Patents

Literature

104results about How to "Uniform and fine tissue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

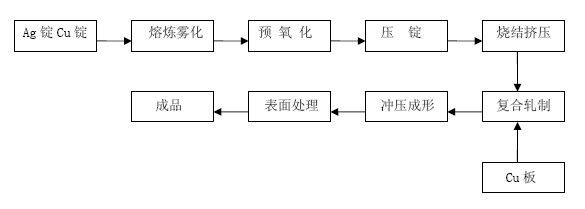

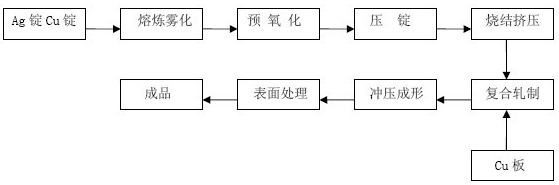

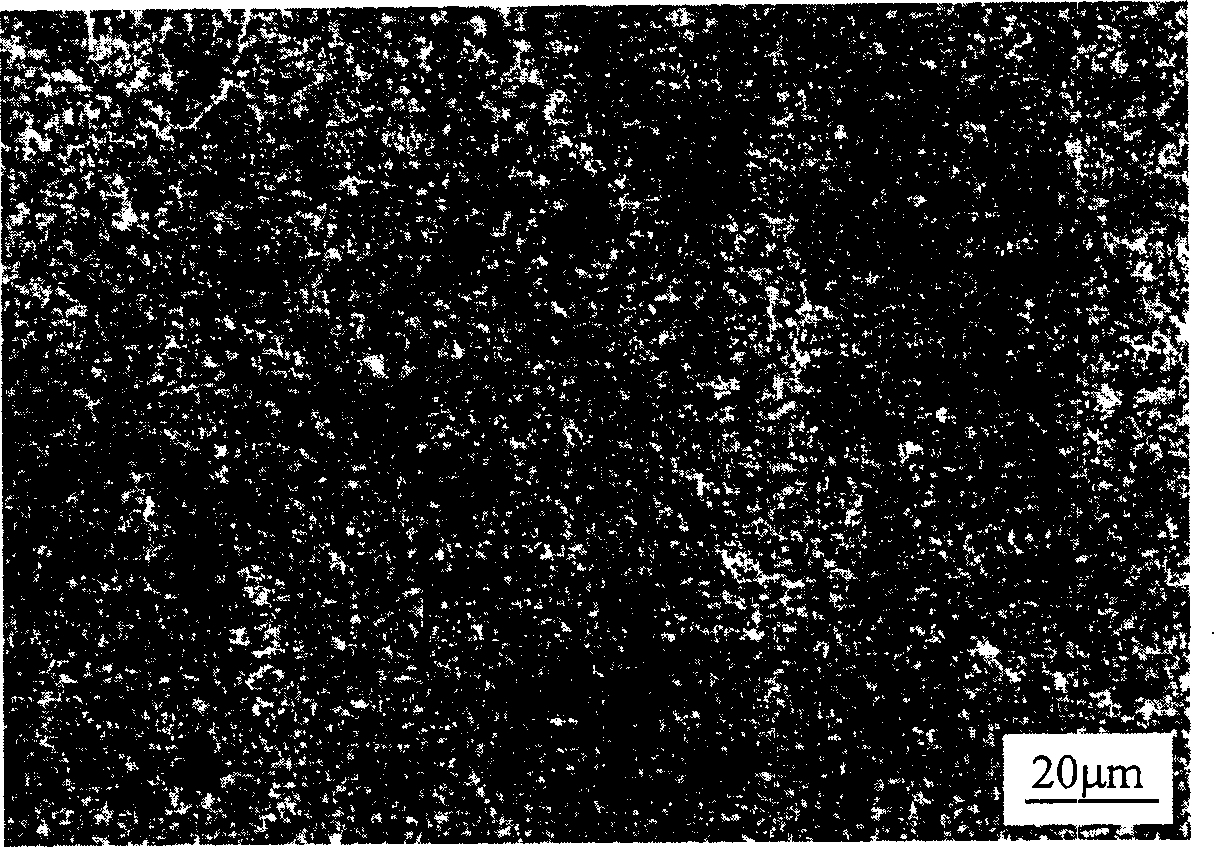

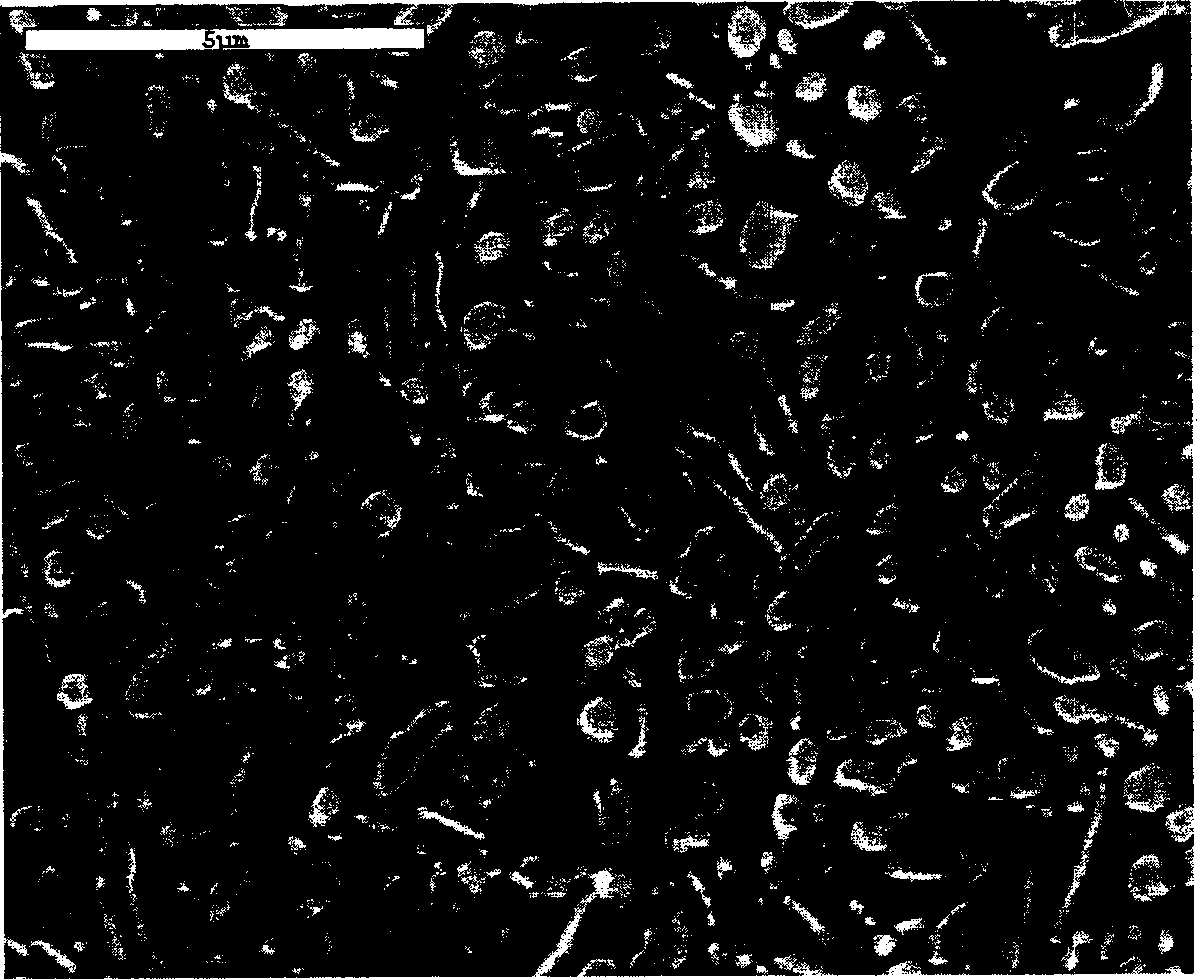

Silver copper oxide/copper composite electrical contact material and preparation process thereof

ActiveCN102054598AGuaranteed uniformityGrain refinementContactsMetal rolling arrangementsCopper oxideHigh pressure water

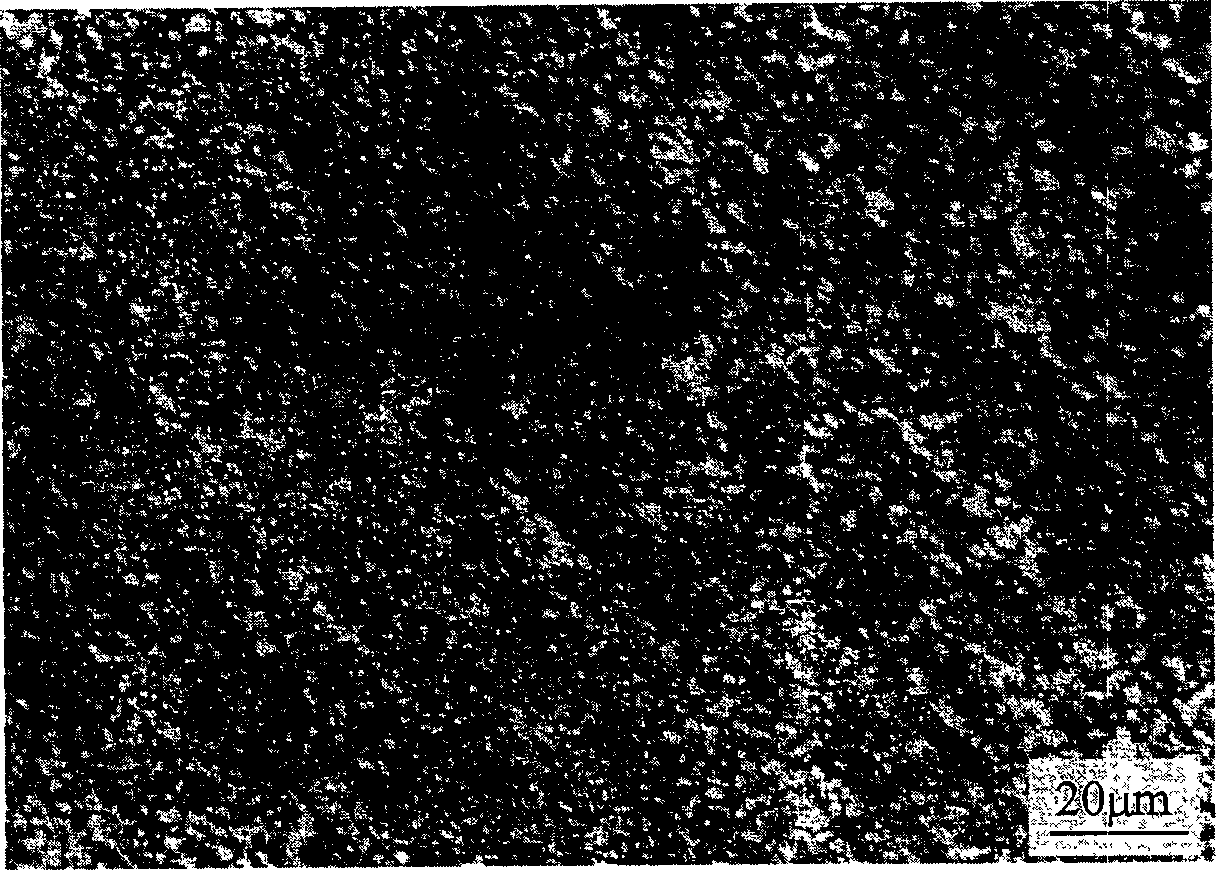

The invention discloses a silver copper oxide / copper composite electrical contact material and a preparation process thereof. The process comprises the following steps: mixing silver and copper according to certain proportions, and then, smelting the mixture in an intermediate frequency furnace; then, carrying out alloy atomization by using high pressure water atomizing equipment; baking after atomization to obtain powder; screening; putting the screened powder into an internal oxidization furnace for oxidizing at certain temperature and oxygen pressure; carrying out isostatic cool pressing after oxidization to form a billet; sintering and extruding to form a plate; and then, carrying out composite rolling with copper to obtain a finished product. Because the formula and process disclosed by the invention are reasonable, the produced electrical contact has the characteristics of high conductivity, uniform and fine tissue, high bonding strength between a working layer and a welding layer, fusion welding resistance, electrical arc erosion resistance and the like.

Owner:WENZHOU LONGSUN ELECTRICAL ALLOY CO LTD

High-strength superhigh-carbon steel and its production process

The high-strength superhigh-carbon steel has the alloy components including C 1.0-2.0 wt%, Cr 0.5-2.0 wt%, Mn 0.2-0.8 wt%, Si or Al and Fe (the balance). The production process includes selection of proper additive elements, spray moulding to obtain blank; great deformation amount hot rolling, and cooling to obtain material with about 1000 MPa yield strength, about 1300 MPa tensile strength and 8-11 % percentage elongation and no need of quenching and tempering. The spray molded blank has fine structure and excellent high temperature deformation capacity and this makes it possible to perform great deformation amount hot rolling to result in high-strength superhigh-carbon steel with compact and fine structure. The process is simple, efficient, and has low power consumption and low production cost.

Owner:CHINA BAOWU STEEL GRP CORP LTD +1

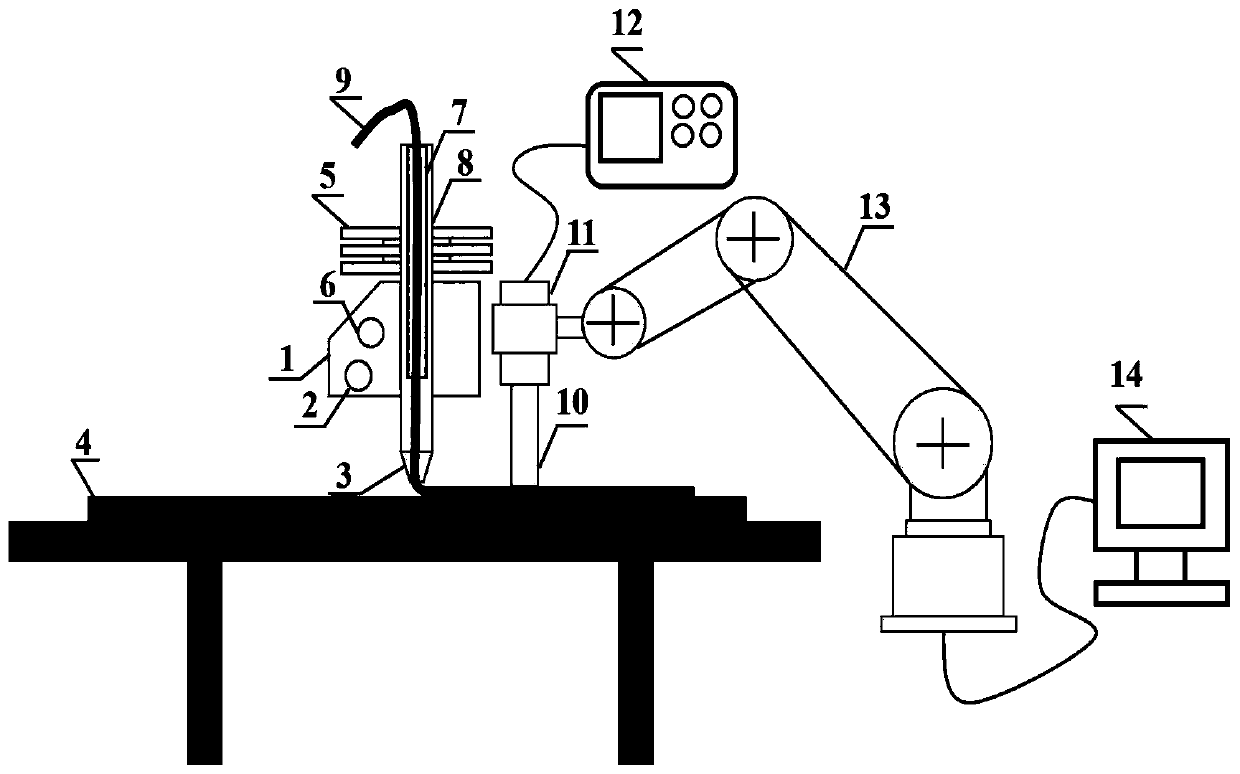

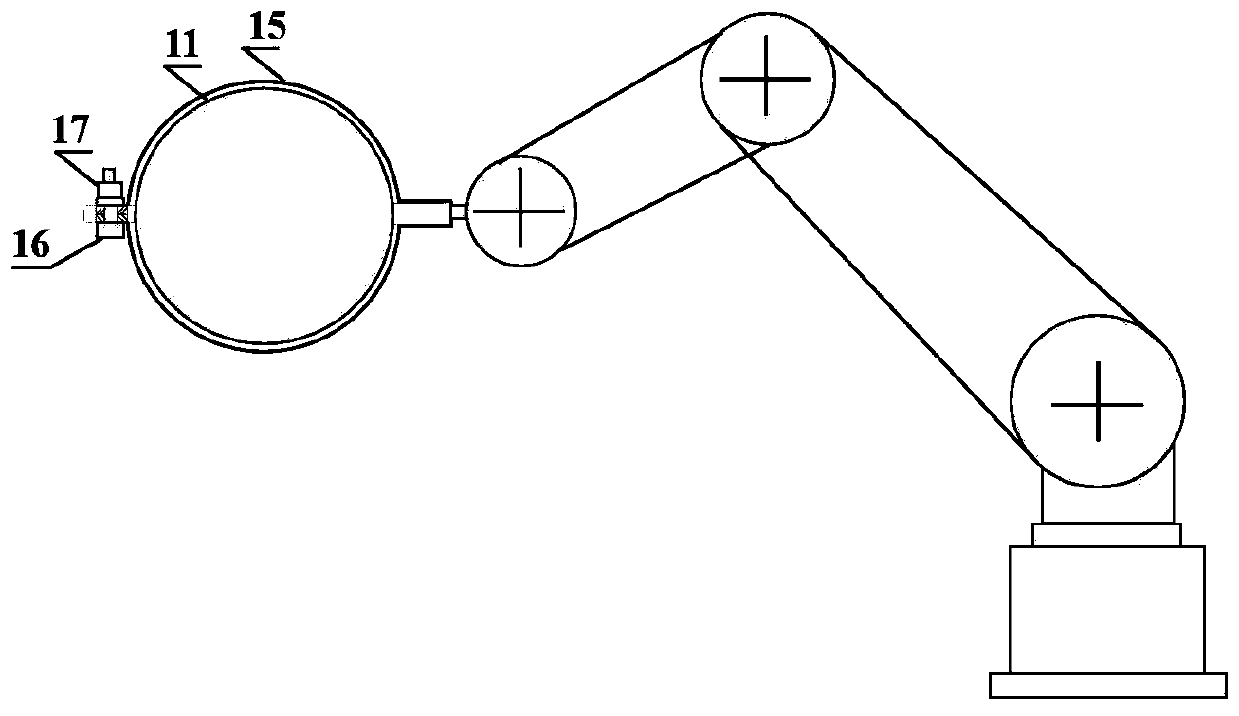

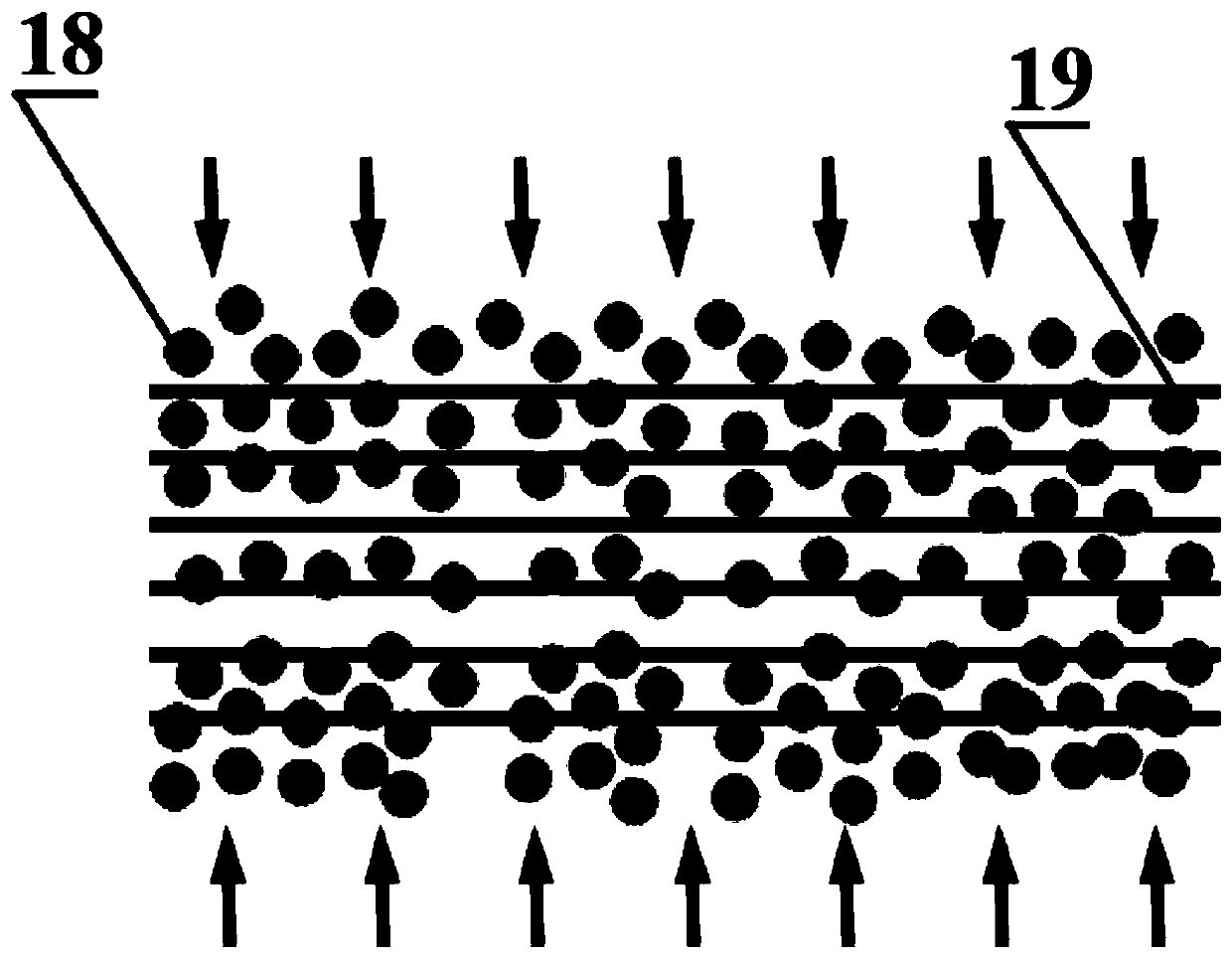

Ultrasonic vibration assisted 3D printing method

InactiveCN110481003AUniform and fine tissueGood adhesionManufacturing heating elements3D object support structuresMolten stateEngineering

The invention discloses an ultrasonic vibration assisted 3D printing method, belongs to the technical field of 3D printing, and relates to a device and method based on ultrasonic vibration assisted 3Dprinting. According to the method, the specially-made ultrasonic-assisted 3D printing device is adopted, and the device is composed of a 3D printing mechanism and an ultrasonic vibration structure. According to the ultrasonic vibration assisted 3D printing method, the 3D printing device is assembled firstly, and when ultrasonic vibration is assisted for 3D printing, firstly, a printing material is fed into a printing nozzle through a stepping motor; the printing material in the nozzle is converted into a molten state from a solid state under the action of a high temperature and is extruded toa printing bottom plate through the nozzle; and at the moment, under the control of a six-degree-of-freedom mechanical arm and an ultrasonic generator, an ultrasonic amplitude-variable rod carries out the ultrasonic vibration on the material which is not completely solidified, so that a high-performance 3D printing part with few pores and good interphase, interline and interlayer combination is formed after repeated layer by layer printing. The method has the advantages of being high in material adaptability and wide in application prospects and the like.

Owner:DALIAN UNIV OF TECH

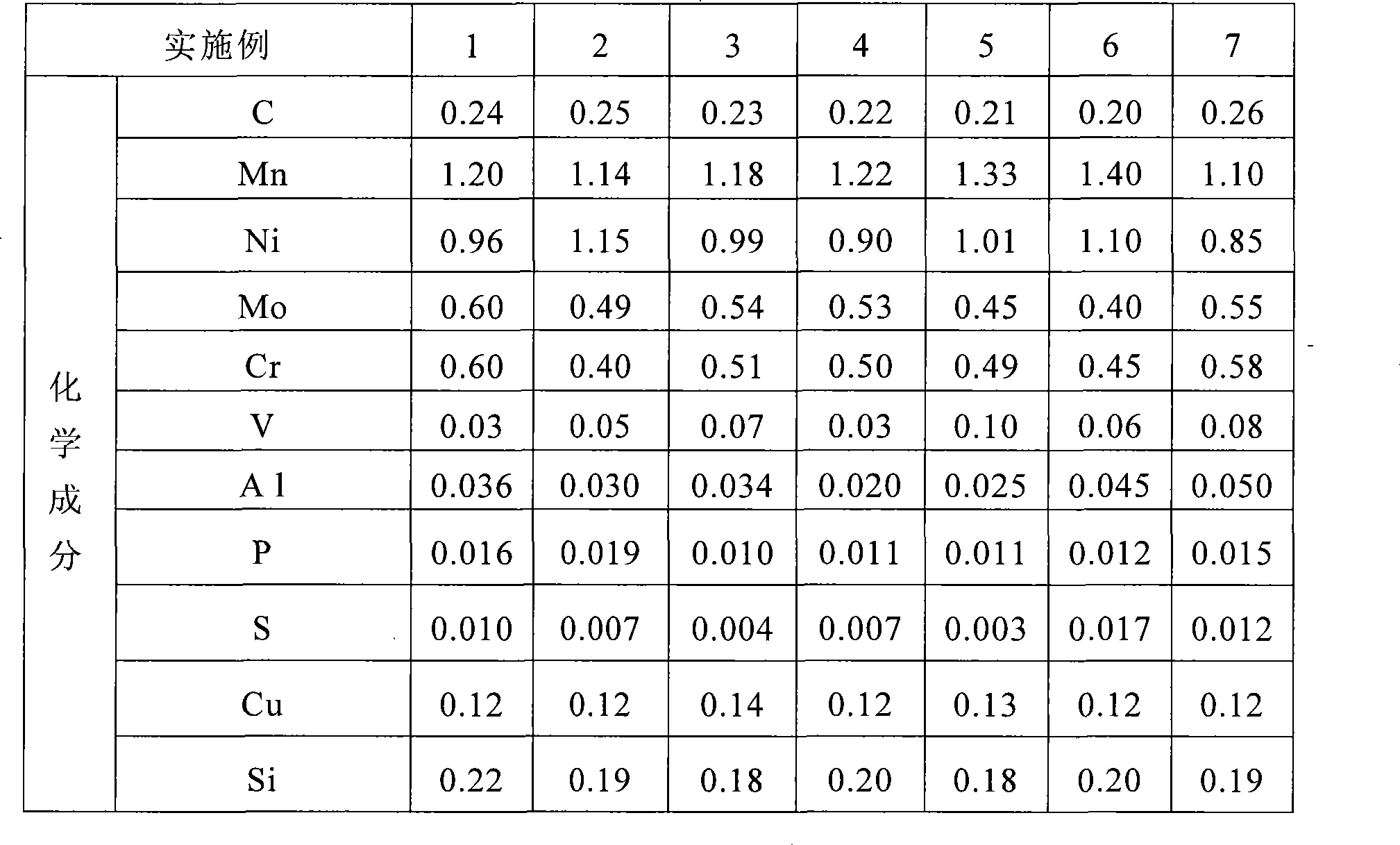

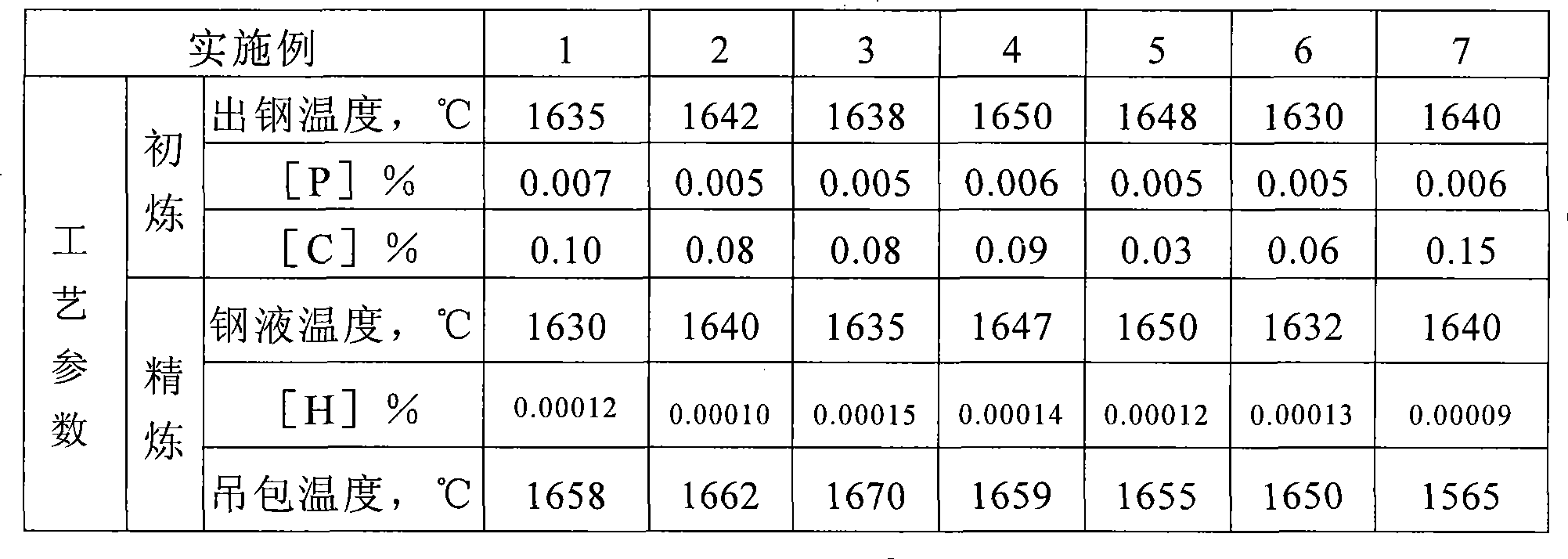

High toughness ring chain steel for mine and method for producing the same

InactiveCN101397636AUniform and fine tissueImprove purityTemperature control deviceAlloy elementPearlite

The invention discloses a high strength and toughness steel used for a ring chain, wherein, the chemical elementary compositions based on weight percentage are as follows: C: 0.20 to 0.26 percent, Mn: 1.10 to 1.40 percent, Ni: 0.85 to 1.15 percent, Cr: 0.40 to 0.60 percent, Mo: 0.40 to 0.60 percent, V: 0.03 to 0.10 percent, Al: 0.020 to 0.050 percent, Si: less than or equal to 0.25 percent, Cu: less than or equal to 0.25 percent, S: less than or equal to 0.020 percent, P: less than or equal to 0.020percent, and Fe and inevitable impurity as the rest. According to general arc melting, refining technology and given alloy elements ratio, the invention uses continuous casting techniques to produce casting billets. The average casting temperature is 1150 to 1200 DEG C, beginning temperature of rolling is 1130 to 1180 DEG C, and final temperature of rolling is 760 to 800 DEG C; after being rolled, the billets are cooled in water and air; Then the hot rolled steel bars are annealed at 680 to 710 DEG C for 8 to 12 hours, and the tapping temperature is less than or equal to 250 DEG C, and then cooled in air, and wind is avoided. Therefore, the high strength and toughness ring chain steel forms into spherical pearlite, and has high cleanliness, uniform and fine structure, uniform and moderate hardness and excellent comprehensive mechanical properties after heat treatment.

Owner:宝钢特钢有限公司

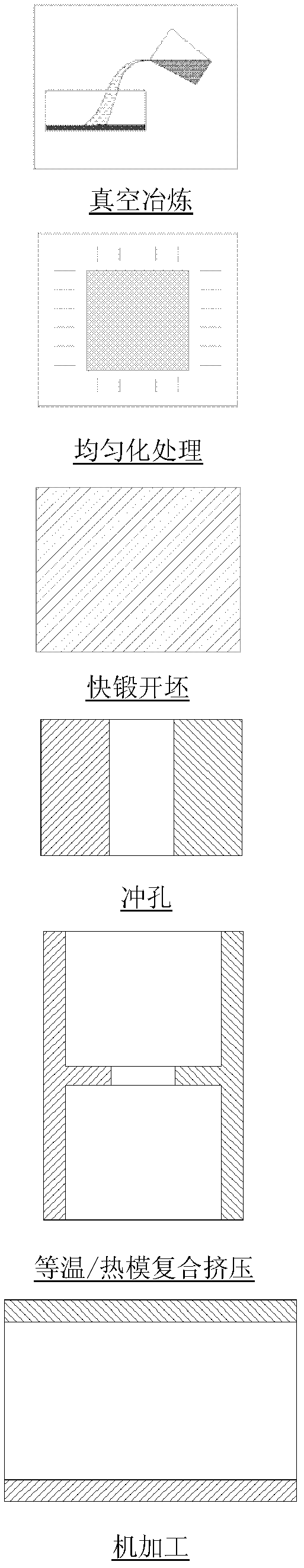

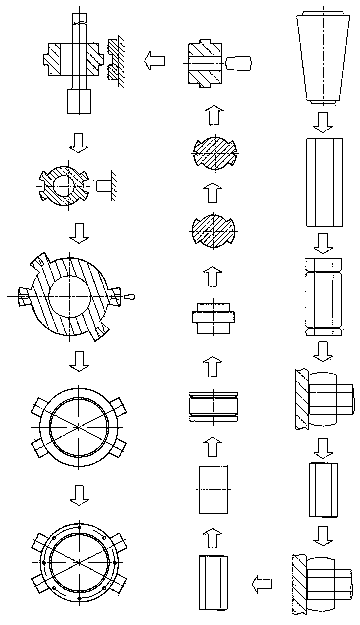

Compound extrusion preparation method of large-diameter high-quality tube blank or annular blank

ActiveCN103170797AUniform and fine tissueForming labor-savingMetal-working apparatusHeat processingUtilization rate

The invention relates to a compound extrusion preparation method of a large-diameter high-quality tube blank or an annular blank. The compound extrusion preparation method is mainly aimed at materials which are large in deformation resistance, narrow in heat processing temperature range, difficult in heat processing, and difficult to deform. The compound extrusion preparation method comprises the following steps: (1) a high-quality ingot blank with high purity is prepared through a vacuum melting process; (2) homogenization treatment is carried out alternatively, multi-pass pier drawing fast forging cogging-down is carried out, an organization is refined, and the homogeneity of the organization is improved; (3) hollow blank material is prefabricated in a punch mode; (4) isothermality / heat molding compound extrusion is carried out on the prefabricated hollow blank material, the tube blank with the uniform and thin organization is prepared; and (5) subsequent machining is carried out, and a finished tube (ring) and the high-quality ingot blank are obtained. The novel preparation method is used for preparing the large-diameter tube (ring) blank with the uniform and thin organization. The preparation method is labor-saving in shaping, energy-saving, high in material utilization rate, high in product quality, and capable of resolving the problems that a tube (ring) blank prepared through a traditional process is thick in organization, poor in uniformity, large in shaping force and the like.

Owner:GRIMAT ENG INST CO LTD

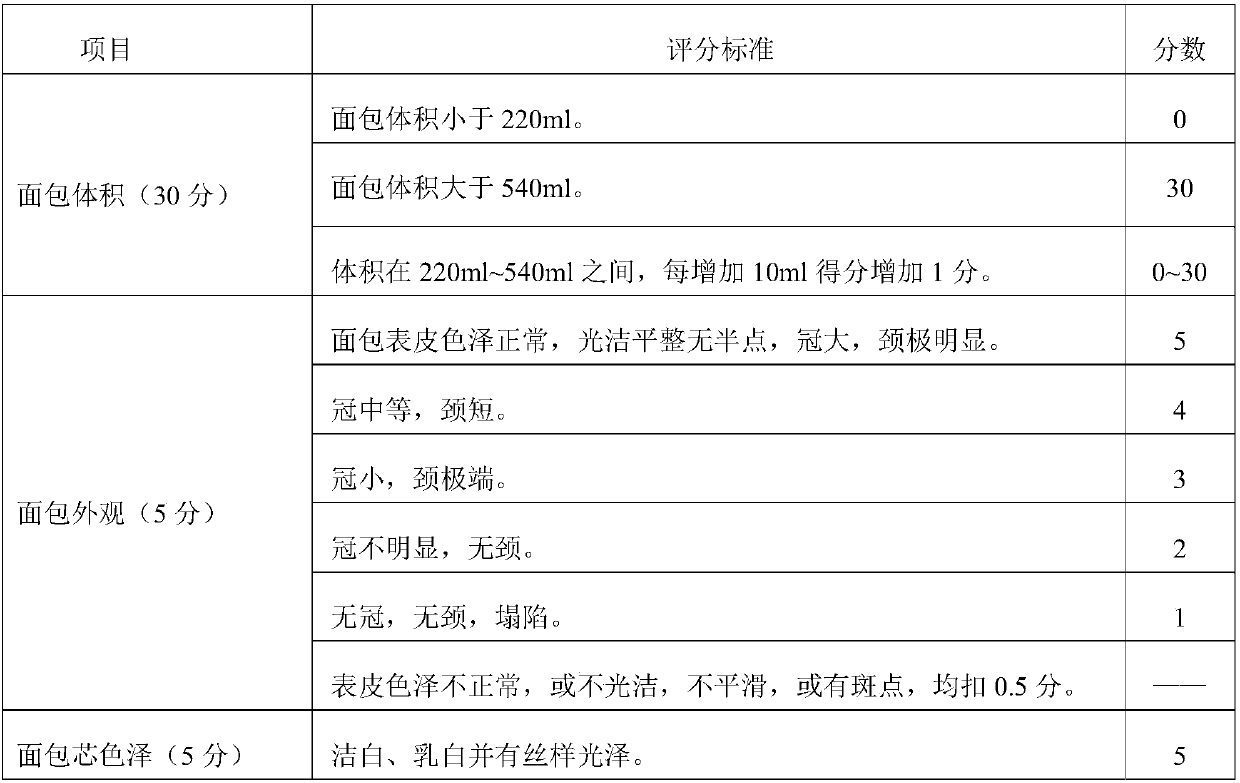

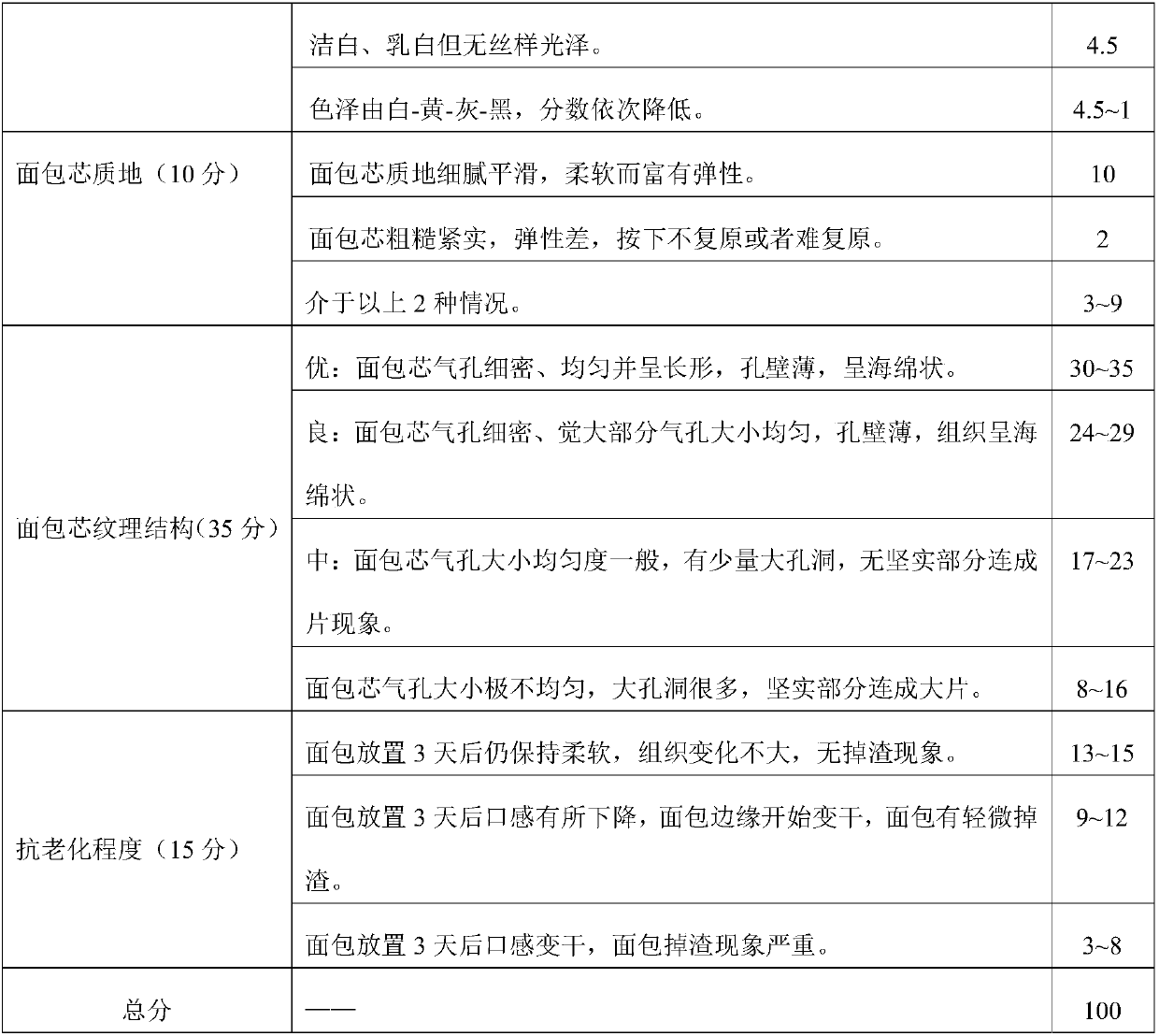

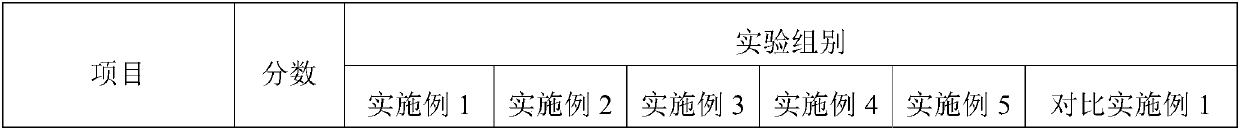

Fruit-flavored bread and its preparation method

ActiveCN102578184AHigh nutritional valueIncrease in sizeDough treatmentBakery productsYeastFermentation

The invention discloses a fruit-flavored bread and its preparation method, taking fruit fermentation liquor as flavoring agent and yeast supplement, falling into the technical field of food processing. The method includes sorting fruits, washing, pulping, sterilizing, inoculating aroma-producing yeast, and fermenting to give fruit fermentation liquor; adding partial flour into the fermentation liquor, standing and fermenting to give fermenting agent; adding the rest of flour, salt, sugar, dry yeast, milk powder and water, mixing, adding oil / fat to make into dough, fermenting, cutting, rounding, relaxing, shaping, fermenting, baking and cooling. The obtained bread has deep surface color with slight variation depending on fruit type, large specific volume, high-grade interior color, fine and uniform structure, flexible and elastic mouth feeling, unique and strong fermentation aroma and slight fruit fragrance, and unique flavor.

Owner:JIANGNAN UNIV

Functional Ziyu Chinese yam and fruit composite juice and preparation method thereof

InactiveCN105146637AIncrease elasticityImprove smoothnessFood ingredient as taste affecting agentFood preparationFruit juiceAlpha-amylase

The invention provides functional Ziyu Chinese yam and fruit composite juice and a preparation method thereof, belonging to the technical field of fruit juice processing. The composite juice is prepared from the following raw materials in parts by weight: 20-35 parts of Ziyu Chinese yam, 8-15 parts of red pitaya pulp, 10-18 parts of mulberry fruits, 8-15 parts of red beans, 12-20 parts of color fixative, 2-5 parts of stabilizer, 15-50 parts of sweetening agent, 2-8 parts of acidity agent, 0.2-0.3 part of alpha-amylase, 0.2-0.4 part of glucoamylase, 0.15-0.25 part of cellulase, 0.15-0.25 part of protease, 0.02-0.03 part of pectase and 360-650 parts of water. The fruit juice has efficacy of nourishing yin, supplementing blood, tonifying spleen, nourishing stomach, maintaining beauty and keeping young. With the adoption of the preparation method, nutrition and fragrance of each component can be well kept. A purple color can be kept due to the addition of the suitable color fixative. In addition, the produced beverage is uniform, fine and smooth in texture, and is sour, sweet and delicious in taste without precipitation.

Owner:广西南宁瑶康生态农业发展有限责任公司

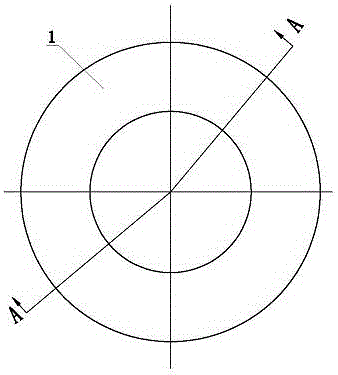

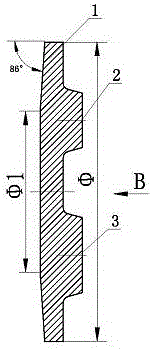

Pressure vessel integrated end socket for nuclear power, end socket plate blank of pressure vessel integrated end socket and forging method of pressure vessel integrated end socket

ActiveCN106051721AImprove mechanical propertiesImprove operational safetyMetal-working apparatusSteam boilersFiberPunching

The invention discloses a pressure vessel integrated end socket for nuclear power, an end socket plate blank of the pressure vessel integrated end socket and a forging method of the pressure vessel integrated end socket. According to the pressure vessel integrated end socket for nuclear power, a manhole base and a pipe hole base are arranged on an end socket body which is of a spherical crown structure; the manhole base and the pipe hole base are integrated with the end socket body in a forged mode; and the intersection point of the hole center line of a manhole and the hole center line of a pipe hole is located in the center of the sphere where the end socket body is located. A plate blank body of the end socket plate blank is of a circular plate structure, one surface of the plate blank body is provided with two manhole circular truncated cones and two pipe hole circular truncated cones, and the other surface of the plate blank body is a large-cone-angle circular truncated cone surface. The forging method comprises the following steps of steel ingot heating, forged blank blanking, forged blank upsetting and drawing, die forging formation, plate blank heat treatment, plate blank rough machining, end socket formation, end socket punching, forge piece heat treatment, machining of a forge piece, performance heat treatment and finished product machining. The integrated formation of the end socket of a vapor generator is achieved, the forge piece is uniform and compact in texture, the metal flow line is complete, and the fiber texture and the appearance of the forge piece tend to be more coincident.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

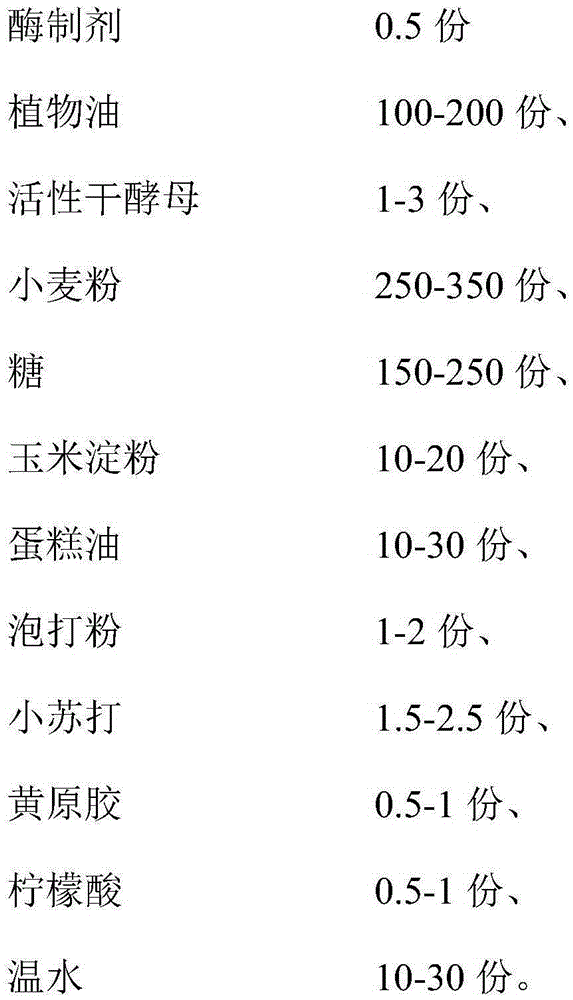

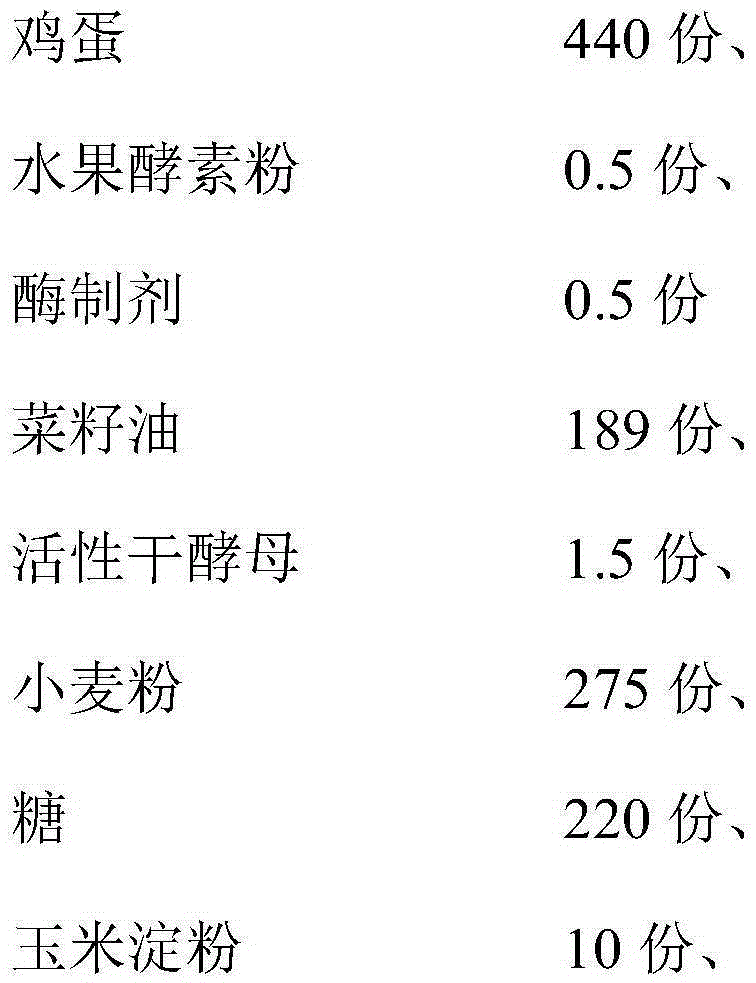

Fruit enzyme cake and preparing method thereof

InactiveCN105309577AEvenly distributedUniform and fine tissueDough treatmentBakery productsCorn starchFlavor

The invention discloses a fruit enzyme cake. The fruit enzyme cake is mainly prepared from, by weight, 300-500 parts of eggs, 0.5-1 part of fruit enzyme powder, 0.5 part of an enzymic preparation, 100-200 parts of vegetable oil, 1-3 parts of active dry yeast, 250-350 parts of wheat flour, 150-250 parts of sugar, 10-20 parts of corn starch, 10-30 parts of cake oil, 1-2 parts of baking powder, 1.5-2.5 parts of sodium bicarbonate, 0.5-1 part of xanthan gum, 0.5-1 part of citric acid and 10-30 parts of warm water. By the adoption of the technical scheme, the fruit enzyme powder is added into the fruit enzyme cake and is an enzyme in essence to have the catalysis effect, fast fermentation of the active dry yeast is catalyzed by the fruit enzyme powder and the enzymic preparation to generate the fruit enzyme cake with the surface mouthfeel like that of bread, and the fruit enzyme cake is unique in flavor and convenient to manufacture.

Owner:FUZHOU JIAOTIANXIA BIOTECH CO LTD

Integrated forging and forming method for reactor pressure vessel barrel flange adapter tube section

ActiveCN110090914AReduce potential riskWork stress homogenizationEngine componentsReactor pressure vesselIngot

The invention discloses an integrated forging and forming method for a reactor pressure vessel barrel flange adapter tube section. The integrated forging and forming method for the reactor pressure vessel barrel flange adapter tube section comprises the steps of (1) heating a steel ingot, and pressing the steel ingot to obtain an eight-edge prism steel billet; (2) blanking a forging billet: cutting a head part and a tail part of the eight-edge prism steel billet so as to obtain an eight-edge prism forging billet; (3) upsetting and drawing the forging billet: upsetting and drawing out the forging billet; (4) carrying out upsetting and rolling: upsetting and rolling the forging billet to obtain a short cylindrical forging billet; (5) carrying out marking and dividing in the circumferential direction: cutting two marking and dividing grooves at two ends of the short cylindrical forging billet; (6) carrying out rolling and necking: forming an adapter tube billet with a convex ring in the middle section; (7) carrying out marking and dividing in the axial direction: cutting four axial dividing grooves arranged along the axial direction; (8) circularly pressing a hemline; (9) marking anddividing a hemline boss: forming four sections of bosses on a hemline adapter tube billet; (10) punching a main hole; (11) carrying out chambering and forming; (12) carrying out shaping and chambering; (13) punching an adapter tube hole; (14) carrying out heat treatment after forging; (15) roughly machining the billet; (16) carrying out quenching; (17) carrying out hardening and tempering; and (18) processing a finished product. According to the method, integrated forming and forming is realized, the structure is uniform and dense, and a metal flow line is complete.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

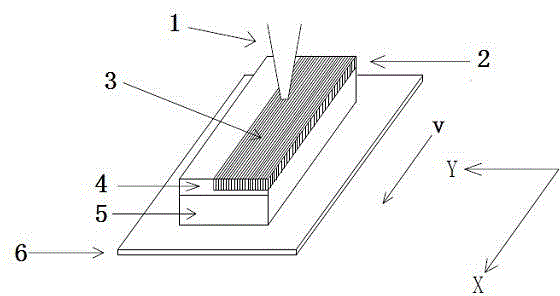

Material for laser cladding of titanium alloy surface and laser cladding method

InactiveCN103060800AHigh hardnessImprove wear resistanceMetallic material coating processesHardnessWear resistance

The invention discloses a material for laser cladding of a titanium alloy surface and a laser cladding method, and belongs to the field of a material surface strengthening technology. The material for the laser cladding of the titanium alloy surface is formed by mixing the components by mass percent: 63-86% of Fe3Al powder and 14-37% of Tic-TiB2 ceramic hard phase powder. Through cladding Fe3Al and TiC-TiB2 ceramic hard phase on the titanium alloy surface by laser, the titanium alloy surface strengthened coat with significantly improved hardness and wearing resistance can be obtained, and the production cost can be reduced by 30% to 40%.

Owner:SHANDONG JIANZHU UNIV

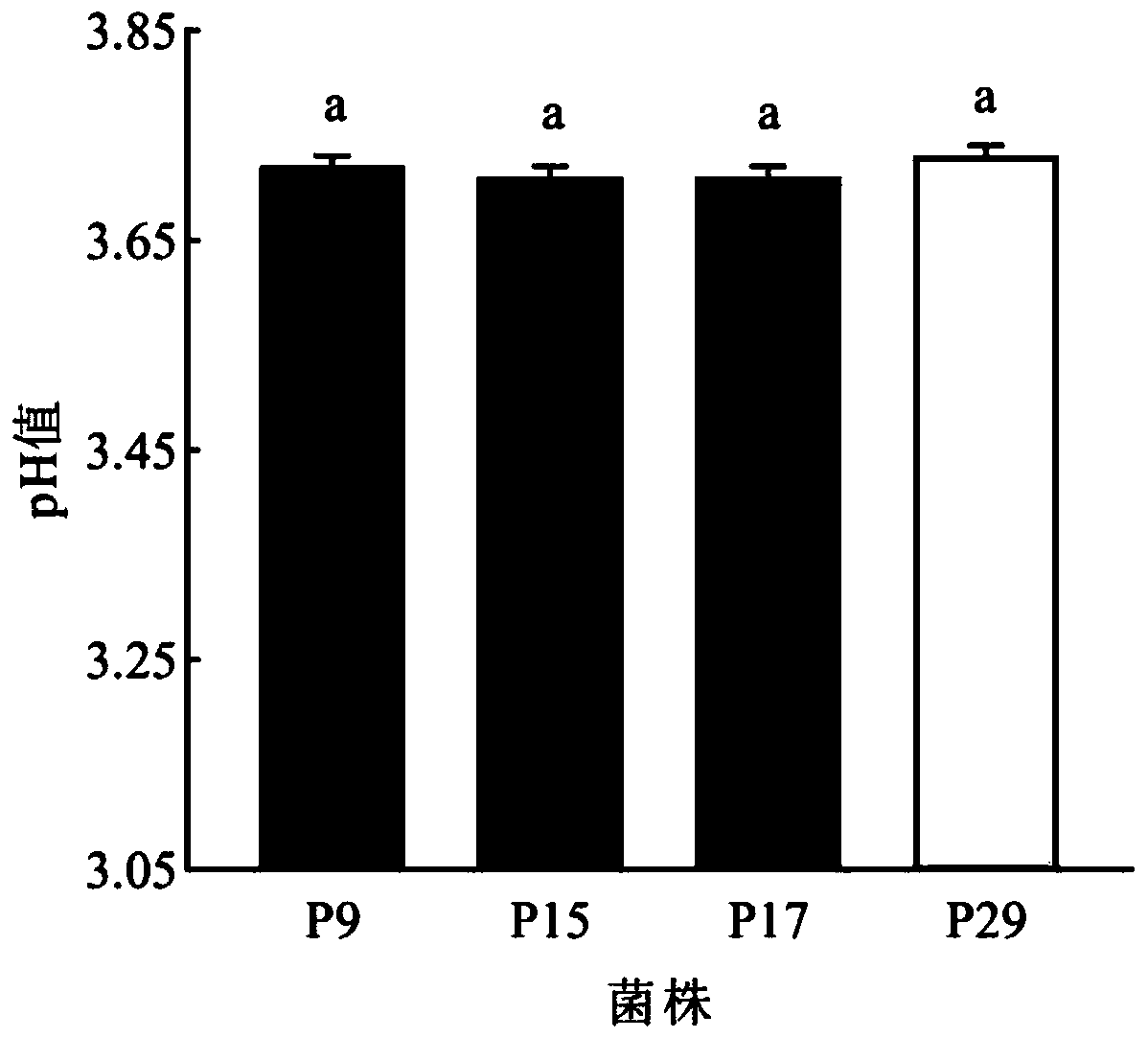

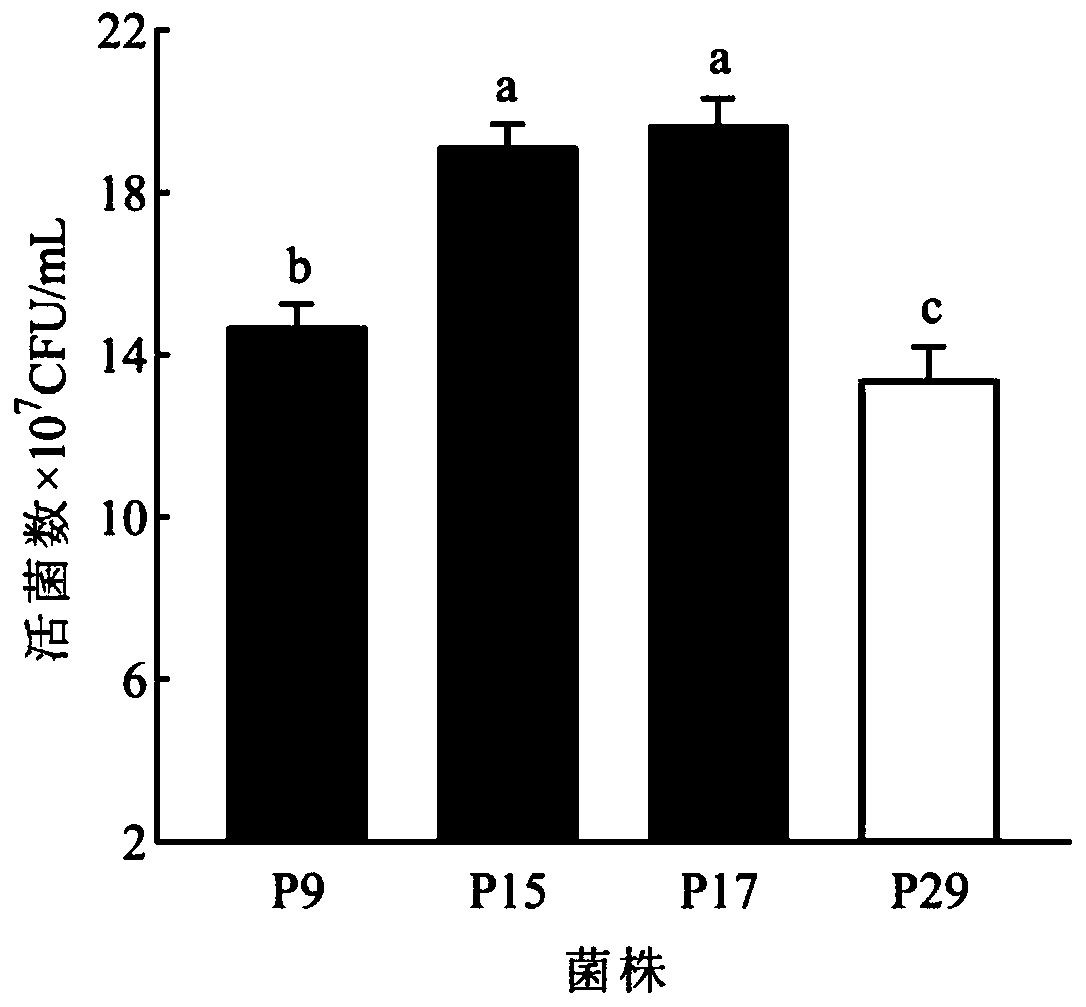

Lactobacillus plantarum P _ 17 and method for preparing fermented apple juice by using lactobacillus plantarum P _ 17

ActiveCN111280355AOutstanding acid resistanceProminent sugar toleranceBacteriaMicroorganism based processesBiotechnologyMicrobiology

The invention discloses lactobacillus plantarum P _ 17 and a method for preparing fermented apple juice by using the lactobacillus plantarum P _ 17. According to the method, apple juice is used as a raw material, and lactobacillus plantarum P _ 17 with the preservation number of CGMCC NO.19251 is used for fermentation, so that the product is prepared. The lactobacillus plantarum P _ 17 has outstanding acid resistance, sugar resistance and low temperature resistance, has strong pepsase resistance and acid resistance, can resist an artificial intestinal juice stress environment, and has bile salt resistance and high osmotic pressure resistance. The fermented apple juice is uniform and consistent in color and luster and uniform and fine in texture, and has unique aroma and apple aroma of fermentation. The viable count of the fermented apple juice prepared by the method is higher than that of other bacteria, and the gamma-aminobutyric acid, the total acid and the antioxidant value are obviously improved compared with those of common apple juice. The method is simple in production process and rich and easily available in raw materials, and has far-reaching significance in industrial production of the fruit and vegetable juice lactic acid fermented beverage.

Owner:HEBEI AGRICULTURAL UNIV.

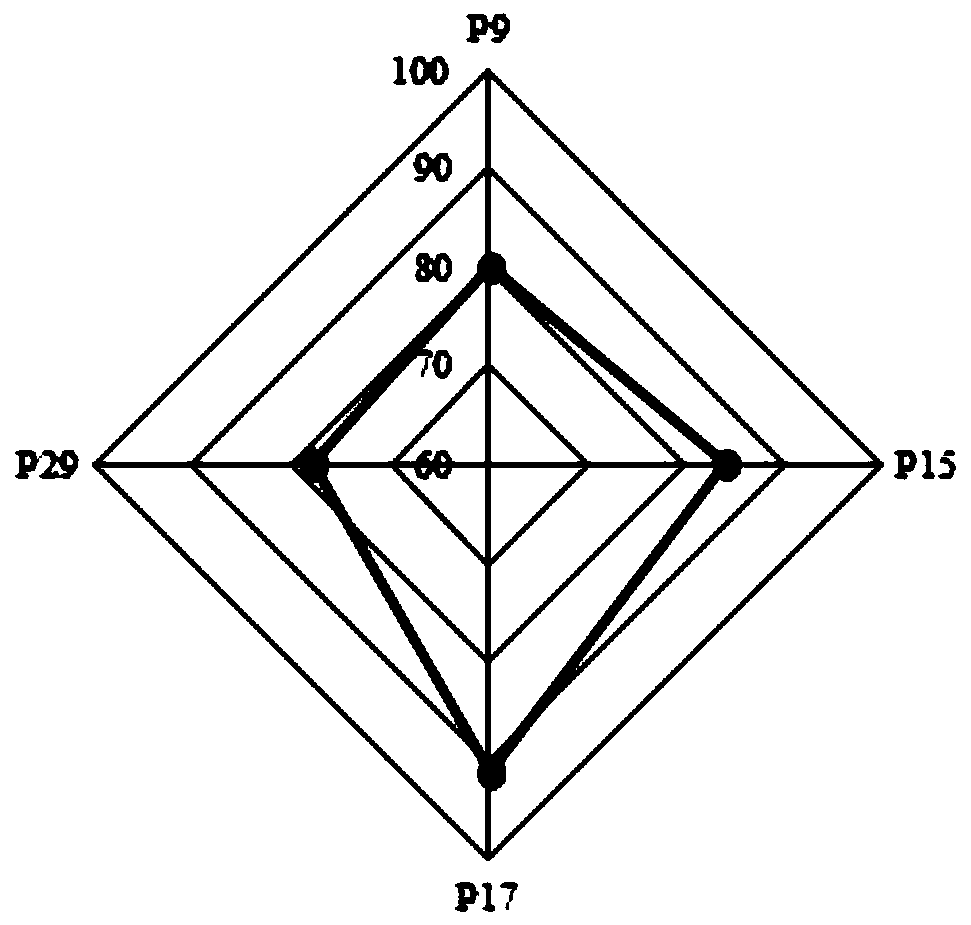

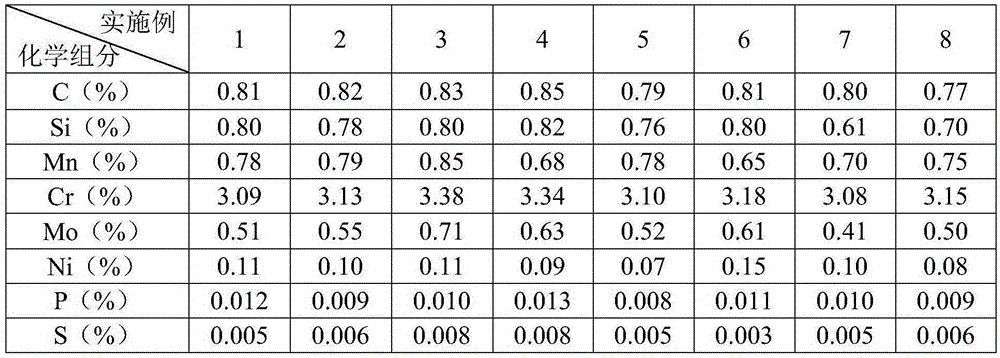

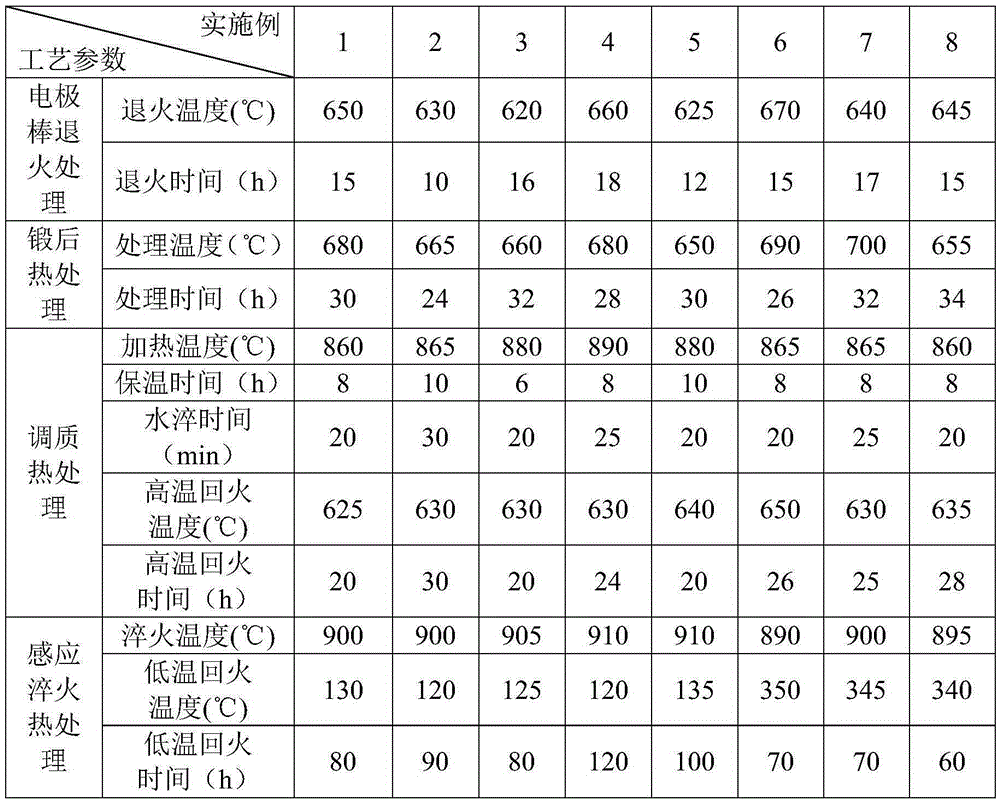

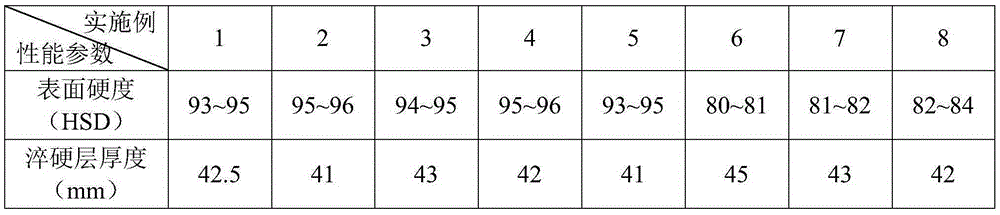

Cold roll with thick quench-hardened layer and manufacturing method thereof

ActiveCN105316582AIncreasing the thicknessThe thickness of the hardened layer is increasedIncreasing energy efficiencyFurnace typesQuenchingImpurity

The invention relates to a cold roll with a thick quench-hardened layer. Chemical constituents in materials of the cold roll include, by weight, 0.70-1.20% of C, 0.5-1.20% of Si, 0.60-1.00% of Mn, 2.50-4.00% of Cr, 0.20-1.00% of Mo, at most 0.30% of Ni, at most 0.015% of S, at most 0.015% of P and the balance Fe and unavoidable impurities. The thickness of the quench-hardened layer of the cold roll is increased, and secondary quenching for the cold roll during usage is avoided.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

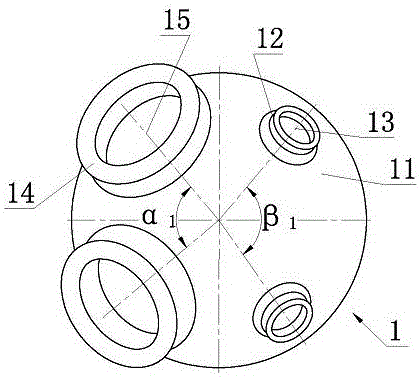

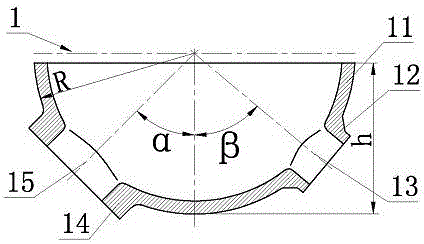

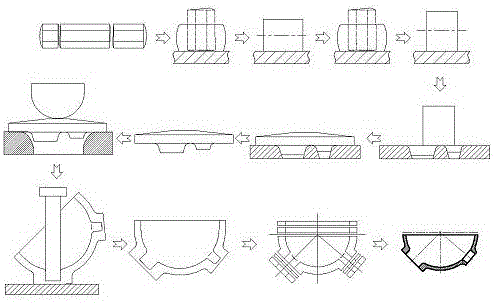

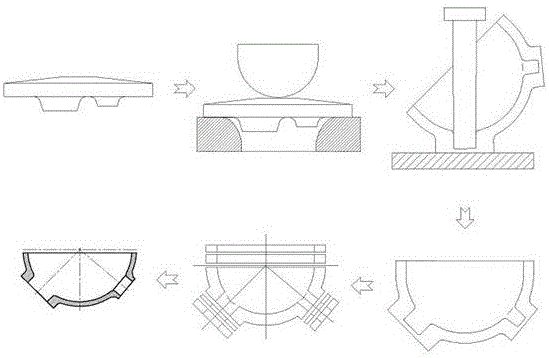

Integral seal punch molding method of nuclear power pressure container

The invention discloses an integral seal punch molding method of a nuclear power pressure container. The punch molding method comprises the following steps: roughening of a plate blank: the heated seal plate blank is machined; heating of the plate blank: the roughened seal plate blank is sent in a heating furnace for heating; molding of a seal: the seal plate blank is shifted to an annular mold with a center hole for punching to mold a semi-spherical seal blank; punching of the seal: a seal punching part with two man holes and two pipe holes is punched; heat treatment of the punched part: the punched part is discharged from a furnace for air cooling when being cooled to 180 DEG C along with the furnace after autoclaving; machining of the punched part: the heated seal punched part is machined as a seal rough finished product; performance heat treatment: the quenching treatment is performed firstly; and then, the thermal refining is performed; and the finished product is machined to a qualified seal finished product. The method realizes integral molding of a steam generator seal, and is uniform and compact in metal structure and complete in streamline.

Owner:SHANGHAI XINMIN DONGTAI HEAVY FORGING

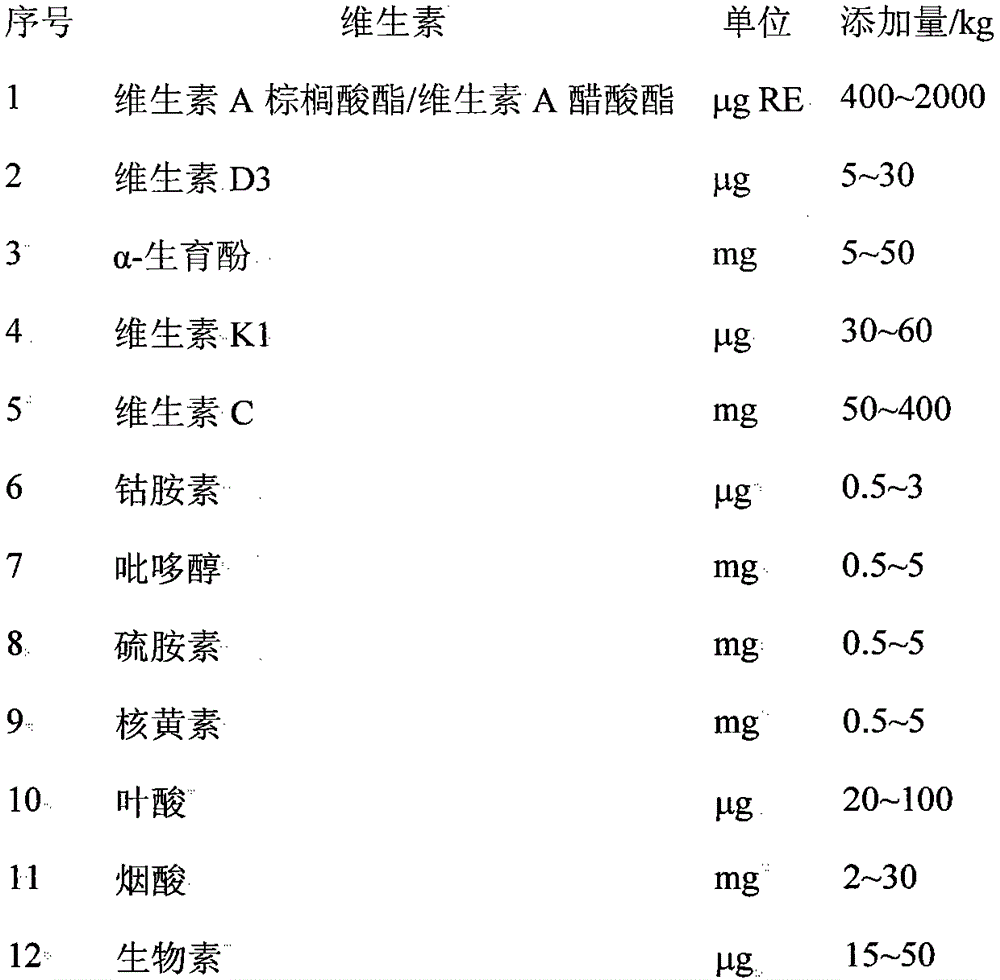

Portable full nutritional yoghurt for spaceflight, yoghurt sheet, and preparation method thereof

The invention discloses portable full nutritional yoghurt for spaceflight, a yoghurt sheet, and a preparation method thereof. The yoghurt comprises proteins originated from plants and animals, multiple plant oils, carbohydrates, vitamins, mineral substances, spirulina, wheat dietary fiber, coenzyme Q10, and xylo-oligosaccharide. The portable full nutritional yoghourt is prepared by the following steps: (1) mixing skim milk and a plurality of saccharides, homogenizing, sterilizing, carrying out enzymatic hydrolysis by using lactase, and cooling; (2) carrying out inoculated fermentation to obtain yoghurt; and (3) evenly mixing the yoghurt with other plant oils, proteins, carbohydrates, vitamins, and mineral substances, homogenizing, pre-freezing, freeze-drying, and sieving to obtain the portable full nutritional yoghurt. The portable full nutritional yoghourt is mixed with D-sorbitol, maltitol, and pre-gelatinized starch, the mixture is pressed into tablets, and finally the tablets are coated to obtain yoghurt sheets. Compared with the common low temperature yoghurt, the provided portable full nutritional yoghurt has the advantages of long shelf life, portability, suitability for spaceflight, full nutrients, low lactose content, and multiple flavors, and can promote the health.

Owner:SCI RES TRAINING CENT FOR CHINESE ASTRONAUTS

Fruit-flavored bread and its preparation method

ActiveCN102578184BHigh nutritional valueIncrease in sizeDough treatmentBakery productsYeastFermentation

The invention discloses a fruit-flavored bread and its preparation method, taking fruit fermentation liquor as flavoring agent and yeast supplement, falling into the technical field of food processing. The method includes sorting fruits, washing, pulping, sterilizing, inoculating aroma-producing yeast, and fermenting to give fruit fermentation liquor; adding partial flour into the fermentation liquor, standing and fermenting to give fermenting agent; adding the rest of flour, salt, sugar, dry yeast, milk powder and water, mixing, adding oil / fat to make into dough, fermenting, cutting, rounding, relaxing, shaping, fermenting, baking and cooling. The obtained bread has deep surface color with slight variation depending on fruit type, large specific volume, high-grade interior color, fine and uniform structure, flexible and elastic mouth feeling, unique and strong fermentation aroma and slight fruit fragrance, and unique flavor.

Owner:JIANGNAN UNIV

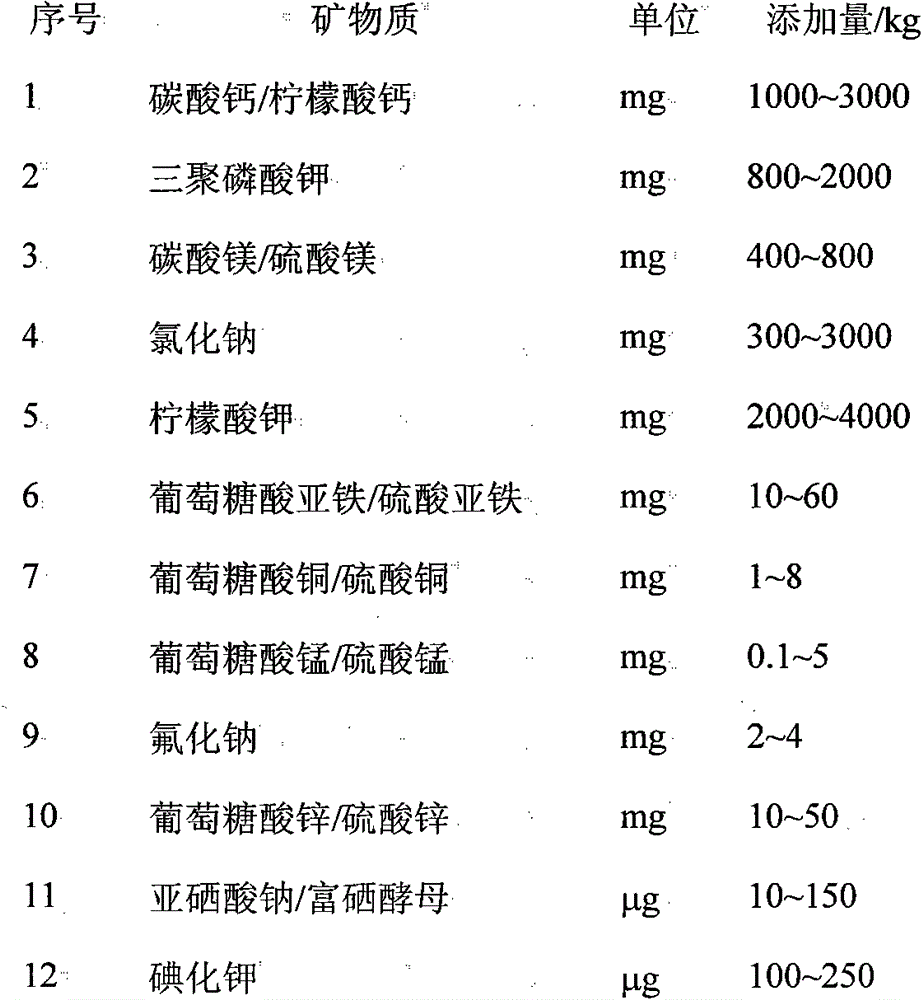

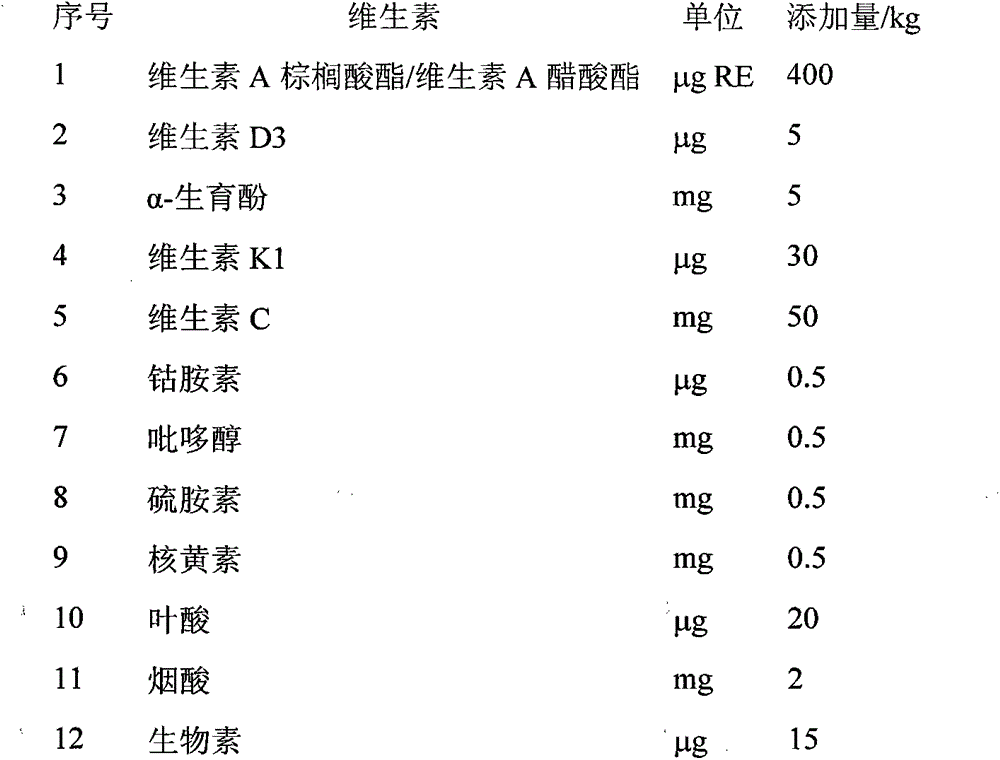

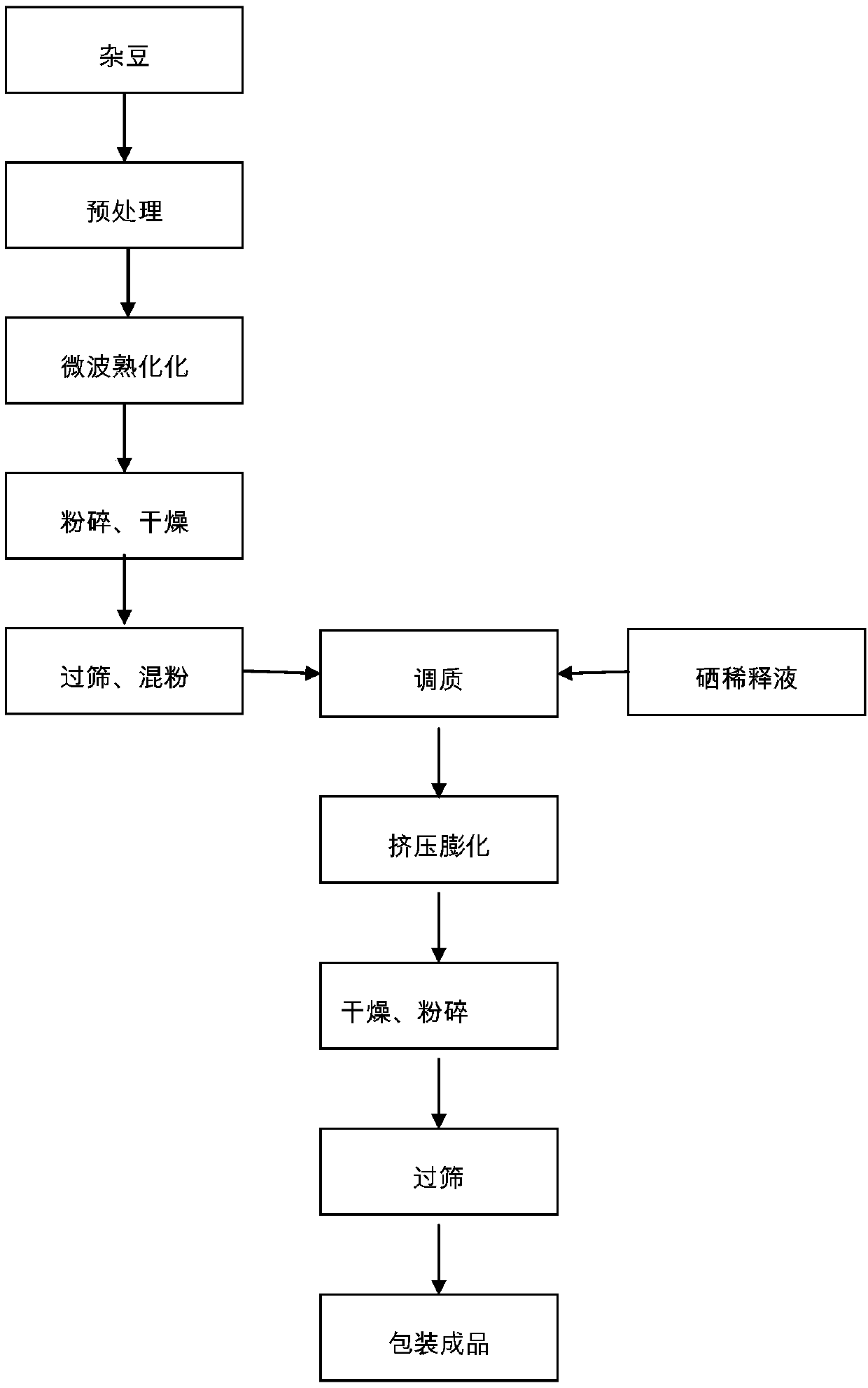

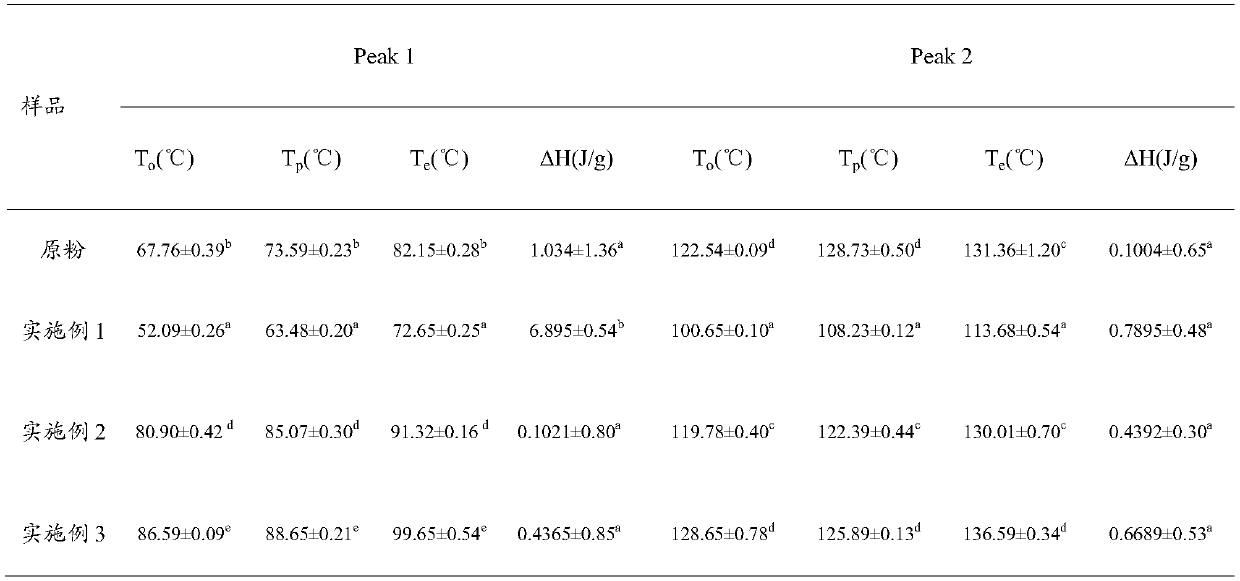

Selenium-enriched nutritious instant coarse cereal powder and preparation method thereof

The invention discloses a preparation method of selenium-enriched nutritious instant coarse cereal powder. The preparation method comprises the steps of precooking coarse cereal raw materials with microwave, performing crushing and screening, fully and uniformly mixing the screened material with rice powder, millet powder, buckwheat powder, taro powder, Chinese yam powder, sesame powder, highlandbarley powder, saffron, maltodextrin, milk powder and a selenium diluent, and adopting an extrusion puffing technology to obtain the selenium-enriched nutritious instant coarse cereal powder. The instant powder is comprehensively balanced, good in brewing effect, and strong in instant solubility, and has no caking, no precipitation at the bottom, uniform and delicate texture, good taste and delicious color. The method improves the defects of traditional coarse cereal powder, such as inconsistent cooking time, rough taste, poor solubility, poor taste and single nutrition. The selenium-enrichednutritious instant coarse cereal powder prepared by the method has increased soluble selenium content, improves the digestibility and absorptivity of selenium by the human body, meets the needs of modern fast-paced life for healthy diet, enriches the variety of coarse cereals and expands the application scope of coarse cereals.

Owner:SHENYANG NORMAL UNIV

Lactobacillus delbrueckii subsp. bulgaricus as well as application thereof and yoghurt prepared from same

ActiveCN107937317ARaise the ratioRich and mellow fermented aromaMilk preparationBacteriaBiotechnologyMicroorganism

The invention belongs to the technical field of milk product application and in particular relates to lactobacillus delbrueckii subsp. bulgaricus as well as application thereof and yoghurt prepared from same. The bacterium is lactobacillus delbrueckii subsp. Bulgaricus LB-81 which is preserved in the China General Microbiological Culture Collection Center, and the preservation number is CGMCC No.12958. The lactobacillus delbrueckii subsp. bulgaricus is combined with streptococcus thermophilus for yoghurt fermentation, a relatively large amount of bacterial bacilli can be provided, after sourness can be relatively well controlled, the fresh and tasty flavor is maintained, and meanwhile a relatively large amount of active bacilli are provided; yoghurt made of the bacterium is uniform milky white or slight yellow, is fragrant, mellow and fine and uniform in texture, the acidity of the yoghurt is greater than 70 degree T when the yoghurt is delivered, the number of lactic acid bacteria is2-7*10<8>cfu / g, and the clarity rate of the yoghurt stored for 10 days at 2-8 DEG C is less than or equal to 1.5%.

Owner:SHANDONG DEYI DAIRY IND

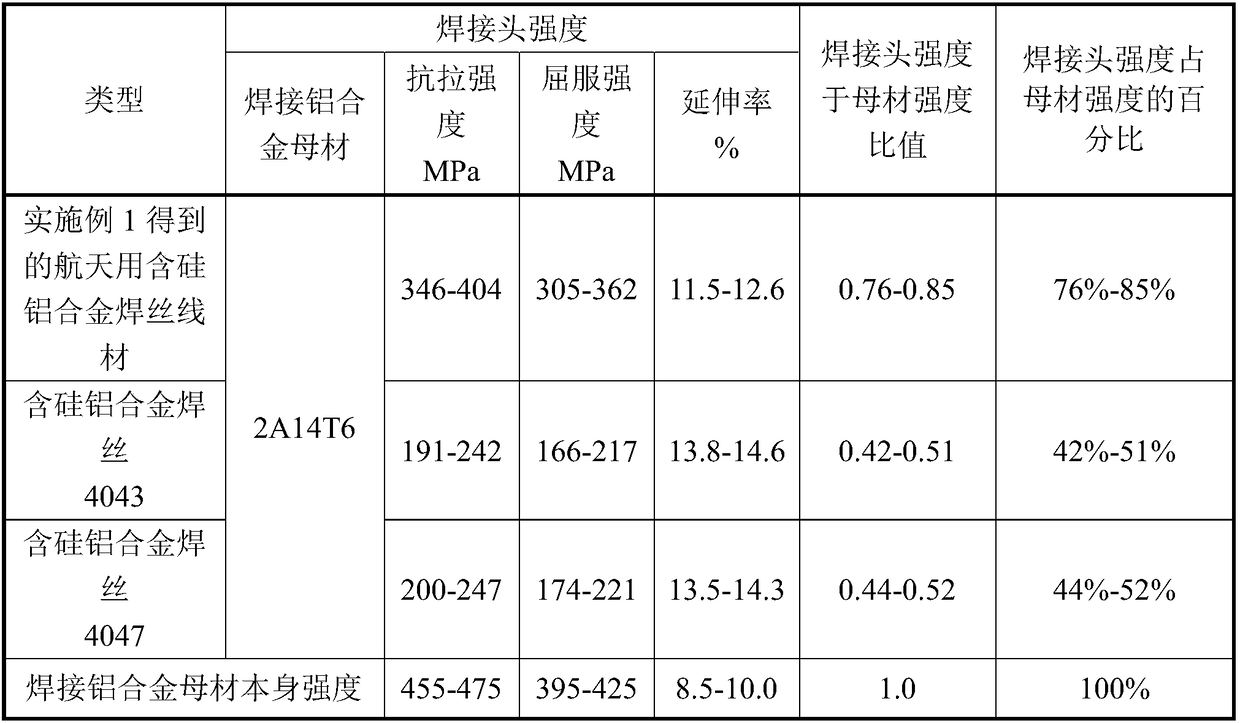

Manufacturing method for silicon-contained aluminum alloy welding wire rod for spaceflight

ActiveCN108531788AStable final welding performanceExcellent final welding performanceWelding/cutting media/materialsSoldering mediaWire rodSlag

The invention discloses a manufacturing method for a silicon-contained aluminum alloy welding wire rod for spaceflight, and relates to a manufacturing method for a welding wire rod. The manufacturingmethod aims to solve the problem that gas holes, slag inclusion and cracks easily occur in the welding process due to the fact that an existing silicon-aluminum alloy welding wire is poor in internalstructure. The manufacturing method comprises the steps of 1, carrying out smelting,2, carrying out casting, 3, carrying out saw cutting, 4, carrying out turning on an oxidation skin, 5, carrying outpreheating; 6, carrying out extruding; 7, carrying out annealing; 8, carrying out primary stretching; 9, carrying out intermediate annealing; and 10, carrying out second stretching so as to obtain thesilicon-contained aluminum alloy welding wire rod for spaceflight. The silicon-contained aluminum alloy welding wire rod manufacture through the manufacturing method has the advantages of being uniform in structure and free of coarse grains. The manufacturing method is mainly used for preparing the silicon-contained aluminum alloy welding wire rod for spaceflight.

Owner:NORTHEAST LIGHT ALLOY CO LTD

Composite emulsifier with emulsification effect and water retention effect and application thereof

The invention relates to a composite emulsifier with an emulsification effect and a water retention effect. The composite emulsifier is prepared from the following raw materials in percentage by weight: 25-40% of water, 10-30% of sorbitol, 10-30% of glycerol, 5-15% of sucrose fatty acid ester, 5-15% of glycerin monostearate, 5-15% of sorbitan monostearate and 3-10% of polyoxyethylene sorbitan monostearate, wherein the HLB value of the sucrose fatty acid ester is 16. In addition, the invention also provides application of the composite emulsifier in preparation of baked foods. The composite emulsifier has the advantages of achieving a rapid emulsification effect, meanwhile achieving a water retention effect on foods, ensuring fluffy and wet product texture and uniform and exquisite tissues,and improving the quality.

Owner:GUANGZHOU BAOTAO FOOD CO LTD

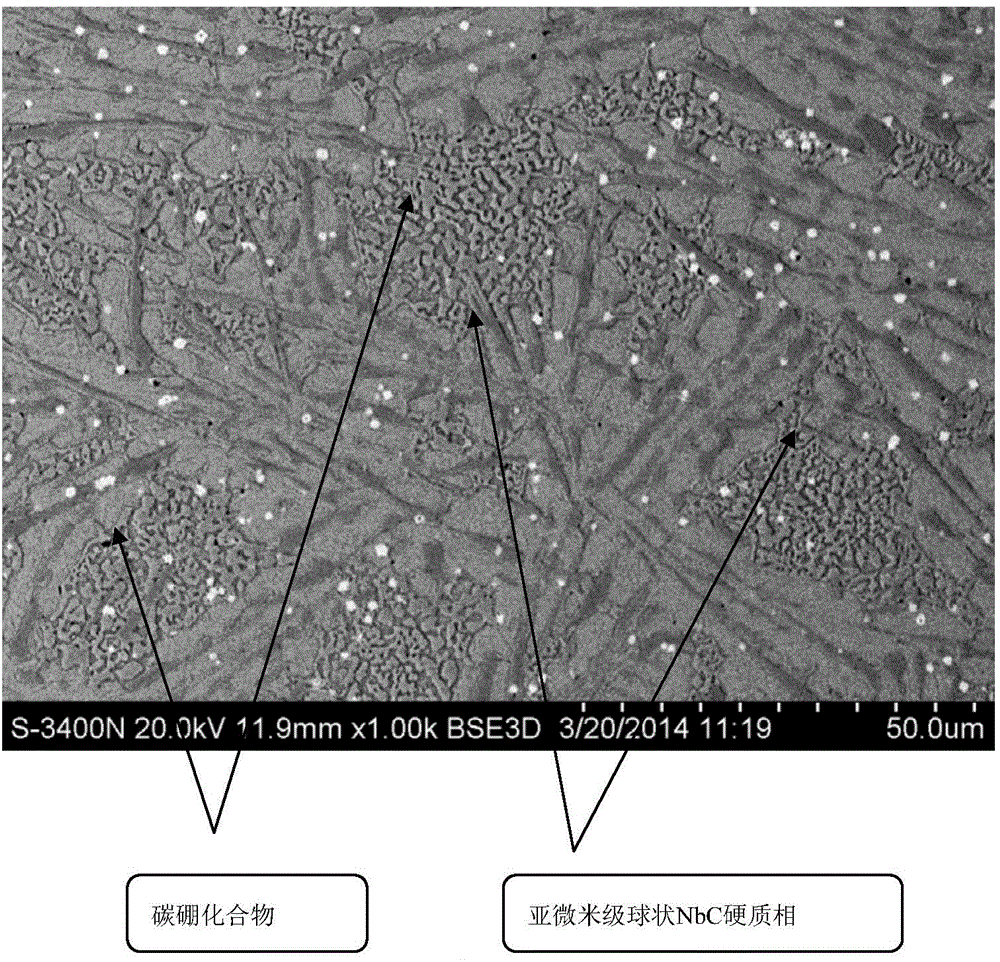

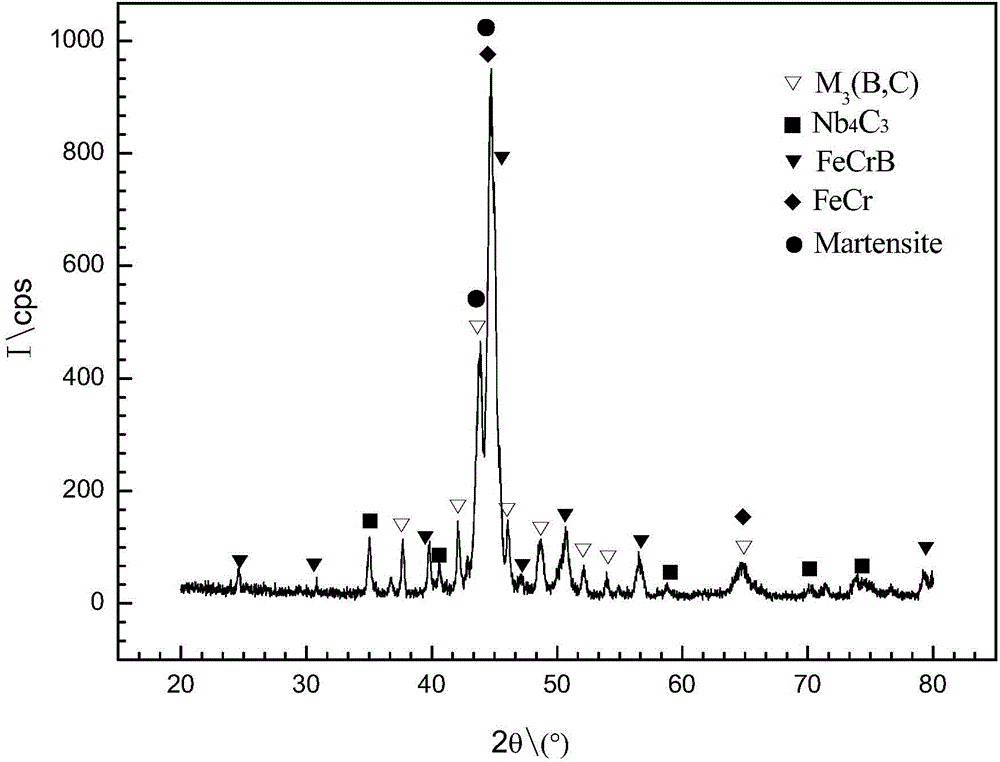

Iron base hardfacing flux-cored wire containing superfine carbide hard phase

InactiveCN103949794AImprove crack resistanceImprove toughnessWelding/cutting media/materialsSoldering mediaMetal powderSteel belt

The invention provides an iron base hardfacing flux-cored wire containing a superfine carbide hard phase and belongs to the field of welding materials. A stainless steel band is adopted for wrapping metal powder. The iron base hardfacing flux-cored wire containing the superfine carbide hard phase comprises the following elementary compositions in percentage by weight: 8.6-20.2% of Cr, 1.2-4.1% of B, 0.5-2.4% of Nb, 0.47-1.9% of C, 1.86-2.9% of Mn, 1.5-2.5% of Si and the balance of Fe. The filling rate of the flux-cored wire is 22-27%; surfacing alloy is prepared by virtue of adopting carbon dioxide gas protective welding; the welding parameters are as follows: the welding current is 180-230A, the voltage is 22-28V, the wire feed speed is 420-480mm / min, the gas flow rate is 17-22L / min, and the length, extending out of a current contact nozzle, of the flux-cored wire is 15-28mm. The rigidity of the iron base hardfacing flux-cored wire alloy is up to 66HRC, the alloy has favorable toughness and rigidity matching, can be used for improving the abrasive resistance, and is especially excellent in abrasive resistance under an impact working condition; the surfacing manufacturability is good; no cracks are generated in a welding process, and formation of weld is attractive.

Owner:BEIJING UNIV OF TECH

Process method for vibration casting molding of lost foam casting

InactiveCN104259387AUniform and fine tissueImprove compactnessFoundry mouldsFoundry coresLow frequency vibrationCrystallite

The invention relates to a process method for vibration casting molding of lost foam casting. The process method comprises high-frequency vibration mold filling, high-frequency vibration crystallization, low-frequency vibration crystallization and annealing. By adopting the process method, the compactness of an internal structure of a lost foam casting product can be improved, and fatal defects that the surface structure compactness is generated in lost foam casting and internal structure crystalline grains are coarse can be overcome; and meanwhile, the unqualified rate of castings can be reduced, the enterprise cost can be reduced, and the economic benefits can be improved.

Owner:ANHUI NINGGUO HUADA WEAR RESISTANT MATERIALS

Alkaline cyanide-free brush plating solution for multielement coordination system and preparation method of alkaline cyanide-free brush plating solution

The invention discloses an alkaline cyanide-free brush plating solution for a multielement coordination system and a preparation method of the alkaline cyanide-free brush plating solution. The alkaline cyanide-free brush plating solution is prepared from solvent water and the following components: 80 to 160 g / L of AgNO3, 240 to 300 g / L of succinimide, 100 to 200 g / L of 5,5-dimethyl hydantoin, 80 to 160 g / L of potassium pyrophosphate, 160 to 320 g / L of potassium methanesulfonate, 15 to 40 g / L of ammonium acetate, 15 to 30 g / L of potassium carbonate, 1.5 to 3 g / L of bismuth nitrate, 0.8 to 1.2 g / L of dipyridyl and 0.6 to 1.0 g / L of thiosemicarbazide. The pH value of the plating solution is adjusted to 8.5 to 10. The succinimide system can effectively solve the problem that a coating is easyto yellow and discolor after being set aside in the silver plating process of a traditional succinimide system; in addition, the thickness and the hardness of an obtained silver coating both can reachthe standards.

Owner:ELECTRIC POWER RESEARCH INSTITUTE OF STATE GRID SHANDONG ELECTRIC POWER COMPANY +1

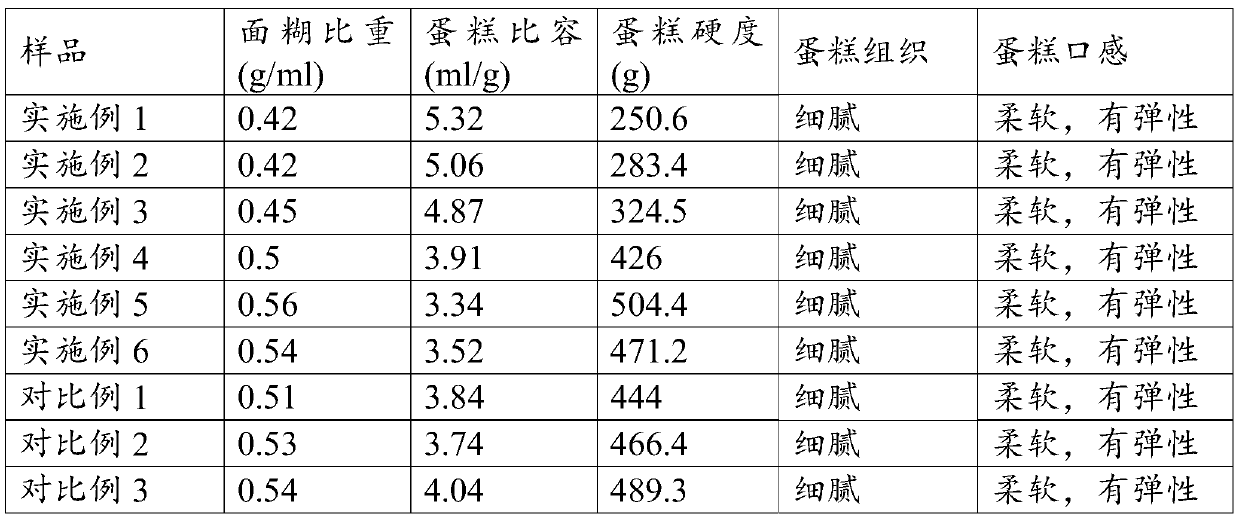

Pastry emulsifying paste

The invention discloses pastry emulsifying paste which comprises the following components in parts by weight: 10-30 parts of polyglycerol fatty acid ester, 2-10 parts of sucrose fatty acid ester, 2-10parts of sodium stearoyl lactylate, 0.1-1 part of potassium stearate, 5-12 parts of glycerol and 1-5 parts of ethanol. The pastry emulsifying paste system disclosed by the invention does not containpropylene glycol, so that the risk that the content of propylene glycol in cake products exceeds the standard is avoided, and the safety, the health and the use convenience of the pastry emulsifying paste are improved; the pastry emulsifying paste system does not contain a polymorphic emulsifying agent, so that the use performance is very stable within the quality guarantee period, and the performance reduction and even failure of the emulsifying paste due to the change of the crystal form are avoided; the pastry emulsifying paste has excellent foamability, foam persistence, moisture retentionand aging resistance, and a prepared cake product is high in expansion degree, uniform and fine in texture, soft, moist and elastic in taste and not prone to aging.

Owner:广东奇乐趣食品科技有限公司

Lung moistening and cough stopping peach jam

InactiveCN105767993ASweet and sour tasteSoft tasteFood preservationCheese manufactureSalty tasteVitamin C

The present invention discloses a lung moistening and cough stopping peach jam. The lung moistening and cough stopping peach jam is made from the following raw materials: peaches, pears, white fungus, lily bulbs, tofu, duck eggs, crystal sugar, towel gourd flowers, asparagus schoberioides, Chinese wolfberry roots, common rue herb, cochinchina leafflower herb, solanum melongena roots, herb of bastardtoadflax-like swallowwort, glutinous rice powder, citric acid, and vitamin C. The product tastes sweet and sour, is mellow in fruit flavor and rich in nutrition, and can harmonize blood and stimulate menstrual flow, clear away heat and toxic materials, relieve inflammation and stop pains, harmonize stomach and moisten lungs, and reduce phlegm and relieve cough. The peach jam is abundant in raw materials, comprehensive in nutrition, scientific in compatibility, supplementary to each other, and obvious in lung moistening and cough stopping effects; the tofu is soaked with hot edible salt water, so that the jam is sweet with some salty taste and rich in mouthfeel; the traditional Chinese medicines are crushed, the crushed traditional Chinese medicines are subjected to twice extractions, the active ingredients are fully obtained, so that the traditional Chinese medicines are high in utilization rate and save costs; each of the components are added sequentially into a peach pulp, the raw materials are homogenized and the homogenized material is subjected to low-temperature and long-time sterilization, so that the active ingredients are fully integrated, the bitterness of the traditional Chinese medicines is removed, the mouthfeel is soft, the tissue is delicate, and the peach jam is sour, sweet and palatable, and easy to absorb; and after being filled, the peach jam is subjected to ultraviolet sterilization, the shelf life is prolonged, and the consumption is safe and healthy.

Owner:阜阳市颍州区金湖丰种植农民专业合作社

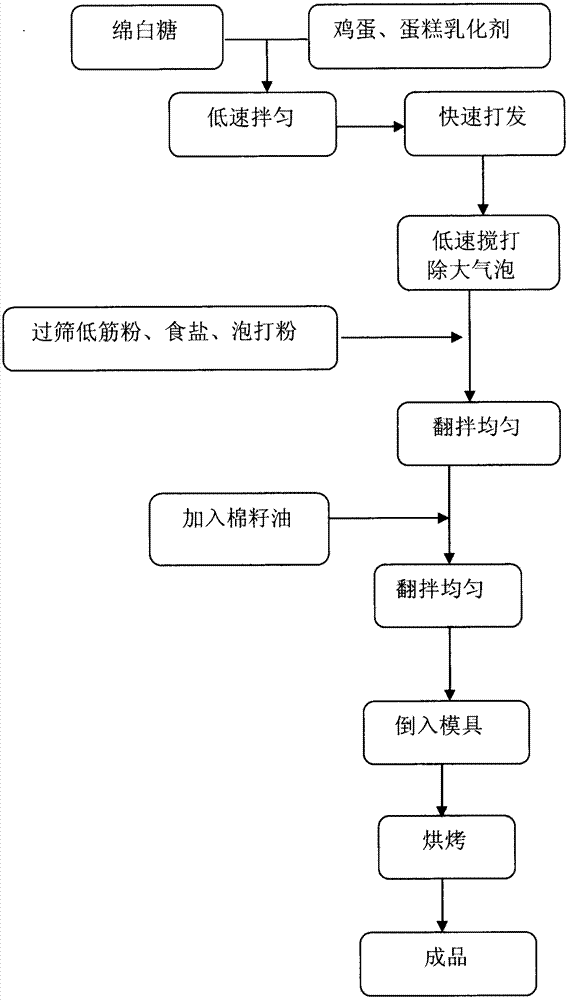

Method for producing sponge cake by using cottonseed oil

InactiveCN102919321ALow in trans fatty acidsImprove qualityDough treatmentBakery productsCottonseed oilSponge cake

The invention relates to an application of cottonseed oil to a sponge cake and belongs to the field of food processing. The sponge cake is made by the following processing steps of fully agitating soft sugar, cake emulsifying agents and eggs in a stirrer to be white, adding sieved flour, salt and baking powders, continuing agitating the mixture to be pasty, pouring the cottonseed oil into the mixture, stirring the mixture to be uniform, and pouring the cake paste into a mold for baking to obtain the sponge cake. According to the application of the cottonseed oil to the sponge cake, cottonseed oil resources are fully used, trans-fatty acid contents in the cake are obviously reduced, and simultaneously, qualities of the cake are obviously improved so that the obtained cake is large in size, delicate and uniform in structure, spongy and soft and tastes wet.

Owner:黄卫宁

Green tea and averrhoa carambola low-sugar jam and making method thereof

InactiveCN106579203ANatural colorFlavor is hearty and freshFood ingredient as antioxidantFood homogenisationThirstBody fluid

The invention discloses green tea and averrhoa carambola low-sugar jam and a making method thereof. The making method comprises the following steps of compounding green tea and averrhoa carambola, and adding functional oligosaccharide, so that the green tea and averrhoa carambola low-sugar jam is obtained. The obtained jam is yellowish green in color and low in sugar content, has rich fragrance of the averrhoa carambola and green grass fragrance of the green tea, has the nutrient and health-care functions of the green tea, the averrhoa carambola and the functional oligosaccharide, has the efficacies of removing wind heat, promoting the production of body fluid to quench thirst, preventing cancer, resisting ageing, beautifying faces, nourishing faces, regulating the health of the intestinal tracts and preventing dental caries, and is broad in market prospects.

Owner:ZHANGZHOU COLLEGE OF SCI & TECH

Method for processing portulaca oleracea health care beverage

InactiveCN105231205AEnhance immune functionPrevent heart diseaseFood ingredient functionsBiotechnologyNutrition

The invention discloses a method for processing a portulaca oleracea health care beverage and belongs to the field of beverage processing. The method is characterized by comprising the steps of material selection and cleaning, precooking and conversion, pulping and glue milling, mixing, homogenizing, filling, sealing and sterilization, cooling and packaging and finished product warehousing. The method has the advantages that the product is fine and uniform in texture, coordinated and soft in taste, moderate in sweetness and acidity, sweet, fragrant and delicious, and has specific faint scent flavor of portulaca oleracea; the product is rich in various nutrient substances and favorable for enhancing human immunity functions, can clear heat, promote diuresis and remove toxicity for detumescence and have effects of lowering and stabilizing blood pressure and preventing heart disease and is a health care beverage which is rich in nutrition and economical.

Owner:宇琪

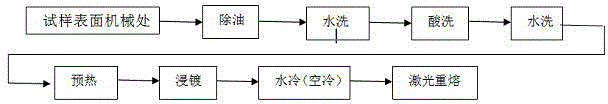

Method for refining hot-dipping coating material by employing laser heat treatment

InactiveCN104630682AEasy to operateImprove processing efficiencyHot-dipping/immersion processesLight spotDip-coating

The invention discloses a method for refining a hot-dipping coating material by employing laser heat treatment. The method comprises the following steps: preparing the hot-dipping coating material on the surface of an apparatus; carrying out laser remelting treatment on the coating material surface by the heat action of the laser to melt alloy on the coating surface; refining crystalline grains of hot-dipping coating alloy through quick cooling, wherein when the laser remelting treatment is performed on the hot-dipping coating material, the laser power for laser remelting selection is 1.0-2.0kw; the laser beam scanning speed is 10-20mm / s; and the diameters of light spots are 1-3mm. The crystalline grains of the coating are refined by a laser remelting method to improve the surface property of the coating material. According to the technology, the surface quality of the coating material can be effectively improved; the application range can be expanded; and the requirements of industrial production can be met.

Owner:SHANGHAI UNIV

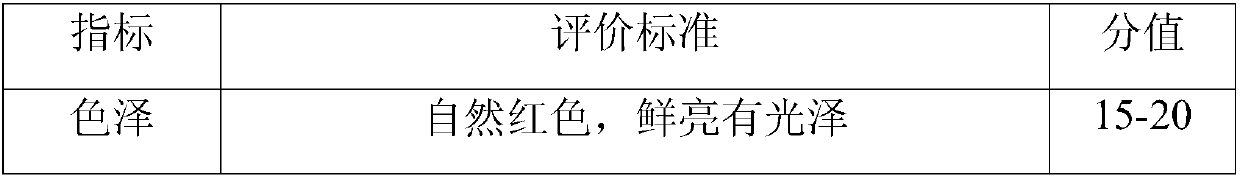

Preparation method of chili sauce

InactiveCN107668659AInhibit the activity of polyphenolaseMaintain colorFood thermal treatmentMaterials preparationFlavor

The invention belongs to the technical field of food processing, and particularly relates to a preparation method of a chili sauce. The method comprises the following steps of material preparation, pretreatment, beating, mixing and fermentation. According to the chili sauce prepared by the invention, the total acid content of the chili sauce is controlled by special hot soup treatment and a special fermentation process, and the total acid content can reach up to 0.88% at a minimum. If the total acid content is too high, product is not safe. The flavor of chili is ensured, and finally the chilisauce has a natural red color, is bright and glossy, and has little juice, poor fluidity, moderate viscosity, fine and uniform texture, no layering, a strong fermentation flavor, coordinating smells,no peculiar smell, fine taste, mild sourness, spiciness and saltiness, and soft sourness.

Owner:代浩

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com