Patents

Literature

367results about How to "High saturation magnetic induction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy

ActiveCN101840764AStrong Amorphous Formation AbilityHigh saturation magnetic inductionMagnetic materialsIron basedMagnetism

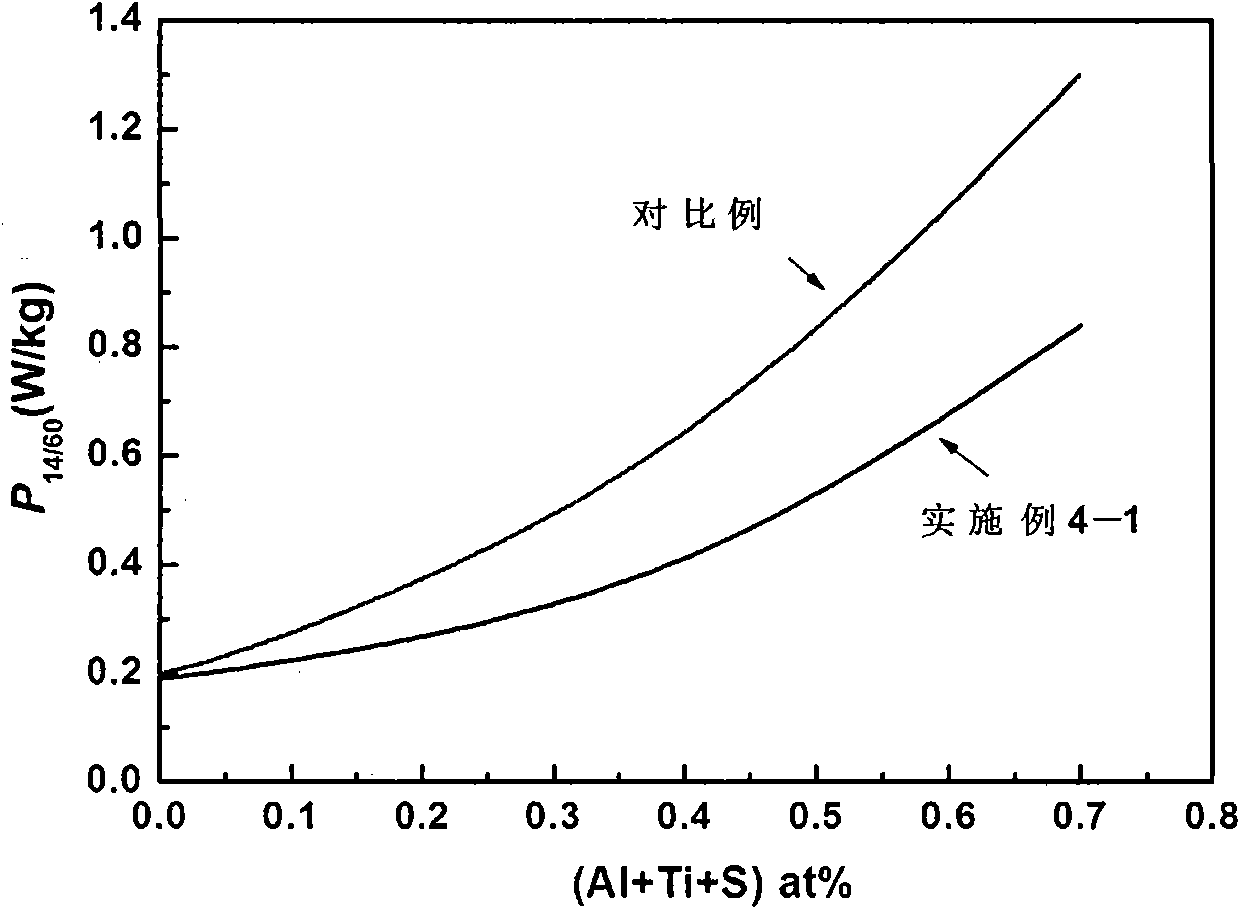

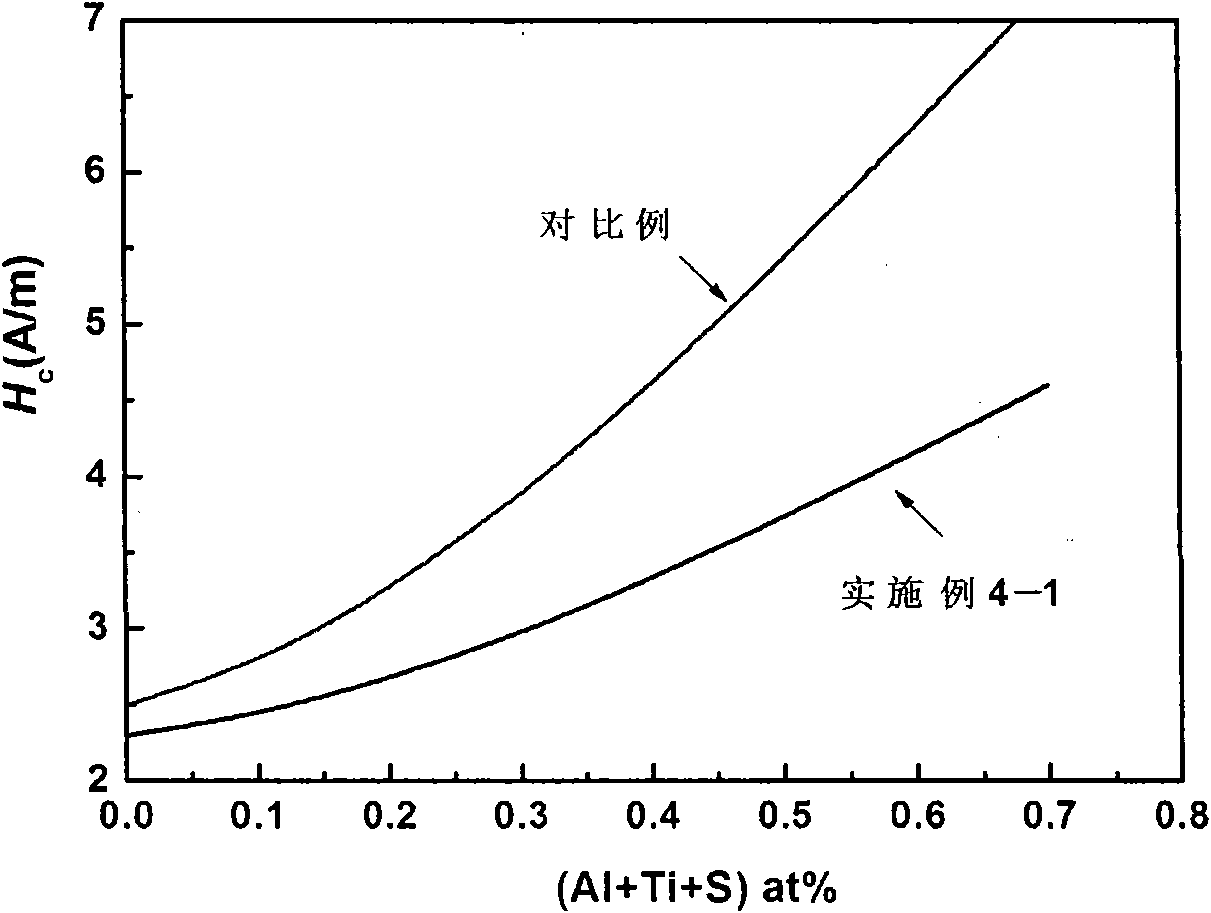

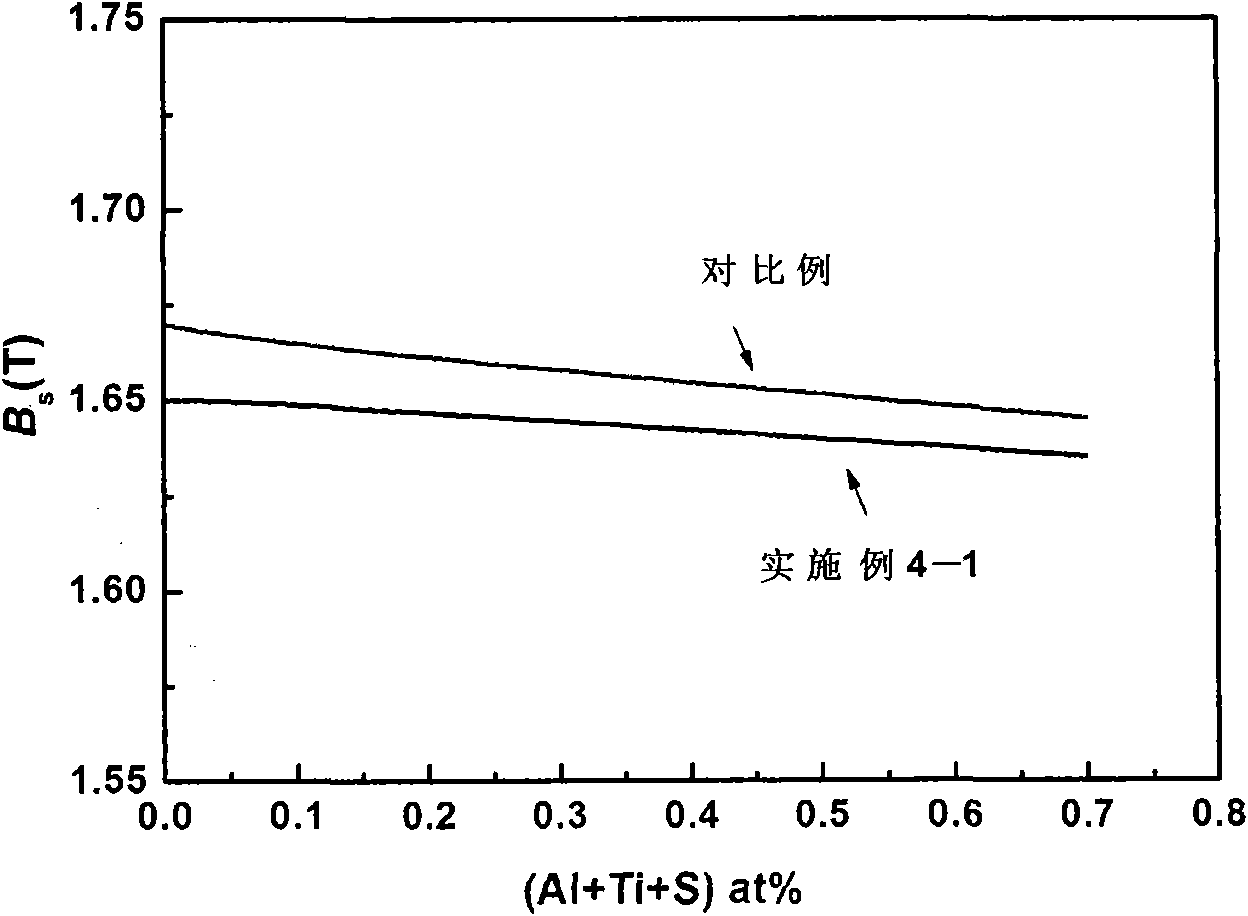

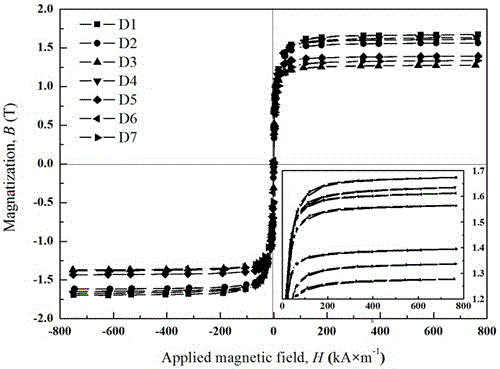

The invention provides a low-cost high-saturation magnetic induction intensity iron-based amorphous soft magnetism alloy. The alloy comprises the following ingredients in percentage by atoms: 0 to 15 of Si, 3 to 20 of B, 0.001 to 12 of P, 0.001 to 5 of C, 0.0001 to 0.1 of Al, 0.001 to 0.5 of Mn, 0.0001 to 0.5 of Sb, 0.0001 to 0.1 of Ti, 0.0001 to 0.5 of S, 0.0001 to 0.5 of Sn, 0.0003 to 0.2 of W and the balance of Fe and unavoidable impurities. The soft magnetism alloy of the invention has the characteristics of strong amorphous forming capability, high saturation magnetic induction intensity, low cost and the like. After the alloy is annealed, the saturation magnetic induction intensity is higher than 1.6 T, and the coercive force is lower than 5A / m.

Owner:AT&M AMORPHOUS TECH CO LTD

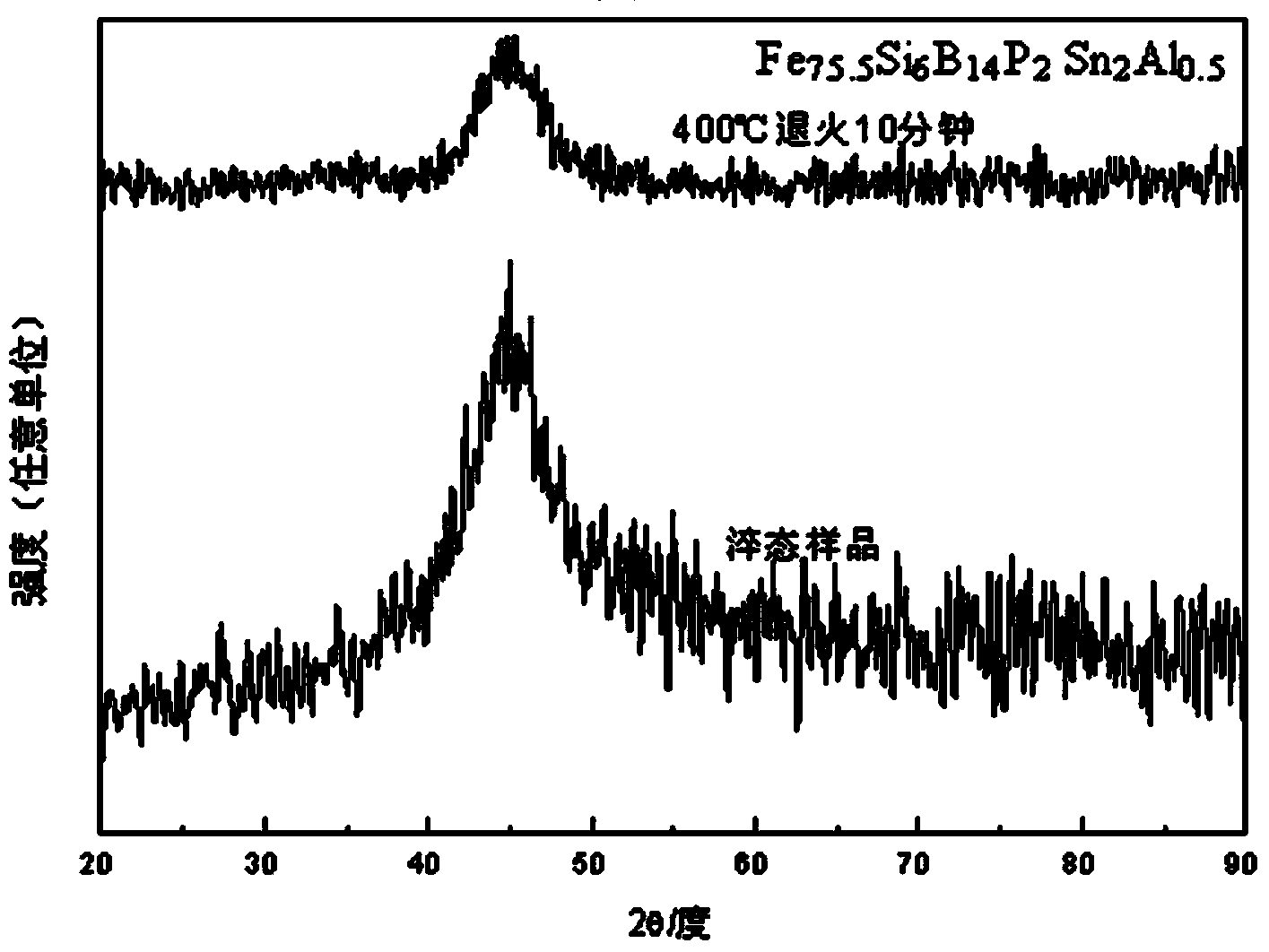

Iron-based amorphous magnetically soft alloy with uniform element distribution and preparation method thereof

ActiveCN104073749AImprove thermal stabilityHigh saturation magnetic inductionMagnetic materialsTransformerMaterials science

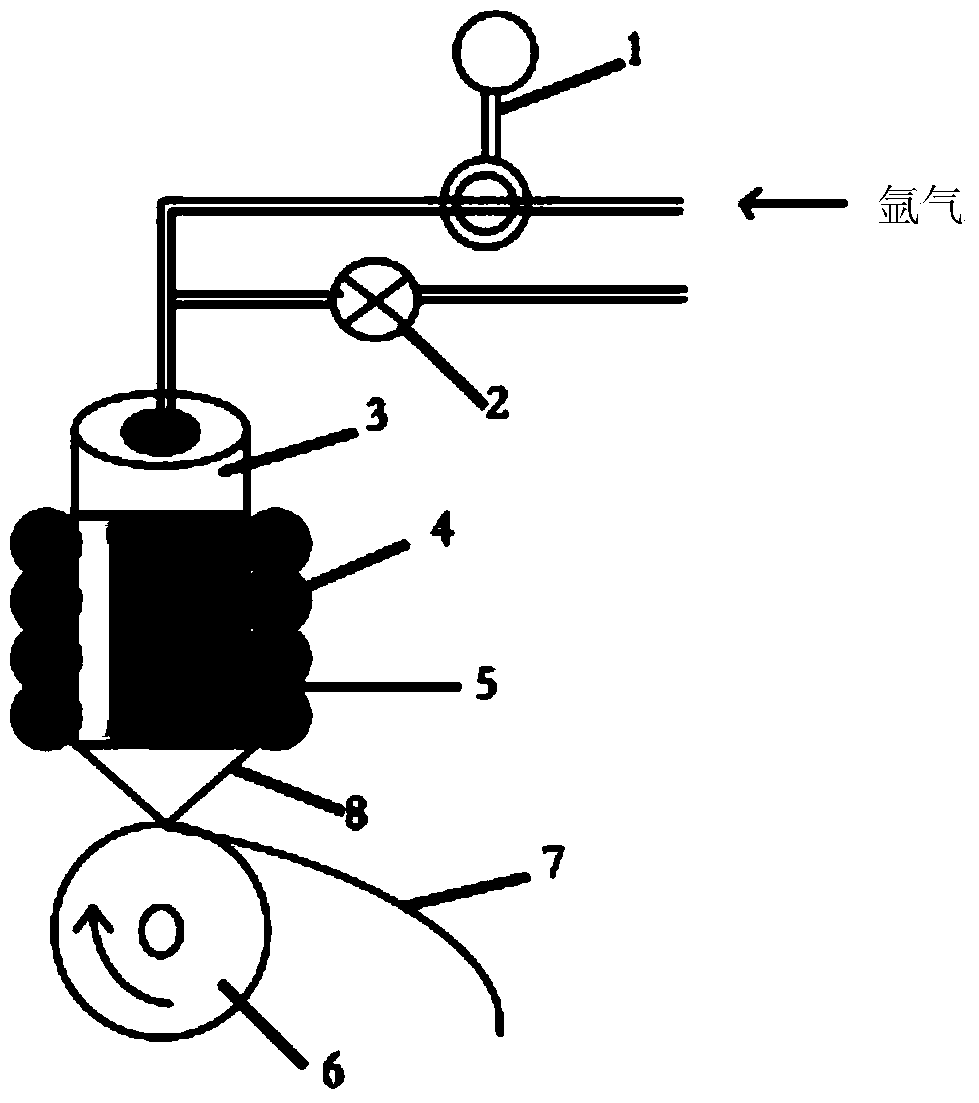

The invention discloses an iron-based amorphous magnetically soft alloy with uniform element distribution and a preparation method thereof. The expression of the alloy is FeaSibBcPdMe, a, b, c, d and e in the expression represent the atomic percent contents of corresponding components respectively, and meet the following conditions: a is not less than 70 and not greater than 84, b is not less than 2 and not greater than 10, c is not less than 5 and not greater than 18, d is not less than 0.001 and not greater than 8, e is not less than 0.0001 and not greater than 2.5, a+b+c+d+e=100%, and M is one or more of C, N, Sn, Ge, Ga, Al, S, Te, Be, Pb, Mg and Cu. The amorphous strip prepared from the alloy under a high vacuum and argon shield has the characteristic of uniform element distribution, particularly solves the problem of non-uniform distribution of element P in the amorphous alloy, has excellent magnetically soft performance, and is suitable for transformers, engines, power generators, magnetic sensors and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

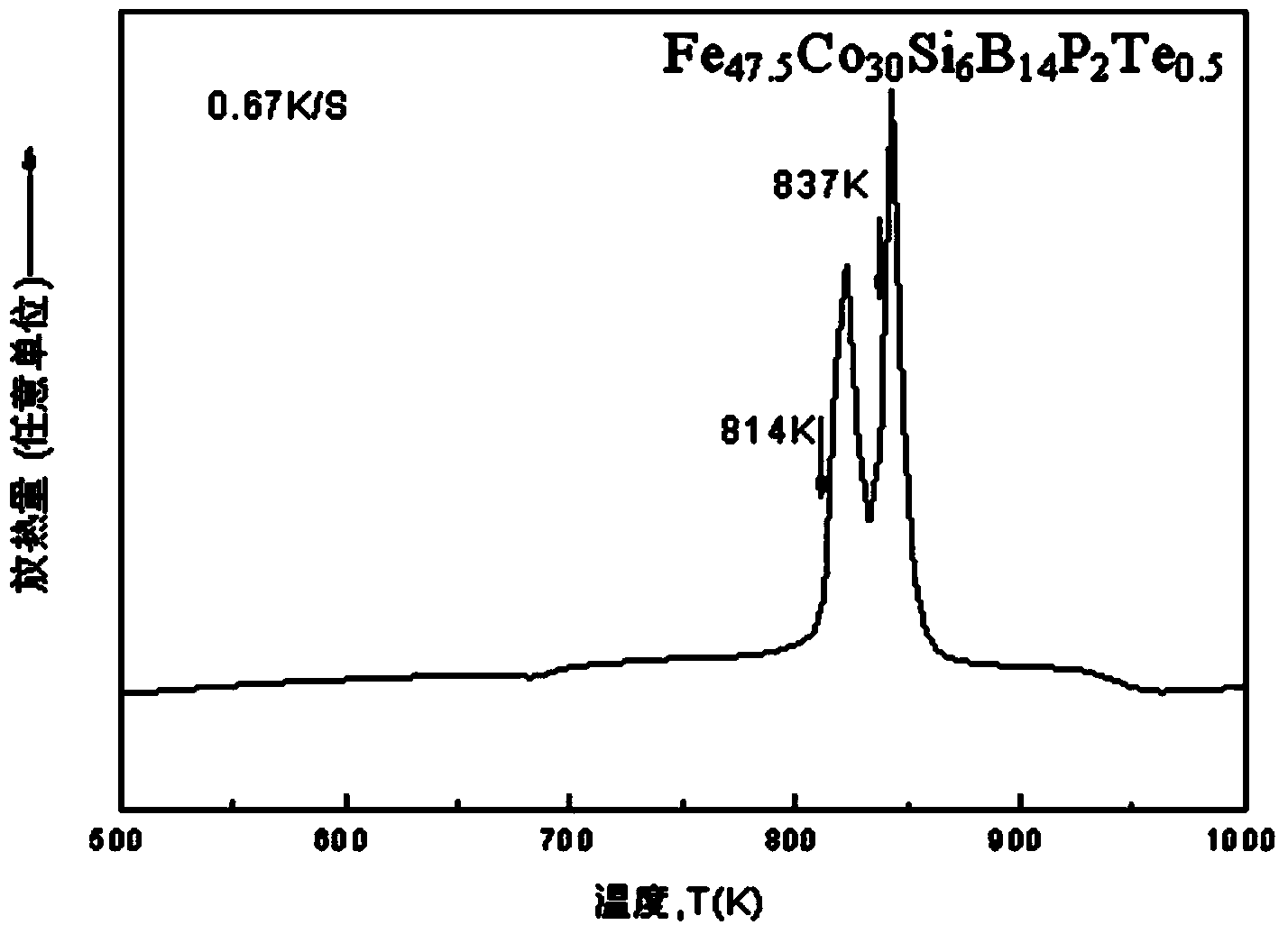

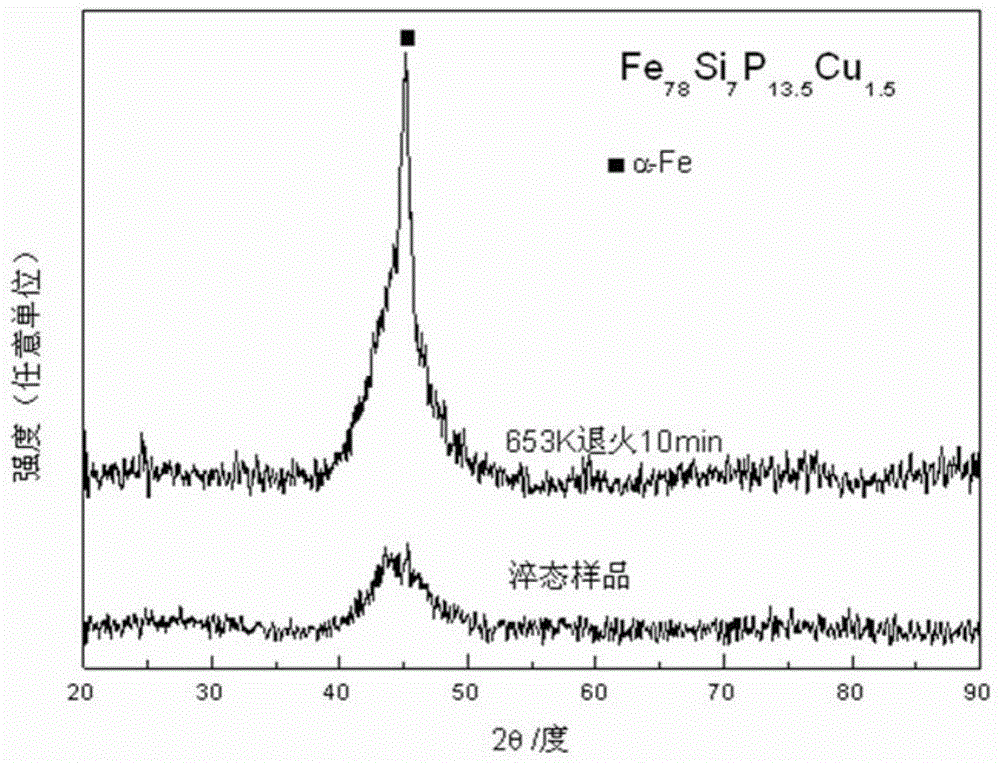

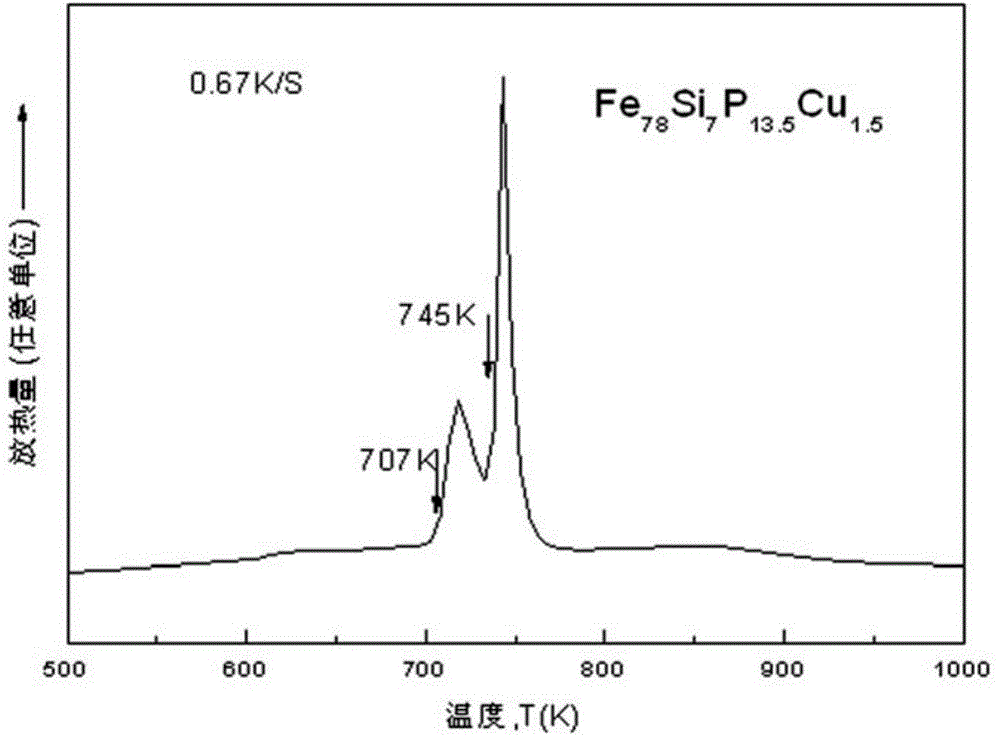

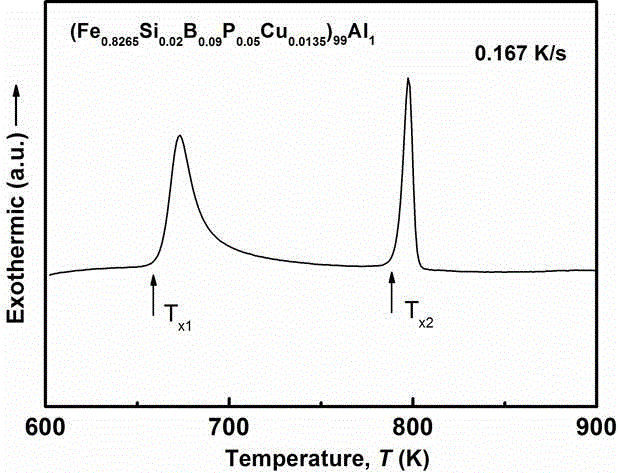

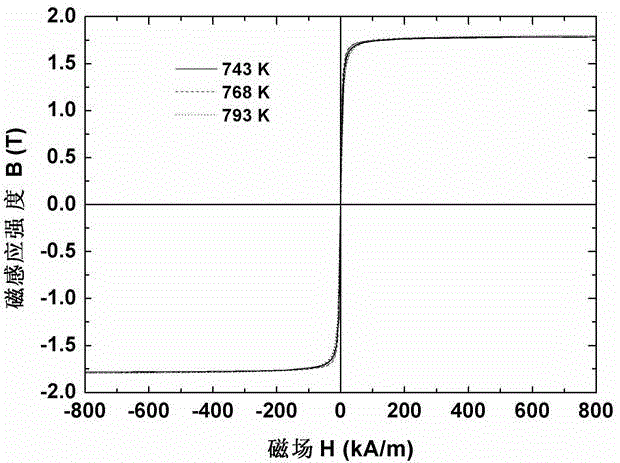

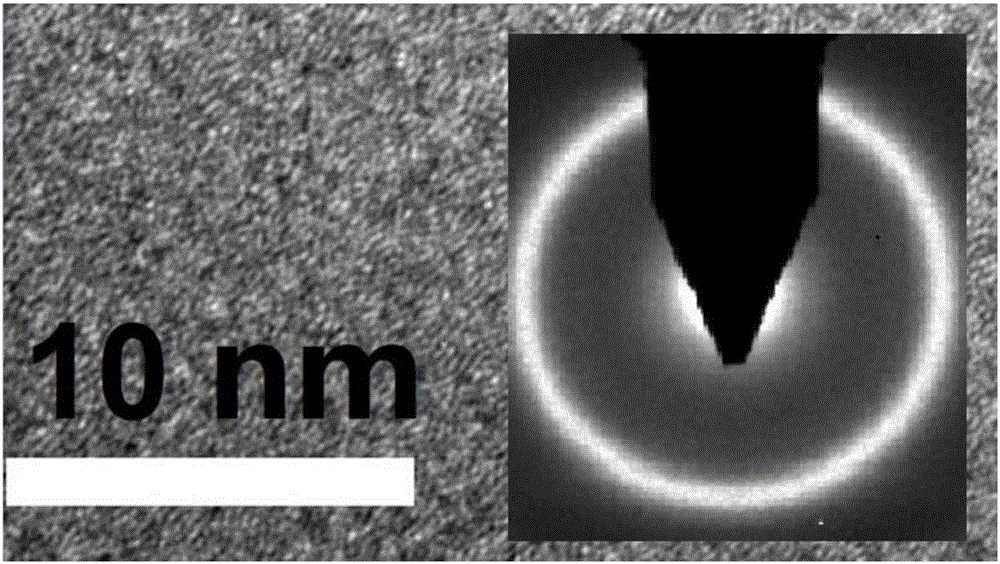

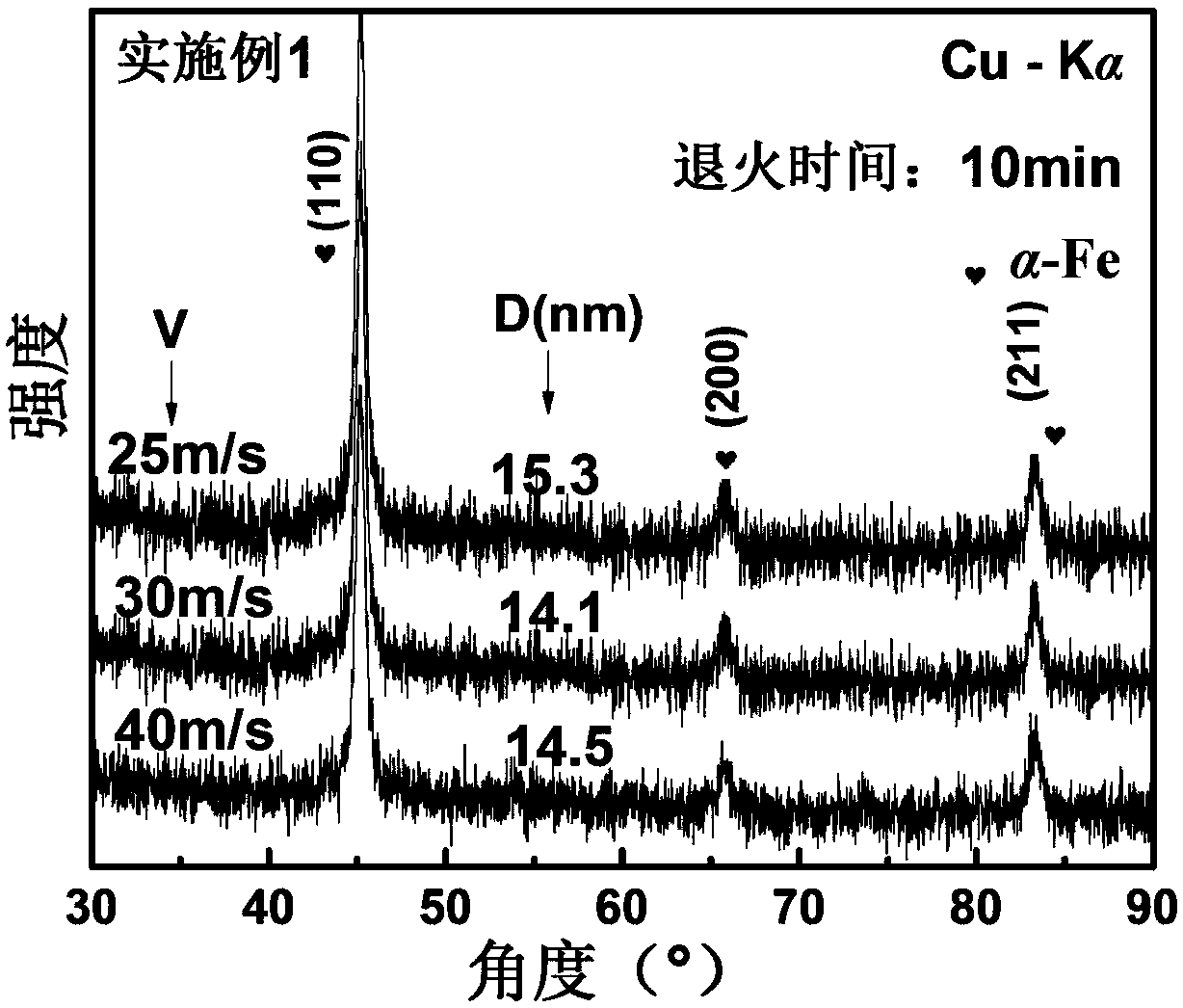

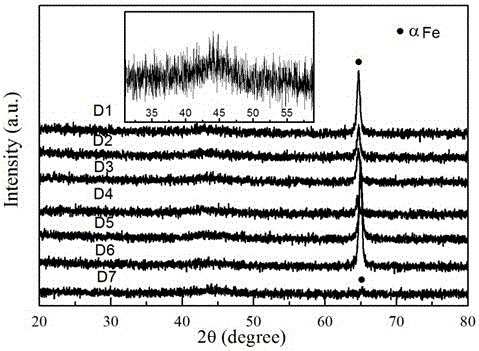

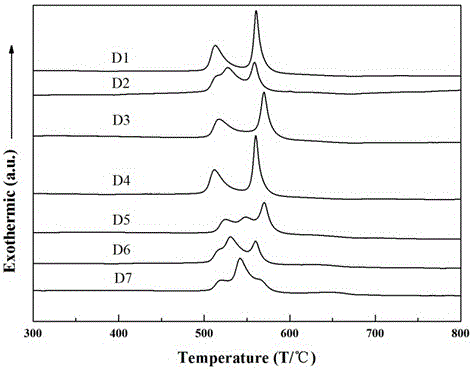

Iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and preparation method thereof

ActiveCN104087833AHigh saturation magnetic inductionImprove thermal stabilityMagnetic materialsRare-earth elementNanocrystalline silicon

The invention discloses iron-based nanocrystalline soft-magnetic alloy with excellent high-frequency performance and a preparation method thereof. The expression of the alloy is FeaSibPcCuxMy, wherein a, b, c, x and y respectively represent the atomic percent content of corresponding compositions and satisfy the following conditions: 70<=a<=85, 5<=b<=15, 5<=c<=18, 0.0001<=x<=3, 0<=y<=5, a+b+c+x+y=100%, and M is one or more of Zr, Ti, Ta, Hf, Nb, V, W, Mo, Mn, Cr, Re, Zn, In, As, Sb, Bi, Ca, platinum group elements, rare earth elements, N, Sn, Ge, Ga and Al. The alloy is a nanocrystalline soft-magnetic alloy band prepared by employing a single-roller quick-cooling method under the conditions of high vacuum and argon protection. The alloy does not contain B elements, is good in soft magnetic property, high in thermal stability, low in high-frequency loss and low in magnetostriction coefficient.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

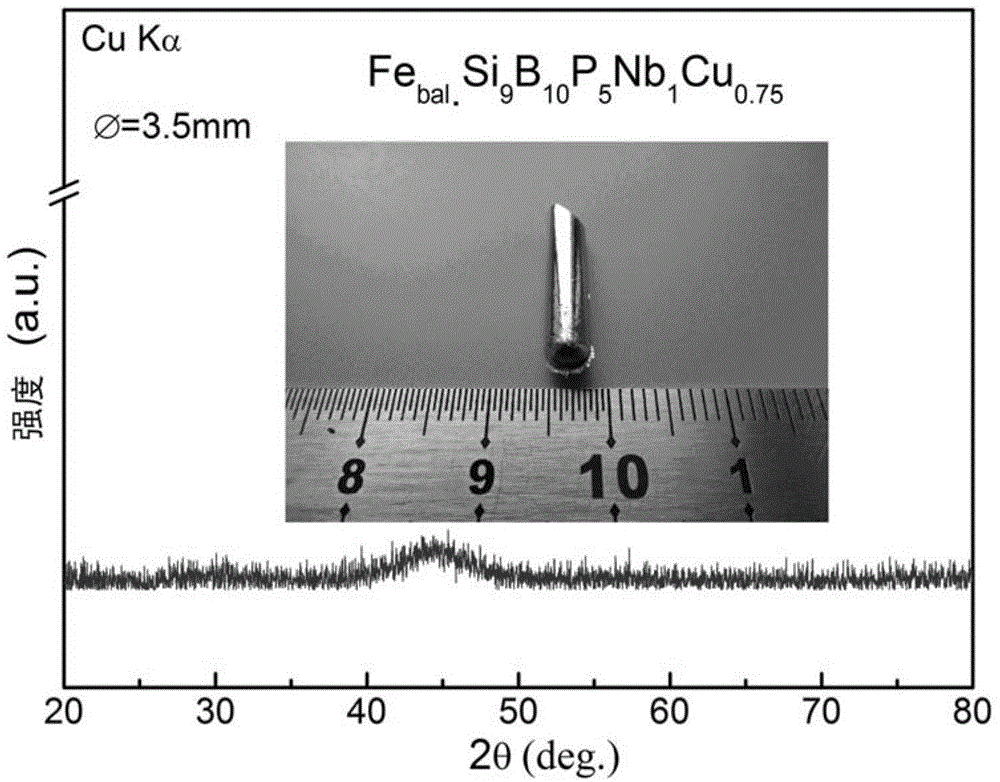

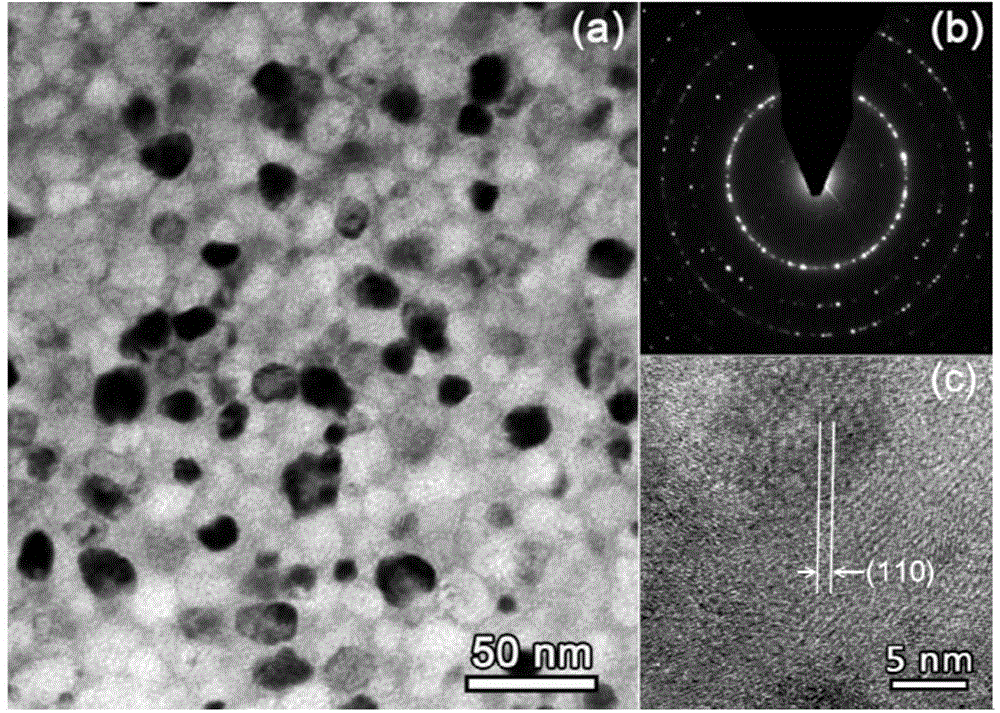

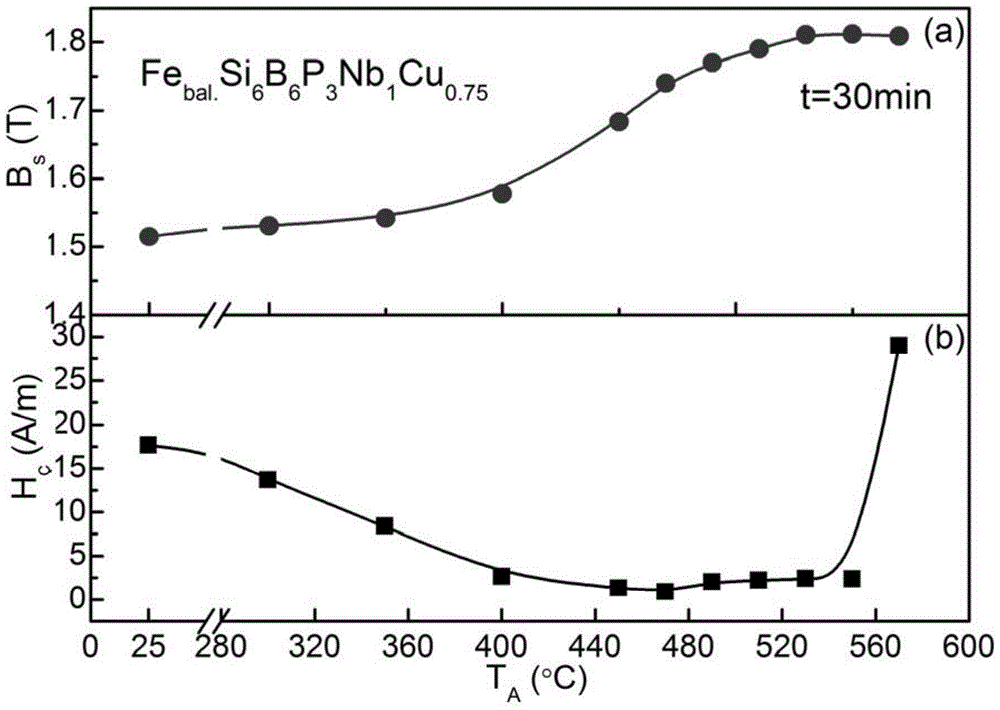

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

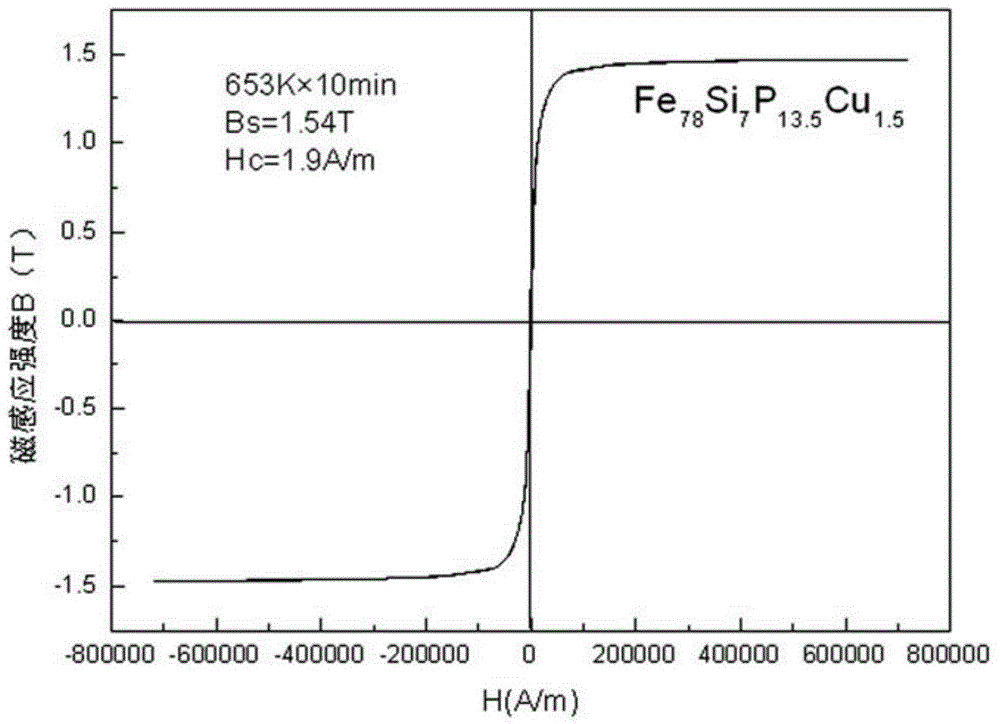

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Preparation method of mu90 high-permeability Fe-based amorphous magnetic powder core

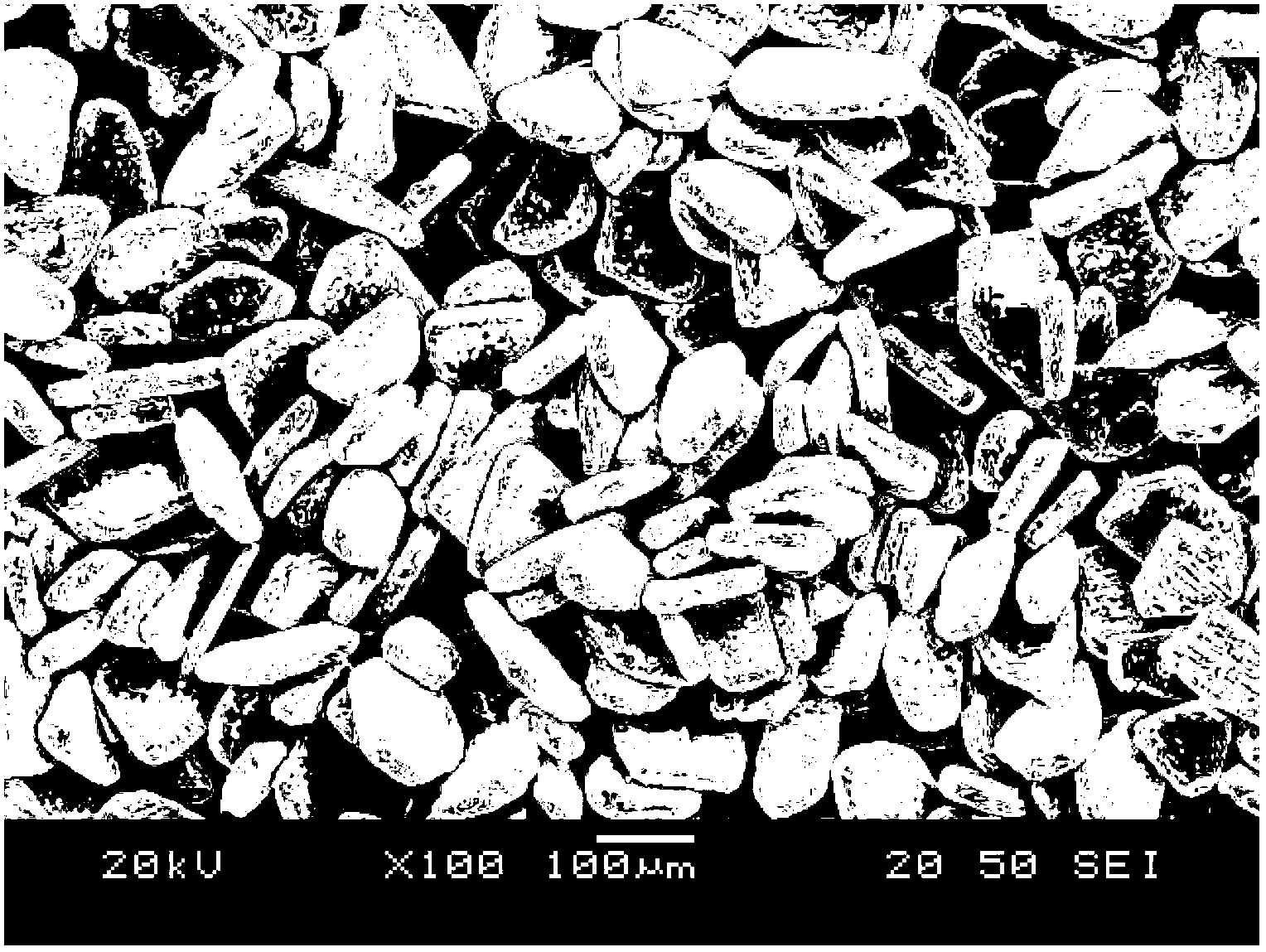

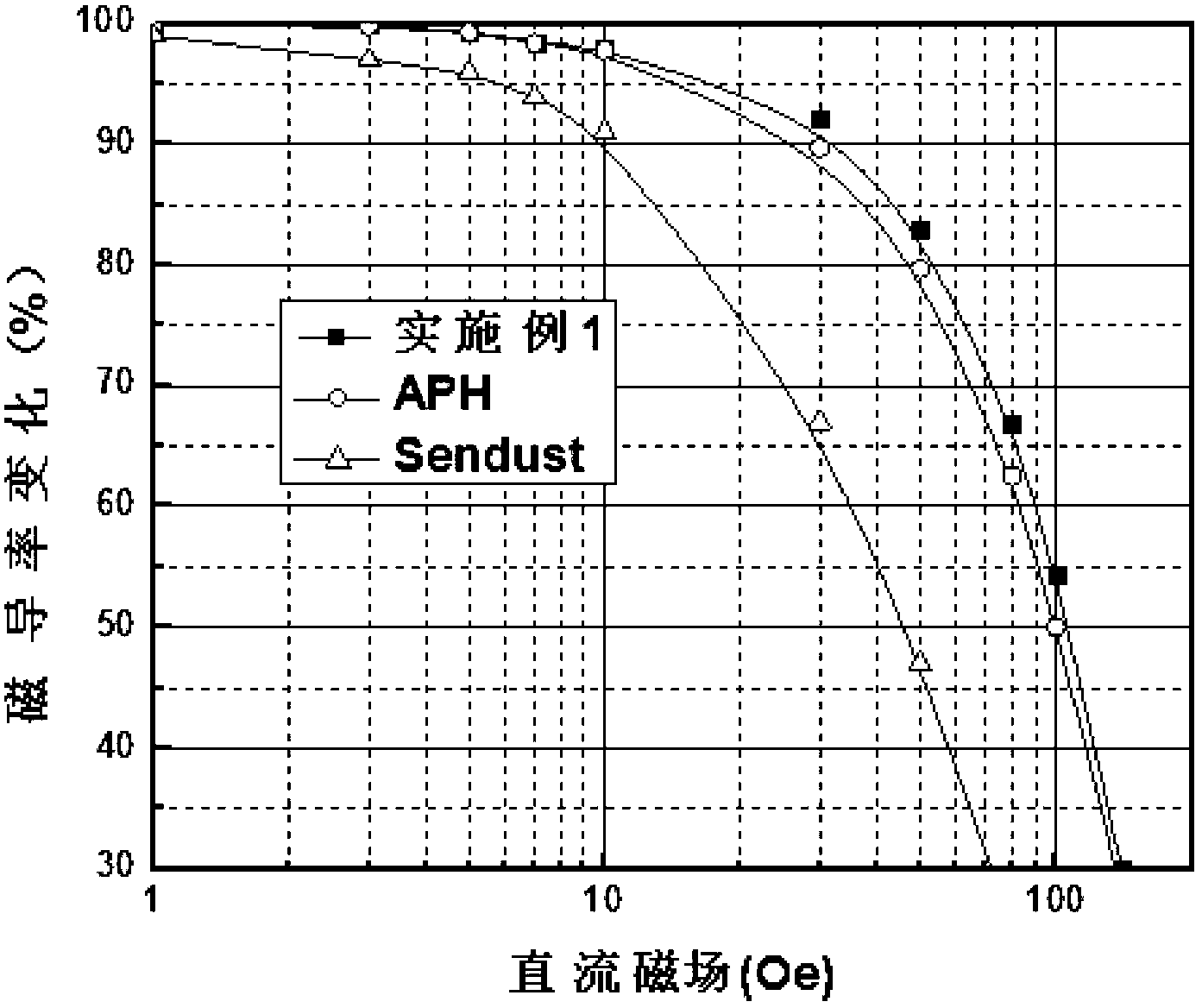

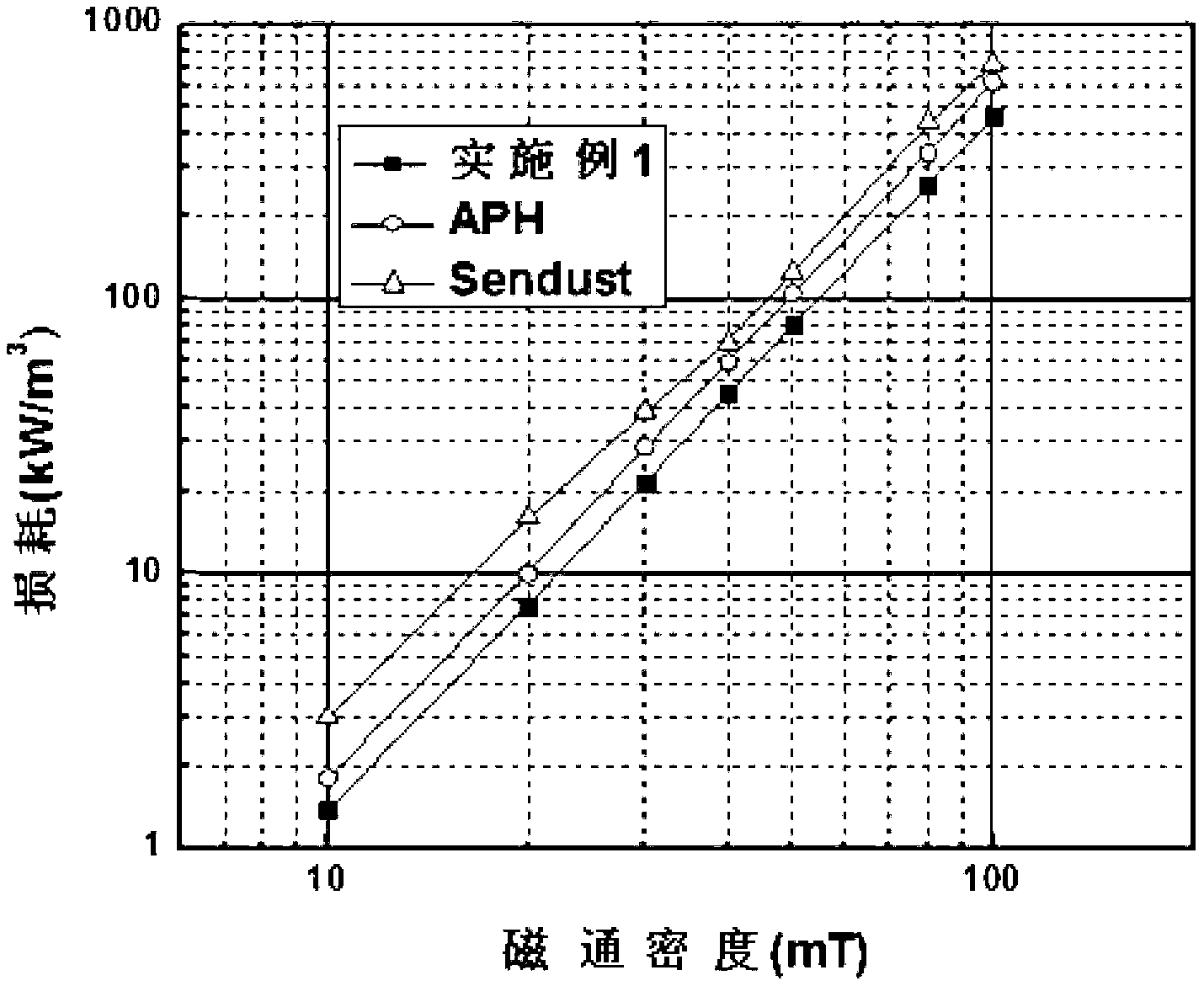

InactiveCN103219119AExcellent DC bias characteristicsHigh permeabilityInorganic material magnetismQuenchingMagnetic powder

The invention belongs to the field of Fe-based soft magnetic materials and particularly relates to a preparation method of a mu90 high-permeability Fe-based amorphous magnetic powder core. The preparation method comprises the steps of conducting preheating treatment to Fe-based amorphous ribbon which is prepared by adopting a single-roller rapid quenching method; crushing the amorphous ribbon by adopting a mechanical milling and air-current milling combination method; screening amorphous powder to obtain Fe-based amorphous powder with grain size being less than 100-mesh; conducting passivation and insulation treatment to the screened Fe-based amorphous powder, then mixing the Fe-based amorphous powder with adhesive and conducting coating granulation; molding the granulated coated powder to obtain the Fe-based amorphous magnetic powder core; and conducting stress relief annealing to the molded magnetic powder core. The Fe-based amorphous magnetic powder core which is prepared by adopting the method provided by the invention has high permeability and excellent loss and biasing characteristic.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

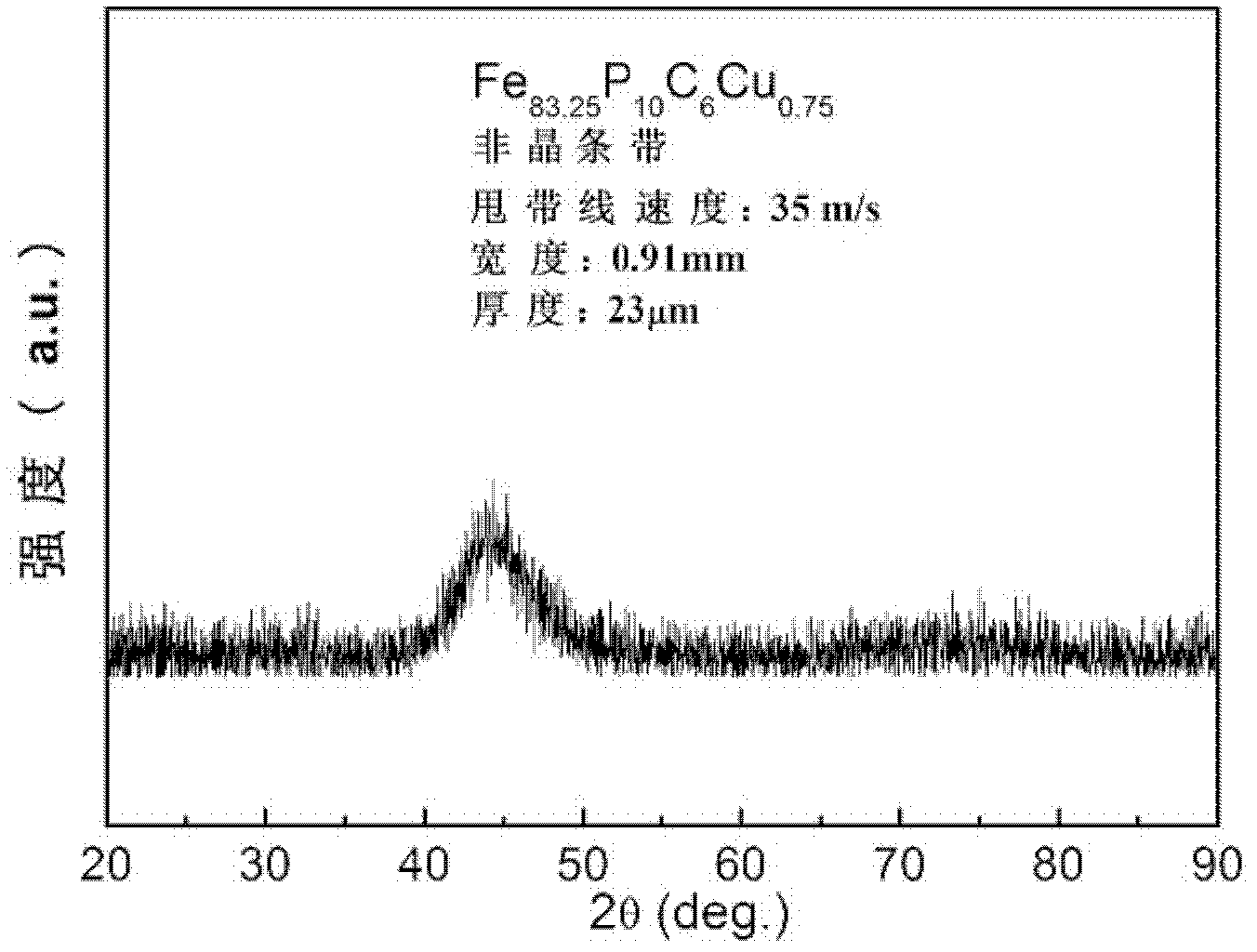

Iron-based nanometer crystal magnetically soft alloy and preparation method thereof

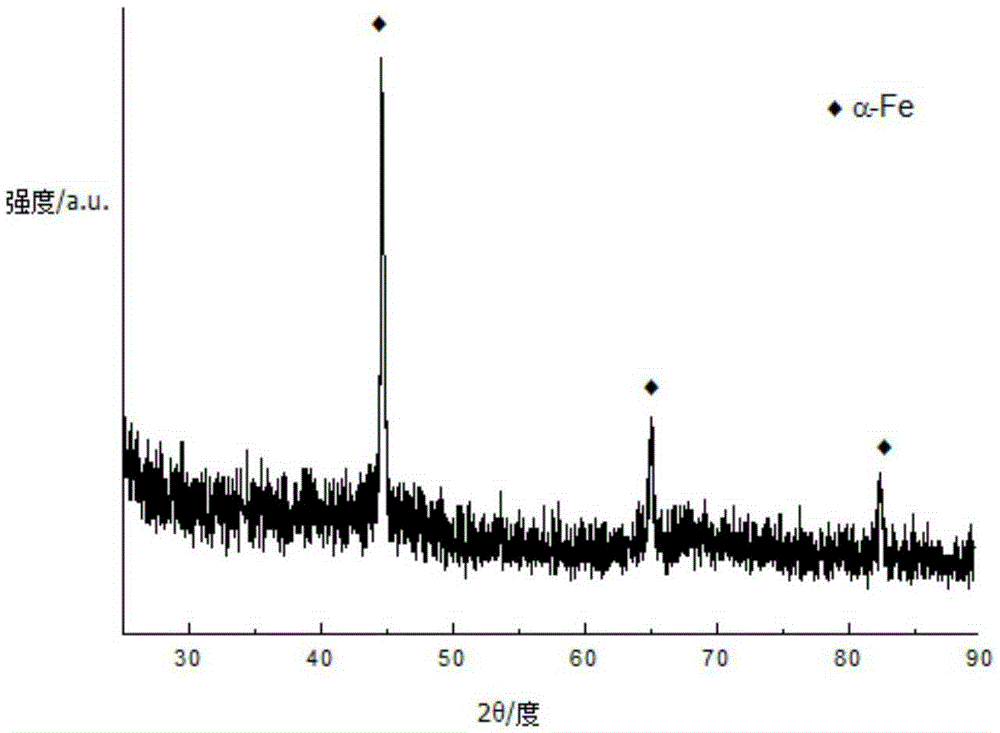

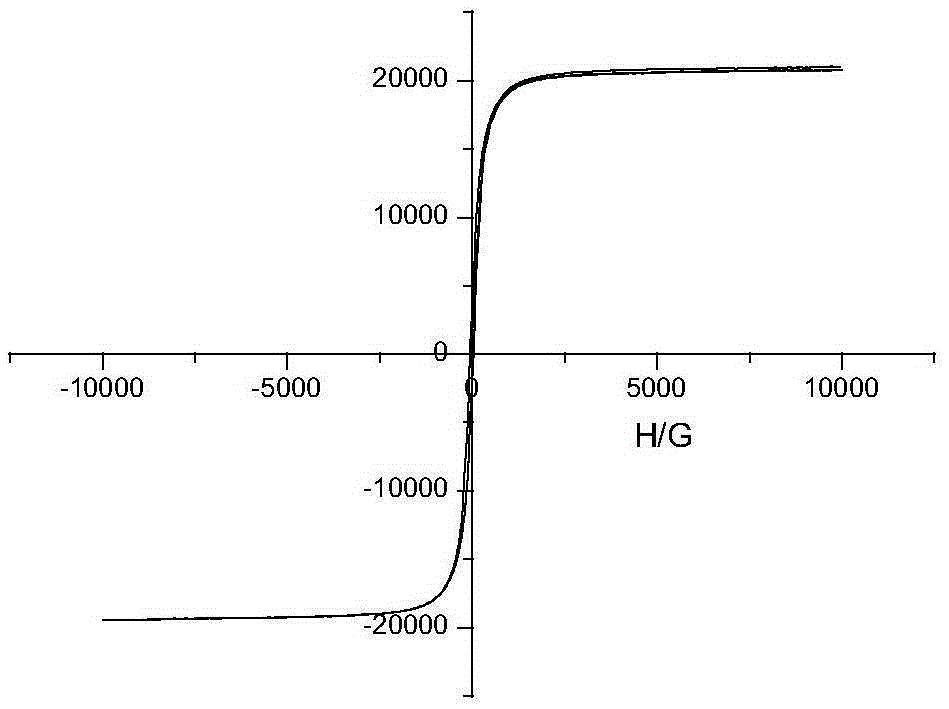

ActiveCN102543347AReduce processing costsHigh saturation magnetic inductionMagnetic materialsAmorphous phaseAlloy

The invention discloses a novel iron-based nanometer crystal magnetically soft alloy and a preparation method thereof. The molecular formula of the iron-based nanometer crystal magnetically soft alloy is FexPyCzMaCub, wherein the M in the molecular formula is one or more than one of B, Si, Al, Cr, Mn, Mo and Ge; x,y,z,a and b respectively represent atom percentage composition of each corresponding component, wherein 70<=x<=90, 1<=y<=20, 1<=z<=20, 0<=a<=10, 0.1<=b<=2, and x+y+z+a+b=100; and a microstructure is coexistence of a body-centered stand alpha-Fe nanometer crystalline phase the size of which is 5-40 nm and a rich phosphatic and carbon amorphous phase. Compared with the existing nanometer crystal magnetically soft alloy, the alloy disclosed by the invention meanwhile has the advantages of high saturation induction density, low coercive force, low iron loss and high magnetic permeability; and in addition, precious metals such as Nb, Zr, Co, Ni, Y and the like are not contained, thus the processing cost is greatly reduced and the application prospect is good.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and preparation method thereof

ActiveCN105047348AReduce magnetic lossReduce lossTransformers/inductances magnetic coresInductances/transformers/magnets manufactureChemical compositionAlloy

The invention discloses a current transformer iron core of amorphous and nano-crystalline magnetically soft alloy and a preparation method of the current transformer iron core. The chemical component atomic percent of the iron core is FeaSibBcMdCueM'f, wherein a is not more than 85 and is not less than 65; b is not more than 25 and is not less than 5; c is not more than 15 and is not less than 0; d is not more than 15 and is not less than 0; e is not more than 5 and is not less than 0, and f is not more than 1 and is not less than 0, and a plus b plus c plus d plus e plus f equals to 100, and M is at least one of Nb, Mo or V, and M' is at least one of Sn, Al, Y and Sb. The preparation method comprises the steps as follows: preparing materials according to atomic percent and smelting to prepare a mother alloy; then crushing the prepared mother alloy to re-melt and covering steel-making slagging constituent to prevent oxidation and deslagging; preparing amorphous alloy ribbons with the re-melted mother alloy by using a single roll rapid solidification ribbon preparation method under ordinary pressure, and finally winding the amorphous alloy ribbons as the amorphous iron core, and performing isothermal annealing crystallization in a vacuum annealing furnace to obtain the amorphous and nano-crystalline magnetically soft alloy of a mutual inductor iron core. The iron core of the invention has high saturation flux density, high permeability, and low magnetic loss so that the mutual inductor has ultrahigh precision and accuracy class.

Owner:NEW MATERIALS TECH JIANGSU AMORPHD +1

Fe-Si-Al magnetic core preparation method and inorganic composite insulation coating material for magnetic core

ActiveCN105304308AEasy to processGood temperature characteristicsInductances/transformers/magnets manufactureMagnetic materialsHeat treatingSurface coating

The invention discloses a Fe-Si-Al magnetic core preparation method and an inorganic composite insulation coating material for a magnetic core, belonging to the field of Fe-Si-Al magnetic material and used for solving the high eddy-current loss problem of existing magnetic cores and such problems caused by the fact that the existing magnetic cores usually use organic coating materials as stress is difficult to eliminate in a forming process, the insulation property of the material is poor, and the volatilization quantity of organics is large in heating processes such as heat treatment. The Fe-Si-Al magnetic core preparation method disclosed by the invention comprises the following steps: cast ingot smelting, powder making, surface phosphorization, insulation coating, compression moulding, annealing treatment and surface coating; the prepared Fe-Si-Al magnetic core has the advantages of low eddy-current loss, small magnetic conductivity temperature coefficient, good temperature stability, high direct current superposition characteristic, high saturation flux density and good high-frequency characteristic and meets the requirements for high frequency, small size, high power and electromagnetic interference resistance of electronic devices.

Owner:临沂银凤新材料技术服务有限公司

Fe-based amorphous or nanocrystalline soft magnetic alloy and preparation method thereof

InactiveCN101650999AImprovement and optimization of comprehensive soft magnetic propertiesLow costMagnetic materialsElectric arc furnaceAmorphous matrix

The invention discloses a Fe-based amorphous or nanocrystalline soft magnetic alloy, aiming to favorable performance and low cost. Alloy components can be expressed as FeaSibBcCudNbeMf, wherein M is Al, Ni or P; a, b, c, d, e and f are atom percentages, and the change range is as follows: a is more than or equal to 65 and less than or equal to 85, b is more than or equal to 5 and less than or equal to 20, c is more than or equal to 5 and less than or equal to 25, d is more than or equal to 0 and less than or equal to 5, e is more than or equal to 0 and less than or equal to 5, and f is more than or equal to 0.1 and less than or equal to 10; and a+b+c+d+e+f=100. The preparation method comprises the following steps: placing raw materials of pure ferrum, pure copper, and the like into a vacuum electric arc furnace to smelt to obtain an alloy ingot; crushing, placing into a quartz test tube, and preparing an amorphous alloy ribbon by using a single-rolling ribbon throwing method; placing into a tubular annealing furnace, adjusting the temperature to 510-580 DEG C, isothermally annealing under the protection of Ar gas and getting out of the furnace to cool; and obtaining amorphous alloys with different microstructures or nanocrystalline alloys with nanometer crystal particles evenly arranged on an amorphous matrix through controlling alloy cooling speed and heat treatment temperature as well as time.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

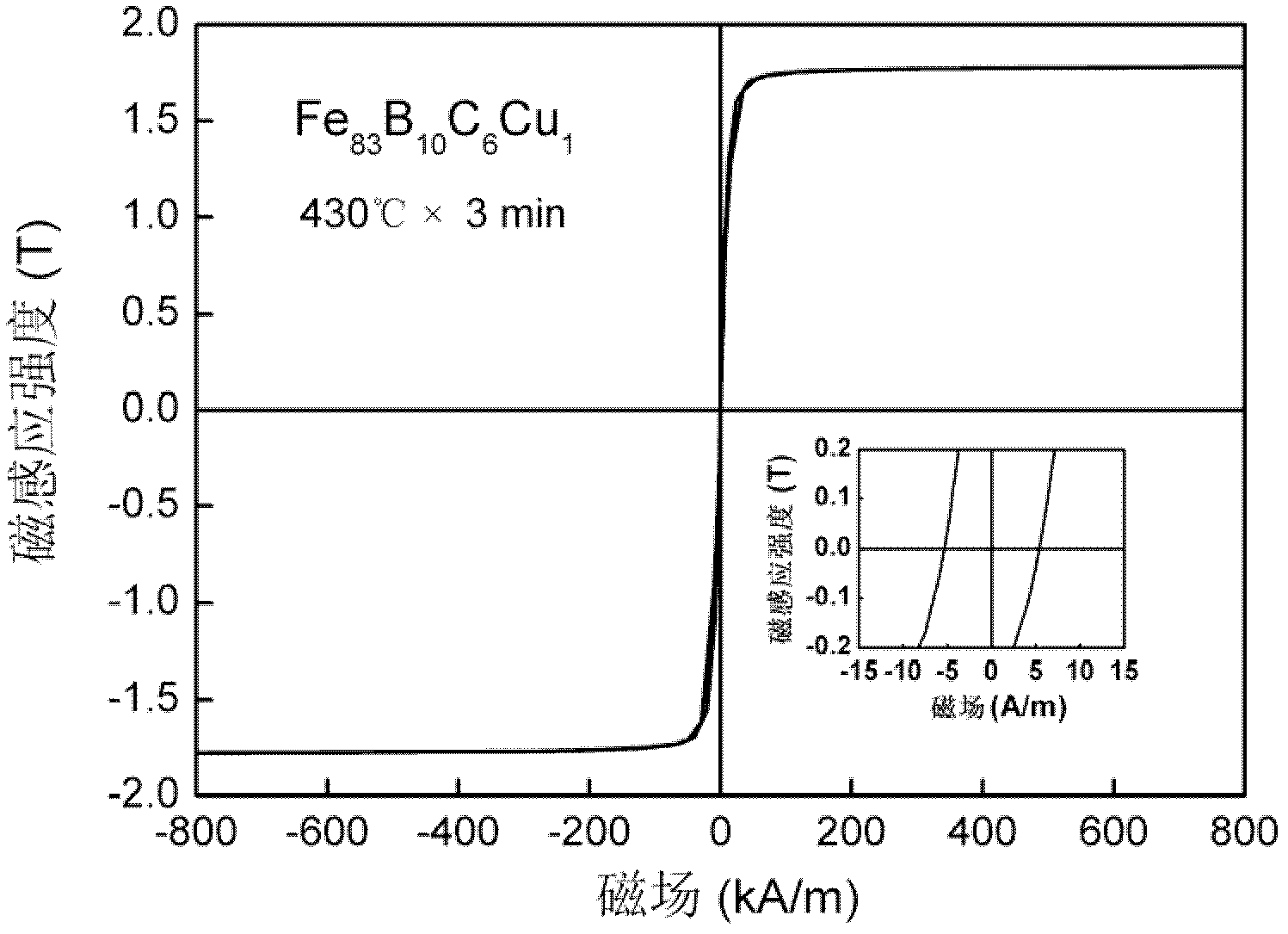

Iron-based nanocrystalline soft magnetic alloy with high saturation magnetic induction and low cost

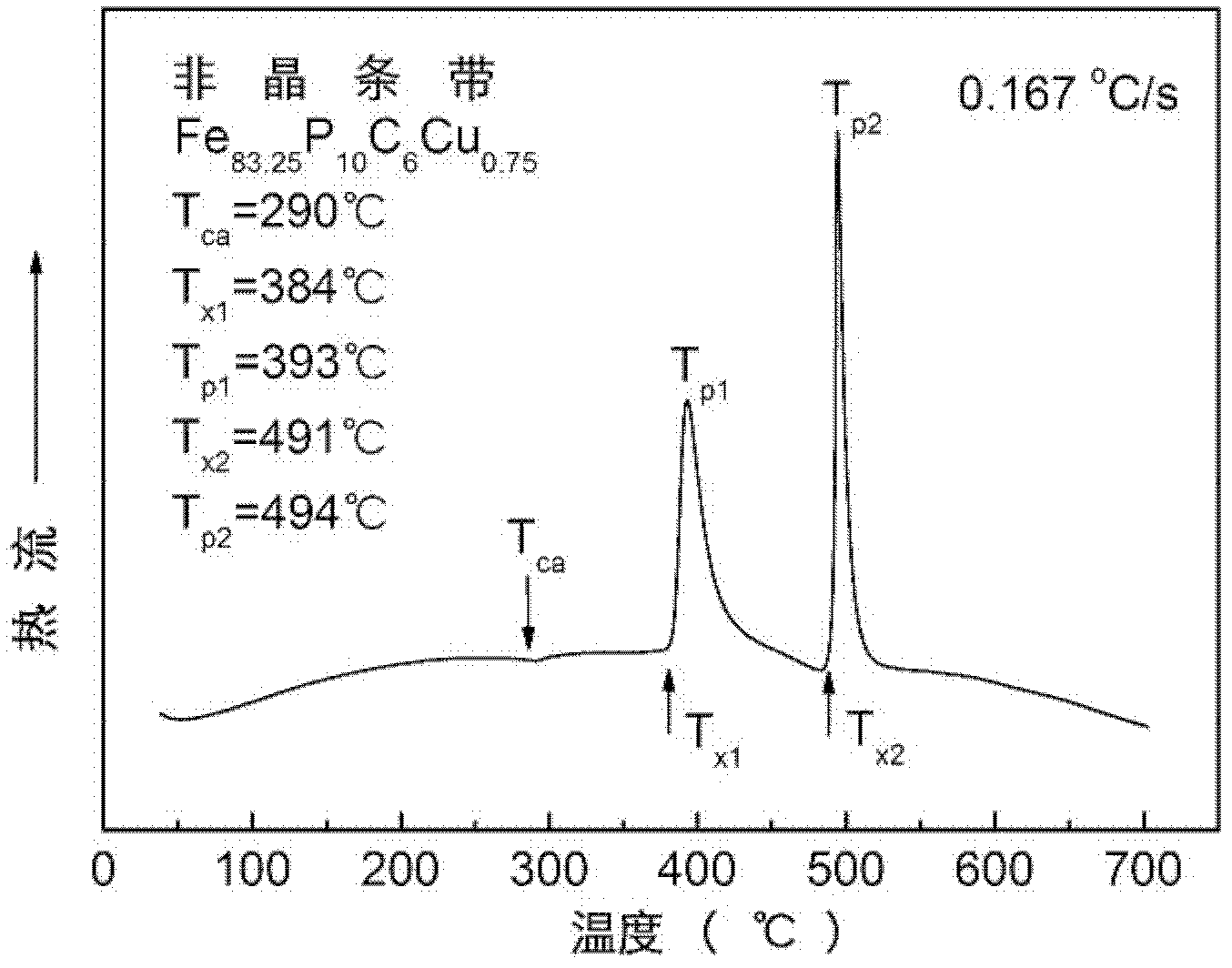

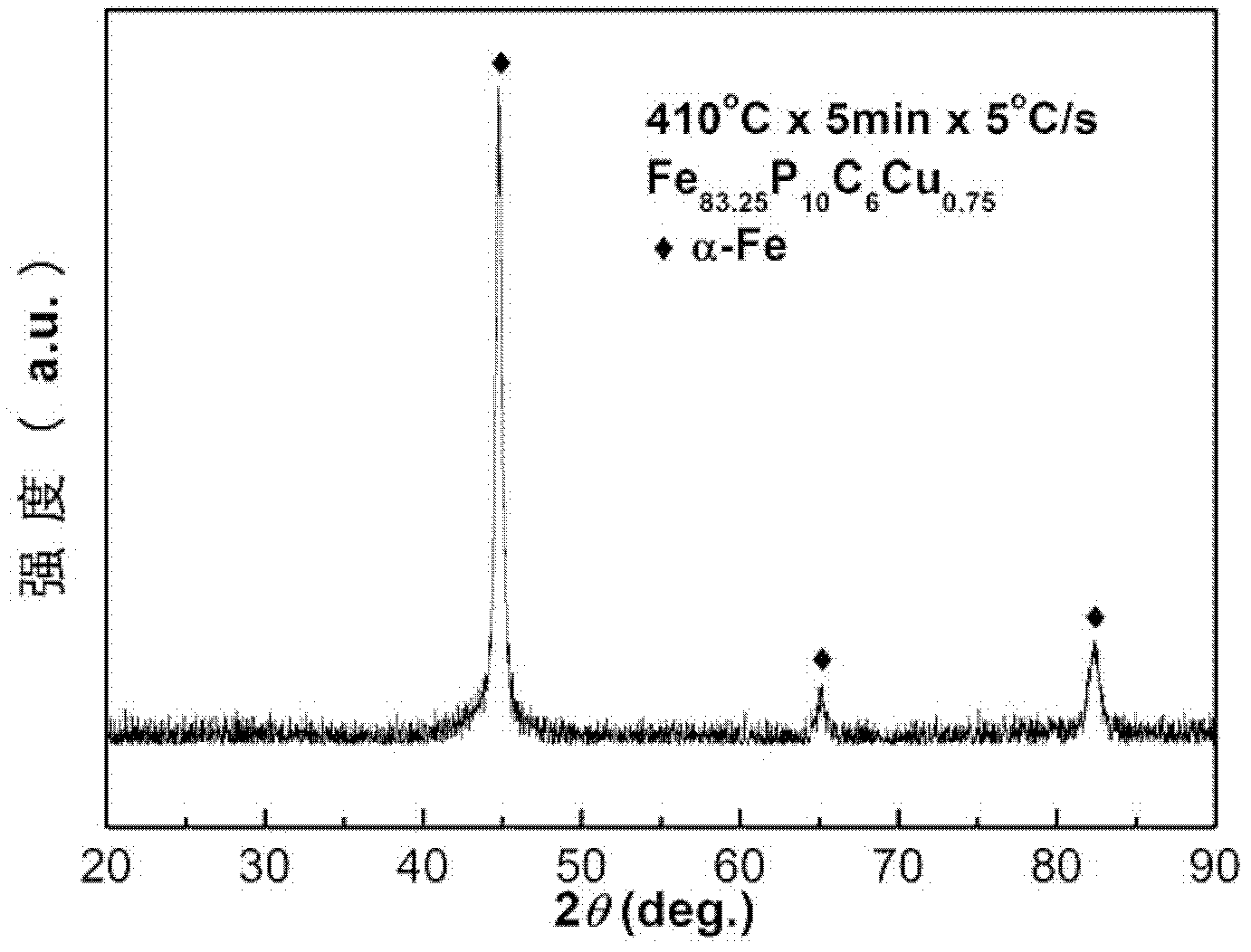

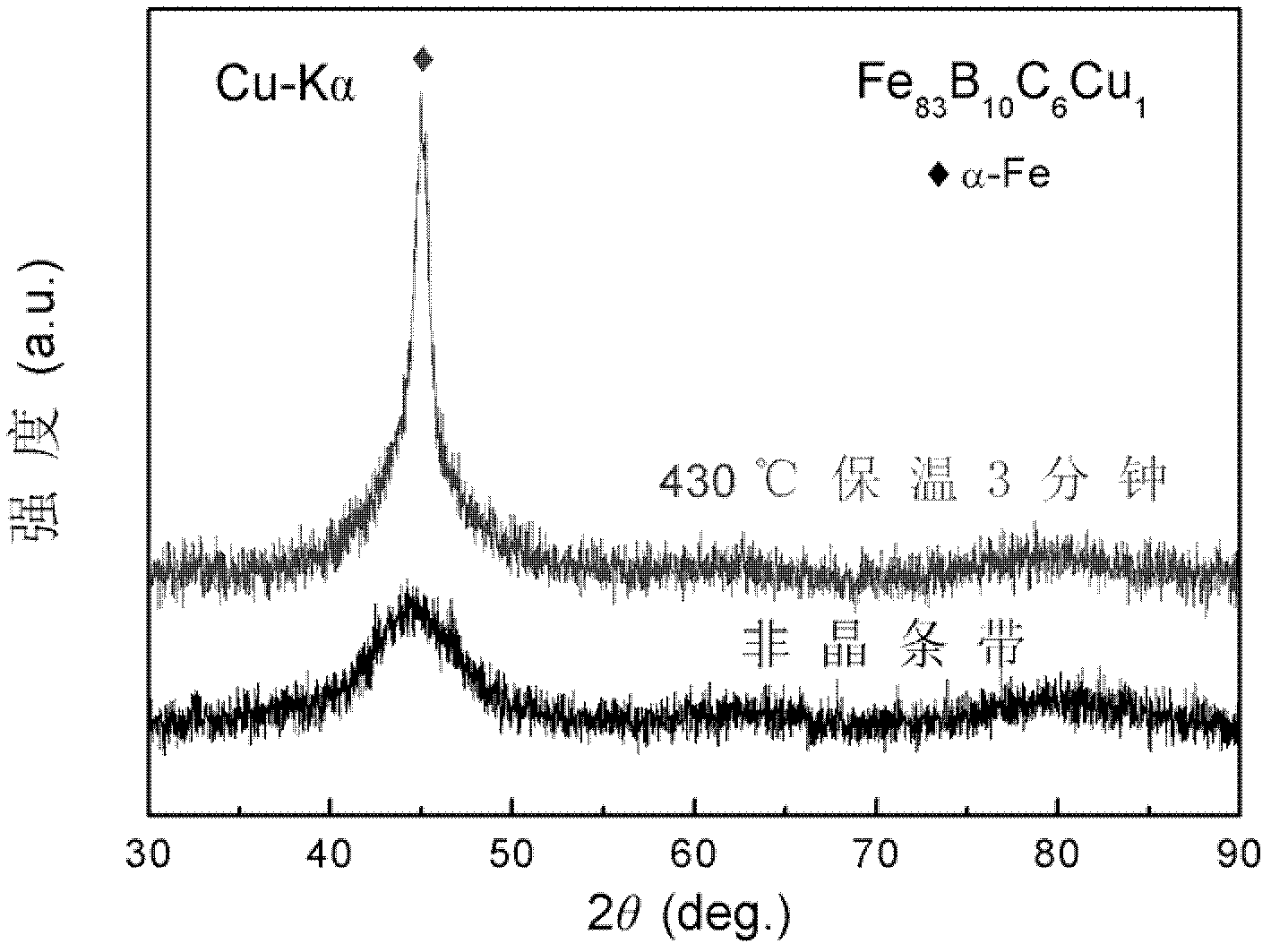

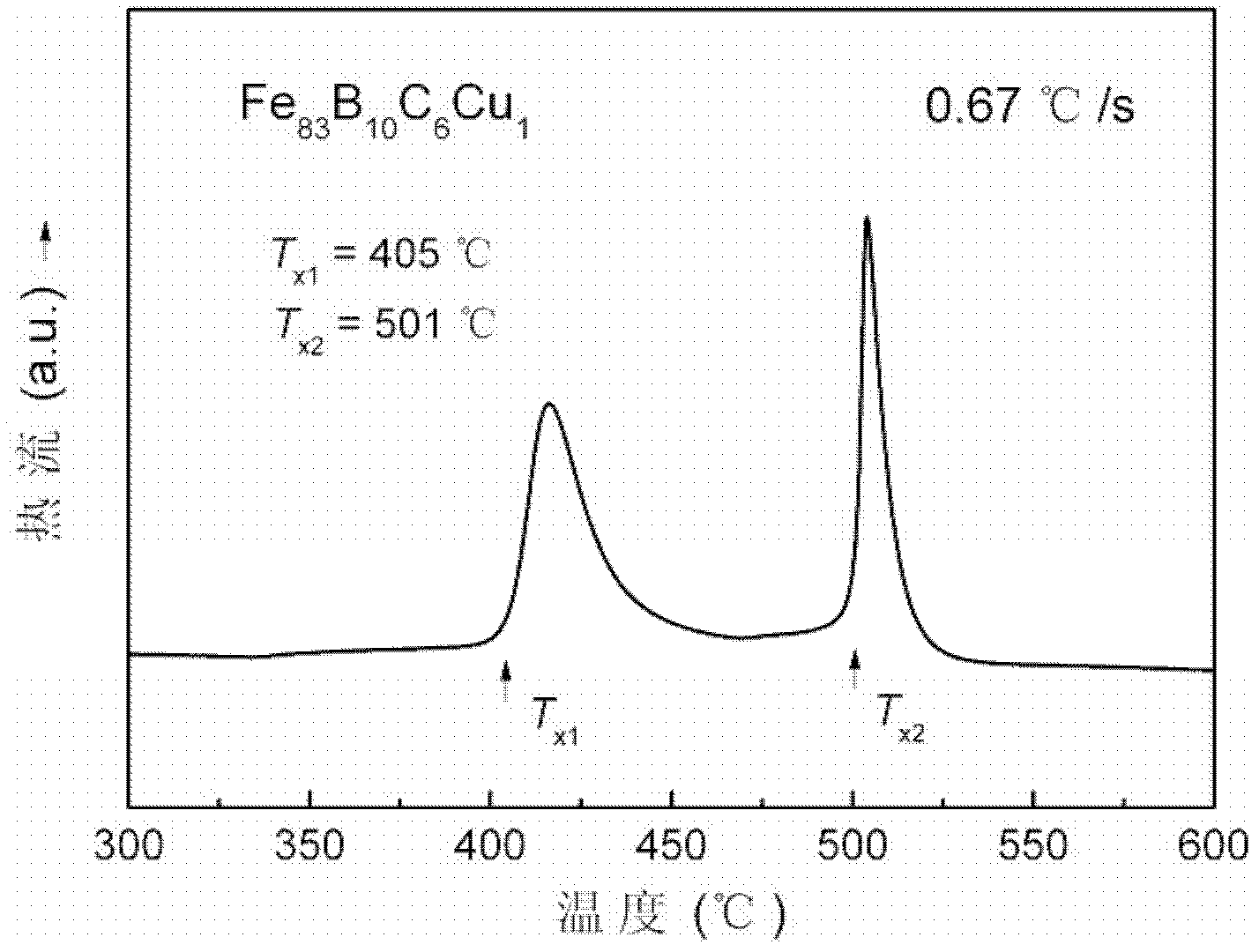

ActiveCN102304669AHigh saturation magnetic inductionLow coercivityMagnetic materialsProcessing costAmorphous matrix

The invention relates to an iron-based nanocrystalline soft magnetic alloy. The alloy is characterized in that: the alloy meets the following relation in composition: FeaBbCcMdCue, wherein M represents one or more of Si, Al, Cr and Mn, the subscripts a, b, c, d and e represent the atom percents of the corresponding elements of the alloy respectively and meet the following conditions: 78<=a<=88, 4<=b<=16, 3<=c<=10, 0<=d<=8, 0.3<=e<=1.5 and a+b+c+d+e=100. The iron-based nanocrystalline alloy consists of an amorphous matrix phase and a nanocrystalline phase. The alloy is obviously characterized in that: the alloy has excellent soft magnetic performances such as high saturation magnetic induction, low coercivity, low loss and the like; and the alloy does not contain precious metal elements and volatile elements, thereby reducing the processing cost of the raw materials and bringing convenience to popularization and application. The invention also relates to a preparation method of the alloy.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

High saturation induction density iron-based nanocrystalline magnetically soft alloy material and preparation method thereof

InactiveCN102808140AHigh saturation magnetic inductionLow costMagnetic materialsIngotThermal treatment

The invention relates to a high saturation induction density iron-based nanocrystalline magnetically soft alloy material and a preparation method thereof. According to the scheme provided by the invention, the alloy material consists of the following chemical components in percentage by atom: 72.5-76.5 percent of Fe, 9-12 percent of Si, 9-9.6 percent of B, 0.8-1.2 percent of Cu, 0.3-0.5 percent of Co, 1.5-2 percent of Mo, 0.8-1.5 percent of Cr, 1-2 percent of P, 0.002-0.06 percent of Y and other inevitable impurities. The preparation method of the alloy material comprises the following steps of: preparing the chemical components according to the percentage by atom, mixing uniformly, and smelting and casting in vacuum to obtain a master alloy ingot; remelting the master alloy ingot, and spraying into an amorphous belt material with a single roll melt-spinning method; and performing thermal treatment to obtain the high saturation induction density iron-based nanocrystalline magnetically soft alloy material. The method has the characteristics of low production cost and easiness in realizing a thermal treatment process; and the product has high saturation induction density, low coercive force and a wide application range, and is particularly suitable for the fields of transformers and mutual inductors.

Owner:WUHAN UNIV OF SCI & TECH

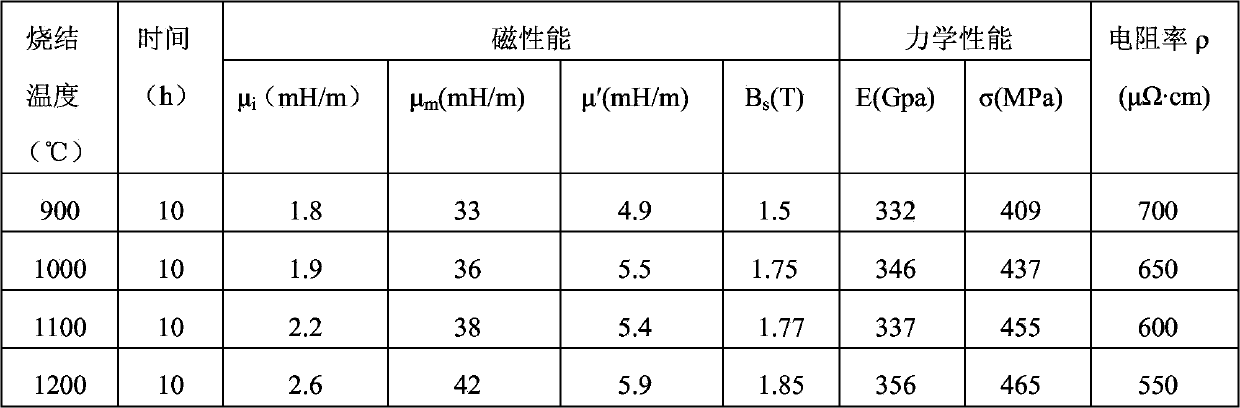

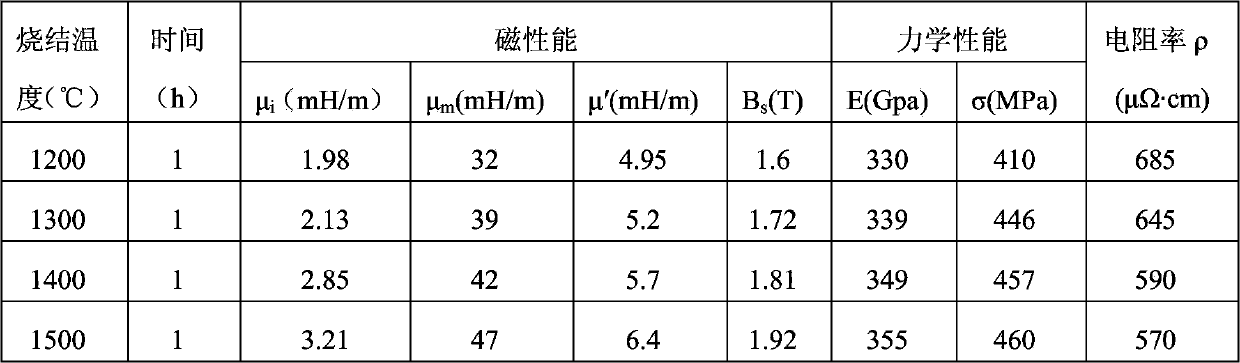

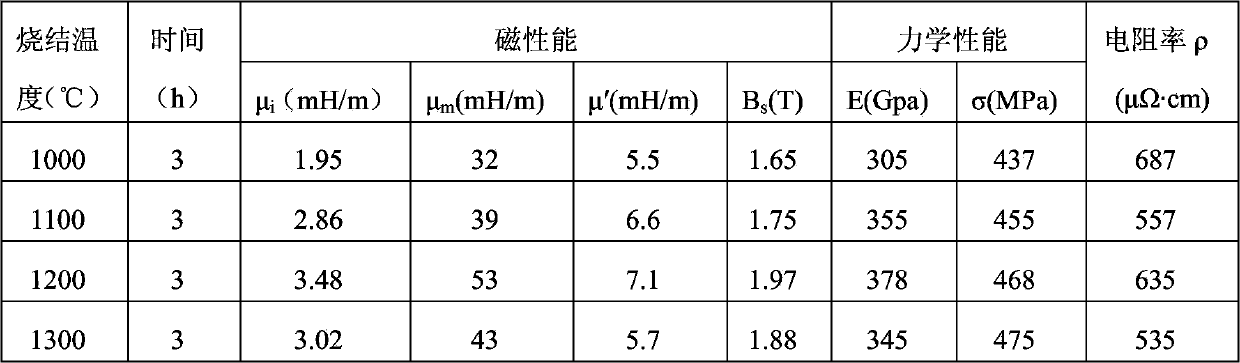

Iron-based soft magnetic composite magnetic powder core and preparation method thereof

ActiveCN104078182AThickness controllable and adjustableGuaranteed uniformityInorganic material magnetismAlcoholHeat stability

The invention relates to an iron-based soft magnetic composite magnetic powder core and a preparation method thereof. The invention adopts the technical scheme as follows: sequentially adding iron-based alloy powder, absolute ethyl alcohol, a silane coupling agent and distilled water into a reaction vessel according to the mass ratio of 1:(6-10):(0.04-0.10):(0.2-0.4), and stirring; adding tetraethyl orthosilicate or methyl silicate, then adding ammonia water, stirring continuously, washing, filtering and drying; placing the obtained composite powder with a core-shell heterostructure into an annealing furnace, performing heat preservation for 1-3 h under the condition of 600-800 DEG C, performing furnace cooling and performing compression moulding; sintering for 1-10 h under the condition of 900-1350 DEG C, so that the iron-based soft magnetic composite magnetic powder core is obtained after furnace cooling. The prepared iron-based soft magnetic composite magnetic powder core has the characteristics that the insulating property is good, the iron loss is low, high magnetic strength is achieved, the heat stability is good and the service life is prolonged when the iron-based soft magnetic composite magnetic powder core is used at a higher environment temperature.

Owner:WUHAN UNIV OF SCI & TECH

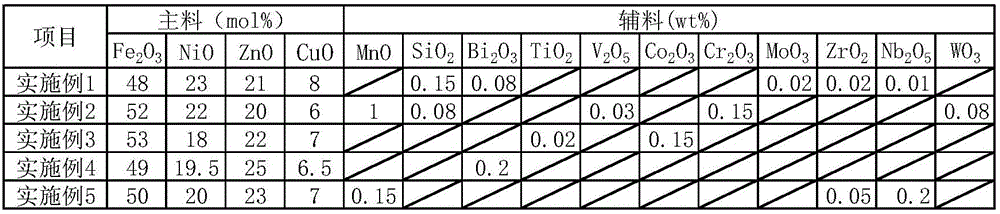

Power type nickel-zinc ferrite material and preparation method thereof

ActiveCN106587977AThe preparation method is simple and easyEasy to operateInorganic material magnetismNickel-zinc ferriteZinc

The invention discloses a power type nickel-zinc ferrite material. The power type nickel-zinc ferrite material is prepared from a main material and an auxiliary material. The main material is prepared from, by molar percentage, 48-53 mol% of Fe2O3, 18-23 mol% of NiO, 20-25 mol% of ZnO and 6-8 mol% of CuO. The auxiliary material is selected from at least one of MnO, SiO2, Bi2O3, TiO2, V2O5, Co2O3, Cr2O3, MoO3, ZrO2, Nb2O5 and WO3. The power type nickel-zinc ferrite material has high magnetic conductivity, ultrahigh saturation flux density, ultralow power loss and high high-temperature-resisting soldering tin temperature, and the application range of the nickel-zinc ferrite material can be widened. The invention further provides a preparation method of the power type nickel-zinc ferrite material. The preparation method is simple in step, high in operability and suitable for industrial production.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

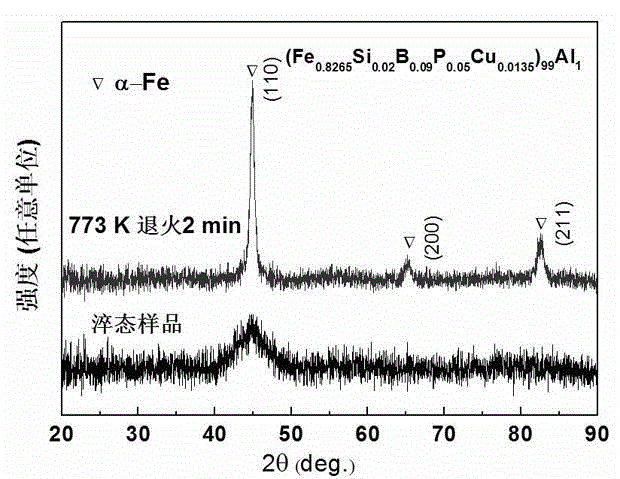

Iron-based nanocrystalline magnetically soft alloy material and preparation method thereof

The invention discloses an iron-based nanocrystalline magnetically soft alloy which is characterized in that the alloy is represented by (FeaSibBcPdCue)fMg, wherein a, b, c, d and e are the contents of corresponding atoms, and f and g are the percentage of corresponding components or atoms; 0.75<=a<=0.87, 0 <b<=0.08, 0<c<=0.14, 0<d<=0.08, 0<e<=0.02, 97<=f<100, 0<g<=3, and meets a + b + c + d + e = 1, f + g = 100, and M is selected from one of Cr, Mn, Al, Mo, Zr, Hf, Ta, W, V and Nb. Meanwhile, the invention also provides the preparation method of the iron-based nanocrystalline magnetically soft alloy. The iron-based nanocrystalline magnetically soft alloy has the beneficial effects that the iron-based nanocrystalline magnetically soft alloy material provided by the invention has high saturated magnetic induction intensity and low loss, does not contain expensive metal, and is low in cost.

Owner:苏州宝越新材料科技有限公司

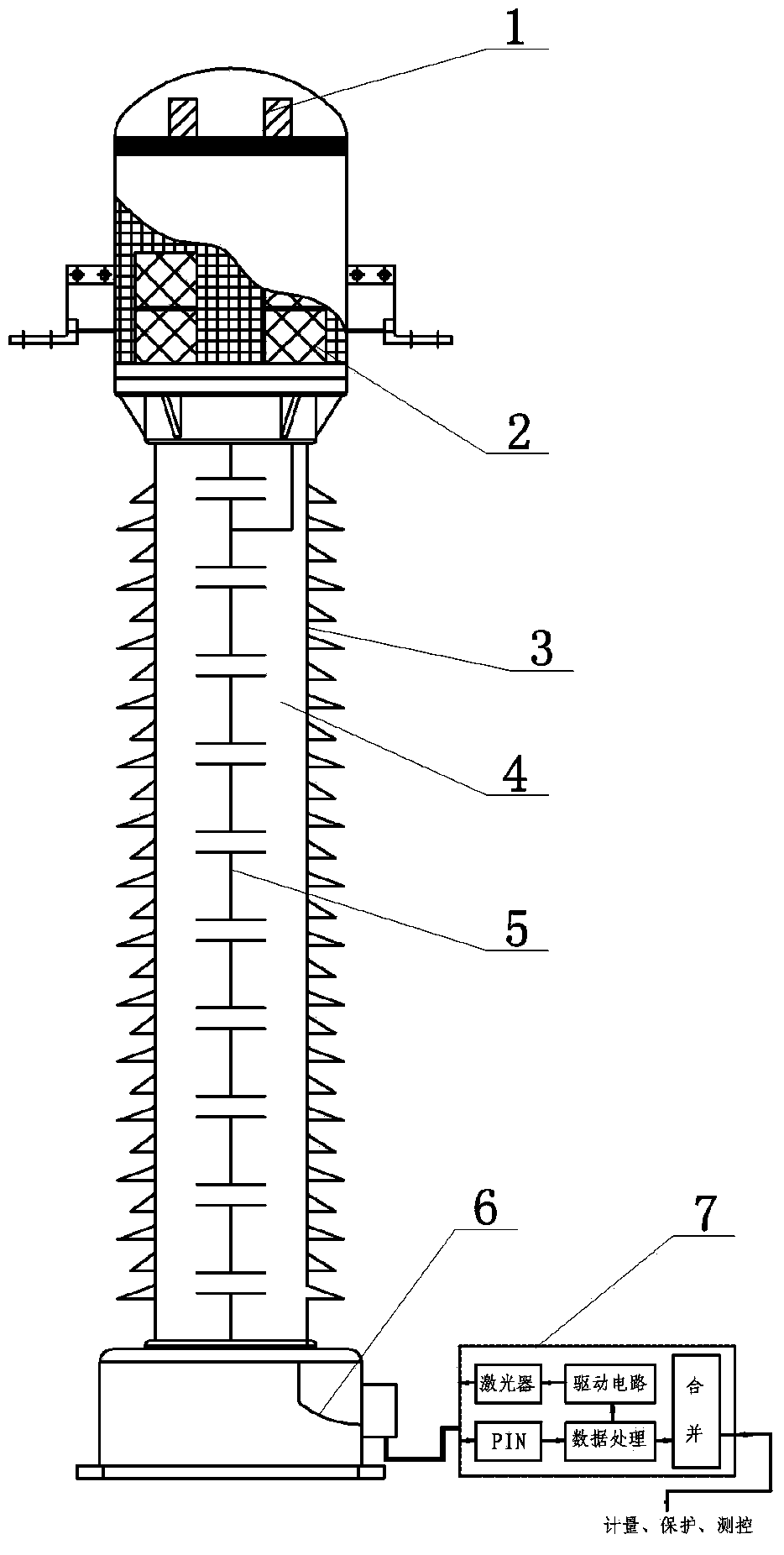

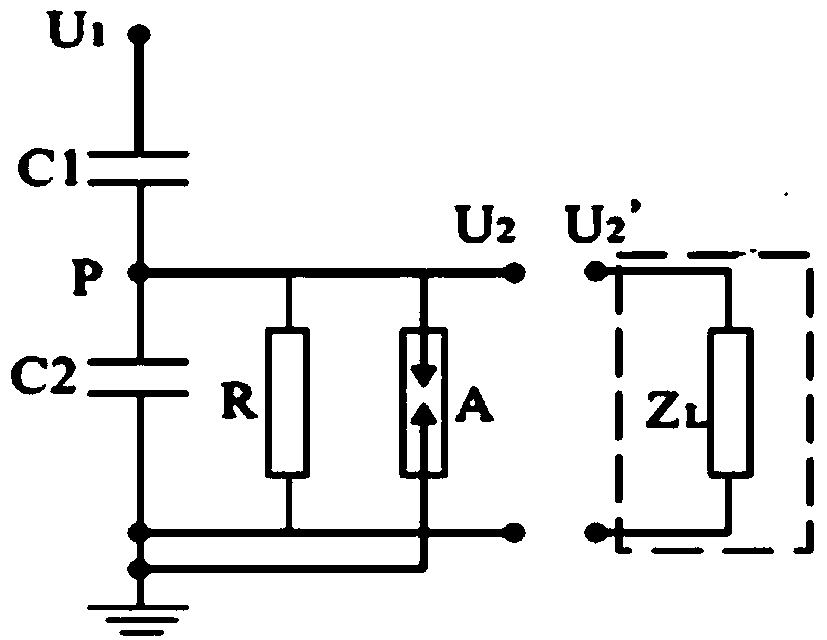

Intelligent electronic type voltage transformer

ActiveCN103558440AEasy to controlRealize the control functionCurrent/voltage measurementTransformers/inductances coils/windings/connectionsLow noiseComposite insulators

The invention discloses an intelligent electronic type voltage transformer. The intelligent electronic type voltage transformer comprises a far-end module, an amorphous iron core, an optical fiber composite insulator, an insulating oil layer, a resistance-capacitance voltage divider, an optical fiber and a combination unit. According to the intelligent electronic type voltage transformer, the iron core is made of amorphous materials, a resistance-capacitance voltage division principle is used as a design principle, and a transformer body is formed by pouring insulting silicone rubber on the amorphous iron core, a primary winding and a secondary winding. According to the intelligent electronic type voltage transformer, the iron core is made of amorphous alloy, so that the intelligent electronic type voltage transformer has high saturated magnetic induction and low loss, the weight and the size of the intelligent electronic type voltage transformer can be reduced greatly, and efficiency can be improved greatly. In addition, the intelligent electronic type voltage transformer has low noise, is easy and convenient to install and use, does not need maintaining in an operation process, is light in weight, high in accuracy, good in linearity and wide in measuring range, overcomes the defects that a conventional electromagnetic voltage transformer is narrow in frequency band, slow in response and the like, and has practical significance to transformation of and improvement to existing electrical equipment, and the ability to resist electromagnetic interference is enhanced.

Owner:JIANGSU JINGJIANG INSTR TRANSFORMER FACTORY

Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon and preparation method thereof

InactiveCN105261435AHigh saturation magnetic inductionGood soft magneticInductances/transformers/magnets manufactureMagnetic materialsTransformerThermal stability

The invention provides a Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon. Components of the Fe-based amorphous and nanocrystalline soft magnetic ribbon are as shown in FeSiB<c>P<d>Cu<e>Me<f>, wherein a, b, c, d, e and f respectively represent the content of Fe, Si, B, P, Cu and Me in the alloy ribbon on the basis of mass fractions of atoms; a is less than or equal to 90 and greater than or equal to 80; b is less than or equal to 5 and greater than or equal to 0.5; c is less than or equal to 12 and greater than or equal to 5; d is less than or equal to 9 and greater than or equal to 1; e is less than or equal to 2 and greater than or equal to 0.3; f is less than or equal to 3 and greater than or equal to 0.3; and a+b+c+d+e+f=100. According to the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon, by addition of microelements, the Fe-based amorphous and nanocrystalline soft magnetic alloy ribbon with high saturation flux density can be obtained without a heat treatment; and the alloy ribbon can be prepared in high vacuum or argon protection, has excellent soft magnetic property and high heat stability and is suitable for a transformer, an engine, a motor, a generator, a magnetic sensor and the like.

Owner:WANGWEI NEW MATERIALS (PIZHOU) CO LTD

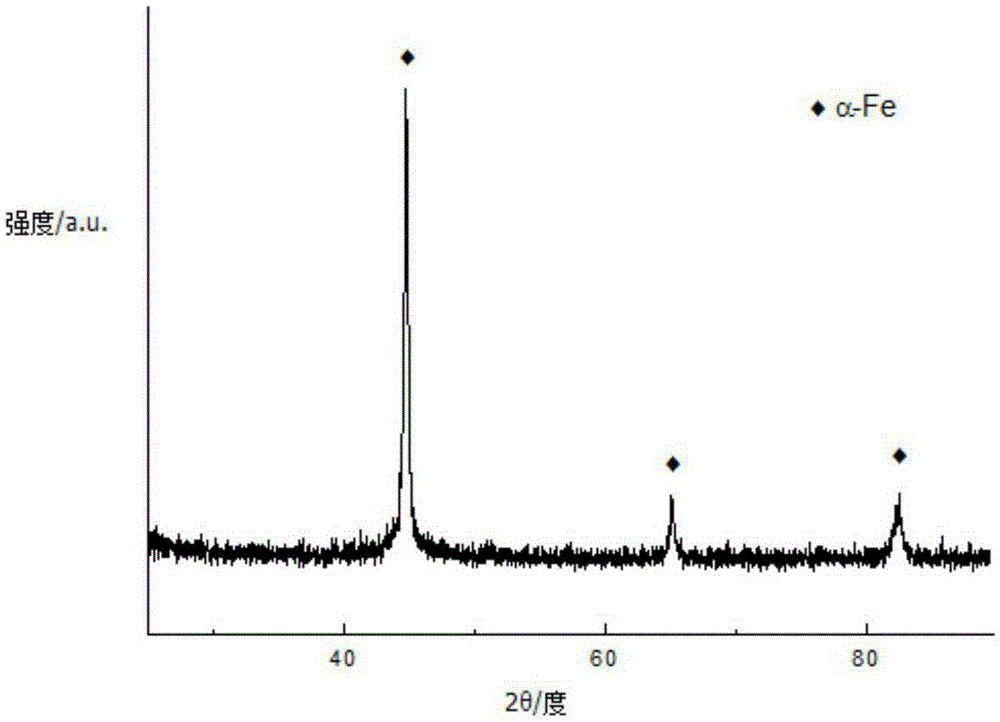

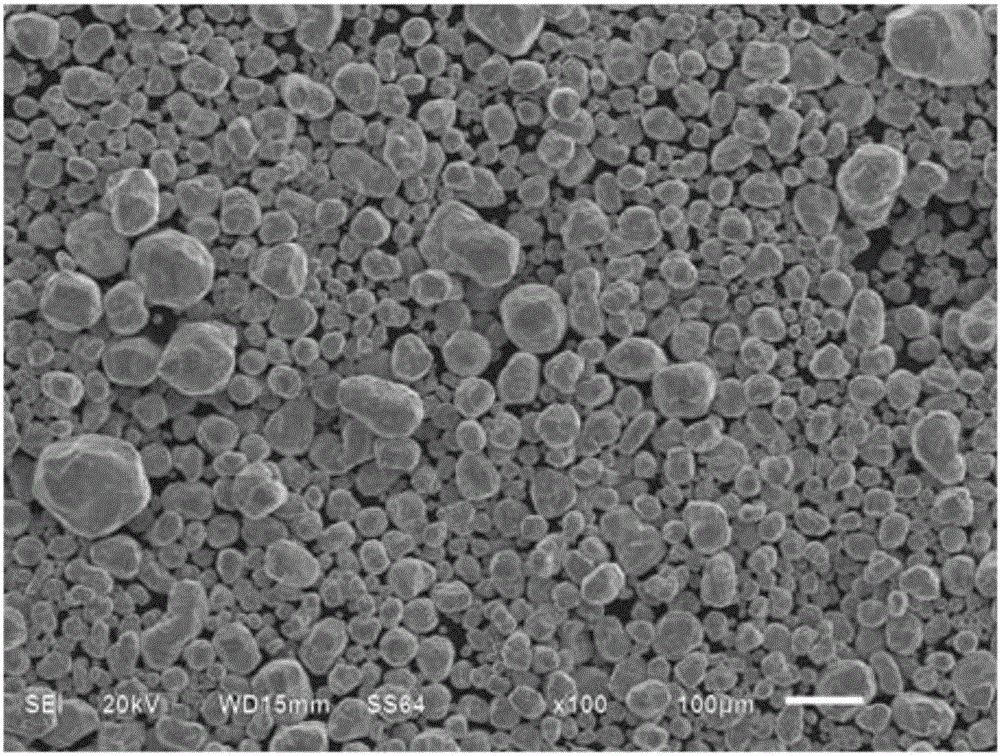

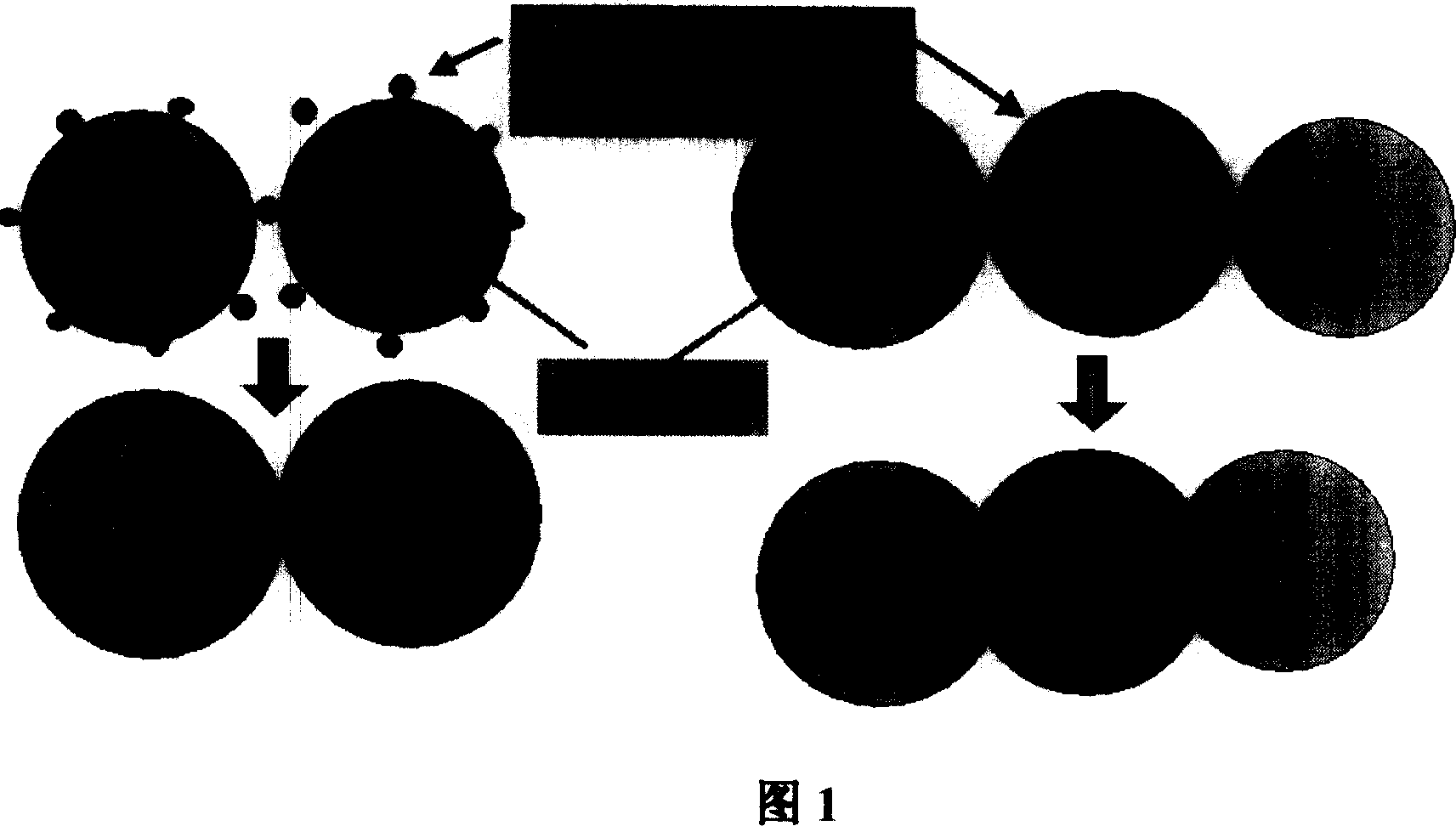

Preparing method for ball-like metal magnetically soft alloy powder

ActiveCN105710378ALow impurity contentGood formability and magnetic propertiesTransportation and packagingMetal-working apparatusForming processesSingle crystal

The invention relates to a preparing method for ball-like metal magnetically soft alloy powder, and belongs to the technical field of powder preparing. The method comprises the steps that raw materials of a metal magnetically soft alloy are weighed and mixed according to the weight ratio, intermediate-frequency induction smelting is adopted, and the molten alloy is prepared into an alloy casting strip through a thin-strip continuous casting technology; the alloy casting strip is placed into a crushing device, and the alloy casting strip is crushed into particle powder under the inert gas shielding condition; the crushed powder is placed into a shaping treatment device to be shaped, ball-like powder with the regular shape is obtained, the powder is subjected to annealing heat treatment, and fine powder is prepared through screening and collecting. According to the method, the uniformity of alloy powder components can be obviously improved, meanwhile, the powder wrapping insulating and pressing forming are facilitated through the prepared ball-like single-crystal particle powder, the uniformity degree of a soft magnetism powder core pressing insulating layer and the mechanical strength obtained after pressing forming can be obviously improved, the probability of damage of the insulating layer in the powder pressing forming process is greatly reduced, and accordingly the application field of the soft magnetism powder core is greatly enlarged.

Owner:有研增材技术有限公司

Rare-earth-doped iron-based amorphous thick strip and preparing method thereof

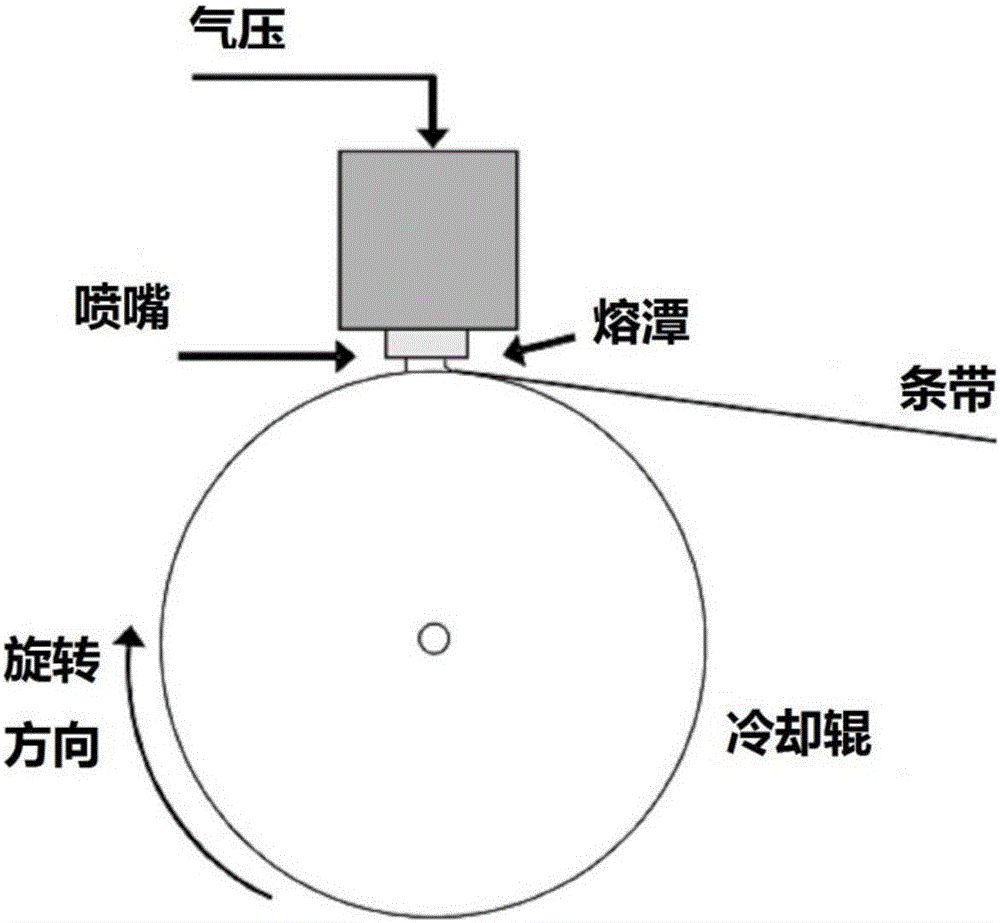

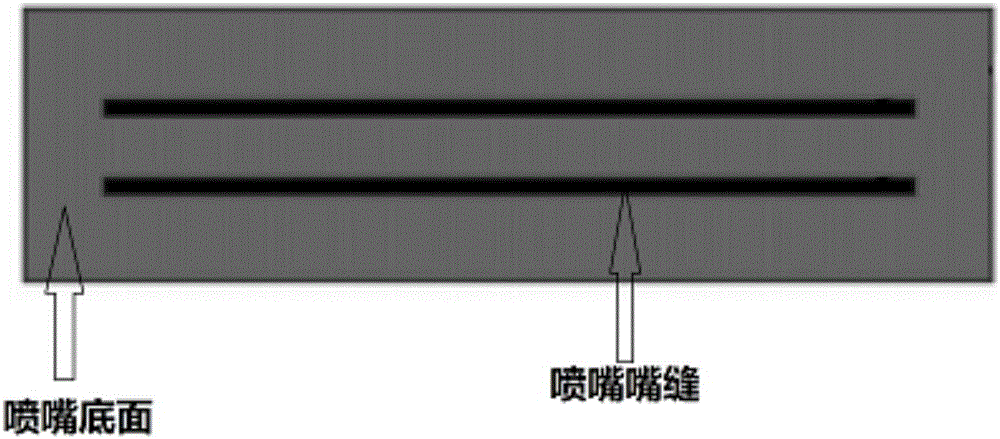

The invention relates to a rare-earth-doped iron-based amorphous thick strip and a preparing method thereof. The component expression of the iron-based amorphous thick strip is FexSiaBbPcYd, wherein x, a, b, c and d are atomic percents of corresponding elements, wherein a is larger than or equal to 0.5 and smaller than or equal to 10, b is larger than or equal to 0.5 and smaller than or equal to 12, c is larger than or equal to 0.5 and smaller than or equal to 8, d is larger than or equal to 0.001 and smaller than or equal to 0.5, and x+a+b+c+d is equal to 100. A plane flow casting method is adopted for manufacturing the strip, during strip manufacturing, a double-line nozzle is adopted, the thickness of the prepared amorphous thick strip ranges from 50 micrometers to 100 micrometers, the lamination coefficient is larger than 0.92, the saturated magnetic induction density is larger than 1.67T. Micro rare earth yttrium is contained in an alloy, the content of impurities of oxygen, sulphur and the like is greatly reduced, and the molten steel mobility is improved; meanwhile the rare earth yttrium improves the amorphous forming capacity of an alloy system, and the amorphous alloy strip with the thickness ranging from 50 micrometers to 100 micrometers can be prepared through the technology method.

Owner:南京腾元软磁有限公司 +3

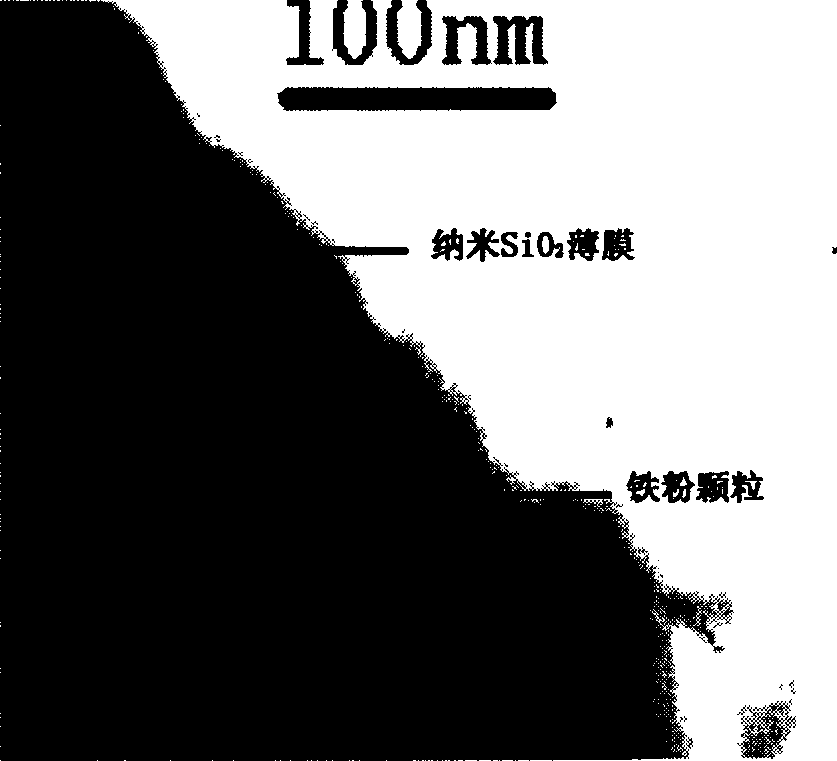

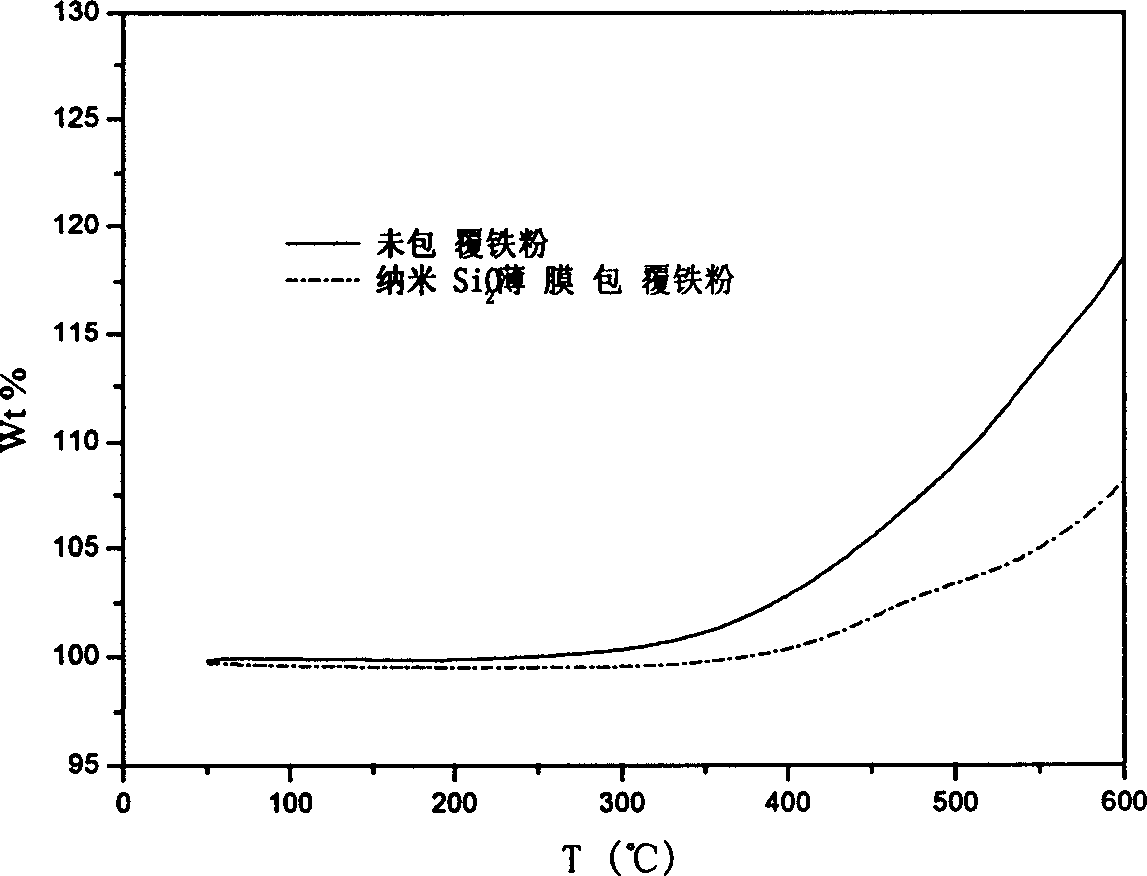

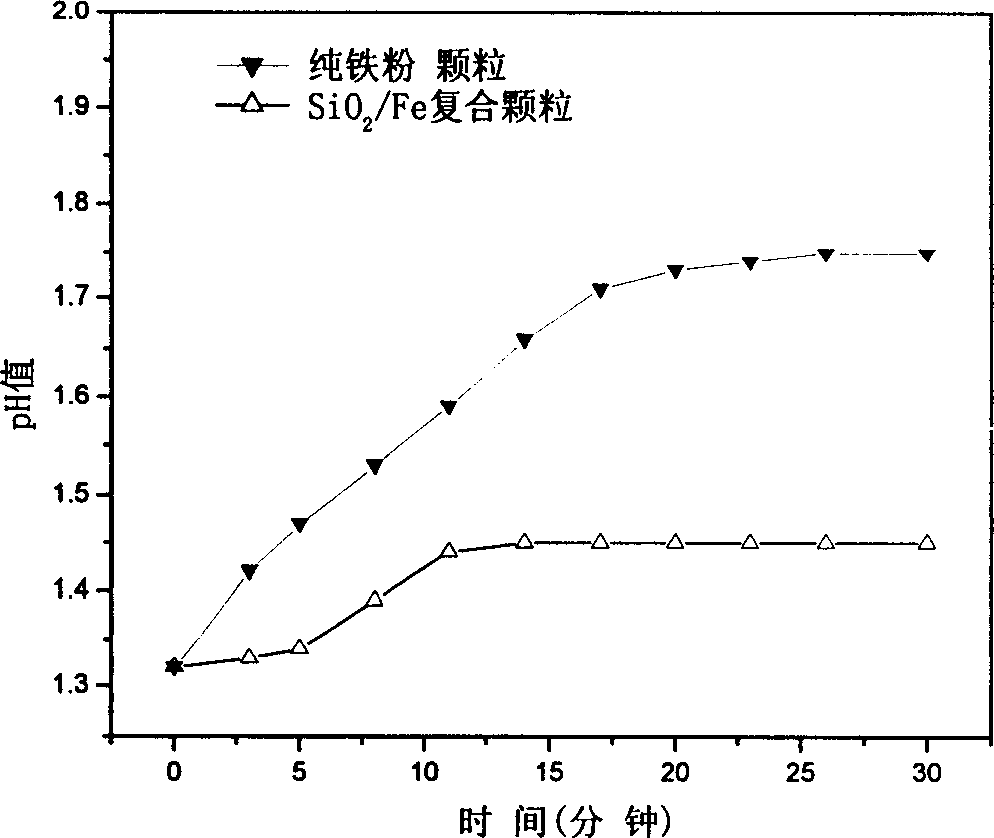

Magnetic particle with high antioxidant for magnetic flow liquid and preparation method thereof

InactiveCN1725388AImprove antioxidant capacityGood acid corrosion resistanceMagnetic liquidsAntioxidantAcid corrosion

This invention relates to iron-base soft magnetic particles with high non-oxidation used in magnetic rheological liquid and its preparation method, which utilizes TEOS hydrolytic condensation reaction to cover a layer of SiO2 film on the magnetic particle surface to prepare magnetic composite particles, which have good non-oxidation performance, acid corrosion resistance and rather high magnetic strength.

Owner:TONGJI UNIV

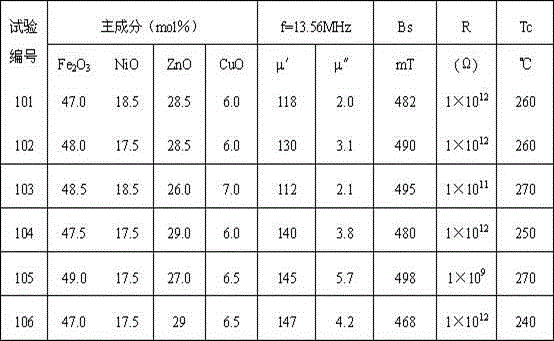

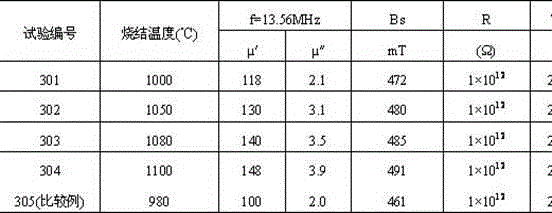

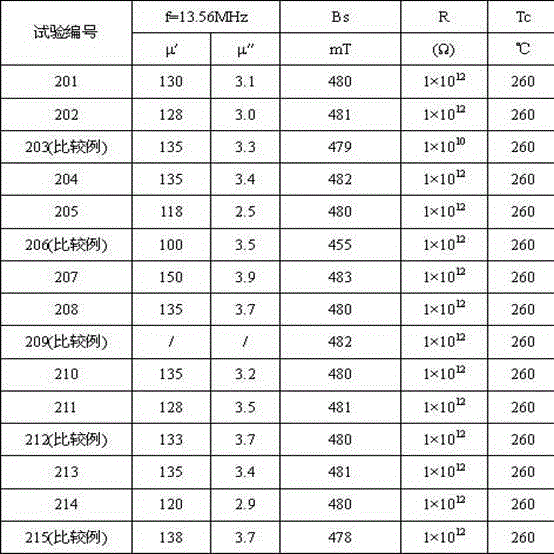

Soft-magnetic nickel-copper-zinc ferrite material and preparation method thereof

The invention belongs to the field of soft-magnetic ferrite materials. The objective of the invention is to provide a soft-magnetic nickel-copper-zinc ferrite material and a preparation method thereof. The material provided by the invention comprises major components and minor components. The major components comprise the following raw materials in mole percentage: 47.0-49.0mol% of Fe2O3, 17.5-18.5mol% of NiO, 26.0-29mol% of ZnO and 6.0-7.0mol% of CuO. The minor components comprise, based on the total weight of the major components, 0.1-0.40% of MnO, 0.1-0.5% of Bi2O3 and 0.3-0.5% of Co2O3. Under a high frequency of 13.56 MHz, the material provided by the invention has the characteristics of high magnetic conductivity ([mu]' is approximately equal to 130), low complex magnetic permeability [mu]''(namely low loss), high resistivity, high Curie temperature, high saturation magnetic induction density Bs, and the like.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Composite soft magnetic material and method for preparing material

ActiveCN103632794AHigh saturation magnetic inductionImprove permeabilityInorganic material magnetismLiquid/solution decomposition chemical coatingFerrite powderMetal

The invention discloses a composite soft magnetic material and a method for preparing the material. The composite soft magnetic material is composed of soft magnetic ferrite powder and a soft magnetic alloy film, wherein the particle size of the soft magnetic ferrite powder ranges from 10 microns to 120 microns, the soft magnetic alloy film wraps the surface of the soft magnetic ferrite particles, and the thickness of the soft magnetic alloy film ranges from 0.01 micron to 10 microns. According to the composite material, due to the fact that the metal soft magnetic film wraps the surface of the soft magnetic ferrite powder particles, the obtained composite soft magnetic particles are sintered to obtain the composite soft magnetic material. The material not only has high saturation induction intensity, but also has high magnetic permeability. The material has the features of both soft magnetic ferrite and metal soft magnetic material, and meanwhile the material has good mechanical performance and is mainly applied to the medium-high frequency field.

Owner:GRIREM ADVANCED MATERIALS CO LTD

Iron base amorphous alloy and preparation method thereof

InactiveCN106702291AHigh saturation magnetic inductionGood Amorphous Formation AbilityTransformerVolumetric Mass Density

The invention provides an iron base amorphous alloy expressed in a formula (I), wherein a, b, c, d and e respectively represent the atomic percentage contents of corresponding components: a is not bigger than 84.0 and not smaller than 80.5, b is not bigger than 9.0 and not smaller than 3.0, c is not bigger than 15.0 and not smaller than 8.0, d is not bigger than 0.3 and not smaller than 0.001, e is not bigger than 0.4, and the sum of a, b, c, d and e is 100; and M is an impurity element. In the iron base amorphous alloy provided by the invention, the saturation induction density of an alloy material is not lower than 1.62 T. The invention further provides a preparation method of the iron base amorphous alloy; further, the excellent soft magnetic properties can be obtained after proper heat treatment; the alloy material can be used for manufacturing iron core materials of power transformers, generators and engines; and FeaSibBcPdMe (I).

Owner:QINGDAO YUNLU ADVANCED MATERIALS TECH CO LTD

Application of nano material in ferrite

The present invention relates to the application of nano-material in ferrite. The nano-material is an ideal crystal micro-structure 'control agent', and can be partly dissolved on a grain boundary in a solid way; thus the nano-material can effectively reduce the sintering temperature, prevent the excessive growth of ferrite, maintain the ferrite of single domain, and improve the function of density of sintered ferrite at the same time so as to improve the magnetic properties. Besides, the nano-material is a good ''replacement agent of ion''.In the solid-phase reaction, some elements enter the crystallite structure to perfect the crystal structure, so as to further improve saturated magnetic field strength of ferrite and improve the anisotropic constant and other functions of magnetic crystal.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

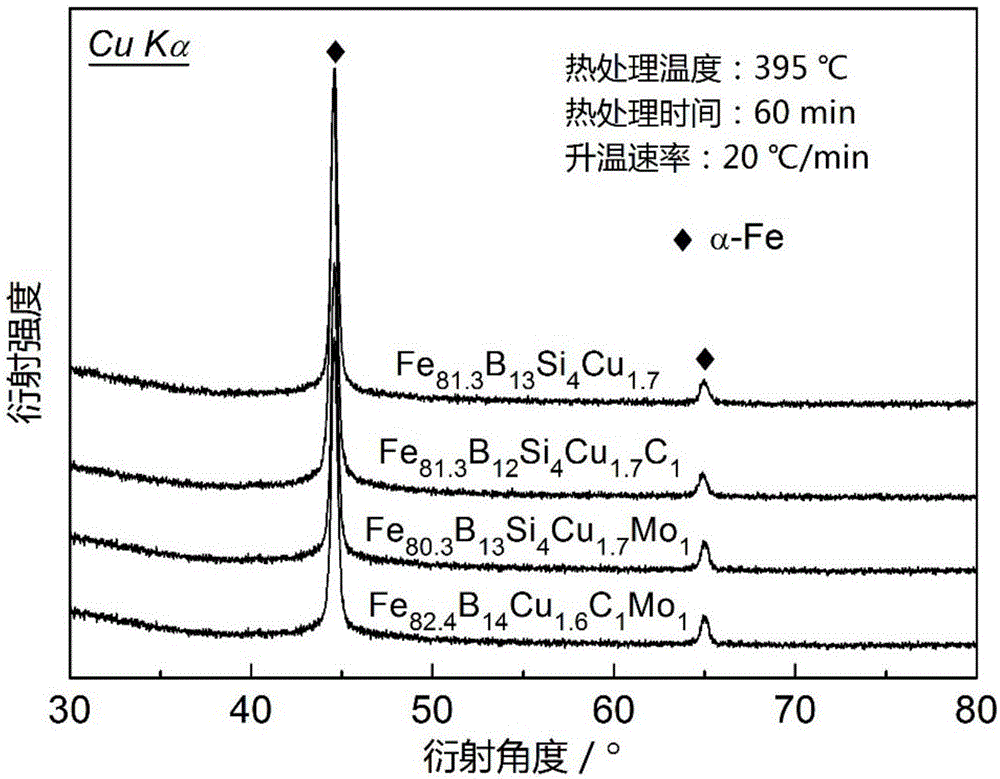

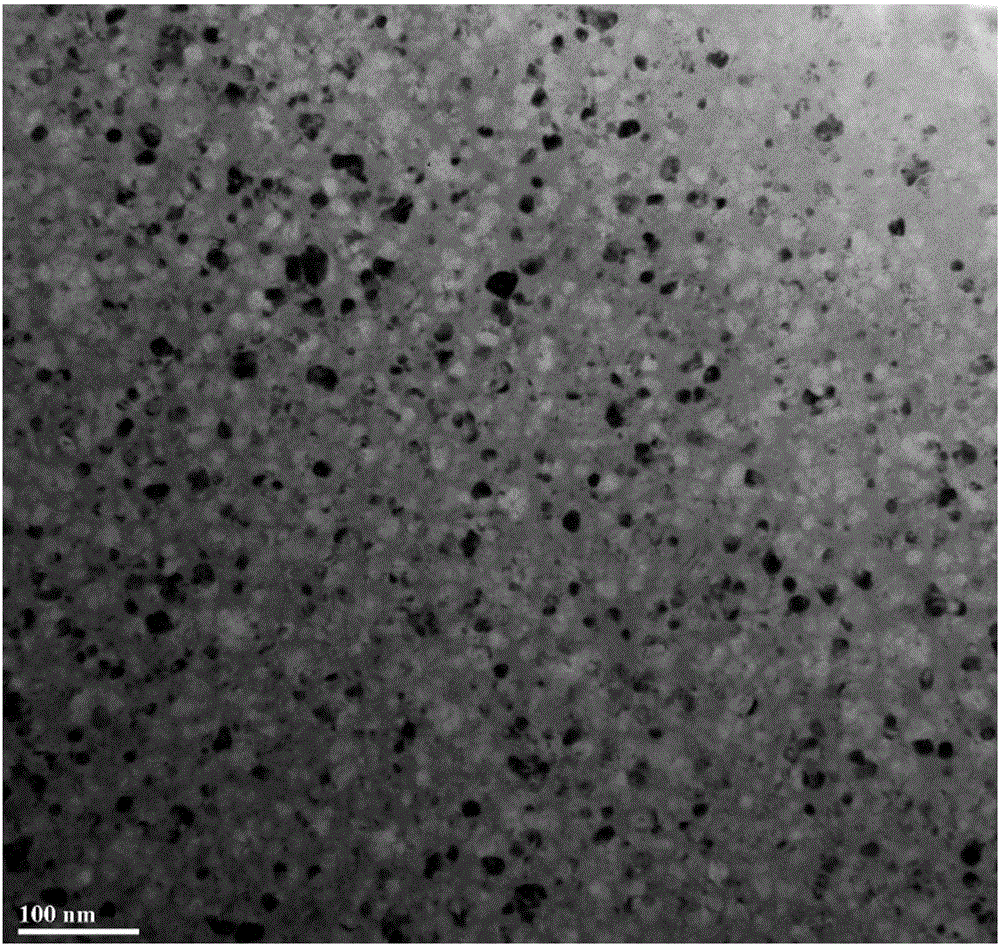

Nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and preparation method therefor

InactiveCN106373690AGood workmanshipHigh saturation magnetic inductionMagnetic materialsThermal insulationAlloy

The invention discloses a nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and a preparation method therefor, and belongs to the technical field of a new material. The chemical formula of the nanocrystal magnetically soft alloy is FeBSi<c>Cu<d>C<e>M<f>Z<g>, wherein M is at least one kind of elements Co or Ni; Z is at least one kind of elements Al, Cr, Mn, Ti, Nb, Ta or Mo; a, b, c, d, e, f and g are atomic percentage contents of corresponding elements, and satisfy the formula as follows: a+f is greater than or equal to 80 and less than or equal to 84; b is greater than or equal to 10 and less than or equal to 15; c is greater than or equal to 0 and less than or equal to 6; d is greater than or equal to 1.6 and less than or equal to 2.2; e is greater than or equal to 0 and less than or equal to 2; f is greater than or equal to 0 and less than or equal to 5; and g is greater than or equal to 0 and less than or equal to 2. The alloy is formed by uniformly dispersing an <alpha>-Fe phase, which is obtained by heat treatment of amorphous stripes and has the crystal grain sizes of less than 50nm, into residual amorphous phase tissues, wherein the saturation magnetic induction strength is greater than 1.7T, and the coercivity is less than 15A / m. The alloy has no volatile phosphorus element; in addition, the heat treatment process is simple, and high temperature-rise rate is not required; the heat treatment temperature range and the thermal insulation time range are wide; industrial production can be realized easily; and the nanocrystal magnetically soft alloy and the preparation method therefor are convenient to popularize and use.

Owner:DALIAN UNIV OF TECH

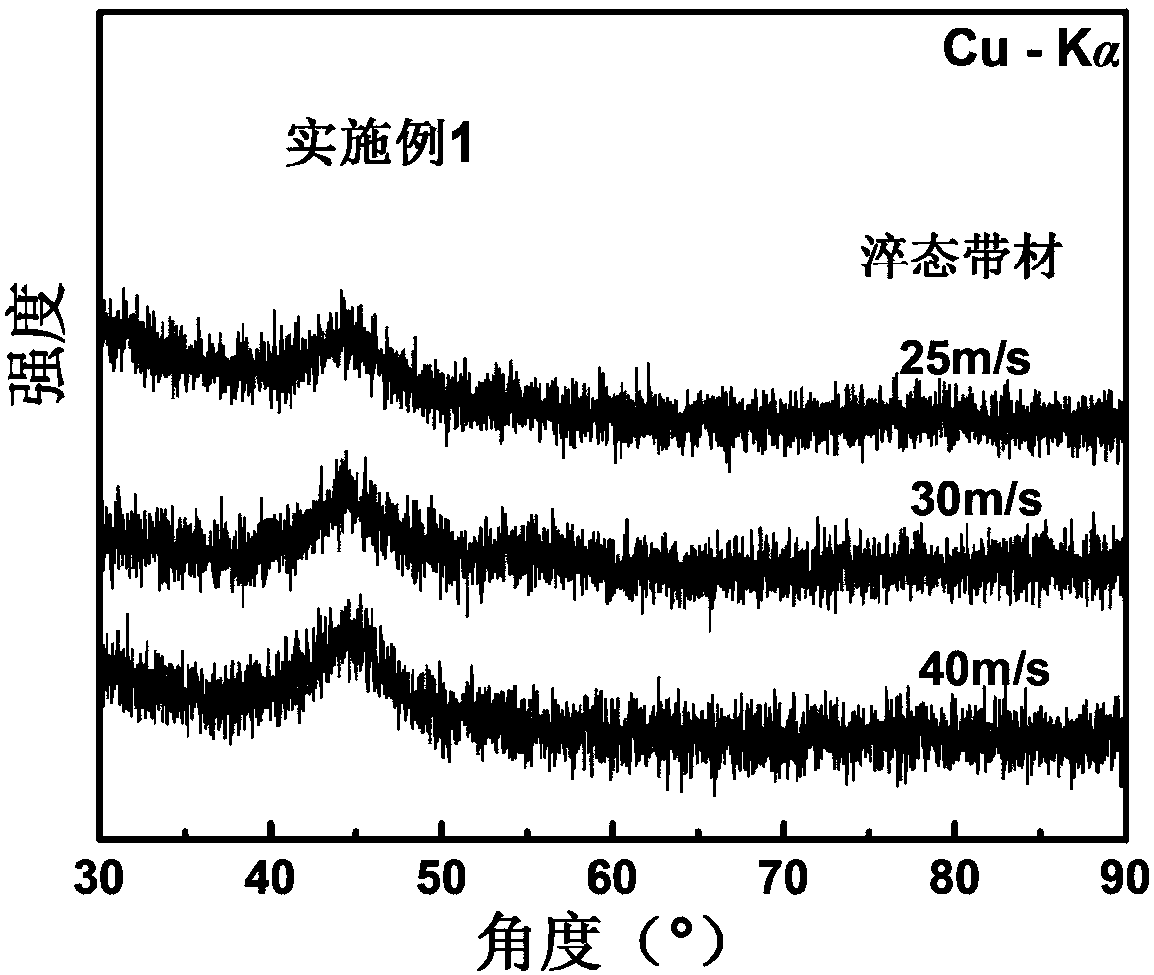

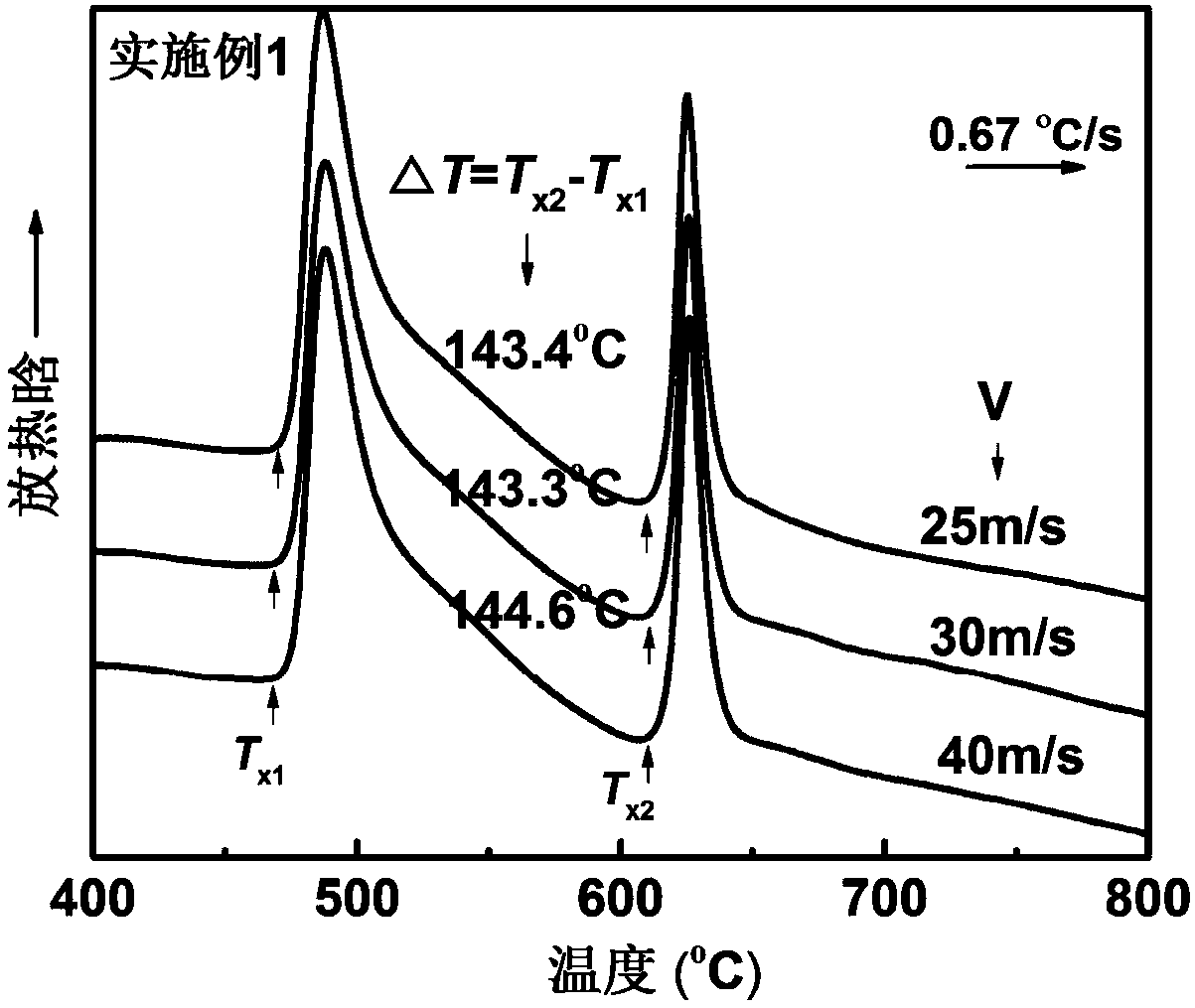

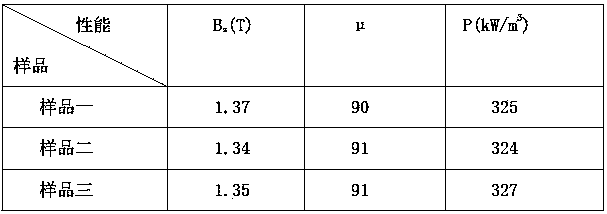

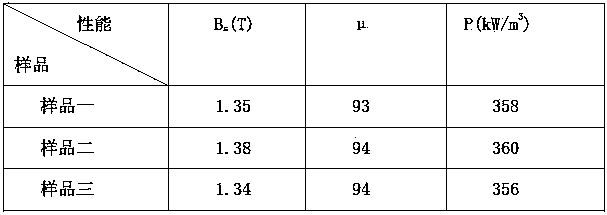

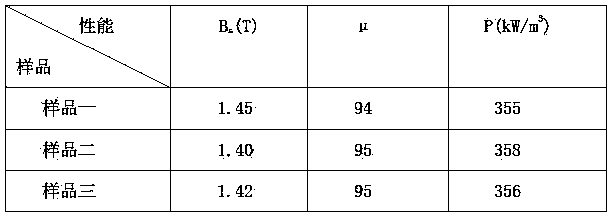

High-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and preparation method thereof

ActiveCN110387500AExcellent soft magnetic propertiesImprove thermal stabilityMagnetic materialsTransformerThermal stability

The invention discloses a high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and a preparation method thereof. The molecular formula of the iron-based nanocrystalline soft magnetic alloy is FeaSibBcPdNbeVfMogCuh, the a, the b, the c, the d, the e, the f, the g and the h in the molecular formula correspondingly represent the atomic percentage contents of all thecorresponding alloy elements, and satisfy the following conditions that the a is greater than or equal to 75.5 and less than or equal to 77.5, the b is greater than or equal to 8.5 and less than or equal to 13.5, the c is greater than or equal to 7 and less than or equal to 10, the d is greater than or equal to 0.2 and less than or equal to 1, the e is greater than or equal to 1.0 and less than orequal to 1.7, the f is greater than or equal to 0.05 and less than or equal to 0.4, the g is greater than or equal to 0.1 and less than or equal to 1.5, the h is greater than or equal to 0.8 and lessthan or equal to 1.2, and the sum of the a, the b, the c, the d, the e, the f, the g and the h is 100. The high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy material has the advantages of excellent comprehensive soft magnetic performance, low cost, high thermal stability and the like, particularly, the high-frequency performance is good, the magnetic conductivity under the condition of 10 kHz can reach 28000 or above, a good application prospect is achieved, and the high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy material can be applied to the technical fields of high-frequency transformers, common mode chokes, wireless charging and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

High saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and manufacturing method thereof

InactiveCN104036904AHigh saturation magnetic inductionImprove self-fluxingMagnetic materialsCompression moldingElectron

The invention discloses a high saturation magnetic induction intensity iron-based amorphous soft magnetic composite material and a manufacturing method of the composite material. The atomic ratio expression of the alloy composition forming the amorphous soft magnetic composite material is Fe100-a-b-c-dREaMbPcSd, wherein 0<a<=8, 10<=b<=25, 0<c<=10, 0<d<=0.5, RE is one or a mixture selected from Y, La, Eu, Gd, Dy, Ho, Er, Tm, Yb and Lu, and M is one or a mixture selected from C, Si and B. The manufacturing method of the iron-based amorphous soft magnetic composite material includes the technical steps of alloy smelting, atomizing and pulverizing, insulating cladding, compression molding and heat treating. The iron-based amorphous soft magnetic composite material prepared through the method is high in saturation magnetic induction intensity and can be applied to electronic devices high in power and frequency.

Owner:ZHEJIANG UNIV

Preparation for block amorphous nanometer crystal double-phase composite soft magnetic alloy

InactiveCN1614070AHigh saturation magnetic inductionSimple preparation processMagnetic materialsMagnetic coreVoltage

The invention was involved in the preparation method of block amorphous nanocrystalline two-phase composite magnetically soft alloy. The soft magnetic alloy was Fe-Zr-Nb alloy. Firstly, mother alloy was melt in the vacuum medium-frequency induction furnace. Secondly, single-roll quench flailing machine was used to produce amorphous ribbon and the non-metal powder was finished by ball milling under low temperature. Thirdly, during the temperature range of the over-cooling zone, product was finished by high-pressure rapid-sintering process. The characteristics of the invention include simple technology, low cost and easy to realize modernization. All the products with high saturation magnetic induction intensity were used in electric engine magnetic core, load distribution voltage changer and electric source of large power switch.

Owner:TONGJI UNIV

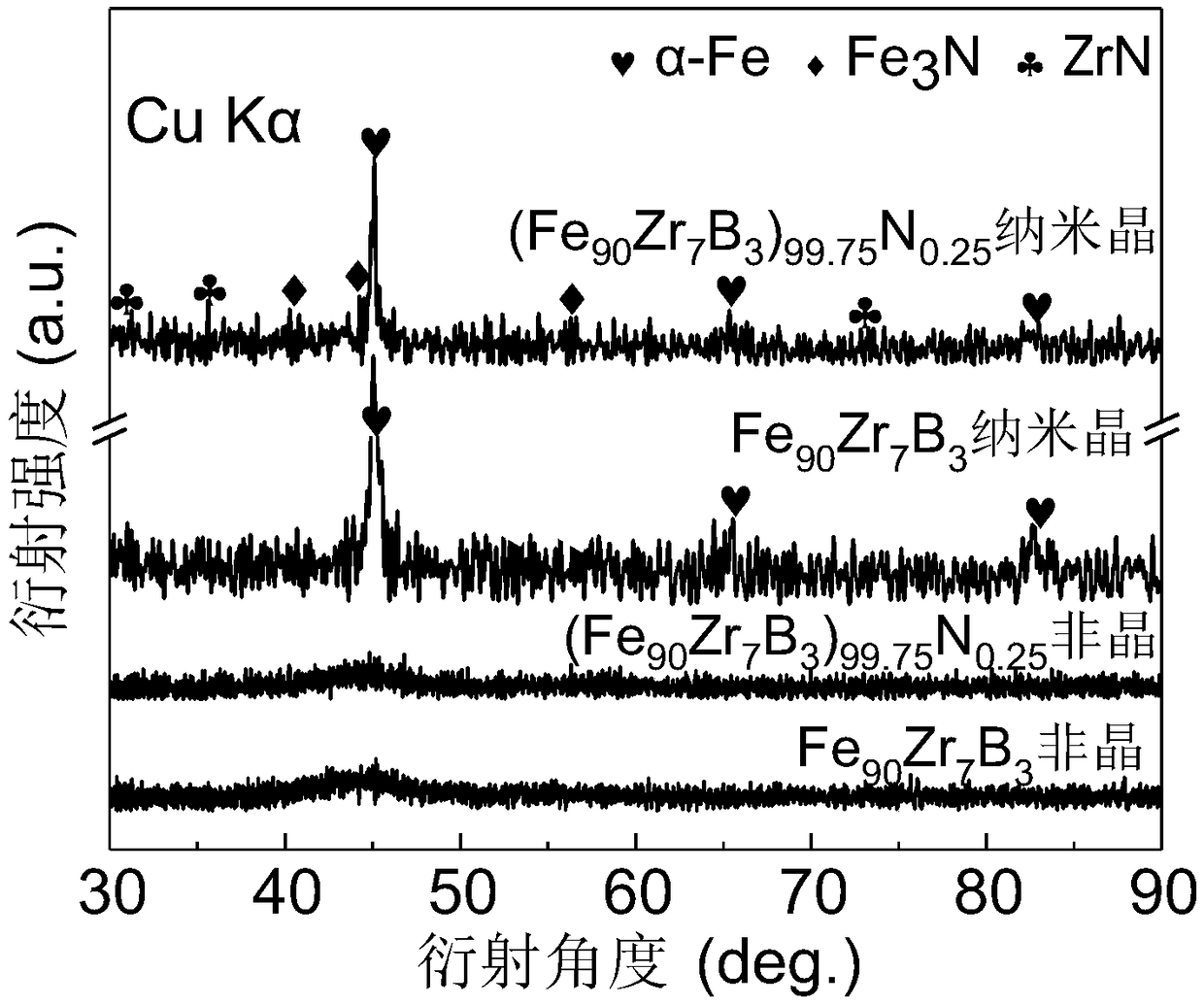

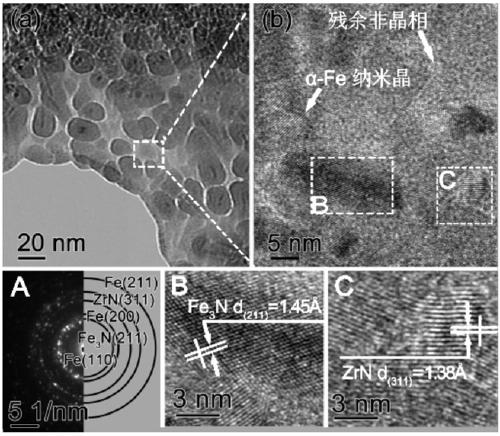

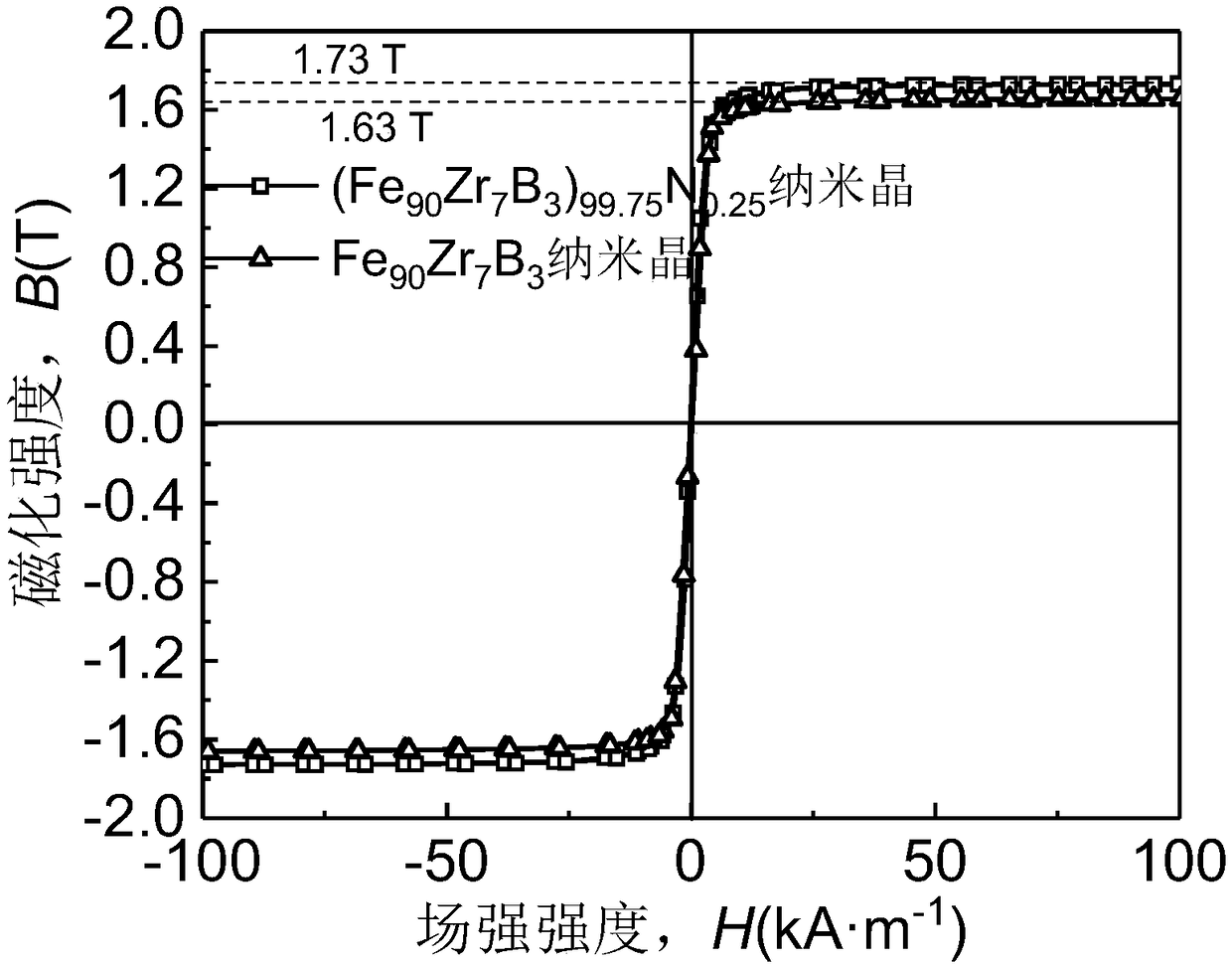

High magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy and preparation method thereof

ActiveCN109440023AHigh nitrogen contentControllable nitrogen contentMagnetic materialsIngot castingNitrogen

The invention discloses a high magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy and a preparation method thereof. The method comprises the steps that (1) nitrogen-containing raw materials are smelted into a nitrogen-coupled iron-based alloy ingot casting; (2) the obtained nitrogen-coupled iron-based alloy ingot casting is crushed and refused, and then a completely amorphous nitrogen-coupled iron-based amorphous alloy is obtained through a rapid quenching preparation technology; and (3) the obtained completely amorphous nitrogen-coupled iron-based amorphous alloy is sequentially subjected to two-stage annealing and tempering to obtain the high magnetic induction nitrogen-coupled iron-based amorphous nanocrystalline alloy, wherein the temperature of the first-stage annealing of the two-stage annealing is lower than the first crystallization starting temperature by 20-50 DEG C, and the temperature of the second-stage annealing is between the first crystallization starting temperature and the second crystallization starting temperature. The method improves the saturation flux density of the iron-based amorphous nanocrystalline alloy and also improves the service performance of the iron-based amorphous nanocrystalline magnetically soft alloy in a complex and hostile environment.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

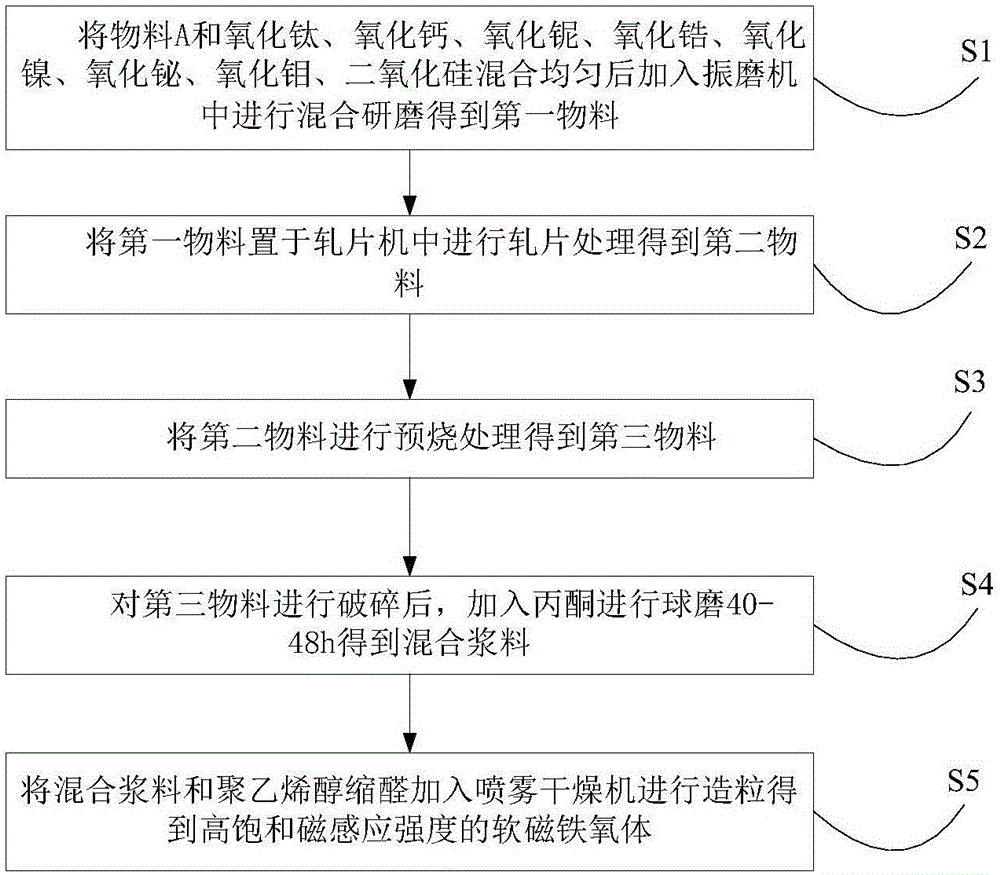

Soft-magnetic ferrite with low loss and high saturation flux density and preparation method therefor

The invention discloses a soft-magnetic ferrite with low loss and a high saturation flux density. The raw materials comprise materials A and materials B. The materials A comprise, by mole, 56-60 parts of iron oxide, 40-45 parts of manganese oxide, 7-10 parts of zinc oxide and 2-4 parts of copper oxide. With the total weight of the materials A as a base, the materials B comprise 2500-3000ppm, 300-700ppm of calcium oxide, 100-300ppm of niobium oxide, 400-800ppm of zirconium oxide, 1500-2000ppm of nickel oxide, 300-800ppm of bismuth oxide, 300-500ppm of molybdenum oxide, 200-500ppm of silicon oxide and 2000-2500ppm of bonding agents. The invention also discloses a preparation method for the soft-magnetic ferrite with low loss and a high saturation flux density.

Owner:ZHONGDE ELECTRONICS

Iron-based amorphous nanocrystalline magnetically soft alloy and preparation method thereof

ActiveCN106119739AHigh saturation magnetic inductionLow coercivityMagnetic materialsStress reliefImpurity

The invention relates to novel iron-based amorphous nanocrystalline magnetically soft alloy which can be directly obtained through rapid cooling without the need for annealing and a preparation method thereof. The composition of the magnetically soft alloy is FeaSibBcCdMnePfCrgNihCujMojCok except for unavoidable impurities. The iron-based amorphous nanocrystalline magnetically soft alloy has high saturated magnetic induction density Bs, low coercivity Hc, high and stable magnetic conductivity [mu]i and other excellent soft magnetic properties after stress relief annealing. Compared with existing nanocrystalline alloy applied in the industry and obtained through crystallization annealing, the annealing temperature is greatly lowered, and the iron-based amorphous nanocrystalline magnetically soft alloy does not contain or contain a trace of precious metal elements, so that the production cost is greatly lowered.

Owner:ZHENGZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com