Copper product machining method

A processing method and technology of copper products, applied in the field of copper product processing, can solve the problems of dimensional deformation, economic loss, waste of copper processing enterprises, etc., and achieve the effects of good mechanical properties, reduction of product cost, and improvement of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

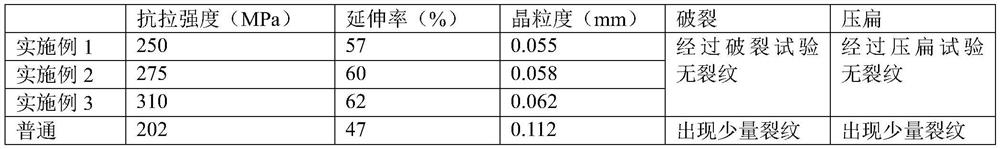

Examples

Embodiment 1

[0027] A method for processing copper products, comprising the steps of:

[0028] S1. Casting:

[0029] a. Polish the oxide film on the surface of the copper ingot, and place it in a beaker filled with absolute alcohol to prevent it from oxidizing;

[0030] b. Stack the copper ingots in the water-cooled copper mold crucible, cover the furnace cover, and vacuumize twice to 5.0×10 before the formal melting -3 Pa, and filled with high-purity Ar gas to dilute residual oxygen;

[0031] c. After two times of vacuuming, fill it with high-purity Ar gas of 0.5 atmospheres to dilute the residual oxygen in the furnace;

[0032] d. Turn on the magnetic stirring for smelting, the smelting time is 2 minutes, turn over the smelted copper repeatedly to continue smelting, the number of smelting times is greater than or equal to 5;

[0033] e. Casting the copper liquid in the molten state into a copper column through a crystallizer;

[0034] S2. Preparation of thin strips: place the copper ...

Embodiment 2

[0038] A method for processing copper products, comprising the steps of:

[0039] S1. Casting:

[0040] a. Polish the oxide film on the surface of the copper ingot, and place it in a beaker filled with absolute alcohol to prevent it from oxidizing;

[0041] b. Stack the copper ingots in the water-cooled copper mold crucible, cover the furnace cover, and vacuumize twice to 5.0×10 before the formal melting -3 Pa, and filled with high-purity Ar gas to dilute residual oxygen;

[0042] c. After two times of vacuuming, fill it with high-purity Ar gas of 0.5 atmospheres to dilute the residual oxygen in the furnace;

[0043] d. Turn on the magnetic stirring for smelting. The smelting time is 3 minutes. Turn over the smelted copper repeatedly to continue smelting. The number of smelting times is greater than or equal to 5;

[0044] e. Casting the copper liquid in the molten state into a copper column through a crystallizer;

[0045] S2. Preparation of thin strips: place the copper ...

Embodiment 3

[0049] A method for processing copper products, comprising the steps of:

[0050] S1. Casting:

[0051] a. Polish the oxide film on the surface of the copper ingot, and place it in a beaker filled with absolute alcohol to prevent it from oxidizing;

[0052] b. Stack the copper ingots in the water-cooled copper mold crucible, cover the furnace cover, and vacuumize twice to 5.0×10 before the formal melting -3 Pa, and filled with high-purity Ar gas to dilute residual oxygen;

[0053] c. After two times of vacuuming, fill it with high-purity Ar gas of 0.5 atmospheres to dilute the residual oxygen in the furnace;

[0054] d. Turn on the magnetic stirring for smelting, the smelting time is 2.5min, turn over the smelted copper repeatedly to continue smelting, the number of smelting times is greater than or equal to 5;

[0055] e. Casting the copper liquid in the molten state into a copper column through a crystallizer;

[0056] S2. Preparation of thin strips: place the copper col...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com