High-strength superhigh-carbon steel and its production process

A technology of ultra-high carbon steel and production process, which is applied in the field of high-strength ultra-high carbon steel and its production process, and can solve problems such as low productivity, application range and production scale limitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

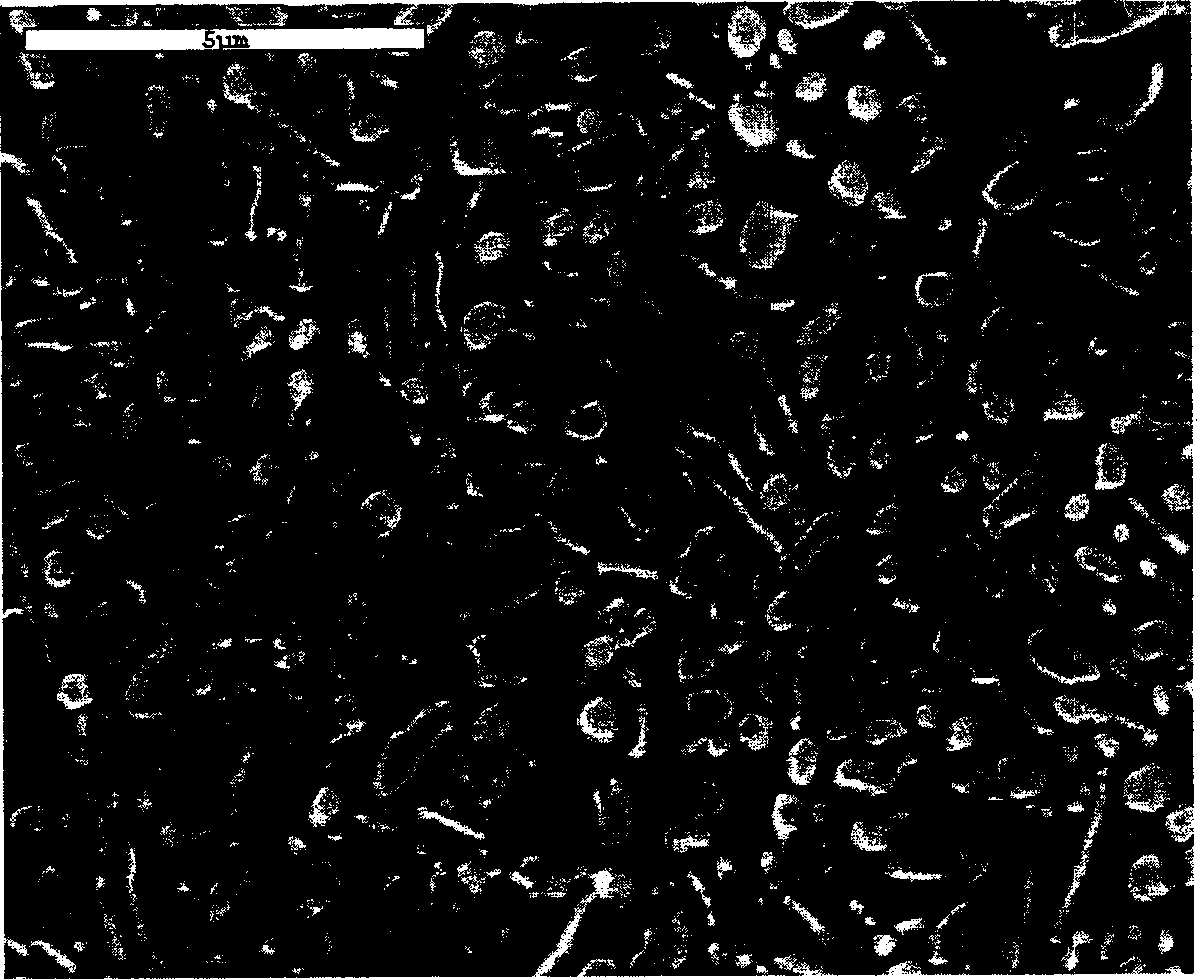

Image

Examples

Embodiment 1

[0103] 1. Alloy composition (results of chemical analysis): 1.24C-2.55Si-1.55Cr-0.62Mn-Fe (wt%)

[0104] 2. Spray forming

[0105] The specific parameters are: Put the master alloy material into the crucible to melt, the superheat of the melt is about 150°C; the inner diameter of the catheter is 4mm; the pressure of the atomizing gas (nitrogen) is 2.2MPa, the distance between the atomizer and the substrate The distance is 360mm, the substrate rotation speed is 10rpm; the gas / melt flow ratio (G / M) is about 0.30M 3 / kg.

[0106] Strip specimens of 16 mm thickness were prepared from spray-formed blanks, with the front end wedge-shaped to facilitate bite during rolling.

[0107] 3. Hot rolling

[0108] The above-mentioned samples were respectively placed in a furnace preheated to 820°C and 850°C for 35 minutes.

[0109] After taking out the sample, it is immediately sent to a hot rolling mill with a maximum rolling force of 3000KN for rolling. From the time the sample is take...

Embodiment 2

[0118] 1. Alloy composition (results of chemical analysis): 1.78C-1.46Al-1.61Cr-0.52Mn-Fe (wt%)

[0119] 2. Injection forming, the specific parameters are the same as in Example 1.

[0120] Strip specimens of 16 mm thickness were prepared from spray-formed blanks, with the front end wedge-shaped to facilitate bite during rolling.

[0121] 3. Hot rolling

[0122] Put the above-mentioned samples into the furnaces preheated to 910°C and 970°C respectively for 35 minutes.

[0123] After taking out the sample, it is immediately sent to a hot rolling mill with a maximum rolling force of 3000KN for rolling. From the time the sample is taken out to the start of rolling, the temperature of the sample drops by 70°C to 90°C (measured by an infrared temperature tester).

[0124] Rolling mill condition is the same as embodiment 1.

[0125] One sample was heated at 910°C and 970°C, and rolled from 16mm to 4.8mm in one pass, the reduction was 70%, and the rolling rate was ~7 / s.

[0126]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com