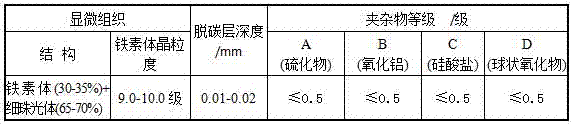

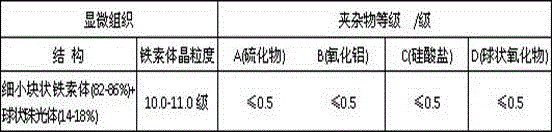

CrNiMo high-strength pinion steel and preparation method thereof

ActiveCN104372258AImprove heat treatment effectGuaranteed mechanical propertiesProcess efficiency improvementPinionUltimate tensile strength

The invention relates to a CrNiMo high-strength pinion steel and a preparation method thereof. The pinion steel comprises the following chemical components in percentage by mass: 0.19%-0.25% of C, 0.17%-0.37% of Si, 0.70%-1.00% of Mn, at most 0.030% of P, at most 0.030% of S, 0.85%-1.25% of Cr, 0.40%-0.70% of Ni, 0.30%-0.40% of Mo, 0.015%-0.050% of Al, at most 2.5*10<-4>% of H, 30*10<-4>%-80*10<-4>% of N, at most 15*10<-4>% of T.O, and the balance of Fe and inevitable impurities. The invention also provides a preparation method of the pinion steel. The nickel molybdenum alloy is added to improve the heat treatability of the material, thereby ensuring the mechanical properties of the material. The hardenability of the material is enhanced, and the material satisfies the performance requirements for large module pinions.

Owner:SHANDONG IRON & STEEL CO LTD

Controlled atmosphere gas infusion

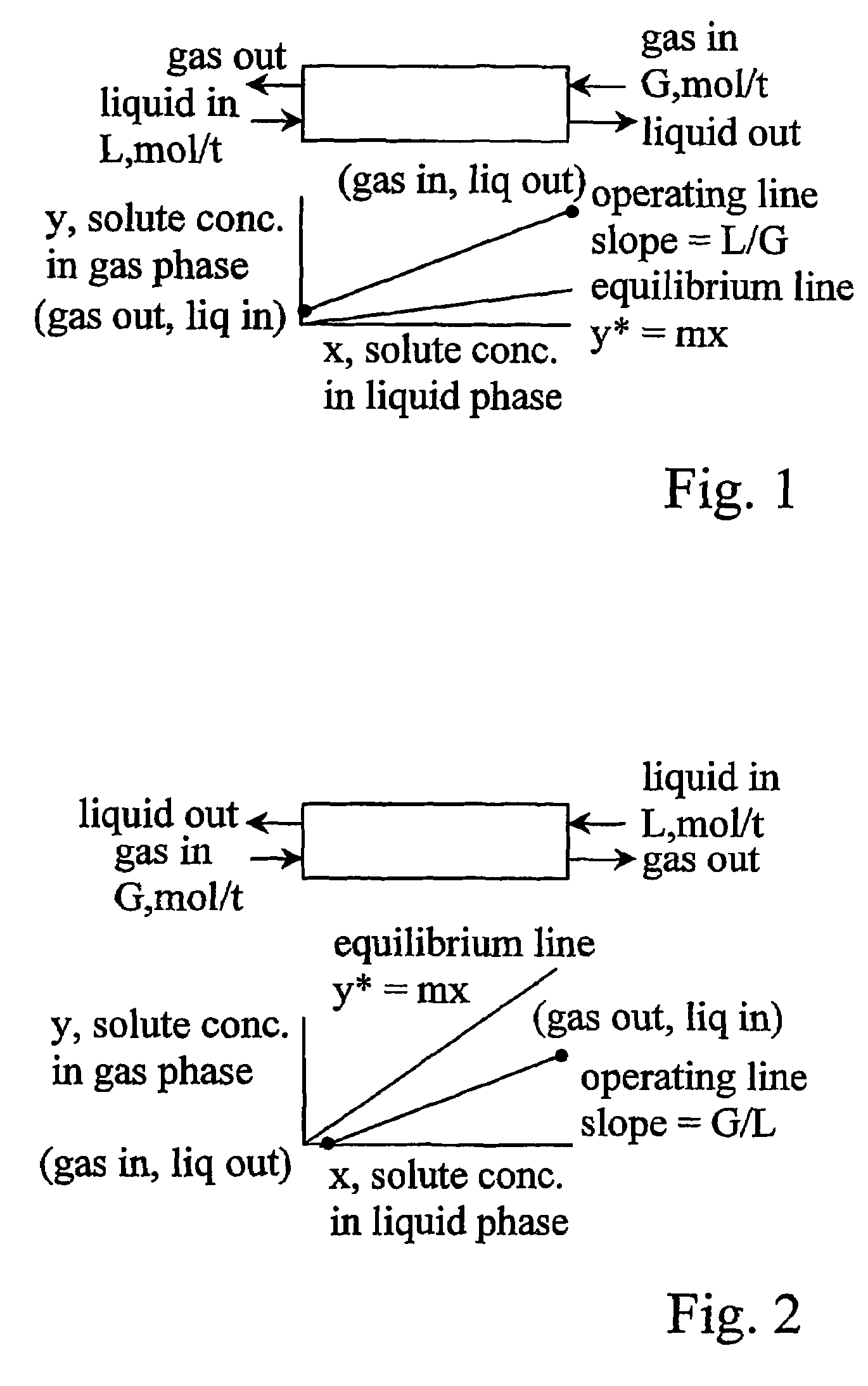

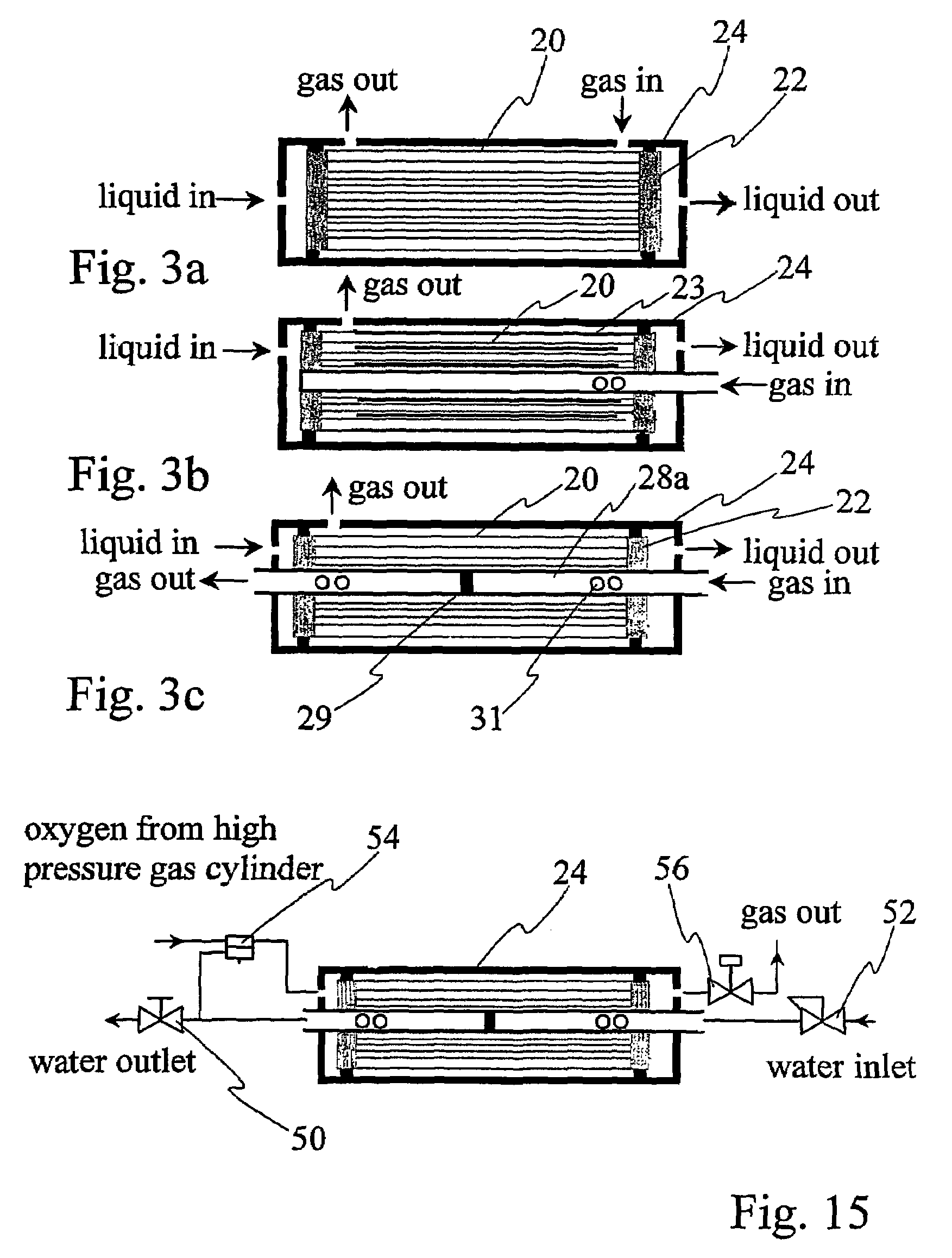

ActiveUS7537200B2Reduce gas contentLowering total dissolved gas pressure(TG)Treatment using aerobic processesFlow mixersFiberHollow fibre membrane

The invention disclosed relates to a method and apparatus for controlling the dissolved gas content of aqueous liquid containing a dissolved gas by providing a microporous hydrophobic hollow fibre membrane, to provide at equilibrium a stable interface between an aqueous liquid phase containing dissolved gas on one side of the membrane and a gaseous phase on the other side of the membrane, and controlling the aqueous phase and gaseous phase pressures, such that in operation the gaseous phase pressure is up to but not exceeding the aqueous phase pressure, and flowing the gaseous and liquid phases across the membrane, to provide simultaneous mass transfer through the membrane of a first gas in the gaseous phase into the liquid phase and of a second gas dissolved in the aqueous liquid into the gaseous phase, whereby the gas content of the first gas in the aqueous phase is increased, the gas content of the second gas in the gaseous phase is decreased and the total dissolved gas pressure (TG) of the aqueous phase is altered.

Owner:CANZONE

Production method of large high chromium steel cold roll blank

InactiveCN1686666AAdvanced technologyStrong maneuverabilityOther manufacturing equipments/toolsChromiumProduction cycle

A production method for the blank of large cold-rolling high-Cr steel roller includes smelting in arc furnace, refining outside the furnace, conveying hot steel ingot, heating in high-temp homogenizing mode, drawing by V-shaped stock, upsetting twice, and post treating. Its advantages are short productive period and low cost.

Owner:SHANGHAI IRON & STEEL CO LTD NO 5 BAOSHAN IRON & STEEL GRP

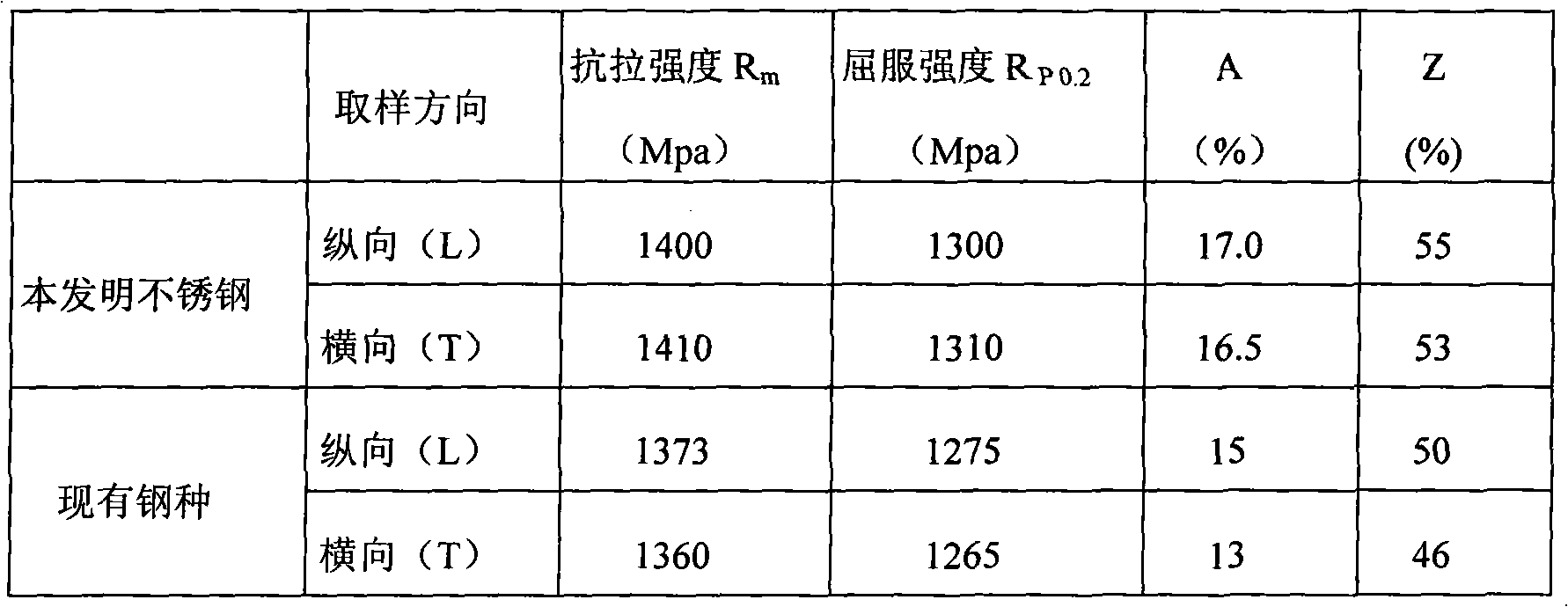

Martensite precipitation hardening stainless steel for structural member and manufacturing method thereof

The invention provides a martensite precipitation hardening stainless steel for structural member and a manufacturing method thereof. The martensite precipitation hardening stainless steel comprises the following chemical components in percentage by weight: less than or equal to 0.05 percent of C, 13.50 to 15.50 percent of Cr, 2.5 to 4.0 percent of Cu, 3.0 to 5.0 percent of Ni, 0.15 to 0.40 percent of Nb and Ta, 0.010 to 0.040 percent of N, 0.050 to 0.15 percent of V, less than or equal to 0.80 percent of Si, less than or equal to 1.00 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, and the balance of Fe and inevitable impurities. The stainless steel is smelted by combining an electric furnace, AOD refining and vacuum self-consuming technology, so the stainless steel has the characteristics of high strength, good plasticity, good corrosion resistance and the like, and can meet the requirements of high-strength components such as high-pressure values, oil drill, efficient heavy-duty machinery and the like on material performance.

Owner:宝武特种冶金有限公司

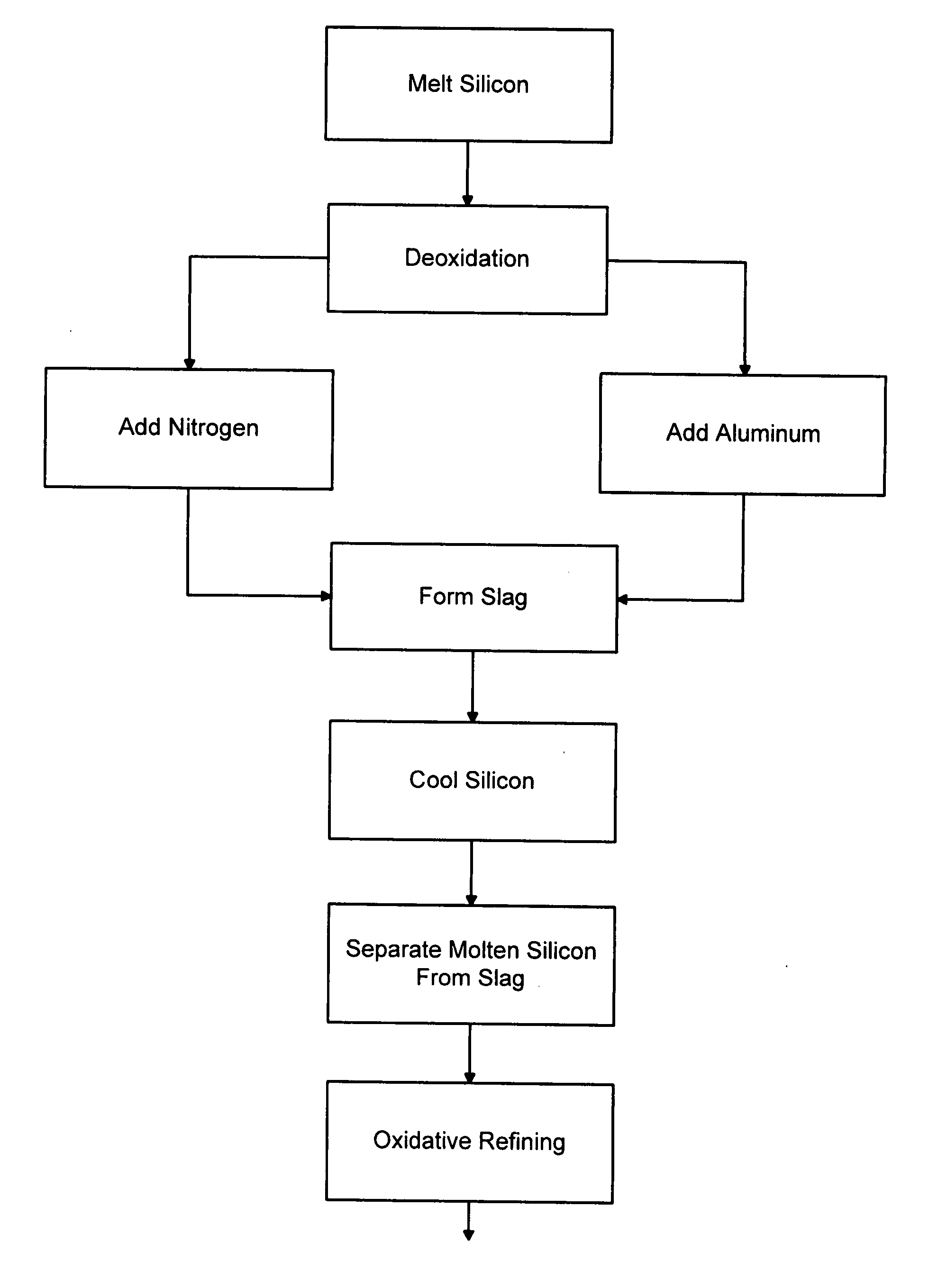

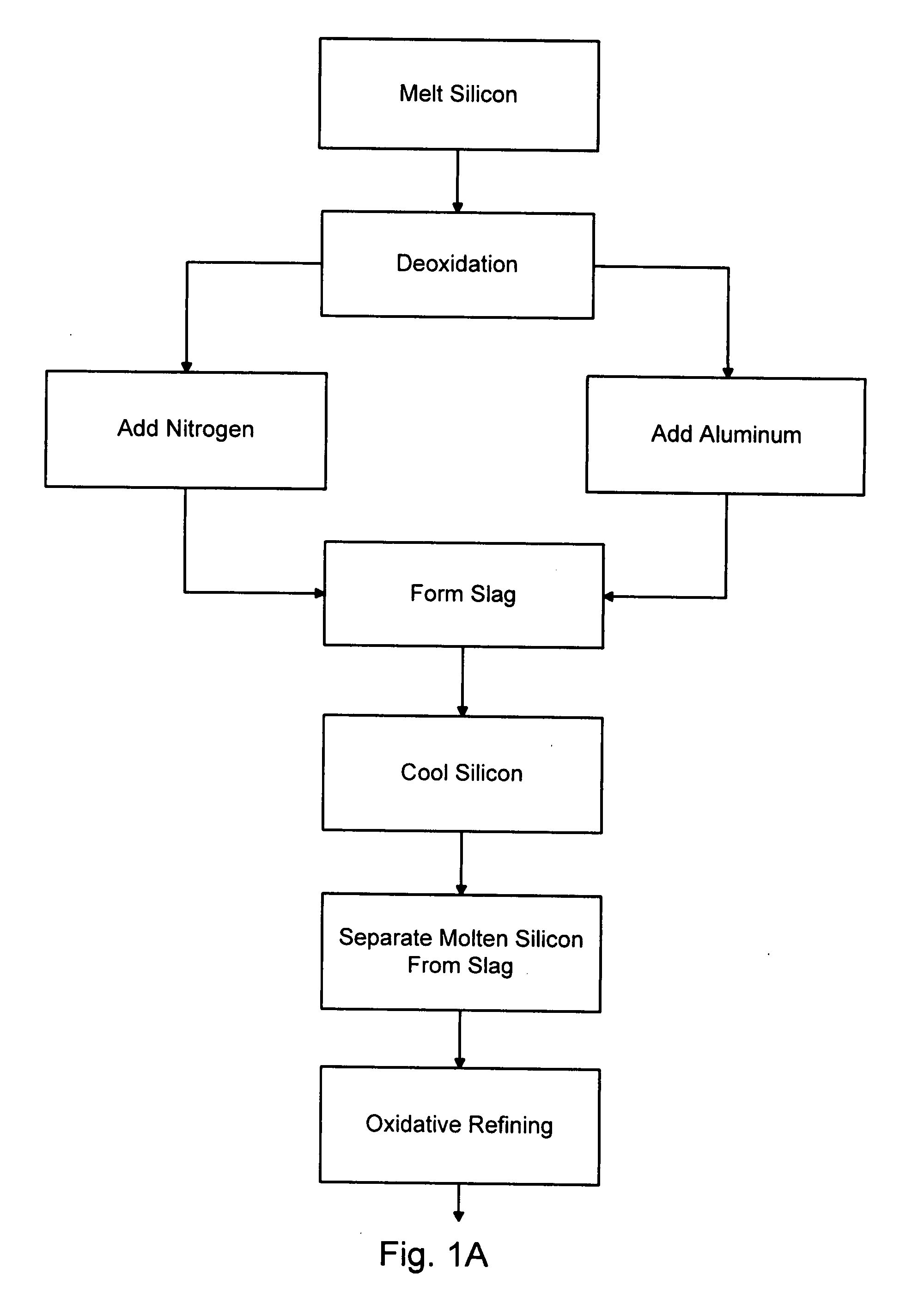

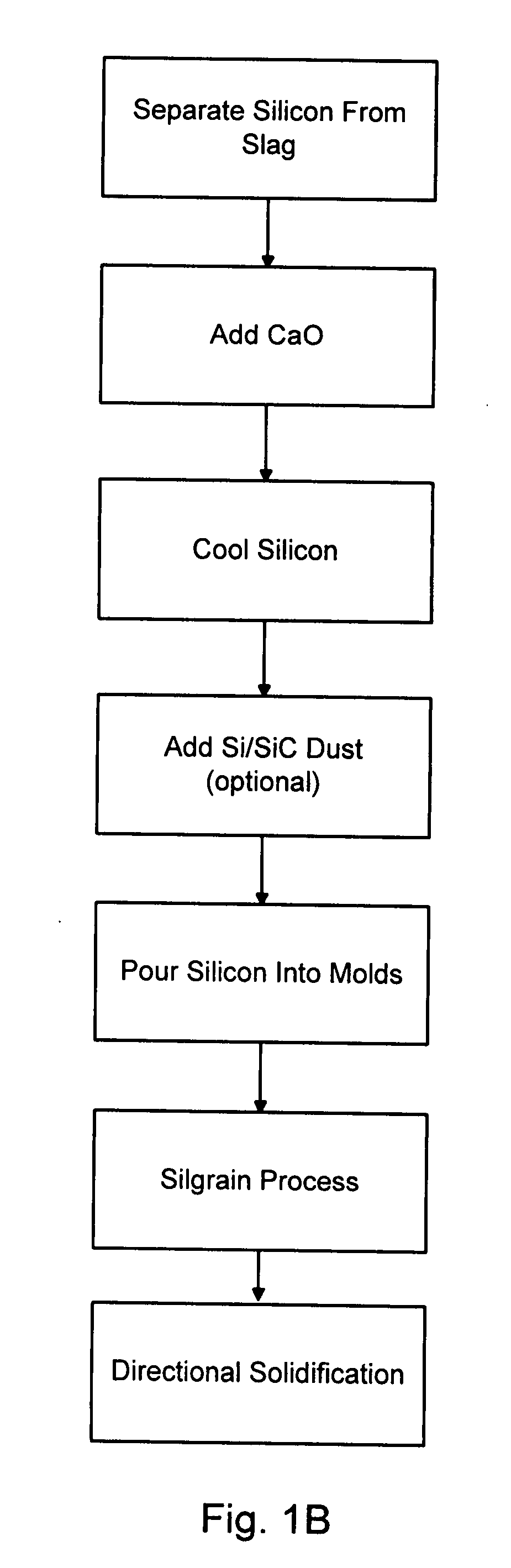

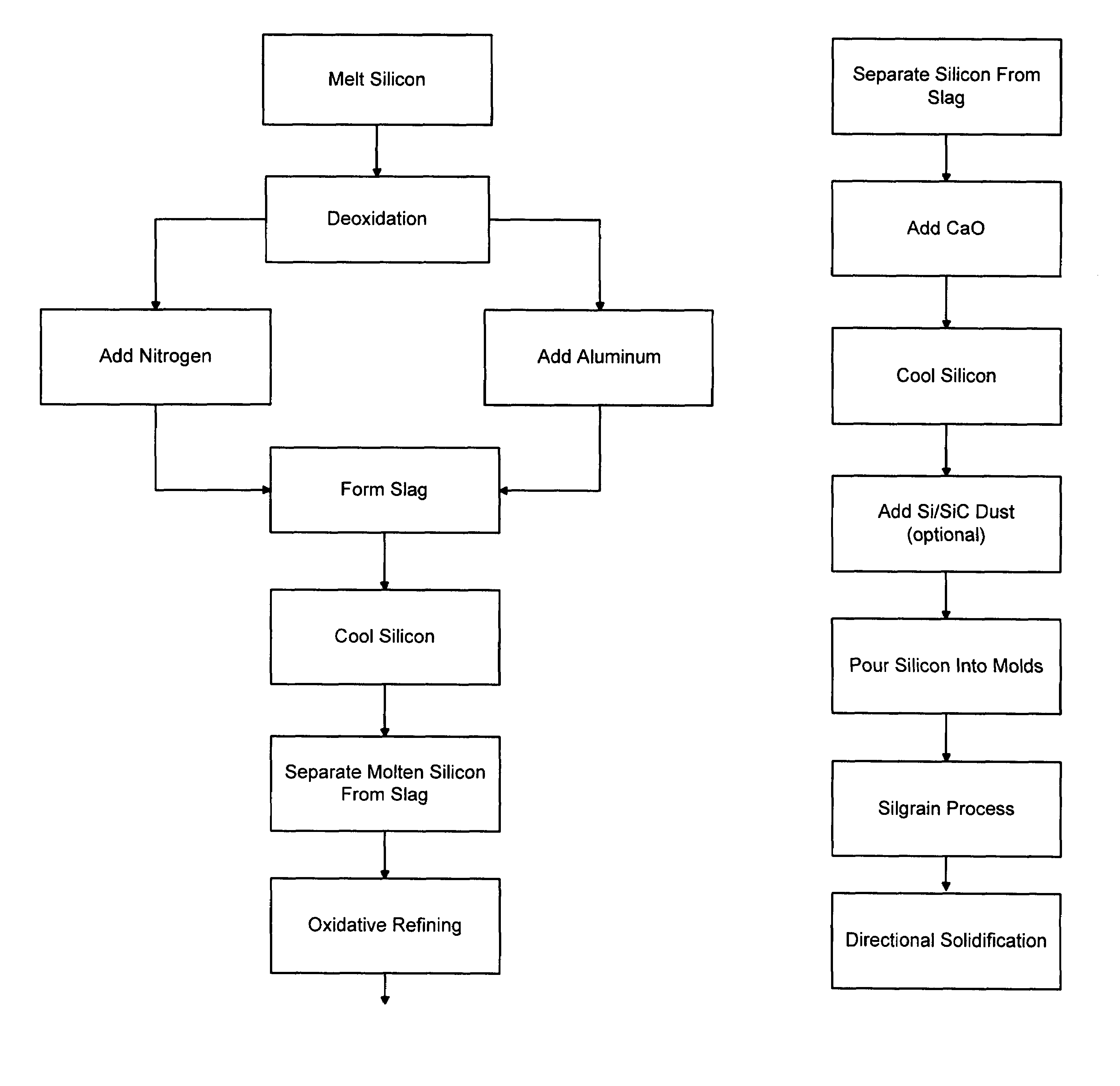

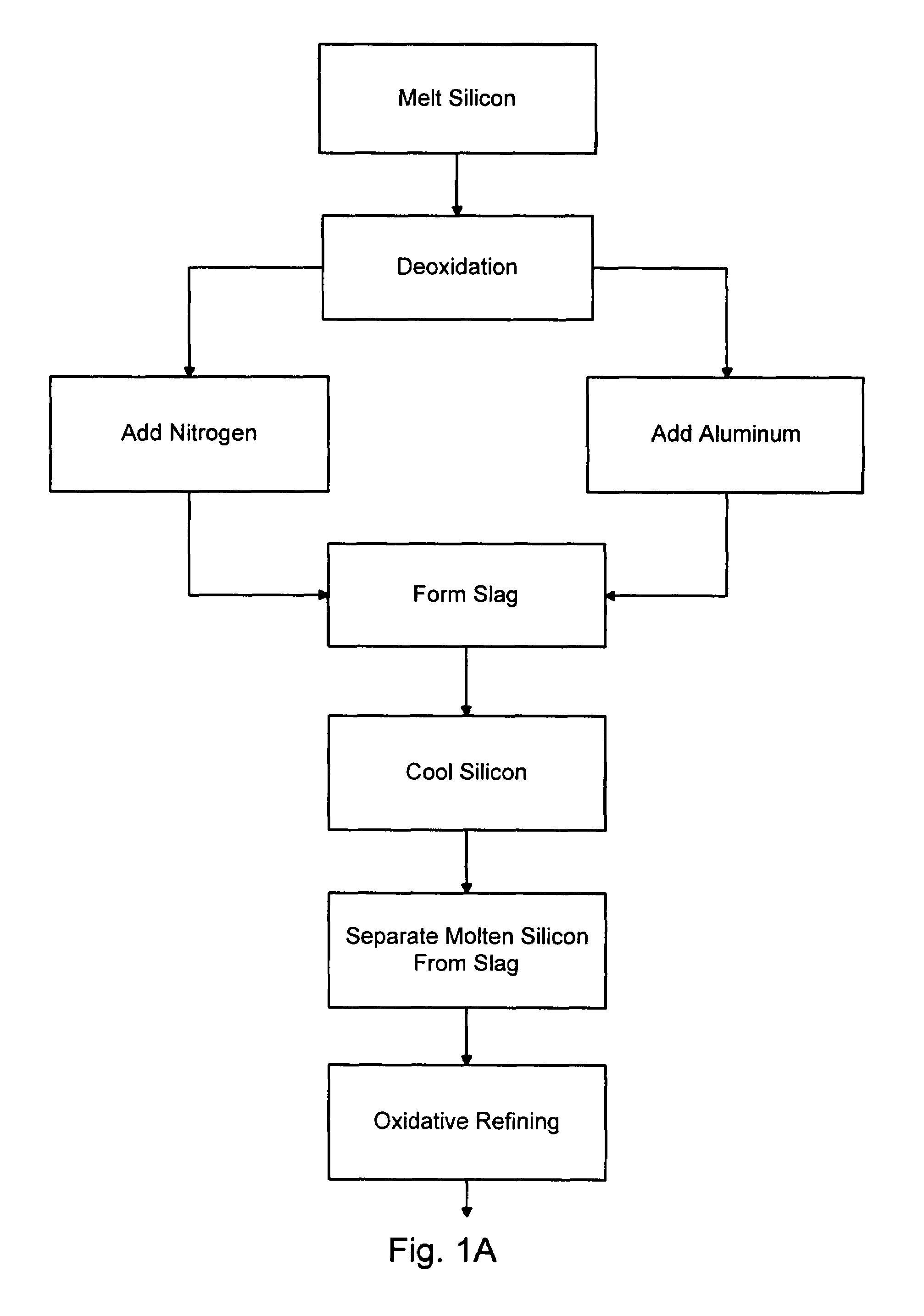

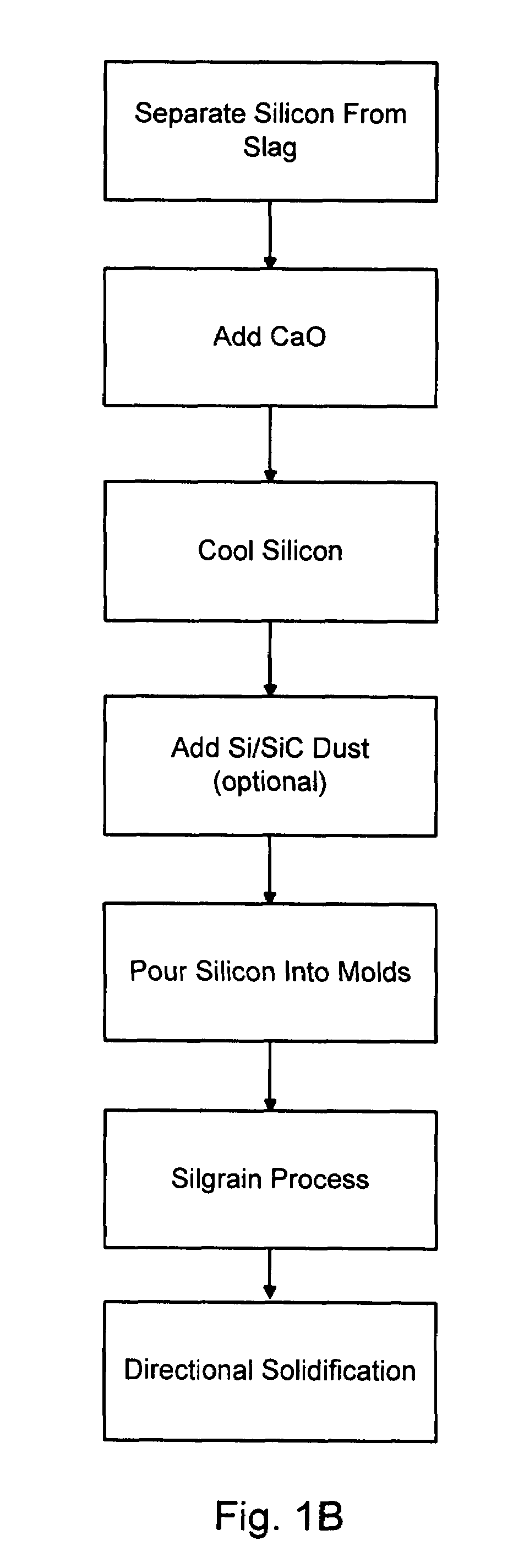

Silicon refining process

Nitrogen and aluminum and fluxing agents (Al2O3, SiO2, CaO and MgO) are added to molten silicon to create an oxy-nitride slag that acts as a sink for dissolved boron and phosphorus. The nitrogen can be added by bubbling nitrogen gas through the molten silicon; the aluminum can be added as aluminum metal or as Al2O3. Normally, the silicon must initially be deoxidized to allow the boron and phosphorus refining reactions to occur. The process may be followed by oxidative refining, SiC settling, the Silgrain process and directional solidification to remove other impurities and produce silicon suitable for use in solar cells. In an alternative version of the process, the molten silicon is passed through a particulate bed formed of a nitrogen-containing compound and an aluminum-containing compound.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

High-flowability polymide composite

The invention discloses a high-flowability polymide composite which comprises the following components in parts by weight: 100 parts of thermoplasticity polymide, 0.5-10 parts of polybutylene, 15-70 parts of reinforcing material, 10-30 parts of fire retardant and 3-10 parts of other additives, wherein the melting point of the thermoplasticity polymide is 280-330 DEG C, and the relative viscosity of the thermoplasticity polymide is 2.0-2.3. The polymide composite provided by the invention has the advantages of high flowability and good mechanical processing property, and can meet thin wall and multi-cave forming requirements; the content of the gas in the obtained composite is less, the surface of the formed product is good, and raw materials can be obtained easily and are low in price; and the high-flowability polymide composite has a wide market space.

Owner:KINGFA SCI & TECH CO LTD +1

Large-thickness lamellar tearing-resistant high-strength steel plate with 960 MPa-level yield strength and production method thereof

ActiveCN110318008APromoting degenerationImproved through-thickness performanceFurnace typesIncreasing energy efficiencyMechanical propertyMaterials science

The invention relates to a large-thickness lamellar tearing-resistant modulated high-strength steel plate with 960 MPa-level yield strength and a production method thereof. The chemical components ofthe large-thickness lamellar tearing-resistant modulated high-strength steel plate with 960 MPa-level yield strength comprises, by weight, 0.15-0.20% of carbon, 0.10-0.40% of silicon, 0.90-1.30% of manganese, 0.010-0.040% of niobium, 0.010-0.045% of vanadium, smaller than or equal to 0.010% of titanium, 0.03-0.06% of aluminum, 0.50-1.00% of nickel, smaller than or equal to 0.1% of copper, 0.30-0.80% of chromium, 0.20-0.70% of molybdenum, 0.001-0.005% of boron, 0.001-0.005% of calcium, smaller than or equal to 0.010% of phosphorus, smaller than or equal to 0.002% of sulphur, smaller than or equal to 0.002% of oxygen, smaller than or equal to 0.004% of nitrogen, smaller than or equal to 0.00015% of hydrogen and the balance iron and inevitable impurity elements. The technological steps of thesteel plate comprises smelting, secondary refining, vacuum degassing, calcium treatment, continuous casting, heating, rolling, steel plate slow cooling, quenching and tempering. The large-thickness lamellar tearing-resistant modulated high-strength steel plate with 960 MPa-level yield strength has high comprehensive mechanical property; the yield strength is greater than or equal to 960 MPa; thetensile strength is greater than or equal to 1000 MPa; the Charpy impact power at a low temperature of minus 40 DEG C is greater than or equal to 30J; the Z-direction tensile fracture surface shrinking rate is greater than or equal to 35%; and the lamellar tearing-resistant property is good.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

Sulfurated hydrogen stress etching-resisting petroleum casing pipe and manufacturing method thereof

InactiveCN101413088AHigh strengthImprove hardenabilityProcess efficiency improvementElectric furnaceHydrogenMartensite

The invention discloses a petroleum casing pipe with sulfurated hydrogen stress corrosion resistance and a producing method thereof, which aims to proceed from improvement on purity and tensile ratio of steel, tempered martensite proportion, grain refinement, remained stress reduction and other aspects, and provide the petroleum casing pipe with high obdurability and sulfurated hydrogen stress corrosion resistance and the production method thereof. The petroleum casing pipe comprises the following compositions in weight percentage: 0.12 to 0.18 percent of C, 0.10 to 0.60 percent of Si, 0.05 to 1.0 percent of Mn, 0.20 to 1.0 percent of Cr, 0.10 to 0.80 percent of Mo, 0.005 to 0.05 percent of Al, 0.005 to 0.02 percent of Ti, 0.05 to 0.15 percent of V, 0.002 to 0.02 percent of Nb, 0.0003 to 0.005 percent of Ca, 0.0003 to 0.005 percent of Mg, 0.0003 to 0.003 percent of B, less than or equal to 0.020 percent of P, less than or equal to 0.005 percent of N, and the balance being Fe, wherein the weight percentages of carbon, manganese, chromium and molybdenum are determined by a comprehensive control formula, that is A is equal to the sum of percentage of C, percentage of Mn divided by 5, percentage of Cr divided by 5, and percentage of Mo divided by 3, and the range of A is between 0.45 and 0.60 percent.

Owner:TIANJIN UNIV OF COMMERCE

High strength and ductility oil casing with hydrogen sulfide corrosion resistance and manufacturing method for oil casing

The invention discloses a high strength and ductility oil casing with hydrogen sulfide corrosion resistance and a manufacturing method for the oil casing, and aims to provide an oil casing with high impact resistance and capable of meeting the requirement for exploiting a deep oil-gas layer containing hydrogen sulfide gas and a manufacturing method for the oil casing. The oil casing consists of the following components in percentage by weight: 0.15 to 0.20 percent of C, 0.1 to 0.2 percent of Si, 0.4 to 0.6 percent of Mn, 0.6 to 0.8 percent of Cr, 1.2 to 1.6 percent of Mo, 0.01 to 0.05 percent of Al, 0.002 to 0.05 percent of Ti, 0.05 to 0.10 percent of V, 0.005 to 0.015 percent of Nb, 0.0003 to 0.005 percent of Ca, less than 0.002 percent of B, less than or equal to 0.015 percent of P, less than or equal to 0.005 percent of S, 0.003 to 0.010 percent of N, and the balance of Fe, wherein the adding amount of Mo, V, Cr and Mn satisfies that 12V+1-Mo is more than or equal to 0 and Mo-(Cr+Mn) is more than or equal to 0. According to the oil casing, the content of manganese, chromium and molybdenum is controlled through a comprehensive control formula, and hydrogen sulfide corrosion resistance and impact ductility are improved by optimizing the content of each component.

Owner:TIANJIN UNIV OF COMMERCE

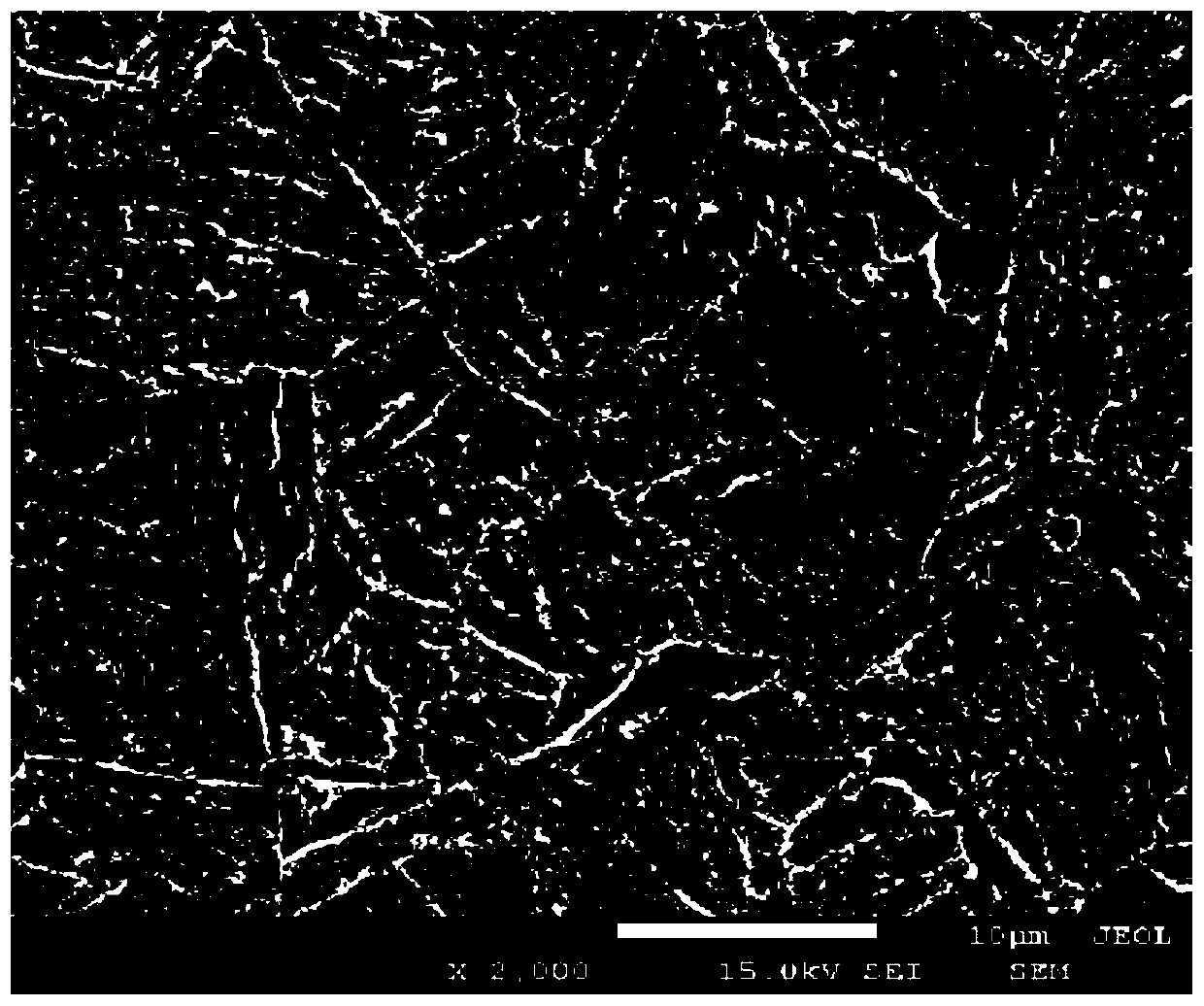

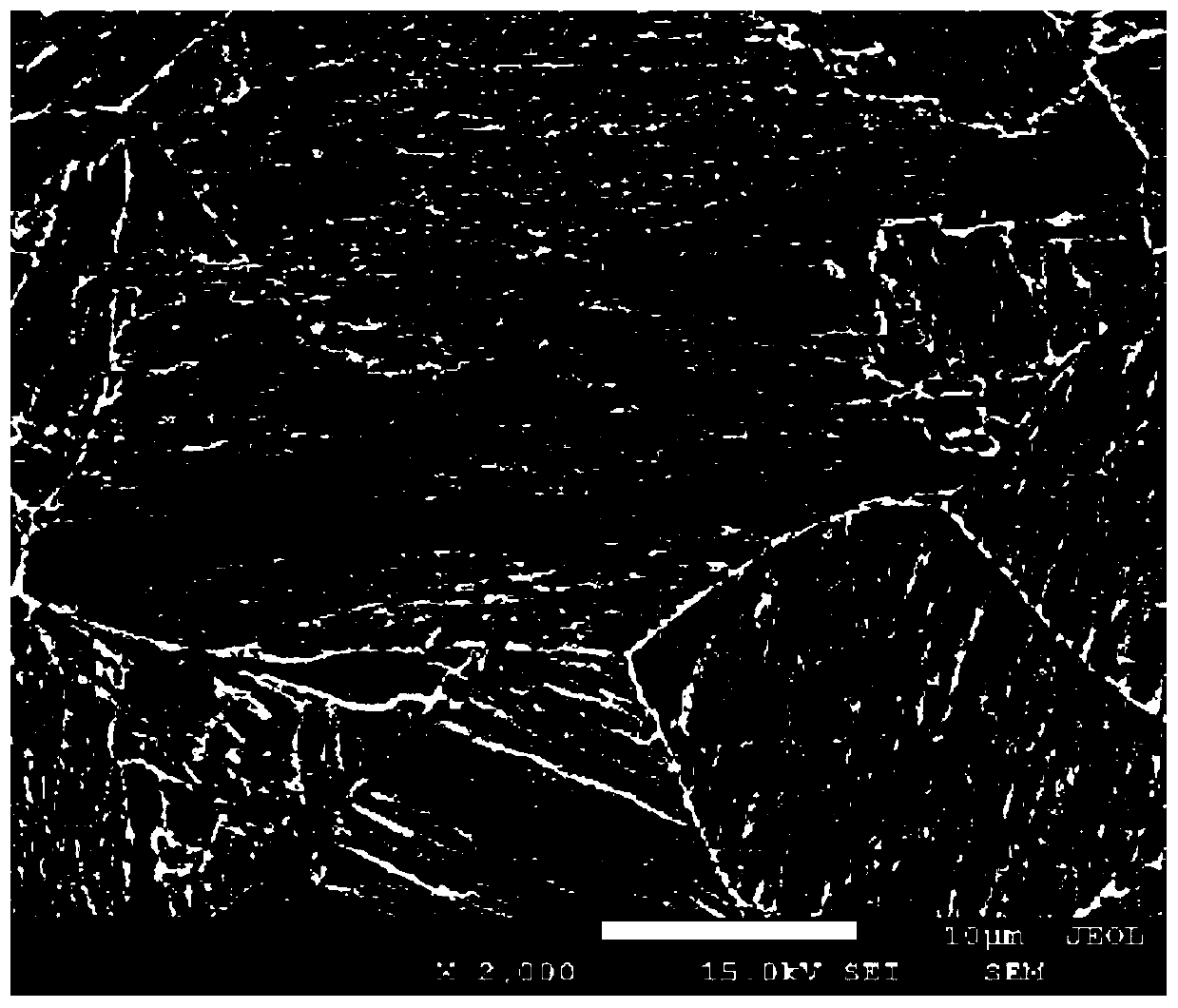

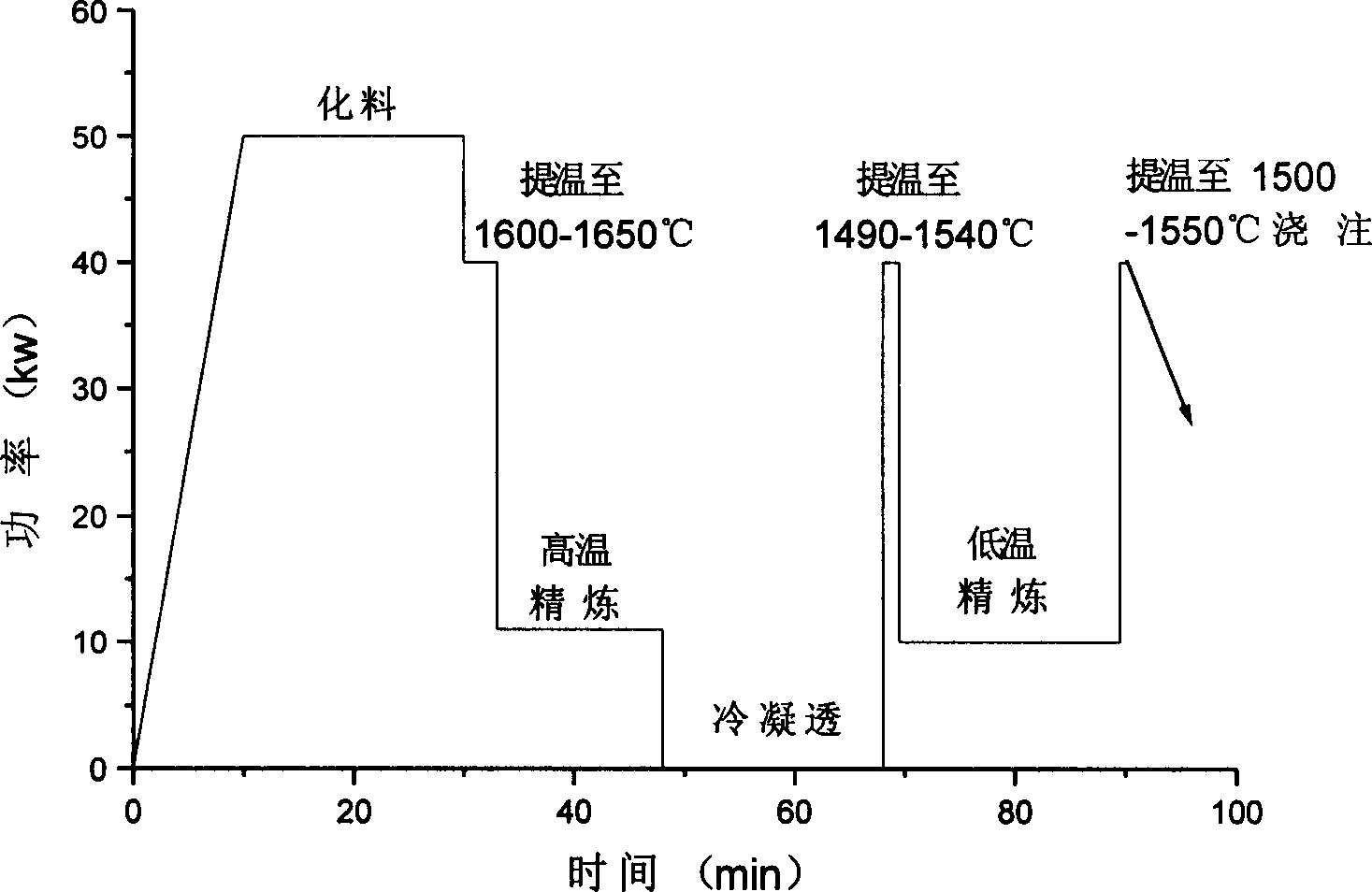

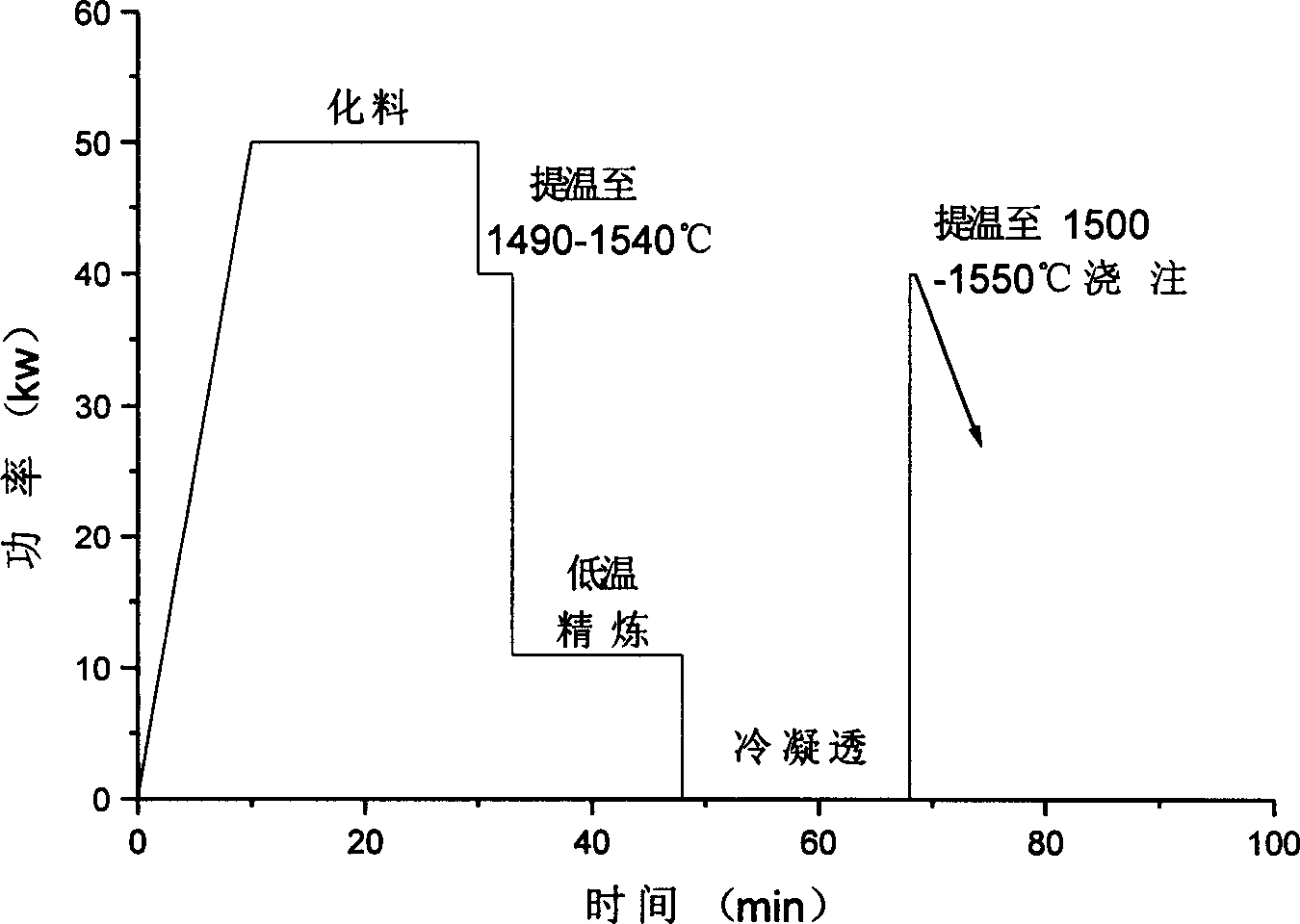

Ultrapure smelting process for nickel-base high-temperature alloy

Process for melting Ni based high temperature alloy with super purity is carried out by degassing at first, purifying alloy elements and heating-up to 1600 - 1650 deg.C for 15 - 20 minutes, cooling to condense, next, heating-up to 1490 - 1540 deg.C for 20 - 30 minutes again, casting into ingots at 1500 - 1550 deg.C, then, melting degassed elements as raw materials to produce Ni based alloy with low carbon and gas contents. Because the raw material is degassed, no carbon is added, and melting time is not long, The Ni based alloy with low carbon and gas contents is obtained.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

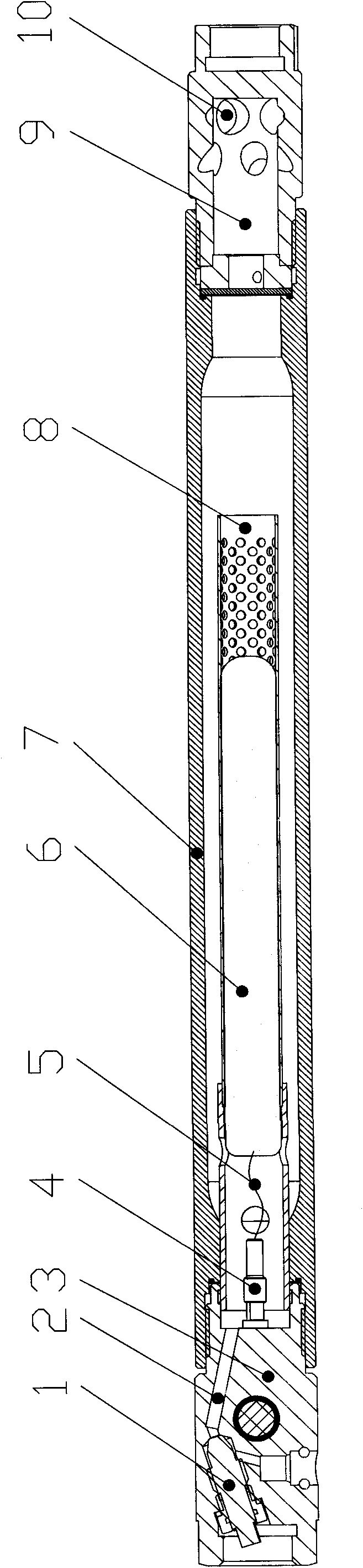

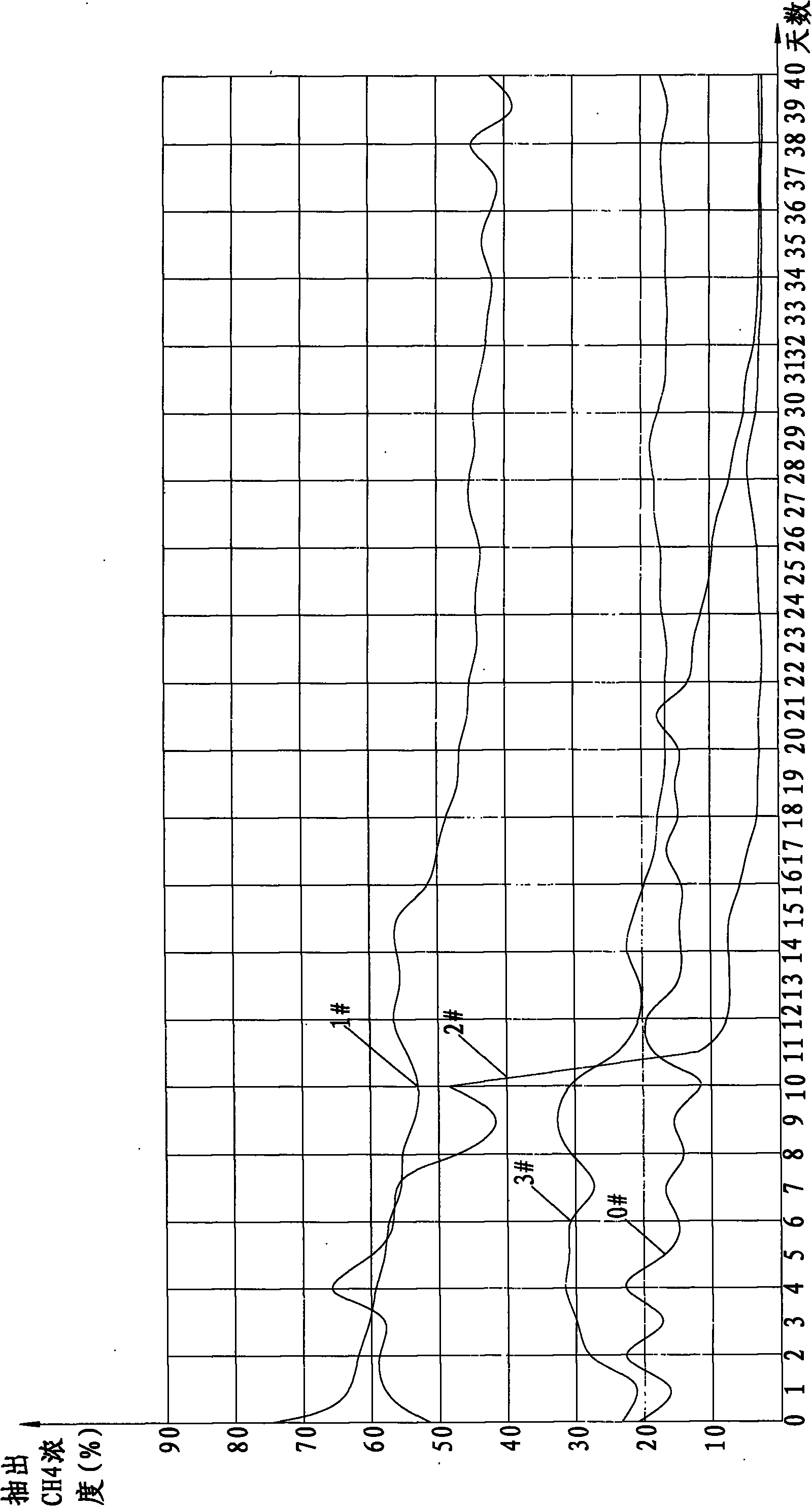

Method for extracting protruded coal-bed downward bedding long-borehole step-by-step covering area gas

InactiveCN101029575AReduce gas contentEliminate outstanding hazardsGas removalSealing/packingEngineeringGas concentration

This is a gas extraction method for a single burst coal bed of stable coal occurrence, angle less than 10o, and firm index over 0.5. Drill a hole from top working face downward along the coal bed from shallow bed to deep, from low gas concentration zone to high for pre-extraction to lower down the gas concentration.

Owner:淮北矿业股份有限公司祁南煤矿 +1

Preparation method for high-quality 40Cr alloy structural steel hot rolled coil rod

ActiveCN106929622AImproved ductility and processing deformation abilityPromote refinementManufacturing convertersProcess efficiency improvementDeoxygenationSteel quality

The invention discloses a preparation method for a high-quality 40Cr alloy structural steel hot rolled coil rod. The preparation method comprises the following steps of A, hot metal pretreatment desulfurization, B, molten steel smelting, C, deoxygenation alloying, D, molten steel LF furnace refining, E, molten steel VD furnace vacuum refining, F, molten steel casting, G, billet heating, and H, controlled rolling and controlled cooling. The high-quality 40Cr alloy structural steel hot rolled coil rod produced through the method is high in steel cleanliness and fewer in occluded foreign substance and has high-strength as well as excellent plastic toughness and cold heading machining deformation capacity, the production requirement of a high-level fastener is met, and steel gas content and the occluded foreign are greatly reduced.

Owner:WUKUN STEEL

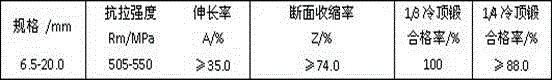

Steel wire rod for high-strength boron-contained and annealing-free fastening piece and preparation method thereof

The invention discloses a steel wire rod for a high-strength boron-contained and annealing-free fastening piece and a preparation method thereof. The steel wire rod for the high-strength boron-contained and annealing-free fastening piece comprises the following chemical components in percentage by weight: 0.20-0.24 wt% of C, Si not more than 0.04 wt%, 0.50-0.70 wt% of Mn, 0.25-0.35 wt% of Cr, 0.035-0.055 wt% of Ti, 0.035-0.055 wt% of Als, 0.0045-0.0060 wt% of B, S not more than 0.004 wt%, P not more than 0.012 wt%, O not more than 0.0015 wt%, H not more than 0.00015 wt%, and the balance of Fe and inevitable impurities. The preparation method comprises the steps of molten iron pretreatment desulfurization, molten steel smelting, deoxidation alloying, molten steel LF furnace refining, molten steel VD furnace vacuum refining, molten steel pouring, steel blank heating and controlled rolling and controlled cooling. The steel wire rod for high-strength boron-contained and annealing-free fastening piece is high in cleanness, few in inclusions, excellent in hardenability, proper in strength and hardness and excellent in ductility and toughness and cold heading and upsetting deformation capacity, can directly form a 10.9-grade high-level standard part through cold heading without needing spheroidizing annealing, reduces the processing procedures and the steel consumption, and reduces the production cost.

Owner:WUKUN STEEL

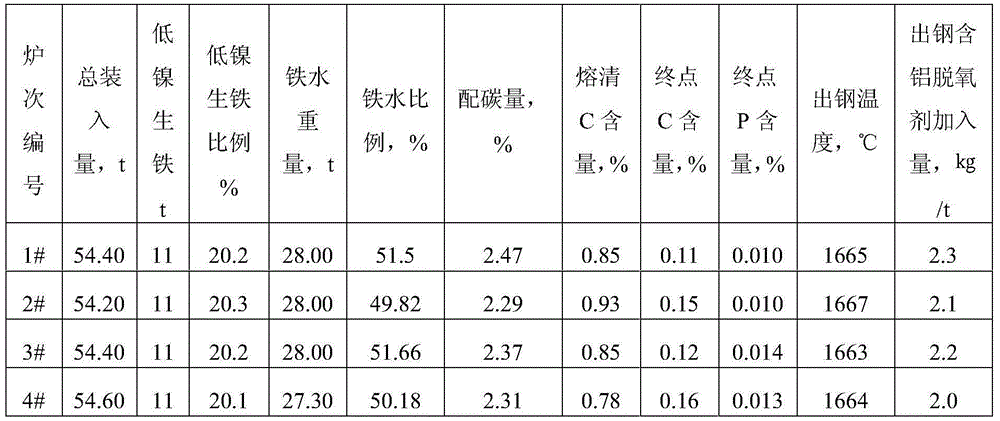

Method for producing continuous casting alloy steel containing S and Al

InactiveCN1434145AImprove purityStrong process applicabilityElectric furnaceProcess efficiency improvementSteelmakingAlkalinity

The production method of S and Al contained continuous casting alloy steel adopts four-step technological process: (1). smelting steel by using D.C. electric furnace; at the time of tapping (1640-1660 deg.C) adding proper quantity of SiAlFe deoxidant, carbon powder, alloy and slag material; (2) refining by using LF furnace, (a). adding lime (CaO is greater than or equal to 90%), SiFe and C powderin batches, making white slag and bottom blowing argon; (b). for boron-containing steel feeding Ti and retaining B, (c). top slag alkalinity is 2.8, Al2O3 content in the slag is 25%, regulating Al and S; (3) vacuum furnace treatment, its vacuum degree is less than or equal to 140 Pa, and treatment time is 20 min.; and (4) continuous pouring, its pouring speed is 320 kg / min.

Owner:宝钢特钢有限公司

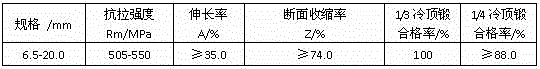

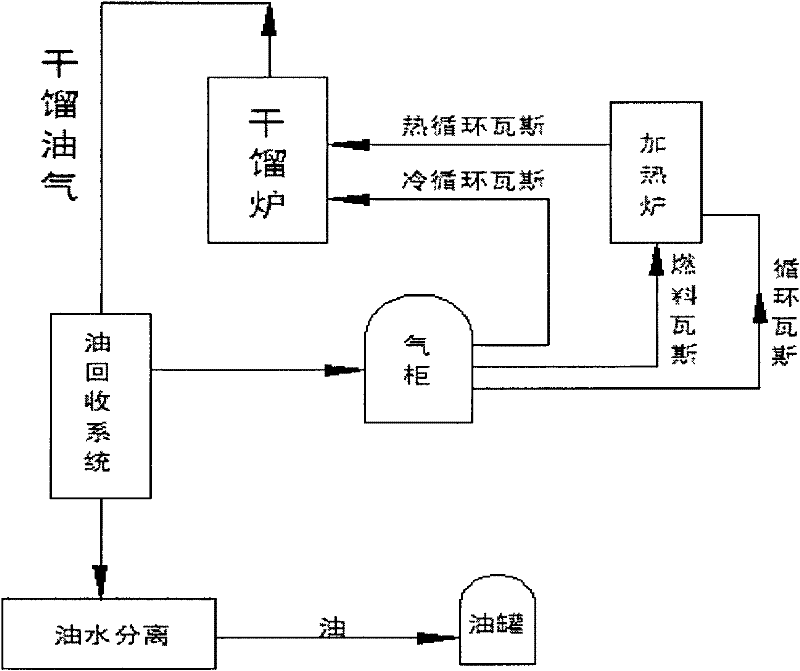

Methane-circulating retort capable of handling 500 to 1,000 tons of oil shale daily

InactiveCN102260509ASmall pressure lossReduce masonry costsDirect heating destructive distillationSpecial form destructive distillationWater contentChemistry

The invention discloses a process and a device for refining oil by dry distillation of oil shale. The process is characterized in that methane generated in the dry distillation process of the oil shale can be repeated used as a hot carrier in the dry distillation of the oil shale. The retort for realizing the dry distillation oil refining process is characterized in that: the retort has a vertical round-square structure, namely the cross section of the upper part is round, the cross section of the lower part is square, and the inside diameters of the upper and lower parts are the same; and array umbrellas, a herringbone baffle plate, a device shaped like a Ding(ancient cooking vessel of China) or in an Asi structure, an air distribution and material distribution tracery wall, a coke discharging tank, a cooling water jacket, a water seal pool, a coke pushing machine and a scraper conveyor are arranged in the retort from top down in turn. The daily handling capacity of the retort is 500 to 1,000 tons. The invention is suitable for refining oil by dry distillation of oil shale with low methane content, low solid carbon content, low water content and a particle size of 5 to 75 milliliters, and the recovery rate of the oil is 85 to 90 percent.

Owner:辽宁成大能源科技有限公司

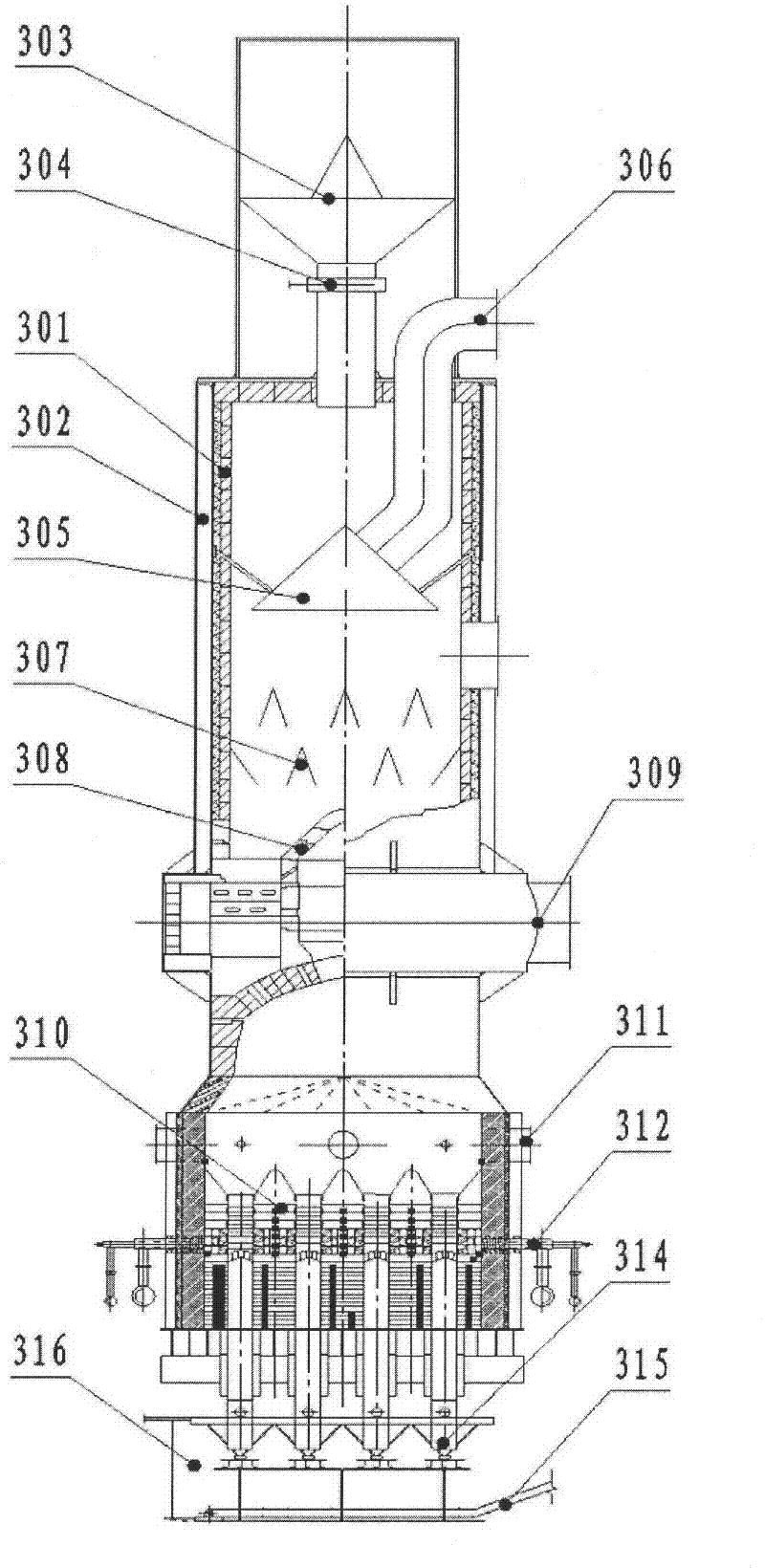

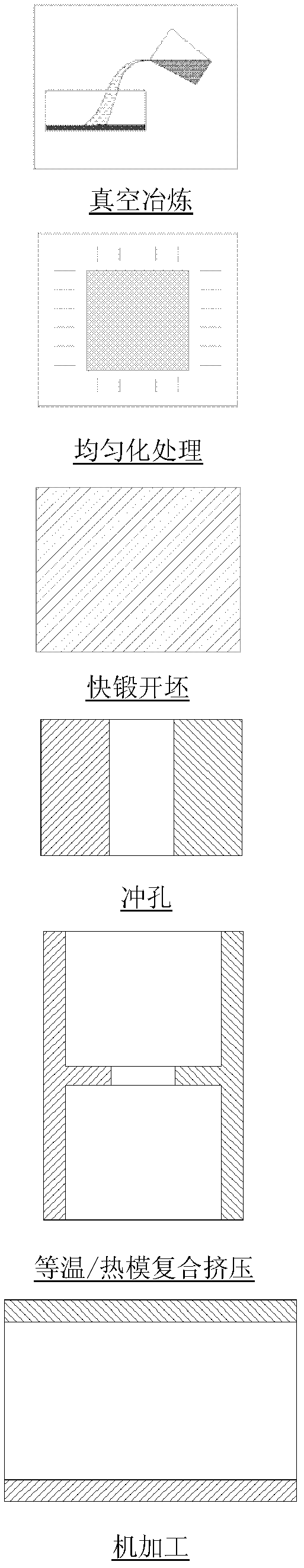

Compound extrusion preparation method of large-diameter high-quality tube blank or annular blank

ActiveCN103170797AUniform and fine tissueForming labor-savingMetal-working apparatusHeat processingUtilization rate

The invention relates to a compound extrusion preparation method of a large-diameter high-quality tube blank or an annular blank. The compound extrusion preparation method is mainly aimed at materials which are large in deformation resistance, narrow in heat processing temperature range, difficult in heat processing, and difficult to deform. The compound extrusion preparation method comprises the following steps: (1) a high-quality ingot blank with high purity is prepared through a vacuum melting process; (2) homogenization treatment is carried out alternatively, multi-pass pier drawing fast forging cogging-down is carried out, an organization is refined, and the homogeneity of the organization is improved; (3) hollow blank material is prefabricated in a punch mode; (4) isothermality / heat molding compound extrusion is carried out on the prefabricated hollow blank material, the tube blank with the uniform and thin organization is prepared; and (5) subsequent machining is carried out, and a finished tube (ring) and the high-quality ingot blank are obtained. The novel preparation method is used for preparing the large-diameter tube (ring) blank with the uniform and thin organization. The preparation method is labor-saving in shaping, energy-saving, high in material utilization rate, high in product quality, and capable of resolving the problems that a tube (ring) blank prepared through a traditional process is thick in organization, poor in uniformity, large in shaping force and the like.

Owner:GRIMAT ENG INST CO LTD

Preparation method of abrasion-proof and corrosion-resistant nickel-based alloy wire

The invention discloses an abrasion-proof and corrosion-resistant nickel-based alloy wire and a preparation method thereof. The alloy wire comprises the following components: 17-21% of C, 20-25% of Co, 1.8-2.2% of W, 6.4-9.5% of Mo, 1.4-1.8% of Al, 3.2-4.5% of Ti, 0.1-0.5% of Nb, 0.1-0.5% of Hf, 1.2-1.8% of Ta, 0.03-0.06% of Re, 0.01-0.05% of Ce, 0.02-0.1% of C, 0.005-0.015% of B, 0.02-0.07% of Zr, 0.005-0.008% of Mg, and the balance Ni. The preparation technology of the alloy comprises the steps of vacuum smelting, remelting, forging, hot rolling, drawing, solid solution treatment and aging treatment, namely, raw materials are prepared and smelted based on mass percent and then smelted; the smelted materials are forged and rolled into obtain alloyed wire rods; the alloyed wire rods are drawn at a plurality of times to obtain phi 0.05-0.4mm alloy wires; finally the alloy wires are subjected to solid solution treatment and aging treatment. The abrasion-proof and corrosion-resistant nickel-based alloy wire can be used as a brush wire material for brush sealing of an aircraft engine, a gas turbine, etc., thus the brush sealing effect can be effectively improved, and the service life can be prolonged.

Owner:江苏鑫信润科技股份有限公司

Silicon refining process

Nitrogen and aluminum and fluxing agents (Al2O3, SiO2, CaO and MgO) are added to molten silicon to create an oxy-nitride slag that acts as a sink for dissolved boron and phosphorus. The nitrogen can be added by bubbling nitrogen gas through the molten silicon; the aluminum can be added as aluminum metal or as Al2O3. Normally, the silicon must initially be deoxidized to allow the boron and phosphorus refining reactions to occur. The process may be followed by oxidative refining, SiC settling, the Silgrain process and directional solidification to remove other impurities and produce silicon suitable for use in solar cells. In an alternative version of the process, the molten silicon is passed through a particulate bed formed of a nitrogen-containing compound and an aluminum-containing compound.

Owner:THE ARIZONA BOARD OF REGENTS ON BEHALF OF THE UNIV OF ARIZONA

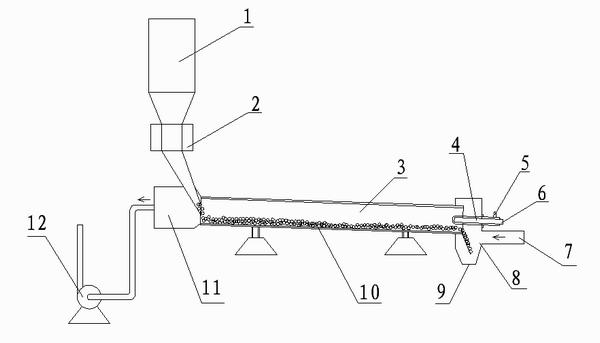

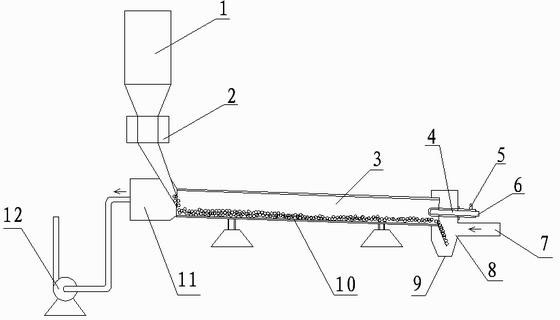

Presintering treatment process of glass batch and device thereof

ActiveCN102320715ADon't worry about flyingShorten clarificationCharging furnaceGlass productionGlass meltingHeating furnace

The invention discloses a presintering treatment process of a glass batch and a device thereof, and the process is performed according to the following steps: (1) adding 0.5 wt%-3 wt% of binders and 6 wt%-8 wt% of water into a glass batch, well mixing, pressing into spherical particle materials with a diameter of 3-25 mm; (2) adding the spherical particle materials into a rotary heating furnace, preheating at 1020-1250 DEG C for 0.5-2 hours, adding the sintered densified spherical particle materials into a glass melting furnace from the rotary heating furnace. According to the invention, the decomposition of carbonates in the glass batch is performed outside the glass melting furnace, which greatly reduces the gas content in the glass batch, effectively increases the heat transfer, shortens the time for glass clarification and homogenization, that is, increases the single-line yield and reduces the energy consumption without the enlargement of the glass melting furnace area; the invention can realize the increase of the melting amount by 20%-30% without the enlargement of a current melting furnace scale.

Owner:GLASS TECH RES INST OF SHAHE CITY OF HEBEI PROVINCE

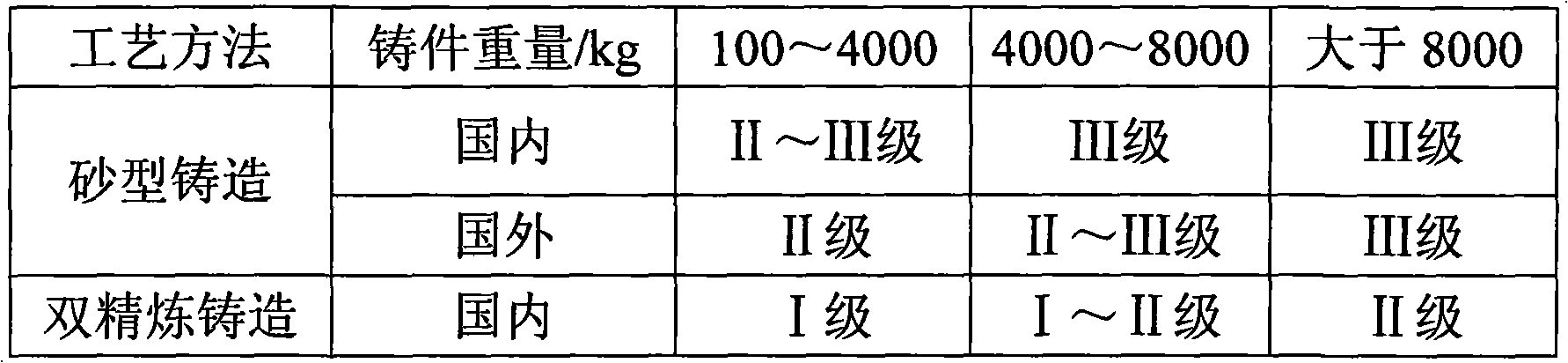

Electroslag smelting casting method of fixed blades of water turbine

The invention relates to an electroslag smelting casting method of fixed blades of a water turbine. Consumable electrodes are prepared by adopting a voltaic arc furnace refining method and the fixed blades are prepared by adopting an electroslag smelting casting process through a mould. The chemical components of the consumable electrodes are controlled as follows: C is 0.14-0.19 percent, Si is less than or equal to 0.6 percent, Mn is 1.5-1.9 percent, P is less than or equal to 0.035 percent, S is less than or equal to 0.035 percent, V is 0.02-0.15 percent, Nb is 0.015-0.06 percent, Ti is 0.15-0.25 percent, Al is more than or equal to 0.015 percent, O is less than or equal to 0.0040 percent, N is less than or equal to 0.0080 percent, H is less than or equal to 0.00035 percent, and the balance is Fe. The electroslag smelting casting system and the electroslag guide are controlled as follows: CaF2 is 60-80 percent, Al2O3 is 40-20 percent, or less MgO and CaO (the total is less than or equal to 20 percent); and the electroslag amount is usually 1.5-5 percent of the weight of a casting. The invention has less amount of oxide and sulfide, small size, even distribution, clean casting base body, high cooling speed, large crystallization temperature gradient at the front of solid and fluid, compact casting texture, high size precision and little distortion, and can greatly improve the product property of the refined casting.

Owner:SHENYANG RES INST OF FOUNDRY

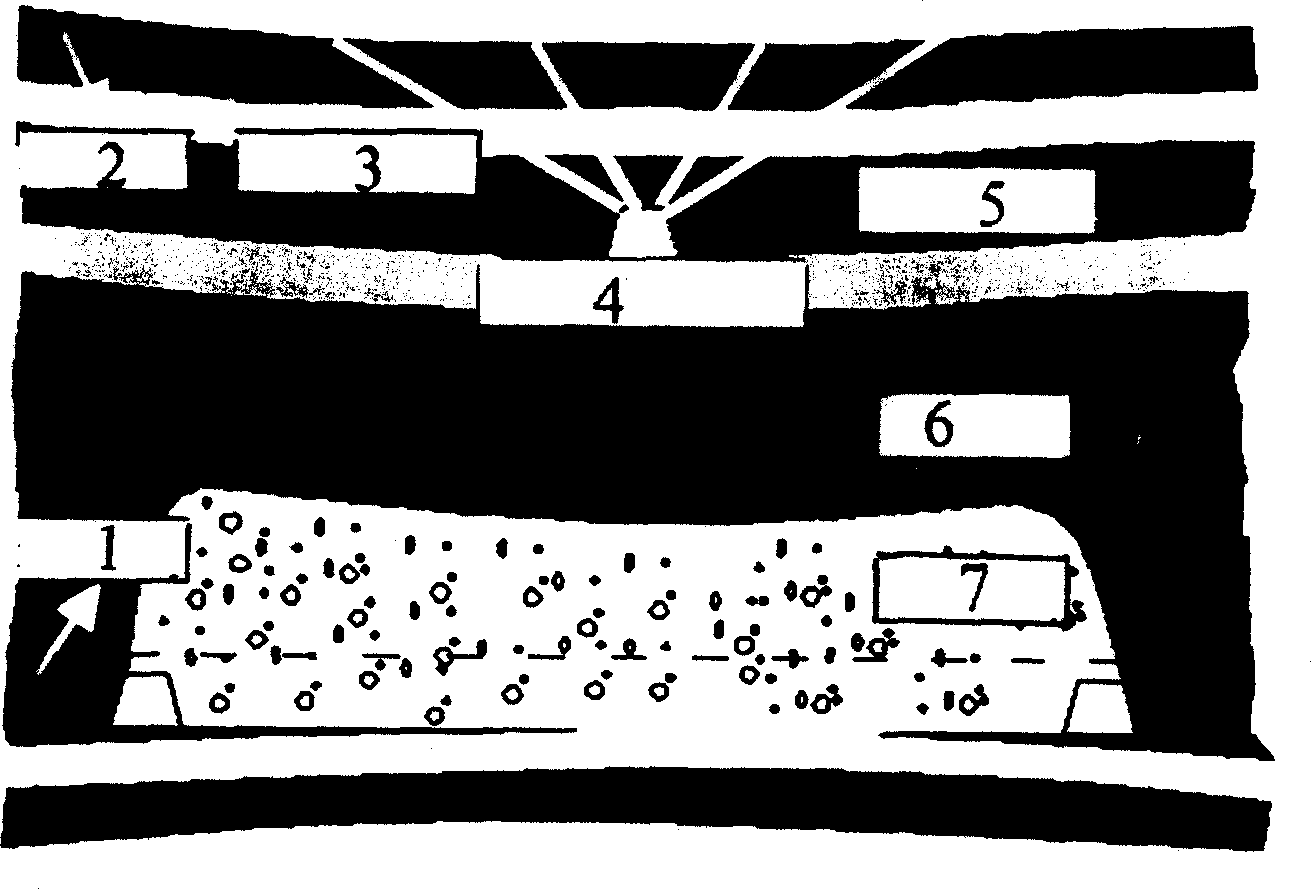

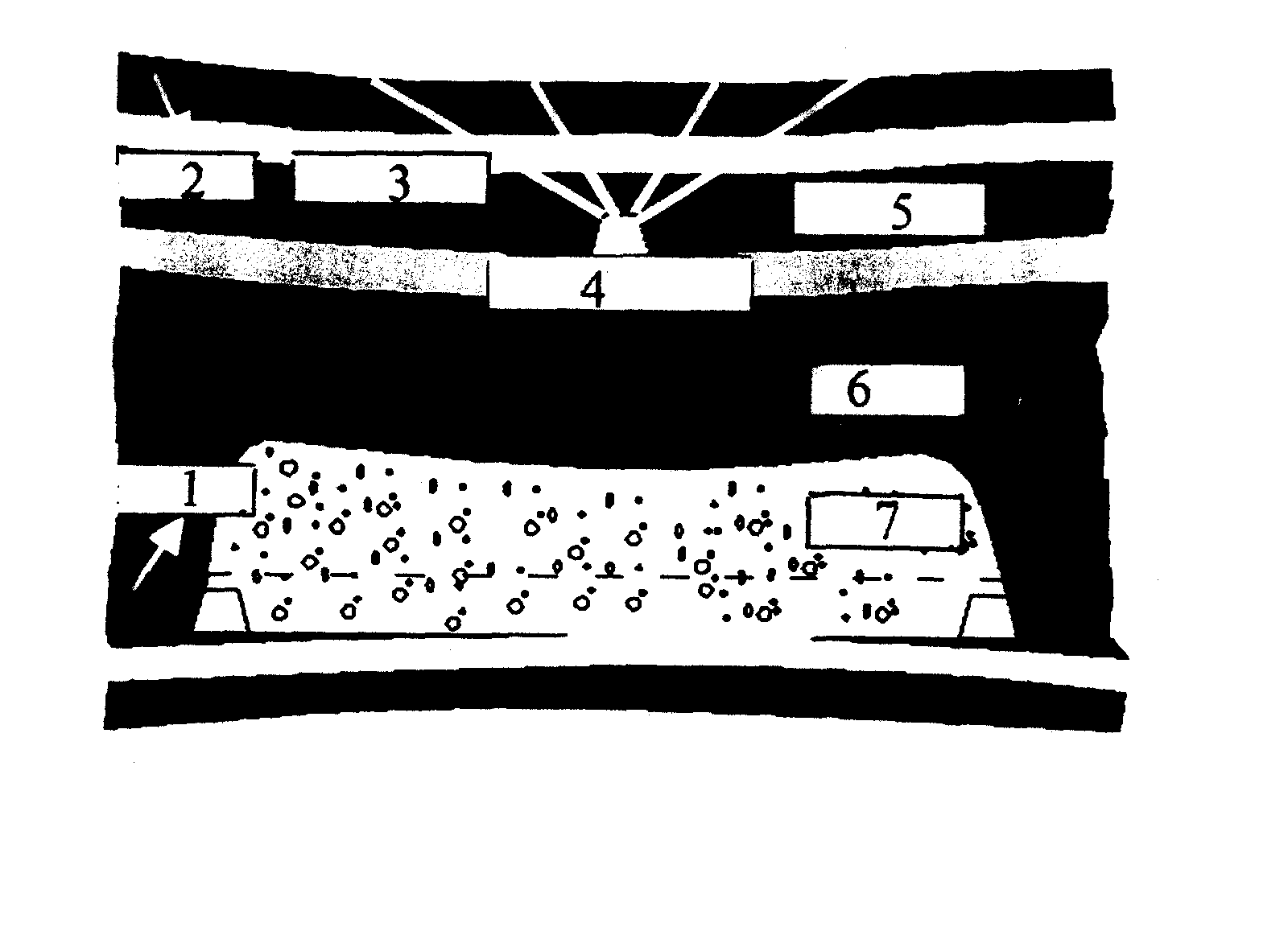

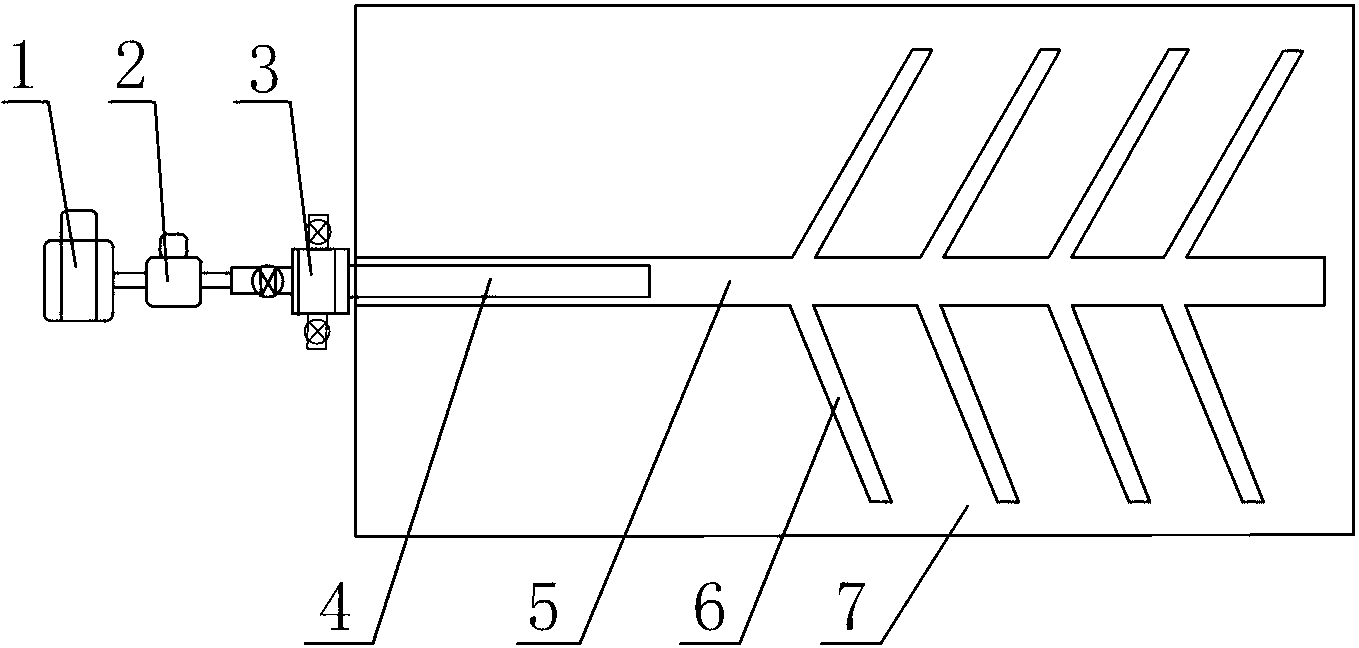

Down-hole pump drainage laneway exploitation system for mixing gas dispelling coal gas, and the method

InactiveCN101122217AImprove the security environmentReduce the impactFluid removalGas removalProduct gasHigh pressure

The invention discloses a system and a method for exploitation of mixed-gas coal-bed methane exploitation in a drainage roadway in an oil well, and relates to a coal-bed methane exploitation technology. The exploitation method comprises the following procedures: 1.various gases are integrated into a mixed gas; the mixed gas comprises a or a plurality of strongly exchanged gases, which comprises H2S, SO2 and CO2; the mixed gas also comprises a or a plurality of weakly exchanged gases, which comprises N2, H2 and He; 2. the mixed gas is injected into a coal bed (5) through an injection hole (1) with high pressure; 3. gas comprising the coal-bed methane is obtained from an drainage hole (6) with a drainage device, until the methane content is lower than the economic exploitation content and safety content. The invention promotes the exploitation rate and unit output of the coal-bed methane, and produces quite an obvious effect in reducing the greenhouse gas emission. Meanwhile, the invention is provided with the effect of reducing the outstanding risks of gas, and is applicable in the low-penetration exploitable coal-bed methane exploitation field.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Process of producing iron alloy with low carbon and chromium

The invention discloses a preparing craft of low-micro carbon chromium iron alloy, which comprises the following steps: 1) loading high carbon chromium iron into medium-frequency induction furnace; melting; heating-up at above 1600 deg.c; pouring into tank; 2) transferring the tank to station; air refining; 3) taking-up oxygen gun; inserting argon oxygen gun into solution liquid level 300-400mm of tank; setting the discharge of oxygen at 300-500 L / min; blowing at 5 min with argon oxygen ratio at 1 : 3; blowing at 5 min with argon oxygen ratio at 1 : 2; blowing at 5 min with argon oxygen ratio at 1 : 1; adding into silicon iron; 4) transferring the tank into vacuum chamber; switching in argon oxygen pipe at the bottom of tank; blowing into argon oxygen mixed gas; controlling the discharge capacity of argon gas at 150-250 L / min, discharge capacity of oxygen at 40-80 L / min, vacuum degree at 5-200Pa and time of air refining at 20-30 min; 5) relieving the vacuum; hanging the tank to casting position; casting; getting the product. The good effect of this invention is: simple producing craft; high productive efficiency; low power; good environment; low cost.

Owner:刘巍

Horizontal-drilling staged-fracturing pressure relief method for underground coal bed

InactiveCN103233768AImprove permeabilityReduce riskFluid removalGas removalWell cementingHigh pressure

The invention discloses a horizontal-drilling staged-fracturing pressure relief method for an underground coal bed. The method mainly comprises the steps of drilling a main horizontal hole which is 500m-1000m in length through a drill on a working face of the underground coal bed; placing an oil casing pipe into the main horizontal hole, cementing a well by G-level cement, placing a single-bending screw after cement curing, and drilling 8-10 branch drill holes which are 100-200m in length on the main horizontal hole; cleaning the drill holes thoroughly, installing a high-pressure hole sealing device at the opening of the main horizontal hole, connecting a high-pressure pump injection device through a high-pressure line, feeding a polymer gel liquid containing a natural quartz sand proppant into the hole, pumping the high pressure to open the coal bed in which a seepage channel with a flowing capacity is formed; and installing a water ring vacuum pump at the opening of the main horizontal hole, and pumping out gas in the main horizontal hole and branch drill holes. According to the method, a crack with the maximum volume can be formed in the working face of the coal bed, the permeability of the coal bed can be improved to the greatest extent, so that partings of the coal bed can be communicated so as to form a crack loose belt at a certain scale, the stress focused in the coal bed can be released, risks of rock burst of the coal bed and the content of gas in the coal bed are reduced, and safety production is guaranteed.

Owner:珲春市耀天新能源开发利用有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com