Coal seam pre-splitting method based on gas extraction

A technology for gas drainage and coal seam, applied in the field of gas drainage, can solve the problems of not being widely promoted, high drainage cost, difficult drilling, etc., so as to solve major safety hazards, reduce drainage system, and widen drainage. The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

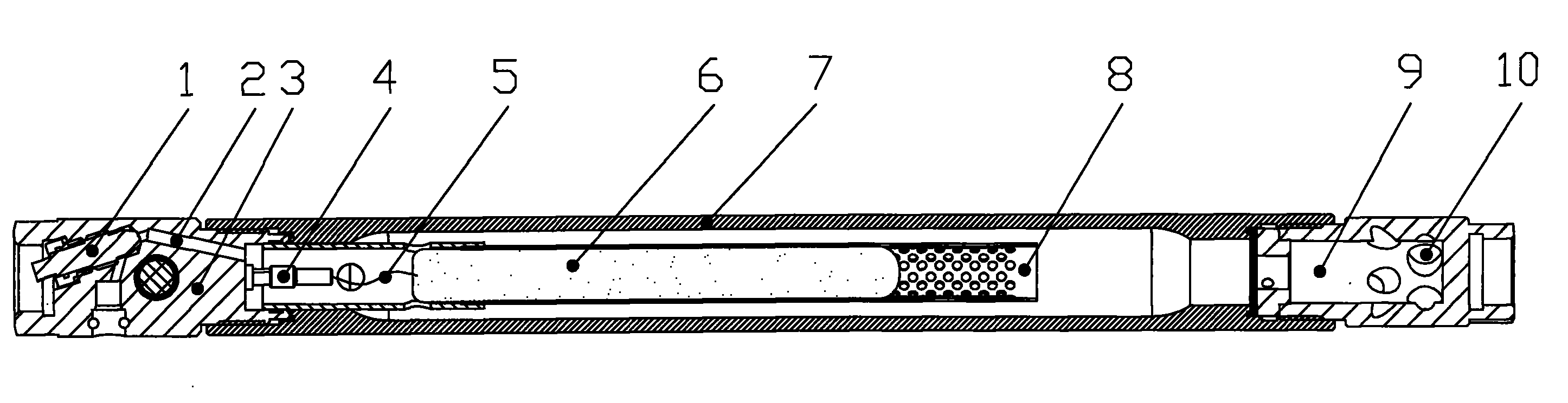

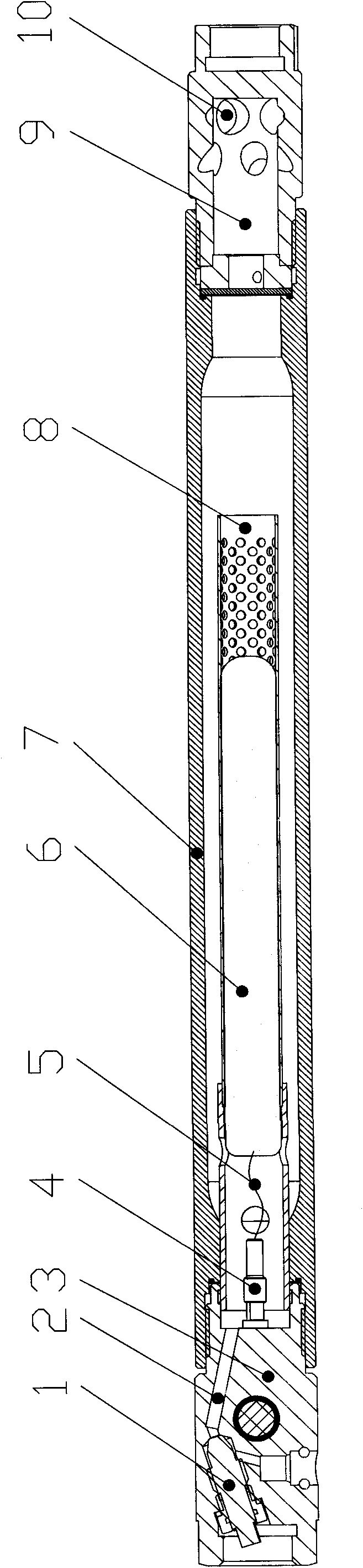

Method used

Image

Examples

Embodiment 1

[0052] Dongzhuang Coal Mine in Wuxiang County is a high-gas mine, and it is also one of the most difficult mines in Changzhi City to pump gas. The No. 3 coal seam is mainly coking coal, which has high gas content, extremely poor air permeability, and strong gas adhesion. The coal that has been piled up in the well for several months can still be detected after being broken.

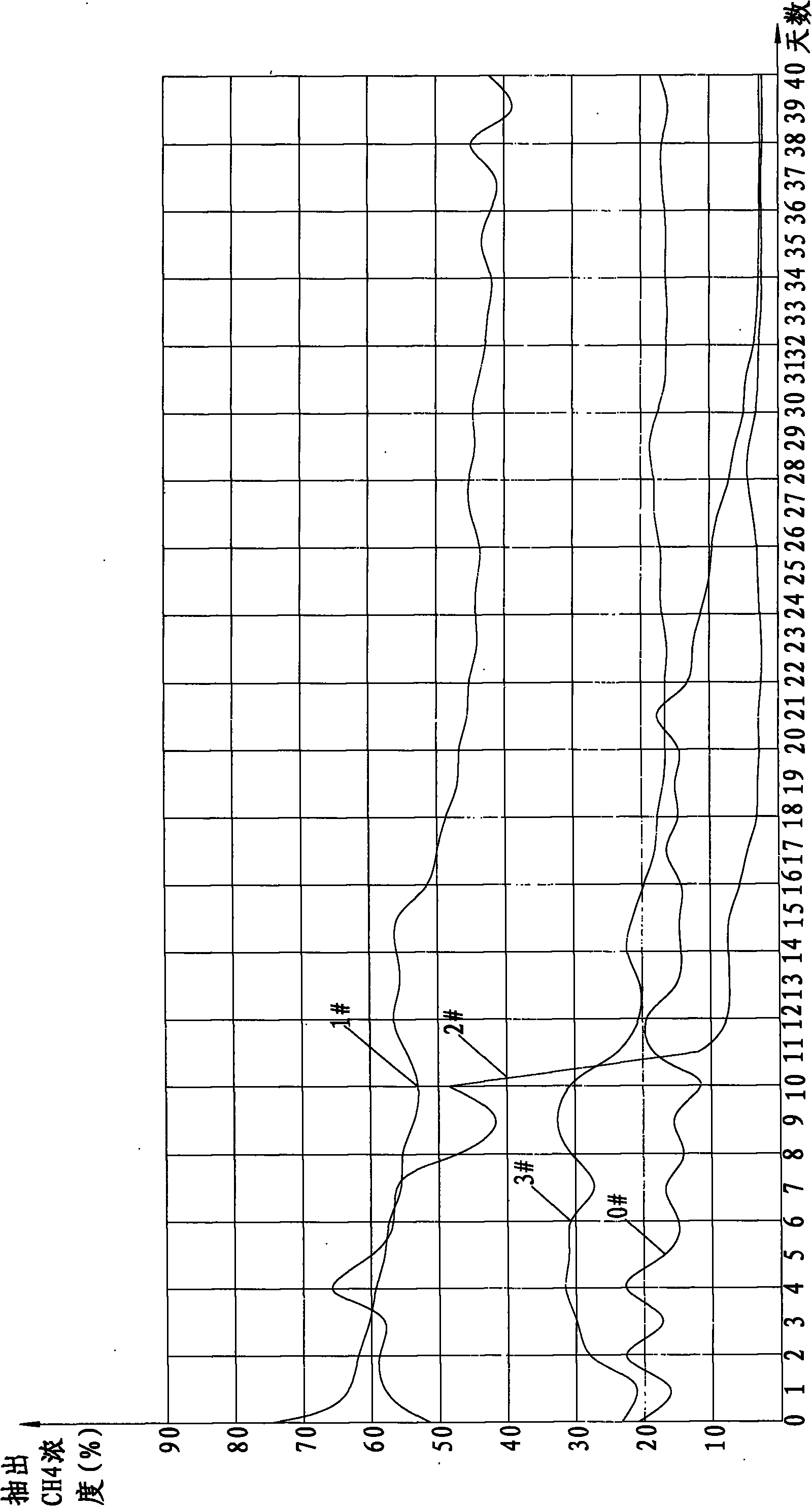

[0053] The mine has a 30101 mining face in its No. 3 coal seam. Due to the high gas content in the coal seam, it cannot meet the coal mining standards. The Gas Research Institute of Fushun Coal Academy of Sciences designed and installed an underground gas drainage system for gas pre-drainage. put. In the two parallel grooves of the working face, an extraction hole is drilled every 5 meters on average. There are three types of hole diameters: 75, 90, and 110mm, and the hole depth is 30-70 meters, with an average of about 50 meters. The pumping began in November 2007. The initial gas concentration is about...

Embodiment 2

[0070] The Xinyuan Coal Mine of Qinxin Coal Coke Company in Changzhi City mainly has coking coal in its coal seams, with an average thickness of 1.7 meters and a gas content of 3.18 to 9.86 cubic meters per ton of coal, with an average of 6.96 cubic meters. The solidity coefficient of the coal seam is 0.305, the air permeability system is 0.474-0.961, and the gas flow attenuation coefficient of the 100-meter borehole is 0.0927-0.2453, which belongs to the difficult-to-pump coal seam.

[0071] The underground drainage system of the mine was designed by Yangquan Coal Industry Group. According to the original records of the coal seam drainage, the gas extraction concentration was about 13% on the first day of drainage, about 7% on the second day, and about 7% on the third day. The concentration is only about 2%, and there will be no rebound phenomenon in the future.

[0072] On December 28, 2009, a test aimed at the radius of pre-cracking was carried out in the 1219 working face ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com