Patents

Literature

505 results about "Copper mold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

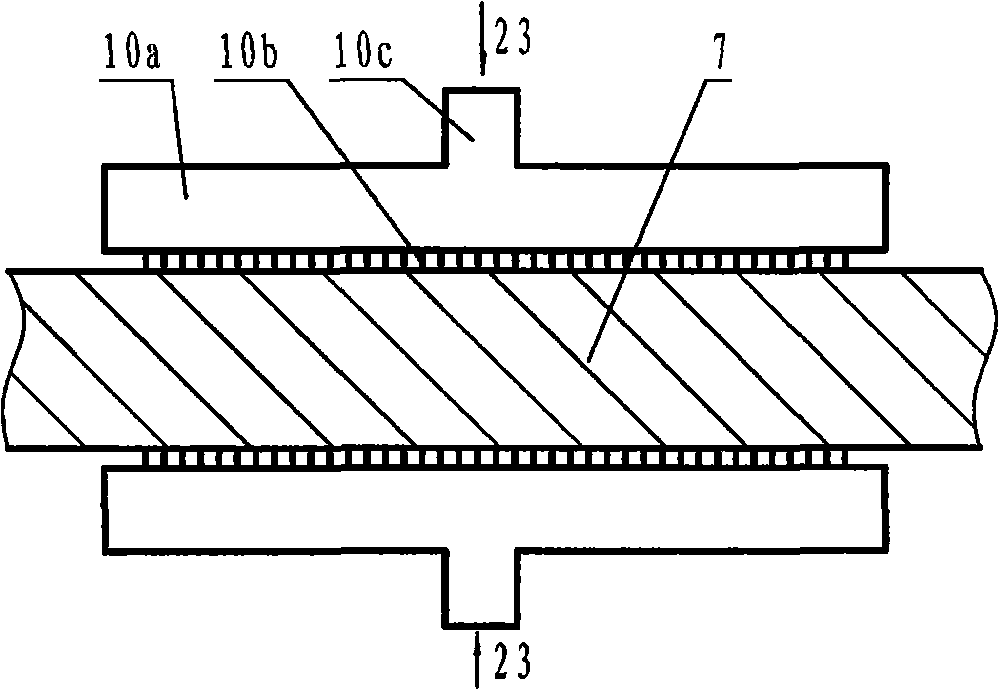

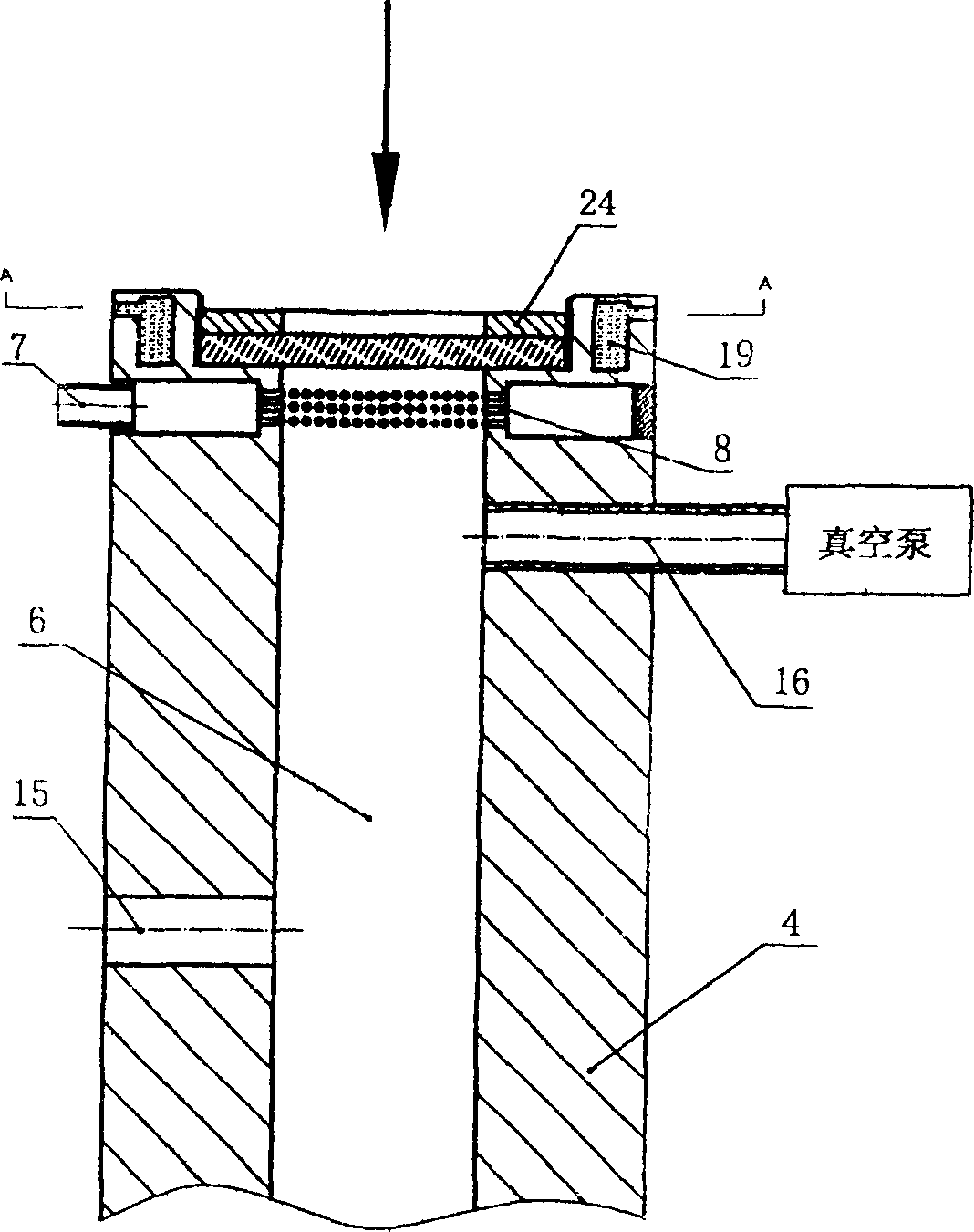

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

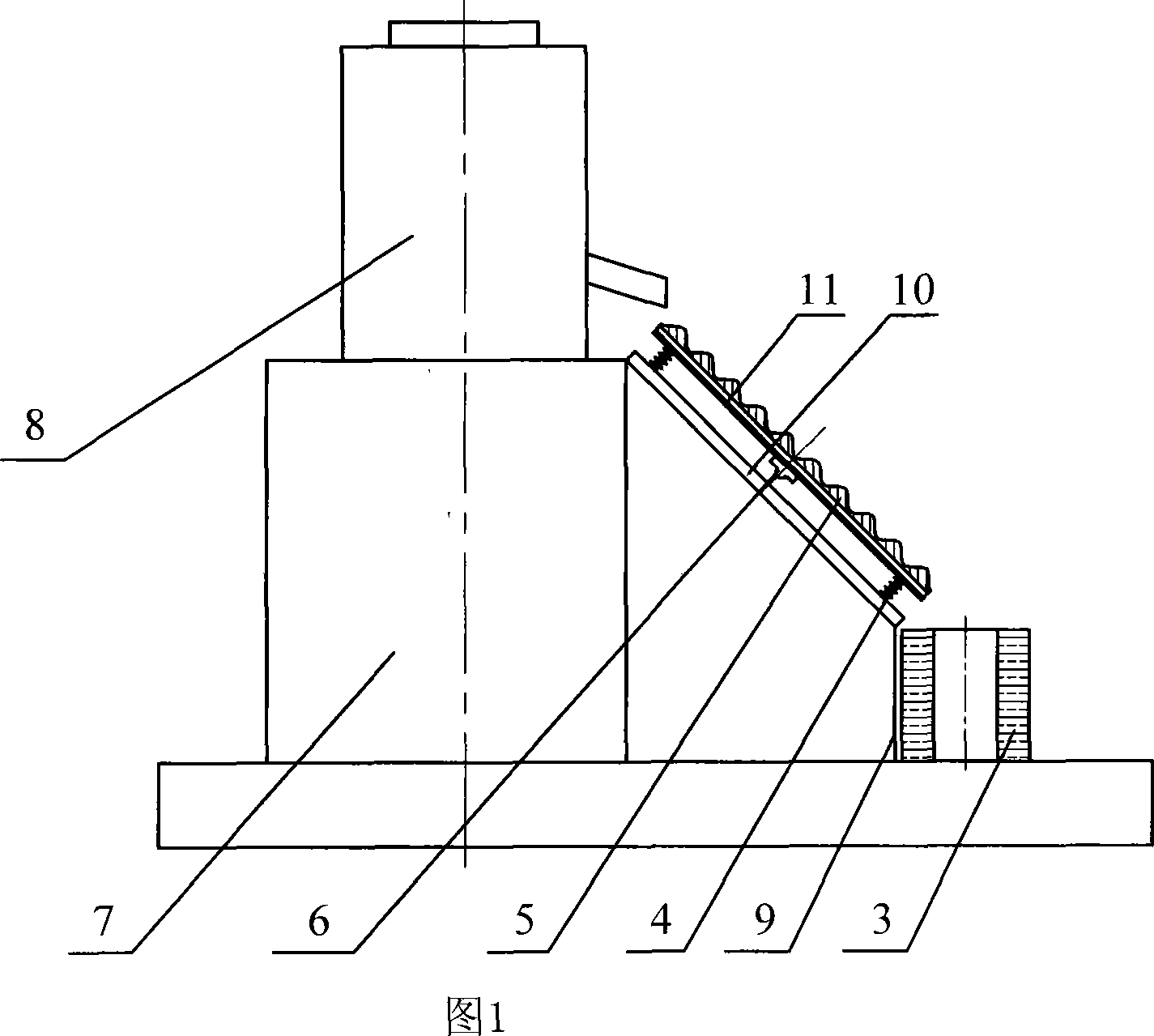

Wave type inclined plate vibration device for preparing semisolid state alloy and preparation method thereof

A wave-type inclined plate vibration device for preparing semi-solid alloy belongs to the field of preparation of semi-solid alloy technology. Said device includes a bracket , a wave-type metallic plate, a cam wheel vibration mechanism, a water-cooling typpe matrix, an electric motor and a frequency modulation mechanism, wherein a pouring box is fixed on the bracket, a supporting plate is fixed parallel to the bracket, the water-cooling typpe matrix is set at one side of the supporting plate, a fixed plate is mounted between the supporting plate and the bracket and is connected to the lug support of the wave-type metallic plate through a spring, the cam roller assembly is fixed at the lug support of the wave-type metallic plate, and the electric motor is connected respectively to the cam roller assembly and the voltage-regulating transformator.Said invention possesses the advantages of low cost of manufacture, short process flow, enhanced stirring action effects, excellent semi-solid alloy organization prepared, fine and round organizing, high spheroidizing degree, with a minimum of 10 mu m reached.Said invention is capable of preparing semi-solid-state materials of high melting point and realizing semi-solid condition shaping of steel material with high melting point.

Owner:NORTHEASTERN UNIV

3D (Three Dimensional) forming method for large-sized porous amorphous alloy part of complex shape

ActiveCN104399978ASolve difficult-to-machine defectsOvercoming the Deficiencies of Difficult ChoicesSelective laser sinteringAlloy

The invention discloses a 3D (Three Dimensional) forming method for a large-sized porous amorphous alloy part of a complex shape. The method comprises the following steps: preparing amorphous alloy powder through mechanical alloying pulverization in combination with plasma spherizing or atomization; then sintering metal powder by using selective laser so as to prepare the large-sized porous amorphous alloy part with the complex shape. The method has the advantages that the problems such as small critical dimension of amorphous alloy formed by a water quenching method and a copper mold casting method and difficulty in selection of a pore forming agent are solved, the 3D preparation and forming of the large-sized porous amorphous alloy part are realized, the part with the complex shape can be prepared, the defect of difficulty in machining of the amorphous alloy material is overcome, the amorphous alloy part of the porous structure can be conveniently formed, the pore size and the volume fraction can be flexibly adjusted, and the method has the advantages of raw material saving, high efficiency, low cost and the like and is suitable for industrialized preparation of the amorphous alloy part.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of whole continuous nano-porous copper

The invention relates to a preparation method of whole continuous nano-porous copper, comprising the following steps: (1) heating the pure metallic aluminum and copper to the molten state, stirring and mixing the mixture to form Cu-Al alloy liquid; (2) fast blowing the alloy liquid out with inert gas to solidify the molten liquid metal on the copper rollers which rotate in high speed and prepare alloy strips, or solidify the molten liquid metal in copper molds to prepare alloy plates or alloy bars; and (3) performing dealloying process to the obtained alloy, cleaning the alloy in the distilled water to be neutral and airing the alloy to obtain nano-porous copper. The beneficial effects of the invention are as follows: (1) the produced nano-porous copper is whole continuous and whole continuous nanosize bulk materials can also be prepared; (2) low concentration of corrosion solution is used to prepare nano-porous copper in the method of the invention, and the operation process is simple and the method is suitable for large-scale industrialized production; and (3) according to the components of the mother alloy and the types of corrosion solution, the structure and size of nanoporous copper can be regulated.

Owner:UNIV OF JINAN

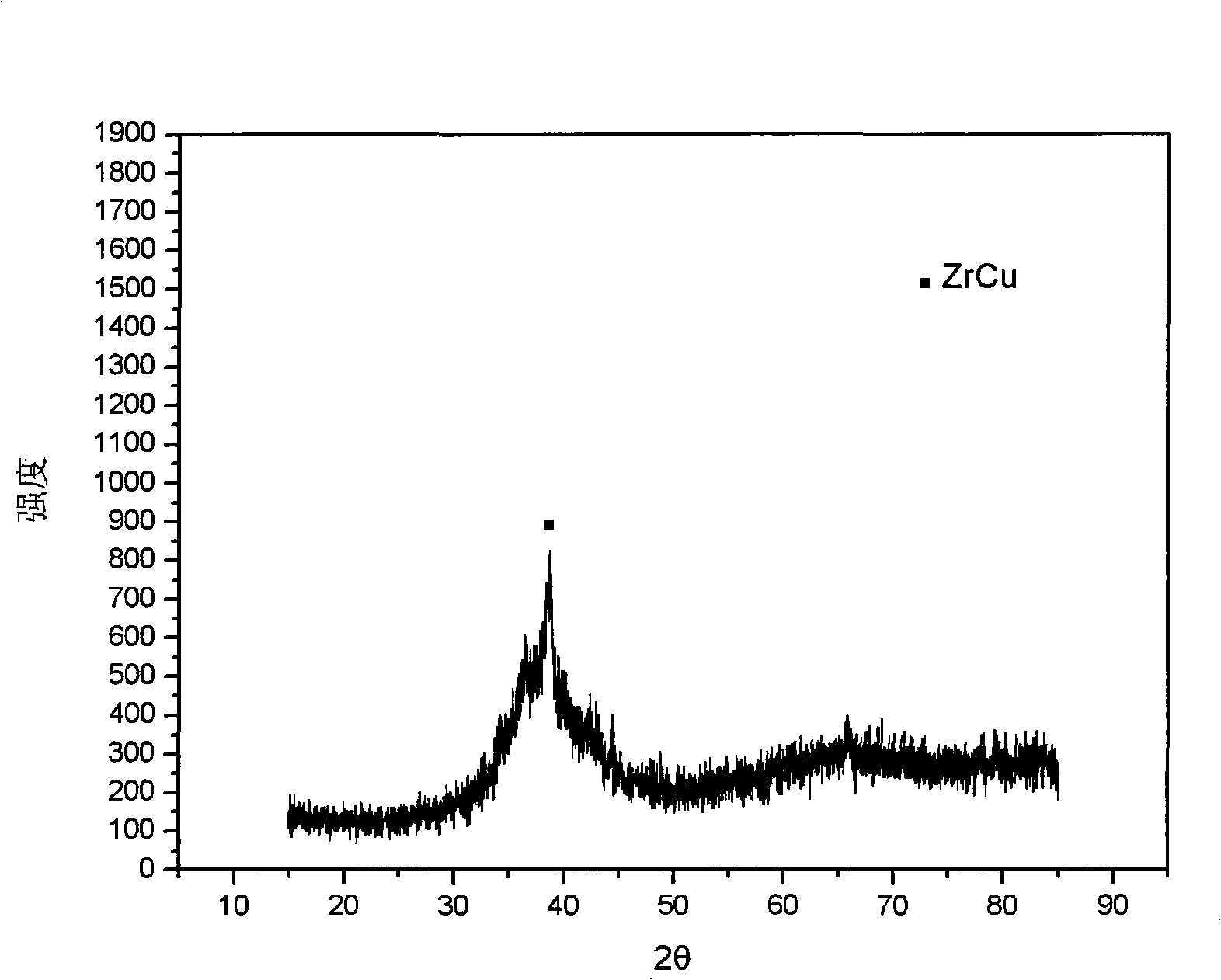

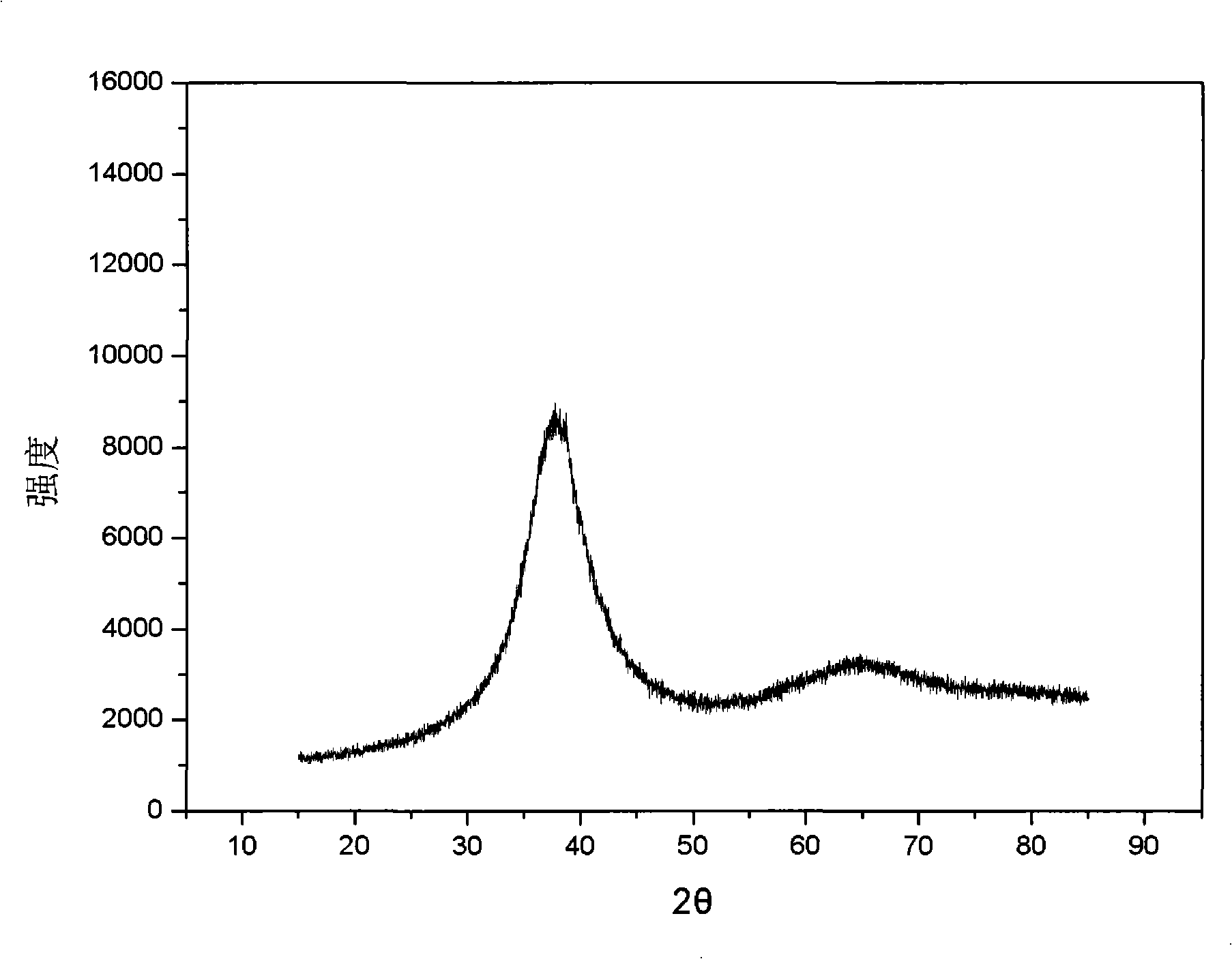

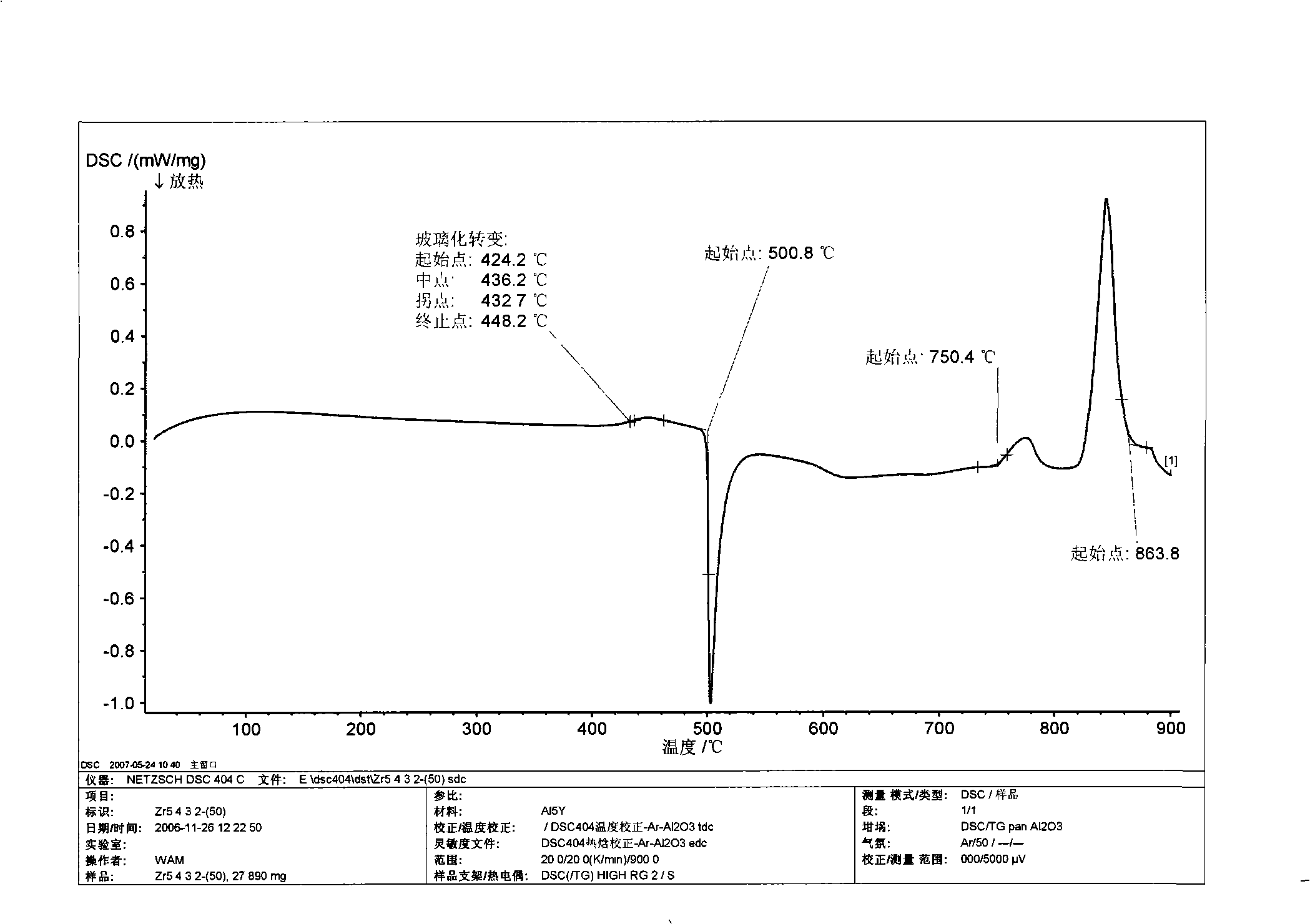

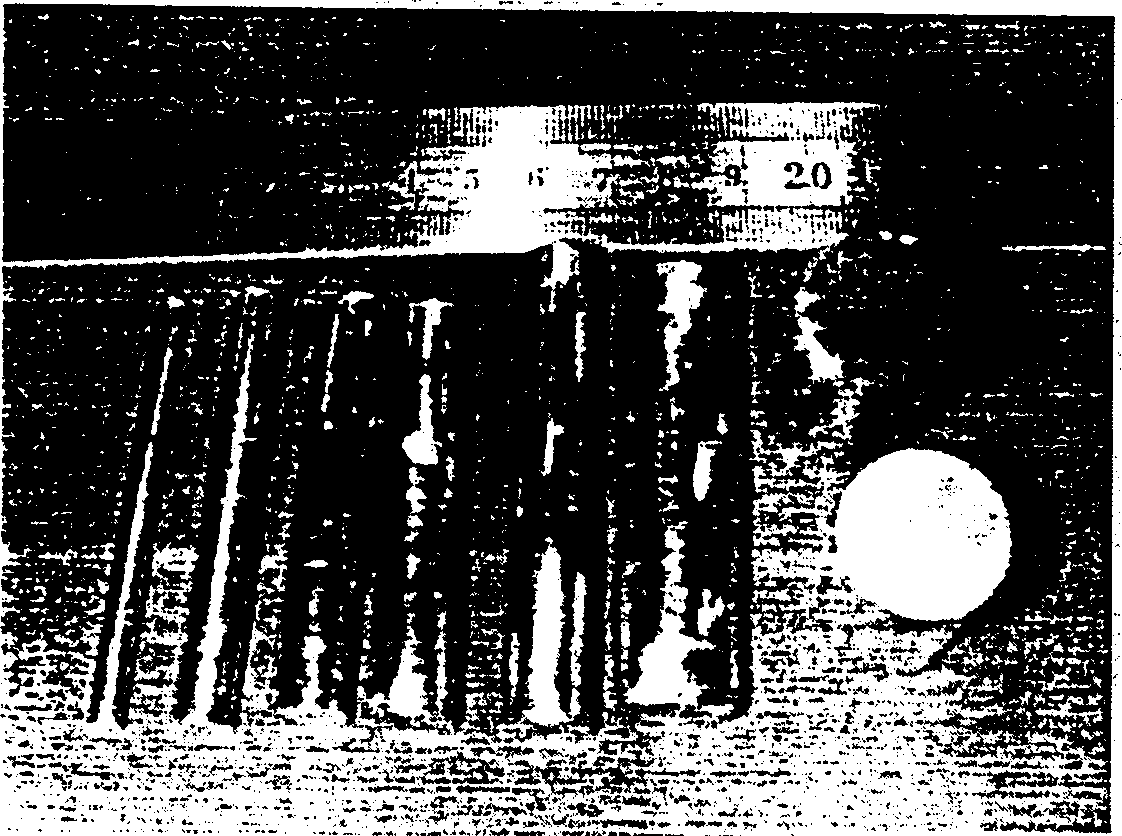

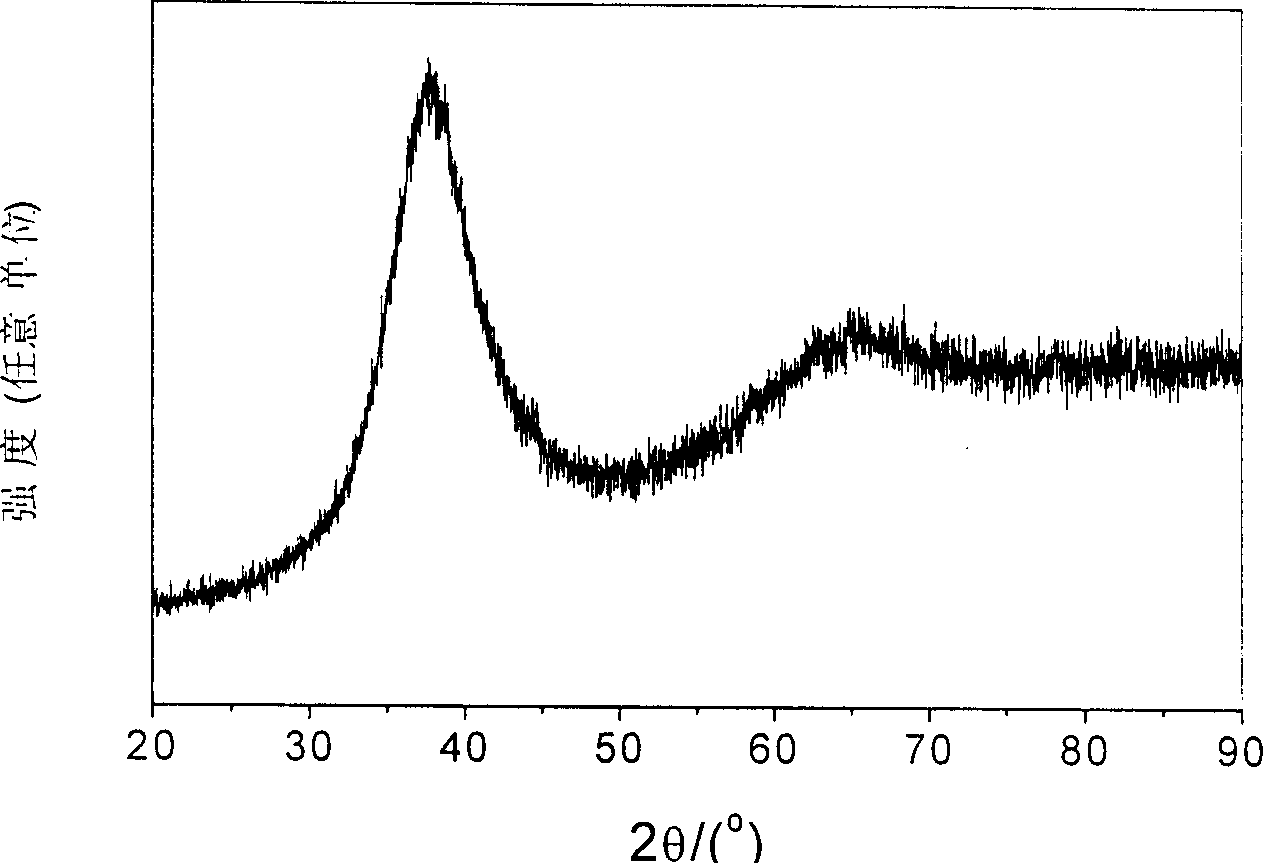

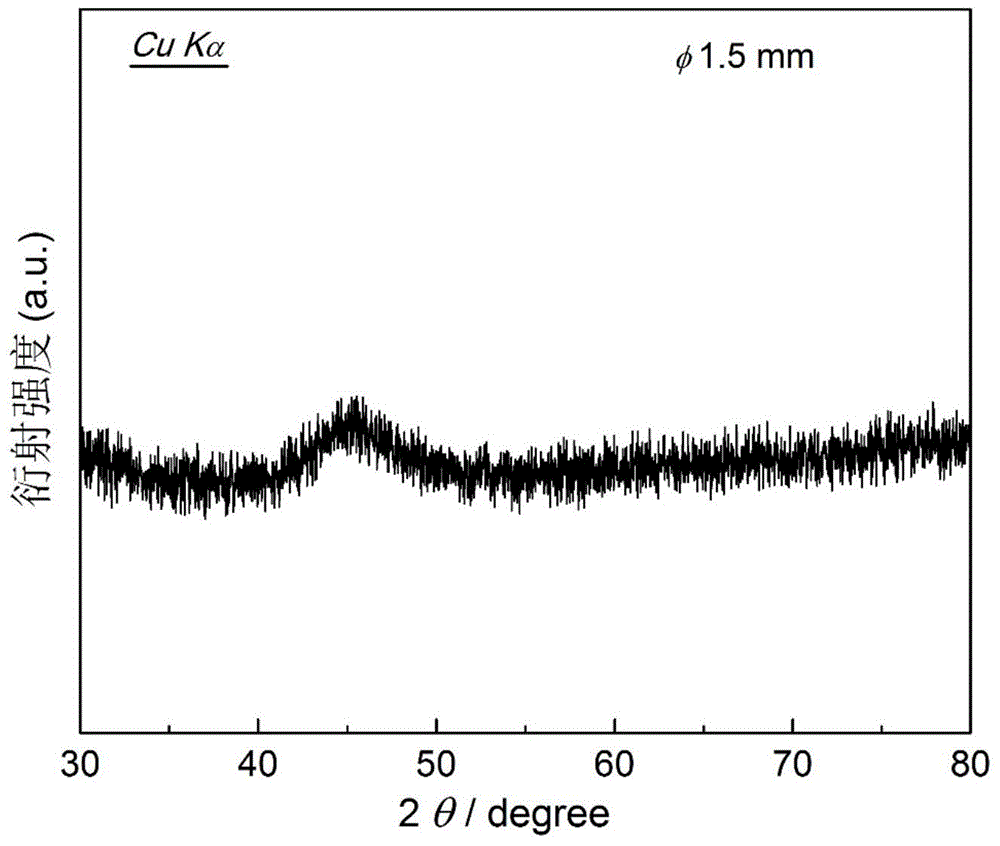

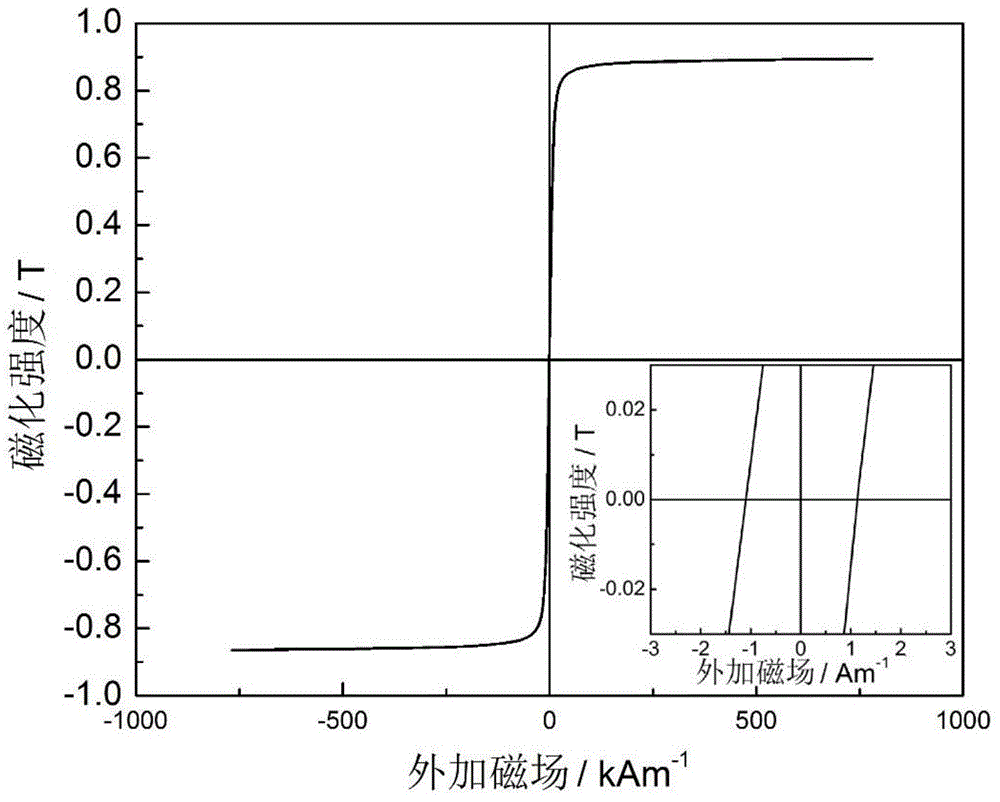

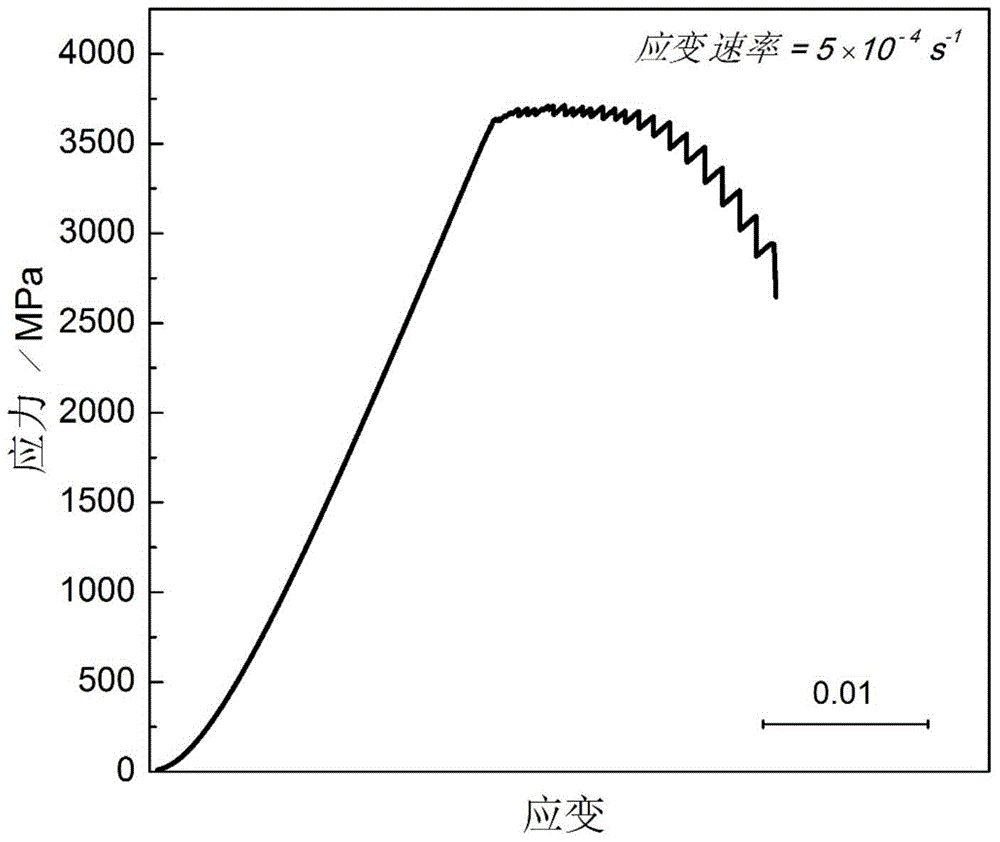

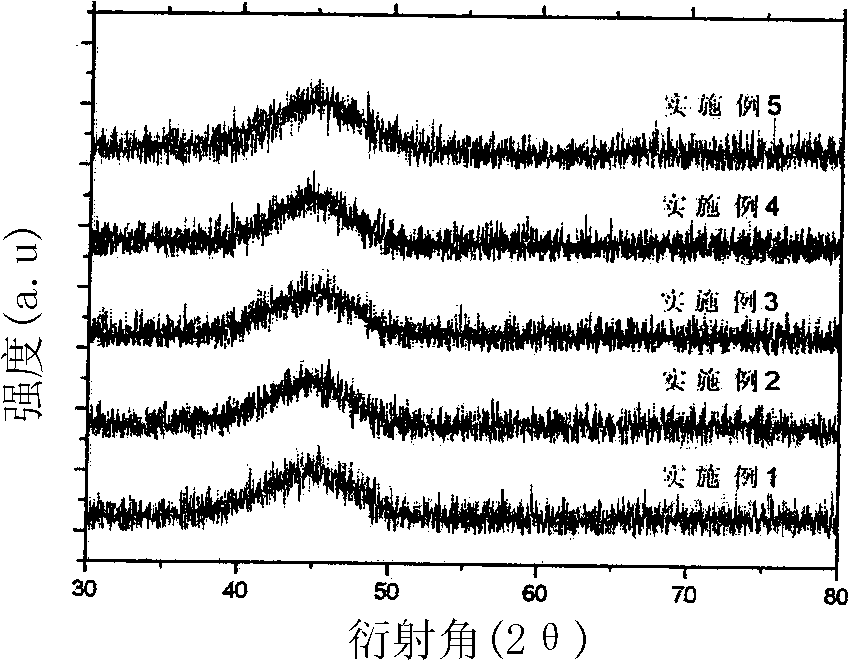

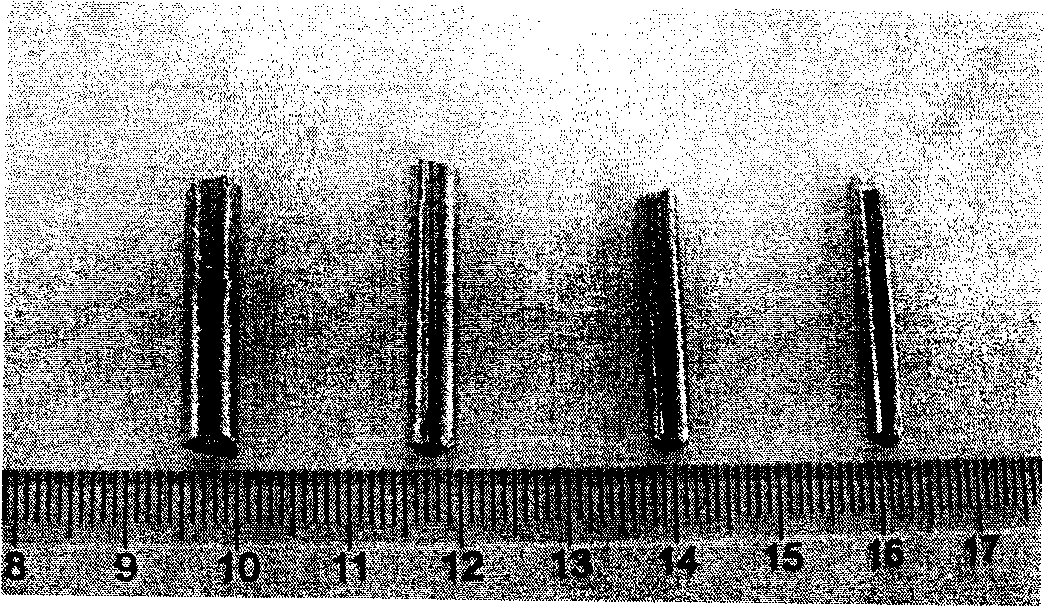

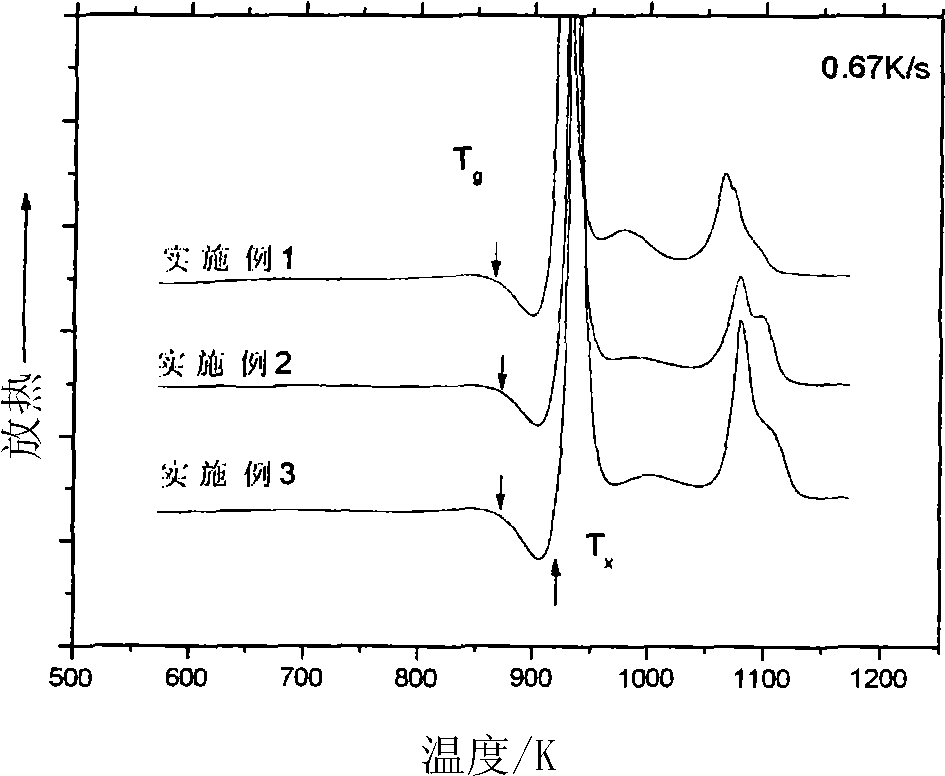

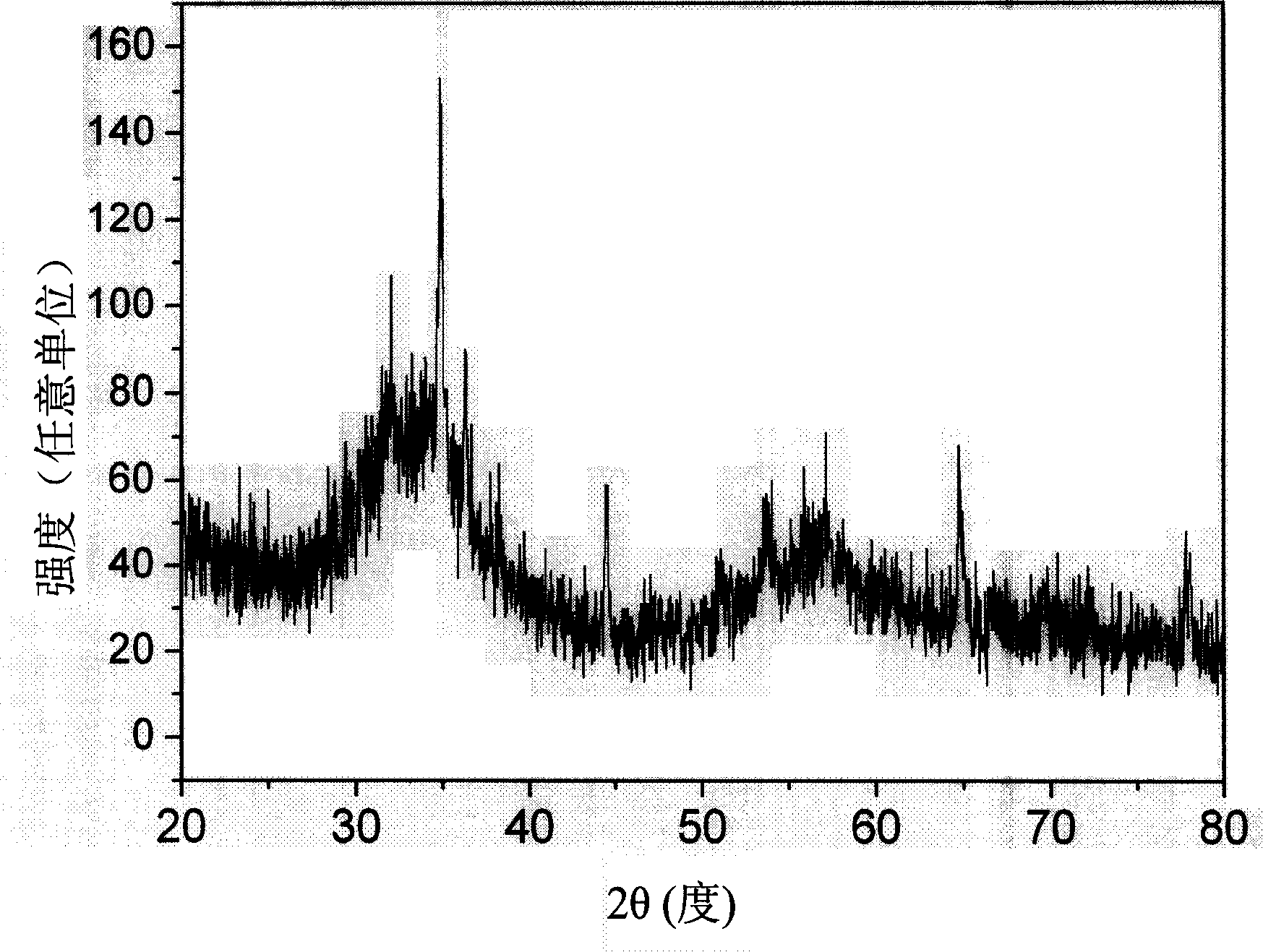

Zr-Cu-Ni-Al-Ag alloy with higher amorphous forming ability and production method thereof

The invention relates to a preparation technology of a block zirconium-base amorphous alloy, in particular to a Zr-Cu-Ni-Al-Ag alloy with higher glass-forming ability and a preparation method thereof, and the characteristic thermodynamics parameter and the mechanical property of the alloy are characterized and tested at the same time. The alloy system is the Zr-Cu-Ni-Al-Ag alloy, which has the component ranges (by atom percentage) that Zr is 41 to 63, Cu is 18 to 46, Al is 4 to 15, Ni is 1.5 to 12.5, and Ag is 1.5 to 26. Based on a Zr-Cu-Ni-Al quaternary alloy, the forming ability of the amorphous alloy is increased through inhibiting the precipitation of a crystalline state phase. The preparation technology adopts an electric arc melting method to prepare a master alloy ingot, then adopts a copper mold casting method to prepare amorphous alloy rods with different diameters, and the alloy in the system can easily prepare amorphous round bars, the diameter of which can reach 2cm. Due to stronger amorphous forming ability and good mechanical property, the alloy has good application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

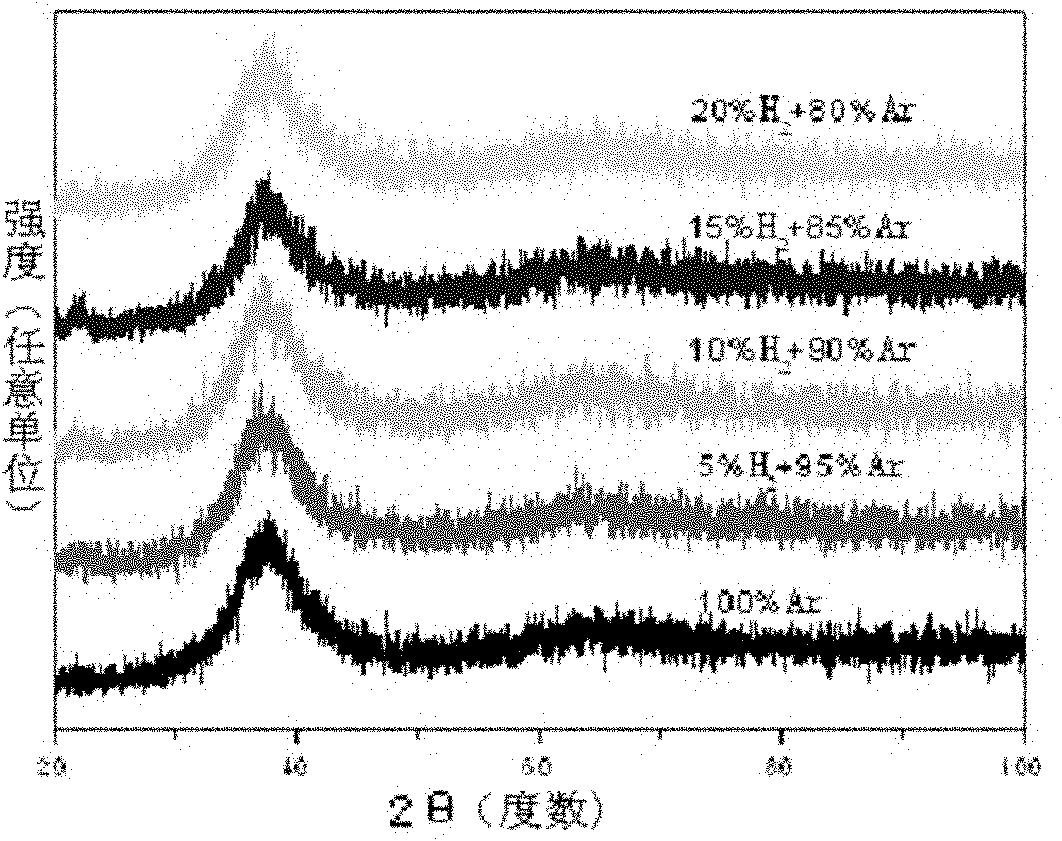

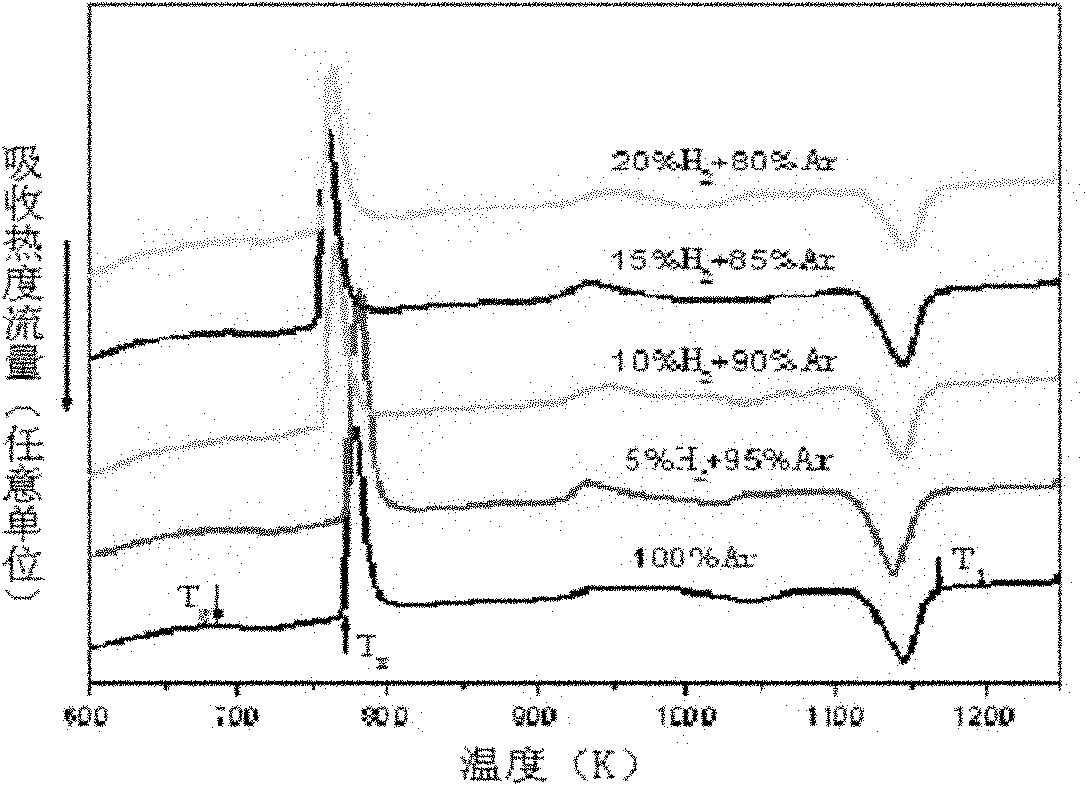

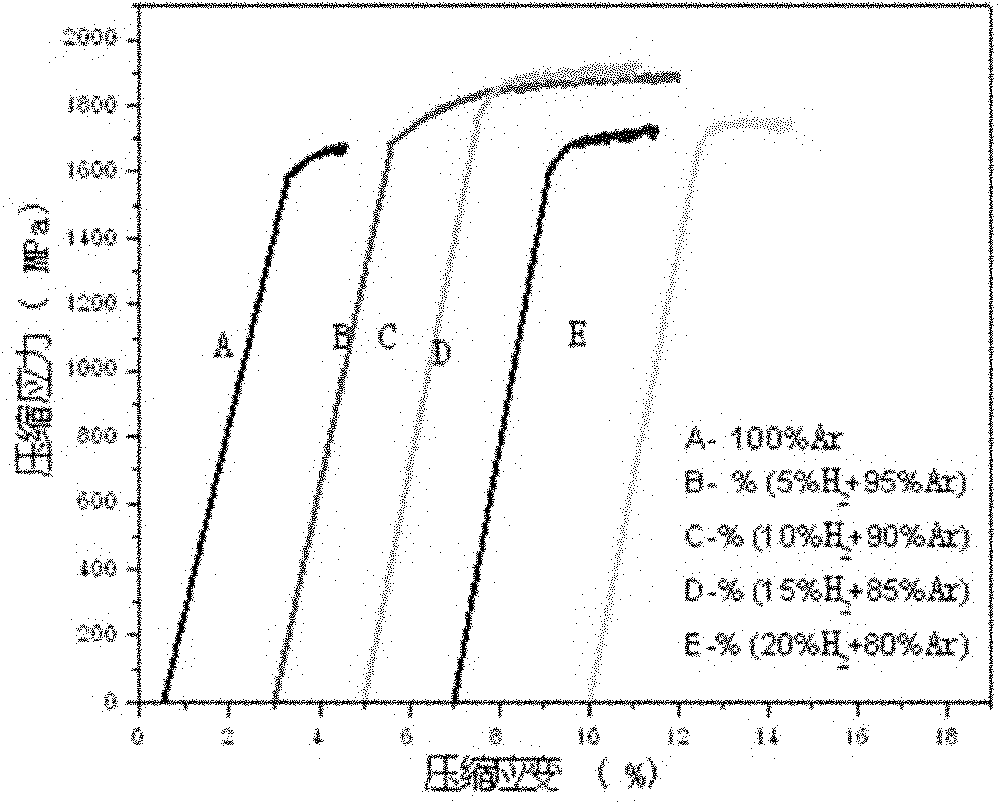

Method for preparing zirconium-base amorphous alloy with plasticity at room temperature

The invention relates to a method for preparing zirconium-base amorphous alloy with plasticity at room temperature, and relates to a method for preparing amorphous alloy, which solves the problem of poor plasticity at room temperature of the amorphous alloy in the prior art. The method comprises the following steps of: filling a zirconium-base amorphous alloy raw material into a water-cooling copper crucible of an arc furnace, vacuumizing a smelting chamber, introducing hydrogen and argon into the smelting chamber according to a certain ratio, smelting the raw material of the zirconium-base amorphous alloy in a mixed atmosphere, and preparing by a copper mold suction casting method to obtain the zirconium-base amorphous alloy with the plasticity at room temperature. The zirconium-base amorphous alloy has excellent plasticity at room temperature, and the plasticity is improved by 7 times. The method can be widely applied to the plastification of massive amorphous alloy, so that the amorphous alloy can be applied in fields of aerospace, weapon industry, precision machines, information technology and the like.

Owner:安徽哈特三维科技有限公司

High-entropy AlCoCrFeNiCuC alloy and preparation method thereof

The invention discloses a corrosion-resistant high-entropy AlCoCrFeNiCuC alloy and a preparation method thereof; the corrosion-resistant high-entropy AlCoCrFeNiCuC alloy comprises the following components in atomic percentage: 100% of Al, 100% of Co, 100% of Cr, 100% of Fe, 100% of Ni, 50% of Cu and 10-100% of C. The preparation method comprises the steps of (1) burdening, (2) smelting of a mother alloy, and (3) spray casting of a copper mold. The high-entropy AlCoCrFeNiCuC alloy system, related by the invention, is prepared by adopting the copper mold spray casting method. The alloy prepared by the copper mold spray casting method has excellent corrosion resistant performance. The high-entropy AlCoCrFeNiCu0.5C0.1 (atomic percent) alloy structure prepared by the copper mold spray casting method consists of solid solution with a simple structure without appearing complex intermetallic compound, so that the corrosion resistance of the alloy is preferably improved.

Owner:SHENYANG UNIV

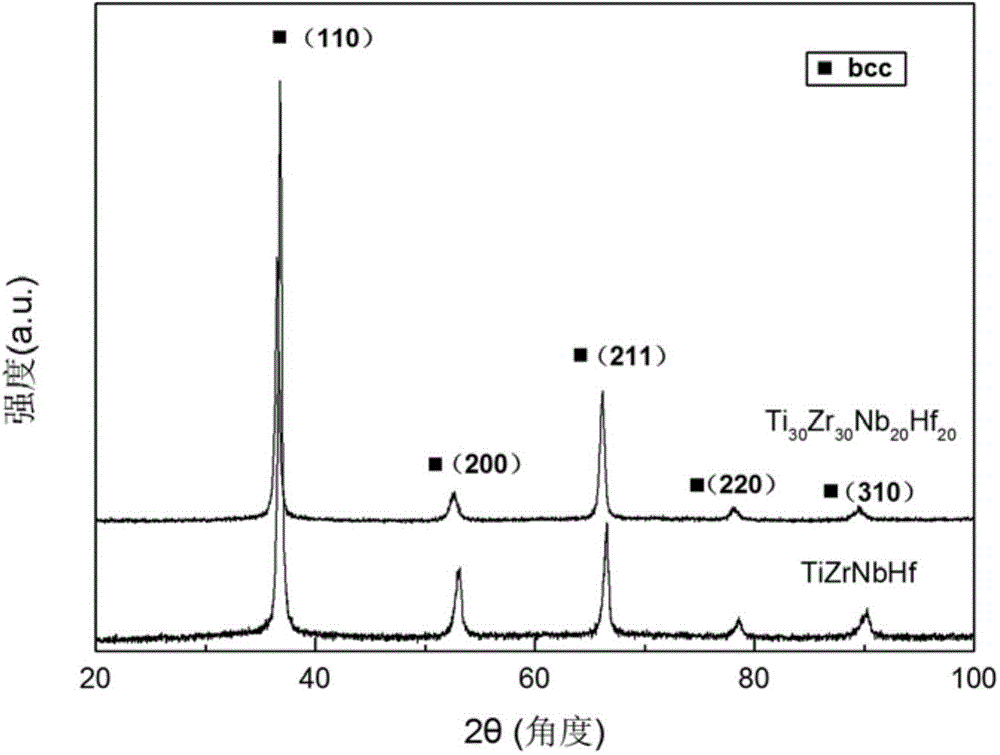

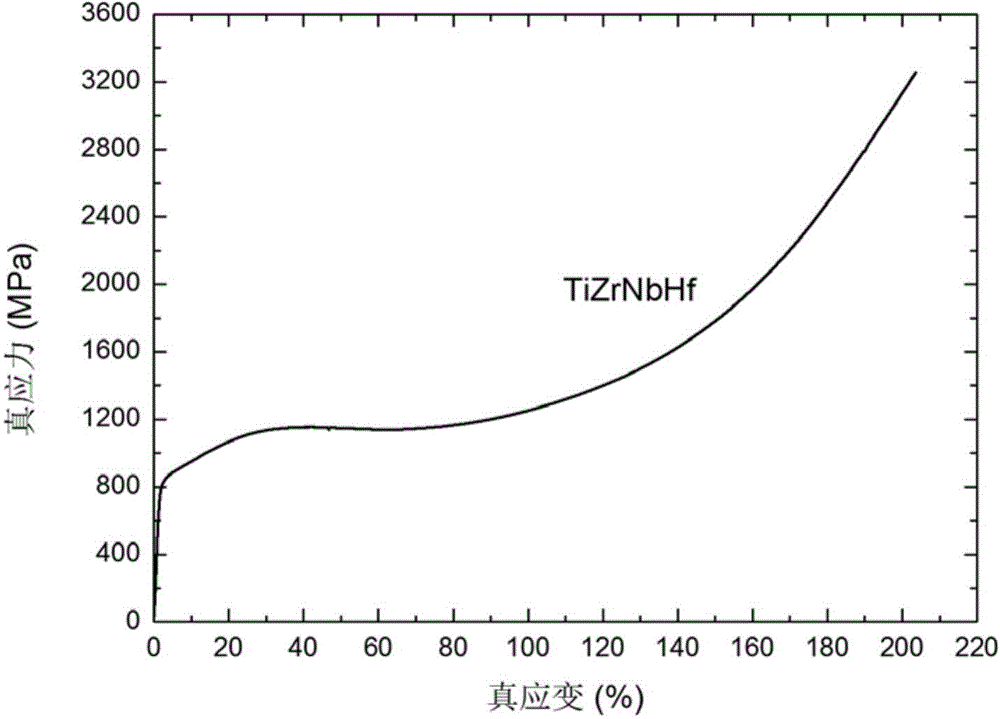

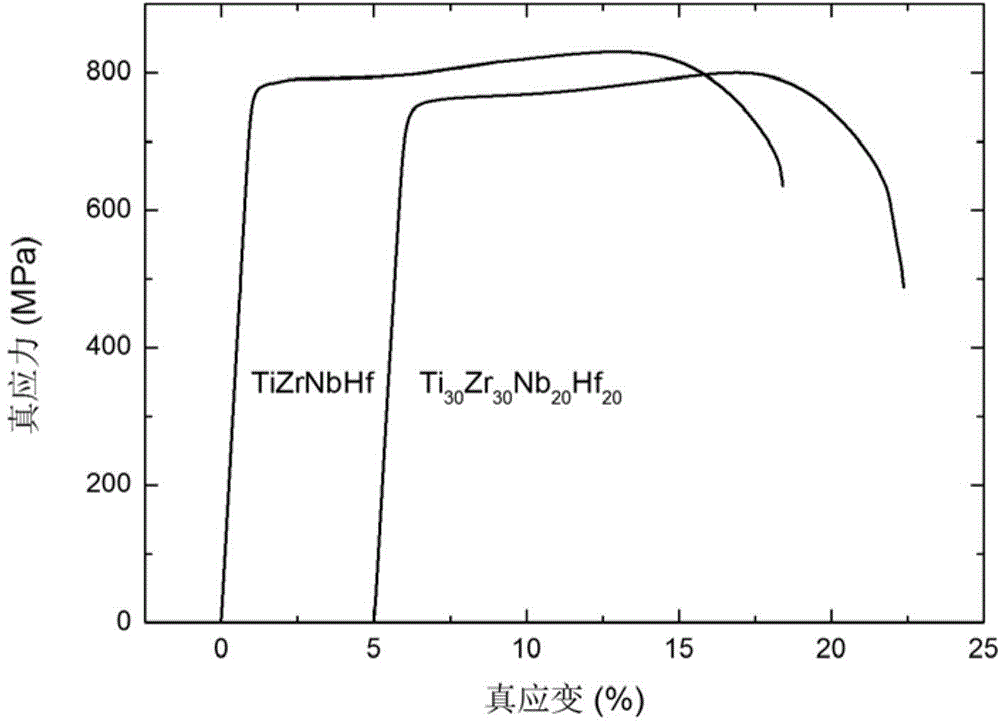

High-strength low-elasticity modulus TiZrNbHf high-entropy alloy and preparation method thereof

ActiveCN103602874ALow Young's modulusExcellent structural stabilityHigh entropy alloysYoung's modulus

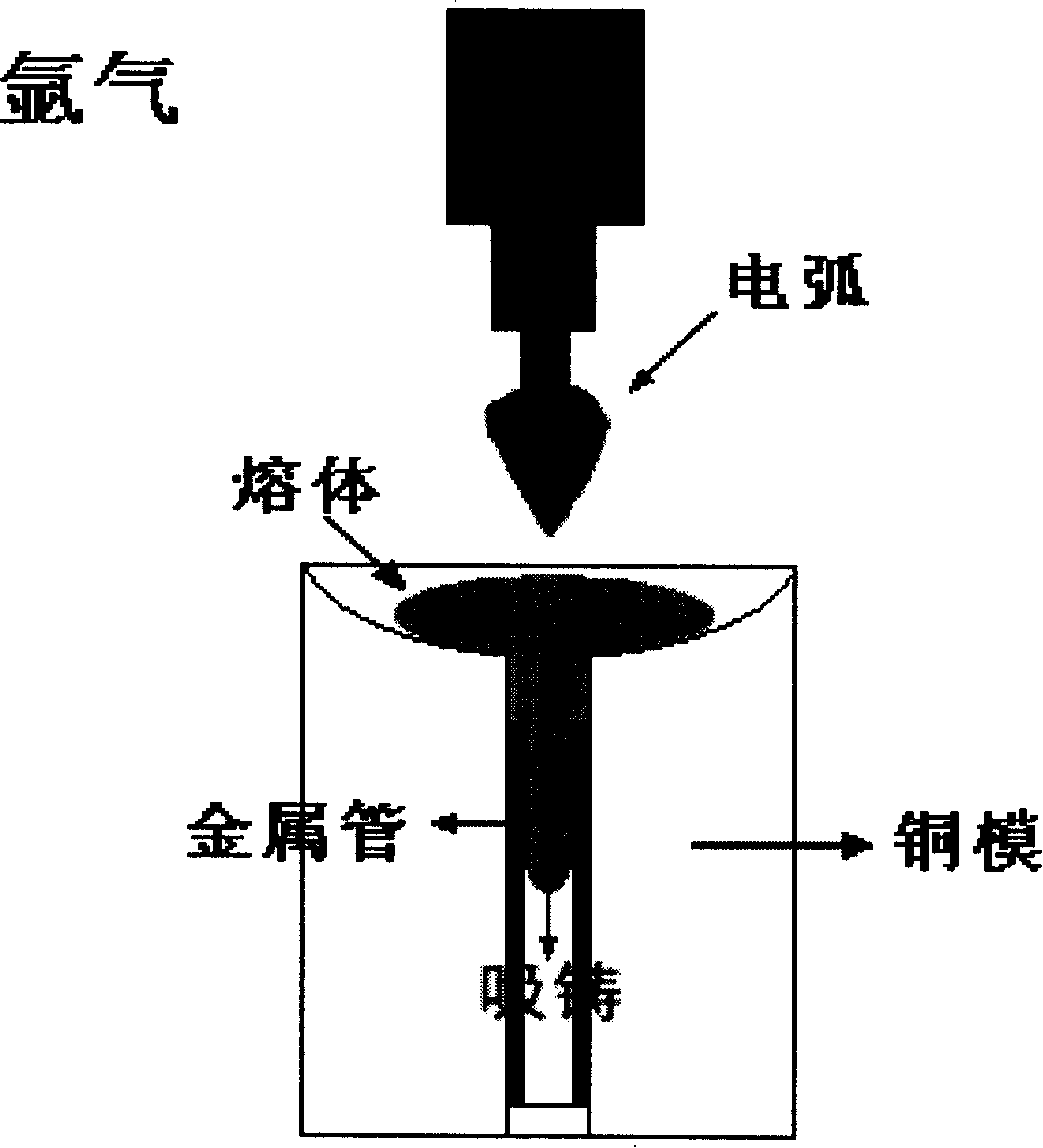

The invention relates to a high-strength low-elasticity modulus TiZrNbHf high-entropy alloy and a preparation method thereof; the component of the high-entropy alloy is TiaZrbNbcHfd, wherein a is not less than 20 and not more than 35, b is not less than 20 and not more than 35, c is not less than 20 and not more than 35, and d is not less than 20 and not more than 35. The preparation method of the alloy comprises the following steps: descaling metallurgy raw materials (Ti, Zr, Nb and Hf metals), precisely weighing and proportioning according to a mole ratio for smelting alloy; smelting the alloy by using a non-consumable vacuum arc furnace or a cold crucible suspension furnace, smelting the alloy in a water-cooling copper crucible, suction casting or pouring the alloy in a copper mold through vacuum suction casting or metal mold equipment so as to obtain high-entropy alloy rod or platy material. The high-entropy alloy has high strength, low Young modulus, and excellent structure property stability at a high temperature, the alloy element is non-toxic to human body or low in toxicity; and therefore, the high-entropy has good application prospect on biomedical and high-temperature components.

Owner:UNIV OF SCI & TECH BEIJING

Plasticity enhancement massive metal glass material and preparation method thereof

The invention relates to a bulk metallic glass material with improved plasticity which is a metallic glass alloy cylindrical material covered by a metal pipe. The inner diameter of the metal pipe is between 3 and 10 mm, the thickness is between 0.5 and 2mm, the length is between 3 and 10 cm; the covered metallic glass alloy is alloy systems such as zirconium-based, copper-based, iron-based, rare-earth-based and so on, which amorphous formation abilities are more than 3 mm; the metal pipe can be various metal pipes with good plasticity. A preparation method for the bulk metallic glass material with improved plasticity provided by the invention is that: the single element metal with the purity not lower than 99.9 percent is prepared according to the atomic formula of the amorphous alloy, then is melted and cooled to obtain the mother alloy ingot; the mother alloy ingot is melted, then is made a suction casting into the metal pipe which is treated and is clamped in a water-cooled copper mold, and finally is cooled. The invention improves the amorphous plasticity, also has no influence on the forming ability of the bulk metallic glass, and is applicable to all the bulk m etallic glass systems.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

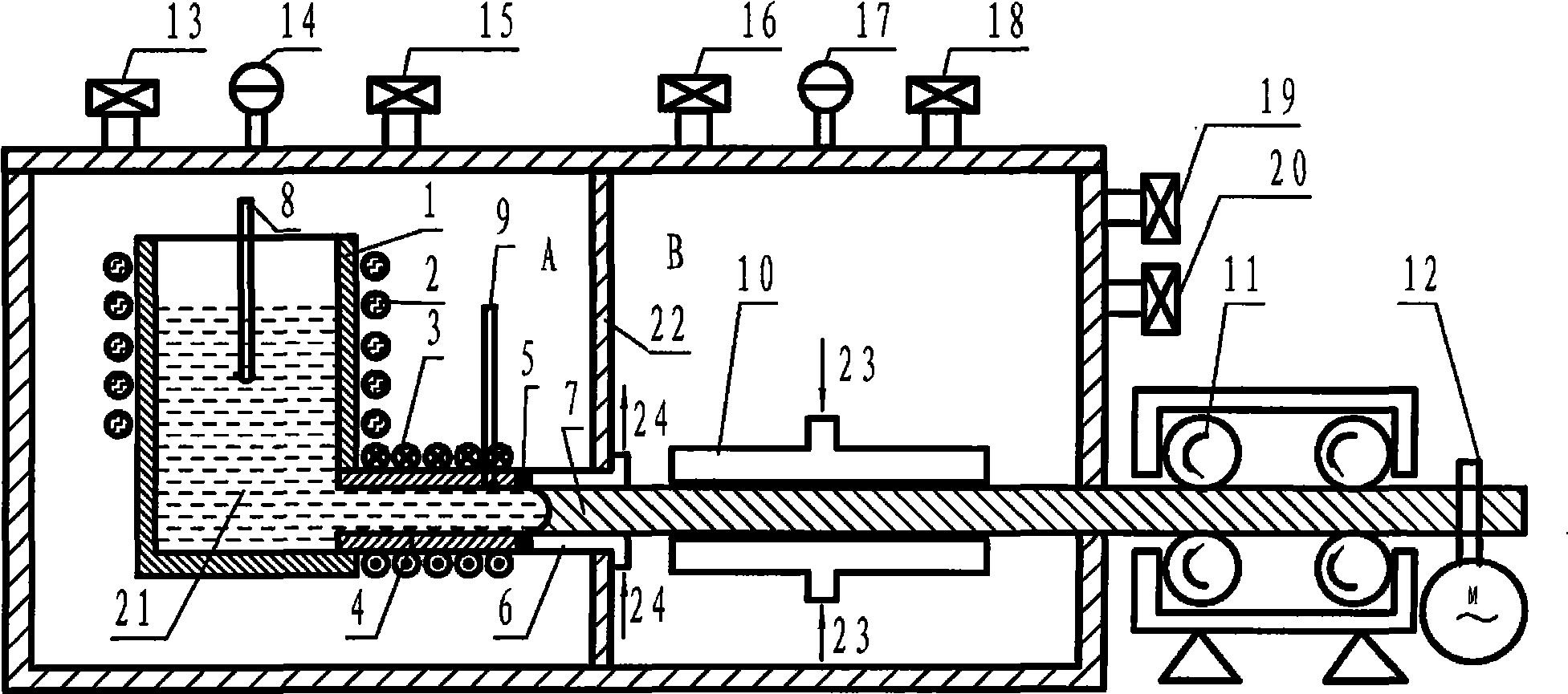

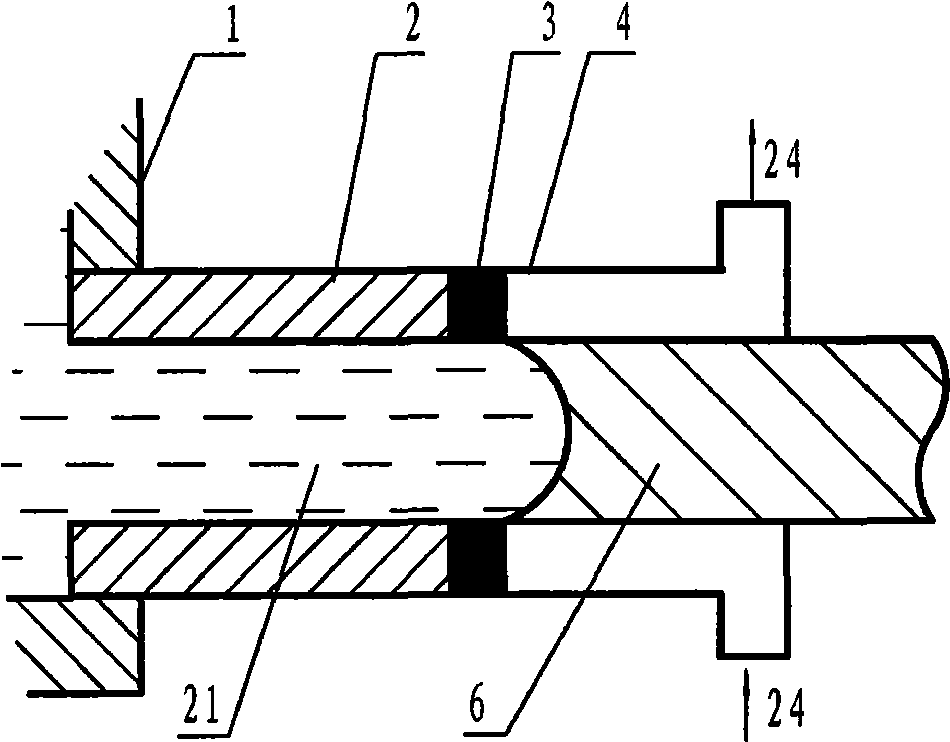

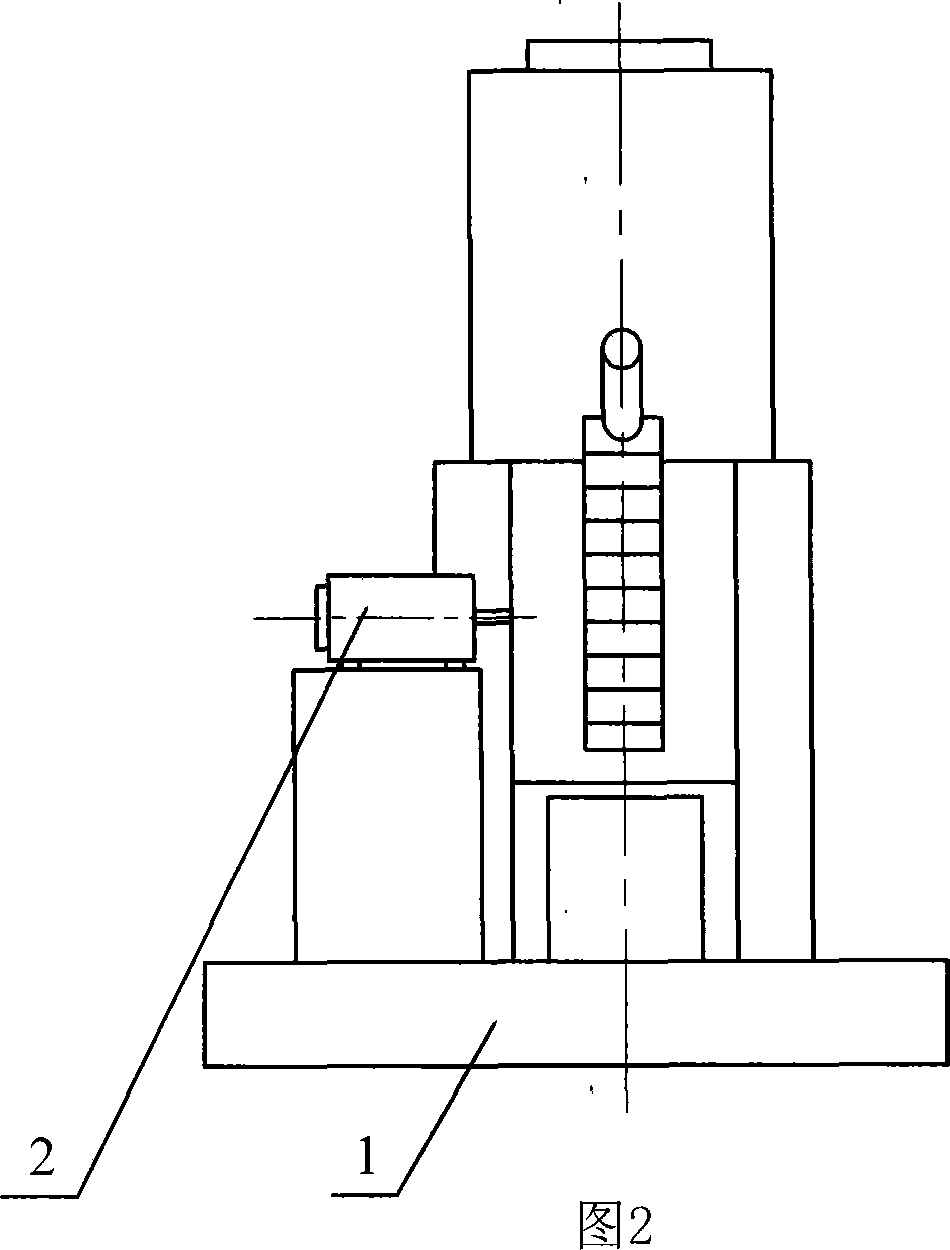

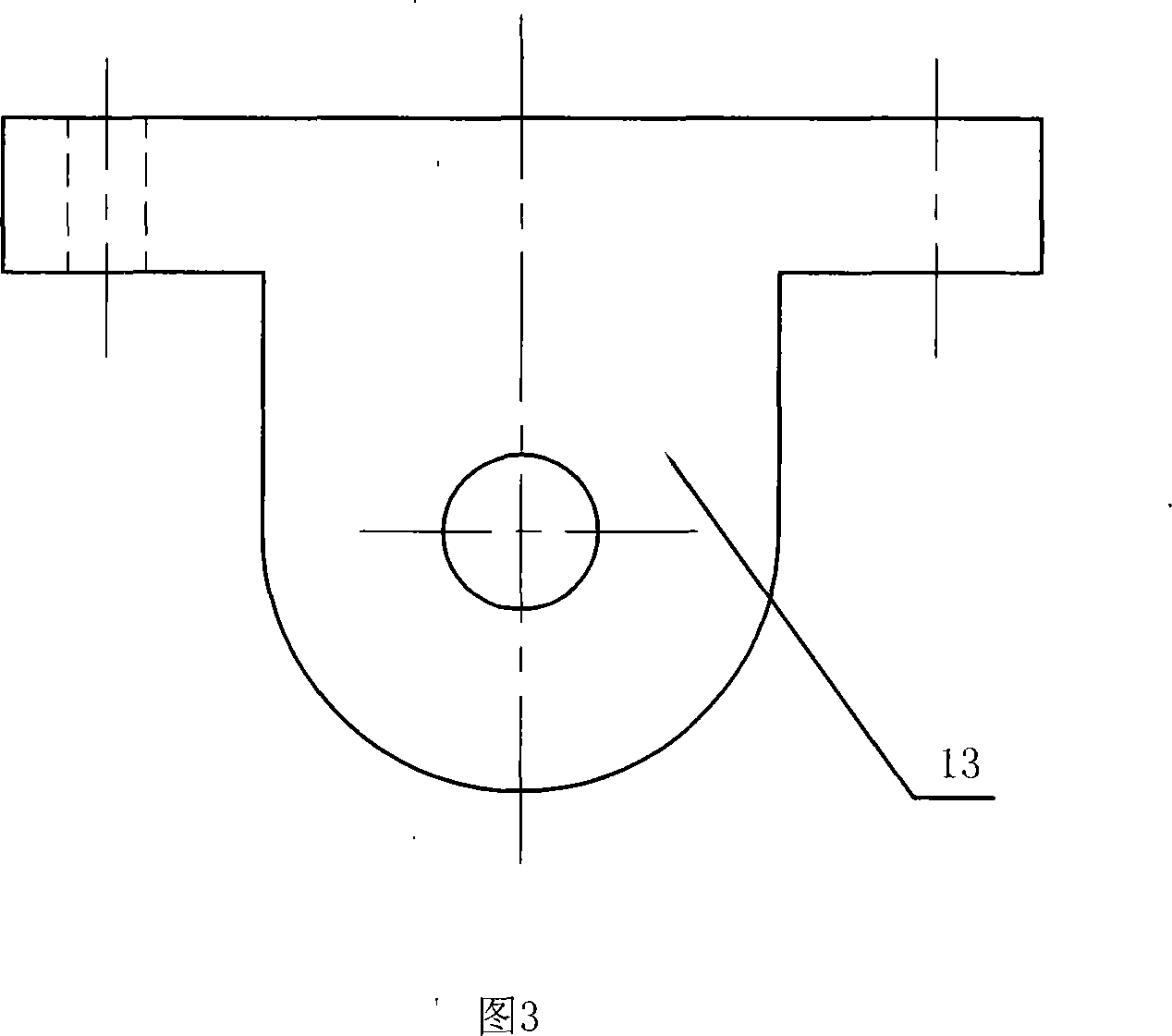

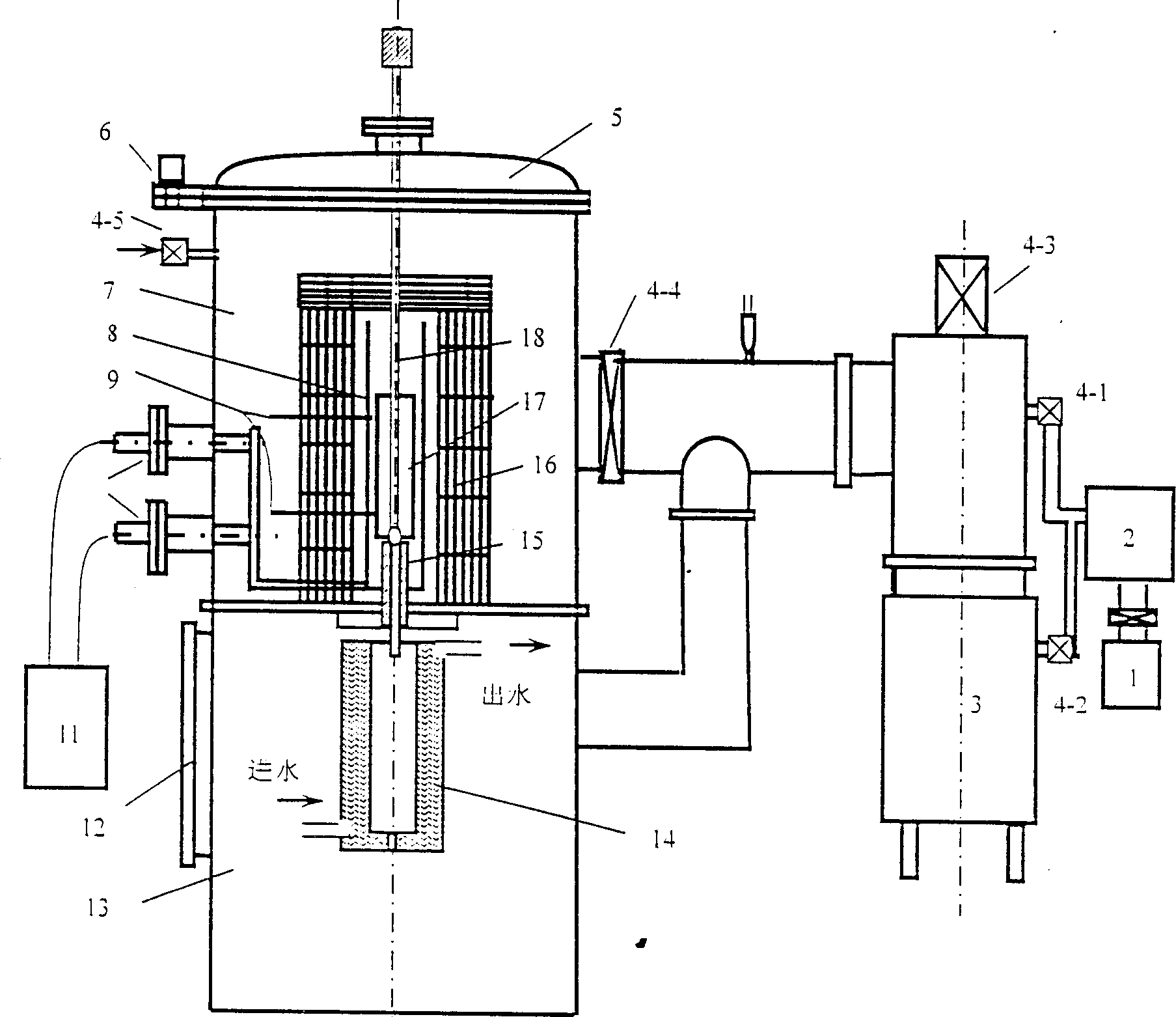

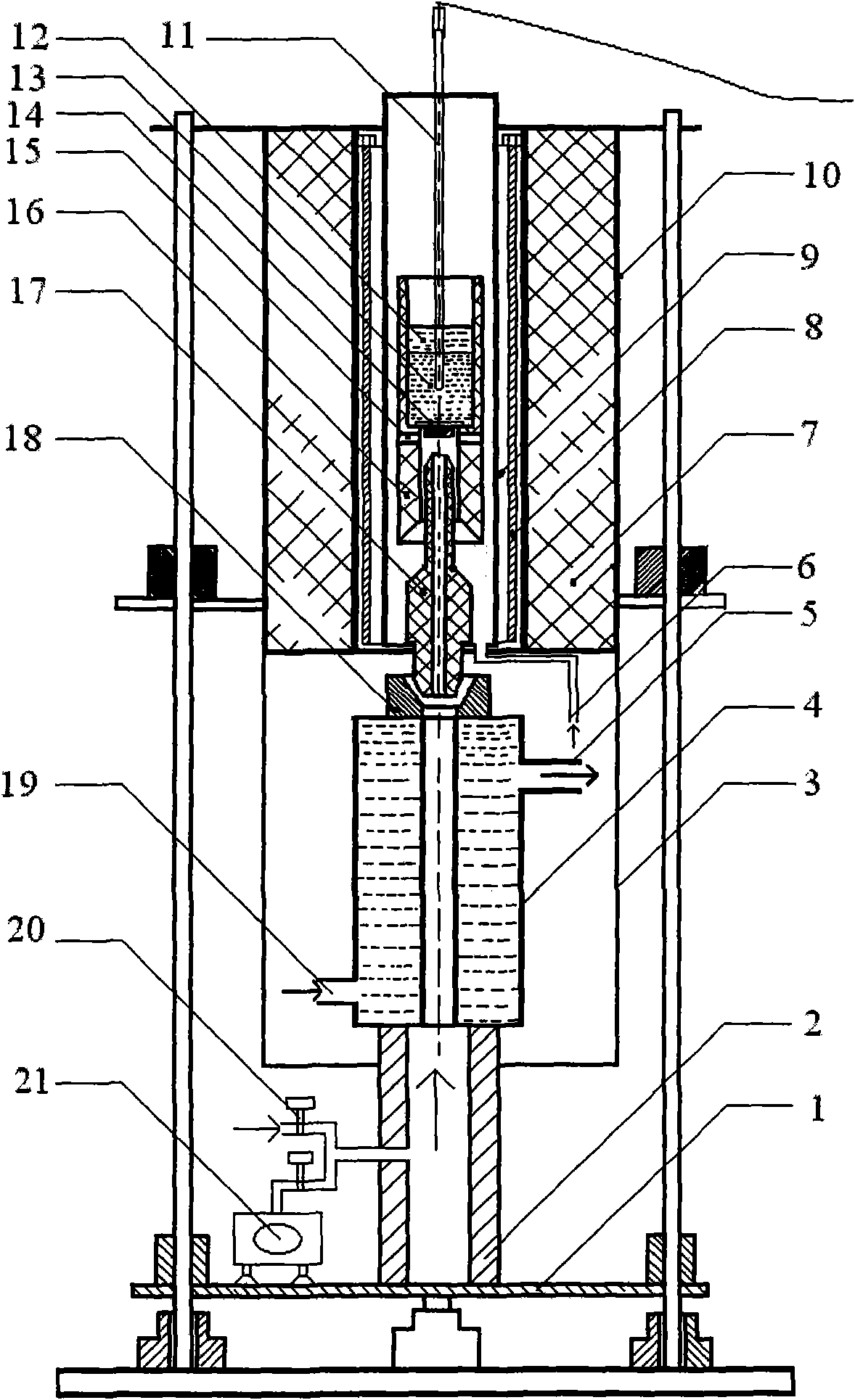

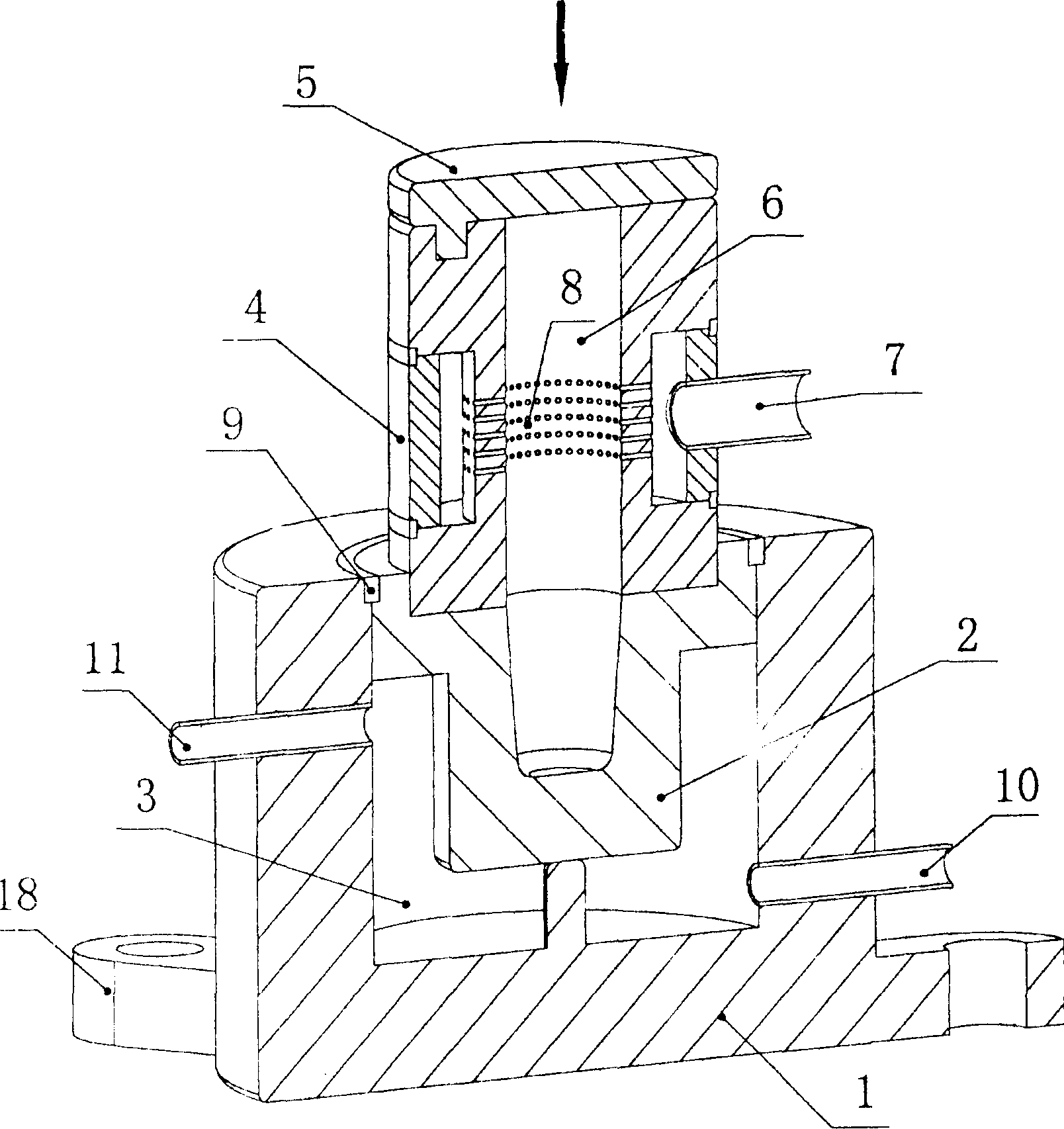

Spray casting-suction casting method and equipment for preparing large non crystal alloy

A spray casting-suction casing apparatus for preparing great non-crystal alloy block is composed of upper and lower furnace chambers, water-cooled partition between said chambers, heating body consisting of one Mo sheet layer and 6 reflecting screen layers, mould made of quartz glass or graphite arranged in said heating body and passing through said partition, U-shaped seals, plug pulling unit for the quartz glass (or graphit) plug of the circular hole on the bottom of mould, and water-cooled copper mould made of red copper.

Owner:UNIV OF SCI & TECH BEIJING

Soft-magnetic high-entropy block amorphous alloy FeCoNiMB and preparation method thereof

ActiveCN104878324AEnhanced Amorphous Formation AbilityImprove thermal stabilityMagnetic materialsMagnetizationIngot

The invention provides a soft-magnetic high-entropy block amorphous alloy FeCoNiMB. M represents at least one of P, C and Si elements, and typical compositions include Fe25Co25Ni25Si7.5B17.5, Fe25Co25Ni25Si10B15, Fe25Co25Ni25P5C4Si6B10, Fe25Co25Ni25P12C8B5 and Fe25Co25Ni25P10C10B5. The saturation magnetization of the alloy is 0.80-0.87T, coercivity is 1.1-3.4A / m, and effective magnetic conductivity under 1kHz is 12500-19800. The invention further provides a preparation method of the soft-magnetic high-entropy block amorphous alloy. The preparation method includes preparing a master alloy ingot through arc melting or induction melting, and preparing an amorphous band and an amorphous bar by single-roll melt-spinning and copper-mold casting respectively. The technical blank in preparation of the soft-magnetic high-entropy block amorphous alloy is filled up, and the provided alloy has an application prospect of serving as a soft-magnetic functional device.

Owner:DALIAN UNIV OF TECH

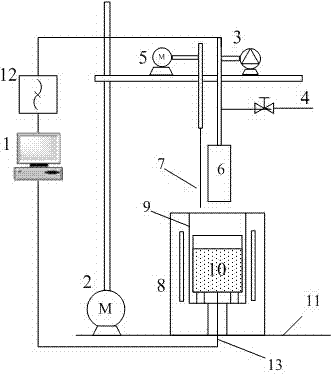

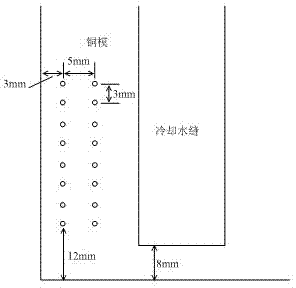

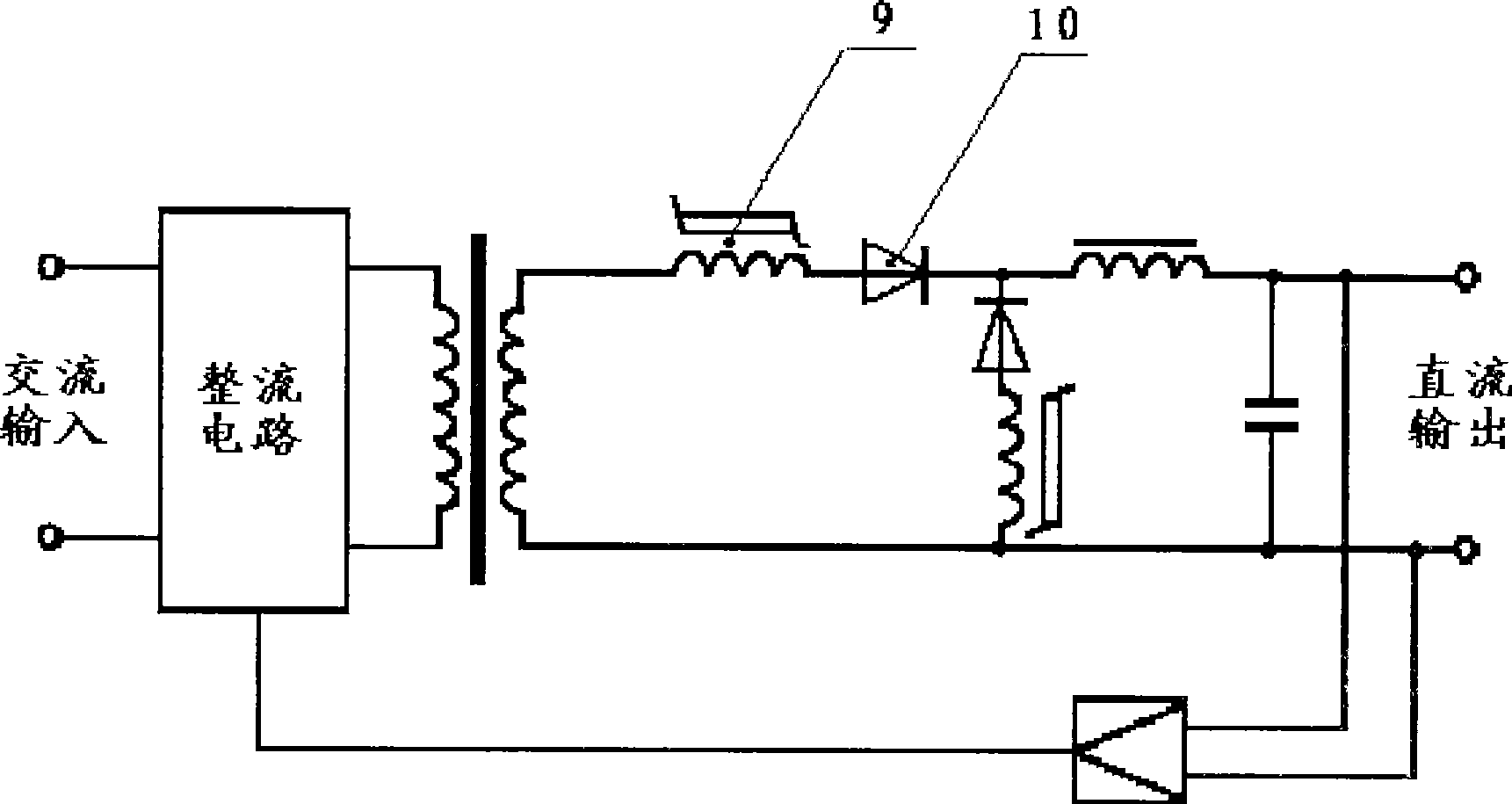

Testing device and method for comprehensive heat transferring flow of protective slag of continuous casting crystallizer

ActiveCN103969292APrecise and controllable melt pool temperatureConvenient experimentMaterial heat developmentCalorimeterMolten stateSlag

The invention discloses a testing device and method for comprehensive heat transferring flow of protective slag of a continuous casting crystallizer. The method comprises the following steps: a graphite crucible is used for melting the protective slag for continuous casting and keeping the protective slag warm in an electric induction furnace, and ingredients and temperature of the protective slag are uniform and consistent; a positioning electrode is used for calibrating the liquid level of a melting pool, a copper mold for simulating the crystallizer is inserted into a protective slag pool in a molten state under mechanical driving, water is introduced into the copper mold for cooling, and the liquid protective slag is quickly cooled on the copper mold so as to form a protective slag film; a temperature data acquisition system tests process temperature data by four thermoelectric couples in two rows embedded in the copper mold, and the heat transferring flow passing through the protective slag is calculated in real time by a computer; in the whole process, vibration with certain amplitude and frequency of the copper mold can be realized, and the vibration mode of the continuous casting crystallizer in the process of metallurgical production of steel iron can be simulated. The method disclosed by the invention has the advantages that the liquid level of the melting pool can be accurately controlled, the comprehensive heat transferring flow of the protective slag is tested in real time, and the data accuracy is high; the testing process is convenient, stable and reliable, and the experimental cost is low.

Owner:CENT SOUTH UNIV

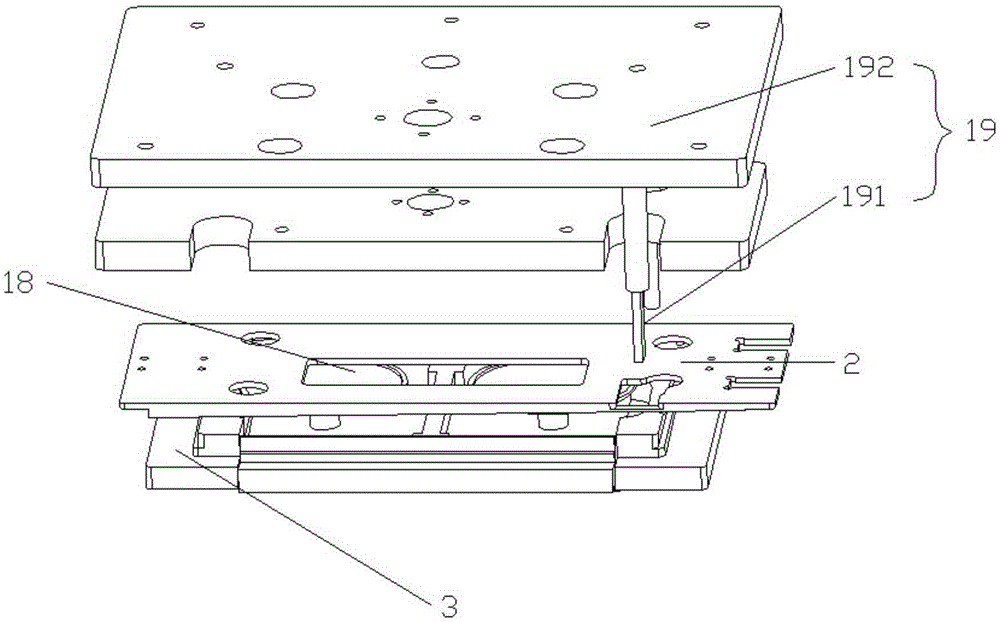

Mobile terminal screen detaching device and detaching method thereof

InactiveCN105290763AImprove yield rateImprove stabilityMetal working apparatusTelephone set constructionsComputer terminalComputer engineering

The invention discloses a mobile terminal screen detaching device and a detaching method thereof. The mobile terminal screen detaching device comprises a base, a sucker, a clamp, a copper mold and a cylinder; the copper mold is provided with a limiting groove and a heater; the sucker and the copper mold are arranged in the base; the clamp is arranged above the base; the cylinder is arranged on the top of the clamp; the heater is arranged in the copper mold; the sucker is used for being connected with a mobile terminal screen; the clamp is used for being connected with a mobile terminal face shell; the limiting groove is used for containing the mobile terminal screen; and the cylinder is used for fixing the mobile terminal face shell. By means of the mobile terminal screen detaching device, the mobile terminal screen detaching stability is good, the problems that hidden faults such as screen breakage are caused in the manual mobile terminal screen detaching process, a circuit is prone to scratches, and detaching is difficult because the manual balance degree cannot be easily mastered are solved, and the yield of screen detachment is greatly improved.

Owner:SHENZHEN EYCOM TECH CO LTD

Laser 3D printing method of amorphous alloy composite material

InactiveCN106978577AOvercome sizeOvercome the disadvantage of simple shapeAdditive manufacturing apparatusIncreasing energy efficiencyAlloy compositeOxygen

The present invention discloses a laser 3D printing method of an amorphous alloy composite material. Amorphous alloy composite material alloy powder whose grain size is 20-150 [mu]m is formed into amorphous alloy composite material components through a coaxial powder feeding 3D printing method under the conditions that the laser power is 100-600 W, the scanning speed is 500-1200 mm / min, the laser spot diameter is 0.5-4 mm, the overlap rate is 15-50%, the printing layer thickness is 0.5-2 mm, the printing environment oxygen concentration is lower than 50 ppm, and the substrate preheating temperature is 0-300 DEG C. The amorphous alloy composite material components are annealed for 2-12 hours under the protection of an inert gas and at a temperature of 300-600 DEG C. With adoption of the laser 3D printing method, defects of the amorphous alloy composite material formed through a water quenching method and a copper mold casting method are overcome, the problem that the amorphous alloy composite material is hard to mechanically process is solved, and the method has the advantages of being economical in raw material and high in efficiency.

Owner:DALIAN JIAOTONG UNIVERSITY

Cobalt-based bulk amorphous alloy and preparation method thereof

The invention relates to a cobalt-based bulk amorphous alloy and a preparation method thereof. The alloy comprises the following components by atomic percentage: 33 to 55 percent of Co, 13 to 34 percent of Fe, 18 to 26 percent of B, 2 to 7 percent of Si, and 3 to 8 percent of Nb. Cobalt-based bulk metallic glass is proportioned according to the atomic mol ratio as required by the components, then the glass is forged for a plurality of times in a vacuum arc furnace, and the bulk amorphous alloy is prepared by casting in a vacuum copper mold. The bulk amorphous alloy has strong amorphous forming ability and excellent soft magnetic property, the size of the prepared amorphous material is not less than 3 millimeters at each dimensionality, the maximum size can reach 5 millimeters, the coercive force is between 1.17 and 2.35 A / m, and the maximum effective magnetic conductivity can reach 36,000 (1KHz 1A / m). The cobalt-based bulk amorphous alloy can be applied to magnetic devices in the fields of information, communication and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

Active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis and preparation method thereof

InactiveCN102560198AHigh hydrogen production rateEasy to prepareHydrogen productionVacuum induction furnaceLiquid alloy

The invention relates to an active aluminum-rich alloy for preparing high purity hydrogen through hydrolysis. The alloy is characterized in that the alloy which is composed of four elements of Al, Ga, In and Sn comprises the following two phases: an Al solid solution and GaIn3Sn. A preparation method of the alloy concretely comprises the following steps: 1, melting the alloy to form a molten alloy by adopting a vacuum induction furnace, wherein the vacuum degree of the vacuum induction furnace is 10<-2>-10<-3>Pa; and 2, stirring the molten alloy by adopting an electromagnetic stirring technology, casting the molten alloy to a water-cooled copper mold, and solidifying, wherein the cooling rate is 101-103DEG C / s. The alloy has the advantages of high hydrogen yield, no pollution, low cost, simple preparation method, convenient operation and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Amorphous nickel-free zirconium alloy

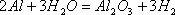

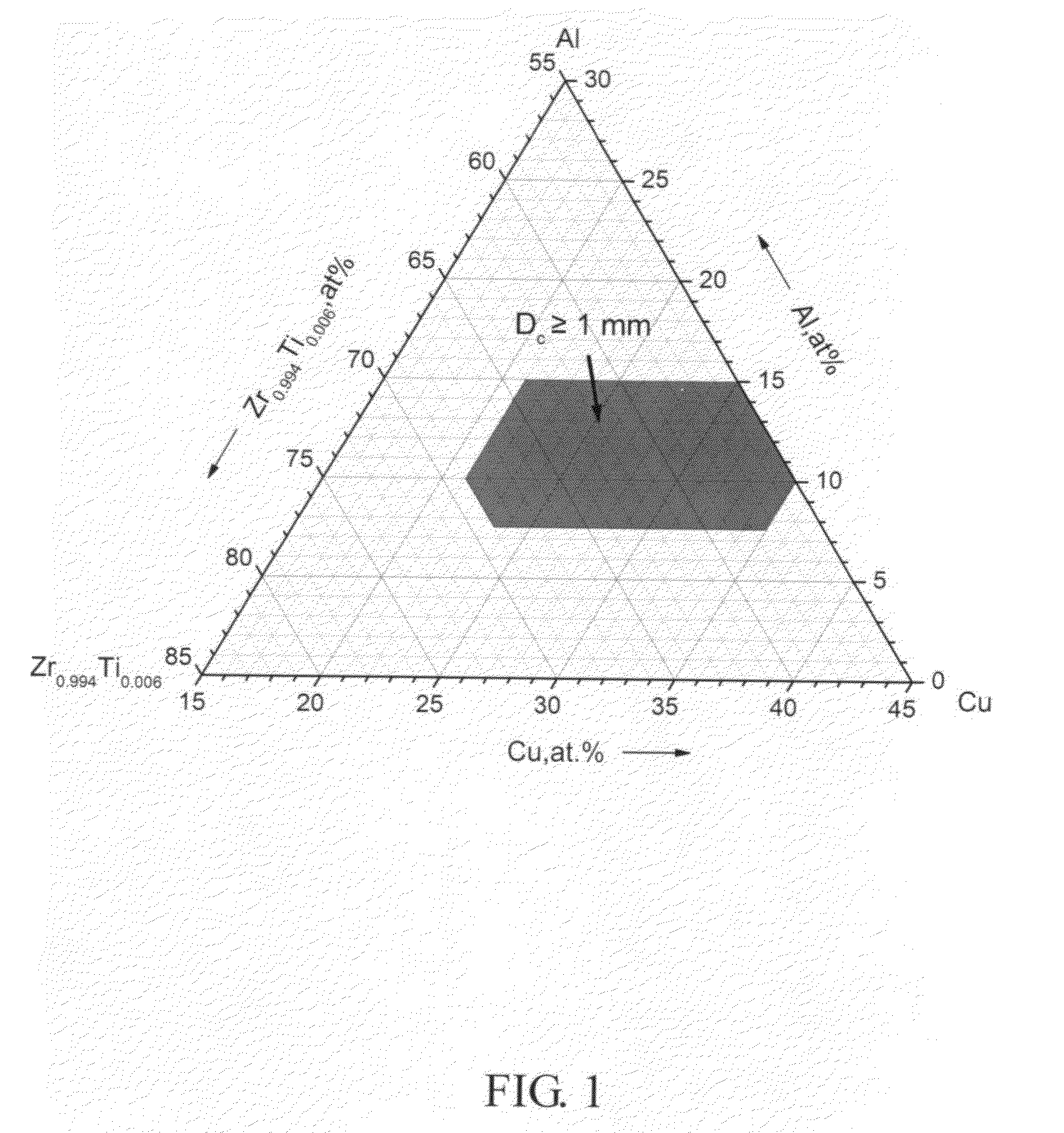

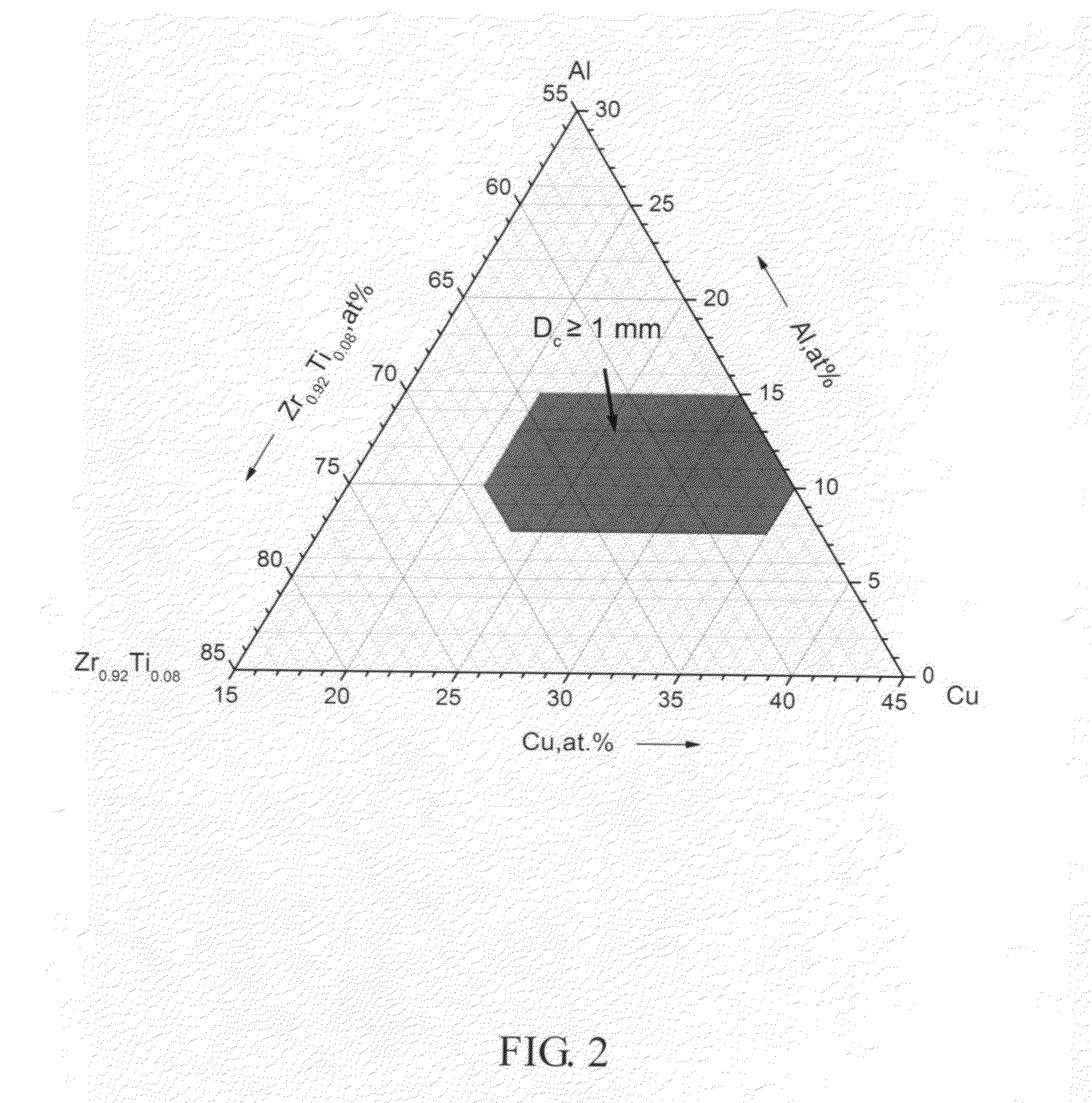

An amorphous Nickel-Free Zirconium alloy which is readily formed through copper mold casting, comprising a composition consisting of four elements in which the first element is Zr, the second element is Ti, the third element is Cu and the fourth element is Al, wherein an atomic percent of the first to the fourth elements in the composition are represented by a, b, c and d respectively, wherein a=45˜69%, b=0.25˜8%, c=21˜35%, and d=7.5˜15%, where a sum of a, b, c and d is smaller than or equal to 100%. The composition of the amorphous alloy within the above range is melted in a copper mold to form bulk amorphous materials or parts which have characteristics of high tensile strength, high fracture toughness, low Young's modulus and high corrosion resistance.

Owner:INST OF METAL RES CHINESE ACADEMY OF SCIENECE

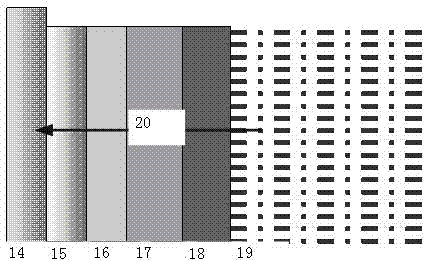

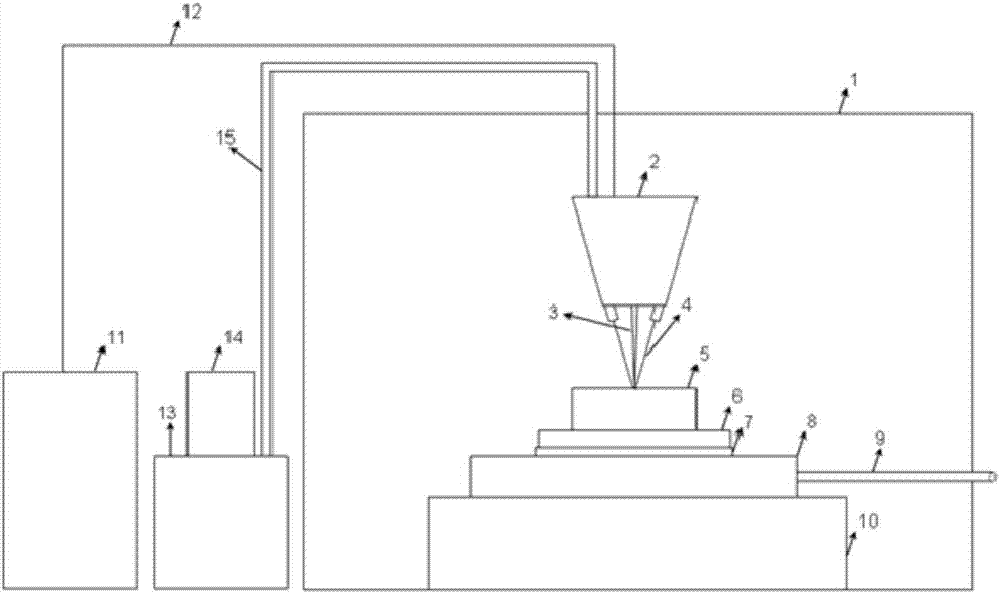

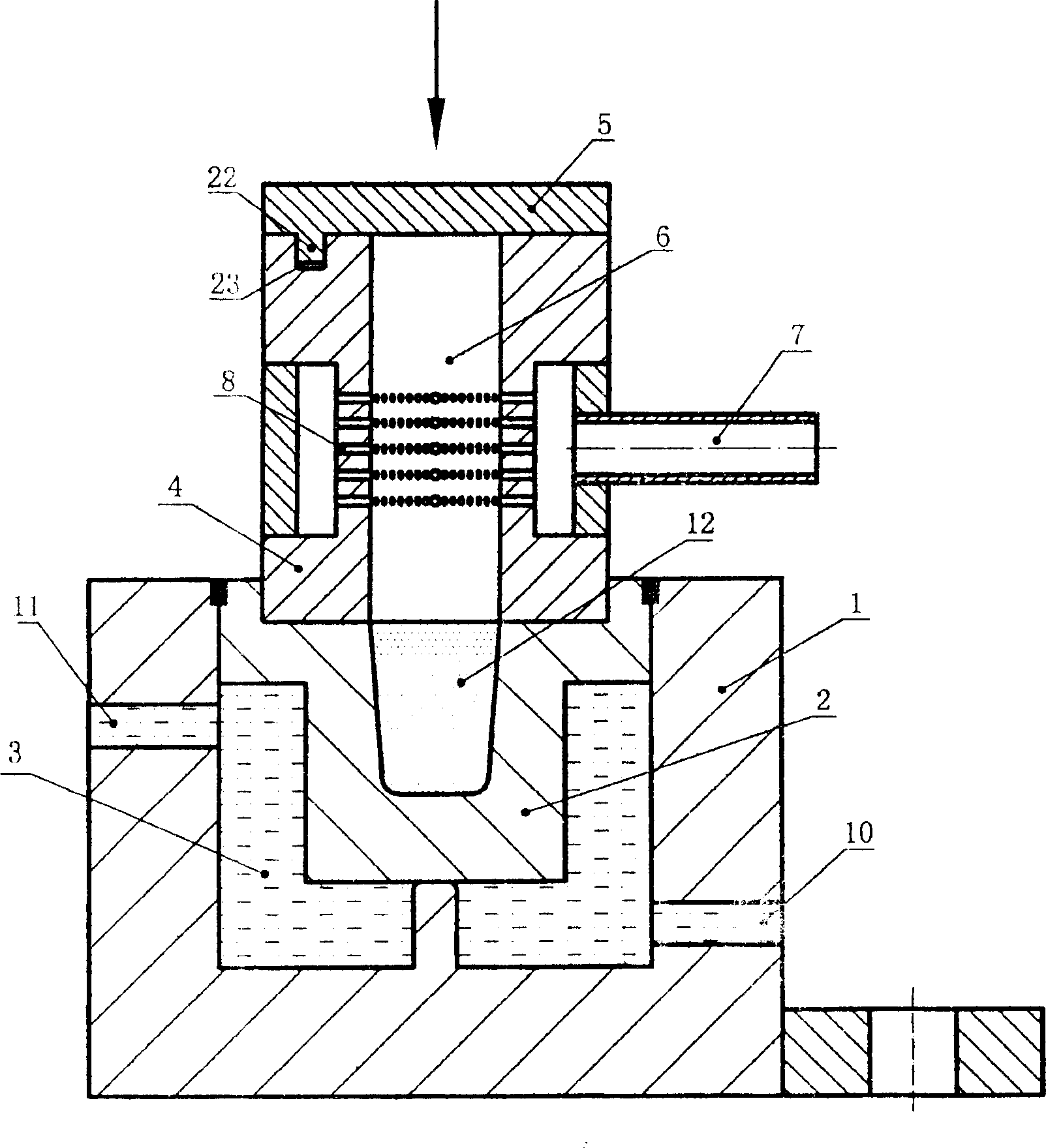

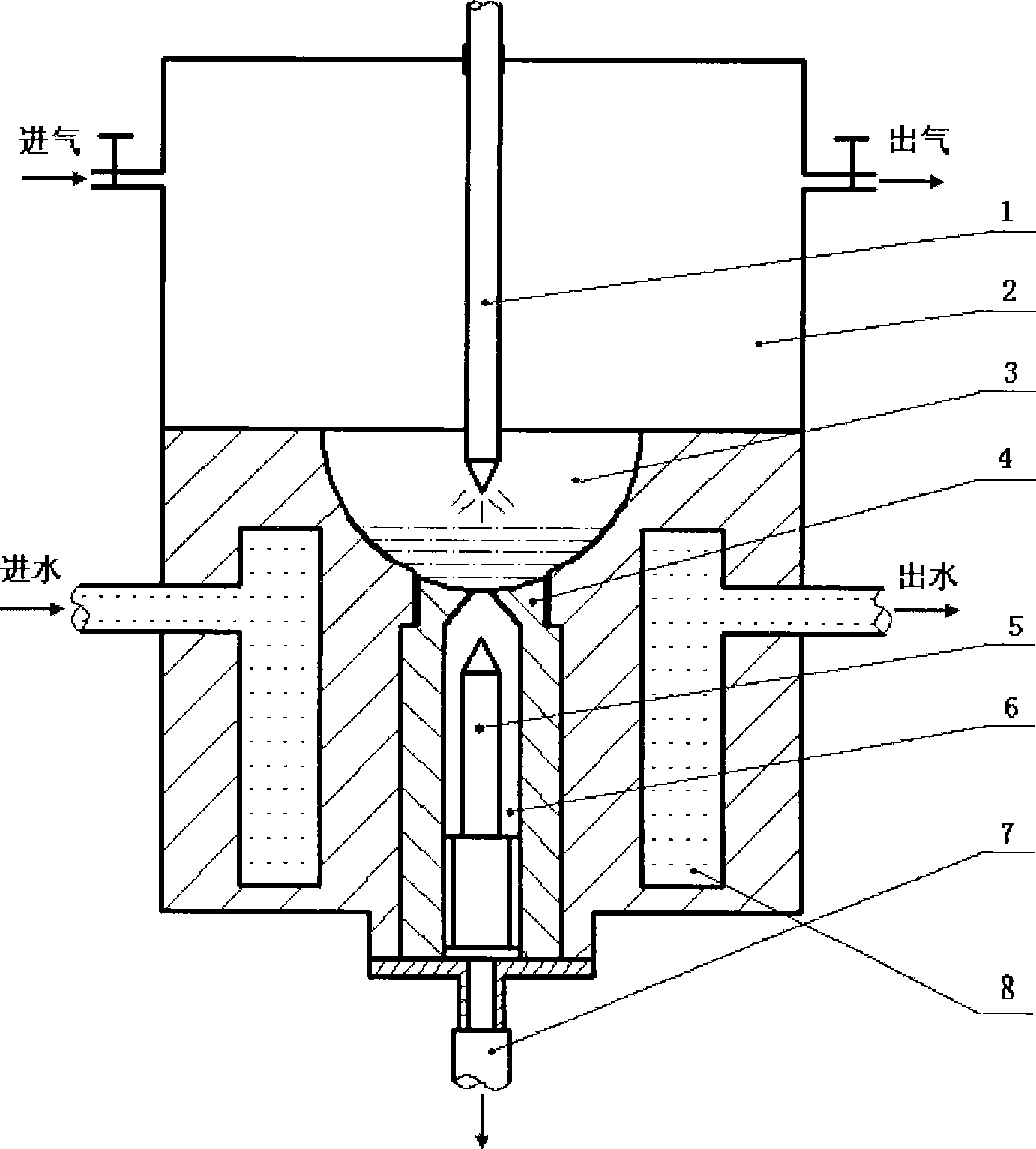

Method for preparing bulk amorphous alloy under non-vacuum condition and equipment

The invention provides a method for preparing bulk amorphous alloy under the non-vacuum condition and equipment. The equipment are characterized by consisting of an upper furnace chamber (10) and a lower furnace chamber (3), wherein, the upper furnace chamber is a tube type resistance furnace, a heating element (8) is a silicon carbon tube, and the highest heating temperature is 1500 DEG C; a furnace tube (9) is made of corundum material, a crucible (16) is arranged inside a constant temperature area of the furnace tube, is made of high purity graphite materials, and has the outside dimension of 20-40mm and the height of 300-500mm; a round orifice with the diameter of 5-10mm is arranged at the lower part of the crucible and is plugged up by a graphite plug (14) when smelting alloy; a graphite sleeve (17) passes through the upper and the lower furnace chambers; during suction casting, an elevating gear (2) is started, a water-cooling copper mold rises, is connected with the graphite sleeve (17) and rises together with the graphite sleeve to open the graphite plug (14); meanwhile, a capacity pump is started, the suction casting operation is completed, amorphous master alloy is absorbed into the copper mold, and the bulk amorphous alloy is prepared through rapid cooling by utilizing the strong capacity of heat transmission of the copper mold. The method has the advantage that molten slag smelting technology is integrated with the copper mold suction casting method, thus realizing preparation of the bulk amorphous alloy under the non-vacuum condition.

Owner:UNIV OF SCI & TECH BEIJING

Biodegradable metal alloys

Owner:UNIVERSITY OF PITTSBURGH

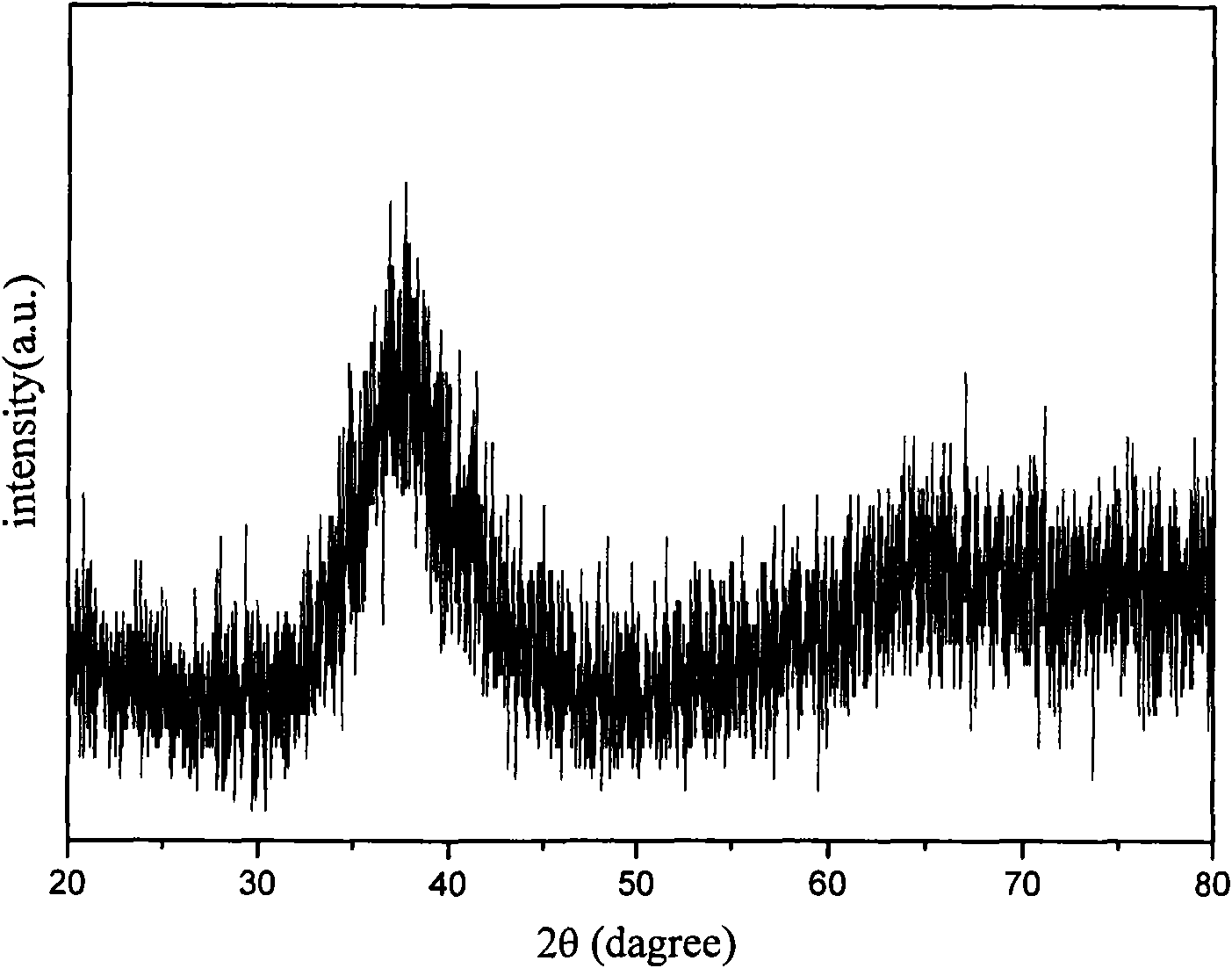

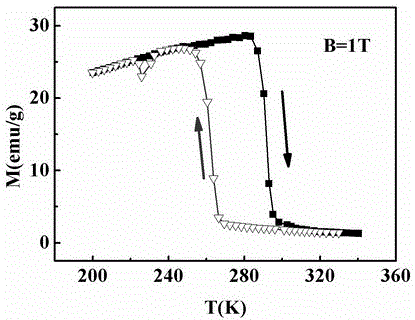

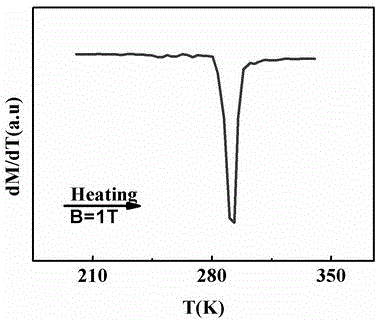

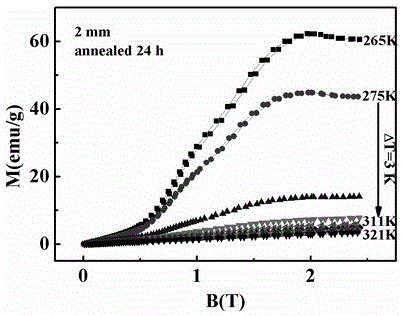

Method for preparing magnetic heat material Mn-Ni-Ge:Fe-based series alloy bar through electric arc melting and copper mold spray casting

InactiveCN105154694AReduce consumptionReduce pollutionIncreasing energy efficiencyNitrogen gasSmall hole

The invention discloses a method for preparing a magnetic heat material Mn-Ni-Ge:Fe-based series alloy bar through electric arc melting and copper mold spray casting. The method comprises the specific steps that burdening is conducted, wherein the masses of needed metal simple substances of Mn, Ni, Fe, Ge and the like are calculated according to the stoichiometric ratio, and MnNi1 xFexGe and Mn1 xFexNiGe are adopted as the composition proportion; electric arc melting is conducted, wherein the burdened raw materials are put into a water cooling type copper crucible, argon is back charged into the vacuum environment to conduct electric arc melting, and an Mn-Ni-Ge:Fe-based alloy ingot is obtained; copper mold spray casting is conducted, wherein the Mn-Ni-Ge:Fe-based alloy ingot is sheared and loaded into a quarts tube with the inner diameter being 10 mm, the ingot in the quarts tube is melted through a high-frequency induction heating device, a melted sample is sprayed to a copper mold with water cooling through a small hole in the bottom of the quarts tube through nitrogen pressurizing, and the alloy bar is obtained; and heat treatment is conducted, wherein a part of the bar sample is taken and sealed in the quarts tube, annealing heat treatment is conducted in a high-temperature furnace, and a part of the bar sample is put into cold water to be quenched or cooled to the room temperature along with the furnace. The preparing method is simple and convenient to implement and is used for easily preparing bars in regular shapes to serve as magnetic refrigerating materials, and the preparing cost and the energy consumption are reduced.

Owner:NANCHANG HANGKONG UNIVERSITY

High heat stability block ferromagnetic metal glas synthetic method

InactiveCN1552940ARational Ingredient DesignStrong Amorphous Formation AbilityMagnetic materialsCopperFerromagnetism

This invention relates to high thermally stable ferromagnetic metal glass blocks and their synthesis. The constituent of the said blocks comprises Co 35 - 45 at%, Fe 12 - 35 at%, Hf 2 - 10 at%, Mo 0 - 8 at%, Ti 2 - 8 at%, B 22 - 35 at%, and V 0 - 3 at%. The blocks can be prepared in copper molds, with excellent amorphization at >650 deg.C and the constituent designed more reasonable than the present materials, and used widely at higher temperature.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Laser smelting furnace with water cooled copper mould and method for smelting ingot

Owner:BEIHANG UNIV

AB3-type hydrogen storage alloy and preparation method

InactiveCN102660700AImprove electrochemical reactivityImprove cycle lifeElectrochemical responseBall mill

The invention discloses an AB3-type hydrogen storage alloy and a preparation method. The chemical formula of the AB3-type hydrogen storage alloy is La0.35Pr0.30MgxNi2.90Al0.30, wherein x=0.30-0.35. The preparation method includes steps of (1), weighing and batching 99.9% of analytically pure metal elementary substance materials according to the chemical formula La0.35Pr0.30MgxNi2.90Al0.30 with the x ranging from 0.30 to 0.35; (2), smelting the metal elementary substance materials except magnesium in the step (1) in a copper mold in a magnetic levitation furnace to obtain intermediate alloy; (3) breaking the intermediate alloy obtained from the step (2), mixing the broken intermediate alloy with the magnesium weighed in the step (1) and placing the mixture into a magnesia crucible of a vacuum induction furnace, filling argon after vacuumizing, heating and smelting, pouring molten alloy into the cool water copper mold and cooling the alloy to obtain alloy ingots, breaking the alloy ingots mechanically, and finally treating the broken alloy ingots by ball milling for 30-60 minutes at a revolution speed of 225-250 turn / minute. The service life of alloy electrodes prepared by the preparation method is prolonged and electrochemical reaction activity thereof is improved.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

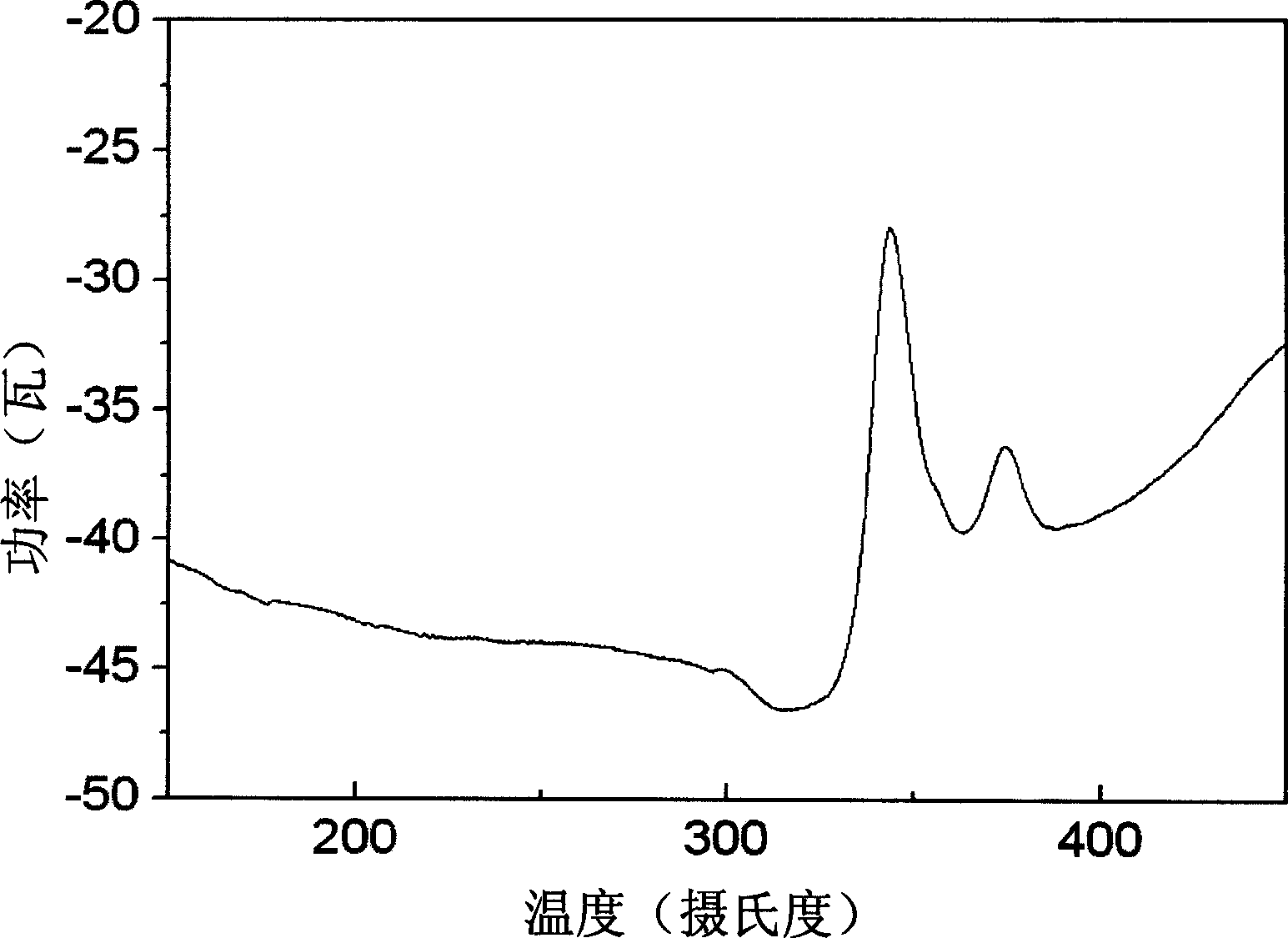

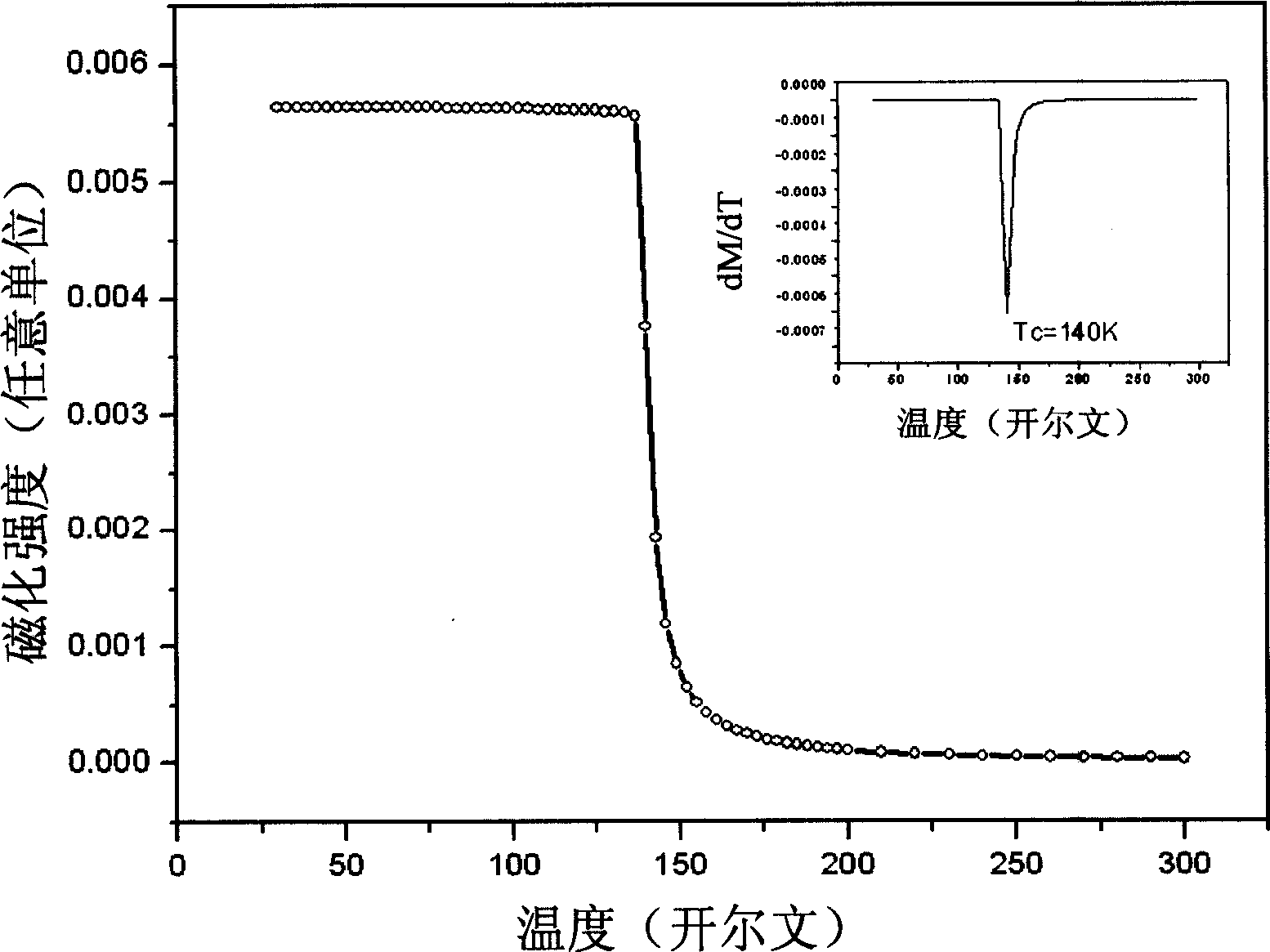

Block gadolinium-based composite amorphous magnetic cooling material and preparation thereof

The invention provides a massive gadolinium-based composite amorphous magnetic frigorific material and a preparation method thereof, which belong to the field of metal material technology. The massive gadolinium-based composite amorphous magnetic frigorific material has a chemical general formula: Gd60Co26Al14-xGex, wherein x is more than 0 and less than or equal to 10. The main material is a massive amorphous alloy body formed through fusing Gd, Co, Al and Ge and also comprises a Gd5Ge3 crystal primary phase. In a magnetic field of between 0 and 5T, Curie temperature converted from a high-temperature paramagnetic state to a low-temperature ferromagnetic state is between 100 and 200 K; the largest magnetic entropy change of the Curie temperature is more than 7 J / kgK; and the relative refrigerating output is more than 700 J / kg. The preparation method comprises the following steps: firstly, ingredients are subjected to electric arc melting to obtain a Gd60Co26Al14-xGex master alloy; and secondly, a suction casting mould is obtained by a copper mould suction casting method. The massive gadolinium-based composite amorphous magnetic frigorific material has continuous and adjustable Curie temperature, equivalent magnetic entropy change with rare-earth gadolinium, and higher relative refrigerating output which is at least 35 percent higher than that of gadolinium, and is an ideal magnetic frigorific material. The method has the advantages of simple process, easy control of material structure and the like.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

AlCoCrFeMn high-entropy alloy with non-equal atomic ratio and preparation method of AlCoCrFeMn high-entropy alloy

ActiveCN111235454AHigh strengthGood thermal stability at high temperatureHigh entropy alloysAl element

The invention discloses an AlCoCrFeMn high-entropy alloy with a non-equal atomic ratio and a preparation method of the AlCoCrFeMn high-entropy alloy. The atomic ratio of all elements of Al to Co to Crto Fe to Mn in the high-entropy alloy is equal to (0.3-0.7): to 2 to 1 to 1 to 1. The preparation method comprises the following steps that (1) a raw material is taken in proportion, and cleaning anddrying are conducted; (2) the raw material is put into a non-consumable arc melting furnace, vacuumizing is conducted and protective gas is added; (3) Ti which is arranged in the furnace in advance is firstly smelted, then the raw material is smelted, and suction casting is conducted by using a copper mold to form an alloy ingot; (4) the alloy ingot is subjected to solid solution, water quenchingand rolling deformation; and (5) the deformed alloy ingot is annealed to obtain the AlCoCrFeMn high-entropy alloy with the unequal atomic ratio. According to the AlCoCrFeMn high-entropy alloy with the non-equal atomic ratio and the preparation method of the AlCoCrFeMn high-entropy alloy, by adding a certain amount of Co element, the strength of the high-entropy alloy is improved, the content of the Co element is increased, and the alloy has good thermal stability; and the plasticity of the high-entropy alloy is adjusted by adding a certain amount of Al element, and the prepared high-entropy alloy has good strength and plasticity.

Owner:JIANGSU UNIV OF TECH

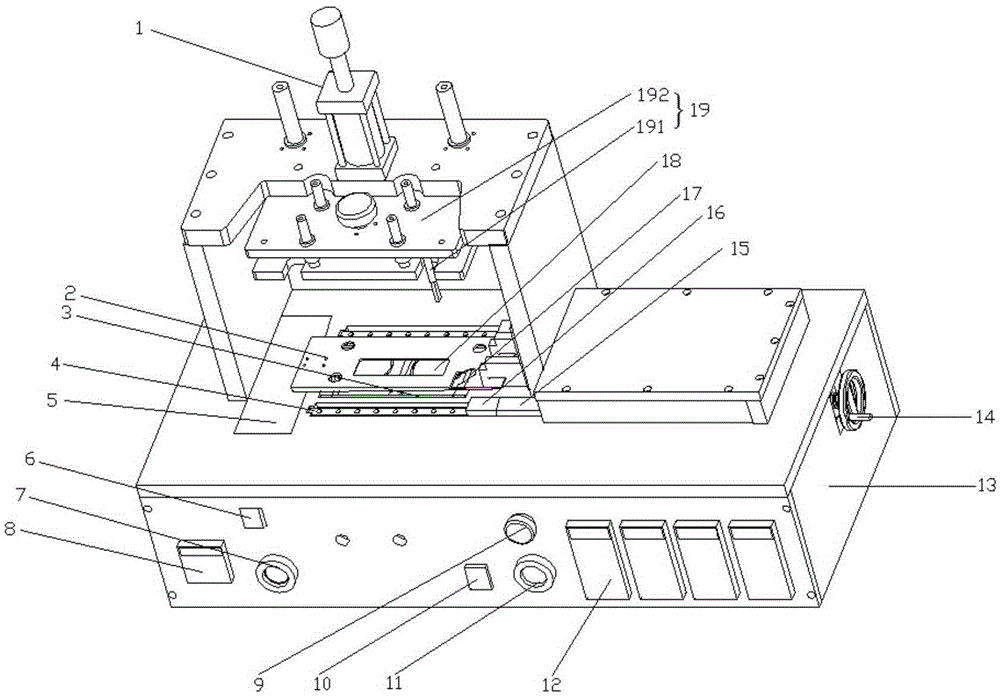

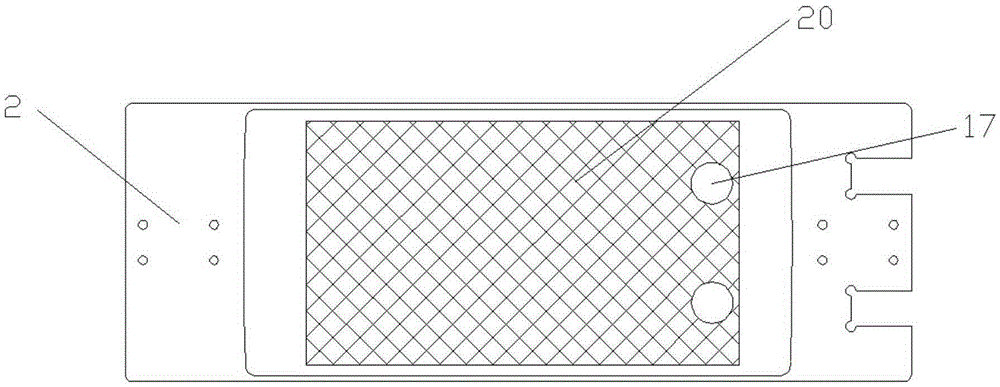

Copper mold suction casting preparation device of iron-based bulk amorphous alloy annular magnet core and method thereof

The invention provides a copper mould suction casting preparation device of an iron-based bulk amorphous alloy toroidal magnetic core and a method therefore. The preparation device of the invention comprises an electrode, a furnace chamber, copper crucibles, a copper mould, a mould core, a mould cavity, a suction casting pipe and a water cooling device. A plurality of copper crucibles are arranged in the furnace cavity, wherein, at least one copper crucible is used for suction casting, and the residues are used for melting. The electrode penetrates the furnace chamber and extends into the copper crucibles used for melting in the furnace cavity. Iron-based bulk amorphous alloy raw materials which are prepared according to the content requirement and are provided with soft magnet are put in the copper crucibles used for melting. The copper crucibles used for suction casting are provided with the water cooling device at the lower parts. The copper mould is arranged in the water cooling device. The mould cavity is internally provided with the mould cavity which is communicated with the copper crucible used for suction casting. The mould core is arranged in the mould cavity. The suction casting pipe which can suck alloy liquid in the copper crucible used for suction casting into the mould cavity with the mould core is arranged outside the mould cavity. The preparation device has the advantages of simple structure and convenient operation. The preparation method of the invention has the advantages of high preparation efficiency and simple processing conditions and can be carried out easily under the industrial production condition.

Owner:GUANGDONG UNIV OF TECH

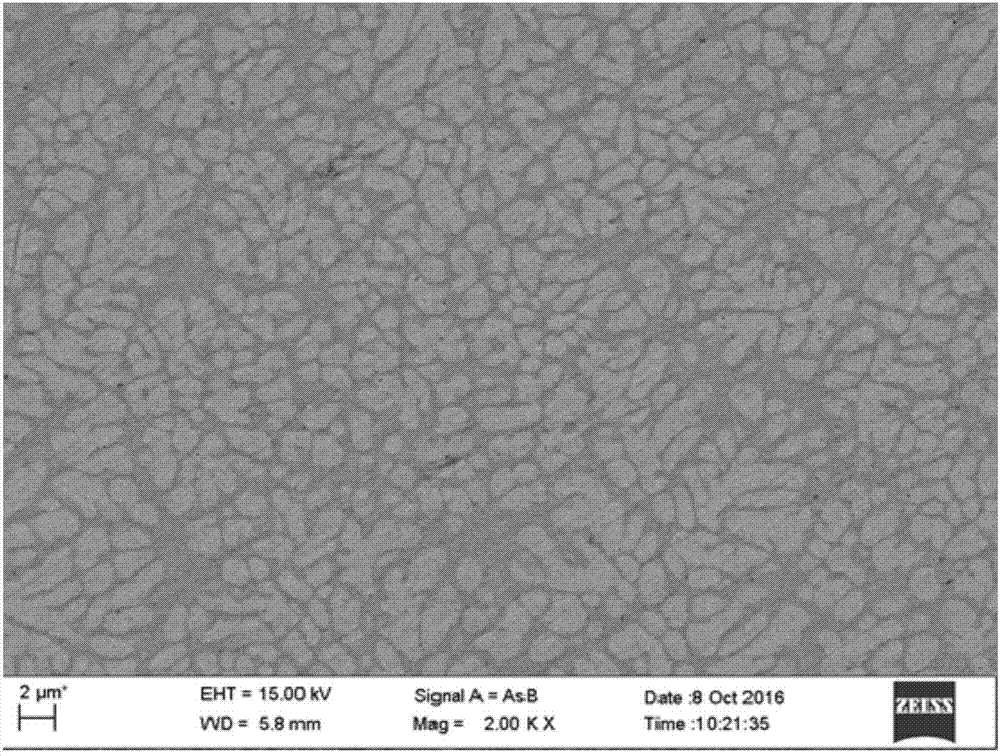

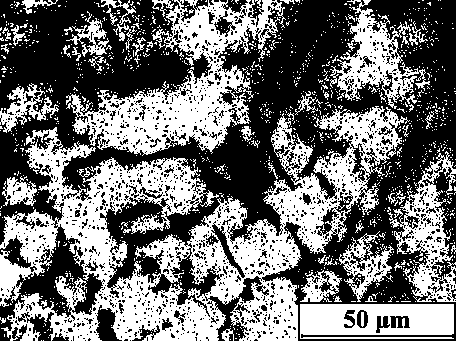

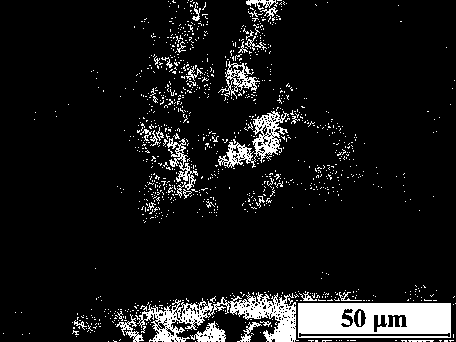

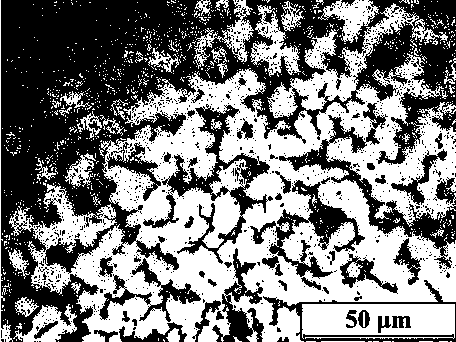

Process method capable of improving refinement and modification effects of A356 aluminum alloy

The invention relates to a process method capable of improving refinement and modification effects of an A356 aluminum alloy and belongs to the technical field of smelting of the aluminum alloy. The process method is characterized in that an Al-10Sr intermediate alloy is adopted as a modifying agent, the A356 aluminum alloy is adopted as a to-be-modified object, in the step of smelting the Al-10Sr intermediate alloy, after slag is completely skimmed and oversize particles in a molten alloy are removed by filtration, the molten alloy is rapidly poured into a water-cooled copper mold so as to obtain the Al-10Sr intermediate alloy subjected to water-cooled copper mold process treatment and the A356 aluminum alloy is refined and modified by virtue of the Al-10Sr intermediate alloy subjected to water-cooled copper mold process treatment of which the addition accounts for 0.10%-0.50% of the mass of the A356 aluminum alloy melt. The microstructure and properties of the refined and modified A356 aluminum alloy can be significantly improved.

Owner:JIANGSU UNIV

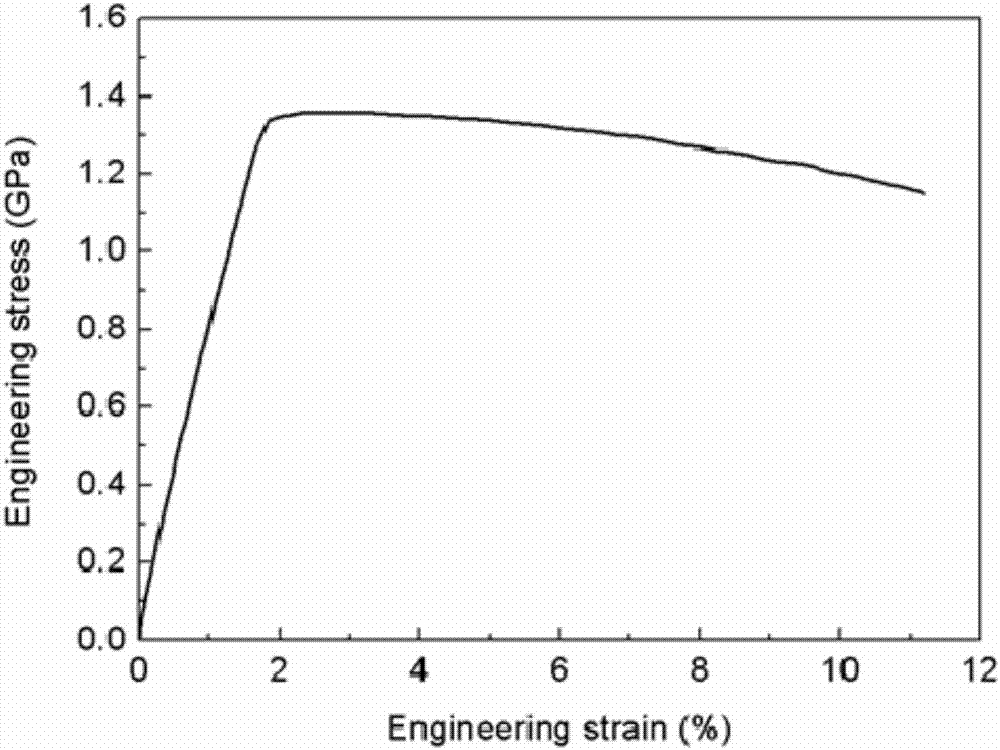

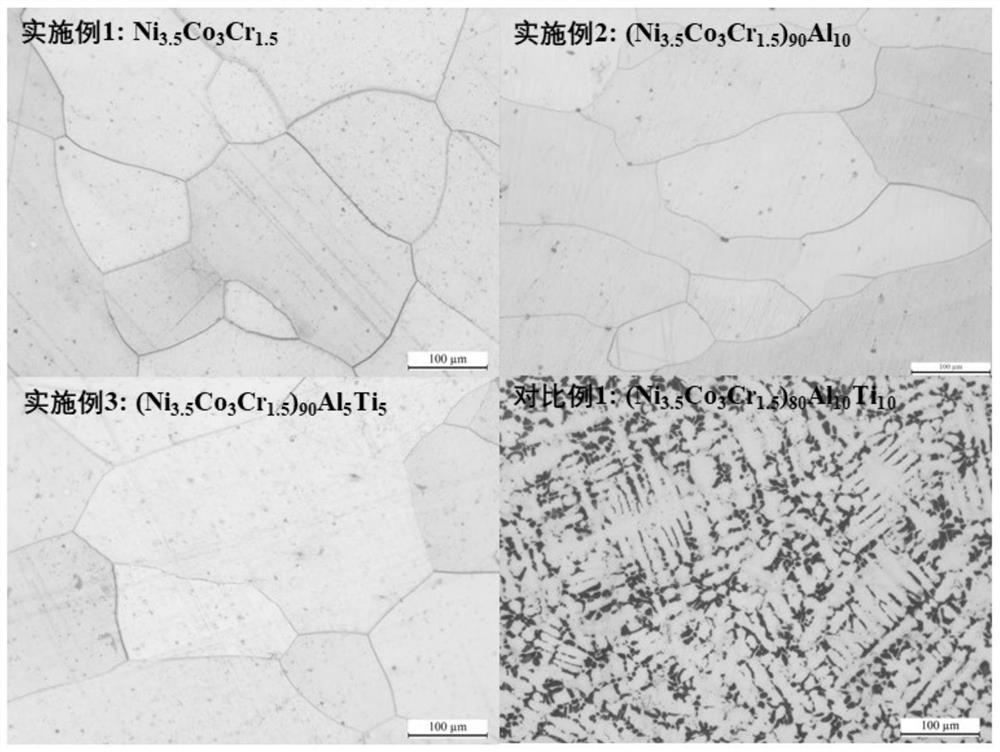

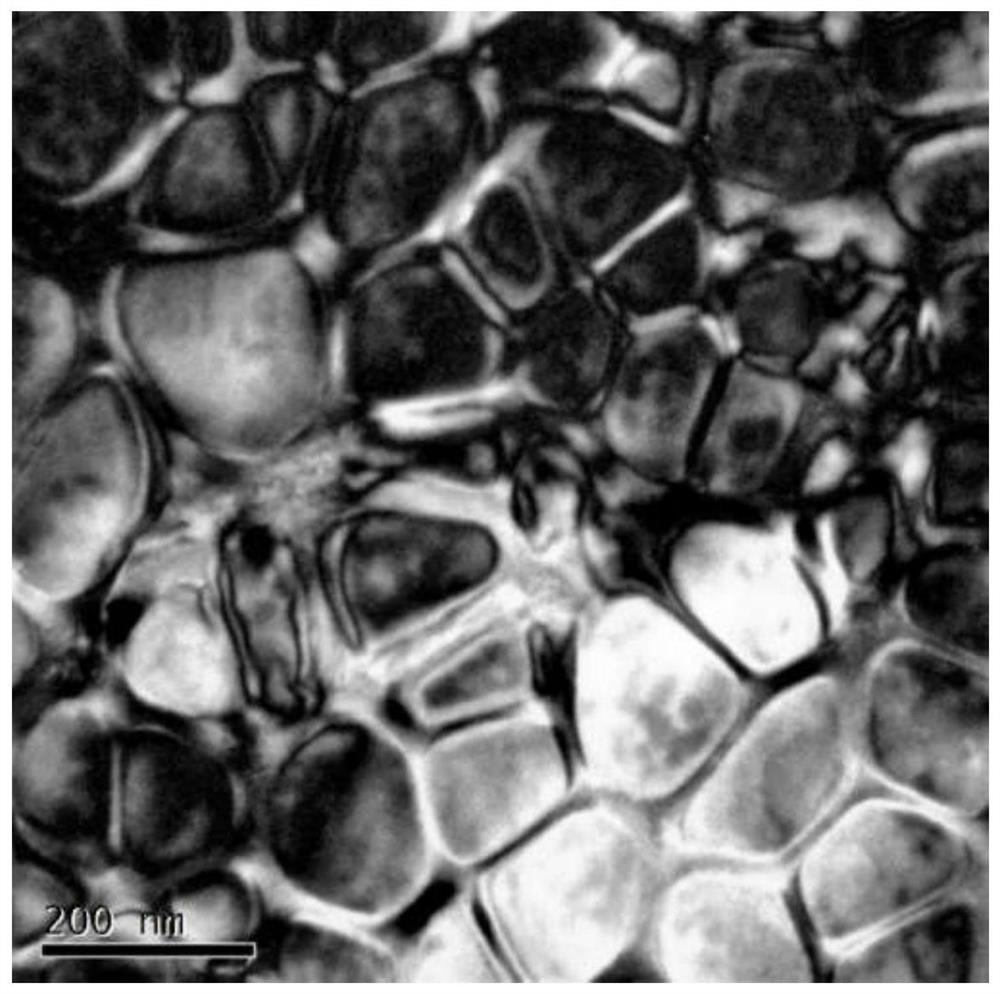

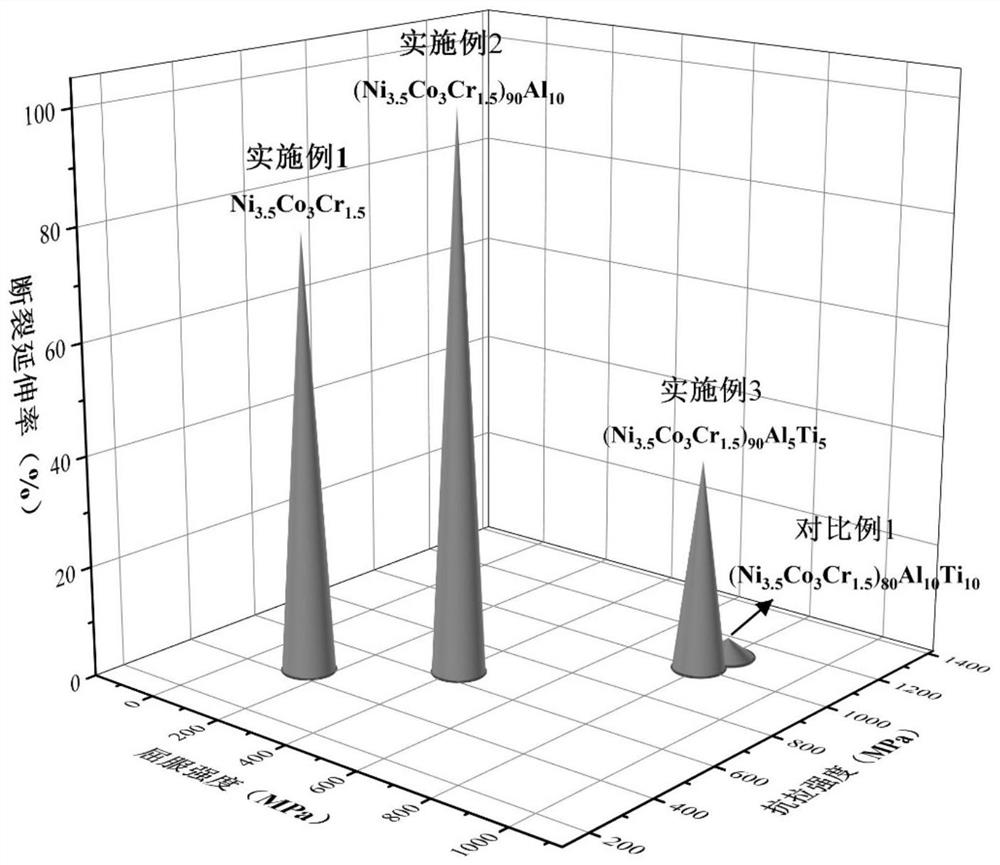

NiCoCr-containing medium/high-entropy alloy with non-equal atomic ratio and preparation method thereof

ActiveCN112725678AExcellent elongation at room temperatureLow densityHigh entropy alloysArgon atmosphere

The invention belongs to the field of medium / high-entropy alloys, and particularly relates to a NiCoCr-containing medium / high-entropy alloy with a non-equal atomic ratio and a preparation method of the NiCoCr-containing medium / high-entropy alloy. The medium / high-entropy alloy comprises the following components in percentage by atom: 30%-50% of Ni, 20%-40% of Co, 10%-30% of Cr and 0%-12% of M, wherein M is selected from 0-2 of Al and Ti. The preparation method comprises the following steps of: putting a high-purity metal block raw material into a water-cooled copper mold crucible of an electric arc smelting furnace according to a certain proportion, and smelting under the protection of an argon atmosphere to obtain an as-cast product. The components of the NiCoCr-containing medium / high-entropy alloy are reasonable in design; the preparation process is simple and controllable; and the obtained product is excellent in performance.

Owner:CENT SOUTH UNIV

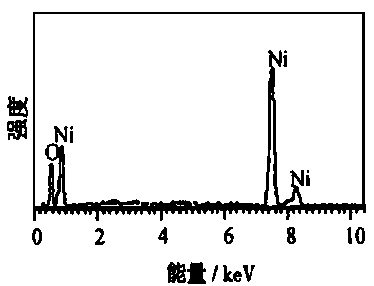

Preparation method of porous nickel

The invention provides a preparation method of porous nickel. The preparation method is characterized by comprising the steps: melting pure nickel and pure zinc in a crucible by specified proportions to obtain a nickel-zinc alloy melt, adjusting the temperature of the melt to the range from 950 DEG C to 1000 DEG C, casting in a copper mold, and then performing vacuum evaporation on the obtained nickel-zinc alloy to obtain the material, namely the porous nickel material. The method has the advantages of simple process, low environmental pollution, adjustable pore size and porosity and the like.

Owner:XINGHUA PRECISION CASTING & FORGING IND RES INST CO LTD

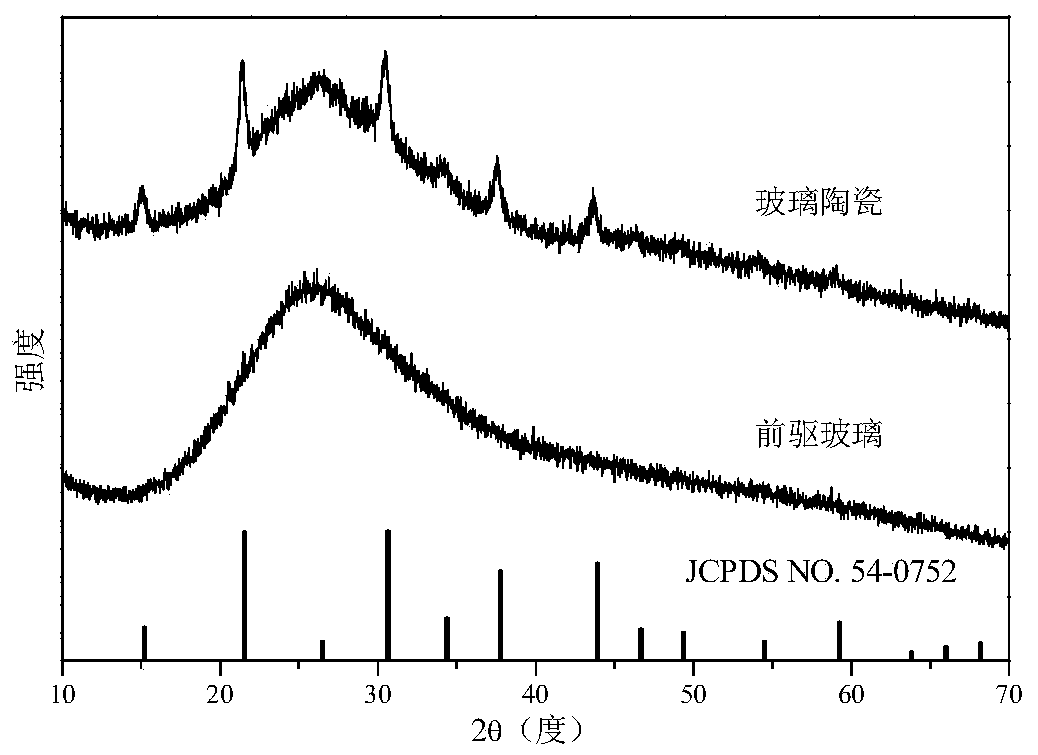

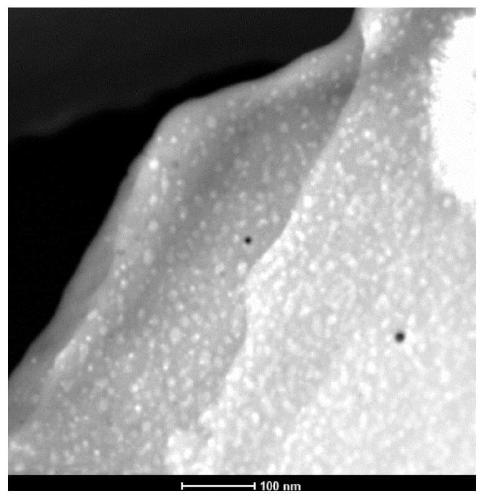

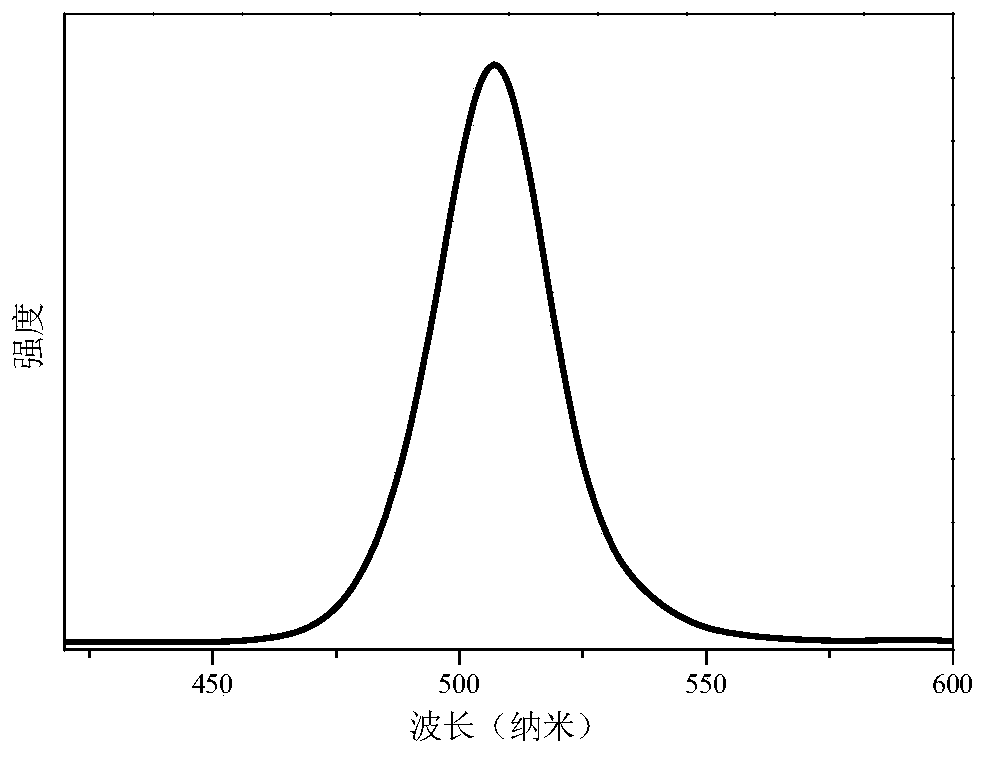

Method for promoting crystallization of all-inorganic perovskite quantum dots in glass by adding fluoride

The invention relates to a method for promoting the crystallization of all-inorganic perovskite quantum dots in glass by adding a fluoride. The method includes: placing the powder raw materials SiO2,B2O3, ZnO, Cs2CO 3, PbX2, NaX and a fluoride compound in an agate mortar to be ground evenly, then putting the product in a crucible and placing the crucible in a resistance furnace for heating to 1150-1200DE C, and conducting heat preservation for 8-15min, thus obtaining molten glass; pouring the molten glass rapidly into a copper mould for molding to obtain precursor glass; putting the precursorglass into a 480-520DEG C resistance furnace and performing heat treatment for 8-15min to crystallize perovskite in the precursor glass, thus obtaining the perovskite quantum dot embedded borosilicate glass. The CsPbX3 (X=Cl, Br, I) quantum dots in the obtained perovskite quantum dot glass can all grow up, can realize visible light full-spectrum emission, and are uniform in luminescence and goodin transparency.

Owner:HANGZHOU DIANZI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com