Zinc-based massive amorphous alloy and preparation method thereof

An amorphous alloy and bulk technology, applied in the field of zinc-based bulk amorphous alloys, can solve the problems of high glass transition temperature, high energy consumption, and unfavorable processing of iron-cobalt-zirconium-based alloys, and achieve good oxidation resistance and low cost , the effect of strong antioxidant capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1, zinc-based bulk amorphous alloy Zn 40 Mg 11 Ca 35 Yb14 preparation of

[0031] After the four components of Zn, Mg, Yb with a purity of not less than 99.9wt% and Ca with a purity of not less than 99wt% are prepared in a molar ratio of 40:11:14:35, the raw materials are placed in a quartz tube and placed in a high frequency induction furnace. Use a vacuum pump to evacuate to 5.0×10 -4 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. When the electromagnetic stirring is uniform, it is spray-cast into a copper mold cooled with liquid nitrogen, and the composition is Zn 40 Mg 11 Ca 35 Yb 14 , a bulk amorphous alloy with a diameter of 1 mm.

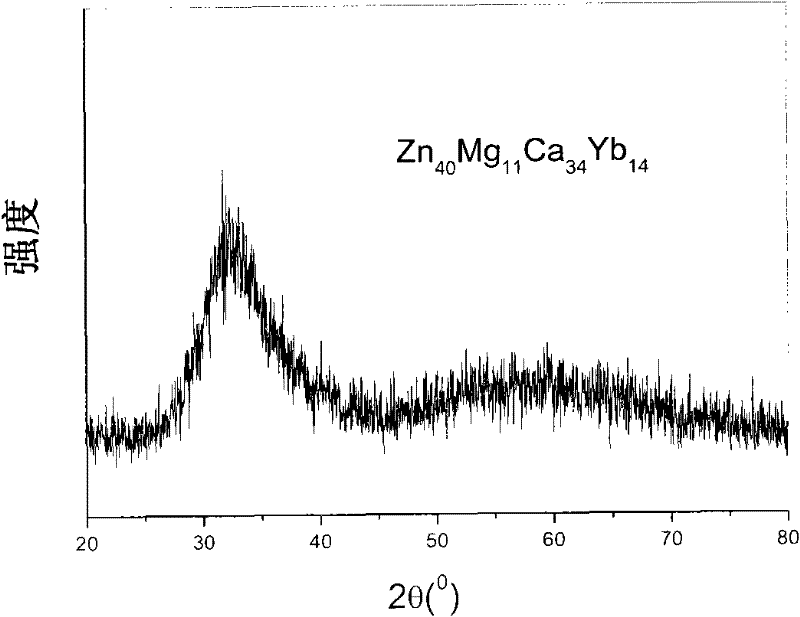

[0032] Its X-ray diffraction (XRD) as figure 1 As shown, it can be seen that the alloy is a completely amorphous alloy.

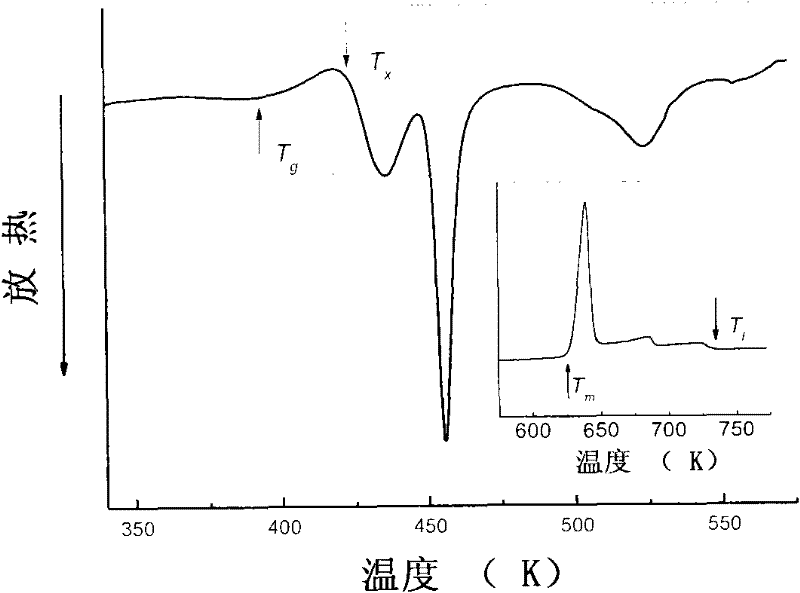

[0033] The Zn 40 Mg 11 Ca 35 Yb 14 Thermal analysis (DSC) of zinc-based bulk amorphous alloys ...

Embodiment 2

[0034] Embodiment 2, zinc-based bulk amorphous alloy Zn 40 Mg 11 Ca 31 Yb 18 preparation of

[0035] After the four components of Zn, Mg, Yb with a purity of not less than 99.9wt% and Ca with a purity of not less than 99wt% are prepared in a molar ratio of 40:11:18:31, the raw materials are placed in a quartz tube , into a high-frequency induction furnace. The raw material is placed in a quartz tube and placed in a high frequency induction furnace. Use a vacuum pump to evacuate to 5.0×10 -4 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. When the electromagnetic stirring is uniform, it is spray-cast into a copper mold cooled with liquid nitrogen, and the composition is Zn 40 Mg 11 Ca 31 Yb 18 , a bulk amorphous alloy with a diameter of 2 mm.

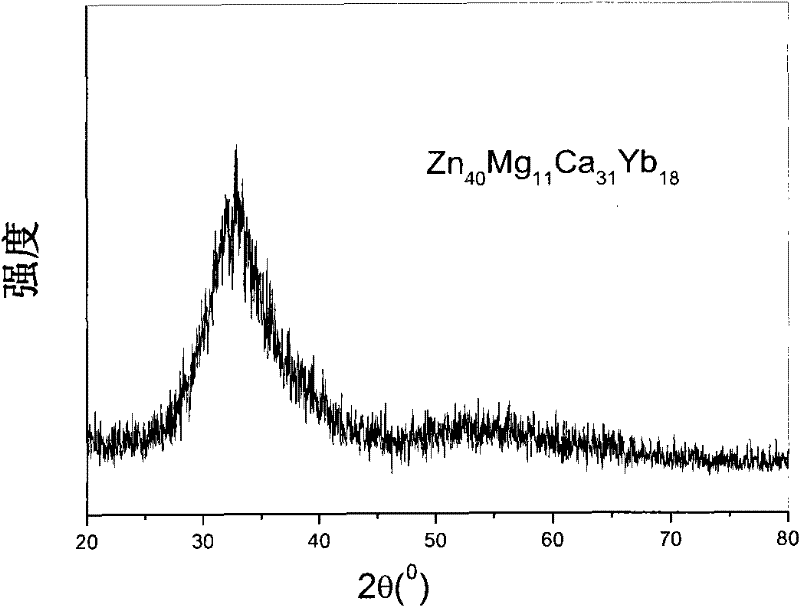

[0036] Its X-ray diffraction (XRD) as image 3 As shown, it can be seen that the alloy is a completely amorphous alloy.

[0037] T...

Embodiment 3

[0038] Embodiment 3, zinc-based bulk amorphous alloy Zn 45 Mg 11 Ca 25 Yb 15 Sr 4 preparation of

[0039] After the five components of Zn, Mg, Yb with a purity of not less than 99.9wt% and Ca and Sr with a purity of not less than 99wt% are prepared in a molar ratio of 45:11:15:25:4, the raw materials are placed In the quartz tube, put into a high-frequency induction furnace. The raw material is placed in a quartz tube and placed in a high frequency induction furnace. Use a vacuum pump to evacuate to 5.0×10 -4 Above Pa, after filling with an appropriate amount of high-purity argon, heat it with a high-frequency coil and small current until it melts. When the electromagnetic stirring is uniform, it is spray-cast into a copper mold cooled with liquid nitrogen, and the composition is Zn 45 Mg 11 Ca 25 Yb 15 Sr 4 , a bulk amorphous alloy with a diameter of 3 mm.

[0040] Its X-ray diffraction (XRD) as Figure 5 As shown, it can be seen that the alloy is a completely a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com