Copper mold suction casting preparation device of iron-based bulk amorphous alloy annular magnet core and method thereof

A technology of amorphous alloy and ring magnetic core, which is applied in the field of copper mold suction casting preparation device, can solve the problems of great difficulty and unfavorable development trend of circuit miniaturization, achieve excellent performance, avoid contact with air and external pollution, and simple process conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

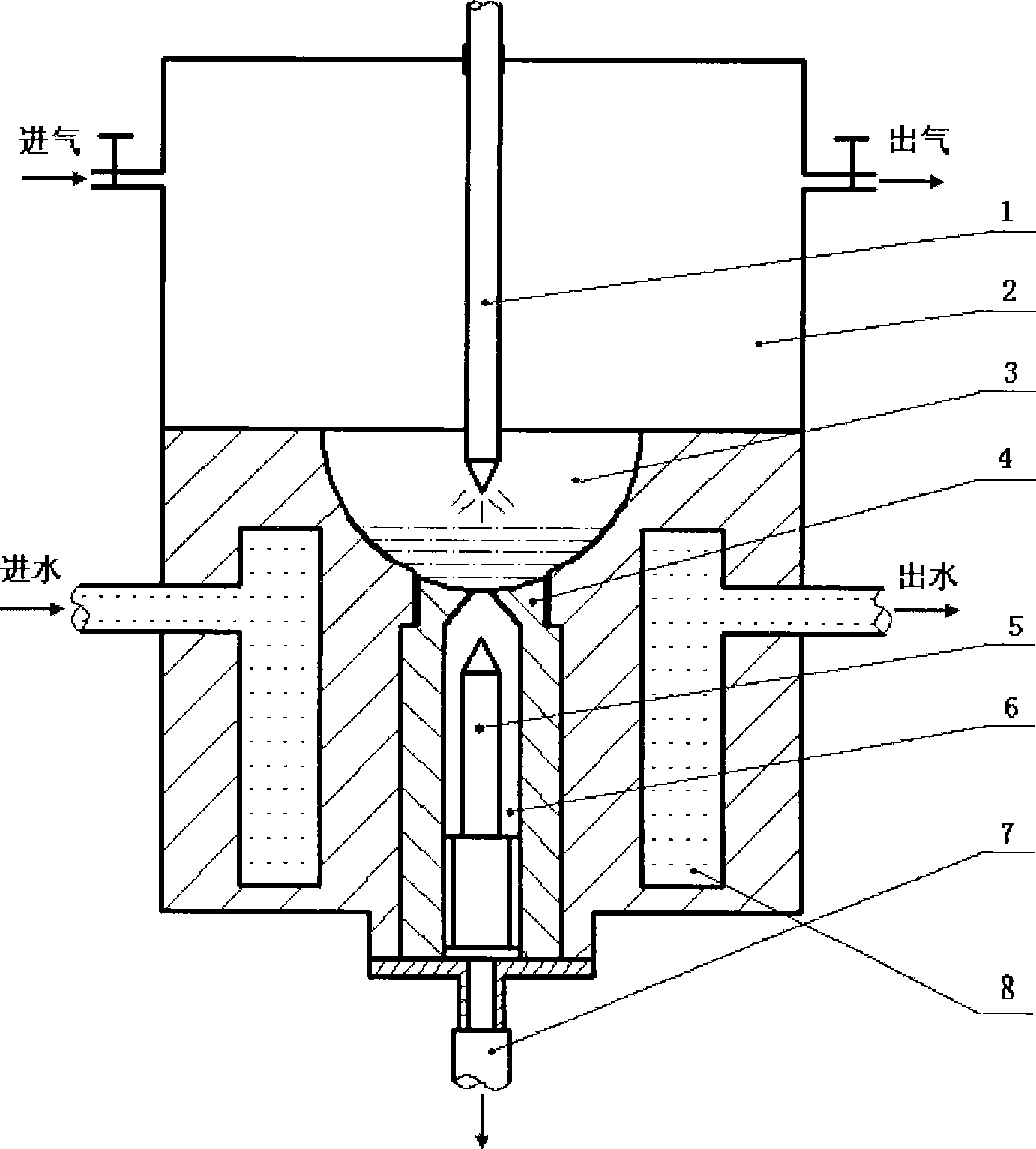

[0019] The structure diagram of the copper mold suction casting preparation device of the iron-based bulk amorphous alloy ring magnetic core of the present invention is as follows figure 1 As shown, it includes electrode 1, furnace cavity 2, copper crucible 3, copper mold 4, core 5, cavity 6, suction casting pipe 7, water cooling device 8, and several copper crucibles 3 are arranged in the furnace cavity 2, wherein At least one copper crucible 3 is a copper crucible for suction casting, and the rest are copper crucibles for smelting. The electrode 1 passes through the furnace shell and extends into the copper crucible 3 for smelting in the furnace cavity 2. Prepared soft magnetic iron-based bulk amorphous alloy raw material, the bottom of the copper crucible (3) for suction casting is provided with a water cooling device 8, and the water cooling device 8 is provided with a copper mold 4, and the copper mold 4 is provided with a The cavity 6 connected with the copper crucible 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com