Iron base hardfacing flux-cored wire containing superfine carbide hard phase

A technology of flux-cored welding wire and hard phase, applied in welding medium, welding equipment, welding/cutting medium/material, etc., can solve the problems of high brittleness, hard phase peeling and wear resistance, body splitting, etc., and achieve alloy structure. The effect of uniform and fine, beautiful welding seam, and improved crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

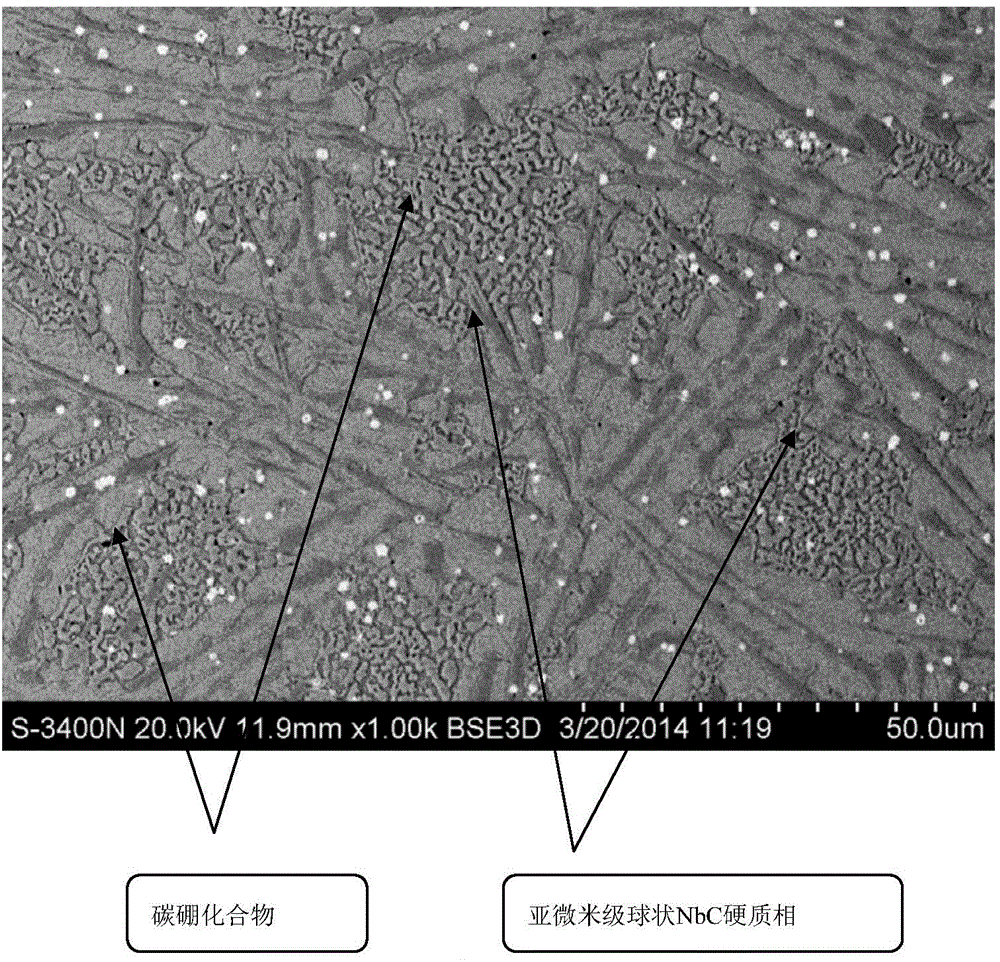

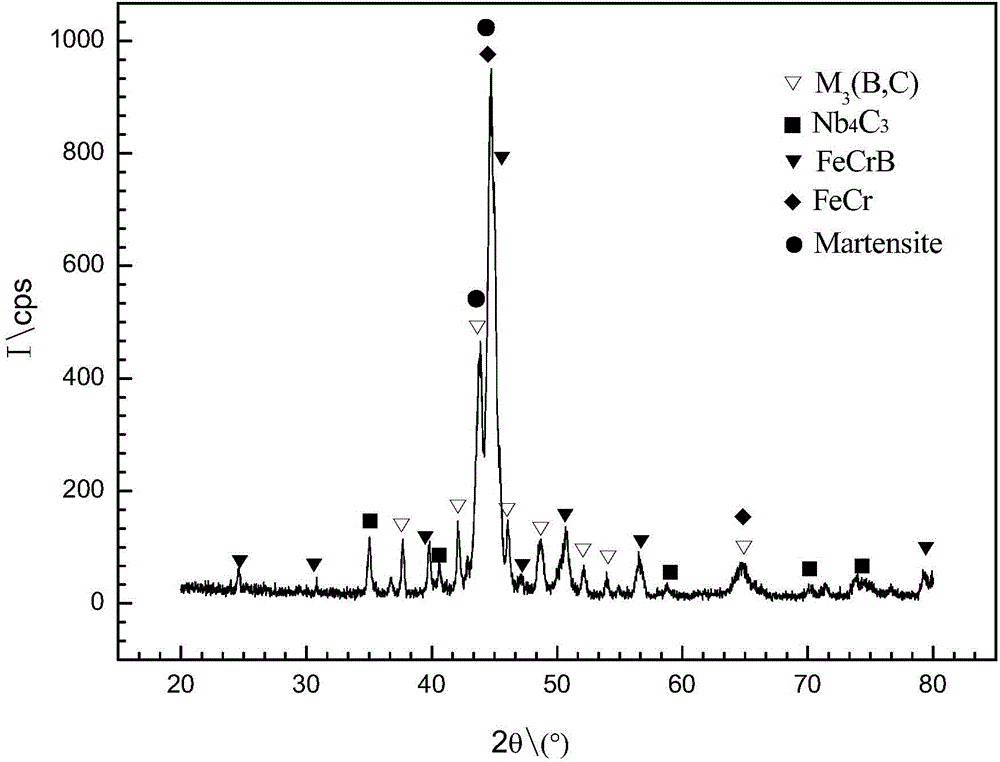

[0032] 1. An iron-based wear-resistant surfacing flux-cored wire containing ultrafine carbide hard phase, the weight ratio of the wire composition is: Cr: 19%; B: 3.9%; Nb: 2.75%; C: 1.9%; Mn : 2.75%; Si: 2.5%; Fe: balance. Filling rate of flux cored wire: 25%. The welding process parameters using carbon dioxide gas shielded welding are: voltage 28V; current 230A; wire feeding speed 480mm / min; gas flow rate 22L / min; distance between the welding wire and the contact tip is 28mm. The composition of the surfacing alloy prepared by the above process is: Cr: 18wt.%; B: 3.5wt.%; Nb: 2.2wt.%; C: 1.6wt.%; Mn: 2.2wt.%; Si: 2.0wt. %; Fe: margin.

[0033] 2. An iron-based wear-resistant surfacing flux-cored wire containing ultrafine carbide hard phase. The weight ratio of the wire composition is: Cr: 16.8%; B: 3.1%; Nb: 2.25%; C: 1.4%; Mn : 2.25%; Si: 2.0%; Fe: balance. Filling rate of flux cored wire: 25%. The welding process parameters using carbon dioxide gas shielded welding are: v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com