Patents

Literature

48results about How to "Low critical cooling rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and manufacturing method thereof

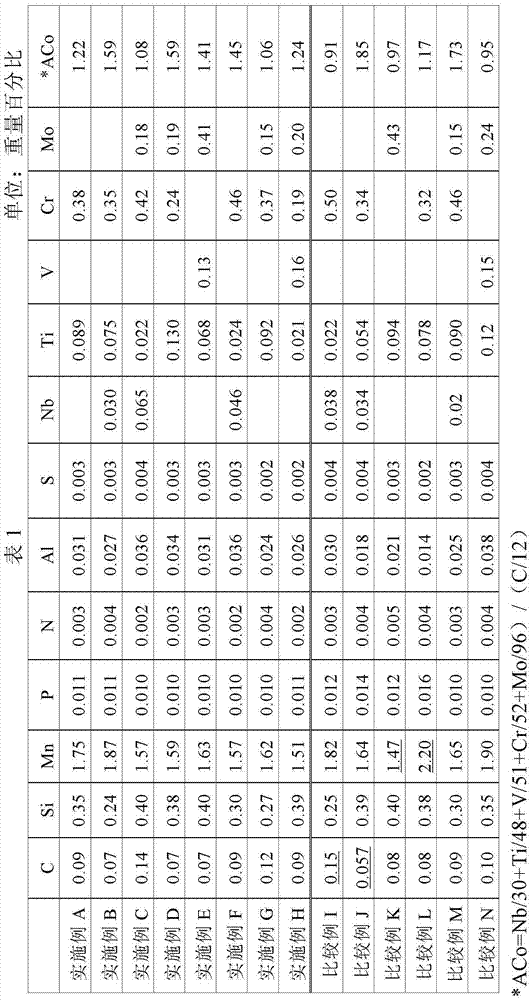

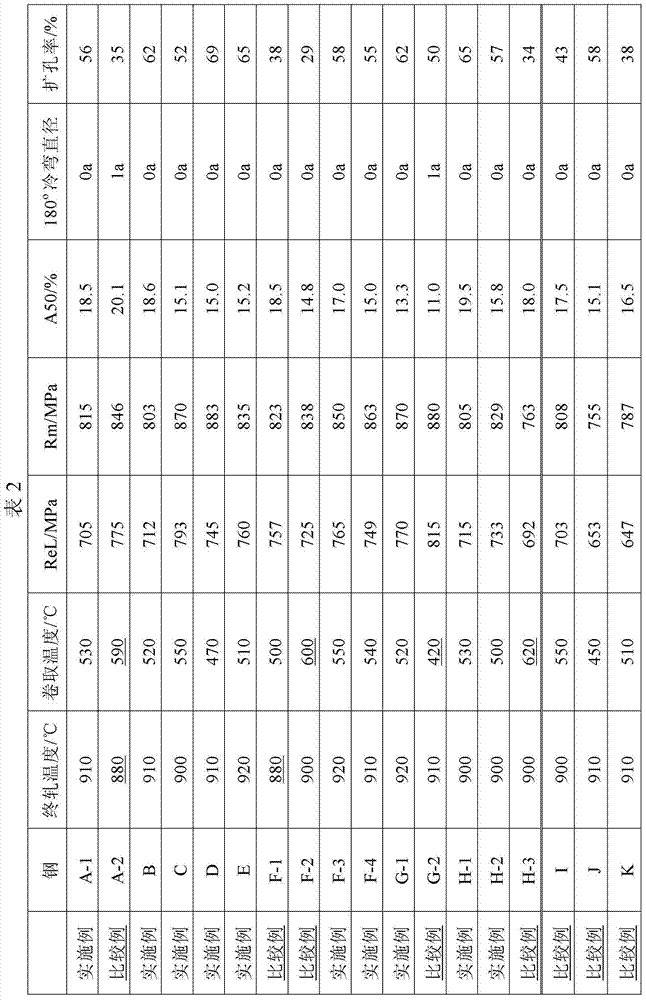

The invention discloses an ultrahigh-strength hot-rolled complex phase steel plate and steel strip with good bending and broaching performance and a manufacturing method thereof. The ultrahigh-strength hot-rolled complex phase steel plate and steel strip comprise the following components in percentage by weight: 0.07-0.14% of C, 0.1-0.4% of Si, 1.55-2.00% of Mn, less than or equal to 0.015% of P, less than or equal to 0.004% of S, 0.01-0.05% of Al and less than or equal to 0.005% of N, and further comprises at least one of alloy elements of less than or equal to 0.07% of Nb, 0.02-0.15% of Ti and 0.10-0.20% of V, at least one of alloy elements of 0.15-0.50% of Cr and 0.15-0.50% of Mo, and the balance of Fe and inevitable impurities. The ultrahigh-strength hot-rolled complex phase steel has the tensile strength of above 800 MPa, the yield strength of above 700 MPa, the cold bending performance of 0a at 180 DEG C, the broaching rate of above 50%, and the microstructure of bainite (at least 80%) and a small amount of ferrite, martensite and retained austenite, wherein the bainite is mainly lower bainite. The ultrahigh-strength hot-rolled complex phase steel can be applied to manufacture of an automobile chassis, a hanging component, a bumper and other products.

Owner:BAOSHAN IRON & STEEL CO LTD

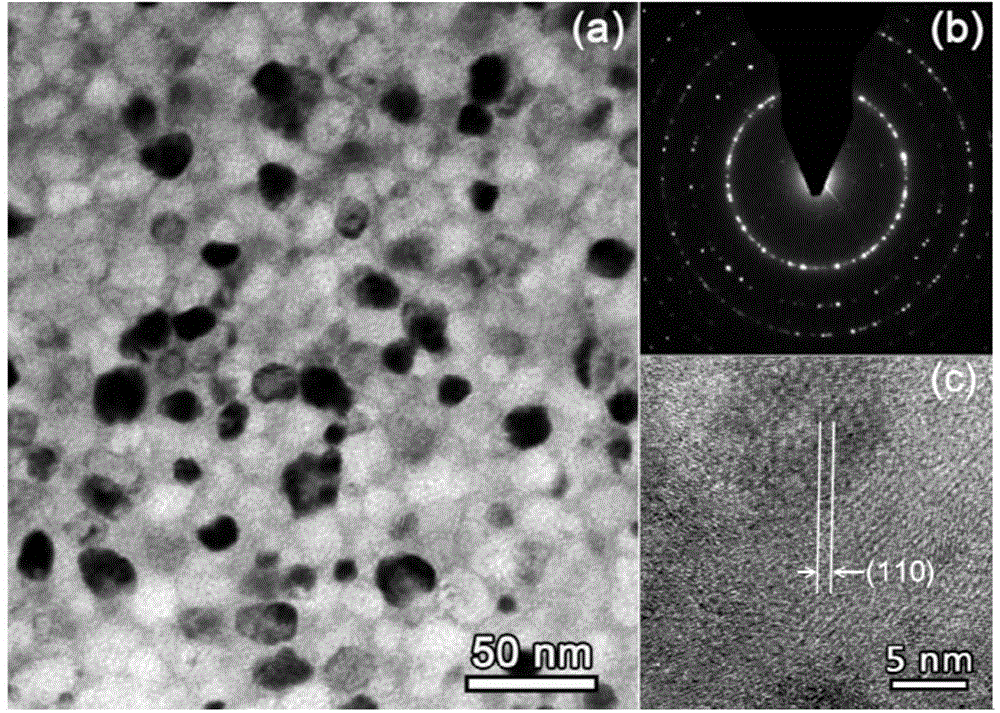

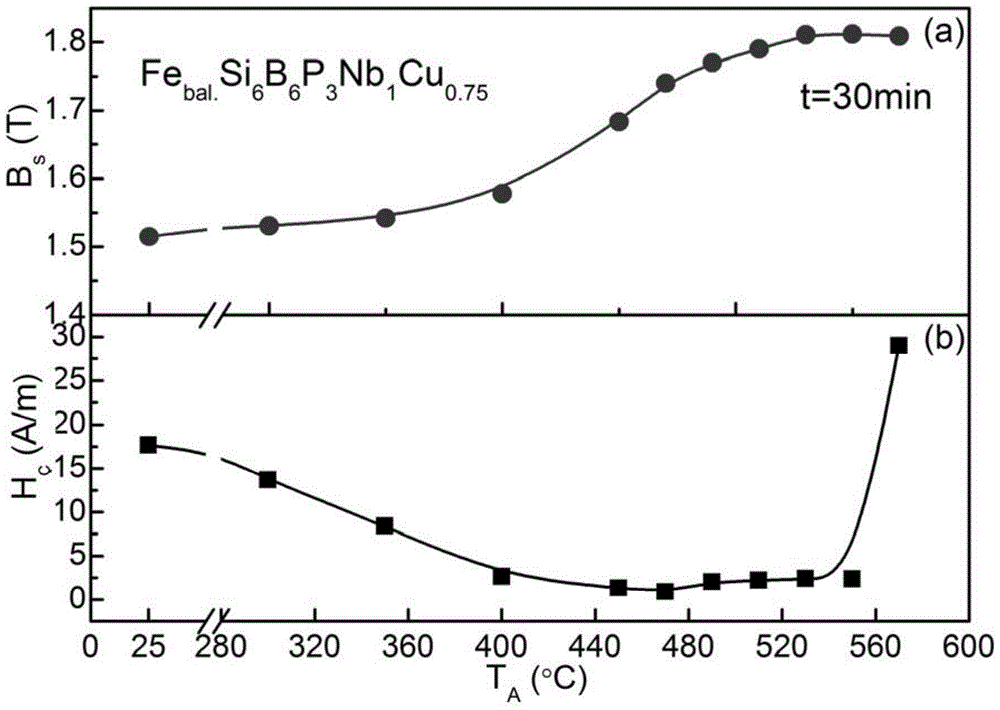

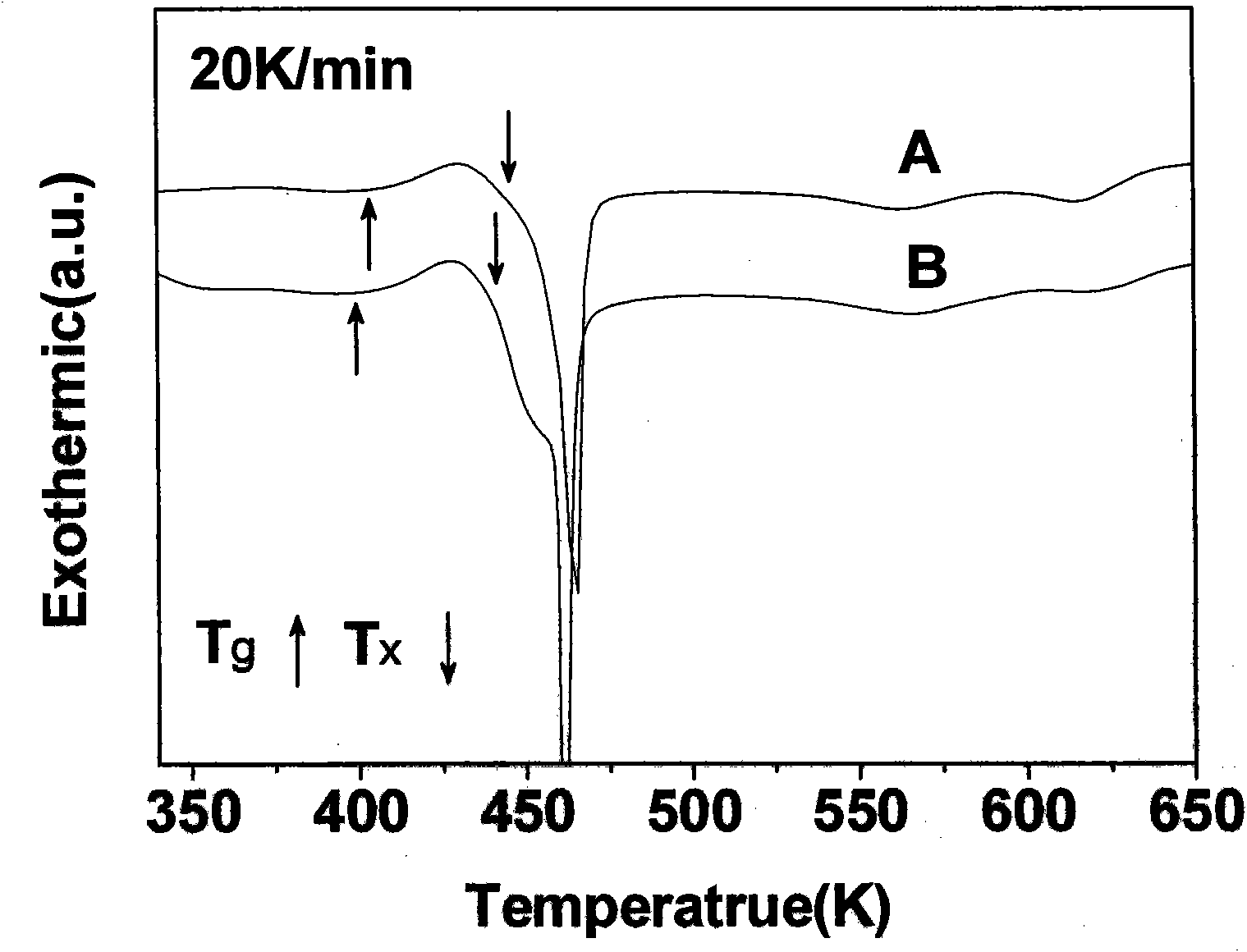

Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and preparing method of Fe-based nanocrystalline soft magnetic alloy

ActiveCN104934179AHigh saturation magnetic inductionLow coercivityMagnetic materialsCopper moldMagnetic alloy

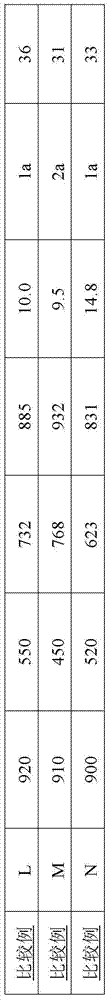

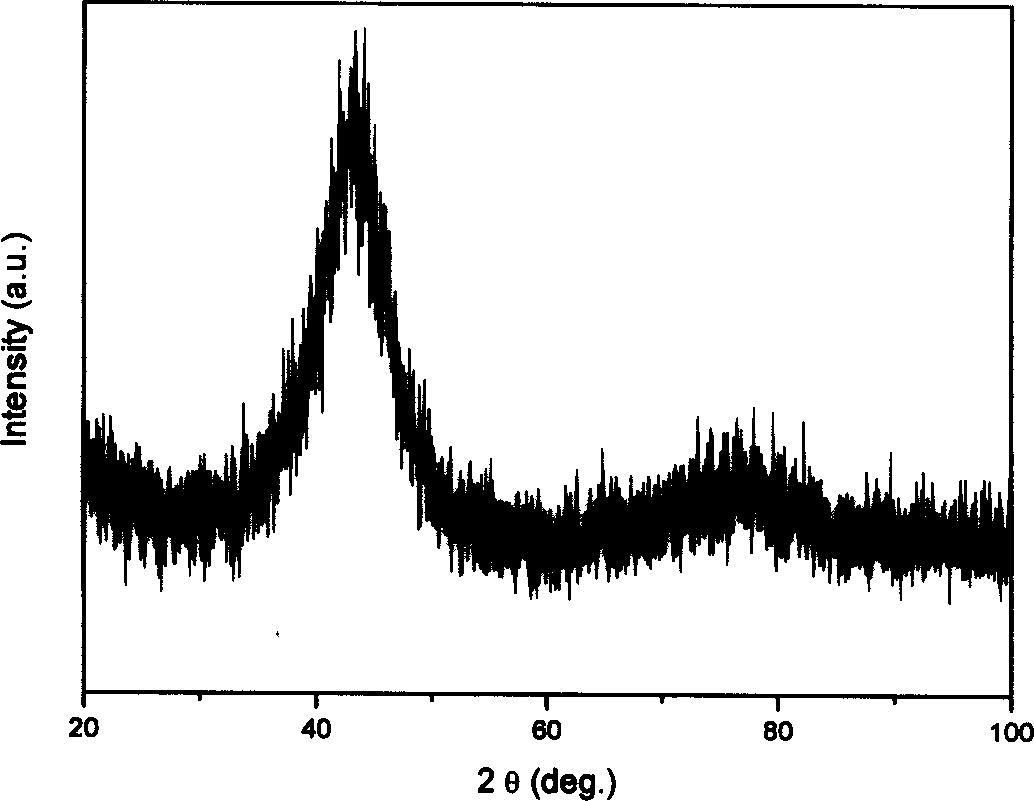

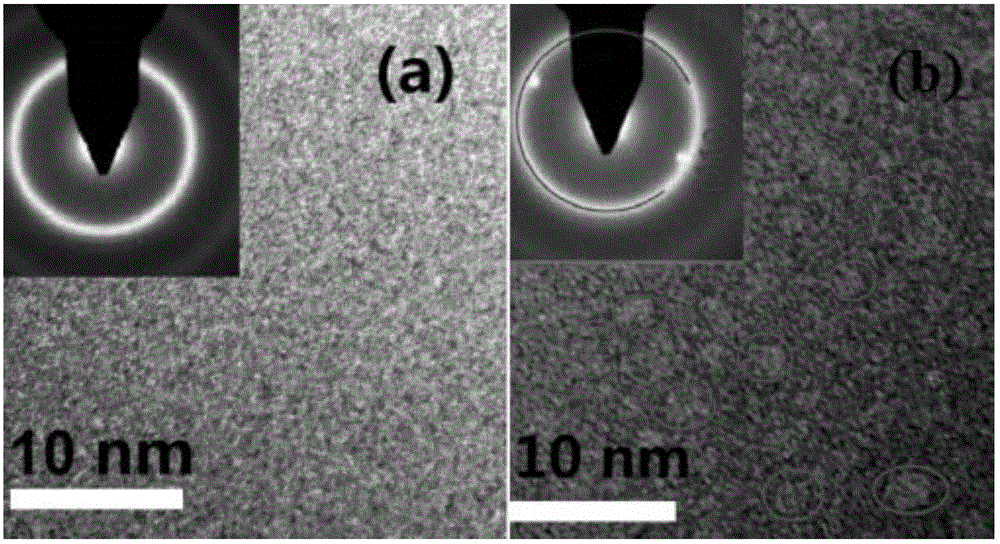

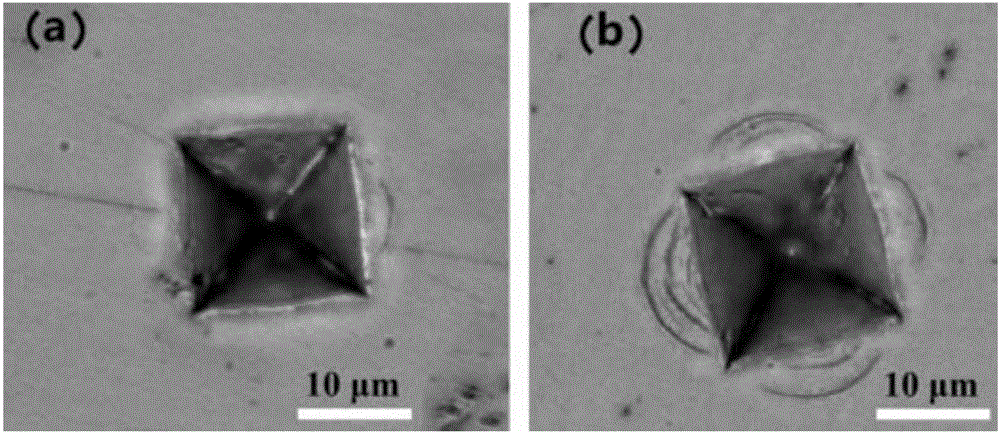

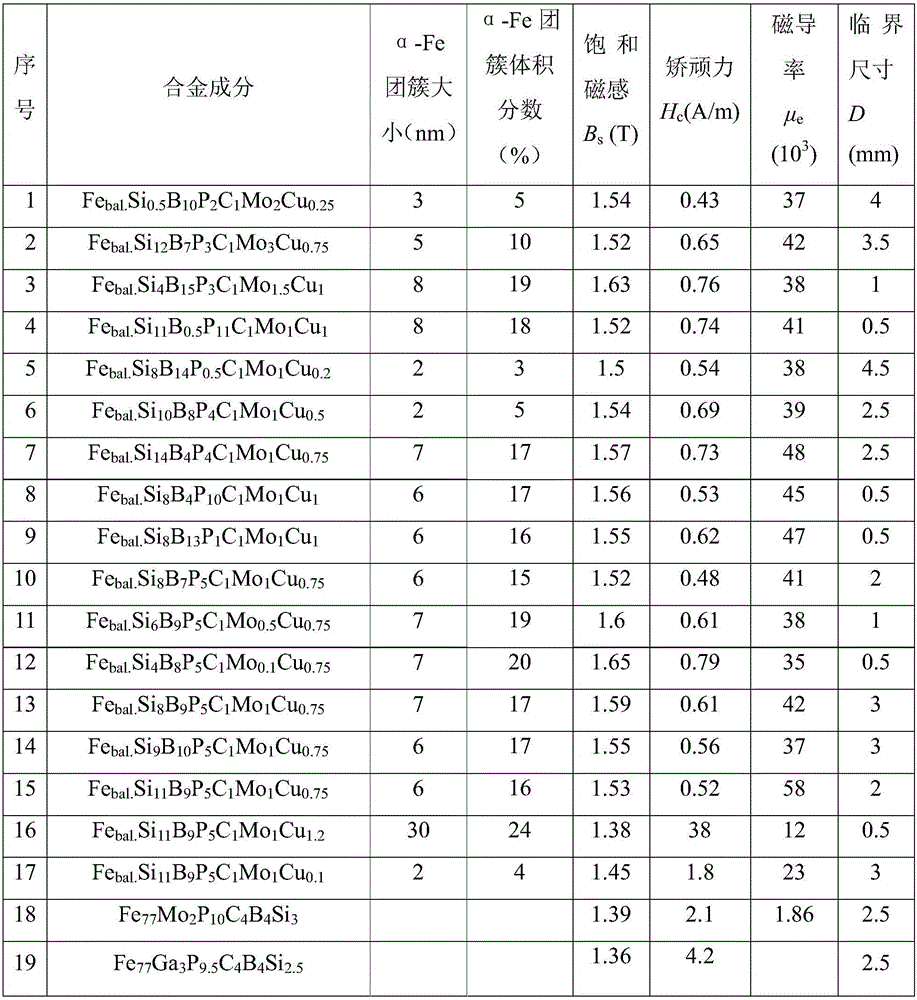

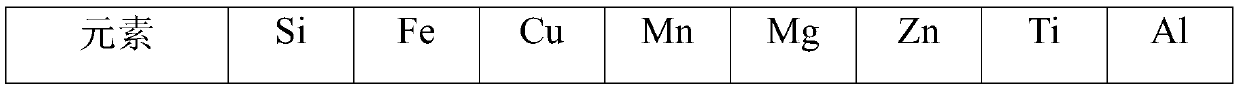

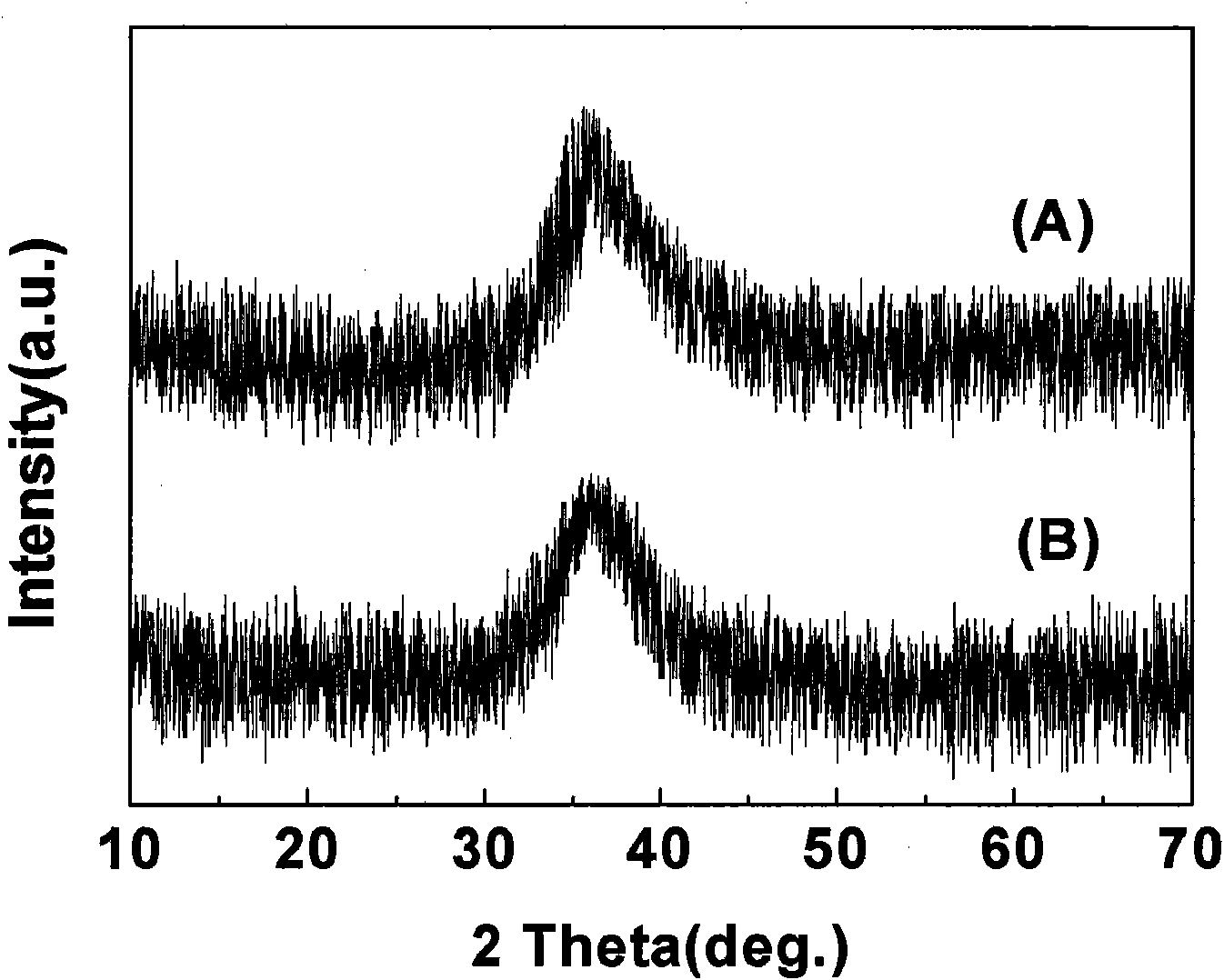

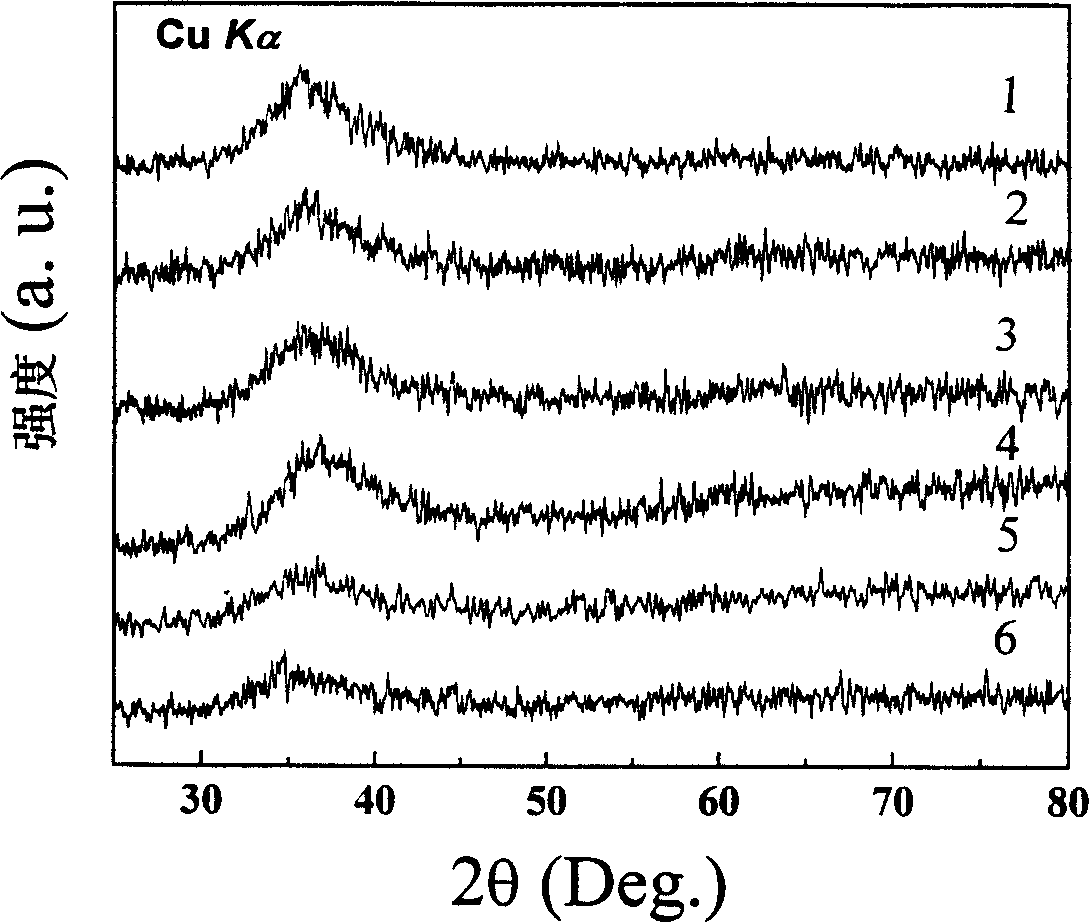

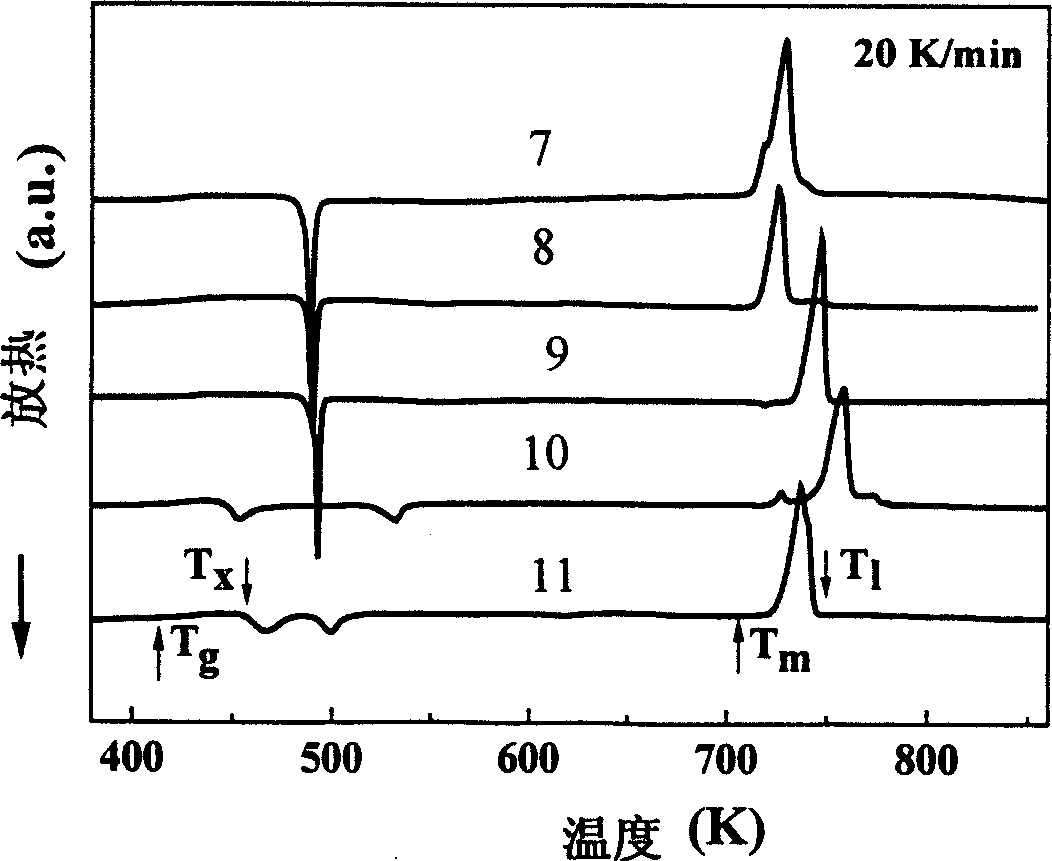

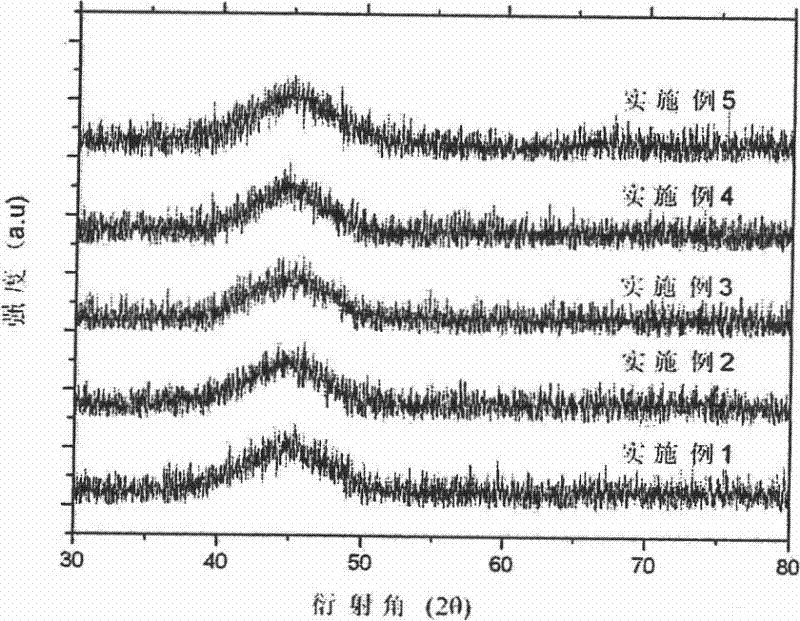

The invention discloses a Fe-based nanocrystalline soft magnetic alloy with strong amorphous forming ability and a preparing method of the Fe-based nanocrystalline soft magnetic alloy. The alloy has an expression of Fe<x>SiBP<c>Nb<d>Cu<e>, wherein in the expression, each of the x, the a, the b, the c, the d and the e shows the atomic percentage content of the corresponding ingredient, and meets the following conditions that the a is greater than or equal to 0.5 but smaller than or equal to 12; the b is greater than or equal to 0.5 but is smaller than or equal to 15; the c is greater than or equal to 0.5 but smaller than or equal to 12; the d is greater than or equal to 0.1 but smaller than or equal to 3; the e is greater than or equal to 0.1 but smaller than or equal to 3; the x is greater than or equal 70 but smaller than or equal to 85; and the sum of the x, the a, the b, the c, the d and the e is 100 percent. The soft magnetic alloy has the advantages that an ordinary copper mold casting method can be used for preparing a Fe-based amorphous alloy with the critical dimension being 3.5mm; after the annealing; the saturation flux density is greater than 1.5T; and the coercive force value is smaller than 1A / m.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

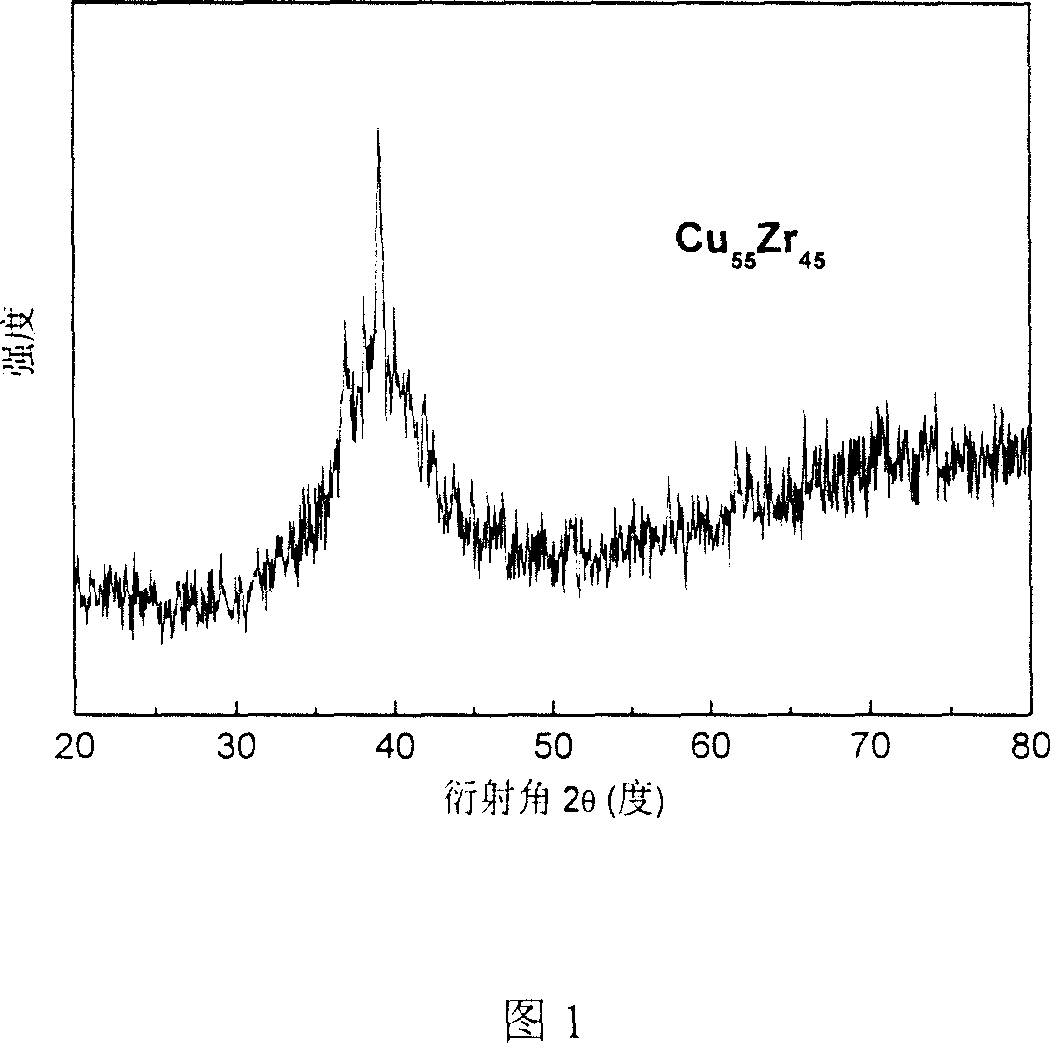

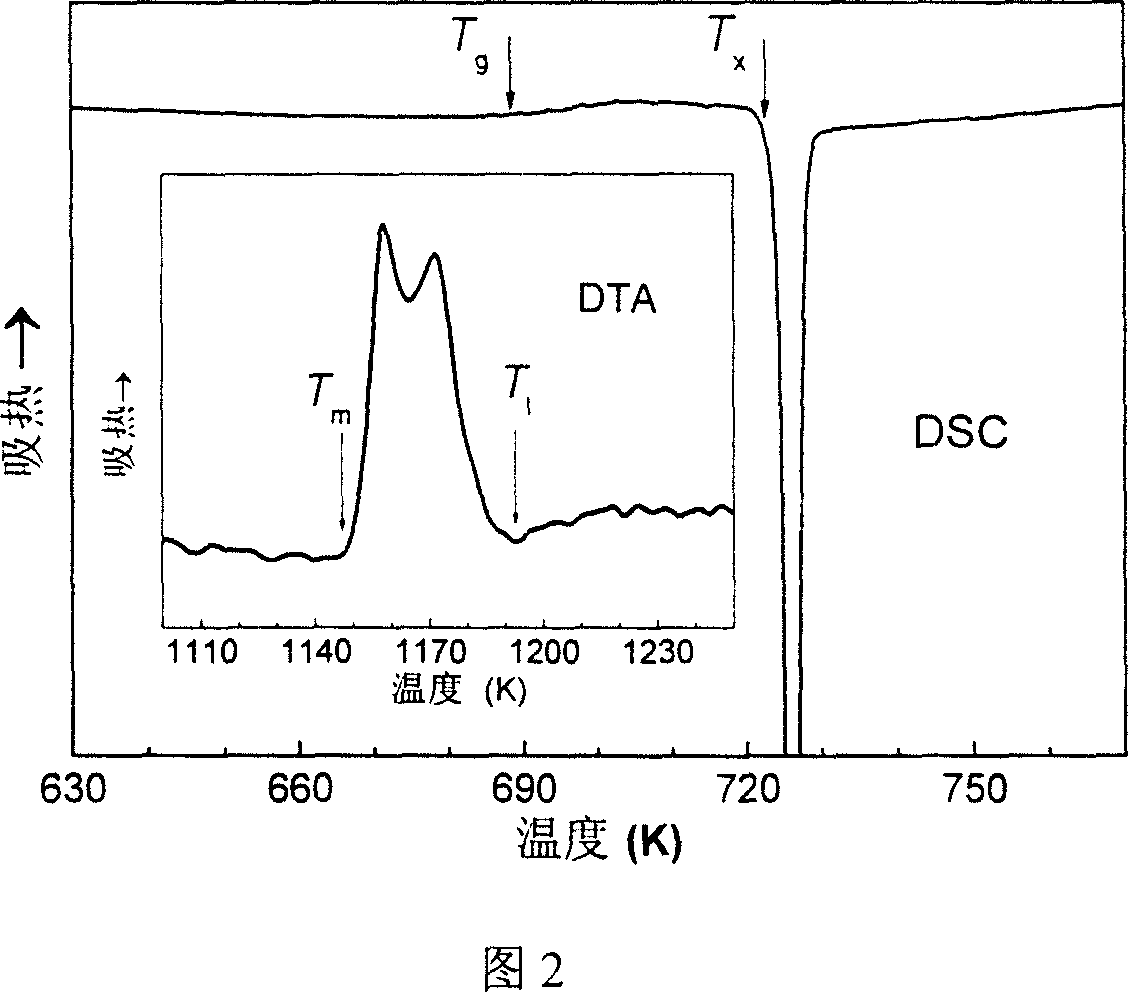

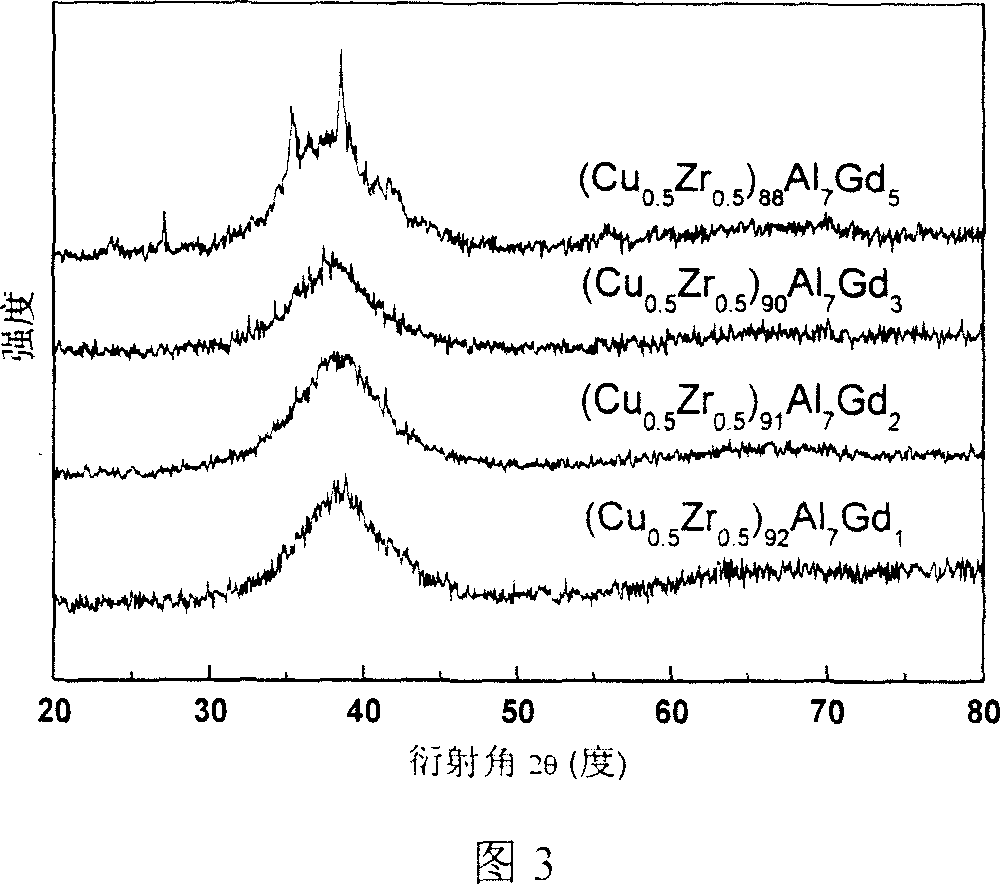

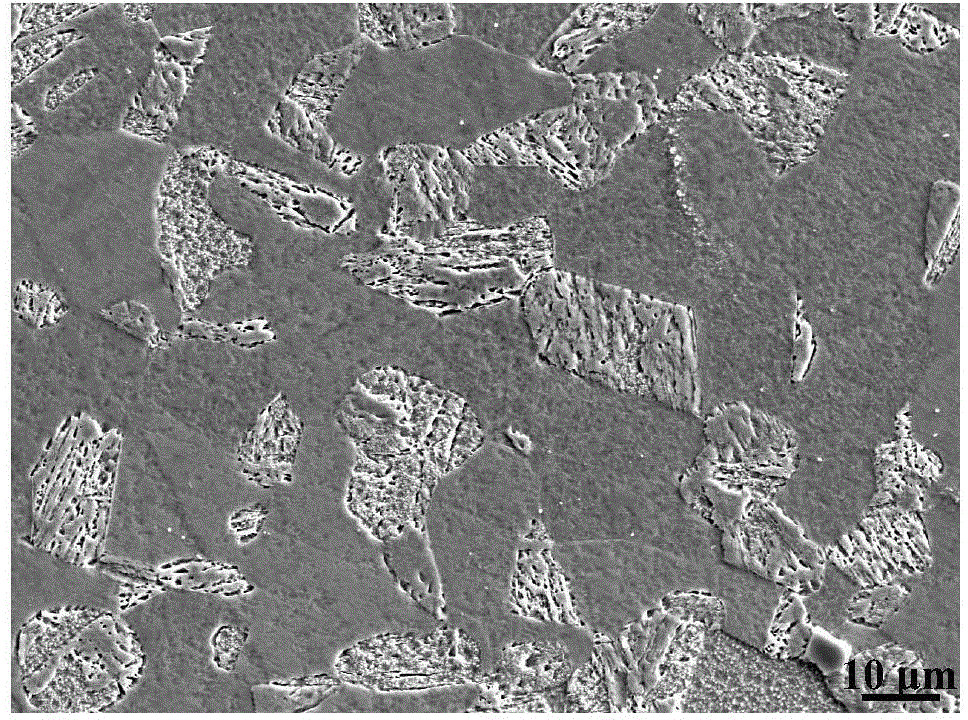

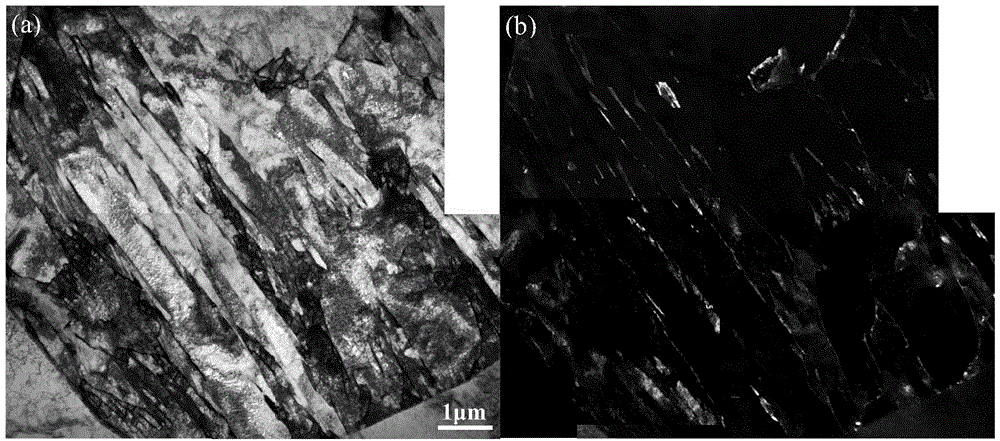

Copper-zirconium based amorphous alloy, and preparation method

InactiveCN1958831AImprove mechanical propertiesHigh plastic deformationMolten metal pouring equipmentsElectric arc furnaceAmorphous metal

This invention relates to a Cu-Zr-based amorphous alloy, whose general formula is (Cu1-xZrx)aAlbMc, where, x is 0.40-0.60; a is 80-100; b is 0-14; c is 0-20; a + b + c is 100; M is Y, La, Ce, Pr, Nd, Gd, Tb, Dy, Ho, Er, Ti, Ag, Ga, Hf, Ta, Nb, Ni, Co or Fe. The preparation method comprises: (1) mixing Cu, Zr, Al and M according to the ratio in Ti-adsorbed Ar atmosphere in an arc furnace, smelting and cooling to obtain mother alloy ingot; (2) re-melting the mother alloy ingot in air, and casting into a water-cooling metal mold to obtain the Cu-Zr-based amorphous alloy. The alloy has high glass formation ability, high crystallization inhibition and large size at a very low cooling speed.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Galvanization-free high-strength and plasticity cold-rolled stainless steel plate for automobile and manufacturing method of galvanization-free high-strength and plasticity cold-rolled stainless steel plate

ActiveCN104532129AReduced service lifeGood and stable corrosion resistanceHigh intensityUltimate tensile strength

The invention relates to a galvanization-free high-strength and plasticity cold-rolled stainless steel plate for an automobile and a manufacturing method of the galvanization-free high-strength and plasticity cold-rolled stainless steel plate, and belongs to the technical field of metallurgy. The galvanization-free high-strength and plasticity cold-rolled stainless steel plate comprises, by weight, 11.0-17.0% of Cr, 0.01-0.12% of C, 0.2-0.5% of Mn, 0.2-1.1% of Si, 0.005-0.5% of Al, less than 0.3% of Ni, less than 0.2% of Nb, less than 0.2% of Ti, less than 0.2% of V, less than 0.1% of Mo, less than 0.03% of Cu, less than 0.05% of N, less than 0.003% of S and the balance Fe. The manufacturing method of the galvanization-free high-strength and plasticity cold-rolled stainless steel plate comprises the steps of casting, heat rolling, cold rolling and heat treatment based on the quenching-partition (Q&P) technology. According to the galvanization-free high-strength and plasticity cold-rolled stainless steel plate, the process of surface galvanization is omitted, the material cost is obviously lower than that of austenitic stainless steel, texture comprises martensite, retained austenite and selectable ferrite, good strength and plasticity are combined, and the galvanization-free high-strength and plasticity cold-rolled stainless steel plate is especially suitable for structural parts, strengthening parts and the like for manufacturing automobiles.

Owner:NORTHEASTERN UNIV

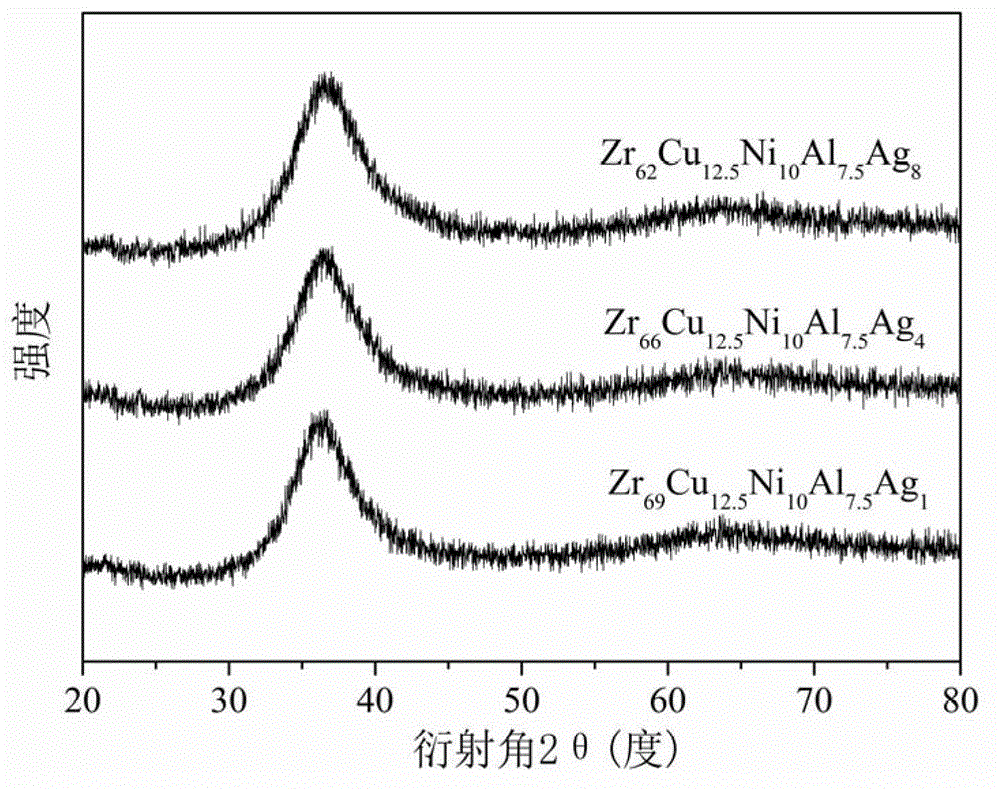

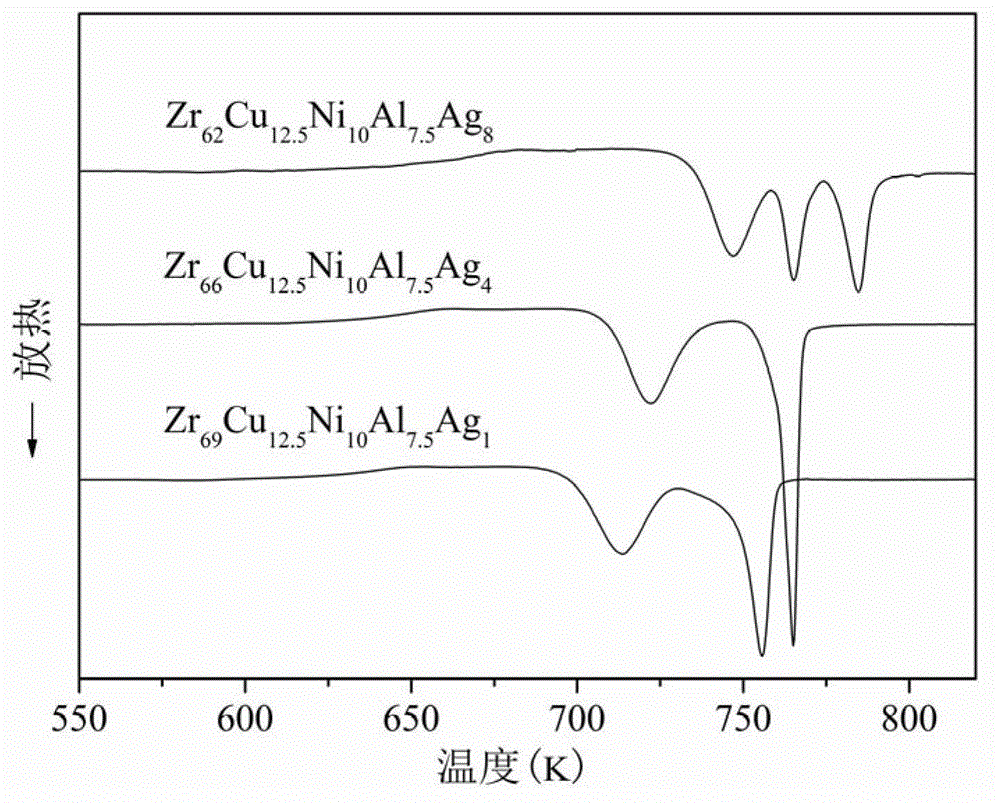

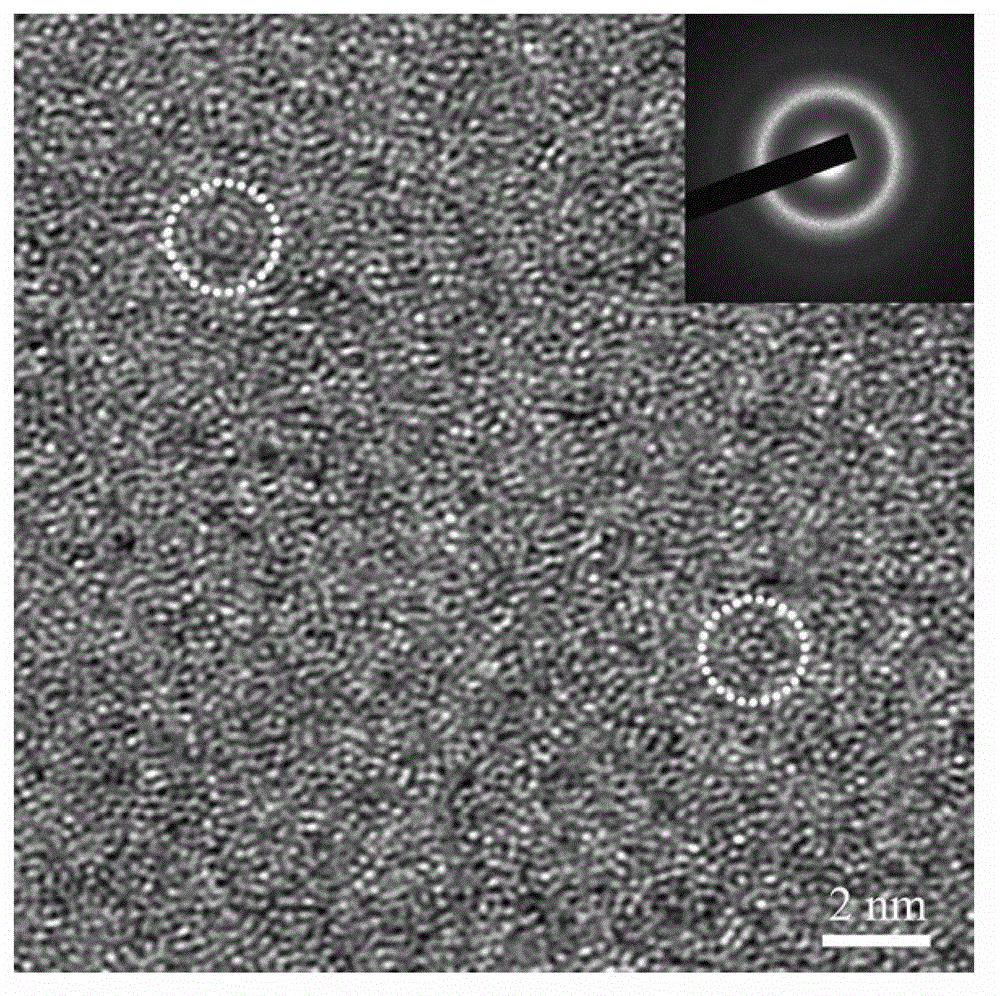

Zirconium-based amorphous alloy and preparation method thereof

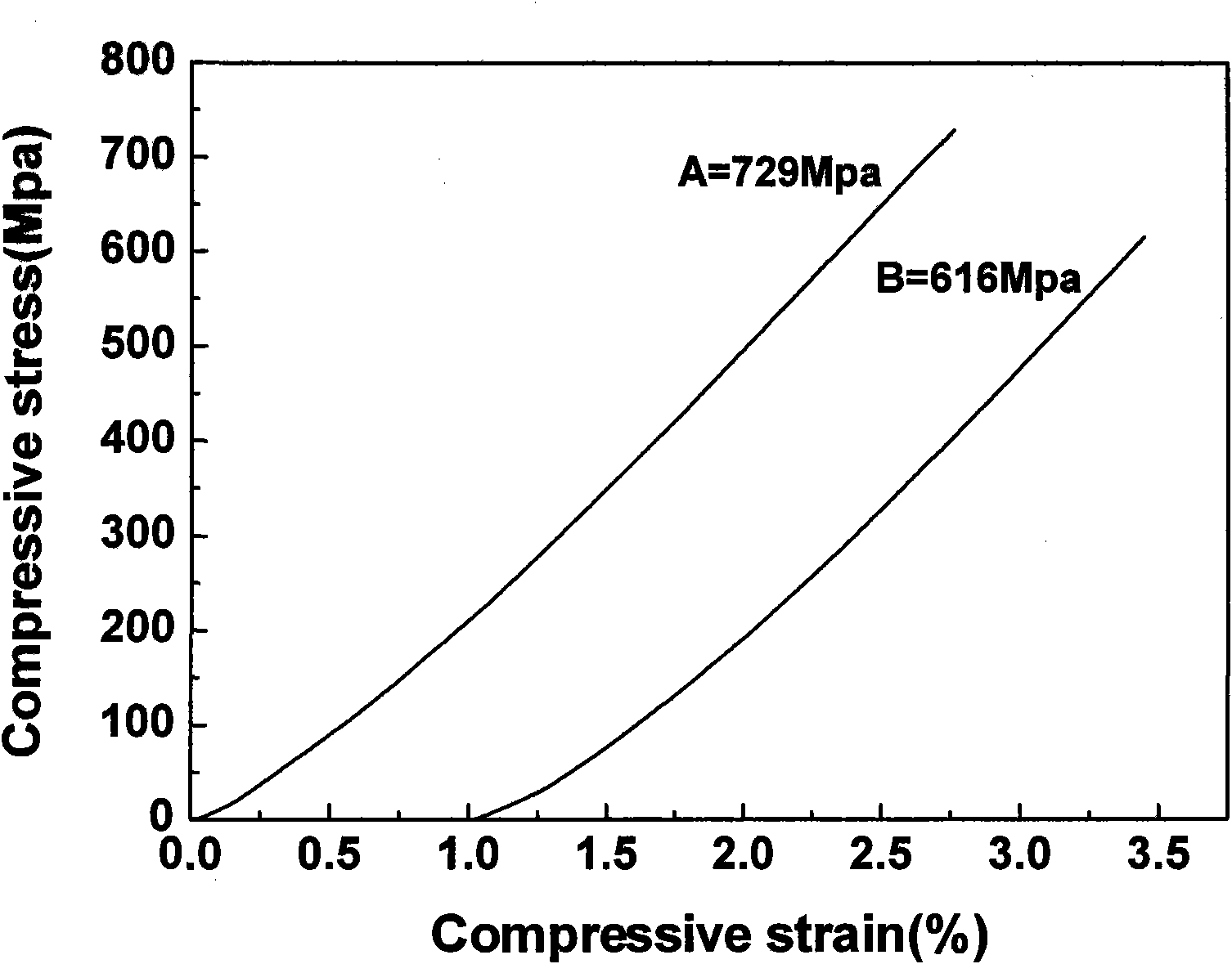

InactiveCN102912261AHigh compressive strengthImprove plastic deformation abilityCopperGlass transition

The invention relates to a zirconium-based amorphous alloy. The zirconium-based amorphous alloy comprises zirconium, copper, nickel, aluminum and sliver; and the zirconium-based amorphous alloy is shown by the following formula: Zr70-xCu12.5Ni10Al7.5Agx, wherein x is more than or equal to 1 and less than or equal to 10. The preparation method comprises the steps of replacing zirconium element by a silver part, and melting by arc under vacuum, and then carrying out suction casting, so as to obtain the zirconium-based amorphous alloy. The zirconium-based amorphous alloy is excellent in plastic deformation capacity and high in strength; the amorphous alloy is high in glass transition temperature and initial crystallizing temperature, and wide in sub-cooled liquid phase area, and has a potential application prospect.

Owner:SHANGHAI JIAO TONG UNIV

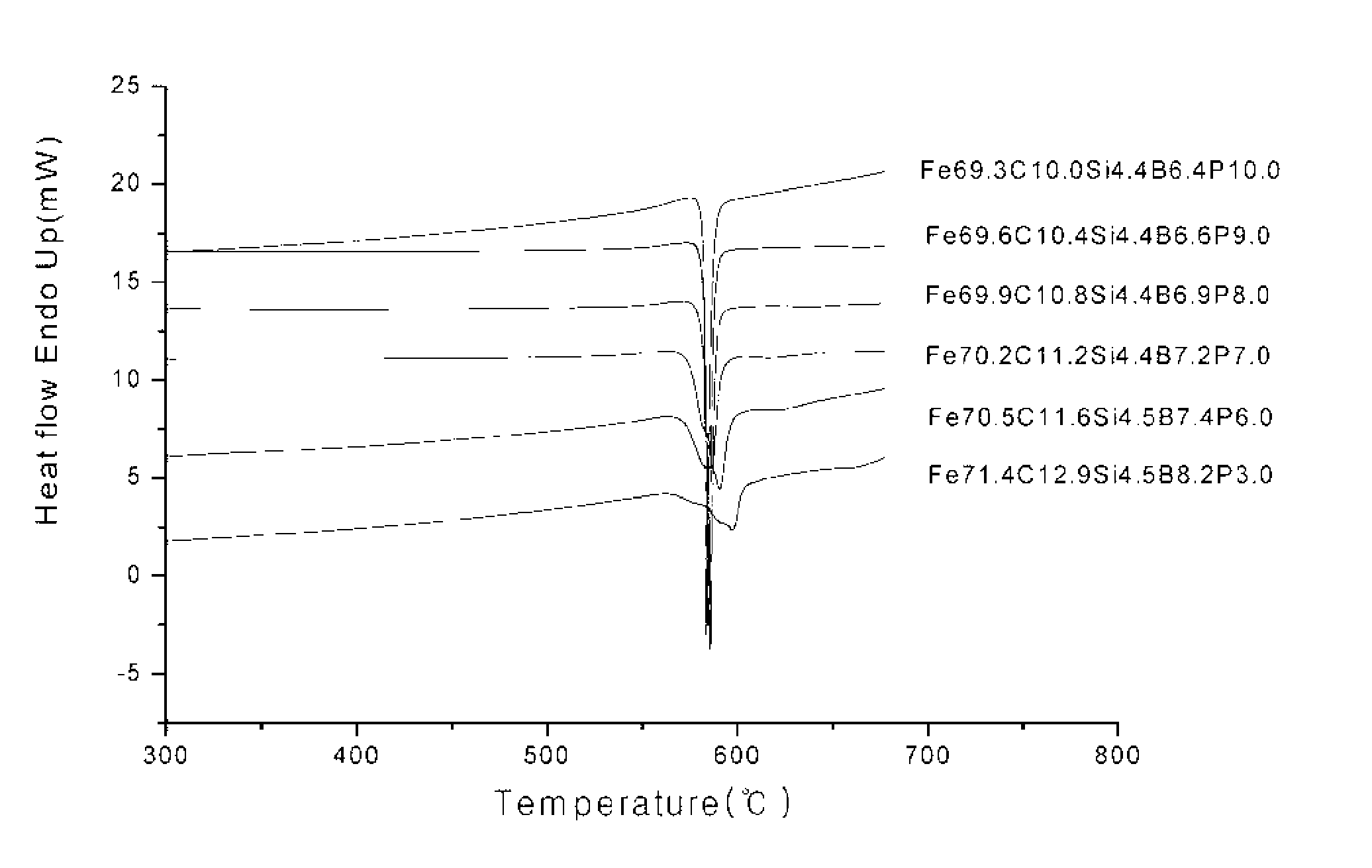

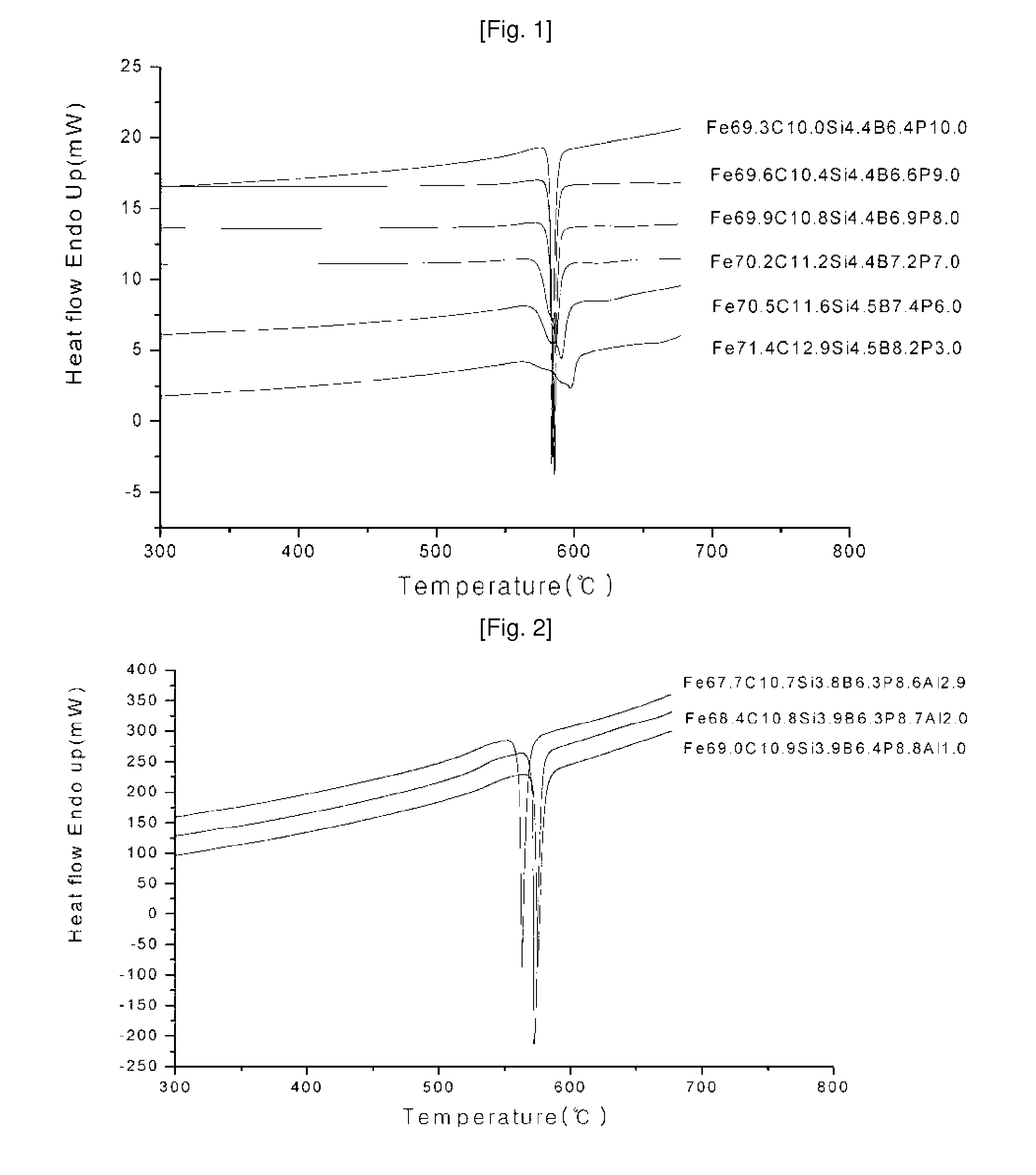

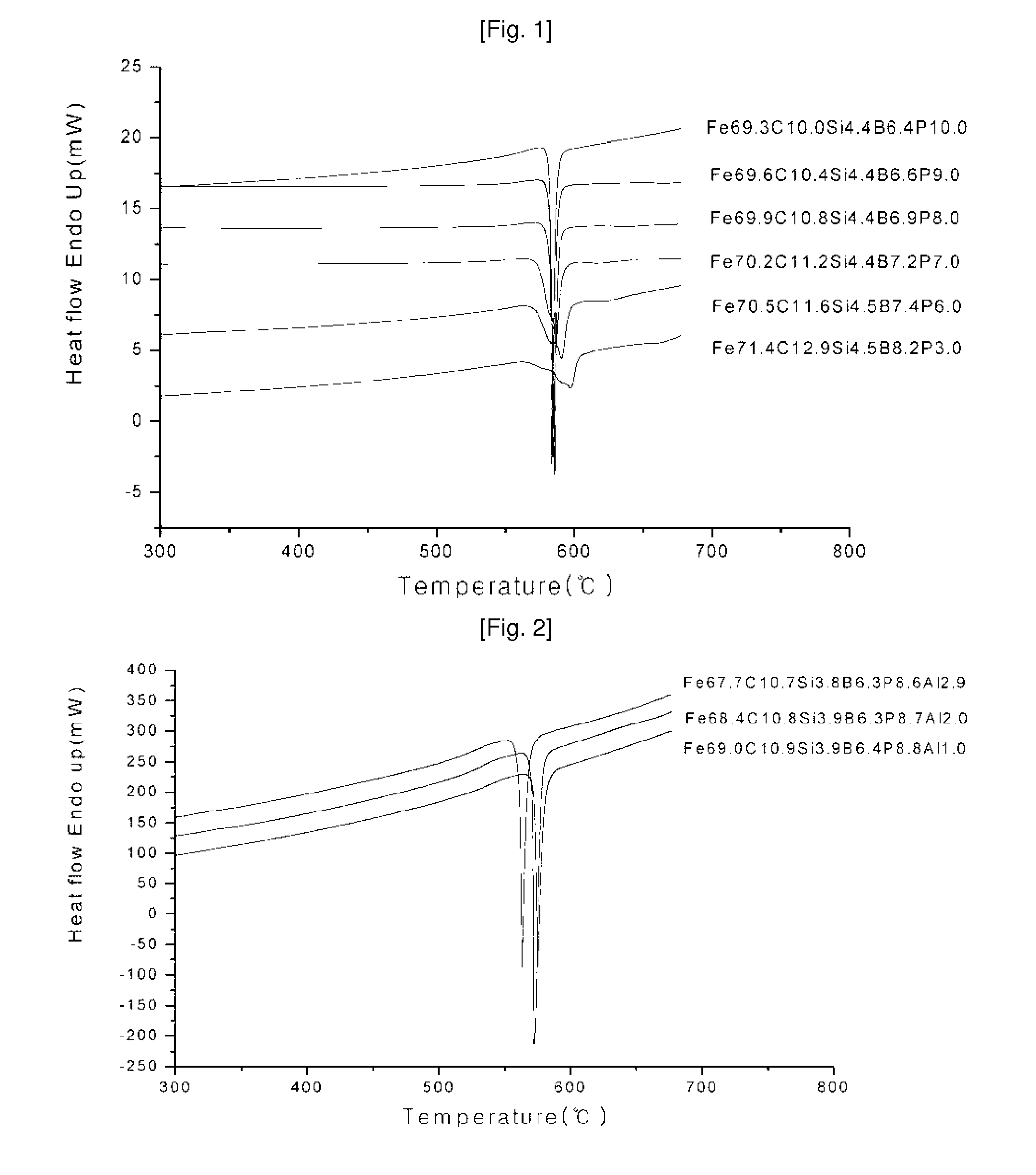

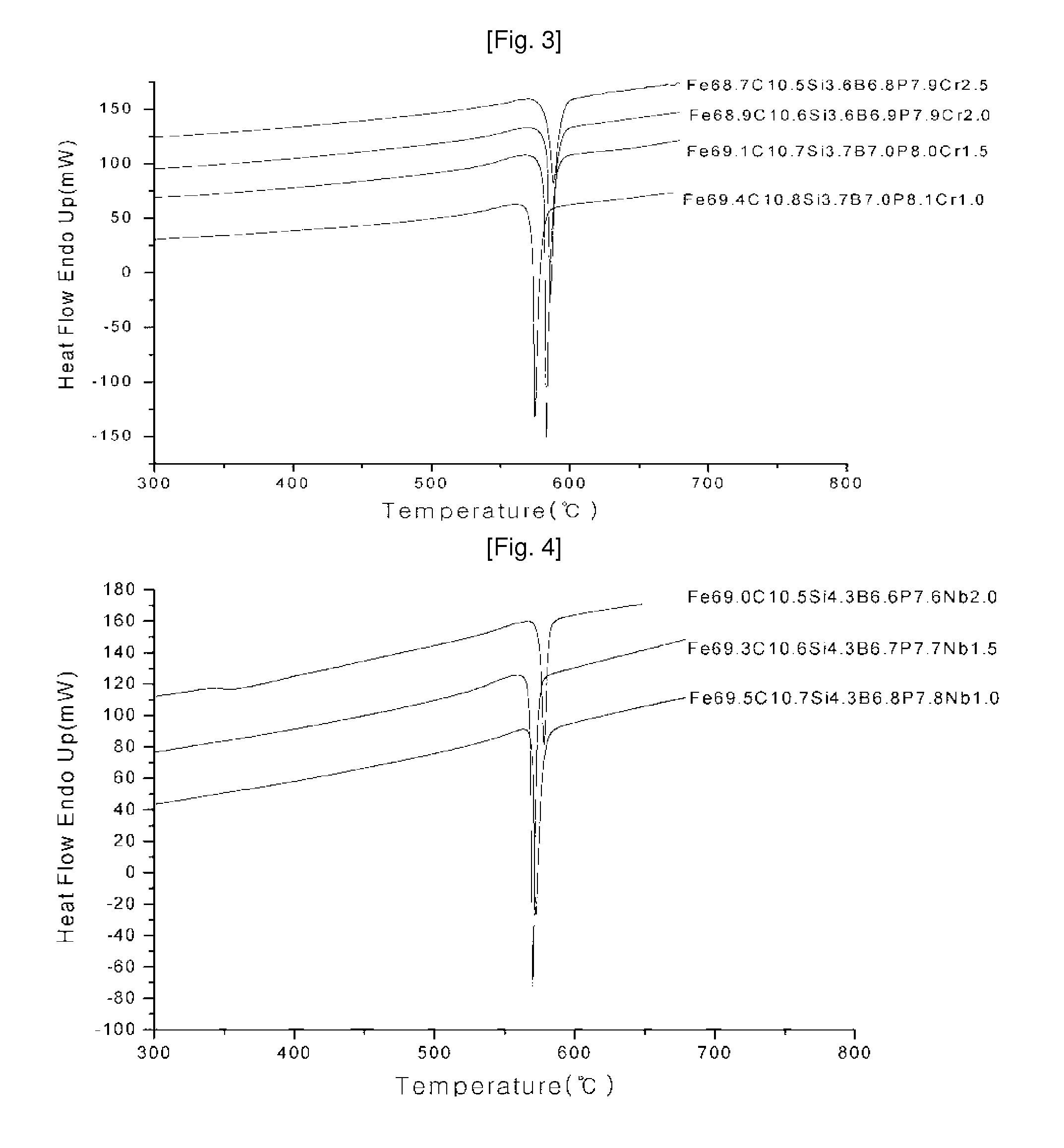

Fe-Based Bulk Amorphous Alloy Compositions Containing More Than 5 Elements And Composites Containing The Amorphous Phase

Disclosed is a Fe-based bulk amorphous alloy composition which forms a bulk amorphous substance due to its excellent amorphous formability when it is cooled to a temperature lower than its glass transition temperature from the liquid state at a relatively low cooling rate of 1000 K / s or less, has high warm processability in a low temperature range owing to its supercooled liquid region of 20K or higher and has excellent fluidity in the liquid state and thereby good castability. The Fe-based multi-element bulk amorphous alloy composition is represented by a formula of Feα, CβSiγBxPyMa, in which M is at least one element selected from Ti (titanium), Cr (chromium), Mo (molybdenum), Nb (niobium), Zr (Zirconium), Ta (tantalum), W (tungsten) and V (vanadium), α, β, γ, x, y, and a each represent atomic % of iron (Fe), Carbon (C), silicon (Si), boron (B), phosphorus (P) and the selected metal element, in which α is 100-(β+γ+x+y+a) atomic %, β is 6 atomic % or more and 13 atomic % or less, γ is 1 atomic % or more and 5 atomic % or less, x is 4.5 atomic % or more and 9.5 atomic % or less, y is 3 atomic % or more and 10 atomic % or less and a is 0.1 atomic % or more and 6 atomic % or less.

Owner:POHANG IRON & STEEL CO LTD

Iron-base bulk amorphous alloy with high glass-forming ability

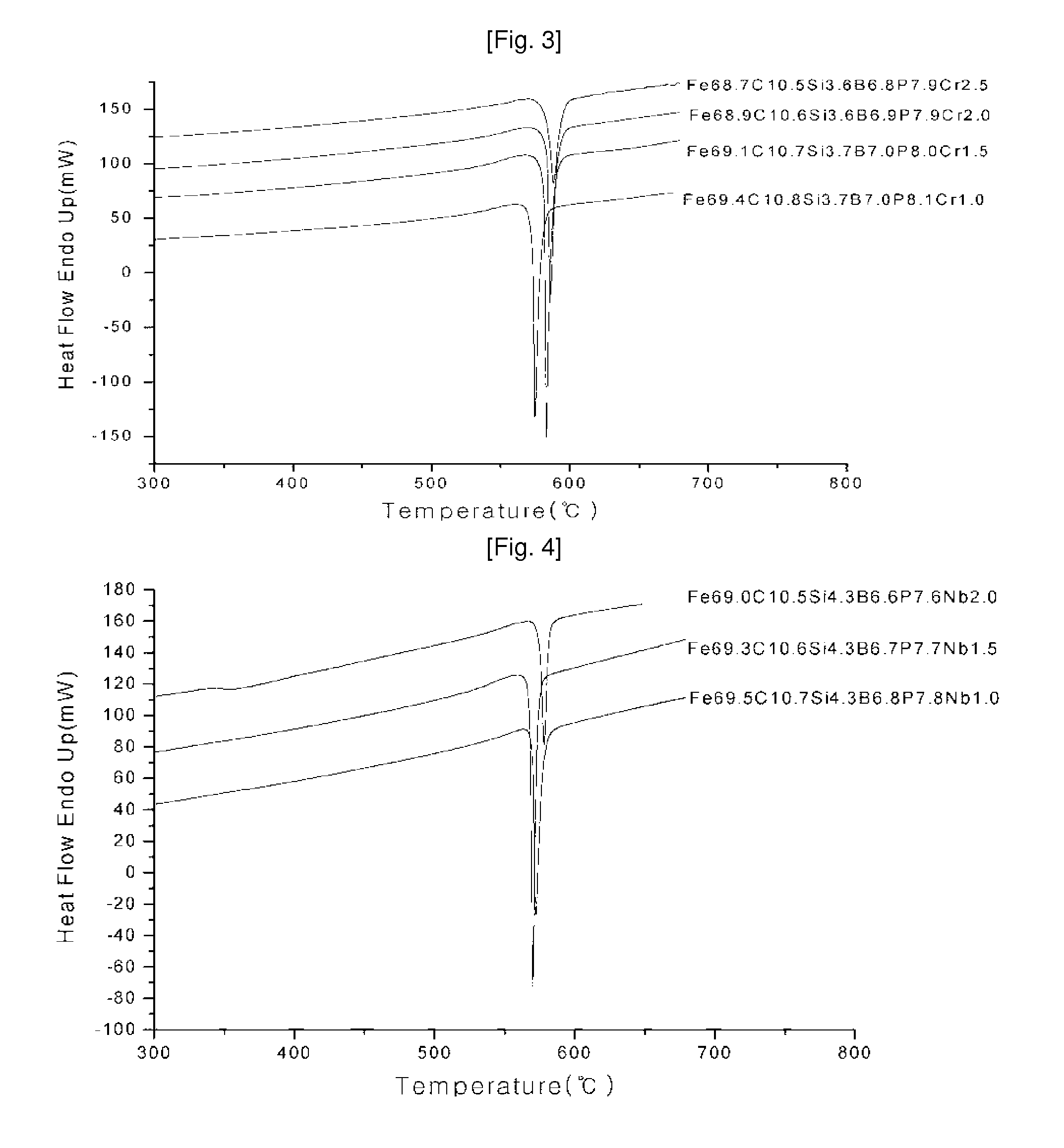

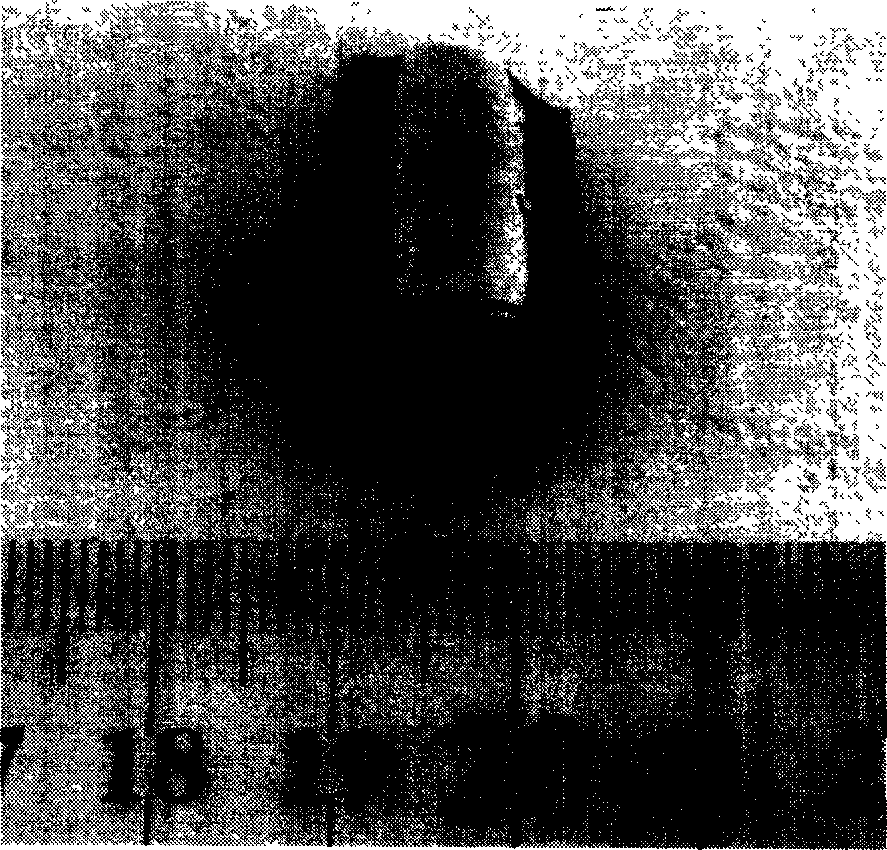

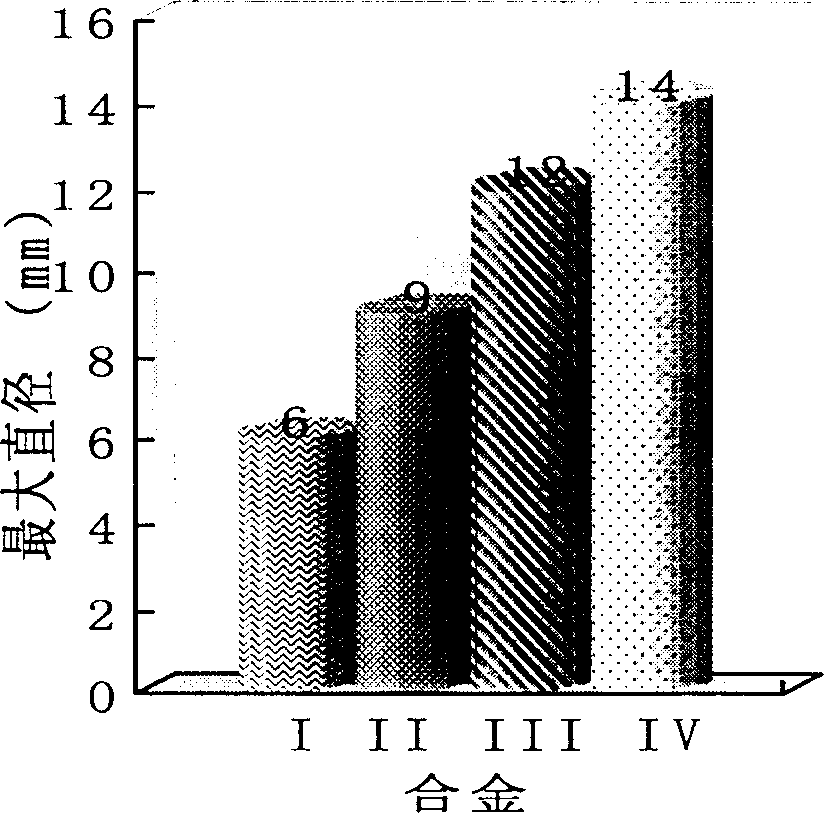

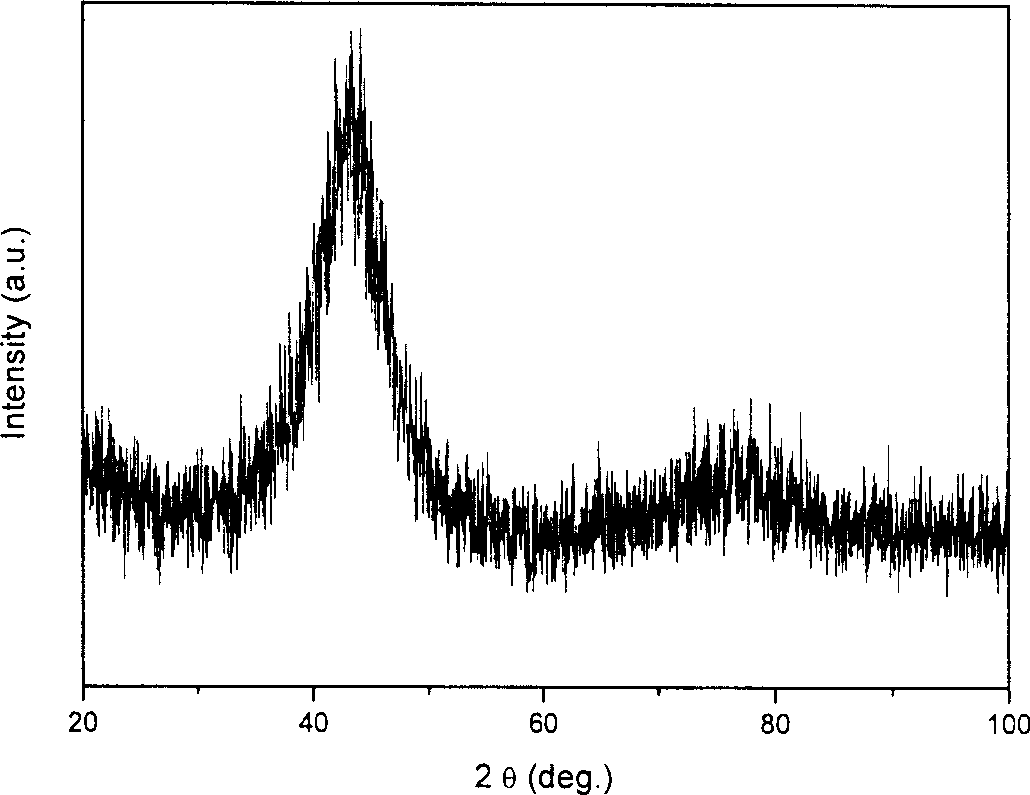

One kind has the high glass to form the ability the hard matrice body crystalless alloy, it involves a kind of crystalless alloy material, specifically designs a kind to have the high glass to form the ability the hard matrice body crystalless alloy. The invention block body crystalless alloy by Fe, Co, Cr, Mo, C, B, Y is composed, various elements atomic percentage is: Fe36~~45%, Co5~~10%, Cr15%, Mo14%, C15%, B6%, Y1~~5%. The invention has the high glass to form the ability, uses the ordinary type mold casting to be allowed to prepare the critical dimension not to be smaller than the 14mm hard matrice body crystalless alloy, has low critical cooling speed 6.5K / s, the high resistant to compression breaking strength approximately is equal to 3500MPa, Gao Weishi degree of hardness Hv approximately is equal to 1230, needs the raw material majority is the industry purity, thus reduced the cost, simultaneously prepares the craft simply, may prepare the critical dimension biggest Fe matrice body crystalless alloy, the industry application potential is very big.

Owner:辽宁峰阁钛业集团有限公司

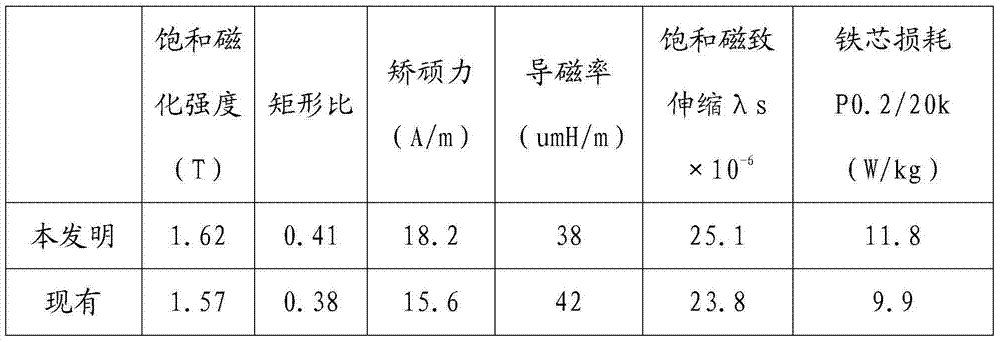

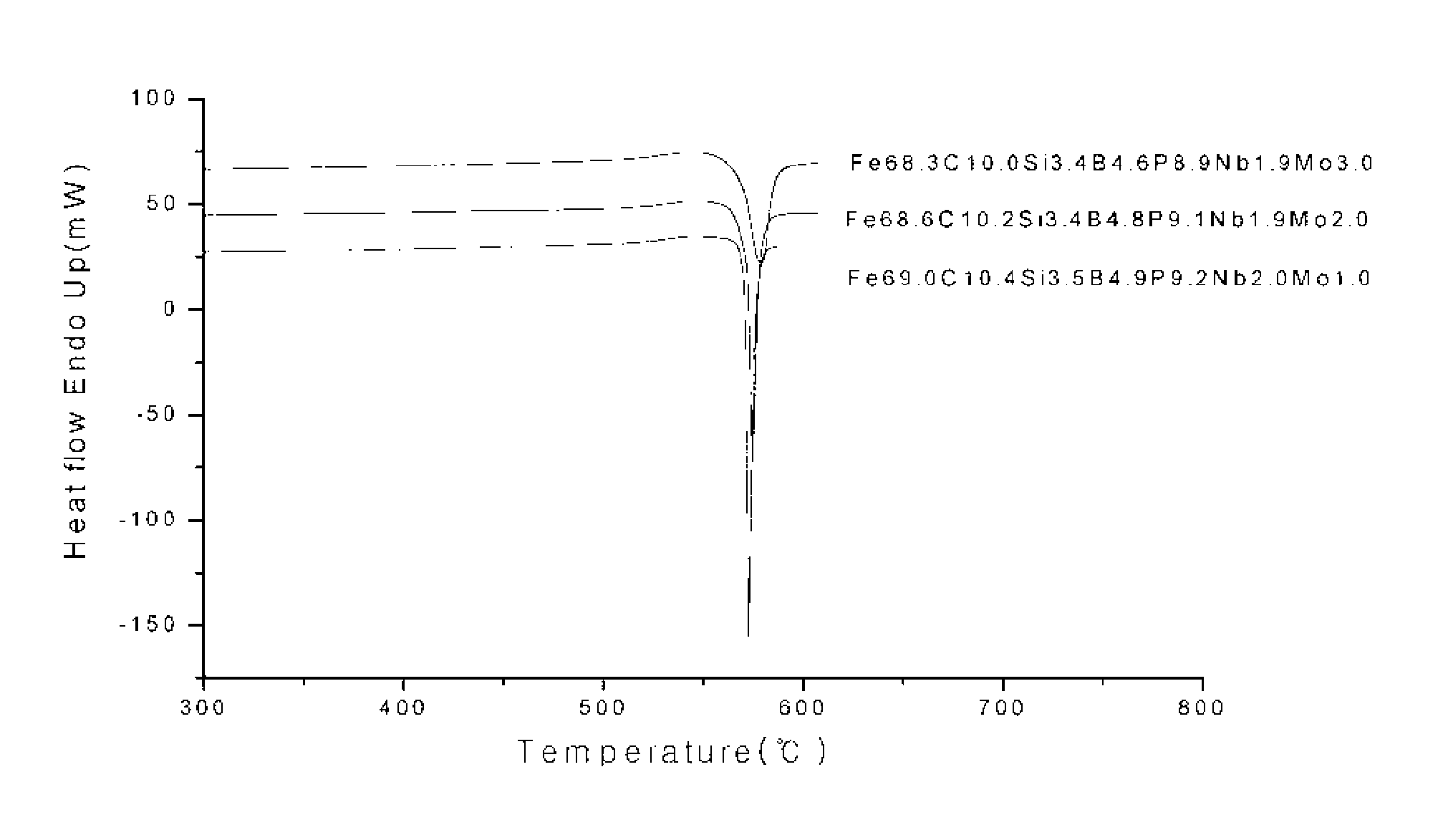

Toughness-enhanced iron-based bulk amorphous soft magnetic alloy and preparation method thereof

ActiveCN105741998AHigh saturation magnetic inductionLow coercivityMagnetic materialsToughnessElectron

The invention relates to toughness-enhanced iron-based bulk amorphous soft magnetic alloy and a preparation method thereof, belonging to the field of a magnetic functional material. The expression formula of the alloy is Fe<x>SiBP<c>C<d>Mo<e>M<f>, wherein M is at least one of Cu, Ag and Au, x, a, b, c, d, e and f respectively represent atomic percent content of each corresponding constituent, a is more than or equal to 0.5 but less than or equal to 14, b is more than or equal to 0.5 but less than or equal to 15, c is more than or equal to 0.5 but less than or equal to 14, d is more than or equal to 0.1 but less than or equal to 5, e is more than or equal to 0.1 but less than or equal to 5, f is more than or equal to 0.2 but less than or equal to 1, x is more than or equal to 72 but less than or equal to 85, and (x+a+b+c+d+e+f) is equal to 100%. With the preparation method provided by the invention, the saturation magnetic induction and the plastic deformation capability of iron-based bulk amorphous can be simultaneously improved; moreover, the production process is simple, is low in cost and is easy for industrialization; and the product has excellent soft magnetic performance and toughness, and can be taken as a structure and a functional soft magnetic material applied to the fields of power, electrons, information, communication and the like.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Double-phase steel and production method thereof

The invention discloses double-phase steel and a production method thereof. The double-phase steel comprises the following components in percentage by mass: not more than 0.12 percent of C, not less than 0.40 percent of Si, not more than 2.50 percent of Mn, not more than 0.020 percent of P, not more than 0.010 percent of S and not more than 0.030 percent of Nb. The production method comprises the following steps of: pretreatment of molten iron, smelting in a converter, fine adjustment of alloys, treatment in an LF (ladle furnace), continuous casting, hot continuous rolling, acid-washing and cold-rolling, and continuous annealing, wherein in the continuous annealing step, an N2-H2 mixed gas in which H2 accounts for 5-35 percent is used for cooling, the heating temperature T1 is 760-840 DEG C, the slow cooling temperature T2 is 640-670 DEG C and the overaging temperature T3 is 300-320 DEG C. The double-phase steel disclosed by the invention is good in surface quality.

Owner:MAANSHAN IRON & STEEL CO LTD

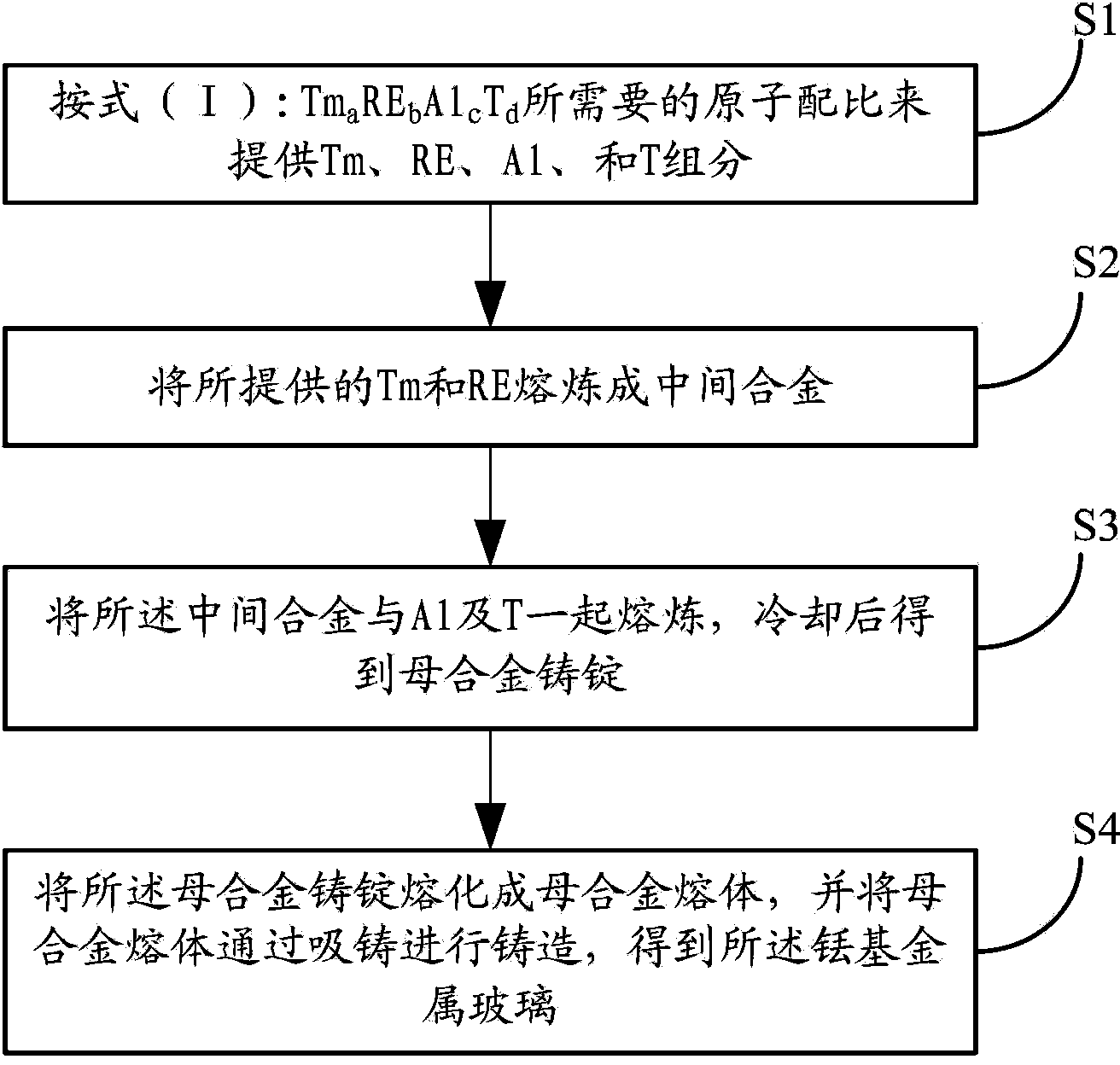

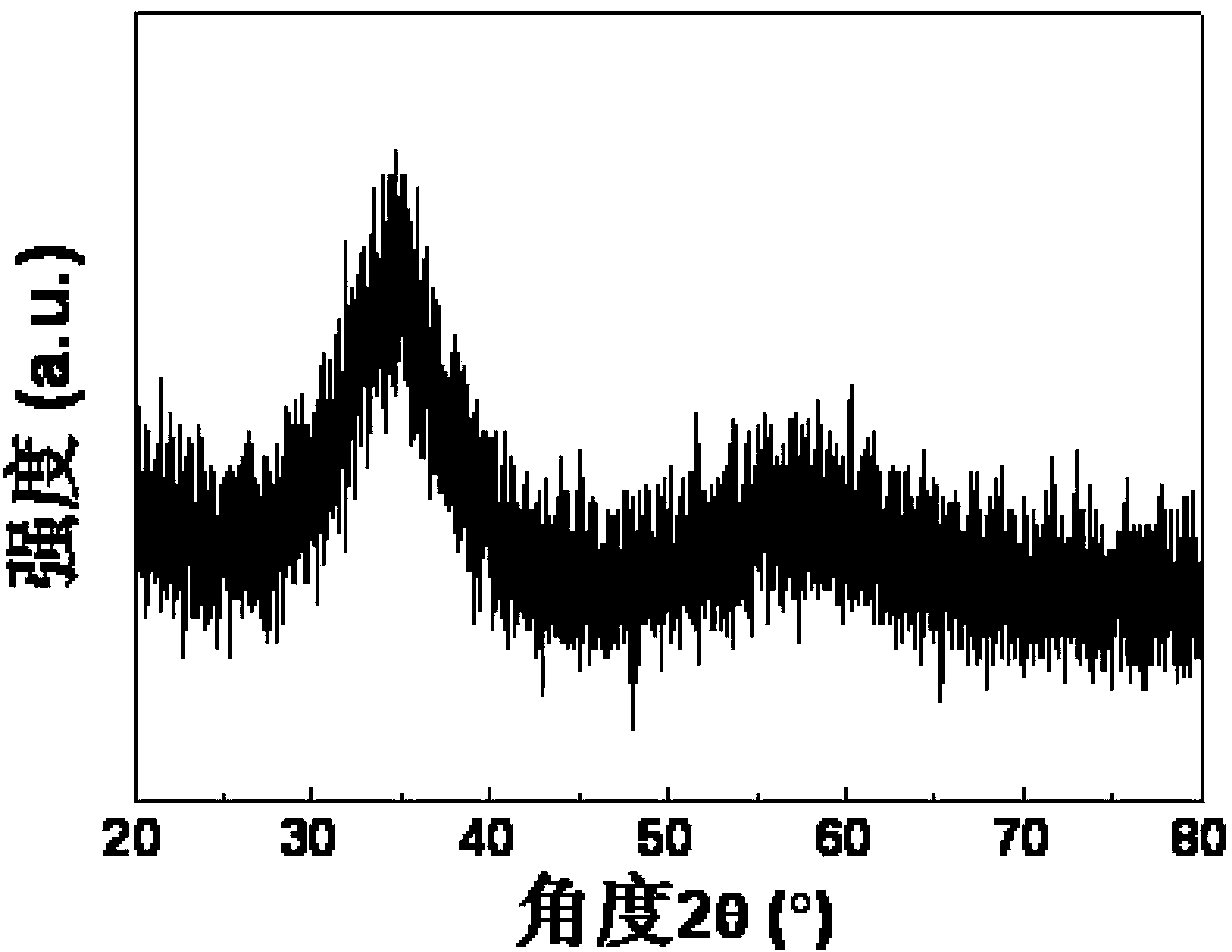

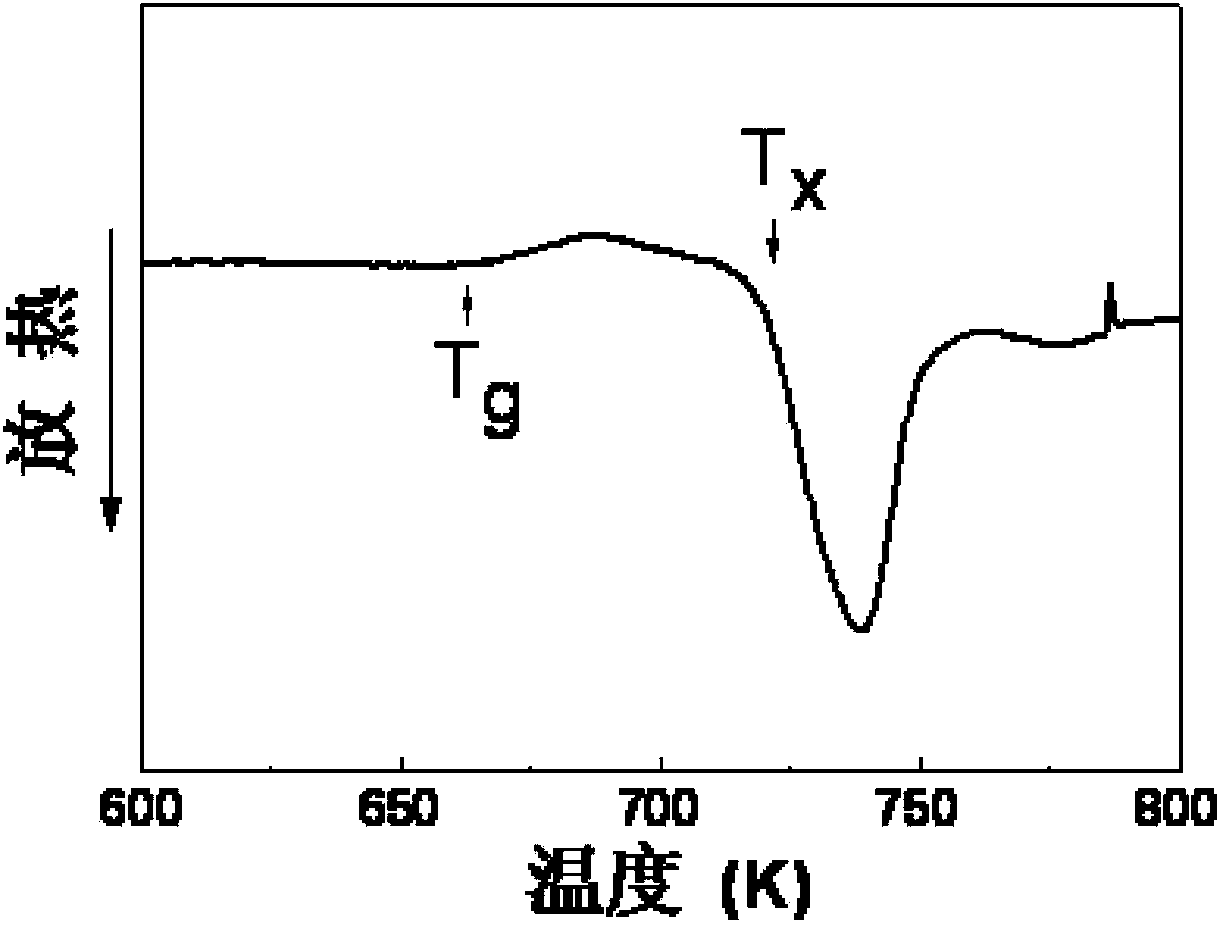

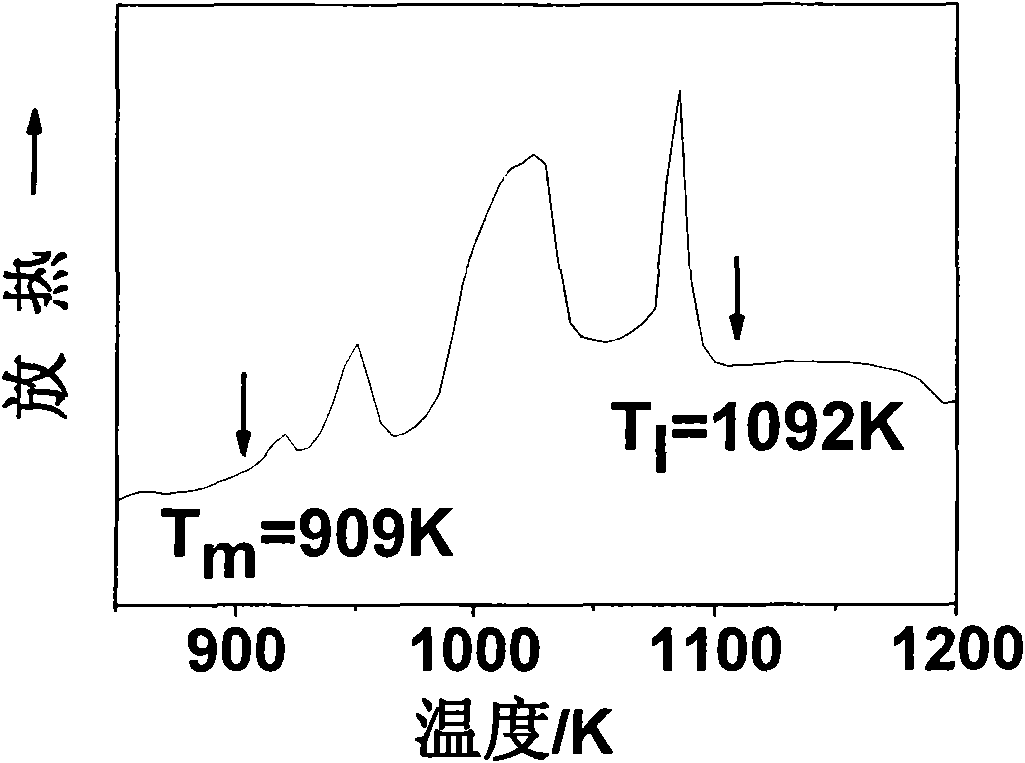

Thulium-based metal glass, preparation method and application thereof

ActiveCN103668008AMagnetic transition temperature range is wideLow critical cooling rateRare-earth elementThulium

The invention discloses thulium-based metal glass, a preparation method and an application thereof. Based on thulium as the major component, the formula of the thulium-based metal glass is shown in a formula (I), RE represents one or more rare earth elements selected from Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho and Er; T represents Co or Ni; a, b, c and d represent atomic percents of elements, wherein a is greater than or equal to 30 and less than or equal to 60, b is greater than or equal to 5 and less than or equal to 30, c is greater than or equal to 20 and less than or equal to 25, d is greater than or equal to 15 and less than or equal to 25, (a+b) is greater than or equal to 50 and less than or equal to 60, and (a+b+c+d) is equal to 100. According to the thulium-based metal glass disclosed by the invention, on the one hand, the amorphous forming ability can be modulated by changing RE and T, and on the other hand, the temperature interval of the thulium-based metal glass on magnetic transformation can be modulated to expand the magnetic transformation area, so that the thulium-based metal glass has great magnetocaloric effect in a wider temperature interval. TmaREbALcTd(I).

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

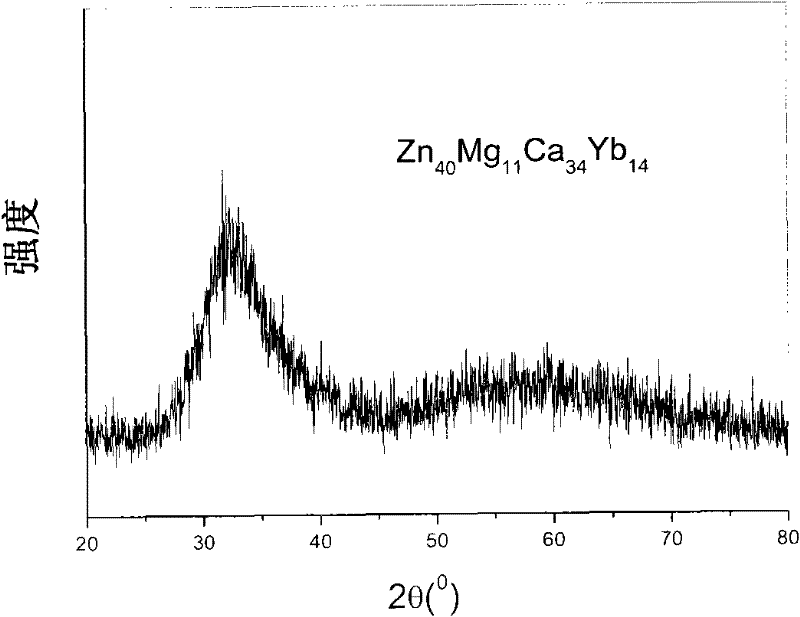

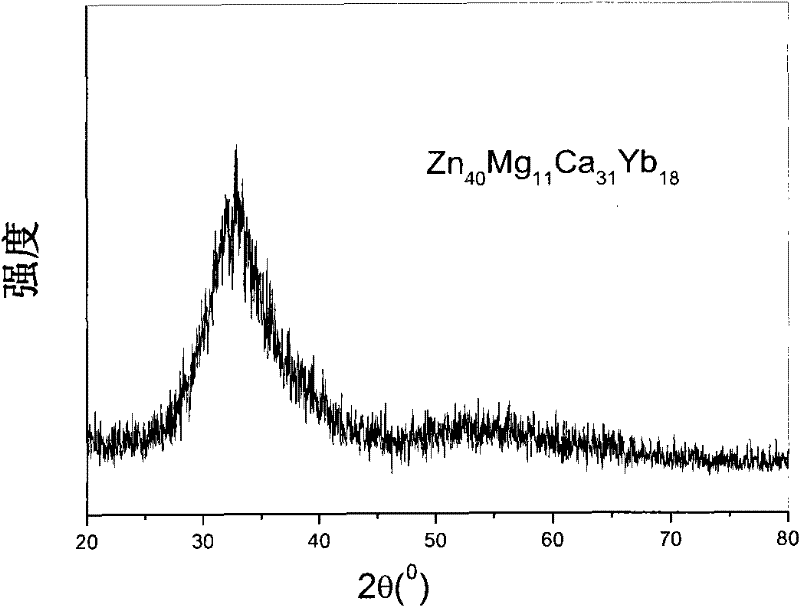

Zinc-based massive amorphous alloy and preparation method thereof

The invention relates to a zinc-based massive amorphous alloy and application thereof. Zinc is a main component of the alloy, and the composition of the alloy is represented by the following formula: ZnaMgbCacYbdXe, wherein subscripts represent atom ratios (molar ratios), a is more than or equal to 36 and less than or equal to 60, b is larger than or equal to 9 and less than or equal to 15, c is larger than or equal to 5 and less than or equal to 39, d is larger than or equal to 0 and less than or equal to 19, e is more than or equal to 0 and less than or equal to 25, and a+b+c+d+e=100; and the element X is one or more elements selected from Sr, Ba, La, Ce, Pr, Nd, Sm, Sc, Li, Ga, Sn, Ni, Cu, Ag and Al. The alloy contains at least 50% of amorphous phase in volume percent. Because of good inoxidability, low cost, low glass transformation temperature, wide supercooling liquid phase zone and the like, the alloy is extremely suitable for micro-nano scale formation.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

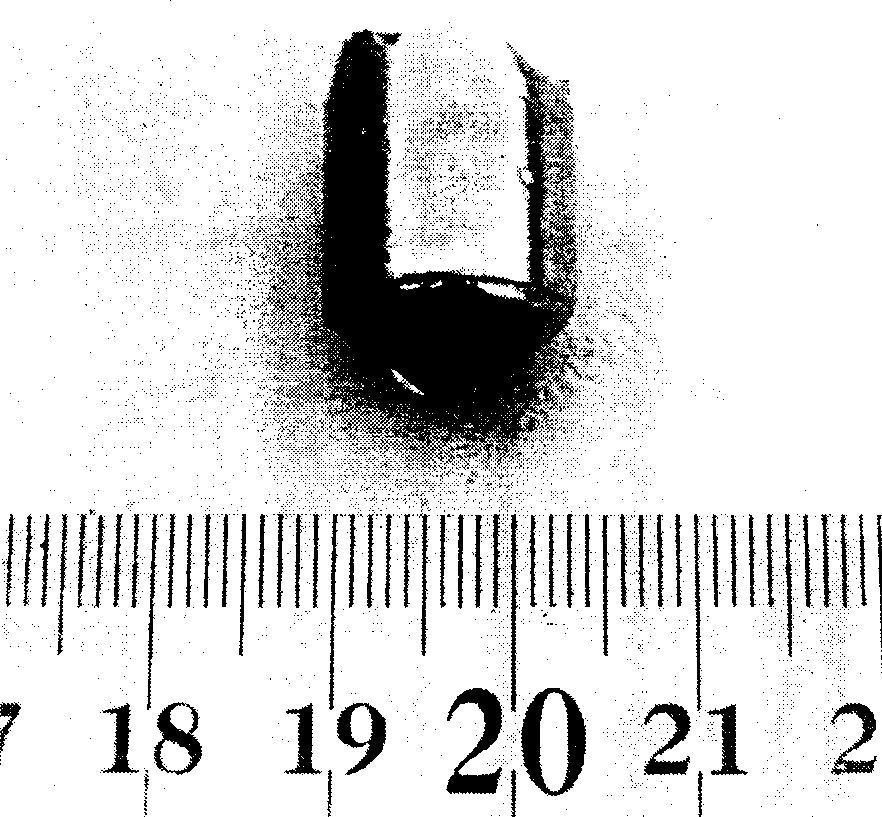

Polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate and manufacturing method thereof

InactiveCN102364738ALow critical cooling rateStrong ability to inhibit crystallizationCell electrodesElectric arcCorrosion

The invention discloses a polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate and a manufacturing method thereof. Materials are prepared according to a required atomic moore proportion of a composition formula, namely Zr60-xNbxCu20Al10Ni10 (x is equal to a value ranging from 0 to 20). A mother alloy ingot is smelted by electric arc under the protection of argon; and the mother alloy ingot is re-smelted for at least three times, so that the chemical uniformity can be guaranteed. Current of a vacuum electric arc furnace is 150 to 250 amperes; and a zirconium-base bulk metallic glass plate with a thickness of between 0.1 and 3 millimeters is cast and formed by a Cu die. The purity of elements, namely Zr, Nb, Cu, Ni and Al is more than or equal to 99.95 weight percent; the zirconium-base bulk metallic glass at least contains 95 vol percent of amorphous phase; a corrosion speed is lower than 16 mu A per square centimeters; and the conductivity is more than 5,000 S per centimeters. The polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate has higher conductivity and high corrosion resistance, and the cost can be reduced greatly; and the polymeric electrolyte membrane fuel cell bulk metallic glass bipolar plate can be applied to the field of manufacturing of fuel cells.

Owner:DALIAN JIAOTONG UNIVERSITY

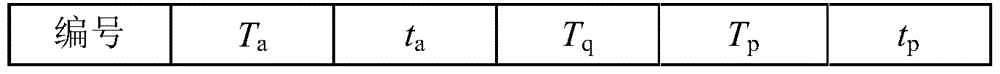

Hot isostatic pressing treatment process method for casting forming ZL101A aluminum alloy

The invention relates to a hot isostatic pressing treatment process method for a casting forming ZL101A aluminum alloy, belongs to the technical field of aluminum alloy casting and heat treatment, andsolves the problems that defects exist in a casting forming ZL101A aluminum alloy material, the fatigue performance of the material is affected, the heat treatment is carried out separately after hotisostatic pressing, many production processes are needed, and the period is long in the prior art. The hot isostatic pressing treatment process method for the casting forming ZL101A aluminum alloy comprises the following steps of step 1, casting ZL101A aluminum alloy castings; and step 2, carrying out hot isostatic pressing treatment on the ZL101A aluminum alloy castings in hot isostatic pressingequipment, wherein the step of carrying out hot isostatic pressing treatment comprises the steps of sequentially carrying out heating and boosting, high-temperature-segment heat preservation and pressure maintaining, pressure maintaining and quick cooling, low-temperature-segment heat preservation and pressure maintaining and cooling and depressurization. According to the method, the improvementof the strength and the anti-fatigue mechanical property of the ZL101A aluminum alloy material is realized, the production cycle of the conventional hot isostatic pressing treatment casting aluminum alloy is shortened, and the production cost is saved.

Owner:钢研昊普科技有限公司 +1

Preparation method of Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy

The invention provides a preparation method of Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy. The method comprises the following steps: mixing high purity magnesium block, lithium block, nickel block, high purity copper ingot and high purity yttrium block according to a nominal formulation-Mg65LixCu20-xNi5Y10 (0<x<5at.%), wherein firstly smelting by using the vacuum induction melting method to obtain Cu-Ni-Y ternary alloy, secondly polishing the Cu-Ni-Y alloy, grinding the alloy to mix with magnesium block and lithium block and then using the same smelting method to prepare Mg-Li-Cu-Ni-Y quinary master alloy; and (2) after grinding the Mg-Li-Cu-Ni-Y quinary master alloy prepared by smelting, and performing vacuum rapid quenching on an ultrafast quenching device to prepare the high-strength Mg-Li matrix Mg-Li-Cu-Ni-Y series bulk amorphous alloy. The preparation method of the invention avoids large ignition loss of Mg and Li and impurity elements and increases the purity of the amorphous alloy, and the obtained Mg-Li matrix amorphous alloy has high strength, low density and good corrosion resistance.

Owner:HARBIN ENG UNIV

Fe-based bulk amorphous alloy compositions containing more than 5 elements and composites containing the amorphous phase

Owner:POHANG IRON & STEEL CO LTD

Magnesium base massive amorphous alloy and preparation method thereof

The massive amorphous magnesium-base alloy has Mg as main component and proper amount of RE element, and contains at least 50 vol% of amorphous phase. It has composition of Mg100-b-cMb[R1-aYa]c, where an is 0-1, b is 0-31, and c is 5-21. The preparation process of the alloy includes mixing and smelting M and R components in arc furnace with Ti adsorbed Ar to obtain binary alloy ingot; smelting the crushed binary alloy and Mg lump in an inducing furnace with 0.01 atm Ar filled for 2-5 min to obtain the main alloy ingot; and re-smelting the main alloy ingot in air atmosphere and casting in metal mold to obtain the alloy. The alloy has high glass-forming capacity and high crystallization inhibiting ability, and may have great size obtained at low cooling rate.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Gadolinium-base block amorphous alloy and its preparing method

This invention refers to a kind of Gd big amorphous alloy, whose main component is Gd. It also contains at least 50% by volume of amorphous phase, and its composition can be indicated by the formula below: GdaAlbNicCudMe. (50<=a<=80, 5<=b<=20, 5<=c<=20, 5<=d<=20, 0<=e<=15, a+b+c+d+e=100). The transitional subgroup metal element M said above is Sc, Nb, Ti, Cr, Mn, Fe, Co, Y, La, Pr, Nd or Hf. The alloy is made in arc furnace of argon atmosphere, and the argon is adsorbed by Ti. The components said above are melted in the arc furnace to get mother alloy cast ingot. Then the conventional metal casting method is used to molt the mother alloy cast ingot. After that, we use the inspiring-and-casting device in the arc furnace to inspire the bath into the water-cooling copper mould. At last, the alloy comes out. This alloy has the strong ability to suppress crystallization, so it is easy to form big amorphous alloy. Besides, it is easy to make and costs little. Also, the alloy has good magnetic performance and magneto-optic performance, so it can be used as function material.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

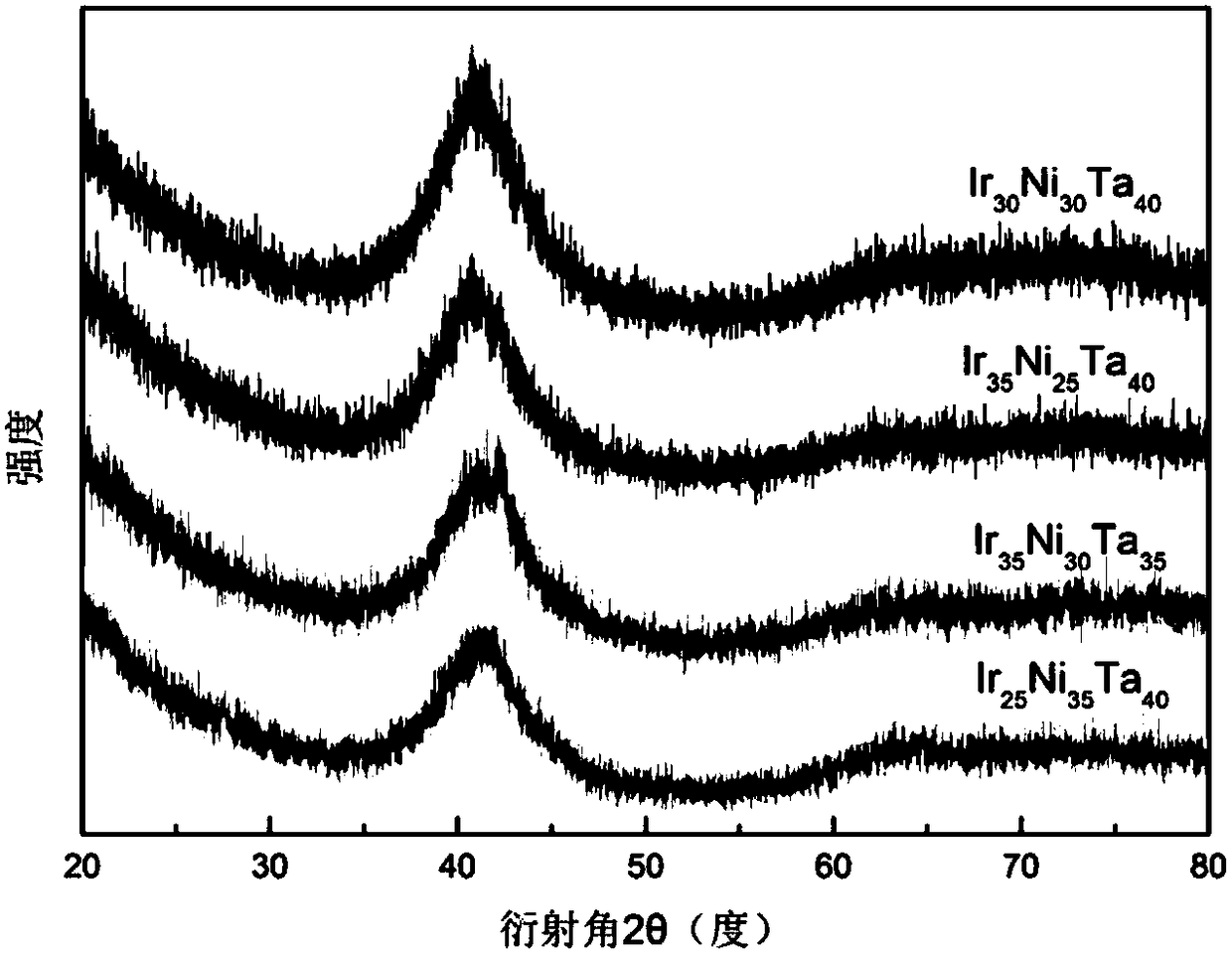

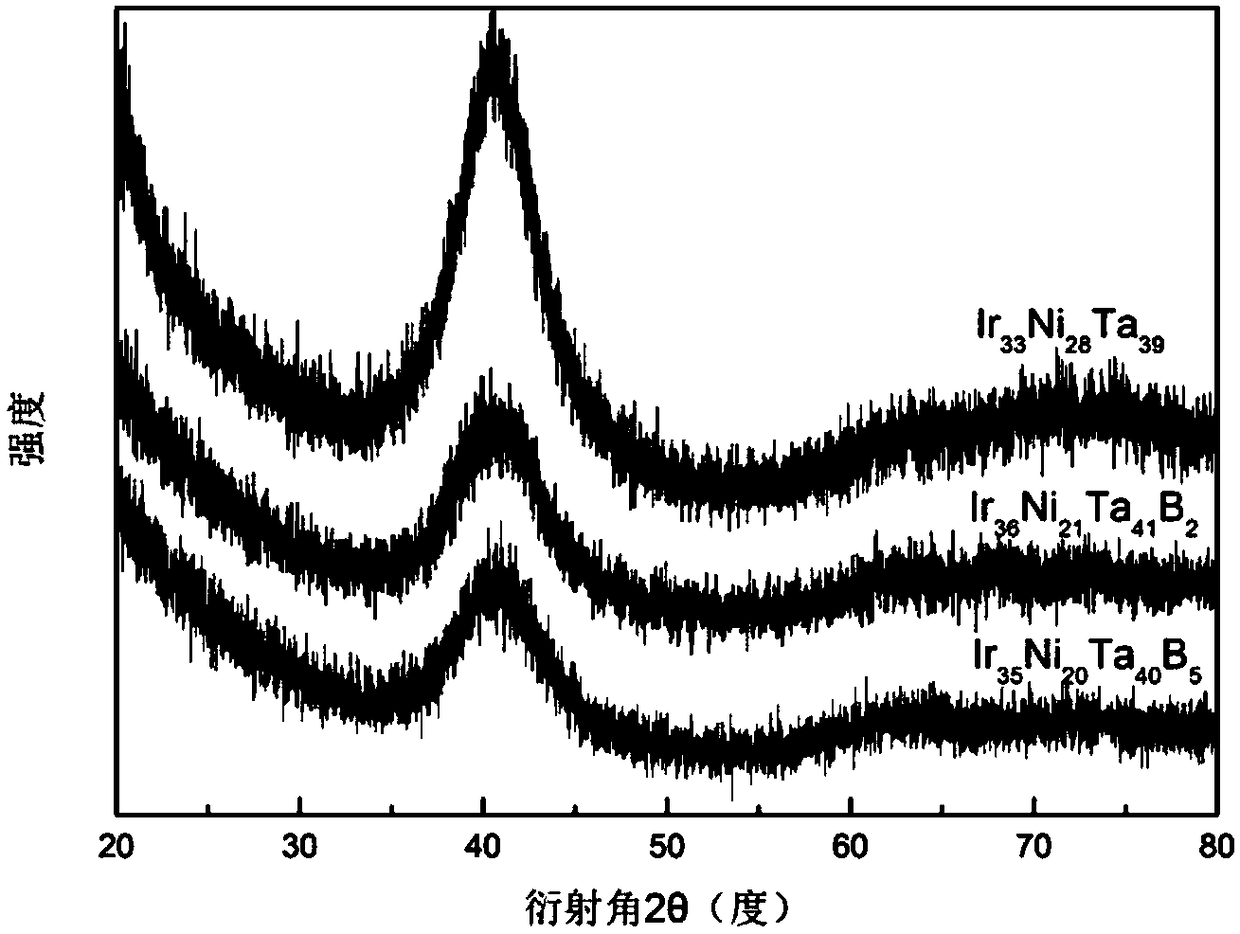

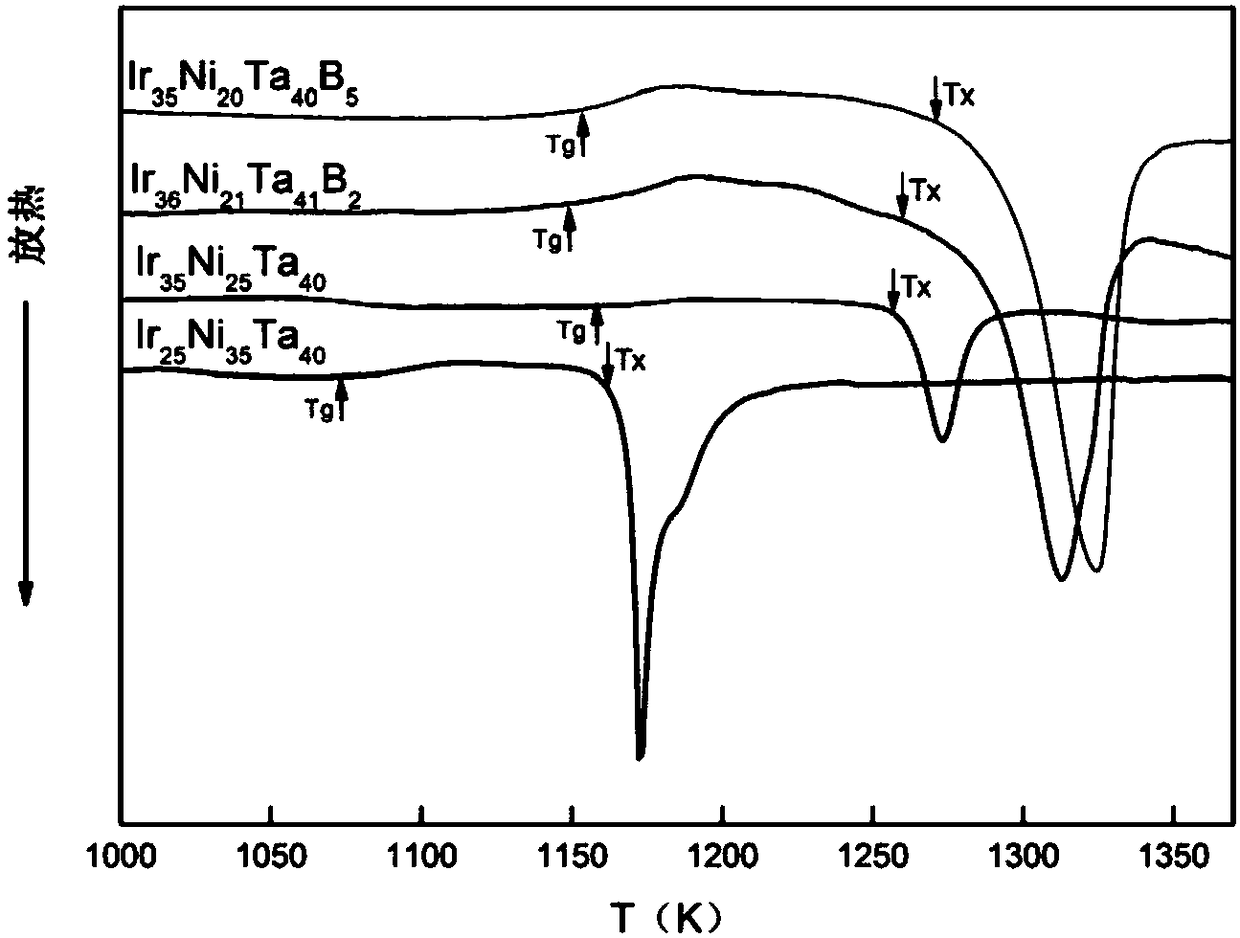

Block metal glass containing iridium and preparation method thereof

The invention relates to block metal glass containing iridium. The block metal glass takes the iridium as a basic element, and the composition formula is Ir[Ta<x>(Nb)<1-x>][Ni<y>(Co)<z>(Fe)<r>(Cu)<m>(V)<n>(W)<k>]<c>B<d>. The invention further relates to a preparation method of the block metal glass containing the iridium. Compared with the prior art, the block metal glass has the original antioxidant and corrosion resistance characteristics of an iridium alloy, and has an ultra-wide supercooling liquid phase region (about 100 K); the amorphous alloy can be subjected to thermoplastic molding in the temperature interval, the temperature is much lower than the processing temperature of a traditional iridium alloy, and thus the processing difficulty is greatly lowered; and meanwhile, theamorphous alloy uses non-precious metal components such as tantalum and nickel, thus the cost of the original iridium alloy is also lowered, and the amorphous alloy has wide application prospects.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Cobalt-based bulk amorphous alloy and preparation method thereof

The invention relates to a cobalt-based bulk amorphous alloy and a preparation method thereof. The alloy comprises the following components by atomic percentage: 33 to 55 percent of Co, 13 to 34 percent of Fe, 18 to 26 percent of B, 2 to 7 percent of Si, and 3 to 8 percent of Nb. Cobalt-based bulk metallic glass is proportioned according to the atomic mol ratio as required by the components, thenthe glass is forged for a plurality of times in a vacuum arc furnace, and the bulk amorphous alloy is prepared by casting in a vacuum copper mold. The bulk amorphous alloy has strong amorphous forming ability and excellent soft magnetic property, the size of the prepared amorphous material is not less than 3 millimeters at each dimensionality, the maximum size can reach 5 millimeters, the coercive force is between 1.17 and 2.35 A / m, and the maximum effective magnetic conductivity can reach 36,000 (1KHz 1A / m). The cobalt-based bulk amorphous alloy can be applied to magnetic devices in the fields of information, communication and the like.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

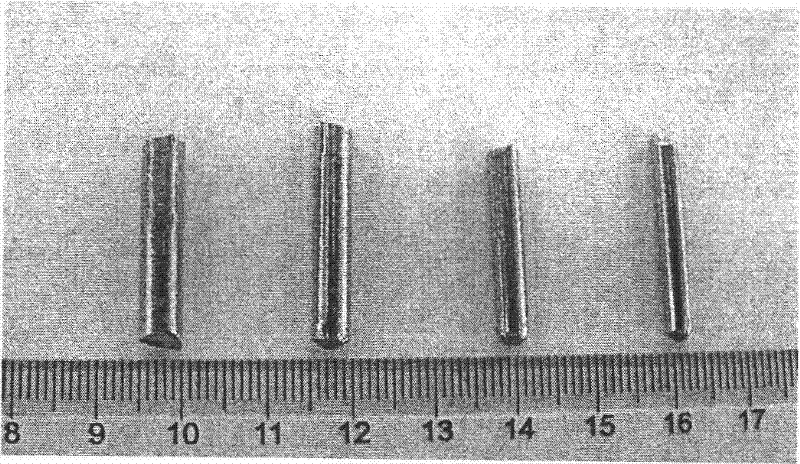

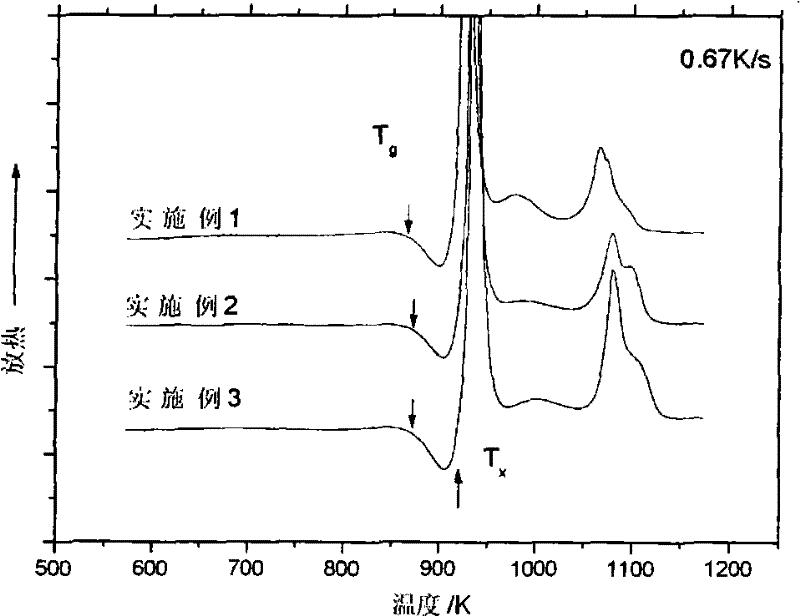

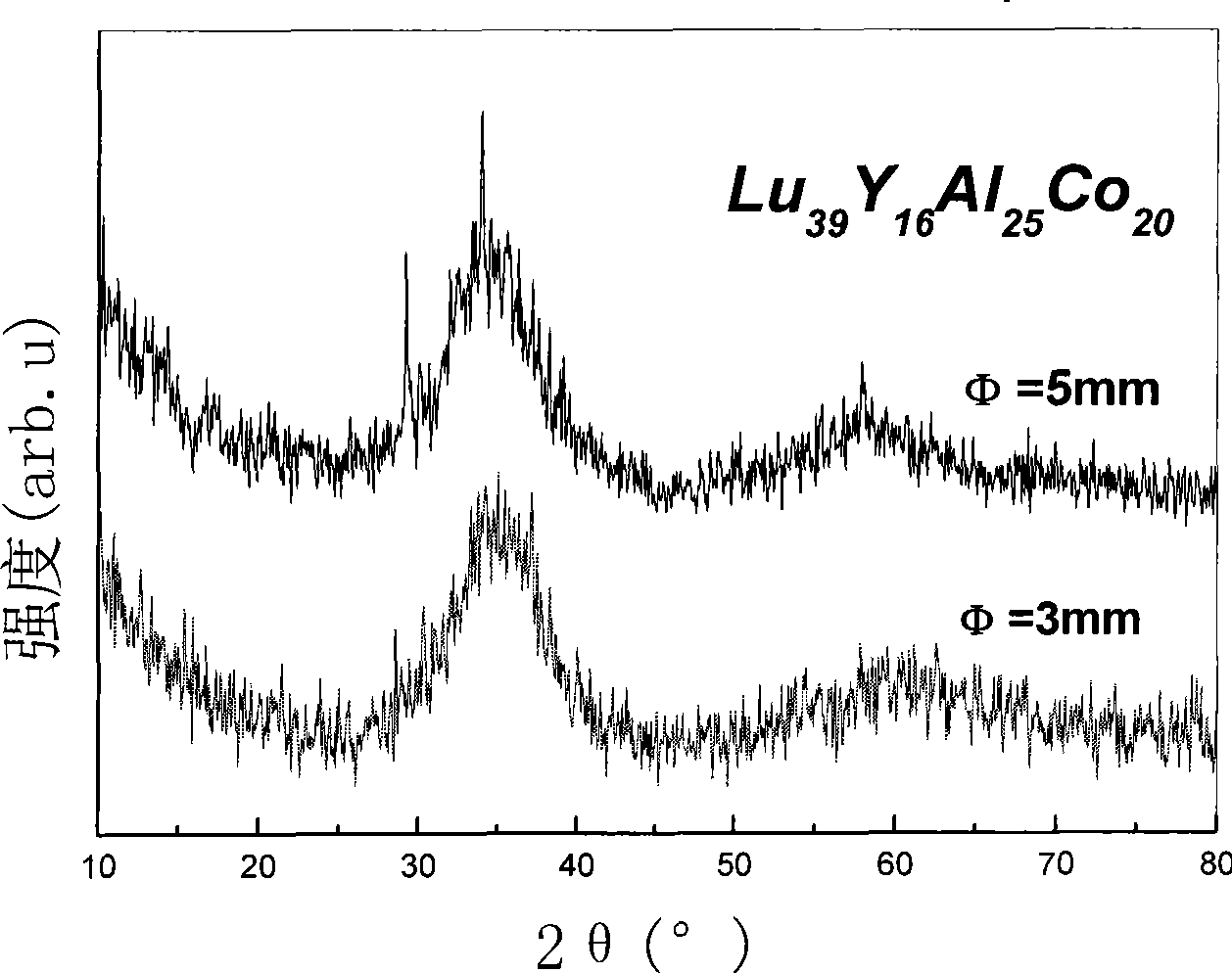

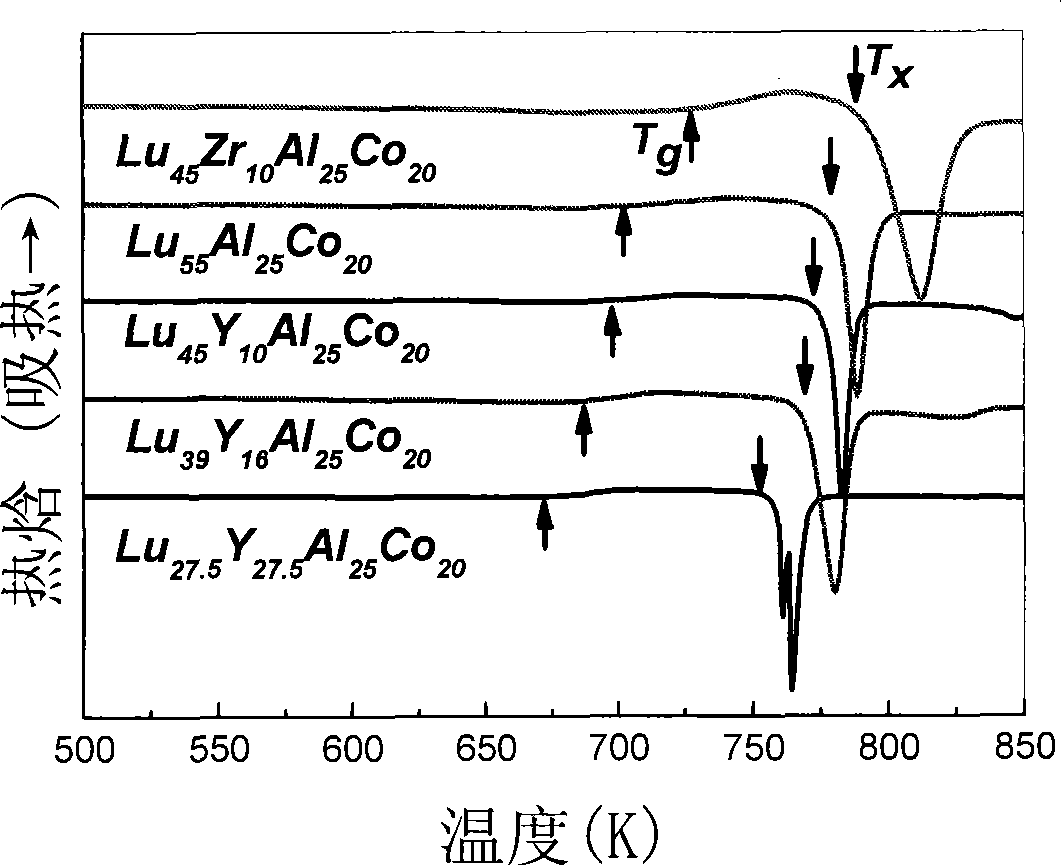

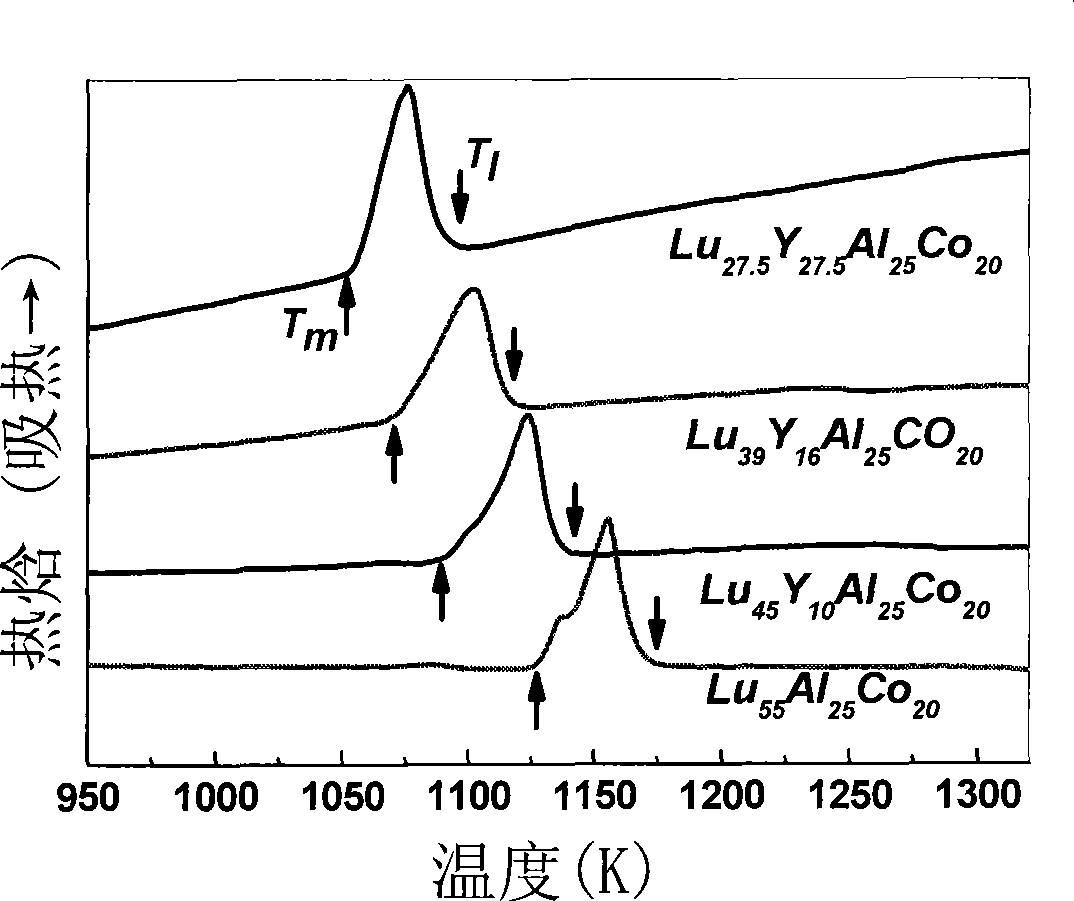

Lutetium based bulk amorphous alloy and preparation thereof

InactiveCN101497973AImprove the ability to formLow critical cooling rateLutetiumElectric arc furnace

The invention relates to a lutetium-based block amorphous alloy which takes lutetium as major components and contains at least 50 percent of amorphous phase according to percentages by volume, and the components of the lutetium-based block amorphous alloy are shown as in a formula I, wherein X is zirconium or / and yttrium, a is larger than or equal to 20 and less than or equal to 60, b is larger than or equal to 0 and less than 30, c is larger than or equal to 20 and less than 30, d is larger than or equal to 10 and less than 30, and in addition, a plus b plus c plus c plus d equals 100. A preparation method of the lutetium-based block amorphous alloy comprises the following steps: the components are molten according to required atomic proportions in an electric arc furnace with titanium-absorption argon atmosphere to obtain a master alloy cast ingot; the master alloy cast ingot is remolten by a conventional metal mold casting method, and melts are sucked into a water-cooling copper mould by a suction casting device in the electric arc furnace to obtain the lutetium-based block amorphous alloy. The invention has strong crystallization-inhibited capacity, simple preparation and lower cost and is easy to form large-size amorphous alloy. And the formula I is LuaXbAlcCod.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

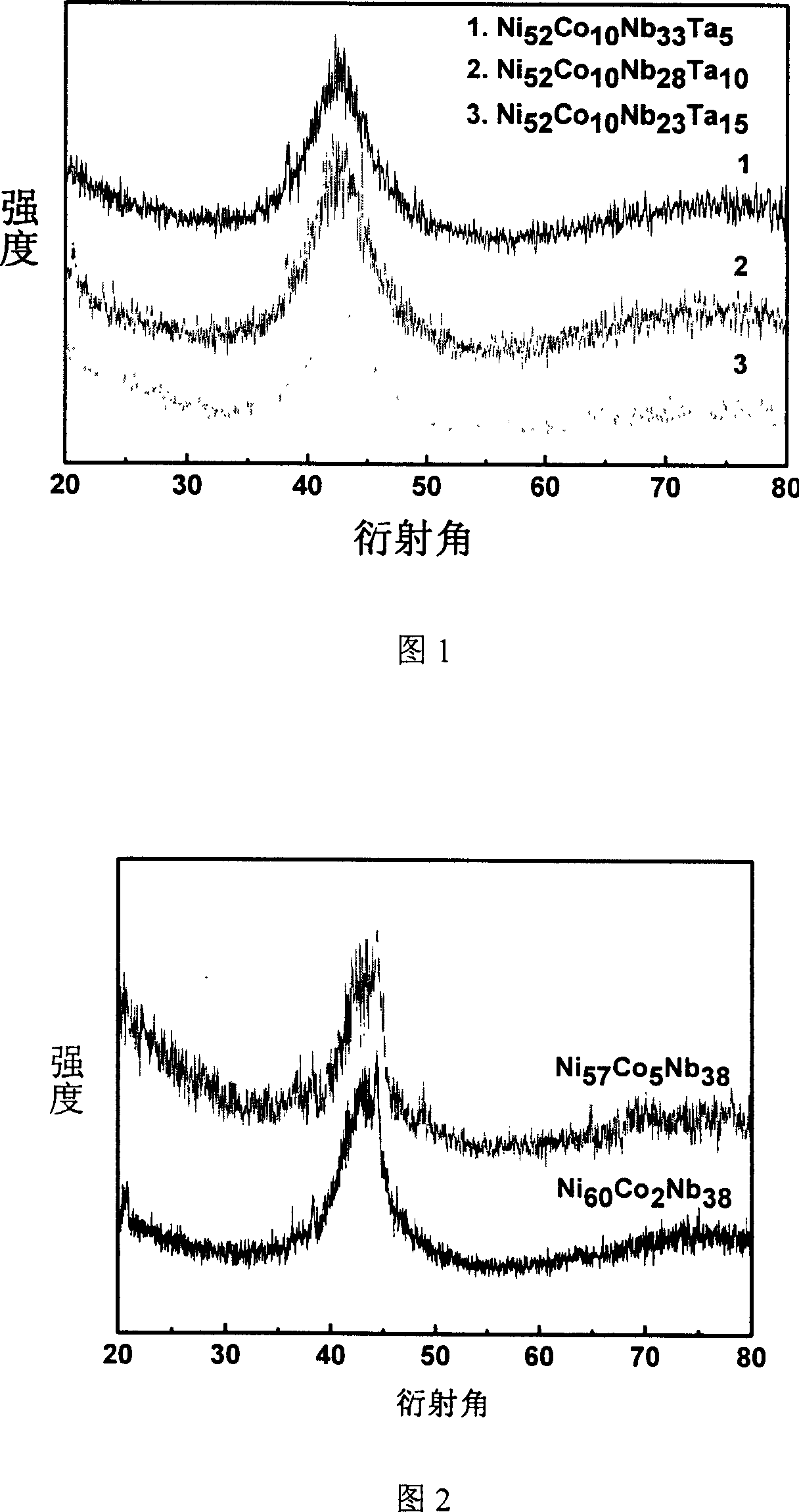

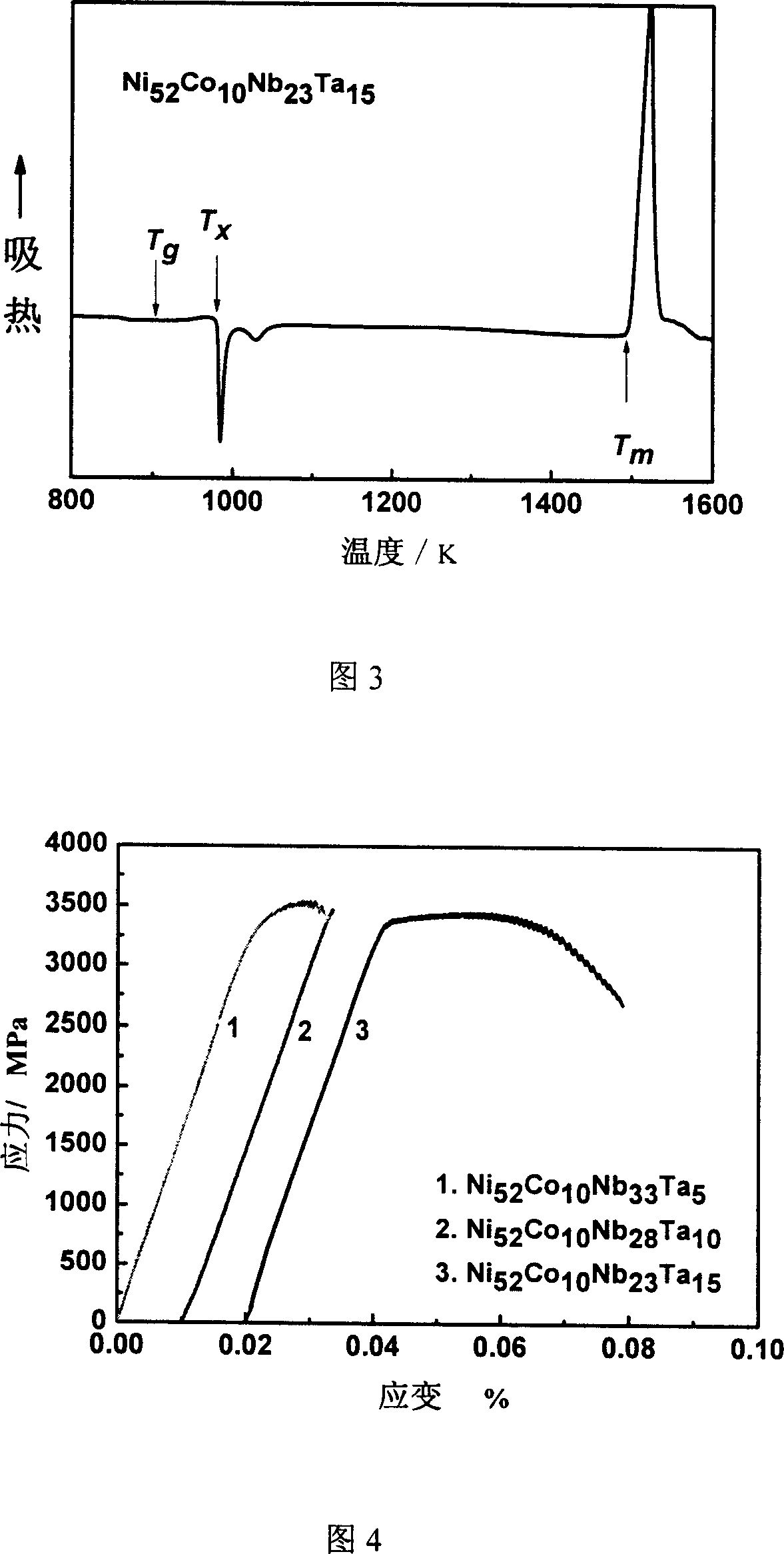

Nickle-based block metal glass and its production

A nickel-based block metal glass and its production are disclosed. It takes nickel, infusible metal niobium or / and tantalum as main ingredients and other metal components as alloy components, the composition is Ni62-xCoxNb38-yTay, 2<=x<=15, 0<=y<=38. The alloy contains amorphous-phase above 80 wt% volume. The process is carried out by burdening proportionally, casting ingot and absorb casting. It has excellent glass conversion and crystallizing temperature, thermal stability and mechanical performance.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

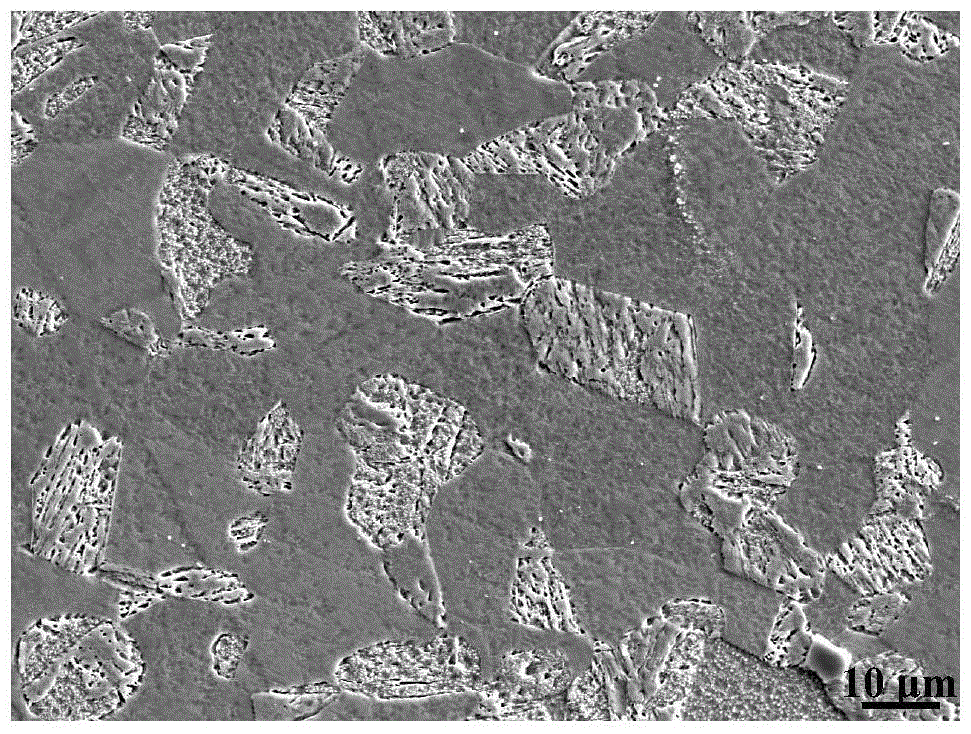

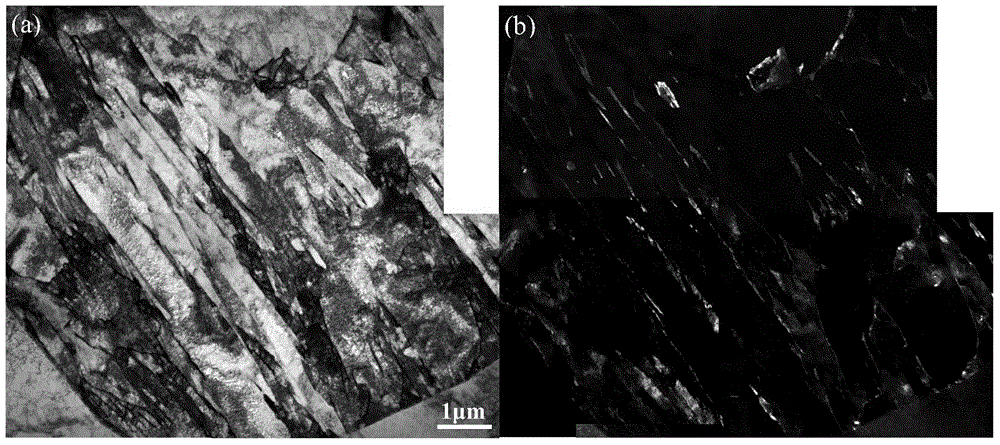

Galvanized-free high-strength and plastic cold-rolled stainless steel sheet for automobiles and manufacturing method thereof

ActiveCN104532129BReduced service lifeGood and stable corrosion resistanceSS - Stainless steelMartensite

A galvanized-free high-strength and plastic cold-rolled stainless steel plate for automobiles and a manufacturing method thereof, belonging to the field of metallurgical technology. Its composition contains Cr 11.0~17.0%, C 0.01~0.12%, Mn 0.2~0.5%, Si 0.2~1.1%, Al 0.005~0.5%, Ni<0.3%, Nb<0.2%, Ti<0.2% by weight. , V<0.2%, Mo<0.1%, Cu<0.03%, N<0.05%, P<0.03%, S<0.003%, the balance is Fe; its manufacturing methods include casting, hot rolling, cold rolling and quenching ‑Heat treatment for dispensing Q&P processes. The galvanized-free high-strength and plastic cold-rolled stainless steel plate for automobiles of the present invention eliminates the need for surface galvanizing. The material cost is significantly lower than austenitic stainless steel. The structure contains martensite, residual austenite and optional ferrite, and has Good combination of strength and plasticity, especially suitable for processing automobile structural parts and reinforcement parts.

Owner:NORTHEASTERN UNIV LIAONING

Iron-base bulk amorphous alloy with high glass-forming ability

One kind has the high glass to form the ability the hard matrice body crystalless alloy, it involves a kind of crystalless alloy material, specifically designs a kind to have the high glass to form the ability the hard matrice body crystalless alloy. The invention block body crystalless alloy by Fe, Co, Cr, Mo, C, B, Y is composed, various elements atomic percentage is: Fe36~~45%, Co5~~10%, Cr15%, Mo14%, C15%, B6%, Y1~~5%. The invention has the high glass to form the ability, uses the ordinary type mold casting to be allowed to prepare the critical dimension not to be smaller than the 14mm hard matrice body crystalless alloy, has low critical cooling speed 6.5K / s, the high resistant to compression breaking strength approximately is equal to 3500MPa, Gao Weishi degree of hardness Hv approximately is equal to 1230, needs the raw material majority is the industry purity, thus reduced the cost, simultaneously prepares the craft simply, may prepare the critical dimension biggest Fe matrice body crystalless alloy, the industry application potential is very big.

Owner:辽宁峰阁钛业集团有限公司

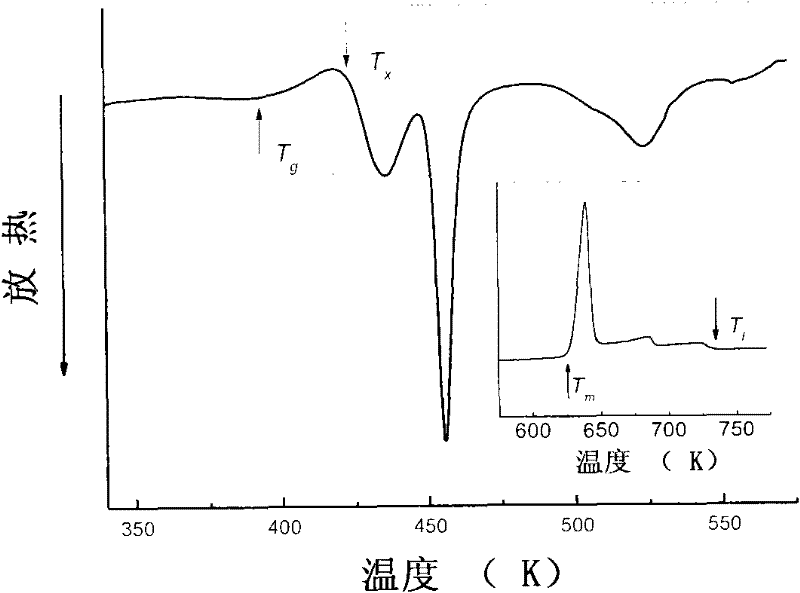

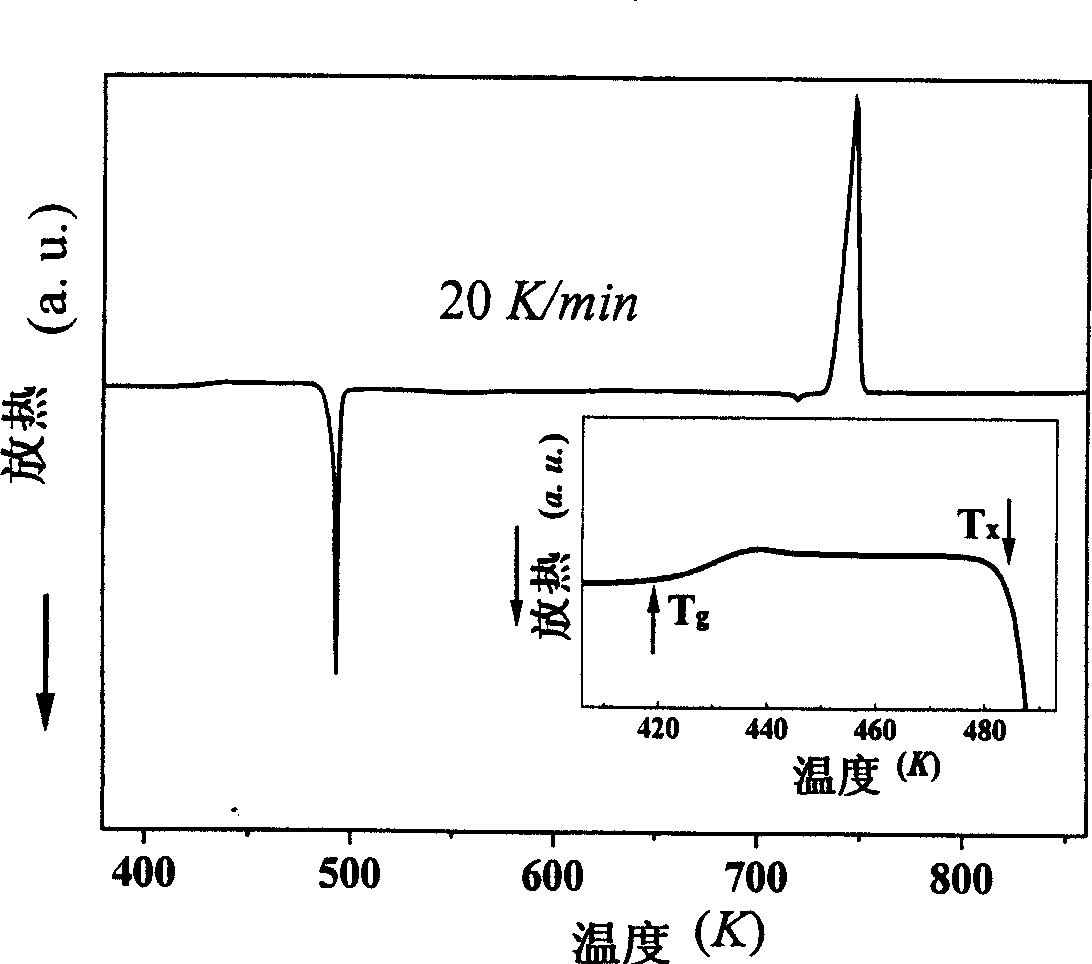

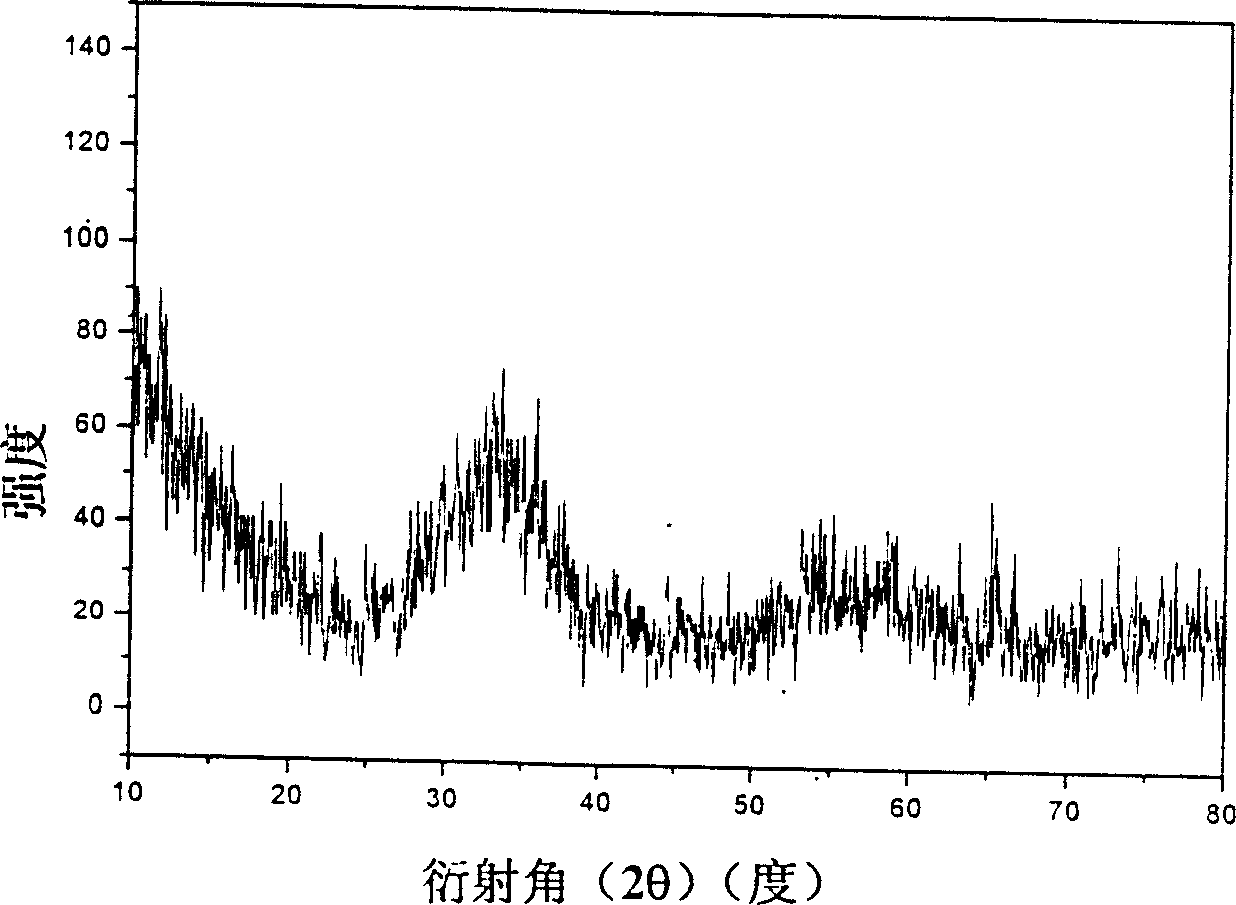

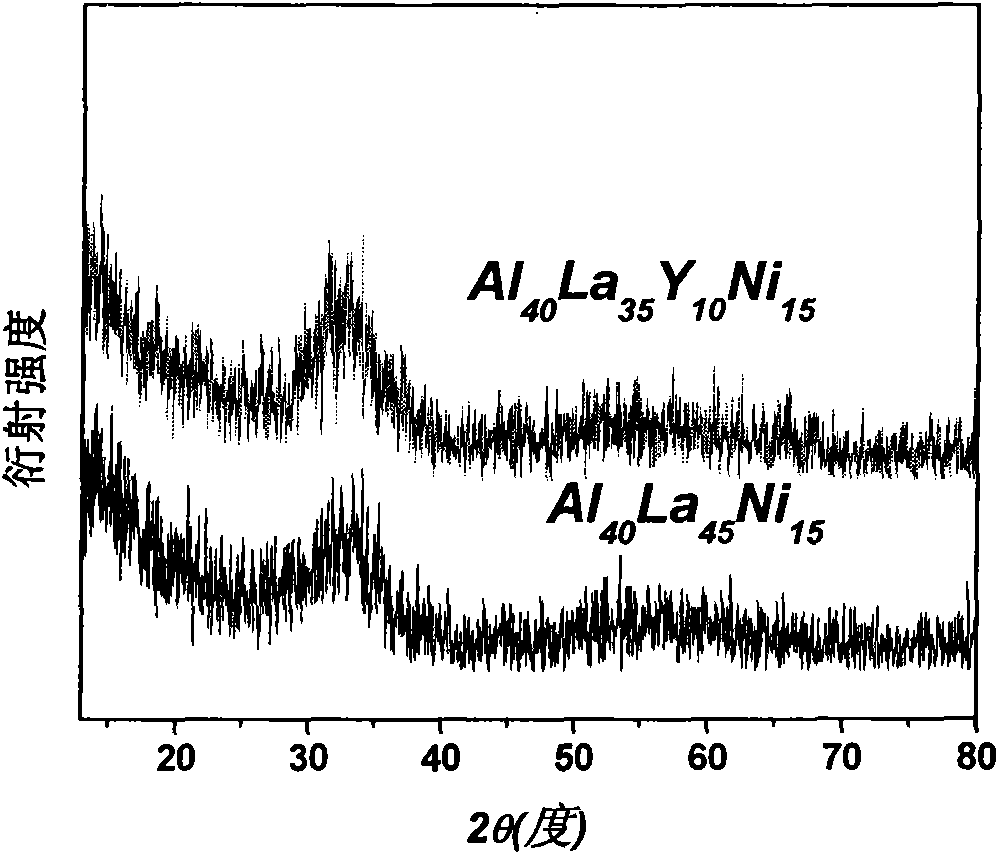

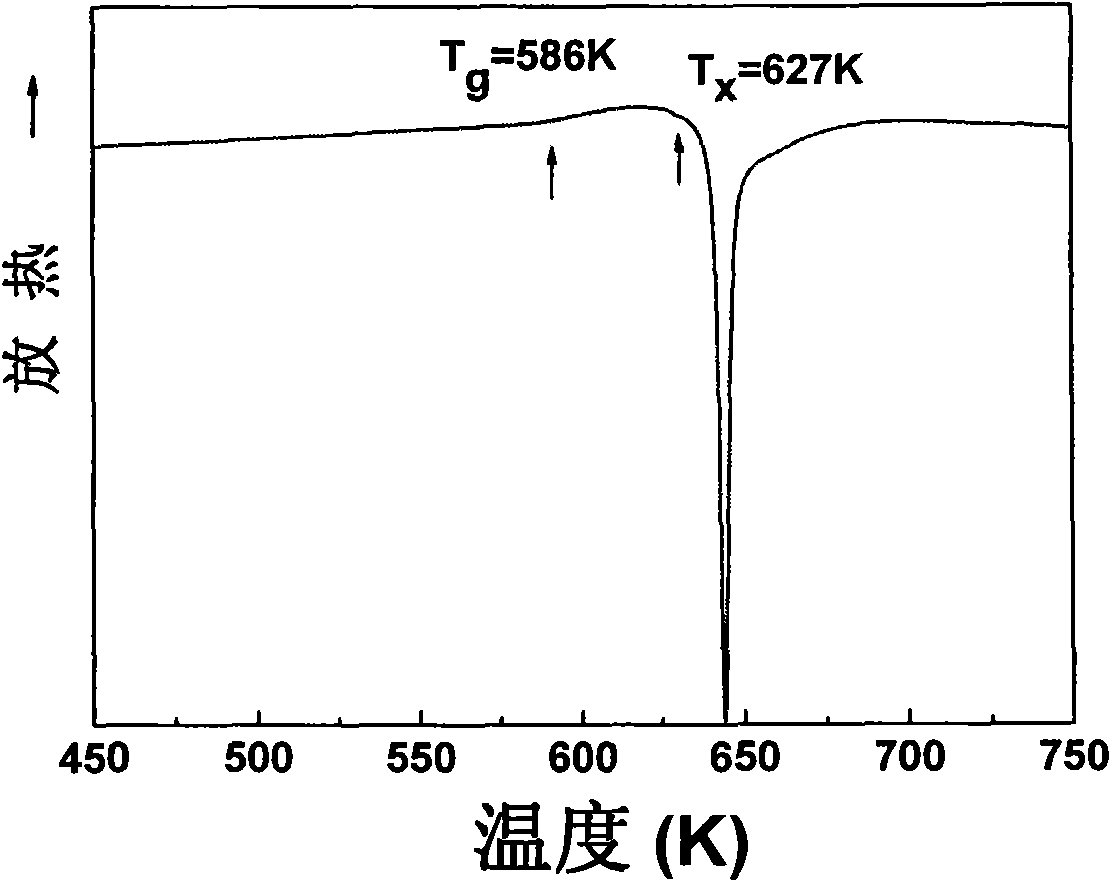

Aluminum rich bulk amorphous alloy and preparation method thereof

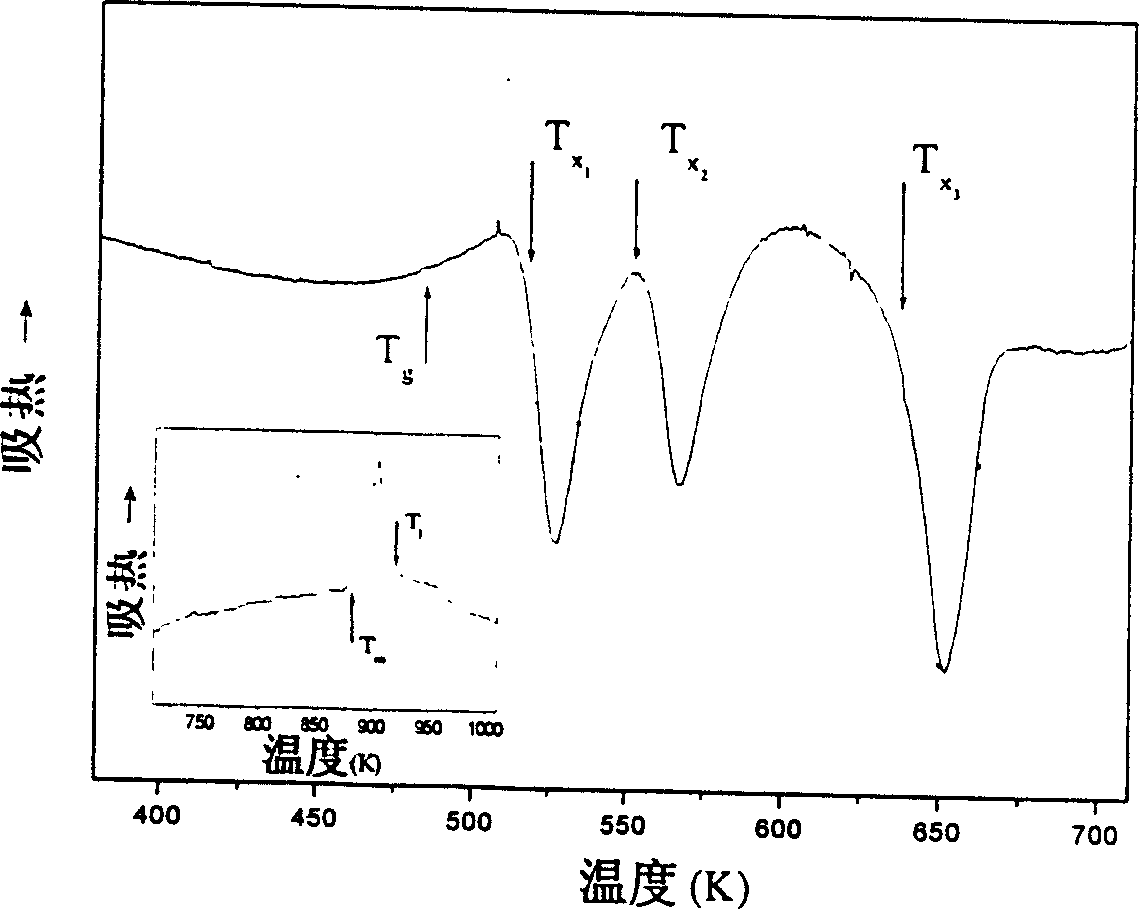

The invention relates to an aluminum rich bulk amorphous alloy which comprises Al[a]La[b]X[c]Ni[d]M[e], wherein X is cerium, yttrium, gadolinium or a combination thereof, M is cobalt or copper, a is larger than or equal to 35 but less than or equal to 40, b is larger than or equal to 30 but less than or equal to 55, c is larger than or equal to 0 but less than or equal to 20, d is larger than or equal to 5 but less than or equal to 15, e is larger than or equal to 0 but less than or equal to 10, and the sum of a, b, c, d and e is 100. The invention relates to another aluminum rich bulk amorphous alloy which comprises Al35Gd[f]Er[50-f]Co15, wherein f is larger than or equal to 0 but less than or equal to 22. The invention also relates to the preparation method of the aluminum rich bulk amorphous alloy, which comprises the following steps: preparing each metal ingredient according to the required ratio, smelting, cooling, cracking, remelting and suction-casting. The sizes of the aluminumrich bulk amorphous alloy provided by the invention are not less than 1mm in all dimensions, the aluminum rich bulk amorphous alloy has a high glass forming ability, the crystallization temperature is between about 590K and 680K, the glass transformation temperature is between 530K and 640K, and the width of a supercooled liquid phase region is between 35K and 70K.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

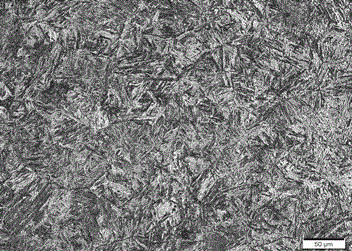

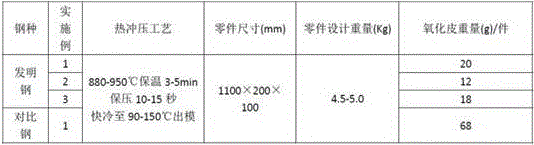

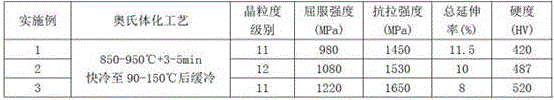

A high-temperature oxidation-resistant steel for non-coating hot stamping

A high-temperature oxidation-resistant non-coated hot stamping steel, the chemical composition of which is C0.18-0.28% by weight, Si0.05-0.50%, Mn0.20-0.90%, P≤0.010%, S≤0.005 %, Cr0.20~1.50%, Mo0.01~0.30%, B0.0006~0.0030%, Nb+V+Ti 0.02~0.25%, Al0.010~0.100%, the balance is Fe and other unavoidable impurities The element; its preparation method can only be prepared through the hot stamping forming process after the steelmaking, billet casting, hot rolling, pickling and cold rolling processes; the metallographic structure is full martensite. The steel for hot stamping forming of the present invention has the characteristics of fine grain, anti-oxidation, low critical cooling rate, etc., can be used normally under the condition of no protective atmosphere, and its performance meets the requirements of the oxidation resistance of the hot stamping forming plate and the strength of the hot stamping forming member .

Owner:HENAN SUDA ELECTRIC AUTOMOBILE TECH

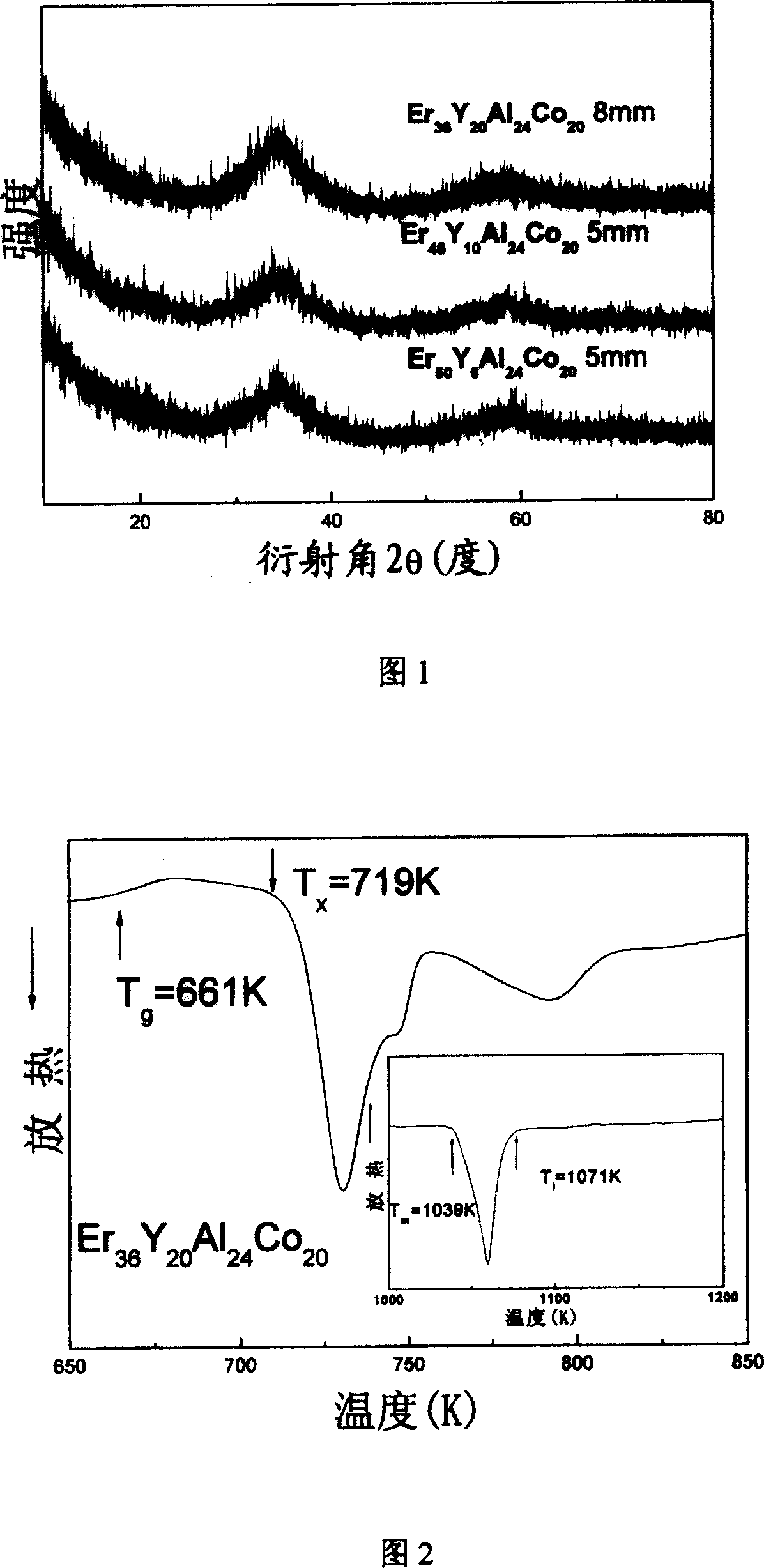

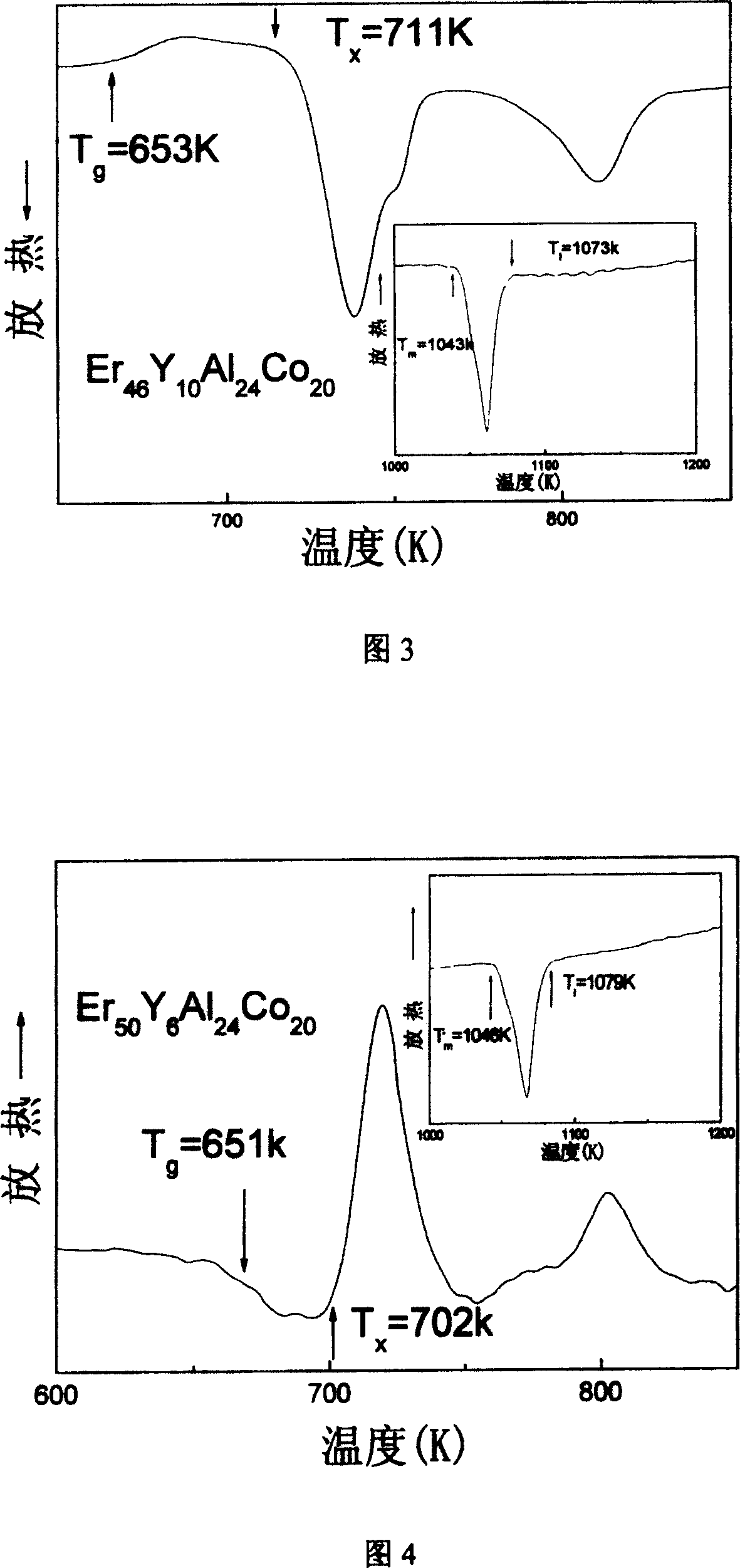

Erbium-base lorge-cube non-crystal alloy and making method

This invention relates to the Er base big non-crystal alloy and its preparation method, which takes Er as the main component and the composition can be expressed by the following formula: EraYbAlcXd, in which, 36<=a<=70, 0<=b<=20, 10<=c<=28, 6<=d<=20, a+b+c+d=100 and element X is Co or Cu, the purities of Er, Y, Al, Co and Cu are not less than 99.9wt% and the alloy includes at least 50% volume percentage of non-crystal phase. The preparation method includes: mixing Er, Y and X in terms of the above mentioned proportion to be smelted repeatedly for many times in an arc furnace under Ti adsorbed Ar atmosphere to get a mother alloy cast ingot, which is smelted again to be absorbed into a water-cooled Cu mould by an cast-absorbing device in the arc furnace.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

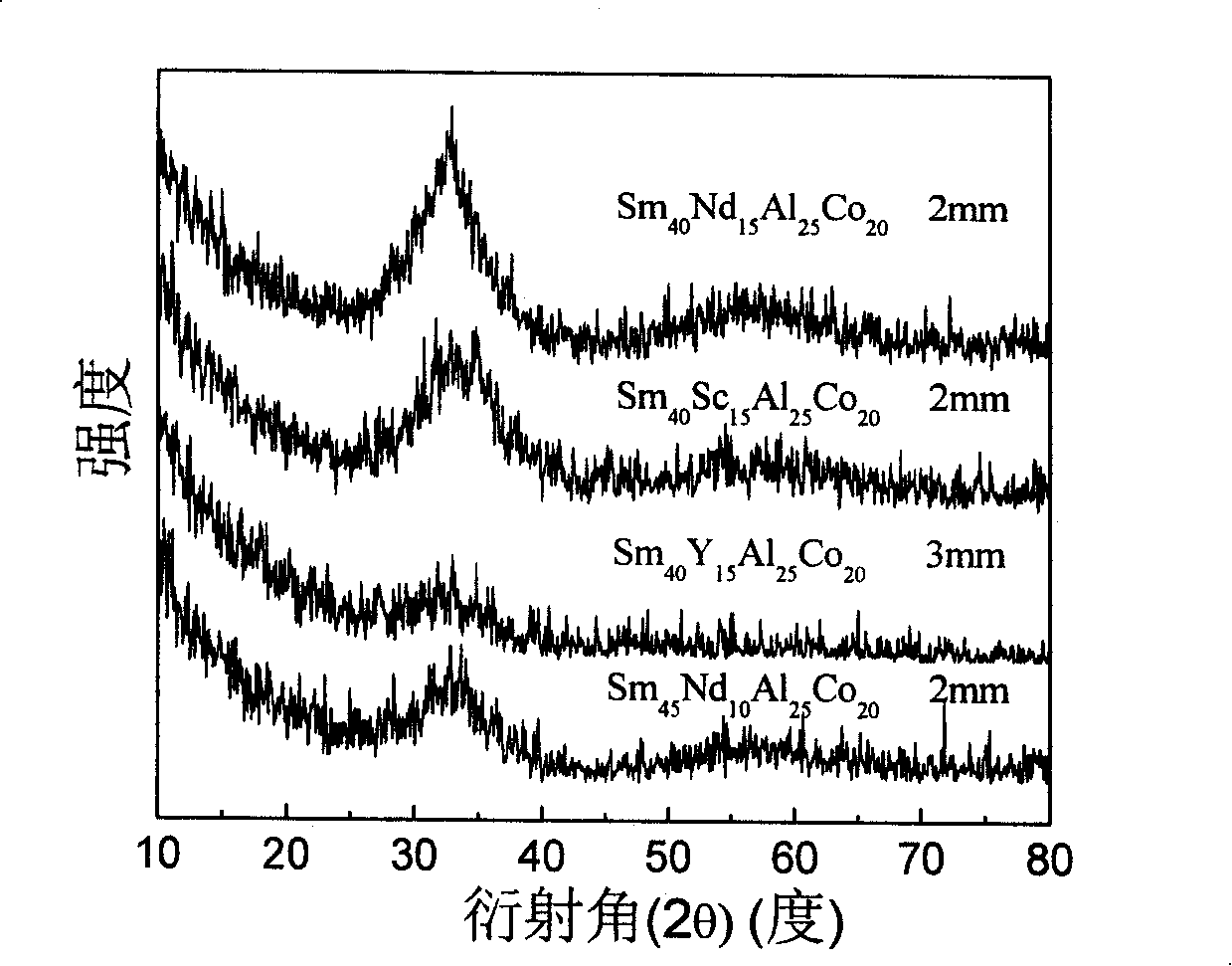

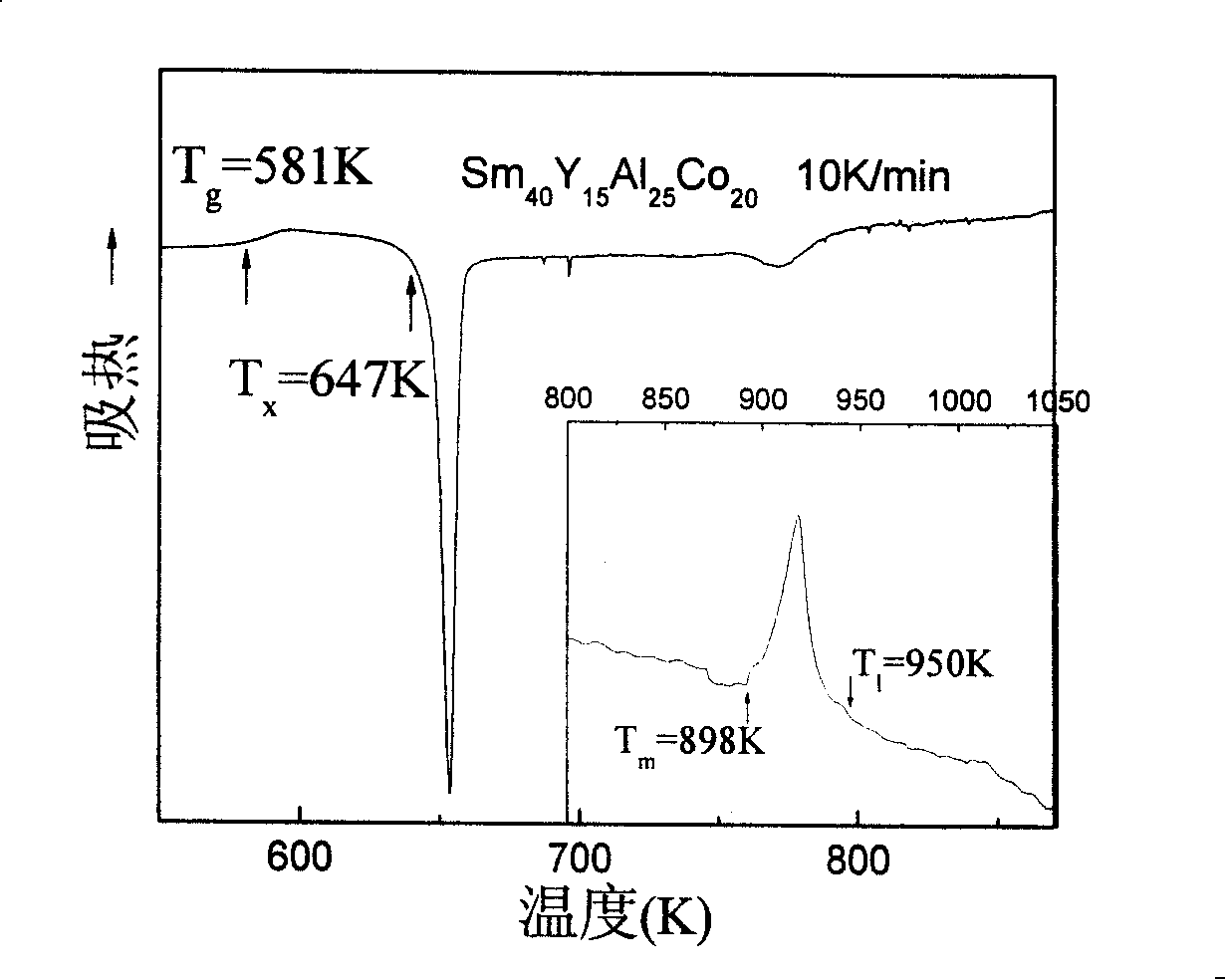

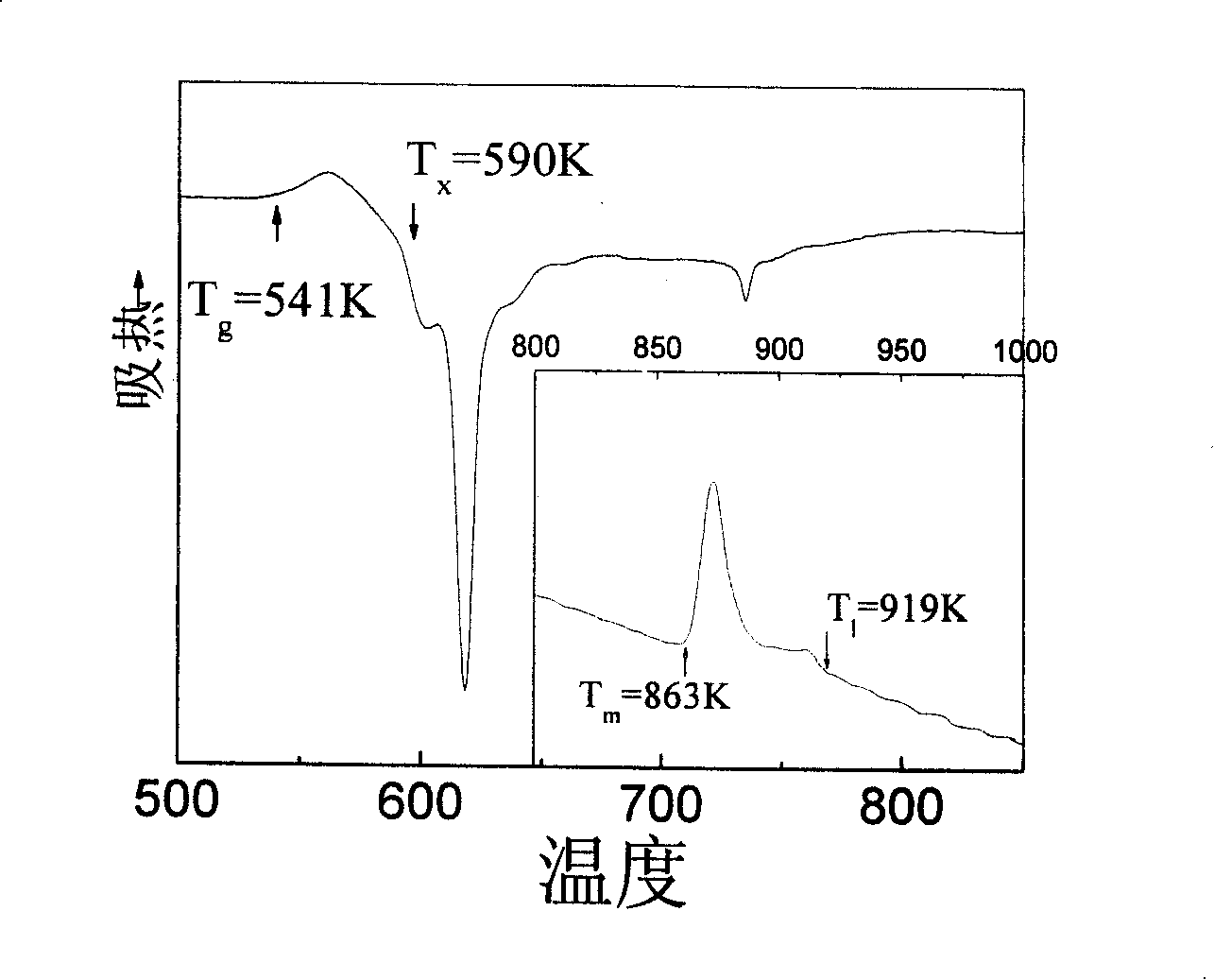

Samarium based amorphous alloy and preparation method thereof

InactiveCN100398687CHigh glass forming abilityImprove thermal stabilityCrystal structureHeat stability

The invention discloses a samarium-based amorphous alloy, which is based on samarium as main component with SmaMbAlcCod as component, wherein metal element M is Y, Sc or Nd (40<=a<=55,0<=b<=16,22<=c<=25,20<=d<=22, a+b+c+d=100); the alloy possesses higher glass forming ability and heat stability with glass transition temperature at 541-584K and crystallizing temperature at 590-652K, whose breadth of cool liquid phase area is 49-89K; the alloy is easy to form large-size amorphous alloy with each dimension not less than 1mm, whose critical diameter is not less than 1mm.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

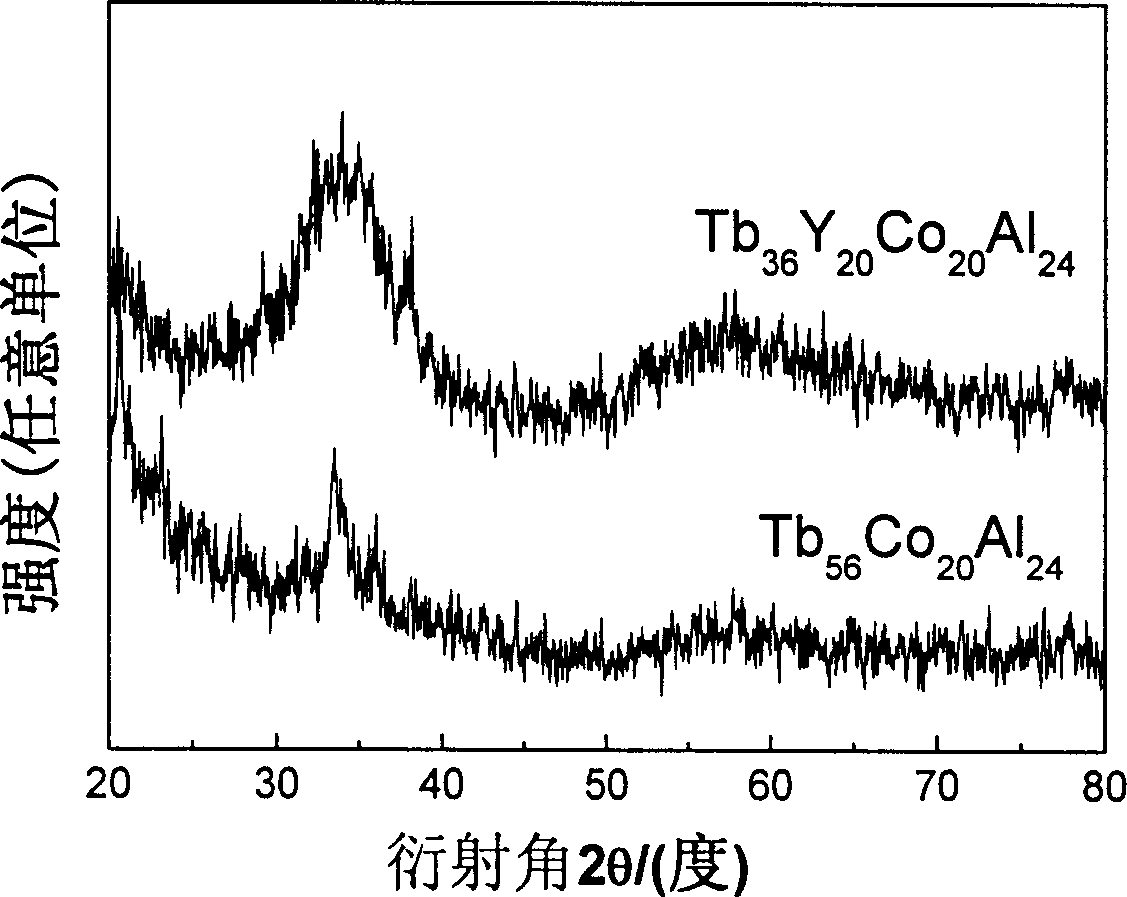

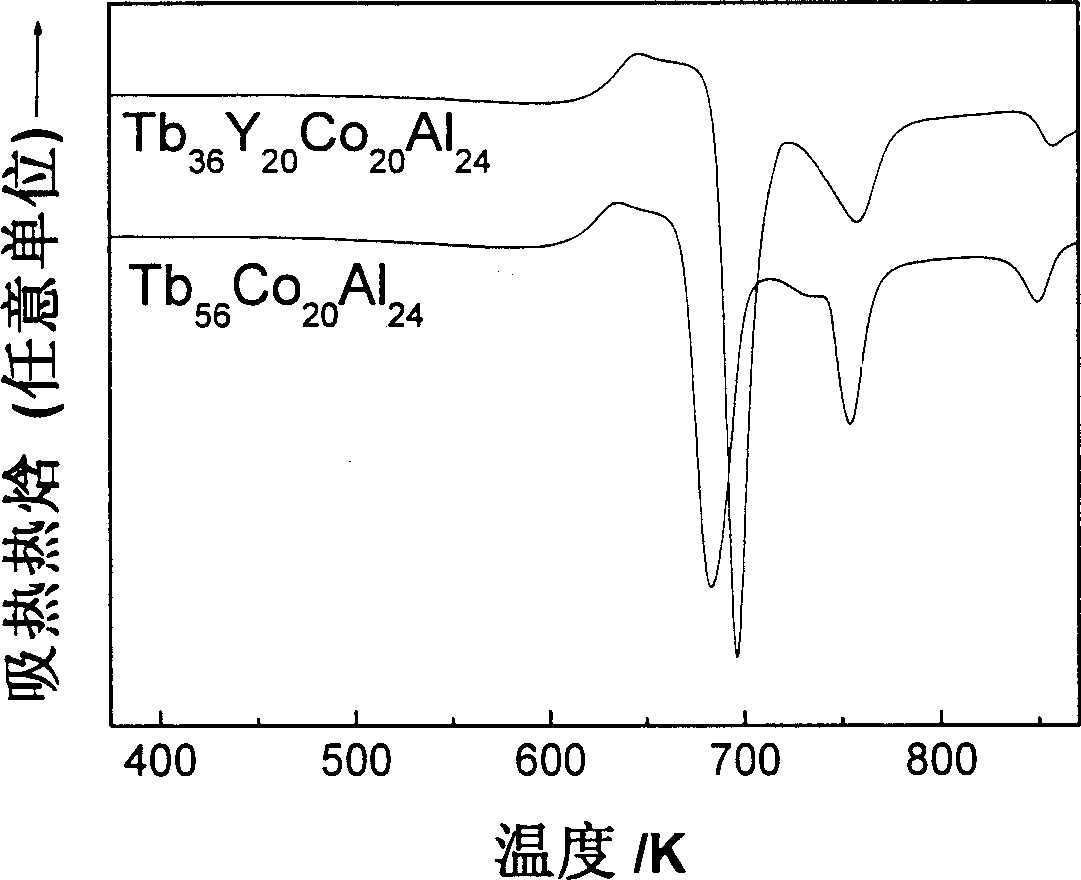

Terbium base noncrystal alloy and its preparing method

The present invention relates to a terbium base alloy, using terbium as main constituent. It is composed of TbaCobAlc or TbdCoeAlfYgMh; said M being transition group metallic element Sc, Nb, Ti, Cr, Mn, Fe, La, Pr, Ce or Nd..Every dimensionality of said terbium base bulk amorphous alloy dimension is not less than one mm, cut-off diameter not less than 3mm, having high glass forming ability, crystallization temperature at 650-700 k, glass transition temperature at 600-650 k,supercooling liquid field width at 25-75 k; having good magnetic characteristics and magnetostrictive property.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

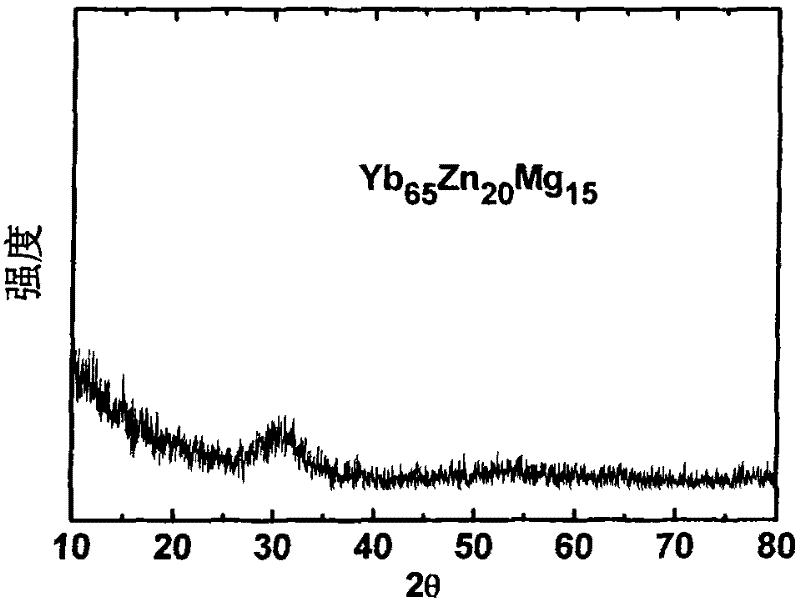

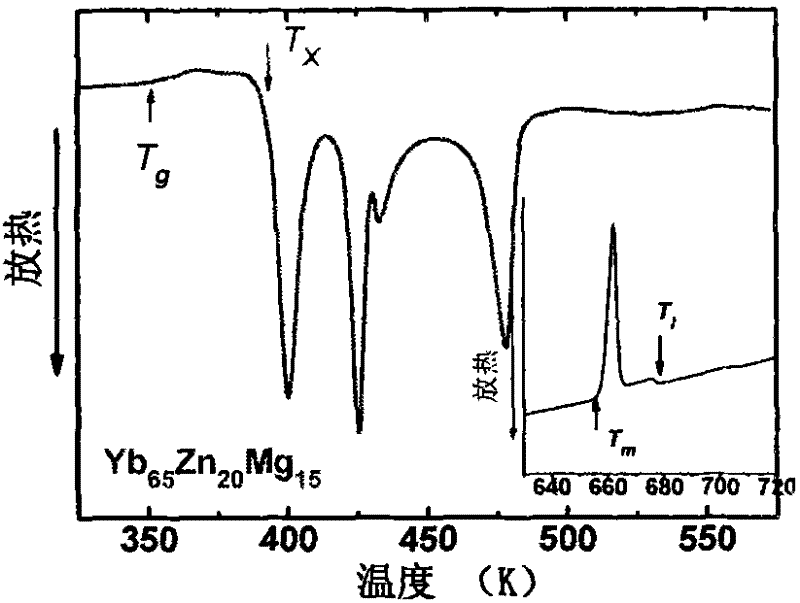

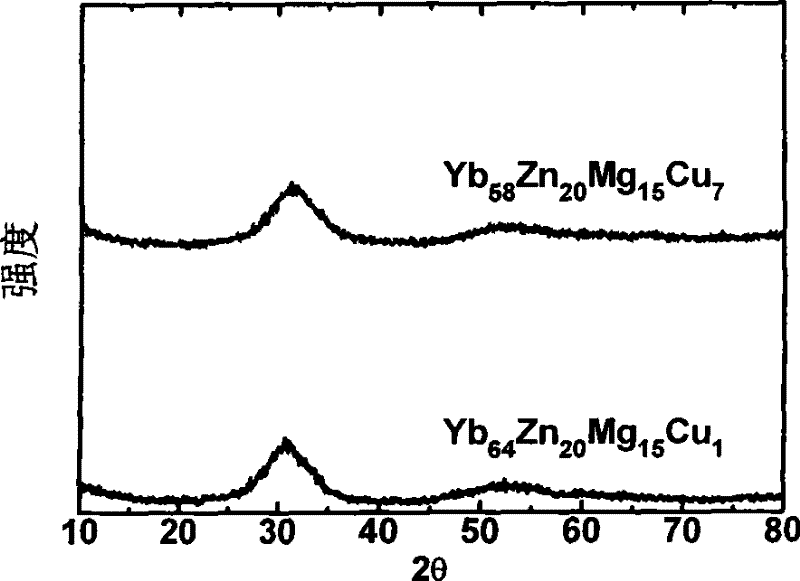

Ytterbium-based bulk amorphous alloy and preparation method thereof

The invention relate to an ytterbium-based bulk amorphous alloy and a preparation method thereof. The alloy takes ytterbium as a main component and the components thereof can be shown in the following formula: YbaZnbMgcXd, wherein X is a transition metal element, such as Fe, Cu, Al and the like; subscripts a, b, c and d are atom percentage; a is more than or equal to 50 and less than or equal to 70; b is more than or equal to 5 and less than or equal to 30; c is more than or equal to 5 and less than or equal to 30; d is more than or equal to 0 and less than or equal to 15; and a+b+c+d=100. The ytterbium-based bulk amorphous alloy has the characteristics of the high glass forming capacity, the strong capacity of inhibiting crystallization, capacity of being prepared into a larger size at alower cooling speed and the like, and has wide application prospect.

Owner:INST OF PHYSICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com